Page 1

24-9601-0, Rev. C

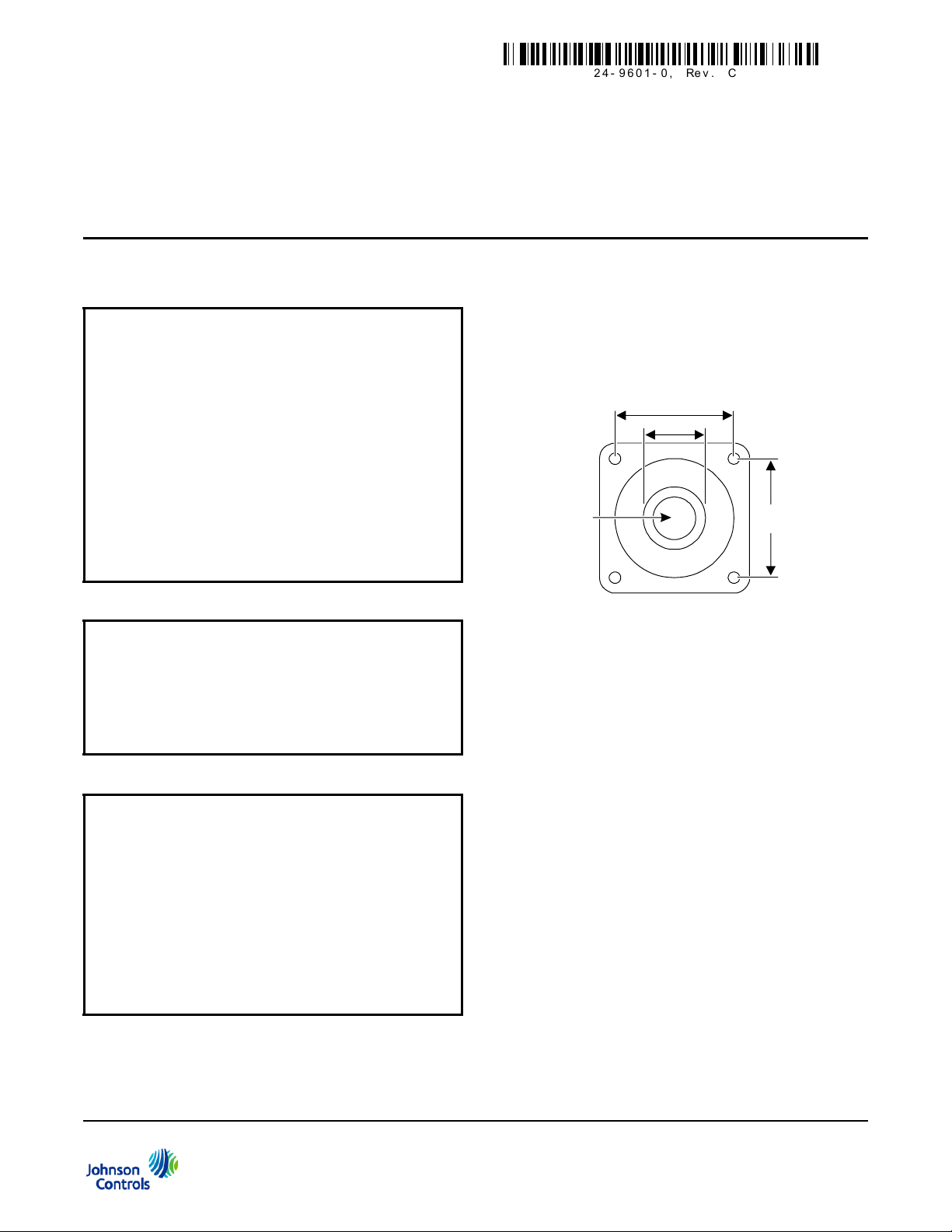

Figure 1: Mounting Holes on the Flange

Dimensions in. (mm)

0.87 (22)

Center

Hole

1.65 (42)

1.54 (42)

FIG:dim

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter

Installation Instructions

CD-Pxx-00-0

Refer to the QuickLIT website for the most up-to-date version of this document.

