Page 1

LX Series Unit Ventilator Controller

User’s Guide

Code No. LIT-12011486

Issued June 22, 2009

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sensor Configuration Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LONMARK Functional Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Units in LONWORKS Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Language Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Selecting a Measurement System or Selecting a Language . . . . . . . . . . . . . . . . . . . . . 16

Unit Ventilator Controller Installation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10k Ohm or Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 to 20 mA Analog Input, Externally Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sensors and Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Auxiliary Alarm Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bypass Contact Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CO

Level Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

Discharge Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Economizer Enable Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Emergency Contact Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fan Speed Selector Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fan State Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mixed Air Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mode Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Occupancy Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Outdoor Enthalpy Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1LX Series Unit Ventilator Controller User’s Guide

Page 2

Outdoor Humidity Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Outdoor Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Return Air Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setpoint Offset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Space Enthalpy Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Space Humidity Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Space Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Water Temperature Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Window Contact Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Analog Output Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Staged Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Output Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fan Speed 1–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Heating Outputs 1–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cooling Outputs 1–4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Reversing Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Humidifier and Dehumidifier Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Minimum Fresh Air Enable (MIN_FRESH_AIR_ENABLE) . . . . . . . . . . . . . . . . . . . . . . . . . 30

Economizer Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Heat Valve ON-OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cool Valve ON-OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Heat Cool Valve ON-OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Heat Valve Open or Close. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cooling Valve Open or Close. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Heat Cool Valve Open or Close. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fan Speed Modulate (FAN_SPEED_MOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Heating Modulate (HEATING_MOD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LX Series Unit Ventilator Controller User’s Guide2

Page 3

Heating or Cooling Valve Modulate (HEATING_VALVE_MOD) (COOLING_VALVE_MOD)31

Fresh Air Damper Modulate (FRESH_AIR_DAMPER_MOD) . . . . . . . . . . . . . . . . . . . . . . . 31

Fresh Air Damper Open or Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mode Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Network Variables Used for Mode Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ending Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Unoccupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Starting Unoccupied Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ending Unoccupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Starting Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ending Bypass Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Starting Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ending Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Slave Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

State Selection and Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Supervisory Control and Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Calculating the Space Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The Effect of nviSetPoint on the Active Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The Effect of a Setpoint Offset on the Active Setpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ventilation Separate from Free Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control of the Fresh Air Intake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Outputs That Control the Fresh Air Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cooling State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Free Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

LX Series Unit Ventilator Controller User’s Guide 3

Page 4

When Free Cooling is Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Mechanical Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cooling Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cooling Output Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ending the Cooling State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Heating States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Heating Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Heating Output Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cooling Outputs Used to Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ending the Heating State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Night Purge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Morning Warm-up State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Using Night Purge and Morning Warm-up with DCV . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Heating Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cooling Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Networking Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Load Shedding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Setting-up Network Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Network Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Optimum Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Requirements for Optimum Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Emergency Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Emergency Initiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

The PID Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Proportional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

LX Series Unit Ventilator Controller User’s Guide4

Page 5

Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

How It Is Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Derivative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Deadband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Alarm Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Alarm Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Alarm Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Heartbeat Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Disconnect Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Emergency Mode Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

User-Set Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Setting up the Unit Ventilator Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Persistent Network Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Setting Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

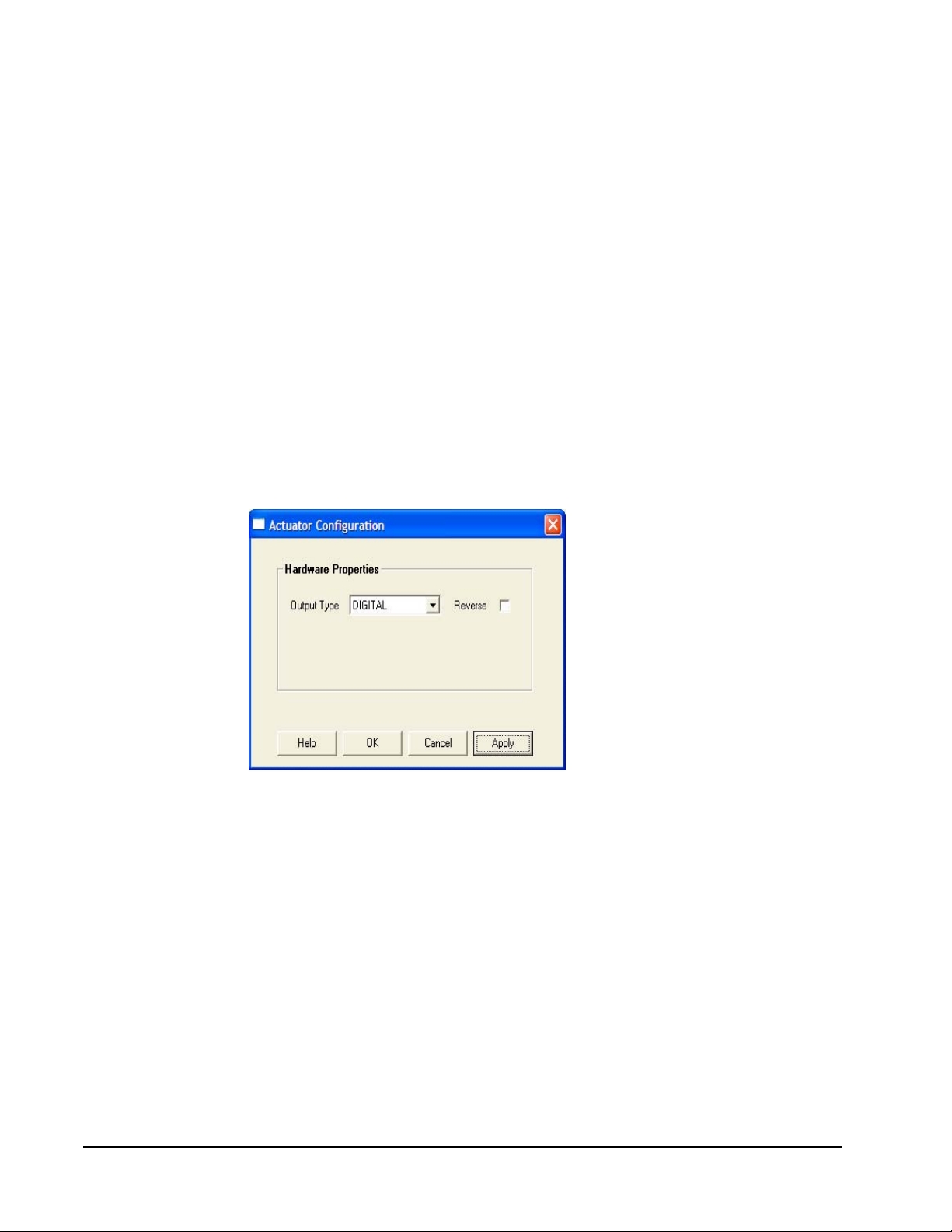

Output Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Output Signal Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configuring an Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configuring an Output Represented as a Functional Block. . . . . . . . . . . . . . . . . . . . . . . . . 71

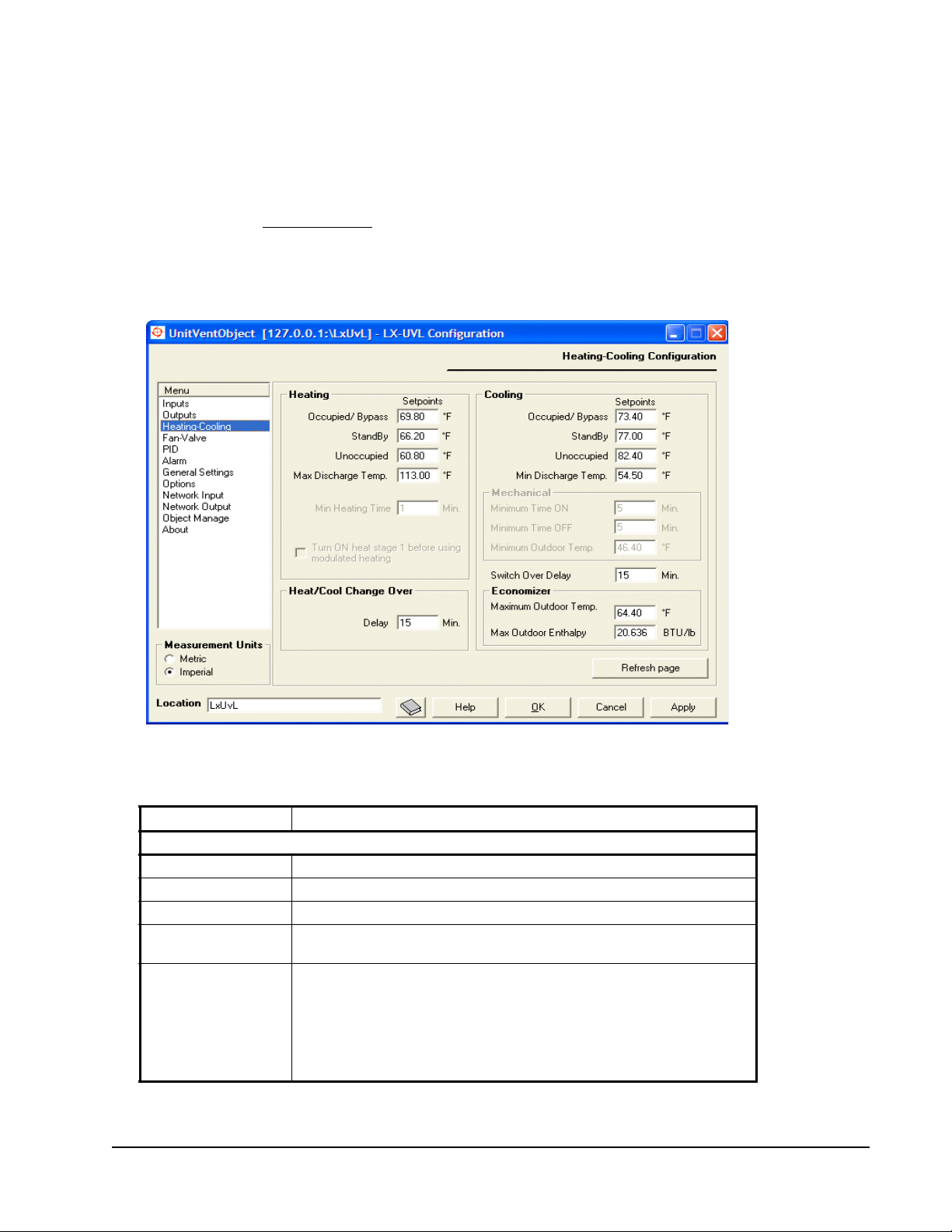

Heating-Cooling Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Optimum Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

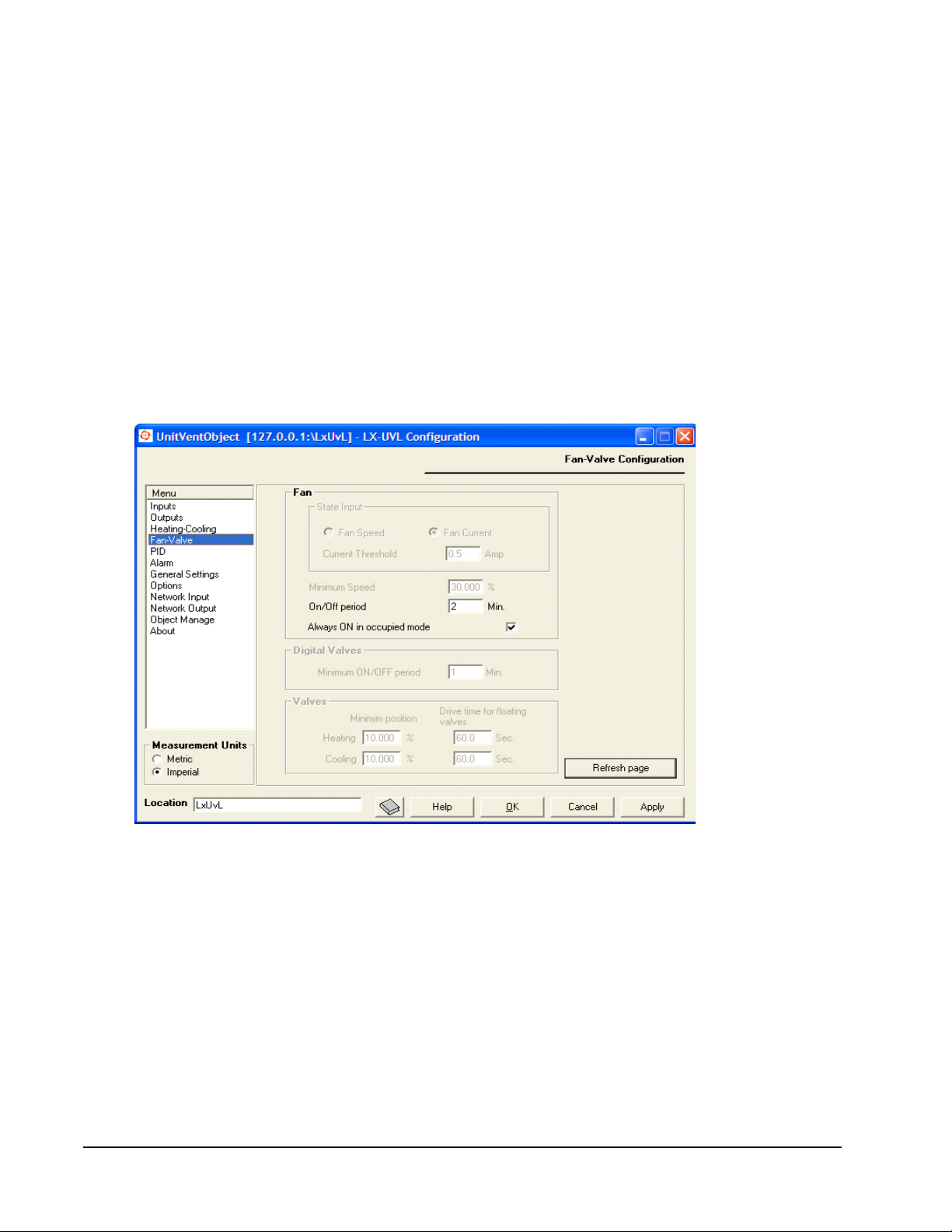

Fan-Valve Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

PID Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Space and Return Temperatures and Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

