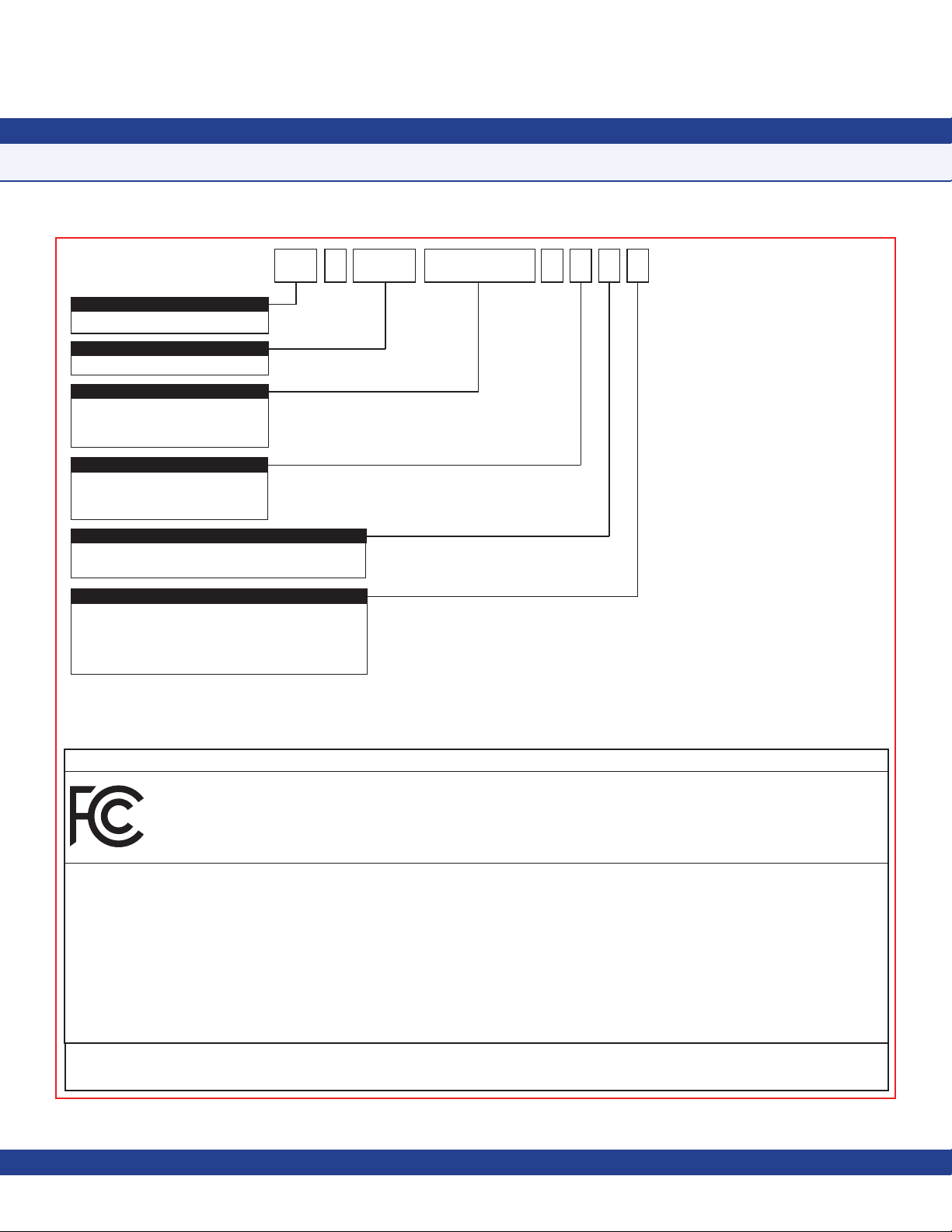

Johnson Controls LB-FMS1655-F01, LB-FMS1655-F11, LB-FMS1655-F04, LB-FMS1655-F10, LB-FMS1655-F12 Installation Manual

...Page 1

FMS-1655 Room Pressure Controller (BACnet

®

/ N2 only products)

Installation Manual

LB-FMS1655-F01

LB-FMS1655-F02

LB-FMS1655-F03

LB-FMS1655-F04

LB-FMS1655-F10

LB-FMS1655-F11

LB-FMS1655-F12

LB-FMS1655-F13

Application

These installation instructions guide the installer through the installation of the FMS-1655 Room Pressure Controller.

Please read these instructions thoroughly before beginning installation.

North American Emissions Compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when this equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area may cause harmful interference, in which case users will be required to correct the interference

at their own expense.

LB-FMS1655-S01

LB-FMS1655-S02

LB-FMS1655-S03

LB-FMS1655-S04

LB-FMS1655-T01

LB-FMS1655-T02

LB-FMS1655-T03

LB-FMS1655-T04

Code No. LIT-12013117, Rev. A

Issued August 2018

Canada

This Class (A) digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Installation

NOTICE

Risk of Property Damage.

Ensure that the power source conforms to the requirements of the equipment. Failure to use a correct power source may

result in permanent damage to the equipment.

NOTICE

Risque de dégâts matériels.

S’assurer que la source d’alimentation électrique est conforme aux spécications de l’équipement. L’utilisation d’une source

d’alimentation électrique inappropriée risque d’endommager irrémédiablement l’équipement.

IMPORTANT: The FMS-1655 Room Pressure Controller must be wired to 24 VAC only. Wiring the unit to 110 VAC will cause

serious damange and void the warranty.

Use of the software that is in (or constitutes) this product or access to the cloud or hosted services applicable to this product,

if any, is subject to applicable terms set forth at www.johnsoncontrols.com/techterms. Your use of this product constitutes an

agreement to such terms. If you do not agree to be bound by such terms, you may return the unused product to your place of

purchase.

Central Monitoring Station

The Next Generation in Critical Airow Controls

Room Pressure Controller

JCI CMS-1655

JCI FMS-1655

JCI FMS-1655

Page 2

Notes

Page 3

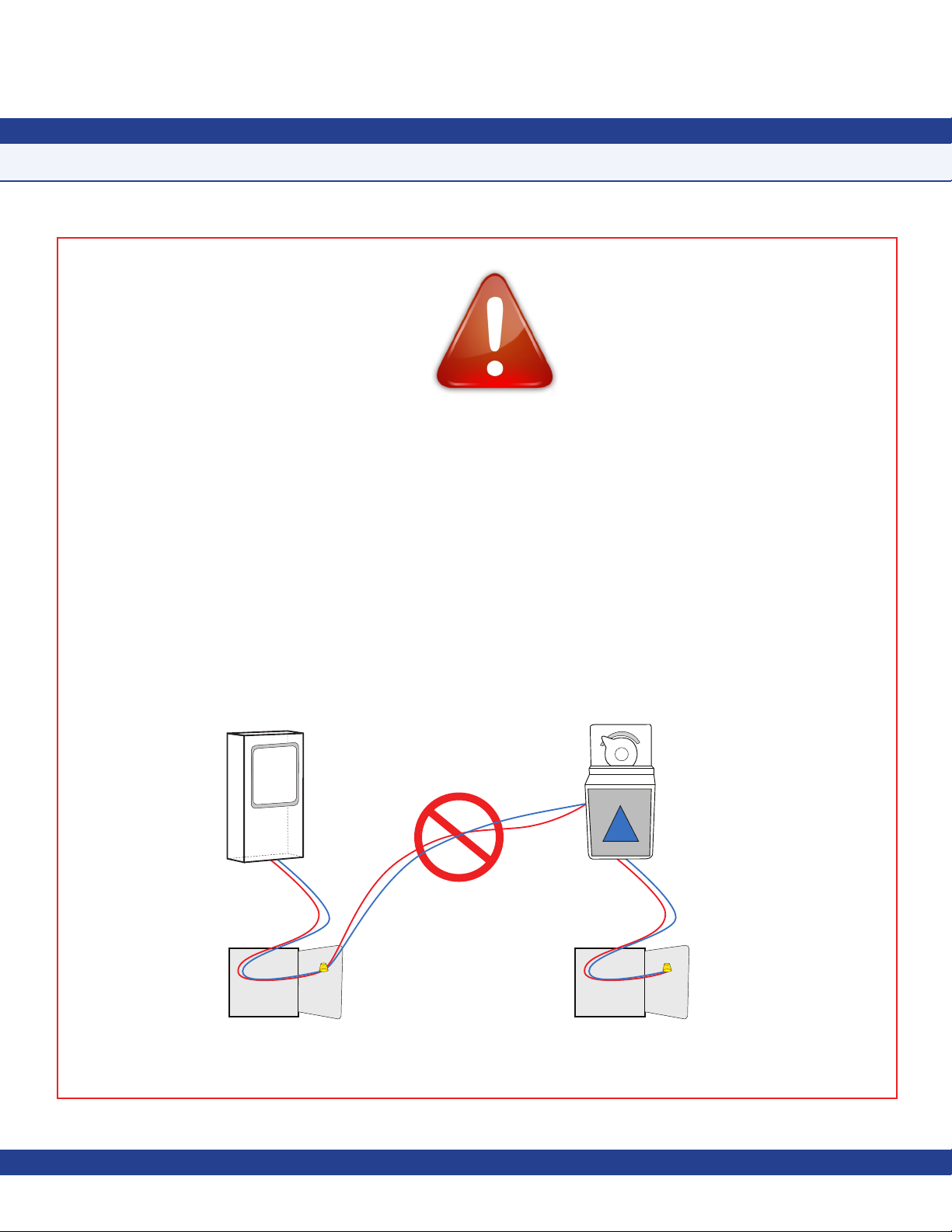

Warning

Failure to follow the wiring diagrams could result in damage to your equipment and could void your warranty.

Under no circumstances should a single transformer be split between actuator and controller. Doing so

will damage the actuator, the transformer, the controller or all units. A single 120/24V 30Va transformer

is required for the controller and a separate 120/24V 20Va transformer is required for the actuator. This

equipment contains electrostatic sensitive components. To prevent possible damage, take precautions to

prevent electrostatic discharge when handling or servicing this equipment by wearing an approved ESD

grounding wrist strap connected to an earth ground source.