Part No. 24-9601-0, Rev. C

Issued April 2016

North American Emissions Compliance

United States

This equipment has been tested and found to

comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when this equipment is

operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

the user will be required to correct the interference

at his/her own expense.

Canada

This Class (A) digital apparatus meets all the

requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte

toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Installation

Parts Included

The duct mount CO2 transmitter is shipped assembled.

It consists of three main pa rts: ba se and Pr inted Circuit

Board (PCB), cover, and mounting flange with four

screws (for probe depth adjustment). A conduit adaptor

is also included.

Dimensions

Mounting

Location Considerations

When selecting a location for the transmitter, note the

following:

• The transmitter is designed for duct mounting in

any position.

IMPORTANT: The CD-Pxx-00-0 Duct Mount CO

Transmitter is intended to provide an input to

equipment under normal operating conditions.

Where failure or malfunction of the transmitter could

lead to personal injury or property damage to the

controlled equipment or other property, additional

precautions must be designed into the control

system. Incorporate and maintain other devices,

such as supervisory or alarm systems or safety or

limit controls, intended to warn of or protect against

failure or malfunction of the transmitter.

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter Installation Instructions

2

• The probe is best mounted in the return airstream.

• The device should penetrate the duct by a

minimum of 3.0 in. (76.2 mm) to ensure the

sensing part of the element is fully in the airstream.

• The transmitter should be placed in an area free of

condensation.

The transmitter is duct mounted using a flange. The

mounting flange adjusts the distance betwee n the

probe and the inner duct wall. Fasten the mounting

flange with the four screws as follows:

1. Loosen the probe retention screw, and separate

the flange from the assembled unit.

2. Drill a hole 7/8 to 1 in. (22 to 25 mm) diameter in

the duct for the transmitter’s probe.

