Page 1

D-304286 SD-304C PG2 Installation Instructions 1

Installation Instructions

SD-304C PG2

PowerG, Wireless Shock and Contact detector

with Wired Input

1. INTRODUCTION

The SD- 304C PG2 is a wireless PowerG innovative shock detector with optional magnetic contact and

auxiliary input interfacing with all PowerMaster control panels, version 16 or higher. The SD-304C PG2 fits

windows, doors, walls or roofs and is ideal for residential or commercial installations. It detects and analyzes

gross attacks or a series of low level shocks (up to 10 low level shocks within 30 seconds) and provides early

warning of any attempt of intrusion before a burglar actually breaks-in.

The detector incorporates:

• A shock / vibration piezoelectric sensor.

• Optional reed switch (with optional anti-mask sensor to prevent attempts at disabling it with an extra

magnet).

⚫ Optional auxiliary input to use with installer supplied contacts or other wired devices.

Installer added-value features:

• Digital display enables fast and easy shock level adjustment

• Full remote configuration from PowerMaster control panel or Monitoring Station saves the need to

physically access the shock detector for configuration

• Remote view of: Low Battery, front and back Tamper, Supervision

• An LED lights whenever alarm or tamper events are reported (the LED does not light while a supervision

message is being transmitted).

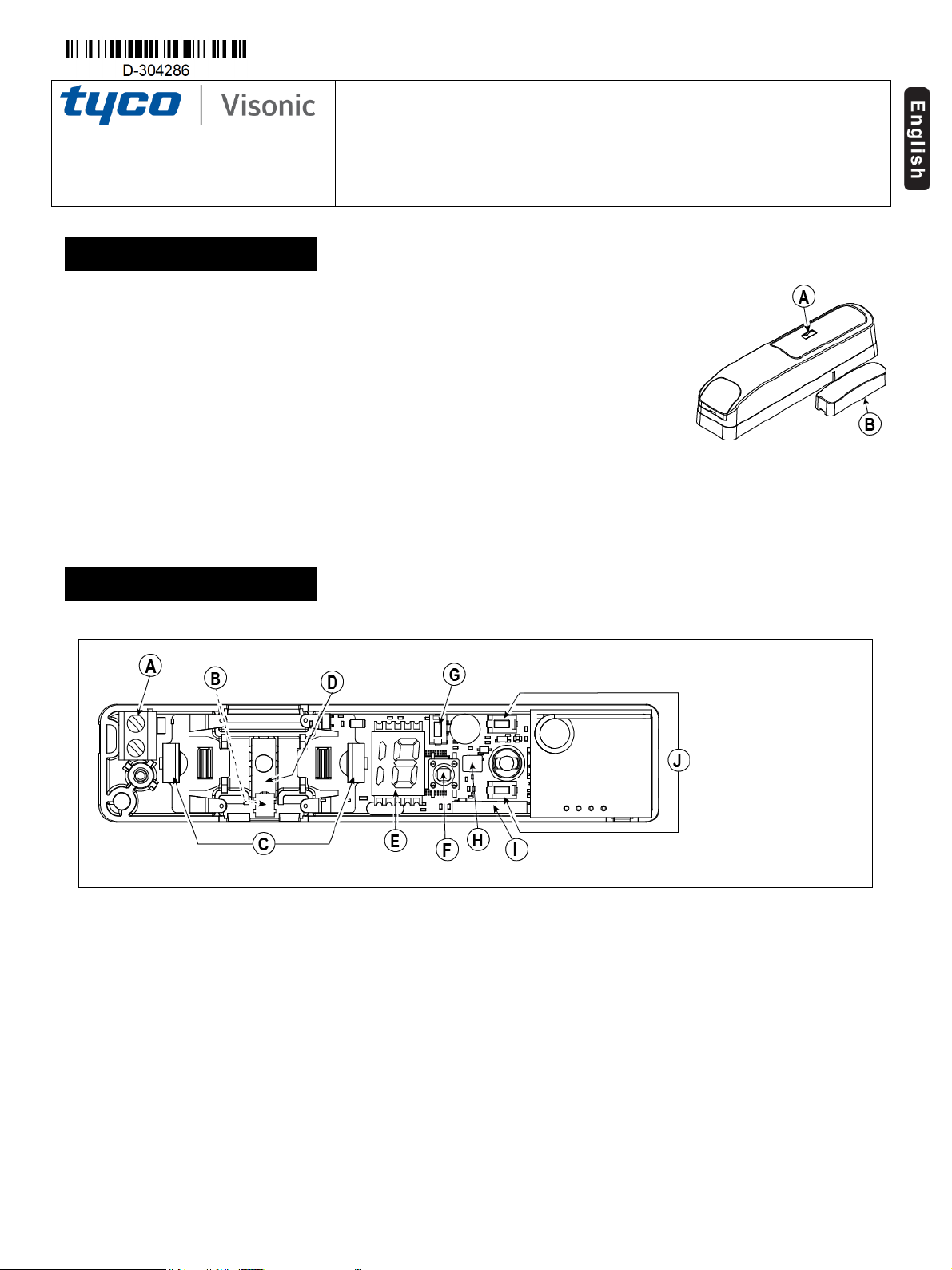

A. Transmission LED

B. Magnet

Figure 1: External View

2. INSTALLATION

2.1 Mounting

A. Auxiliary input

terminals

B. Back tamper switch

(behind P.C. board)

C. Battery clips

