Page 1

JOHN DEERE

WORLDWIDE COMMERCIAL & CONSUMER

EQUIPMENT DIVISION

M154566

H6

John Deere

Z225, Z425, Z445 EZtrak

OMM154566 H6

OMM154566 H6

OPERATOR’S MANUAL

North American Version

Litho in U.S.A.

Page 2

INTRODUCTION

c WARNING: The Engine Exhaust

from this product contains chemicals known

to the State of California to cause cancer,

birth defects or other reproductive harm.

California Proposition 65 Warning

Table of Contents

Introduction................................................................................................ 1

Product Identification ................................................................................. 2

Safety Labels ............................................................................................. 2

Safety ........................................................................................................ 4

Assembly ................................................................................................... 7

Operating - Controls .................................................................................. 9

Operating................................................................................................. 10

Service Intervals...................................................................................... 18

Service Lubrication.................................................................................. 19

Service Engine ........................................................................................ 19

Service Transmission ............................................................................. 26

Service Mower......................................................................................... 30

Service Electrical..................................................................................... 36

Service Miscellaneous ............................................................................ 38

Troubleshooting ....................................................................................... 40

Storage .................................................................................................... 42

Specifications .......................................................................................... 42

Warranty .................................................................................................. 44

Getting Quality Service ........................................................................... 46

Service Record........................................................................................ 47

Introduction

Thank You for Purchasing a John Deere Product

We appreciate having you as a customer and wish you many years of safe

and satisfied use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and should remain with

the machine when you sell it.

Reading your operator’s manual will help you and others avoid personal

injury or damage to the machine. Information given in this manual will

provide the operator with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly will allow you to

train others who may operate this machine.

If you have an attachment, use the safety and operating information in the

attachment operator’s manual along with the machine operator’s manual to

operate the attachment safely and correctly.

This manual and safety signs on your machine may also be available in

other languages (see your authorized dealer to order).

Sections in your operator’s manual are placed in a specific order to help

you understand all the safety messages and learn the controls so you can

operate this machine safely. You can also use this manual to answer any

specific operating or servicing questions.

The machine shown in this manual may differ slightly fr om your machine,

but will be similar enough to help you understand our instructions.

RIGHT-HAND and LEFT-HAND sides are determined by facing in the

direction the machine will travel when going forward. When you see a

broken line (------), the item referred to is hidden from view.

Before delivering this machine, your dealer performed a predelivery

inspection to ensure best performance.

Special Messages

Your manual contains special messages to bring attention to potential

safety concerns, machine damage as well as helpful operating and

servicing information. Please read all the information carefully to avoid

injury and machine damage.

All information, illustrations and

specifications in this manual are based on

the latest information at the time of

publication. The right is reserved to make

changes at any time without notice.

COPYRIGHT© 2006

John Deere Worldwide Commercial and

Consumer Equipment Division

Deere & Co.

All rights reserved

Previous Editions

COPYRIGHT©

c CAUTION: Avoid injury! This symbol and text highlight

potential hazards or death to the operator or bystanders that may

occur if the hazards or procedures are ignored.

IMPORTANT: Avoid damage! This text is used to tell the operator

of actions or conditions that might result in damage to the

machine.

NOTE: General information is given throughout the manual that may

help the operator in the operation or service of the machine.

Introduction - 1

Page 3

PRODUCT IDENTIFICATION

Product Identification

Record Identification Numbers

Lawn Tractors

Z225, Z425 and Z445 PIN (010001-)

If you need to contact an Authorized Service Center for information on

servicing, always provide the product model and identification numbers.

You will need to locate the model and serial number for the machine and

for the engine of your machine and record the information in the spaces

provided below.

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

PRODUCT IDENTIFICATION NUMBER:

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER:

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

Register Your Product and Warranty Online

To register your product through the Internet, simply go to

www.JohnDeereWarrantyRegistration.com. Completing the information,

either online or with the product warranty card, will ensure the customer

that their product receives all post sales service and important product

information.

• If machine stops going uphill, stop blade and back down slowly.

• Read operator's manual.

• Keep safety devices (guards, shields, and switches) in place and

working.

• Remove objects that can be thrown by blade.

• When leaving machine: -Stop engine, -Lock park brake, -Remove key.

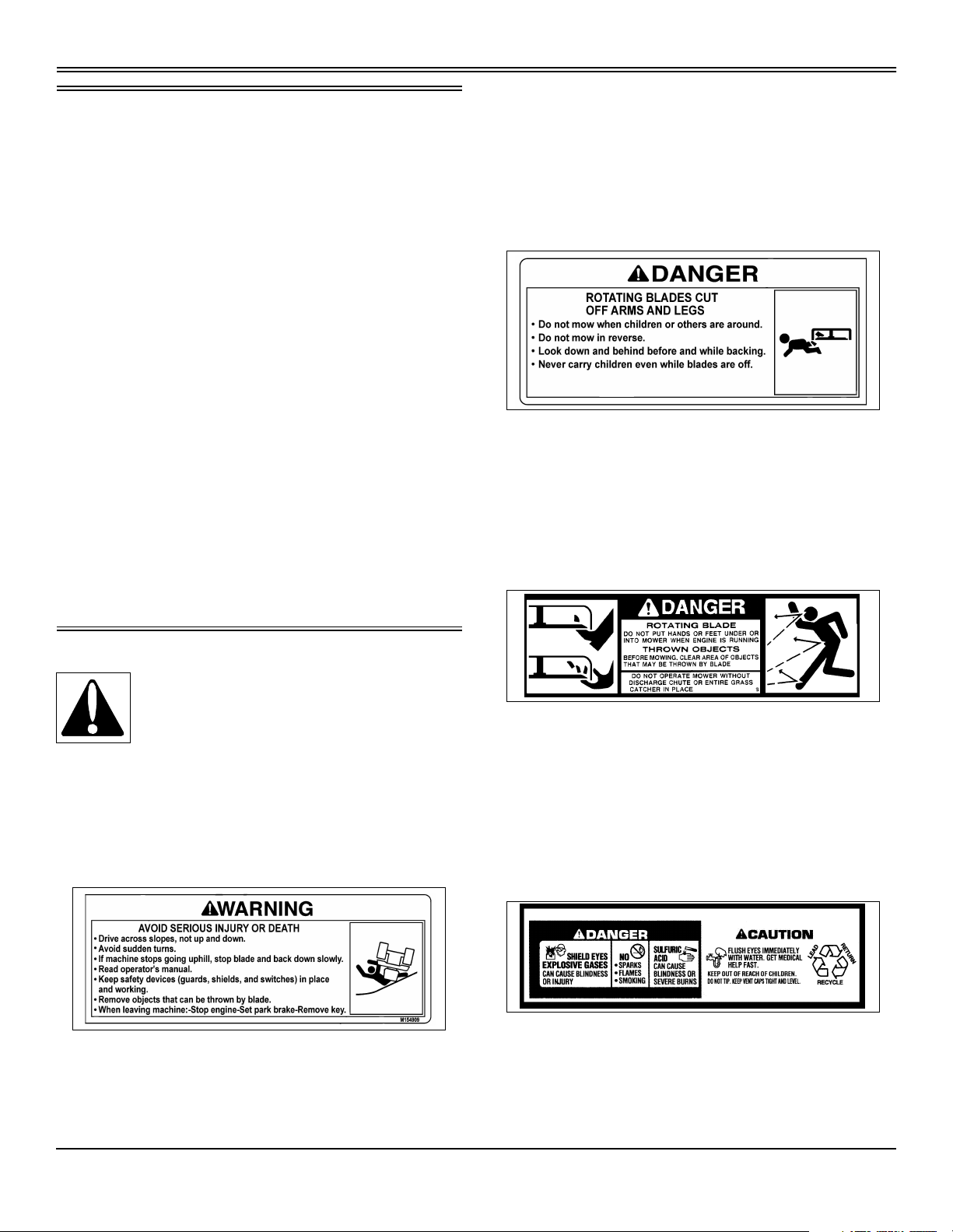

DANGER

M154909

ROTATING BLADES CUT OFF ARMS AND LEGS

• Do not mow when children or others are around.

• Do not mow in reverse.

• Look down and behind before and while backing.

• Never carry children even while blades are off.

DANGER

Safety Labels

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed

in important areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert symbol.

DANGER identifies the most serious hazards.

The operator’s manual also explains any potential safety hazards

whenever necessary in special safety messages that are identified with

the word, CAUTION, and the safety-alert symbol.

WARNING

M154909

AVOID SERIOUS INJURY OR DEATH

• Drive across slopes, not up and down.

• Avoid sudden turns.

M89504

ROTATING BLADE

• Do not put hands or feet under or into mower when engine is running.

THROWN OBJECTS

• Before mowing, clear area of objects that may be thrown by blade.

• Do not operate mower without discharge chute or entire grass catcher in

place.

DANGER - CAUTION

M128699

Picture Note: Located on battery

• Shield eyes, explosive gases can cause blindness or injury.

• No sparks, flames, smoking.

• Sulfuric acid can cause blindness or severe burns.

Product Identification - 2

Page 4

SAFETY LABELS

• Flush eyes immediately with water. Get medical help fast.

• Keep out of reach of children.

• Do not tip.

• Keep vent caps tight and level.

WARNING

TCU51051

• To avoid injury from rotating belts, keep all shields and guards in place.

DANGER

To avoid injury from rotating blades and thrown objects:

Emission Control System Certification Label

NOTE: Tampering with emission controls and components by

unauthorized personnel may result in severe fines or penalties.

Emission controls and components can only be adjusted by EPA

and/or CARB authorized service centers. Contact your John Deere

Commercial and Consumer Equipment Retailer concerning emission

controls and component questions.

The presence of an emissions label signifies that the engine has been

certified with the United States Environmental Protection Agency (EPA)

and/or California Air Resources Board (CARB).

The emissions warranty applies only to those engines marketed by John

Deere that have been certified by the EPA and/or CARB; and used in the

United States and Canada in off-road mobile equipment.

Emission Compliance Period

If your engine has the emission compliance category listed on the

emission control system certification or air index label, this indicates the

number of operating hours for which the engine has been certified to meet

EPA and/or CARB emission requirements. The following table provides

the engine compliance period in hours associated with the category found

on the certification label.

Agency Category Hours

EPA C 250

EPA B 500

M139128

• Keep hands and feet away from rotating blades. Keep bystanders a safe

distance away. Do not operate mower without discharge chute or entire

grass catcher in place.

DANGER

M131748

To avoid injury from rotating blades and thrown objects, stay clear of deck

edge and keep others away. Do not mow without discharge chute or entire

grass catcher in place.

DANGER

ROTATING BLADE

EPA A 1000

CARB Moderate 125

CARB Intermediate 250

CARB Extended 500

M118610

• Do not put hands or feet under or into mower when engine is running.

Safety Labels - 3

Page 5

SAFETY

Safety

Operating Safely

This cutting machine is capable of amputating hands and

feet and throwing objects. Failure to obser ve the following

safety instructions could result in serious injury or death.

• Read, understand and follow all instructions on the

machine and in manuals provided, and view safety video, before starting.

Be thoroughly familiar with the controls and the proper use of the machine

before starting.

• The residential zero radius lawn mower drives differently than a

traditional riding mower. Learning to operate the controls smoothly and

safely will take some time.