Controller

FAST ACTING

ELECTRONIC ACTUATOR

CORRECT

120/24VAC, 30Va Transformer

Supplied by JCI

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

120/24VAC, 20Va Third Party

Transformer

Actuator

CORRECT

Page 4

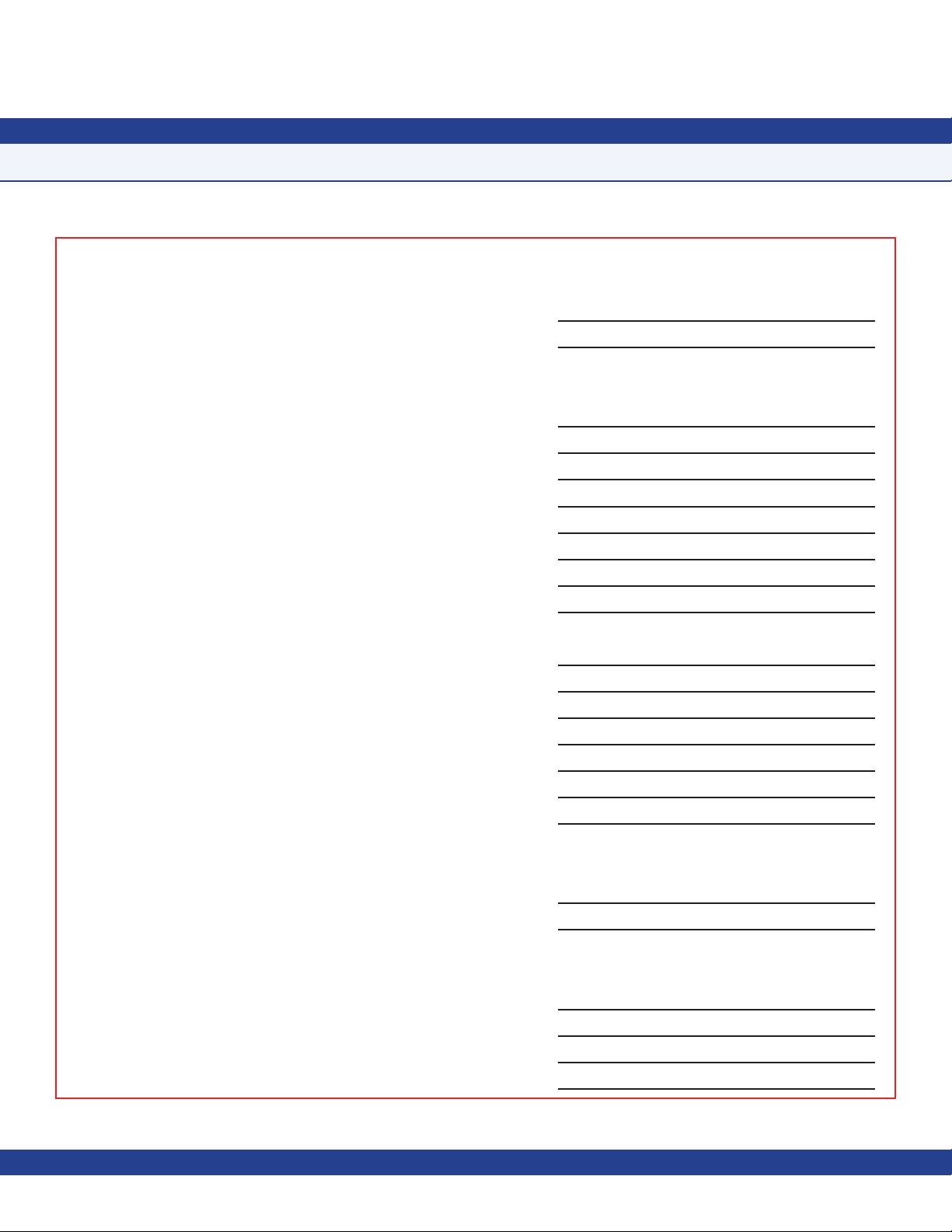

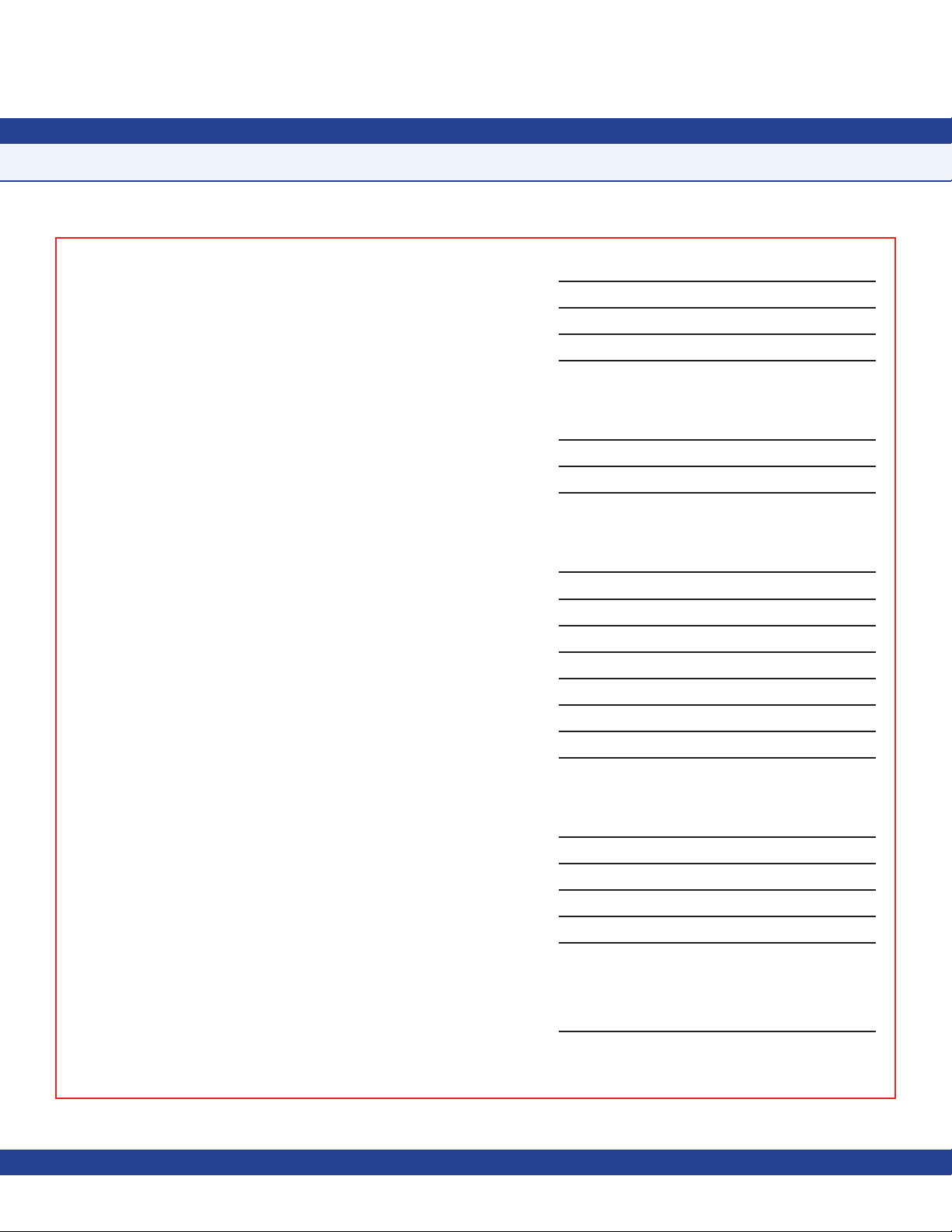

CONTROLLER SETTINGS

FMS-1655 Room Pressure Controller Settings

This form should be completed during the initial configuration for each room pressure controller. Be sure to configure the unit

for either Positive, Negative, or both using the Isolation Mode Configuration setup procedure.

Room Name / Number

Unit Model Number and Serial Number (ESN)

Analog Input

Normal Operating Pressure (reading with door closed)

Sensor Input Mode (normal or inverted)

Sensor Input Range (zero-based or offset)

Sensor Pressure Range

Positive Isolation Setpoint

Negative Isolation Setpoint

Neutral Isolation Setpoint

Pressure Deadband

Analog Output

Operating Mode (Direct or PID)

Analog Output Range (zero-based or offset)

Analog Output Upper Limit (0 – 100%)

Analog Output Lower Limit (0 – 100%)

Analog Output Input Channel (AI-1 thru AI-4, TI-1 or TI-2)

Analog Output Action (Direct or Reverse)

Analog Output Range (zero-based or offset)

Door Switch

Operating Mode (normally-open or normally-closed)

Delay Setting (0 - 240 secs)

Relay Output

Trigger Mode (Setpoints, Isolation Mode or Occupancy)

Input Channel (AI-1 thru AI-4, TI-1 or TI-2)

Positive Isolation High Setpoint

Positive Isolation Low Setpoint

Page 5

Negative Isolation High Setpoint

Negative Isolation Low Setpoint

Relay Acting Mode (Direct or Reverse)

Delay Setting (0 - 180 secs)

PID Constants

Proportional Constant (0.5 – 100.0 %)

Integral Constant (0.0 – 100.0 %)

Derivative Constant (0.0 – 100.0 %)

Alarm Limits

Positive Isolation High Alarm Setpoint

Positive Isolation High Warning Setpoint

Positive Isolation Low Warning Setpoint

CONTROLLER SETTINGS

FMS-1655 Isolation Room Pressure Controller Settings

Positive Isolation Low Alarm Setpoint

Negative Isolation High Alarm Setpoint

Negative Isolation High Warning Setpoint

Negative Isolation Low Warning Setpoint

Negative Isolation Low Alarm Setpoint

Audible Alert

Enabled Input Channels (AI-1 thru AI-4, TI-1, TI-2)

Operating Mode (audible or silent)

Delay Time Base (secs or mins)

Delay Setting (0 – 60)

Alarm Quiet Period Starting Hour (0 – 23)

Alarm Quiet Period Ending Hour (0 – 23)

Engineering Units

Inches of Water or Pascals

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Page 6

INSTALLATION MANUAL

Table of Contents

GENERAL

Specifications………………………………………………………………………………...……………………………………………1 - 2

Part Number Guide…………………………………………………………………………………………………………………………2

Overview……………………………………………………………………..…………………….………………………………………3 - 4

MOUNTING/WIRING

FMS-1655 Flush Mount With Internal Sensor

Introduction…………………………………………………………………………………………………………………………………5

Mounting Procedure………………………………………………………………………………………....……………………………5 - 6

Internal Sensor Illustration………………………………………………………………………….....……………………………………7

FMS-1655 With Remote Sensor

Introduction…………………………………………………………………………………………………………………………………9

Mounting Procedure………………………………………....………………………………………………………………………………9

FMS-1655 With Standard Remote Sensor Illustrations………………………………………………………………………....…10 - 11

Remote Sensor Configuration Illustration……………………………………………………………………………………………..12

Analog Output to Electric and Pneumatic Damper Actuator Illustrations (Internal Sensor Model)………………....………13 - 14

Analog Output to Variable Speed Drive Illustration (Internal Sensor Model)………………………………………………..………15

Analog Output to Modulated Air Controller Illustration (Internal Sensor Model)……………………………………………………16

Analog Output to Pneumatic Damper Actuator Illustration (Internal Sensor Model)………………………………………………17

Analog Output to Variable Speed Drive Illustration……………………………………………………………………………………18

Adding Remote Pressure Sensor with 4-20mA Out to Internal Sensor Model Illustration……………………………………19

Analog Input to 2 Remote Pressure Sensor 4-20mA Out Illustration……………………………………………………………… 21

Analog Input to 3 Remote Pressure Sensor 4-20mA Out Illustration……………………………………………………………… 22

Analog Input to 4 Remote Pressure Sensor 4-20mA Out Illustration……………………………………………………………… 23

Analog Input to Temperature Sensor Illustration……………………………………………………………………………………… 24

Custom Sensor Illustration………………………………………........................................................................……………………25

Digital Input to Door Switch Illustration………………………………………………………………………………………………… 26

Digital Input to Occupancy Sensor……………………………………………………………………………………………………28

Relay Output Alarm Illustration………………………….………………………………………………………………………………29

Relay Output to Warning Illustration……………......…………………………………………………………………………………30

Relay Output 1 Illustration…………………........………………………………………………………………………………………31

Relay Output 2 Illustration………………........……....…………………………………………………………………………………32

Power Illustration……………………………...….…………………………………………………………………………………………33

Isolated Power Supply………………………..……………………………………………………………………………………………34

COMMUNICATIONS - BACnet MS/TP

Wiring Illustration………………………………………………………………………………………………………...…………………36

COMMUNICATIONS - METASYS N2 OPEN

Wiring Illustration…………………………………………………………………………………………………....………………………37

FMS-1655 QUICK START GUIDE

Quick Start Guide………………………………………………………………………………………………………....………………38

Main Display Screen………………………………………………………………….....…………………………………………………38

Automated Clean Cycle ………………………………………………………………...……………………………………………38 - 39

Configuring Room Pressure Monitor…………………………………………......………………………………………………………39

Setting Up Analog Output………………………………………………………..………………………………………………………39

Enabling Door Switch………………………………………………………………………………………………………………39 - 40

Setting Up Alarm Relay Output....……………………………………………….………………………………………………………40

Setting Alarm Limits...…………………………………………..…………………………………………………………………………40

Changing Isolation Mode.……………………………………..........……………………………………………………………………40

Page 7

INSTALLATION MANUAL

Table of Contents

Invoking Auto Clean Cycle.………………………………..........…………………………………………………………......……….....40

Changing Network Settings..………………………….....…………………………………………………………………………………40

Adding Password Security…………………………...……………………………………………………………………………………40

Changing Display Settings……………….……………………………………………………………………………......…………40 - 41

Built-in Diagnostics………………………...………………………………………………………………………………………………41

MODULE SETTINGS

Configuring Display Module Settings……………………………...……………………………………………………………………43

Configuring Main Controller Module Settings………....………………………………………………………………………………44

Configurations and Settings………………………………………………………………………………………………………………45

BACnet® OBJECTS

Analog Input Objects………………………...…….………………………………………………………………………………………46

Analog Output Objects……………………..……...………………………………………………………………………………………46

Binary Input Objects………………………..……..………………………………………………………………………………………46

Binary Output Objects……………………....………..……………………………………………………………………………………46

Analog Value Objects……………………....…………..……………………………………………………………………………46 - 47

Multistate Output Objects……………..………………...…………………………………………………………………………………47

METASYS® N2 OBJECTS

Analog Input Objects…………………………....…………………………………………………………………………………………48

Analog Output Objects……………………….....…………………………………………………………………………………………48

Binary Input Objects……………………………...………………………………………………………………………………………48

Binary Output Objects………………………….....………………………………………………………………………………………48

Internal Float Value Objects………………………..………………………………………………………………………………48 - 49

Multistate Output Objects……………………….....………………………………………………………………………………………49

CLEANING THE DISPLAY

Cleaning the FMS-1655……………………….....………………………………………………………………………………………51

DIAGRAMS

Wiring Illustration……………………………………………………………………......…………………………………………………52

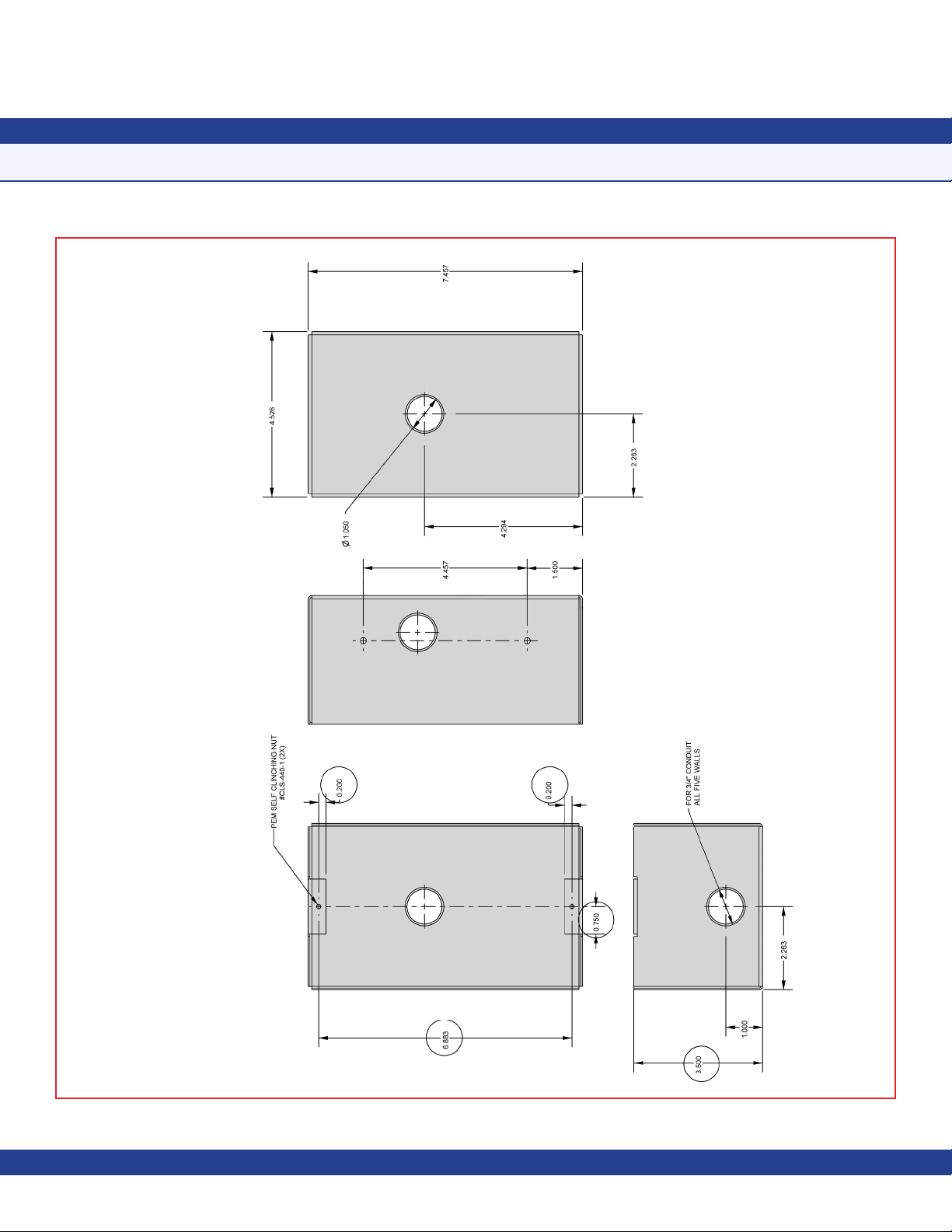

Integrated Flush Mount Wiring Box Dimensions………………....……………………………………………………………………53

Flush Mount Bracket Dimensions………………………………………………………………………………………………………54

Thin Mount Wiring Box Dimensions……………………..………………………………………………………………………………55

FLOW DIAGRAMS

Unit Setup Tree………………………………….....………………………………………………………………………………………57

System Setup Tree……………...……………………………………………………………………………………………………58 - 60

Display Setup Tree…………....……………………………………………………………………………………………………………61

Diagnostics Tree………………..…………………………………………………………………………………………………………62

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.Due to continuous improvement, JCI reserves the right to change product specifications without notice. Due to continuous improvement, JCI reserves the right to change product specifications without notice.

