Johnson Controls HIC2018B21S, CIC2024B21S, CIC2018B21S, YIC2018B21S, HIC2024B21S Operation Manual

...Page 1

Operation

Manual

INVERTER-DRIVEN

MULTI-SPLIT SYSTEM

HEAT PUMP

AIR CONDITIONERS

Type Model

2-Way Cassette

(H,Y,C)IC2018B21S

(H,Y,C)IC2024B21S

IMPORTANT:

READ AND UNDERSTAND

THIS MANUAL BEFORE

USING THIS HEAT PUMP

AIR CONDITIONER.

KEEP THIS MANUAL FOR

FUTURE REFERENCE.

P5417051

Page 2

Page 3

Important Notice

● Johnson Controls, Inc. pursues a policy of continuing improvement in design and performance in its

products. As such, Johnson Controls reserves the right to make changes at any time without prior

notice.

● Johnson Controls cannot anticipate every possible circumstance that might involve a potential hazard.

● This heat pump air conditioning unit is designed for standard air conditioning applications only. Do not

use this unit for anything other than the purposes for which it was intended.

● The installer and system specialist shall safeguard against leakage in accordance with local codes. The

following standards may be applicable, if local regulations are not available. International Organization

for Standardization: (ISO 5149 or European Standard, EN 378). No part of this manual may be

reproduced in any way without the expressed written consent of Johnson Controls.

● This heat pump air conditioning unit is operated and serviced in the United States of America and

comes with a full complement of the appropriate Safety, Dangers, Cautions, and Warnings.

● If you have questions, please contact your distributor or contractor.

● This manual provides common descriptions, basic and advanced information to maintain and service

this heat pump air conditioning unit which you operate, as well for other models.

● This heat pump air conditioning unit has been designed for a specic temperature range. For optimum

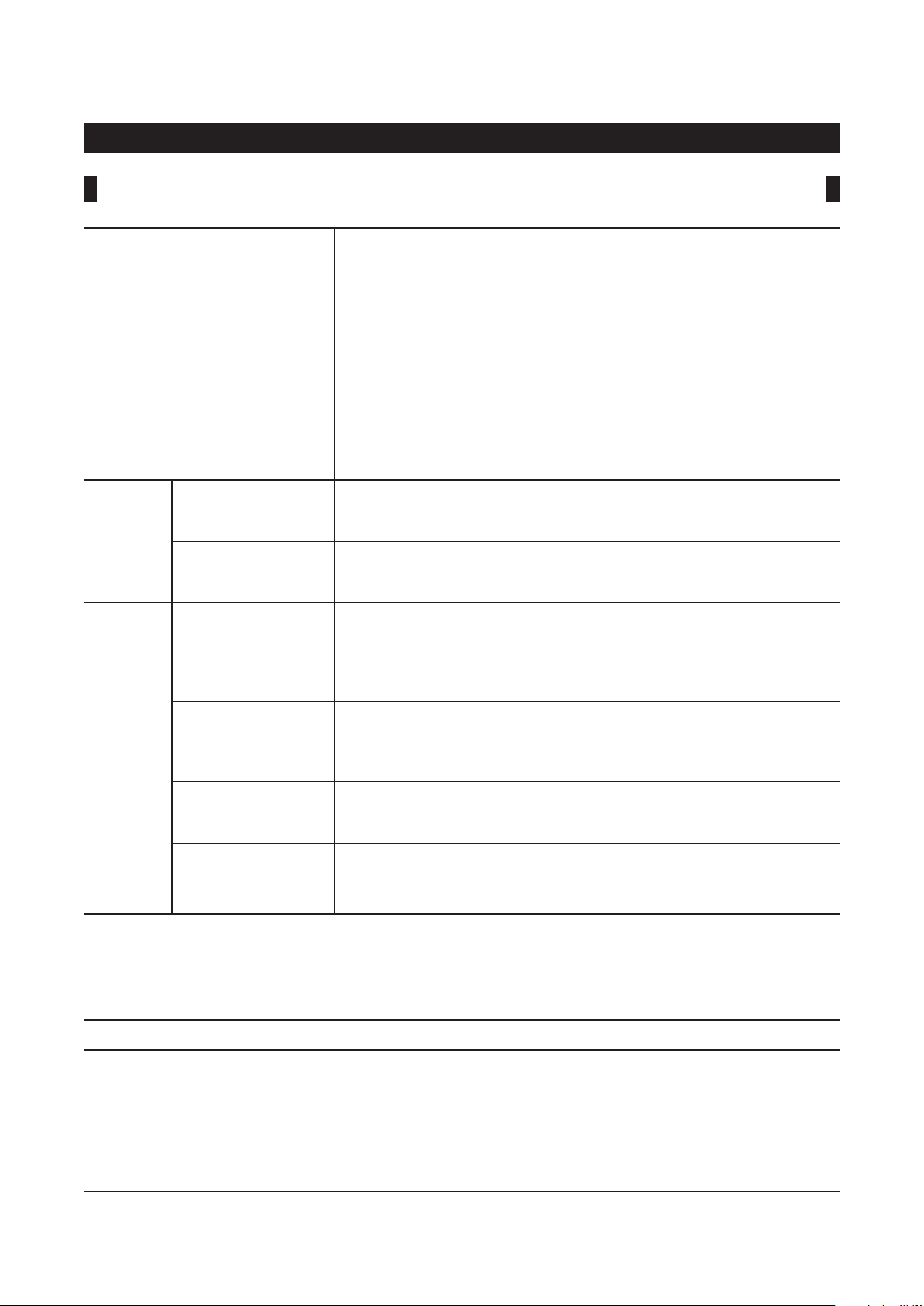

performance and long life, operate this unit within the range limits according to the table below.

Temperature

Maximum Minimum

Cooling

Operation

Heating

Operation

Indoor 89

Outdoor 118

Indoor 80

Outdoor 59

DB: Dry Bulb, WB: Wet Bulb

* The temperature may change depending on the outdoor unit.

o

F DB/73oF WB (32oC DB/23oC WB) 69oF DB/59oF WB (21oC DB/15oC WB)

o

F DB (48oC DB) * 14oF DB (-10oC DB) *

o

F DB (27oC DB) 59oF DB ( 15oC DB)

o

F WB (15oC WB) * -4oF WB (-20oC WB) *

● This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

P5417051-rev.1

i

Page 4

TABLE OF CONTENTS

1. Introduction .....................................................................................................................................................1

2. Safety Instructions ..........................................................................................................................................1

3. Before Operation .............................................................................................................................................6

3.1 Operating Range ....................................................................................................................................6

3.2 Efcient Use of Indoor Unit .....................................................................................................................6

3.3 Efcient Use of Cooling and Heating ......................................................................................................7

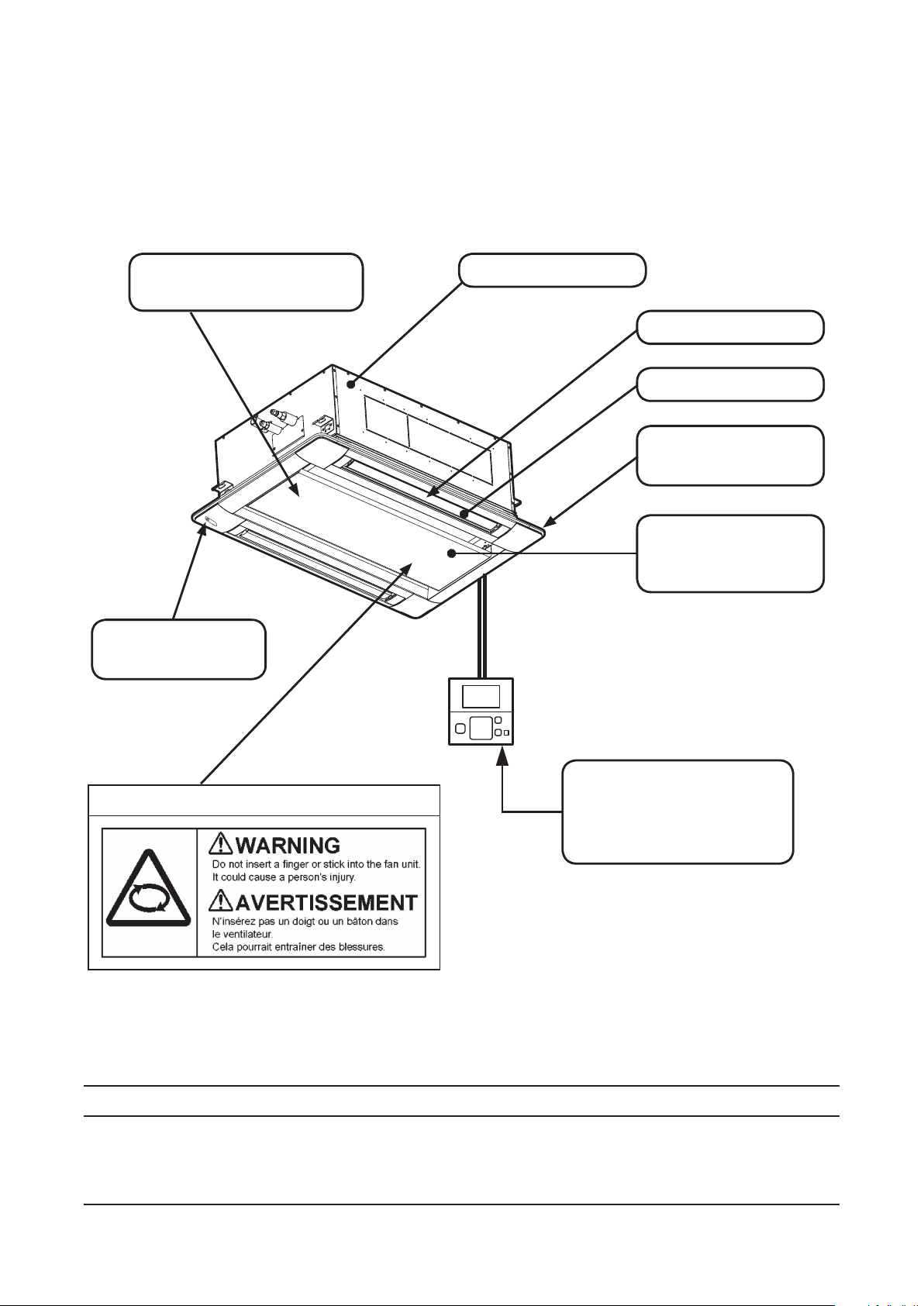

4. Names of Parts and Indications for Safety Consideration ..............................................................................8

