Page 1

R-410A

INSTALLATION MANUAL

®

OUTDOOR SPLIT-SYSTEM

HEAT PUMP

MODELS:

CHJD FLEX SERIES

LIST OF SECTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

LIST OF FIGURES

Typical Installation with Required Clearances . . . . . . . . . . . . . . . . . . . 2

Minimum Suction Line Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Excess Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Insulation of Vapor Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Typical Quick Connect Refrigerant Line Set . . . . . . . . . . . . . . . . . . . .4

Quick Connect Coupling Connections . . . . . . . . . . . . . . . . . . . . . . . . . 4

LIST OF TABLES

TEST Input Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

X/L Output Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SECTION I: GENERAL

These outdoor heat pump units are designed to be connected to a

matching UPG indoor coil. They are equipped with a solid core filterdrier located in the discharge line and a high pressure switch.

These units are supplied with quick-connect coupling connections that

are factory charged with refrigerant to be matched with the appropriate

pre-charged line set, and UPG indoor coil.

The outdoor unit is designed to be placed near the perimeter of the

home, typically alongside or at the back of the home, remote from the

indoor coil. The outdoor unit has been factory run-tested and all components of the system are ready for easy, immediate installation.

SYSTEM OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTRUCTING THE OWNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Outdoor Unit Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical Wiring with Thermostat and Furnace / Air Handler . . . . . . . . 5

Demand Defrost Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Defrost Operation Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Heat Pump Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Defrost Initiate Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service, or maintenance

can cause injury or property damage. Refer to this manual for assistance or for additional information, consult a qualified contractor,

installer, or service agency.

SECTION II: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or moderate injury. It is also used to

alert against unsafe practices and hazards involving only property damage.

.

.

This product must be installed in strict compliance with the enclosed

installation instructions and any applicable local, state, and national

codes including, but not limited to building, electrical, and mechanical

codes.

INSPECTION

As soon as a unit is received, it should be inspected for possib le damage during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s delivery receipt. A separate request for

inspection by the carrier’s agent should be made in writing. See Local

Distributor for more information.

LIMITATIONS

The unit should be installed in accordance with all National, State, and

Local Safety Codes and the limitations listed below:

1. Limitations for the indoor unit, coil, and appropriate accessories

must also be observed.

2. The outdoor unit must not be installed with any duct work in the air

stream. The outdoor fan is the propeller type and is not designed to

operate against any additional external static pressure.

3. The maximum and minimum conditions for operation must be

observed to assure a system that will give maximum performance

with minimum service.

689103-BIM-B-1012

Page 2

689103-BIM-B-1012

NOTICE

60" OVERHEAD

CLEARANCE

NOTE: ALL OUTDOOR WIRING

MUST BE WEATHERPROOF

TO INDOOR COIL

THERMOSTAT

TO FURNACE OR

AIR HANDLER

TERMINAL BLOCK

MINIMUM 18" SERVICE ACCESS

CLEARANCE ON ONE SIDE

WEATHERPROOF

DISCONNECT

SWITCH

SEAL OPENING(S) WITH

PERMAGUM OR EQUIVALENT

6" CLEARANCE

COIL AREA

NEC CLASS 1 WIRING

NEC CLASS 2 WIRING

NOTICE

NOTICE

AIR TEMPERATURE AT

OUTDOOR COIL, °F

Min. Max. Min. Max.

DB

Cool

50 -10 115 75 57

1. Operation below this temperature is permissible for a short period of time,

2. The maximum allowable line length for this product is 75 feet.

DB

HeatDBCool

during morning warm-up.