1

Page 2

3. Using the mounting flange as a template centered

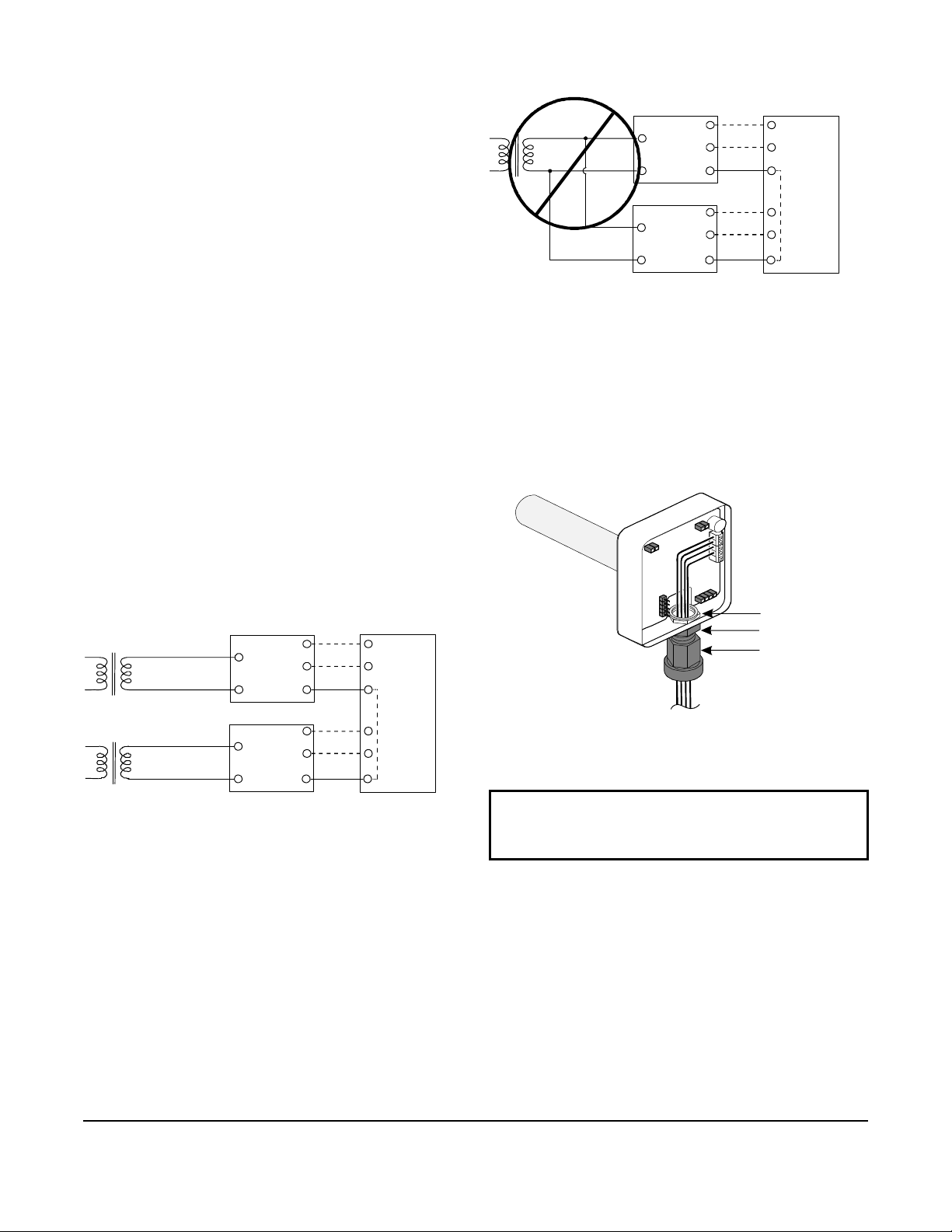

Figure 2: Connecting Separate AC Supplies

(Recommended)

~

+

~

-

~

+

~

-

0

Shared

Common

Line

24 VAC

Supply

Voltage

CO Transmitter

2

24 VAC

Supply

Voltage

Output

SignalsCO Transmitter

2

Controller

V

0

mA

or

V

mA

or

FIG:conn ac1

0

Line

Supply

Voltage

CO Transmitter

2

24 VAC

Supply

Voltage

SignalsCO Transmitter

2

Controller

~

+

~

-

~

+

~

-

mA

or

mA

or

FIG:conn_ac2

Figure 3: Connecting One AC Supply to Several

Transmitters (Not Recommended)

Figure 4: Inserting the Conduit Adaptor

Nut

Adaptor Body

Adaptor

FIG:ins_cond

on the hole, drill four 1/8 in. (3.18 mm) holes for the

mounting screws positioned as in Figure 1.

4. Fasten the mounting flange onto the duct using the

four screws provided.

5. Insert the probe a minimum of 3.0 in. (76 .2 mm) ,

and tighten the probe retention screw on the

mounting flange.

Wiring

Power Supply Requirements

The transmitter requires a 24 VAC/VDC, Class 2 power

supply maintaining voltages of 18 to 30 VDC or 20 to

30 VAC. Although the power input includes a halfwave

rectifier, we recommend using a DC supply to avoid

excessive current peaks (current consumption: peak,

170 mA; average, 85 mA).

24 VAC Power Supply Connections

When more than one transmitter is connected to one

24 VAC transformer, a common loop is formed at the

controller, an d the risk of a short circuit increases.

All commons must be at the same potential.

Output

V

0

Shared

V

Common

Connecting the Conduit Adaptor

1. Align the nut with the opening inside the enclosure,

and hold it in place.

2. Insert the adaptor body into the transmitter conduit

opening.

3. Manually tighten the adaptor into the nut, turning in

a Clockwise (CW) direction (see Figure 4).

Note: To avoid a short circuit, isolate the 24 V power

supply by providing a separate transformer for each

transmitter as shown in Figure 2.

If several transmitters share one transformer, the

phase (~) must always be the same at each transmitter

to maintain polarity and avoid a short circuit via a

shared common line at the controller, as shown in

Figure 3.

IMPORTANT: Do not overtighten the conduit

adaptor. Overtighting the conduit adaptor may

damage or displace the PCB.

4. Insert the wires through the conduit adaptor body

opening.

5. Tighten the adaptor onto the adaptor body by

turning the adaptor in a CW direction.

