Page 1

ENGINEERING MANUAL

INVERTER-DRIVEN MULTI-SPLIT SYSTEM

HEAT PUMP AIR CONDITIONERS

Engineering Manual

TC-16004

Technical Catalog for Outdoor Unit

< Indoor Units >

●Ducted Medium Static (EconoFresh) Type

(H,Y,C)IDM030B21E

(H,Y,C)IDM036B21E

(H,Y,C)IDM048B21E

with EF-456NE

Page 2

Page 3

TC-16004-rev.2

i

IMPORTANT NOTICE AND SAFETY SUMMARY

1. Introduction

2. Important Safety Instructions

This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

(Transportation/Installation Work) > (Refrigerant Piping Work) > (Electrical Wiring Work) > (Ref. Charge Work) > (Test

Run) > (User)

This Engineering Manual concentrates on heat pump air conditioning units. Read this manual carefully

before performing installations or operations.

Signal Words

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related

(for example, messages relating to property damage).

General Precautions

To reduce the risk of serious injury or death, read these instructions

thoroughly and follow all warnings or cautions included in all manuals that

accompanied the product and are attached to the unit. Refer back to these

instructions as needed.

● This system should be installed by personnel certied by Johnson Controls, Inc. Personnel must be

qualied according to local, state and national building and safety codes and regulations. Incorrect

installation could cause leaks, electric shock, re or explosion. In areas where Seismic ‘’Performance

requirements are specied, the appropriate measures should be taken during installation to guard

against possible damage or injury that might occur in an earthquake if the unit is not installed

correctly, injuries may occur due to a falling unit.

● Use appropriate Personal Protective Equipment (PPE), such as gloves and protective goggles and,

where appropriate, have a gas mask nearby. Also use electrical protection equipment and tools

suited for electrical operation purposes. Keep a quenching cloth and a re extinguisher nearby during

brazing. Use care in handling, rigging, and setting of bulky equipment.

● When transporting, be careful when picking up, moving and mounting these units. Although the

unit may be packed using plastic straps, do not use them for transporting the unit from one location

to another. Do not stand on or put any material on the unit. Get a partner to help, and bend with

your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum ns on the air

conditioner can cut ngers, so wear protective gloves.

● Do not touch or adjust any safety devices inside the indoor or outdoor units. All safety features,

disengagement, and interlocks must be in place and functioning correctly before the equipment is

put into operation. If these devices are improperly adjusted or tampered with in any way, a serious

accident can occur. Never bypass or jump-out any safety device or switch.

● Johnson Controls will not assume any liability for injuries or damage caused by not following steps

outlined or described in this manual. Unauthorized modications to Johnson Controls products are

prohibited as they…

◦ May create hazards which could result in death, serious injury or equipment damage.

◦ Will void product warranties.

◦ May invalidate product regulatory certications.

◦ May violate OSHA standards.

Page 4

ii

TC-16004-rev.2

Take the following precautions to reduce the risk of property damage.

● Be careful that moisture, dust, or variant refrigerant compounds not enter the refrigerant cycle during

installation work. Foreign matter could damage internal components or cause blockages.

● If air lters are required on this unit, do not operate the unit without the air lter set in place. If the air

lter is not installed, dust may accumulate and breakdown may result.

● Do not install this unit in any place where silicon gases can coalesce. If the silicon gas molecules

attach themselves to the surface of the heat exchanger, the nned surfaces will repel water. As a

result, any amount of drainage moisture condensate can overow from the drain condensate pan and

could run inside of the electrical box, possibly causing electrical failures.

● When installing the unit in a hospital or other facility where electromagnetic waves are generated

from nearby medical and/or electronic devices, be prepared for noise and electronic interference

Electromagnetic Interference (EMI). Do not install where the waves can directly radiate into the

electrical box, controller cable, or controller. Inverters, appliances, high-frequency medical equipment,

and radio communications equipment may cause the unit to malfunction. The operation of the unit

may also adversely affect these same devices. Install the unit at least 10 ft. (approximately 3m) away

from such devices.

● When a wireless controller is used, locate at a distance of at least 3.3 ft. (approximately 1m) between

the indoor unit and electric lighting. If not, the receiver part of the unit may have difculty receiving

operation commands.

● Do not install the unit in any location where animals and plants can come into direct contact with the

outlet air stream. Exposure could adversely affect the animals and plants.

● Do not install the unit with any downward slope to the side of the drain boss. If you do, you may have

drain water owing back which may cause leaks.

● Be sure the drain hose discharges water properly. If connected incorrectly, it may cause leaks.

● Do not install the unit in any place where oil can seep onto the units, such as table or seating areas in

restaurants, and so forth. For these locations or social venues, use specialized units with oil-resistant

features built into them. In addition, use a specialized ceiling fan designed for restaurant use. These

specialized oil-resistant units can be ordered for such applications. However, in places where large

quantities of oil can splash onto the unit, such as a factory, even the specialized units cannot be used.

These products should not be installed in such locations.

● If the wired controller is installed in a location where electromagnetic radiation is generated, make

sure that the wired controller is shielded and cables are sleeved inside conduit tubing.

● If there is a source of electrical interference near the power source, install noise suppression

equipment (lter).

● During the test run, check the unit’s operation temperature. If the unit is used in an environment

where the temperature exceeds the operation boundary, it may cause severe damage. Check the

operational temperature boundary in the manual. If there is no specied temperature, use the unit

within the operational temperature boundary of 35 to 104°F (0 to 40°C).

● Read installation and appropriate user manuals for connection with PC or peripheral devices. If a

warning window appears on the PC, the product stops, does not work properly or works intermittently,

immediately stop using the equipment.

Page 5

TC-16004-rev.2

iii

Installation Precautions

To reduce the risk of serious injury or death, the following installation

precautions must be followed.

● When installing the unit into…

◦ A wall: Make sure the wall is strong enough to hold the unit’s weight. It may be necessary to

construct a strong wood or metal frame to provide added support.

◦ A room: Properly insulate any refrigerant tubing run inside a room to prevent “sweating” that can

cause dripping and water damage to wall and oors.

◦ Damp or uneven areas: Use a raised concrete pad or concrete blocks to provide a solid, level

foundation for the unit to prevent water damage and abnormal vibration.

◦ An area with high winds: Securely anchor the outdoor unit down with bolts and a metal frame.

Provide a suitable air bafe.

◦ A snowy area (only for Heat Pump Model): Install the outdoor unit on a raised platform that is

higher than drifting snow. Provide snow vents.

● If the remote sensors are not used with this controller, then do not install this controller…

◦ in a room where there is no thermostat.

◦ where the unit is exposed to direct sunshine or direct light.

◦ where the unit will be in close proximity to a heat source.

◦ where hot/cold air from the outdoors, or a draft from elsewhere (such as air vents, diffusers or

grilles) can affect air circulation.

◦ in areas with poor air circulation and ventilation.

● Do not install the unit in the following places. Doing so can result in an explosion, re, deformation,

corrosion, or product failure.

◦ Explosive or ammable atmosphere.

◦ Where re, oil, steam, or powder can directly enter the unit, such as in close proximity or directly

above a kitchen stove.

◦ Where oil (including machinery oil) may be present.

◦ Where corrosive gases such as chlorine, bromine, or sulde can accumulate, such as near a hot

tub or hot spring.

◦ Where dense, salt-laden airow is heavy, such as in coastal regions.

◦ Where the air quality is of high acidity.

◦ Where harmful gases can be generated from decomposition.

● Do not position the drain pipe for the indoor unit near any sanitary sewers where corrosive gases

may be present. If you do, toxic gases can seep into breathable air spaces and can cause respiratory

injuries. If the drainpipe is installed incorrectly, water leakage and damage to the ceiling, oor,

furniture, or other possessions may result. If condensate piping becomes clogged, moisture can back

up and can drip from the indoor unit. Do not install the indoor unit where such dripping can cause

moisture damage or uneven locations: Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the unit to prevent water damage and abnormal vibration.

● Before performing any brazing work, be sure that there are no ammable materials or open ames

nearby.

● Perform a test run to ensure normal operation. Safety guards, shields, barriers, covers, and protective

devices must be in place while the compressor/unit is operating. During the test run, keep ngers and

clothing away from any moving parts.

● Clean up the site when nished, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being installed.

● During transportation, do not allow the backrest of the forklift make contact with the unit, otherwise,

it may cause damage to the heat exchanger and also may cause injury when stopped or started

suddenly.

● Remove gas inside the closing pipe when the brazing work is performed. If the brazing ller metal is

melted with remaining gas inside, the pipes will be blown off and it may cause injury.

● Be sure to use nitrogen gas for an airtight test. If other gases such as oxygen gas, acetylene gas or

uorocarbon gas are accidentally used, it may cause explosion or gas intoxication.

After installation work for the system has been completed, explain the “Safety Precautions,” the proper use

and maintenance of the unit to the customer according to the information in all manuals that came with the

system. All manuals and warranty information must be given to the user or left near the Indoor Unit.

Page 6

iv

TC-16004-rev.2

Refrigerant Precautions

To reduce the risk of serious injury or death, the following refrigerant

precautions must be followed.

● As originally manufactured, this unit contains refrigerant installed by Johnson Controls. Johnson

Controls uses only refrigerants that have been approved for use in the unit’s intended home country

or market. Johnson Controls distributors similarly are only authorized to provide refrigerants that

have been approved for use in the countries or markets they serve. The refrigerant used in this unit

is identied on the unit’s faceplate and/or in the associated manuals. Any additions of refrigerant into

this unit must comply with the country’s requirements with regard to refrigerant use and should be

obtained from Johnson Controls distributors. Use of any non-approved refrigerant substitutes will void

the warranty and will increase the potential risk of injury or death.