DB

Heat

AIR TEMPERATURE AT

INDOOR COIL, °F

WB

Cool

DB

Heat

50

1

WB

Cool

72 80

DB

Heat

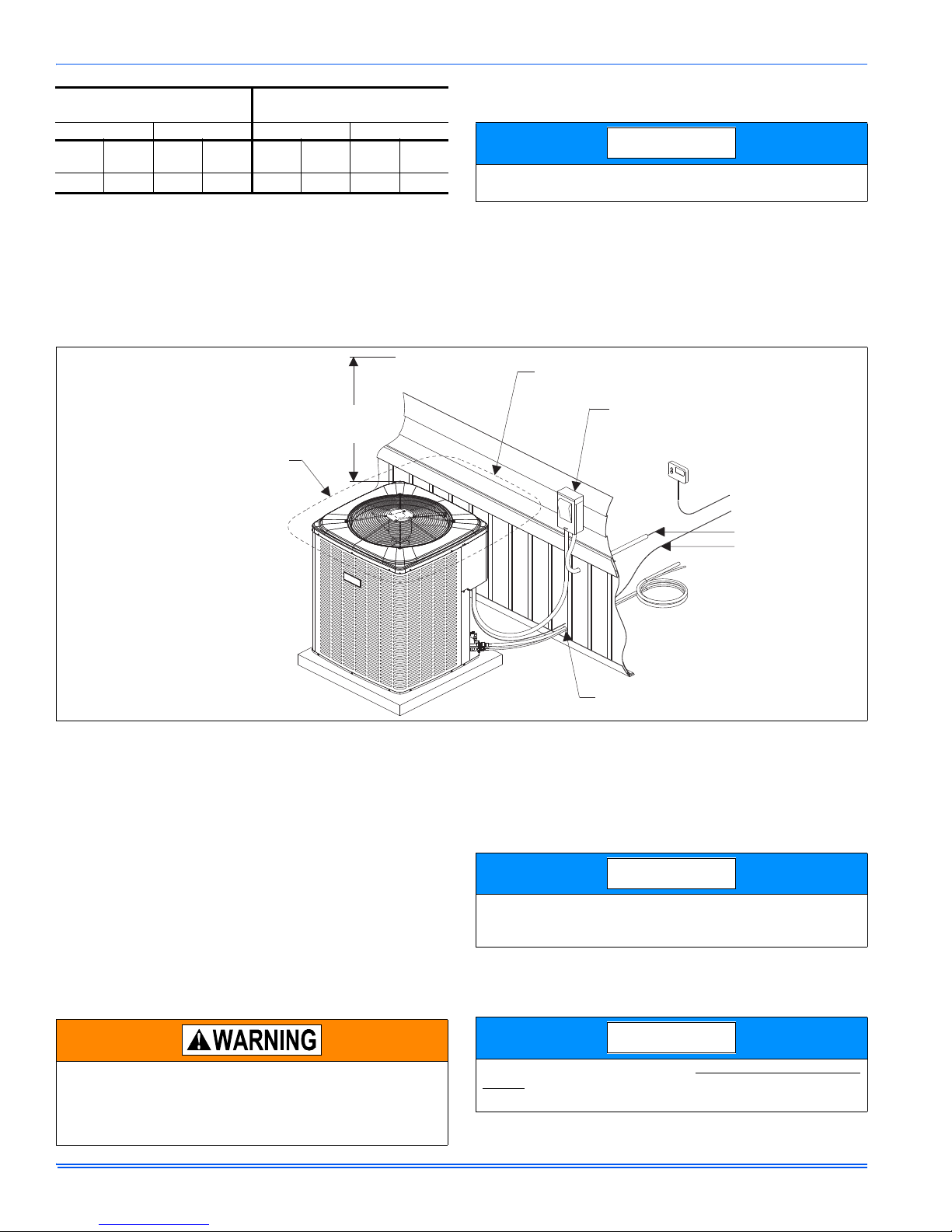

SECTION III: UNIT INSTALLATION

LOCATION

Before starting the installation, select and check the suitability of the

location for both the indoor and outdoor unit. Observe all limitations and

clearance requirements.

The outdoor unit must have sufficient clearance for air entrance to the

condenser coil, for air discharge, and for service access. See Figure 1.

For multiple unit installations, units must be spaced a minimum of 18

inches apart (coil face to coil face).

If the unit is to be installed on a hot sun exposed roof or a black-topped

ground area, the unit should be raised sufficiently above the roof or

ground to avoid taking the accumulated layer of hot air into the outdoor

unit.

Provide an adequate structural support.

FIGURE 1: Typical Installation with Required Clearances

GROUND INSTALLATION

The unit may be installed at ground level on a solid base that will not

shift or settle, causing strain on the refrigerant lines and possible leaks.

Maintain the clearances shown in Figure 1 and install the unit in a level

position.

Normal operating sound levels may be objectionable if the unit is placed

directly under windows of certain rooms (bedrooms, study, etc.).

Condensate will drain from beneath the coil of the outdoor unit during

the defrost cycle. Normally this condensate may be allowed to drain

directly on the ground.

Elevate the unit sufficiently to prevent any blockage of the air entrances

by snow in areas where there will be snow accumulation. Check the

local weather bureau for the expected snow accumulation in your area.