D. Break-away segment

(for back tamper)

E. Digital display

F. Front tamper switch

G. Enroll button

H. LEDs indication

I. Reed switch

J. Up and down buttons

Figure 2. Base with P.C. Board Removed

Refer to the Shock Detection Radius, in the Specifications section, according to the surface material used. Install the device in a location where a

strong shock impact is expected. The unit should be mounted on a flat surface and firmly fixed using both mounting screws.

For magnetic contact detection, it is highly recommended to attach the detector to the door or window on the fixed frame and the magnet to the

movable part (door or window). For optimal magnetic sensor activity and better security it is recommended to apply the magnet as close as

possible to the

detector’s marked side.

Note: Once the cover is removed, a tamper message is transmitted to the control panel. Subsequent removal of the battery prevents transmission

of "TAMPER RESTORE", leaving the detector in permanent alert. To avoid this, press the tamper switch while you remove the battery.

Caution!

Risk of explosion if battery is replaced by an incorrect type. Dispose of used battery according to manufacturer's instructions.

Attention! The unit has a back tamper switch (optional) under the PCB. As long as the PCB is seated firmly within the base, the switch lever will

be pressed against a special break-away base segment that is loosely connected to the base (Figure 2). Be sure to fasten the break-away

segment to the wall. If the detector unit is forcibly removed from the wall, this segment will break away from the base, causing the tamper switch

to open.