● If installed in a small room, take measures to prevent the refrigerant from exceeding the maximum

allowable concentration in the event that refrigerant gases should escape. Refrigerant gases can

cause asphyxiation (0.026 lbs/ft

3

(0.42 kg/m3) based on ISO 5149 for R410A). Consult with your

distributor for countermeasures (ventilation system and so on). If refrigerant gas has leaked during the

installation work, ventilate the room immediately.

● Check the design pressure for this product is 601 psi (4.15MPa). The pressure of the refrigerant

R410A is 1.4 times higher than that of the refrigerant R22. Therefore, the refrigerant piping for

R410A shall be thicker than that for R22. Make sure to use the specied refrigerant piping. If not, the

refrigerant piping may rapture due to an excessive refrigerant pressure. Besides, pay attention to

the piping thickness when using copper refrigerant piping. The thickness of copper refrigerant piping

differs depending on its material.

● The refrigerant R410A is adopted. The refrigerant oil tends to be affected by foreign matters such

as moisture, oxide lm, (or fat). Perform the installation work with care to prevent moisture, dust, or

different refrigerant from entering the refrigerant cycle. Foreign matter can be introduced into the cycle

from such parts as expansion valve and the operation may be unavailable.

● To avoid the possibility of different refrigerant or refrigerant oil being introduced into the cycle, the

sizes of the charging connections have been changed from R407C type and R22 type. It is necessary

to prepare the appropriate tools before performing installation work.

● Use refrigerant pipes and joints which are approved for use with R410A.

● A compressor/unit comprises a pressurized system. Never loosen threaded joints while the system is

under pressure and never open pressurized system parts.

● Before installation is complete, make sure that the refrigerant leak test has been performed. If

refrigerant gases escape into the air, turn OFF the main switch, extinguish any open ames and

contact your service contractor. Refrigerant (Fluorocarbon) for this unit is odorless. If the refrigerant

should leak and come into contact with open ames, toxic gas could be generated. Also, because the

uorocarbons are heavier than air, they settle to the oor, which could cause asphyxiation.

● When installing the unit, and connecting refrigerant piping, keep all piping runs as short as

possible, and make sure to securely connect the refrigerant piping before the compressor starts

operating. If the refrigerant piping is not connected and the compressor activates with the stop

valve opened, the refrigerant cycle will become subjected to extremely high pressure, which can

cause an explosion or re.

● Tighten the are nut with a torque wrench in the specied manner. Do not apply excessive force to the

are nut when tightening. If you do, the are nut can crack and refrigerant leakage may occur.

● When maintaining, relocating, and disposing of the unit, dismantle the refrigerant piping after the

compressor stops.

● When pipes are removed out from under the piping cover, after the insulation work is completed,

cover the gap between the piping cover and pipes by a packing (eld-supplied). If the gap is not

covered, the unit may be damaged if snow, rain water or small animals enter the unit.

● Do not apply an excessive force to the spindle valve at the end of opening. Otherwise, the spindle

valve ies out due to refrigerant pressure. At the test run, fully open the gas and liquid valves,

otherwise, these devices will be damaged. (It is closed before shipment.)

● If the arrangement for outdoor units is incorrect, it may cause owback of the refrigerant and result in

failure of the outdoor unit.

● The refrigerant system may be damaged if the slope of the piping connection kit exceeds +15

o

.

Page 7

TC-16004-rev.2

v

Electrical Precautions

Take the following precautions to reduce the risk of electric shock, re or

explosion resulting in serious injury or death.

● Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause

serious injury or death.

● Perform all electrical work in strict accordance with this installation and maintenance manual and all

the relevant regulatory standards.

● Before servicing, open and tag all disconnect switches. Never assume electrical power is

disconnected. Check with meter and equipment.

● Only use electrical protection equipment and tools suited for this installation.

● Insulate a wired controller against moisture and temperature extremes.

● Use specied cables between units.

● The new air conditioner may not function normally in the following instances:

◦ If electrical power for the new air conditioner is supplied from the same transformer as the device*

referred to below.

◦ If the power source cables for this device* and the new air conditioner unit are located in close

proximity to each other.

Device*: (Example): A lift, container crane, rectier for electric railway, inverter power device,

arc furnace, electric furnace, large-sized induction motor and large-sized switch.

Regarding the cases mentioned above, surge voltage may be inducted into the power supply

cables for the packaged air conditioner due to a rapid change in power consumption of the device

and an activation of a switch.

Check eld regulations and standards before performing electrical work in order to protect the

power supply for the new air conditioner unit.

● Communication cabling shall be a minimum of AWG18 (0.82mm

2

), 2-Conductor, Stranded Copper.

Shielded cable must be considered for applications and routing in areas of high EMI and other

sources of potentially excessive electrical noise to reduce the potential for communication errors.

When shielded cabling is applied, proper bonding and termination of the cable shield is required

as per Johnson Controls guidelines. Plenum and riser ratings for communication cables must be

considered per application and local code requirements.

● The polarity of the input terminals is important, so be sure to match the polarity when using contacts

that have polarity.

● Use an exclusive power supply for the air conditioner at the unit’s rated voltage.

● Highly dangerous electrical voltages may be used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause

serious injury or death.

● Before installing the controller or remote devices, ensure that the indoor and outdoor unit operation

has been stopped. Further, be sure to wait at least ve minutes before turning off the main power

switch to the indoor or outdoor units. Otherwise, water leakage or electrical breakdown may result.

● Do not open the service cover or access panel to the indoor or outdoor units without turning OFF the

main power supply. Before connecting or servicing the controller or cables to indoor or outdoor units,

open and tag all disconnect switches. Never assume electrical power is disconnected. Check with a

meter and equipment.

● This equipment can be installed with a Ground Fault Circuit Breaker (GFCI), which is a recognized

measure for added protection to a properly grounded unit. Install appropriate sized breakers / fuses

/ overcurrent protection switches, and wiring in accordance with local, state and NEC codes and

requirements. The equipment installer is responsible for understanding and abiding by applicable

codes and requirements.

Page 8

vi

TC-16004-rev.2

- CONTENTS -

1. General Information (Features) .................................................................................................................. 1-1

2. Ducted Medium Static (EconoFresh) Type ................................................................................................ 2-1

2.1 Unit Nomenclature ............................................................................................................................. 2-1

2.2 Line-up .............................................................................................................................................. 2-1

2.3 General Data ..................................................................................................................................... 2-2

2.4 Dimensional Data .............................................................................................................................. 2-3

2.5 Structure ............................................................................................................................................ 2-4

2.6 Component Data ............................................................................................................................... 2-5

2.7 Operation Space ............................................................................................................................... 2-6

2.8 Sensible Heat Factor (SHF) .............................................................................................................. 2-6

2.9 Combinations of Outdoor Units and Indoor Units .............................................................................. 2-7

2.10 Damper Minimum Setting (Optional Function d7) ............................................................................. 2-7

2.11 Working Range .................................................................................................................................. 2-8

2.12 Fan Performance ............................................................................................................................... 2-10

2.13 Electrical Data ................................................................................................................................... 2-11

2.14 Sound Data ....................................................................................................................................... 2-12

2.15 Control System .................................................................................................................................. 2-13

2.15.1 Refrigerant System .................................................................................................................. 2-13

2.15.2 Standard Operation Sequence ................................................................................................ 2-14

2.15.3 Safety and Control Device Setting ........................................................................................... 2-17

2.15.4 Wiring Diagram ........................................................................................................................ 2-18

IMPORTANT NOTICE AND SAFETY SUMMARY ......................................................................................... i

1. Introduction ................................................................................................................................................ i

2. Important Safety Instructions ..................................................................................................................... i

Page 9

TC-16004-rev.2

vii

- CONTENTS -

3. Optional Parts ............................................................................................................................................ 3-1

3.1 Line Up .............................................................................................................................................. 3-1

3.2 Optional Air Filter: KW-PP456E ........................................................................................................ 3-2

3.2.1 Procedures .............................................................................................................................. 3-2

3.2.2 Service and Maintenance ........................................................................................................ 3-2

3.3 Infrared (IR) Receiver Kit: CWDIRK01 .............................................................................................. 3-3

3.3.1 Specications ........................................................................................................................... 3-3

3.3.2 Dimensions .............................................................................................................................. 3-3

3.3.3 Applicable Models .................................................................................................................... 3-3

3.3.4 Accessories / Options .............................................................................................................. 3-4

3.3.5 Installation ................................................................................................................................ 3-4

3.3.6 Electrical Wiring ....................................................................................................................... 3-7

3.3.7 Setting DIP Switches on Indoor Unit Side ............................................................................... 3-7

3.3.8 Setting DIP Switch on IR Receiver Kit Side ............................................................................. 3-8

3.3.9 Identifying Indoor Units Installed in a Side-by-Side Operation ................................................ 3-9

3.3.10 Simultaneous Operation .......................................................................................................... 3-10

3.3.11 Test Run by Wireless Controller (CIR01) ................................................................................. 3-12

3.3.12 Alarm Indication ....................................................................................................................... 3-12

3.4 3P Connector Cable: PCC-1A ........................................................................................................... 3-13

3.5 Remote Sensor: THM-R2A ................................................................................................................ 3-13

3.6 Relay and 3 Pin Connector Kit: PSC-5RA ......................................................................................... 3-14

4. Selection Data ............................................................................................................................................ 4-1

4.1 Selection Guide ................................................................................................................................. 4-1

4.2 Capacity Table ................................................................................................................................... 4-1

4.2.1 Cooling Capacity ...................................................................................................................... 4-1

4.2.2 Heating Capacity ..................................................................................................................... 4-2

Page 10

Page 11

FEATURES

TC-16004-rev.2

1-1

VRF Air Conditioners

Johnson Controls proudly introduces new Variable Refrigerant Flow (VRF) air conditioners, a highly-efcient

and reliable air-conditioning system. Recently, increased numbers of buildings are requiring "intelligent"

facilities that include communication networks, ofce automation, and a comfortable environment. In

particular, a comfortable environment is becoming more of a year-around requirement in ofce buildings.

