FFoorrccee

44

G6 RAID System

6-bay Desktop Enclosure

Installation Guide

May 29, 2002 • Revision B

Patent Pending

FORTRAForce4G6 Installation Guide Rev B

ii

Copyright

Copyright 1998, 1999, 2001 by JMR Electronics, Inc. All Rights Reserved. No part of this publication may

be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language, in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise, without the express written

permission of JMR Electronics, Inc.

Sales and Ordering Information

JMR Electronics, Inc.

20400 Plummer Street

Chatsworth, CA 91311 USA

Phone: 818-993-4801

Fax: 818-993-9173

Office Hours: Monday-Friday 8:00 A.M. to 5:00 P.M., Pacific Standard Time

European Corporate Headquarters

JMR Electronics United Kingdom

Iain Pickthall

P.O. Box 3058 Wokingham

Berkshire - RG40 3FU - United Kingdom

Phone: + 44-118-973-6018

Fax: + 44-118-973-7191

E-Mail: Iain@jmr.com

Internet: http://www.jmr.com

Trademarks

JMR, the JMR logo, and FORTRAare registered trademarks of JMR Electronics, Inc. All other product and

brand names are the property of their respective holders.

Changes

The material in this document is for information only and is subject to change without notice. JMR Electronics,

Inc. reserves the right to make changes to this manual and the equipment described herein without notice. JMR

has made all reasonable efforts to ensure that the information in this manual is accurate and complete. However,

JMR shall not be liable for any technical or editorial errors or omissions made herein or for incidental, special,

or consequential damage of whatsoever nature resulting from the furnishing of this manual, or operation and

performance of equipment with this manual.

Disclaimer

The original product packaging has been tested and is safe under normal shipping circumstances. Reshipping

the product without using the original product packaging will void the warranty. Do not ship the unit with

canisters or power supplies installed as this will void the warranty and could cause damage to the unit and drives.

The canisters should be packaged separately within the product packaging as provided.

FCC Information

The FORTRAequipment generates, uses and can radiate radio frequency energy. If the FORTRAArray is

not installed and used properly (that is, in strict compliance with these instructions), it may cause interference to

radio and television reception.

The FORTRAequipment and its contents are designed to comply with the limits for a Class A computing

device in accordance with the specifications in Part 15 of FCC rules. These rules are designed to provide

reasonable protection against radio interference in a commercial installation. However, there is no guarantee

that interference will not occur in a particular installation. Operation of this equipment in a residential area is

likely to cause interference, in which case the user, at his own expense, will be required to take whatever

measures are necessary to correct the interference.

Y ou may find the FCC booklet, How to Identify and Resolve Radio Interference Problems, helpful. This booklet

is available from the U.S. Government Printing Office, Washington, DC 20402. Stock #004-000-00345-4.

Printed in the USA

Part Number PUB-00282

Revision B, May, 2002 SCS

Patent Pending

WARNING: Changes or modifications, not expressly approved by the

manufacturer, could void the user's authority to use the equipment.

WARNUNG: Nicht ausdrücklich durch den Hersteller genehmigte Änderungen

oder Modifikationen können die Erlaubnis Zur benutzung der Produkte

gefährden.

FORTRAForce4G6 Installation Guide Rev B

iii

Table of Contents

1. Introduction

2/4/6/8/10/12/15-bay Product Family Features . . . . . . . . . . . . . . . . . . . . .1-1

6-bay Desktop Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Fibre Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Loop Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Dual Loops (A & B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

ID Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2. Hardware Specification

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Packaging Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Thermal Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Rotation Vibration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Fault Indication Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Fault Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Audible Alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

3. Device Installation

SCA Connection and Hot-Swapping . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Locking/Unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Canister Removal/Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

4. Fibre Channel Setup

Default Slot ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Setting Slot ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Option Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Rear I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

CH-A 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

CH-A 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

CH-B 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

CH-B 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

System Fault Audible Alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Alarm Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Table of

Contents

5. Blower Operation

Blower Removal/Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Blower Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

6. Power Supply Operation

Power Supply Removal/Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

7. Installing the Intel PCI RAID Controller

Installing the PCI Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Configuring RAID Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

8. Product Support

US Corporate Headquarters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Appendix A. Drive and Controller Manufacturers

Drive Manufacturers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

RAID Controller Manufacturers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Host Bus Adapter Manufacturers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