Isolate the unit from rain gutters to avoid any possible wash out of the

foundation.

The outdoor unit should not be installed in an area where mud or ice

could cause personal injury. Remember that condensate will drip

from the unit coil during heat and defrost cycles and that this condensate will freeze when the temperature of the outdoor air is below

32°F.

UNIT PLACEMENT

1. Provide a base in the pre-determined location.

2. Remove the shipping carton and inspect for possible damage.

3. Compressor tie-down bolts should remain tightened.

4. Position the unit on the base provided.

Heat pumps will defrost periodically resulting in water drainage. The

unit should not be located where water drainage may freeze and create a hazardous condition - such as sidewalks and steps.

LIQUID LINE FILTER-DRIER

The heat pumps have a solid core bi-flow filter/drier located on the liquid

line.

Replacements for the liquid line drier must be exactly the same as

marked on the original factory drier. See Source 1 for O.E.M.

replacement driers.

2 Johnson Controls Unitary Products

Page 3

Failure to do so or using a substitute drier or a granular type may

12“

12“

Center Point

NOTICE

result in damage to the equipment.

689103-BIM-B-1012

Filter-Drier

Source 1 Part No.

S1-52636219000 All

*As listed on the “Energy Guide yellow sticker on the unit.

Apply with Models

OUTDOOR THERMOSTATS

(All installations of this heat pump in Manufactured Homes built

per HUD standards SHALL have an outdoor thermostat installed at

the time of installation by the installer. In accordance with HUD

std. 3280.714 (a) (1) (ii). Outdoor thermostat, Part number 30246881/D or equivalent shall be used and should be ordered at your

nearest UPG Parts Source). See last page of these instructions.

Select the proper location for mounting the outdoor thermostat (see

instructions packed with outdoor thermostat).

INDOOR UNITS

Install the indoor coil in the furnace or air handler according to the

installation instructions packed with each component.

REFRIGERANT LINE

Do not remove protective caps from couplings until pre-charged lines

are routed and ready for final connection. Protective caps prevent dirt

from entering couplings and contaminating system when connected

together.

1. Refer to the tabular data sheet for the correct line set kit part number for your unit.

a. Check the size of the pre-charged refrigerant lines to insure that

they are correct for the model being installed.

b. Check the final routing of the tubing, and insure tubing will be of

adequate length, with allowance for connection at the coil and

outdoor unit.

The line set part number, size, and length are shown in the tabular data

sheet. Do not use any line sets other than those shown. Refer to the

appropriate line set Installation Manual.

2. Copper tubing will work-harden (for copper tubing only).

a. The pre-charged tubing should be handled carefully.

b. Do not bend or work the tubing any more than necessary. (The

larger size tubing 3/4" for example, will work-harden rapidly as it

is formed. As the tubing becomes harder, it is more susceptible to

kinking and damage).

3. Forming Copper (for copper tubing only).

a. No attempt should be made to bend the suction line in a shorter

radius than 12". See Figure 2.

FIGURE 2: Minimum Suction Line Form

4. How to dispose of excess tubing.

a. Tubing may be longer than required. Coil excess tubing nearer

the indoor coil rather than the outdoor unit.

b. Excess tubing must be coiled horizontally so the flow of refriger-

ant is from top to bottom of the coil and toward the outdoor unit.

Another method is to form a horizontal “U” large enough to take

care of excess. See Figure 3.

FIGURE 3: Excess Tubing

5. Slope tubing toward outdoor unit.

a. When the coil is above the outdoor unit, the suction line should be

sloped with a fall of a least 1/4" per foot toward the outdoor unit.

b. When the outdoor unit is above the coil, the tubing should be

sloped downward along lateral distance to the bottom, or from the

vertical riser.

6. Insulation of suction line.

a. Standard suction lines come pre-insulated from the factory with 3/

8" closed cell insulation, adequate for average installations.

In regions of extreme temperatures and humidity, additional insulation may be required to prevent excessive condensation and serious

loss of capacity.

b. Do not insulate liquid and suction lines together.

c. Liquid lines should not be insulated.

d. Liquid lines should not be in bare contact with suction line. See

Figure 4.