The VRF multi-split system air conditioner meets these requirements. The proven combination of the scroll

compressor and inverter provides the best air conditioning for small and medium ofce buildings.

■ VRF System

Johnson Controls has developed the VRF system with its customers in mind.

This system, which is unique in the world, allows the interconnection of indoor units for all our VRF air

conditioners.

This system provides the consumer with greater exibility for installation, which means that the airconditioning systems will integrate better within complex facility structures.

1. General Information (Features)

● Wide Range Line-up

Indoor Unit Type

Capacity (MBH)

6 8 12 15 18 24 30 36 48

Ducted Medium Static (EconoFresh) (H,Y,C)IDM_B21E

: Available

Table 1.1 Indoor Unit Type List

■ Ducted Medium Static (EconoFresh) Type Models

(H,Y,C)IDM030B21E, (H,Y,C)IDM036B21E and (H,Y,C)IDM048B21E with EF-456NE

● Improvement of Energy-Saving

Air renewal has a downside of increased energy consumption. These models save energy while renewing

room air and reducing levels of CO

2

while also eliminating unpleasant smells, smoke and pollution.

(1) Supplies fresh new air into the room while keeping the correct indoor temperature, and also provides

natural cooling for increased energy saving (reducing energy consumption).

(2) Allows inow of fresh air into the room through the indoor unit, even when the thermostat is switched

off (Thermo-OFF*). Depending on the supply air and outlet air temperatures, this unit works like an

intelligent system, controlling the air ow by modifying the position of the damper.

NOTE:

Thermo-On: The outdoor unit and some indoor units are running.

Thermo-OFF: The outdoor unit and some indoor units stay on, but don’t run.

(3) Effectively increases the installation performance when the outdoor temperature is lower than the

room temperature (in cooling mode), allowing the inlet of fresh air and cooling to the set temperature

without activating the outdoor unit. For example, it can supply up to 100% of fresh air and is able to

provide “natural cooling” through a damper when the outdoor temperature is lower than the set indoor

temperature (in cooling mode), leading to signicant energy savings particularly in spring and autumn.

(4) EconoFresh can operate with CO

2

or enthalpy sensors to control the air quality in the room.

NOTE:

The enthalpy sensor and CO

2

gas sensor cannot be installed together.

The enthalpy sensor and CO2 gas sensor have no effect on the EconoFresh operation when the All

Fresh process is activated.

Page 12

FEATURES

1-2

TC-16004-rev.2

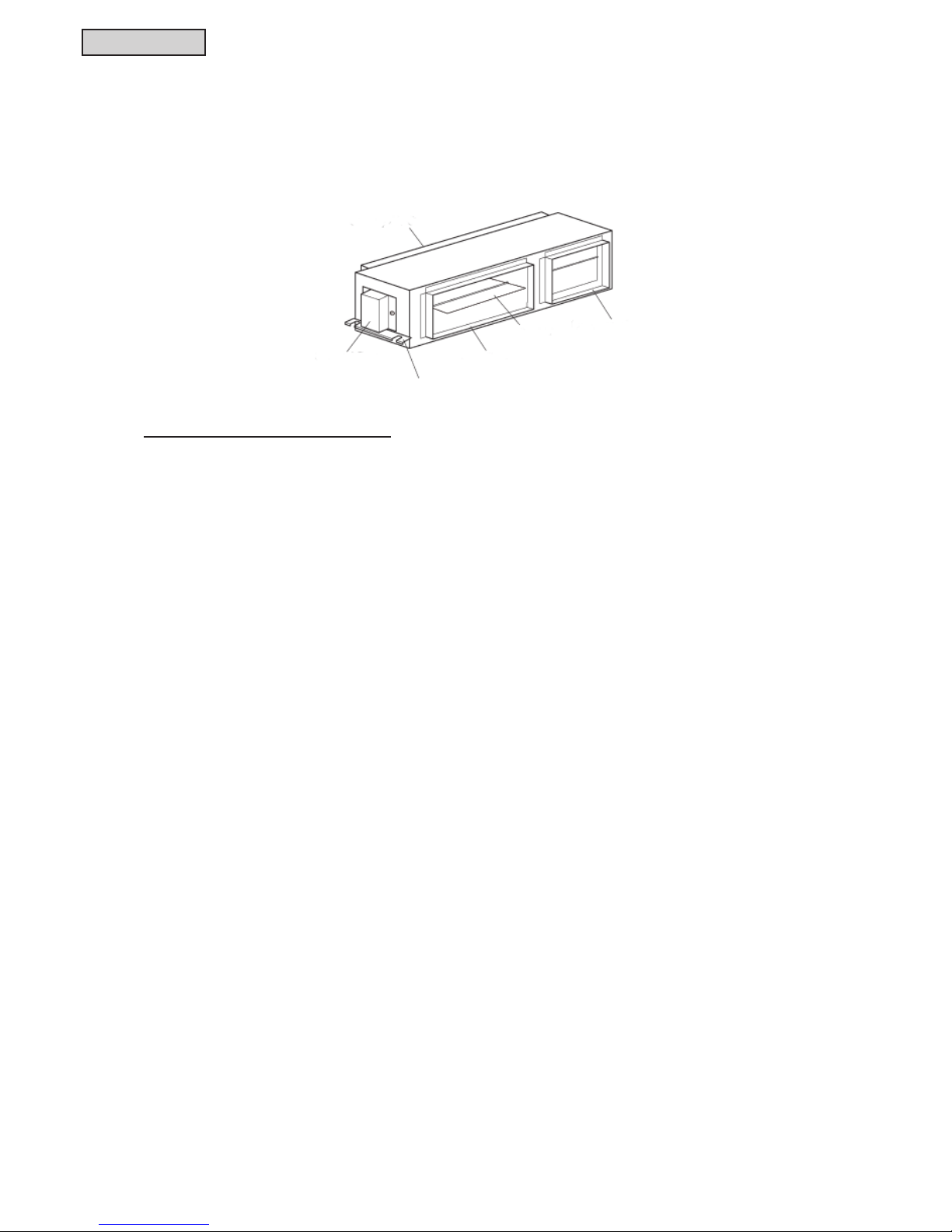

● Damper Control

The EconoFresh kit is equipped with an outdoor air damper control mechanism, and the system provides

various operation modes, such as free cooling, all fresh, in cooling and heating mode.

A micro-computer controls the angle of the damper according to air temperatures to adjust the fresh air

ow, thus keeping the room temperature constant with excellent comfort.

Selectable Minimum Damper Opening

The minimum opening for fresh outdoor air damper is selectable through the wired controller (d7 optional

function setting). This allows establishing a minimum air volume renewal in the room.