Page 8

GENERAL

Specications

Electrical

Optional External Remote Sensor Distance……………………………………………………………………………………………………Up to 1,000 feet

Optional External Remote Sensor....………………………………………………………………………………Wiring 18-22 AWG, shielded twisted pair

Power Supply..…………………………………………………………………………………………………………………………………24 Vac ±10%, 30Va

Accuracy of Measurement.....……………………………………………………………………………………………………………………………±0.5%FS

Pressure Range (NIST Traceable / Individual certication available as option)…………………………………………………………………±0.2500 “WC

Pressure/Flow……………………………………………………………………………………………………………………………………up to 0.25 ”WC

4 Analog Inputs…………………………………………………………………………………………………………………4-20mAdc, 0-5Vdc or 0-10Vdc

4 Analog Outputs………………………………………………………………………………………………………………4-20mAdc, 0-5Vdc or 0-10Vdc

2 Thermistor Inputs…………………………………………………………………………………………………………NTC Type 2 or 3, 10kΩ @ 25°C

4 Digital Inputs………………………………………………………………………………………………0-5Vdc or 0-24Vdc, Active-High or Active-Low

3 Relay Outputs...………………………………………………………………………………………………………………………………………1A@24Vdc

Control Signal Wire Size............……………………………………………………………………………………………………………………18-22 AWG

Power Supply………………………Class 2, 24Vac ±10%, 30VA universal 120/240 to 24 Vac, 60/50 Hz, step-down isolation transformer provided

Communications

BACnet® MS/TP network....…………………………………………………………………………………………Two-Wire Twisted Pair, RS-485 signaling

Metasys N2 network...………………………………………………………………………………………………Two-Wire Twisted Pair, RS-485 signaling

Recommended Cable Type...……………………………………………………………………………………………………………………… Belden 3107A

Touchscreen User Interface

LCD Size....……………………………………………………………………………………………………………………………………………3.2” diagonal

LCD Type.....……………………………………………………………………………………………………………………………………………Transmissive

Resolution...………………………………………………………………………………………………………………………………………240 x 320 portrait

Viewing Area..……………………………………………………………………………………………………………………………50.60 mm x 66.80 mm

Color Depth.…………………………………………………………………………………………………………………………………18-bit or 262K colors

Backlight Color.....………………………………………………………………………………………………………………………………………………White

Luminous Intensity...………………………………………………………………………………………………………………………………Min 2500 cd/m2

Recommended Cable Type (applicable to surface mount models FMS-1655-s-x only)…………………………………………………… Belden 3125A

Mechanical

FMS-1655 Internal Sensor Flush Mount Housing (Brushed Stainless Steel) Housing..……………………………………………5.6”W x 8.5”H x 1.9”D

FMS-1655 Display Module Housing………………………………………………………………………………………………………3”W x 5”H x 1.13”D

Stainless Steel Cover Plate for Flow Tube……………………………………………………………………………………………2.7”W x 4.5”H x 0.2”D

Stainless Steel Cover Plate for Remote Sensor………………………………………………………………………………………2.7”W x 4.5”H x 0.2”D

FMS-1655 with Flow Tube Cover Plate……………………………………………………………………………………………………………approx. 3.5 lb

FMS-1655 with Optional External Remote Sensor………………………………………………………………………………………………approx. 4.0 lb

FMS-1655 Mounting Options...……………………………………………………………………………………………………………………Surface, Flush

Flow Tube Cover Plate Mounting.. ……………………………………………………………………………………………………………………………Flush

Environmental

Operating Temperature..…………………………………………………………………………………………………………………32° to 125° F Operating

Operating Humidity……………………………………………………………………………………………………………10% - 95% RH, Non-condensing

- 1 -

Due to continuous improvement, JCI reserves the right to change product specifications without notice.

Page 9

- -

BRAND

LB = Johnson Controls

UNIT

FMS = Flow Monitor Station (FMS)

SERIES

1655 = BACnet / N2 Controller

1655L = LonWorks Controller

1655M = BACnet Monitor

STYLE

S = Surface mount

F = Flush mount

T = Thin mount

INTERNAL SENSOR

0 = No internal sensor

1 = Standard internal sensor

REMOTE SENSOR

0 = No remote sensors

1 = One remote sensor

2 = Two remote sensors

3 = Three remote sensors

4 = Four remote sensors (Not available with LonWorks Controllers)

(BACnet / N2 controllers only)

(Flush mount controller only)

(Not available with LonWorks Controllers)

GENERAL

Specications

FCC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

• This device may not cause harmful interference, and

• This device must accept any interference received, including interference that may cause undesired operation.

Please Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a commercial installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee the interference will not occur in a particular installation. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

Caution: To comply with the limits for an FCC Class A computing device, always use the isolated power supply module and recommended interface

cables with this unit.

The Federal Communications Commission warns that changes or modifications to the unit not expressly approved by the part responsible for compliance could

void the user’s authority to operate the equipment.

This Class-A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe-A est conforme à la norme NMB-003 du Canada.

- 2 -

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.Due to continuous improvement, JCI reserves the right to change product specifications without notice.

Page 10

GENERAL

Overview

The JCI FMS-1655 Room Pressure Controller

is an ultra-sensitive instrument used to

monitor and/or control air pressure in hospital

rooms, labs, and clean rooms. This unit

is capable of measuring and displaying

differential air pressures as low as 0.0001

“WC or 0.0249 Pa. The FMS-1655 may be

used to control differential pressures down to

0.0040 ”WC or 1 Pa.

Key features of the FMS-1655 include:

• Full-color touchscreen display with

programmable display options and

adjustable backlight

• Intuitive user interface simplifies setup

and configuration of unit

• Display background changes color to

indicate room status at a glance

• Patented Safety Halo™ with color-coded

180° edge lighting

• Automated clean cycle with fully

programmable duration for quick

turnaround of patient or isolation room

• Audible and visual alarm annunciation

• Internal or remote sensor options

available with up to four sensors total

(one internal, three remotes OR four

remotes)

• Auxiliary universal analog inputs for use

with optional sensors

• Four independent PID control loops for

controlling damper actuators, speed

drives, hot water valves, humidifiers, etc.

• Digital input used to monitor the door

switch of the monitored room

• Relay outputs used for transmitting alarm

condition to remote location

• Dedicated thermistor inputs for

temperature control applications

• Multi-level password protection of

touchscreen user interface

• Zero calibration feature allows in-field

recalibration of zero pressure reading

• Multi-protocol native (BACnet® or

Metasys® N2) for easy integration with

any BMS

• Manual override of analog and relay

outputs assist with test and balance

procedures

• Comprehensive real-time view

• Built-in diagnostics tool

• Easy-to-install backplane/backplate

assembly facilitates permanent

termination of all wiring

The FMS-1655 features enhanced graphics

the patented Safety Halo.™ This simple yet

elegant feature significantly enhances the

alarm status indication of the FMS-1655 by

providing full 180-degree visibility. The Safety

Halo™ is shipped from the factory enabled at

full brightness, but may be dimmed or even

disabled completely from the display setup

menus.

The FMS-1655 is equipped with a 3.2”

diagonal full-color touchscreen display

in portrait orientation (240 x 320). The

password-protected menu tree is very intuitive

and simplifies the setup and configuration of

the unit. The menus incorporate touch-based

interfaces such as sliders, radio buttons, and

dialog popups to facilitate the ease-of-use of

the FMS-1655.

The display implements bright graphical color

changes to indicate the three different alarm

status indications of the monitored isolation

room. These graphical backgrounds indicate

“Normal” when the differential pressure is

within defined limits, “Warning” when the

differential pressure is approaching an

out-of-limits condition, and “Alarm” when the

differential pressure is outside the defined

acceptable and safe limits.

The differential pressure ranges for these

conditions are easily configured by the user

for the specific installation when necessary,

either directly from the touchscreen display or

over the network from the BMS. The graphical

background changes provide an at-a-glance

overview of the monitored isolation room

differential pressure conditions.

Alarm conditions may be defined by the

user, in terms of desired differential pressure

settings for the room being monitored.

When an alarm condition occurs, it may be

annunciated in four user-definable ways:

1) on the display, 2) with an audible alarm,

and 3) transmitted via contacts to a remote

monitoring station and 4) over the BMS

network. The alarm will automatically reset

when the unit has sensed that the room

differential pressure has returned to proper

limits. The attendant may easily mute the

audible alarm by touching the alarm audible

button on the bottom of the display.

For many applications, it is important to have

other variables such as anteroom differential

pressure or relative humidity displayed along

with the isolation room differential pressure.

The FMS-1655 provides for this by means of

three additional universal analog inputs, which

may be configured for either current loop

operation or voltage input operation. Each

input may be scaled as needed to display

correct values, and may have an engineering

units selection associated. The configuration

of each analog input is field selectable

through the use of miniature dipswitches on

the controller unit.

- 3 -

Due to continuous improvement, JCI reserves the right to change product specifications without notice.

Page 11

GENERAL

Overview

For those applications requiring monitoring

and/or control based on temperature

variances, the FMS-1655 provide two

dedicated thermistor inputs in addition to the

four universal analog inputs. Therefore, a total

of six analog inputs are available for control

applications. The two thermistor inputs may

be used with negative temperature coefficient

(NTC) Type 2 or Type 3 sensors.

The FMS-1655 provides four universal

analog outputs, which may be configured for

either current loop operation or for voltage

operation.

Each analog output may be configured for

proportional operation to provide a linear

signal to the BMS, or for PID (proportionalintegral-derivative) control operation for

closed-loop feedback control of damper

actuators, variable frequency (speed) drives,

hot water valves, humidifiers, or other analogcontrolled devices.

Each universal analog output may be fieldconfigured for the required application using

onboard configuration dipswitches on the

controller module. Each analog output may

also be temporarily overridden using the builtin diagnostic tools for troubleshooting during

the installation and commissioning phase.

The FMS-1655 provides four digital inputs that

may be used for monitoring door switches,

override switches, or other devices with binary

outputs. The configuration and operation of

each input may be configured by the user to

define the effect of a change in its state. Each

digital input may have a programmable delay

duration associated with it. Each digital input

may be configured for either normally-closed

or normally-open operation, and may also

be configured to be active-high or active-low

triggered. The global configuration of the

digital inputs is field selectable through the use

of miniature dipswitches on the controller unit.

The FMS-1655 provides three relay outputs,

which may be configured for either directacting or reverse-acting operation, and may

have a programmable delay associated

to meet the specific needs of the required

application.

A unique feature of the FMS-1655 is its ability

to trigger a relay output based on the current

mode of isolation, thereby providing support

for transfer grilles, supplemental exhaust

dampers, etc. Each relay output may also

be temporarily overridden using the built-in

diagnostic tools for troubleshooting during the

installation and commissioning phase.

The user may set up multiple multi-level

passwords to prevent unauthorized or casual

access to the FMS-1655 configuration

settings. Up to 10 passwords of up to eight

digits may be programmed, with each

having one of four associated access levels.

Administrators and facility management

personnel may have unrestricted access,

while general staff may be assigned restricted

access passwords which limit the functionality

of the user menus.

Room pressure selection of positive, negative,

or neutral isolation may be protected using

limited access passwords, thereby eliminating

the need for keylock switches and keys.

An optional keylock switch may be used to

further control access to change in isolation

modes. In some locales, it is prohibitive to

allow an isolation room controller to switch

between positive and negative modes of

isolation. To accommodate this situation, the

FMS-1655 may be configured at the factory

for either positive- and neutral-isolation modes

only or negative- and neutral-isolation modes.

The FMS-1655 provides native support for

multiple networking protocols, including

BACnet® MS/TP and Metasys® N2 Open.

With multi-protocol native support, the FMS1655 is able to communicate room status

information to the building automation system,

regardless of which protocol is used. (For

applications requiring LonWorks® networking

capability, contact the factory about JCI’s

FMS-1655L series) The configuration of the

desired protocol is field selectable through the

use of miniature dipswitches on the controller

unit.

The FMS-1655 provides a unique set of

built-in diagnostics tools that are extremely

valuable for facilitating the troubleshooting

process during the installation and

commissioning phase.

Included in these built-in diagnostics tools

are manual override capabilities for both

analog outputs and relay outputs, and a

comprehensive real-time view capability that

allows the real-time values and states of each

analog and digital input and output to be

displayed conveniently. This is an extremely

useful tool that facilitates the verification

and certification processes conducted by

typical test and balance personnel during the

commissioning of the system.

There are also options for storing configuration

settings and for restoring those settings, as

well as performing a complete restoration of

the factory default configuration settings.

The FMS-1655 incorporates an innovative

backplane/backplate assembly which greatly

facilitates the installation process and permits

all wiring terminations to be permanent.

The FMS-1655 serves as a direct drop-in

functional replacement for all previous models

of the FMS-1600 series of isolation monitors.

- 4 -

Page 12

MOUNTING/WIRING

FMS-1655 Flush-Mount with Internal Sensor

Introduction

The FMS-1655 flush-mount model has an

integrated internal sensor and should be

installed outside of the isolation room to be

monitored in the corridor wall. Sensor tubing

should be between this corridor and isolation

room in the most direct and shortest path.

The FMS-1655 is calibrated with configuration

settings programmed at the factory according

to the customer specifications, if provided.

Otherwise, each unit is shipped with factorydefault configuration settings. The user

may change these settings by following the

procedures outlined in the configuration/

programming section of this manual.

