Page 1

INSTALLATION MANUAL

VARIABLE SPEED ECM

SINGLE PIECE MULTI-POSITION

AIR HANDLERS

MODELS: A VC SERIES

LIST OF SECTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

DUCT WORK AND CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . .8

COIL METERING DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

REFRIGERANT LINE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . .11

CONDENSATE DRAIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . .12

ELECTRIC HEATER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . .13

LINE POWER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

LIST OF FIGURES

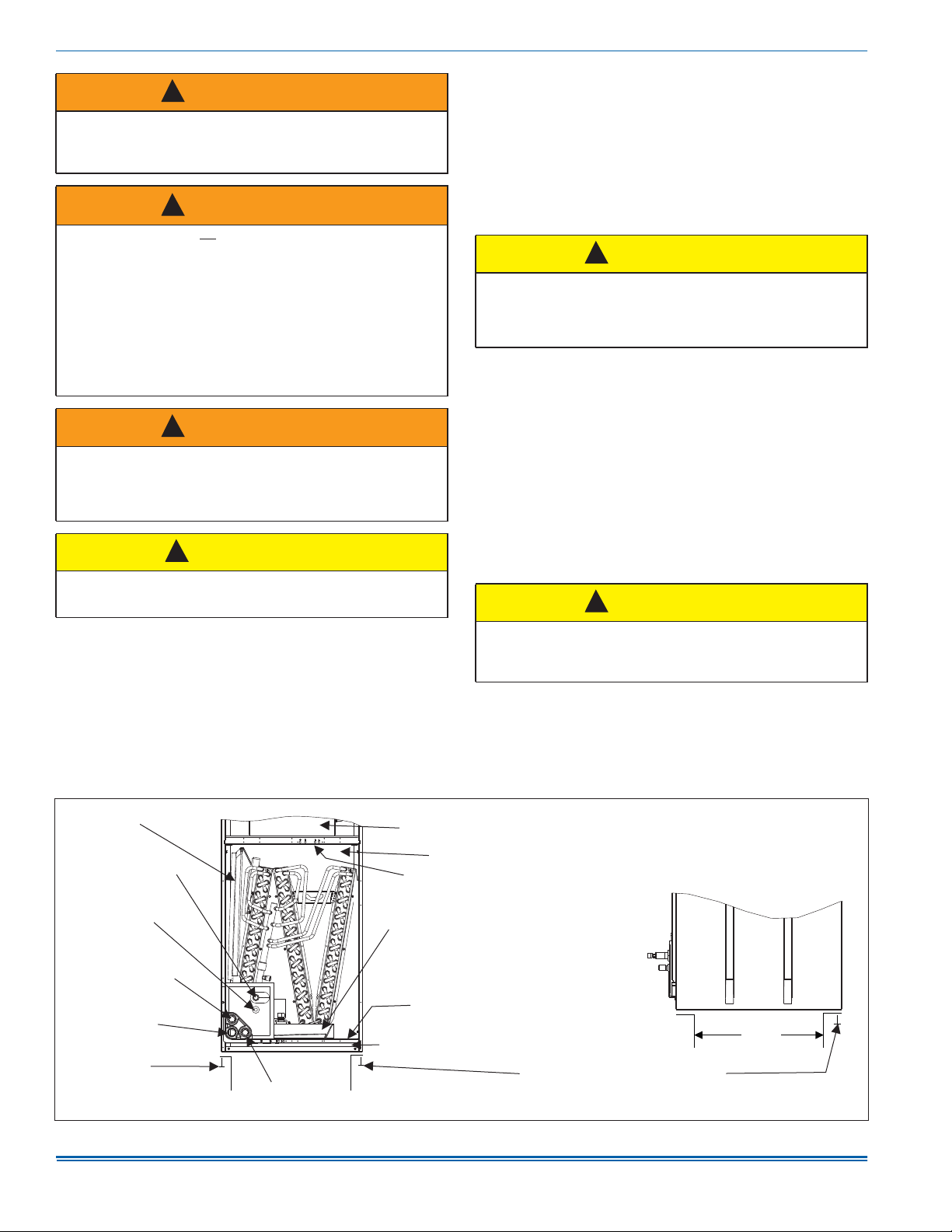

Return Air Duct Attachment & Component Location . . . . . . . . . . . . . .2

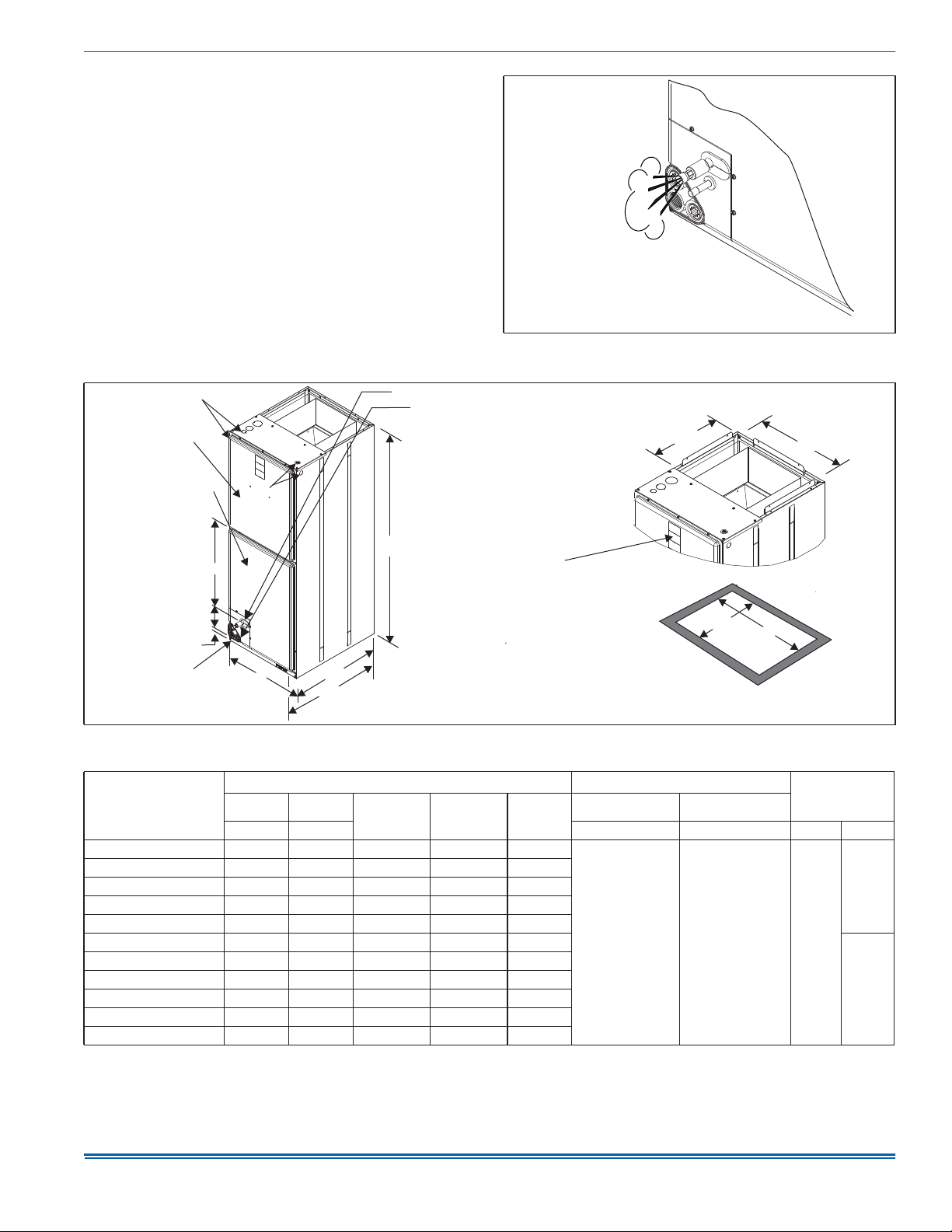

Pressure Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

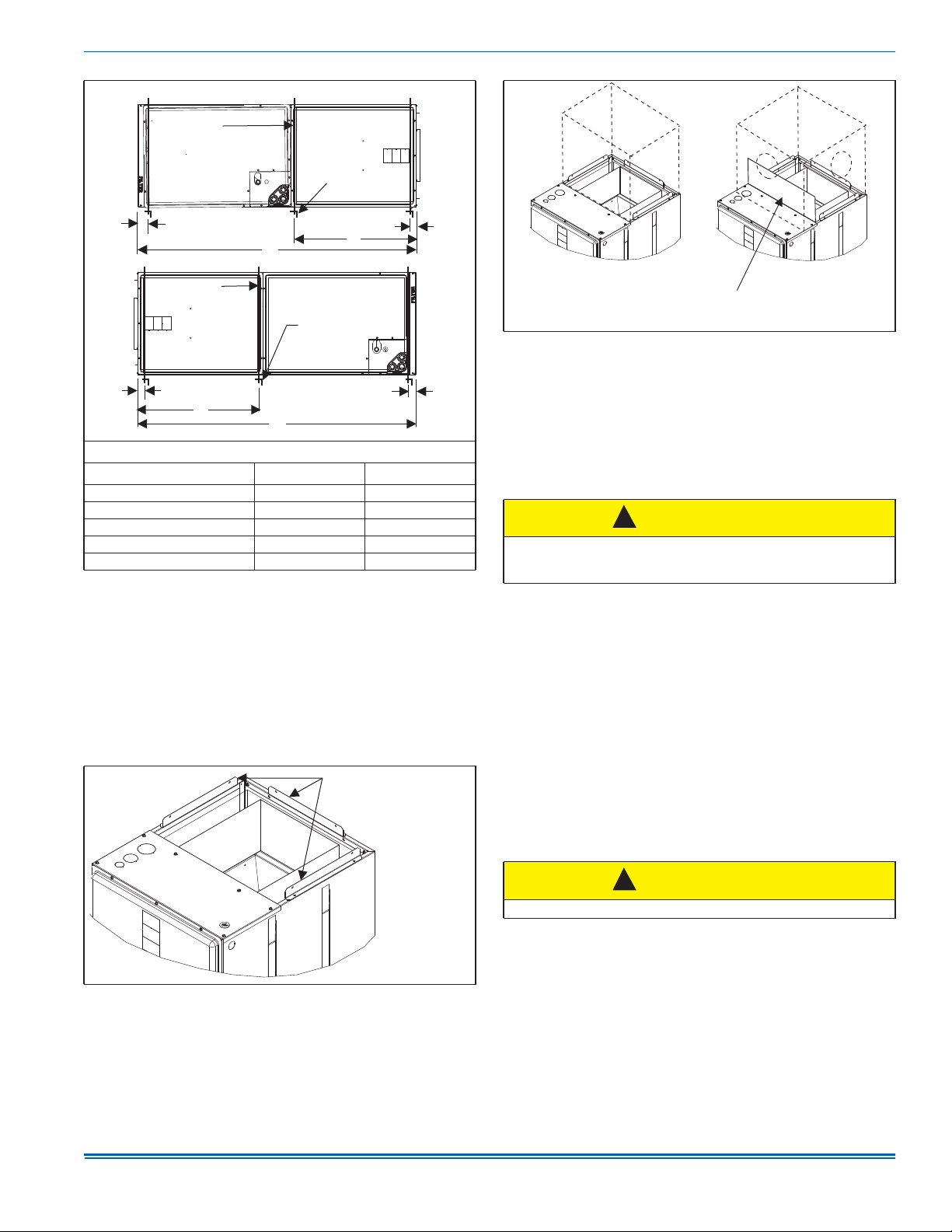

Dimensions & Duct Connection Dimensions . . . . . . . . . . . . . . . . . . . .3

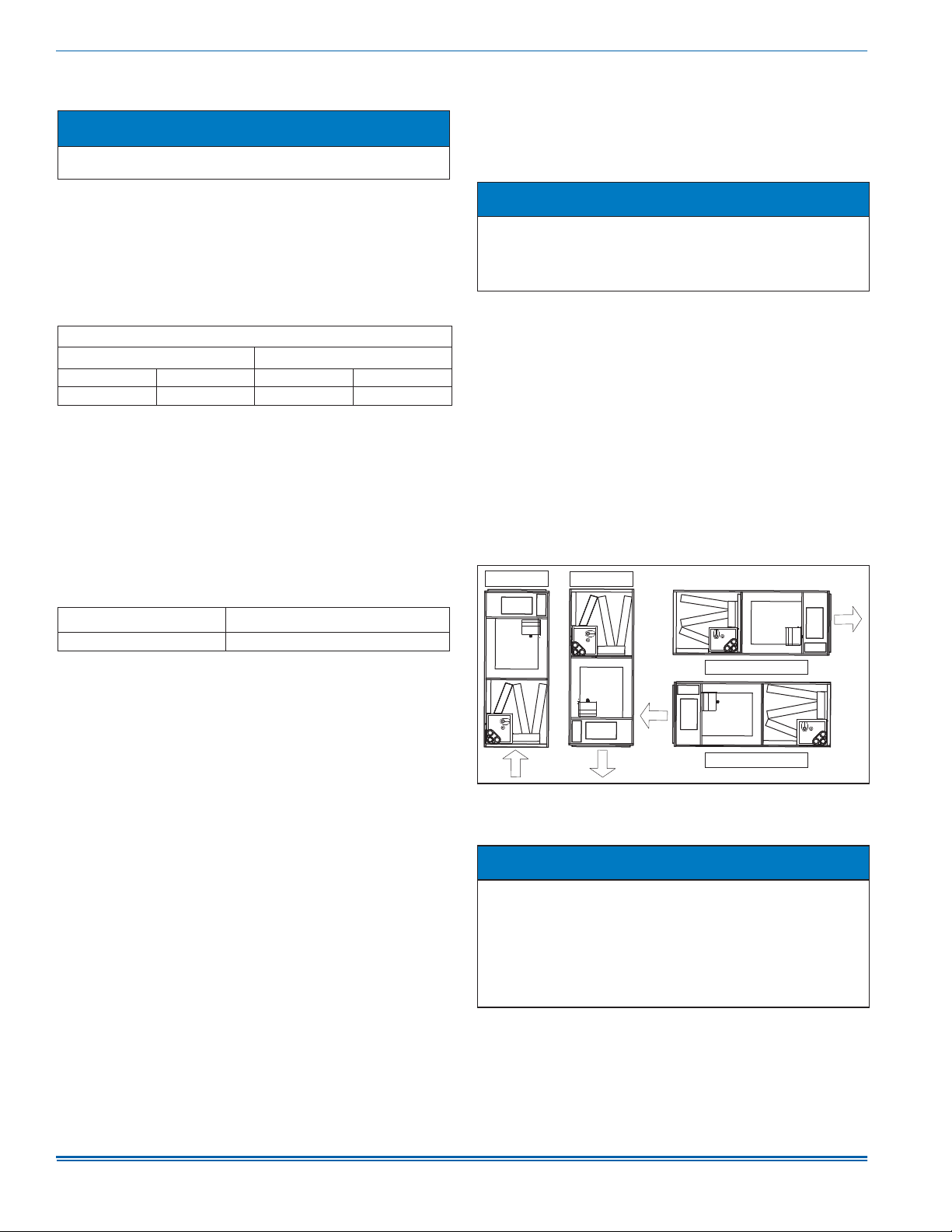

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Horizontal Pan Adjustment Strap Hole Reference . . . . . . . . . . . . . . . .5

Coil Condensate Deflector Installation . . . . . . . . . . . . . . . . . . . . . . . . .6

Recommended Position of Coil to Install Downflow/Horizontal Right

Condensate Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation of Downflow Condensate Diverter Shields . . . . . . . . . . . . .7

60C Horizontal Right Condensate Deflectors . . . . . . . . . . . . . . . . . . .7

60C Horizontal Right Coil Condensate Final Assembly . . . . . . . . . . . .7

Condensate Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Horizontal Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Duct Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Duct Work Transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Recommended Distributor Adjustment . . . . . . . . . . . . . . . . . . . . . . .10

Piston Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

LOW VOLTAGE CONTROL CONNECTIONS . . . . . . . . . . . . . . . . . 13

REQUIRED CONTROL SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AIRFLOW AND COMFORT SETTING SELECTION . . . . . . . . . . . . 17

UNIT DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

AIR SYSTEM ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

INSTALLATION VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

START UP SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

TXV Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TXV Bulb and Equalizer line Installations . . . . . . . . . . . . . . . . . . . . . 11

Proper Bulb Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Vertical Temperature Bulb Orientation . . . . . . . . . . . . . . . . . . . . . . . 11

Vapor Line Grommet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Line Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooling Models with and without Electric Heat Wiring . . . . . . . . . . . 15

Two-Stage Heat Pump Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Air Handler with Communicating AC or HP . . . . . . . . . . . . . . . . . . . 16

Multi-wire Terminal Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Duct Static Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Drain Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Location of Coil Trapped and Plugged Drain Connections . . . . . . . . 26

Wiring Diagram - ECM - Single Phase Heat Kits . . . . . . . . . . . . . . . 27

Wiring Diagram - Three Phase Heat Kits 208-230V . . . . . . . . . . . . . 28

ISO 9001

Certified Quality

Management System

LIST OF TABLES

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Horizontal Pan Strap Settings for Horizontal Left . . . . . . . . . . . . . . . . .5

Low Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Heat Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Comfort Setting Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Physical and Electrical Data - Cooling Only . . . . . . . . . . . . . . . . . . . .18

Electrical Data - Cooling Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SECTION I: GENERAL

The single piece air handler series provides the flexibility for installation

in any position. This unit may be used for upflow, downflow, horizontal

right, or horizontal left applications.

These units may be located in a closet, utility room, attic, crawl space,

or basement. These versatile models may be used for cooling or heat

pump operation with or without electric heat.

Top or side power and control wiring, color coded leads for control

wiring, easy to install drain connections, and electric heaters all

combine to make the installation easy and minimize installation cost.

Electric heat kits are available as field installed accessories. Single

phase kits are available from 2.5 kW to 25 kW. 208-230 volt three

phase kits are available from 10kW to 25kW.

Electrical Heat: Minimum Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . 18

KW & MBH Conversions - For Total Power Input Requirement . . . . 19