CO

2

LX Series Unit Ventilator Controller User’s Guide 5

Page 6

Discharge Temperature and Auxiliary Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Mixed Air Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Fan Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

General Settings Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Radiation Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

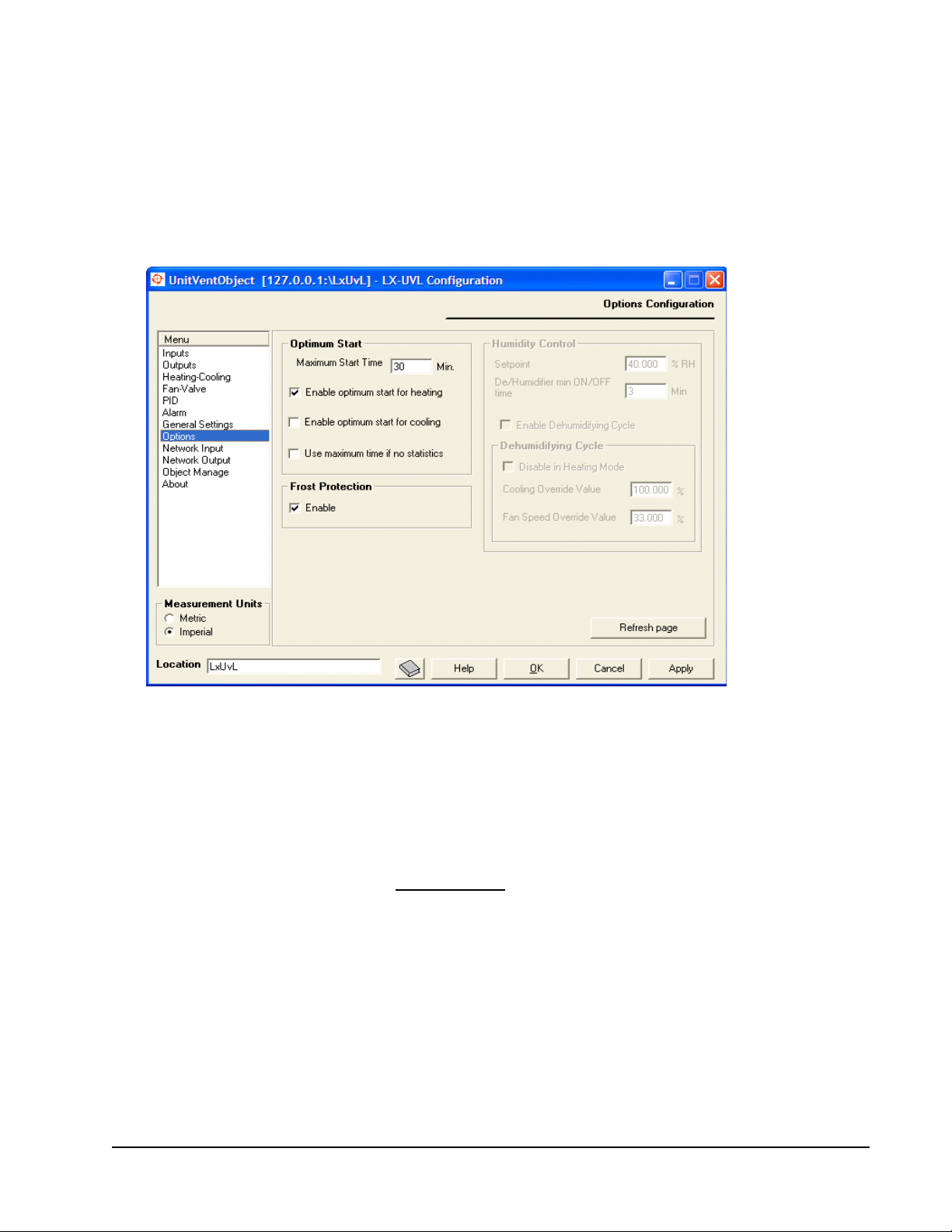

Options Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Optimum Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Frost Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Network Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Heartbeat Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Network Output Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Object Manage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Object Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Communication Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Electrical Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Out of Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Disabled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

In Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

In Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Out of Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Network Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

nviApplicMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviCO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviDischargeTemp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviEconoEnable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviEmergCmd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviExtCmdOutputx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviFanSpeedCmd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviFanState. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

LX Series Unit Ventilator Controller User’s Guide6

Page 7

nviHotWater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviMixedAirTemp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviOccCmd and nviOccManCmd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviOutdoorEnth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviOutdoorRH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviOutdoorTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviReturnTemp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviSetPoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviSetPointOffset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviShedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviSlave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviSpaceEnth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nviSpaceRH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nviSpaceTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nviWaterTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nvoCtrlOutputx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nvoDischargeSetPt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nvoEconoEnable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nvoEffectSetPt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

nvoFanSpeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

nvoHwInputx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

nvoOccState. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

nvoUValarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

nvoUVstate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

nvoSpaceTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

nvoTerminalLoad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

nvoUnitStatus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Standard Network Variable Types (SNVTs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

SNVT_hvac_emerg (103). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

SNVT_hvac_mode (108) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

LX Series Unit Ventilator Controller User’s Guide 7

Page 8

SNVT_hvac_status (112). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Alarm State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

SNVT_lev_percent (81) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

SNVT_occupancy (109) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

SNVT_ppm (29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

SNVT_switch (95). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Switch Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

SNVT_temp_p (105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

SNVT_tod_event (128) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

LX Series Unit Ventilator Controller User’s Guide8

Page 9

LX Series Unit Ventilator Controller

User's Guide

Introduction

The LX Series Unit Ventilator Controller (UVC) seamlessly integrates into a

LONWORKS® network for the control of almost any Unit Ventilator Controller due

to its wide range of output types and LONMARK® certification.

The LX Series Unit Ventilator Controller controls the following equipment:

• up to four stages of mechanical heating or cooling

• modulating heating or cooling valves

• reversing valves for application requiring a heat pump

• floating valves for heating or cooling

• unit ventilator with or without an economizer

• up to three fan speeds or variable speed fans

• humidifier and dehumidifier

• an economizer that requires analog, digital, or Pulse Width Modulation (PWM)

control signals

The UVC has five digital outputs supplying 1.0 ampere at 24 VAC. These outputs

produce digital or PWM signals.

There are also two tri-mode analog outputs on the circuit board. These outputs

provide the following signals:

• linear signals over a 0 to 10 VDC range

• 10 VDC digital or PWM signals

• digital signals of 60 mA at 12 VDC

The controller has six inputs, each capable of one of 21 possible input types. Inputs

have 12-bit resolution and are configured completely by software.

For easy maintenance and installation, the controller is equipped with plug-in

connectors that accept flat cable or wires. The controller uses a TP/FT-10 78 kbps

network configuration.

The information in this guide helps you to set up the UVC, understand the

operation of the UVC, and troubleshoot problems of the device. Information is

organized to follow the UVC configuration wizard menu.

LX Series Unit Ventilator Controller User's Guide 9

Page 10

Sensor Configuration Wizard

The UVC incorporates the sensor configuration wizard. The wizard provides

powerful and simple configuration tools for the hardware inputs. You can select

the digital or analog inputs through the software, which means there are no circuit

board jumpers to move.

Analog input signal types - resistive, voltage, current - are selected in software

without hardware jumpers. Built-in conversion tables are provided for a large

number of thermistors or other sensor types. You can easily create custom

conversion tables by setting the offset, minimum, and maximum values in one

dialog box for the input.

The sensor configuration wizard also provides direct access to network properties

of the analog or digital input including the Standard Network Variable Type

(SNVT), Heartbeat, Send on Delta, Override, Default Value, and Throttle settings.

All input features are conveniently located on one screen, which avoids the hassle

of switching back and forth between screens to fully configure an input. In

addition, the wizard provides warnings of configuration errors as they occur,

enabling you to correct mistakes quickly.

Shown by the LX-UVL wizard view in FX Workbench, the sensor configuration

wizard exists as a separate object. A separate functional block represents each

hardware input. To configure an input, select the hardware input on the left side of

the LX-UVL wizard view of the device and click the Launch button. The sensor

configuration wizard allows you to control network inputs not directly controlled

by the Unit Ventilator Controller.

Control Features

The Unit Ventilator Controller provides Proportional plus Integral plus Derivative

(PID) loops for advanced control of humidity, discharge temperature, and space

temperature. Each PID loop has an individual, configurable deadpan. In addition,

each PID loop provides gain and time adjustment for the integral and derivative

terms, and gain adjustment for the proportional term.

Whereas space temperature control is done with a PI loop only , the presence of the

derivative term adds the ability to precisely adjust space temperature control to

provide better comfort and increased savings.

The PID loop is especially useful in controlling the CO2 concentration, since this

can vary quickly and greatly as individuals enter and exit meeting rooms, and work

areas. The quick response of the PID loop also maintains duct pressure within

acceptable limits.

Humidification and dehumidification sequences provide the UVC with the ability

to maintain the space humidity at the desired level. The Unit Ventilator Controller

also provides advanced control features often associated with air handlers. These

features include Optimum Start and load shedding.

LX Series Unit Ventilator Controller User's Guide10

Page 11

The Optimum Start function maintains statistics that enable the Unit Ventilator

Controller to predict the warm-up or cool-down time period needed to make the

building ready for occupancy. The precise Optimum Start period is calculated

every day using the current outdoor air temperature.

LONMARK Functional Profile

The LX Series Unit Ventilator Controller uses LONWORKS network protocol and is

LONMARK certified for interoperability on any LONWORKS network. The Unit

Ventilator Controller is set up through its own configuration wizard and the Sensor

configuration wizard. You can use FX Workbench or any other network

management tool to install the device onto the network and bind variable

connections.