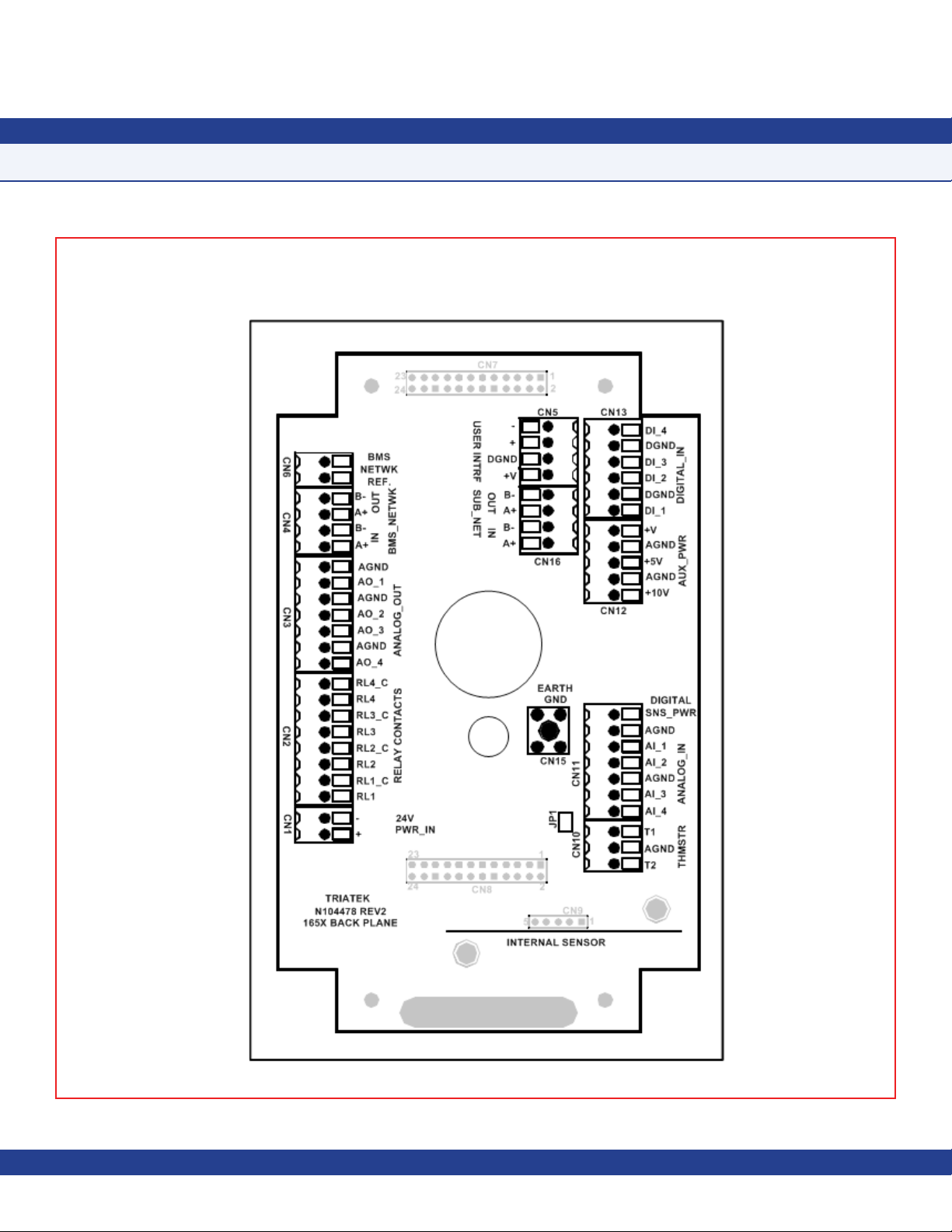

The electrical connections to the FMS-1655

are made via convenient terminal block

connectors on the backplane/backplate

assembly as shown on page 7. All wiring

should conform to local regulations and to the

National Electrical Code (NEC). Precautions

must be taken to avoid running sensor wiring

in the same conduit as line voltage or other

conductors that supply highly inductive loads

such as generators, motors, solenoids,

contactors, and other sources of induced

noise. Use 22 AWG or larger for all electrical

wiring terminations.

Following the proper installation of the FMS1655, apply power to the unit and confirm

that you hear a brief chirp at the touchscreen

display, which indicates that the display

module is communicating with the controller

module.

There will be a six second power up delay

during which the Safety HaloTM will cycle

through the following colors: red, green, blue,

yellow, magenta, cyan, and white. After this

power up delay, the unit will display a brief five

second animation of the action icons, followed

by the FMS-1655 splash screen. This

splash screen displays the model number,

electronic serial numbers, firmware version

numbers, protocol selection, and current

network address. The splash screen remains

displayed for about 15 seconds, and then

proceeds to the main differential pressure

screen.

Mounting Procedure

1. Choose a location free of airflow

obstructions, and minimal air turbulence.

The installation should also avoid stagnant

air or “short circuiting” of the supply air to the

exhaust. Typically, the FMS-1655 should be

installed at eye level. It should be mounted

in a location that provides convenient access

such that the display may be viewed with

minimal glare and the touchscreen is easily

accessible to facilitate silencing the unit in the

event of an alarm.

The FMS-1655 is pre-configured at the factory

with the Safety Halo™ status indicator bezel

connected to the internal circuitry on the

display board, and has been tested for proper

operation. The Safety Halo™ should not be

removed from the flush mount faceplate, as it

may damage the internal circuitry and/or the

bezel itself. Attempting to separate the Safety

Halo™ from the flush mount faceplate will

void the manufacturer’s warranty.

2. Before disassembling the flush-mount

electronics assembly, locate the clear

pressure tubing that extends from the lower

corner of the metal backplate to the nipple at

the inside face of the bottom of the faceplate

and disconnect it. The other end of this tubing

should remain attached to the right-angle

barbed fitting at the lower corner of the metal

backplate.

3. Disassemble the flush-mount electronics

assembly by grasping the metal backplate

and pulling it apart from the faceplate.

The metal backplate is attached to the

backplane subassembly which incorporates

all of the wiring termination points.

4. Run the conduit and all wiring according to

local regulations and National Electrical Code.

IMPORTANT: Use the 24 VAC stepdown

isolation transformer, provided with the

unit, to power the FMS-1655; this will

prevent inadvertent ground loop issues and

other problems that might otherwise be

encountered.

5. Pull slack from the tube on the opposite

side of the wall as the backplane/backplate

assembly is moved toward the wall for

mounting. On the opposite side, the return

air stainless base and louvered plate must be

mounted as shown on page 10. Caulk behind

the stainless mounting plate so that there may

be no air flow through the wall. Mount the

backplane/backplate assembly to the wall with

the appropriate screws (and wall anchors if

using the alternate installation method).

- 5 -

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Page 13

6. Terminate all electrical connections at the

backplane taking note of the terminal labels.

Note that the power connector is distinguished

as it is of a different color and separated

from the other connectors. The 45-degree

positioned wire openings on the connectors

should greatly facilitate the wire termination

process.

7. On the opposite side of the wall, a length

of pressure tubing will be protruding from

the wall. Cut the tubing as needed to leave

approximately two inches protruding. Press

the tubing onto the barbed fitting of the flow

tube mounting plate (see page 10). Push

the mounting plate and tube toward the

wall, forcing the excess into the wall space.

Fasten the mounting plate to the wall using

appropriate hardware.

MOUNTING/WIRING

SUBHEAD

FMS-1655 Flush-Mount with Internal Sensor

8. Mount the louvered stainless steel cover

plate to the mounting plate with the screws

supplied.

9. Apply power to the FMS-1655 and confirm

that following a brief initialization sequence,

the unit displays the room differential pressure

and the Safety Halo™ status matches that of

the main display screen. FMS-1655 units are

shipped from the factory in neutral isolation

mode.

- 6 -

Page 14

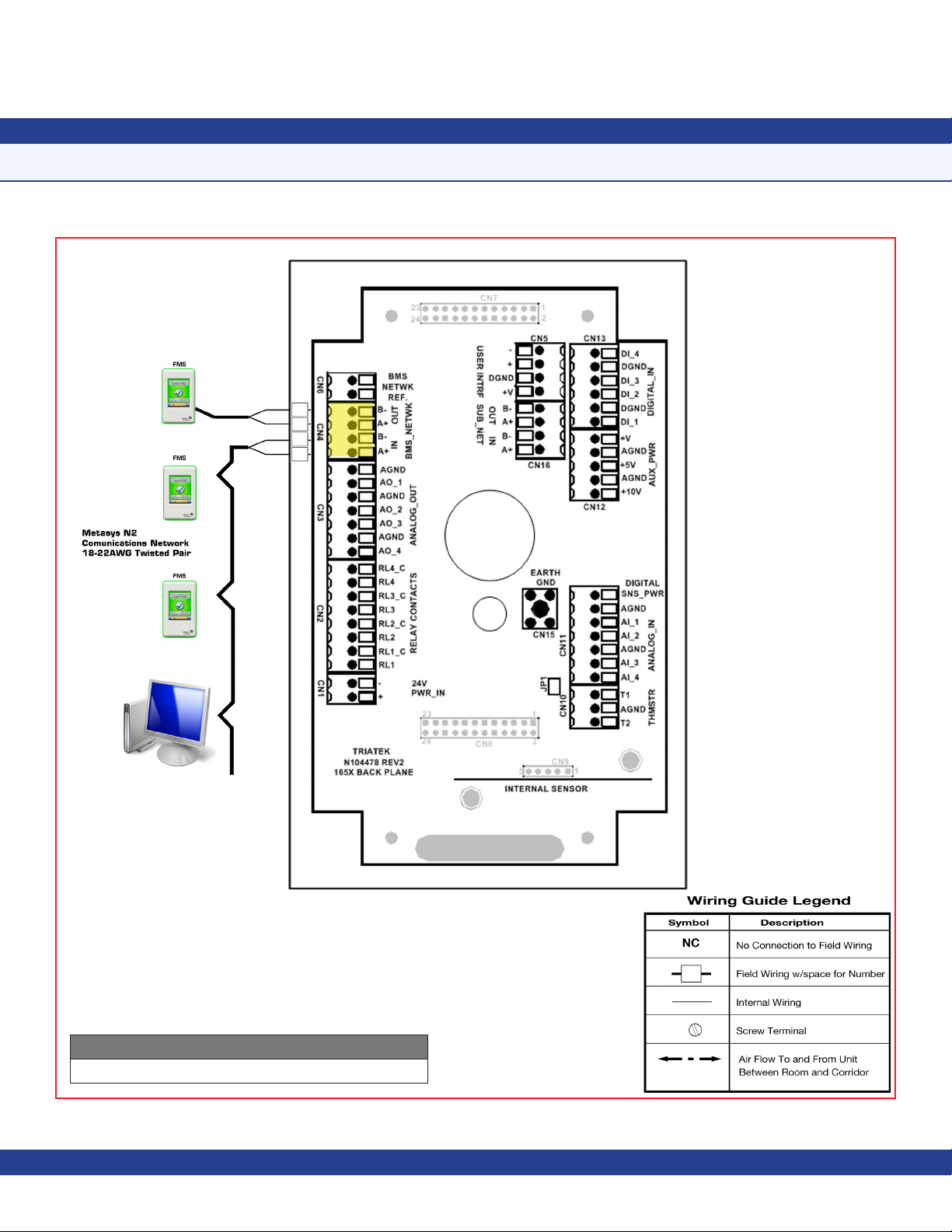

MOUNTING/WIRING

Internal Sensor

The FMS-1655 is calibrated with settings programmed in the factory according to the customer specifications. The user can change the settings

by using the instructions provided in the Quick Start section of this manual beginning on page 38.

- 7 -

Page 15

MOUNTING/WIRING

Notes

- 8 -

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

JCI reserves the right to change product specifications without notice.

Page 16

MOUNTING/WIRING

FMS-1655 With Remote Sensor

Introduction

The flexibility of the FMS-1655 provides for

several different configurations with respect to

the sensor location.

FMS-1655 models without an internal

sensor include at least one remote sensor

for measuring the differential pressure of the

monitored room. This remote sensor module

must be installed in the wall between the

monitored isolation room and the adjoining

corridor or anteroom.

The remote sensor module should be installed

with the attached stainless steel mounting

plate facing the isolation or patient room and

the reference plate facing the corridor or

anteroom. Please see illustrations on pages

10 and 11 for more details.

With this sensor orientation, a positive

pressure value indicates that the isolation

room is positive with respect to the corridor.

A 3-conductor (22 AWG) cable MUST be

connected between the remote sensor

module and the main controller module for

each sensor included with the unit. The length

of this cable should not exceed 1,000 feet.

The display unit may be installed outside

the room, at the nurses’ station, in the

engineering office, or at any other location as

needed.

Mounting Procedure

1. Cut an opening in the wall of the isolation

room to receive the supplied low voltage

mounting bracket for the remote sensor

electronics. Nominal hole dimensions are

3.65” H x 2.15” W.

2. Drill a 7/16” hole through the opposite wall

for the flow tube as shown.

3. Bring the 3-conductor signal wire through

the cut out.

4. Install the included low-voltage mounting

bracket in the drywall opening, and pull

the 3-conductor signal cable through the

mounting bracket.

5. Push a length of flow tube through the back

hole on through the 7/16” hole in the opposite

wall.

6. Attach the flow tube to the sensor port.

Then, push the tube and sensor module into

place and secure to the mounting enclosure

with two 6-32 x 3/4 screws supplied.

7. Install the louvered cover plate.

8. On the opposite side (corridor) attach the

flow tube to the barbed fitting of the flow tube

mounting plate.

9. Press the mounting plate into place,

allowing the excess tube length to go into

the wall space. Secure with the screws and

anchors.

11. At the FMS-1655 backplane, assuming

the colors of the 3-conductor signal cable

being red, black, and green, connect the

leads to the terminals as follows:

Red: Digital SNS_PWR

Black: AGND

Green: AI_1

If more than one remote sensor is being

used with the FMS-1655, then each must

be connected as above with the green leads

connected to the subsequent analog input

terminals AI_2 through AI_4.

12. Connect the 3-conductor signal cable to

remote sensor as follows:

Red: +Vin

Black: GND

Green: Io

10. Install the louvered cover plate.

- 9 -

Page 17

NCNCGNDNCNCIoNC

GND

+Vin

~

~

MOUNTING/WIRING

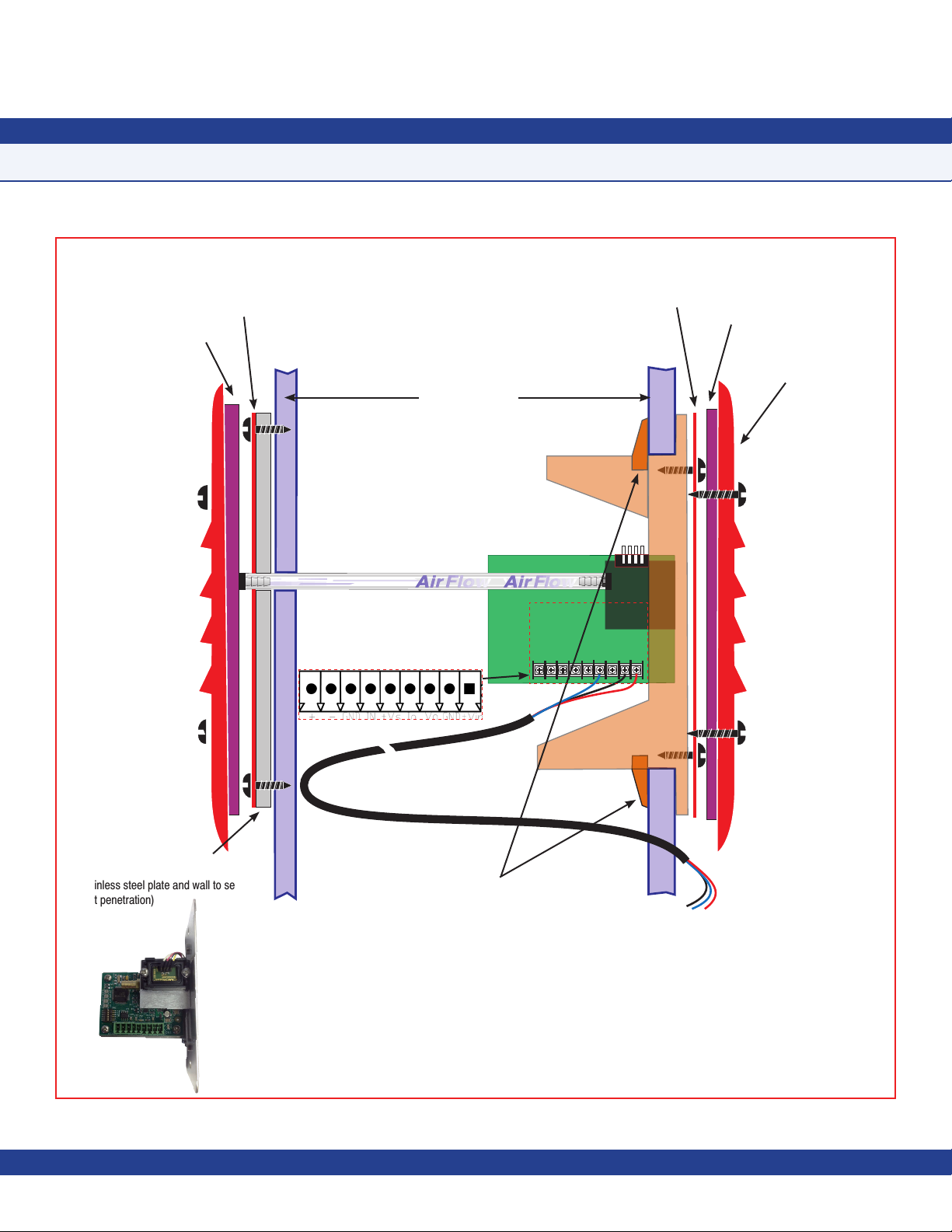

FMS-1655 with Standard Remote Sensor (9-Pin)

CORRIDOR

Gasket

Stainless Steel

Flow Tube

Mounting Plate

Wall Section

(cutaway view)

Flow Tube

When Flow Tube mounting plate

is located directly opposite the

sensor, flow tubing must be cut as

short as possible to prevent kinks.