FORTRAForce4G6 Installation Guide Rev B

iv

FORTRAForce4G6 Installation Guide Rev B

1-1

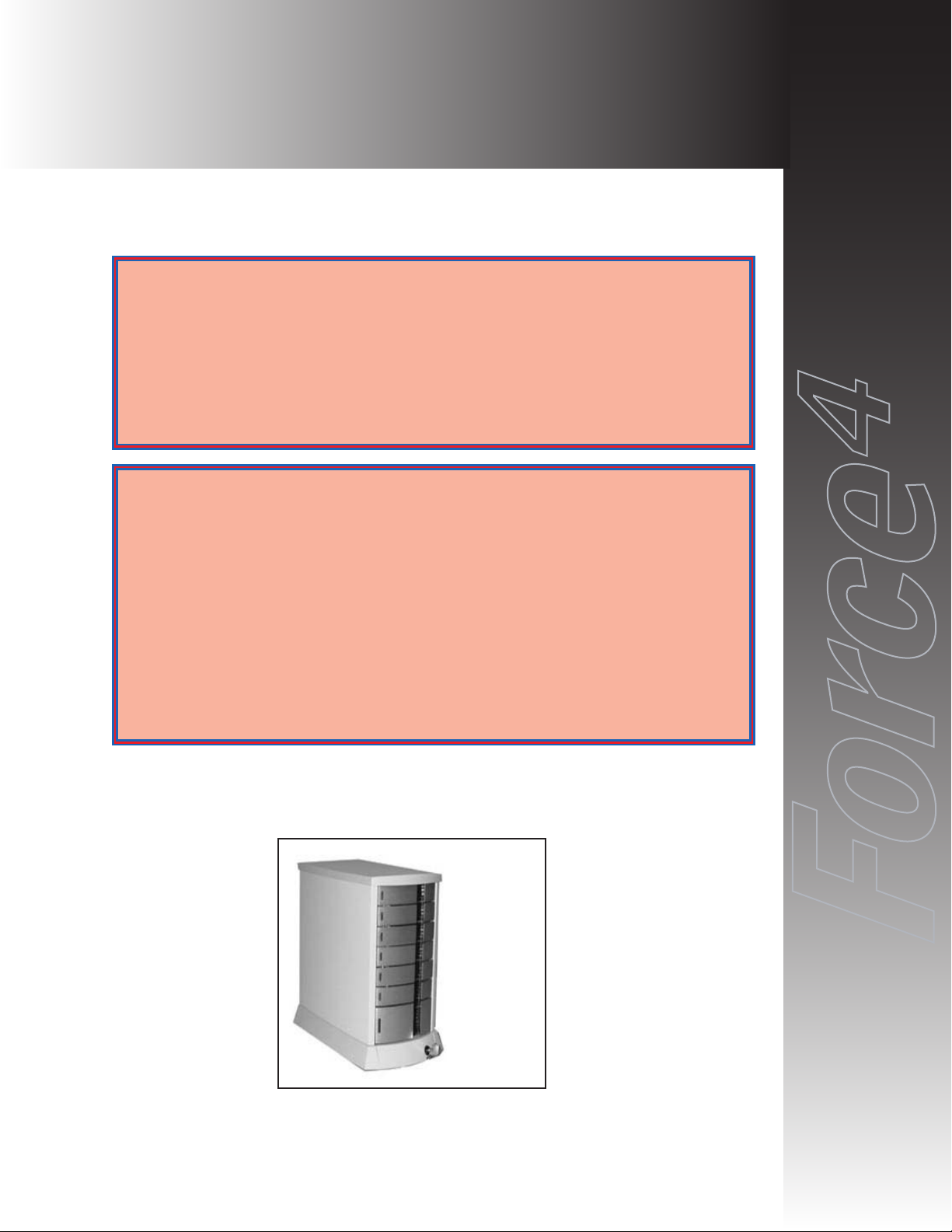

The FORTRA

FFoorrccee

44

G6 RAID System is designed for use with a host system

to provide a high-end desktop RAID storage solution. The following is a

summary of the G6 RAID System features:

• The FORTRA

FFoorrccee

44

G6 RAID System is a six drive Desk Top

enclosure that supports up to six 3.5" LP (Low-Profile) SCA (40-pin)