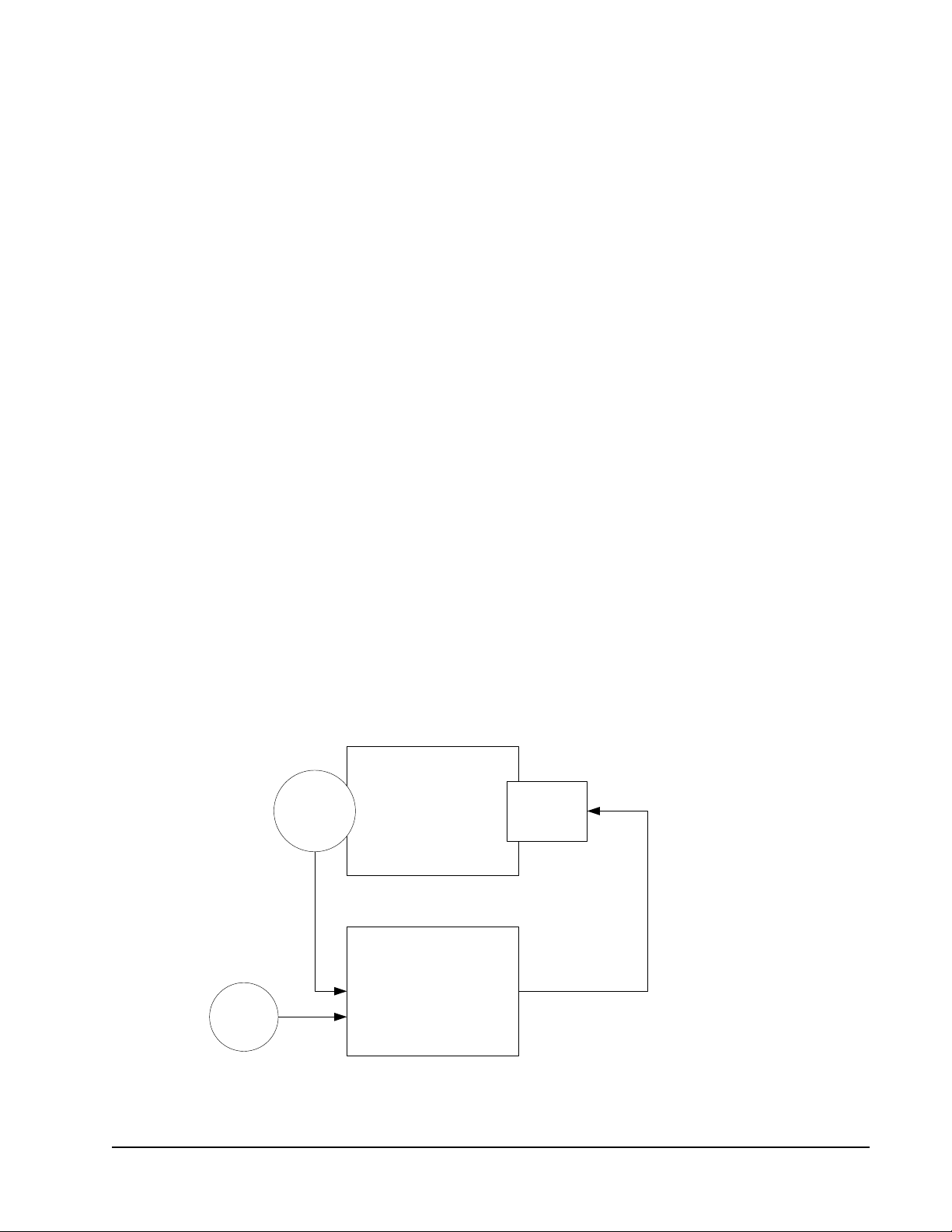

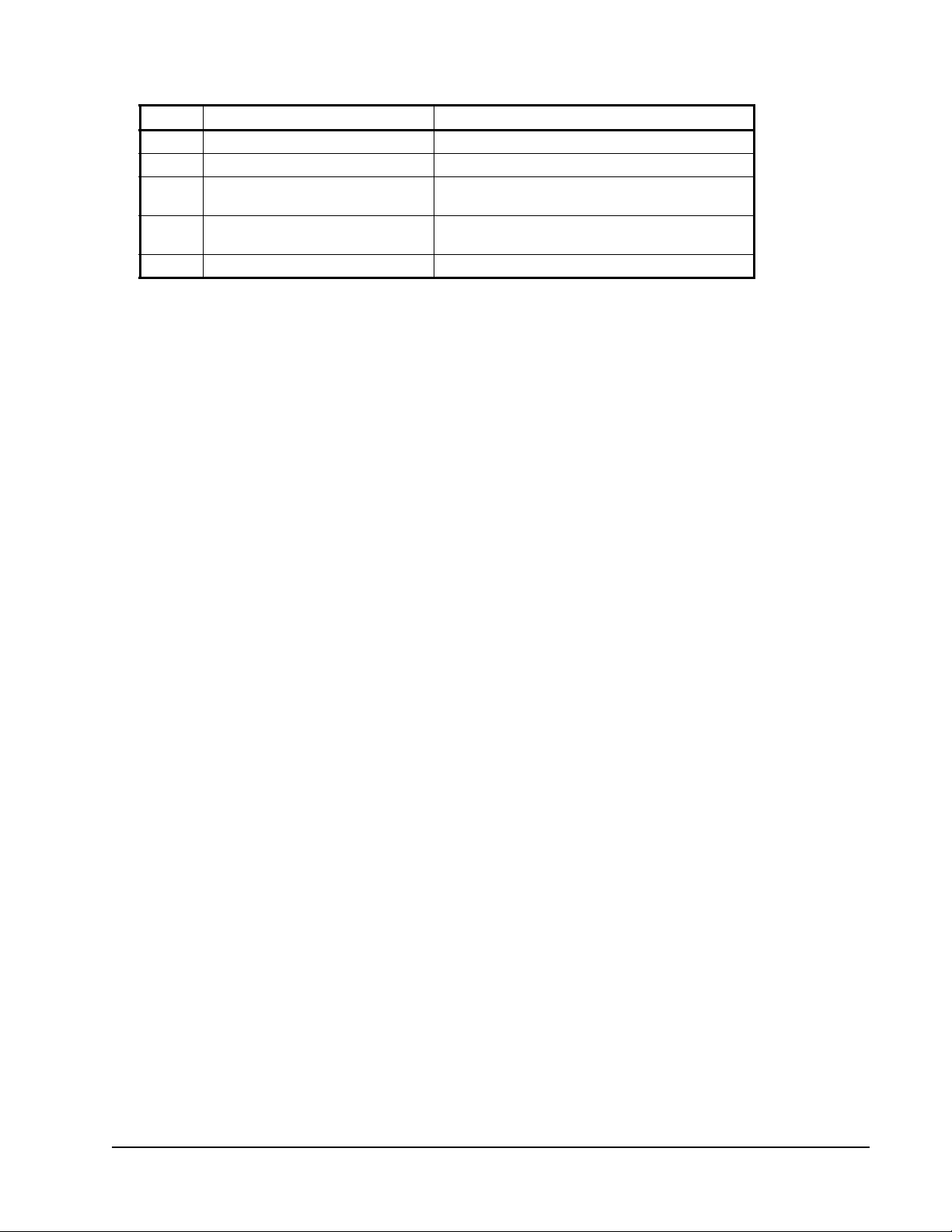

Figure 1 shows that the Unit Ventilator Controller meets the LONMARK standard

by providing the network variable inputs, network variable outputs, and

configuration properties specified by the profile. In addition, the Unit Ventilator

Controller provides many extra network variable inputs and outputs. These extra

network variables provide a greater flexibility and number of functions than

required in the LONMARK profile.

For example, you can use network input nviSlave, to slave the UVC to another

unit, whereas network output nvoUnitStatus, enables the UVC to act as the master

node. The Unit Ventilator Controller has network inputs that permit the use of

outside enthalpy sensors and space enthalpy sensors. These inputs provide better

calculation of the cooling or heating effect of the outside air upon the conditioned

space.

The input object has conversion tables and hardware properties present as

configuration properties in the area marked Manufacturer Configuration

Properties. By choosing from a list of standard thermistors, you can select different

conversion properties. The conversion tables configuration property allows you to

create your own custom tables. Hardware properties, located in the same area,

allow you to modify your input from the software object.

LX Series Unit Ventilator Controller User's Guide 11

Page 12

nviSpaceTemp

SNVT_ temp_p

nviApplicMode

SNVT_ hvac_ mode

nviSetP tOffset

SNVT_ temp_p

nviOutdoorTem p

SNVT_ temp_p

nviOutdoorR H

SNVT_lev_ percent

nviSpaceRH

SNV T_ lev_ percent

nviCO2

SNVT_ ppm

nviEmergCmd

SNV T_ hvac_ emerg

Occ. Temperature Set Points (mandatory)

nviEconoEnable

SNVT_ switch

nviFanState

SNVT_ switch

nviFanSpeedCmd

SNVT_ switch

nv iM ixed A ir Te m p

SNVT_ temp_p

nviOccManCmd

SNVT_ occupancy

nviReturnTemp

SNVT_ temp_p

nviShedding

SNVT_ switch

nviS lav e

SNVT_ hvac_ status

nviSupplyTem p

SNVT_ temp_p

nviOccCm d

SNV T_ tod_event

nviSpaceEnth

SNV T_ enthalpy

nviOutdoorE nth

SNVT_ enthalpy

nviWaterTemp

SNVT_ temp_p

nviHotWater

SNVT_ switch

nviSetpoint

SNVT_ temp_p

Manufacturer Configuration Properties

LX-UVL- 1 Unit Ventilator

Object Type # 808 0

Mandatory

Netw ork

Variables

Optional

Netw ork

Variables

C o n fig ura t io n P r o p e r tie s

Maximum S end Time (mandatory)

Minimum Send Time (optional)

Maximum R eceive Time ( optional)

CO 2 limit (optional)

Local Bypass Time (optional)

Manufacturer

Netw ork

Variables

Please see the m anual for details.

Wizard for configuration provided.

nvoSpaceTemp

SNVT_ temp_p

nv oU n itSta tu s

SNVT_ hvac_ status

nv oE ffe c tS e tp t

SNVT_ temp_p

nvoEconoEnable

SNVT_ switch

nvoFanSpeed

SNVT_ switch

nv oO ccS ta te

SNVT_ occupancy

nvoTerminalLoad

SNV T_ lev_ percent

nvoCtrlO utput1

SNVT_ switch

.

.

.

nvoCtrlO utput7

SNVT_ switch

nvoSupplySetPt

SNVT_ temp_p

Figure 1: LX Series Unit Ventilator Controller:

L

ONMARK Functional Profile

LX Series Unit Ventilator Controller User's Guide12

Page 13

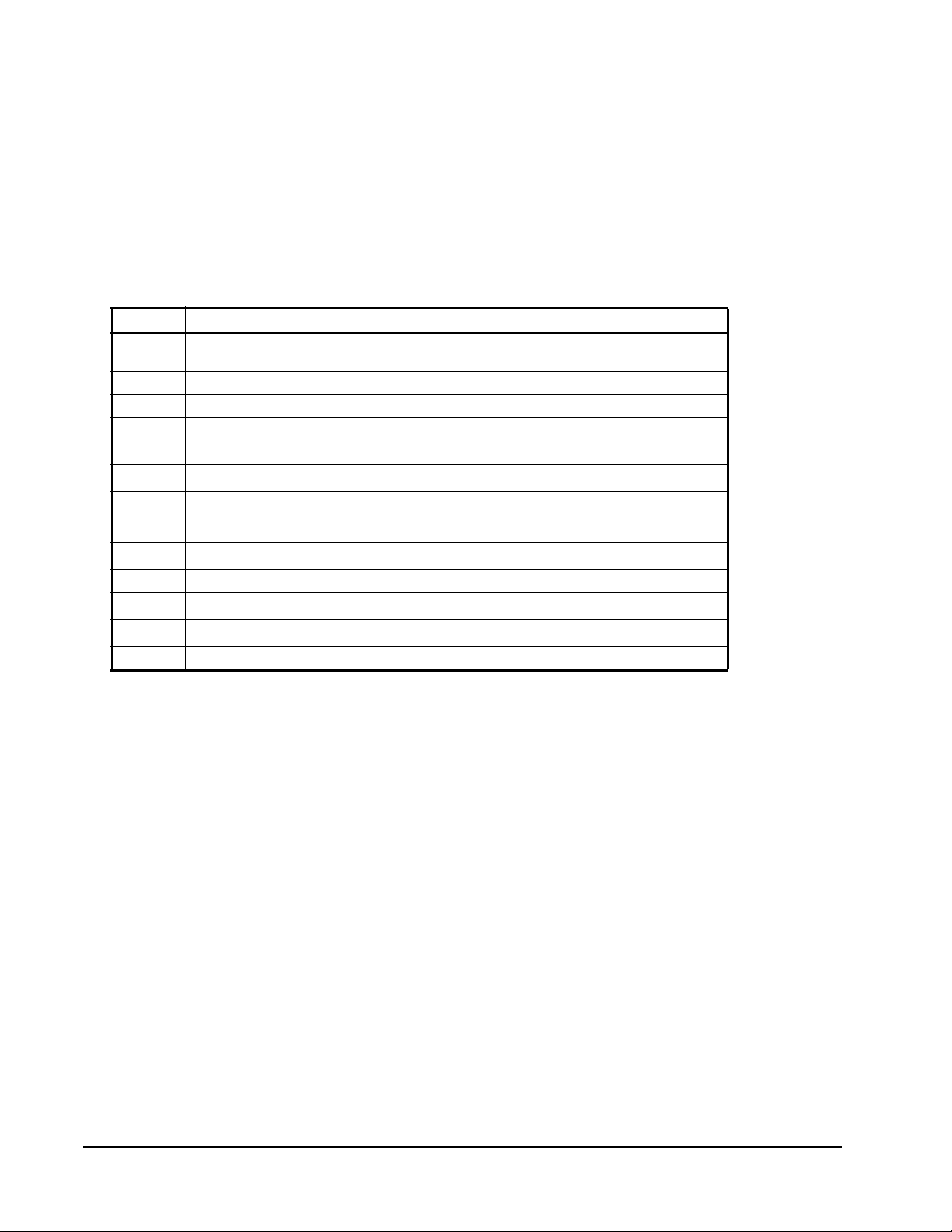

Figure 2 shows the Unit Ventilator Controller input object and the output object.

6 x LX-UVL-1 Hardware Input

Object Type #1

Mandatory

Network

Variables

Configuration Properties

Offset ( optional)

Maximum Range (optional)

Minimum Range (optional)

Minimum Send Delta (optional)

Maximum Send Time (optional)

Minimum Send Time (optional)

Override Value (optional)

Manufacturer Configuration Properties

Object M ajo r Ve rsion

Object Minor Version

Input Signal Conditioning

Hardware Properties

Translation Table

Default Value

nvoHwInput1

SNVT _xxx

nviExtCmdOutput1

SNVT _switch

Figure 2: LX Series Unit Ventilator Controller Inputs and Outputs

7 x LX-UVL-1 Hardware Output

Object Type #3

Mandatory

Network

Variables

Configuration Properties

Maximum Receive Time ( optional)

Override Value (optional)