Wiring the PCB

To wire the PCB’s input and output connections:

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter Installation Instructions

1. Open the transmitter cover.

2

Page 3

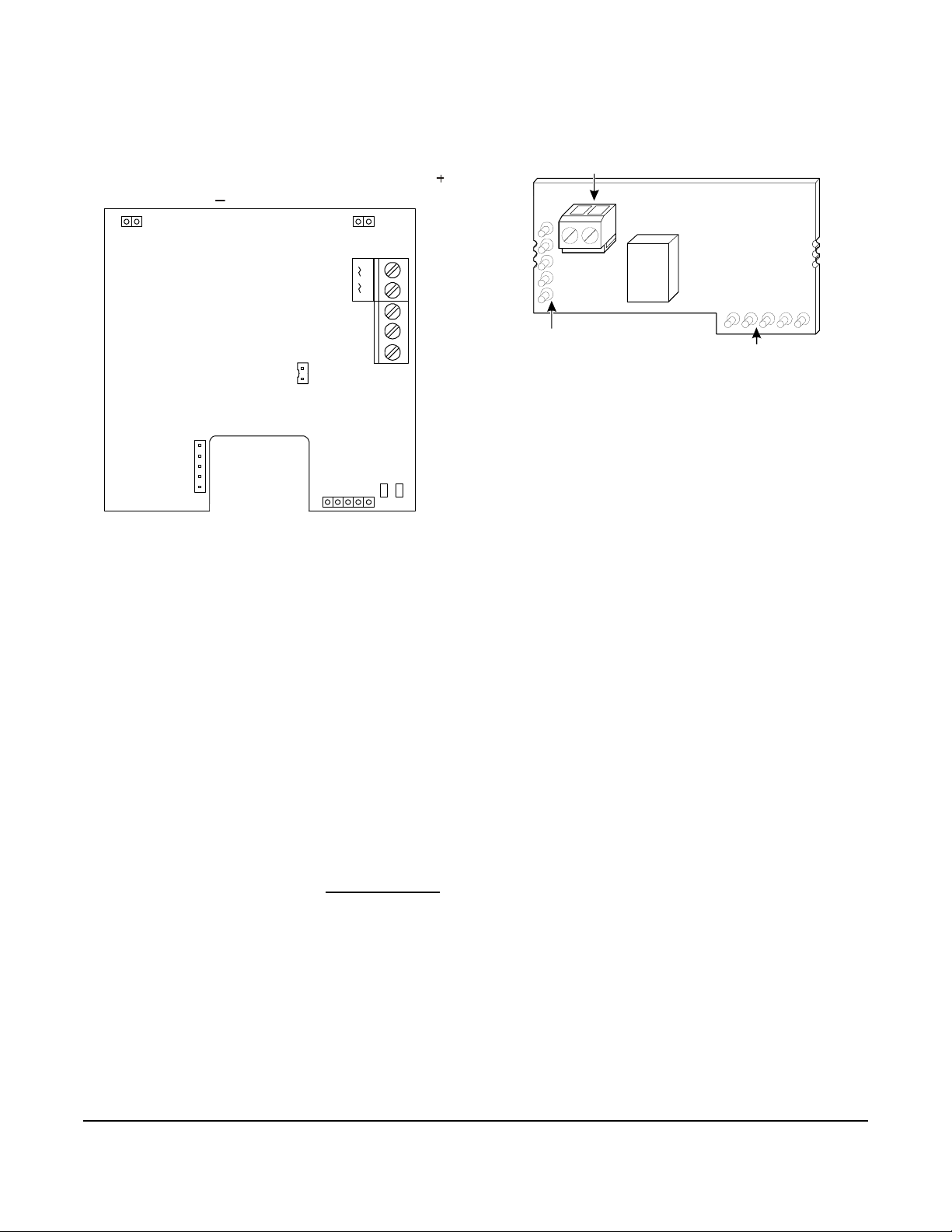

2. Insert the wire carefully through the conduit

S

V7

X3

X6

X5

FIG:trans_PCB

Figure 5: Transmitter PCB

Screw Terminals

Connect to X5

FIG:Rel_PCB

Figure 6: Relay PCB

adaptor and then strip 1/4 in. (6.35 mm) of the wire

insulation to prepare the wire for connection to the

terminal block.