Electric Heat Performance Data: 208/230-1-60 & 208/230-3-60 . . . 19

Electrical Data For Single Source Power Supply: 208/230-1-60 . . . 20

Electrical Data For Multi-source Power Supply: 208/230-1-60 . . . . . 22

Electrical Data For Single Source Power Supply: 208/230-3-60 . . . 23

Electrical Data For Multi-source Power Supply: 208/230-3-60 . . . . . 24

Air Flow Data (CFM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SECTION II: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or moderate injury. It is also used to

alert against unsafe practices and hazards involving only property

damage.

Johnson Controls Ducted Systems 5493974-UIM-B-0419

Page 2

5493974-UIM-B-0419

!

WARNING

FIRE OR ELECTRICAL HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage. A fire or electrical hazard may result

causing property damage, personal injury or loss of life.

!

WARNING

The air handler area must not be used as a broom closet or for any other

storage purposes, as a fire hazard may be created. Never store items

such as the following on, near or in contact with the furnace.

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum cleaners or other cleaning tools.

2. Soap powders, bleaches, waxes or other Cleaning compounds;

plastic items or containers; gasoline, kerosene, cigarette lighter

fluid, dry cleaning fluids or other volatile fluid.

3. Paint thinners and other painting compounds.

4. Paper bags, boxes or other paper products

Never operate the air handler with the blower door removed. To do so

could result in serious personal injury and/or equipment damage.

!

WARNING

Improper installation, adjustment, alteration, or maintenance may create a condition where the operation of the product could cause personal injury or property damage. Refer to this manual for assistance,

or for additional information, consult a qualified contractor, installer, or

service agency.

!

CAUTION

This product must be installed in strict compliance with the installation

instructions and any applicable local, state, and national codes

including, but not limited to building, electrical, and mechanical codes.

SAFETY REQUIREMENTS

1. Failure to carefully read and follow all instructions in this manual

can result in air handler malfunction, death, personal injury and/or

property damage.

2. This air handler should be installed in accordance with all national

and local building/safety codes and requirements, local plumbing

or wastewater codes, and other applicable codes.

3. This air handler should be installed only in a location and position

specified in the “Unit Installation” section of this Instruction Manual.

4. The air handler is not to be used for temporary heating of buildings

or structures under construction.

5. Always install the air handler to operate within the air handler’s

intended maximum outlet air temperature.

6. The unit rating plate displays the air handler model number. The

unit dimensions for the supply air plenum are provided in Figure 3

and Table 1 of this Instruction Manual. The plenum must be

installed according to the instructions.

7. Clearance from combustible material is provided under “Clearances” in the “Unit Installation” section.

!

CAUTION

DO NOT lift air handler by the cabinet braces. The cabinet braces are

held in place by the coil channels. The cabinet braces could become

disengaged from the cabinet causing the air handler to fall, potentially

causing injury or damaging property. See Figure 1 for location of cabinet braces. Lift the air handler by tightly gripping the casing.

8. It is necessary to maintain clearances for servicing. Access must be

allowed for electric heaters and blower.

9. The unit rating plate and power supply must be verified to ensure

that the electrical characteristics match.

10. Air handler shall be installed so the electrical components are pro-

tected from water.

11. Installing and servicing heating/cooling equipment can be hazard-

ous due to the electrical components. Only trained and licensed

personnel should install, repair, or service heating/cooling equipment. Unlicensed service personnel can perform basic maintenance functions such as cleaning and replacing the air filters. When

working on heating/cooling equipment, the precautions in the manuals and on the labels attached to the unit and other safety precautions must be observed as applicable.

!

CAUTION

These air handlers should be transported & handled in an upright,

upflow position. Failure to do so may result in unit damage and personal injury. Configuration conversions should be done at site of

installation.

12. These instructions cover minimum requirements and conform to

existing national standards and safety codes. In some instances

these instructions exceed certain local codes and ordinances,

especially those who have not kept up with changing residential

and non-HUD modular home construction practices. These instructions are required as a minimum for a safe installation.