Manufacturer Configuration Properties

Ob je c t Major Ve rsion

Ob je c t Minor Ve rsion

Output Signal Conditioning

PWM Period

Hardware Properties

Default Value

LX Series Unit Ventilator Controller User's Guide 13

Page 14

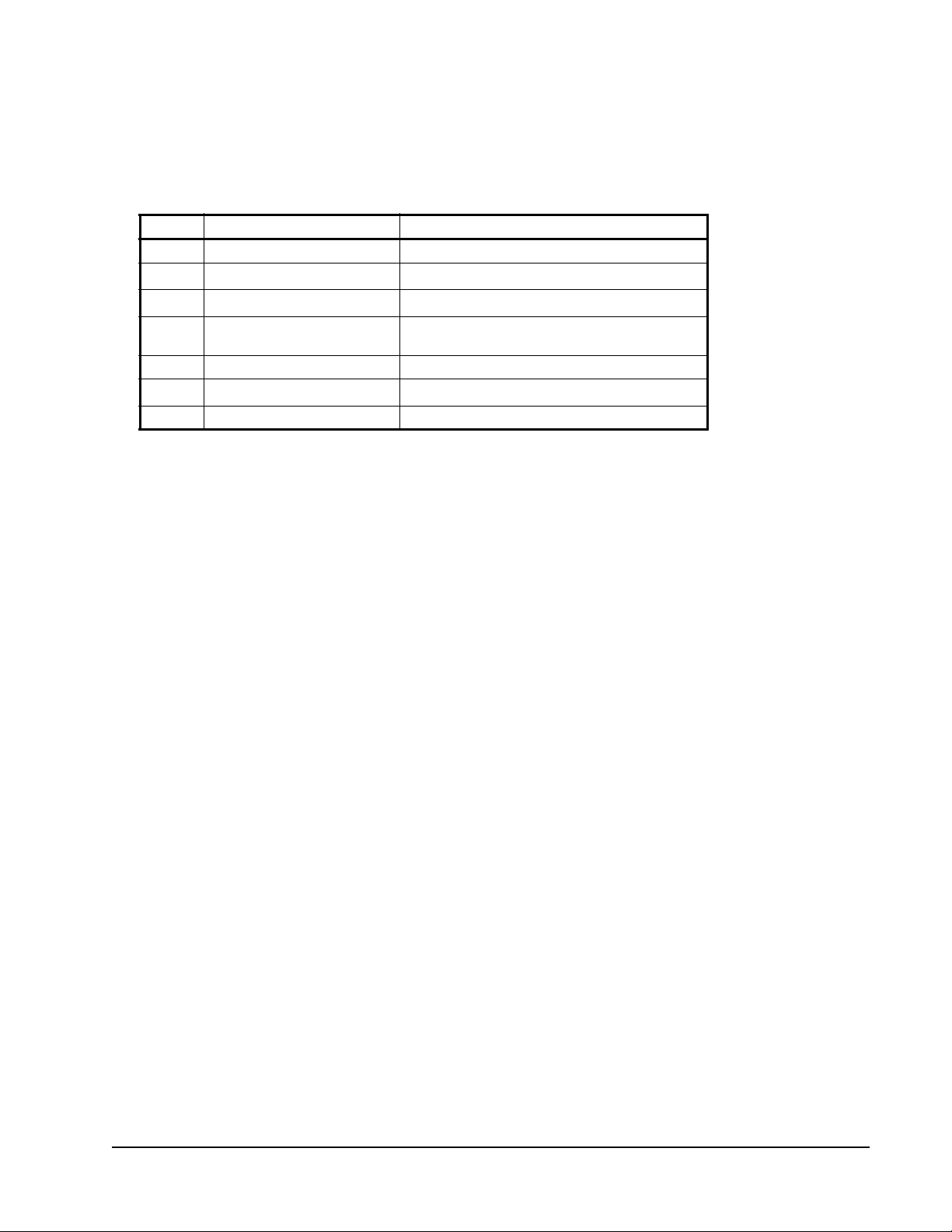

The node object displays the nvoUVstate and nvoUValarm variables as

manufacturer’s variables. These variables provide information about the alarm

conditions in the Unit Ventilator Controller and about the operating state of the

device (Figure 3).

LX-UVL - 1 Node

Object Type #0

nviRequest

SNVT _obj_request

Mandatory

Network

Variables

Optional

Network

Variables

Configuration Properties

Location (optional)

Device Major Version (optional)

Device Minor Version (optional)

Manufacturer

Network

Variables

nvoStatus

SNVT _obj_ status

nvoFileDirectory

SNVT _ address

nvoUVstate

SNVT _state_64

nvoUValarm

SNVT _state_64

Manufacturer Configuration Properties

Maximum Send Time

Figure 3: LX Series Unit Ventilator Controller

Node Object Type

Units in LONWORKS Networks

Note: Use this section if you are using the Imperial System of measure.

The Imperial System and the International System (SI) are the two main

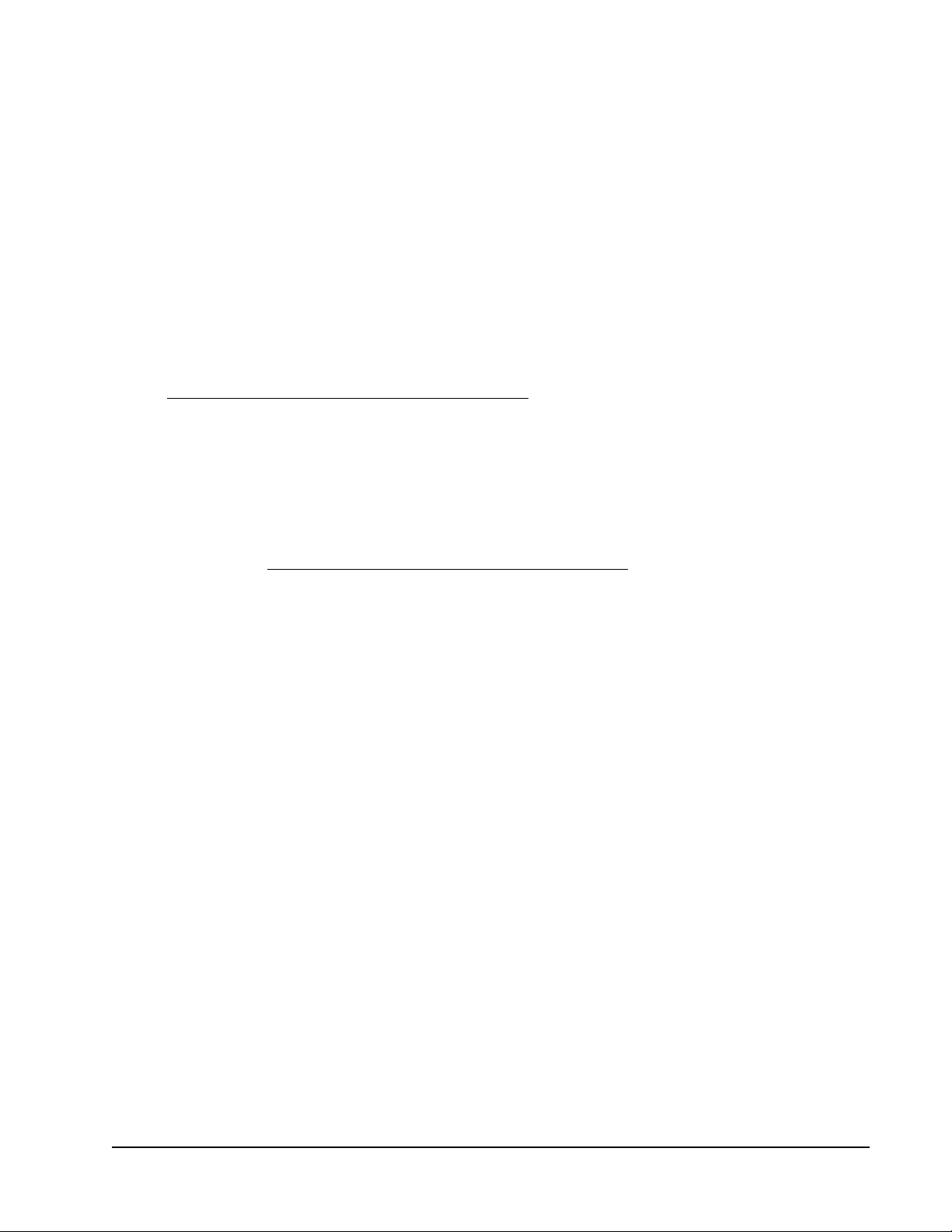

measurement systems used today. Table 1 compares Imperial units and SI units.

Table 1: Comparing Imperial and SI Units

Imperial Units SI

inch centimeter

yard meter

mile kilometer

degrees Fahrenheit degrees Centigrade

Echelon® SNVTs are based upon SI units. Thus, the most basic structure of the

ONWORKS network is SI based. This basis can lead to some unavoidable

L

problems in data conversion if you are using Imperial units.

LX Series Unit Ventilator Controller User's Guide14

Page 15

The LX-UVL wizard in FX Workbench provides some automatic conversion

between SI and Imperial units. However, these are not ideal conversions because a

whole number in one system becomes a long decimal fraction in the other. For

example, 72°F is approximately equal to 22.22222°C.

Value is written in

Imperial Units.

Data is displayed

for monitoring in

Imperial Units.

Value is translated

to SI units.

Value is rounded.

Value is stored

in SNVT.

Value is read

from SNVT.

Value is rounded.

Value is translated

to SI units.

Units

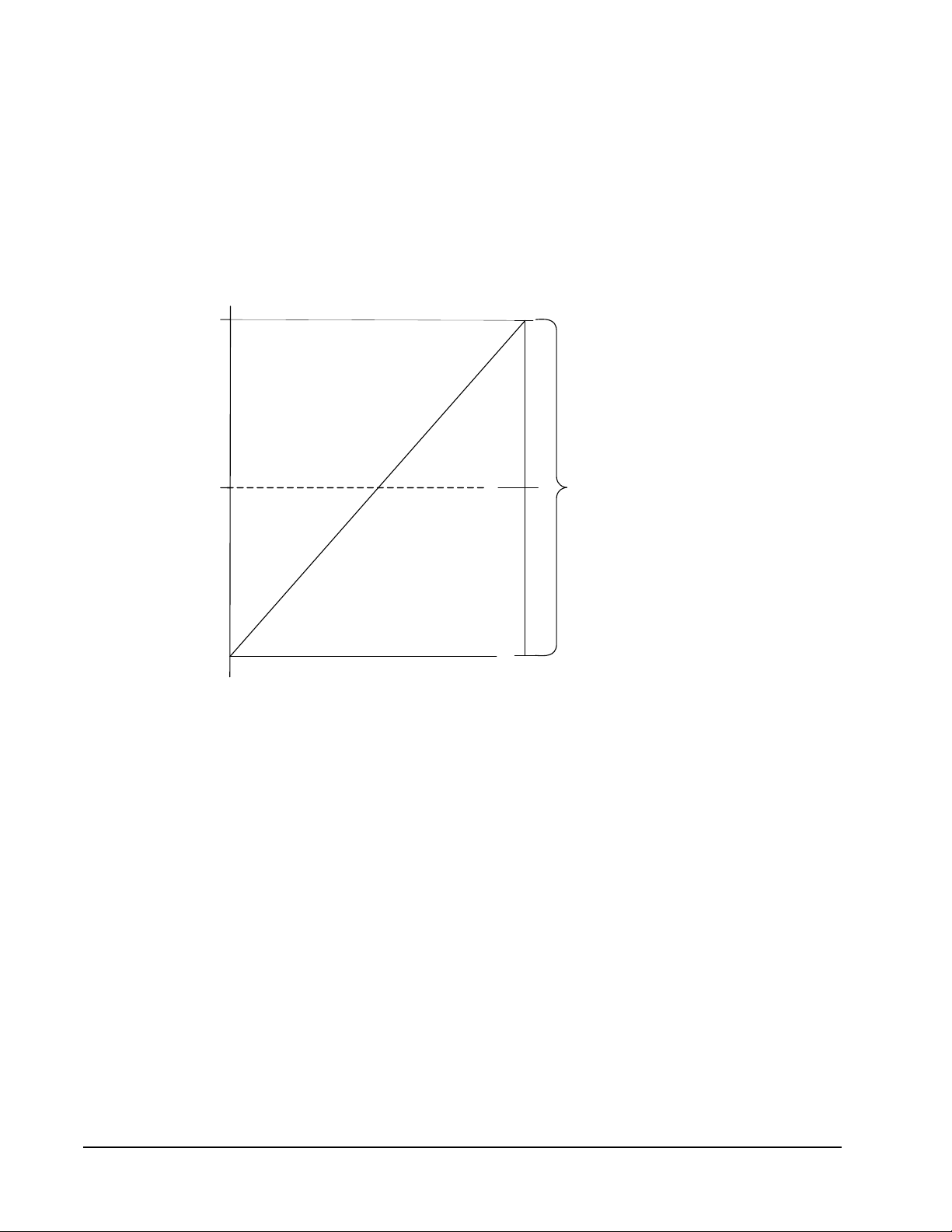

Figure 4: Writing and Reading Data in Imperial Units in the

ONWORKS Network

L

The values created by converting Imperial to SI or SI to Imperial are subject to

rounding errors. If you enter an Imperial value into a LONWORKS SNVT by using

the LX-UVL Controller configuration wizard, the value is converted after it is

entered, then rounded and written to the SNVT. When you want to monitor the

SNVT, the value must be read from the SNVT, converted, and rounded again

before it is displayed. Due to the two conversions and two rounding operations, the

value may differ slightly from what you originally entered (Figure 4).

The same process and resulting rounding error applies to Standard Configuration

Property Types (SCPTs).

Instructions for changing or modifying the units of measure used on your computer

are provided in the Selecting a Measurement System or Selecting a Language

section.

Language Selection

The following may require you to change your language settings:

• You changed your regional settings by selecting a different region in the

Regional and Language Options dialog box.

• You are working on a site that is in a linguistic region other than your own.

• You are dissatisfied with the language displayed on program menus and dialog

boxes.

LX Series Unit Ventilator Controller User's Guide 15

Page 16

You can change your language settings in the Advanced tab of the Regional and

Language Options dialog box. Instructions are provided in the following Selecting

a Measurement System or Selecting a Language section.

Selecting a Measurement System or Selecting a Language

To select units of measurement or to select a language:

1. In Microsoft® Windows XP® operating system, click Start > Control Panel.

The Control Panel appears.

2. In the Control Panel, open Date, Time, Language, and Regional Options.

3. Under the list titled Pick a Task, select and open the second item titled Change

the format of numbers, dates, and times (Figure 5).

Figure 5: Date, Time, Language, and Regional Options Screen

LX Series Unit Ventilator Controller User's Guide16

Page 17

4. Select your language region from the drop-down list provided. The number,

time, and date formats fill automatically (Figure 6).

Figure 6: Regional and Language Options Dialog Box

5. In the Number box, verify the number format uses a decimal point to indicate

numerals representing values less than 1. For example, use 123,456,789.00,

not 123 456 789,00. You must use a decimal point for the correct display of

numerals.