• Practice operating the residential zero radius lawn mower in a large open

area with the blades off. Keep practicing until you feel confident in your

maneuvering and driving skills.

• Only allow responsible adults, who have practiced driving the residential

zero radius lawn mower and are familiar with the instructions to operate

the machine. Local restrictions may restrict the age of the operator.

• Do not put hands or feet near rotating parts or under the machine. Keep

clear of the discharge opening at all times.

• Clear the area of objects such as rocks, wire and toys which could be

thrown by the blades.

• Be sure the area is clear of bystanders before operating. Stop machine if

anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary. Always look down

and behind before and while backing.

• Never direct discharged material toward anyone. Avoid discharging

material against a wall or obstruction. Material may ricochet back toward

the operator. Stop the blades when crossing gravel surfaces.

• Do not operate the machine without the entire grasscatcher, discharge

guard, or other safety devices in place and working. Never operate with

the discharge deflector raised, removed, or altered, unless using a

grasscatcher.

• Slow down before turning.

• Never leave a running machine unattended. Always turn off blades, lock

park brake, stop engine and remove key before dismounting.

• Disengage blades when not mowing. Shut off engine and wait for all

parts to come to a complete stop before cleaning the machine, removing

the grasscatcher, or unclogging the discharge chute.

• Operate machine only in daylight or good artificial light.

• Do not operate the machine while under the influence of alcohol or

drugs.

• Watch for traffic when operating near or crossing roadways. Stop blades

before crossing roads or sidewalks.

• Use extra care when loading or unloading the machine into a trailer or

truck.

• Always wear safety goggles or safety glasses with side shields when

operating machine.

• Data indicates operators 60 years and above are involved in a large

percentage of riding mower-related injuries. These operators should

evaluate their ability to operate the riding mower safely enough to protect

themselves and others from serious injury.

• Follow the manufacturer’s recommendation for wheel weights or

counterweights.

• Inspect machine before you operate. Be sure hardware is tight. Repair or

replace damaged, badly worn, or missing parts. Be sure guards and

shields are in good condition and fastened in place. Make any necessary

adjustments before you operate.

• Before using, always visually inspect to see that the blades, blade bolts

and the mower assembly are not worn and damaged. Replace worn and

damaged blades and bolts in sets to preserve balance.

• Make sure spark plug, muffler, fuel cap and air cleaner are in place

before star ting the engine.

• Be sure all drives are in neutral and parking brake is locked before

starting engine. Only start engine from the operator’s position.

• Do not change the engine governor settings or overspeed the engine.

Operating the engine at excessive speed can increase the hazard of

personal injury.

• If you hit an object or if abnormal vibration occurs, stop the machine and

inspect it. Make repairs before you operate.

• Use only accessories and attachments approved by the manufacturer of

the machine. Keep safety labels visible when installing accessor ies and

attachments.

• Do not wear radio or music headphones. Safe ser vice and operation

requires your full attention.

• When machine is left unattended, stored, or parked, lower the mower

deck unless a positive mechanical lock is used.

Using a Spark Arrestor

The engine in this machine is not equipped with a spark arrestor muffler. It

is a violation of California Public Resource Code Section 4442 to use or

operate this engine on or near any forest-covered, brush-covered or

grass-covered land unless the exhaust system is equipped with a spark

arrestor meeting any applicable local or state laws. Other states or federal

areas may have similar laws.

A spark arrestor for your machine may be available from your authorized

dealer. An installed spark arrestor must be maintained in good working

order by the operator.

Checking Mowing Area

• Clear mowing area of objects that might be

thrown. Keep people and pets out of mowing

area.

• Low-hanging branches and similar obstacles

can injure the operator or interfere with

mowing operation. Before mowing, identify potential obstacles such as

low-hanging branches, and trim or remove those obstacles.

• Study mowing area. Set up a safe mowing pattern. Do not mow where

traction or stability is doubtful.

• Test drive area with mower lowered but not running. Slow down when

you travel over rough ground.

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Disengage mower blades.

3. Move motion control levers out to the Start/Shutdown position.

4. Lock the park brake.

5. Stop the engine.

6. Remove the key.

Safety - 4

Page 6

SAFETY

7. Wait for engine and all moving parts to stop before you leave the

operator’s seat.

8. Disconnect the negative battery cable or remove the spark plug wire (for

gasoline engines) before servicing the machine.

Rotating Blades are Dangerous

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

• Rotating blades can cut off arms and legs,

and throw objects. Failure to observe safety

instructions could result in serious injury or

death.

• Keep hands, feet and clothing away from mower deck when engine is

running.

• Be aler t at all times, drive forward and in reverse carefully. People,

especially children can move quickly into the mowing area before you

know it.

• Before backing up, stop mower blades or attachments and look down

and behind the machine carefully, especially for children.

• Do not mow in reverse.

• Shut off blades when you are not mowing.

• Park machine safely before leaving the operator’s station for any reason

including emptying the grasscatchers or unplugging the chute.

• The mower blades should stop in approximately five seconds when the

mower is disengaged. If you believe that your blades may not be stopping

in that period of time, take your machine to your authorized dealer where

they can safely check and service your machine.

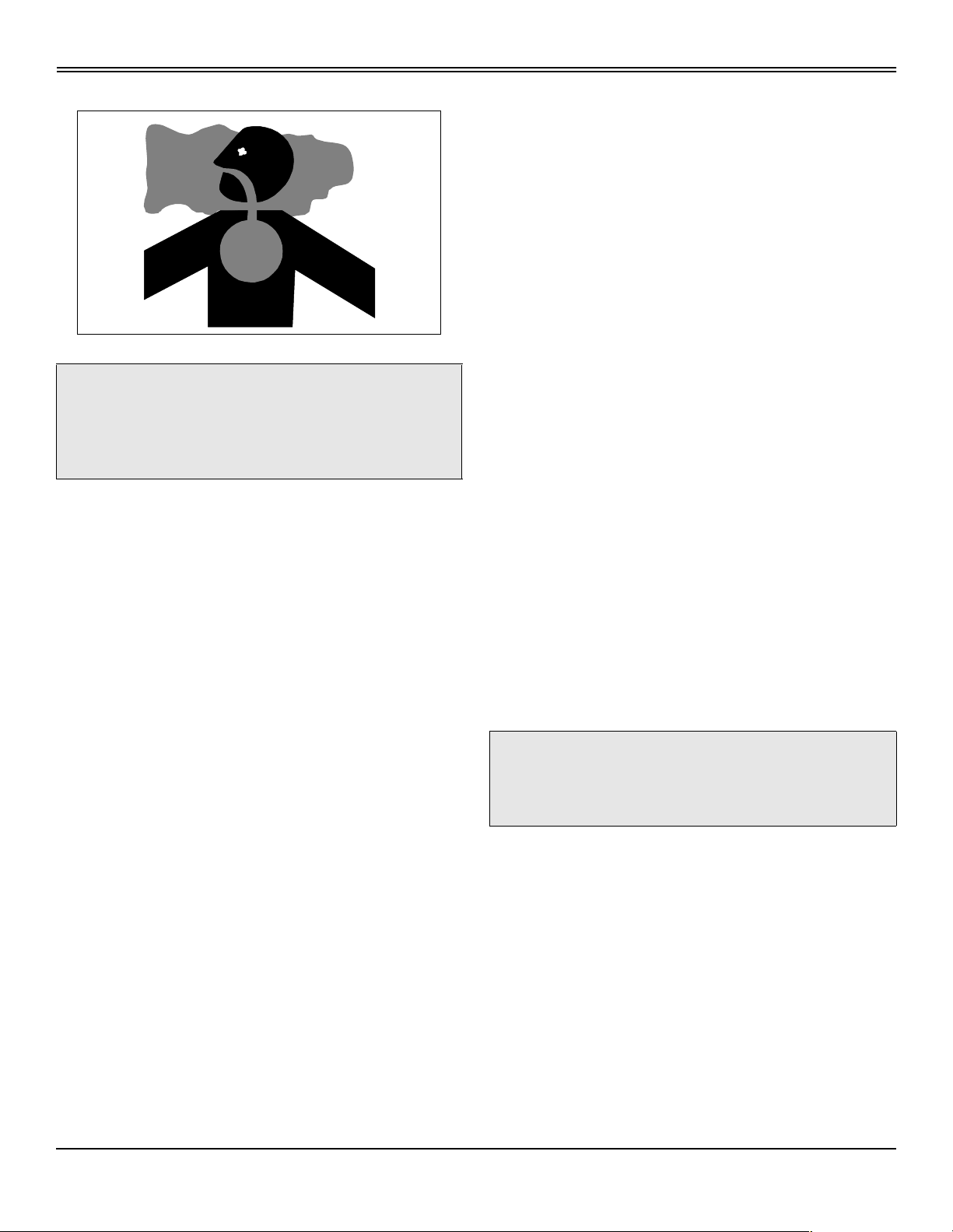

Protect Children

• Death or serious injury can occur when

young children associate having fun with

a lawn mowing machine simply because

someone has given them a ride on a

machine.

• Children are attracted to lawn mowing machines and mowing activities.

They don’t understand the dangers of rotating blades or the fact that the

operator is unaware of their presence.

• Children who have been given rides in the past may suddenly appear in

the mowing area for another ride and be run over or backed over by the

machine.

• Tragic accidents with children can occur if the operator is not alert to the

presence of children, especially when a child approaches a machine from

behind. Before and while backing up, stop mower blades and look down

and behind the machine carefully, especially for children.

• Never carry children on a machine or attachment, even with the blades

off. Do not tow children in a cart or trailer. They can fall off and be seriously

injured or interfere with safe machine operation.

• Never use the machine as a recreational vehicle or to entertain children.

• Never allow children or an untrained person operate the machine.

Instruct all operators not to give children a ride on the machine or in an

attachment.

• Keep children indoors, out of the mowing area, and in the watchful eye of

a responsible adult, other than the operator, when a mower is being

operated.

• Stay alert to the presence of children. Never assume that children will

remain where you last saw them. Turn the machine off if a child enters the

work area.

• Use extreme care when approaching blind corners, shrubs, trees, or

other objects that may block your view of a child.

Avoid Tipping

• Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. Operation on all

slopes requires extra caution.

• Mow across slopes, not up and down.

• Never mow on any slope that is more than 10 degrees, or a slope that

rises more than 3-1/2 feet within a distance of 20 feet of distance.

• Make a safe choice when operating on slopes. If you feel uncomfortable

on a hillside, or if you feel the front of the machine start to creep down the

slope, stop mowing immediately and proceed slowly and safely down the

slope.

• If steering direction cannot be maintained with slight steering corrections,

the slope is too steep to mow.

• Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven

terrain could overturn the machine. Tall grass can hide obstacles.

• Choose a low ground speed so you will not have to stop or shift while on

a slope.

• Do not mow or operate machine on wet grass. Tires may lose traction.

Tires may lose traction on slopes even though the brakes are functioning

properly.

• Avoid starting, stopping or turning on a slope. If the tires lose traction,

disengage the blades and proceed slowly, straight down the slope.

• Keep all movement on slopes slow and gradual. Do not make sudden

changes in speed or direction, which could cause the machine to roll over.

• Use extra care while operating machine with grasscatchers or other

attachments, they can affect stability of the machine. Do not use on steep

slopes.

