Page 1

JLBIHD908

Built-in cooker hood

Instruction manual

Page 2

Important safety information

It is most important that this instruction manual should be retained with the appliance for future

reference. Should the appliance be sold or transferred to another owner, or should you move house and

leave the appliance, always ensure that the book is supplied with the appliance in order that the new

owner can get to know the functioning of the appliance and the relevant warnings. These warnings

have been provided in the interest of safety . You MUST read them carefully before use or installation by a qualified person. If you are unsure of the meanings of these warnings contact the John Lewis

branch from which you purchased the appliance.

Installation

• Any installation work must be undertaken by a qualified and

competent person to the relevant National Standards.

• This hood must be installed in accordance with the installation instructions and all measurements must be adhered

to.

• If the cooker hood is installed for use above a gas appliance

then the provision for ventilation must be in accordance

with the Gas Safety Codes of Practice BS.6172, BS.5440

and BS.6891 (Natural Gas) and BS.5482 (LP Gas) 1994,

the Gas Safety (Installation & Use) Regulations, the Building

Regulations issued by the Department of the Environment,

the Building standards (Scotland) (Consolidated) Regulations issued by the Scottish Development Department.

• The fan motor of this cooker hood incorporates a cut-out

device which will operate if the cooker hood is installed

below the minimum height recommended under section

‘Clearance Height’, or if the motor becomes overheated.

If the cut-out device is activated, switch off the fan motor

and allow the cooker hood to cool. The cut-out device will

reset itself when the fan motor has cooled significantly.

• It is dangerous to alter the specifications or modify this

product in any way.

• When installed between adjoining wall cabinets the wall

cabinets must not overhang the hob.

• If the room where the hood is to be used contains a fuel

burning appliance such as a central heating boiler then its

flue must be of the room sealed or balanced flue type.

• If other types of flue or appliances are fitted ensure that

there is an adequate supply of air to the room.

• The ducting system for this appliance must not be connected to any existing ventilation system which is being

used for any other purpose.

• Do not install above a cooker with a high level grill.

Child Safety

• This appliance is designed to be operated by adults. Children should not be allowed to tamper with the controls

or play with the appliance.

• Keep all packaging materials away from children.

Use

• This product is for domestic use only.

• Never leave frying pans unattended during use as overheated fats and oils might catch fire.

• Never do flambé cooking under this cooker hood.

• Do not leave naked flames under the hood.

• This cooker hood is designed to extract unpleasant odours

from the kitchen, it will not extract steam.

Maintenance and Cleaning

• This appliance can be a hazard if the synthetic paper and

charcoal filters are not replaced as recommended.

Service

• Under no circumstances should you attempt to repair the

appliance yourself. Repairs carried out by inexperienced

persons may cause injury or more serious malfunction.

Refer to your local Service Force Centre. Always insist

on genuine spare parts.

Environmental Information

• After installation please dispose of the packaging with due

regard to safety and the environment.

• The symbol on the product or on its packaging

indicates that this product should not be treated as

normal household waste. Instead it should be taken to the

appropriate collection point for the recycling of electrical and electronic equipment. By ensuring this product

is disposed of correctly, you will help prevent potential

negative consequences for the environment and human

health, which could otherwise be caused by inappropriate

waste handling of this product. For more detailed information about recycling of this product, please contact your

local council, your household waste disposal service or

the shop where you purchased the product.

2

Page 3

Contents

For the User

Important Safety Information 2

Description of the Appliance 4

Using the cooker hood 9

Cooker Hood Controls 9

To Operate 10

Recirculation 10

Extraction 10

Maintenance and Cleaning 11

External Cleaning 11

Cleaning the Ducting panels 11

Metal Grease Filters 11

Charcoal Filters 12

To Remove/Replace Charcoal Filter 12

Changing the Halogen Spot Lamp 13

Something Not Working 14

Repairs and After Sales Service 14

For the Installer

Electrical Connections 8

Electrical Requirements 8

Electrical Connection 8

Installing the Cooker Hood 5

Installation Requirements 5

Unpacking 5

Fitting the Wall Brackets 6

Fitting the Canopy Hood 6

Extraction 7

Recirculation 7

Guide to use the Instruction Manual

The following symbols will be found in the text to guide

you through the instruction book

Safety instructions

Step by step instructions

Environmental Information

This appliance complies with the followings E.E.C. Directives:

- 89/336 (Electromagnetic Compatibility Directive)

- 73/23 (Low Voltage Directive)

- 93/68 (General Directives)

and subsequent modifications

3

Page 4

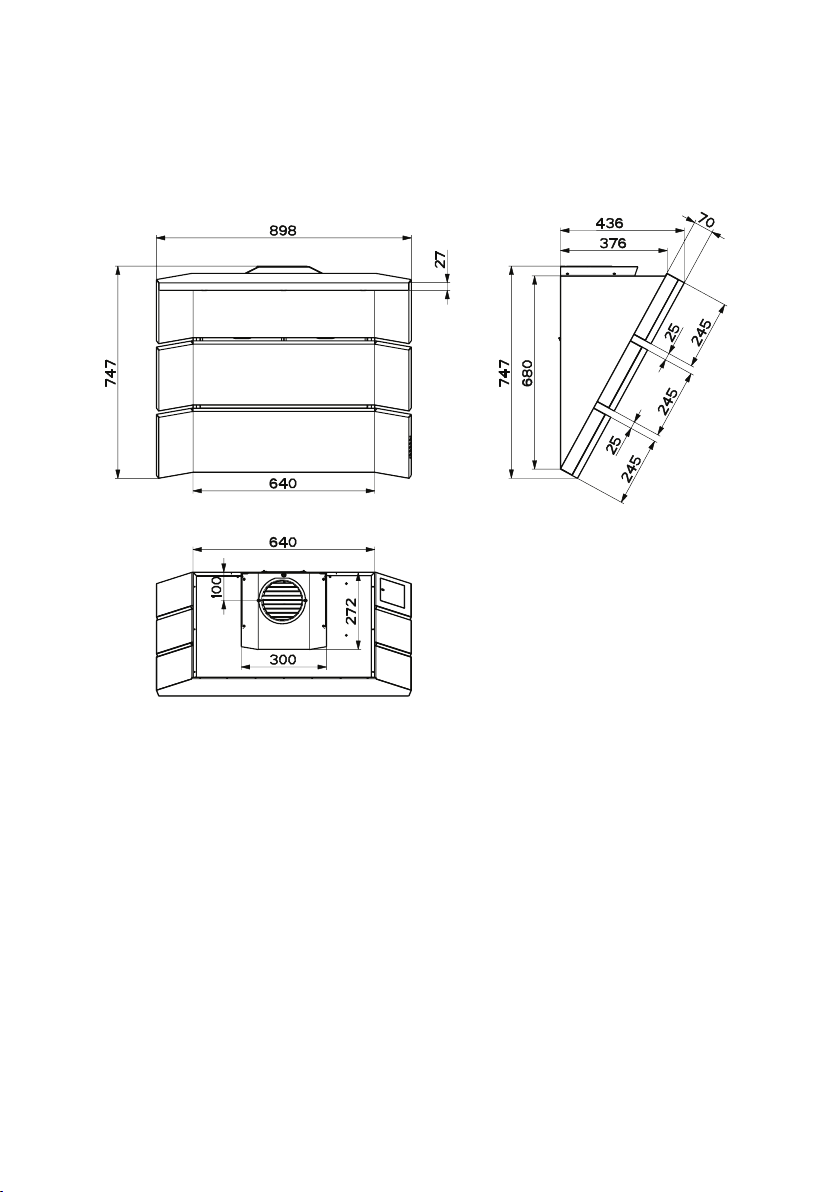

Description of the appliance

4

Page 5

Installation

Please ensure that when the appliance is installed

it is easily accessible to an engineer in the event

of a breakdown.

All installations must comply with the local

authorities requirements for the discharge of

exhaust air.

Incorrect installation may affect the safety of

this cooker hood.