6. In the Regional Options dialog box, click Customize.

LX Series Unit Ventilator Controller User's Guide 17

Page 18

7. Click on the drop-down arrow next to the box labeled Measurement system

and select Metric (Figure 7).

Figure 7: Customize Regional Options

8. Verify the Decimal symbol box contains a decimal symbol. If the Decimal

symbol box does not contain a decimal symbol, select the symbol in the box,

and click Apply.

9. Click OK.

10. Click the Advanced tab and choose a language region by selecting from the

drop-down list. Verify the correct language appears on program menus.

11. Click OK.

You have now set the units to appear in the LX-UVL wizard. If you have chosen to

display Imperial units, remember that the SNVTs are still using SI units. If you are

viewing the data in Imperial units, you are viewing a converted, rounded value.

LX Series Unit Ventilator Controller User's Guide18

Page 19

Unit Ventilator Controller Installation Overview

Figure 8 shows one possible installation of the Unit Ventilator Controller. Inputs,

outputs, ducts, and heating or cooling units have been marked for your

convenience.

Note: Not all possible sensors are shown.

LX-UVL- 1 Installation Overview

Unit Ventilator Enclosure

Damper

Intake A ir

Filter

OAH

Fresh Air

(Economizer)

Damper

Damper

Unit Ventilator Enclosure

Mixed

Air

C

O

3 Fan

Speeds

Return

MAT DATOAT

Air

RAT

Heating

Coolin g

Unit Ventilator Enclosure

Humidifier

Discharge

Air

Sensor Symbols

Humidity

Temperature

Carbon Dioxide

Digital Input

Humidity

Temperature

Setpoint Offsett

MAT Mixed Air Temperature

C

O

OAH Outside Air Humidity

OAT Outside Air Temperature

Occupancy

Conditioned Space

RAT Return Air Temperature

DAT Discharge Air Temperature

Figure 8: Possible LX-UVL Installation

Inputs

The Unit Ventilator Controller has six universal inputs. You can configure

universal inputs by using the Unit Ventilator Controller configuration wizard.

Universal inputs are configured as either:

• analog inputs sensing either current or voltage, or

• digital inputs or 10k ohm resistance inputs

Note: Because the Unit Ventilator Controller can connect to a maximum of six

sensors, you may want to connect some sensors using the LONWORKS

network. All valid network inputs have priority over hardware inputs.

LX Series Unit Ventilator Controller User's Guide 19

Page 20

10k Ohm or Digital Input

The universal input, when configured as a 10k ohm or digital input, accepts a 10k

ohm resistance input or a digital input such as a switch, also known as a cold

contact.

The 10k ohm resistance range accommodates 10k ohm thermistors used in space

temperature sensors or duct temperature sensors, or a 10k ohm potentiometer used

as a setpoint offset.

Use the conversion table for resistance input of more than 10k ohm. The digital

range accommodates the occupancy contact, bypass switch, and window switch.

See Figure 9 for wiring information for both 10k ohm resistance and digital inputs.

LX-UVL

1

I

+

Both inputs are configured as 10 k Ohm

or Digital Input Configuration could be done

with either the LX -UVL wizard in or the

Hardware Input Wizard

Figure 9: 10k Ohm or Digital Input

3

I2I

–

++ + + +

I4 I6I5

––

Thermistor

10kO hm

Contact

NO -NC

LX Series Unit Ventilator Controller User's Guide20

Page 21

Analog Inputs

Analog inputs include current inputs with a range of 4 – 20 mA, and voltage inputs

with a range of 0 – 10 VDC.

4 to 20 mA Analog Input, Externally Supplied

Current inputs require a power supply either on the sensor or wired in series with

the sensor. To construct the current input, a 500-ohm 0.25-watt resistor is placed

across the Unit Ventilator Controller’s input terminals. See Figure 10 and

Figure 11.

LX--UVL

1

I

–

++++++

I2I

3

4

I

I

5

––

6

I

1

8

0

Resistor:

500

Ω −

Watt

Internal 24

powersupply

¼

VDC

4–20mA

–

+

Controller source

output 4 – 20 mA

Sensor

Figure 10: Sensor Powered Analog Input

LX-UVL

Resistor:

500

24

VDC

1

I

++++++

–

Ω −

–

+

I2I

Watt

3

¼

4

I

I

5

––

4–20mA

6

I

1

8

0

O=ohm

Senso

r

–

+

O=ohm

Figure 11: Externally Powered Analog Input

LX Series Unit Ventilator Controller User's Guide 21

Page 22

Sensors and Switches

The following sensors and switches can be connected to the Unit Ventilator

Controller. See Table 3 for the sensor and switches preferred SNVT types.

Auxiliary Alarm Input

This input is used to relay an alarm from an external device onto the building

network.

Bypass Contact Input

If the UVC is in unoccupied or standby mode, you can use switch closure on the

bypass contact input to cause the controller to enter occupied mode for the time

period time set as the bypass time.

CO2 Level Input

Use this input to monitor the CO2 concentration. The CO2 concentration can be

used for Demand Control Ventilation (DCV) and to set the minimum damper

position during heating or cooling operations.

If you do not want to use the CO2 concentration input, the minimum damper

position can be set in a fixed position, or as a fixed percentage of fresh air intake.

You can find the fresh air intake percentage by a calculation of the return air,

outdoor air, and mixed air temperatures.

Discharge Temperature Input

Use the discharge temperature input to maintain the discharge air temperature

between the minimum and maximum discharge air temperature.

The discharge temperature setpoint is determined by a linear equation between the

minimum and maximum discharge air temperature and the terminal load. When

there is a high heating demand, the discharge temperature setpoint moves to its

maximum temperature. Conversely, for a high cooling demand, the discharge

temperature setpoint moves to its minimum temperature. The discharge

temperature setpoint can be viewed in the nvoDischargSetPt.

Economizer Enable Input

Select this input to allow switch closure to enable the economizer . The economizer

position can then be controlled in several different ways. See the Ventilation

section.

Emergency Contact Input

Use switch closure on this input to cause the UVC to begin emergency operation.

See the Emergency Operation

Fan Speed Selector Input

section.

Fan speed selector gives the Unit Ventilator Controller the ability to select up to

three different fan speeds.

LX Series Unit Ventilator Controller User's Guide22

Page 23

Fan State Input

The fan state input detects whether one of the three fan speeds is ON or OFF . If the

fan state input does not correspond with one of the fan outputs for a time period

known as the alarm delay, then an alarm becomes active. If the fan state input is

OFF, while one of the fan outputs is ON, then equipment requiring air circulation

remains OFF or does not modulate.

Note: All outputs except for the fan are disabled when the fan state is OFF.

Mixed Air Temperature Input

The mixed air temperature can be monitored by an alarm, thereby provide early

warning of any malfunction.

Without mixed air and discharge air temperatures, the outside air damper cannot

exceed the minimum position as determined by the Fresh Air Minimum Input

Damper Position on the General Settings screen of the LX-UVL configuration

wizard.

See the Return Air Temperature Input section for more information.

Mode Selector

Mode Selector enables selection of different modes of operation by means of an

analog signal, such as resistance, voltage, or current input.

The modes of operation available for selection from this input are auto, heat, cool,

fan only, and OFF. Table 2 describes the modes of operation.

Table 2: Modes of Operation

Mode of

Operation

Auto Operates according to its setpoints and scheduled occupancy states; this means

Heat Operates according to the heating setpoints in heating mode only. The heating

Cool Operates accordin g to the cooling setpoints in cooling mode only. The cooling

Fan Only Configures the fan ON during the scheduled occupied state. Heating and cooling is

OFF Disables the control loop to OFF. All outputs are in the OFF state.

Description

that the Unit Ventilator Controller controls heating, cooling, duct pressure, and the

fresh air damper, according to the setpoints and the configuration properties you

enter. The Unit Ventilator Controller switches between unoccupied, occupied,

standby , and bypass modes according to its schedule, and between the occupancy

and bypass contacts if these contacts are present.

setpoint may change as the controller switches scheduled states. Cooling mode is

unavailable. The fan is ON when heating is ON; the fan is OFF at other times

unless configured as ON during occupied periods.

setpoints may change as the controller switches scheduled states. Heating mode

is unavailable. The fan is ON when cooling is ON; the fan is OFF at other times

unless configured as ON during occupied periods.

not available. Fan configuration is found on the Fan-Valve screen of the Unit

Ventilator Controller configuration wizard.

LX Series Unit Ventilator Controller User's Guide 23

Page 24

Occupancy Input

Use the switch closure on the occupancy input to set the Unit Ventilator Controller

to occupied mode. The UVC exits occupied mode when the switch is opened.

Unless the controller is in bypass mode, the occupied contact does not function if

the network variables nviOccCmd and nviOccManCmd are set to unoccupied.

Outdoor Enthalpy Input

Use outdoor air enthalpy to determine if free cooling is permitted. The Ventilator

Unit Controller also accepts input directly from an outdoor enthalpy sensor.

Outdoor Humidity Input

You can use outdoor humidity and temperature to calculate the outdoor enthalpy.

Outdoor enthalpy can be used to determine if free cooling is permitted.

Outdoor Temperature Input

If outdoor humidity is available, use outdoor temperature to calculate outdoor

enthalpy and Optimum Start times. Outdoor temperature or outdoor enthalpy is

used to determine if free cooling is permitted. See the Optimum Start and

Ventilation sections for more information.

Return Air Temperature Input

The return air temperature is used to prevent the coils from freezing due to cold

bypass air. See the General Settings Configuration section.

Position the return air temperature sensor either before or after the bypass damper.

Indicate the position of the return air temperature sensor in the General Settings tab

of the Ventilation Controller configuration wizard.

When the return air temperature sensor is positioned before the bypass damper,

return air temperature can be used instead of the space temperature. To do this, the

fan must be ON and the space temperature must be unavailable.

When the return air temperature sensor is positioned after the bypass damper, use

the following temperatures to calculate the required amount of intake air:

• mixed air temperature

• outdoor air temperature

• return air temperature

Return air temperature can be monitored by an alarm. See the General Settings

Configuration section for more information.

Setpoint Offset Input

This input provides a means of varying the setpoint during occupied and standby

modes. The values from this input are added to the pair of active setpoints. See the

Calculating the Space Temperature Setpoint section.

LX Series Unit Ventilator Controller User's Guide24

Page 25

Space Enthalpy Input

Use the space enthalpy input value and the outdoor space enthalpy to enable or

disable free cooling. The Rooftop Unit Controller also accepts input directly from

a space enthalpy sensor.

Space Humidity Input

Use the space humidity sensor to provide the UVC with the space relative

humidity. Relative humidity can be used as an input to the humidity control PID

loop.

The UVC can calculate space enthalpy when provided with relative humidity and

temperature. Space enthalpy can be compared to outside enthalpy to enable or

disable free cooling.

Space Temperature Input

The UVC uses the space temperature to control heating or cooling operations. One

of the following inputs must be present for the controller to work:

• space temperature

• nviSlave

The space temperature sensor can be a 10k ohm thermistor or provide a voltage or

current input to the board.

Water Temperature Input

The Unit Ventilator Controller provides heating or cooling through a single

two-pipe system with a heating or cooling valve. If this system is used, the device

must know the state, either hot or cold, of the available water. When the hardware

water temperature input is used, the Unit Ventilator Controller determines if the

water is hot or cold enough for heating or cooling.

The network inputs nviHotW ater and nviWaterT emp are available for receiving the

water state or temperature. If nviHotWater state and value are zero, then the UVC

functions as if the water is cold. If nviHotWater state and value are not zero, then

the controller functions as if the water is hot. If the water temperature is colder

then the space temperature, the water is considered cold; if water temperature is

higher than the space temperature, the water is considered hot. Both inputs have

priority over the hardware input; however, if both values are received,

nviHotWater has priority over the nviWaterTemp.

LX Series Unit Ventilator Controller User's Guide 25

Page 26

Window Contact Input

If the Unit Ventilator Controller is in occupied, bypass, or standby mode, and the

ventilator is in operation (meaning that one of the fan speeds is ON), then a switch

closure on the window contact input causes the UVC to enter unoccupied mode.

All outputs are turned OFF until a demand from the unoccupied cooling and

heating space temperature setpoints arrives and commands the unit into heating or

cooling.

