Page 1

ENGINEERING GUIDE

Water-Cooled

Self-Contained Units

L-Series, Vertical

FORM 145.05-EG2 (618)

Page 2

FORM 145.05-EG2 (618)

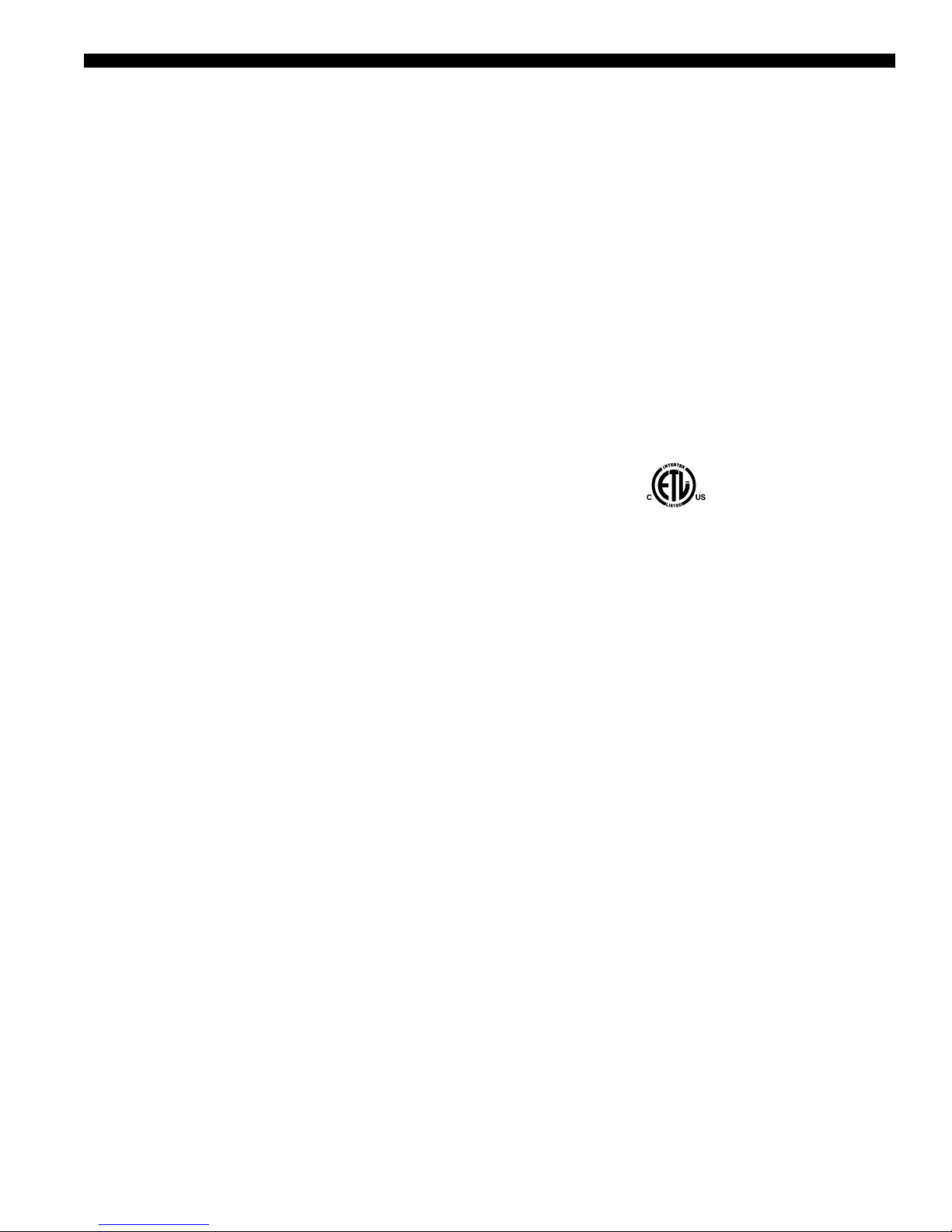

Nomenclature

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

L S W U 0 9 5 S E A 4 6 S P D 4 0 O H 3 6 P 2 V V C O 0 0 0 S

UNIT TYPE

L = “L” Series

S = Self-Contained

W = Water-Cooled

U/D = Upflow/Downflow

NOMINAL

CAPACITY

025 = 25 Ton

032 = 32 Ton

035 = 35 Ton

040 = 40 Ton

050 = 50 Ton

060 = 60 Ton

062 = 62 Ton

070 = 70 Ton

080 = 80 Ton

095 = 95 Ton

105 = 105 Ton

SUPPLY VOLTAGE

17 = 208V-3-6-0

28 = 230V-3-6-0

46 = 460V-3-6-0

58 = 575V-3-6-0

DESIGN SEQUENCE

A = Initial Design

EVAPORATOR COIL

SE = Standard Efficiency

HE = High Efficiency

POWER SUPPLY CONNECTION

SPT = Single Point Terminal Block

SPD = Single Point Disconnect Switch

DPT = Dual Point Terminal Block

DPD = Dual Point Disconnect Switch

SUPPLY

MOTOR HP

05 = 5 HP

07 = 7.5 HP

10 = 10 HP

15 = 15 HP

20 = 20 HP

25 = 25 HP

30 = 30 HP

40 = 40 HP

50 = 50 HP

60 = 60 HP

SUPPLY MOTOR TYPE

OP = ODP Premium Eff.

TP = TEFC Premium Eff.

FAN SIZE

25 = 25 inch

28 = 28 inch

32 = 32 inch

36 = 36 inch

40 = 40 inch

FAN CLASS

P2 = CL2, Plenum

P3 = CL3, Plenum

VFD OPTION

CV = Constant Volume

VV = Variable Air Volume

(VAV )

VB = VAV with Bypass

ELECTRIC

HEAT SIZE

000 = No EH

017 = 17.5 KW

035 = 35 KW

052 = 52.5 KW

070 = 70 KW

105 = 105 KW

HEAT OPTION

CO = Cooling Only

HW = Hot Water

EH = Electric Heat

ENTERING WATER

TEMPERATURE

S = Standard Temperature

H - High Temperature

2

JOHNSON CONTROLS

Page 3

FORM 145.05-EG2 (618)

Table of Contents

FEATURES AND BENEFITS .................................................................................................................................... 5

FEATURES AND OPTIONS .................................................................................................................................... 11

SELECTION PROCEDURE .................................................................................................................................... 15

OPERATING LIMITATIONS .................................................................................................................................... 18

PHYSICAL DATA .................................................................................................................................................... 19

COOLING PERFORMANCE DATA ........................................................................................................................22

DIMENSIONAL DATA ............................................................................................................................................. 33

AIR PRESSURE DROPS ........................................................................................................................................ 57

SUPPLY FAN DATA ................................................................................................................................................ 63

WATER PRESSURE DROP .................................................................................................................................... 65

ELECTRICAL DATA ............................................................................................................................................... 68

OPERATING WEIGHTS .......................................................................................................................................... 69

GUIDE SPECIFICATIONS ...................................................................................................................................... 71

JOHNSON CONTROLS

3

Page 4

FORM 145.05-EG2 (618)

THIS PAGE INTENTIONALLY LEFT BLANK.

4

JOHNSON CONTROLS

Page 5

Features and Benefits

LOW OWNERSHIP COST

Lower Installation Cost

• Single point power connections.

• Single condenser water inlet and outlet connections. Factory installed internal piping.

• Comprehensive factory testing of refrigerant, condenser water piping, supply fan,

and control system.

• Factory installed internal condensate drain connection.

• Compact design allows smaller mechanical equipment room.

• Optional low service clearance units allow installation in even smaller mechanical

equipment rooms.

FORM 145.05-EG2 (618)

• Optional multiple piece shipment allows installation in tight spaces. No eld refrigerant or water piping is required.

• Condenser water piping connections from the top of the unit minimizes piping in

mechanical equipment room.

LOWER OPERATING COST

Efficient Operation

• Plenum fan with backward inclined airfoil blades provides required airow at a low-

er energy consumption compared to the most competitive units.

• All scroll compressors combined with highly efcient condenser and evaporator coil

design provides efcient cooling, lowering energy consumption.

• Water economizer and air economizer options provide free cooling to reduce power

consumption.

• Partial occupancy on any oor reduces power consumption, due to multiple compressor operation and optional variable frequency drive (VFD) to match capacity to

the load.

• After hours operation on any oor only requires unit on that oor with partial op-

eration of cooling tower and pumps. This saves signicant amount of energy over

chilled water systems.

• Variable condenser water ow option, with internal actuated valve(s), prevents ow

• Evaporator coil circuiting supports low leaving air temperature designs to reduce

• High efciency evaporator coil available for lower air ow, low leaving air tempera-

JOHNSON CONTROLS

through units not requiring cooling, saving pump energy.

design air ow and reduce fan operating energy.

ture applications.

5

Page 6

FORM 145.05-EG2 (618)

Features and Benefits (Cont’d)

Easier Maintenance

• Large, intuitive operator interface makes for quick set up and easier diagnostics. It is

on the external panel for easy viewing.

• Operator interface for optional VFD on the external panel.

• Easy access to important components through hinged doors for easy maintenance.

• Easily accessible components out of the air stream allow adjustment of components,

including expansion valves, while unit is operating.

• Easy lter access for inspection, removal, and replacement.

• Internally trapped condensate drain cleanout with easy access.

• Available BACnet® communications with Building Automation System (BAS) allows for easier control of larger installations.

• Emergency stop input.

Indoor Air Quality

• Condensate drain pan sloped in all directions to the drain point.

• Stainless steel drain pan standard

• High efciency lters option with pre-lters.

• Evaporator and waterside economizer coils surface may be cleaned from air entering

side as well as air leaving side.

• Easy access to internally trapped condensate drain cleanout.

• Matt faced berglass insulation.

Quieter Acoustic Performance

• Plenum fan with backward inclined airfoil blades provides required airow at a low-

er sound power level compared to the most competitive units.

• Unique placement of internal components minimizes amount of acoustic energy

leaving the unit.

• Supply fan and motor assembly mounted on a frame and isolated with springs.

• Optional discharge plenum congurations allow horizontal supply air discharge,

minimizing the outlet sound and pressure losses.

• Optional inlet plenum conguration minimizes sound escaping the unit inlet.

• Multiple scroll compressors, due to their smoother ow and stepped operation, mini-

mize the sound associated with the refrigerant system.

• The compressors are located out side air stream, including all the refrigerant piping

and condenser water piping.

6

JOHNSON CONTROLS

Page 7

FORM 145.05-EG2 (618)

STANDARD FEATURES

Controls

• Microprocessor based control system proven algorithms.

• Large 32-key operator interface with large display, in clear language, accessible

without opening panel.

• Alarms and faults displayed and stored in the controller memory.

• Occupied and Unoccupied mode operation.

• Timed Override operation.

• Supply airow proving switch.

• Condensing pressure control when condenser valves are present.

• All refrigerant controls like thermostatic expansion valves, sight glass are out of the

air stream and adjustable while unit is working.

• ETL and CETL listing for US and Canada.

Refrigerant Circuits

• Multiple scroll compressors for better temperature control. Up to six compressors.

• All compressors have independent refrigerant circuits and independent short circuit

protection.

• Automatic compressor lead-lag on units larger than 40 tons.

• Environmentally friendly R-410A refrigerant.

• Completely factory piped, charged, and protected refrigerant circuits.

• Each refrigerant circuit with suction and discharge pressure transducers for enhanced

diagnostics and control.

• Evaporator coil frost protection

• Mechanically cleanable shell and tube condenser, factory tested and piped.

• Factory leak and pressure tested refrigerant piping

• Low ambient compressor lockout.

Supply Fan

• Plenum fan with backward inclined airfoil blades provides required airow at lower

energy consumption and sound compared to the most competitive units.

• Minimum class II fans for high static requirements. Class III fans available.

• Supply fan and motor assembly is isolated with springs to minimize the vibration and

• Bearing lubrication line brought to one location for easy maintenance.

JOHNSON CONTROLS

sound transmission to the rest of the unit and beyond.

7

Page 8

FORM 145.05-EG2 (618)

Features and Benefits (Cont’d)

Unit Cabinet

• Welded base made out of 10-gauge galvanized steel frame and structural members.

• External cabinet parts made out of painted 16-gauge galvanized steel.

• External panels made out of painted 18-gauge galvanized steel.

• Lifting lugs to lift the unit without skid.

• Hinged 2-inch thick access doors covering the coil, compressors, condensers, water

piping, electrical components, and fan access. Insulated where necessary with 2-inch

matt faced berglass insulation.

• Stainless steel drain pan with insulation, sloped in all directions.

• Condensate drain with cleanout and proper slope towards the drain.

Filters Section

• Filter section made out of 18-gauge painted galvanized steel.

• 4-inch thick MERV 8 lters are standard.

Condenser Water Piping

• Factory installed and tested condenser water piping.

• Condenser water piping exiting unit from the top for easier and shorter eld connec-

tions.

OPTIONAL FEATURES

Variable Frequency Drive (VFD)

• Factory installed, wired, and commissioned VFD controls the fan speed in conjunction with the unit controller, based on a signal from controller.

• Unit installed duct static pressure sensor to sense duct static using elds installed

pneumatic tubes.

• Optional manual electrical bypass manually enables unit to run the supply fan motor

at full speed in case the VFD failure.

Waterside Economizer

• Waterside economizer, which uses colder condenser water available during colder

outdoor conditions, to provide cooling by passing cold condenser water through ad-

ditional water economy coil upstream of the evaporator coil in terms of air ow.

Internal temperature sensors determine suitability of condenser water for full or partial free cooling and route condenser water flow through the water economy coil

when suitable. Internal water piping and valves are included.

• Water economy coil with optional mechanically cleanable return bends is available.

• Condenser water ow through the unit is enabled only in cooling mode. Minimum

condenser water temperature for unit compressor operation in this mode is 40.0°F.

8

JOHNSON CONTROLS

Page 9

FORM 145.05-EG2 (618)

Condenser Water Regulating Valves

• Units without waterside economizer will permit compressor operation up to 55.0°F

and above. For condenser water temperatures below this threshold, optional condenser water regulating valve(s) are available. Optional condenser water valve con-

trols the water ow though unit condensers to maintain minimum discharge pressure

for all compressors with ow through unit enabled only in the cooling mode.

Optional Condenser and Bypass water valves maintain minimum discharge pressure

for all compressors with flow through unit always enabled.

Heating

• Hot water coil with factory installed and tested water piping and valve for modulated

control. Controlled by the unit controller.

• Electric heat, factory installed, wired, and tested.

• All of the heating options are in reheat position. However, the heating will only be

used when cooling is off.

• Only one heating option is available in any unit.

Controls

• Factory installed and wired non-fused disconnect switch for the unit power. Disconnect switch is accessible without opening unit doors.

• Static pressure transducer is installed and wired on all variable air volume (VAV)

units to control VFD operation.

• Additional static pressure transducer installed and wired with comparative logic built

in.

• Duct static pressure limit switch mounted and wired in unit to disable unit operation

in case of high duct static.

• BACnet (MS/TP) interface for communication with BAS.

• Water Flow Switch will lock out all compressors in the unit if minimum water ow

is not present.

High Efficiency Air Filtration

• Optional High Efciency MERV 13 4-inch thick lters are available with 4-inch

thick MERV 8 pre-lter.

High Efficiency Evaporator Coils

• High efciency evaporator coil for lower air ow, low leaving air temperature applications. Provides higher EER and higher capacity.

Modular Construction

• Unit shipped in multiple sections. All refrigerant piping, condenser water piping, and

JOHNSON CONTROLS

condensate drain piping is factory assembled and does not require additional eld

work. Various sections are as follows:

• Refrigerant and heating section consisting of evaporator coil, water economy

coil, condensers, compressors, condenser water piping, and heating options.

9

Page 10

FORM 145.05-EG2 (618)

Features and Benefits (Cont’d)

• Fan and power section consisting of supply fan and motor assembly, power and

control panels, and VFD.