Page 2

2 D-304286 SD-304C PG2 Installation Instructions

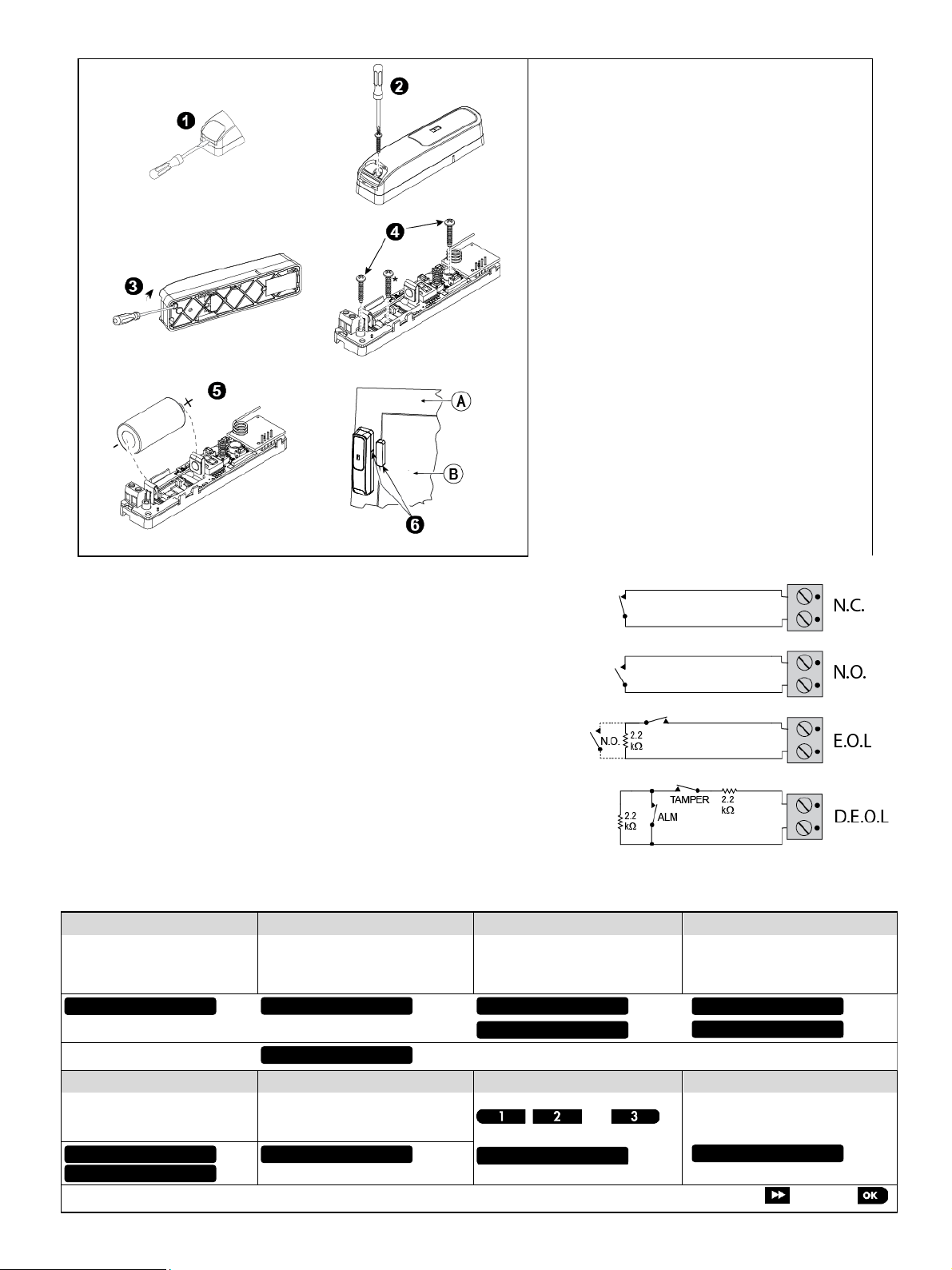

Figure 3. Mounting

Note: Use a manual or electronic screwdriver. Do not use

a drill as a screwdriver.

1. Insert a flat-edged screwdriver into the slot and push

upward to remove cover.

2. Remove screw.

3. Separate base from cover.

4. Secure the base to the mounting surface using only the

screws supplied in the package.

CAUTION! Do not remove the PCB to mark holes. Use

one of the following: a slim pencil, nails or the attached

paper model.

CAUTION! Do not use double-sided tape, as this will

tend to insulate the detector from vibrations.

5. Insert the battery while observing polarity.

6. Mount the magnet near its location mark with 2 screws.

A. Fixed frame

B. Moving part

Note: 868 MHz device is illustrated in the example. The

same mounting procedure should be performed for 433

MHz and 915 MHz devices.

* This additional screw is used for back tamper only.

2.2 Auxiliary Input Wiring (Fig. 4)

A. Connect the auxiliary sensor contacts across the SD-304C PG2 auxiliary input

terminals.

Note: Maximal guaranteed cable length is 10m.

B. If the auxiliary input of the SD-304C PG2 is defined as a Normally Closed (N.C.) type,

series connected N.C. sensor contacts must be used exclusively. An alarm message is

transmitted once the loop is opened.

C. If the auxiliary input of the SD-304C PG2 is defined as a Normally Open (N.O.) type,

parallel connected N.O. sensor contacts must be used exclusively. An alarm message

is transmitted once the loop is closed.

D. For End of Line (EOL) supervision:

Normally Closed (N.C.) or Normally Open (N.O.) sensor contacts can be used, as

shown in Figure 4. A 2.2k E.O.L. resistor must be wired at the far end of the zone

loop. An alarm message is transmitted once the loop is opened or short circuited.

E. For Double End of Line (DEOL) supervision:

Two Normally Closed (N.C.) sensor contacts can be used, as shown in Figure 4. Two

2.2k E.O.L. resistors must be wired at the far end of the zone loop which is opened

or short circuited. Events messages are transmitted according to connected inputs, for

example, Alarm or Tamper contacts.