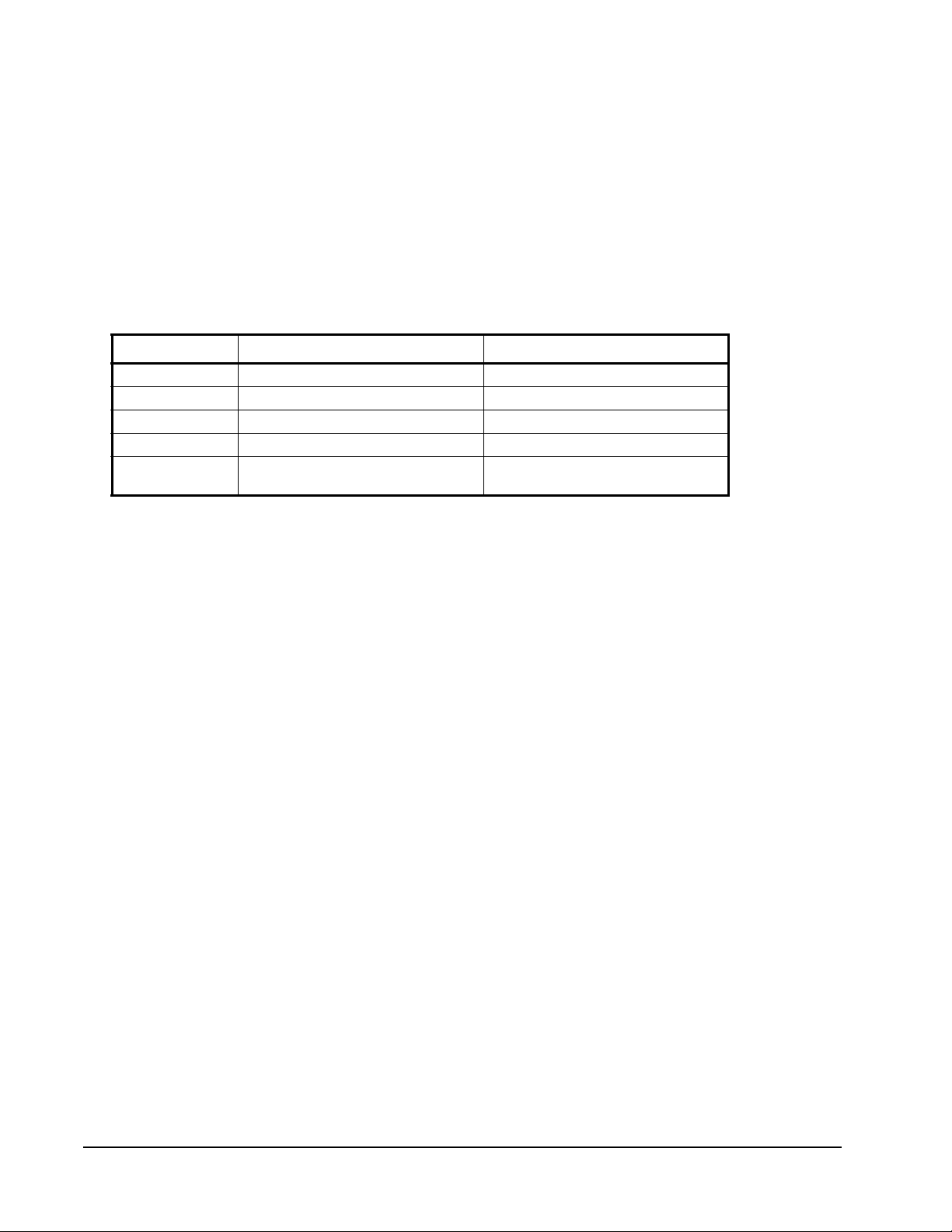

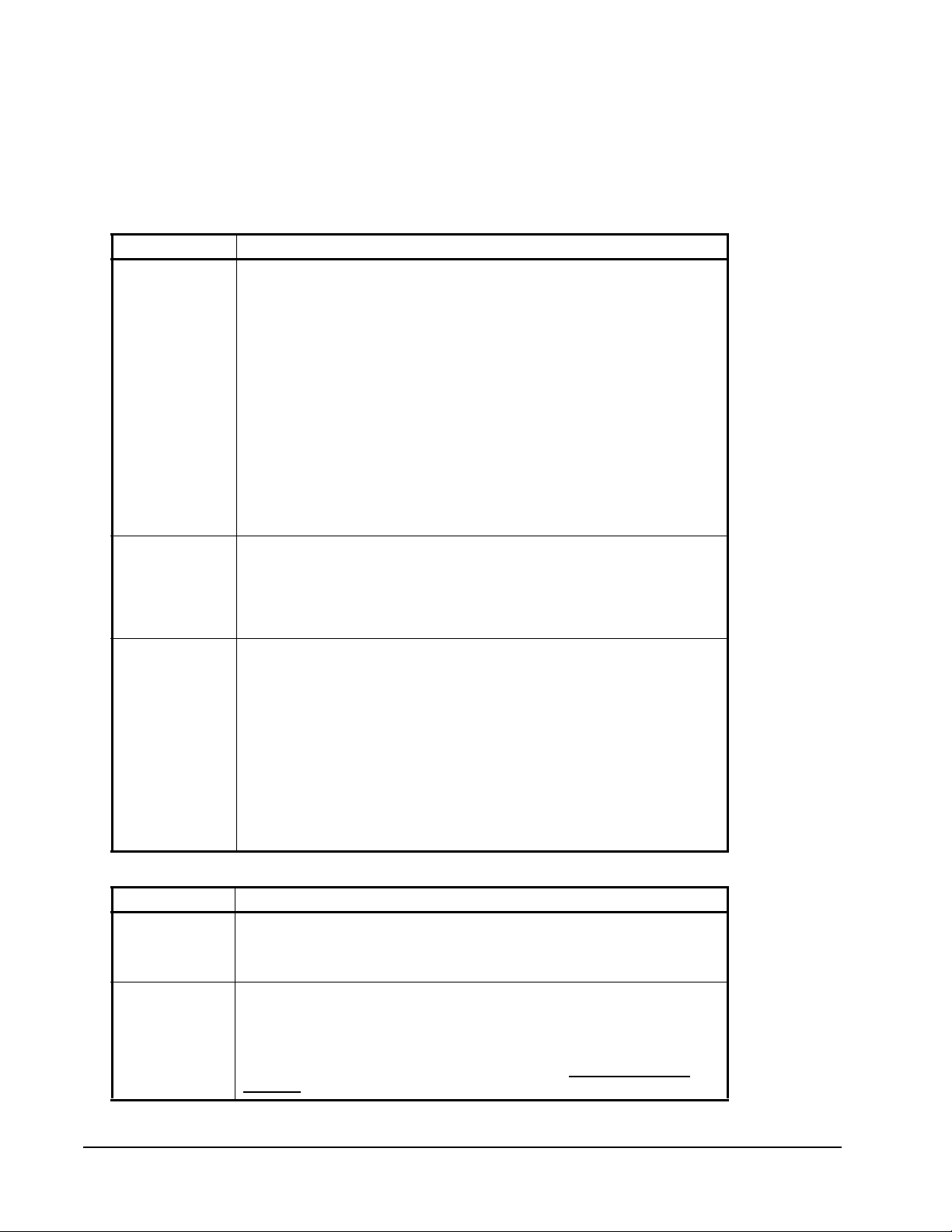

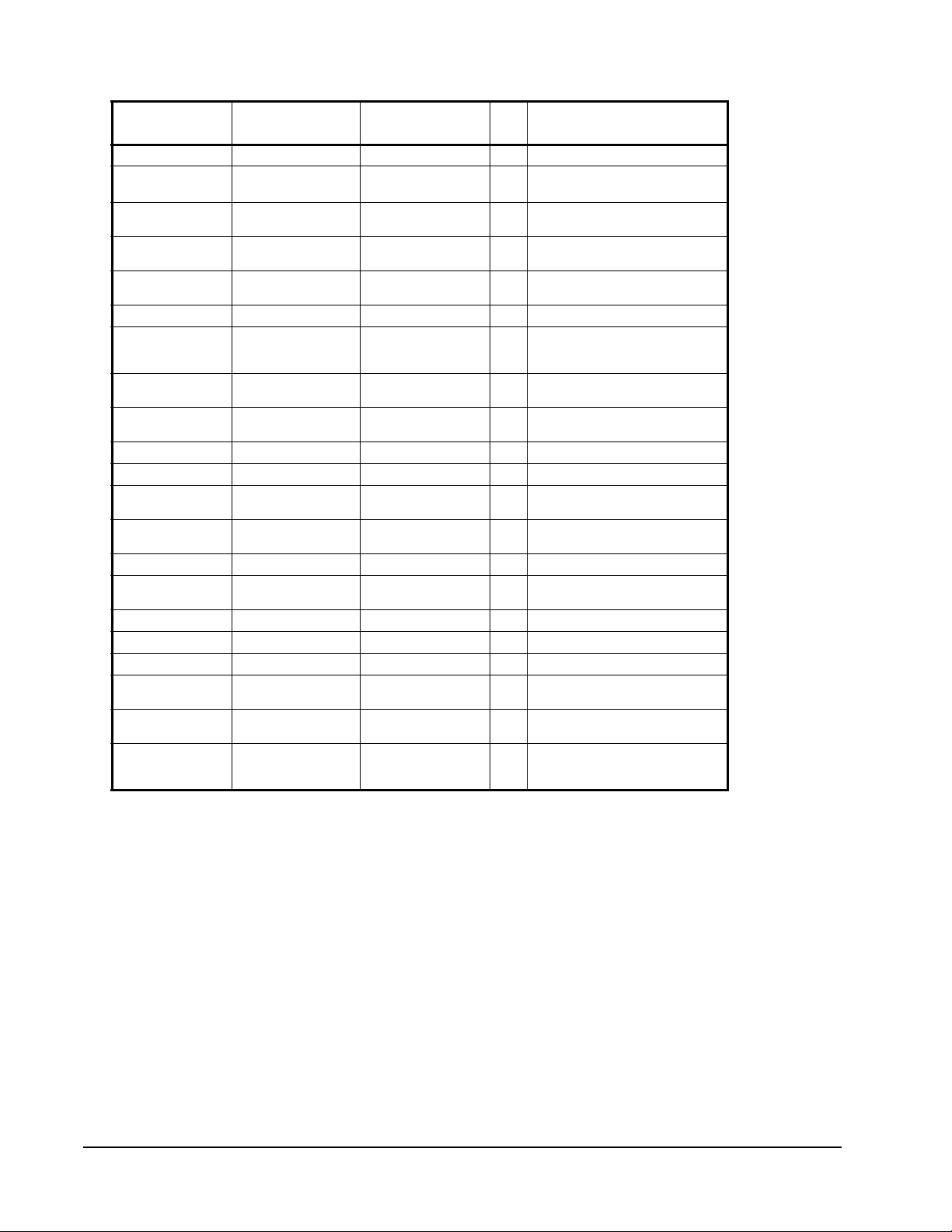

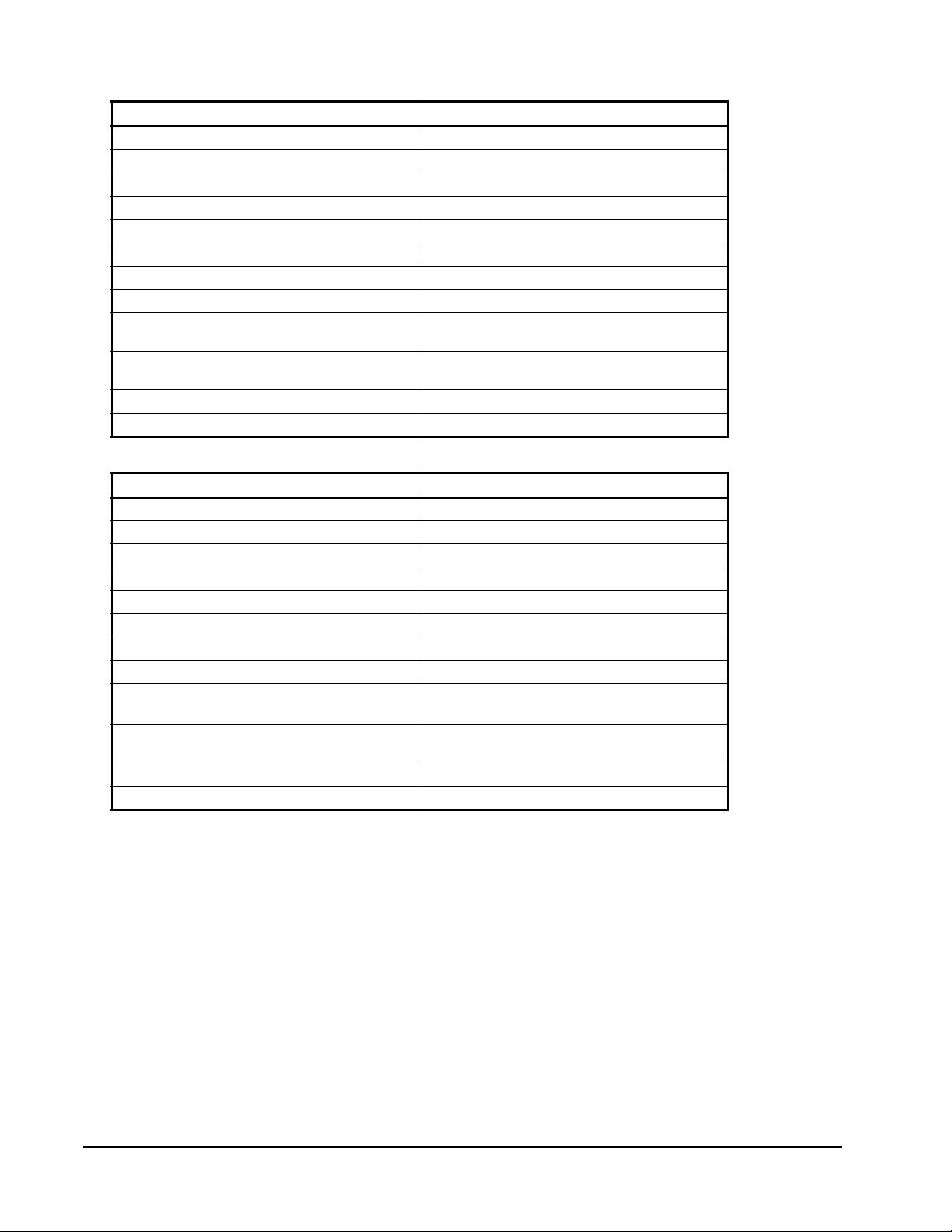

Table 3: Sensor and Switch Preferred SNVT Type

Sensor or Switch Preferred SNVT Type

Auxiliary Alarm Input SNVT_amp

Bypass Contact Input SNVT_lev_disc

CO

Level Input SNVT_ppm

2

Discharge Temperature Input SNVT_temp

Emergency Contact In put SNVT_lev_disc

Fan Speed Selector Input SNVT_lev_disc

Fan State Input SNVT_amp

Mixed Air Temperature Input SNVT_temp

Mode Selector SNVT_hvac_mode

Occupancy Input SNVT_lev_disc

Outdoor Enthalpy Input SNVT_enthalpy

Outdoor Humidity Input SNVT_percent

Outdoor Temperature Input SNVT_temp

Return Air Temperature Input SNVT_temp

Setpoint Offset Input SNVT_temp

Space Enthalpy Input SNVT_enthalpy

Space Humidity Input SNVT_lev_percent

Space Temperature Input SNVT_temp

Water Temperature Input SNVT_temp

Window Contact Input SNVT_lev_disc

SNVT_amp_ac

SNVT_amp_f

SNVT_lev_disc

SNVT_lev_occupancy

SNVT_temp_p

SNVT_lev_occupancy

SNVT_lev_occupancy

SNVT_amp_ac

SNVT_amp_f

SNVT_temp_f

SNVT_lev_occupancy

SNVT_temp_p

SNVT_temp_f

SNVT_temp_diff

SNVT_temp_f

SNVT_temp_f

SNVT_switch

SNVT_lev_percent

SNVT_switch

SNVT_temp_f

SNVT_temp_p

SNVT_switch

SNVT_temp_f

SNVT_switch

SNVT_switch

SNVT_lev_percent

SNVT_switch

SNVT_lev_disc

SNVT_temp_p

SNVT_switch

SNVT_temp_f

SNVT_temp_p

SNVT_temp_f

SNVT_temp_p

SNVT_temp_p

SNVT_temp_p

SNVT_occupancy

LX Series Unit Ventilator Controller User's Guide26

Page 27

Outputs

The Unit Ventilator Controller has five digital outputs (DO1, DO2, DO3, DO4, and

DO5), and two analog outputs (AO1 and AO2). Descriptions of these outputs

follow.