• Filter section, including the filters.

Low service clearance

• For areas with limited mechanical equipment room space, optional conguration of

the unit requiring less (3 inch) than standard clearance on left of the unit as looking

at the unit from the fan side is required. Less (3 inch) service clearance on the fan

side is also available.

Field Installed Accessories

• Discharge plenum/Outlet plenum.

• Full discharge plenum is factory manufactured discharge plenum with 3-inch

thick matt faced insulation and 20-gauge perforated galvanized steel liner, with

or without factory cut openings.

• Half discharge plenum is factory manufactured discharge plenum with 3-inch

thick matt faced insulation and 20-gauge perforated galvanized steel liner, with

or without factory cut openings.

• Airside economizer with outdoor air connection, damper, and damper actuator at the top,

return air connection, damper, and damper actuator at the back. Provided with connecting

harness for the actuators and sensors, installed by others. Different control options:

• Dry bulb

• Single enthalpy

• Dual enthalpy

• Inlet sound attenuating plenum attaches to the lter section for further reducing the

sound emitted through the unit air inlet.

10

JOHNSON CONTROLS

Page 11

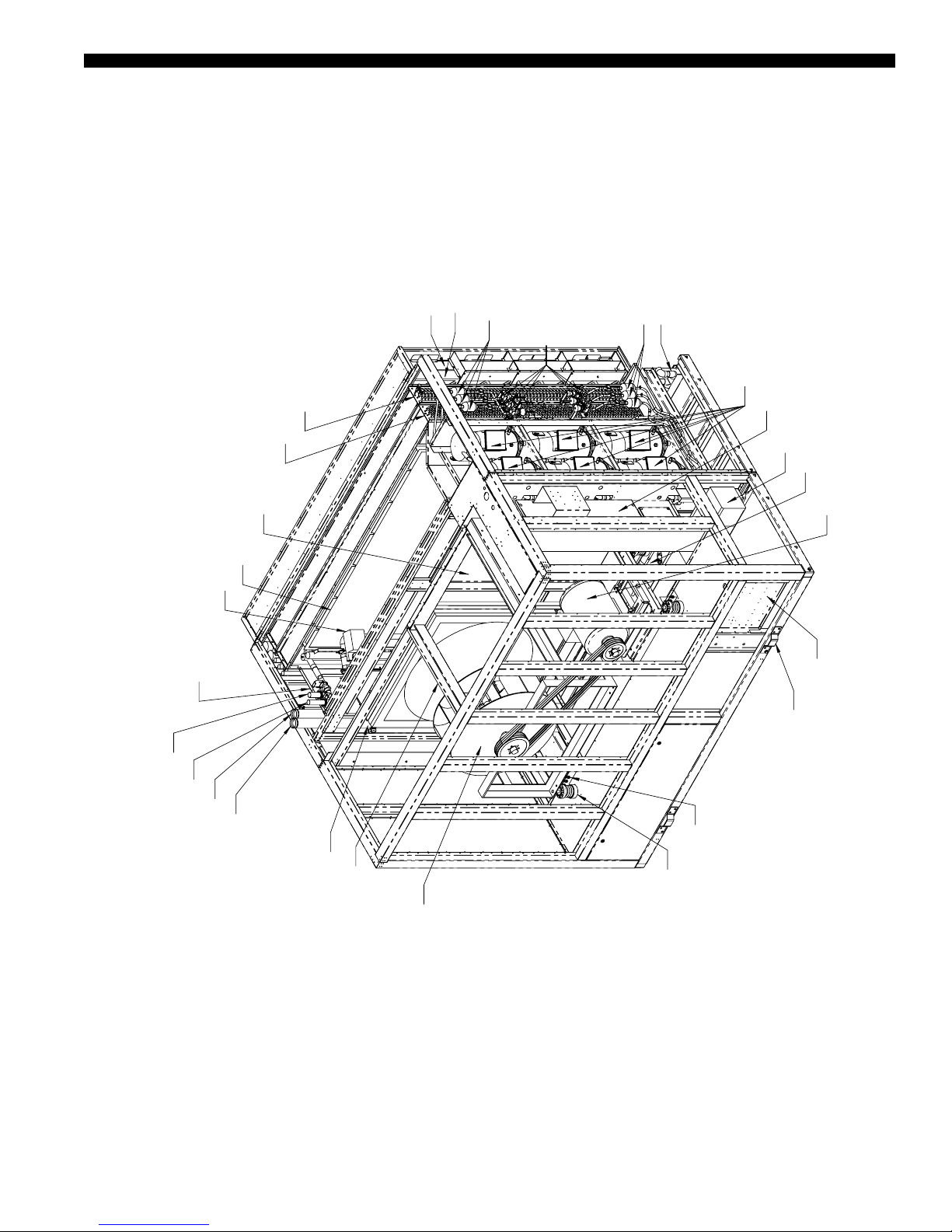

Features and Options

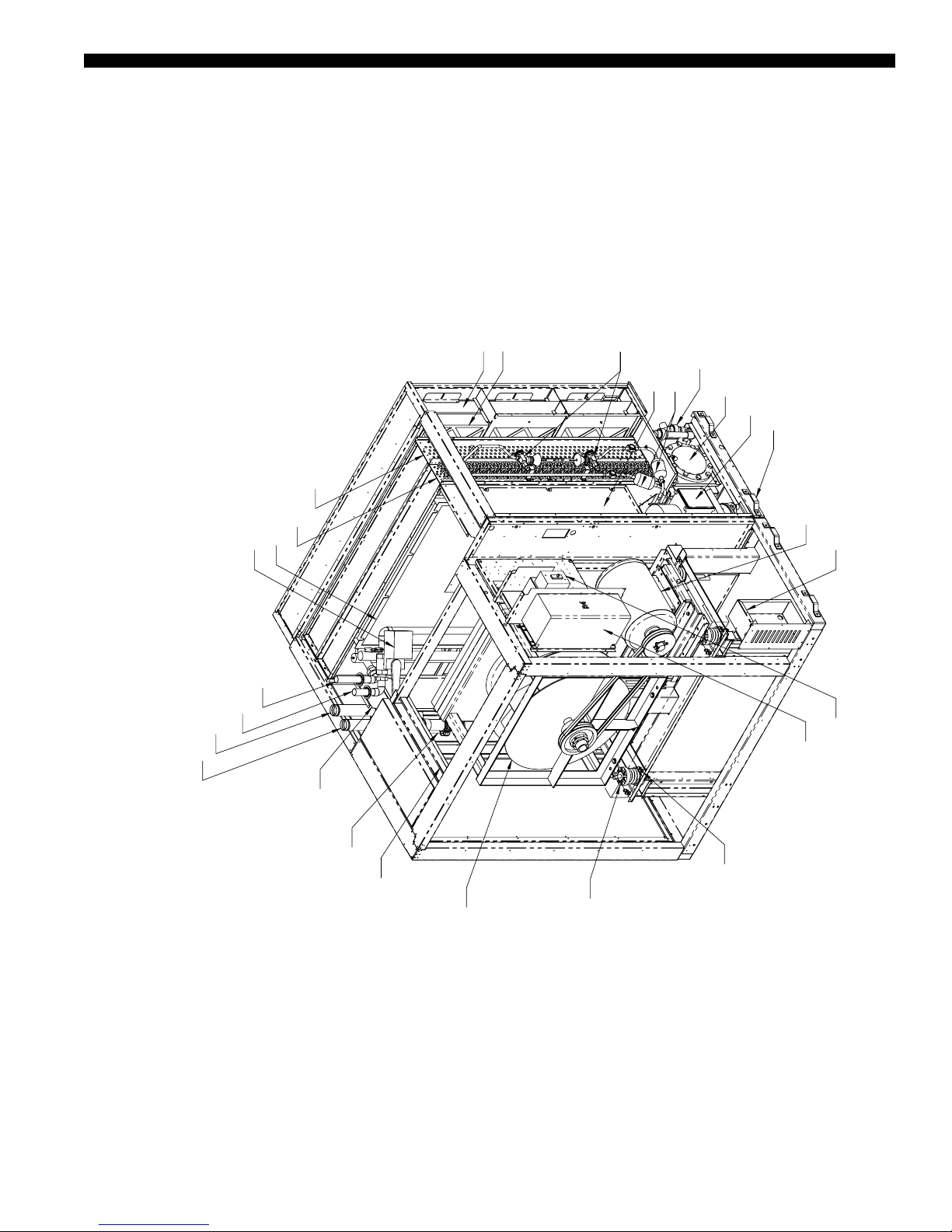

**OPTIONAL HOT WATER OR

ELECTRIC HEAT

* OPTIONAL

WATER ECONOMY COIL*

STANDARD AIR FILTERS

HIGH EFFICIENCY FILTERS*

FORM 145.05-EG2 (618)

THERMOSTATIC EXPANSION VALVES

CONDENSATE DRAIN TRAP

FAN INLET & COIL CLEANING ACCESS DOOR

FILTER DRIERS

SHELL & TUBE CONDENSER

COMPRESSORS

LIFTING LUGS(8)

EVAPORATOR COIL

HOT WATER COIL**

HOT WATER VALVE**

HOT WATER OUT**

HOT WATER IN**

CONDENSER WATER OUT

CONDENSER WATER IN

FAN MOTOR & FRAME

ELECTRIC HEAT CONTROLS**

ELECTRICAL CONTROLS

AIR SAFE-OFF

VARIABLE FREQUENCY DRIVE*

JOHNSON CONTROLS

PLENUM FAN

CONDENSER WATER VALVES

ELECTRIC HEATER FRAME**

SEISMIC ISOLATION*

INTERNAL FAN ISOLATION

11

Page 12

FORM 145.05-EG2 (618)

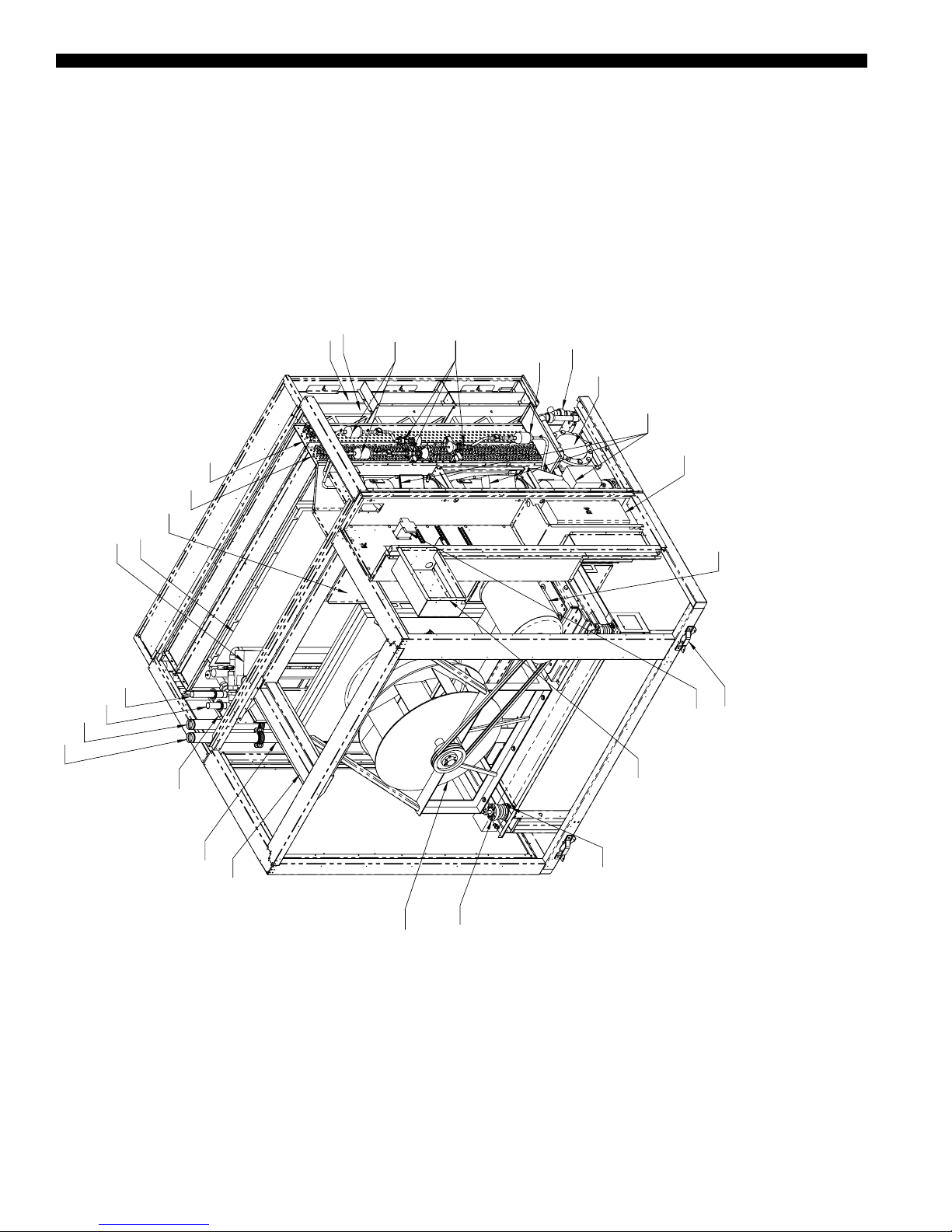

*OPTIONAL

**OPTIONAL HOT WATER OR

ELECTRIC HEA

INTERNAL FAN ISOLATIO

CONDENSER WATER IN

Features and Options (Cont’d)

HOT WATER COIL**

HOT WATER VALVE**

HOT WATER OUT**

HOT WATER IN**

CONDENSER WATER OUT

STANDARD AIR FILTERS

HIGH EFFICIENCY FILTERS*

WATER ECONOMY COIL*

EVAPORATOR COIL

FAN INLET & COIL CLEANING ACCESS DOOR

FILTER DRIERS

THERMOSTATIC EXPANSION VALVES

CONDENSATE DRAIN TRAP

FILTER DRIER

SHELL & TUBE CONDENSERS

COMPRESSORS

VARIABLE FREQUENCY DRIVE*

FAN MOTOR & FRAME

AIR SAFE-OFF

CONDENSER WATER VALVES

ELECTRIC HEATER FRAME**

12

N

PLENUM FAN

ELECTRICAL CONTROLS

ELECTRIC HEAT CONTROLS**

SEISMIC ISOLATION*

JOHNSON CONTROLS

LIFTING LUGS (4)

T

Page 13

FORM 145.05-EG2 (618)

* OPTIONAL

** OPTIONAL HOT WATER OR

ELECTRIC HEA

STANDARD AIR FILTERS

HIGH EFFICIENCY FILTERS*

WATER ECONOMY COIL*

FILTER DRIERS

THERMOSTATIC EXPANSION VALVES

CONDENSATE DRAIN TRAP

FILTER DRIERS

COMPRESSORS

ELECTRICAL CONTROLS

FAN INLET & COIL CLEANING ACCESS DOOR

HOT WATER COIL**

HOT WATER VALVE**

AIR SAFE-OFF

HOT WATER OUT**

HOT WATER IN**

EVAPORATOR COIL

VARIABLE FREQUENCY DRIVE*

SHELL & TUBE CONDENSERS

FAN MOTOR & FRAME

LIFTING LUGS (4)

ELECTRIC HEAT CONTROLS**

CONDENSER WATER IN

CONDENSER WATER OUT

JOHNSON CONTROLS

PLENUM FAN

CONDENSER WATER VALVES

ELECTRIC HEATER FRAME**

SEISMIC ISOLATION*

INTERNAL FAN ISOLATION

T

13

Page 14

FORM 145.05-EG2 (618)

THIS PAGE INTENTIONALLY LEFT BLANK.

