Page 1

JLTDC01

condenser dryer with heat pump

Instruction manual

Page 2

1 Important Safety Information

It is most important that this instruction manual should be retained with the appliance for future reference.

Should the appliance be sold or transferred to another owner, or should you move house and leave the appliance, always ensure that the book is supplied with the appliance in order that the new owner can get to know

the functioning of the appliance and the relevant warnings. These warnings have been provided in the interest

of safety. You MUST read them carefully before use or installation by a qualified person. If you are unsure of the

meanings of these warnings contact the John Lewis branch from which you purchased the appliance.

• Please make sure that no gas lighters have accidentally

Installation

• The appliance is heavy. Care should be taken when moving it.

• It is dangerous to alter the specifications or attempt to

modify this product in any way.

• Any electrical work required to install this appliance

should be carried out by a qualified electrician or competent person.

• Care must be taken to ensure that the appliance does not

stand on the electrical supply cable.

• If the machine is situated on a carpeted floor, please adjust the feet in order to allow air to circulate freely.

• If the tumble dryer is placed on top of a washing machine,

it is compulsory to use the stacking kit (optional accessory).

Child safety

• This appliance is designed to be operated by adults. Children should not be allowed to tamper with the controls

or play with the product.

• Pets and children have been known to climb into tumble

dryers. Please check your drum before use.

• Keep all packaging well away from children.

• When the appliance is to be scrapped, cut off the electri-

cal supply cable and destroy the plug with the remaining

cable. Disable the door catch in order to prevent children

from becoming trapped inside while playing.

Use

• Do not overload the appliance (see programme chart).

• Clothes which are dripping wet should not be placed in

the dryer.

• Risk of fire: items that have been spotted or soaked with

vegetable or cooking oil constitute a fire hazard and

should not be placed in the tumble dryer.

• If you have washed your laundry with stain remover you

must execute an extra rinse cycle before loading your

tumble dryer.

• As some bulky items such as duvets and eiderdowns

should be dried in large commercial machines because of

their bulk, check with the manufacturer of the item if it is

suitable for drying in a domestic machine, even if the dry

weight of the item is within the limit advised.

been left in pockets of garments to be loaded into appliance.

• Danger of explosion: Never tumble dry items that have

been in contact with flammable solvents (petrol, methylated spirits, dry cleaning fluid and the like). As these substances are volatile, they could cause an explosion. Only

tumble dry items washed with water.

• In order to avoid danger of fires caused by excessive drying, do not use appliance to dry the following items:

Cushions, quilts and the like (these items accumulate

heat).

Items containing rubber foam or materials similar to rubber foam.

• Leave the door slightly ajar when the appliance is not beeing used. This will allow the seal to be preserved.

• Do not allow fluff to accumulate around the dryer.

• Under no circumstances should you attempt to repair the

machine yourself. Repairs carried out by inexpirienced

persons may cause injury or serious malfunctioning. Contact the telephone number given under Repairs - After

Sales Service (page 23).

Always insist on genuine John Lewis spare parts.

Maintenance and Cleaning

• Clean fluff filters after using tumble dryer. To prevent fire

risks, do not use the appliance if the fluff filters are damaged.

• Switch off the dryer before all cleaning, care or maintenance work. Also disconnect the mains plug from the

socket or – with permanent connections – switch off the

LS switch in the fuse box and/or remove the fuse.

• Do not spray down the dryer with jets of water. Risk of

electric shock!

Service

• This dryer should only be repaired or serviced by an authorised Service Engineer and only genuine approved

spare parts should be used.

2

Page 3

2 Ecological hints

To save energy we recommend that you follow these hints:

• Try to load the maximum capacity of the machine as small

loads are uneconomical.

• Always load well spun laundry. The higher the spin speed,

the lower the electricity consumtion and the shorter the

drying times.

• Do not over-dry laundry, this avoids creasing and saves

energy.

• Clean the filters regularly to avoid excessive drying times

and high electricity consumption.

• The room should be well ventilated for the tumble dryer

to operate efficiently. The room temperature should not

exceed +35°C during drying.

2 Environmental Information

• After unpacking please dispose of the packaging with due

regard to safety and the environment.

• Materials marked with the symbol are recyclable.

• Check with your local Council or Environmental Health

Office to see if there are facilities in your area for recycling this appliance.

• When the appliance is to be scrapped, cut off the power

supply cable and make the door closing device unusable

to prevent young children from being trapped inside.

g

1 War ning

A cut off plug inserted into a 13 amp socket is a serious safety (shock) hazard. Please ensure the cut off

plug is disposed of safely.

The symbol

indicates that this product may not be treated as

household waste. Instead it shall be handed over to

the applicable collection point for the recycling of

electrical and electronic equipment. By ensuring this

product is disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could otherwise

be caused by inappropriate waste handling of this

product. For more detailed information about recycling of this product, please contact your local city

office, your household waste disposal service or the

shop where you purchased the product.

W on the product or on its packaging

3

Page 4

Contents

For the User

Important Safety Information 2

Description of the Appliance 5

The Control Panel 10

Programme Chart 12

Using the tumble dryer 13

Hints & Tips on Drying 15

Maintenance and Cleaning 16

External cleaning 16

Cleaning the filters 16

Cleaning the door 16

Cleaning the door seal 16

Cleaning the fluff filter 17

Emptying the water reservoir 18

Cleaning the drum 18

Clean operating screen and housing 18

Changing the bulb for interior lighting 18

For the Installer

Installation 6

Technical Specifications 6

Unpacking 7

Transporting the appliance 7

Positioning 7

Stacking kit (optional accessory 7

Door reversal 8

Electrical connection 9

Guide to use the Instruction Manual

The following symbols will be found in the text to guide

you throughout the Instructions:

Programming options 19

Something Not Working 20

Repairs - After Sales Service 23

Spare Parts 23

1

3

2

Safety Instructions

Hints and Tips

Environmental Information

5 This appliance complies with the following

E.E.C. Directives:

- 73/23 or 19.2.73 (Low Voltage Direc-

tive) and subsequent modifications;

- 89/336 or 3.5.89 (Electromagnetic

Compatibility Directive) and subsequent modifications.