4.1 Indoor Unit ..............................................................................................................................................8

4.2 Wired Controller (CIW01) .......................................................................................................................9

5. Operation Method .........................................................................................................................................10

5.1 Basic Operation ....................................................................................................................................10

5.2 Cooling / Heating / Fan Operation ........................................................................................................ 11

5.3 Temperature Setting .............................................................................................................................12

5.4 Fan Speed ............................................................................................................................................13

5.5 Operation ..............................................................................................................................................13

5.6 Louver Swing Direction ........................................................................................................................14

5.7 Individual Louver Setting ......................................................................................................................15

5.7.1 Individual Louver Settings ........................................................................................................... 15

5.7.2 Cancellation of Louver Setting .................................................................................................... 17

5.8 Motion Sensor ......................................................................................................................................18

5.8.1 Function ...................................................................................................................................... 18

5.8.2 Details for Motion Sensor Control ............................................................................................... 19

5.8.3 Descriptions for Setting Functions .............................................................................................. 19

5.8.4 Setting the Motion Sensor .......................................................................................................... 20

5.9 Automatic Heating/Cooling Operation ..................................................................................................22

5.10 Setback Operation ................................................................................................................................22

6. Automatic Control .........................................................................................................................................23

7. Maintenance .................................................................................................................................................24

7.1 Maintenance .........................................................................................................................................24

7.1.1 Cleaning Air Filter .......................................................................................................................24

7.1.2 Removing, Cleaning and Attaching Air Inlet Flat Grille ...............................................................26

7.2 Maintenance Before and After Use ......................................................................................................26

8. Troubleshooting ............................................................................................................................................27

8.1 These are Not Abnormal ......................................................................................................................27

8.2 Before Contact .....................................................................................................................................28

8.3 Contact Distributor ................................................................................................................................29

8.4 Alarm Codes .........................................................................................................................................30

ii

P5417051-rev.1

Page 5

1. Introduction

Read this manual carefully before working with this product.

Keep this information with the product.

Forward this manual and the warranty to the next team of installers and then users.

Ask them to keep this manual with the air conditioning unit.

(Refrigerant Piping Work) (Electrical Wiring Work) (Ref. Charge Work) (Test Run) (User)

● For details on wiring between the indoor unit and the outdoor unit, refer to the installation and maintenance

manual for the outdoor unit.

● For details on the optional decorative panel, refer to the installation and maintenance manual for the

optional decorative panel.

● For details on the optional controller, refer to the installation and maintenance manual for that optional

controller module.

● For details on each optional part, refer to the installation and maintenance manual for each optional part.

● For central controller, refer to the installation and maintenance manual for the central controller.

2. Safety Instructions

Signal Words

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury.

Indicates information considered important, but not hazard-related (for example,

messages relating to property damage).

General Precautions

To reduce the risk of serious injury or death, read these instructions thoroughly

and follow all warnings or cautions included in all manuals that accompanied the

product and are attached to the unit. Refer back to these safety instructions as

needed.

● This system, including the controller, should be installed by personnel certied by Johnson Controls, Inc.

Personnel must be qualied according to local, state and national building and safety codes and regulations.

Incorrect installation could cause leaks, electric shock, re or an explosion. In areas where Seismic

Performance requirements are specied, the appropriate measures should be taken during installation

to guard against possible damage or injury that might occur in an earthquake. If the unit is not installed

correctly, injuries may occur because of a falling unit.

P5417051-rev.1

1

Page 6

● Use appropriate personal protective equipment (PPE), such as gloves, protective goggles and electrical

protection equipment and tools suited for electrical operation purposes.

● When transporting, be careful when picking up, moving and mounting these units. Although the controller

may be packed using plastic straps, do not use them for transporting from one location to another. Do not

stand on or put any material on the controller.

● When installing the controller cabling to the units, do not touch or adjust any safety devices inside

the indoor or outdoor units. All safety features, disengagement, and interlocks must be in place and

functioning correctly before the equipment is put into operation. If these devices are improperly adjusted

or tampered with in any way, a serious accident can occur. Never bypass or jump-out any safety device

or switch.

● Use only Johnson Controls recommended, provided as standardized, or replacement parts.

● Johnson Controls will not assume any liability for injuries or damage caused by not following steps outlined

or described in this manual. Unauthorized modications to Johnson Controls products are prohibited as

they…

◦ May create hazards that could result in death, serious injury or equipment damage.

◦ Will void product warranties.

◦ May invalidate product regulatory certications.

◦ May violate OSHA standards.

Take the following precautions to reduce the risk of property damage.

● Do not touch the main circuit board or electronic components in the controller or remote devices. Make

sure that dust and/or steam does not accumulate on the circuit board.

● When installing the unit in a hospital or other facility where electromagnetic waves are generated from

nearby medical and/or electronic devices, be prepared for Electromagnetic Interference (EMI). Do not

install where the waves can directly radiate into the electrical box, controller cable, or controller. Inverters,

appliances, high-frequency medical equipment, and radio communications equipment may cause the unit

to malfunction. The operation of the unit may also adversely affect these same devices. Install the unit at

least 10 ft. (approximately 3m) away from such devices.

● Locate the wireless controller at a distance of at least 3 ft. (approximately 1m) between the indoor unit and

electric lighting. Otherwise, the receiver part of the unit may have difculty receiving operation commands.

● If the wired controller is installed in a location where electromagnetic radiation is generated, make sure

that the wired controller is shielded and cables are sleeved inside conduit tubing.

● If there is a source of electrical interference near the power source, install noise suppression equipment

(lter).

● During the test run, check the unit’s operation temperature. If the unit is used in an environment where

the temperature exceeds the operation boundary, it may cause severe damage. Check the operational

temperature boundary in the manual. If there is no specied temperature, use the unit within the operational

temperature boundary of 32 to 104°F (0 to 40°C).

● Read installation and appropriate user manuals for connection with PC or peripheral devices. If a warning

window appears on the PC, the product stops, does not work properly or works intermittently, immediately

stop using the equipment.

Installation Precautions

To reduce the risk of serious injury or death, the following installation precautions

● If the remote sensors are not used with this controller, then do not install this controller

- in a room where there is no thermostat.

- where the unit is exposed to direct sunshine or direct light.

- where the unit will be in close proximity to a heat source.

- where hot/cold air from the outdoors, or a draft from elsewhere (such as air vents, diffusers or

grilles) can affect air circulation.

- in areas with poor air circulation and ventilation.

2

must be followed.

P5417051-rev.1

Page 7

● Perform a test run using the controller to ensure normal operation. Safety guards, shields, barriers,

covers, and protective devices must be in place while the compressor/unit is operating. During the test

run, keep ngers and clothing away from any moving parts.

After installation work for the system is completed, explain the “Safety Precautions,” use, and maintenance

of the unit to the customer according to the information in all manuals that accompanied the system. All

manuals and warranty information must be given to the user or left near the Indoor Unit.

Electrical Precautions

Take the following precautions to reduce the risk of electric shock, re or explosion

● Only use electrical protection equipment and tools suited for this installation.

● Insulate the wired controller against moisture and temperature extremes.

● Use specied cables between units and the controller.

● Communication cabling shall be a minimum of AWG18 (0.82mm2), 2-Conductor, Stranded Copper.

Shielded cable must be considered for applications and routing in areas of high EMI and other sources

of potentially excessive electrical noise to reduce the potential for communication errors. When shielded

cabling is applied, proper bonding and termination of the cable shield is required as per Johnson Controls

guidelines. Plenum and riser ratings for communication cables must be considered per application and

local code requirements.

● This equipment can be installed with a Ground Fault Circuit Breaker (GFCI), which is a recognized measure

for added protection to a properly grounded unit. Install appropriate sized breakers/fuses/overcurrent

protection switches, and wiring in accordance with local, state and NEC codes and requirements. The

equipment installer is responsible for understanding and abiding by applicable codes and requirements.

● The polarity of the input terminals is important, so be sure to match the polarity when using contacts that

have polarity.

● Highly dangerous electrical voltages may be used in this system. Carefully refer to the wiring diagram

and these instructions when wiring. Improper connections and inadequate grounding can cause serious

injury or death.