Johnson Controls Unitary Products 3

Page 4

689103-BIM-B-1012

Liquid

Line

Incorrect

Correct

Tape

Sheet Metal Hanger

Insulated Vapor Line

FIRST CONNECTION

TO INDOOR COIL

SECOND CONNECTION

TO OUTDOOR COIL

INSULATION

TIGHTEN

BACK UP

BACK UP

TIGHTEN

FIGURE 4: Insulation of Vapor Line

Liquid refrigerant under pressure. Liquid refrigerant can cause

severe frostbite. To avoid possible loss of sight and/or frostbite use

eye protection (safety glasses or safety face shield). Wearing leather

gloves will offer protection to hands.

7. Install refrigerant lines to indoor coil first. The couplings without

Schrader Valves are to be connected to the indoor coil. See Figure

5.

a. Form the tubing so it is properly aligned with the connections on

the coil.

b. Remove plugs and caps from connections.

c. Check that the rubber seals in connection ends are intact.

d. Be sure surfaces are clean.

e. Lubricate the rubber seals with clean POE oil and make connec-

tions.

f. Thread couplings together by hand to be sure they are not cross

threaded. Tighten coupling so diaphragms are touching (do not

puncture diaphragms at this time).

FIGURE 6: Quick Connect Coupling Connections

9. Tightening couplings (for Flexi Fit & Copper only).

a. Tighten indoor coil couplings with wrenches; using wrench on sta-

tionary fitting of coupling and liquid line fitting at coil while nut is

being tightened. See Figure 6. Tighten the nut until the coupling

bottoms out.

b. Then tighten an additional 1/6 turn to complete the knife edge

seal.

c. Tighten outdoor unit couplings, with wrenches using a wrench on

the stationary fitting of the coupling while nut is being tightened.

Tighten the nut until the coupling bottoms out.

d. Then tighten an additional 1/6 turn to complete the knife edge

seal.

10.Check for leaks.

a. After the line set connections have been made they should be

checked for leaks.

b. If the valves were kept clean and lubricated per instruction no

leaks should be found.

c. Use leak detect solution or soap solution for leak testing. An elec-

tronic leak detector is recommended.

FIGURE 5: Typical Quick Connect Refrigerant Line Set

8. Install refrigerant line to outdoor unit. The couplings with Schrader

Valves are to be connected to the outdoor unit.

a. Form the tubing so it is properly aligned with the connections on

the outdoor unit. Insure the Schrader Valves are accessible.

b. Check that the rubber seals in connection ends are intact.

c. Be sure surfaces are clean.

d. Lubricate the rubber seals with clean POE oil and make connec-

tions.

e. Thread couplings together by hand to be sure they are not cross

threaded. Tighten coupling so diaphragms are touching (do not

puncture diaphragms at this time).

4 Johnson Controls Unitary Products

IT IS UNLAWFUL TO KNOWINGLY VENT, RELEASE OR DISCHARGE REFRIGERANT INTO THE OPEN AIR DURING REPAIR,

SERVICE, MAINTENANCE OR THE FINAL DISPOSAL OF THIS

UNIT.

WHEN THE SYSTEM IS FUNCTIONING PROPERLY AND THE

OWNER HAS BEEN FULLY INSTRUCTED, SECURE THE

OWNER’S APPROVAL.

REFRIGERANT LINE SUPPORT

Refrigerant lines should be supported in a way that no dips or sags

occur. We recommend four feet between supports. If refrigerant lines

are to be attached to the home structure, care should be taken to eliminate the transmission of vibrations. Attach the refrigerant lines to the

indoor coil first. Remove plugs from the indoor coil, then clean joints to

be brazed. Braze refrigerant lines to the indoor coil. Attach refrigerant

lines to the outdoor unit.

CHARGING AND LEAK TESTING

On systems with or without service valves the refrigerant should be

recovered or recycled in accordance with EPA regulations. In some

cases this may require putting piercing valves on both the high and low

sides of the system.

Page 5

DO NOT vent refrigerant to the outdoors.

Start

Relay

(Optional)

Defrost

Control

Board

Start Capacitor

(Optional)

Ground

Lug

“Fingered”

Bushing

Low

Voltage

Box

Reversible High

Voltage Conduit Plate

Contactor

Dual

Run/Fan

Capacitor

NOTICE

NOTICE

Y

O

R

L

X

W2

G

Y

O

R

X/L

C

W

YEL

ORG

RED

PUR

BLK

BRN

WHT

WALL

THERMOSTAT

YEL (NOT USED)

YEL (NOT USED)

MANUFACTURED HOUSING

ELECTRIC FURNACE

WITH 4 WIRE CONTROL BOX

TYPICAL MANUFACTURED HOUSING INSTALLATION

W / SINGLE STAGE OUTDOOR THERMOSTAT 3024-6881/D

E

G

R

C

W

WHT

GRN

WHT

BLK

RED

+

2

4

5

1

2

+

Confirm that wire is connected

to terminal 2, not terminal 5.