4

Page 5

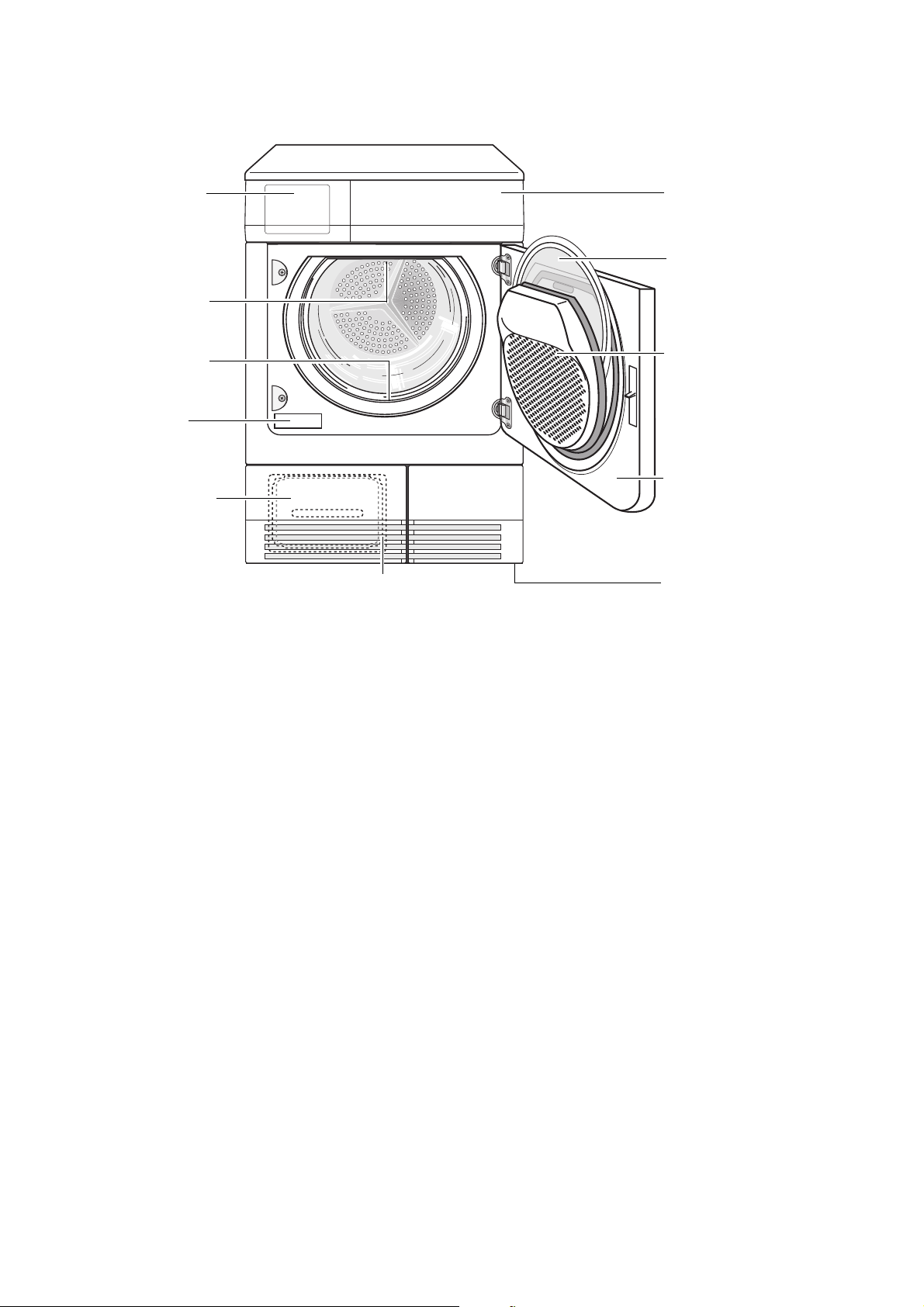

Description of the Appliance

Wat er reser voir

Lamp for interior

illumination

icro-fine filter

lint filter)

Rating plate

Base door

upstream of

fluff filter and

heat exchanger

Display panel

Fine strainer

(lint filter)

Large mesh filter

(lint filter)

Loading door

(reversible)

Screwed feet

(with height

adjustment)

Air slots

5

Page 6

Installation

1 It is dangerous to alter the specifications or attempt

to modify this product in any way.

1 Care must be taken to ensure that the appliance

does not stand on its electrical supply cable.

1 Any electrical work required to install this appliance

should be carried out by a qualified electrician or

competent person.

Technical Specifications

Height

DIMENSIONS

POWER SUPPLY VOLTAGE

TOTAL POWE R AD SOR BED

MAX LOAD CAPACITY

DRUM VOLUME 108 l

CONSUMPTIONS

Width

Depth

Cotton, linen

Synthetics

Cotton, linen

Cotton, linen

Synthetics

2.1 kWh (6kg cupboard dry)

1.7 kWh (6kg iron dry)

0.9 kWh (3kg cupboard dry)

85 cm (33.5’’)

60 cm (23.6’’)

60 cm (23.6’’)

230-240 V/50 Hz

1200 W (6 A)

6kg (13.2 lbs)

3kg (6.6 lbs)

6

Page 7

Unpacking

Positioning

Warning!

1 Slide out the polystyrene bag containing the polysty-

rene block before using the appliance. Pull off adhesive strips from inside machine on top of drum.

Keep all packaging away from children.

It is recommended that, for your convenience, the machine

is positioned close to your washing machine.

The tumble dryer must be installed in a clean place, where

dirt does not build up.

To keep vibration and noise to a minimum when the dryer is

in use, it should be placed on a firm, level surface.

Once in its permanent operating position, check that the

dryer is absolutely level with the aid of a spirit level. If it is

not, raise or lower the feet until it is.

The feet must never be removed.

Specialist accessories

The following special accessories are available from your

Service Force Centre.

Stacking kit (optional accessory):

It should be possible to stack your new dryer on top of a

front loading washing machine with a covers depth of 60 cm

and width of 60cm.

Read carefully the instructions supplied with the stacking

kit.

Please contact your local John Lewis branch for further advice.

Version to be supplied:

– with extractable stacker plate 916 019 103

Transporting the appliance

1 War ning: Only tip the appliance on its left side to

transport (see illustration), if it cannot be transported in an upright position.

Installation kit for external condensate

drain

Installation kit (125 122 510) for direct draining of condensate into a basin, siphon, gully, etc. The condensate tank

then no longer has to be drained, it must however remain in

its intended position in the machine. Refer to the “Programme options” section for how to deactivate the FULL

TANK display.

Max. displacement height: 1m from the base of the dryer;

max. displacement length: 3 m

7

Page 8

Door reversal

1 War ning! The door may only be reversed by a

specialist.

Instructions for qualified personnel/specialist

War ning! Before reversing the door, disconnect the mains

plug; with a permanent connection: remove the fuse.

1.Open door.

7.Unscrew cover plates E from the front of the machine,

rotate through 180, screw on the opposite side.

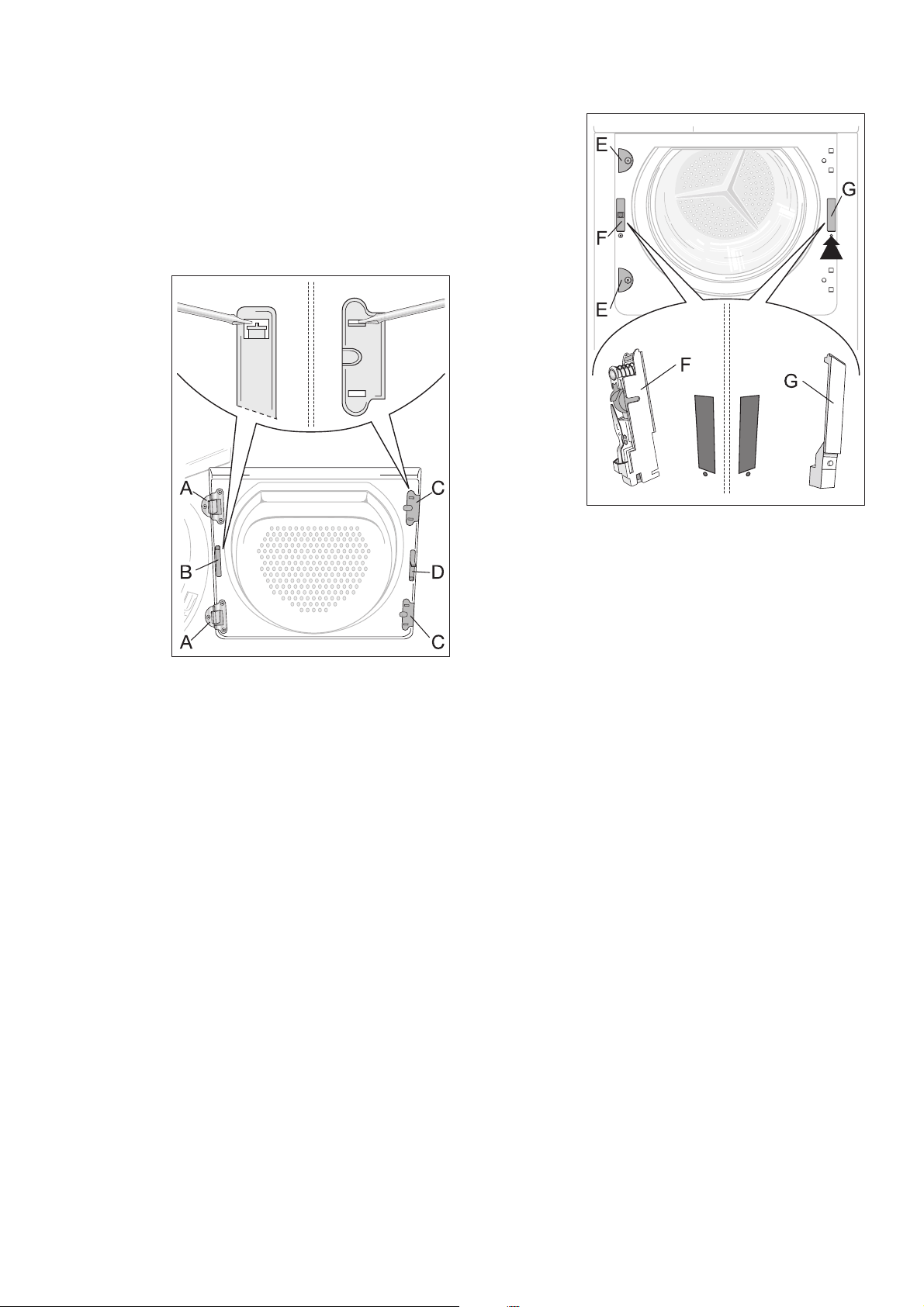

2.Unscrew hinge A from the front of the machine and take

off the door.

