Page 1

SETRA

OPERATING INSTRUCTIONS

SERIES DPT 209

PRESSURE TRANSDUCERS

1.0 GENERAL INFORMATION

Every Model DPT209 has been tested and calibrated before shipment.

Setra Systems DPT209 pressure transducers sense gauge pressure and convert this pressure

difference to a proportional high level analog output. Three standard output and excitation

versions are offered:

Excitation Output

9 to 28 VDC 4 to 20mA – (Must Observe Polarity)

9 to 30 VDC 0.5 to 5.5 VDC – (Reverse Excitation Protection)

4.9 to 8.1 VDC 0.5 to 4.5 VDC – (No Reverse Wire Protection)

2.0 MECHANICAL INSTALLATION

2.1 Media Compatibility

Model DPT209 transducers are designed to be used with any gas or liquid compatible with 17-4 PH

stainless steel. Never totally submerge the unit in any liquid.

2.2 Environment

The operating temperature limits of the DPT209 are –40° to +185°F (-40 to +85°C). The

compensated temperature range is –4 to +176°F (-20 to +80°C)

2.3 Pressure Fittings

Typically, standard pipe fittings should be used. However, for pressure ranges in excess of 500 psig,

we suggest the use of a sealant such as Loctite Hydraulic Sealant. Excessive torquing of metal

fittings may cause a slight zero shift. The use of plastic fittings typically results in no noticeable

zero shift. Torquing does not appreciably affect linearity or sensitivity.

2.4 Tube Stub Welding Instructions

Standard welding practices should be followed. Caution must be taken to protect the sensor against

current paths that could damage the circuit board. Apply a heat sink between the weld zone and

the sensor that is large enough to protect the sensor from overheating. Failure to use a heat sink

may damage the housing seal or circuit board.

2.5 Venting

Because the reference pressure in a sealed gage transducer will vary due to changes in

temperature and will affect overall accuracy (especially in units of less than 500 psig range), all

DPT209 Series transducers are available as vented or sealed to atmosphere.

Vented units are ordered as PSIG ranged units. Sealed units are ordered as PSIS range units. The

DPT209 PSIG transducers are vented through the cable. Hirschmann PSIG transducers are vented

through the connector. Packard PSIG units are vented through a porous filter plug supplied on the

unit.

3.0 ELECTRICAL INSTALLATION

The Model DPT209 is available in four electrical terminations:

1. Two foot Cable

2. Packard Connector

3. Hirschmann Connector

4. Conduit Adapter, 1/2 inch

Page 2

3.1 Voltage Output Units

black

The Model DPT209 voltage output is a 3-wire circuit. If the DPT209 is supplied with 2 feet of

cable, the electrical connection is as follows:

Red = + Excitation; connect to appropriate power supply

Green = + Output; connect to controls or monitor.

Black = Common; connect to return of power supply.

White = -Output; connect to controls or monitor.

Shielding = Connected to system or earth ground.

3.2 Current Output Units

The Model DPT209 (current output) transducer is a true 2-wire, 4-20 mA current output device and

delivers rated current into any external load of 0-800 ohms. The 4-20 mA current output units are

designed to have current flow in one direction only - PLEASE OBSERVE POLARITY. We suggest

that the electrical cable shield be connected to the system’s loop circuit ground to improve

electrical noise rejection. The electrical connection is as follows:

Model C209

Setra

Transmitter

(4-20 mA)

red +

Power Supply

The DPT209 has a 2-wiere cable, where red is positive and black is negative.

_ _

_

+

++

Load

(Monitor)