Control Box

Suspension Bracket

Return Air Inlet

Damper

Outdoor Air Inlet

Supply Air Outlet

Page 13

FEATURES

TC-16004-rev.2

1-3

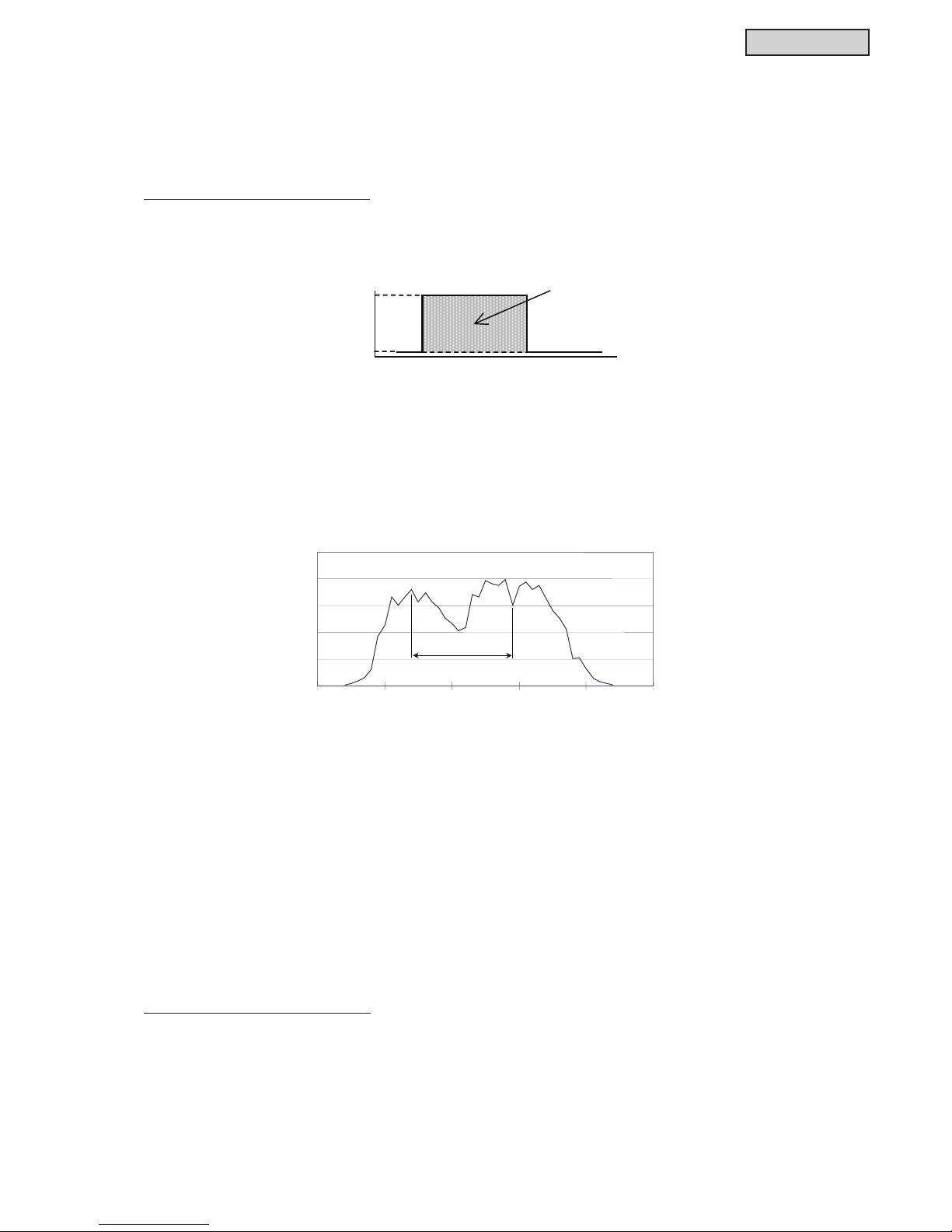

● Standard and All Fresh Process Modes

Two different process modes are selectable:

(1) Standard Process

Standard Process in Cooling Mode

In a situation where the outdoor ambient temperature is lower than 66

o

F (19oC), the compressor stops and

the indoor temperature is cooled down with an intake of outdoor fresh cold air controlled by the damper.

The minimum guaranteed fresh air intake can be set through the d7 setting (7% or more of the total outlet

air).

• Cooling Economizer

An energy saving control is adopted which uses fresh cold air from the outdoors for cooling the

intermediate seasons. The compressor is not used during this control, which results in outstanding

energy saving.

• Three Different Economizer Cooling Controls

In order to optimize energy savings, EconoFresh can manage three types of control: normal cooling,

outdoor air cooling or fan cooling. Each type is managed according to the outdoor air temperature.

• Comfort Control

When Thermo OFF is requested, EconoFresh compares temperatures in order to offer a comfortable

environment in the room. EconoFresh control compares the set temperature (set in the wired controller)

and the inlet air temperature in the Indoor Unit, and requests Thermo ON under certain conditions, in

order to achieve the requested room temperature as soon as possible.

Standard Process in Heating Mode

Depending on the temperature of indoor air return, the damper remains either opened for a minimum

guaranteed intake of fresh air, or fully closed for 10 minutes. After this time, the damper is opened for a

minimum guaranteed intake of fresh air intake; this opening can be set through the d7 setting (7% or more

of the total outlet air).

23

(-5)39(4)

66

(19)

109

(43)

o

F

(

o

C)

100%

7%

Outdoor Temperature

Fresh Air

Working Area

14

(-10)

32

(0)

50

(10)

68

(20)

86

(30)

104

(40)

0

50

100

150

200

250

(h/year)

Outdoor Temperature

Time

Example of Temperature Distribution (8:00-21:00)

Compressor not used for Cooling

o

F

(

o

C)

Page 14

FEATURES

1-4

TC-16004-rev.2

(2) All Fresh Process in Cooling and Heating Mode

This operation mode is very useful for buildings with many tenants, or for public buildings.

Basically, the damper is fully opened (100% fresh air) when activated through the wired controller (E1

optional function setting).

The following parameters are controlled by the All Fresh process in an independent fashion:

* Thermo ON/OFF status

* Damper opening

* Fan speed

Thermo ON/OFF Status

The general principle is that the compressor remains stopped when the outdoor ambient temperature is

lower than 63

o

F (17oC) in cooling mode and higher than 75oF (24oC) in heating mode.

Damper Opening

The damper is set to be either fully open or closed to the minimum opening to ensure an intake of fresh air

(7% or more of the total outlet air, by the d7 setting).

Additionally, the damper is closed to the minimum opening to ensure an intake of fresh air, under certain

temperature combinations.

Fan Speed

The fan speed is adjusted one tap lower when the air outlet temperature...

* rises higher than 68oF (20oC) in cooling mode

* drops lower than 86oF (30oC) in heating mode

In the above cases, the fan speed is changed from high to medium, or from medium to low.

The fan speed is adjusted back to fan setting tap when air outlet temperature returns to the following

ranges:

* 59

o

F (15oC) or lower in cooling mode

* 95oF (35oC) or higher in heating mode

Draft Prevention Control

Additionally, while the All Fresh process is activated, the EconoFresh control keeps monitoring and

comparing several temperature parameters. The damper may be closed to the minimum opening to

ensure the intake of fresh air under certain circumstances, and in order to avoid discomfort and unwanted

changes to room temperature due to inlet outdoor air conditions.

This function is active if the outdoor ambient temperature is

* 9

o

F (5oC) higher than the setting temperature in cooling thermo-OFF

* 9oF (5oC) lower than the setting temperature in heating thermo-OFF

100%

7%

39

(4)

o

F

(

o

C)

Outdoor Temperature

Fresh Ai

r

● Easy Installation

Equipped with AC drain pump to force condensates up to 33-7/16 inch (850mm) in height in relation to the

unit. The pump is automatically enabled when the accumulated water level is too high.

< 33-7/16 inch

(850mm)

Page 15

TC-16004-rev.2

2-1

DUCTED MEDIUM STATIC (ECONOFRESH)

2. Ducted Medium Static (EconoFresh) Type

2.1 Unit Nomenclature

Model Descriptions

Example

H I DM 030 B 2 1 E

Nomenclature Description

H = Hitachi Brand

Y = York Brand

C = Coleman Brand

H

Indoor Unit I

Indoor Unit Type

DM = Medium Static

DM

Capacity (MBH) 030

Refrigerant Type

B = R410A

B

Voltage

2 = 208/230Volts - 1Phase - 60Hz

2

1 = 1st Generation 1

E = Economizer Type E

2.2 Line-up

Type

Capacity

Model

RT MBH

Indoor Unit

Ducted Medium Static

(EconoFresh)

2.5 30 (H,Y,C)IDM030B21E

3.0 36 (H,Y,C)IDM036B21E

4.0 48 (H,Y,C)IDM048B21E

Page 16

2-2

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.3 General Data

NOTES:

*1. Nominal capacity is based on combinations within the VRF system and the following conditions:

Cooling Operation Conditions Heating Operation Conditions

Indoor Air Inlet Temperature: 80°F DB (26.7°C DB) Indoor Air Inlet Temperature: 70°F DB (21.1°C DB)

67°F WB (19.4°C WB) Outdoor Air Inlet Temperature: 47°F DB (8.3°C DB)

Outdoor Air Inlet Temperature: 95°F DB (35.0°C DB) 43°F WB (6.1°C WB)

Piping Length: 24 ft. 7-3/16 in. (7.5m)

Piping Lift: 0 ft. (0m)

*2. The sound pressure level is based on the following conditions.

4.9 ft. (1.5m) beneath the unit, connection with the EconoFresh Kit, EconoFresh Pressure Mode Setting, damper opening

is OA 50% and RA 50%, at rated airow volume and lter is not used.

The above data was measured in an anechoic chamber so that reected sound should be taken into consideration in the

eld.

*3. The data for external pressure is based on a connection with the EconoFresh Kit (with a damper setting of maximum

pressure drop (damper opening at OA 100%)), EconoFresh Pressure Mode Setting and the lter is not used.

Indoor Unit Type

Model (H,Y,C)IDM030B21E (H,Y,C)IDM036B21E (H,Y,C)IDM048B21E

Indoor Unit Power Supply

Nominal Cooling Capacity *1 Btu/h 48,000

(kW) (14.1)

Nominal Heating Capacity *1 Btu/h 54,000

(kW) (15.8)

dB

Outer Dimensions

Height in. (mm) 10-7/8 (275) 10-7/8 (275) 10-7/8 (275)

Width in. (mm) 58-1/16 (1474) 58-1/16 (1474) 58-1/16 (1474)

Depth in. (mm) 23-5/8 (600) 23-5/8 (600) 23-5/8 (600)

Net Weight lbs (kg) 106 (48) 106 (48) 106 (48)

Refrigerant

Indoor Fan

Air Flow Rate *3 cfm

(Hi-Me-Lo)

(m

3

/min)

External Pressure *3

in.W.G

(Hi-Me-Lo) (Pa)

Refrigerant Piping

Liquid Line in. (mm) 3/8 (9.52) 3/8 (9.52) 3/8 (9.52)

Gas Line in. (mm) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88)

Condensate Drain VP25

OD in. (mm) 1-1/4 (32) 1-1/4 (32) 1-1/4 (32)

ID in. (mm) 1 (25) 1 (25) 1 (25)

Adaptable EconoFresh Kit Model

Outer Dimensions

Height in. (mm)

Width in. (mm)

Depth in. (mm)

Net Weight lbs. (kg)

(35-31-28)

40-36-33

1271-1130-1024

(36-32-29)

0.15-0.11-0.09 0.13-0.11-0.09 0.11-0.10-0.08

1059-953-847

R410A

(30-27-24)

Ducted Medium Static (EconoFresh)

Sound Pressure Level *2

(Overall A Scale)

30,000 36,000

(8.8) (10.5)

34,000 40,000

(10.0) (11.7)

AC 1 Phase, 208/230V, 60Hz

38-35-32 39-35-33

1236-1094-988

EF-456NE

VP25 VP25

(37-27-22) (32-28-22) (27-25-20)

(12.5)

10

55-1/2

12-3/16

28

(254)

(1410)

(270)

Page 17

TC-16004-rev.2

2-3

DUCTED MEDIUM STATIC (ECONOFRESH)

2.4 Dimensional Data

Unit: inch (mm)

Models: (H,Y,C)IDM030B21E, (H,Y,C)IDM036B21E and (H,Y,C)IDM048B21E

with EconoFresh Kit EF-456NE

NOTE:

Connect the EconoFresh kit directly to the indoor unit.