● Before installing the controller or remote devices, ensure that the indoor and outdoor unit operation has

been stopped. Further, be sure to wait at least ve minutes before turning off the main power switch to

the indoor or outdoor units. Otherwise, water leakage or electrical breakdown may result.

● Do not open the service cover or access panel to the indoor or outdoor units without turning OFF the

main power supply. Before connecting or servicing the controller or cables to indoor or outdoor units,

open and tag all disconnect switches. Never assume electrical power is disconnected. Check with a

meter and equipment.

● Use an exclusive power supply at the controller’s rated voltage.

● Be sure to install circuit breakers (ground fault circuit interrupter, isolating switch, molded case circuit

breaker, and so forth) with the specied capacity. Ensure that the wiring terminals are tightened securely

to recommended torque specications.

● Clamp electrical wires securely with a cable band after all wiring is connected to the terminal block. In

addition, run wires securely through the wiring access channel.

● When installing the power lines, do not apply tension to the cables. Secure the suspended cables at

regular intervals, but not too tightly.

● Make sure that the terminals do not come into contact with the surface of the electrical box. If the

terminals are too close to the surface, it may lead to failures at the terminal connection.

● Do not clean with, or pour water into, the controller as it could cause electric shock and/or damage the

unit. Do not use strong detergent such as a solvent. Clean with a soft cloth.

● Check that the ground wire is securely connected. Do not connect ground wiring to gas piping, water

piping, lighting conductor, or telephone ground wiring.

resulting in serious injury or death:.

P5417051-rev.1

3

Page 8

Operation

NOTICE

● Do not insert ngers or objects into an air inlet/outlet. Injury can result from rotating fan blades or

energized electrical components.

● Do not touch the wired controller with wet hands. It can result in a malfunction of the wired controller or

an electrical shock.

● Hair spray, insecticides, lacquers, and other pressurized substances should not be used within 3.3ft (1m)

of any air conditioning unit. It can react with energized electrical components and cause re.

● Do not install the indoor unit anywhere discharge airow can pass directly toward nearby heating

equipment (space heaters). It may interfere with the combustion process in these units.

● When the indoor unit is operating in an area with heat sources, ventilate a room sufciently. Any leaked

refrigerant gases that happen to come into contact with any heat source can become toxic on contact

which can cause asphyxiation in the immediate area.

● Shut down at the main power source if the GFCI (Ground Fault Circuit Interrupter) activates frequently.

Contact your distributor or contractor immediately. Failure to act accordingly can result in serious injury

and damage to the unit.

● If you smell anything burning, shut down the unit and turn OFF the power at the main power source.

Contact the re department and your installer or electrical contractor.

● Make sure that a test for leakage of refrigerant gases has been performed. The refrigerant used for this

unit (HFC R410A), is a non-ammable, non-toxic, and odorless gas. However if refrigerant should leak

and make contact with sparks, re and toxic gas will be generated. Also, because uorocarbon is heavier

than air, it will accumulate on the oor causing asphyxiation.

● If uorocarbon gas should leak, turn OFF all heating equipment and ventilate the room immediately. Mop

or vacuum oor areas to remove residual toxic particulate.

● Do not operate indoor units with the electrical box and switch panel open and exposed. Accidental contact

with energized components can be fatal.

● Air circulation should be optimized to achieve the best distribution pattern and not settle into isolated

pockets creating an uncomfortable environment.

4

P5417051-rev.1

Page 9

Repair / Relocation

NOTICE

● When the air conditioner is to be repaired or transported to a new location, contact your distributor or

contractor. If the repair and the installation are not completed correctly, it may cause an electric shock or

re.

Other

● Turn OFF all power at the main power source before performing maintenance work. Failure to do so can

result in damage to internal components with severe or fatal electrical shock.

● Insulate all electrical components and connections from exposure to moisture. Failure to do so can result

in an electrical short circuit and re.

● Do not tamper with or attempt to "repair" electrical wiring or connections. Call your installer or electrical

contractor. Serious or fatal injury can occur.

● Perform all maintenance work on a rm and stable foundation to minimize the risk of injury.

● Do not attempt to "clean" indoor unit components with liquid or powdered cleaning agents during

maintenance. Electric shock, sparks, ame, and serious or fatal injury can occur.

● System piping is charged with refrigerant and highly pressurized.

● Hold the air lter and the air inlet at grille rmly when attaching or removing it. Carelessness can result in

accident or injury.

● When cleaning the lens surface of the motion sensor, do not make unnecessary contact as it can be easily

scratched.

P5417051-rev.1

5

Page 10

3. Before Operation

NOTICE

Apply power to the outdoor unit(s) at least 12 hours prior to system operation to allow for preheating

of the compressor oil. Do not start the system immediately without preheating the compressor.

Otherwise, the compressor can be damaged. Check that the outdoor unit is free of ice and snow

cover. If snow covered, remove with hot water at 122°F (50°C). If hot water temperature is higher

than 122oF (50oC), it can cause damage to plastic parts.

● When the system is restarted after a shutdown longer than approximately three months, it is recommended

that the system be checked over by your service contractor.

● Turn OFF at the main switch when the system has been off for a long period of time.

If the main switch is not turned OFF, electricity is consumed because the oil heater is always energized

during periods of compressor stoppage.

3.1 Operating Range

This heat pump air conditioner has been designed for the following temperatures. Operate the heat pump air

conditioner within this range.

Temperature

Maximum Minimum

Cooling

Operation

Heating

Operation

DB: Dry Bulb, WB: Wet Bulb

* The temperature may change depending on the outdoor unit.

Indoor 89

Outdoor 118

Indoor 80

Outdoor 59

o

F DB/73oF WB (32oC DB/23oC WB) 69oF DB/59oF WB (21oC DB/15oC WB)

o

F DB (48oC DB) * 14oF DB (-10oC DB) *

o

F DB (27oC DB) 59oF DB ( 15oC DB)

o

F WB (15oC WB) * -4oF WB (-20oC WB) *

3.2 Efcient Use of Indoor Unit

● Do not leave windows or doors open.

Operating efciency will be degraded.

Condensation and problems relating to it can result. (Also ventilate a room sufciently.)

● Attach a curtain or a blind to a window.

Direct sunlight is blocked so the cooling efciency is enhanced.

● Avoid using heating equipment during the cooling operation as much as possible.

Cooling efciency will be decreased. It may cause condensation and dripping.

● Use the built-in circulating fan if warm air tends to remain around the ceiling.

Comfort will be increased. Contact your distributor for details.

● Redirect airow downward if ceiling surface areas become discolored due to airborne particulate.

It is recommended that airow be redirected 35° downward.

● Turn OFF power at the main power source if the indoor unit is not being used over a prolonged

period of time.

This results in excess electrical consumption while the unit rests in standby mode.

6

P5417051-rev.1

Page 11

3.3 Efcient Use of Cooling and Heating

HEATINGCOOLING

(1) Airow Direction

The appropriate air outlet angle is approximately 35

If cooling is not sufcient, change the airow direction.

35°

35°

(1) Airow Direction

o

.

The appropriate air outlet angle is approximately 60

If heating is not sufcient, change the airow direction.

60° 60°

o

.

Air Outlet Angle (Above Center)

Louver

Angle

(2) Airow Volume

”AUTO” should usually be used.

Air Outlet Angle (Below Center)

(2) Airow Volume

”AUTO” should usually be used.

Louver

Angle

NOTE

For Multi-Split Systems

When the number of the indoor units in operation or the operating mode is changed, the change in air outlet

temperature can cause the indoor temperature to change. In this case, adjust the settings as follows.

● During Cooling Operation: Lower the temperature setpoint slightly.

● During Heating Operation: Raise the temperature setpoint slightly.

P5417051-rev.1

7

Page 12

4. Names of Parts and Indications for Safety Consideration

Safety labels are afxed to the indoor unit in order to ensure safe use.

Read and understand this manual before using the indoor unit.

4.1 Indoor Unit

Specication Label

(Electrical Box Cover)

Motion Sensor Kit

(Optional)

Indoor Unit

Air Outlet

Louver

Decorative Panel

(Optional)

Air Inlet Flat Grille

(The air lter is attached

inside.)

Wired Controller

WARNING Label

The operating condition is

displayed on the LCD.

(Optional)

NOTE

● Press switches lightly to control the wired controller. Do not press them with a sharp object such as a pen,

as it could cause damage to the controller.

● Review the installation manual for the optional Wireless Controller and Receiver Kit.