14

JOHNSON CONTROLS

Page 15

Selection Procedure

1. Design Criteria should be available to select a unit. These criteria include:

a. Design airflow

b. Entering air conditions

c. Total and sensible loads

d. Condenser water entering and leaving temperatures

e. External static pressure

f. Factory installed options required

FORM 145.05-EG2 (618)

• Summer

• Winter (if heating is required)

2. Based on design air ow, select the smallest unit with maximum air ow higher than

design air ow and minimum airow lower than design air ow from Unit Physical

Data Tables on page 19 through page 21. Please note that standard and high ef-

ciency units of the same size have different air ow limits.

3. Divide the design air ow by the air ow indicated at the top of the appropriate Cooling Performance Table for the selected unit and efciency, on page 22 through

page 31. Use Table 2 on page 17 to determine the correction factors for total and

sensible capacities and compressor power.

4. Multiply the total and sensible capacities and compressor power from appropriate

Cooling Performance Table for design air and water conditions with the correction

factors above to determine the unit capacity adjusted for the airow.

5. Determine if the cooling performance of this unit is acceptable. If not, repeat steps 2

through 4 above with a higher capacity unit.

6. If waterside economizer option is chosen, follow steps 3 and 4 above with appropriate Waterside Economizer Cooling Performance Table on page 32.

7. If hot water heating option is required, follow steps 3 and 4 with appropriate Hot

Water data from Physical Data tables on page 19–20.

8. If electric heat option is required, obtain heating capacity based on electric heat capacity and unit voltage from Electric Heat Capacity Table on page 68.

9. Select ltration types and efciencies needed with corresponding air pressure drop

10. Select either airside economizer or inlet sound attenuating plenum, if required, with

11. Select half or full outlet plenum, if required, with corresponding air pressure drop

12. With all options selected, add air pressure drops of all the components selected, in-

JOHNSON CONTROLS

from Table 30 on page 69 and Table 31 on page 70.

corresponding air pressure drop from Table 19 and Table 20 on page 57.

from Table 19 and Table 20 on page 57.

cluding evaporator coil, to external static pressure required to determine total static

pressure required for the supply air fan.

15

Page 16

FORM 145.05-EG2 (618)

Selection Procedure (Cont’d)

13. Select appropriate fan for the unit to deliver design air ow at required static pressure. There may be more than one supply air fan option available for the unit being

selected.

14. Add 5% belt drive losses to the motor BHP calculated, and select next available supply fan motor.

15. Supply fan motor heat gain in MBH, based on 93.5% motor efciency, may be calculated by multiplying above BHP plus the belt drive losses by 2.72.

16. Minimum Circuit Ampacity (MCA) of the unit may be calculated, using electrical

data in Table 27 and Table 28 on page 68, as follows:

a. For units without electric heat:

MCA = 1.25 * (largest motor RLA or FLA) + (FLA or RLA of all the rest of the

motor) + two transformers FLA

b. For units with electric heat, MCA is the lower of the heating and cooling mode

MCA. Cooling mode MCA is as shown in step a above.

• Electric heat less than 50 kW

Heating mode MCA = 1.25 * (electric heat FLA + supply fan motor FLA)

+ two transformers FLA.

• For units with electric heat 50 kW or more, MCA is the lower of the heating

and cooling mode MCA

Heating mode MCA = 1.25 * supply fan motor FLA + electric heat FLA +

two transformers FLA.

17. Maximum Overcurrent Protection (MOP) for the unit is calculated as follows:

a. For units without electric heat:

• MOP = 2.25 * (largest motor RLA or FLA) + (FLA or RLA of all the rest

of the motor) + two transformers FLA.

b. For units with electric heat, MOP is the lower of the heating and cooling mode

MOP. Cooling mode MOP is as shown in step a above.

• Heating mode MOP = 2.25 * (electric heat FLA + supply fan motor FLA)

+ two transformers FLA.

c. MOP is equal to next lower fuse size available of the higher of the values cal-

culated above, unless:

• Value in step c is lower than MCA, in which case the MOP value is the next

size higher than the MCA.

18. The component weights are in Table 30 on page 69 and Table 31 on page 70.

Add weights of the components covered by the options selected. To obtain operating weight, add water weights corresponding to the option selected carrying water

weights.

16

JOHNSON CONTROLS

Page 17

FORM 145.05-EG2 (618)

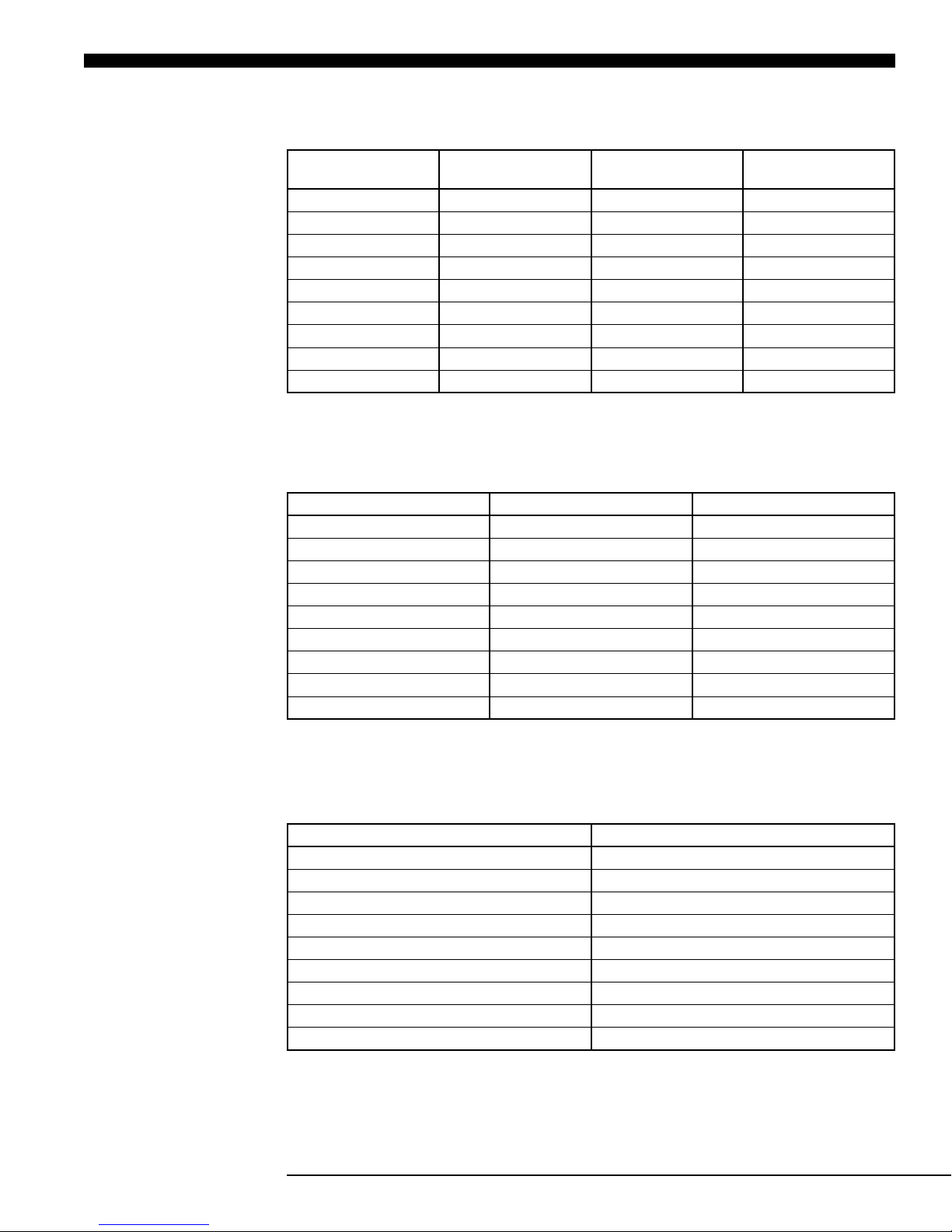

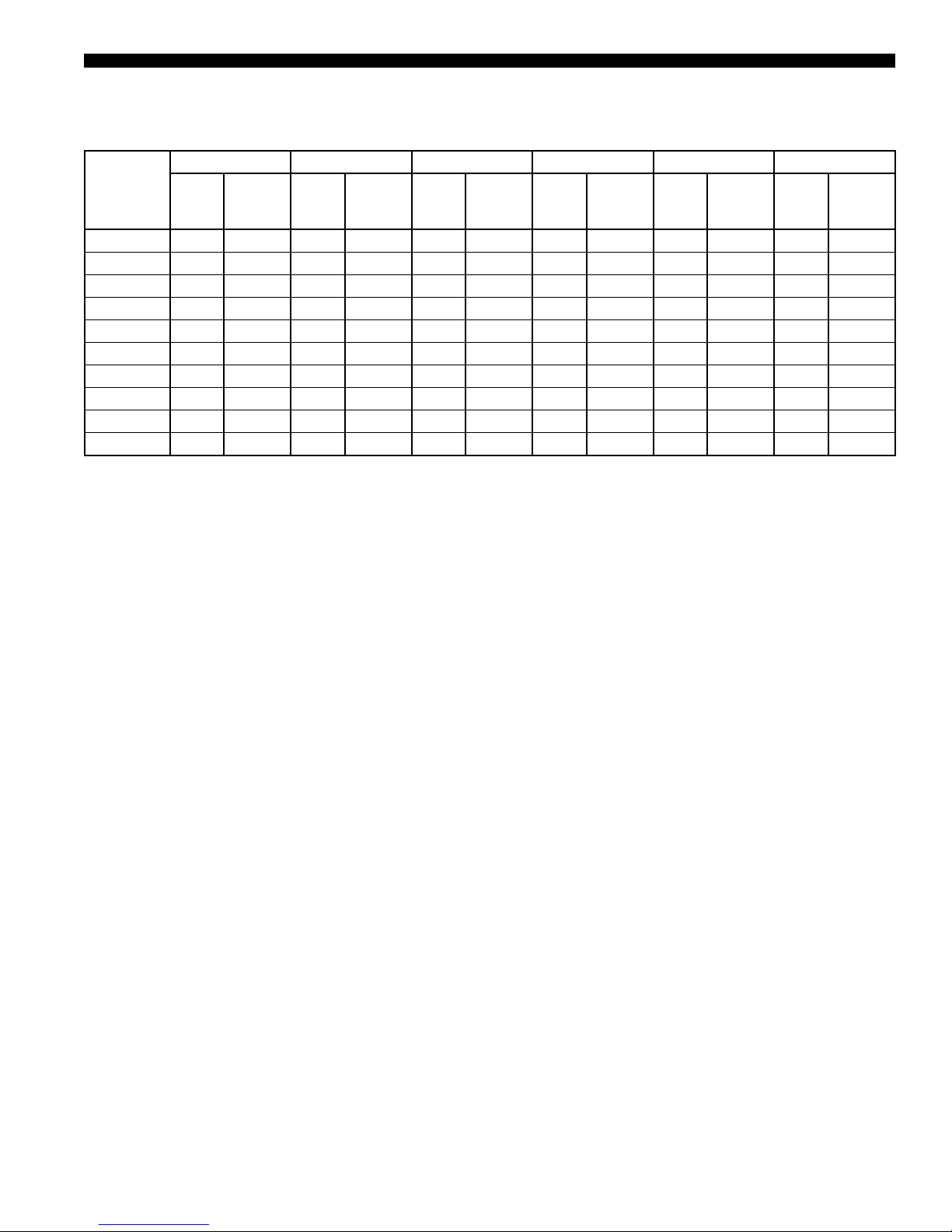

TABLE 1 - DX COOLING CORRECTION FACTORS

AIR FLOW PERCENT TOTAL CAPACITY

80 0.967 0.900 0.980

85 0.976 0.926 0.985

90 0.984 0.951 0.990

95 0.991 0.976 0.995

100 1.000 1.000 1.000

105 1.006 1.024 1.003

110 1.013 1.047 1.007

115 1.019 1.070 1.012

120 1.025 1.093 1.016

SENSIBLE

CAPACITY

COMPRESSOR

TABLE 2 - WATERSIDE ECONOMIZER CORRECTION FACTORS

AIR FLOW PERCENT TOTAL CAPACITY SENSIBLE CAPACITY

80 0.883 0.863

85 0.914 0.899

90 0.944 0.934

95 0.973 0.968

100 1.000 1.000

105 1.026 1.031

110 1.052 1.061

115 1.076 1.090

120 1.100 1.118

POWER

TABLE 3 - HOT WATER HEATING CORRECTION FACTORS

JOHNSON CONTROLS

AIR FLOW PERCENT TOTAL CAPACITY

80 0.903

85 0.929

90 0.953

95 0.977

100 1.000

105 1.020

110 1.042

115 1.061

120 1.082

17

Page 18

FORM 145.05-EG2 (618)

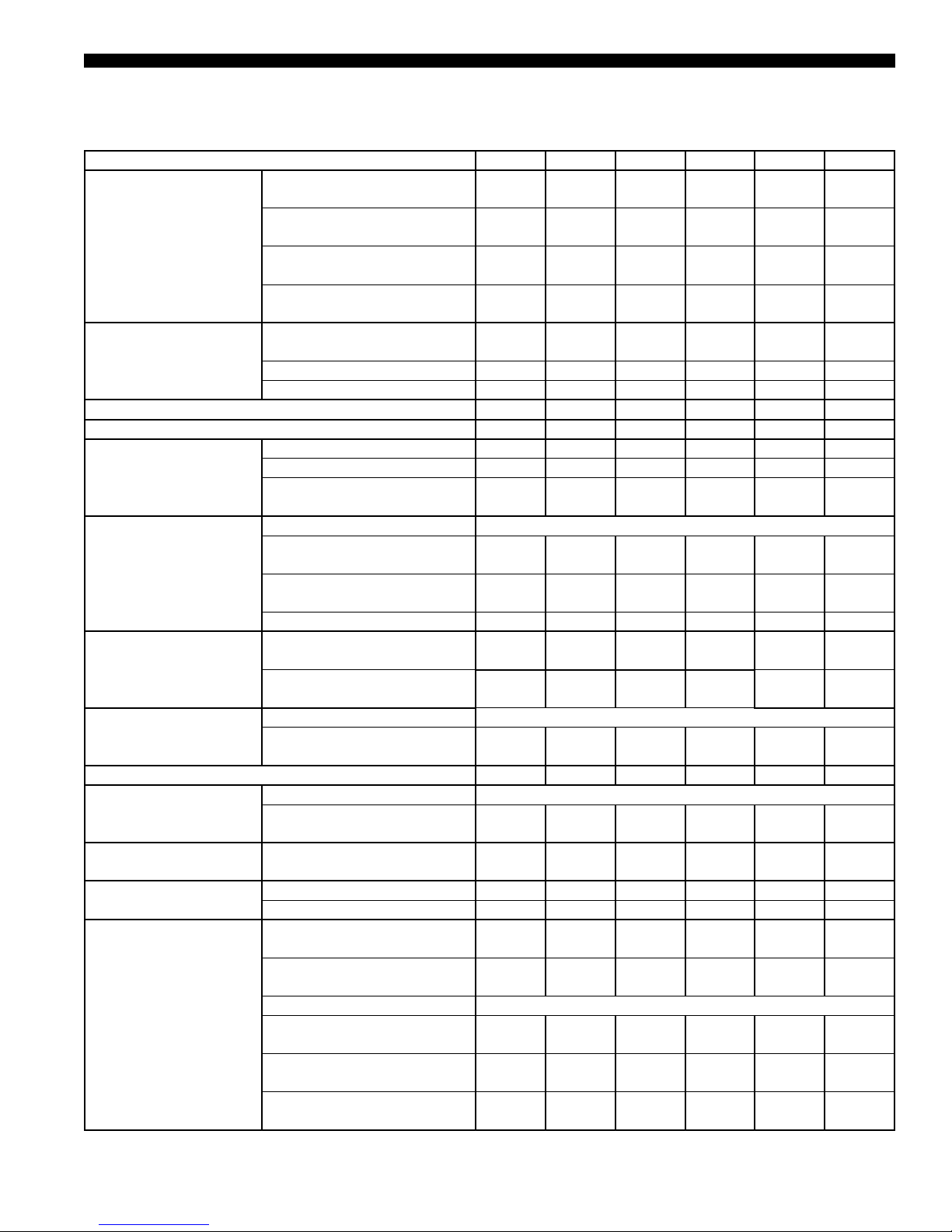

Operating Limitations

TABLE 4 - OPERATING LIMITATIONS — LSWU025-LSWU105

MINIMUM MAXIMUM

Entering Air DX Coil-Dry Bulb 75.0°F 85.0°F

Entering Air DX Coil-Wet Bulb 62.0°F 72.0°F

Condenser Water Flow 2.5 GPM/Ton 3.0 GPM/Ton

Entering Cond. Water Temp with Economizer 40.0°F 90.0°F

Entering Cond. Water Temp with Condenser

Water Control Valve

Entering Cond. Water Temp w/o Condenser

Water Control Valve

Steam Heat-Steam Pressure 5 psig 15 psig

Hot Water Heat Entering Water Temp 140.0°F 160.0°F

40.0°F 90.0°F

60.0°F 90.0°F

18

JOHNSON CONTROLS

Page 19

FORM 145.05-EG2 (618)