3.Carefully pry off cover plates B and C. To do this, insert a

thin screwdriver into the slots as shown in the illustration, press downwards slightly and pry out the cover

plates.

4.Unfasten locking block D from the snap-on fixture, take

out and reinsert on the other side, having rotated the

block through 180°.

5.Unscrew hinge A from the door, rotate through 180°, re-

insert on the opposite side and screw down.

6.Reinsert cover plates B and C on the opposite site having

first rotated them through 180°.

8.Unscrew door lock F, push down slightly and remove

from the front of the machine.

9.Press snap-in button G in and down, press cover down

slightly and remove from front of the machine.

10.Transfer door lock F to the oppositeside and screw

down.

11.Fix cover G on to the other side and allow the snap-in

button to lock in place.

12.Insert door and hinges into recesses on the front of the

machine and screw down.

Note regarding contact protection: The machine is

only secure for operations again once all plastic parts have

been inserted.

8

Page 9

Electrical connection

Any electrical work required to install this appliance should

be carried out by a qualified electrician or competent person.

1 WARNING – THIS APPLIANCE MUST BE

EARTHED.

Should the appliance power supply cable need

to be replaced, this must be carried out by a

Service Force agent (see page 23).

The manufacturer declines any liability should

these safety measures not be observed.

Before switching on, make sure the electricity supply voltage

is the same as that indicated on the appliance rating plate

(See picture on page 5).

The appliance is supplied with a 13 amp plug fitted. In the

event of having to change the fuse in the plug supplied, a

13 amp ASTA approved (BS 1363/A) fuse must be used.

Should the plug need to be replaced for any reason, proceed as described below.

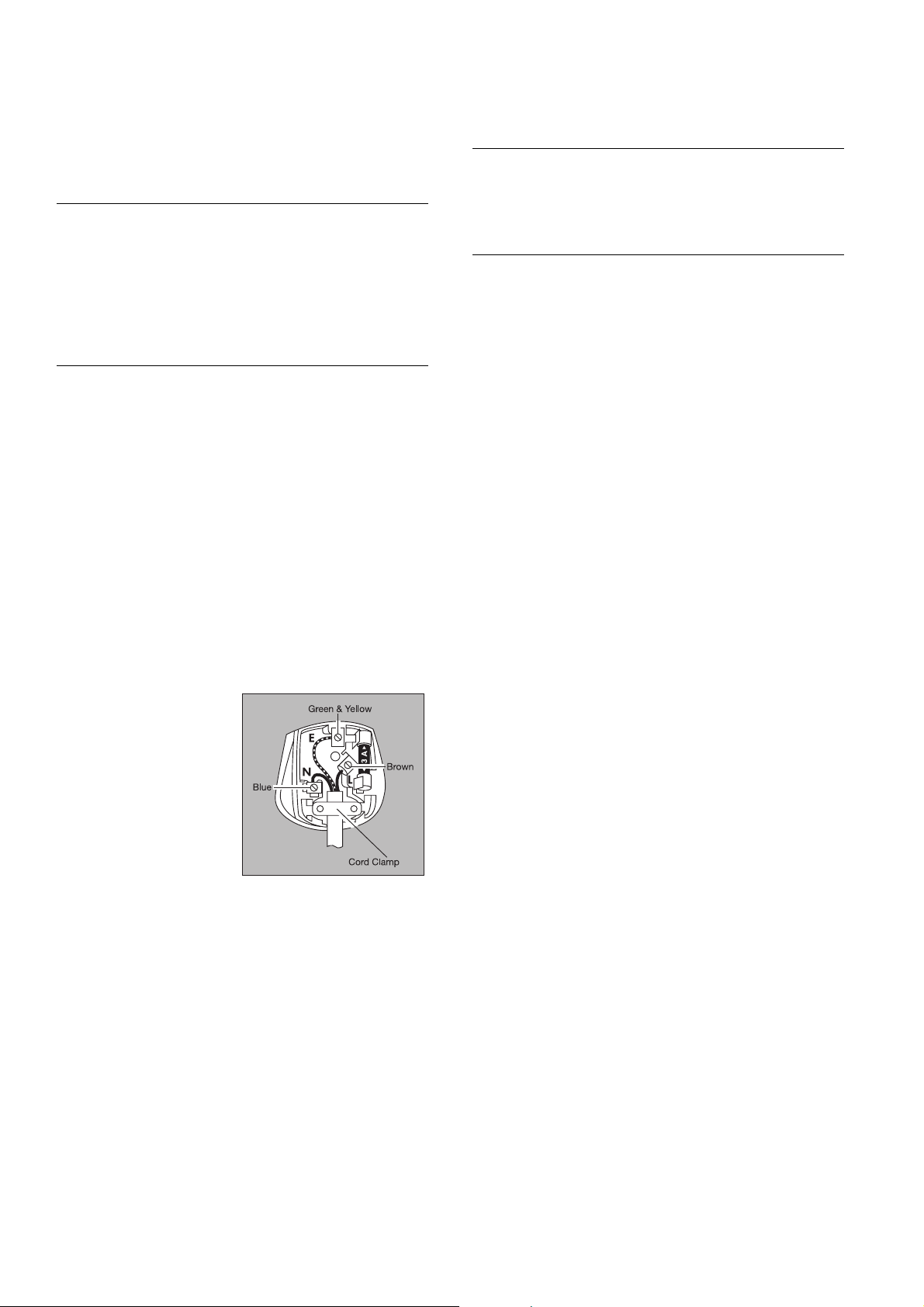

The wires in the mains lead are coloured in accordance with

the following code:

Green and Yellow: Earth

Blue: Neutral

Brown: Live

1 WARN ING!

1 The plug must still be accessible after the ap-

1 The appliance should not be connected to the

Permanent Connection

In the case of a permanent connection it is necessary that

you install a double pole switch between the appliance and

the electricity supply (mains), with a minimum gap of 3mm

between the switch contacts and of a type suitable for the

required load in compliance with the current electrical regulations.

The switch must not break the yellow and green earth cable

at any point.

A cut off plug inserted into a 13 amp socket is

a serious safety (shock) hazard.

Ensure that the cut off plug is disposed of safely.

pliance has been installed.

electrical supply by means of an extension cable.

If you fit your own plug, the colours of the wires in the

mains lead of your appliance may not correspond with the

markings identifying the terminals in your plug.

Proceed as follows:

1. Connect the Green and Yellow (earth) wire to the terminal in the plug which is marked with the letter “E“ or by

the earth symbol E or coloured green and yellow.

2. Connect the Blue (neutral) wire to the terminal in the

plug which is marked with the letter “N“ or coloured

black.

3. Connect the Brown (live) wire to the terminal in the plug

which is marked with the letter “L“ or coloured red.

4. Upon completion there must be no cut, or stray strands

of wire present and the cord clamp must be secure over

the outer sheath.

9

Page 10

The control panel

101112

312 54

89

7

6

1 Wool button

To select the Wool programme after setting the programme

selector to WOOL/SILK. If no button is pressed, the Wool

programme is automatically set.

2 Silk button

To select the SILK programme after setting the programme

selector to WOOL/SILK.

3 Anti-crease button

The anti-crease phase at the end of the drying cycle is

lengthened by 60 minutes. The laundry can be removed at

any time during the anti-crease phase.

4 Alarm button

When the drying cycle has finished, an intermittent acoustic

signal will sound, if this button has been pressed.

5 Start/Pause button

After having selected the programme and the options, press

this button to start the dryer. The relevant light will stop

flashing.

If you have choosen a delayed start, the machine will begin

the count down.

If you want to interrupt the programme, press the START/

PAUSE button. To restart the drying cycle, press the START/

PAUSE button again.

6 Maintenance display

The related light comes up when

• the tank must be emptied or

• the filters must be cleaned.

7 Programme selector

The appliance will be switched on by turning the programme selector away from the OFF position to the left or

to the right.

If the LIGHT position or a programme is selected, the interior illumination is switched on if the door is opened.

Electronically controlled or time controlled drying can be

selected.

Electronically controlled drying (automatic)

The appliance runs these programmes with the help of sensors which detect the degree of dampness of the laundry.

Time controlled drying

This can be used to finish off drying if necessary. Select the

30 minutes programme for synthetics.

Cancelling a programme

To cancel a running drying programme, turn the programme

selector to OFF.