Page 18

2-4

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.5 Structure

Models: (H,Y,C)IDM030B21E, (H,Y,C)IDM036B21E and (H,Y,C)IDM048B21E

with EconoFresh Kit EF-456NE,C

Unit: inch (mm)

Condensate Pan

Electronic Expansion Valve

Condensate Pump

Page 19

TC-16004-rev.2

2-5

DUCTED MEDIUM STATIC (ECONOFRESH)

2.6 Component Data

Indoor Heat Exchanger and Fan

TubMaterial

Outer Diameter φin. (mm) 1/4 (7.0) 1/4 (7.0) 1/4 (7.0)

Rows

Number of Tube/Coil

Fin Material

Pitch in. (mm) 0.071 (1.8) 0.071 (1.8) 0.063 (1.6)

psi (MPa) 601 (4.15) 601 (4.15) 601 (4.15)

ft

2

(

m

2

)

Number/Unit

Outer Diameter φin.

(mm)

Nominal Air Flow cfm

(Hi-Me-Lo)

(

m3/min

)

Starting Method

Nominal Output W

Quantity

Insulation Class

7-1/16

3.20

2

Copper Tube

Model (H,Y,C)IDM030B21E (H,Y,C)IDM036B21E (H,Y,C)IDM048B21E

Multi-Pass Cross Finned TubeHeat Exchanger Type

EEE

111

250 250 250

7-1/16

1059-953-847 1236-1094-988 1271-1130-1024

(180) (180)

(30-27-24) (35-31-28) (36-32-29)

Drip-Proof Type Enclosure

DC Motor

(180)

7-1/16

Aluminum

22

111

Multi-Blade Centrifugal Fan

3.20

Indoor Fan Motor

444

Indoor Fan

Number of Coil/Unit

Maximum Operating Pressure

Total Face Area 3.20

(0.30) (0.30) (0.30)

48 48 48

Page 20

2-6

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.7 Operation Space

2.8 Sensible Heat Factor (SHF)

Models: (H,Y,C)IDM030B21E, (H,Y,C)IDM036B21E and (H,Y,C)IDM048B21E

with EconoFresh Kit EF-456NE

Model SHF*

(H,Y,C)IDM030B21E 0.83

(H,Y,C)IDM036B21E 0.85

(H,Y,C)IDM048B21E 0.85

NOTE:

SHF is based on combinations within the VRF system and the following conditions:

Cooling Operation Conditions

Indoor Air Inlet Temperature: 80

o

F DB (26.7oC DB)

67oF WB (19.4oC WB)

Outdoor Air Inlet Temperature: 95oF DB (35.0oC DB)

Piping Length: 24 ft. 7-3/16 in. (7.5m)

Piping Lift: 0 ft. (0m)

Rear Side

≥ 15-3/4

(400)

≥ 39-3/8

(1000)

View from Top

Front Side

(5-1/8 (130))

≥ 23-5/8

(600)

≥ 23-5/8

(600)

Electrical Box

Unit: inch (mm)

Service Access Door

(≥ □17-11/16 (450))

If the ceiling board

cannot be found

for servicing,

prepare a service

access door

below the indoor

unit for removing

the indoor unit.

Page 21

TC-16004-rev.2

2-7

DUCTED MEDIUM STATIC (ECONOFRESH)

NOTES:

● If the Damper Minimum Setting (optional function d7) of this indoor unit is set to a higher step, then this

will affect the air outlet temperature of other standard indoor units.

● Airow volume must be at the lower limit for All Fresh operation.

● Make sure to enable the EconoFresh Pressure Mode (optional function C5) on the wired controller

before operation. Otherwise, this unit will not operate effectively.

EconoFresh Pressure Mode is “01”. (Optional function C5 on the wired controller is set to “00” by

default)

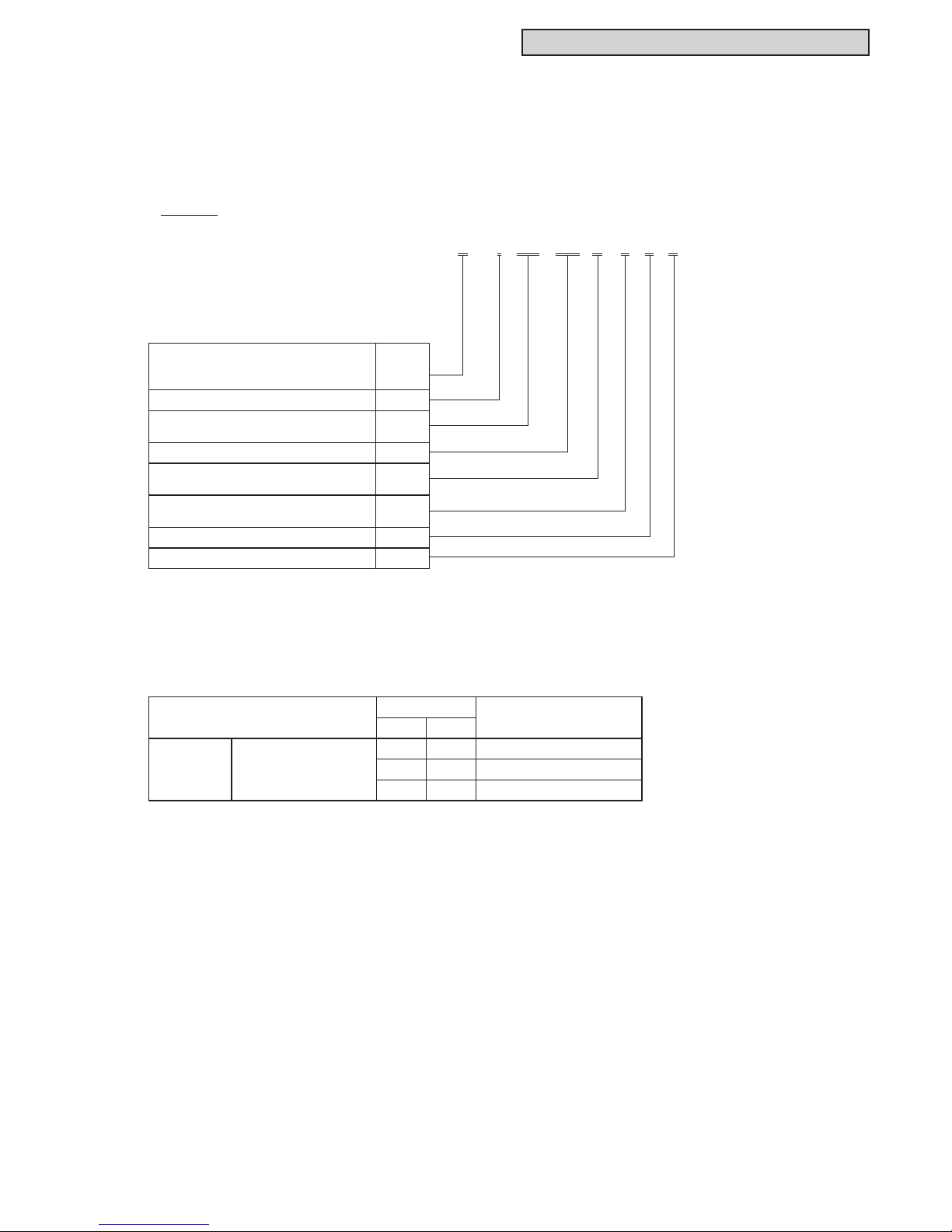

2.9 Combinations of Outdoor Units and Indoor Units

Indoor units can be connected with the outdoor unit (VRF system).

2.10 Damper Minimum Setting (Optional Function d7)

Relationship between damper minimum opening (optional function d7) and OA airow volume ratio should

be referred to below table.

However, OA airow volume ratio will change by duct installation.

For example if the OA intake duct is long then the ratio becomes small.

In case precise OA airow volume ratio is required then nd out from outdoor air temperature, indoor

temperature and air outlet temperature during fan mode.

NOTE:

When the opening is bigger, the outdoor air intake increases and this become additional load.

Outdoor Unit Type Combinations of Outdoor Units and Indoor Units

VRF Standard

VRF Less Module

Ducted (EconoFresh)

only

Total capacity of Ducted (EconoFresh) is

70%~100% of the outdoor unit capacity.

Ducted (EconoFresh)

+

Other Standard

Indoor Unit

Total capacity of Ducted (EconoFresh) is

30% or below the outdoor unit capacity.

AND

Total capacity of indoor unit (including Ducted (EconoFresh)) is

70%~100% of the outdoor unit capacity.