If not, then move wire from

terminal 5 to terminal 2.

W1/66

SINGLE-STAGE OUTDOOR THERMOSTAT

HEAT

PUMP

When recovering refrigerant from a system, with a burnout, follow a

safe procedure due to possible contamination.

Avoid getting the refrigerant in the eyes or on the skin.

Contaminated refrigerant must be recovered and returned to the local

refrigeration supply house for proper disposition.

SECTION IV: ELECTRICAL CONNECTIONS

GENERAL INFORMATION & GROUNDING

Check the electrical supply to be sure that it meets the values specified

on the unit nameplate and wiring label.

Power wiring, control (low voltage) wiring, disconnect switches and over

current protection must be supplied by the installer. Wire size should be

sized per NEC requirements.

All field wiring must USE COPPER CONDUCTORS ONLY and be in

accordance with Local, National, Fire, Safety & Electrical Codes.

This unit must be grounded with a separate ground wire in accordance with the above codes.

The complete connection diagram and schematic wiring label is located

on the inside surface of the unit service access panel.

FIELD CONNECTIONS POWER WIRING

1. Install the proper size weatherproof disconnect switch outdoors and

within sight of the unit.

2. Remove th e screws from the control box cover and remove from

unit.

3. Run power wiring from the disconnect switch to the unit.

4. Route wires from disconnect through power wiring opening provided

and into the unit control box as shown in Figure 7.

5. Install the proper size time-delay fuses or circuit breaker, and make

the power supply connections.

689103-BIM-B-1012

FIGURE 7: Outdoor Unit Control Box

FIELD CONNECTIONS CONTROL WIRING

1. Route low voltage wiring into bottom of control box as shown in Figure 7. Make low voltage wiring connections inside the low voltage

box per Figure 8.

2. The complete connection diagram and schematic wiring label is

located on the inside surface of the unit service access panel.

3. Replace the control box cover removed in Step 2.

4. All field wiring to be in accordance with national electrical codes

(NEC) and/or local-city codes.

5. Mount the thermostat about 5 feet above the floor, where it will be

exposed to normal room air circulation. Do not place it on an outside

wall or where it is exposed to the radiant effect from exposed glass

or appliances, drafts from outside doors or supply air grilles.

6. Route the 24-volt control wiring (NEC Class 2) from the outdoor unit

to the indoor unit and thermostat.

To eliminate erratic operation, seal the hole in the wall at the thermostat with permagum or equivalent to prevent air drafts affecting the

operation of in the thermostat.

FIGURE 8: Typical Wiring with Thermostat and Furnace / Air Handler

Johnson Controls Unitary Products 5

A Start Assist Kit is available and recommended for long line set

applications or in areas of known low voltage problems.

Page 6

689103-BIM-B-1012

TEST

AMBIENT

AMBG

COIL G

COIL

1

2

3

4

COND

FAN

HIGH VOLTAGE

PRESSURE

M

SWITCH

REV

VALVE

X/L

R

C

Y

O

W

W1/66

X/L

R

C

Y

O

W

W1/66

DEMAND

DEFROST CURVE

SELECTION JUMPER

P

SECTION V: SYSTEM OPERATION

ANTI-SHORT CYCLE DELAY

The control includes a five-minute anti-short cycle delay (ASCD) timer

to prevent the compressor from short cycling after a power or thermostat signal interruption. The ASCD timer is applied when the control is

first powered from the indoor unit thermostat and immediately following

the completion of a compressor run cycle. The compressor and the out-

TEST INPUT

The control includes a TEST input connector that can be used for various testing functions during installation and service. The TEST input

connector is shown in Figure 9. The following table summarizes the

behavior of the control when the two TEST pins are connected. More

detailed descriptions of the various functions are included in other sections of this document.

door fan will not operate during the five minutes that the timer is active.

The ASCD timer can be bypassed by connecting the TEST terminals

for three seconds while the thermostat is calling for compressor operation (Y input signal energized).

LOW VOLTAGE DETECTION

The control monitors the transformer secondary (24 VAC) voltage and

provides low voltage protection for the heat pump and its components.