Analog Output

The Unit Ventilator Controller analog outputs are versatile and can be configured

as analog, digital, or PWM outputs. When the analog output is configured with the

wizard as a digital output, it supplies 60 mA at 12 VDC. This ability is useful when

driving relays external to the board. See Figure 12.

The characteristics of the analog outputs are described in Table 4.

Analog Output Protection

Analog Outputs are protected by an auto-reset fuse with a maximum current

capacity defined by the following two points:

• 100 mA at 68°F (20°C)

• 0 mA at 140°F (60°C)

Connect a diode to

the relay terminal.

(Ir = 1A at Vr=25 V)

K

12Vdc Relay

Max load 200 Ohm

180

DO1 C DO2 C DO3 C DO4 C DO5 C AO1 AO2–

Figure 12: Analog Output Driving an External Relay

Table 4: Tri-Mode Analog Output Characteristics

Mode Maximum Current and Voltage Voltage Range

Digital 60 mA at 12 VDC (200 ohm load) 0 – 12 VDC

Analog 50 mA at 10 VDC 0 – 10 VDC (linear)

PWM 50 mA at 10 VDC 0 or 10 VDC

Digital Outputs

The digital outputs of the UVC use triacs to switch the output signal. Each digital

output is capable of conducting 1 ampere.

The digital outputs work as a switch to control the current (Figure 13). The current

source is separate from the transformers supplying the current for the UVC

controller.

LX Series Unit Ventilator Controller User's Guide 27

Page 28

The UVC uses a half-wave power supply. Any other half-wave power supply that

connects with the controller through the outputs or inputs must be in phase with the

power supply of the controller. Do not share grounds between a full-wave and a

half-wave power supply.

Power Supply

24 VAC

LC

Max. Current

1A at 24 VAC

DO1 C DO2 C DO3 C DO4 C DO5 C AO1 AO2–

Figure 13: Unit Ventilator Controller Digital Outputs

You can reverse each of the digital output’s scales by using the Unit Ventilation

configuration wizard. Normally , ON is a 100% output; when the output is reversed,

ON is a 0% output.

You can override all digital outputs to a previously set value using the UVC object

override command. The override values are set during the configuration process.

The configuration wizard provides a menu for issuing object commands, including

the override command. See the Object Manage section for more information.

LX Series Unit Ventilator Controller User's Guide28

Page 29

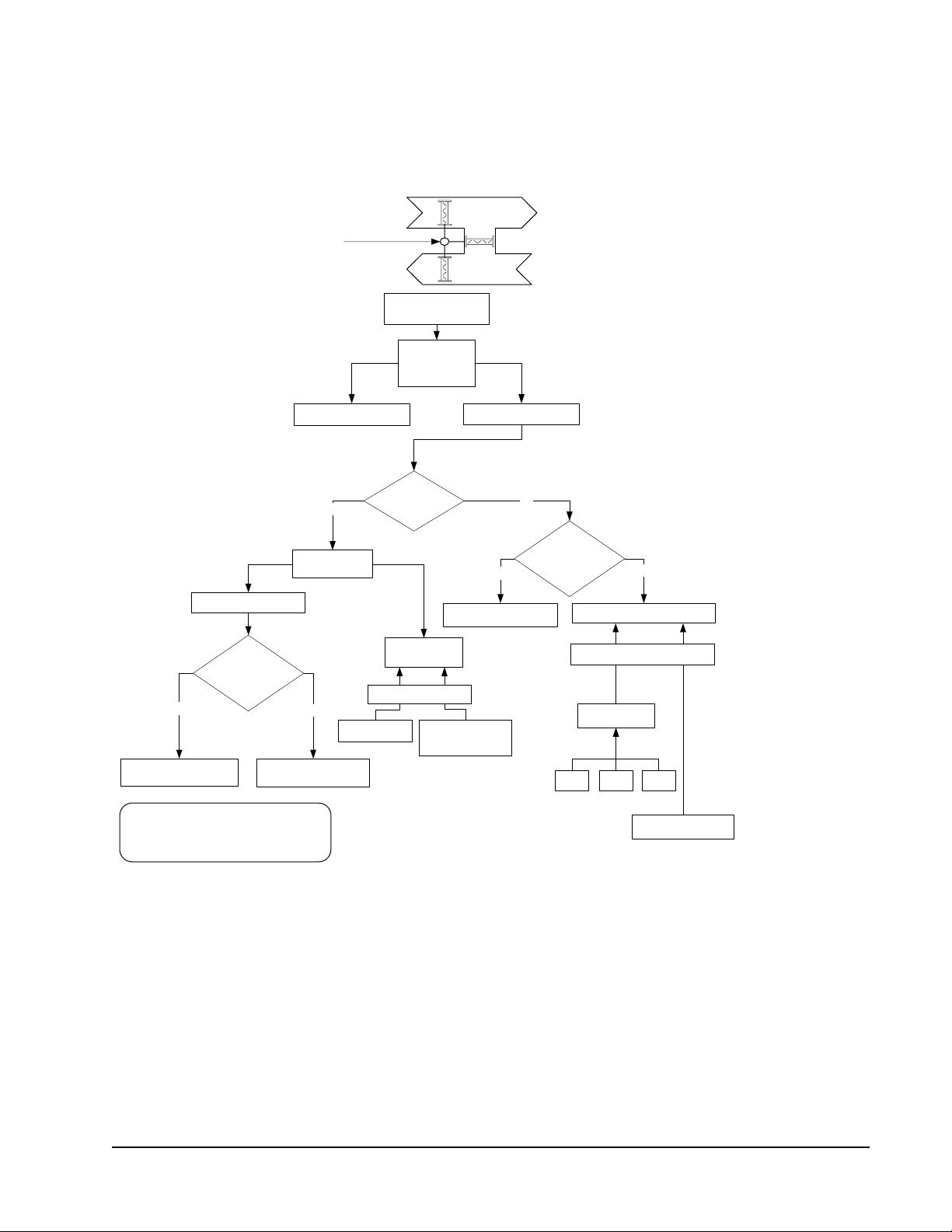

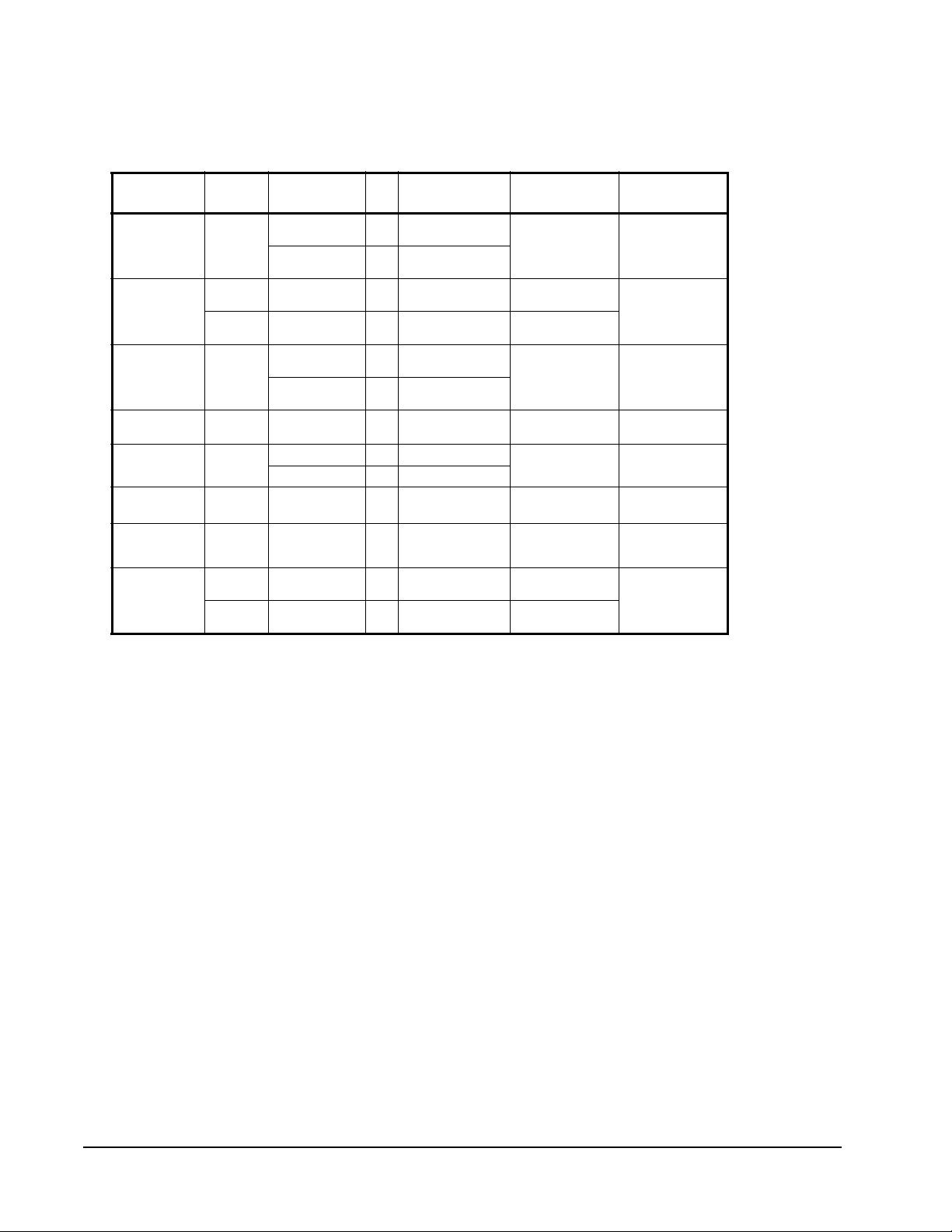

Staged Outputs

You can organize the outputs into stages when there are multiple heating or cooling

outputs. Stages turn on sequentially one after the other. The heating or cooling

stages (n) must be open for the period of time specified in the minimum heating

period before heating or cooling stage (n+1) can turn on. For example, heating

stage 1 must be open for the minimum heating period before duct heating stage 2

turns on. See Figure 14.

Heating

commanded to

100% ON at

this time.

Stage 1

turns ON.

100%

Stage 1 ON Stage 1 ON

Heating

Effort

Time

Minimum

heating

period

Stage 2

turns ON.

Stage 2 ON

Minimum

heating

period

Stage 3

turns ON.

Stage 3 ON

Stage 2 ON

Stage 1 ON

Minimum

heating

period

Figure 14: Staged Outputs

Output Selections

There are 31 possible output selections. Several output selections are dependent

upon other output selections. For example, cooling 1–4 can be blocked depending

on the setting of the reversing valve.

Fan Speed 1–3

This output provides digital fan speed control. See the Fan Operation section for

more information on fan speed operation.

Heating Outputs 1–4

Heating outputs one to four are staged outputs that are turned ON after heating

valve outputs, if any, are 100% open.

Cooling Outputs 1–4

Cooling outputs 1-4 are staged outputs, which are turned ON after cooling valve

outputs, if any, are 100% open.

Reversing Valve

The reversing valve has two states. If the reversing valve is defined and is ON,

then cooling outputs 1–3 act as heating outputs.

LX Series Unit Ventilator Controller User's Guide 29

Page 30

Humidifier and Dehumidifier Outputs

Both digital and analog humidifier and dehumidifier outputs are available. The fan

must be ON to enable the humidifier and dehumidifier outputs.

The UVC uses the assigned outputs to maintain the humidity at a level defined by

the humidity setpoint on the general settings menu. A delay occurs when switching

between humidification and dehumidification. You can enter the time period for

the delay on the general settings screen. The Unit Ventilator Controller also offers

the ability to dehumidify with the cooling coil. See the Humidity Control section

for more information.

Minimum Fresh Air Enable (MIN_FRESH_AIR_ENABLE)

This output enables the fresh air damper to move to the minimum position.