HORIZONTAL

DRAIN PAN

VAP OR

REFRIGERANT

LINE CONNECTION

LIQUID

REFRIGERANT

LINE CONNECTION

SECONDARY DRAIN

HORIZONTAL FLOW

3/4” NATIONAL PIPE

THREAD (NPT)

PRIMARY DRAIN

3/4” NPT

DUCTWORK MAY

BE FASTENED

CAUTIOUSLY WITH

SCREWS TO THE

SIDES AND REAR OF UNIT

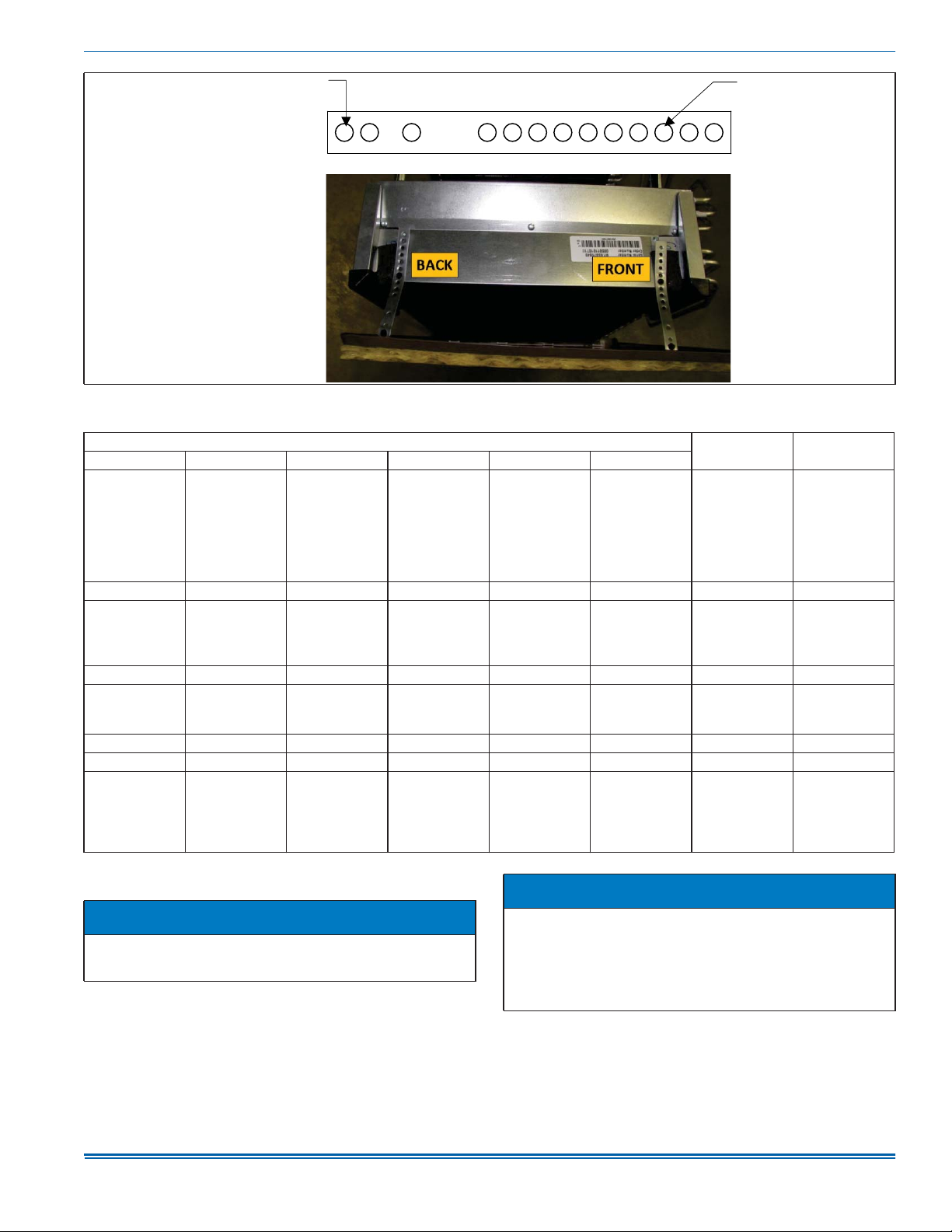

FIGURE 1: Return Air Duct Attachment & Component Location

FRONT VIEW

SECONDARY DRAIN

UPFLOW 3/4” NPT

BLOWER

COMPAR TMENT

COIL COMPART MENT

(Access panel removed)

CABINET BRACE

VERTICAL

DRAIN PAN

CABINET BRACE

FILTER DOOR

WHEN ATTACHING DUCTWORK WITH

SCREWS - KEEP SCREWS WITHIN 5/8”

OF SIDES AND BACK OF AIR HANDLER

SIDE VIEW

RETURN AIR

DUCT

A0328-001

2 Johnson Controls Ducted Systems

Page 3

INSPECTION

As soon as a coil is received, it should be checked to insure it is still

under pressure per Figure 2. The coil should be inspected for possible

damage during transit. If damage is evident, the extent of the damage

should be noted on the carrier’s freight bill. A separate request for

inspection by the carrier’s agent should be made in writing. The Local

Distributor should be consulted for more information. The drain pan

should be checked for cracks or breakage. Before installation, the unit

should be checked for screws or bolts which may have loosened in

transit. There are no internal shipping or spacer brackets that need to

be removed.

It should be verified that all accessories such as heater kits are

available. Installation of these accessories or field conversion of the unit

should be accomplished before setting the unit in place or connecting

any wiring, duct work or piping.

DEPRESS SCHRADER

CORE TO CHECK FOR

PRESSURE ONE TIME.

NOTE:

Verify that the coil is under

pressure when received.

FIGURE 2: Pressure Check

5493974-UIM-B-0419

A0271-001

F

BLOWER

COMPAR TMENT

COIL

COMPAR TMENT

7-11/32

1-1/2”

FILTER ACCESS

C

G

B

20-1/2”

21-7/16”

FIGURE 3: Dimensions & Duct Connection Dimensions

TABLE 1: Dimensions

Dimensions

Models

AB

Height Width Power Control Liquid Vapor

18B 41 17-1/2 12-7/8 14-1/4 16-1/2

24B 41 17-1/2 12-7/8 14-1/4 16-1/2

30B 47-1/2 17-1/2 19-1/2 14-1/4 16-1/2

36B 47-1/2 17-1/2 19-1/2 14-1/4 16-1/2

36C 51-1/2 21 22-5/8 17-3/4 20

42C 51-1/2 21 22-5/8 17-3/4 20

48C 51-1/2 21 22-5/8 17-3/4 20

48D 55-1/2 24-1/2 26-5/8 21-1/4 23-1/2

49C 51-3/4 21 26-5/8 17-3/4 20

60C 55-3/4 21 26-7/8 17-3/4 20

60D 55-1/2 24-1/2 26-5/8 21-1/4 23-1/2

1. All dimensions are in inches.

2. Actual size (Conduit size in parenthesis).

REFRIGERANT CONNECTIONS

DRAIN CONNECTIONS

FOR UPFLOW APPLICATIONS

A

1

SERVICE

DISCONNECT

PANEL

CDE

1-23/32 (1-1/4)

12-3/16”

18-5/8”

Wiring Knockouts

D

2

FG

7/8 (1/2)

1-3/8 (1)

7/8 (1/2) 3/8

TOP OUTLET

DIMENSIONS

E

BOTTOM INLET

DIMENSIONS

A0329-001

Refrigerant

Connections

Line Size

3/4

7/8

Johnson Controls Ducted Systems 3

Page 4

5493974-UIM-B-0419

SECTION III: UNIT INSTALLATION

NOTICE

Avoid handling aluminum coil components after handling the copper

line set or other tubing without first cleaning hands.

UNIT SIZING

1. The size of the unit should be based on an acceptable heat loss or

gain calculation for the structure. The ACCA – Manual J or other

approved methods may be used. Reference Figure 3 & Table 1.

2. Only connect the air handler to a duct system which has an external

static pressure within the allowable range.

3. Airflow must be within the minimum and maximum limits approved

for electric heat, indoor coils and outdoor units.

Entering Air Temperature Limits

Wet Bulb Temp. °F Wet Bulb Temp. °F

Min. Max. Min. Max.

57 72 65 95

4. When an air handler is installed so that supply ducts carry air circulated by the air handler to areas outside the space containing the

air handler, the return air shall also be handled by duct(s) sealed to

the air handler casing and terminating in the space to be cooled/

heated.

5. Refer to the unit rating plate for the air handler model number, and

then see the dimensions page of this instruction for supply air plenum dimensions. The plenum must be installed according to the

instructions.

6. The installer must check available supply power and verify that it is

within the normal operating voltage range for the unit. The acceptable voltage range for these units is as follows:

Air Handler Voltage

208V-230V-1-60 187V-253V

1. Rated in accordance with ARI Standard 110, utilization range “A”.

Normal Operating 1 Voltage Range

3. Normal operating sound levels may be objectionable if the air handler is placed directly over some rooms such as bedrooms, study,

etc.

4. Select a location that will permit installation of condensate line to an

open drain or outdoors allowing condensate to drain away from

structure.

NOTICE

The primary and secondary drain line must be trapped to allow proper

drainage of condensate water. The secondary drain line should be

piped to a location that will give the occupant a visual warning that the

primary drain is clogged. If the secondary drain line is not used, it

must be capped.

5. When an indoor coil is installed in an attic or above a finished ceiling, an auxiliary drain pan should be provided under the air handler

as is specified by most local building codes.

6. Proper electrical supply must be available.

7. If unit is located in an area of high humidity (i.e. an unconditioned

garage or attic), nuisance sweating of casing may occur. On these

installations, unit duct connections and other openings should be

properly sealed, and a wrap of 2” fiberglass insulation with vinyl

vapor barrier should be used.

AIR HANDLER CONFIGURATION

These air handler units are supplied ready to be installed in an upflow

or horizontal left position. Refer to Figure 4. If the unit requires either

downflow or horizontal right airflow configurations, the unit must have

the coil assembly repositioned. Refer the Downflow or Horizontal Right

Conversion procedures.

UPFLOW

HEAT

DOWNFLOW

HEAT

HORIZONTAL RIGHT

CLEARANCES

Clearances must be taken into consideration, and provided for as

follows:

1. Refrigerant piping and connections - minimum 12” recommended.

2. Maintenance and servicing access - minimum 36” from front of unit

recommended for blower motor / coil replacement.

3. Condensate drain lines routed to clear filter and panel access.

4. Filter removal - minimum 36” recommended.

5. The duct work connected to this unit is designed for zero clearance

to combustible materials.

6. A combustible floor base accessory is available for downflow applications of this unit, if required by local code.

LOCATION

Location is usually predetermined. Check with owner’s or dealer’s

installation plans. If location has not been decided, consider the

following in choosing a suitable location:

1. Select a location with adequate structural support, space for service

access, and clearance for air return and supply duct connections.

2. Using hanging brackets to wall mount this single piece air handler

unit is not recommended.