Installation Requirements

Before installation check the wall to which

the cooker hood is to be fitted for electric

cables, water pipes or gas.

The chimney hood must be installed accord-

ing to the instructions suppliers below and

by qualified and competent personnel to the

relevant National Standards.

This cooker hood is designed to be fixed to any vertical

surface over a cooking area, and can be used in the extraction (ducted to the outside) or recirculation mode.

The installation work must be undertaken by a qualified

and competent person.

The manufacturer disclaims any responsibility for damage due to incorrect installation of the cooker hood or

if the hood is not installed in compliance with relevant

regulations controlling this type of installation.

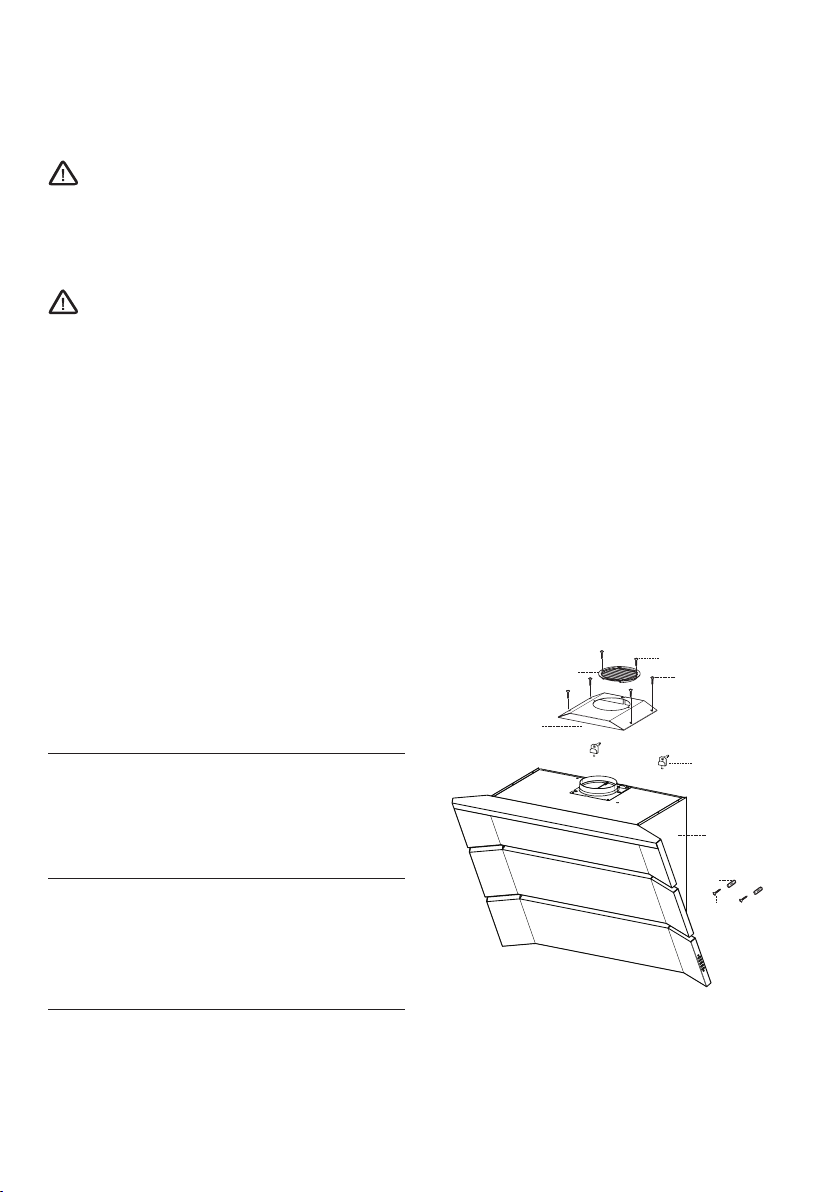

Unpacking

Before unpacking the cooker hood position the carton

with the arrows pointing upwards as illustrated on the

carton.

The cooker hood is made up of the following compo-

nents:

Ref Qty Product Components

1 1 Canopy complete with: Controls, Light-

ing, Fan Assembly, Grease Filter, Charcoal

Filter.