• Do not mow near drop-offs, ditches, embankments, or bodies of water.

The machine could suddenly roll over if a wheel goes over the edge or the

edge caves in.

• Leave at least the width of the machine as a safety area between the

machine and any safety hazard. Mow those areas with a hand-held

trimmer or walk-behind mower.

• Follow the manufacturer’s recommendations for wheel weights or

counterweights for added stability when operating on slopes or using front

or rear mounted attachments. Remove weights when not required.

• Drive machine slowly and avoid quick stops if attachment has been

removed for servicing mower or machine.

Keep Riders Off

• Only allow the operator on the machine. Keep

riders off.

• Riders on the machine or attachment may be

struck by foreign objects or thrown off the

machine causing serious injury.

• Riders obstruct the operator’s view resulting in the machine being

operated in an unsafe manner.

Wear Appropriate Clothing

• Always wear eye protection when operating

the machine.

• Wear close fitting clothing and safety

equipment appropriate for the job.

Safety - 5

Page 7

SAFETY

• While mowing, always wear substantial footwear and long trousers. Do

not operate the equipment when barefoot or wearing open sandals.

• Wear a suitable protective device such as earplugs. Loud noise can

cause impairment or loss of hearing.

Driving Safely on Public Roads

Avoid personal injury or death resulting from a

collision with another vehicle on public roads:

• Use safety lights and devices. Slow moving

machines when driven on public roads are

hard to see, especially at night.

• Whenever driving on public roads, use flashing warning lights and turn

signals according to local regulations. Extra flashing warning lights may

need to be installed.

Practice Safe Maintenance

• Only qualified, trained adults should service

this machine. Understand service procedure

before doing work.

• Never operate machine in a closed area

where dangerous carbon monoxide fumes can collect.

• Keep all nuts and bolts tight, especially blade attachment bolts, to be

sure the equipment is in safe working condition.

• Never tamper with safety devices. Check their proper operation regularly.

• Keep machine free of grass, leaves or other debris build-up. Clean up oil

or fuel spillage and remove any fuel-soaked debris. Allow the machine to

cool before stor ing.

• If you strike a foreign object, stop and inspect the machine. Repair, if

necessary, before restarting.

• Never make any adjustments or repairs with the engine running. Wait for

all movement to stop on machine before adjusting, cleaning or repairing.

• Check grasscatcher components and the discharge guard frequently and

replace with manufacturer’s recommended parts, when necessary.

Grasscatcher components are subject to wear, damage, and deterioration

which could expose moving parts or allow objects to be thrown.

• Mower blades are sharp. Wrap the blade or wear gloves, and use extra

care when servicing them. Only replace blades. Never straighten or weld

them.

• Check brake operation frequently. Adjust and service as required.

• Maintain or replace safety and instruction labels, as necessary.

• On multi-bladed machines, take care as rotating one blade can cause

other blades to rotate.

• Keep hands, feet, clothing, jewelry, and long hair away from any moving

parts, to prevent them from getting caught.

• Lower any attachments to the ground before cleaning or servicing

machine. Disengage all power and stop the engine. Lock park brake and

remove the key. Let machine cool.

• Securely support any machine elements that must be raised for service

work. Use jack stands or lock service latches to support components

when needed.

• Disconnect battery or remove spark plug wire (for gasoline engines)

before making any repairs. Disconnect negative terminal first and positive

last. Install positive terminal first and negative last.

• Before servicing machine or attachment, carefully release pressure from

any components with stored energy, such as hydraulic components or

springs.

• Keep all parts in good condition and properly installed. Fix damage

immediately. Replace wor n or broken parts.

• Charge batteries in an open, well-ventilated area, away from sparks.

Unplug battery charger before connecting or disconnecting from the

battery. Wear protective clothing and use insulated tools.

• Do not strike the flywheel with a hammer or hard object because the

flywheel may later shatter during operation.

• If equipped with hydraulic lift - release hydraulic pressure by lowering

attachment or cutting units to the ground or to a mechanical stop and

move hydraulic control levers back and forth.

Avoid High Pressure Fluids

• Hydraulic hoses and lines can fail due to

physical damage, kinks, age, and exposure.

Check hoses and lines regularly. Replace

damaged hoses and lines.

• Hydraulic fluid connections can loosen due to physical damage and

vibration. Check connections regularly. Tighten loose connections.

• Escaping fluid under pressure can penetrate the skin causing serious

injury. Avoid the hazard by relieving pressure before disconnecting

hydraulic or other lines. Tighten all connections before applying pressure.

• Search for leaks with a piece of cardboard. Protect hands and body from

high pressure fluids.

• If an accident occurs, see a doctor immediately. Any fluid injected into

the skin must be surgically removed within a few hours or gangrene may

result. Doctors unfamiliar with this type of injury should reference a

knowledgeable medical source. Such information is available from Deere

& Company Medical Depar tment in Moline, I llinois, U.S.A. Information may

be obtained in the United States and Canada only by calling 1-800-822-

8262.

Prevent Fires

• Remove grass and debris from engine compartment and muffler area,

before and after operating machine, especially after mowing or mulching

in dry conditions.

• Empty the grasscatcher completely before storing.

• Always shut off fuel when storing or transporting machine, if the machine

has a fuel shutoff.

• Do not store machine near an open flame or source of ignition, such as a

water heater or furnace.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks.

Replace if necessar y.

Handling Fuel Safely

To avoid personal injury or property

damage, use extreme care in handling fuel.

Fuel is extremely flammable and fuel

vapors are explosive:

• Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

• Use only an approved fuel container. Use

only non-metal, portable fuel containers

approved by the Underwriter’s Laboratory

(U.L.) or the American Society for Testing &

Materials (ASTM). If using a funnel, make sure

it is plastic and has no screen or filter.

• Never remove the fuel tank cap or add fuel with the engine running. Allow

engine to cool before refueling.

Safety - 6

Page 8

ASSEMBLY

• Never add fuel to or drain fuel from the machine indoors. Move machine

outdoors and provide adequate ventilation.

• Clean up spilled fuel immediately. If fuel is spilled on clothing, change

clothing immediately. If fuel is spilled near machine, do not attempt to star t

the engine but move the machine away from the area of spillage. Avoid

creating any source of ignition until fuel vapors have dissipated.

• Never store the machine or fuel container where there is an open flame,

spark, or pilot light such as on a water heater or other appliance.

• Prevent fire and explosion caused by static electric discharge. Static

electric discharge can ignite fuel vapors in an ungrounded fuel container.

• Never fill containers inside a vehicle or on a truck or trailer bed with a

plastic liner. Always place containers on the ground away from your

vehicle before fueling.

• Remove fuel-powered equipment from the truck or trailer and refuel it on

the ground. If this is not possible, then refuel such equipment with a

portable container, rather than from a fuel dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank or container

opening at all times until the fueling is complete. Do not use a nozzle lockopen device.

• Never overfill fuel tank. Replace fuel tank cap and tighten securely.

• Replace all fuel container caps securely after use.

• For gasoline engines, do not use gas with methanol. Methanol is harmful

to your health and to the environment.

Tire Safety

Explosive separation of a tire and rim parts

can cause serious injury or death:

• Do not attempt to mount a tire without the

proper equipment and experience to perform

the job.

• Always maintain the correct tire pressure. Do not inflate the tires above

the recommended pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in air pressure resulting in a

tire explosion. Welding can structurally weaken or deform the wheel.

• When inflating tires, use a clip-on chuck and extension hose long enough

to allow you to stand to one side and NOT in front of or over the tire

assembly.

• Check tires for low pressure, cuts, bubbles, damaged rims or missing lug

bolts and nuts.

Checking Wheel Hardware

• A serious accident could occur causing serious injury if wheel hardware

is not tight.

• Check wheel hardware tightness often during the first 100 hours of

operation.

• Wheel hardware must be tightened to specified torque using the proper

procedure anytime it is loosened.

chemical products: physical and health hazards, safety procedures, and

emergency response techniques. The seller of the chemical products

used with your machine is responsible for providing the MSDS for that

product.

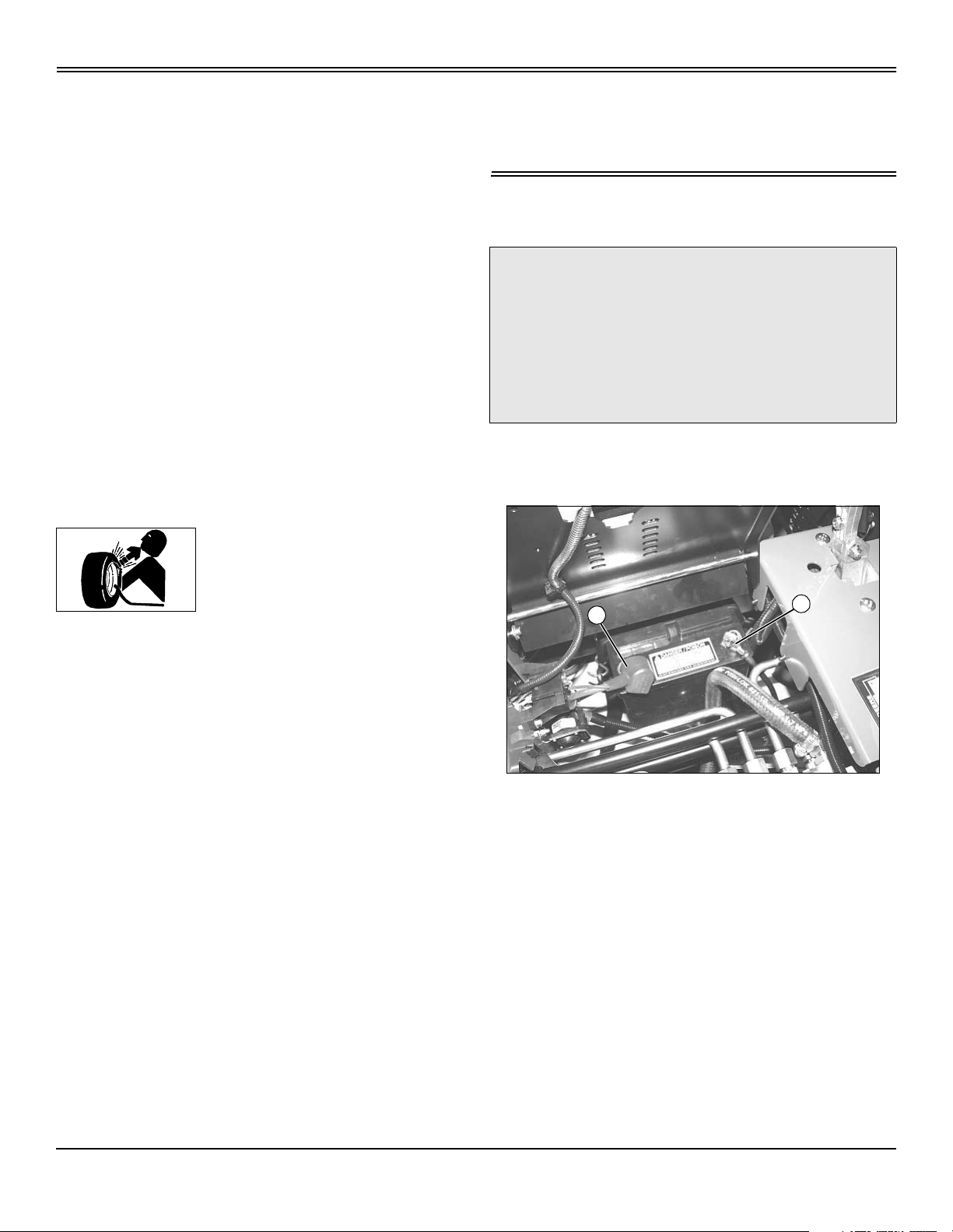

Assembly

Charge and Connect Battery

c CAUTION: Avoid injury! The battery produces a flammable

and explosive gas. The battery may explode:

• Do not smoke or have open flame near battery.