T

HEAT

FIGURE 4: Typical Installation

HEA

HORIZONTAL LEFT

A0330-001

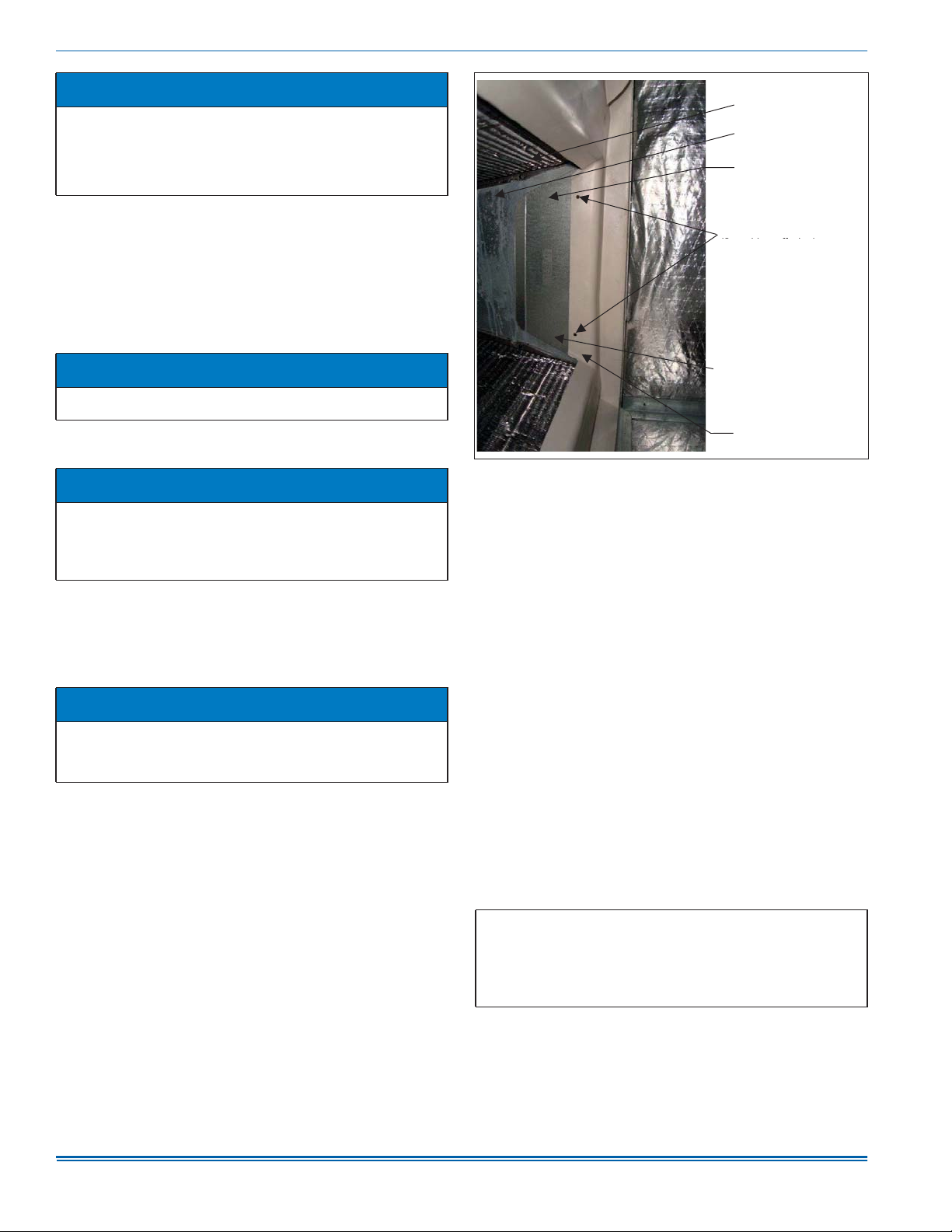

Horizontal Left Conversion

NOTICE

For horizontal left applications, high airflow can prevent the collected

condensate from draining properly since the direction of the airflow

opposes the direction of the draining condensate. The horizontal pan

must be angled properly in order to ensure proper drainage in high

airflow applications. Ensure that the pan is angled properly by checking that the correct hole is used on the pan straps per TABLE 2. Use

FIGURE 5 to identify the "BACK" and "FRONT" straps since, in some

cases, these settings are not the same.

4 Johnson Controls Ducted Systems

Page 5

5493974-UIM-B-0419

$77$&+0(17+2/()25

+25,=217$/'5$,13$1

FIGURE 5: Horizontal Pan Adjustment Strap Hole Reference

TABLE 2:

Horizontal Pan Strap Settings for Horizontal Left

Model

AP RFCX-P2 AE RFCX-E2 AVC CM

AP24B

AP30B

AP36B

AP60C RFCX60CP AE60C RFCX60CE AVC60C CM60C 3 4

AP36C

AP37C

AP42C

AP48C

– – AE60D RFCX60DE AVC60D CM64D 4 5

– – AE36C RFCX36CE AVC36C

–––––CM24C 6 6

AP18B RFCX18BP AE18B RFCX18BE AVC18B CM18B 7 7

AP48D

AP60D

RFCX24BP

RFCX30BP

RFCX36BP

RFCX36CP

RFCX37CP

RFCX42CP

RFCX48CP

RFCX48DP

RFCX60DP

AE24B

AE30B

AE36B

AE42C

AE48C

AE48D RFCX48DE AVC48D

RFCX24BE

RFCX30BE

RFCX36BE

RFCX42CE

RFCX48CE

AVC24B

AVC30B

AVC36B

AVC42C

AVC48C

CM24A

CM24B

CM25B

CM30A

CM30B

CM36A

CM36B

CM42C

CM48C

CM37C

CM30C

CM36C

CM30D

CM36D

CM42D

CM48D

CM60D

+2/(/2&$7,21

180%(56

$

Back Front

22

44

55

88

Downflow or Horizontal Right Conversion

NOTICE

NOTICE

Convert air handler to the desired orientation prior to installation.

Conversion must be made before brazing the refrigerant connections

to the coil.

1. Remove coil access panel.

2. Slide coil/drain pan assembly out of air handler.

Johnson Controls Ducted Systems 5

The center support bar for the coil/drain pan has a position identifier

embossed into the cabinet structure between the two forward fingers

of the support bar. There are four position identifiers: A, B, C, or D.

The lettered hole location can differ from unit to unit due to the cabinet width of the air handler. After removal and re-installation, the center support bar must be installed in the same lettered position that it

was originally.

3. Note the lettered position of the center support bar for the coil/drain

pan. Remove the center support bar by sliding the forward end of

the support bar to the right or left until the lower finger clears the

structure.

Page 6

5493974-UIM-B-0419

NOTICE

The position identifier for the coil slide rail is embossed into the back

corner vertical angle of the cabinet structure. There are four position

identifiers: 1, 2, 3, or 4. The numbered attachment location can differ

from unit to unit due to the cabinet height of the air handler. After

removal and re-installation, the coil slide rail must be installed in the

same numbered position that it was originally.

4. Note the numbered position of the coil slide rail located at the upper

right hand side of the indoor coil compartment. Remove slide rail

from air handler cabinet by removing front screw and lowering

bracket down to disengage hook on back of slide rail.

5. Turn air handler cabinet upside down (downflow position).

6. Install coil slide rail by hooking the hook end into holes at the numbered position the slide rail was originally in right rear corner post,

and secure rail into right front edge of cabinet with screw in the predrilled hole.

NOTICE

The rear of the center support bar are longer than the fingers on the

forward end of the support bar.

7. Install center support bar for the coil/drain pan onto the lettered

position that it was originally mounted.

NOTICE

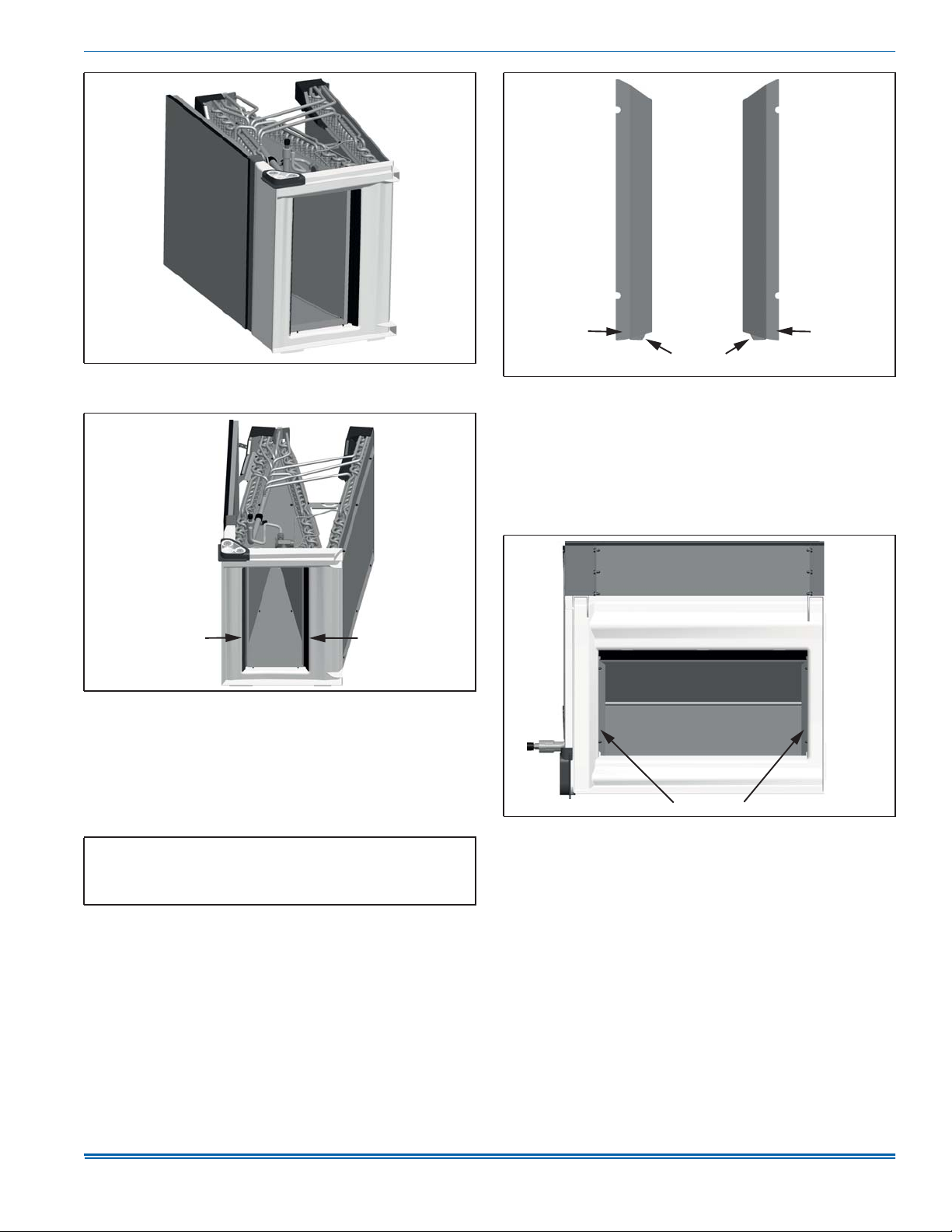

When installing a coil condensate deflector, make sure that each

notch in the coil condensate deflector slides around the anchor screw

with the bottom of the notch fully set against the screw.

Ensure that the coil condensate deflector is installed with the flange

bending away from the coil delta plate.

8. For horizontal right applications, install front and back coil condensate deflectors (condensate deflectors shipped as loose parts with

the unit). Locate 4 screws securing coil delta plates to coil drain

pan. Loosen the screws. Slide each coil condensate deflector

between the drain pan and the coil delta plate. Tighten screws to

securely anchor coil condensate deflectors. Refer to Figure 6.

NOTICE

Some models contain condensate deflectors that are not symmetrical

and must be installed in the correct orientation. If this air handling unit

is a **60C model, refer to the horizontal right conversion section on

the next page.

9. Slide the coil back into the cabinet. Be sure to engage the side coil

slide into the slide rail on the air handler cabinet.

10. Install coil access panel. Conversion is now complete.

COIL

DELTA PLATE

CONDENSATE

BLOW OFF WING

DEFLECTOR

SCREWS

(2 per deflector)

(2 per blow off wing)

INSTALL COIL CONDENSATE

INSTALL COIL BLOW

OFF WING ON FRONT

DEFLECTOR ON FRONT

AND BACK OF COIL

AND BACK OF COIL

DRAIN PAN

FIGURE 6: Coil Condensate Deflector Installation

Handling Coil Assemblies when Removed from Casing

When the coil assembly is removed from its casing, it must be handled

in such a manner that does not compromise the foam gasket that seals

the attachment point of the horizontal drain pan and primary drain pan.

DO NOT position the coil so that the coil weight rests on the horizontal

drain pan. By doing so, the horizontal drain pan straps could deform or

become damaged which will not allow the pan to be positioned/angled

correctly when the unit is horizontally installed, and if the foam gasket

that seals the attachment point becomes compromised by the movement of the horizontal drain pan, condensate may leak at this point and

cause damage to the unit/property.