VRF Low Ambient

Ducted (EconoFresh)

only

Total capacity of Ducted (EconoFresh) is

55%~80% of the outdoor unit capacity.

Ducted (EconoFresh)

+

Other Standard

Indoor Unit

Total capacity of Ducted (EconoFresh) is

20% or below the outdoor unit capacity.

AND

Total capacity of indoor unit (including Ducted (EconoFresh)) is

55%~80% of the outdoor unit capacity.

Mini VRF

Ducted (EconoFresh)

only

Single Ducted (EconoFresh) only

AND

Total capacity of Ducted (EconoFresh) is

within 100% of the outdoor unit capacity.

Wired Controller Set Description

C5 01 EconoFresh Pressure Mode

C5 00 Not Available (Factory Setting)

C5 02 Not Available

Relationship between Optional Function d7 and OA Airow Volume Ratio

d7 Setting Conditions OA Airow Volume Ratio OA Damper Opening (Angle)

00 5% 6°

01 9% 12°

02 13% 18°

03 17% 24°

04 21% 30°

05 25% 36°

06 29% 42°

07 34% 48°

Page 22

2-8

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

< Heating Mode Operation Range >

23

(-5)

32

(0)

50

(10)

(*1) (*2)68

(20)

86

(30)

104

(40)

109

(43)

92

(33.5)95(35)

89 (32)

Air Inlet Wet Bulb Temperature

(Outdoor Temperature) (

o

F (

o

C) WB)

Air Inlet Dry Bulb Temperature

(Outdoor Temperature) (

o

F (oC) DB)

75

(24)

41

(5)

Normal Heating

Outdoor Air

Heating

Relative Humidity : 30%RH

Relative Humidity : 90%RH

NOTES:

1. Make sure to apply extra insulation on the unit and duct to prevent condensation when the outdoor temperature is low.

2. Make sure the air inlet wet bulb temperature (outdoor temperature) is below 59

o

F WB (15oC WB).

3. Outdoor air damper of this unit may remain opened at “Damper Minimum Opening” setting (optional function d7) or

prohibits OA intake for All Fresh mode below 41oF (5oC). (*1)

4. Unit may not operate when the outdoor temperature is high for All Fresh mode. (*2)

5. Compressor is stopped during outdoor air heating.

6. Air inlet dry bulb temperature (outdoor temperature) indicates the temperature detected by the unit's outdoor thermistor

.

2.11 Working Range

This heat pump air conditioner has been designed for the following temperatures. Operate the heat pump

air conditioner within this range.

< Cooling Mode Operation Range >

23

(-5)

32

(0)

50

(10)

(*1) (*2)68

(20)

86

(30)

104

(40)

109

(43)

92

(33.5)95(35)

89 (32)

64

(18)

Air Inlet Wet Bulb Temperature

(Outdoor Temperature) (

o

F (

o

C) WB)

Air Inlet Dry Bulb Temperature

(Outdoor Temperature) (

o

F (oC) DB)

41

(5)

Relative Humidity : 90%RH

Relative Humidity : 30%RH

Normal Cooling

Outdoor Air

Cooling

Normal Cooling

NOTES:

1. Make sure to apply extra insulation on the unit and duct to prevent condensation when the outdoor temperature is low.

2. Outdoor air damper of this unit may remain opened at “Damper Minimum Opening” setting (optional function d7) or

prohibits OA intake for All Fresh mode below 41

o

F (5oC). (*1)

3. Unit may not operate when the outdoor temperature is high for All Fresh mode. (*2)

4. Compressor is stopped during outdoor air cooling.

5. Air inlet dry bulb temperature (outdoor temperature) indicates the temperature detected by the unit's outdoor thermistor.

Page 23

TC-16004-rev.2

2-9

DUCTED MEDIUM STATIC (ECONOFRESH)

< Operation Sequence >

14

(-10)

32

(0)

50

(10)

64

(18)

23

(-5)

41

(5)

75

(24)

109

(43)

86

(30)

104

(40)

68

(20)

step1 (*)

ON OFFON

step15 (**)

ON OFFON

step1step controlstep1

ON/OFF

ON OFF

step1step15

ON

step1

step15

step1

Backup Compressor

Cooling

Mode

Compressor

All-Fresh

Compressor

Damper

Heating

Mode

All-Fresh

All-Fresh

All-Fresh

Standard

Economizer

Standard

Economizer

Standard

Economizer

Damper

Fan

Mode

Dry

Mode

Damper

Damper

Compressor

Compressor

ON

step1

Standard

Economizer

Damper

Compressor

Outdoor Temperature

o

F (ºC)

(*) Damper Step 1: Fresh Outdoor Air Damper Minimum Opened

(**) Damper Step 15: Fresh Outdoor Air Damper Fully Opened

Compressor operation and the angle (step) of the damper are controlled according to both room air

temperature and outdoor temperature to adjust the fresh air ow, thus keeping the room temperature

constant.

Page 24

2-10

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.12 Fan Performance

NOTE:

Field-supplied duct should be installed so that it does not exceed the upper limit of airow volume. When the

internal pressure drop of the duct is limited, the airow volume is higher.

This will cause abnormal stoppage, malfunction, and water splash.

Therefore, ensure that the internal pressure drop of the duct is equal to external static pressure by adjusting the

damper.

Above gure shows when the EconoFresh Pressure Mode is selected on the wired controller.

It is recommended to use at lower limit of airow volume during the All Fresh mode.

(H,Y,C) IDM030B21E

with EF-456NE

(H,Y,C) IDM036B21E

with EF-456NE

(H,Y,C) IDM048B21E

with EF-456NE

Page 25

TC-16004-rev.2

2-11

DUCTED MEDIUM STATIC (ECONOFRESH)

2.13 Electrical Data

VOL: Rated Unit Power Supply Voltage (V)

PH: Phase

HZ: Frequency (Hz)

MCA: Maximum Circuit Ampacity (A)

MFA: Maximum Fuse Ampacity (A)

OPT: Rated Motor Output (kW)

FLA: Full Load Ampacity (A)

Model

Unit Main Power Applicable Voltage Power Supply

Indoor

Fan Motor

Unit

VOL PH HZ Maximum Minimum MCA MFA OPT FLA

(H,Y,C)IDM030B21E

208/230 1 60 253 188

1.7 15 0.25 1.3

(H,Y,C)IDM036B21E 2.2 15 0.25 1.7

(H,Y,C)IDM048B21E 2.3 15 0.25 1.8

NOTE:

Power supply voltage should be satised with the following.

Supply Voltage: Rated Voltage within ±10%

Starting Voltage: Rated Voltage within -15%

Operating Voltage: Rated Voltage within ±10%

Page 26

2-12

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.14 Sound Data

NOTES:

1. The sound pressure level is based on the following:

Measurement Point: 4.9 ft. (1.5m) beneath the unit.

2. The above data was measured in an anechoic chamber so that reected sound should be taken into consideration in the eld.

3. Above gure shows when the EconoFresh Pressure Mode is selected on the wired controller, damper opening is OA 50% and

RA 50% and at rated airow volume.

(H,Y,C)

(H,Y,C)

Model: (H,Y,C) IDM048B21E

with EF-456NE

Model: (H,Y,C) IDM030B21E

with EF-456NE

Model: (H,Y,C) IDM036B21E

with EF-456NE

Page 27

TC-16004-rev.2

2-13

DUCTED MEDIUM STATIC (ECONOFRESH)

2.15 Control System

2.15.1 Refrigerant System

Mark Part Name

1

Heat Exchanger

2

Distributor

3

Strainer

4

Electronic Expansion Valve

Models: (H,Y,C)IDM030B21E, (H,Y,C)IDM036B21E and (H,Y,C)IDM048B21E

Unit: inch (mm)

Model Distributor

(A) Gas Pipe

Connection

(B) Liquid Pipe

Connection

(C) (OD×T) (D) (OD×T)

(H,Y,C)IDM030B21E 10 Pass

f

5/8

(15.88)

f

3/8

(9.52)

f

3/4×t0.047

(19.05×1.2)

f

1/2×t0.031

(12.7×0.8)

(H,Y,C)IDM036B21E 10 Pass

f

5/8

(15.88)

f

3/8

(9.52)

f

3/4×t0.047

(19.05×1.2)

f

1/2×t0.031

(12.7×0.8)

(H,Y,C)IDM048B21E 10 Pass

f

5/8

(15.88)

f

3/8

(9.52)

f

3/4×t0.047

(19.05×1.2)

f

1/2×t0.031

(12.7×0.8)

Design

Pressure

601 PSIG

(4.15 MPa)

Page 28

2-14

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.15.2 Standard Operation Sequence

I.U.: Indoor Unit

Auto Cooling/Heating

Operation

I.U. Air

Intake

Temp.

I.U. Air

Intake

Temp.

< Set Temp.

< Set Temp.

> Set

Temp.

> Set Temp.

> Set Temp.

> Set Temp. +1

o

F

(0.5oC)

> Set Temp. +3

o

F (2oC)< Set Temp. -3oF (2oC)

< Set Temp. -1oF

(0.5oC)

Heating

Mode

Cooling

Mode

I.U. Air

Intake

Temp.

Fan

Mode

Fan

Mode

I.U. Air

Intake

Temp.

I.U. Air

Intake

Temp.

< Set Temp.

NOTE:

I.U fan operates continuously when in Cooling, Heating and Fan Mode.

■ Cooling Operation

The sequence may be different depending on the outdoor unit model to be connected. Refer to the “Outdoor

Unit Engineering Manual” for details.

■ Dry Operation

The sequence may be different depending on the outdoor unit model to be connected. Refer to the “Outdoor

Unit Engineering Manual” for details.