10

Page 11

Changing a programme

To change a programme which has been selected by mistake

once the programme has started, first turn the programme

selector to OFF and then reset the programme.

The programme can no longer be changed directly once the

programme has started. If nevertheless there is an attempt

to change the programme on the programme selector, the

programme progress display and the maintenance indicators

flash. If an option button (excluding the SIGNAL button) is

pressed, Err appears in the multidisplay. The drying programme is not however affected by this (laundry protection).

Switch off the appliance

To switch off the appliance at the end of the drying cycle,

turn the programme selector to OFF.

8 Programme progress display

The lights indicate the different phases of the drying cycle.

Drying:

The light indicates the drying phase.

Cooling:

The light indicates a cooling phase of 10 minutes.

End:

The light indicates the end of the cooling phase and the end

of the programme.

Crease guard:

The drying cycles (except for the WOOL programme) are

automatically followed by an anti-crease phase which lasts

around 30 minutes. The drum rotates at intervals during

this phase. This keeps the laundry loose and free of creases.

The laundry can be removed at any time during the anticrease phase. (The laundry should be taken out towards the

end of the anti-crease phase at the latest to prevent creases

from forming.)

9 Display

The display shows the following information:

• Duration of the selected programme

• Delayed start

• End of programme

• Incorrect selection of programme options

• Error code

10 Delay start button

By pressing the DELAY START button, the start of a programme can be delayed by between 30 minutes (30') and a

maximum of 23 hours (23h).

This option must be selected after having selected the programme and before pressing START/PAUSE to start the programme.

Every time the button is pressed, the time is increased by 30

minutes until the display shows a delay of 2 hours. After

this, the delay is displayed hour by hour.

If 23h is displayed and you press the button again, the time

delay will be cancelled. The display will show 0' and then

the duration of the selected programme.

To activate the count down, the START/PAUSE button has

to be pressed. The amount of time remaining until the programme is set to start is continuously displayed (e.g. 12h,

11h, 10h, … 30

During the delayed start, it is not possible to change the

programme or the delay time selected. To do this, you must

first switch off the appliance by setting the programme selector to OFF.

If you wish to add more laundry while the countdown is

running, simply open the door. When you close the door,

press the START/PAUSE button again to cause the count

down to be resumed.

' etc).

11 Intensity button

For precise setting of the residual moisture content of the

laundry, the degrees of dryness +, ++ or +++ can be set in

addition to most programmes. Laundry becomes drier from

+ to +++.

The INTENSITY button must be pressed repeatedly until

the light for the residual moisture required is lit.

In the programmes WOOL or SILK further drying can also

be set by restarting the programmes with the residual moisture levels +, ++ or +++ set in addition, as required. In the

case of a drying cycle with relatively dry laundry, the length

of the programme cycle displayed at the beginning is corrected after a while.

Important: Do not over dry wool or silk.

12 Level of dryness

Depending on the selected programme the lights indicate

the level of dryness reached while the drying cycle is running. The level of dryness increases from IRON DRY to EXTRA DRY.

11

Page 12

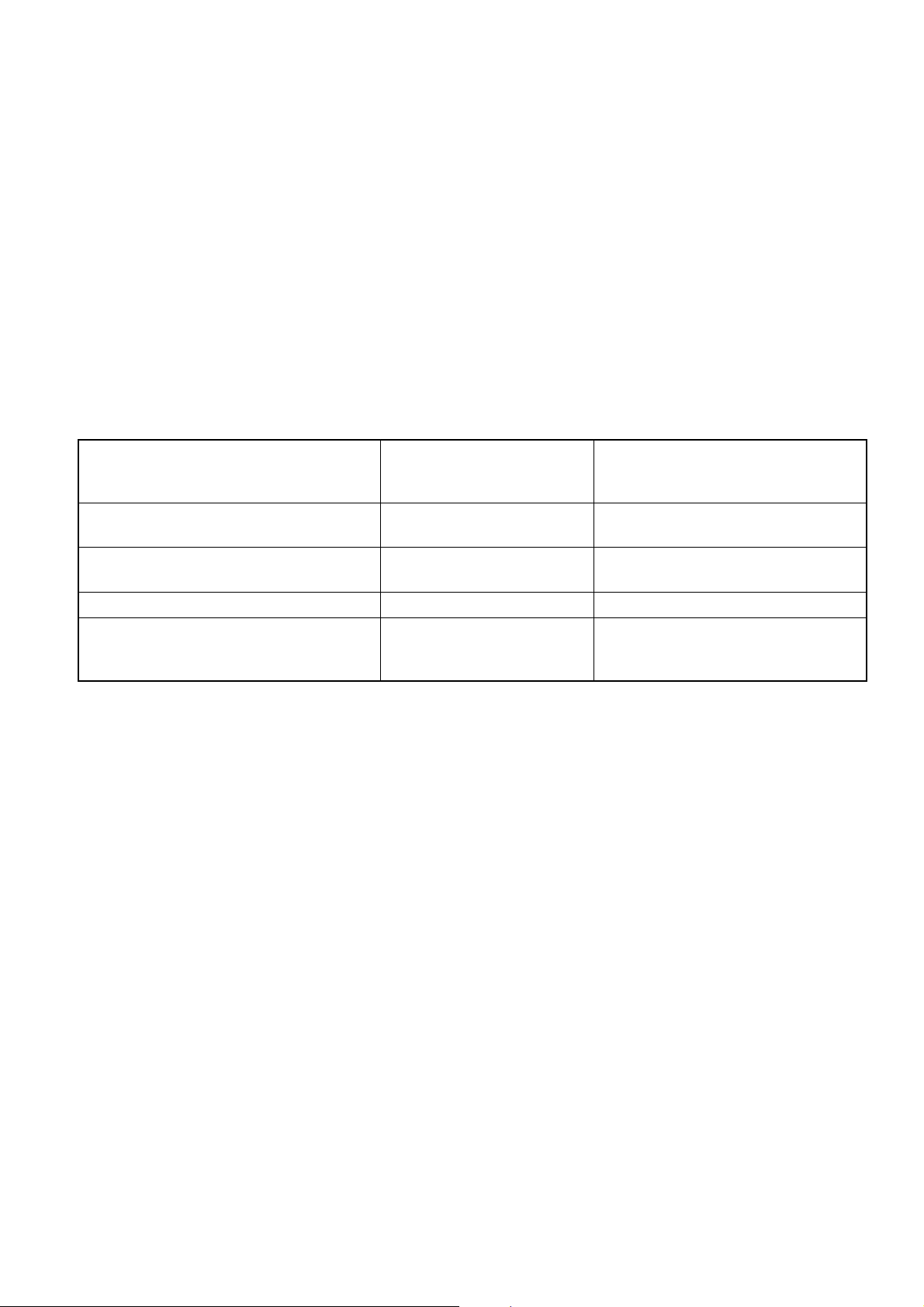

Programme Chart

Automatic drying

Type of laundry Degree of drying required Max-load

Extra dry 6kg

Store dry 6kg

Cottons

Synthetics

Jeans Heavy cotton 6kg

Easy care fabrics Easy iron 1kg

Woole n f abrics Wool 1 kg

Silk Silk 1kg

Synthetics Refresh 1kg

1) Never overfill the drum (do not load large quilts, for example)

• Easy iron is a special programme with anti-crease mechanism for easy care fabrics such shirts and blouses; for minimum ironing effort. The result depends on the type of

fabric and its finish.

• Wool is a special programme for drying woollen fabrics

after they have been washed, using warm air at minimum

mechanical load. Recommendation: Remove fabrics immediately after drying, as no anti-crease programme follows.

Cupboard dry 6kg

Damp dry 6kg

Iron dry 6kg

Extra damp 6kg

Extra dry 3kg

Cupboard dry 3kg

Iron dry 3kg

• Silk is a special programme for drying silk using warm air

and gentle movement.

• Refresh ia a special programme, lasting around 35 minutes, for refreshing or gently cleaning textiles with commercially available dry cleaning products (only use those

products which are declared as suitable for the dryer by

the manufacturer; please observe the manufacturer’s instructions for use).

1)

Time controlled drying

Type of laundry Drying time Max-load

Synthetics 30 min 1kg 30 minutes

1) Never overfill the drum (do not load large quilts, for example)

Drying times vary according to:

• The type of laundry

• The size of the load

• The degree of water extraction obtained during the spin

cycle of the washing machine

• The degree of dryness required

Load

It is often difficult to estimate the weight of items to be

dried. We therefore recommend that you adopt the following guidelines:

• cotton, linen: drum full but not too tightly packed;

• synthetics: drum no more than half full;

• delicate fabrics: drum no more than one third full.