2.3 Enrollment

Figure 4. AUX Input Wiring Examples

Refer to the PowerMaster panel's Installer Guide and follow the procedure under the "02:ZONES/DEVICES" option of the Installer Menu.

A general description of the procedure is provided in the following flow chart.

Step 1

Step 2

Step 3

Step 4

Enter the Installer menu and

select “02:ZONES/DEVICES”

Select "ADD NEW DEVICE"

See Note 1

Enroll the detector: press the enroll

button and then release it as soon as

the yellow LED lights, or, enter the

device ID (on the back of device)

Select the desired Detector

Number for the new device

Step 5

Step 6

Step 7

Step 8

Configure Location and Zone

Type Parameters

Enter PARTITIONS.

See Note 2

Assign partitions by pressing the

, and

buttons

Select "Device Settings" and see

below to configure the (AUX)

button.

means scroll and select

Z02:DEV SETTINGS

Z02:P1◼ P2 P3◼

Z02:PARTITIONS

Z02.ZONE TYPE

Z02.LOCATION

MODIFY DEVICES

ID No. 170-XXXX

Z02:Shk+AX+CntG3

ENTR ID:XXX-XXXX

ENROLL NOW or

ADD NEW DEVICES

02.ZONES/DEVICES

Page 3

D-304286 SD-304C PG2 Installation Instructions 3

Notes:

1. If the shock detector is already enrolled, you can configure the device parameters and assign partitions via the “Modify Devices” option – see

Step 2.

2. PARTITIONS will appear only if PARTITIONING was previously enabled in the panel.

2.4 Configuring the Magnetic Contact Device Parameters

Enter the Device Settings menu and follow the configuration instructions for the SD-304C PG2 shock detector as described in the following table.

Option

Configuration Instructions

Determine whether or not the alarm LED indication will be activated.

Optional settings: ON (default) or OFF.

•

Determine whether to enable or disable the internal reed switch.

Optional settings: Enabled or Disabled (default).

Define whether to enable or disable the detection of magnetic tampering.

Notes:

1. The selected option of this menu is functional only if the Reed Swtich menu was previously set to "Enabled".

2. Supported only by specific control panels.

Optional settings: Enabled or Disabled (default).

Define the external input according to the installer's requirements.

Optional settings: Disabled (default), End of Line, Normally open, Normally close or Double EOL.

•

Define the sensitivity threshold of the shock detector when configuring from the panel.

Optional settings: Sens. Thresh. 1 to Sens. Thresh. 19 (default setting is Sens. Thresh. 8).

Note: Configuration of this feature can be performed either from the panel or from the device on condition that the

device was already enrolled and there is synchronization between the panel and device. If an “E” appears on the

device’s digital display, this indicates no synchronization.

Define whether Accumulation mode, when configuring from the panel, is Enabled or Disabled.

Optional settings: Enabled or Disabled (default).

2.5 Local Operating and Calibrating of the Shock Detector

The SD-304C PG2 can be calibrated locally only when the device is in Local Diagnostics mode (first 15 minutes after opening the cover). When

the device is not in this mode, but further calibration is required, the installer should reset the device by closing the tamper switch.

1. Press on the "Up" or "Down" button to turn on the digital display. The letter 'G' appears on the display for 3 seconds to indicate Gross Attack

levels (thresholds). Then, the menu appears on the display to enable you to select a number in the range of 1-19. If, instead of a number the

letter "E" appears on the display, this indicates that there is no communication link between the unit and control panel and, therefore, local

adjustment is not allowed.

Note: If no buttons are pressed within 20 seconds, the digital display turns off.

2. Change the threshold by pressing the "Up" or "Down" button.

Note: The lower the threshold, the higher the sensitivity, therefore, the lowest thresholds are more suitable for harder materials, such as

concrete.

3. While the SD-304C PG2 threshold menu is active, knock on the surface with the required force for the detector to set the required threshold.

The power of the detected knock will be presented on the display of the SD-304C PG2 as a blinking number for 3 seconds. The displayed

number will be in the range of 1 to 19, where 1 is very weak and 19 is very strong.