8 1 Recirculation grille

16 1 Filter Cover

Ref Qty Installation Components

11 2 Security Wall plugs

11a 2 Wall plugs SB 12/10

12a 2 Security screws

12c 4 Filter cover fixing screws

12d 2 Recirculation grille fixing screws

Ref Qty Documentation

1 Instruction booklet

5

Page 6

Installing the cooker hood

Fitting the wall brackets

• Draw a vertical line on the supporting wall up to the

ceiling, or as high as practical, at the centre of the area

in which the hood will be installed.

• Draw a horizontal line at 850 mm above the hob.

• Mark a point (1) on the horizontal line, 250 mm to the

right of the vertical reference line.

• Repeat this operation on the other side, checking that

the two marks are level.

• Mark a reference point (2) as indicated at 200 mm from

the vertical reference line and 540 mm above the hob.

• Repeat this operation on the other side, checking that

the two marks are level.

• Drill at the points (1) marked, using a ø 12 mm drill

bit.

• Drill at the points (2) marked, using a ø 8 mm drill bit.

• Insert the bracket plugs 11a into the holes 1 and screw

into place.

• Insert the wall plugs 11 in the holes. 2.

Note: If the hood is to be installed onto a hollow

construction or plaster or partition board wall

then special fixing screws will be required (not

supplied).

Fitting the canopy hood

• Disconnect by pulling only the central ducting panels.

• Remove the metal grease filters (see Maintenance paragraph)

• Adjust the two screws Vr, on brackets 11a, to a minimum.

• Hook the hood canopy onto the two brackets 11a.

• From inside the hood canopy, adjust the screws Vr to

set the Hood Canopy level.

• Tighten the safety screw 12a.

6

Page 7

Extraction (Ducted)

The cooker hood is more effective when installed in the

extraction mode (ducted to the outside).

Venting kits may be purchased through your retailer or

DIY store, and must be evacuated through an outside

vent of ø125 (5ins) or ø150mm (6ins).

The ducting used must be manufactured from fire retardant material conforming to the relevant British Standard

or DIN 4102-B1.

When the cooker hood is ducted to the outside

the charcoal filter must be removed.

Fitting the Ducting

• To install the Ducting Version of the hood, the optional

Ducting chimney kit must be purchased.

Recirculation Mode

The cooker hood is supplied specified for use in the recirculation mode, with the charcoal filter fitted.

In the recirculation mode contaminated air is passed through

the charcoal filter to be purified and recirculated into the kitchen through the grille outlets on either side of the chimney.

• Screw the filter cover item 16 onto the air outlet, using

four screws 12c (2.9 x 12.5) supplied.

• Fix the directional grille item 8 on the recirculation air

outlet using the 2 screws 12d (2,9 x 9,5) supplied.

• Ensure the activated charcoal filter has been fitted.

7

Page 8

Electrical connection

THIS APPLIANCE MUST BE EARTHED

Electrical requirements

Any permanent electrical installation must comply with

the latest I.E.E. Regulations and local Electricity Board

regulations. For your own safety this should be undertaken by a qualified electrician e.g. your local Electricity

Board, or a contractor who is on the roll of the National

Inspection Council for Electrical Installation Contracting

(NICEIC).

Electrical connection

Before connecting to the mains supply ensure that the

mains voltage corresponds to the voltage on the rating

plate inside the cooker hood.

Remove the grease filters (see paragraph Maintenance)

making sure that the connector of the feeding cable is

correctly inserted in the socket placed on the side of

the fan.

This appliance is fitted with a 3 core mains cable and

must be permanently connected to the electricity supply

via a double-pole switch having 3mm minimum contact

gap on each pole. A Switched Fuse Connection Unit to

BS1363 Part 4, fitted with a 3 Amp fuse, is a recommended mains supply connection accessory to ensure

compliance with the Safety Requirements applicable to

fixed wiring instructions.

This appliance conforms to BS 800: 1988 and EEC Directive No. 78 308 regarding suppression of radio and

television interference.