1)

Programme selector dial

position

12

Page 13

Using the tumble dryer

1 If the appliance was not transported in an upright po-

sition, leave it to stand for 12 hours before connecting it to the electricity supply and using it for the first

time, so that the oil can flow back to the compressor. Otherwise the compressor could be damaged.

In order to remove any residues which may have been produced during production, wipe the dryer drum with a damp

cloth or carry out a brief drying cycle (30 MINUTES) with

damp cloths in the machine.

1 If the appliance was not transported in an upright po-

sition, leave it to stand for 12 hours before connecting it to the electricity supply and using it for the first

time, so that the oil can flow back to the compressor. Otherwise the compressor could be damaged.

Switching machine on / switching light on

Turn the programme selector to any programme or turn it

to LIGHT. The machine has been switched on. When the

door is opened, the drum is illuminated.

Opening loading door / loading

Selecting additional functions

INTENSITY

For precise setting of the residual moisture content of the

laundry, the degrees of dryness +, ++ or +++ can be set in

addition to most programmes. Laundry becomes drier from

+ to +++.

1. Press the INTENSITY button repeatedly until the light for

the residual moisture required is lit.

In the programmes WOOL or SILK further drying can also

be set by restarting the programmes with the residual moisture levels +, ++ or +++ set in addition, as required. In the

case of a drying cycle with relatively dry laundry, the length

of the programme cycle displayed at the beginning is corrected after a while.

Important: Do not over dry wool or silk.

laundry

1. Open loading door:

Push against the loading door (push point )

2. Load your laundry (do not force it in/overload the ma-

chine).

1 War ning! Be careful not to trap laundry in between

the loading door and rubber seal.

3. Close loading door securely. Lock must audibly lock.

Selecting the programme

Use the programme selector to set the programme you require.

The probable programme run time is displayed (in minutes)

on the multi-display.

ANTI-CREASE

If this additional function is selected, the anti-crease phase

at the end of the drying cycle is lengthened by 60 minutes.

The laundry can be removed at any time during the anticrease phase.

ALARM

When the drying cycle has finished, an intermittent acoustic

signal will sound.

13

Page 14

Setting time delay

3 With the DELAY START button, you can delay the

start of a programme by between 30 minutes (30'

and a maximum of 23 hours (23h).

1.Select the programme

2.Press the DELAY START button as many times as neces-

sary until the required start delay appears on the multi

display, e.g. 12h if the programme is to be started in

12 hours. The DELAY START display is illuminated.

3 If 23h is displayed and you press the button again,

the time delay will be cancelled. The display will

show 0' and then the duration of the selected programme.

3.To activate the delay timer, press the START/PAUSE but-

ton. The amount of time remaining until the programme

is set to start is continuously displayed (e.g. 12h, 11h,

10h, … 30

' etc).

3 Until the start of the programme the drum is moved

at longish intervals to loosen the laundry.

Starting the programme

Press the START/PAUSE button. The programme is started.

The programme progress display and the display showing

the level of dryness show drying progress.

Drying cycle complete / removing laundry

Once the drying cycle is complete, the END and CREASE

GUARD indicators light up. If the ALARM button has been

pressed, an acoustic signal sounds intermittently.

3 The drying cycles (except for the WOOL pro-

gramme) are automatically followed by an anti-crease

phase which lasts around 30 minutes. The drum rotates at intervals during this phase. This keeps the

laundry loose and free of creases. The laundry can

be removed at any time during the anti-crease phase.

(The laundry should be taken out towards the end of

the anti-crease phase at the latest to prevent creases

from forming.) If ANTI-CREASE has been selected,

the anti-crease phase is lengthened by 60 minutes.

1.Open door.

2.Before removing the laundry, remove fluff from the micro-

fine filter. It is best to use a damp hand for this purpose.

(See “Cleaning and maintenance” section.)

3.Remove laundry.

4.Turn the programme selector to OFF.

Important: After each drying cycle

– Clean the micro-fine filter and fine filter

– Drain the condensed water container

(See section “Cleaning and maintenance”.)

5.Close door.

Changing programme

To change a programme which has been selected by mistake

once the programme has started, first turn the programme

selector to OFF and then reset the programme.

3 The programme can no longer be changed directly

once the programme has started. If nevertheless

there is an attempt to change the programme on the

programme knob, the programme progress display

and the maintenance indicators flash. If an option

button (excluding the ALARM button) is pressed,

Err appears in the multidisplay. The drying programme is not however affected by this (laundry protection).

Removing laundry or loading

laundry when necessary

1.Open loading door

1 War ning! Laundry and drum can become hot.Risk

of burns!

2.Load or remove laundry items.

3.Close the door securely. Lock must audibly lock.

4.Press the START/PAUSE button to continue the drying cy-

cle.

14

Page 15

3 Hints & Tips on Drying

Before placing articles of laundry in your tumble dryer,

check the care labels to ensure they are recommended for

tumble drying.

Care labels you may find on your laundry

n

may be tumble dried

m normal drying (high temperature)

l delicate drying (low temperature)

k do not tumble dry

1 Do not overload the appliance

Here is a list of the approximate weight of some common

laundry items.

Sheet 700 to 1000 g

Pillowcase 100 to 200 g

Tablecloth 400 to 500 g

Table Napkin 50 to 100 g

Kitchen Towel 700 to 120 g

Linen Hand Towel 100 to 150 g

Hand Towel 150 to 250 g

Bath Towel 700 to 1000 g

Bathrobe 1000 to 1500 g

Shirt 200 to 300 g

Apron 150 to 200 g

• Always load well spun laundry. The higher the spin speed

the lower the electricity consumption and the shorter the

drying time.

• DO NOT load dripping wet laundry into the dryer. Roll

the article in a towel or spin to remove excess water.

• Close poppers and zips and fasten any buttons.

• Sort the laundry. Separate synthetics from cotton/linens,

and dry separately.

• Remove the laundry immediately after the programme

has finished.

• Use a fabric conditioning sheet to reduce static. We recommend the sheet is pinned to an article of laundry (using a safety pin).

• Mix the load i. e. large and small articles.

• When drying large items such as sheets, we recommend

you periodically stop the dryer to redistribute the load.

DO NOT use the tumble dryer to dry the following:

• Articles contaminated with inflammable substances e. g.

petrol, cleaning solvents, cooking oil, fats or hair lacquer.

• Very large and bulky items such as duvets or sleeping

bags.

15

Page 16

Maintenance and Cleaning

You must disconnect the appliance from the electricity supply, before you can carry out any cleaning

or maintenance work.

External cleaning

Use only soap and water and then dry thoroughly.

Important: Do not use methylated spirit, diluents or similar products.