• Wear eye protection and gloves.

• Do not allow direct metal contact across battery posts.

• Remove negative cable first when disconnecting.

• Install negative cable last when connecting.

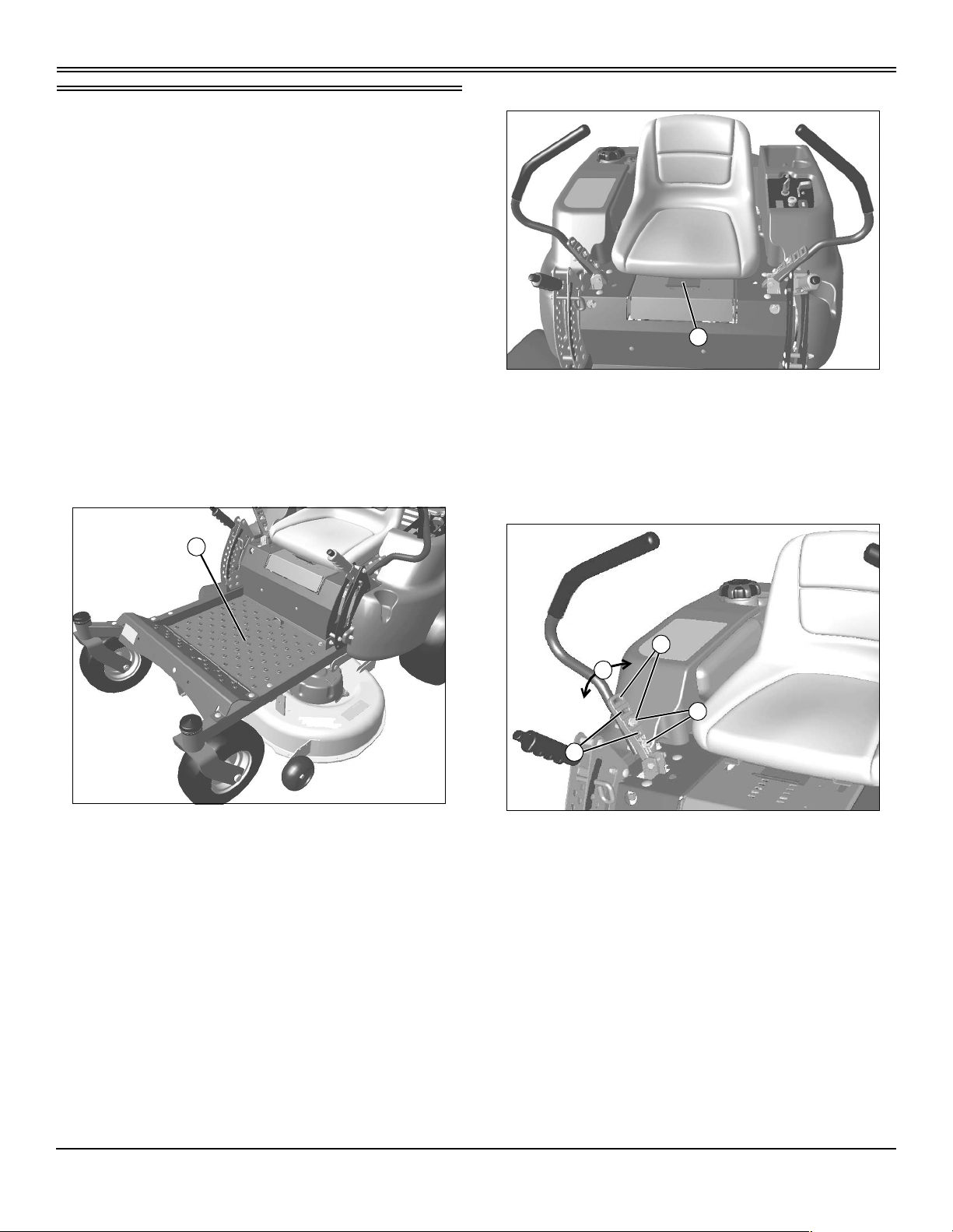

1. Raise seat.

2. Remove and discard the protective caps from the battery terminals.

3. Charge the battery. Battery is fully charged at 12.6 volts.

A

4. Connect positive (+) battery cable (A) to battery.

5. Connect negative (-) battery cable (B).

6. Apply general purpose grease or silicone spray to terminal to help

prevent corrosion.

7. Slide red cover over positive battery cable.

8. Lower seat.

B

MX38104

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries,

can harm the environment and people:

• Do not use beverage containers for waste fluids - someone may drink

from them.

• See your local Recycling Center or authorized dealer to learn how to

recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides specific details on

Assembly - 7

Page 9

ASSEMBLY

Install Deck Height Pin

B

A

MX37775

1. Be sure mower is fully raised to the transpor t lock position, as shown,

and insert the pin (A) in the hole just below the mower deck lift lever (B).

Install Seat

1. Remove and discard four bolts and wood block holding seat onto foot

plate.

B

ENGINE section.)

Check Machine Safety System

Perform safety system check to make sure the electronic safety interlock

circuit is functioning properly. Perform all tests. (See Testing Safety

System in the OPERATING section.)

C

A

2. Raise seat platform (A), and install seat (B) onto platform. Secure with

washers and bolts (C).

3. Route harness connector (D) up and onto seat switch, and secure

harness plug (E) into hole in seat platform.

4. Lower seat.

D

E

C

MX38092

Check Tire Pressure

Check tire pressure. (See Checking Tire Pressure in the SERVICE

MISCELLANEOUS section.)

Adjust Mower Deck Level

Adjust mower deck level. (See Adjusting Mower Deck Level in the

OPERATING section.)

Check Engine Oil Level

Check engine oil level. (See Checking Engine Oil Level in the SERVICE

Assembly - 8

Page 10

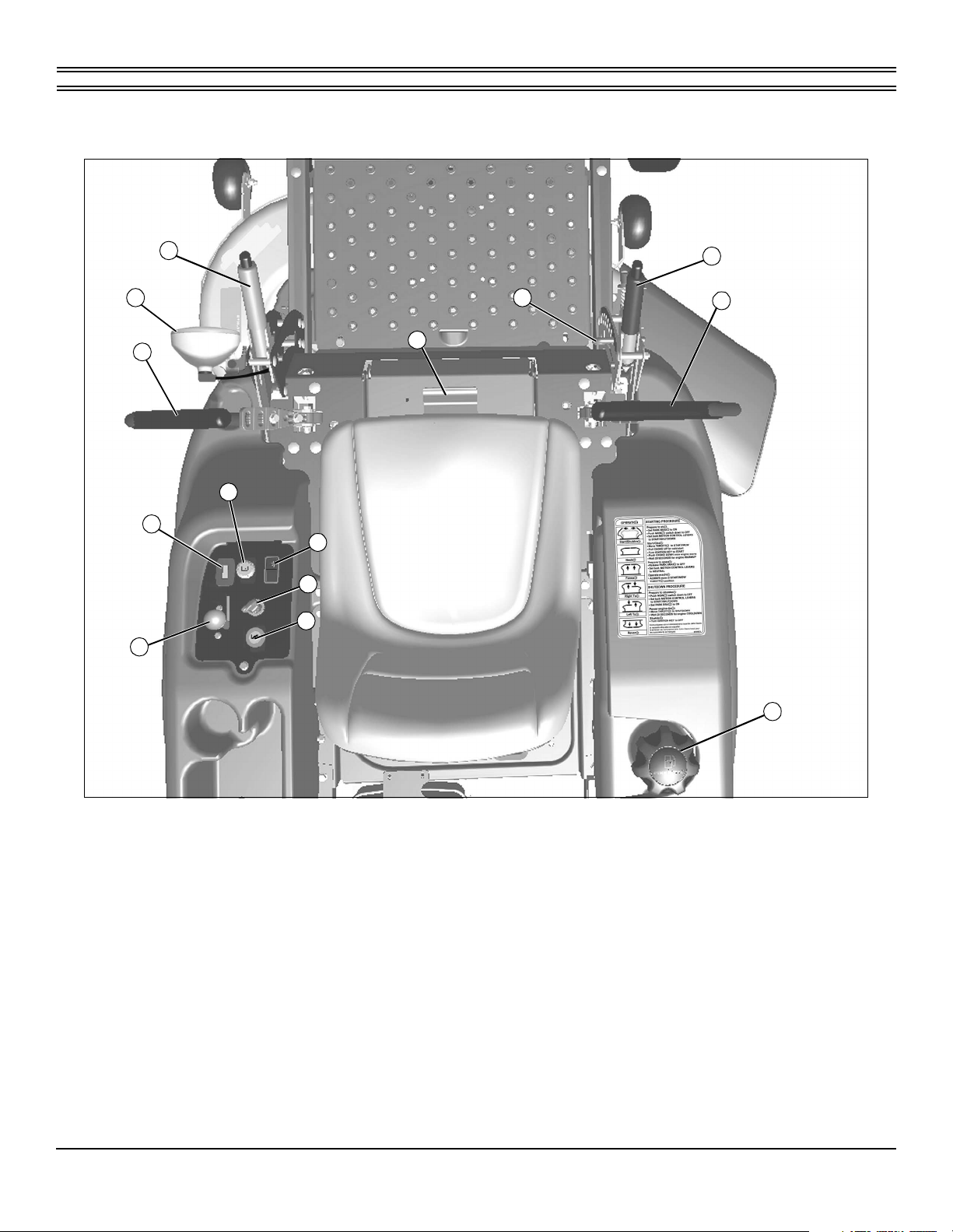

Operating - Controls

Operator Station Controls

OPERATING - CONTROLS

C

B

A

L

M

K

J

I

N

D

E

F

G

Key Description Key Description

A Left Motion Control Lever H Fuel Tank Cap

B Headlight (If equipped) Left available for Z225, Left and

Right available for Z425 and Z445

C Park Brake Lever J Ignition Key Switch

D Seat Adjustment Lever K Headlight Switch (If equipped)

E Height-of-Cut (HOC) Adjustment Pin L Mower Engagement Switch

F Mower Deck Lift Lever M Hourmeter

G Right Motion Control Lever N Throttle Control Lever

I Choke (Z425 and Z445)

H

MX37885

Operating - Controls - 9

Page 11

OPERATING

Operating

Daily Operating Checklist

❏ Test safety systems.

❏ Check fuel level.

❏ Check engine oil level.

❏ Remove grass and debris from engine compar tment and muffler

area, before and after operating machine.

❏ Check transaxle oil level - sight bottle.

❏ Clean air intake screen.