3. Connect the 24V supply between the po sitiv e ( )

and negative ( ) terminals as shown in Figure 5.

~

X7

— +

~

Wiring the Relay

Model CD-PR0-00-0 is shipped with a relay module. To

wire the relay, see Figure 6, and attach the relay wires

to the relay PCB's two screw terminals.

mA V 0

0/4mA

ERIAL COM

V10

Configuring the Output

The transmitter is capable of generating either voltage

or current output. To select, refer to Figure 5 and:

1. Connect the common wire to Terminal 0.

2. Connect the other wire to:

• Terminal V (for voltage output)

• Terminal mA (for current output) and configure

the pins marked 0/4mA as follows:

- 4 to 20 mA: connect the jumper so that it

shorts the pins (default)

- 0 to 20 mA: disconnect (do not discard) the

jumper

Connect to X3

The relay has two setpoint values: the On level and the

Off level. These levels provide hysteresis and desired

control function. The On level must be higher than the

Off level. When CO

concentration is increasing; the

2

relay closes at the On level, and the relay opens when

concentration is reduced to the Off level.

Note: The default relay setpoints are 1,000 ppm On

and 950 ppm Off. Change these settings by entering

new values using the Relay Setpoint Software

ACCCDS.

Setup and Adjustments

Commissioning

Johnson Controls® Carbon Dioxide (CO2) transmitters

come from the factory calibrated for the following:

• output signal (0 to 10 V) proportional to CO

concentration (0 to 2,000 parts per million [ppm])

• altitude range of 0 to 1,969 ft (0 to 600 m) above

sea level without compensation

• default relay output trigger point of 1,000 ppm

2

3. If the unit has an optional relay accessory, follow

the procedure described in the Wiring the Relay

section and then reposition the cover .

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter Installation Instructions

3

Page 4

Altitude Compensation

CF

Altitude (Feet)

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

01,000

2,000

3,000

4,000

FIG:alt_ft

Figure 7: Altitude Compensation in Feet Above Sea Level

CF

Altitude (Meters)

0200

400

600 800 1,000 1,200 1,400 1,600

1,800 2,000 2,200

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

FIG:alt_mtr

Figure 8: Altitude Compensation in Meters Above Sea Level

The sensors are calibrated for an altitude of 984 ft

(300 m) above sea level and are intended for

applications within the range of 0 to 1,969 ft

(0 to 600 m) without compensation.

For altitudes above 1,969 ft (600 m) where optimum

accuracy of the CO

essential, modify the Building Automation System

(BAS) controller’s Analog Input (AI) high range to

compensate for sensor placement at other than the

standard calibration altitude.

Note: For altitude compensation, only adjust the AI

high range. The AI low range should remain at zero.

1.30

concentration measurement is

2

To modify the controller’s AI, reset the 2,000 ppm value

using the controller's Compensation Factor (CF) shown

in Figure 7 or Figure 8 as follows:

Corrected Value = CF x 2,000

For example, if the sensor is situated at an altitude of

3,000 ft (914.4 m) above sea level, CF, from either

Figure 7 or Figure 8, is 1.10.

The new value is calculated as follows:

Corrected Value = (1.10)(2,000 ppm) = 2,200 ppm

1.30

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter Installation Instructions

4

6,000

7,000

Page 5

Troubleshooting

The transmitter is not field repairable.

In the event the unit is not functioning properly, perform

the following to identify the symptoms and determine a

solution; verify that:

1. the unit is mounted properly and the ap pr o pr iate

output jumper is selected

2. all wiring is correct

3. the power supply voltage level is 20 to 30 VAC or

18 to 30 VDC

Note: The diagnostic Light Emitting Diodes (LEDs)

shown in the lower right-hand corner of Figure 5

indicate operational status:

• V7 lights up if the self-diagnostics procedure

detects an abnormality.

• V10 pulses to indicate that the device is

operational.

If the transmitter does not operate after completing

these steps, replace the unit.

5. Determine whether the contacts are open or

closed.