8

P5417051-rev.1

Page 13

FLTR

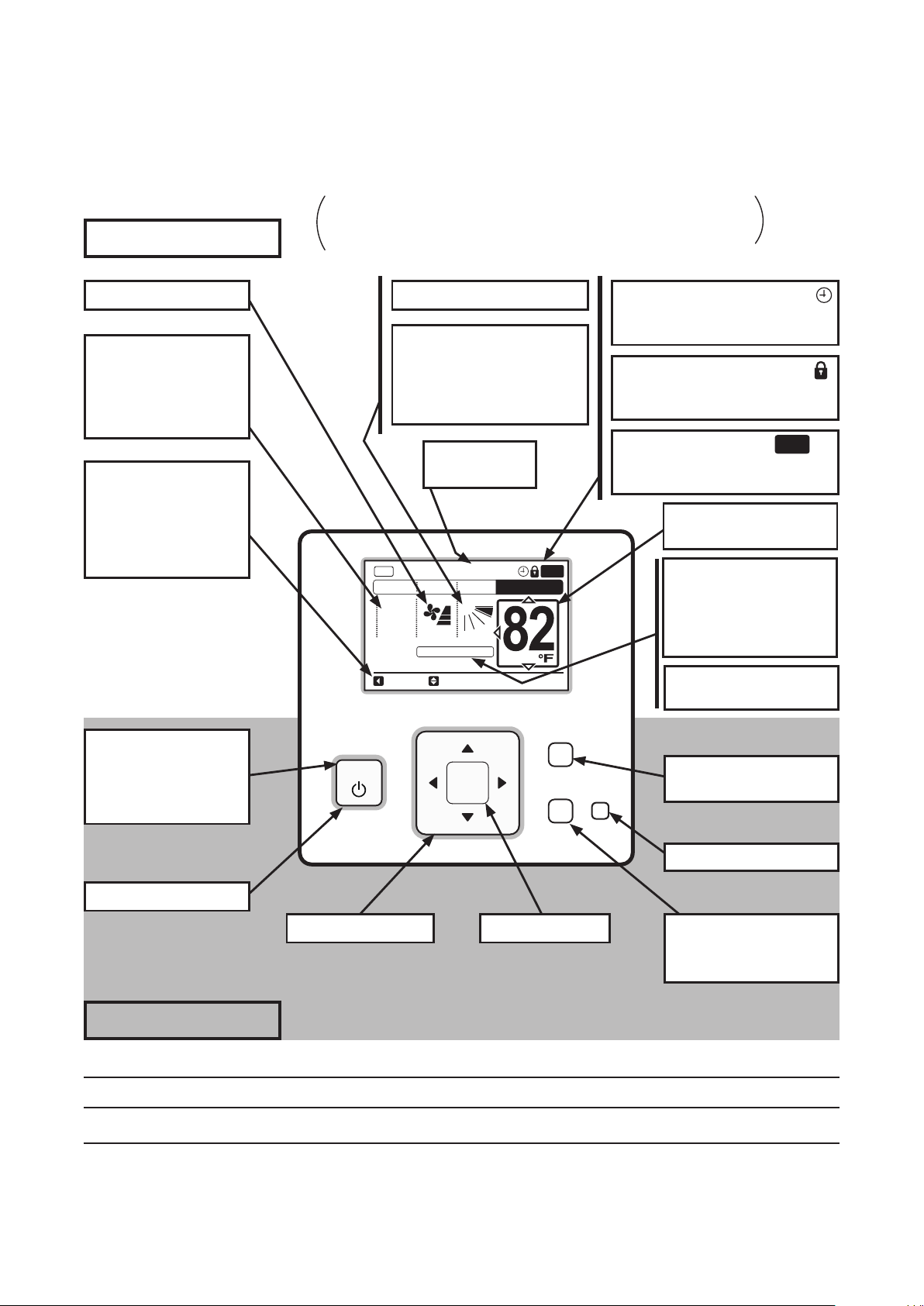

4.2 Wired Controller (CIW01)

Following is an example of how the CIW01 is utilized. If other models of the controller are utilized, operate

the unit according to the manual for that controller.

The example below references the control panel and all

adjustable settings. The wired controller display may be

Display Part

different during actual operation.

Operation Mode

Indicator

“HEAT” and “AUTO” are

indicated only for the

heat pump type models.

Operation Guide

Indicator

“Central Control” is

indicated while the

controller operation is

prohibited.

Run Indicator

Illuminates while the

unit is operating. It

ashes during abnormal

conditions.

On/Off

Swing Louver IndicatorFan Speed Indicator

Avoid Air and Receive

Indicator

is displayed only for the

decorative panel with motion

sensor.

Room Name

Indicator *

A/C

MODE SPEED

COOL

Meeting Room

Motion Sensor ON

LOUV. Adj.

LOUV.

Avoid

TEMP

OK

FLTR

Menu

Back/Help

Schedule Timer Indicator

is displayed when the schedule

timer function is set. *

Operation Lock Indicator

is displayed when the operation

lock function is set. *

Filter Sign Indicator

is displayed to indicate that the

lter needs to be cleaned.

Setting Temperature

Indicator

Motion Sensor

Indicator

is displayed only for

the decorative panel with

motion sensor.

Cold Draft Rest

Indicator

Menu Switch

ECO

To display Menu.

*

On/Off Switch

Directional Key Enter Key

Operation Part

NOTE

* For detailed descriptions, refer to the "Operation Manual" for the wired controller.

P5417051-rev.1

ECO Switch

*

Back/Help Switch

To return to the previous

screen.

9

Page 14

Menu

p

Menu

p

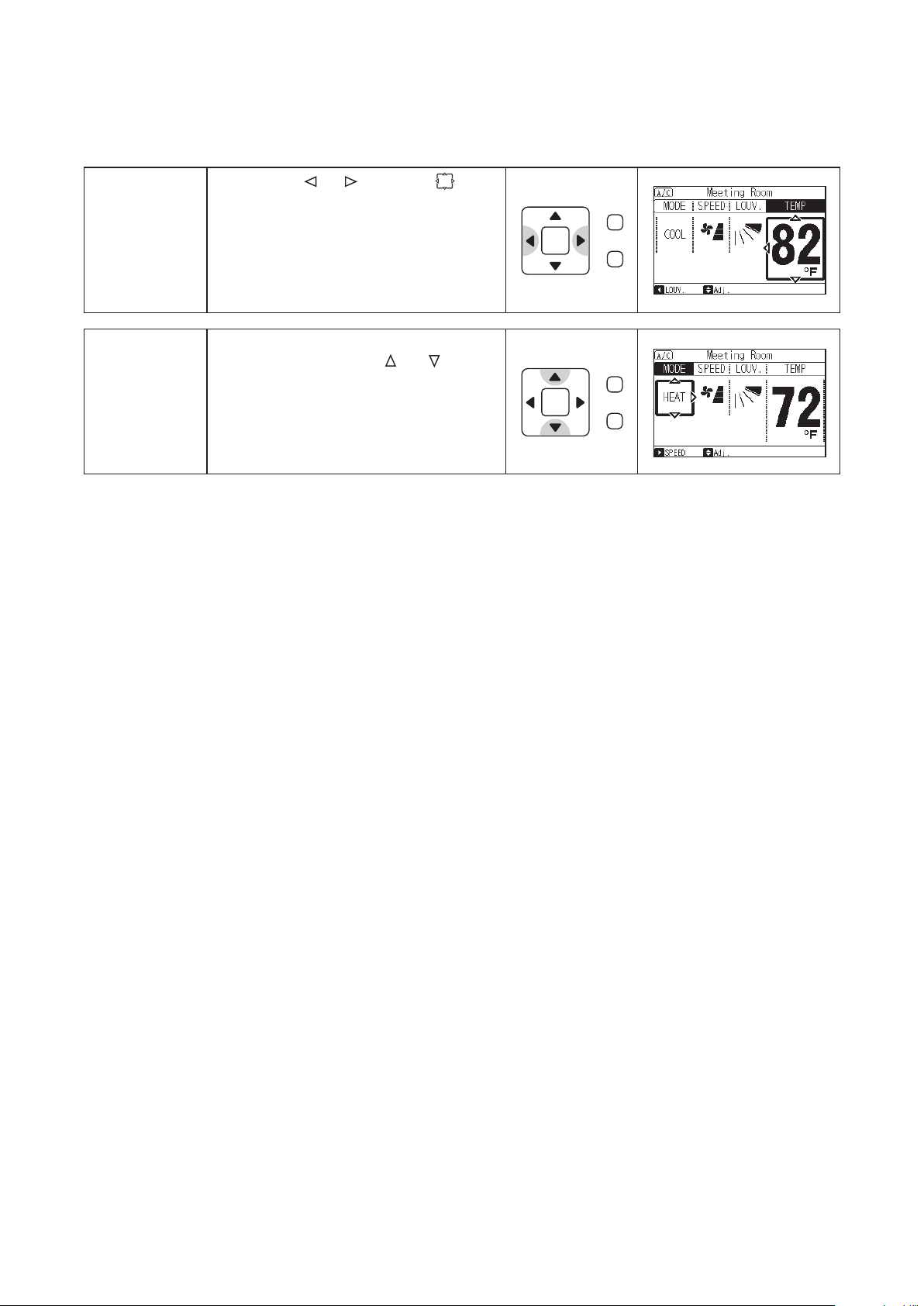

5. Operation Method

5.1 Basic Operation

By pressing “ ”or “ ”, the icon “ ”

will move between “MODE”, “SPEED”,

“LOUV.” and “TEMP”.

Item

Selection

With “MODE”, “SPEED”, “LOUV.” or

“TEMP” selected, press “ ” or “ ”.

The setting will change.

Change of

Settings

OK

OK

Back/Hel

Back/Hel

10

P5417051-rev.1

Page 15

Menu

p

Menu

p

5.2 Cooling / Heating / Fan Operation

Heating Operation is for VRF systems only and is not available for typical systems.

Function

* Cooling Operation: To decrease room temperature.

* Heating Operation: To increase room temperature.

* Dry Operation: To decrease humidity in the room.

* Fan Operation: To increase air circulation in the room.

● Dry operation may not run properly if there are other heat sources that exceed the capacity of the unit.

● The humidity control is unavailable for this unit. If you require dehumidification and the control of humidity,

choose specialized equipments.

● Decreasing of the humidity during dry operation might be unavailable.

Turn ON the power supply.