Positioning the Unit in Horizontal Applications

Set unit so that it is sloped 1/4” towards the drain plug.

A0417-001

A0417-002

AVC60C Downflow or Horizontal Right

The AVC60C model contains a unique coil assembly in that additional

pieces are required to be installed in horizontal right and downflow

applications to reduce the potential for condensate blow-off. The large

cooling capacity and high volumetric airflow (1800 CFM and above)

required for these coils put them more at risk of condensate blow-off.

The installation of additional shields should mitigate condensate management issues while allowing the coil to perform adequately for proper

cooling/heating.

When installing any of the shield provisions, it is advised to position the

coil such that the primary drain pan opening can be easily accessed to

attach the shields. See Figure 7.

IMPORTANT: DO NOT position the loose coil so that it rests on the

horizontal drain pan. The weight of the coil will deform the horizontal

pan straps, and the movement of the horizontal pan could potentially

compromise the foam gasket that seals the horizontal drain pan to the

primary drain pan. This could lead to water leaking at this attachment

point and damaging the insulation/cabinet/property.

6 Johnson Controls Ducted Systems

Page 7

5493974-UIM-B-0419

A1076-001

FIGURE 7: Recommended Position of Coil to Install Downflow/

Horizontal Right Condensate Components

Condensate Shield

- Downflow Only

Condensate Shield

(Factory Installed)

(Field Installed)

A1074-001

FIGURE 8: Installation of Downflow Condensate Diverter Shields

AVC60C Horizontal Right

1. Attach the additional condensate deflectors that were included in

the loose parts kit to the coil assembly by loosening the screws that

secure the front and rear delta plates to the primary drain pan. DO

NOT remove the screws completely. Loosen them enough so that

you can insert the deflectors between the drain pan and the delta

plate.

IMPORTANT: FOR 60C (21.0”) COIL ASSEMBLIES: While the

shields may appear similar, they are actually different in that there is a

front and rear shield. Due to their asymmetry, these shields will not fit

correctly if they are oriented incorrectly. See Figure 9 for details.

Front Deflector

(Orient Towards Bottom Coil Slab)

Drip Leg

Rear Deflector

A1075-001

FIGURE 9: 60C Horizontal Right Condensate Deflectors

2. Insert the deflectors between the primary drain pan and the delta

plates. Make sure that the slots in the deflectors nest firmly against

the loosened screws between the primary drain pan and delta

plates.

3. Tighten the screws that secure the delta plates to the primary drain

pan. The interactive fit of the delta plate, primary drain pan, and

screws will hold the shields firmly in place during operation. Figure

10 shows the final assembly.

Condensate Deectors

A1077-001

FIGURE 10: 60C Horizontal Right Coil Condensate Final Assembly

Johnson Controls Ducted Systems 7

Page 8

5493974-UIM-B-0419

Upflow or Downflow Applications (All Models)

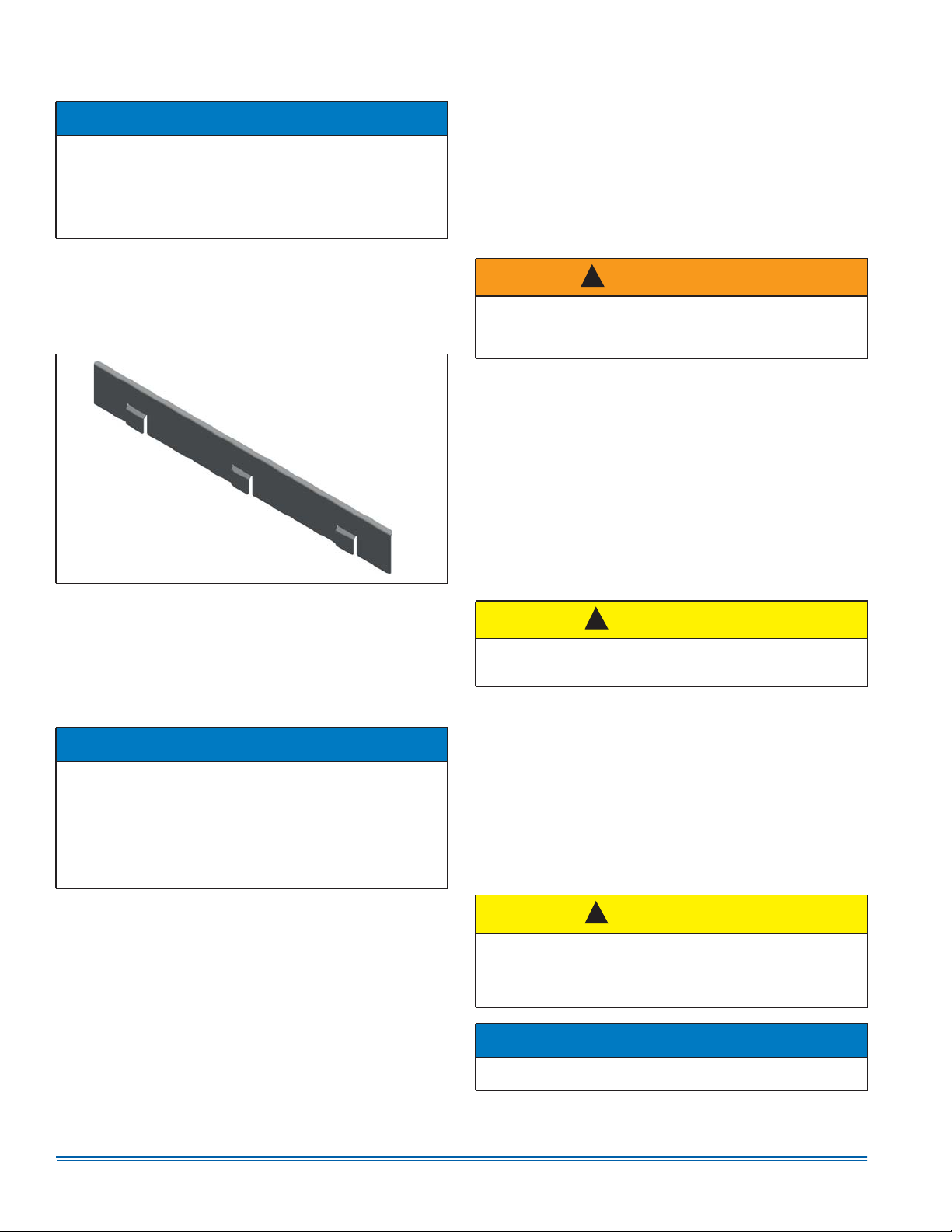

NOTICE

For maximum performance, if an air handling unit is being installed in

Upflow or Downflow orientation, it is recommended that the horizontal

drain be removed from the assembly. This can be achieved by removing the horizontal drain pan support straps, cutting the foam gasket

that seals the attachment point of the horizontal drain pan and primary drain pan, and removing the entire horizontal drain pan assembly.

AVC60C Downflow Conversion

1. Rotate equipment cabinet so that the bottom of the primary (plastic)

drain pan can be accessed.

2. Locate the downflow condensate shield (as shown in Figure 11)

and foam gasket strip shipped in the loose parts kit included with

the coil.

A1073-001

FIGURE 11: Condensate Shield

3. Install the condensate shield to the primary drain pan (as shown in

Figure 8). There should be an identical condensate shield that was

factory installed on the opposite side of the primary drain pan.

4. Apply the foam gasket strip to the condensate shield evenly so that

it covers the condensate shield and primary drain pan.

Horizontal Left Applications (All Models)

NOTICE

For horizontal left applications, high airflow can prevent the collected

condensate from draining properly since the direction of the airflow

opposes the direction of the draining condensate. The horizontal pan

must be angled properly in order to ensure proper drainage in high

airflow applications. Ensure that the pan is angled properly by checking that the correct hole is used on the pan straps per TABLE 2. Use

FIGURE 5 to identify the FRONT and REAR straps since, in some

cases, these settings are not the same.

The vast majority of problems encountered with heating and cooling

systems can be linked to improperly designed or installed duct systems.

It is therefore highly important to the success of an installation that the

duct system be properly designed and installed.

When installing a central air return grille in or near the living space, it is

advisable to design the duct work so that the grille is not in direct line

with the opening in the unit. One or two elbows and acoustical duct liner

assures a quieter system. Operation where return air duct is short or

where sound may be a problem, acoustical duct liner should be used

inside the duct. Use flexible duct connectors to minimize the

transmission of vibration/noise into the conditioned space.

!

WARNING

Do not bring in return air from a location which could introduce hazardous substances into the airflow.

Use 1/2” screws to connect duct work to cabinet. If pilot holes are

drilled, drill only through field duct and unit flange.

Insulation of duct work is a must where it runs through an unheated

space during the heating season or through an uncooled space during

the cooling season. The use of a vapor barrier is recommended to

prevent absorption of moisture from the surrounding air into the

insulation.

The supply air duct should be properly sized by use of a transition to

match unit opening. All ducts should be suspended using flexible

hangers and never fastened directly to the structure.

Duct work should be fabricated and installed in accordance with local

and/or national codes. This includes the standards of the National Fire

Protection Association for Installation of Air-Conditioning and

Ventilating Systems, NFPA No. 90B. Duct systems should be designed

in accordance with the Air Conditioning Contractors of America (ACCA)

– Manual D.

!

CAUTION

This unit is not designed for non-ducted (freeblow) applications. Do

not operate without duct work attached to unit.

Equipment should never be operated without filters.

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space. If electric heat is used, non-flammable

material must be used.

All ducts should be suspended using flexible hangers and never

fastened directly to the structure.

HORIZONTAL SUSPENSION

These air handlers may be suspended in horizontal applications. It is

recommended to use angle steel support brackets with minimum 3/8”

threaded rods, supporting the unit from the bottom. Attach the threaded

rods at the locations shown in the Figure 12, leaving enough clearance

between door and rod so that doors maybe easily removed for service.

Air handling units are supplied ready to be installed in a horizontal left

position. A horizontal drain pan is factory installed. If horizontal right

application, refer to the horizontal right conversion before proceeding.

See sections on “Refrigerant Line Connections” and “Condensate Drain

Connections” for further installation instruction.

SECTION IV: DUCT WORK AND

DO NOT lift air handler by the cabinet brace. The cabinet brace is

held in place by the coil channel. The cabinet brace could become

disengaged from the cabinet causing the air handler to fall, potentially

causing injury or damaging property. See Figure 1 for location of cabinet braces.

!

CAUTION

CONNECTIONS

Air supply and return may be handled in one of several ways best

suited to the installation. Upflow, horizontal or downflow applications

may be used.

When assembling the support structure, make sure to size to provide

clearance for access door removal.

8 Johnson Controls Ducted Systems

NOTICE

Page 9

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTAL APPLICATIONS

MIN. 3/8”

THREADED ROD

MIN. 1-1/2” x 1-1/2”

Angle Recommended

length 26” minimum

with 2” clearance

on both sides

of Air Handler

5493974-UIM-B-0419

2”

MIN. 3/8”

THREADED ROD

1-1/2”

X

H

MIN. 1-1/2” x 1-1/2”

Angle Recommended

length 26” minimum

with 2” clearance on

both sides of

Air Handler

H

1-1/2”

X

1-1/2”

A0331-001

Dimension in Inches

Air Handler Cabinet Size X H

17-1/2 Width-Short H 21 41

17-1/2 Width-Long H 21 47-1/2

21 Width-Short H 21-1/2 51-1/2

21 Width-Long H 21-1/2 55-3/4

24-1/2 Width 21-1/2 55-1/2

FIGURE 12: Horizontal Suspension

DUCT FLANGES

Three duct flanges are provided to assist in positioning and attaching

duct work to the air handler. These flanges are included in the unit parts

bag. With the screws from the parts bag, install one of the duct flanges.