Note: If the installer knocks on the surface but nothing appears on the display, this indicates that no shock is detected. If a hyphen blinks, this

indicates that the knock is above the highest threshold of the detector.

4. Repeat the same test several times.

5. Press the "Up" or "Down" button to navigate to the threshold number to be set and then press the "Up" and "Down" buttons simultaneously to

set the threshold.

6. The detector now moves to the next menu, the Accumulated menu (shown as "A" on the display). Press the "Up" or "Down" buttons to Enable

("1" on the display) or Disable ("0" on the display) the Accumulation mode. Press the "Up" or "Down" buttons simultaneously to set the

selected option.

Note: When Accumulation is enabled, the power of impact will still indicate the strength of a single knock, therefore, it is recommended to

disable this parameter while the Threshold is tested and to enable the Accumulation mode only after setting the Threshold.

7. If after the "Up" and "Down" buttons are simultaneously pressed the letter “E” appears, this likely indicates that there is no communication link

between the unit and control panel. Check if the panel is properly powered.

Accumulated

Sens. Threshold

AUX input

Magnetic AM

Reed Switch

Alarm LED

Page 4

4 D-304286 SD-304C PG2 Installation Instructions

3. LOCAL DIAGNOSTICS TEST

Before testing, separate the base from the cover (see Figure 3).

A. Press the tamper switch once and release it.

B. Put back the cover to return the tamper switch to its normal (undisturbed) position, and then secure the front cover to the base with the case

closure screw.

C. Use a hammer to apply shock in close proximity to the detector and verify the red LED blinks, indicating detection.

D. After 2 seconds the LED blinks 3 times.

The following table indicates received signal strength indication.

LED response

Reception

Green LED blinks

Strong

Orange LED blinks

Good

Red LED blinks

Poor

No blinks

No communication

IMPORTANT! Reliable reception must be assured. Therefore, "poor" signal strength is not acceptable. If you receive a "poor" signal from the

device, re-locate it and re-test until a "good" or "strong" signal strength is received.

Note: For detailed Diagnostics Test instructions, refer to the control panel Installer Guide.

4. EVENT INDICATIONS

LED Indications

Event

Red LED ON 0.2 sec.

Tamper open / close

Red on 2 sec.

Shock

Red on 2 sec.

Open close door

Red on 2 sec.

Open close Aux input

Yellow LED on

AM detection – diagnostic mode

Yellow LED blinks slowly (0.2 sec. ON, 30 sec. OFF)

AM detection – Normal mode

5. MISCELLANEOUS COMMENTS

Visonic Ltd. wireless systems are very reliable and are tested to high standards. However, due to low transmitting power and limited range

(required by FCC and other regulatory authorities), there are some limitations to be considered:

A. Receivers may be blocked by radio signals occurring on or near their operating frequencies, regardless of the digital code used.

B. A receiver responds only to one transmitted signal at a time.

C. Wireless devices should be tested regularly to determine whether there are sources of interference and to protect against faults.

6. COMPLIANCE WITH STANDARDS

Compliance with Standards

The SD -304C PG2 complies with the following standards:

Europe: EN 301 489-3, EN 50130-4, EN 300 220-2, EN 62368-1, EN 50131-5-3, EN 50130-5, EN 50131-1,

EN 50131-6 Type C, EN 50131-2-8, EN 50131-2-6, Grade 2, Class II.

Certified by Applica Test & Certification AS in accordance with EN 50131-2-6 EN 50131-2-8, EN 50131-5-3,

EN 50131-6, EN 50130-4, EN 50130-5.

UK: This product is suitable for use in systems installed to conform to PD6662

USA: CFR 47 part 15 (FCC)

Canada: RSS-247, RSS-102

Hereby, Visonic Ltd. declares that the radio equipment type SD-304C PG2 is in compliance with Directive

2014/53/EU. The full text of the EU declaration of conformity is available at the following internet address:

http://www.visonic.com/download-center.

This device complies with Part 15 of the FCC Rules and with ISED license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

Le present appareil est conforme aux CNR d'ISED applicables aux appareils radio exempts de

licence. L'exploitation est autorisee aux deux conditions suivantes :(1) l'appareil ne doit pas produire

de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioelectrique

subi, meme si le brouillage est susceptible d'en compromettre le fonctionnement.