Turn ON the main power approximately

12 hours before operation in order to

Before

preheat the compressor.

Connecting

Operation

Do not turn OFF the main power to the

indoor unit during heating or cooling

season.

Press “ ” or “ ” to select “MODE”.

1

OK

Back/Hel

By pressing “ ” or “ ”, the mode is

changed as follows.

2

OK

FAN(AUTO)DRYHEATCOOL

Back/Hel

● Automatic heating/cooling operation requires extra settings. Contact your distributor or contractor for

details.

P5417051-rev.1

11

Page 16

Menu

p

Menu

p

5.3 Temperature Setting

Press “ ” or “ ” and select “TEMP”.

1

OK

Back/Hel

By pressing “ ”, temperature is increased

by 1oF (0.5oC).

(Max. 86oF (30oC))

2

By pressing “ ”, temperature is

decreased by 1oF (0.5oC).

OK

Back/Hel

COOL, FAN operation: Min. 66oF (19oC)

HEAT operation: Min. 62oF (17oC)

● If the optional function “Automatic Reset of Setting Temperature” is set.

Even if changing the temperature setpoint on the wired controller, it automatically returns to the set

temperature by “Automatic Reset Temperature” after a set time.

● The minimum/maximum temperature settings can be changed by adjusting the lower limit for the set

temperature for cooling (or the upper limit for setting temperature for heating) from the function selection.

● Contact your distributor for details on optional functions “Automatic Reset for Setting Temperature”,

"Cooling Lower Limit for Set Temperature”, and “Heating Upper Limit for Set Temperature.”

12

P5417051-rev.1

Page 17

Menu

p

Menu

p

5.4 Fan Speed

Press “ ” or “ ” and select “SPEED”.

1

OK

Back/Hel

By pressing “ ” or “ ”, fan speed is

changed as follows.

2

HIGH 2

HIGH MED LOW

OK

AUTO

Back/Hel

● During the dry operation, the fan speed is automatically adjusted to “LOW” and cannot be changed to any

other fan speed. (“LOW” is NOT displayed on the Liquid Crystal Display (LCD) at this time. The present

setting condition is displayed on the LCD.)

● The fan speed setting “HIGH 2” may not be available depending on the indoor unit type.

5.5 Operation

Press “ On/Off”.

The RUN indicator is turned ON and the

Operation

operation will start.

On/Off

OK

Start

Temperature/Airow Setting

● The setting condition is memorized. Therefore, no daily setting is required. Temperature setpoint and

airow settings are retained after the indoor unit is turned OFF at the controller. In case the setting

change is required, refer to Sections 5.2 to 5.4.

Press “ On/Off” again.

The RUN indicator is turned OFF and the

operation will stop.

Operation

On/Off

OK

Stop

● The indoor unit fan may continue to operate for up to two minutes following the heating cycle to dissipate

residual heat from the indoor unit.

P5417051-rev.1

13

Page 18

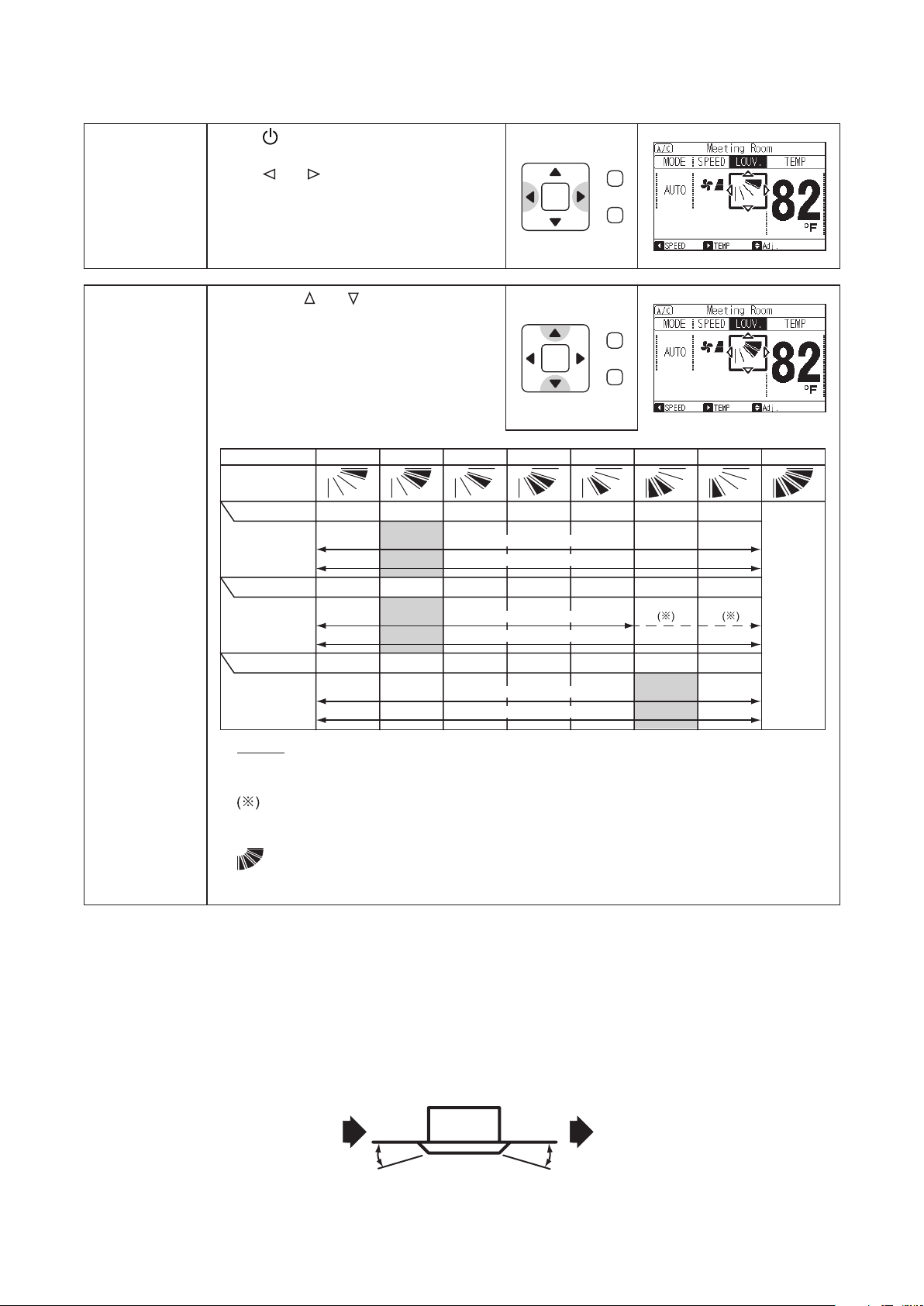

5.6 Louver Swing Direction

Menu

p

Menu

p

Approx. 30

o

Approx. 30

7-

Press “ On/Off”.

Make sure that the operation is started.

Press “

” or “ ” and select “LOUV.”.

1

By pressing “ ” or “ ”, the louver

direction will be changed as follows.

OK

Back/Hel

2

OK

Step 1 23456

LCD Indication

o

Louver Angle

FAN

Louver Angle Approx. 25

COOL and DRY

Louver Angle

HEAT

Approx. 25

Approx. 30

Approx. 35oApprox. 42oApprox. 52oApprox. 60oApprox. 65oApprox. 70

Recommended

Angle

o

Approx. 35oApprox.42oApprox. 52oApprox. 60

Recommended

Angle

o

Approx. 35oApprox. 41oApprox. 47oApprox. 53oApprox. 60oApprox. 65

Angle Range

Auto-Swing Range

Angle Range

Auto-Swing Range

Angle Range

Auto-Swing Range

Back/Hel

o

Approx. 65oApprox. 70

Recommended

Angle

o

o

Auto

Swing

o

NOTE:

Even if 65o or 70o is selected during cooling and drying operations, the louver angle

is automatically xed at 60o.

If “Individual Louver Setting” mode is used, a louver setting of 65o or 70o can be

corrected.

: Auto-swing operation is activated.

At this time, animated louver graphic on the LCD will appear to swing.

● The louver angle indicated on the LCD and the actual louver angle do not correspond precisely with

each other during auto-swing mode operation. When the louver angle is established, set the louver angle

according to the louver position indicated on the LCD.

● Louver movement may NOT stop immediately after the switch is pressed.

Swing Louver Direction during Heating Operation

* When the heating operation

starts

The louver angle is xed

approximately 30o.

* When the defrost operation

starts

* When thermo-controller

14

activates

o

When the discharge temperature

is higher than 86°F(30°C), the

louver angle is automatically

returned to the setting condition.

P5417051-rev.1

Page 19

5.7 Individual Louver Setting

NOTICE

Menu

p

Menu

p

Function

● This setting is available only for indoor models equipped with the individual louver.

● Each louver angle can be set individually.

Example

Units equipped with Auto-Swing have a set of options to allow for airow adjustment from vertical to

horizontal.

● This function cannot be set if the unit is not operating.

● After the individual louver setting is set during the heating operation, the louver angles can be adjusted

automatically to 30

● Fan speed slows down to “LOW” while this function is being set. (After the setting process is completed,

the unit operation will return to normal speed.)

● As for “Start-up of Heating Operation”, “During Defrost Operation” and “Activation of Thermistors”, all

louver angles will become xed at 30

● This function will not be displayed if two controllers (including wired controller + wireless controller) are

used.