For connection of

transmitter to FMS-1655.

Terminal

Stainless Steel

Mounting Plate

Gasket

Louvered Cover

Plate

ISOLATION

ROOM

NCNCGNDNCNCIoNC

GND

+Vin

Thin Silicone Caulking

(apply around tube and between

stainless steel plate and wall to seal

unit penetration)

~

~

Orange wall bracket

to be installed first

by using the rotating

clamps for secure

wall attachment.

Standard Remote Sensor Detail

(Side View)

- 10 -

To FMS-1655 Controller

Page 18

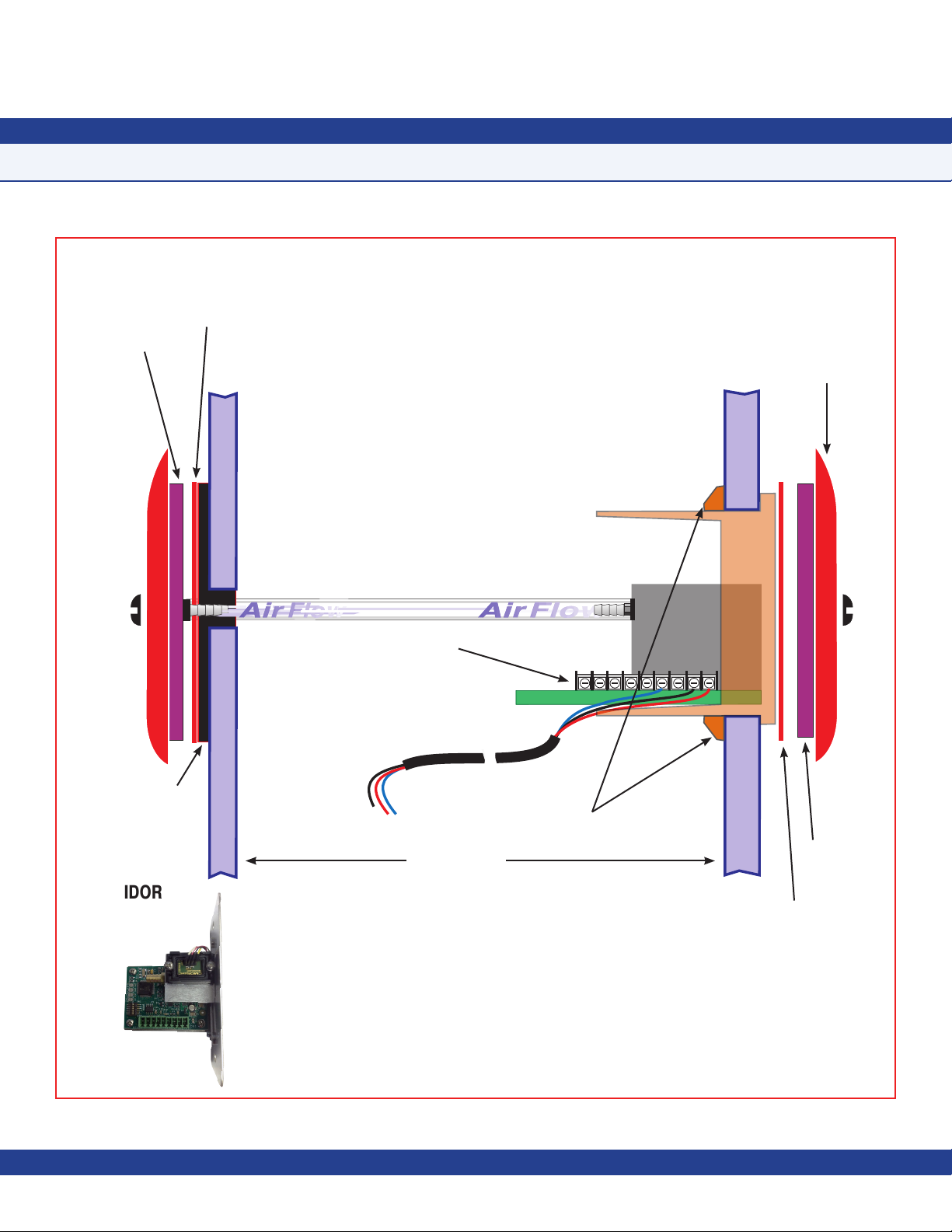

MOUNTING/WIRING

FMS-1655 with Standard Remote Sensor (9-Pin)

Stainless Steel

Flow Tube

Mounting Plate

ISOLATION

ROOM

Gasket

Thin Silicone Caulking

(apply around tube and

between stainless steel

plate and wall to seal unit

penetration)

Sensor installation requires the use of a three

conductor wire between the sensor and the main

controller module.

Flow Tube

When Flow Tube mounting plate is located

directly opposite the sensor, flow tubing must

be cut as short as possible to prevent kinks.

Terminal

For connection of

transmitter to

FMS-1655 .

To FMS-1655

Controller

Wall Section

(cutaway view)

~

~

NCNCGNDNCNCIoNC

Rotating clamps secure

assembly to wall board

GND

Louvered Cover

Plate

+Vin

Gasket

CORRIDOR

Stainless Steel

Mounting Plate

Standard Remote Sensor Detail

(Bottom View)

- 11 -

Page 19

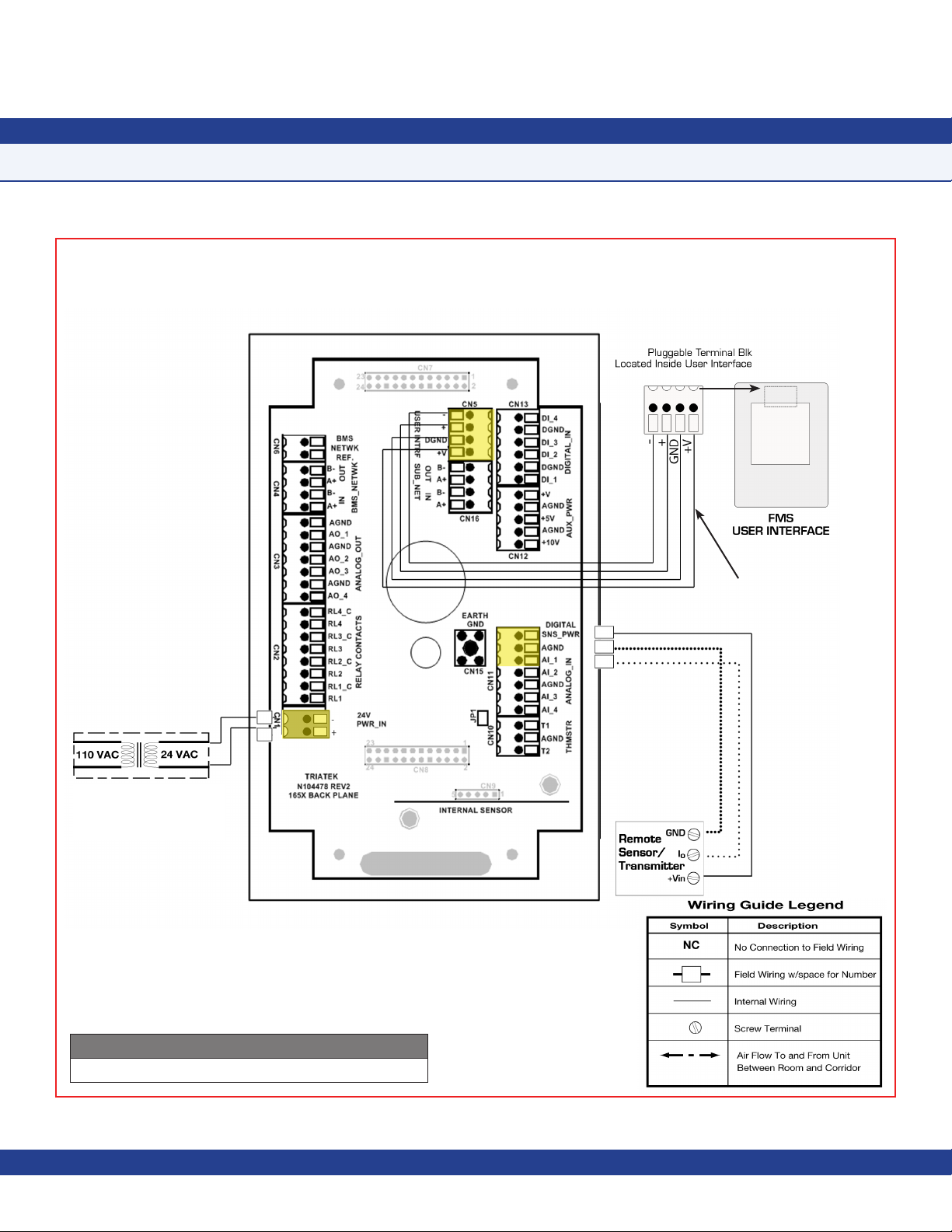

MOUNTING/WIRING

Remote Sensor Conguration

The electrical connections to the FMS-1655 made via a convenient backplate/backplate assembly is shown below. All wiring should conform

to the local regulations and National Electric Code. Take care not to run sensor wiring in the same conduit as the line voltage or other

conductors that supply highly inductive loads such as generators, motors, solenoids, contactors, etc. Use 22AWG or larger.

{

Recommended 4-conductor

connection: Belden 1325A

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 1 = ON, S1 - 5 = OFF (AI - 1 set at 4 - 20mA Input)