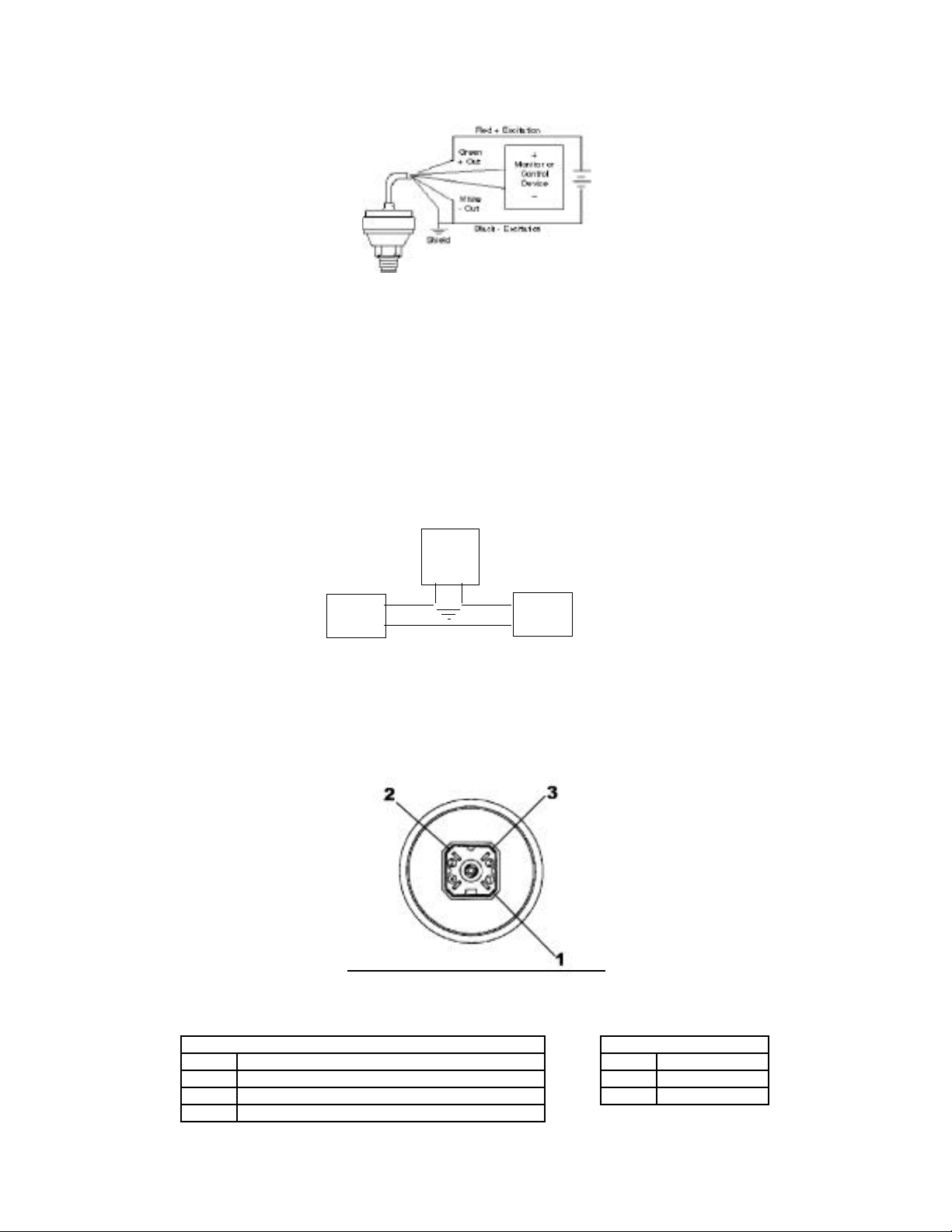

3.3 Hirschmann or Packard Connectors – Voltage and Current Output

If the unit is provided with a Hirschmann or a Packard Connector, pin number designation are as

follows:

Hirschmann Connector

Top View: Hirschmann Connector

Type: G4A1M#931807-106

Voltage Output Current Output

Pin # Function Pin # Function

1 + Excitation (connect to appropriate power supply 1 Positive

3 + Output (connect to controls or monitor 2 Negative

2 Common (connect to return of power supply)

Page 3

3-Pin Packard Connector

Voltage Output Current Output

Pin # Function Pin # Function

B + Excitation (connect to appropriate power supply B Positive

C + Output (connect to controls or monitor A Negative

A Common (connect to return of power supply)

4-Pin Packard Connector

Top View: 3-Pin Packard Connector

Type: P25 Series 150

Top View: 4-Pin Packard Connector

Type: Metri-Pack 150

Voltage Output Current Output

Pin # Function Pin # Function

A + Excitation (connect to appropriate power supply A Positive

C + Output (connect to controls or monitor B Negative

B Common (connect to return of power supply)

D (Not Used

Setra does not supply the mating connectors as a standard. They can be ordered separately.

Consult Factory.

Page 4

3.4 Conduit Adapter Electrical Termination – Voltage and Current Output Units

If the unit is provided with the conduit adapter version, terminal designations are as follows:

Conduit Adapter Version

(Voltage and Current Output Units)

For current (4-20 mA) output use + and – terminals

For voltage output, use COM, OUT, and EXC terminals

3.5 Conduit Fitting Installation

1. Connect the pressure port to the system.

2. Install a 1/2” conduit fitting into the DPT209 top cover and fasten the retaining nut.

3. Feed wires from a flexible conduit through the DPT209 top cover; fasten the wires to terminals.

4. Screw on the Model DPT209 top cover.

5. Fit conduit into conduit fitting and tighten conduit watertight strain relief.

3.6 EMC Certification

This product complies with EN61326 Electrical Equipment for Measurement Control and

Laboratory use – EMC Requirements for Minimum Requirements and Industrial Locations. Special

caution should be taken to meet Standard EN61000-4-5: 1995 Surge Immunity if any of the

following conditions apply to the installation: the product is installed outside; all or any part of the

cable is exposed to the outside; the cable is greater than 30 meters in length. In order to meet the

CE Surge Immunity requirements, the following conditions must be followed during installation:

1. Shielded cable must be used, and the shield must be tied to earth ground (not

power supply ground) on at least one end of the cable shield/drain wire. The shield

must be maintained all the way from sensor to the power supply.

2. If unshielded cable is used, an earth grounded metal conduit should be used to

replace the shielded cable.

3. For a sensor with a metal body or enclosure, the body/enclosure must be grounded

to earth. If a protective metal housing is used, the housing must be able to

withstand at least 2 kV from the housing to earth ground without damaging the

circuit.

Loading...

Loading...