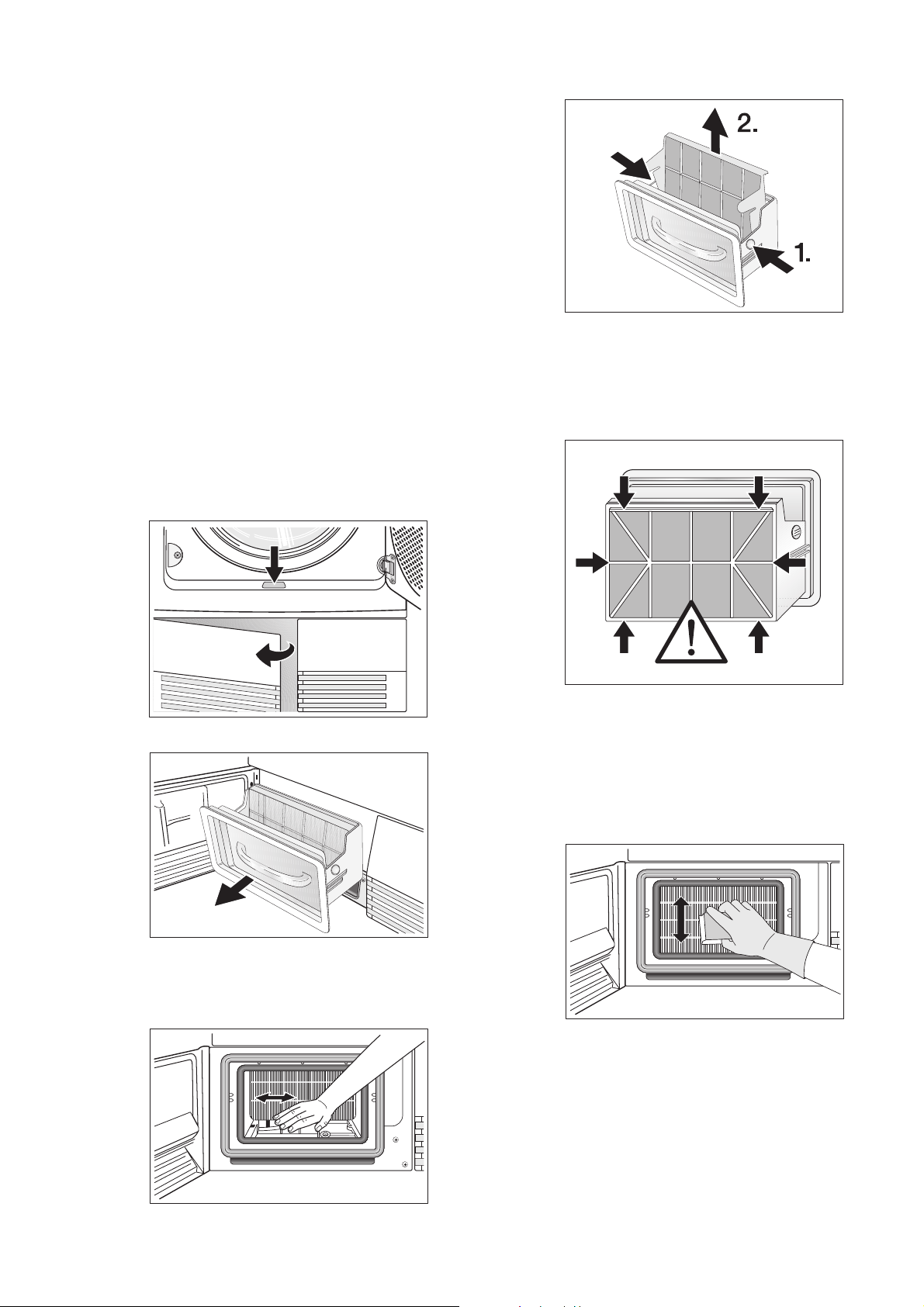

Cleaning the filters

To ensure that the dryer works efficiently, the lint filters

(micro-fine filter and fine strainer) must be cleaned after

every drying cycle.

1 Caution! Never operate the dryer without fluff fil-

ters or with damaged or blocked fluff filters.

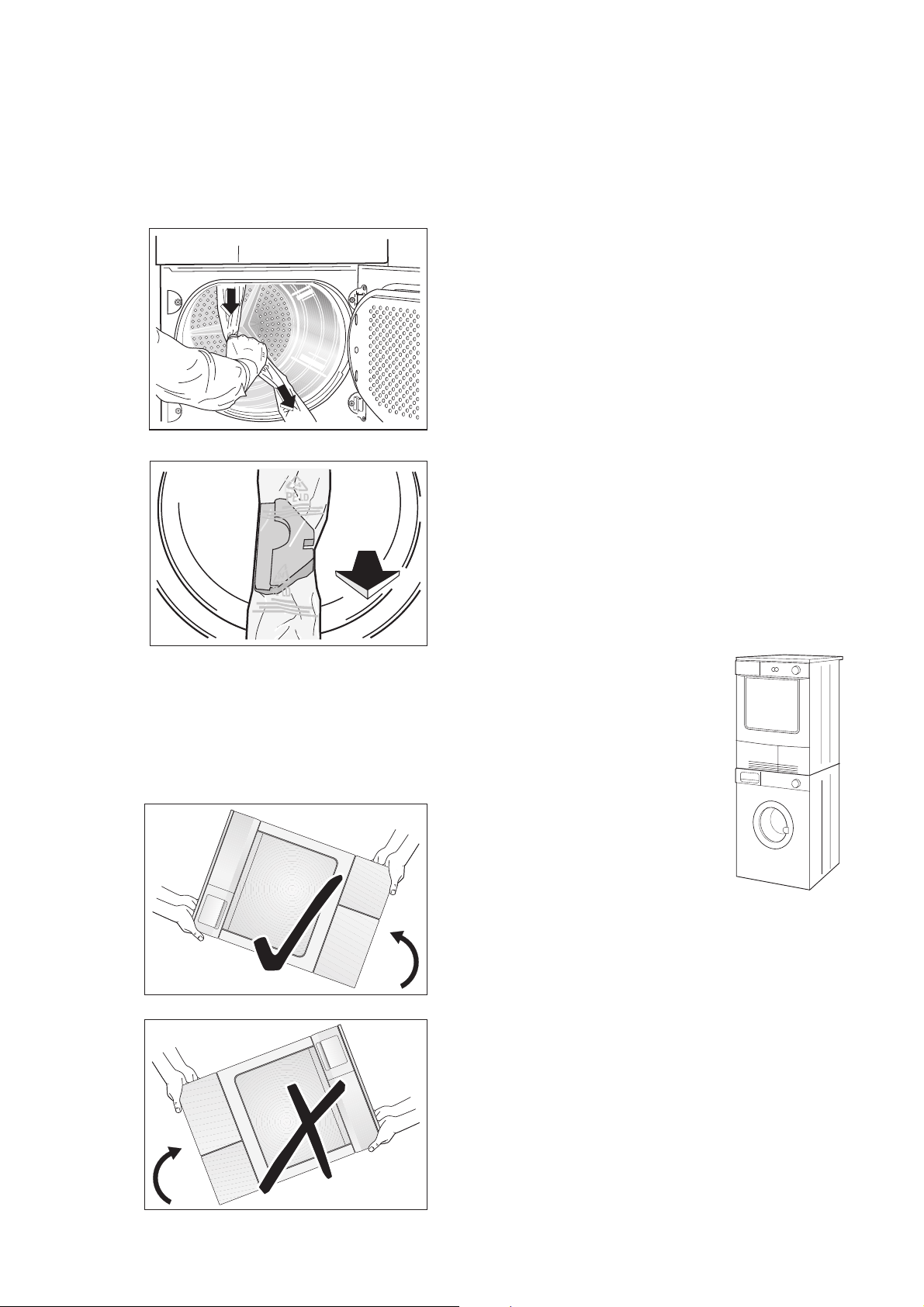

1.Open door

2.Use a damp hand to clean the micro-fine filter, which is

built into the lower part of the loading aperture.

5.Remove fluff from fine strainer. It is best to use a damp

hand for this purpose.

Clean the entire filter area

3 The strainer area does not have to be cleaned after

every drying cycle, but should be checked regularly

and cleaned of fluff if necessary.

6.To do this, grip the top of the large mesh filter and pull it

forwards until it comes loose from the two brackets.

7.Remove fluff from the entire filter area. It is best to use a

vacuum cleaner for this purpose.

8.Press both lugs of the large mesh filter into the brackets

on the loading door until they snap into place.

9.Re-insert fine strainer.

10.Press against the large mesh filter until it locks into the

interlock.

3.Push down unlock button on large mesh filter.

Large mesh filter elevates.

4.Take out fine strainer.

3 If the fine strainer is not fitted, the large mesh filter

will not snap into place and the door cannot be

closed.

Cleaning the door

Clean periodically the interior part of the door to remove

any fluff from the seals around the filter.

Regular cleaning ensures correct drying.

Cleaning the door seal

Wipe the door seal with a damp cloth immediately after the

drying cycle has finished.

16

Page 17

Cleaning the fluff filter

If the indicator PLINTH FILTER lights up, the fluff filter and

the filter mat in the base of the appliance must be cleaned.

3 To protect the heat pump from dirt, the dryer is fit-

ted with a special filter mat, which is located in the

filter housing. Here too large amounts of fluff build

up over time, which affect the function of the appliance.

1 Important

• Operating when the fluff filter is clogged with fluff can

damage the dryer. This also increases energy consumption.

• Never operate the dryer without the fluff filters.

• Do not use the dryer without the filter mat. A dirty heat

pump requires more energy and can only be cleaned up

by means of a costly process.