Duct flanges have holes on both legs with one leg longer than the other.

The longer leg can be used to mate against the air handler so that

different thicknesses of duct board can be made flush with the outer

surface of the air handler. Repeat the procedure for the other two

flanges. Refer to Figure 13. If the flanges are not used, they may be

discarded.

DUCT FLANGES

(Shipped in bag with unit)

RECOMMENDED

TRANSITION

SUGGESTED LOCATION

OF BLOCK OFF PLATE

A0332-001

FIGURE 14: Duct Work Transition

UNIT CONNECTIONS

There are several ways to handle the supply and return air duct

connections. The location and sizing of the connections depends on the

situation and the method best suited to the installation. Upflow,

horizontal or downflow applications may be used.

The supply air duct should be properly sized by use of a transition to

match unit opening. Refer to Table 1 for air handler unit inlet and outlet

dimensions.

!

CAUTION

Use 1/2” screws to connect duct work to unit. Longer screws will

pierce the drain pan and cause leakage. If pilot holes are drilled, drill

only though field duct and unit bottom duct flange.

Duct work that is not designed to match the supply air opening can

cause turbulence inside the plenum. This turbulence can change the air

flow patterns across the electric heater limit switches. If the factory

suggested transition cannot be fabricated, it is recommended that a

block off plate (approximately 8" high and running the full width of the

plenum) be attached to the supply opening. Refer to Figure 14 as a

visual aid. The use of this block off plate will enable better air circulation

across the limit switches.

AIR FILTERS

Return air filters are required and must be field supplied. Filtration can

be accomplished external to the unit or the integral filter rack may be

used. A 1" filter access rack has been built into the unit. Remove filter

access cover shown. Install proper size filter. Standard 1" size

permanent or throw away filter may be used, or permanent washable

filters are available using model numbers: 1PF0601, 602 or 603. See

Table 7 for filter size.

.

!

CAUTION

Equipment should never be operated without filters.

SECTION V: COIL METERING DEVICES

A0445-001

FIGURE 13: Duct Attachment

Johnson Controls Ducted Systems 9

A piston or a TXV is to be installed in the field. There is an installation

manual that comes with the TXV kit. It is recommended to install the

piston or TXV kit prior to installation of coil and brazing of line set. Until

brazing is completed and cooled, the TXV sensing bulb must not be

installed.

The outdoor technical guide for outdoor units should be consulted for

required piston or TXV on the indoor coil. The piston and the Schrader

core are supplied with the outdoor unit. When the piston is used instead

of the TXV, the Schrader core is installed in the suction line equalizer

connection port and is capped with the supplied plastic cap. The

Schrader core must not be installed if the TXV is installed, because the

TXV equalizer line attaches to the equalizer connection port.

Page 10

5493974-UIM-B-0419

$

!

CAUTION

COIL UNDER PRESSURE.

Verify that pressure has been released by depressing schrader valve

core.

The coil requires a metering device to be added.

See outdoor unit documentation for correct TXV or piston to be used.

NOTICE

To prevent moisture and contaminates from entering the system, the

coil should not be open to atmosphere for extended periods of time. If

the coil cannot be brazed into the refrigeration system during a routine installation period, the ends should be temporarily closed or

plugged. For a short term delay, use masking tape over the ends of

the copper tubing to close the tube from the air. For a longer term

delay, use plugs or caps. There is no need to purge the coil if this procedure is followed.

PISTON INSTALLATION

!

WARNING

Failure to install Schrader Valve Core in the vapor line equalizer connection port for piston applications could result in total refrigerant loss

of the system!

Install Schrader Valve Core and

1. After holding charge is completely discharged, remove black plastic

cap from equalizer connection port on the vertical part of the vapor

line.

2. Distributor position must be adjusted to allow the preformed liquid

line assembly to properly line up with the hole in the tubing access

panel. Raise the distributor body approximately 2” toward the top of

the coil or what would be the top of the coil if coil was in the upflow

position. See Figure 15. Adjust as necessary.

3. Install Schrader valve core supplied with the outdoor unit into the

equalizer fitting connection port using a valve core tool.

4. Loosen and remove the liquid line connection nut and the sealing

disc from the distributor assembly. Note that the fitting has right

hand threads.

5. Slide the nut over the liquid line to be installed, and discard the seal

disc.

6. Install required size piston into the distributor. Refer to supplied

Tabular Data Sheet for specific piston size and indoor coil match

up. See Figure 16.

7. Verify that the Teflon washer is still in place in the distributor open-

ing. See Figure 16.

Piston as follows:

LIQUID LINE SWIVEL COUPLING

(This fitting is a right-handed thread.

Turn counter-clockwise to remove.)

PISTON

TEFLON WASHER

DISTRIBUTOR

A0305-001

FIGURE 16: Piston Installation

!

CAUTION

Do not overtorque. Do not use slip joint pliers. This will distort the aluminum distributor and the brass fitting (potentially causing leaks).

8. After piston is installed, install the liquid line to the top of the piston/

distributor assembly. Hand tighten, and turn an additional 1/4 turn

to seal. Do not over tighten fittings.

9. Replace black plastic cap on unused equalizer fitting connection

port.

10. After line set is installed, leak test the system.

THERMOSTATIC EXPANSION VALVE (TXV) INSTALLATION

!

CAUTION

Outdoor unit model numbers ending with an “H” have a factory

installed hard start kit which is required when a TXV is installed. Outdoor unit model numbers with no “H” ending do not require a hard

start kit unless local regulations dictate it.

The following are basic steps for installation. For detailed instructions,

refer to the Installation Instructions accompanying the TXV kit. Install

TXV kit as follows:

IMPORTANT: Refer to the Technical Guide for the unit to determine

the proper TXV kit to be used on this product.

1. Relieve the holding charge by depressing Schrader core on the

suction manifold stub out.

2. After holding charge is completely discharged, loosen and remove

the Schrader core.

3. Place a backup wrench on distributor, loosen and remove brass

distributor nut. Retain brass nut for use on liquid line. Keep Teflon

washer in place and discard clear disk.

4. Install the thermal expansion valve to the distributor assembly with

supplied fittings. Ensure Teflon washer is seated in distributor.

Hand tighten and turn an additional 1/4 turn to seal.

tighten fittings. See Figure 17.

Do not over-

!

CAUTION

Do not over-torque. Do not use slip joint pliers. This will distort the

aluminum distributor and the brass fitting (potentially causing leaks).

5. Slide the nut removed in step 3 over the supplied liquid line. Place

supplied Teflon washer from TXV kit in place on TXV, and install liquid line to the top of the thermal expansion valve. Adjust assembly

FIGURE 15: Recommended Distributor Adjustment

so liquid line aligns with hole in access panel. See Figure 18. Hand

tighten the liquid line, and apply an additional 1/4 turn to seal.

10 Johnson Controls Ducted Systems

Page 11

5493974-UIM-B-0419

LIQUID LINE / TXV COUPLING

TEFLON WASHER

TXV

TXV / DISTRIBUTOR COUPLING

TEFLON WASHER

DISTRIBUTOR

A0281-002

FIGURE 17: TXV Installation

!

WARNING

Schrader valve core MUST NOT be installed with TXV installation.

Poor system performance or system failure could result.

6. Install the TXV equalizer line onto the vapor line by hand tightening

the 1/4” SAE coupling nut to the equalizer fitting, and apply an additional 1/3 turn to seal. See Figure 18.

!

CAUTION

In all cases, mount the TXV temperature sensing bulb after vapor line

is brazed and sufficiently cooled.

Failure to use suction line split grommet may result in TXV failure.

9. After line set is installed, leak test the system.

Bulb at

10 o’clock

position.

CLAMP

VAPOR

LINE

TXV SENSING BULB

(Pass through split hole

in grommet.)

SCREW

NUT

CLAMP

Bulb at

2 o’clock

NUT

SCREW

DETAIL A

position.

VAPOR LINE

OF LINE SET

FIGURE 19: Proper Bulb Location

CLAMP

VAPOR LINE

OF LINE SET

TXV BULB

(Cover completely

with insulation.)

TAIL END UP

TXV

TEMPERATURE

BULB

A

A0269-002

7. Pass the temperature sensing bulb tube for the TXV through the

tube opening in the split grommet of the access panel.

8. Install the TXV bulb to the vapor line near the cabinet, using the

bulb clamp(s) furnished with the TXV assembly. Ensure the bulb is

making maximum contact. See Figures 18 & 19, and accomplish

the following:

a. If possible, install the temperature bulb on a horizontal run of

the vapor line. Ensure that the bulb is installed at a 10 o’clock

or 2 o’clock position.

b. If bulb installation is made on a vertical run, ensure that the

bulb is a minimum of 8 inches (20.3 cm) away from elbow

coming out of the coil. Position the bulb with the tail of the

bulb at the top, so that the bulb acts as a reservoir. See Figure 20.

c. Insulate the bulb using thermal insulation provided to protect

it from the effect of the surrounding ambient temperature.

Cover completely to insulate.

TXV BULB

(Wrap with

insulation.)

DISTRIBUTOR

BODY

VAPOR LINE

LIQUID LINE

TVX

EQUALIZER

LINE

THERMAL EXPANSION

VALVE (TXV)

A0279-002

FIGURE 18: TXV Bulb and Equalizer line Installations

NOTE:

Ensure bulb is on opposite

side of tubing bend plane.

8” (20.3 cm)

A0378-002

FIGURE 20: Vertical Temperature Bulb Orientation

SECTION VI: REFRIGERANT LINE CONNECTION

!

CAUTION

Coil is under inert gas pressure. Relieve pressure from coil by

depressing Schrader core at end of suction manifold stub out.

!

CAUTION

Dry nitrogen should always be supplied through the tubing while it is

being brazed, because the temperature required is high enough to

cause oxidation of the copper unless an inert atmosphere is provided.

The flow of dry nitrogen should continue until the joint has cooled.

Always use a pressure regulator and safety valve to insure that only

low pressure dry nitrogen is introduced into the tubing. Only a small

flow is necessary to displace air and prevent oxidation.

Johnson Controls Ducted Systems 11

Page 12

5493974-UIM-B-0419

$

*5200(7

)RU9DSRU/LQH

NOTICE

Avoid handling aluminum coil components after handling the copper

line set or other tubing without first cleaning hands.

Connect lines as follows:

NOTICE

Route the refrigerant lines to the coil in a manner that will not obstruct

service access to the coil, air handling system, furnace flue or filter.

1. Suction and liquid line connections are made outside the cabinet.

Leave the tubing connection panel attached to the cabinet. Coil

access panel should be removed for brazing. The lines are

expanded to receive the field line set tubes for most outdoor unit

matches.

2. Remove grommets where tubes exit the cabinet to prevent burning

them during brazing. In some units, the vapor line grommet may be

shipped as a loose part with the unit. Refer to Figure 21.

3. Cut the end of the suction tube using a tube cutter. Place the tube

cutter as close as possible to the end of the tube to allow as much

depth as possible for the connection and brazing of the suction line.

To ensure suction line fits into connection, deburr the stub out

(including inner pressure protrusion from cutting).

4. If coil does not have a factory installed TXV, install the required size

piston or TXV kit. See coil metering devices section for detailed

instructions.