8

Page 9

Using the cooker hood

The cooker hood is designed to extract unpleasant odours from the kitchen, it

will not extract steam. The appliance can be installed to recirculate or extract

contaminated air.

Cooker hood controls

The hood can be switched on pushing directly onto the requested speed

without firstly having to select 0/1 button.

KEY LED FUNCTIONS

L 0/1 Light Turns lighting on and off.

T1 0/1 Motor on First speed.

When pressed for about 1 second the motor is

switched off.

Flashing 24h Changeover

This is enabled by pressing and holding the button

for approximately 5 seconds. It allows a suction

level of 100 m3/h with a noise level of just 28dB(A).

Can be enabled at any speed, even with the hood

turned off. To disable, press and hold the button for

approximately 5 seconds.

T2 Speed on Second speed.

Flashing Delay (30 minutes)

Press the button for approximately 2 seconds to

enable automatic shutdown with a 30 minutes delay.

Suitable to complete elimination of any residual

smells. Can be enabled at any speed and is disabled

by pressing the button briefly.

T3 Speed on Third speed.

T4 Speed Fixed Max. speed

Flashing Intensive speed.

Suitable for the strongest cooking vapours and

odours. The function becomes active when the

S1 Led Fixed Indicates that the Metal grease filters saturation

Flashing Indicates that the activated charcoal odour filter

button is pushed for about 2 seconds. After 10

minutes of functioning it turns off automatically.

This function can be interrupted by means of

pressing any of the buttons.

alarm has been triggered, and the filters need to be

washed. The alarm is triggered after 100 working

hours. (Reset; check the Maintenance-paragraph)

saturation alarm has been triggered, and the filter

has to be replaced; the metal grease filters must also

be washed. The activated charcoal odour filter is

triggered after 200 working hours. (Activation and

Reset; check the Maintenance-paragraph)

9

Page 10

To operate

Select the required fan speed and light if required.

Recirculation

In the recirculation mode the contaminated air enters

the cooker hood through the grease filters. The air is

cleaned by passing through the charcoal filters before

being passed back into the kitchen through the grilles in

either side of the chimney stack.

Extraction

In the extraction mode the contaminated air enters the

cooker hood passing through the grease filters and is

passed out through the ducting into the atmosphere.

To obtain the best performance when cooking it is advisable to switch the cooker hood on for a few minutes

before you start cooking and leave it running for about

15 minutes after finishing.

When used in the ducting mode the charcoal

filters are not required.

Never do flambé cooking under this cooker

hood.

Never leave frying pans unattended during

use, as over-heated fats and oils can catch fire.

Do not leave naked flames under the cooker

hood.

Ensure heating areas on your hob are covered

with pots and pans when using the hob and

cooker hood simultaneously.

10

Page 11

Maintenance and cleaning

Before carrying out any maintenance or

cleaning isolate the cooker hood from the

mains supply.

The cooker hood must be kept clean, as a

build up of grease or fat can be a fire hazard.

External cleaning

Wipe the cooker hood frequently with warm soapy water

using a mild detergent.

Never use scouring pads or abrasive cleaners.

Never use excessive amounts of water when

cleaning particularly around the control panel.

Cleaning the ducting panels

• Disconnect by pulling only the central ducting panels.

• Clean the outside using a damp cloth and neutral liquid

detergent.

• Clean the inside using a damp cloth and neutral detergent;

do not use wet cloths or sponges, or jets of water; do

not use abrasive substances.

Metal grease filters

The grease filters absorb grease and dust during cooking

to help keep the cooker hood clean inside, and should

be cleaned when the led S1 light up or at least every 2

months of operation, or more frequently for particularly

heavy usage.

Cleaning the filters

• Disconnect by pulling only the central ducting panels.

• Remove the filters one at a time by pushing them towards

the back of the group and pulling down at the same

time.

• The metal grease filters should be washed, by hand, in mild

soapy water or in a dishwasher. Allow to dry completely

before replacing. Any kind of bending of the filters has

to be avoided when washing them.