Physical Data

TABLE 5 - LSWU025-LSWU060

Model Nominal Tons 025 032 035 040 050 060

Maximum Design Air Flow Standard - CFM

Maximum Design Air Flow- High

Air Flow Range

Cabinet Dimensions

EER 14.3 13.6 13.3 13.1 14.2 13.3

EER - High Efciency 15.3 14.2 14.2 13.6 14.9 13.8

Cooling Coil 3/8" OD

Supply Fan

Filters

Compressors

Number of Capacity Steps 6 6 6 6 9 9

Condensers

Condenser Water

Connections

Waterside Economizer

Coil 1/2" OD

Heating

Efciency - CFM

Minimum Design Air Flow Standard - CFM

Minimum Design Air Flow - High

Efciency CFM

Depth (Excluding Filter Section)

- Inches

Length - Inches 78 78 78 78 100 100

Height - Inches 79.5 79.5 79.5 79.5 90 90

Face Area - Square Feet 17.8 22.2 26.7 26.7 40.1 40.1

Rows 4 4 4 6 5 6

Fins Per Inch (Standard/High

Efciency)

Fan Type Airfoil Plenum Fan (SWSI)

Diameter - Inches/Class Standard

Diameter - Inches/Class - High

Capacity Fan

Fan Motor HP 5 - 20 10 - 25 10 - 25 10 - 25 15 - 40 15 - 40

4 Inch Deep - MERV 8

20X20X4 / 24X20X4 / 24X24X4

4 Inch Deep - MERV 13

20X20X4 / 24X20X4 / 24X24X4

Type Scroll / *Scroll with Capacity Modulation

Compressor Quantity / Nominal

HP

Type Shell and Tube

Quantity (2 refrigerant circuits

per condenser)

Water In and Out Copper

Victaulic Connections - Inches

Face Area - Square Feet 17.8 22.2 26.7 26.7 40.1 40.1

Rows/Fins Per Inch 4/11 4/11 4/11 4/11 4/11 4/11

Hot Water Coil Face Area Square Feet

Hot Water Coil Rows/Fins Per

Inch

Steam Coil Consult Factory

Electric Heat - KW - 240/3/60

Nominal

Electric Heat - KW - 480/3/60

Nominal

Electric Heat - KW - 600/3/60

Nominal

10,500 13,300 15,500 16,000 20,000 24,000

8,600 11,000 13,200 13,200 20,000 20,000

7,200 9,000 10,800 10,800 16,000 16,000

6,300 7,800 9,400 9,400 14,100 14,100

70 70 70 70 76 76

12/17 12/17 12/17 12/17 12/17 12/17

25/Class II25/Class II28/Class II28/Class II32/Class II36/Class

None None None None

3 / 6 / 0 3 / 6 / 0 3 / 6 / 0 3 / 6 / 0 0 / 6 / 6 0 / 6 / 6

3 / 6 / 0 3 / 6 / 0 3 / 6 / 0 3 / 6 / 0 0 / 6 / 6 0 / 6 / 6

10* + 10 15* + 11 15* + 13 15* + 15 15*+2-11 15*+2-15

1 1 1 1 2 2

2.625 2.625 2.625 2.625 2.625 2.625

8.8 12.0 15.2 15.2 23.3 23.3

1/12 1/12 1/12 1/12 1/12 1/12

17.5 17.5/35.0 17.5/35.0 17.5/35.0 35.0/52.5 35.0/52.5

17.5 17.5/35.0 17.5/35.0 17.5/35.0 35.0/52.5 35.0/52.5

17.5 17.5/35.0 17.5/35.0 17.5/35.0 35.0/52.5 35.0/52.5

II

JOHNSON CONTROLS

19

Page 20

FORM 145.05-EG2 (618)

Physical Data (Cont’d)

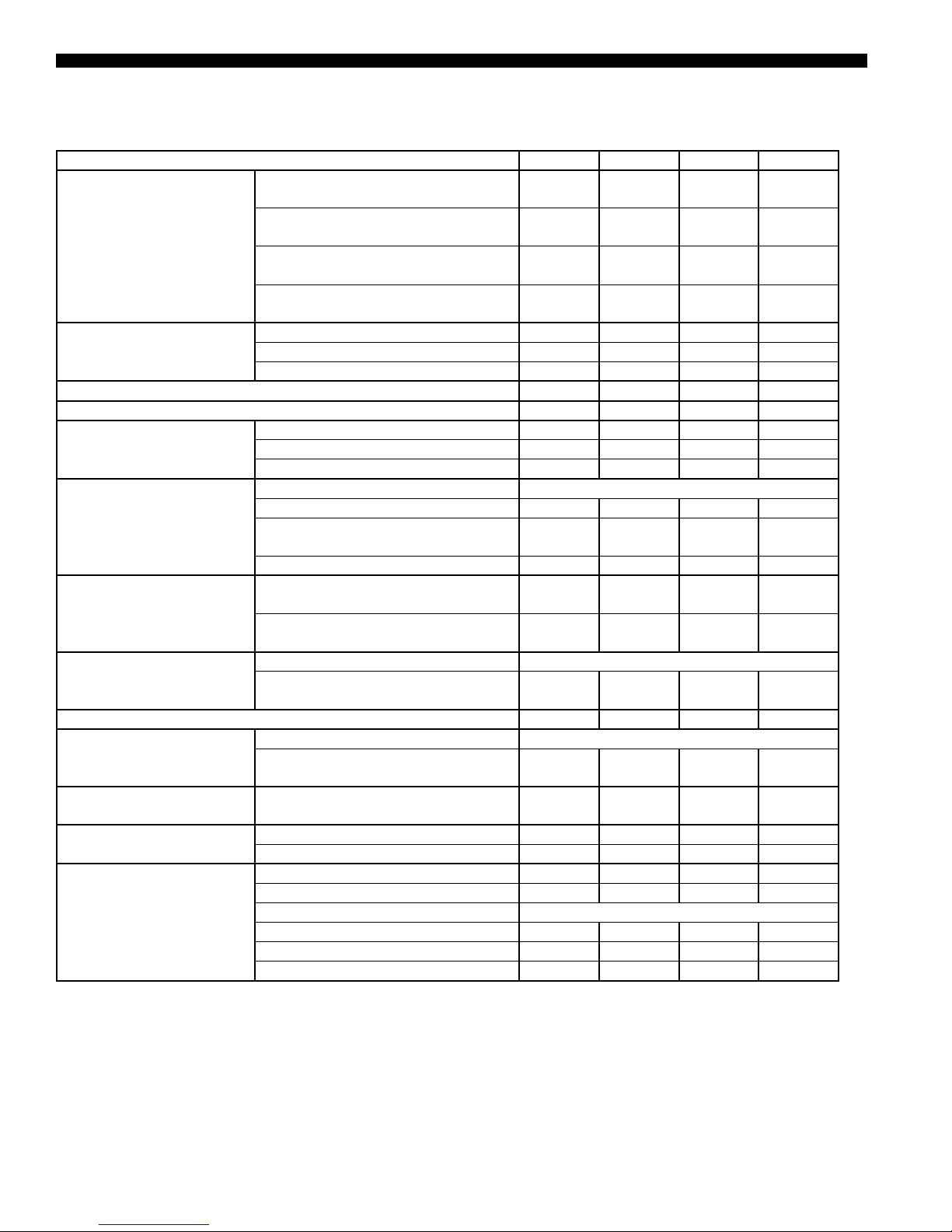

TABLE 6 - LSWU070-LSWU105

Nominal Capacity, Tons 70 80 95 105

Maximum Design Air Flow - Standard CFM

Maximum Design Air Flow- High

Air Flow Range

Cabinet Dimensions

EER 14.1 13.7 13.7 13.3

EER - High Efciency 14.5 14.1 14.1 13.7

Cooling Coil

Supply Fan

Filters

Compressors

Number of Capacity Steps 4 4 6 6

Condensers

Condenser Water

Connections

Waterside Economizer Coil

Heating

Efciency - CFM

Minimum Design Air Flow - Standard CFM

Minimum Design Air Flow - High

Efciency - CFM

Depth (Excluding Filter Section) - Inches 96 96 96 96

Length - Inches 130 130 130 130

Height - Inches 102 102 102 102

Face Area - Square Feet 49.7 56.5 60.3 60.3

Rows 4 5 5 6

Fins Per Inch (Standard/High Efciency) 12/17 12/17 12/17 12/17

Fan Type Airfoil Plenum Fan (SWSI)

Diameter - Inches/Class - Standard 36/Class II 36/Class II 40/Class II 40/Class II

Diameter - Inches/Class - High Capacity

Fan

Fan Motor HP 15 - 40 15 - 40 20 - 50 20 - 50

4 Inch Deep - MERV 8 20X20X4 /

24X20X4

4 Inch Deep - MERV 13 20X20X4 /

24X20X4

Type Scroll

Compressor Quantity / Nominal HP

Type Shell and Tube

Quantity (2 refrigerant circuits per

condenser)

Water In and Out Copper Victaulic

Connections - Inches

Face Area - Square Feet 49.7 56.5 60.3 60.3

Rows/Fins Per Inch 4/11 4/11 4/11 4/11

Hot Water Coil Face Area - Square Feet 35.8 40.6 43.3 43.3

Hot Water Coil Rows/Fins Per Inch 1/12 1/12 1/12 1/12

Steam Coil Consult Factory

Electric Heat - KW - 240/3/60 Nominal 17.5/35.0 17.5/35.0 35.0/52.5 35.0/52.5

Electric Heat - KW - 480/3/60 Nominal 17.5/35.0 17.5/35.0 35.0/52.5 35.0/52.5

Electric Heat - KW - 600/3/60 Nominal 17.5/35.0 17.5/35.0 35.0/52.5 35.0/52.5

29,800 33,900 36,100 36,100

24,800 28,200 30,100 30,100

19,900 22,600 24,200 24,200

17,400 19,800 21,200 21,200

40/Class II 40/Class II None None

8 / 12 8 / 12 8 / 12 8 / 12

8 / 12 8 / 12 8 / 12 8 / 12

2 - 15 +

2 - 13

2 2 3 3

3.125 3.125 3.125 3.125

4 - 15 6 - 13 6 - 15

20

JOHNSON CONTROLS

Page 21

FORM 145.05-EG2 (618)

TABLE 7 - REFRIGERANT CHARGE DATA – LSWU060-LSWU105

COMP A COMP B COMP C COMP D COMP E COMP F

MODEL #

LSWU025 10 20.0 10 20.0 - - - - - - - -

LSWU032 15 21.5 11 21.5 - - - - - - - -

LSWU035 15 23.0 13 23.0 - - - - - - - -

LSWU040 15 27.0 15 27.0 - - - - - - - -

LSWU050 15 28.5 11 25.0 11 25.0 - - - - - -

LSWU060 15 26.5 15 26.5 15 27.5 - - - - - -

LSWU070 15 22.5 15 22.5 15 22.50 15 22.5 - - - -

LSWU080 15 23.25 15 23.25 15 25.3 15 25.3 - - - -

LSWU095 13 19.0 13 19.0 13 23.50 13 23.5 13 23.5 13 23.5

LSWU105 15 19.0 15 19.0 15 23.50 15 23.5 15 27.5 15 27.5

NORM

HP

410A

CHARGE-

LBS

NORM

HP

410A

CHARGE-

LBS

NORM

HP

410A

CHARGE-

LBS

NORM

HP

410A

CHARGE-

LBS

NORM

HP

410A

CHARGE-

LBS

NORM

HP

CHARGE-

410A

LBS

JOHNSON CONTROLS

21

Page 22

FORM 145.05-EG2 (618)

Cooling Performance Data

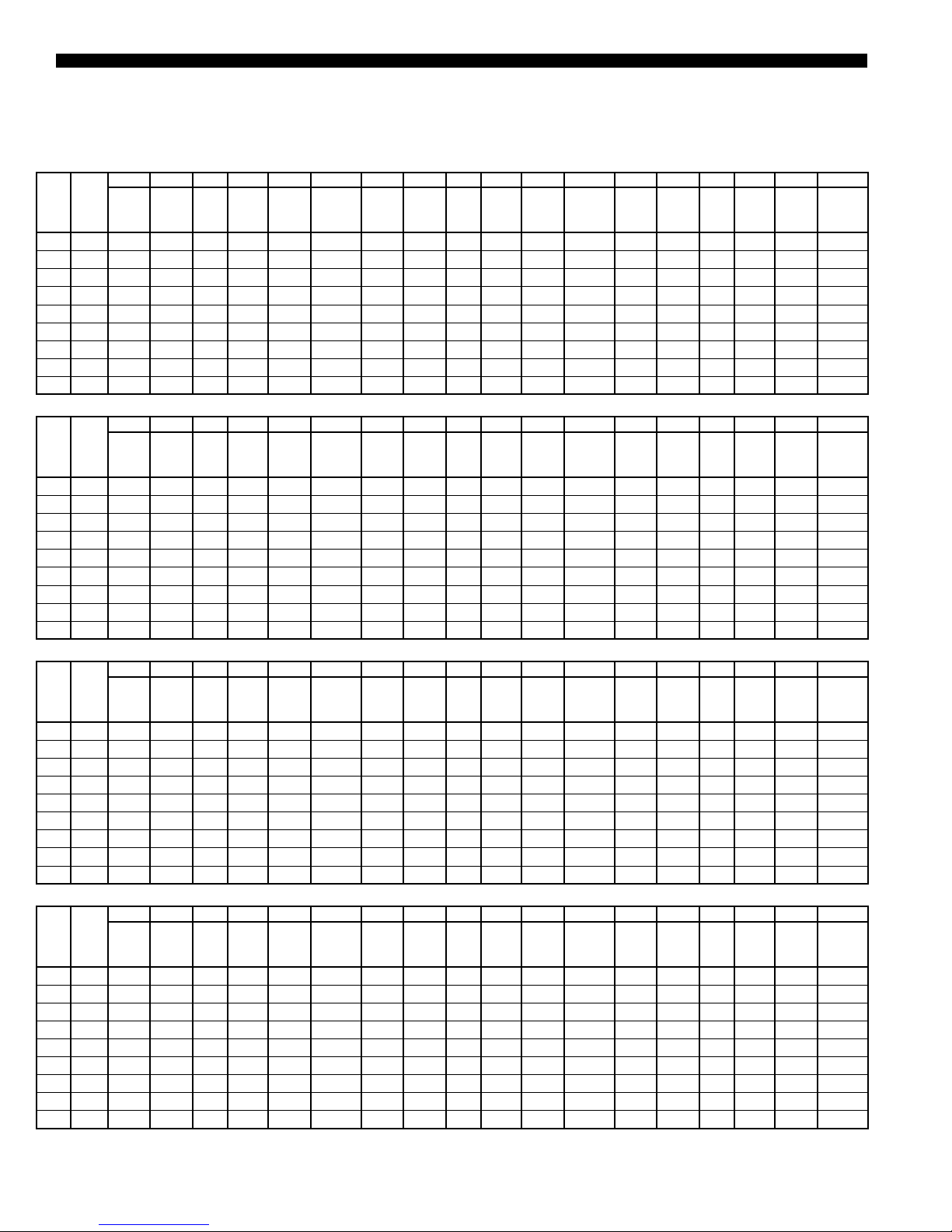

TABLE 8 - LSWU025

AIR FLOW 10,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 292 249 52.4 51.7 14.6 68.3 290 248 52.5 51.8 15.0 56.8 287 246 52.6 51.9 15.6 67.9