In particular, the control prevents contactor chatter during low voltage

conditions. If the voltage drops below approximately 19 VAC, the control will continue to energize any relays that are already energized but

will not energize any additional relays until the voltage level increases.

If the voltage drops below approximately 16 VAC, the control will immediately de-energize the relay outputs and will not energize any relays

until the voltage level increases.

FIGURE 9: Demand Defrost Control Module

TABLE 1:

TEST Input Functionality

Duration of connection (seconds) Control behavior

Less than 2 No response

2-6

Bypass ASCD. If Y is present and pressure switch is

closed, contactors will be energized.

Clear lockout

More than 6

Initiate defrost cycle ignoring the liquid line and outdoor ambient temp.

Energize X/L with active defrost curve flash code

Connection removed Terminate defrost as normal.

Connection not removed Continue defrost cycle and X/L flash code until TEST connection removed.

FAULT CODE DISPLAY

X/L Output

The X/L terminal of the heat pump control is typically connected to the

X/L input of the room thermostat. The thermostat uses this signal to

notify the homeowner of a problem with the heat pump using an LED or

LCD display. When the control energizes the X/L terminal, the thermostat displays the flash code so the homeowner can see it.

TABLE 2:

Condition X/L

Pressure Switch lockout - last mode of operation was heating 2 flashes

Pressure Switch lockout - last mode of operation was defrost 3 flashes

When the control locks out the compressor because of a pressure

switch lockout, it will energize the X/L output as shown in Table 2. The

control has a three second delay between fault code flashes.

DEFROST OPERATION

General

The control maintains proper airflow through the outdoor coil during

heating operation by melting frost and ice that may form on the coil.

Frost may accumulate unevenly in different sections of the coil because

of the arrangement of the refrigeration circuit within the coil. The control

may initiate a defrost cycle even when the coil is not completely covered with frost. This is normal operation.

6 Johnson Controls Unitary Products

X/L Output Categories

The control regulates the defrost operation of the heat pump.

• Defrost is based on accumulated compressor run time, outdoor

coil temperature, and outdoor ambient temperature.

The control will cause the unit to operate in the normal heating mode

until it determines that a defrost cycle is needed.

All defrost timings are based on accumulated compressor run time.

Operation

The defrost mode is equivalent to the cooling mode except that the outdoor fan motor is de-energized. The control shall do the following to initiate a defrost cycle.

• De-energize the outdoor fan

• Energize the reversing valve

• Energize the auxiliary heat output through the W1/66 terminal.

• Begin the maximum defrost cycle length timer

If the call for heating (Y) is removed from the control during the defrost

cycle, it will terminate the defrost cycle and de-energize the compressor. The control will also stop the defrost cycle length timer but not reset

it. When the control receives another call for heating, it will restart the

defrost cycle and the timer at the point at which the call for heating was

removed. This will happen only if the liquid line temperature conditions

allow defrost to occur.

Page 7

689103-BIM-B-1012

Defrost Curves

The control uses a set of defrost curve parameters that are selected

using the defrost curve selection jumper. The location of the defrost

curve selection jumper is shown in Figures 10. Table 3 shows the

jumper position that is appropriate for each heat pump model. Jumper

position 4 is not used and the control will not allow the compressor to

operate when the jumper is in this position.

Defrost Curve Selection

The factory activates the correct defrost curve during production. They

will place the defrost curve selection jumper in the P position or in a

numbered position appropriate for the specific heat pump model. You

should not have to change the defrost curve selection jumper during initial installation.

If the jumper is inadvertently moved, it should be placed in the appropriate numbered location based on the model number and Table 3. If the

factory has activated the curve using the P position, the jumper may

also be returned to that position. If, however, the factory has not activated the curve in the P position and the jumper is placed in the P position, the control will not energize the compressor. The control will also

not energize the compressor if the defrost curve selection jumper is in a

numbered position that is not described in Table 3 or if the defrost curve

selection jumper is missing. The control will display the proper fault

code when a defrost curve jumper error is present. If the jumper is missing, the control will behave as if the jumper was in the P position. If the

jumper is placed in a numbered position, the defrost curve selected by

the jumper will override the defrost curve activated at the factory until

the jumper is returned to the P position. The control will display the

active defrost curve using the X/L terminal when the heat pump is operating in a defrost cycle that has been forced using the TEST inputs.