❏ Check area below machine for leaks.

Avoid Damage to Plastic and Painted Surfaces

• Do not wipe plastic parts unless rinsed first.

• Insect repellent spray may damage plastic and painted surfaces. Do not

spray insect repellent near machine.

• Be careful not to spill fuel on machine. Fuel may damage surface. Wipe

up spilled fuel immediately.

Mounting and Dismounting Machine

Adjusting Seat

A

MX37772

1. Pull lever (A) upward.

2. Slide seat forward or rearward to desired position.

3. Release lever.

Adjusting Motion Control Levers

1. Park machine safely. (See Parking Safely in the SAFETY section.)

A

MX37771

• Do not step on the mower deck when mounting and dismounting the

machine.

• Mount the machine from the front using the foot plate (A).

• Park machine safely before dismounting (see Parking Safely in the

SAFETY section).

• Keep the foot plate clean.

A

D

C

B

MX37941

2. To adjust motion control lever height, remove two bolts and nuts and

raise or lower each control lever to your comfort level.

• For highest lever position, use holes (A).

• For medium lever position, use holes (B).

• For lowest lever position, use holes (C).

3. You can also adjust motion control levers slightly forward or rearward

(D) within slotted holes.

Adjusting Cutting Height

Cutting height can be adjusted from approximately 25-100 mm (1-4 in.).

When mower deck is in transpor t position cutting height is approximately

100 mm (4 in.).

1. Check tire pressure and adjust as needed.

Operating - 10

Page 12

OPERATING

A

C

D

MX37775

2. Raise mower deck:

3. Insert the pin (A) in the proper hole for the desired height of cut.

4. Lower mower deck.

Adjusting Mower Level

c CAUTION: Avoid injury! Rotating blades are dangerous.

Before adjusting or servicing mower:

• Disconnect spark plug wire(s) or battery negative (-) cable to

prevent engine from starting accidently.

• Always wear gloves when handling mower blades or working

near blades.

NOTE: Mower wheels should not contact the ground when leveling

the deck.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Inflate tires to the correct pressure.

3. Set mower to preferred cutting height, and lower deck into the mowing

position.

4. Measure mower level (side-to-side).

MX4896

b.Turn left blade (C) as show n. Hold drive belt and turn right blade (D) as

shown. Take measurement for both blades.

The difference between blade measurements must not be more than 3

mm (1/8 in.).

E

MX37773

c.Adjust mower level, if necessary, by turning rear nuts (E) clockwise to

raise the side of the mower deck, or counterclockwise to lower the

mower deck.

5. Measure mower level (front-to-rear).

B

A

Picture Note: A convenient leveling gauge (A) (AM130907) is

available from your dealer.

a.Position mower blades as follows and measure from each outside

blade tip (B) to the level surface.

Operating - 11

D

MIF

MX4896a

a.Turn right blade (D) so blade tip points straight forward.

b.Measure from blade tip to the surface. Take measurement for both

blades. The front blade tip must be 3 - 6 mm (1/8 - 1/4 in.) lower than

rear blade tip.

Page 13

OPERATING

SAFETY section).

2. Inflate tires to correct pressure.

3. Raise mower deck lift lever, and lock in transport position.

4. Adjust mower wheels to correct height:

42 Inch Mower

F

G

MX37774

c.42 inch mower deck: Adjust mower level, if necessary, by loosening

rear nut (F) on front lift rod. Turn front nut (G) clockwise to raise front of

mower or counterclockwise to lower it. Tighten rear nut after adjustment

is complete.

H

J

I

d.48 and 54 inch mower decks: Adjust mower level, if necessary, by

loosening rear nuts (H) on front lift rod. Turn front nuts (I) clockwise to

raise front of mower or counterclockwise to lower it. Make sure front lift

rod contacts mower deck bracket on both sides (J) to maximize stability

of deck. Tighten rear nut after adjustment is complete.

NOTE: Verify that deck will latch in transport position. If it does not

latch, turn both rear adjusting nuts counter-clockwise equally to

lower rear of deck until deck latch will engage. Check front lift rod

adjustment, adjust if necessary.

J

MX37887

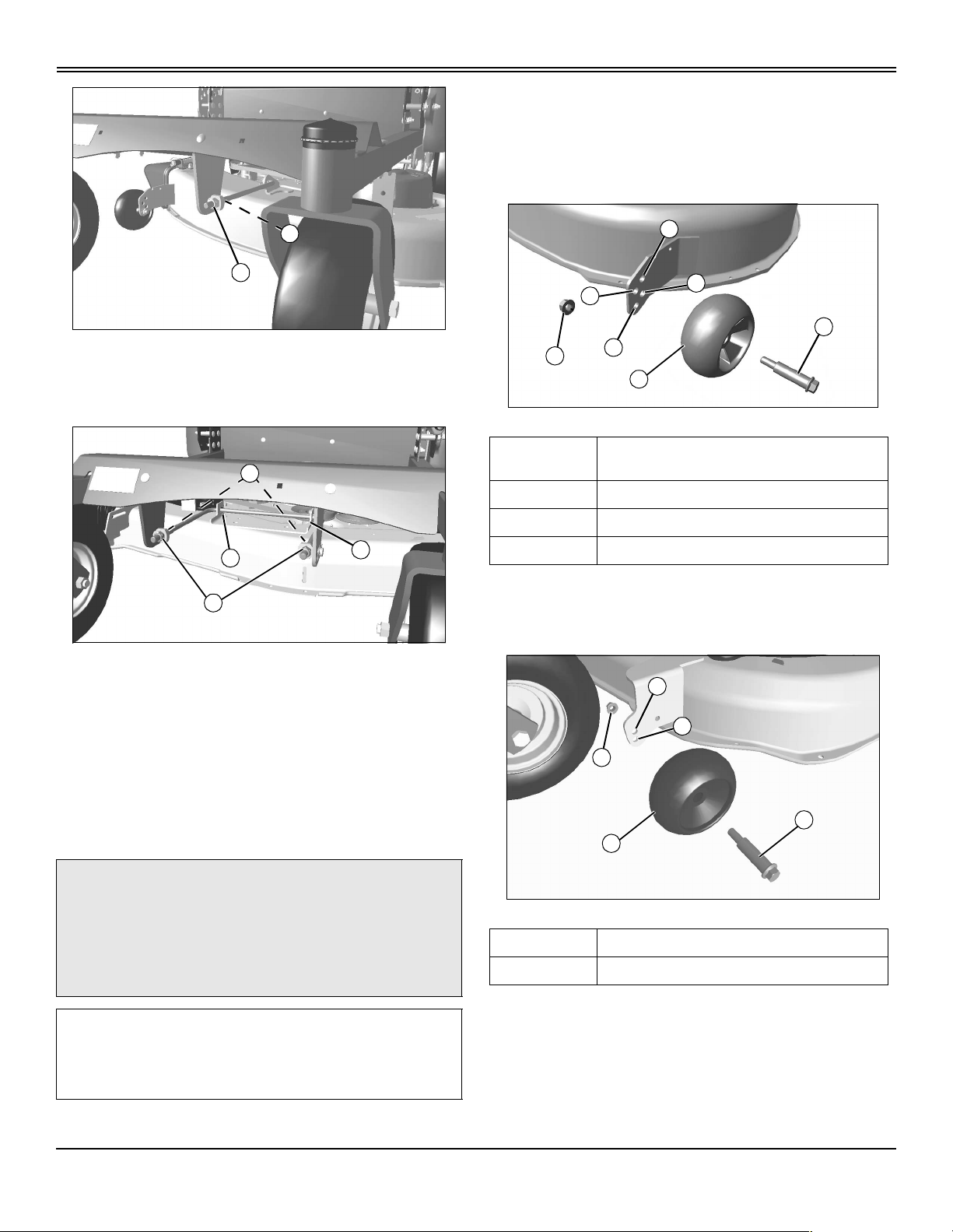

Adjusting Mower Wheels

A

B

F

Position 1 (A) Disables anti-scalp feature

Position 2 (B) 25 - 50 mm (1 - 2 in.) Height of Cut

Position 3 (C) 57 - 76 mm (2-1/4 - 3 in.) Height of Cut

Position 4 (D) 82 - 101 mm (3-1/4 - 4 in.) Height of Cut

• Remove shoulder bolt (E) and nut (F). Move wheel (G) to proper hole

position. Secure with shoulder bolt and nut. Tighten nut to 34 N•m (25 lbft).

48 and 54 Inch Mowers

D

G

(should not be used)

K

L

C

E

MX36202

H

I

J

c CAUTION: Avoid injury! Rotating blades are dangerous.

Before adjusting or servicing mower:

• Disconnect spark plug wire(s) or battery negative (-) cable to

prevent engine from starting accidently.

• Always wear gloves when handling mower blades or working

near blades.

IMPORTANT: Avoid damage! The mower deck can be damaged if

mower wheels are adjusted wrong:

• Wheels must not ride on ground supporting mower weight.

• Check wheel adjustment each time cutting height is changed.

1. Park machine safely on a level surface. (See Parking Safely in the

MX37884

Position 1 (H) 25 - 76 mm (1 - 3 in.) Height of Cut

Position 2 (I) 82 - 101 mm (3-1/4 - 4 in.) Height of Cut

• Remove shoulder bolt (J) and nut (K). Move wheel (L) to proper hole

position. Secure with shoulder bolt and nut. Tighten nut to 34 N•m (25 lbft).

Operating - 12

Page 14

OPERATING

Testing Safety Systems

c CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Do not run an engine in an enclosed area, such as a garage, even

with doors or windows opened.

Move the machine to an outside area before running the engine.

The safety systems installed on your machine should be checked before

each machine use. Be sure you have read the machine operator manual

and are completely familiar with the operation of the machine before

performing these safety system checks.

Use the following checkout procedures to check for normal operation of

machine.

If there is a malfunction during one of these procedures, do not operate

machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing Park Brake Switch

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Sit on seat.

3. Unlock the park brake.

4. Try to star t engine.

Result: Engine must not crank. If engine cranks, there is a problem with

your safety interlock circuit.

Testing Park Brake

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Engage bypass valve lever.

3. Lock the park brake.

4. Try to push machine manually.

Result: Park brake must prevent machine from moving. If machine moves,

parking brake needs to be adjusted.

Result: Engine must not crank. If engine cranks, there is a pr oblem with

your safety interlock circuit.

Testing Seat Switch

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

2. First test:

a.Star t engine.

b.Move throttle lever up to maximum engine speed.

c.Unlock park brake.

d.Engage mower.

e.Raise up off seat. Do not get off machine.

Result: Engine and mower blades should stop. If engine and mower

blades do not stop, there is a problem with your safety interlock circuit.

3. Second test:

a.Lock park brake.

b.Disengage mower.

c.Start engine.

d.Unlock park brake.

e.Raise up off seat. Do not get off machine.

Result: Engine should stop. If engine does not stop, there is a problem

with your safety interlock circuit.

4. Third test:

a.Disengage mower.

b.Star t engine.

c.Lock park brake.

d.Raise up off seat. Do not get off machine.

Result: Engine should continue to run. If engine stops, there is a problem

with your safety interlock circuit.

Using Park Brake

c CAUTION: Avoid injury! Children or bystanders may

attempt to move or operate an unattended machine.