• If the contacts are closed, the relay is

functioning properly, and no further testing is

necessary.

• If the contacts are open, increase the CO

concentration by exhaling near the probe,

looking for a change in the resistance value.

• If no change is noted, confirm that the CO

concentration has been raised above the trip

point.

- Check the transmitter output signal with a

voltmeter to make sure the signal has risen

above the 1,000 ppm relay trip point.

- If the output signal has not reached the trip

point, it may be necessary to further

increase the CO

concentration.

2

• If the contacts are open after exceeding the trip

point, replace the unit with the appropriate

module, and restart this procedure.

2

2

Testing the Relay Module

To confirm that the relay is operating correctly, perform

the following procedure:

IMPORTANT: To expose the sensing portion of the

probe, loosen the probe retention screw, and

remove the probe from the duct. After testing is

complete, reinstall the probe, and tighten the probe

retention screw.

1. Temporarily shut off power to the unit.

2. Temporarily remove wires connected to the relay

screw terminal.

3. Connect a multimeter to the relay terminals.

4. Read the resistance level to determine whether the

contacts are open or closed.

• If the contacts are closed, replace the unit with

the appropriate relay module, and restart this

procedure.

• If the contacts are open, apply power to the

transmitter.

6. Disconnect power to the transmitter.

7. Disconnect the multimeter from the relay terminals.

8. Reconnect the wires to the relay screw terminal.

9. Reconnect power to the transmitter.

10. Reposition the cover.

Repair Information

If the CD-Pxx-00-0 Series Duct Mount CO2 Transmitter

fails to operate within its specifications, replace the

unit. For a replacement transmitter, contact the nearest

Johnson Controls representative.

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter Installation Instructions

5

Page 6

Metasys® and Johnson Controls® are registered trademarks of Johnson Controls, Inc.

All other marks herein are the marks of their respective owners. © 2016 Johnson Controls, Inc.