75 67 3 11 195 57.6 57.2 14.7 72.2 308 194 57.6 57.3 15.0 59.9 304 193 57.8 57.5 15.6 71.5

75 72 336 141 62.8 62.6 14.7 77.3 334 140 62.9 62.7 15.0 64.2 330 139 63.0 62.9 15.6 76.6

80 62 301 296 53.0 51.3 14.6 70.3 299 294 53.1 51.4 15.0 58.3 296 292 53.3 51.5 15.6 69.7

80 67 312 248 57.7 57.2 14.7 72.4 310 247 57.7 57.2 15.0 60.2 306 245 57.9 57.4 15.6 71.8

80 72 337 194 62.9 62.6 14.7 77.4 334 193 63.0 62.6 15.0 64.3 330 191 63.1 62.8 15.6 76.7

85 62 319 319 55.9 50.6 14.6 73.7 317 317 56.0 50.7 15.0 61.3 313 313 56.4 50.8 15.6 73.3

85 67 323 297 58.1 56.7 14.7 74.7 321 296 58.2 56.8 15.0 62.1 317 294 58.4 56.9 15.6 74.1

85 72 337 246 63.0 62.5 14.7 77.4 335 246 63.0 62.6 15.0 64.3 330 244 63.2 62.7 15.6 76.7

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 284 245 52.8 52.0 15.9 56.4 280.9 243.3 52.9 52.1 16.5 67.4 278.4 242 53.0 52.2 16.9 56.0

75 67 302 192 57.8 57.5 16.0 59.5 297.9 190.4 58.0 57.7 16.5 70.9 295.7 189.5 58.1 57.8 16.9 58.9

75 72 327 138 63.2 63.1 16.0 63.6 323 136 63.3 63.2 16.6 75.9 320 135 63.4 63.3 17.0 63.0

80 62 293 291 53.5 51.6 15.9 57.9 289.9 288.3 53.7 51.7 16.5 69.3 287.4 286.4 53.9 51.8 16.9 57.5

80 67 304 245 57.9 57.4 16.0 59.8 300.6 243 58.1 57.5 16.6 71.4 299 242.3 58.1 57.6 16.9 59.5

80 72 328 190 63.2 62.9 16.0 63.7 323 188.8 63.3 63.0 16.6 75.9 320.4 187.8 63.4 63.1 17.0 63.1

85 62 3 11 311 56.6 50.9 16.0 60.9 307.5 307.5 56.9 51.0 16.6 72.8 305.4 305.4 57.1 51.1 16.9 60.5

85 67 315 293 58.4 57.0 16.0 61.6 311 290.5 58.6 57.1 16.6 73.5 309 289.5 58.7 57.2 16.9 61.1

85 72 328 243 63.3 62.8 16.0 63.7 323.8 241.4 63.4 62.9 16.6 76.1 320.8 240.3 63.5 63.0 17.0 63.1

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 297 235 48.5 48.4 14.6 69.4 295 234 48.6 48.5 15.0 57.6 291 232 48.8 48.7 15.6 68.9

75 67 318 188 54.2 54.1 14.7 73.6 316 187 54.3 54.2 15.0 61.2 312 185 54.5 54.4 15.6 72.9

75 72 345 142 59.7 59.6 14.7 79.1 343 141 59.8 59.7 15.0 65.7 338 139 60.0 59.9 15.6 78.3

80 62 306 281 48.1 48.0 14.6 71.2 304 280 48.2 48.1 15.0 59.2 300 278 48.4 48.3 15.6 70.7

80 67 319 233 53.9 53.8 14.7 73.9 317 232 54.0 53.9 15.0 61.3 313 231 54.1 54.0 15.6 73.3

80 72 346 187 59.5 59.4 14.6 79.2 343 186 59.6 59.5 15.0 65.7 338 184 59.8 59.7 15.6 78.4

85 62 319 319 48.5 47.2 14.6 73.9 317 317 48.7 47.4 15.0 61.4 314 314 49.1 47.5 15.6 73.4

85 67 330 280 53.4 53.3 14.6 76.0 327 279 53.5 53.4 15.0 63.1 324 277 53.7 53.6 15.6 75.4

85 72 346 232 59.3 59.2 14.7 79.2 343 231 59.4 59.3 15.0 65.8 339 229 59.6 59.5 15.6 78.4

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 289 231 48.9 48.8 15.9 57.2 285 229 49.2 49.1 16.5 68.3 283 228 49.3 49.2 16.9 56.7

75 67 309 184 54.6 54.5 16.0 60.6 305 182 54.8 54.7 16.6 72.2 302 181 54.9 54.8 16.9 60.0

75 72 336 138 60.1 60.0 16.0 65.0 331 137 60.3 60.2 16.6 77.5 328 136 60.4 60.3 17.0 64.4

80 62 298 277 48.5 48.4 15.9 58.8 294 275 48.7 48.6 16.5 70.1 292 274 48.8 48.7 16.9 58.3

80 67 3 11 230 54.2 54.1 16.0 60.9 307 228 54.4 54.3 16.6 72.7 304 227 54.6 54.5 17.0 60.4

80 72 336 183 59.9 59.8 16.0 65.1 331 181 60.1 60.0 16.6 77.6 328 180 60.2 60.1 17.0 64.4

85 62 312 312 49.3 47.6 16.0 61.1 309 309 49.7 47.8 16.6 73.0 306 306 50.0 48.0 16.9 60.7

85 67 321 276 53.8 53.7 16.0 62.6 317 274 54.1 54.0 16.6 74.7 314 273 54.2 54.1 17.0 62.0

85 72 336 228 59.7 59.6 16.0 65.1 332 226 59.9 59.8 16.6 77.7 329 225 60.0 59.9 17.0 64.4

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

AIR FLOW 10,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 8,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 8,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

WATER

WATER

WATER

FLOW

GPM

FLOW

GPM

FLOW

GPM

FLOW

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

22

JOHNSON CONTROLS

Page 23

FORM 145.05-EG2 (618)

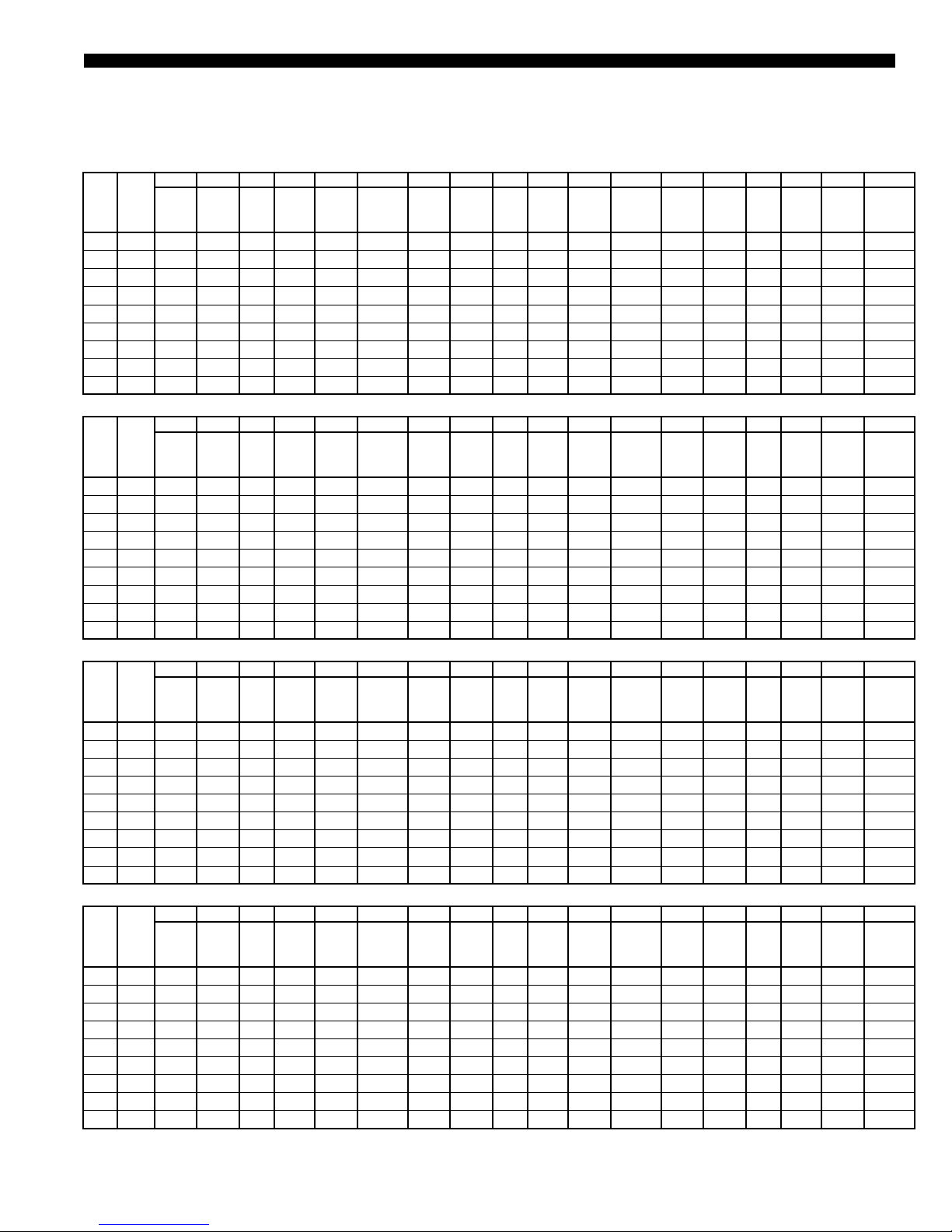

TABLE 9 - LSWU032

AIR FLOW 12,800 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 371 320 52.3 51.8 19.8 87.7 369 319 52.4 51.9 20.2 72.9 364 316 52.6 52.0 20.9 87.1

75 67 399 251 57.5 57.2 20.1 93.5 395 249 57.6 57.3 20.5 77.5 390 247 57.8 57.5 21.2 92.5

75 72 431 181 62.7 62.6 20.6 100.2 427 179 62.9 62.7 21.0 83.1 422 177 63.0 62.9 21.6 99.1

80 62 385 380 52.9 51.3 20.0 90.7 382 378 53.0 51.4 20.4 75.3 378 375 53.3 51.5 21.1 89.9

80 67 399 318 57.6 57.2 20.1 93.6 396 316 57.7 57.2 20.6 77.7 392 315 57.8 57.3 21.2 92.8

80 72 431 248 62.9 62.6 20.6 100.3 428 247 63.0 62.6 21.0 83.2 423 245 63.1 62.8 21.6 99.3

85 62 407 407 55.9 50.6 20.4 95.3 404 404 56.1 50.7 20.8 79.2 400 400 56.4 50.8 21.4 94.7

85 67 413 382 57.9 56.7 20.4 96.5 410 381 58.0 56.8 20.8 80.1 405 378 58.2 56.9 21.4 95.7

85 72 432 316 62.9 62.5 20.6 100.5 429 315 63.0 62.6 21.0 83.4 423 313 63.1 62.7 21.7 99.5

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 362 315 52.7 52.1 21.3 72.4 357 313 52.8 52.2 22.0 86.4 355 311 52.9 52.3 22.5 71.9

75 67 387 246 57.8 57.5 21.6 76.8 382 244 58.0 57.7 22.3 91.5 378 243 58.0 57.8 22.7 76.0

75 72 418 176 63.1 62.9 22.0 82.3 412 174 63.2 63.1 22.7 97.9 409 173 63.3 63.2 23.2 81.3

80 62 375 374 53.3 51.6 21.5 74.8 370 370 53.6 51.8 22.2 89.2 368 368 53.8 51.8 22.7 74.2

80 67 388 313 57.9 57.5 21.6 77.0 383 3 11 58.1 57.6 22.3 91.9 379 310 58.1 57.7 22.8 76.2

80 72 419 244 63.2 62.9 22.1 82.4 414 242 63.3 63.0 22.7 98.3 410 241 63.4 63.1 23.2 81.5

85 62 398 398 56.6 50.9 21.9 78.7 393 393 56.9 51.0 22.6 94.0 391 391 57.1 51.1 23.0 78.2

85 67 402 377 58.3 57.0 21.9 79.5 397 374 58.5 57.2 22.6 94.9 394 373 58.5 57.2 23.1 78.7

85 72 420 3 11 63.3 62.8 22.1 82.6 415 309 63.4 62.9 22.7 98.4 411 308 63.5 63.0 23.2 81.7

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 377 298 48.1 48.0 19.9 89.0 374 296 48.3 48.2 20.3 73.9 370 294 48.5 48.4 20.9 88.2

75 67 407 239 53.8 53.7 20.3 95.2 404 237 54.0 53.9 20.7 79.0 398 235 54.2 54.1 21.3 94.3

75 72 440 181 59.4 59.3 20.8 102.3 437 180 59.5 59.4 21.2 84.9 431 178 59.7 59.6 21.8 101.2

80 62 390 356 47.7 47.6 20.1 91.6 387 355 47.8 47.7 20.5 76.1 382 353 47.9 47.8 21.2 90.9

80 67 408 296 53.5 53.4 20.3 95.4 405 294 53.7 53.6 20.7 79.3 399 292 53.8 53.7 21.3 94.4

80 72 442 237 59.2 59.1 20.8 102.6 438 236 59.3 59.2 21.2 85.0 432 234 59.5 59.4 21.8 101.4

85 62 406 406 47.9 47.0 20.4 95.2 404 404 48.0 47.0 20.8 79.1 400 400 48.4 47.2 21.5 94.6

85 67 419 355 53.0 52.9 20.5 97.7 416 353 53.1 53.0 21.0 81.2 411 351 53.3 53.2 21.6 96.9

85 72 442 294 58.9 58.8 20.8 102.7 439 292 59.1 59.0 21.2 85.2 433 290 59.2 59.1 21.8 101.5

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 367 293 48.5 48.4 21.4 73.3 362 290 48.8 48.7 22.1 87.4 359 289 48.9 48.8 22.5 72.6

75 67 395 234 54.2 54.1 21.7 78.1 390 232 54.4 54.3 22.4 93.2 386 230 54.6 54.5 22.9 77.4

75 72 428 176 59.7 59.7 22.2 84.0 422 174 60.0 59.9 22.9 100.1 418 173 60.1 60.0 23.4 83.0

80 62 380 351 48.1 48.0 21.6 75.6 375 349 48.3 48.2 22.3 90.1 372 347 48.5 48.4 22.8 74.9

80 67 396 291 53.9 53.8 21.8 78.4 391 289 54.1 54.0 22.5 93.6 388 287 54.3 54.2 23.0 77.7

80 72 429 233 59.5 59.4 22.2 84.2 423 230 59.8 59.7 22.9 100.3 419 229 59.9 59.8 23.4 83.2

85 62 396 396 48.8 47.4 21.9 78.5 392 392 49.1 47.6 22.6 93.9 389 389 49.4 47.7 23.1 78.0

85 67 408 350 53.4 53.3 22.0 80.5 403 347 53.7 53.6 22.7 96.0 400 346 53.8 53.7 23.2 79.8

85 72 430 289 59.3 59.2 22.3 84.2 423 287 59.5 59.4 22.9 100.3 420 285 59.7 59.6 23.4 83.3

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

AIR FLOW 12,800 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 10,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 10,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