● Maximum of 16 units can be set for Individual Louver Setting using one wired controller.

o

. Louver angles will assume this setting after a short period of time.

o

automatically, even when this function is set.

5.7.1 Individual Louver Settings

Press “Menu”.

Select “Individual Louver Setting” from

the menu by pressing “ ” or “ ” and

press “OK”.

1

The Individual Louver Setting menu is

displayed.

Select “Individual Louver Setting” from the Individual Louver

Setting menu and press “OK”.

The connected indoor unit's selection for the individual louver

2

setting will be displayed.

NOTE:

If the connected indoor unit is one (1) in the system, the

louver direction setting at procedure “4” is displayed.

Select the indoor unit to change the louver direction by

pressing “ ”, “ ”, “ ” or “ ”. Press “OK”.

The louver direction setting will be displayed.

3

NOTE:

The indoor unit displayed on the screen ashes when the

individual louver is set.

OK

OK

Back/Hel

Back/Hel

Menu

Individual Louver Setting

Louver Open/Close

VENTI

Total Heat Exchanger SET

Motion Sensor Setting

OK Back

Individual Louver Setting

Individual Louver Setting

Cancel INDV Louver SET

OK Back

Individual Louver Setting

01-01

01-02

01-03

01-04

Select unit to set.

OK Back

15:10(Fri)

03

/

05

Entr RtrnSel.

Entr RtrnSel.

Entr RtrnSel.

P5417051-rev.1

15

Page 20

Press “ ” or “ ” and select the louver direction from 1 to 2 (as

INDVINDVINDVINDVINDVINDVINDVINDV

shown). The selected louver is opened and the other louvers

Individual Louver Setting:01-03

1 2

are seen horizontally.

4

Adjust air direction & louver angle.

● If the louver position is hard to distinguish, press “ ” or “ ” to set the position .

● In the default setting, the louver on the side where the electrical box position is located is the number one

louver. Looking up from underneath the unit, the louver numbers run in a clockwise direction: numbered

"one" and "two". The louver number can also be changed. Contact your distributor for details.

Select the louver angle by pressing “ ” or “ ” and press “OK”.

The conrmation screen will be displayed.

The louver angle will be changed as shown below.

Individual Louver Setting:01-03

1 2

OK Back

Entr RtrnSel. Adj.

5

NOTE:

The louver direction without “INDV” complies with the setting

of the normal mode.

Adjust air direction & louver angle.

OK Back

Entr RtrnSel. Adj.

6

7

Select “Yes” by pressing “ ” or “ ” and press “OK”. The

setting is conrmed and the screen returns to the normal

mode.

Verify that “INDV” is turned on at the airow section on the

normal mode.

Individual Louver Setting:01-03

Fix individual louver setting?

Yes No

Sel. Entr Rtrn

A/C

MODE SPEED LOUV. TEMP

COOL

SPEED Adj.

OK Back

Meeting Room

INDV

16

P5417051-rev.1

Page 21

Menu

p

Menu

p

5.7.2 Cancellation of Louver Setting

Press “Menu”.

Select “Individual Louver Setting” from

the menu by pressing “ ” or “ ” and

press “OK”.

1

The Individual Louver Setting menu is

displayed.

Select “Cancel INDV Louver SET” from the Individual Louver

Setting menu and press “OK”.

The connected indoor unit's selection of the cancelled louver

setting will be displayed.

2

NOTE:

If the connected indoor unit is one (1) in the system,

the Cancel Individual Louver Setting at procedure “4” is

displayed.

OK

OK

Back/Hel

Back/Hel

Menu

Individual Louver Setting

Louver Open/Close

VENTI

Total Heat Exchanger SET

Motion Sensor Setting

OK Back

Individual Louver Setting

Individual Louver Setting

Cancel INDV Louver SET

OK Back

15:10(Fri)

03

/

05

Entr RtrnSel.

Entr RtrnSel.

3

4

Select the indoor unit to cancel by pressing “ ”, “ ”, “ ” or

“ ”. Press “OK”.

NOTE:

The indoor unit displayed on the screen ashes when the

individual louver is set.

Select “Yes” by pressing “ ” or “ ” and press “OK”. The

Individual Louver Setting is canceled and the screen returns

to the normal mode.

NOTE:

All the individual louver settings are canceled.

Cancel INDV Louver SET

01-01

01-02

01-03

01-04

Select unit to cancel.

Cancel INDV Louver SET:01-01

Cancel individual

louver setting?

Yes No

Sel. Entr Rtrn

OK Back

Entr RtrnSel.

OK Back

P5417051-rev.1

17

Page 22

5.8 Motion Sensor

NOTICE

5.8.1 Function

This setting is available only for the decorative panel with motion sensor kit.

● The motion sensor can detect human activity by measuring the level of change in infrared light emitted by

humans or objects.

This function saves air conditioning capacity (adjusting the set temperature, the airow volume and the

airow direction) automatically depending on a situation.

● The operation after the motion sensor detects an absence can be selected from “Running”, “Stand-by” or

“Stop” on the controller with the capacity saving.

● The motion sensor detects human activity (room occupancy). Do not use the motion sensor function in

situations where there may be little or no activity such as for disabled persons or infants. The motion

sensor may detect an absence and the operation may be stopped if there is too little motion during a period

of time.

● The motion sensor may detect human activity if the indoor unit with the motion sensor is installed near a

moving object which is difference in temperature against the atmosphere.

● If the indoor units are operated by two controllers, the motion sensor setting is available only from the main

controller.

● The indoor unit operation can be stopped by the motion sensor control.

NOTE:

Indoor units with and without a motion sensor kit can be integrated together into a system installation.

In this instance, when the operation is stopped by the motion sensor control, the indoor unit without the

motion sensor kit will also stop the operation.

● While air conditioning capacity is saved or operation is stopped by the motion sensor control, “Motion

sensor is activated” is displayed on the LCD.

● If the function “Prohibiting operation by controller” is activated from the centralized controller, select the

command “Running” or “Standby” inside an “If absent” condition at the motion sensor controls setting. If

the command “Stop” is selected, the motion sensor control is lost and cannot be performed correctly as

follows.

* In an instance where “If absent: Stop” of motion sensor setting is set by the controller and “Prohibiting

operation by controller” (for all functions) is set by the centralized controller, the operation will not be

stopped even if in the indoor unit operation stoppage condition of “If absent: Stop”.

* In an instance where “If absent: Stop” of motion sensor setting is set and “Prohibiting operation by

controller” (for some functions) is set by the centralized controller, the indoor unit operation will be

stopped by the motion sensor control. However, the indoor unit operation cannot be restarted from the

centralized controller.

18

P5417051-rev.1

Page 23

5.8.2 Details for Motion Sensor Control

The motion sensor control automatically adjusts the following functions depending on a situation.

* Setting Temperature:

The temperature is adjusted 2

o

F or 3oF (1oC or 2oC) for saving capacity.

* Airow Volume:

The airow volume is adjusted to lower one volume or to “Slow” (except during the dry operation).

* Airow Direction:

The airow direction is adjusted to horizontal.

5.8.3 Descriptions for Setting Functions

● Motion Sensor Setting

* ON: The operating control function by the motion sensor is activated.

* OFF: The operating control function by the motion sensor is not activated.

(The default setting is “ON”.)

● If Absent

The operation mode for activations can be selected from “Running”, “Stand-by”, or “Stop” on the wired

controller. It is set for the indoor unit operation after the motion sensor detects as an absence for set

time in “Check Interval”.

* Running:

The operation is continued with saving capacity after detected as an absence.

If human activity (occupancy) is detected over a period of time, the normal operation will be performed

again.

* Stand-by:

The operation mode is the fan operating at “Slow” speed. If human activity is detected for a period of

time, the normal operation will be performed again.

* Stop:

The operation is stopped by the wired controller when all the indoor units with motion sensor kits

detect an absence and are connected with the same wired controller. If human activity is detected for

a period of time by the stoppage, the normal operation will be performed again.

● Check Interval

When the motion sensor kit detects an absence at selected check time interval, the function “If absent”

(Function 1) will be executed. The interval can be selected from choices ranging from: 30, 60, 90, 120,

or 180 minutes.

(The default setting is 30 minutes.)

P5417051-rev.1

19

Page 24

5.8.4 Setting the Motion Sensor

Menu

p

Menu

p

Menu

p

Menu

p

Menu

p

Menu

p

Menu

p

Press “Menu”.

Select “Motion Sensor Setting” from the

menu by pressing “ ” or “ ” and press

“OK”.

1

"Motion Sensor Setting” is displayed.

The highlighted item changes to “Sensor”,

“If absent”, and “Check interval” by

pressing “ ” or “ ”.

2

• To set “Sensor”,

go to procedure “3” below.

• To set “If absent”,

go to procedure “5” below.

• To set “Check interval”,

go to procedure “7” below.

OK

OK

OK

Back/Hel

Back/Hel

Back/Hel

Menu

Individual Louver Setting

Louver Open/Close

VENTI

Total Heat Exchanger SET

Motion Sensor Setting

OK Back

Motion Sensor Setting

Sensor

If absent

Check interval

Running

30MIN

OK Back

15:10(Fri)

03

/

05

Entr RtrnSel.

ON

Entr RtrnSel. Adj.

3

4

5

Press “ ” or “ ” and select “Sensor”.

The display is switched “ON” and “OFF”

in order by pressing “ ” or “ ” to change

the setting.