5. If the coil does have a factory installed TXV, remove the liquid line

copper cap which is soft soldered onto the outside of the 3/8” stub

protruding from front of the coil cabinet tubing panel as follows:

a. Screw a sheet metal screw into the center of the cap.

b. Apply a small amount of heat to the cap while pulling on the

screw using slip joint pliers.

6. Insert liquid and suction lines into the coil connections at the coil

cabinet tubing panel.

7. Wrap a water soaked rag around the coil connection tubes inside

the cabinet to avoid transferring excess heat to the coil or TXV.

8. Purge refrigerant lines with dry nitrogen.

FIGURE 21: Vapor Line Grommet

SECTION VII: CONDENSATE DRAIN CONNECTIONS

All drain lines should be trapped a minimum of three inches, should be

pitched away from unit drain pan and should be no smaller than the coil

drain connection.

!

CAUTION

DO NOT use TeflonTM tape, pipe thread compound, or other

sealants. The use of a sealant may cause damage and premature

failure of the drain pan.

Threaded drain connection should be hand-tightened, plus no more

than 1 turn.

Avoid Double Trapping of a single drain line.

Route the drain line so that it does not interfere with accessibility to the

coil, air handling system or filter and will not be exposed to freezing

temperatures. See Figures 29 & 30 for drain connection locations.

NOTICE

All indoor coil connections are copper-to-copper and should be

brazed with a phosphorous-copper alloy material such as Silfos-5 or

equivalent. DO NOT use soft solder.

9. Braze the suction and liquid lines, and allow the joints to cool.

10. Route the TXV sensing bulb through suction line opening.

11. Secure sensing bulb and equalizer line capillary tubes with nylon

cable ties to prevent leaks from tubes rubbing.

12. If piston is used, install Schrader core into suction header, and reinstall cap.

13. Re-attach the grommets to the lines carefully to prevent air leakage. In some units, the vapor line grommet may be shipped as a

loose part with the unit. Refer to Figure 21.

14. Attach the coil access panel to the cabinet.

15. Refer to Outdoor unit Installation Manual, and accomplish evacuation, leak check and charging instructions. Check all field brazed

joints and metering device connections.

16. Ensure lines are sound isolated by using appropriate hangers or

strapping.

!

CAUTION

When the unit is installed in an attic or above a finished ceiling, an

auxiliary drain pan should be provided under the coil as specified by

most local building codes. When this exterior secondary drain pan is

used that drain should be piped to a location that will give the occupant a visual warning that the primary drain is clogged.

If the coil is provided with a secondary drain it should be piped to a

location that will give the occupant a visual warning that the primary

drain is clogged. If a secondary drain is not used it must be plugged.

Instruct the owner that the indoor coil drain pan should be inspected

and cleaned regularly to prevent odors and assure proper drainage. If a

secondary drain is not used it must be plugged. See Figures 29 & 30.

Coils should be installed level or pitched slightly toward the drain end.

Suggested pitch should not exceed 1/4 inch per foot of coil.

The drain pan connections are designed to ASTM Standard D 2466

Schedule 40. Use 3/4” PVC or steel threaded pipe. Since the drains are

not subject to any pressure it is not necessary to use Schedule 40 pipe

for drain lines.

12 Johnson Controls Ducted Systems

Page 13

5493974-UIM-B-0419

SECTION VIII: ELECTRIC HEATER INSTALLATION

If the air handler requires electric heat, install the electric heat kit

according to the installation instructions included with the kit. After

installing the kit, mark the air handler nameplate to designate the heater

kit that was installed. If no heater is installed, mark the name plate

appropriately to indicate that no heat kit is installed.

Use only 6HK Revision C or later heater kits, as listed on air handler

name plate and in these instructions. Use data from Tables 9 & 16 for

information on required minimum motor speed tap to be used for

heating operation and maximum over-current protection device

required as listed for combination of air handler and heater kit.

For Upflow, Downflow and Horizontal left-hand applications, the kits can

be installed without modification.

Field modification is required for Horizontal right-hand airflow application only. Follow instructions with heater for modification.

NOTICE

In some horizontal applications, the service disconnects on the electric heat kits must be rotated 180° so the up position of the disconnect is the ON position. This service disconnect orientation change is

required by UL1995, Article 26.19 (in reference to all circuit breakers).

3+$6((/(&75,&+($7237,216

6,1*/(6285&(32:(5

*1'

12(/(&75,&+($7

*1'

32:(5

6833/<

&20321(17&2'(6

*1'*5281'/8*

6'6(59,&(',6&211(&7

&.7&,5&8,7

&1:,5(&211(&725187

),(/'32:(5:,5,1*

9

&1

&1

32:(5

6833/<

/

/

7(50,1$/%/2&.25

6(59,&(',6&211(&7

6,1*/(6285&(32:(5

32:(5

6833/<

FIGURE 22: Line Power Connections

SECTION X: LOW VOLTAGE CONTROL CONNECTIONS

The 24 volt power supply is provided by an internally wired low voltage

transformer which is standard on all models, However, if the unit is connected to a 208 volt power supply, the low voltage transformer must be

rewired to the 208 volt tap. See the unit wiring label.

Remove desired knockout and pierce foil faced insulation to allow wiring to pass through. Use as small of a hole as possible to minimize air

leakage.

Install a 7/8” plastic bushing in the selected hole and keep low voltage

wiring as short as possible.

To further minimize air leakage, seal the wiring entry point at the outside of the unit.

32:(5

6833/<

3+$6((/(&75,&+($732:(5237,216

*1'

/

/

/

7(50,1$/%/2&.25

6(59,&(',6&211(&7

SECTION IX: LINE POWER CONNECTIONS

Power may be brought into the unit through the supply air end of the

unit (top left when unit is vertical) or the left side panel. Use the hole

appropriate to the unit’s orientation in each installation to bring conduit

from the disconnect. The power lead conduit should be terminated at

the electrical control box. To determine proper wire sizing, refer to

Tables 7 - 10 and the latest edition of the National Electric Code or in

Canada the Canadian electrical Code and local codes to determine

correct wire sizing. To minimize air leakage, seal the wiring entry point

at the outside of the unit.

All electrical connections to air handlers must be made with copper

conductors. Direct connection of aluminum wiring to air handlers is

not approved.

If aluminum conductors are present, all applicable local and national

codes must be followed when converting from aluminum to copper

conductors prior to connection to the air handler.

If wire other than uncoated (non-plated), 75° C ambient, copper wire is

used, consult applicable tables of the National Electric Code (ANSI/

NFPA 70). The chosen conductor and connections all must meet or

exceed the amperage rating of the overcurrent protector (service

disconnect or fuse) in the circuit.

Additionally, existing aluminum wire within the structure must be sized

correctly for the application according to National Electric Code and

local codes. Caution must be used when sizing aluminum rather than

copper conductors, as aluminum conductors are rated for less current

than copper conductors of the same size.

08/7,6285&(32:(5

:,7+-803(5%$5

/

/

-803(5%$5

&,5&8,7621N:N:

&,5&8,7621N:

*1'

6'

6'

6'

32:(5

6833/<

32:(5

6833/<

08/7,6285&(32:(5

&.7

&.7

08/7,6285&(32:(5

&.7

&.7

&.7

&,5&8,7621N:N:

&,5&8,7621N:

*1'

/

/

/

/

/

/

6'

6'

/

/

/

/

/

/

The field wiring is to be connected with wire connectors to the wires

provided. Refer to Figures 24 & 25.

NOTICE

All wiring must comply with local and national electrical code requirements. Read and heed all unit caution labels.

NOTICE

It is possible to vary the amount of electric heat turned on during the

defrost cycle of a heat pump. Standard wiring will only bring on the

first stage of electric heat during defrost. See Table 5 for additional

information on heat during defrost cycle.

*1'

6'

6'

6'

$

Johnson Controls Ducted Systems 13

Page 14

5493974-UIM-B-0419

HUMIDIFIER

OUTPUT

ELECTRONIC

AIR CLEANER

EAC

CFM

INDICATOR

LEAVING AIR TEMP

SENSOR TERMINALS

SERVICE

TOOL

PORT

COMM

PORT

FUSE

FLOAT SWITCH

INPUT

FIGURE 23: Control Board

Humidity Switch Input

The air handler control is designed to work with a humidity control that

closes when the humidity is below the set-point. The control is open

when the humidity is above the set-point. This humidity control may be

referred to as a humidistat or a dehumidistat.

The humidity switch controls de-humidification operation of the control

during cooling operation. The humidity switch should be connected to

HUM wire of the control. See Figures 23 & 24.

STATUS

INDICATOR

BLOWER

SPEED

JUMPERS

HUMIDISTAT

JUMPER

AC/HP JUMPER

MODEL

ID PLUG

A0405-001

NOTICE

All wiring must comply with local and national electrical code requirements. Read and heed all unit caution labels.

It is possible to vary the amount of electric heat turned on during the

defrost cycle of a heat pump. Standard wiring will only bring on the

first stage of electric heat during defrost. See Heat Output and Limit

Connections and Table 5 for additional information on heat during

defrost cycle.

TABLE 3:

Low Voltage Connections

Wire Colors Signals Comment

R Red 24 VAC power (fused)

G Green Continuous Fan operation Fan Speed, 63% of high cool speed.

Y/Y2 Yellow Second or full stage compressor operation

Y1 Yellow & Black First stage compressor operation Not used with outdoor units having one stage compressors.

W2 Brown Second stage heat operation

W1 White First stage heat operation

O Orange Reversing valve operation

EAC Field Supplied Wiring Electric Air Cleaner

X/L Field Supplied Wiring

HUM Purple Humidity switch input

C (COM) Blue 24 VAC common

Connection point for heat pump fault indicator

Located on P2 connector. There is 24VAC output during indoor blower

operation to energize a pilot duty relay for an electronic air cleaner.

This terminal is a connection point only and does not affect air handler control operation.

The field wiring is to be connected at the pigtails supplied with the control board harness.

14 Johnson Controls Ducted Systems

Page 15

FIGURE 24: Cooling Models with and without Electric Heat Wiring

$LU+DQGOHU&RQWURO:LULQJ

7\SLFDO$&&RROLQJRQO\$SSOLFDWLRQV

7+(50267$7

321$,5

+$1'/(5

%2$5'

67$*(

$,5&21',7,21,1*

55

*

<

:

:

&

*

:

:

<

&

<<

<

2

+80

&

&20

+80,',67$7

$

7+(50267$7

67$*(

$,5&21',7,21,1*

55

*

<

:

:

&

*

:

:

<

&

<<

<

2

+80

$LU+DQGOHU&RQWURO:LULQJ

7\SLFDO$&ZLWK(OHFWULF+HDW$SSOLFDWLRQV

+80,',67$7

321$,5

+$1'/(5

%2$5'

&

&20

321$,5

+$1'/(5

%2$5'

+80

($&

(/(&75,&$,5

&/($1(55(/$<

67$*(

$,5&21',7,21,1*

$FFHVVRU\

&RQWURO:LULQJ

9+80,',),(5

+80,',67$7

&21752/:,5,1*$LU+DQGOHU83*+36\VWHPV

7ZR6WDJH+3ZLWK<RUN*XDUG9,%RDUG

&RQYHQWLRQDO$SSOLFDWLRQ1RW+RW+HDW3XPS

7+(50267$7

$,5+$1'/(5

%2$5'

67$*(6&52//

+($73803

55 5

**

<

(

:

:

2 2

2

;/ ;/ ;/

&

&

<<

<

<

<287

<

:287

:287

%6

:

:

+80

&20

+80,',67$7

<

$

* Optional dehumidification humidistat switch contacts open on humidity rise.