WATER

FLOW

WATER

FLOW

WATER

FLOW

GPM

GPM

GPM

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

JOHNSON CONTROLS

23

Page 24

FORM 145.05-EG2 (618)

Cooling Performance Data (Cont’d)

TABLE 10 - LSWU035

AIR FLOW 14,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 402 348 52.4 51.9 21.4 95.0 399 346 52.6 52.0 21.8 78.9 394 344 52.7 52.1 22.5 94.1

75 67 428 272 57.7 57.4 21.7 100.4 424 271 57.7 57.5 22.2 83.3 419 269 57.8 57.6 22.8 99.4

75 72 462 195 62.9 62.8 22.3 107.7 459 194 63.0 62.9 22.7 89.4 453 192 63.1 63.0 23.4 106.5

80 62 415 413 53.1 51.5 21.6 97.8 413 4 11 53.2 51.5 22.1 81.4 408 407 53.5 51.7 22.7 97.2

80 67 429 346 57.7 57.3 21.8 100.8 427 345 57.8 57.4 22.2 83.7 421 343 57.9 57.5 22.9 99.9

80 72 463 270 63.0 62.8 22.3 107.9 459 268 63.1 62.8 22.7 89.5 454 266 63.2 63.0 23.3 106.7

85 62 440 440 56.2 50.8 22.1 103.1 438 438 56.4 50.8 22.5 85.7 433 433 56.7 51.0 23.1 102.4

85 67 445 416 58.0 56.9 22.1 104.2 442 415 58.1 57.0 22.5 86.6 437 412 58.3 57.1 23.2 103.3

85 72 464 344 63.0 62.7 22.3 108.0 460 343 63.1 62.8 22.7 89.7 454 341 63.2 62.9 23.4 106.8

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 391 342 52.8 52.2 22.9 78.2 386 340 52.9 52.3 23.7 93.4 383 338 53.1 52.4 24.2 77.6

75 67 415 267 58.0 57.7 23.3 82.4 410 265 58.1 57.9 24.0 98.3 406 264 58.2 58.0 24.5 81.6

75 72 449 190 63.2 63.1 23.8 88.4 443 188 63.4 63.3 24.5 105.3 439 187 63.4 63.3 25.0 87.4

80 62 405 405 53.6 51.8 23.2 80.8 401 401 53.9 51.9 23.9 96.6 398 398 54.0 52.0 24.4 80.3

80 67 419 342 58.0 57.6 23.3 83.1 414 339 58.2 57.7 24.1 99.1 411 338 58.2 57.8 24.6 82.4

80 72 450 265 63.3 63.0 23.8 88.5 444 263 63.4 63.2 24.5 105.5 440 261 63.5 63.3 25.0 87.5

85 62 430 430 56.9 51.0 23.6 85.1 425 425 57.2 51.2 24.3 101.6 422 422 57.4 51.3 24.8 84.4

85 67 434 410 58.4 57.2 23.6 85.7 429 408 58.5 57.3 24.3 102.3 425 406 58.7 57.4 24.8 85.0

85 72 451 339 63.3 63.0 23.8 88.7 445 337 63.5 63.1 24.5 105.7 441 336 63.5 63.2 25.0 87.7

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 406 323 48.5 48.4 21.4 95.8 402 321 48.7 48.6 21.9 79.5 398 319 48.8 48.7 22.5 94.9

75 67 435 258 54.2 54.1 21.9 101.9 431 256 54.4 54.3 22.3 84.6 425 254 54.5 54.4 23.0 100.8

75 72 472 194 59.7 59.7 22.5 109.7 468 193 59.9 59.8 22.9 91.0 462 191 60.0 59.9 23.5 108.4

80 62 419 387 48.0 47.9 21.7 98.5 416 386 48.1 48.0 22.1 81.8 411 383 48.4 48.3 22.8 97.7

80 67 437 321 53.8 53.7 21.9 102.4 433 319 54.0 53.9 22.3 84.9 428 317 54.2 54.1 23.0 101.3

80 72 472 256 59.6 59.5 22.5 109.8 468 255 59.6 59.5 22.9 91.1 462 252 59.9 59.8 23.5 108.5

85 62 438 438 48.6 47.3 22.1 102.6 435 435 48.8 47.4 22.5 85.2 430 430 49.2 47.6 23.1 101.9

85 67 450 385 53.4 53.3 22.2 105.2 447 384 53.5 53.4 22.6 87.4 441 381 53.7 53.6 23.3 104.1

85 72 473 318 59.3 59.2 22.5 109.9 469 317 59.4 59.3 22.9 91.2 463 315 59.5 59.4 23.5 108.6

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 394 317 49.0 48.9 23.0 78.8 390 315 49.1 49.0 23.7 94.1 386 313 49.3 49.2 24.2 78.1

75 67 422 252 54.7 54.6 23.4 83.7 417 250 54.8 54.7 24.1 99.8 412 248 55.0 54.9 24.6 82.7

75 72 458 189 60.2 60.1 24.0 89.9 452 187 60.4 60.3 24.7 107.1 448 185 60.4 60.4 25.1 88.9

80 62 407 382 48.4 48.3 23.3 81.1 402 379 48.7 48.6 24.0 96.8 399 377 48.9 48.8 24.5 80.4

80 67 425 315 54.3 54.2 23.5 84.1 419 313 54.5 54.4 24.2 100.3 416 312 54.6 54.5 24.7 83.3

80 72 459 251 60.0 59.9 24.0 90.1 453 249 60.1 60.0 24.7 107.4 448 247 60.3 60.2 25.2 89.0

85 62 427 427 49.5 47.7 23.6 84.6 422 422 49.9 47.9 24.3 101.1 419 419 50.2 48.0 24.8 84.0

85 67 438 380 53.8 53.7 23.7 86.6 433 377 54.0 53.9 24.4 103.3 430 376 54.1 54.0 24.9 85.8

85 72 459 313 59.7 59.6 24.0 90.2 453 3 11 59.9 59.8 24.7 107.4 449 310 59.9 59.8 25.2 89.2

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

AIR FLOW 14,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 11,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 11,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

WATER

FLOW

WATER

FLOW

WATER

FLOW

GPM

GPM

GPM

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

24

JOHNSON CONTROLS

Page 25

FORM 145.05-EG2 (618)

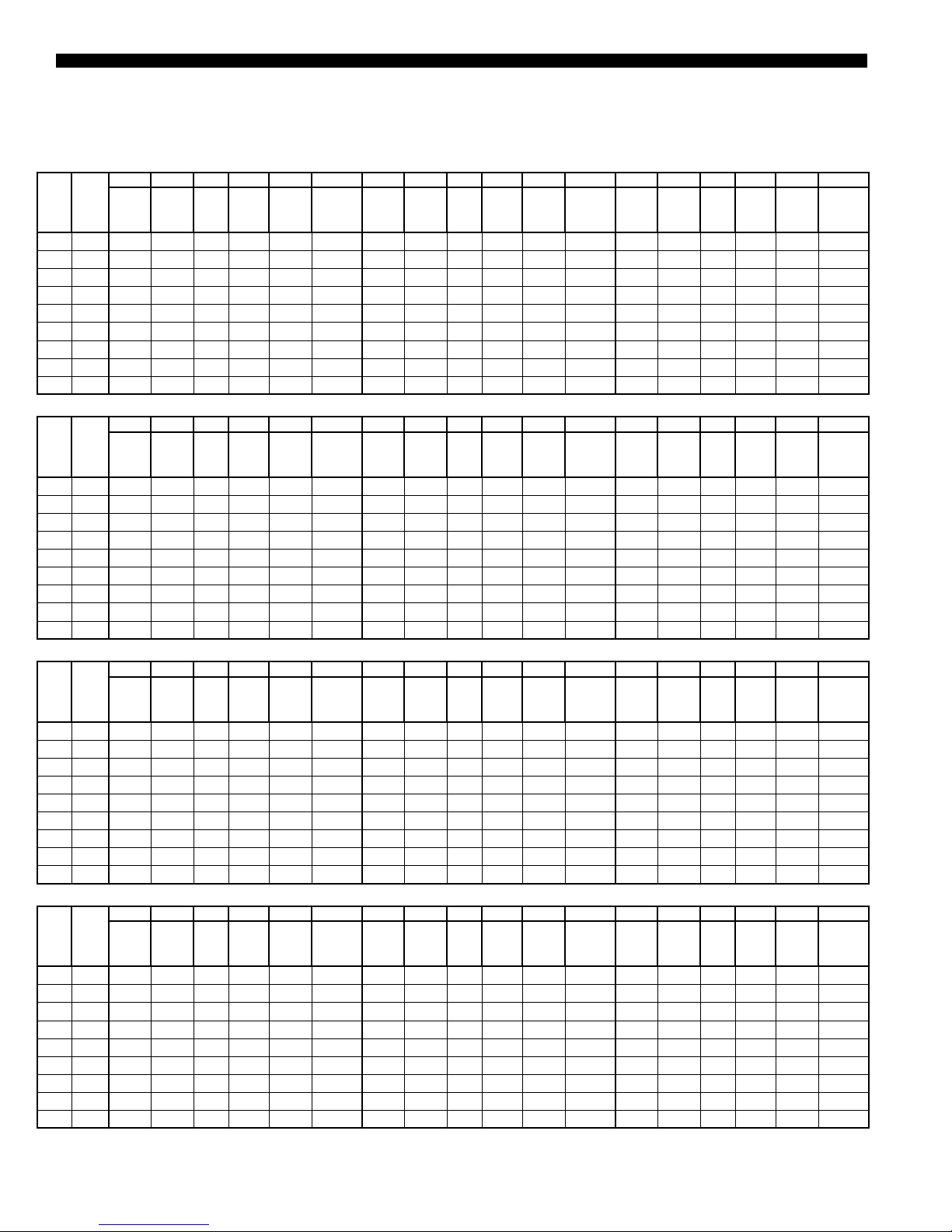

TABLE 11 - LSWU040

AIR FLOW 16,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 454 399 52.4 52.0 23.4 106.7 451 398 52.4 52.1 23.9 88.7 445 395 52.6 52.2 24.6 105.8

75 67 479 3 11 57.7 57.6 23.8 112.0 475 309 57.7 57.7 24.3 93.0 469 307 58.0 57.9 25.0 110.9

75 72 517 221 63.1 63.0 24.7 120.3 513 219 63.1 63.1 25.1 99.8 507 217 63.3 63.2 25.8 119.0

80 62 473 473 53.0 51.5 23.8 110.9 470 470 53.2 51.6 24.3 92.1 465 465 53.5 51.7 25.0 110.0

80 67 488 399 57.5 57.4 24.1 114.1 485 397 57.6 57.4 24.5 94.7 479 394 57.8 57.6 25.2 113.0

80 72 518 308 63.1 63.0 24.7 120.4 514 307 63.1 63.0 25.1 100.0 508 305 63.2 63.1 25.8 119.2

85 62 500 500 56.4 50.8 24.3 116.7 497 497 56.6 50.9 24.8 97.0 492 492 56.9 51.0 25.5 115.8

85 67 503 482 57.6 57.0 24.4 117.3 500 480 57.8 57.1 24.9 97.4 494 477 57.9 57.2 25.6 116.2

85 72 524 398 62.8 62.7 24.8 121.8 520 396 62.9 62.8 25.3 101.1 514 394 63.0 62.9 26.0 120.6

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 442 394 52.6 52.3 25.1 87.9 436 391 52.8 52.5 25.9 104.9 432 389 52.9 52.6 26.4 87.1

75 67 465 306 58.0 57.9 25.5 92.0 459 303 58.1 58.1 26.3 109.7 455 302 58.2 58.1 26.8 91.0

75 72 503 216 63.4 63.3 26.3 98.7 496 213 63.5 63.5 27.0 117.6 491 212 63.6 63.5 27.6 97.6

80 62 462 462 53.6 51.8 25.5 91.4 457 457 53.9 51.9 26.3 109.2 453 453 54.2 52.0 26.8 90.7

80 67 475 393 57.8 57.7 25.7 93.9 469 390 58.0 57.8 26.5 111.9 465 388 58.1 57.9 27.1 92.9

80 72 504 303 63.2 63.2 26.3 98.9 497 301 63.4 63.3 27.1 117.8 492 299 63.6 63.5 27.6 97.7

85 62 489 489 57.0 51.1 26.0 96.3 483 483 57.4 51.2 26.8 115.0 480 480 57.6 51.3 27.4 95.5

85 67 491 475 58.0 57.3 26.1 96.6 484 472 58.2 57.4 26.8 115.2 481 470 58.3 57.5 27.4 95.7

85 72 510 392 63.2 63.1 26.5 100.1 504 390 63.3 63.2 27.2 119.4 500 388 63.3 63.2 27.8 99.1

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 455 370 49.3 49.2 23.4 107.0 452 369 49.4 49.3 23.9 88.9 446 366 49.4 49.3 24.6 106.0

75 67 483 292 55.1 55.0 23.9 113.0 479 291 55.1 55.0 24.4 93.8 474 288 55.1 55.0 25.1 111.9

75 72 523 217 60.6 60.5 24.8 121.6 519 216 60.7 60.6 25.2 100.9 513 214 60.7 60.6 25.9 120.3

80 62 469 447 48.7 48.6 23.7 110.1 467 446 48.8 48.7 24.2 91.5 461 443 48.8 48.7 24.9 109.2

80 67 490 368 54.6 54.5 24.1 114.4 487 367 54.7 54.6 24.6 95.1 480 364 54.7 54.6 25.3 113.3

80 72 524 290 60.4 60.3 24.8 121.7 520 289 60.5 60.4 25.3 101.0 513 287 60.5 60.4 25.9 120.3

85 62 494 494 50.2 48.1 24.2 115.4 491 491 50.4 48.2 24.7 95.8 485 485 50.4 48.2 25.4 114.4

85 67 505 445 54.1 54.0 24.4 117.7 501 443 54.2 54.1 24.9 97.7 495 441 54.2 54.1 25.6 116.5

85 72 527 365 60.0 59.9 24.9 122.4 523 364 60.1 60.0 25.3 101.6 517 361 60.1 60.0 26.0 121.1

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 443 365 49.6 49.5 25.1 88.1 437 362 49.8 49.7 25.9 105.1 434 360 50.0 49.9 26.4 87.3

75 67 470 287 55.4 55.3 25.6 92.8 463 284 55.6 55.5 26.4 110.7 459 283 55.7 55.6 26.9 91.8

75 72 509 212 61.0 60.9 26.4 99.8 501 210 61.1 61.0 27.2 118.8 497 208 61.2 61.1 27.7 98.6

80 62 457 441 49.2 49.1 25.4 90.7 451 438 49.4 49.3 26.2 108.1 448 437 49.4 49.3 26.8 89.9

80 67 477 362 55.0 54.9 25.8 94.1 470 360 55.2 55.1 26.6 112.2 467 358 55.3 55.2 27.1 93.2

80 72 509 285 60.7 60.6 26.4 99.9 503 283 60.9 60.8 27.2 119.1 498 281 61.0 60.9 27.7 98.7

85 62 482 482 51.1 48.4 25.9 95.1 477 477 51.4 48.6 26.7 113.6 473 473 51.7 48.7 27.3 94.4

85 67 492 439 54.5 54.4 26.1 96.8 485 436 54.7 54.6 26.9 115.4 482 435 54.8 54.7 27.4 95.8

85 72 513 360 60.4 60.3 26.5 100.5 506 357 60.6 60.5 27.3 119.9 502 356 60.6 60.5 27.8 99.5

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

AIR FLOW 16,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 13,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 13,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

WATER

FLOW

WATER

FLOW

WATER

FLOW

GPM

GPM

GPM

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

JOHNSON CONTROLS

25

Page 26

FORM 145.05-EG2 (618)

Cooling Performance Data (Cont’d)

TABLE 12 - LSWU050

AIR FLOW 20,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 572 503 52.2 51.9 28.4 133.7 567 500 52.3 52.0 29.0 111.0 560 497 52.4 52.2 29.9 132.5