Minimum fresh air is enabled when the occupancy state is OC_OCCUPIED, or

OC_BYPASS and the fan is ON.

Economizer Enable

When this output is ON, the economizer can be used for free cooling. This output

is enabled when the outdoor air temperature is below the economizer maximum

outdoor temperature.

Heat Valve ON-OFF

This output operates the digital heating valve.

Cool Valve ON-OFF

This output operates the digital cooling valve.

Heat Cool Valve ON-OFF

This output operates the digital heating-cooling valve according to the water

temperature.

Heat Valve Open or Close

These outputs operate heating floating valves.

Cooling Valve Open or Close

These outputs operate cooling floating valves.

Heat Cool Valve Open or Close

These outputs operate heating-cooling floating valves according to the water

temperature.

Fan Speed Modulate (FAN_SPEED_MOD)

Provides a variable speed fan control output.

LX Series Unit Ventilator Controller User's Guide30

Page 31

Heating Modulate (HEATING_MOD)

Provides the modulated heating control output.

Heating or Cooling Valve Modulate (HEATING_VALVE_MOD) (COOLING_VALVE_MOD)

These outputs provide modulated heating or cooling valve outputs.

Fresh Air Damper Modulate (FRESH_AIR_DAMPER_MOD)

This output provides a modulated fresh air damper signal.

Fresh Air Damper Open or Close

These outputs operate the floating fresh air damper.

Mode Selection

The UVC has several different modes of operation. Each mode has a unique set of

setpoints. Modes can be initiated as a result of any one item in the following list:

• change of value in nviOccCmd

• change of value in nviOccManCmd

• occupied button press

• bypass button press

• window open/close contact

While in any mode, the controller can enter a heating or cooling state as required to

maintain the space within the limits of the setpoints. Setpoints for each mode are

shown in Table 5.

Network Variables Used for Mode Selection

Table 5: Values of nviOccCmd or nviOccManCmd and Modes

Identifier Unit Ventilator Controller

Mode

OC_OCCUPIED Occupied mode Occupied heat and cool

OC_UNOCCUPIED Unoccupied mode Unoccupied heat and cool

OC_BYPASS Bypass mode Occupied heat and cool

OC_STANDBY Standby mode Standby heat and cool

OC_NUL Invalid data Unoccupied heat and cool

The network variable nviOccCmd commands the UVC to change modes according

to the value of the variable. The value of nviOccCmd is changed by a schedule or

other supervisory input.

Setpoints

LX Series Unit Ventilator Controller User's Guide 31

Page 32

You can manually command the UVC to change modes through network variable

nviOccManCmd. Because manual commands (commands entered by the operator)

have priority over mode commands from a scheduler node, nviOccManCmd has

priority over nviOccCmd. Both network variable inputs have priority over the

occupancy contact or bypass button press. Table 5 shows possible values of

nviOccCmd and nviOccManCmd.

The network variable nviOccManCmd has priority over nviOccCmd. Therefore,

mode commands entered manually have priority over mode commands from a

scheduler node. Both network variable inputs have priority over the occupancy

contact or bypass button press. See Table 6.

Table 6: Priorities of Mode Changing Inputs

1

Priority Level

1 Window Contact Enter unoccupied mode

2 nviOccManCmd Manual mode change

3 nviOccCmd Scheduled mode change

4 Occupancy contact Enter occupied mode

5 Bypass button press Enter bypass mode and start the

1. Priority 1 is the highest.

Input Function

bypass timer

Certain conditions must exist for the controller to be in either unoccupied or

occupied mode. If nviOccCmd and nviOccManCmd are set to OC_NUL,

OC_BYPASS, or OC_STANDBY, and the occupancy contact is OFF or

unassigned, then the UVC is in unoccupied mode. If nviOccCmd and

nviOccManCmd are set to OC_NUL, OC_BYPASS, or OC_STANDBY, and the

occupancy contact is ON, then the Unit Ventilator Controller is in occupied mode.

However, when you press the bypass button in either unoccupied or standby mode,

it causes the Unit Ventilator Controller to enter bypass mode.

When the window contact is ON, the schedule is set to OC_UNOCCUPIED. The

effect on the Unit Ventilator Controller is to shut down the fan and all other

mechanical equipment. For example, if the window is opened, an unoccupied

room remains unheated ensuring that heat and energy is not lost.

Occupied Mode

Occupied mode ensures the building environment is comfortable for building

occupants.

LX Series Unit Ventilator Controller User's Guide32

Page 33

Starting Occupied Mode

Occupied mode uses the occupied setpoints that you set in the configuration

wizard. During occupied mode, the UVC uses the damper and outputs to heat or

cool as required to maintain the space within the limits set by the occupied

setpoints. If configured, the UV also controls fresh air intake to maintain CO2

concentration as configured. Occupied mode begins as result of one of the

following events:

• A command is received on nviOccManCmd or nviOccCmd. To modify these

network variables, use a computer connected to a network to manually

command nviOccManCmd, or use the building schedule to modify

nviOccCmd.

• The occupancy switch is closed when both nviOccCmd and nviOccManCmd

are set to OC_NUL, OC_BYPASS, or OC_STANDY.

Ending Occupied Mode

The Unit Ventilator Controller exits occupied mode when any one of the following

events occurs:

• Another state is commanded through network variable nviOccManCmd. This

method could be used for a manual override from a computer.

• Another state is commanded through network variable nviOccCmd. This

method could be used with a scheduler node.

• The occupancy contact opens while nviOccCmd and nviOccManCmd are set

to OC_NUL, OC_BYPASS, or OC_STANDY.

• The window contact is closed; the occupancy status sets to

OC_UNOCCUPIED.

Unoccupied Mode

Unoccupied mode is the mode used by the Unit Ventilator Controller when the

building is empty overnight or over a weekend. By allowing the space temperature

to vary greater than in occupied mode, unoccupied mode reduces cost. Despite the

greater temperature variance, unoccupied mode keeps the building close enough to

the occupied range of temperature ensuring it can be made ready quickly for

occupancy on a regular schedule.

Starting Unoccupied Mode

Unoccupied mode uses the unoccupied setpoints that you set in the configuration

wizard. It cannot begin if the Unit Ventilator Controller is currently in bypass

mode. Unoccupied mode begins as result of one of the following events:

• The unoccupied state is commanded by nviOccManCmd. This method could

be used for a manual override.

LX Series Unit Ventilator Controller User's Guide 33

Page 34

• A schedule change by a supervisory node sets the network variable

nviOccCmd to OC_UNOCCUPIED. Because nviOccManCmd has priority

over nviOccCmd, nviOccManCmd must be set to OC_NUL for the schedule

change to occur.

• The occupancy contact is open or not assigned and both nviOccManCmd and

nviOccCmd are set to OC_NUL. This method can be used to manually switch

between occupied and unoccupied modes.

• The window contact is opened.

During the unoccupied state, the controller heats or cools the space as required to

maintain the temperature within the limits described by the unoccupied setpoints.

The fresh air damper is closed unless a cooling demand exists and the damper is

enabled.

Note: In unoccupied mode, the setpoint offset from input or network variable has

no effect on the effective setpoint.

Ending Unoccupied Mode

Unoccupied mode ends when any one of the following occurs:

• Another mode is commanded by nviOccCmd while nviOccManCmd is set to

OC_NUL. This method can be used to implement a schedule.

• Another mode is commanded by nviOccManCmd. This method can be used as

a manual override.

• The bypass button on the space temperature sensor is pressed. This button

short-circuits the sensor.

• The occupied contact is closed and both nviOccCmd and nviOccManCmd are

invalid.

• The bypass contact input is pressed.

• The window contact is closed. The Unit Ventilator Controller enters the

currently scheduled mode or the mode currently commanded by the occupancy

contact.

Bypass Mode

Bypass mode uses the occupied setpoints to provide a comfortable environment

when individuals are using a space outside of the normal scheduled time.

Bypass mode is temporary. The duration of bypass mode is a time period called

bypass time. Bypass time is set on the General Settings configuration screen.

When the Unit Ventilator Controller enters bypass mode, the bypass time period

begins; when the bypass time period ends, the Unit Ventilator Controller exits

bypass mode.

LX Series Unit Ventilator Controller User's Guide34

Page 35

Starting Bypass Mode

The Unit Ventilator Controller can be commanded to enter bypass mode by either

nviOccManCmd or by nviOccCmd. See the Network Variables Used for Mode

Selection section for more information.

The Unit Ventilator Controller enters bypass mode when any of the following

occurs during unoccupied or standby mode:

• The bypass button on the space temperature sensor is pressed.

• The bypass contact is closed.

Note: The Unit Ventilator Controller does not enter bypass mode if the bypass

time is set to zero.

Ending Bypass Mode

Bypass mode ends as a result of one of the following events:

• Occupancy contact is closed–the Unit Ventilator Controller exits bypass mode

and enters occupied mode.

• The window contact is closed

• The bypass timer expires–the Unit Ventilator Controller enters the currently

scheduled mode, or the mode currently commanded by the occupancy contact.

If bypass mode ends due to the expiration of bypass time and nviOccManCmd is

set to OC_BYPASS, the controller sets nviOccManCmd to OC_NUL. This

scenario returns occupancy control to a scheduler using network input nviOccCmd

or to an occupancy contact.

If nviOccManCmd is not set to OC_NUL, it has priority over nviOccCmd and the

occupancy contact.

Standby Mode

In standby mode, the space temperature is allowed a greater amount of variance

than in occupied mode. Like unoccupied mode, the space is maintained at a

temperature close enough to the occupied setpoints ensuring it can be made ready

for occupancy quickly. Standby is intended for areas such as meeting rooms that

are intermittently occupied during the normal working day.

Starting Standby Mode

Standby mode setpoints are entered during the Unit Ventilator Controller

configuration.

The Unit Ventilator Controller enters standby mode as a result of:

• a scheduler node writing to nviOccCmd, or

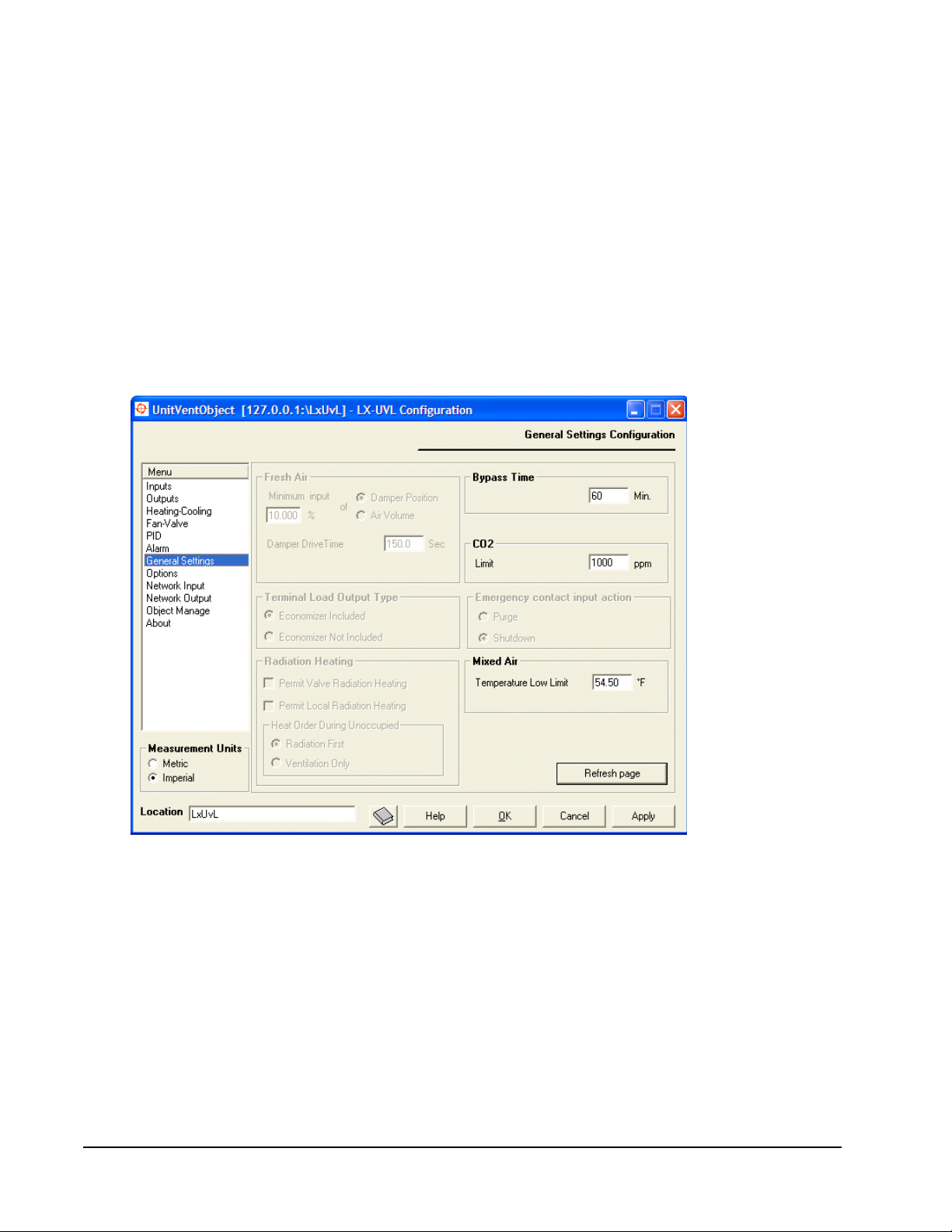

• an operator writing a command to nviOccCmd and/or nviOccManCmd