It will also display the active defrost curve using the X/L terminal when

the operational mode is being displayed using the LED’s. For instance,

the X/L output will be energized with two flashes when defrost curve 2 is

active. The control only reads the jumper input when the Y and W thermostat inputs are de-energized. If a jumper position is changed while

either of these inputs is energized, the control will not act upon the

jumper changes until the thermostat calls are de-energized or power

(24 VAC) to the control is cycled.

Defrost Cycle Initiation

The control will allow the heat pump to operate in the heating mode until

the combination of outdoor ambient and outdoor coil temperatures indicate that a defrost cycle is necessary.

The control will initiate a defrost cycle when the liquid line temperature

is below the initiate point for the measured ambient temperature (See

Figure 10) continuously for 4-1/2 minutes. This delay eliminates unnecessary defrost cycles caused by refrigeration surges such as those that

occur at the start of a heating cycle.

The control will initiate a defrost cycle every 6 hours (accumulated compressor run time) to recirculate refrigerant lubricants. This forced

defrost timer will be reset and restarted following the completion or termination of a defrost cycle.

The control will also initiate a defrost cycle when the TEST terminals

are shorted. This feature allows an installer or service technician to start

a defrost cycle immediately as required. When the TEST terminals are

shorted for more than six seconds with a Y input energized and the

pressure switch input is closed, the ASCD will be bypassed and the

compressor and the W1/66 terminal to auxiliary heat will be energized.

When the TEST inputs are used to force a defrost cycle, the control will

ignore the state of the liquid line temperature and outdoor ambient temperature inputs. The coil does not have to be cold and the outdoor temperature does not have to be within a certain range for the heat pump to

be forced into a defrost cycle. After the TEST input jumper is removed,

the defrost mode will be terminated as normal. The defrost cycle length

timer will not be started until the TEST input is removed. If the TEST terminals remain shorted, the control will keep the unit in defrost mode.

Defrost Inhibition

The control will not initiate a defrost cycle if the liquid line temperature is

above 40F unless the defrost cycle is forced using the TEST input.

The control will not initiate a defrost cycle when the outdoor ambient

temperature is below –25F or above 55F unless the defrost cycle is

forced using the TEST input.

The control will also prevent a defrost cycle from being initiated too

soon after the initiation of the previous defrost cycle. When power is

applied to the control and after the completion or termination of each

defrost cycle, the control will start a 40-minute timer. When this timer

expires, the control will allow another defrost cycle when needed. The

timer is based on accumulated compressor run time.

Defrost Termination

The control will terminate the defrost cycle immediately after the liquid

line temperature reaches 80F or after eight minutes of defrost operation.

The control will do the following to terminate a defrost cycle.

• Energize the outdoor fan

• De-energize the reversing valve

• De-energize the auxiliary heat output through the W1/66 terminal

• Reset and restart the 40-minute defrost inhibit timer

TABLE 3:

Defrost Curve Selection Jumper Position1234

All Units All None None None

Defrost Initiate Curves

Johnson Controls Unitary Products 7

Page 8

689103-BIM-B-1012

REGION C

TERMINATE CURVE

INHIBIT CURVE

INITIATE CURVE

REGION A

REGION B

REGION D

REGION E

AMBIENT TEMPERATURE

LIQUID LINE (COIL) TEMPERATURE

Defrost prevented from starting

No call for defrost

Time Defrost (6 hour) prevented

No call for Defrost

Time Defrost (6 hour) allowed

Call for Defrost

Defrost Terminated

FIGURE 10: Defrost Operation Curves

COOLING OPERATION

During cooling operation, the control will receive thermostat signals at

the Y and O input terminals. The control will energize the M compressor

output terminal. This signal energizes the coil of the compressor contactor causing the compressor to run. The control also delivers power to

the COND FAN terminals causing the outdoor fan to operate. The control energizes the REV VALVE terminal with 24VAC to switch the

reversing valve.

HEATING OPERATION

During normal heating mode, the control will receive a thermostat signal

at the Y input terminal. The control will energize the M compressor output terminal. This signal energizes the coil of the compressor contactor

causing the compressor to run. The control also delivers power to the

COND FAN terminals causing the outdoor fan to operate. The reversing

valve is not energized in heating mode.

EMERGENCY HEAT

When the thermostat calls for emergency heat operation (W signal without a Y signal), the control will de-energize the compressor and energize the W1/66 terminal immediately.