75 67 607 392 57.6 57.5 28.8 141.0 601 390 57.7 57.6 29.4 117.0 593 387 57.8 57.7 30.3 139.3

75 72 656 279 62.9 62.9 29.5 151.3 651 277 63.0 63.0 30.0 125.5 642 274 63.1 63.1 30.9 149.4

80 62 596 596 52.8 51.4 28.6 138.7 592 592 53.0 51.5 29.2 115.3 586 586 53.3 51.6 30.1 137.7

80 67 613 503 57.4 57.3 28.9 142.2 608 501 57.5 57.4 29.5 118.1 601 497 57.6 57.5 30.4 140.9

80 72 657 389 62.9 62.8 29.5 151.6 651 387 63.0 62.9 30.1 125.6 642 384 63.1 63.0 31.0 149.6

85 62 632 632 56.1 50.7 29.0 146.1 627 627 56.3 50.8 29.6 121.3 620 620 56.6 50.9 30.5 144.9

85 67 637 604 57.6 56.9 29.1 147.3 632 602 57.7 56.9 29.7 122.2 624 598 57.8 57.1 30.6 145.6

85 72 659 499 62.8 62.7 29.5 151.9 653 497 62.8 62.7 30.1 125.9 644 494 63.0 62.9 31.0 150.0

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 555 494 52.6 52.3 30.5 109.9 548 490 52.7 52.4 31.5 131.2 543 488 52.8 52.5 32.1 108.8

75 67 588 385 57.9 57.8 30.9 115.6 580 381 58.0 58.0 31.9 137.7 574 379 58.2 58.1 32.5 114.2

75 72 636 272 63.3 63.2 31.6 124.0 627 269 63.4 63.3 32.5 147.5 622 267 63.5 63.4 33.1 122.4

80 62 581 581 53.5 51.7 30.7 114.4 574 574 53.8 51.9 31.8 136.5 570 570 54.0 51.9 32.4 113.4

80 67 596 495 57.7 57.6 31.0 117.0 589 492 57.8 57.7 32.0 139.7 584 490 57.9 57.8 32.7 115.9

80 72 638 382 63.2 63.1 31.5 124.2 628 379 63.3 63.2 32.5 147.8 622 377 63.4 63.3 33.1 122.5

85 62 616 616 56.8 51.0 31.1 120.4 608 608 57.2 51.2 32.1 143.5 604 604 57.4 51.2 32.8 119.3

85 67 619 595 58.0 57.2 31.2 120.9 6 11 591 58.2 57.3 32.2 144.3 607 589 58.2 57.4 32.8 119.8

85 72 639 492 63.1 63.0 31.5 124.5 630 489 63.2 63.1 32.5 148.3 625 487 63.3 63.2 33.2 123.1

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 569 462 48.9 48.8 28.3 133.2 565 460 49.0 48.9 28.9 110.7 558 457 49.2 49.1 29.8 132.0

75 67 612 367 54.7 54.6 28.9 142.0 607 365 54.8 54.7 29.5 117.9 599 362 54.9 54.8 30.3 140.5

75 72 664 275 60.2 60.1 29.5 152.9 658 273 60.3 60.2 30.1 126.7 649 269 60.5 60.4 31.0 150.9

80 62 592 557 48.4 48.3 28.5 137.8 587 555 48.5 48.4 29.1 114.3 579 551 48.7 48.6 30.0 136.3

80 67 615 459 54.3 54.2 28.9 142.7 609 457 54.4 54.3 29.5 118.3 602 454 54.5 54.4 30.4 141.1

80 72 664 365 60.0 59.9 29.5 153.0 658 363 60.1 60.0 30.1 126.8 650 360 60.2 60.1 31.0 151.1

85 62 621 621 49.5 47.7 28.8 143.9 617 617 49.7 47.8 29.4 119.5 610 610 50.1 48.0 30.3 142.7

85 67 634 554 53.7 53.6 29.1 146.7 629 552 53.8 53.7 29.6 121.8 622 549 54.0 53.9 30.5 145.3

85 72 666 456 59.7 59.6 29.6 153.3 660 454 59.8 59.7 30.1 127.2 652 451 59.9 59.8 31.0 151.5

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 553 454 49.4 49.3 30.5 109.6 546 451 49.5 49.4 31.4 130.8 542 449 49.6 49.5 32.1 108.5

75 67 593 359 55.1 55.0 30.9 116.4 585 356 55.3 55.2 31.9 138.8 579 354 55.4 55.3 32.6 115.0

75 72 644 268 60.6 60.5 31.6 125.2 634 264 60.8 60.7 32.5 148.9 628 262 60.9 60.8 33.2 123.5

80 62 574 549 48.8 48.7 30.6 113.2 567 545 49.0 48.9 31.6 134.9 562 542 49.2 49.1 32.3 112.0

80 67 597 452 54.7 54.6 31.0 117.1 588 448 54.9 54.8 32.0 139.4 582 446 55.0 54.9 32.6 115.6

80 72 644 358 60.3 60.2 31.6 125.4 635 354 60.6 60.5 32.5 149.2 629 352 60.7 60.6 33.2 123.7

85 62 606 606 50.4 48.1 31.0 118.5 598 598 50.8 48.3 31.9 141.4 594 594 51.0 48.4 32.6 117.5

85 67 617 546 54.2 54.1 31.1 120.6 609 543 54.3 54.2 32.1 143.7 604 540 54.5 54.4 32.8 119.3

85 72 646 449 60.0 59.9 31.6 125.6 637 446 60.2 60.1 32.6 149.6 630 443 60.4 60.3 33.2 123.9

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

AIR FLOW 20,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 16,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 16,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

26

JOHNSON CONTROLS

Page 27

FORM 145.05-EG2 (618)

TABLE 13 - LSWU060

AIR FLOW 24,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 677 601 52.3 52.1 35.0 159.3 672 598 52.4 52.2 35.7 132.3 664 594 52.5 52.3 36.8 157.9

75 67 718 467 57.7 57.6 35.8 168.1 713 465 57.8 57.7 36.5 139.5 704 462 57.9 57.8 37.5 166.3

75 72 775 331 63.1 63.0 37.0 180.3 769 329 63.2 63.1 37.7 149.6 760 326 63.3 63.2 38.7 178.4

80 62 707 707 53.1 51.6 35.6 165.8 704 704 53.2 51.6 36.3 137.9 696 696 53.5 51.7 37.4 164.8

80 67 725 601 57.5 57.4 35.9 169.4 719 599 57.6 57.5 36.6 140.6 7 11 596 57.7 57.6 37.7 167.9

80 72 777 464 63.0 62.9 37.0 180.6 771 461 63.1 63.0 37.7 149.9 762 458 63.2 63.1 38.7 178.8

85 62 750 750 56.4 50.8 36.5 174.8 745 745 56.6 50.9 37.1 145.2 737 737 56.9 51.0 38.2 173.4

85 67 755 720 57.8 57.0 36.5 175.8 748 717 57.9 57.1 37.3 145.9 741 713 58.0 57.2 38.3 174.3

85 72 780 597 62.8 62.7 37.1 181.2 773 595 62.9 62.8 37.8 150.4 764 591 63.0 62.9 38.8 179.3

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 659 591 52.6 52.4 37.6 131.1 650 587 52.8 52.5 38.7 156.5 645 584 52.9 52.6 39.6 130.1

75 67 698 459 58.0 57.9 38.3 138.0 688 455 58.2 58.1 39.4 164.5 682 453 58.2 58.1 40.2 136.5

75 72 754 324 63.4 63.3 39.4 148.1 744 320 63.5 63.4 40.6 176.5 737 318 63.6 63.5 41.3 146.4

80 62 691 691 53.7 51.8 38.2 136.8 683 683 54.0 51.9 39.4 163.4 677 677 54.2 52.0 40.2 135.7

80 67 706 593 57.8 57.7 38.4 139.5 697 589 57.9 57.8 39.6 166.4 692 587 58.0 57.9 40.4 138.2

80 72 756 456 63.3 63.2 39.4 148.4 746 452 63.4 63.3 40.6 176.8 738 450 63.5 63.4 41.4 146.6

85 62 732 732 57.1 51.1 39.0 144.1 723 723 57.4 51.3 40.2 172.0 718 718 57.6 51.4 41.0 142.9

85 67 735 710 58.1 57.3 39.0 144.8 726 705 58.3 57.4 40.2 172.7 720 702 58.4 57.5 41.0 143.4

85 72 758 589 63.1 63.0 39.5 148.8 748 586 63.2 63.1 40.7 177.4 742 584 63.3 63.2 41.5 147.3

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 670 547 49.0 48.9 34.9 157.9 665 544 49.1 49.0 35.6 131.0 657 541 49.3 49.2 36.6 156.5

75 67 722 435 54.7 54.6 35.9 168.9 716 432 54.8 54.7 36.6 140.2 708 429 55.0 54.9 37.6 167.3

75 72 782 324 60.3 60.2 37.1 181.8 777 322 60.4 60.3 37.8 150.9 766 319 60.5 60.4 38.8 179.8

80 62 697 659 48.5 48.4 35.4 163.5 691 656 48.6 48.5 36.1 135.7 684 653 48.8 48.7 37.2 162.1

80 67 726 544 54.3 54.2 35.9 169.7 720 542 54.4 54.3 36.6 140.9 712 544 54.3 54.2 37.7 168.2

80 72 783 432 60.0 59.9 37.2 182.0 777 430 60.1 60.0 37.8 151.0 768 426 60.3 60.2 38.9 180.1

85 62 732 732 49.8 47.8 36.1 171.1 727 727 50.0 48.0 36.8 142.1 720 720 50.3 48.1 37.9 169.8

85 67 746 656 53.8 53.7 36.4 174.0 741 654 53.9 53.8 37.1 144.5 732 650 54.1 54.0 38.1 172.5

85 72 784 540 59.7 59.6 37.2 182.1 778 538 59.8 59.7 37.8 151.2 768 534 60.0 59.9 38.8 180.2

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 651 538 49.4 49.3 37.4 129.8 643 534 49.6 49.5 38.6 155.0 638 532 49.7 49.6 39.4 128.7

75 67 702 426 55.1 55.0 38.4 138.9 693 422 55.3 55.2 39.5 165.5 686 420 55.4 55.3 40.3 137.2

75 72 760 316 60.7 60.6 39.5 149.2 750 313 60.8 60.7 40.7 177.8 744 310 61.0 60.9 41.5 147.6

80 62 679 650 48.9 48.8 37.9 134.7 670 646 49.1 49.0 39.1 160.7 664 643 49.2 49.1 40.0 133.4

80 67 705 535 54.7 54.6 38.4 139.4 695 531 54.9 54.8 39.6 166.1 688 529 55.0 54.9 40.4 137.7

80 72 761 424 60.4 60.3 39.6 149.4 751 420 60.6 60.5 40.7 178.0 744 417 60.7 60.6 41.5 147.7

85 62 715 715 50.6 48.2 38.6 141.1 707 707 51.0 48.4 39.9 168.5 701 701 51.2 48.5 40.7 140.1

85 67 726 647 54.2 54.1 38.9 143.1 718 643 54.4 54.3 40.0 170.8 712 641 54.5 54.4 40.8 142.0

85 72 762 532 60.1 60.0 39.6 149.5 751 528 60.3 60.2 40.7 178.1 746 526 60.4 60.3 41.6 148.0

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

AIR FLOW 24,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 19,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 19,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

WATER

FLOW

WATER

FLOW

WATER

FLOW

GPM

GPM

GPM

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

JOHNSON CONTROLS

27

Page 28

FORM 145.05-EG2 (618)

Cooling Performance Data (Cont’d)

TABLE 14 - LSWU070

AIR FLOW 28,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 803.8 693.4 52.5 51.9 42.7 189.9 798.1 690.4 52.6 52.0 43.6 157.8 788 685.3 52.8 52.1 45.0 188.3

75 67 856.6 542.8 57.7 57.4 43.5 201.0 849.3 539.9 57.8 57.5 44.3 166.8 839 535.8 57.9 57.6 45.7 199.0

75 72 926 389.9 62.9 62.8 44.6 215.7 918.7 387.3 63.0 62.9 45.4 179.0 908.4 383.7 63.1 63.0 46.7 213.6

80 62 831.1 821.8 53.2 51.5 43.3 195.7 825.6 818.4 53.3 51.5 44.1 162.7 816.3 811.5 53.5 51.7 45.5 194.3

80 67 861 690.4 57.8 57.3 43.6 202.0 855.9 688.6 57.8 57.4 44.5 167.9 845.5 684 58.0 57.5 45.8 200.4

80 72 928.4 538.3 63.0 62.7 44.7 216.2 920.4 535.4 63.1 62.8 45.5 179.3 910.2 531.8 63.2 62.9 46.8 214.0

85 62 879.9 879.9 56.2 50.8 44.1 206.1 874 874 56.4 50.8 44.9 171.2 865.1 865.1 56.7 51.0 46.3 204.6

85 67 891.2 828 58.2 56.9 44.2 208.4 884.5 824.6 58.3 57.0 45.1 173.0 874.6 819.5 58.5 57.1 46.4 206.6

85 72 929.9 685.6 63.1 62.7 44.7 216.5 923.7 683.3 63.2 62.7 45.5 179.8 911.1 678.5 63.3 62.9 46.8 214.1

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 782.4 682.3 52.9 52.2 45.9 156.5 772.3 677.1 53.0 52.3 47.4 186.8 765.7 673.7 53.1 52.4 48.3 155.1

75 67 832.6 533.3 58.0 57.7 46.5 165.2 820.8 528.7 58.1 57.9 48.0 196.9 813.5 525.8 58.2 58.0 48.9 163.4

75 72 900.4 380.9 63.2 63.1 47.6 177.1 887.5 376.3 63.4 63.2 49.0 210.9 881 374.1 63.4 63.3 50.0 175.3

80 62 810.9 807.9 53.7 51.8 46.4 161.5 801.7 800.8 53.9 51.9 47.9 193.0 795.3 795.1 54.1 52.0 48.9 160.3

80 67 838.6 681 58.1 57.6 46.7 166.3 829.1 677.1 58.2 57.7 48.1 198.7 821.9 673.7 58.3 57.8 49.1 164.9

80 72 902.3 528.9 63.3 63.0 47.7 177.5 891.1 524.9 63.4 63.1 49.1 211.7 883.1 522.1 63.5 63.2 50.0 175.6

85 62 859.2 859.2 56.9 51.1 47.2 170.0 850.3 850.3 57.2 51.2 48.6 203.2 844.1 844.1 57.4 51.3 49.6 168.9

85 67 867.8 816 58.5 57.2 47.3 171.5 857.9 810.8 58.7 57.3 48.7 204.8 851.2 807.3 58.8 57.4 49.7 170.1

85 72 904.8 676.1 63.4 62.9 47.7 177.9 892.6 671.6 63.5 63.1 49.1 212.0 883.8 668.3 63.6 63.2 50.2 175.8

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 822.6 666.5 49.3 49.2 43.0 193.9 815.7 663.1 49.4 49.3 43.9 160.9 806.2 658.5 49.6 49.5 45.3 192.1

75 67 879.6 528.8 54.9 54.8 43.9 205.9 873.3 526.2 55.1 55.0 44.7 171.0 860.7 521.1 55.2 55.1 46.1 203.6

75 72 954.6 395.2 60.5 60.4 45.1 221.7 946.1 392 60.6 60.5 46.0 183.8 933.8 387.6 60.7 60.6 47.3 219.0

80 62 849.1 799.5 48.8 48.8 43.6 199.6 842.7 796.1 49.0 48.9 44.5 165.8 833.5 791.3 49.2 49.1 45.8 198.0

80 67 885.2 662 54.6 54.5 44.0 207.1 878.5 659.2 54.7 54.6 44.8 171.9 867.7 654.8 54.9 54.8 46.2 205.1