■ Heating Operation

The sequence may be different depending on the outdoor unit model to be connected. Refer to the “Outdoor

Unit Engineering Manual” for details.

■ Automatic Cooling and Heating Operation

It is applicable only for the Heat Recovery System.

■ Defrosting Operation

The sequence may be different depending on the outdoor unit model to be connected. Refer to the “Outdoor

Unit Engineering Manual” for details.

Page 29

TC-16004-rev.2

2-15

DUCTED MEDIUM STATIC (ECONOFRESH)

Power Supply

No

Yes

No

No

Yes

Yes

Cooling Operation

Cooling Operation

> 32

o

F(0oC)

< 32oF(0oC)

> 58

o

F(14oC)

< 58oF(14oC)

Gas or Liquid Pipe

Surface Temp. of

Indoor Heat Exchanger

Is it continuous for

more than 3 min.?

Is it continuous

for more than 3 min.?

(6 min. in case of

Dry Operation)

Is compressor

operated for more than

15 min.?

*

* The check interval differs

depending on the conditions.

I.U. Electronic Expansion Valve:

Completely Closed

No

No

Yes

MIF Operation at Set Fan Speed

(In case of Dry Operation,

MIF Operation: OFF for 6 min.)

Gas or Liquid Pipe

Surface Temp. of

Indoor Heat Exchanger

Yes

Elapsed Time:

15 min.

Either of Pipe Surface

Temp.

*2)

> 36oF(2oC)

I.U.: Indoor Unit

a

a

*2): Pipe Surface Temp.

NOT adopted at .

MIF : Motor for Indoor Fan

■ Freeze Protection Control during Cooling or Dry Operation

Page 30

2-16

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

> 149oF(65oC)

< 149oF(65oC)

Thermo-ON/OFF Control for Indoor Unit

I.U.: Indoor Unit

Heating Operation

I.U. Air

Outlet

Temp.

Thermo-OFF

Yes

No

< 149

o

F(65oC)

> 149

o

F(65oC)

No

Yes

I.U. Air

Outlet

Temp.

Elapsed Time:

3 min.

Thermo-ON

Set Temp. is

lower than

Air Intake Temp.

■ Prevention Control for Excessively High Outlet Air Temperature

(High Outlet Air Temperature Heat Lockout)

NOTE:

Thermo-ON: The outdoor unit and some indoor units are running.

Thermo-OFF: The outdoor unit and some indoor units stay on, but don't run.

Page 31

TC-16004-rev.2

2-17

DUCTED MEDIUM STATIC (ECONOFRESH)

2.15.3 Safety and Control Device Setting

Model (H,Y,C)IDM030B21E, (H,Y,C)IDM036B21E, (H,Y,C)IDM048B21E

For Evaporator Fan Motor

Internal Thermostat Automatic Reset, Non-Adjustable

Cut-Out

o

F

(

o

C)

248+13

(120+7)

Cut-In

o

F

(

o

C)

230+13

(110+7)

For Control Circuit

Fuse Capacity A 5

Page 32

2-18

TC-16004-rev.2

DUCTED MEDIUM STATIC (ECONOFRESH)

2.15.4 Wiring Diagram

Ground

DIP

DIP

DIP

DIP

DIP

DIP

Electronic Expansion Valve

Page 33

TC-16004-rev.2

3-1

OPTIONAL PART

Item No. Optional Parts

Optional Parts

Model Name

3.2 Optional Air Filter KW-PP456E

3.3 Infrared (IR) Receiver Kit CWDIRK01

3.4 3P Connector Cable PCC-1A

3.5 Remote Sensor THM-R2A

3.6 Relay and 3 Pin Connector Kit PSC-5RA

3.7 Wired Controller CIW01

3.8 Simplied Wired Controller CIS01

3.9 Wireless Controller CIR01

3.10 Mini Central Controller CCM01

3.11 Large Central Controller CCL01

3.12 Computerized Central Controller Software / Adapter CCCS01 / CCCA01

Refer to the Engineering Manual of Control for details of item 3.7 to 3.12.

3. Optional Parts

3.1 Line Up

Page 34

3-2

TC-16004-rev.2

OPTIONAL PART

3.2 Optional Air Filter: KW-PP456E

KW-PP456E is only available to be used in combination with the indoor unit ducted medium static

(EconoFresh) type models.

3.2.1 Procedures

(1) Remove the support piece (three screws) from the indoor unit.

(2) Insert the Optional Air Filter and reattach the support piece.

NOTE:

1. During the installation or removal of the optional air lter if the insulation

material attached on the cabinet is removed, then reapply and repair the

insulation. Otherwise, condensation may occur when cold air enters.

2. It is recommended to follow below indications depending on the installation.

- Attach the Optional Air Filter in a situation where no Suction Duct has been applied. (Figure A)

- If applying a Suction Duct, it is recommended that the Air Filter is applied at the inlet point of the Suction

Duct. (Figure B)

Optional Air Filter

EconoFresh Kit

Indoor Unit

Optional Air Filter Support

Optional Air Filter

inserting direction

3.2.2 Service and Maintenance

Remove the Optional Air Filter from the ange. Vacuum dust. Use a cleaner or wash the air lter with

water or neutral detergent to clean the air lter. Dry the air lter away from direct light.

Dimensions:

Unit: inch (mm)

Name Illustration

Optional

Air Filter

50-11/16 (1288)

9-9/16

(243)

1/8 (3)

Optional Air Filter

(Field-Supplied)

Figure

A

Air Filter

(Field-Supplied)

Figure

B

Suction Duct

A

A

Page 35

TC-16004-rev.2

3-3

OPTIONAL PART

To Terminal Block (A, B)

in Electrical Control Box

of Indoor Unit

1-1/8 [28]

IR Receiver Part

4-3/4 [120]

3-9/16 [90]

Accessory Cable

(about 16.4ft [5m])

HEAT

COOL

TIMER

FILTER

DEF

RUN

EMERGENCY

3.3.2 Dimensions

3.3.3 Applicable Models

Model CWDIRK01

Applicable Indoor Unit Model

General-Purpose

(Ducted and Wall Mount Type)

Applicable Wireless Controller CIR01

3.3 Infrared (IR) Receiver Kit: CWDIRK01

This IR receiver kit is installed with the ducted and wall mount types to use with the wireless controller.

3.3.1 Specications

Model CWDIRK01

Outer Dimension

< W × H × D >

3-9/16 × 4-3/4 × 1-1/8 inch

(90 × 120 × 28 mm)

Unit: inch [mm]

Page 36

3-4

TC-16004-rev.2

OPTIONAL PART

3.3.4 Accessories / Options

No. Accessory Qty Remarks

1

IR Receiver Kit

CWDIRK01

1 With Connecting Cable

2

Cable Band 1 For Clamping Cable

3

Securing Screw 4 For Installing IR Receiver Kit

4

Securing Screw 2 For Fixing Cable Clamp

5

Cable Clamp 2 For Clamping Cable

3.3.5 Installation

● Turn OFF the power supply completely before setting the DIP switch, installation work, and electrical

wiring work for the IR receiver kit. If not, it may cause an electric shock.

● Perform securely the installation work referring to this manual. If the installation is not completed

correctly, the IR receiver kit may fall and cause injury.

● Do not install the IR receiver kit where ammable gases may generate or enter. It may cause heat

generation or a re.

● Correctly perform the electrical wiring work. If electrical work is not completed correctly, heat generation

at the connection, a re or an electric shock may occur.

● Make sure that the electrical wires are securely xed so that no external force affects the terminal

connections of the wiring. Not doing so may cause heat generation or a re.

● When the IR receiver kit is installed near ambient lighting, it may not receive a signal from the wireless

controller. Therefore, pay particular attention to the installation position of the IR receiver kit.

● Do not run the connecting cable for the IR receiver kit and the power supply cable (208/230V) in

parallel. It may cause a malfunction of the IR receiver kit.

● To ensure correct performance, read this manual together with the “Installation and Maintenance

Manual” for the indoor unit and the wireless controller. Forward this information to the building owner

and request that they maintain all the equipment manuals.

● CWDIRK01 is for a general-purpose IR receiver kit. It is applied for ducted, cassette, wall mount,

ceiling-suspended, and oor type indoor units.

Page 37

TC-16004-rev.2

3-5

OPTIONAL PART

3

Install the IR receiver kit using the length of

connecting cable (accessory).

The cable length is approximately 17 ft. (5m).

4

Open the cover of the IR receiver kit.

Push the slotted screwdriver with a tip width of

approximately 1/4 inch (6mm) into the slot of the

IR receiver kit cover and rotate it to open the

cover as shown in the gure at the right.

1

Perform the installation work for the IR receiver kit while the indoor unit is being installed.

2

Turn OFF the power supply for the indoor unit if the IR receiver kit is attached after the indoor unit is

installed.

5

Mount the IR receiver kit onto the wall or the ceiling surface as shown below.

Situation A

(1) Secure the bracket.

Situation B

(1) Prepare the eld-supplied switch box (JIS

Box). (JIS C8340)

Slot

IR Receiver Ki

t

Mounting Bracket

Rotate

Push and rotate.

Slotted Screwdriver

(Tip Width:

A

pprox. 1/4 inch (6mm))

Securing Screw

(Accessory)

Secure the bracket with four

accessory securing screws.

Any of the following Switch Boxes

can be utilized.