Always lock the park brake and remove the key before leaving the

machine unattended.

Setting Park Brake

1. Press button, and raise park brake lever to lock park brake.

Releasing Park Brake

1. Press button, and lower park brake lever to unlock park brake.

Testing Mower Engagement (PTO) Switch

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Sit on seat.

3. Lock the park brake.

4. Engage the mower.

5. Try to star t engine.

Operating - 13

Page 15

OPERATING

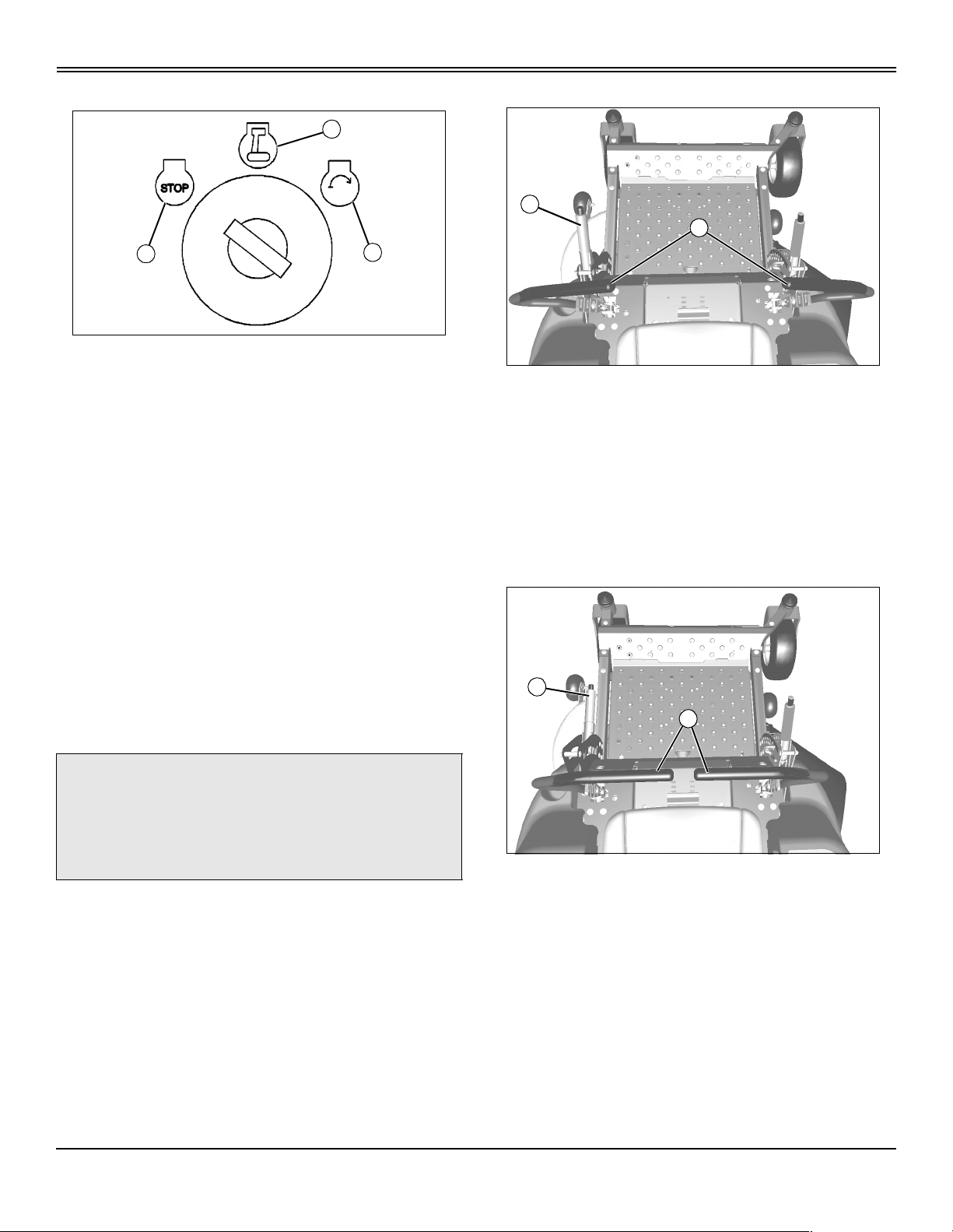

Using Key Switch

B

A

A - STOP (off) position - With key in the STOP position, all switched power

is off, and engine should not run.

B - Run (on) position - Turn key from STOP to this position, and all

switched power circuits will be on.

C - Start position - Turn key to start position to crank the engine. Release

key after engine has started and it will automatically return to the on

position. The engine will continue to run.

C

MX31338

Using Mower Engagement Switch

• To Engage Mower - Pull mower engagement knob up.

• To Disengage Mower - Push mower engagement knob down.

Using the Hour Meter

• The hour meter shows the number of hours the engine has run. The hour

meter does not accumulate hours with the engine off when the key is in

the run position. Use the hour meter to determine when your machine has

reached the recommended service intervals.

• Turn the key to STOP position when not using the machine.

• Hour meter cannot be reset.

Using the Motion Control Levers

Start/shutdown Position

B

A

MX37896

• Motion control levers must be in the start/shutdown position (A) and the

park brake locked (B) to start the engine.

• Forward and reverse movement of the motion control levers is prevented

when levers are moved to the start/shutdown position.

• Operator can exit mower with the engine running when the mower

engagement switch is disengaged, the motion control levers are in the

start/shutdown position and the park brake is locked.

• Motion control levers must be in the start/shutdown position to safely

enter and exit the operator seat.

Neutral Position

D

C

c CAUTION: Avoid injury! Learn use of the motion control

levers and practice at half throttle until becoming proficient and

comfortable with the operation of the machine.

Do not move motion control levers from forward to reverse or

reverse to forward position rapidly. Sudden direction changes

could cause loss of control or damage the machine.

Before using the machine, become familiar with the motion control levers

and how they respond. It is essential to know how the machine

accelerates, st eers and stops.

The functions of the motion control levers are:

• Dual function neutral position.

• Steering.

• Acceleration.

• Braking.

Operating - 14

MX37897

• Machine speed, motion, and direction can be controlled when the engine

is running, motion control levers are in the neutral position (C), and the

park brake is unlocked (D).

• To stop the machine for an emergency, move the motion control levers

quickly back to the neutral position.

Forward and Reverse Travel

Straight forward and reverse travel takes practice. If the machine does not

track in a straight line when going forward or reverse, the motion control

lever tracking may need adjusting.

1. Move throttle lever to the fast position.

2. Unlock park brake.

3. Move both motion control levers from the start/shutdown position inward

to the neutral position.

Page 16

OPERATING

4. Move the motion control levers forward to begin forward travel.

5. Move the motion control levers rearward to begin reverse travel.

6. To stop travel, move motion control levers back to the neutral position.

Forward Travel

A

1. Gradually move both motion control levers evenly forward (A) from

neutral. To speed up, move the levers farther forward. To slow down

smoothly, slowly move the levers toward neutral.

A

MX37898

Left Turn

C

D

MX37900

1. To turn slightly to the left, push right control lever (C) further forward

than the left control lever (D).

Reverse Travel

B

1. Look down and behind, then gradually move both motion control levers

evenly rearward (B) from neutral. To speed up, move the levers farther

rearward. To slow down smoothly, slowly move the levers toward neutral.

B

MX37899

C

D

MX37901

2. To turn sharply to the left, push right control lever (C) forward and pull

left control lever (D) rearward at the same time.

Operating - 15

Page 17

OPERATING

Right Turn

D

C

MX37902

1. To turn slightly to the right, push left control lever (D) fur ther forward

than the right control lever (C).

D

• Warm start: Set throttle lever to the run position.

6. Position choke knob:

• Cold start: Pull knob up and hold in the choke position.

• Warm start: If necessary, pull knob up and hold in choke position.

IMPORTANT: Avoid damage! Starter may be damaged if starter is

operated for more than 20 seconds at a time:

• Wait two minutes before trying again if engine does not start.

7. Turn key switch to the start position.

8. After engine starts, release key switch to the run position, push choke

knob down to off position, and move throttle to run.

IMPORTANT: Avoid damage! Unnecessary engine idling may

cause engine damage. Excessive idling can cause engine

overheating, carbon build-up, and poor performance.

9. Allow the engine to warm up for 20 seconds.

10. Release park brake.

11. Set both motion control levers to the neutral position.

Engaging Mower

c CAUTION: Avoid injury! Clear mowing area of all bystanders

when operating this machine. Thrown objects could cause serious

injury or death.

Keep hands and feet away from blades and discharge opening.

Do not mow in reverse unless absolutely necessary.

C

MX37903

2. To turn sharply to the right, push left control lever (D) forward and pull

right control lever (C) rearward at the same time.

Starting the Engine

c CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Do not run an engine in an enclosed area, such as a garage, even

with doors or windows opened.

Move the machine to an outside area before running the engine.

1. Sit on the operator seat.

2. Lock park brake.

3. Push the mower engagement knob down to disengage the mower.

4. Set both motion control levers to the start/shutdown position.

5. Move throttle lever to set engine speed:

• Cold start: Set throttle lever to the start position.

1. Adjust mower to desired cutting height.

2. Start engine.

3. Release park brake.

4. Move both motion control levers to the neutral position.

5. Set throttle lever to the RUN position.

6. Pull mower engagement switch up to engage mower.

NOTE: The travel speed and turn rate will vary with the amount that

the control levers are moved.

7. Push motion control levers forward slowly. Mow at a safe travel speed.

Stopping the Engine

1. Stop machine on a level surface, not on a slope.

2. Push the mower engagement switch down to disengage mower.

3. Move the motion control levers to the star t/shutdown position.

4. Lock park brake.

5. Move throttle lever to the shutdown position.

6. Allow the engine to cool down for 20 seconds.

7. Turn ignition key to STOP (off) position.

Operating - 16

Page 18

OPERATING

c CAUTION: Avoid injury! Children or bystanders may

attempt to move or operate an unattended machine.

Always lock the park brake and remove the key before leaving the

machine unattended.

8. Remove key.

NOTE: The bypass valves must be fully turned clockwise (closed)

during normal vehicle operation.

1. Lock park brake.

2. Raise operator’s seat.

Moving Machine by Hand

c CAUTION: Avoid injury! When the bypass valve is open, the

machine will have unrestricted motion.

• Do not open the bypass valve when the machine is stopped

on an incline to prevent it from going downhill out of control.

IMPORTANT: Avoid damage! Transmission damage may occur if

the machine is towed or moved incorrectly:

• Move machine by hand only.

• Do not use another vehicle to move machine.

• Do not tow machine.