- 12 -

Page 20

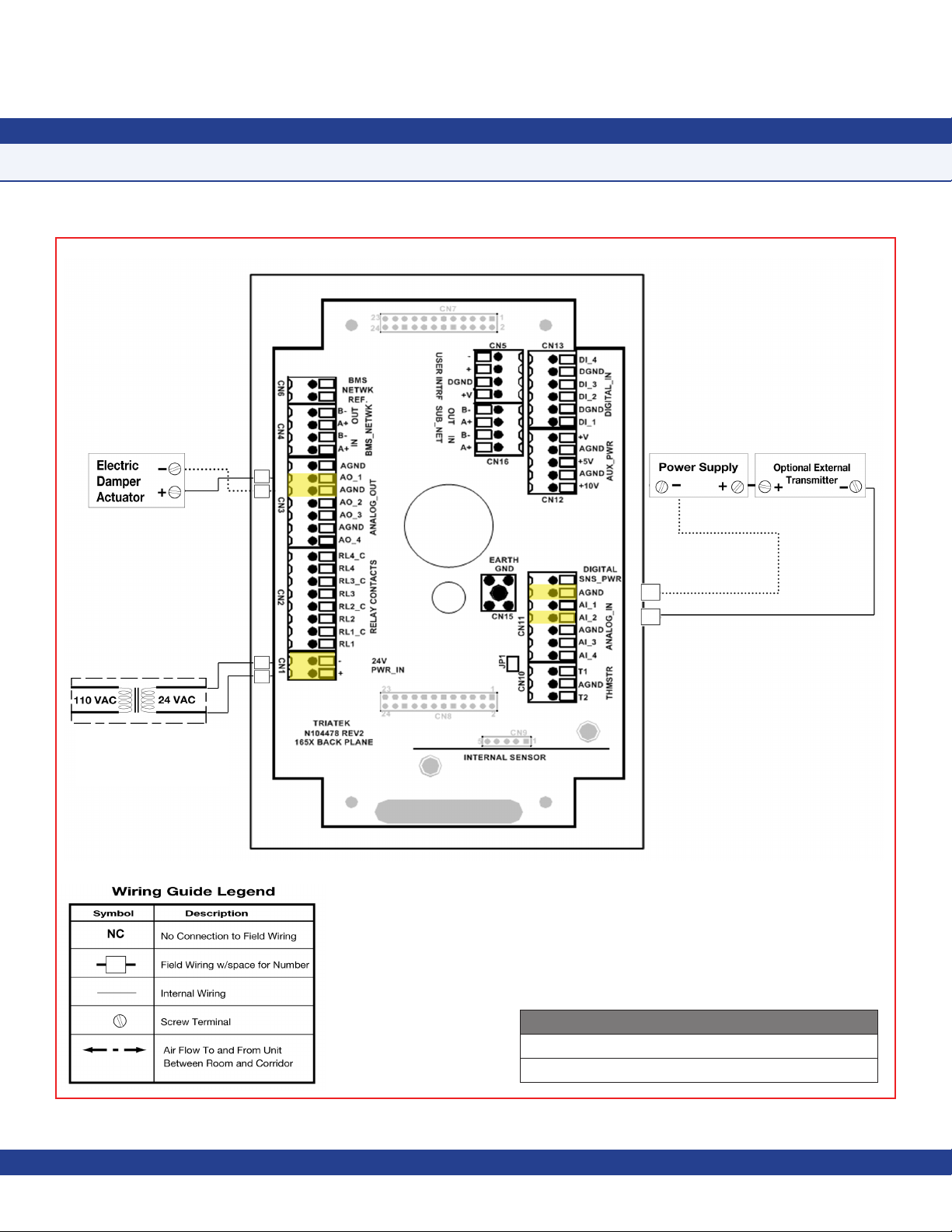

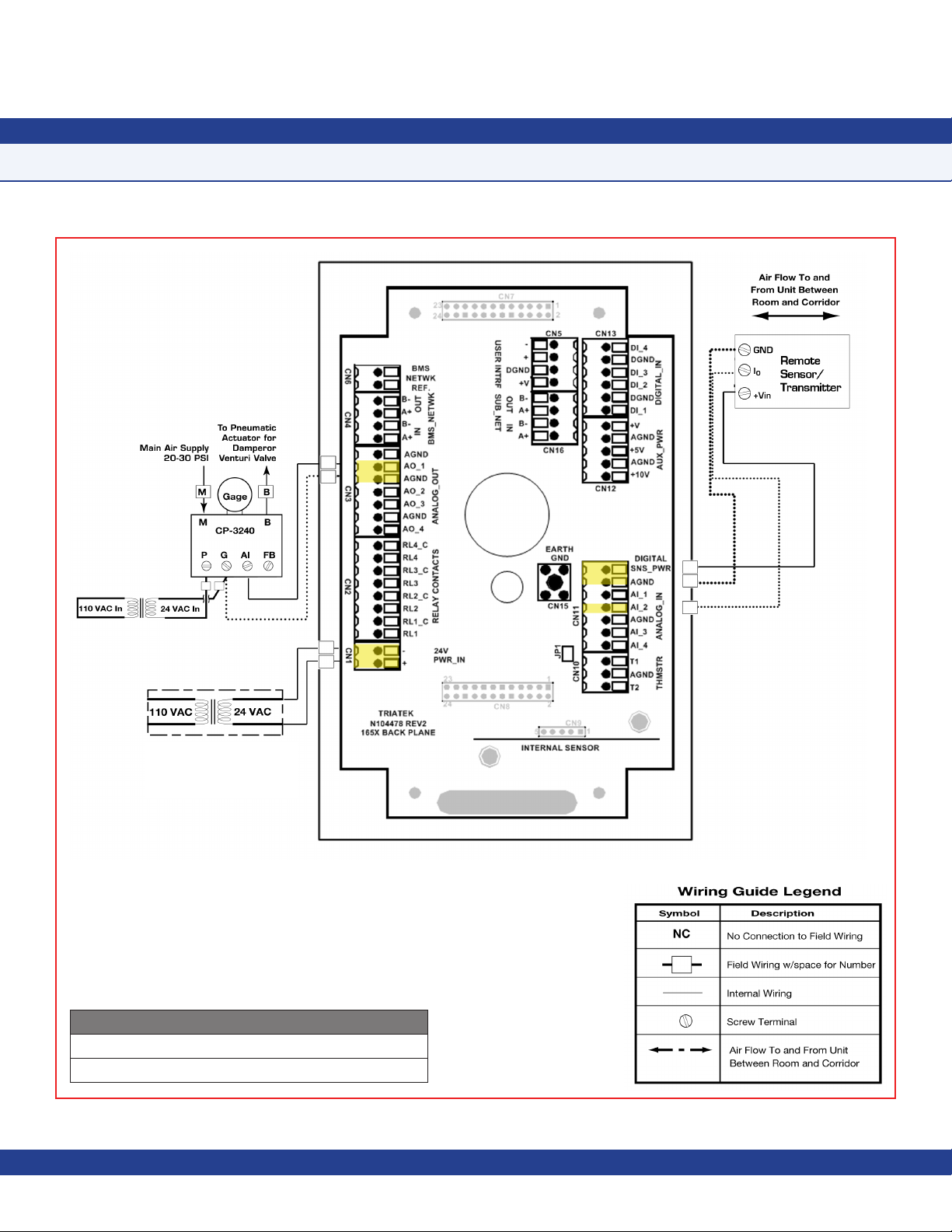

MOUNTING/WIRING - INTERNAL SENSOR

Analog Output to Electric Damper Actuator

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

S4 - 1 = ON (AO - 1 set as Voltage Output)

- 13 -

Page 21

MOUNTING/WIRING - INTERNAL SENSOR

Analog Output to Pneumatic Damper Actuator

Optional remote sensor

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

S4 - 1 = ON (AO - 1 set as Voltage Output)

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 14 -

Page 22

MOUNTING/WIRING - INTERNAL SENSOR

Analog Output to Variable Speed Drive

Optional remote sensor

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

S4 - 1 = ON (AO - 1 set as Voltage Output)

- 15 -

Page 23

MOUNTING/WIRING - INTERNAL SENSOR

Analog Output to Modulated Air Controller

Optional remote sensor

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

S1 - 4 = ON, S1 - 8 = OFF (AI - 4 set as 4 - 20mA Input

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 16 -

Page 24

MOUNTING/WIRING - REMOTE SENSOR

Analog Output to Pneumatic Damper Actuator

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 1 = ON, S1 - 5 = OFF (AI - 1 set as 20mA Input)

S4 - 1 = ON (AO - 1 set as Voltage Output)

- 17 -

Page 25

MOUNTING/WIRING - REMOTE SENSOR

Analog Output to Variable Speed Drive

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 1 = ON, S1 - 5 = OFF (AI - 1 set as 20mA Input)

S4 - 1 = ON (AO - 1 set as Voltage Output)

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 18 -

Page 26

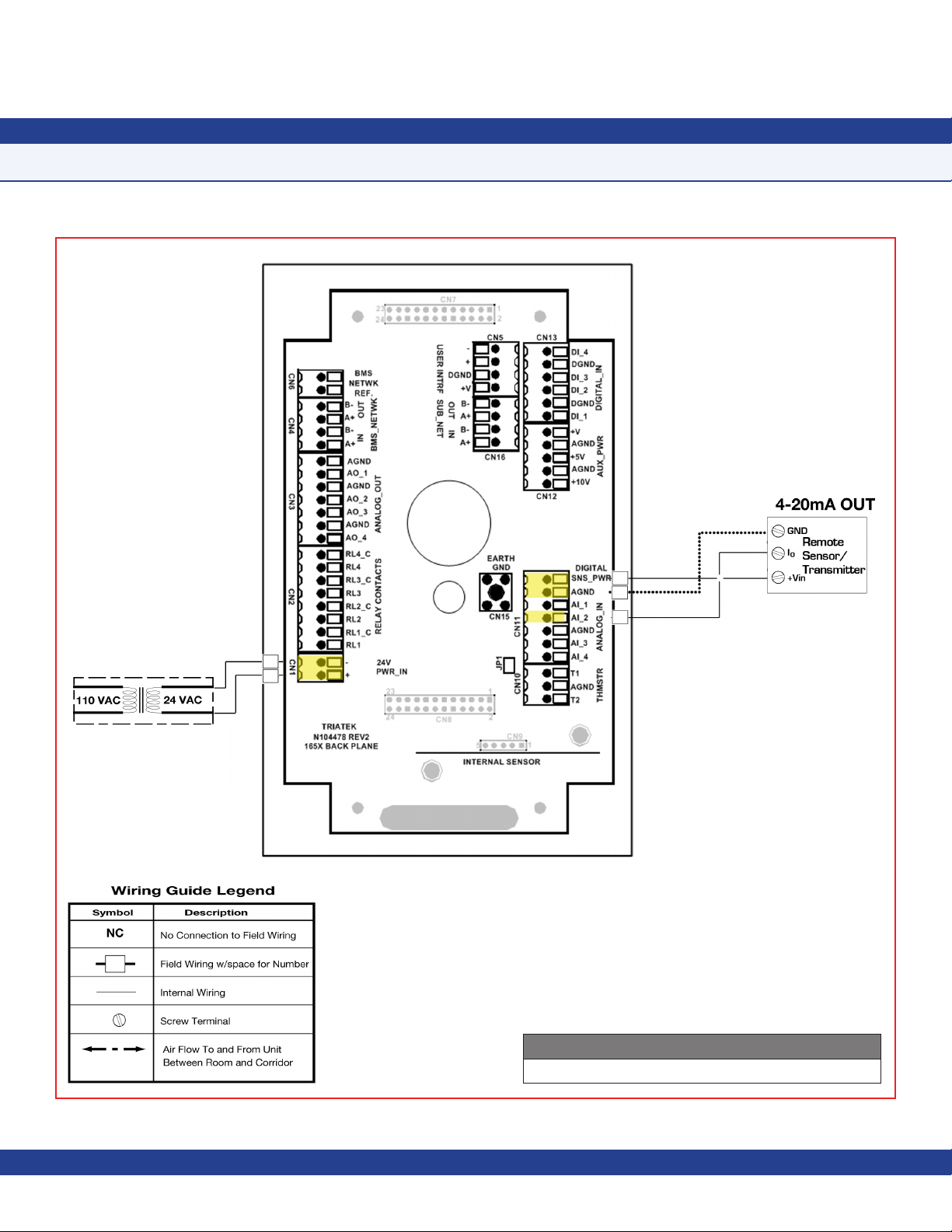

MOUNTING/WIRING

Adding Remote Pressure Sensor with 4-20mA Out to Internal Sensor Model

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

- 19 -

Page 27

MOUNTING/WIRING

Notes

- 20 -

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Page 28

MOUNTING/WIRING

Analog Input to 2 Remote Pressure Sensors 4-20mA Out

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 1 = ON, S1 - 5 = OFF (AI - 1 set as 4 - 20mA Input)

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

- 21 -

Page 29

MOUNTING/WIRING

Analog Input to 3 Remote Pressure Sensors 4-20mA Out

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 1 = ON, S1 - 5 = OFF (AI - 1 set as 4 - 20mA Input)

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

S1 - 3 = ON, S1 - 7 = OFF (AI - 3 set as 4 - 20 mA Input)

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 22 -

Page 30

MOUNTING/WIRING

Analog Input to 4 Remote Pressure Sensors 4-20mA Out

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 1 = ON, S1 - 5 = OFF (AI - 1 set as 4 - 20mA Input)

S1 - 2 = ON, S1 - 6 = OFF (AI - 2 set as 4 - 20mA Input)

S1 - 3 = ON, S1 - 7 = OFF (AI - 3 set as 4 - 20 mA Input)

S1 - 4 = ON, S1 - 8 = OFF (AI - 4 set as 4 - 20 mA Input)

- 23 -

Page 31

MOUNTING/WIRING

Analog Input to Temperature Sensor

**

*

Step Down

Isolation Transformer

(provided with FMS Controller)

* The above example associates the Thermistor with contacts T1

and AGND for illustrative purposes only. In fact, either of the two

T#s can be used.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 24 -

Page 32

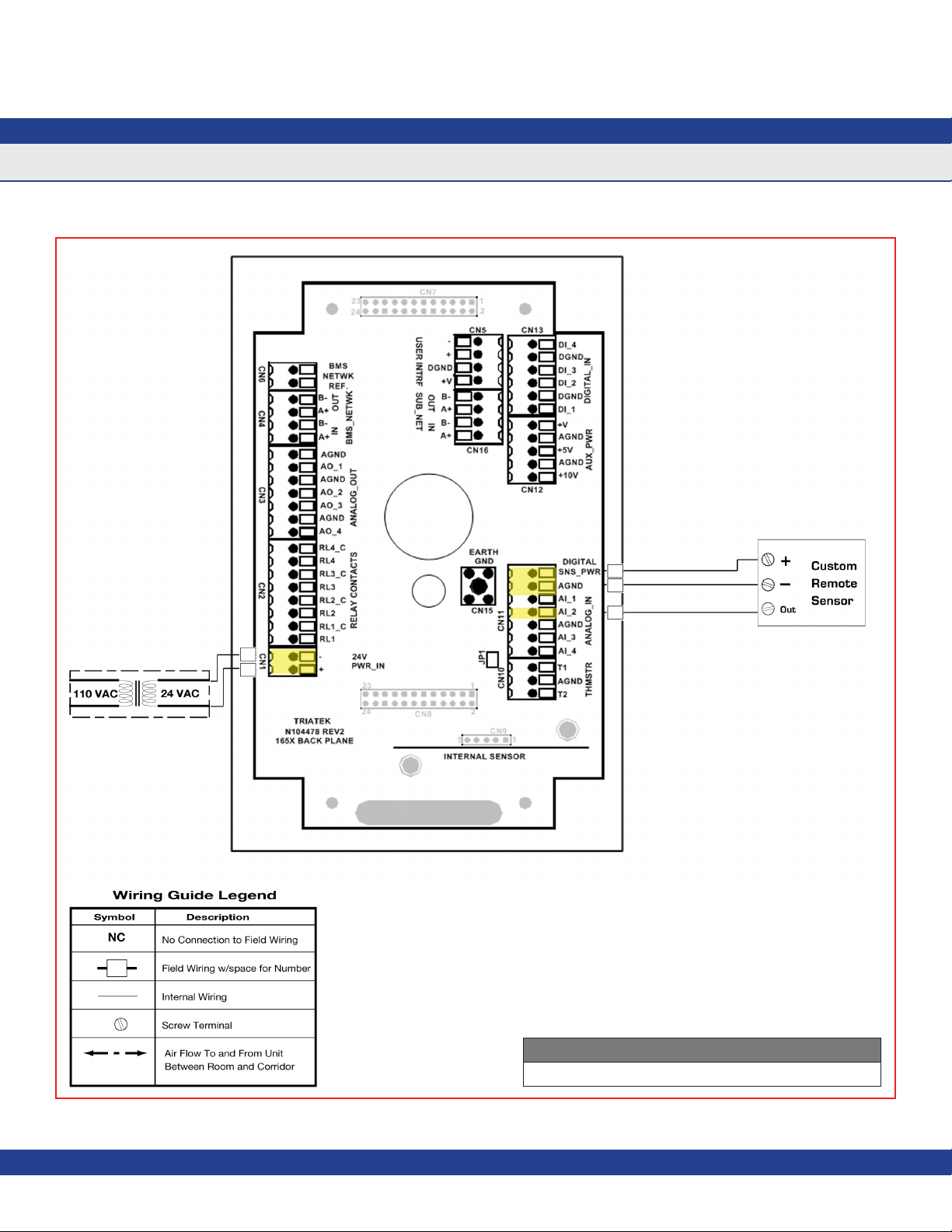

MOUNTING/WIRING

Analog Input to Custom Remote Sensor

Step Down

Isolation Transformer

(provided with FMS Controller)

Controller Configuration Dipswitch Settings

S1 - 2 = OFF, S1 - 6 = ON (AI - 2 set as 0 - 10V Input)

- 25 -

Page 33

MOUNTING/WIRING

Digital Input to Door Switch

A switch having normally-open or normally close contacts may be used with the FMS-1655 to serve as a timed alarm buzzer inhibit, when the

room door has been opened. An optional door switch may be purchased from JCI for this specific purpose.

After the switch has been installed at the door and connected to the FMS unit, its operation may be programmed as described on page 39.

Step Down

Isolation Transformer

(provided with FMS Controller)

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Controller Configuration Slideswitch Settings

S5 = Left (Active - Low Digital Input)

- 26 -

Page 34

MOUNTING/WIRING

SUBHEAD

Notes

- 27 -

Page 35

MOUNTING/WIRING

Digital Input to Occupancy Sensor

Step Down

Isolation Transformer

(provided with FMS Controller)

* The above example associates the Occupancy Sensor with

contacts DI4 and DGND for illustrative purposes only. In fact, any

of the four DI#s can be used.