80 72 956.5 526.1 60.3 60.2 45.2 222.1 948.1 523 60.4 60.3 46.0 184.2 935.6 518.4 60.6 60.5 47.3 219.4

85 62 891.9 891.9 50.1 48.0 44.4 208.7 885.8 885.8 50.4 48.1 45.2 173.3 876.9 876.9 50.7 48.3 46.5 207.1

85 67 913.4 796.6 54.2 54.1 44.7 213.1 906.1 793.2 54.4 54.3 45.5 176.9 896.9 789.1 54.5 54.4 46.8 211.3

85 72 958.5 658.1 60.0 59.9 45.3 222.6 950.4 655.1 60.1 60.0 46.1 184.6 938.7 650.7 60.3 60.2 47.3 220.0

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 799.5 655.3 49.7 49.6 46.2 159.5 789.8 650.6 49.9 49.8 47.7 190.5 783 647.2 50.0 49.9 48.6 158.1

75 67 854.3 518.5 55.3 55.2 46.9 169.1 842.9 513.8 55.5 55.4 48.4 201.6 835.3 510.8 55.6 55.5 49.3 167.3

75 72 925.6 384.6 60.8 60.7 48.1 181.6 913.3 380.1 61.0 60.9 49.5 216.4 904.7 376.9 61.1 61.0 50.5 179.5

80 62 827.7 788.6 49.3 49.2 46.8 164.5 816.9 782.9 49.5 49.4 48.2 196.3 810.9 779.7 49.6 49.5 49.2 163.1

80 67 861.6 652.2 55.0 54.9 47.1 170.4 850.3 647.5 55.2 55.1 48.5 203.2 842.9 644.5 55.3 55.2 49.6 168.7

80 72 928.2 515.6 60.6 60.5 48.1 182.1 916.2 511.2 60.8 60.7 49.5 217.0 907.3 507.9 60.9 60.8 50.5 179.9

85 62 870.9 870.9 50.9 48.4 47.5 172.1 860.6 860.6 51.3 48.6 48.9 205.5 854.6 854.6 51.6 48.7 49.9 170.8

85 67 889.8 785.8 54.7 54.6 47.7 175.4 879.1 780.9 54.8 54.7 49.1 209.4 871.8 777.6 55.0 54.9 50.1 173.8

85 72 932.4 648.6 60.3 60.2 48.2 182.8 919.6 643.7 60.5 60.4 49.6 217.8 911.5 640.7 60.6 60.5 50.6 180.7

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

AIR FLOW 28,000 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 23,400 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

HIGH EFFICIENCY - AIR FLOW 23,400 CFM

WATER

COMP

KW

FLOW

TMBH SMBH LDB LWB

GPM

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

28

JOHNSON CONTROLS

Page 29

FORM 145.05-EG2 (618)

TABLE 15 - LSWU080

AIR FLOW 32,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 901.4 798.5 52.3 52.1 46.6 212.1 894.4 795.2 52.4 52.2 47.6 176.1 884.5 790.4 52.6 52.3 49.0 210.4

75 67 954.7 619 57.7 57.7 47.6 223.5 947 616.1 57.8 57.8 48.6 185.4 935.5 611.5 57.9 57.9 50.0 221.2

75 72 1032 439.7 63.1 63.1 49.2 239.9 1023 436.7 63.3 63.2 50.1 199.0 1010 432.2 63.3 63.3 51.5 237.2

80 62 940.3 940.3 53.2 51.6 47.4 220.4 933.5 933.5 53.4 51.7 48.4 183.1 924 924 53.6 51.8 49.8 218.8

80 67 970.5 796.4 57.6 57.4 48.0 226.8 963 793 57.6 57.5 48.9 188.3 952 788.1 57.8 57.6 50.3 224.7

80 72 1033 614.2 63.0 63.0 49.3 240.2 1026 611.5 63.1 63.1 50.2 199.4 1013 606.9 63.2 63.2 51.6 237.7

85 62 995.5 995.5 56.5 50.9 48.5 232.2 988 988 56.8 51.0 49.5 192.8 978 978 57.0 51.1 50.9 230.4

85 67 998.4 963.7 57.6 57.1 48.6 232.8 993.3 962 57.7 57.1 49.5 193.7 981.7 955.9 57.9 57.3 51.0 231.1

85 72 1041 790.9 62.9 62.9 49.4 241.8 1032 787.6 62.9 62.9 50.3 200.6 1021 783.6 63.1 63.0 51.8 239.4

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 877.5 787.1 52.7 52.4 50.1 174.7 866.4 781.9 52.8 52.5 51.6 208.5 859.4 778.6 52.9 52.6 52.7 173.2

75 67 927.8 608.5 58.0 58.0 50.9 183.6 916.1 603.9 58.1 58.1 52.5 219.0 907.4 600.6 58.2 58.2 53.6 181.7

75 72 1002 429.3 63.4 63.4 52.5 196.8 989.3 424.9 63.6 63.5 54.0 234.7 980.8 421.9 63.6 63.6 55.0 194.8

80 62 917.3 917.3 53.8 51.9 50.8 181.8 908 908 54.1 52.0 52.4 217.4 900.4 900.4 54.3 52.1 53.5 180.5

80 67 944.7 785 57.9 57.7 51.3 186.7 932.5 779.6 58.0 57.9 52.9 222.6 924.5 776 58.1 57.9 54.0 184.8

80 72 1005 604.2 63.3 63.3 52.5 197.4 991.2 599.3 63.4 63.4 54.1 235.1 982.8 596.3 63.5 63.5 55.1 195.1

85 62 972.1 972.1 57.2 51.2 51.9 191.5 960.4 960.4 57.6 51.3 53.5 228.6 954.5 954.5 57.7 51.4 54.5 190.1

85 67 974.5 952 58.0 57.3 52.0 192.0 963.4 946.7 58.1 57.5 53.5 229.2 956 942.4 58.2 57.5 54.6 190.4

85 72 1013 780.8 63.1 63.1 52.7 198.9 999.5 775.7 63.3 63.3 54.2 236.9 993.4 773.6 63.3 63.3 55.3 197.0

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 901.4 798.5 47.2 47.1 46.6 212.1 894.4 795.2 47.3 47.2 47.6 176.1 884.5 790.4 47.5 47.4 49.0 210.4

75 67 954.7 619 53.8 53.7 47.6 223.5 947 616.1 53.9 53.8 48.6 185.4 935.5 611.5 54.0 53.9 50.0 221.2

75 72 1032 439.7 60.4 60.3 49.2 239.9 1023 436.7 60.5 60.4 50.1 199.0 1010 432.2 60.7 60.6 51.5 237.2

80 62 940.3 940.3 47.1 47.0 47.4 220.4 933.5 933.5 47.3 47.2 48.4 183.1 924 924 47.7 47.6 49.8 218.8

80 67 970.5 796.4 52.5 52.4 48.0 226.8 963 793 52.6 52.5 48.9 188.3 952 788.1 52.7 52.6 50.3 224.7

80 72 1033 614.2 59.2 59.1 49.3 240.2 1026 611.5 59.3 59.2 50.2 199.4 1013 606.9 59.4 59.3 51.6 237.7

85 62 995.5 995.5 50.0 47.9 48.5 232.2 988 988 50.2 48.1 49.5 192.8 978 978 50.6 48.2 50.9 230.4

85 67 998.4 963.7 51.4 51.3 48.6 232.8 993.3 962 51.5 51.4 49.5 193.7 981.7 955.9 51.7 51.6 51.0 231.1

85 72 1041 790.9 57.8 57.7 49.4 241.8 1032 787.6 57.9 57.8 50.3 200.6 1021 783.6 58.1 58.0 51.8 239.4

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 877.5 787.1 47.6 47.5 50.1 174.7 866.4 781.9 47.8 47.7 51.6 208.5 859.4 778.6 47.9 47.8 52.7 173.2

75 67 927.8 608.5 54.1 54.0 50.9 183.6 916.1 603.9 54.3 54.2 52.5 219.0 907.4 600.6 54.4 54.3 53.6 181.7

75 72 1002 429.3 60.8 60.7 52.5 196.8 989.3 424.9 60.9 60.8 54.0 234.7 980.8 421.9 61.0 60.9 55.0 194.8

80 62 917.3 917.3 47.9 47.8 50.8 181.8 908 908 48.2 48.1 52.4 217.4 900.4 900.4 48.5 48.4 53.5 180.5

80 67 944.7 785 52.8 52.7 51.3 186.7 932.5 779.6 53.0 52.9 52.9 222.6 924.5 776 53.1 53.0 54.0 184.8

80 72 1005 604.2 59.5 59.4 52.5 197.4 991.2 599.3 59.7 59.6 54.1 235.1 982.8 596.3 59.8 59.7 55.1 195.1

85 62 972.1 972.1 50.8 48.3 51.9 191.5 960.4 960.4 51.2 48.5 53.5 228.6 954.5 954.5 51.4 48.6 54.5 190.1

85 67 974.5 952 51.8 51.7 52.0 192.0 963.4 946.7 52.0 51.9 53.5 229.2 956 942.4 52.2 52.1 54.6 190.4

85 72 1013 780.8 58.2 58.1 52.7 198.9 999.5 775.7 58.3 58.2 54.2 236.9 993.4 773.6 58.4 58.3 55.3 197.0

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

AIR FLOW 32,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 26,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

HIGH EFFICIENCY - AIR FLOW 26,000 CFM

WATER

COMP

KW

FLOW

GPM

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

WATER

FLOW

GPM

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

TMBH SMBH LDB LWB

COMP

KW

COMP

KW

COMP

KW

COMP

KW

WATER

FLOW

WATER

FLOW

WATER

FLOW

WATER

FLOW

GPM

GPM

GPM

GPM

NOTE: EDB-entering dry bulb temp, EWB-entering wet bulb temp, EWT-entering water temp, LWT-leaving water temp, LDB-leaving dry bulb temp,

LWB-leaving wet bulb temp, TMBH-total capacity, SMBH-sensible capacity

JOHNSON CONTROLS

29

Page 30

FORM 145.05-EG2 (618)

Cooling Performance Data (Cont’d)

TABLE 16 - LSWU095

AIR FLOW 34,000 CFM

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 1092 909.3 50.7 50.6 58.7 258.5 1084 905.3 50.9 50.7 59.9 214.6 1068 898.2 51.0 50.8 61.8 255.8

75 67 1173 717 56.2 56.0 59.7 275.2 1163 713.2 56.3 56.2 60.8 228.5 1148 706.9 56.5 56.3 62.6 272.2

75 72 1271 528.3 61.5 61.5 60.7 295.7 1260 524.1 61.6 61.6 61.9 245.1 1242 518 61.8 61.7 63.7 292.0

80 62 1133 1085 50.9 50.0 59.2 267.0 1124 1080 51.0 50.1 60.4 221.7 111 0 1073 51.2 50.3 62.2 264.4

80 67 1175 901.3 56.1 56.0 59.7 275.6 1165 897.2 56.2 56.1 60.8 228.7 1150 891.1 56.4 56.2 62.6 272.7

80 72 1272 711.6 61.5 61.4 60.8 295.8 1261 707.9 61.6 61.5 61.9 245.4 1244 701.6 61.8 61.7 63.7 292.3

85 62 1192 1192 52.9 49.3 59.8 279.2 1183 1183 53.2 49.4 61.1 231.9 1171 1171 53.5 49.5 62.9 277.1

85 67 1214 1088 56.0 55.5 60.1 283.8 1204 1083 56.1 55.6 61.2 235.6 1190 1075 56.3 55.7 63.1 281.0

85 72 1274 896.2 61.5 61.3 60.8 296.4 1263 892.1 61.6 61.4 62.0 245.7 1248 886.4 61.7 61.6 63.7 293.0

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 1060 894.2 51.1 50.9 63.0 212.4 1047 888.3 51.3 51.1 65.0 253.8 1037 883.4 51.4 51.2 66.3 210.5

75 67 1138 703 56.6 56.4 63.8 225.9 1121 696.5 56.7 56.6 65.8 269.2 1112 692.6 56.8 56.7 67.1 223.4

75 72 1232 514.3 61.9 61.8 64.9 242.3 1215 508.3 62.1 62.0 66.8 288.7 1205 504.6 62.1 62.1 68.1 239.5

80 62 1103 1069 51.3 50.4 63.5 219.9 1088 1061 51.5 50.6 65.4 262.3 1080 1056 51.7 50.6 66.7 217.9

80 67 1139 886.7 56.5 56.3 63.9 226.2 1123 880 56.7 56.5 65.8 269.6 111 4 876.1 56.8 56.6 67.1 223.8

80 72 1233 697.7 61.9 61.8 64.9 242.5 1217 691.8 62.0 61.9 66.8 289.0 1206 687.9 62.1 62.0 68.0 239.8

85 62 1162 1162 53.7 49.6 64.1 230.1 1149 1149 54.1 49.8 66.1 275.0 1140 1140 54.3 49.9 67.4 228.3

85 67 1181 1071 56.4 55.8 64.3 233.4 1167 1063 56.6 56.0 66.2 278.5 1158 1059 56.7 56.1 67.5 231.4

85 72 1236 882 61.8 61.7 64.9 242.8 1219 876 62.0 61.8 66.8 289.4 1208 871.9 62.1 61.9 68.1 240.0

EWT 80 LWT 90 EWT 80 LWT 92 EWT 85 LWT 95

EDB EWB

TMBH SMBH LDB LWB

75 62 1110 842.8 46.8 46.7 59.0 262.3 1100 837.9 47.0 46.9 60.2 217.5 1087 831.7 47.2 47.1 62.0 259.6

75 67 1193 683.6 52.5 52.4 59.9 279.5 1183 679.1 52.7 52.6 61.0 231.8 1166 672.3 52.9 52.8 62.8 276.1

75 72 1295 529.3 58.0 58.0 61.1 300.7 1285 525.2 58.1 58.1 62.2 249.5 1267 518.4 58.4 58.4 64.0 297.0

80 62 1141 1005 46.2 46.1 59.3 268.7 1133 1000 46.4 46.3 60.5 223.2 111 9 993.4 46.6 46.5 62.3 266.2

80 67 1200 837.1 52.2 52.1 59.9 280.9 1189 832.5 52.4 52.3 61.1 233.0 1177 827.2 52.6 52.5 62.9 278.3

80 72 1298 680 57.9 57.8 61.1 301.3 1287 676 58.0 57.9 62.2 250.0 1269 669 58.3 58.2 64.0 297.5

85 62 1187 1167 45.6 45.5 59.8 278.2 1178 1162 45.7 45.6 61.0 231.0 1164 1154 45.9 45.9 62.8 275.6

85 67 1224 996.8 51.7 51.6 60.3 285.9 1216 993.2 51.8 51.7 61.4 237.5 1201 986.6 52.0 51.9 63.2 283.3

85 72 1299 831.3 57.7 57.6 61.1 301.4 1288 827.2 57.8 57.7 62.3 250.1 1270 820.2 58.0 57.9 64.0 297.7

EWT 85 LWT 97 EWT 90 LWT 100 EWT 90 LWT 102

EDB EWB

TMBH SMBH LDB LWB

75 62 1078 827.6 47.3 47.2 63.1 215.6 1063 820.6 47.6 47.5 65.1 257.1 1055 816.5 47.7 47.6 66.4 213.5

75 67 1157 668.3 53.1 53.0 64.0 229.2 1142 662.1 53.3 53.2 65.9 273.4 1131 657.6 53.4 53.3 67.2 226.8

75 72 1257 514.5 58.5 58.5 65.1 246.5 1238 507.5 58.8 58.7 67.0 293.4 1227 503 58.9 58.8 68.3 243.3

80 62 1111 989.3 46.7 46.6 63.6 221.3 1096 982 47.0 46.9 65.5 264.0 1088 978 47.1 47.0 66.8 219.4

80 67 1168 823.2 52.7 52.6 64.2 231.1 1152 816.5 52.9 52.8 66.1 275.5 1142 812.4 53.1 53.0 67.4 228.7