Z225 Model:

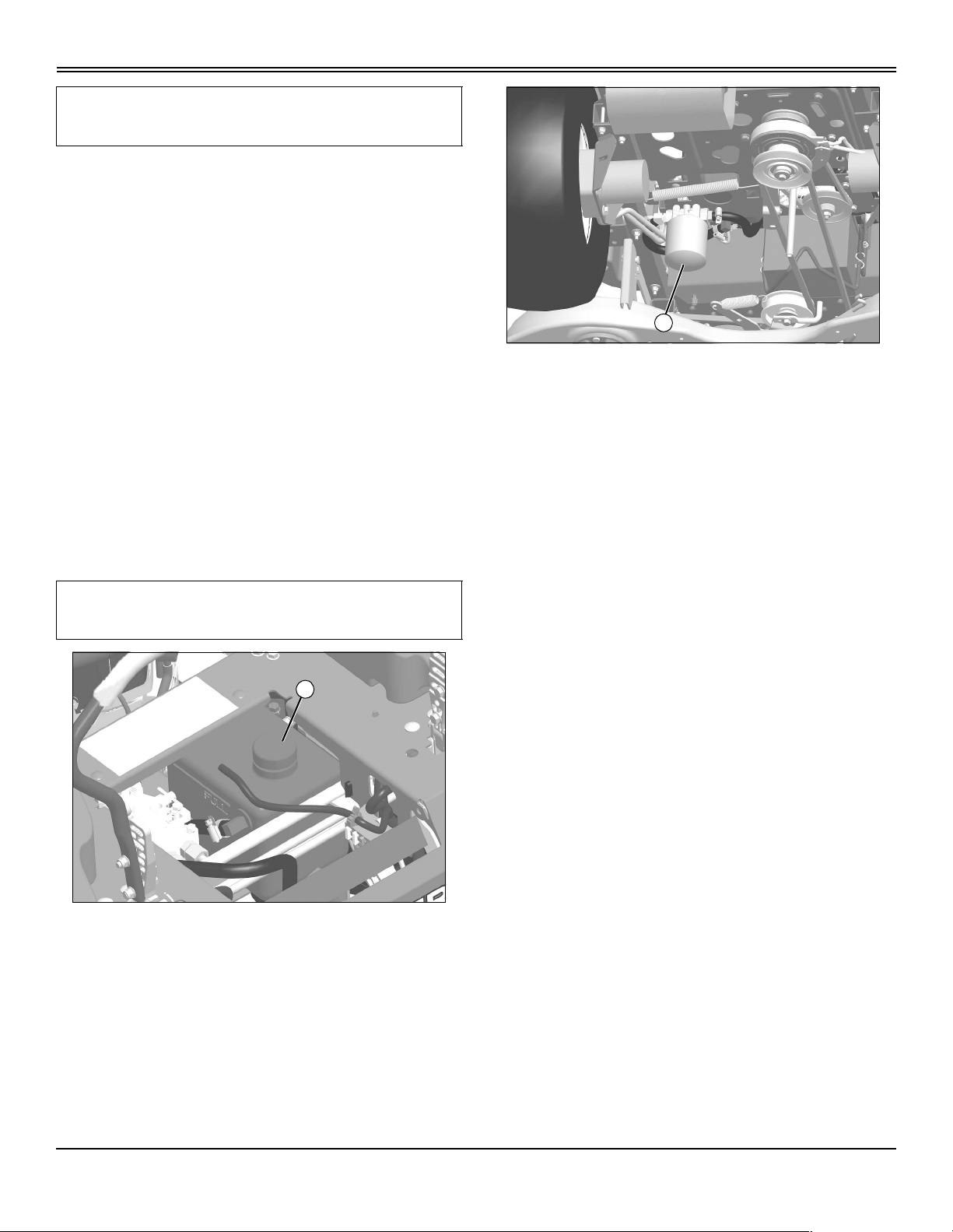

A

MX37905

3. Turn bypass valves (A) on both sides of pump one full turn

counterclockwise (open position).

4. Unlock park brake.

5. Push machine to desired location. Due to hydraulic system drag,

machine will move slowly.

IMPORTANT: Avoid damage! The bypass valves can be damaged

if overtightened. Use care not to overtighten.

NOTE: Bypass valves should be hand tightened only.

6. Turn both bypass valves one full turn clockwise (closed position) until

tight.

7. Lock park brake.

A

MX37904

1. Pull out both bypass valve levers (A) at rear of machine.

2. Release park brake.

3. Push machine to desired location.

IMPORTANT: Avoid damage! The transmission might be damaged

if the bypass valve lever is not pushed back to operating position

before attempting to start the engine. Do not start or operate the

machine with the bypass valve lever in the push position.

4. Push in both bypass valve levers.

Z425 and Z445 Models:

When the machine needs to be moved without starting the engine, use the

bypass valves:

Operating - 17

Unplugging Mower, Bagger, or Material Collection

System

c CAUTION: Avoid injury! Do not attempt to unplug

attachment with machine running.

• Rotating blades are dangerous. Shut off the engine and

remove the key before getting off the seat to inspect the

machine and attachment.

• Thrown objects can cause serious injury. Make sure all

machine parts are stopped before raising hopper top or

removing chutes.

Checking For Plugging While Driving

Check the flow indicator on MCS chute (if equipped) periodically for any

indication of loss of air flow.

If grass builds up in front of mower discharge chute, check for plugged

chute or problems with blower assembly (if equipped).

If there is a trail of clippings behind mower or clippings blow to the side,

check for plugged chute, full collector bags, or problems with blower

assembly.

Page 19

SERVICE INTERVALS

Removing Debris From Inspection Points:

c CAUTION: Avoid injury! Do not use hands or feet to clear

plugged mower deck or blower assembly. Stored energy can cause

blades to rotate.

1. Park machine safely. Wait for all moving parts to stop before getting off

to inspect machine.

2. Open hopper cover. Check chute outlet.

3. Remove chute from mower deck or blower assembly. Check chute inlet.

4. Check under mower deck for debris.

Transporting Machine on Trailer

NOTE: Trailer capacity must exceed combined machine weight an d

attachment weight. (See Specifications section in operator’s

manual).

Be sure trailer has all the necessary lights and signs required by law.

c CAUTION: Avoid injury! Use extra care when loading or

unloading the machine onto a trailer or truck. Machine wheels can

go off the ramp or trailer, causing the machine to tip over.

• To load, back slowly and in a straight line. Keep wheels away

from drop-offs and edges.

• Do not use two separate loading ramps. Use a full width

loading ramp at least 30 cm (12 in.) wider than machine to keep

castor wheels from going off the ramp edge.

• Use a trailer with sides.

1. Park trailer on level surface.

2. Raise mower deck before driving machine onto trailer.

• Properly level mower deck for a smooth cut.

• Mow grass frequently.

• Use a travel speed that fits the conditions:

• Mow tall or wet grass twice. Cut grass at half desired height – then cut

at desired height.

• Travel slow when mowing tall, thick or wet grass.

• Avoid damaging grass by slipping or skidding machine drive wheels.

Practice smooth cont rol lever movements.

• When performing sharp turns, do not allow inside machine drive wheel

to stop and twist on grass.

Service Intervals

Servicing Your Machine

IMPORTANT: Avoid damage! Operating in extreme conditions

may require more frequent service intervals:

• Engine components may become dirty or plugged when

operating in extreme heat, dust or other severe conditions.

• Engine oil can degrade if machine is operated constantly at slow

or low engine speeds or for frequent short periods of time.

Please use the following timetables to perform routine maintenance on

your machine.

Service Intervals

Break-In after 8 Hours

• Change engine oil.

• Change engine filter (Z425 and Z445).

Every 50 Hours or Annually

• Lubricate mower deck spindles (Z425 and Z445).

MX22500

3. Back machine onto heavy-duty trailer with full-width ramp.

4. Lower mower deck completely.

5. Lock park brake.

6. Turn off machine and remove key.

7. Fasten machine at the axle or frame to trailer with heavy-duty straps,

chains, or cables. Both front and rear straps must be directed down and

outward from machine.

Mowing Tips

• Mow grass with throttle lever in the full fast / mow position.

• Mow grass when it is dry.

• Keep mower deck and discharge chute clean.

• Mow with sharp blades.

Service Intervals - 18

Every 100 Hours or Annually

• Change engine oil.

• Change engine filter (Z425 and Z445).

• Replace spark plugs.

• Replace air filter elements, both foam and paper.

• Replace fuel filter.

• Check mower belt.

• Shar pen / Replace blades.

• Clean underside of deck.

• Check tire pressure.

• Clean engine cooling fins.

Every 200 Hours

• Check / adjust engine valve clearance. See your John Deere dealer for

this service.

Page 20

Service Lubrication

Grease

SERVICE LUBRICATION

48 and 54 in. Mower Decks

IMPORTANT: Avoid damage! Use recommended John Deere

greases to avoid component failure and premature wear.

The recommended John Deere greases are effective within an

average air temperature range of -29 to 135 degrees C (-20 to 275

degrees F).

If operating outside that temperature range, contact your

Servicing dealer for a special-use grease.

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

If not using any of the preferred greases, be sure to use a general allpurpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease.

Contact your Servicing dealer for information.

Lubricating Mower Deck Spindles

NOTE: Removal of belt shields is not necessary to lubricate the

spindles.

1. Remove mower deck foot plate.

42 in. Mower Deck

B

B

B

MX37888

• Lubricate three mower deck spindle grease fittings (B) with two pumps of

grease at specified interval.

Lubricating Front Caster Spindles

c CAUTION: Avoid injury! To avoid injury, Do not lubricate

machine while the engine is running.

B

A

A

• Lubricate two mower deck spindle grease fittings (A) with two pumps of

grease at specified interval.

A

MX37890

Service Lubrication - 19

MX37795

• The two front caster wheel suppor ts (A) utilize sealed bearings, which do

not require lubrication. There are no grease fittings in the wheel suppor ts.

• The caster wheel yoke spindle (B) should be lightly greased prior to

assembly if the wheel unit is serviced, to prevent the spindle from seizing

in the bearings.

Service Engine

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and

systems on this engine, which are being done at the customers expense,

may be performed by any non-road engine repair establishment or

individual. Warranty repairs must be performed by an authorized John

Deere dealer.

Page 21

SERVICE ENGINE

Avoid Fumes

c CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Do not run an engine in an enclosed area, such as a garage, even

with doors or windows opened.

Move the machine to an outside area before running the engine.

Engine Oil

Use oil viscosity based on the expected air temperature range during the

period between oil changes.

SAE 10W-40

SAE 10W-30

A

MX37908

Picture Note: Single cylinder Briggs and Stratton shown.

SAE 5W-30

-20 0

-40

-40

-30

-20

The following John Deere oils are preferred:

• TURF-GARD™

• PLUS- 4™

Other oils may be used if above John Deere oils are not available,

provided they meet the following specification:

• API Service Classification SG or higher

20 40 60

32

F

C

0

-10

10

80 10 050122

20 30

40

Checking Engine Oil Level

IMPORTANT: Avoid damage! Failure to check the oil level

regularly could lead to serious engine problems if oil level is low:

• Check oil level before operating.

• Check oil level when the engine is cold and not running.

• Keep level between the FULL and the ADD marks.

• Shut off engine before adding oil.

NOTE: Check oil twice a day if you run engine over 4 hours in a day.

Make sure engine is cold when checking engine oil level.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

IMPORTANT: Avoid damage! Dirt and contamination can enter

engine when checking oil level. Clean area around dipstick before

loosening or removing.

2. Clean area around dipstick to prevent debris from falling into crankcase.

A

MX37939

Picture Note: Twin cylinder Briggs and Stratton shown.

A

MX37910

Picture Note: Twin cylinder Kawasaki shown.

3. Remove dipstick (A). Wipe with clean cloth.

4. Install dipstick:

• Briggs and Stratton Engines: Install and tighten dipstick.