Controller Configuration Slideswitch Settings

S5 = Left (Active - Low Digital Input)

- 28 -

Page 36

MOUNTING/WIRING

SUBHEAD

Relay Output to Alarm

*

Step Down

Isolation Transformer

(provided with FMS Controller)

* The above example associates Monitor Output 1 with contacts

RL3 and RL3_C for illustrative purposes only. In fact, any of the

four RL#s (and the corresponding RL#_C) can be used.

- 29 -

Page 37

MOUNTING/WIRING

Relay Output to Warning

Step Down

Isolation Transformer

(provided with FMS Controller)

* The above example associates Monitor Output 2 with contacts

RL3 and RL3_C for illustrative purposes only. In fact, any of the

four RL#s (and the corresponding RL#_C) can be used.

- 30 -

Page 38

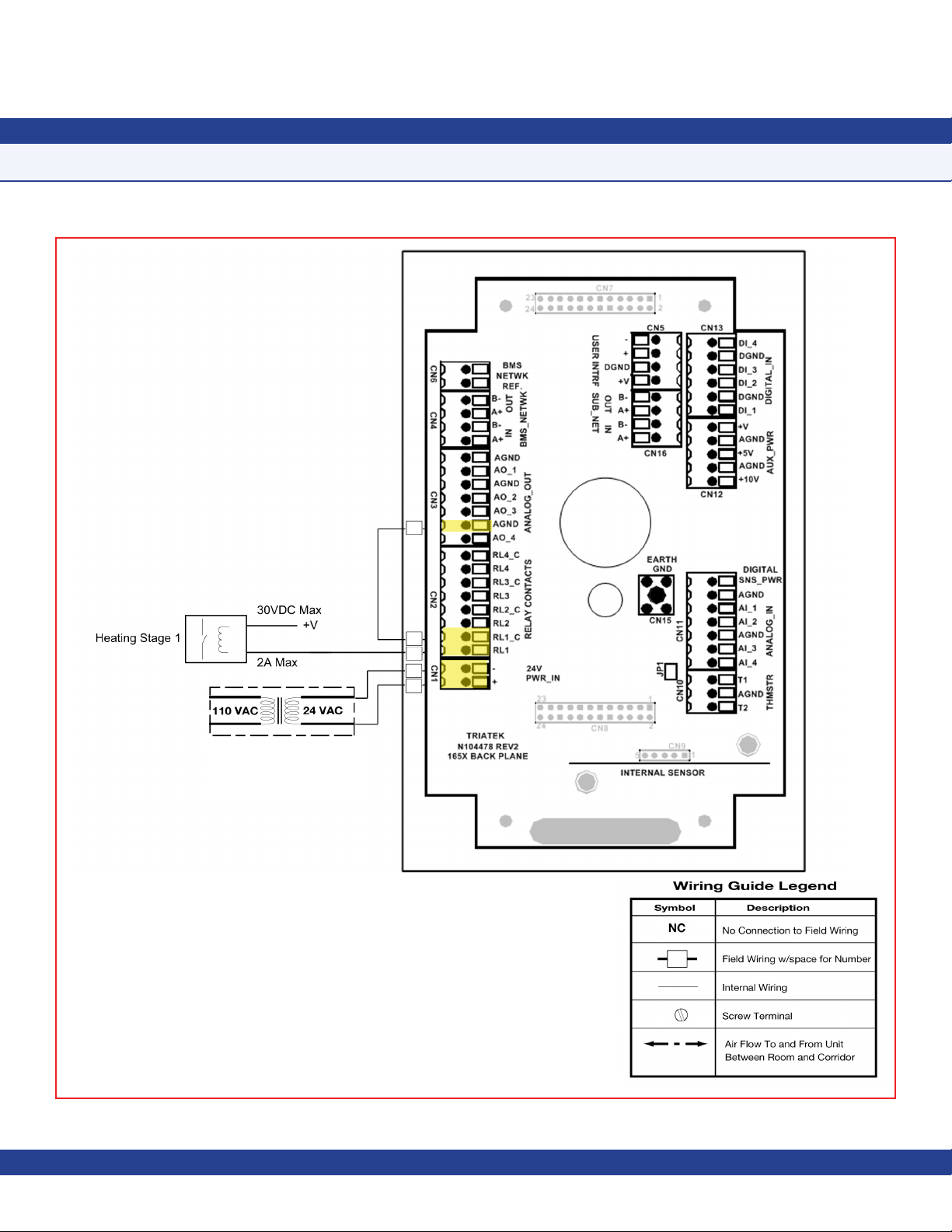

MOUNTING/WIRING

SUBHEAD

Relay Output 1

Step Down

Isolation Transformer

(provided with FMS Controller)

* The above example associates Heating State 1 with contacts

RL1 and RL1_C for illustrative purposes only. In fact, any of the

four RL#s (and the corresponding RL#_C) can be used.

- 31 -

Page 39

MOUNTING/WIRING

Relay Output 2

Step Down

Isolation Transformer

(provided with FMS Controller)

* The above example associates Heating State 2 with contacts

RL2 and RL2_C for illustrative purposes only. In fact, any of the

four RL#s (and the corresponding RL#_C) can be used.

- 32 -

Page 40

MOUNTING/WIRING

SUBHEAD

Power

Step Down

Isolation Transformer

(provided with FMS Controller)

- 33 -

Page 41

Red / 24 VAC / 30VA

connected to the FMS

}

Only Class 2 wiring in

this compartment.

MOUNTING/WIRING

Isolated Power Supply

Transformer

50/60 Hz

Ground

Blue

240 VAC

50/60 Hz

120 VAC

50/60 Hz

White

*

Note:

This product should be installed with the manufacturer provided isolated power supply and connected to an electrical

circuit protected by a minimum 20A circuit breaker. This circuit breaker should be mounted in an approved electrical

enclosure located separately, but in close proximity to this product.

}

}

Black

Stepdown Isolation Transformer

(provided with FMS-1655)

1 Amp Slow

Blow Fuse

- 34 -

Page 42

MOUNTING/WIRING

SUBHEAD

Notes

- 35 -

Page 43

COMMUNICATIONS - BACnet® MS/TP

Wiring

NOTE: For optimum network communications, the reference signal (REF)

must be connected to the "BMS NETWK REF" terminals at the backplane.

To minimize offline conditions on Metasys trunks resulting from delayed

responses from the BACnet controller, the NETWORK TOLERANCE

parameter in Metasys should be set to HIGH.

Controller Configuration Dipswitch Settings

S3 - 7 = ON, S3 - 8 = ON (BACnet MS/TP protocol selected)

- 36 -

Page 44

COMMUNICATIONS - Metasys® N2 Open

SUBHEAD

Wiring

NOTE: For optimum network communications, the reference

signal (REF) must be connected to the "NETWK REF"

terminals at the backplane.

Controller Configuration Dipswitch Settings

S3 - 7 = ON, S3 - 8 = OFF (Metasys N2 Open protocol selected)

- 37 -

Page 45

QUICK START GUIDE

FMS-1655 Quick Start Guide

Introduction

Following the proper installation of the

FMS-1655, apply power to the unit and

confirm that you hear a brief chirp at the

touchscreen display, which indicates that

the display module is communicating with

the controller module. Upon power up, the

Safety Halo

TM

status indication bezel will

cycle through seven colors (red, green, blue,

yellow, magenta, cyan, and white) followed by

three action icons (normal, caution, alarm),

and finally the JCI splash screen will remain

displayed for approximately 10 seconds and

will then disappear to reveal the main display

screen.

NOTE: The information displayed on the

splash screen during the power up sequence

may also be redisplayed using the About This

FMS option on the Diagnostics menu.

Each FMS-1655

comes preconfigured in

neutral isolation

mode.

Main Display Screen

All FMS-1655 units are shipped from the

factory in the neutral isolation mode, which

is represented by a blue graphical screen

with a slashed circle status icon at the center

of the screen as shown in the figure above.

The information that is displayed on the main

screen includes the following from top to

bottom:

• Isolation room name in the upper window

(up to 24 characters)

• Current differential pressure (default units:

in WC)

• Current status and isolation mode

• Status icon centrally located

• Current temperature in the lower window (if

so equipped)

• Current humidity in the lower window (if so

equipped)

• Current time and date in the lower window

Located just below the lower window with the

time and date display is the audible toggle

button, which may be used to temporarily

silence the audible alarm in the event of an

alarm condition.

While in neutral isolation mode, the graphical

background is blue in color. While in either

positive or negative isolation, the graphical

background intuitively represents the current

alarm status of the unit.

A green graphical background with a

checkmark at the center indicates that the

current differential pressure is within allowable

limits of the desired setpoint. A yellow

graphical background with an exclamation

point at the center indicates one of two

conditions: 1) door to the monitored space

is open (if door switch is enabled), or 2)

the current differential pressure has drifted

outside the allowable limits of the desired

setpoint and is in the caution range. A red

graphical background with an exclamation

point at the center indicates that the current

differential pressure has reached a critical

unsafe condition, as it is beyond the safe

operating range. An alarm buzzer will sound

at this screen as well providing an audible

alert of the unsafe conditions.

The FMS-1655 incorporates a full-color

touchscreen and includes an extensive easyto-use menu system that allows the user to

quickly setup the controller for immediate use.

Also integrated into the FMS-1655 display are

several hotspots that provide quick access to

various settings. Refer to page 51 for details

on using these hotspots as display settings

shortcuts. Touching the screen anywhere

other than one of the reserved hotspots

invokes the menu system, unless one or more

security passwords have been entered.

Automated Clean Cycle

If this FMS-1655 is controlling the differential

pressure of the monitored space, there

is a convenient feature that allows quick

turnover of the room referred to as auto clean

cycle mode. When a patient who has been

occupying an isolation room or patient room

is removed, the room must be purged of all

airborne contaminants in preparation for the

next patient. The auto clean cycle feature

of the FMS-1655 automates this cleaning

process and is fully programmable. This

feature may be activated from either the

isolation mode hotspot on the main display

screen, or via the isolation mode option on the

Room Setup Menu.

Clean Cycle

Mode in

operation

displaying time

remaining for

cycle completion.

- 38 -

Page 46

SUBHEAD

QUICK START GUIDE

FMS-1655 Quick Start Guide

When activated, Auto Clean Cycle opens

the exhaust valve or damper to its maximum

position to purge the room of any airborne

contaminants. The exhaust valve or damper

will remain in the maximum position for a

programmable period of time while the room

is being cleaned. The clean cycle duration

may be configured for a minimum of 10

minutes up to 4 hours in increments of one

minute. While the Auto Clean Cycle is in

progress, a countdown timer indicates the

time remaining for the process, and the Safety

HaloTM will flash slowly in cyan to indicate

that the monitored space is being cleaned.

When the Auto Clean Cycle is completed, a

message will appear on the screen indicating

that the room has been successfully cleaned.

This message will remain on the screen

until it has been acknowledged by a user, at

which time it returns the unit to the previously

selected isolation mode.

An active Auto Clean Cycle may be canceled

by touching the countdown timer in the upper

LCD window. A message will be displayed

warning the user that aborting the cleaning

process may result in insufficient cleaning

of the monitored room. Touching the main

display screen anywhere other than the upper

LCD window will result in a warning beep

with no menu access. If at least one security

password has been stored in the system,

touching the screen to abort the Auto Clean

Cycle that is in progress will request a valid

password before aborting the mode.

Configuring Room Pressure Monitor

Configuring the FMS-1655 isolation room

controller settings can be accomplished in

four (4) simple steps:

1. Configure analog output

2. Configure door switch

3. Configure alarm relay output

4. Configure alarm limits

The FMS-1655 comes pre-configured with

either an internal sensor or remote sensor,

depending on the specific model ordered. The

flush-mount models incorporate an internal

differential pressure sensor, while the surfacemount models include a separately installed

remote differential pressure sensor. In either

case, the next step would be to configure

the analog output that controls the damper

actuator in the monitored room, if control

is required. If the application only requires

monitoring, then this step may be omitted.

Setting Up Analog Output

For those applications requiring control of a

damper actuator, the analog output must be

configured accordingly. Select Unit Setup

> Controller Setup > Analog Output and

the user is prompted to select an operating

mode (direct control or PID control) and an

operating range. Most applications will take

advantage of the PID (proportional-integralderivative) control mode, where the control

output can be customized by varying the

control loop constants. The operating range

can either include an offset from zero or not,

independent of whether the analog output is

configured for current or voltage mode.

Once the operating mode and range are

selected, the user is prompted to specify the

upper and lower limits of the analog output as

percentages. Most applications will use the

default settings of zero and 100 percent. But

for those applications where the top or bottom

limits need to be tweaked, these settings may

be adjusted accordingly to further limit the

range of the actual analog output signal.

Finally, the user is prompted to enter the

target setpoint for the current mode of

isolation. This setpoint will be used by the

FMS-1655 to dither the analog output in

order to achieve the desired target differential

pressure. The analog output can be

configured for either direct acting or reverse

acting mode. Each mode of isolation has its

own setpoint and operating mode. Therefore,

switching from positive isolation to negative

isolation can automatically affect both the

target setpoint as well as the acting mode for

the analog output.

To confirm that the analog output is properly

configured for the specific installation at hand,

use the Overrides option on the Diagnostics

menu to manually override analog output

1 which is controlling the exhaust damper

actuator. Moving the slider from zero to

100 percent should cause the damper to

move from closed to full open, or vice versa,

depending upon the acting mode of the

actuator.

Enabling Door Switch

To prevent the FMS-1655’s control output

from ramping up or down unnecessarily when

the door of the monitored space is opened,

a door switch may be configured to suspend

the operation of the PID control output.

This effectively “freezes” the analog output

controlling the exhaust or supply damper until

the door closes. The option for configuring the

door switch can be found on the Controller

Setup menu under the Unit Setup menu. A

delay time of up to 60 minutes (in one-second

increments) may be associated with the door

switch, which effectively delays the return

to normal PID control output mode while

the monitored space resumes its positive

or negative differential pressure. If the door

switch option is enabled, the main display will

- 39 -

Page 47

QUICK START GUIDE

FMS-1655 Quick Start Guide

revert to the yellow graphical caution screen

whenever the door is open and the unit is

not in neutral isolation mode. Once the door

closes, the door delay will count down, and

then release the suspended control output

once it expires.

Setting Up Alarm Relay Output

When the alarm status must be transmitted to

a remote location, like a nurses’ station, the

alarm relay output can be configured using

the following procedure. Select Unit Setup

> Controller Setup > Relay Setup and the

user is prompted to select the trigger mode

(setpoints, isolation mode, or occupancy

mode). The default trigger mode is Setpoints,

which allows the alarm relay to be activated

based on exceeding setpoint limits entered

by the user. Isolation Mode and Occupancy

Mode allow the alarm relay to be activated

based on a change in the mode of isolation

and state of occupancy, respectively. Once

the relay trigger mode is selected, the user

is prompted to enter the high and low relay

setpoints using the sliders on the popup

screen. Finally, the operating mode (direct or

reverse acting) must be specified along with

a delay time. The delay time determines how

long the alarm relay output is delayed before

being activated after one of the relay setpoint

limits has been exceeded. The default setting

for the delay time is zero seconds.