PRESSURE SWITCH FAULT & LOCKOUT

The heat pump is equipped with a pressure switch and an optional low

pressure switch that are connected to the control at the pressure switch

terminals. If the pressure switch input opens for more than 40 milliseconds, the control will de-energize the compressor. If the pressure switch

closes and a thermostat call for compressor operation is present, the

control will apply the five-minute anti-short cycle delay timer and start

the compressor when the timer expires.

When the compressor is started following a pressure switch fault, the

control will start a six-hour timer based on accumulated compressor run

time. If the control senses another opening of the pressure switch

before the timer expires, it will cause a soft lockout condition. The second opening of the pressure switch must be greater than 160 milliseconds for the lockout to occur. If the second opening is between 40 and

160 milliseconds, the control will de-energize the compressor but not

cause a soft lockout condition. If the control does not sense a second

pressure switch opening before the six-hour timer expires, the timer and

counter will be reset.

During the soft lockout mode, the control will de-energize the compressor and energize the X/L output with the appropriate flash code.

The control will reset the soft lockout condition when any of the following occur following removal of the fault condition.

1. Power is cycled to the R or Y inputs of the control. This will cause

the soft lockout condition to be reset when the thermostat is satisfied or when the thermostat is set to SYSTEM OFF and back to

HEAT or COOL mode.

2. The TEST terminals are shorted for more than two seconds.

When the soft lockout condition is reset, the control will stop displaying

the fault code and will respond to thermostat inputs normally.

8 Johnson Controls Unitary Products

Page 9

FIGURE 11: Heat Pump Flow Diagram

CHARGE COMPENSATOR

(Empty in cooling / full in heating)

(Not included in all Units)

FIELD

CONNECTED LINE

INDOOR COIL

OUTDOOR

COIL

4-WAY

REVERSING

VALV E

FILTER DRYER

(Solid core)

SUCTION

ACCUMULATOR

LIQUID

SENSOR

COMPRESSOR

FIELD CONNECTED LINE

SHOWN IN COOLING POSITION.

COOLING CYCLE FLOW

HEATING CYCLE FLOW

BI-FLOW

TXV/CHECK

VALVE (Cooling) **

** NOTE: The indoor coil is shipped

with an orifice. The orifice must be

replaced with a TXV Kit.

BI-FLOW TXV/CHECK

VALVE OR ORIFICE (Heating)

LOW PRESSURE SWITCH

HIGH

PRESSURE

SWITCH

689103-BIM-B-1012

SECTION VI: INSTRUCTING THE OWNER

Assist owner with processing warranty cards and/or online registration.

Review Owners Guide and provide a copy to the owner and guidance

on proper operation and maintenance. Instruct the owner or the operator how to start, stop and adjust temperature setting.

When applicable, instruct the owner that the compressor is equipped

with a crankcase heater to prevent the migration of refrigerant to the

compressor during the “OFF” cycle. The heater is energized only when

the unit is not running. If the main switch is disconnected for long periods of shut down, do not attempt to start the unit until 8 hours after the

switch has been connected. This will allow sufficient time for all liquid

refrigerant to be driven out of the compressor.

The installer should also instruct the owner on proper operation and

maintenance of all other system components.

MAINTENANCE

1. Dirt should not be allowed to accumulate on the outdoor coils or

other parts in the air circuit. Clean as often as necessary to keep the

unit clean. Use a brush, vacuum cleaner attachment, or other suitable means.

2. The outdoor fan motor is permanently lubricated and does not

require periodic oiling.

3. If the coil n eeds to be cleaned, it should be washed with Calgon

Coilclean (mix one part Coilclean to seven parts water). Allow solution to remain on coil for 30 minutes before rinsing with clean water.

Solution should not be permitted to come in contact with painted

surfaces.

4. Refer to the furnace or air handler instructions for filter and blower

motor maintenance.

5. The ind oor coil a nd dra in pan should be inspected and cleaned regularly to prevent odors and assure proper drainage.

Johnson Controls Unitary Products 9

Page 10

SECTION VII: WIRING DIAGRAM

FIGURE 12: Wiring Diagram

Subject to change without notice. Published in U.S.A. 689103-BIM-B-1012

Copyright © 2012 by Johnson Controls, Inc. All rights reserved. Supersedes: 689103-BIM-A-0412

York International Corp.

3110 N Mead

Wichita, KS 67219

Loading...

Loading...