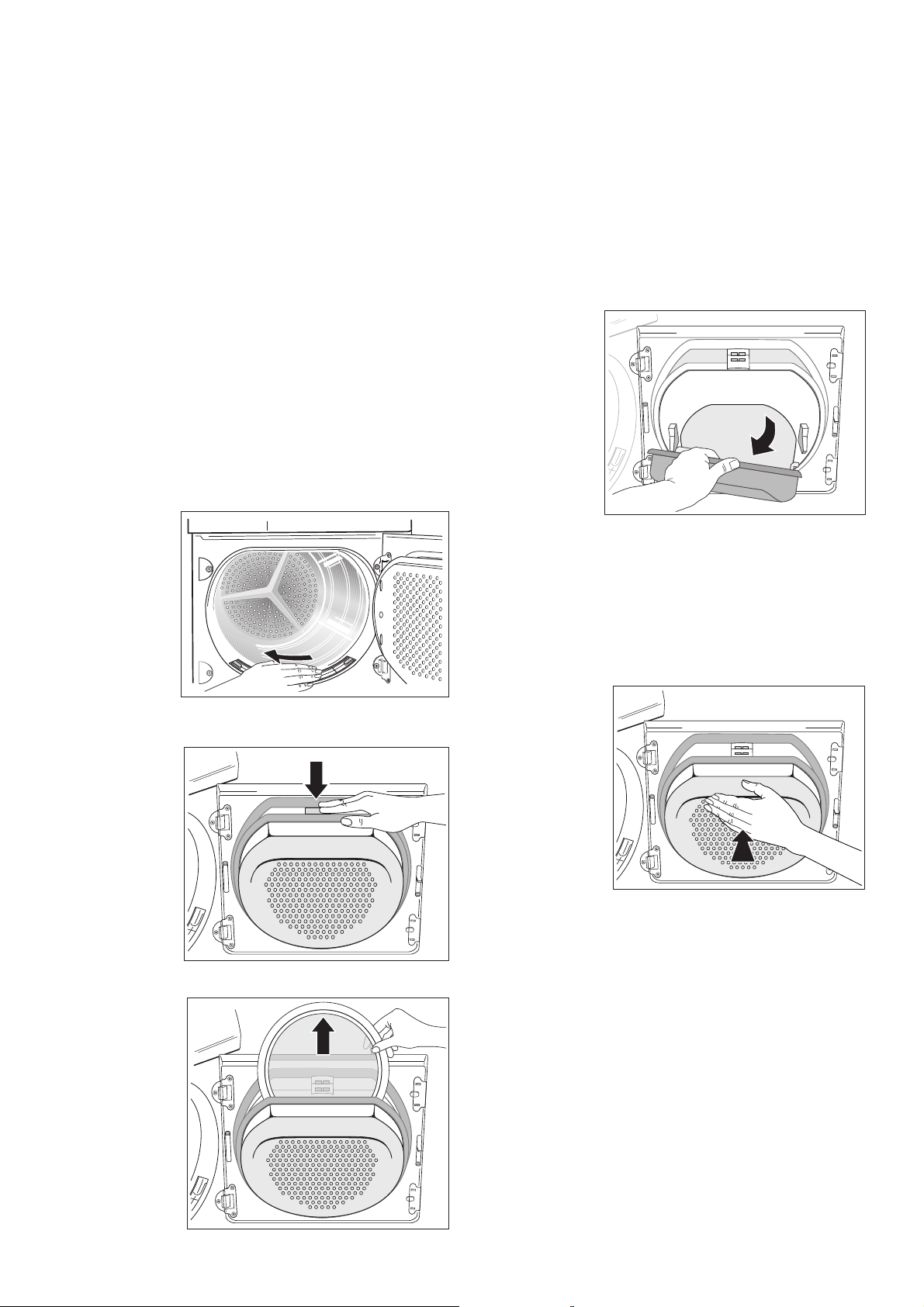

1. Open door.

2. Open door in plinth: To do this, press the release button

on the bottom of the door aperture and open the door in

the plinth to the left.

the pressure points on the sides and pull the filter mat

and frame up and out of the housing.

7. Take the filter mat out of the frame and wash it by hand

or use a vacuum cleaner, when it is has dried out. Fluff,

which has become stuck in the filter mat and has not been

removed by washing, does not affect the function.

8. Insert the filter mat in the frame and then insert with the

frame into the filter housing.

3. Pull filter housing out of the base by the handle.

4. Clean the inside of the door, the fluff filter chamber and

the rubber seals of fluff.

5. Remove fluff from the fluff filter on the floor of the base

with a damp hand.

1 Important: The filter mat must engage tightly with

the frame. Check that the mat is sitting snuggly in the

frame, especially after inserting it into the filter housing.

9. As necessary, approx. once every 6 months, remove the

fluff from the heat exchanger using the sponge supplied.

When doing this, please use rubber gloves.

Tip: The fluff can be removed more easily if it is first

dampened e. g. with a laundry dampener.

10.Re-insert filter housing along with frame and filter mat in

appliance base.

Note: If the filter mat and frame are not inserted in the filter housing, the filter housing cannot be slid into the appliance base.

11.Close door in plinth.

6. To clean the filter mat:

Remove filter mat from filter housing. To do this, press

3 The indicator PLINTH FILTER only goes out when

the programme knob has been positioned to OFF.

17

Page 18

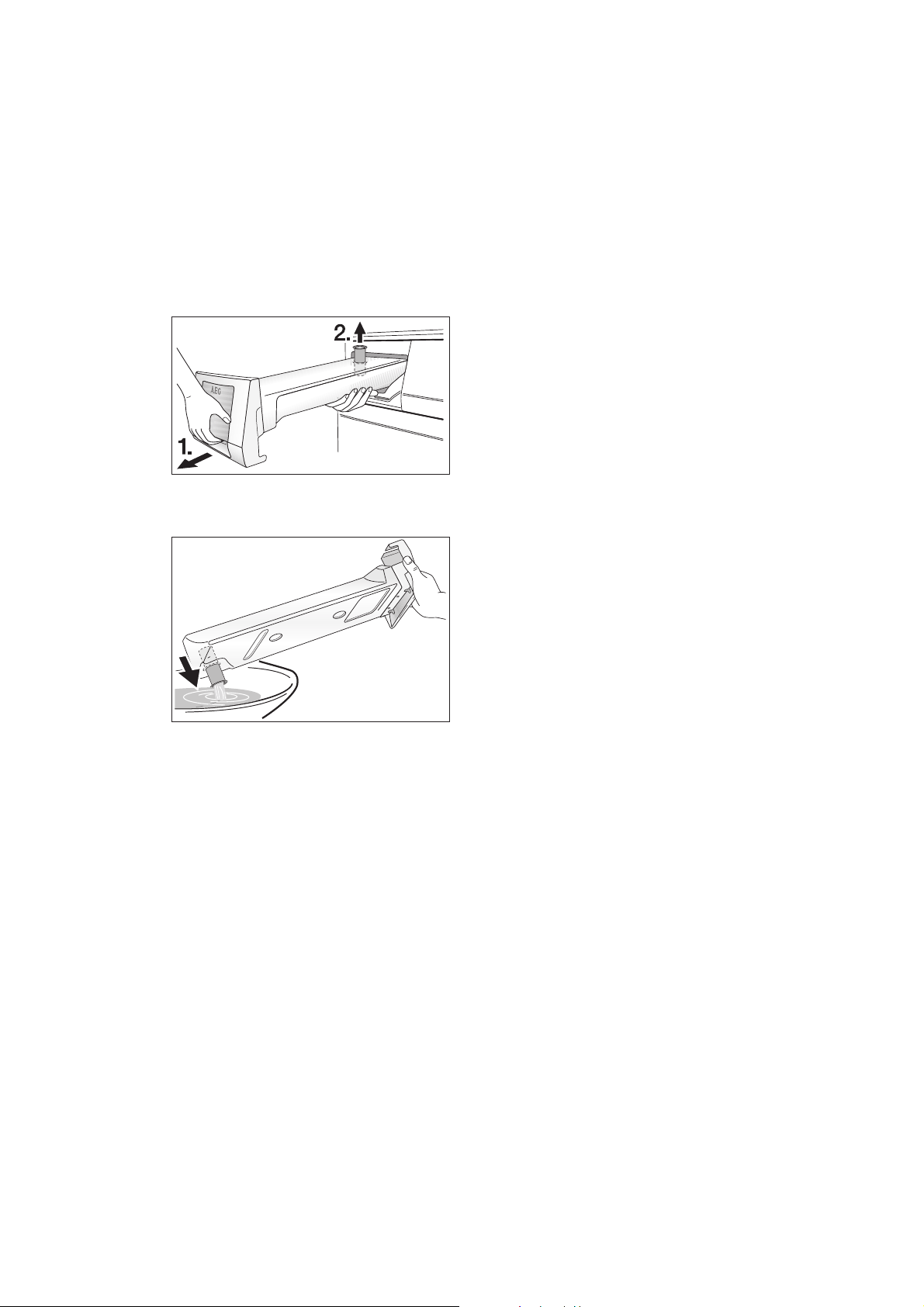

Emptying the water reservoir

Cleaning the drum

Empty water reservoir after every drying cycle.