NOTES:

1. “Y/Y2” Thermostat wire must be connected for full CFM and applications requiring 60 second blower off delay for SEER enhancement.

2. Move HUM STAT jumper on air handler control board to YES position if humidistat is used.

3. For heat pump applications - set AC/HP jumper on air handler control board to the HP position.

.

5493974-UIM-B-0419

FIGURE 25: Two-Stage Heat Pump Wiring

* Optional dehumidification humidistat switch contacts open on humidity rise.

NOTES:

1. “Y/Y2” Thermostat wire must be connected for full CFM and applications requiring 60 second blower off delay for SEER enhancement.

2. Remove humidistat jumper on air handler control board.

3. For heat pump applications - set AC/HP jumper on air handler control board to the HP position.

CONTROL WIRING USING COMMUNICATING

CONTROLS

The Communicating System consists of several intelligent communicating components including the Communicating Thermostat Control

(touch-screen wall thermostat), variable speed air handler, air conditioner (15 and 18 SEER premium air conditioners) or heat pump (13, 15

and 18 SEER premium heat pumps), which continually communicate

with each other via a four-wire connection called the A-R-C-B bus.

Commands, operating conditions, and other data are passed continually between components over the A-R-C-B bus. See Figure 26. The

result is a new level of comfort, versatility, and simplicity.

In order to use this air handler in full communications (COMM) mode, it

MUST be installed with the matching touch-screen Communicating

Control (wall thermostat) and an outdoor air conditioner or heat pump

with a fully communicating control.

Johnson Controls Ducted Systems 15

This air handler may also be used along with the touch-screen Communicating Control and a non-communicating outdoor air conditioner

through the addition of a communicating AC Control board to the outdoor unit. This system allows full communication between the air handler, outdoor unit, and touch-screen Communication Control.

Use the wiring diagram below to connect the air handler control, touchscreen Communicating Control (wall thermostat) and communicating

outdoor unit. Be sure that all of the “A+” terminals are connected

together, all of the “B-” terminals are connected together, all of the “C”

terminals are connected together and all of the “R” terminals are connected together. See Figure 26 & 27. When using a fully communicating

system, removal of the low voltage signal connector at P3 is recommended (C, G, R, etc.). The four small screw terminals in the terminal

block on the end of the air handler control should be used.

Page 16

5493974-UIM-B-0419

A+

R

C

B-

A+

R

C

B-

A+

R

C

B-

!

CAUTION

If any field-supplied wiring is to be connected to the control board,

such as will be the case if the Communicating Control is used or if a

humidistat, float switch or leaving air temperature switch are used,

the additional wires MUST be routed through the hole at the lower left

of the control box. DO NOT add any additional holes to the control

box. After attaching the additional wires to the board, the remaining

hole around the wires must be plugged with the sealant putty supplied

or with a suitable waterproof sealant. FAILURE T O SEAL THIS HOLE

MAY ALLOW WATER TO ENTER THE CONTROL BOX AND DAMAGE THE CONTROL BOARD.

FLOAT SWITCH INPUT

An optional switch may be connected to the FLT terminals on the control board. This feature is only functional when used with the Communicating Control. It is intended for use with a water overflow switch.

LEAVING AIR TEMP SENSOR INPUT

A plenum air temperature sensor (thermistor) can be connected to the

LAS terminals on the control board. The Communicating Control can

the monitor the temperature of the supply air in the plenum.

SECTION XI: REQUIRED CONTROL SET-UP

TOUCH SCREEN

COMMUNICATING

CONTROL

AIR HANDLER

COMMUNICATING

CONTROL

R

G

Y/Y2

Y1

W2

W1

O

HUM

EAC

COM

AC/HEAT PUMP

COMMUNICATING

CONTROL

A0409-001

FIGURE 26: Air Handler with Communicating AC or HP

IMPORTANT: Do not place more than one wire under any single

communication terminal screw (there are four communication terminal screws). If more than one wire must be connected to a terminal

screw, attach only the terminal end of a one wire pigtail no longer than

6“, and use a wire connector to connect the other end of the pigtail to

the other wires. Failure to do this will result in nuisance communication error faults. See Figure 27.

AIR HANDLER

WIRE

CONNECTOR

THERMOSTAT

TERMINAL

SCREW

COMMUNICATING

CONTROL BOARD

A+

R

C

B-

INDOOR UNIT

NOTE:

Ensure only one wire under

terminal screw.

To connect more than one wire:

1. Connect only terminal end of

” wire pigtail.

2. Use wire connector to connect

other end of pigtail

to other wires.

OUTDOOR UNIT

A0237-001

FIGURE 27: Multi-wire Terminal Connection

IMPORTANT: The following steps must be taken at the time of instal-

lation to insure proper system operation.

1. Consult system wiring diagram to determine proper thermostat wiring for your system.

2. If using a communicating control and a humidistat is installed,

change HUM STAT jumper from NO to YES.

3. Set the MODE jumper to A/C (Air Conditioner) or HP (Heat Pump)

position depending on the outdoor unit included with the system.

4. Set airflow and comfort setting jumper to proper positions.

FUNCTIONALITY AND OPERATION

Jumper Positions

Hum Stat Jumper

The HUM STAT jumper configures the control to monitor the humidity

switch input. With the jumper in the NO position, the control will ignore

the HUM input. With the jumper in the YES position, the control will

monitor the HUM input to control the blower speed for de-humidification

during cooling operation.

If the jumper is not present, the control will operate as if the jumper is in

the NO position.

AC/HP Jumper

The AC/HP jumper configures the control to operate properly with an air

conditioner (AC position) or heat pump (HP position). With the jumper in

the AC position, the control will treat any “Y” call as a cooling call. With

the jumper in the HP position, the O input signal is received from the

room thermostat. This allows the control to recognize whether in the

heating or cooling mode and energizes the 24 VAC HUM output when

blower is on and a first stage heating call is present.

If the jumper is not present, the control will operate as if the jumper is in

the HP position.

Airflow and Comfort Setting Jumpers

See separate section.

Status and Fault Codes

The control includes an LED that displays status and fault codes. These

codes are shown in Table 4. The control will display the fault codes until

power is removed from the control or the fault condition is no longer

present.

TABLE 4:

Status

No power to control OFF

Internal control fault ON

2 sec on 2 sec off heartbeat Normal

0.1 sec on, 0.1 sec off Test mode

Call for heat and cool at the same time 7

Model Plug Not inserted 8

Internal fault self-corrected, attempting normal operation 9

Fault Codes

Fault or Status Condition

LED1 (RED)

Flash Code

16 Johnson Controls Ducted Systems

Page 17

5493974-UIM-B-0419

HUM OUT Output

The HUM OUT output can be used to drive an external relay or solenoid

(24 VAC coil) to control a humidifier. The output is energized when the

control has a thermostat call for heating (heat pump or electric heat).

Heat Output

The control is connected to the heater relays using pins 4,5, and 6 of

connector P1. The relay outputs are 24 VAC.

The control energizes the heat relays as shown in Table 5.

TABLE 5:

Depending on the heat kit installed in the air handler, the control provides the flexibility to configure the amount of heat delivered with the

first stage heating call. As an example, when the control’s W1 input is

connected to the room thermostat’s first stage heat signal, a call for first

stage heat will energize one heating element (HT1). If the control’s W2

input is connected to the room thermostat’s first stage heat signal, a call

for first stage heat will energize one heating element (HT2). With either

configuration, the control will energize two heating elements (HT1, and

HT2) when it receives a first and second stage heat input from the thermostat.

Wiring Related Faults

If the control receives a simultaneous call for heating and cooling (fault

code 7), the control will perform both heating and cooling operations.

Heat Relays

Input Heat Relay Output

W1 HT1

W2 HT2

W1 and W2 HT1 and HT2

SECTION XII: AIRFLOW AND COMFORT SETTING SELECTION

AIRFLOW SELECTION

When not using communicating functionality, the airflow and comfort

setting selection jumpers must be set properly at the time of installation

for proper system operation. Place jumpers in the proper locations

based on the information shown in Table 16 & Figure 18.

Inputs to air handler control board are passed to the motor which determines the target CFM to be delivered. The following inputs will produce

the CFM per the appropriate table and selected tap settings.

NOTICE

Incorrect airflow and comfort settings may result in decreased system

efficiency and performance.

These variable speed air handlers are designed to deliver constant airflow (CFM) regardless of the external static pressure (ESP) in the

ductwork. Therefore, if too many supply registers are closed, a filter

becomes clogged, or there is a restriction in the ductwork, the motor will

automatically operate at a higher speed to compensate for the higher

ESP. This may result in a higher operating sound level and motor damage.

To Set Cooling Airflow:

Refer to the outdoor unit technical guide for the recommended airflow

with the matching indoor coil. Refer to Table 16 for the possible high

speed cooling and heat pump airflow selections.

Find the recommended system airflow in Table 16 for the installed air

handler model and outdoor unit.

Select the COOL airflow needed from Table 15. Set the COOL and

ADJUST Jumpers on the control as indicated in Table 16.

To Set Heat Pump Airflow:

The heat pump airflow setting is the same as the cooling airflow setting.

No additional airflow setting is required. However, you must set the AC/

HP jumper to the HP position for proper system operation (See Figure

23).

To Set Electric W1 Heat Airflow:

The blower speed required for 1st stage electric heat is different than

cooling. Refer to Table 16 for the possible CFM selections. Refer to

Table 8 for the minimum required airflow for the electric heater installed.

Find the desired airflow in Table 16 for low heat. Set the HEAT jumper

on the control as indicated in Table 16.

To Set W2 Electric Heat Airflow:

Airflow for any W2 input, which is for second stage of electric heat, is

the indicated CFM for high heat tap selection on Table 16.

!

CAUTION

DO NOT change the ADJUST tap position on the control as this will

change your cooling airflow previously selected.

Blower Ramp-Up /Ramp-Down:

To minimize the sound made by the blower when it speeds up or slows

down, the blower will slowly ramp up or down from one speed to

another. Changes in blower speed during A/C or heat pump heating can

take up to 30 seconds. Changes in blower speed during electric resistance heating can take up to 15 seconds.

COMFORT SETTINGS

TABLE 6:

Comfort Setting Selection

DELA Y TAP COMFORT SETTING

A Normal

B Humid

C Dry

D Temperate

Normal

The normal setting provides a ramp-up from zero airflow to full capacity

and a ramp-down from full capacity back to zero airflow.

Humid

The humid setting is best-suited for installations where the humidity is

frequently very high during cooling season, such as in the southern part

of the country. On a call for cooling, the blower will ramp up to 50% of

full capacity and will stay there for two minutes, then will ramp up to

82% of full capacity and will stay there for five minutes, and then will

ramp up to full capacity, where it will stay until the wall thermostat is satisfied.

Dry

The dry setting is best suited to parts of the country where excessive

humidity is not generally a problem, where the summer months are usually dry. On a call for cooling the motor will ramp up to full capacity and

will stay there until the thermostat is satisfied. At the end of the cooling

cycle, the blower will ramp down to 50% of full capacity where it will stay

for 60 seconds. Then it will ramp down to zero.

Temperate

The temperate setting is best suited for most of the country, where neither excessive humidity nor extremely dry conditions are the norm. On

a call for cooling, the motor will ramp up to 63% of full capacity and will

stay there for 90 seconds, then will ramp up to full capacity. At the end

of the cooling cycle, the motor will ramp down to 63% of full capacity

and will stay there for 30 seconds, then will ramp down to zero.

Johnson Controls Ducted Systems 17

Page 18