If other settings are not required, go to

procedure “9” below.

Press “ ” or “ ” and select “If absent”.

OK

OK

OK

Back/Hel

Back/Hel

Back/Hel

Motion Sensor Setting

Sensor

If absent

Check interval

Motion Sensor Setting

Sensor

If absent

Check interval

Motion Sensor Setting

Sensor

If absent

Check interval

ON

Running

30MIN

OK Back

Entr RtrnSel. Adj.

ON

Running

30MIN

OK Back

Entr RtrnSel. Adj.

ON

Running

30MIN

OK Back

Entr RtrnSel. Adj.

20

6

The display changes to “Running”,

“Stand-by” and “Stop” in order by

pressing “ ” or “ ” to change the setting.

If other settings are not required, go to

procedure “9” below.

OK

Back/Hel

Motion Sensor Setting

Sensor

If absent

Check interval

ON

Running

30MIN

OK Back

Entr RtrnSel. Adj.

P5417051-rev.1

Page 25

NOTICE

7

Menu

p

Menu

p

Menu

p

Menu

p

Menu

p

Press “ ” or “ ” and select “Check

interval”.

OK

Back/Hel

Motion Sensor Setting

Sensor

If absent

Check interval

ON

Running

30MIN

OK Back

Entr RtrnSel. Adj.

8

9

The display shows: “30MIN”, “60MIN”,

“90MIN”, “120MIN”, and “180MIN” in

order by pressing “ ” or “ ” to change

the setting.

If other settings are not required, go to

procedure “9” below.

Press “OK” after the setting is made.

The conrmation screen is displayed.

Select “Yes” by pressing “ ” or “ ” and

press “OK”. The motion sensor setting is

conrmed and the screen returns to the

normal mode (operation mode indicator).

OK

OK

OK

OK

Back/Hel

Back/Hel

Back/Hel

Back/Hel

Motion Sensor Setting

Sensor

If absent

Check interval

Motion Sensor Setting

Save changes in

motion sensor setting?

Yes No

Sel. Entr Rtrn

ON

Running

30MIN

OK Back

Entr RtrnSel. Adj.

OK Back

If more than two controllers are utilized, setting of the motion sensor is available by simply using the main

controller only.

P5417051-rev.1

21

Page 26

An automatic heating/cooling operation and setback operation requires extra settings.

Contact your distributor or contractor for details.

5.9 Automatic Heating/Cooling Operation

In case dual setpoint is selected in automatic heating/cooling

operation, during auto mode both cooling setpoint and heating

setpoint can be selected.

By default, temperature when the heating/cooling mode changes is

as follows.

Cooling mode changes to heating mode when the indoor

temperature is at the heating setpoint -2oF (-1oC).

Heating mode changes to cooling mode when the indoor

temperature is at the cooling setpoint +2oF (+1oC).

If the temperature for changing modes must be changed, contact

your distributor or contractor for details.

5.10 Setback Operation

If the setback operation is enabled and the card key is removed,

the louver starts to open in approximately 5 seconds, the setpoint is

adjusted for setback, and the fan operates at “Low” speed.

During this time, “Setback” is displayed on the LCD.

By default,

Cooling: Setpoint +4oF (+2.5oC)

Heating: Setpoint -4oF (-2.5oC)

If the adjustment for setback operation must be changed, contact

your distributor or contractor for details.

NOTE:

In case of Celsius Indication.

NOTE:

In case of Fahrenheit Indication.

22

P5417051-rev.1

Page 27

6. Automatic Control

This air conditioner automatically starts the following operations based on conditions.

The system is equipped with the following functions:

Enforced Stoppage:

The compressor remains OFF for at least three minutes once it has

stopped.

If the system is restarted within approximately three minutes after it has

stopped, the RUN indicator is activated.

However, the cooling operation or the heating operation remains OFF

Three-Minute Guard

Cooling

Frost Prevention

and

Dry

Self-Cleaning of

Expansion Valve

Hot Start

Defrosting

Heating

Operation

Residual

Heat Removal

and does not start until after three minutes have elapsed.

Enforced Operation:

If all indoor units of a system are Thermo-OFF

three minutes after the compressor has started, compressor operate

continuously during those three minutes.

However, if all indoor units of a system are stopped by a controller, the

compressor is stopped.

When the indoor unit is operating at a low discharge air temperature,

the cooling operation may be changed to a fan operation for a while to

avoid frost formation on the indoor heat exchanger.

Self-cleaning of the expansion valve when the operation is stopped at

cooling. The sound of refrigerant ows may be heard from the indoor

unit during the self-cleaning. However, it is not abnormal.

To prevent cold air discharge into a heated space, the fan speed is

controlled from the SLOW / LOW setting and then to a set position

based on discharge air temperature.

At this time, the louver is in a xed horizontal position and “HOT

START” is displayed on the LCD of the wired controller.

The indoor unit fan operation is stopped to prevent cold air discharge

during the defrosting operation. At this time, the message “HOT-START”

is displayed on the LCD of the wired controller and the indoor unit fan

louver angle is xed horizontally.

When the heating operation is stopped, indoor fan operation may

remain at the slow speed for a maximum of two minutes to lower the

internal temperature of the indoor unit.

within approximately

*

Prevention

of Overload

Operation

* Thermo-OFF: The outdoor unit and some indoor units stay on, but don't run.

Thermo-ON: The outdoor unit and some indoor units are running.

When the outdoor temperature is high (approximately 70oF (21oC) or

more) during heating operation, the operation is stopped by activation

of the outdoor thermistor.

NOTE

● This air conditioner adopts a hot air circulation system for the heating operation.

● Any oversized room with a low ambient air temperature will require an extended amount of time to warm

up. Once the air temperature gets to the required temperature setpoint, the display “HOT START” is

turned OFF.

● If “HOT-START” displays during, or right after, the defrosting operation, this is NOT abnormal. Activation

of the hot start operation prevents cold drafts.

P5417051-rev.1

23

Page 28

7. Maintenance

NOTICE

A

ir Inlet Flat Grille

A

● Turn OFF the power source before maintenance work. If the power source is not turned off, it may cause

a re or an electric shock.

● Perform the maintenance work with a stable foothold or foundation. This may prevent falling or injury.

● Hold the air lter and the air inlet grille securely by hand when attaching or removing it. Not doing so may

cause the unit to fall, resulting in serious injury.

● Use light pressure with a clean soft cloth when cleaning the lens of the motion sensor. The surface

material of the lens is easily scratched, blemished, and can result in degraded performance of the sensor.

7.1 Maintenance

7.1.1 Cleaning Air Filter

Clean the air lter when the lter sign is turned ON.

On/Off

A/C

MODE SPEED

COOL

Motion Sensor ON

LOUV. Adj.

Meeting Room

Avoid

OK

LOUV.

TEMP

FLTR

Menu

Back/Help

Filter Sign

ECO

(1) Open the air inlet at grille.

While sliding the hinge on both sides of the

air inlet at grille, open the air inlet at grille.

(2) Remove the air lter.

Remove the air lter from the decorative

panel by turning the six knobs for air lter

90 degrees.

Knob

24

ir Inlet Flat Grille Air Filter

Knob

Turn

o

90

P5417051-rev.1

Page 29

(3) Clean the air lter.

•Vacuum dust off with a hand-held vacuum cleaner, or wash the air lter with water or a neutral

detergent.

• Dry the air lter in a shaded area.

NOTE

• Do not use water warmer than 122°F (50°C). Filter elements can be damaged.

• Do not dry the air lter by holding it over open ame, with a hair dryer, or any type of heating device. Filter

elements can be damaged by heat.

(4) Install the air lter.

After the air lter is dried, install it in the reverse order from what is shown in procedure “2”.

(5) Close the air inlet at grille.

NOTE

• Be sure to install the air lter.

Operating the indoor unit without a lter installed will cause serious damage and breakdown.

• Make sure that the air inlet at grille is securely locked in place by the knobs. If not properly secured, it

could swing open, strike someone below and cause injuries.

(6) Reset the lter sign.

NOTE

If the accumulated operation time is shorter than that indicated by the lter sign setting, the icon displaying

“ ” activates and “Setting Disabled” is displayed.

•Press “Menu”.

Select “Reset Filter Sign Time” from the menu and press “OK”.

The conrmation screen is displayed.

Menu

Simple Timer

Reset Filter Sign Time

Operation Schedule

Elevating Grille

Power Saving Setting

•Select “Yes” by pressing “

” or “ ” and press “OK”.

The “FLTR” indication is turned OFF and the screen returns to the normal mode.

15:10(Fri)

OK Back

Entr RtrnSel.

01

/

05

P5417051-rev.1

25

Page 30

7.1.2 Removing, Cleaning and Attaching Air Inlet Flat Grille

NOTICE

A

ir Inlet Flat Grille

Air Inlet Flat Grille

Tilting the air inlet flat grille,

Wipe down the decorative panel with a soft cloth soaked in lukewarm water and wrung out.

● Gently wipe down using only a clean soft cloth. Avoid the use of benzene type thinners or chemical

detergents and abrasives such as cleaning agents which will damage the nish of outer plastic surfaces

and louvers. Avoid using excessive force when cleaning these surfaces as they can be easily damaged.

The air inlet at grille can be removed and cleaned.

(1) Open the air inlet at grille.

While sliding the knobs on both sides of the air inlet

at grille, open the air inlet at grille.

(2) Remove the air inlet at grille.