To comply with FCC and IC RF exposure compliance requirements, the device should be located at a

distance of at least 20 cm from all persons during normal operation. The antennas used for this product must

not be co-located or operated in conjunction with any other antenna or transmitter.

Le dispositif doit être placé à une distance d'au moins 20 cm à partir de toutes les personnes au cours de son

fonctionnement normal. Les antennes utilisées pour ce produit ne doivent pas être situés ou exploités

conjointement avec une autre antenne ou transmetteur.

The digital circuitry of this device has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in residential installations. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio and television reception. However, there is no guarantee that interference will not occur

Page 5

D-304286 SD-304C PG2 Installation Instructions 5

in a particular installation. If this device does cause such interference, which can be verified by turning the

device off and on, the user is encouraged to eliminate the interference by one or more of the following

measures:

– Re-orient or re-locate the receiving antenna.

– Increase the distance between the device and the receiver.

– Connect the device to an outlet on a circuit different from the one which supplies power to the receiver.

– Consult the dealer or an experienced radio/TV technician

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe B est conforme a la norme NMB-003 du Canada.

WARNING!

To comply with FCC and IC RF exposure compliance requirements, the device should be located at a

distance of at least 20 cm from all persons during normal operation. The antennas used for this product must

not be co-located or operated in conjunction with any other antenna or transmitter.

WARNING!

The user is cautioned that changes or modifications to the unit, not expressly approved by Visonic Ltd., could

void the user’s FCC or other authority to operate the equipment.

Wood

Supports

Soft Iron

Opening

Closing

Direction

Opening

Closing

20mm+/5mm

15mm+/5mm

X

13mm+/-5mm

11mm+/5mm

15mm+/5mm

13mm+/5mm

Y

14mm+/-5mm

12mm+/5mm

26mm+/5mm

24mm+/5mm

Z

26mm+/-5mm

24mm+/5mm

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from which you orignially purchased it. If you are disca rding this pro duct a nd n o t

returning it for repair then you must ensure that it is returned as identified by your supplier. This product is not to be thrown away with everyday waste.

Directive 2012/19/EU Waste Electrical and Electronic Equipment.

APPENDIX: SPECIFICATIONS

Frequency Band (MHz)

Europe and rest of world: 433-434, 868-869 USA: 912-919

Communication Protocol

PowerG

Alarm Input

One auxiliary

Tamper

Front and back

Supervision

Signaling at 4-min. intervals

Tamper Alert

Reported when a tamper event occurs

Power Supply

Type C

Battery type

3 V Lithium CR-123A type battery, Panasonic, Sanyo or GP only.

Battery Life Expectancy

5 years (for typical use) with all sensors enabled

Low Battery Threshold

2.6 V

Current Consumption

20 – 30 A approx. (150 mA during transmission)

Shock Detection Radius and

Sensitivity Level

Not EN Tested

EN Certified

Plate material

Shock detection

radius

Plate material

Shock

detection

radius

Sensitivity level

Window

4M

Framed glass window

(standard test material

A1)

1M

15

Wood

3.5M

Wooden plate

(Standard test material

A2)

1M

12

Brick/concrete

walls

2.5M

Concrete plate

(Standard test material

A3)

0.5M

4

Operating Temperature

-10C to 55C (14F to 131F)

Storage Temperature

-20C to 60C (-4F to 140F)

Humidity

Average relative humidity of approximate 75% non-condensing. For 30 days per year relative humidity may

vary between 85 % and 95 % non-condensing

Auxiliary Input Cable Length

10m max.

Auxiliary Input EOL Resistor

2.2 KΩ

Dimensions (LxWxD)

118 x 27 x 30 mm (4-5/8 x 1-1/8 x 1-3/16 in.)

Weight (including battery)

130g (4.6 oz)

Figure 5: Axis Definitions

Page 6

6 D-304286 SD-304C PG2 Installation Instructions

WARRANTY

Visonic Limited (the “Manufacturer") warr ants this product only (the "Product") to the orig inal purchaser only (the

“Purchaser”) ag ainst defective workmanship and materials under normal use of the Product for a period of twelve

(12) months from the date of shipment by the Manufacturer.