1. Switch Box for One Switch

(Without Cover)

2. Small Switch Box for One Switch

(Without Cover)

3. Switch Box for One Switch

(With Cover)

Metal Conduit

(larger than I.D. φ13/16 inch (φ20mm)

Two Securing Screws (M4, Field-Supplied)

Page 38

3-6

TC-16004-rev.2

OPTIONAL PART

(2) Run the connecting cable into the metal

conduit.

(3) Lead the connecting cable through the

knock-out hole.

(3) Secure the bracket.

(4) Attach the IR receiver kit.

Do not pinch the cable between the bracket and the IR receiver kit cover when attaching the IR

receiver kit. Attach the IR receiver kit cover following these directions.

(2) Select the connecting cable outlet direction

and cut out one of the knock-out holes on

the cover.

Cover

Connecting

Cable

Mounting Bracket

Cover

Hook the left side

of the cover to the

mounting bracket.

Push the right side

of the cover onto

the bracket.

Click sound is heard

when the cover is

completely hooked

onto the bracket.

Connecting

Cable

The connecting cable should

not be exposed. Lead it through

the metal conduit in the wall.

Connecting Cable

Securing Screw

(M4, Field-Supplied)

Mounting Bracket

Click sound is heard

when the cover is

completely hooked

onto the bracket.

Cover

Hook the left side of

the cover to the mounting

bracket. Push the right

side of the cover onto

the bracket.

Do not loosen the connecting

cable for the IR receiver kit.

Otherwise, it may become

pinched between the two

components causing a

malfunction of the indoor unit.

Select the connecting

cable outlet direction

and cut out of the

knock-out holes ( ).

Secure the tabs of the cover

into the slots on the left side

of the bracket.

Situation A Situation B

Page 39

TC-16004-rev.2

3-7

OPTIONAL PART

The terminal block (TB2) for the controller cable is located as shown in the gure below. Connect the

connecting cable for the IR receiver kit to terminals A and B at TB2. (There is no polarity between terminals

A and B.) The details for wiring methods can be found in the “Installation and Maintenance Manual” for the

indoor unit.

The following wiring method is an example for wall mount indoor units

NOTE:

After running the connecting cable, clamp the extra length of the connecting cable using the accessory cable

band and place it in the electrical box.

Instructions for setting DIP switches for other indoor units can be found in the Installation and Maintenance

Manual for indoor units. The following DIP switch setting is an example for wall mount indoor units.

1

The factory setting of SW2 before shipment is “Wireless”. When using an IR receiver kit (CWDIRK01), set

the SW2 to “Wired”. If not doing so, the operation is not available.

2

Turn OFF the power supply of the indoor and outdoor units completely before setting the DIP switch.

If not turning off the power, the setting becomes invalid.

3

The positions of the DIP switches are shown below.

Open the switch cover. After the DIP switch is set, re-attach the switch cover. The details for setting DIP

switches for an indoor unit can be found in the Installation and Maintenance Manual for indoor units.

TIWM006 - 012B21S TIWM015 - 030B21S

TIWM006 - 012B21S TIWM015 - 030B21S DIP Switch PCB (PCB2)

Insert the connecting

cable from the rear

side of indoor unit.

Switch Cover

PCB

2

Switch Cover

PCB2

DSW5

RSW2

RSW1

DSW6

DSW9 DSW2

SW1

SW2

DSW3

3.3.6 Electrical Wiring

3.3.7 Setting DIP Switches on Indoor Unit Side

A 12

Electrical Box

Cover

Terminal Block for

Power Supply (TB1)

Screw for

Ground Wiring Connection

Connecting Cable

for IR Receiver Kit

Fix the wires with

cable clamp.

Terminal Block for

Controller Cable (TB2)

Terminal Block for Power Supply (TB1)

Screw for

Ground Wiring Connection

Connecting Cable

for IR Receiver Kit

Terminal Block for

Controller Cable (TB2)

AB1

Page 40

3-8

TC-16004-rev.2

OPTIONAL PART

Review the following optional function settings when a function for the IR receiver kit is selected from the

wireless controller or the centralized controller.

● The optional functions “Cooling Lower Limit for Setting Temperature” and “Heating Upper Limit for Setting

Temperature” are not available with the wireless controller.

● The optional function setting “Fixing of Setting Temperature” is not available. When the operation mode is

changed from the wireless controller, the indicated temperature on the wireless controller becomes the set

temperature of the wired controller.

3

The DIP switch (DSW1) is for the optional function selection. If the optional function selection is required,

set the DIP switch as follows.

1

The following switches are on the IR receiver kit.

NOTE:

When the case is closed, pay particular attention to the outlet position for connecting cable.

Turn OFF the power supply completely before setting the DIP switch for an IR receiver kit.

Not doing so may cause an electric shock.

3.3.8 Setting DIP Switch on IR Receiver Kit Side

3412 56

ON

RUN

DEF

FILTER

TIMER

COOL

HEAT

EMERGENCY

“COOL” Button

“HEAT” Button

CoverPCB

Outlet for

Connecting Cable

Case Mounting Bracket

DIP Switch (DSW1)

(Factory Setting)

(1) Remove the mounting

bracket.

(2) Remove two securing

screws to open the case.

2

Emergency Operation Setting

“COOL” and “HEAT” switches are used for emergency operation when the batteries for the wireless

controller are low.

(1) Switch “COOL”: Press “COOL” so that the cooling operation is started.

Press “COOL” again so that the cooling operation is stopped.

(2) Switch “HEAT”: Press “HEAT” so that the heating operation is started.

Press “HEAT” again so that the heating operation is stopped.

NOTE:

During an emergency operation, a yellow light “

” ashes (0.5 second ON/0.5 second OFF).

The temperature setpoint and the fan speed for the cooling/heating operation are the same as before

starting an emergency operation.

Optional Function

DIP Switch Setting (DSW1)

Details

1 2 3 4 5 6

Main/Sub Setting O X X X X X

Change main (OFF setting)/ sub (ON setting) wireless

controller for a two-wireless controller system.

Identifying of

Indoor Unit

X O X X X X

It functions as B Mode (identication of indoor unit) of

the wireless controller when it is “ON”.

Invalidity of

Emergency Operation

X X X O X X The switches for emergency operation are invalid.

O: ON

X: OFF

Page 41

TC-16004-rev.2

3-9

OPTIONAL PART

Turn OFF the power supply completely before setting the DIP switch for the IR receiver kit.

Not doing so can cause an electric shock.

When two indoor units are installed side by side,

the commands from the wireless controller may

be received by both indoor units. The function,

“Identifying of Indoor Units Installed Side by Side”

enables operation of the individual unit correctly

without interfering with the other unit’s operation.

As shown in the gure at the right, the IR receiver

kit of A and B are set side by side. In this instance,

unit B is set as “Identifying Indoor Units Installed

Side by Side”.

Setting of Identifying of Indoor Units Installed Side by Side

1

IR Receiver Kit Setting

Set the Number 2 pin of the IR receiver kit DIP switch (DSW1) at the “Identied” Unit B “ON” side.

2

Wireless Controller

Set the wireless controller according to the Installation and Maintenance Manual for the Wireless

Controller.

Cancellation of Identifying of Indoor Units Installed Side by Side

1

IR Receiver Kit Setting

Set the Number 2 pin of the IR receiver kit DIP switch (DSW1) “OFF” side for cancellation.

2

Wireless Controller

Cancel the wireless controller setting according to the Installation and Maintenance Manual for the

Wireless Controller.

NOTE:

This function setting is required at the receiver side.

It should be set according to the Installation Manual

for indoor units. Contact your distributor for details.

Indoor Unit

A

Indoor Unit

B

"Identified"

IR Receiver Ki

t

"Identified"

Wireless Controller

IR Receiver

Kit A

IR Receiver

Kit B

3.3.9 Identifying Indoor Units Installed in a Side-by-Side Operation

Page 42

3-10

TC-16004-rev.2

OPTIONAL PART

3.3.10 Simultaneous Operation

● Turn OFF the power supply completely before setting the DIP switch and electrical wiring work for the

IR receiver kit. Not doing so can cause an electric shock.

● Accurately perform the electrical wiring work. If the electrical work is not completed correctly, heat

generation at the connection, a re, or an electric shock may occur.

● Make sure that the electrical wires are adequately clamped with a cable clamp and not in a manner that

applies too much external force to the terminal connections of the wirings. If done correctly, the result

could cause heat generation or a re.

● Do not run the connecting cable for IR receiver kit and the power supply cable (208/230V) in parallel.

It may cause a malfunction of the IR receiver kit.

(Example of 4-way cassette type indoor units.)

Up to 16 indoor units can be simultaneously

controlled using one wireless controller.

When multiple indoor units are installed in a large

room, all the indoor units can be controlled to start/

stop with only one wireless controller.

NOTE:

Do not apply a simultaneous operation for the indoor

units installed separately in different rooms.

Some units may be left without turning OFF the

power supply.

Installation of IR Receiver Kit

In an instance of simultaneous operation of multiple (up to 16 ) indoor units by the wireless controller, install

the IR receiver kit only to the unit to be operated. Other units should be the standard units without the IR

receiver kit. If multiple IR receiver kits are required to be installed, two IR receiver kits are the maximum.

Wireless Controller

Indoor Unit

with IR Receiver Kit

Standard

Indoor Unit

Standard Indoor Unit or

Indoor Unit with IR Receiver Kit

Standard

Indoor Unit

Should be Standard Indoor Units

Available to Install IR Receiver Ki

t

Indoor Unit

(Address setting

is required.)

Wireless Controller

Control Cable

between

Indoor Units

Control Example of Simultaneous

Operation of Multiple Units