Building Efficiency

507 E. Michigan Street, Milwaukee, WI 53202

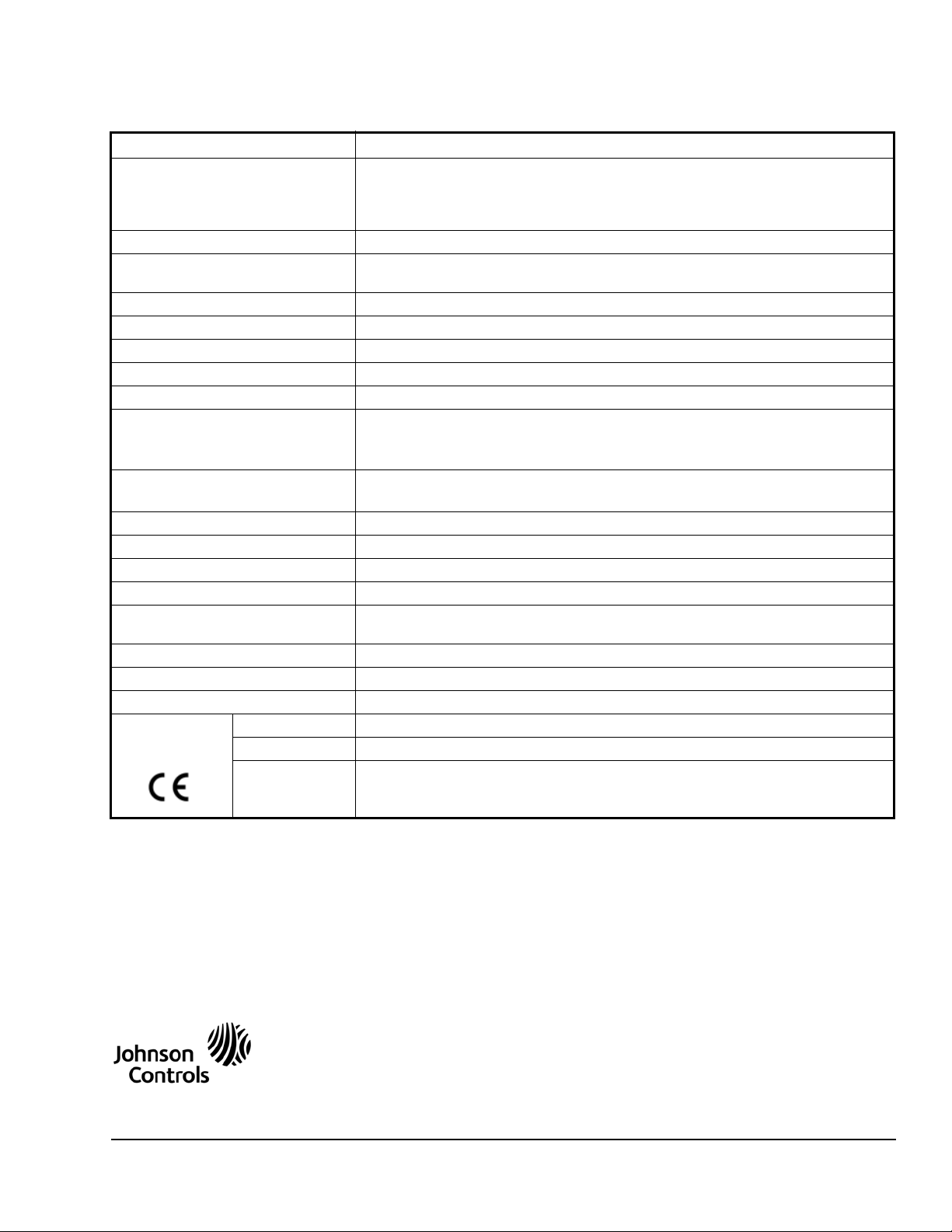

Technical Specifications

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter

Measuring Range 0 to 2,000 ppm CO

Accuracy at 77°F (25°C) < ±[30 ppm CO2 + 2.0% of reading] (includes manufacturing deviation and drift). All

accuracy specifications reflect testing the transmitters using high-grade, certified

gases. Transmitters are intended for an altitude range of 0 to 1,969 ft (0 to 600 m)

above sea level without compensation

Non-Linearity < 0.5% of Full Scale

Temperature of Dependence of

Output

Long-Term Stability < ±5.0% of Full Scale/5 Years

Response Time (0 to 63%) 1 Minute

Operating Temperature Range 23 to 113°F (-5 to 45°C)

Storage Temperature Range -4 to 158°F (-20 to 70°C)

Humidity Range 0 to 85% non-condensing

Transmitter Output Signal CO

Recommended External Load Current Output: Maximum 500 ohms Load Resistance

Power Supply Range 20 to 30 VAC (18 to 30 VDC), Class 2

Power Consumption < 2.5 W Average, 4.1 VA

Warm-up Time < 5 minutes

Airflow Range 0 to 7,500 ft/Minute (0 to 2,286 m/Minute)

Duct Probe Material Duct Probe Meets Plenum Rating Requirements of UL 1995, Heating and Cooling

Housing Material ABS Plastic

Dimensions (H x W x D) 3-5/32 x 3-3/16 x 8 in. (80 x 81 x 204 mm)

Shipping Weight 0.3 lb (140 g)

Compliance United States UL Listed, CCN XAPX

Canada UL, LIsted XAPX7

Europe CE Mark – Johnson Controls, Inc. declares that the CD-Pxx-00-0 Duct Mount CO2

2

< 0.56% of Full Scale/F° (<0.1% of Full Scale/C°)

Jumper Selectable: 0 to 20 mA or 4 to 20 mA or 0 to 10 VDC (Default)

Maximum Output Current: 25 mA; Maximum Output Voltage: 12.5 V

Maximum 30 V, 0.5 A, Class 2

Voltage Output: Minimum 1,000 ohms Load Resistance

Equipment

Transmitters are in compliance with the essential requirements and other relevant

provisions of the EMC Directive.

2

European Single Point of Contact: NA/SA Single Point of Contact: APAC Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

CD-Pxx-00-0 Series Duct Mount CO2 Transmitter Installation Instructions 6

Published in U.S.A.

www.johnsoncontrols.com

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO.22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

Loading...

Loading...