Remove the supporting chain from the decorative panel.

•

Open the air inlet at grille at an approximately 40° angle from the decorative panel surface.

•

Tilt the air inlet at grille and lift it up to remove it.

•

NOTE:

Although the air inlet at grille can be opened up to 90°, it cannot be removed from the decorative panel at

that angle. Tilt it at a 40° angle when removing it.

Ceiling

Decorative Panel

lift it up to remove it.

40°

Chain

(3) Clean the air inlet at grille.

(4) Attach the air inlet at grille.

Attach the air inlet at grille in the reverse procedure to removing.

7.2 Maintenance Before and After Use

Before Use After Use

• Remove any obstacles around the air inlet at

grilles and the air outlets of both the indoor and

outdoor units.

• Check that the air lter is not clogged with dust

and dirt.

26

• Clean the air lter, the air inlet at grille and the

decorative panel.

P5417051-rev.1

Page 31

8. Troubleshooting

8.1 These are Not Abnormal

Event Cause

All indicator LEDs on the

wired controller are turned

OFF.

Operation Stopped

White Steam

from Indoor Unit

White Smoke

from Indoor Unit

Mist from Indoor Unit

Odor from Indoor Unit

Sound from Indoor Unit

Condensation on

Decorative Panel

Temperature Irregularity

“HOT-START” on LCD Illuminated (ON)

Operation Mode on LCD Flashing

“Motion Sensor ON” is turned

ON the wired controller.

After Power Failure

During Heating Operation

At Beginning of Heating

Season

In Restaurant or Kitchen

During Dry Operation

During Cooling Operation

in Humid Environment

Odors Emanating from Indoor

Unit Air Discharge

A grating sound is heard

when starting or stopping the

operation.

Sound of water owing or

bubbling is heard during the

operation.

A growling sound may be

heard temporarily right after

the airow volume is changed.

Condensation on Decorative

Panel or Cabinet

Airow volume and

temperature irregularities exist

for each outlet.

The microprocessor is activated to protect the

device from electromagnetic interference (EMI).

Restart the operation.

The operation has stopped automatically because

the motion sensor is set as “If absent: Stop”. It

detected an absence of motion for a period of time.

(All indoor units connected to the same controller

are stopped.)

Restart the operation. If the instantaneous power

failure is within two seconds, the operation restarts

automatically.

Dust that accumulated over time on the evaporative

coil of the indoor unit will be pushed into the

occupied space, which could generate white steam

coming out of the discharge side of the indoor unit.

This might occur when dust attached to the heat

exchanger has been dried.

This can occur when oily residue coats the ns and

heat exchanger efciency is degraded.

This might occur due to the air outlet temperature

decreasing. Change the operation mode.

This might occur due to the air outlet temperature

decreasing. Raise the set temperature and airow

volume.

The intake of cigarette smoke is the likely reason,

with nicotine deposits coating or clogging the cells

and surfaces of the air lter.

Ventilate the unit well in fan mode and clean the air

lter, the air outlet and air inlet grill.

This is the sound made when the components are

rubbing up against one another due to expansion

and contraction of plastic parts brought on by

temperature change.

This is the sound made when the refrigerant ows

or the drain-up mechanism drains water. The sound

may be heard especially when starting the operation

or stopping the compressor (for approximately three

minutes).

It is generated because the fan motor makes

temporary sound with change of fan speed.

This might occur when the operation is performed

in a humid environment over a prolonged period of

time (relative humidity around 80%).

This might occur for structural reasons, such as

the size of an air outlet and the location of heat

exchanger.

This might occur according to the operation mode

or operational conditions.

P5417051-rev.1

27

Page 32

8.2 Before Contact

Check these problems before contacting a contractor.

Problem Checking Point Action

Check that the main power

source is turned ON.

Operation Unavailable

Cooling

Immediate

shutdown after

start-up

Insufcient Cooling or

Heating

Heating

Check that the fuse is not

blown or the circuit breaker

from the main power source is

not tripped.

Check that the air inlet and

outlet for the outdoor unit are

not obstructed.

Check if there are any

obstacles impeding the airow

near the air inlet and outlet of

the outdoor unit.

Check that the outlet air is not

redirected into the air inlet.

Check that the operation

mode is appropriate.

Check that the set

temperature is appropriate.

Check that the airow

direction is appropriate.

Check that the air lter is not

clogged.

Verify that there are no open

windows and doors.

Check that there are no

obstacles impeding airow

near the air inlet and outlet for

both indoor and outdoor units.

Turn ON the power at the main power source for

the air conditioner.

Replace the fuse or reset the circuit breaker.

If the problem recurs, contact your contractor or

distributor.

Remove objects obstructing the air inlet and outlet.

Remove any obstacles obstructing airow.

If the fan mode is selected, switch the operation

mode to cooling/heating.

If not, change the temperature setting by pressing

” or “ ” with the wired controller.

“

If not, change the airow direction.

If the room is not heated well during the heating

operation, change the louver downward.

Clean the air lter.

Close windows and doors.

Remove the obstacles.

28

P5417051-rev.1

Page 33

8.3 Contact Distributor

Indoor Unit Number

If trouble still persists, even after looking for off previously listed items or detecting problems not mentioned in

the previous pages, stop using this product and call your distributor or contractor immediately.

If there is any perceived abnormality present (noises or odors associated with electrical short,

re, or burning elements), shut down immediately and shut OFF at the main power source.

Contact your distributor or contractor without delay.

Problem Action before Contact

Protection devices (fuses, breakers, and GFCIs) activate

frequently or the operation switch does not work.

Water leakage from the indoor unit. Stop the operation.

"Motion Sensor ON" is ashing.

● The RUN indicator (red) is ashing.

● The indoor unit number, alarm code, unit model code,

and the number of connected indoor units are displayed

on the LCD.

● If multiple indoor units are connected to one controller,

the above abnormality information for each indoor unit

is displayed individually.

Turn OFF the power source.

There is a possibility of malfunction of the motion

sensor. Make the setting of motion sensor and

HEAT Control

invalid and contact your distributor.

”

Floor

“

In that case, after the LCD of the wired controller

display disappears and until service is nished, the

unit is operable.

Check the details on the LCD and contact your distributor.

Refer to the Alarm Code Table.

Contact your distributor and advise of the alarm code

details indicated on the LCD of the wired controller.

01-02

Alarm Code:

MODEL : F .08

I.U. :

IDU :

ODU :

O.U. :

RCI-3.0FSN3

******

RAS-3HVRNM2

******

Sel. OP MODE

23

OK

Chek

AlarmRST

Address

Entr

Provide the following information when contacting your distributor.

1) Unit model

2) Symptoms and nature of the problem.

3) Number of the alarm code or any ashing indicator on the LCD.

P5417051-rev.1

29

Page 34

8.4 Alarm Codes

Code Category Content of Abnormality Code Category Content of Abnormality

01 Indoor Unit Activation of Protection Device 35

02 Outdoor Unit

03

Communication

04

05 Supply Phase Problem of Power Source Phases 42 Overload Heating

06 Voltage

07

Cycle

08

09 Outdoor Unit

11

12 Outlet Air Thermistor Failure 48

13 Freeze Protection Thermistor Failure 51

14 Gas Piping Thermistor Failure 52

19 Fan Motor

20

21 High Pressure Sensor Failure 56

Sensor on

Indoor Unit

Activation of Protection Device

(High Pressure Cut)

Operational Irregularities between

Indoor and Outdoor

Problem between Inverter PCB and

Outdoor PCB

Abnormal Voltage Drop in

Outdoor Unit

Decrease in Superheated Discharge

Gas

Increase in Discharge Gas

Temperature

Activation of Protection Device for

Outdoor Fan

Inlet Air Thermistor Failure 47

Activation of Protection Device for

Indoor Fan

Compressor Thermistor Failure 54

38

39 Compressor

41

43

44

45

46

53

System

Pressure

Protection

Device

Inverter

Incorrect Setting of Indoor Unit No.

Problem with Protective Pickup Circuit

in Outdoor Unit

Problem with Running Current at

Constant Speed Compressor

Overload Cooling

Activation of Pressure Ratio Decrease

Protection Device

Activation of Low Pressure Decrease

Protection Device

Activation of Low Pressure Increase

Protection Device

Activation of High Pressure Increase

Protection Device

Activation of High Pressure Decrease

Protection Device

Activation of Overcurrent Protection

Device

Problem with Inverter Current Sensor

Activation of Inverter Overcurrent

Protection

Activation of Transistor Module

Protection

Abnormality of Inverter Fin

Temperature

Abnormality of Detection for Fan

Motor Position

22 Outdoor Air Thermistor Failure 57 Activation of Fan Controller Protection

23 Discharge Gas Thermistor Failure 58 Abnormality of Fan Controller

24 Evaporating Thermistor Failure b0

29 Low Pressure Sensor Failure b1

31

32

Sensor on

Outdoor Unit

System

Incorrect Capacity Setting of

Outdoor Unit and Indoor Unit

Incorrect Setting of Other Indoor Unit

Number

Outdoor Fan

Incorrect Setting of Unit Capacity

System

EE Compressor Compressor Protection Alarm

Incorrect Setting of Unit and

Refrigerant System No.

30

P5417051-rev.1

Page 35

Page 36

© 2017 Johnson Controls, Inc.

P5417051-rev.1

Code No. LIT-12012966

Revised January 2018

Loading...

Loading...