Setting Alarm Limits

To determine the limits at which the unit status

changes from normal to warning, and from

warning to alarm, the alarm limits must be

configured as follows. Select Unit Setup >

Controller Setup > Alarm Limits and the user

is prompted to specify the high and low alarm

and warning limits. These limits should be

specified to set the differential pressure range

which is considered normal, as well as the

range which indicates a warning condition,

and the range which is considered critical and

indicates an alarm condition.

Changing Isolation Mode

The FMS-1655 isolation room controller

may be configured for Positive, Negative, or

Neutral modes of isolation. To change the

mode of isolation, select Unit Setup > Room

Setup > Isolation Mode and select one of

three isolation modes, or Auto Clean mode.

Auto Clean mode automates the turnover of

an isolation room that has been vacated in

preparation for the next occupant. For those

states or locales that have code restrictions

regarding the accessible modes of isolation,

the unit may be configured to allow either

Positive and Neutral or Negative and Neutral

modes. Changing the mode of isolation

automatically selects the pre-programmed

setpoints and alarm limits associated with

each mode.

Invoking Auto Clean Cycle

When an isolation room has been vacated, it

must be cleaned of all airborne contaminants

before the next patient may occupy the room.

The FMS-1655 includes a convenient feature

called Auto Clean Cycle that automates the

turnover process and cleaning of the room.

Auto Clean Cycle may be invoked using

one of two methods, either from the Status

hotspot on the main display screen or from

the Isolation Mode option on the Isolation

Room Setup menu. Invoking Auto Clean

Cycle automatically commands the exhaust

valve or damper for maximum flow for the

configured duration to facilitate the removal of

all airborne contaminants. If the Safety HaloTM

status bezel has been enabled, it will flash

in cyan color to indicate that an Auto Clean

Cycle is in progress. When the Auto Clean

Cycle is completed, a message will appear

on the main display screen indicating that the

monitored room was successfully cleaned

and is available for use. The Safety HaloTM

will stop flashing but remain cyan until this

message is acknowledged by the user.

Changing Network Settings

Changing network settings on the FMS-1655

can be accessed by selecting Unit Setup >

Network Setup. Depending upon the protocol

selected, the Network Setup menu will

present the user with the available options. All

FMS-1655 demo units have a default protocol

selection of BACnet, and therefore the

Network Setup menu options pertain to this

protocol. From this menu, the user can select

a different baud rate or change the network

address of the unit.

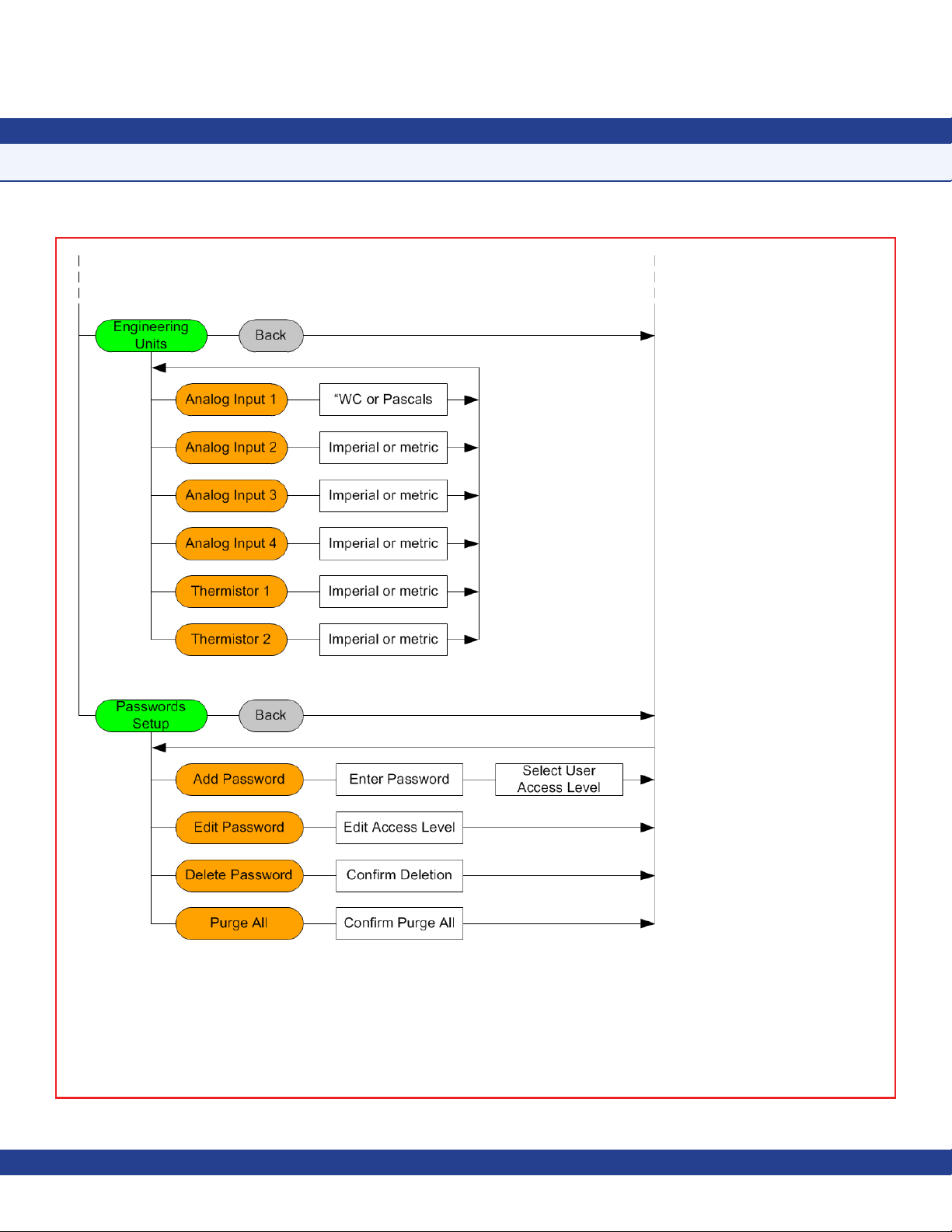

Adding Password Security

The FMS-1655 menu system can be

protected by adding up to ten (10) multi-level

passwords to the system. A password entry

may be created by selecting System Setup

> Next > Passwords Setup > Add Password

and the user is prompted to enter a minimum

of four (4) and up to eight (8) digits. Once

a password has been specified, the user is

prompted to specify one of four access levels:

Unrestricted, Standard, Basic, and Restricted.

All password entries are saved to non-volatile

memory. If a password is forgotten, there is a

factory-default “back door” password that will

provide unrestricted access to the user menu

system. Please consult with the factory for

more information regarding this password.

Note: The first user password is

automatically saved as unrestricted.

Changing Display Settings

The Safety Halo™ feature is exclusive to

- 40 -

Page 48

QUICK START GUIDE

FMS-1655 Quick Start Guide

the 1655 series of controllers from JCI, and

significantly enhances the visibility of the

status of individual units installed along a

long corridor or hallway, and allows an unsafe

condition to be immediately recognized. The

display settings of this enhanced feature

may be configured using the Safety Halo™

option on the Display Setup menu. This

option may be disabled if not required by

the installation, which simply turns off the

Safety Halo™ status indicator. If enabled, the

brightness may be adjusted from full intensity

down to barely visible in daylight conditions.

For convenience, the Safety Halo™ status

indicator incorporates a Nightly Auto-Dim

feature which allows the brightness of the

status indicator to automatically reduce in

intensity at a designated hour every day, and

then resume normal brightness at another

designated hour. The brightness of the

FMS-1655 main display screen may also

be adjusted using the Set Brightness option

on the Display Setup menu. All brightness

settings are stored to non-volatile memory

and remain in effect through a power cycle.

The Display Modes menu option on the

Display Setup menu allows users to select

a display mode based on the number of

pressure sensors being monitored. The

display mode is pre-configured at the factory

based on the sensor count, but may be

changed after adding or removing a sensor.

The main display screen of the FMS-1655

may be customized by using the Display

Setup menus. The Display Options menu

option allows specific information to be

individually suppressed by deselecting the

unwanted items from the Set Display Options

selection screen. Changing the time and

date can be accomplished either by using

the hotspots on the main display screen, or

by selecting the Set Time & Date option. The

time and date settings are volatile and are not

saved to non-volatile memory on demo units.

However, an operational unit connected to a

controller module can retain its time and date

settings for up to two hours in the event of a

power failure.

Built-in Diagnostics

The FMS-1655 incorporates several

useful diagnostic tools that may aid in

troubleshooting the system during the

installation and commissioning phase. The

Overrides option allows both analog and

relay outputs to be overridden individually.

Each analog output may be locked at the

overridden percentage while test and balance

makes adjustments to supply or exhaust

dampers, for example. While in the overridden

state, the analog output is “disconnected”

from its PID control loop, if enabled.

Cancelling the override effectively resumes

the normal PID control loop operation, again

if enabled.

A unique feature of the FMS-1655 is the Real-

Time View option, which allows the user to

see in real-time the actual inputs and outputs,

along with their voltage levels or states. One

of the most useful tools for fine-tuning the

PID loop performance is the Analog I/O Pairs

screen, which displays the analog input and

its current setpoint, along with the analog

output which is mapped to it. This allows the

user to see in real-time the varying analog

input signal and its corresponding analog

output control signal.

To preserve the configuration settings

after verifying that everything is configured

properly, the Save Settings option on the

Diagnostics menu will take a snapshot of

the current configuration settings for later

retrieval. In the event that any configuration

settings are inadvertently overwritten, they

may be restored either to the previously saved

user settings or to the factory-default settings.

To help maintain the long-term accuracy of

the FMS-1655 differential pressure reading, a

zero calibration feature has been incorporated

which allows the user to zero the display after

allowing the differential pressure between the

monitored room and the reference space to

neutralize, e.g., door open. Once the pressure

has stabilized, performing a zero calibration

ensures that the display reading accurately

shows that the pressure has equalized while

the door to the monitored space is left open.

Volumetric Offset Control

The FMS-1655 includes the ability to control

the supply and general exhaust air flow

devices in a laboratory application with

multiple fume hoods. This requires the use of

JCI’s Universal Valve Module to bring the total

supply and exhaust flows into the FMS-1655.

To configure the FMS-1655 for volumetric

offset control, simply configure AI-3 as the

supply flow input, and AI-4 as the exhaust

flow input. The volumetric offset setpoint must

be entered while configuring AI-4. Be sure to

select Vol. Offset Control on the Flow Sensor

Input configuration screen. The volumetric

offset control signal is output on AO-4, which

may be daisy-chained to each of the supply

air flow devices. The secondary temperature

control signal for heating is output on AO-2,

which may be daisy-chained to each of the

reheat valves. For more information on using

the FMS-1655 for volumetric offset control

applications, please refer to the FMS-1655

Programmer’s Guide.

- 41 -

Page 49

QUICK START GUIDE

Notes

- 42 -

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Page 50

SUBHEAD

MODULE SETTINGS

Conguring Display Module Settings

Options Dipswitch (S1) – internal use only

1. Graphics Chip Mode Selection OFF = Programming Mode ON = Run Mode

2. Touch Screen Calibration Mode OFF = Force calibration ON = Auto calibration

3. Reserved

4. Reserved

Options Dipswitch (S2) – mode configuration 1

1. Product Type OFF = FMS/HMS ON = CMS-1655

2. Remote Display OFF = Disabled ON = Enabled

3. Mode Select OFF = FMS-1655 / CMS-1655 ON = HMS-1655

4. Operational Mode: OFF = Demo Mode ON = Run Mode

Pushbutton Switch (SW1): Reset Button

Pushbutton Switch (SW2): Reserved

- 43 -

Page 51

MODULE SETTINGS

Conguring Main Controller Module Settings

Analog Input Configuration Dipswitch (S1)

1. AI-1 Mode Selection: OFF = voltage input ON = current input

2. AI-2 Mode Selection: OFF = voltage input ON = current input

3. AI-3 Mode Selection: OFF = voltage input ON = current input

4. AI-4 Mode Selection: OFF = voltage input ON = current input

5. AI-1 Voltage Range Selection: OFF = 0-5Vdc ON = 0-10Vdc

6. AI-2 Voltage Range Selection: OFF = 0-5Vdc ON = 0-10Vdc

7. AI-3 Voltage Range Selection: OFF = 0-5Vdc ON = 0-10Vdc

8. AI-4 Voltage Range Selection: OFF = 0-5Vdc ON = 0-10Vdc

NOTES: To configure FMS-1655 for an internal sensor, set dipswitch position 1 to OFF and dipswitch position 5 to OFF. To configure

FMS-1655 for a remote sensor, set dipswitch position 1 to ON and dipswitch position 5 to OFF. For other inputs, see Table 1.

Analog Output Configuration Dipswitch (S3)

1. AO-1 Mode Selection: OFF = current output ON = voltage output

2. AO-2 Mode Selection: OFF = current output ON = voltage output

3. AO-3 Mode Selection: OFF = current output ON = voltage output

4. AO-4 Mode Selection: OFF = current output ON = voltage output

Network Configuration Dipswitch (S3)

5. RS485 Network Termination: OFF = disabled ON = enabled

6. RS485 Display Termination: OFF = disabled ON = enabled

7. Protocol Select: see Table 2 below

8. Protocol Select: see Table 2 below

- 44 -

Page 52

SUBHEAD

MODULE SETTINGS

Congurations & Settings

Table 1. Analog Input Configuration Settings (S1)

Mode S1 - 1 S1 - 2 S1 - 3 S1 - 4 S1 - 5 S1 - 6 S1 - 7 S1 - 8

AI-1 5Vdc OFF OFF

AI-1 20mA ON OFF

AI-1 10Vdc OFF ON

Not Valid ON ON

AI-2 5Vdc OFF OFF

AI-2 20mA ON OFF

AI-2 10Vdc OFF ON

Not Valid ON ON

AI-3 5Vdc OFF OFF

AI-3 20mA ON OFF

AI-3 10Vdc OFF ON

Not Valid ON ON

AI-4 5Vdc OFF OFF

AI-4 20mA ON OFF

AI-4 10Vdc OFF ON

Not Valid ON ON

Table 2. Protocol Selection Settings (S3)

Protocol Selection S3-7 S3-8

Reserved OFF OFF

Metasys® N2 ON OFF

BACnet® MS/TP (default) ON ON

Controller Configuration Dipswitch (S4)

1. AO-1 Voltage Range Selection: OFF = 0-10Vdc ON = 0 - 5Vdc

2. AO-2 Voltage Range Selection: OFF = 0-10Vdc ON = 0 - 5Vdc

3. AO-3 Voltage Range Selection: OFF = 0-10Vdc ON = 0 - 5 Vdc

4. AO-4 Voltage Range Selection: OFF = 0-10Vdc ON = 0 - 5 Vdc

Controller Configuration Slideswitch (S5):