If the water reservoir is full, an active programme will be in-

terrupted automatically and the FULL TANK display will

light up. In order to continue the programme, the water

reservoir must be emptied.

1 War ning! The condensed water is not suitable for

drinking or for preparing foodstuffs.

1.Take out drawer containing water reservoir completely

(1) and pull up the water reservoir’s drainage pipe as far

as it will go (2).

2.Pour condensed water out into a sink or other suitable

container.

1 Warni ng ! Do not use abrasives or steel wool to

clean the drum.

3 Lime in the water or cleaning agents may form a

barely visible lining on the inside of the drum. The

degree to which the laundry has been dried is then

no longer detected reliably. The laundry is damper

than expected when removed from the dryer.

Use a damp cloth, which has been soaked in water and a little vinegar, to wipe the inside of the drum and drum ribs.

Clean operating screen and

housing

1 Warni ng ! Do not use furniture cleaners or aggres-

sive cleaning agents to clean the machine.

Use a damp cloth to wipe down the operating screen and

housing.

Changing the bulb for interior

lighting

3.Slide outlet connections in and refit water reservoir.

If the programme has been interrupted as a result of the

water reservoir being full:

Press the START/PAUSE button to continue the drying cycle.

3 The water reservoir has a volume of approx. 4 litres.

This is sufficient for around 6kg of laundry which has

previously been spun at 800 revolutions/minute.

3 The condensed water can be used as distilled water,

e.g. for steam ironing. However first filter it (e.g.

with a coffee filter) to remove any residue and small

pieces of fluff.

3 If there is suitable plumbing located nearby, then the

drain kit could be fitted. Please refer to page 23.

Only use a special bulb which is designed specially for dryers. The special bulb can be obtained from the Customer

Care Department, ET no. 112 552 000-5.

3 Important: When the appliance is switched on, the

interior lighting switches itself off after 5 minutes

when the door is open.

1 Warni ng : Do not use standard bulbs! These devel-

op too much heat and may damage the appliance.

1 Warni ng : Before replacing the bulb, disconnect the

mains plug; with a permanent connection: fully unscrew or deactivate the fuse.

1.Unscrew cover above the bulb (this can be found directly

behind the loading aperture, at the top; refer to “Description of machine” section.)

2.Replace defective bulb.

3.Screw cover back down.

1 Warni ng : For safety reasons, the cover must be

screwed down tightly. If this is not done, the dryer

must not be operated.

18

Page 19

Programming options

Objective Implementation

1. Turn the programme selector to any programme.

Permanently programme on the audible signal which reminds you that the

programme is complete.

Adjust “level of dryness” detection:

If you wish the laundry to be slightly

drier or slightly damper at the end of

the programme than with the standard setting.

To deactivate the FULL TANK display

when using an external drain for the

condensed water.

2. Press the ALARM button and hold down for approx. 5 seconds.

A brief signal sounds several times. The ALARM display flashes several times.

The setting is permanently programmed.

The setting is cancelled as described under 1 and 2.

1. Turn the programme selector to any programme.

2. Press the SILK and ALARM buttons at the same time and hold down for approx. 5

seconds.

The current setting appears on the multi-display:

– C0: Setting for drier laundry

– C1: Standard setting

– C2: Setting for damper laundry

3. Press the START/PAUSE button until the setting required appears on the multi-dis-

play.

4. Turn the programme selector to OFF.

The setting is permanently programmed.

1. Turn the programme selector to any programme.

2. Press the WOOL and ANTI-CREASE buttons at the same time and hold down for

approx. 5 seconds. The multi-display briefly displays ”0”

The FULL TANK display is permanently deactivated.

The setting is cancelled as described under 1 and 2; the multi-display however briefly

displays ”1” (rather than ”0”).

19

Page 20

Something Not Working

If the tumble dryer is not working correctly, please carry out the following checks before contacting your local Service Force

Centre.

If, during operation, the error code (E plus number or letter) appears on the multi-display: Switch the appliance off and on

again. Reset programme. Press the START/PAUSE button.

If the error is still displayed, please inform your local Service Force Centre and quote the error code.

IMPORTANT: If you call an engineer to a fault listed below, or to repair a fault caused by incorrect use or installation a charge

will be made even if the appliance is under guarantee.

Symptom Possible cause Solution

Dryer does not work.

Drying results unsatisfactory.

Loading door does not close.

When a button is pressed, Err appears in the multi-display.

Drum light does not work.

Programme time displayed changes erratically or stays unchanged

for a long time.

Programme inactive, FULL TANK

display illuminated.

Drying cycle ends shortly after

programme starts. END display illuminated.

Drying cycle lasts an unusually

long time.

Note:

After around 5 hours the drying

cycle ends automatically (see

„Drying cycle complete“).

Mains plug is not plugged in or fuse is not

working correctly.

Loading door is open. Close loading door.

Have you pressed the START/PAUSE button?

Wrong programme selected.

Lint filters clogged. Clean lint filters.

Fluff filter clogged. Clean fluff filter.

Overloading of laundry. Observe recommended loading volumes.

Ventilation slots in base area covered up. Uncover ventilation slots in base area.

Residue on inside surface of drum or

drum ribs.

Fine strainer not in place and/or large

mesh filter not locked in place.

Washing protection. After the start of the

programme, the option can no longer be

set.

Programme selector in OFF position.

Defective light bulb. Replace light bulb (see next section).

Programme time is corrected automatically depending on type and volume of

laundry and level of dampness.

Condensate tank is full.

Not enough washing loaded or washing

loaded is too dry for selected programme.

Lint filter clogged. Clean lint filter.

Fluff filter in the base clogged. Clean fluff filter.

Load volume too big. Reduce load volume.

Laundry insufficiently spun. Laundry must be adequately spun.

Particularly high room temperature. Temporary switching off of the compressor to

avoid overload.

Plug in at mains socket. Check fuse in fuse

box (domestic installation).

Press the START/PAUSE button again.

Select a different programme the next time

you dry (see “Programme Chart” section).

Clean inside surface of drum and drum ribs.

Make an adjustment using the INTENSITY

function (see chapter ”Drying, Selecting additional functions”).

Install fine strainer and/or snap large mesh filter into place.

Turn the programme knob to OFF. Set the

programme again.

Turn programme selector to LIGHT or to any

programme.

Automatic process; this is not a machine fault.

Empty condensate tank, then start programme with START/PAUSE button.

Select time programme or higher drying level

(e.g. STORE DRY instead of CUPBOARD

DRY).

Automatic process, there is no fault with the

appliance. If possible, lower the room temperature.

20

Page 21

212223

Page 22

Page 23

Repairs - After Sales Service

Spare Parts

In the unlikely event of your appliance requiring service, or

if you wish to purchase spare parts, please contact our extended warranty administrators by telephoning:

0870 01 07887

They will give you details for your local Service Force Centre.

Before calling out an engineer, please ensure you have read

the details under the heading „Something not Working“.

When you contact the Service Force Centre you will need

to give the following details:

1.Your name, address and post code

2.Yo u r t e l e p h o n e n u mb e r

3.Clear and concise details of fault

4.The model and serial number of the appliance (found on

the rating plate - see picture)

5.The purchase date found on your receipt

.

Always insist on genuine spare parts.

An authorised service engineer should service this product,

and only genuine spare parts should be used.

Under no circumstances should you attempt to repair the

machine yourself. Repairs carried out by inexperienced persons may cause injury or serious malfunctioning. Contact

your local Service Force Centre.

An authorised service engineer always insist on genuine

spare parts.

Please note that a valid purchase receipt is required

for in-guarantee service calls.

So that you always have these numbers at hand, we recommend you to make a note of them here:

Mod.: .......................................................................

PNC: ........................................................................

S.N.: ..........................................................................

Your dryer is covered by a 3 year parts and labour

guarantee (see separate details given at point of

sale). Please retain your purchase receipt safely for

the service ingeneer to verify the purchase details.

Page 24

John Lewis Partnership

171 Victoria Street

London SW1E 5NN

www. johnlewis.com

822 944 856-01-01 03/06

Loading...

Loading...