• When fitting the filters into the hood pay attention that

they are mounted in the correct position and that the

handle faces outwards.

• Close the ducting panels.

11

Page 12

Alarm signal reset

A

B

• Stop the motor and switch off the lights.

• Press button T3 for at least 3 seconds, until the LEDs

start to flash.

Before carrying out any maintenance or

cleaning isolate the cooker hood from the

mains supply.

Charcoal filters

In the recirculation mode the charcoal filters absorb

smells and unwanted odours.

This charcoal filters cannot be washed or regenerated,

and must be replaced when the LED S1 starts to flash,

or at least once every 4 months. The alarm is only triggered when the motor is on.

Enabling/Disabling the alarm

signal

• In Recirculation Version Hoods, the Filter saturation Alarm

must be enabled at the time of installation or later.

• Switch off the lights and the motor.

• Disconnect the mains power supply to the hood by

removing the motor unit power supply cable connector,

switching off the power supply at the Mains or turning

the Main switch off.

• Restore the connection, pressing and holding T1.

• Release the button. All five LEDs are turned on

• Within 3 seconds press T1 until LEDs T1 and T4 flash

in confirmation:

• LED flashes twice - Activated charcoal filter saturation

alarm ENABLED

• LED flashes once - Activated charcoal filter saturation

alarm DISABLED

To Remove/Replace the char-

coal filters

• Disconnect by pulling only the central ducting panels.

• First remove the metal grease filters.

• Remove the saturated charcoal filter as shown in the

drawing (A)

• Position the new charcoal filter as shown in the drawing

(B).

• Replace the metal grease filters.

• Close the ducting panels.

12

Page 13

Reset the alarm signal

• Stop the motor and switch off the lights.

• Press button T3 for at least 3 seconds, until the LEDs

start to flash.

This appliance can be a possible fire hazard if

the grease and charcoal filters are not cleaned

and replaced as recommended.

Changing the halogen spot

lamp

• Remove the lamp from the holder by pulling the lamp

downwards.

• Replace the lamp with a new one of the same type,

making sure that you insert the two pins properly into

the housing on the lamp holder.

• Replace the light cover, fixing it in place with the screws

removed as above.

Replacement filters and light bulbs can be obtained from your local Service Force Centre.

13

Page 14

Something not working

If the appliance is not working correctly, please carry out the following checks, before contacting your local Service

Force agent.

IMPORTANT: If you call out an engineer to a fault listed below, or to repair a fault caused by incorrect use or installation, a charge will be made even if the appliance is under guarantee.

Symptom

The cooker hood will not start

The cooker hood is not working effectively

The cooker hood has switched off during

operation

Solution

• Check the hood is connected to the electricity supply.

• Make sure the switch is in the ‘ON’ position.

• Check that the fan speed is set high enough for the task

• Ensure the grease filter is clean.

• Ensure the kitchen is adequately vented to allow the entry

of fresh air.

• If set up for recirculation, check that the charcoal filter is

still effective.

• If set up for extraction, check that the ducting and outlets

are not blocked.

• The safety cut-out device has been tripped.

• Turn off the hob and then wait for the device to reset.

Repairs and after sales service

In the event of your appliance requiring service, or if

you wish to purchase spare parts, please contact our

extended warranty administrators by telephoning:

0870 01 07887

They will give you details for your local Service Force Centre.

When you contact the Service Force Centre you will

need to give the following details:

1. Your name, address and post code

2. Your telephone number

3. Clear and concise details of fault

4. The model and serial number of the appliance (found

on the rating plate - see picture)

Before calling out an engineer, please ensure you have

read the details under the heading “Something Not

Working”.

Your oven is covered by a 3 year parts and labour

guarantee (see separate details given at point of sale).

Please retain your purchase receipt safely for the service

engineer to verify the purchase details.

5. The purchase date.

Please note that a valid purchase receipt is required for

in-guarantee service calls.

14

Page 15

Page 16

John Lewis Partnership

171 Victoria Street

London SW1E 5NN

www.johnlewis.com

436004228_04 - 080703

Loading...

Loading...