This Warranty is absolutely conditional upon the Product having been properly installed, maintained and

operated under conditions of normal use in accordance with the Manufacturers recommended installation and

operation instructions. Products which have become defective for any other reason, according to the

Manufacturers discretion, such as improper installation, failure to follow recommended installation and

operational instructions, neglect, willful damage, misuse or vandalism, accidental damage, alteration or

tampering, or repair by anyone other than the manufacturer, are not covered by this Warranty.

The Manufacturer does not represent that this Product may not be compromised and/or circumvented or that the

Product will prevent any death and/or personal injury and/or damage to property resulting from burglary,

robbery, fire or otherwise, or that the Product will in all cases provide adequate warning or protection. The

Product, properly installed and maintained, only r educes the risk of such events without warning and it is not a

guarantee or insurance that such events will not occur.

THIS WARRANTY IS EXCLUSIVE AND EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES, WHETHER WRITTEN, ORAL, EXPRESS OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR OTHERWISE. IN

NO CASE SHALL THE MANUFACTURER BE LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR BREACH OF THIS WARRANTY OR ANY OTHER WARRANTIES

WHATSOEVER, AS AFORESAID.

THE MANUFACTURER SHALL IN NO EVENT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES OR FOR LOSS, DAMAGE, OR EXPENSE, INCLUDING LOSS

OF USE, PROFITS, REVENUE, OR GOODWILL, DIRECTLY OR INDIRECTLY ARISING FROM

PURCHASER’S USE OR INA BILITY TO U SE T HE PRODUCT, OR FOR LOSS OR DESTRUCTION OF

OTHER PROPERTY OR FROM ANY OTHER CAUSE, EVEN IF MANUFACTURER HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE.

THE MANUFACTURER SHALL HAVE NO LIABILITY FOR ANY DEATH, PERSONAL AND/OR BODILY

INJURY AND/OR DAMAGE TO PROPERTY OR OTHER LOSS WHETHER DIRECT, INDIRECT,

INCIDENTAL, CONSEQUENTIAL OR OTHERWISE, BASED ON A CLAIM THAT THE PR ODUCT FAILED TO

FUNCTION.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or damage arising under

this limited warranty, THE MANUFACTURER'S MAXIMUM LIABILITY (IF ANY) SHALL NOT IN ANY CASE

EXCEED THE PURCHASE PRICE OF THE PRODUCT, which shall be fixed as liquidated damages and not as

a penalty, and shall be the complete and exclusive remedy against the Manufacturer.

When accepting the delivery of the Product, the Purchaser agrees to the said conditions of sale and warranty

and he recognizes having been informed of.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so these

limitations may not apply under certain circumstances.

The Manufacturer shall be under no liability whatsoever arising out of the corruption and/or malfunctioning of any

telecommunication or electronic equipment or any programs.

The Manufacturers obligations under this Warranty are limited solely to repair and/or replace at the

Manufacturer’s discretion any Product or part thereof that may prove defective. Any repair and/or replacement

shall not extend the original Warranty period. The Manufacturer shall not be responsible for dismantling and/or

reinstallation costs. To exercise this Warranty the Product must be returned to the Manufacturer freight pre-paid

and insured. All freight and insurance costs are the responsibility of the Purchaser and are not included in this

Warranty.

This warranty shall not be modified, varied or extended, and the Manufacturer does not authorize any person to

act on its behalf in the modification, variation or extension of this warranty. This warranty shall apply to the

Product only. All products, accessories or attachments of others used in conjunction with the Product, including

batteries, shall be covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or otherwise, caused by the

malfunction of the Product due to products, accessories, or attachments of others, including batteries, used in

conjunction with the Products. This Warranty is exclusive to the original Purchaser and is not assignable.

This Warranty is in addition to and does not affect your legal rights. Any provision in this warranty which is

contrary to the Law in the state or country were the Product is supplied shall not apply.

Warning: T he user must follow the Manufacturer’s installation and operational instructions including testing the

Product and its whole system at least once a week and to take all necessary precautions for his/her safety and

the protection of his/her property.

1/08

EMAIL: info@visonic.com

INTERNET: www.visonic.com

© 2020 Johnson Controls. All rights reserved. JOHNSON CONTROLS, TYCO and VISONIC are trademarks of Johnson

Controls.

D-304286 SD-304C PG2 (Rev 10, 1/21)

Loading...

Loading...