• Kawasaki Engines: Install dipstick in tube but do not tighten. Allow

dipstick threads to rest on top of tube and rotate cap counterclockwise

until it “clicks” or drops into place.

5. Remove dipstick.

Service Engine - 20

Page 22

SERVICE ENGINE

6. Check oil level on dipstick. Oil must be between ADD and FULL marks.

7. If oil level is low, add oil to bring oil level no higher than FULL mark on

dipstick. Do not overfill.

8. Install and tighten dipstick.

Changing Engine Oil and Filter

IMPORTANT: Avoid damage! Operating in extreme conditions

may require more frequent service intervals:

• Engine components may become dir ty or plugged when

operating in extreme heat, dust or other severe conditions.

• Engine oil can degrade if machine is operated constantly at slow

or low engine speeds or for frequent short periods of time.

1. Run engine to warm oil.

2. Park machine safely on level surface. (See Parking Safely in the

SAFETY section.)

IMPORTANT: Avoid damage! Dirt and contamination can enter

engine when checking oil level. Clean area around dipstick before

loosening or removing.

3. Clean area around dipstick to prevent debris from falling into crankcase.

Single cylinder Briggs and Stratton:

C

B

D

MX38113

1. Put drain pan under hole (A) of drain valve (B), and remove drain cap

(C).

B

C

A

MX37942

2. Install drain hose (D) onto end of drain valve. Loosen engine dipstick.

Turn drain valve counterclockwise and pull outward to allow oil to drain

completely.

3. Push drain valve inward, and turn clockwise to tighten. Remove drain

hose, and install drain cap.

4. Add oil no higher than FULL mark on dipstick. Begin with approximately

1.2 L (1.25 qt). Do not overfill.

5. Install and tighten dipstick.

6. Start and run engine at idle to check for leaks. Stop engine. Fix any

leaks before operating.

7. Check oil level. Add oil if necessary.

Service Engine - 21

Page 23

SERVICE ENGINE

Twin cylinder Briggs and Stratton:

D

A

C

MX37943

A

C

B

MX38114

1. Raise seat, and put drain pan under drain valve (A).

2. Install drain hose (B) onto bottom end of drain valve. Loosen fitting (C)

to drain oil into drain pan.

3. Loosen dipstick (D), and allow oil to drain completely.

8. Add oil no higher than FULL mark on dipstick. Begin with approximately

1.6 L (1.75 qt). Do not overfill.

9. Install and tighten dipstick.

10. Start and run engine at idle to check for leaks. Stop engine. Fix any

leaks before operating.

11. Check oil level. Add oil if necessary.

Twin cylinder Kawasaki:

B

A

1. Put drain pan under drain valve (A), and loosen drain valve to drain oil

into drain pan.

2. Loosen dipstick (B), and allow oil to drain completely.

3. Wipe dirt from around oil filter (C). Place a drain pan under oil filter, and

remove old filter.

4. Put a light coat of fresh, clean oil on the new filter gasket.

5. Install replacement oil filter by turning oil filter to the right (clockwise)

until the rubber gasket contacts filter base. Tighten filter an additional onehalf turn.

6. Tighten oil drain valve (A).

7. Add oil no higher than FULL mark on dipstick. Begin with approximately

1.5 L (1.6 qt). Do not overfill.

8. Install and tighten dipstick.

9. Start and run engine at idle to check for leaks. Stop engine. Fix any

leaks before operating.

10. Check oil level. Add oil if necessary.

C

MX37910

E

MX37939

4. Wipe dirt from around oil filter (E). Place a drain pan under oil filter, and

remove old filter.

5. Put a light coat of fresh, clean oil on the new filter gasket.

6. Install replacement oil filter by turning oil filter to the right (clockwise)

until the rubber gasket contacts filter base. Tighten filter an additional onehalf turn.

7. Tighten oil drain fitting (C), and remove drain hose (B).

Service Engine - 22

Cleaning Air Intake Screen and Engine Fins

c CAUTION: Avoid injury! Compressed air can cause debris

to fly a long distance.

• Clear work area of bystanders.

• Wear eye protection when using compressed air for cleaning

purposes.

• Reduce compressed air pressure to 210 kPa ( 30 psi).

IMPORTANT: Avoid damage! An obstructed air intake screen can

cause engine damage due to overheating. Keep air intake screen

and other external surfaces of the engine, including cooling fins,

clean at all times to allow adequate air intake.

1. Park machine safely. (See Parking Safely in the SAFETY Section.)

Page 24

SERVICE ENGINE

2. Clean air intake screen on top of engine and exter nal surfaces with rag,

brush, vacuum or compressed air.

Checking and Cleaning Air Cleaner Elements (Single Cylinder Briggs & Stratton)

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Let engine cool.

3. Clean dirt and debris from the air cleaner cover.

A

B

MX7680

4. Lift latch (A) to unlock cover (B). Lift cover forward and remove.

6. Inspect the paper filter element (D) without removing it. If the paper filter

element is damaged or dirty:

• Carefully remove the element from the air cleaner housing.

7. Clean air cleaner base very carefully, preventing any dirt from falling into

carburetor.

8. Install new paper filter element.

9. Install foam precleaner on paper filter element.

10. Install air cleaner cover and push latch down to lock.

Checking and Cleaning Air Cleaner Elements (Twin Cylinder Briggs & Stratton)

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Let engine cool.

3. Clean dirt and debris from the air cleaner cover.

B

A

A

IMPORTANT: Avoid damage! Dirt and debris can enter the engine

through a damaged filter element:

• Do not wash paper element.

• Do not attempt to clean paper element by tapping against

another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged or the seal is

cracked.

C

D

B

MX7679

5. Inspect the foam precleaner (C) without removing it. If the foam

precleaner is dirty:

a.Remove it from the filter carefully, leaving the paper element (D) in the

air cleaner housing.

b.Wash precleaner in a solution of warm water and liquid detergent. Do

not use oil.

c.Rinse precleaner thoroughly. Squeeze out excess water in a dr y cloth

until precleaner is completely dry.

MX37939

4. Loosen four knobs (A) and remove cover (B).

IMPORTANT: Avoid damage! To prevent engine damage, do not

allow any foreign objects to fall into the carburetor air intake.

D

C

E

M96094

5. Do not drop anything into the carburetor air intake (C). If anything falls

into the carburetor air intake it must be removed.

6. Lift out filter cartridge (D) and inspect it for damage.

Service Engine - 23

Page 25

SERVICE ENGINE

IMPORTANT: Avoid damage! Dirt and debris can enter the engine

through a damaged filter element:

• Do not wash paper element.

• Do not attempt to clean paper element by tapping against

another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged or the seal is

cracked.

7. Inspect the foam precleaner (E) without removing it. If the foam

precleaner is dirty:

a.Remove it from the filter carefully.

b.Wash precleaner in a solution of warm water and liquid detergent.

c.Rinse precleaner thoroughly. Squeeze out excess water in a dr y cloth

until precleaner is completely dry.

8. Clean air cleaner housing carefully. Prevent any dirt from falling into

carburetor.

9. Install foam precleaner mesh side up.

10. Install car tridge. Make sure car tridge and seal are properly seated and

sealing the carburetor air intake area.

11. Install air cleaner cover and tighten knobs. Do not overtighten.

Checking and Cleaning Air Cleaner Elements (Twin Cylinder Kawasaki)

1. Park machine safely (See Parking Safely in the SAFETY section).

2. Let engine cool.

3. Clean dirt and debris from the air cleaner cover.

A

B

C

B

D

MX37945

5. Inspect the foam precleaner (B) without removing it.

6. If the foam precleaner is dirty:

• Remove the filter carefully.

• Wash precleaner in a solution of warm water and liquid detergent.

• Rinse precleaner thoroughly. Squeeze out excess water in a dry cloth

until precleaner is completely dry.

IMPORTANT: Avoid damage! Dirt and debris can enter the engine

through a damaged filter element:

• Do not wash paper element.

• Do not attempt to clean paper element by tapping against

another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged or the seal is

cracked.

4. Loosen two knobs (A) and remove cover (B).

7. Remove foam precleaner (B), wing nuts (C), and paper element (D).

Inspect paper element.

8. If the paper filter element is damaged or dirty, replace filter.

9. Clean air cleaner base very carefully, preventing any dirt from falling into

carburetor.

MX37910

10. Install foam precleaner (B) onto paper filter element (D). Install paper

element onto carburetor base, and secure with two wing nuts (C). Install

air cleaner cover and tighten wing nuts.

Checking Spark Plug

c CAUTION: Avoid injury! Touching hot surfaces can burn

skin. The engine, components, and fluids will be hot if the engine

has been running. Allow the engine to cool before servicing or

working near the engine and components.

1. Park machine safely (See Parking Safely in the SAFETY section).

Service Engine - 24

Page 26

SERVICE ENGINE

• Pitted or damaged electrodes.

• Other wear or damage.

NOTE: In Canada, replace spark plug with resistor plug only.

6. Replace spark plugs as necessary.

A

Picture Note: Single cylinder Briggs and Stratton shown.

A

A

Picture Note: Twin cylinder Briggs and Stratton shown.

A

MX37938

MX37939

B

M85200

7. Check plug gap (B) with a wire feeler gauge. To change gap, move the

outer electrode. Gap must be 0.75 mm (0.030 in.).

8. Install spark plugs and tighten to 20 N•m (180 lb-in.).

9. Connect spark plug wire(s).

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine manufacturer and is

not adjustable.

If engine is operated at altitudes above 1006 m (3,300 ft), some

carburetors may require a special high altitude main jet. See your

authorized dealer.

If engine is hard to start or runs rough, check the TROUBLESHOOTING

section of this manual.

Possible engine surging will occur at high throttle with transmission in “N”

neutral and mower engagement lever disengaged. This is a normal

condition due to the emission control system.

After performing the checks in the troubleshooting section and your engine

is still not performing correctly, contact your authorized dealer.

Replacing Fuel Filter

A

MX37910

Picture Note: Twin cylinder Kawasaki shown.

2. Disconnect spark plug wire (A). For the twin cylinder engines, there is

one on each side of engine.

3. Remove each spark plug.

4. Clean spark plug carefully with a wire brush.

5. Inspect spark plug for:

• Cracked porcelain.

Service Engine - 25

c CAUTION: Avoid injury! Fuel vapors are explosive and

flammable:

• Do not smoke while handling fuel.

• Keep fuel away from flames or sparks.

• Shut off engine before servicing.

• Cool engine before servicing.

• Work in a well-ventilated area.

• Clean up spilled fuel immediately.

NOTE: Change filter when fuel is low.

1. Park machine safely. (See Parking Safely in the SAFETY section).

2. Let engine cool.

3. Raise operator’s seat.

4. Put a drain pan under fuel filter.

Page 27

SERVICE TRANSMISSION

Service Transmission

Checking Transmission (Z225)

The Z225 transmission is a sealed component. No maintenance is

required on this transmission. If you suspect any transmission problems,

A

please contact your authorized dealer.

Transmission Oil (Z425 and Z445)

NOTE: Machine is filled with John Deere Low Viscosity HY-GARD®

(J20D) transmission oil at the factory. Do not mix oils.

Use only Low Viscosity HY-GARD® (J20D) transmission oil. DO NOT use

type “F” automatic transmission fluid.