drives. The Fibre Channel uses SFP transceiver connections to connect

to an Intel PCI Fibre Channel 2 RAID controller supporting RAID 0 and

1. The G6 RAID System also includes four Seagate 36G or 73G HDDs.

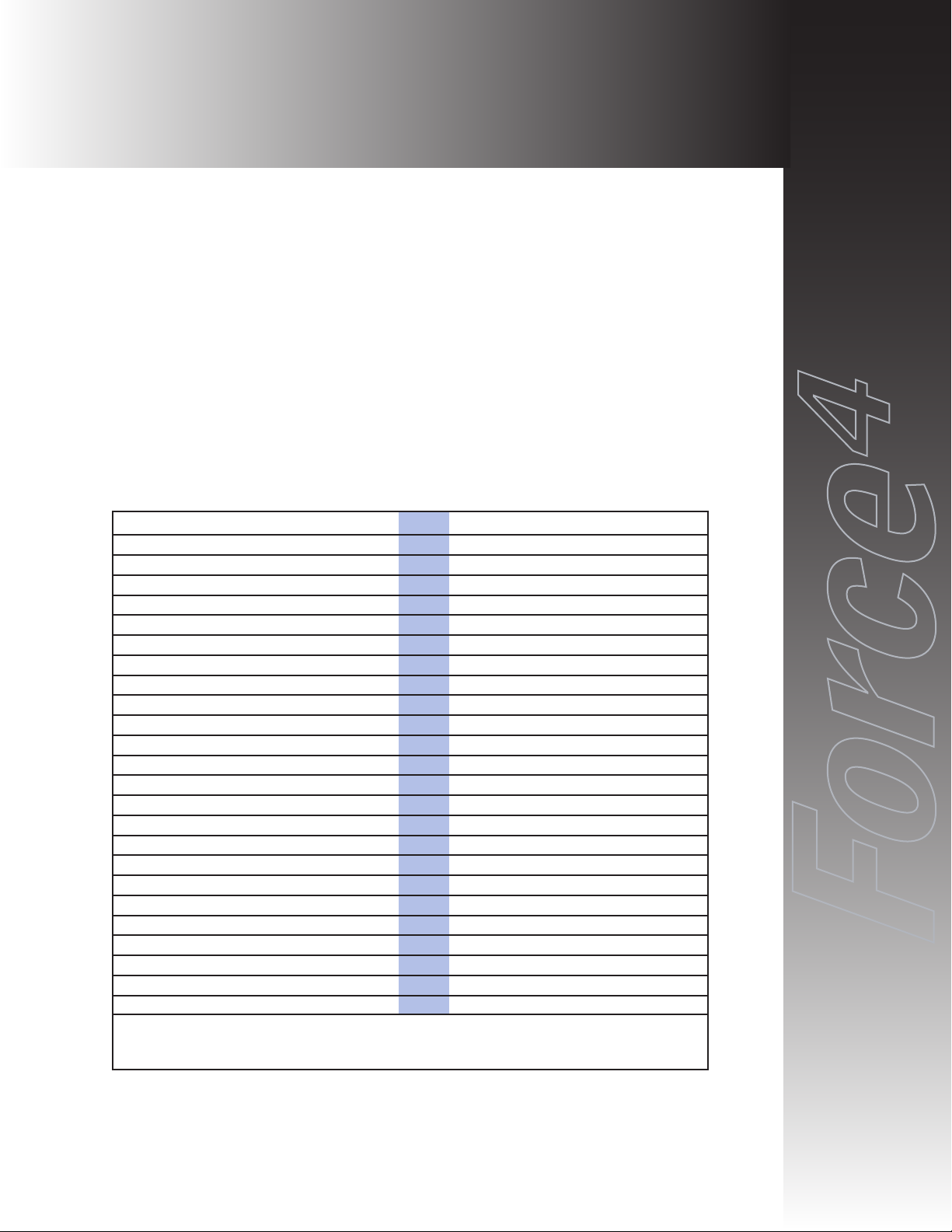

2/4/6/8/10/12/15-bay Product Family Features

FORTRAand StorBladeTMare families of high-end enclosures designed for

high-volume performance storage solutions. The following table shows the

features of the FORTRA

2/4/6/8/10/12/15-bay and StorBladeTMproducts.

1. Introduction

2-bay

4-bay

1,3

6-bay

*1,3

8-bay110-bay

*1,2

12-bay

15-bay

*1,3

StorBlade

Number of Device Bays 2 4 6 8 10 12 15 4

Number of Blowers 1 1 1 or 2 2 2 2 2 2

Number of Power Supplies 1 1 1 or 2 2 2 2 2 1 or 2

Number of I/O Channels (SCSI Only) 1 1 2 2 2 2 2

SCSI SE/LVD Supported

2 2 2 2 2 2 2

Fibre Channel Supported

2 2 2 2 2 2

Hot-Swap Canisters

2 2 2 2 2 2 2 2

Removable Power Supplies

2 2 2 2 2 2 2

Fibre only

Removable Blowers

2 2 2 2 2 2 2

Fibre Only

N+1 Power Supplies

2 2 2 2 2

Fibre only

N+1 Blowers

2 2 2 2 2 2

MIA Support (FC Only)

2 2 2 2

Loop Expansion Support (FC Only)

2 2 2 2 2 2

Daisy Chainable (SCSI Only)

2 2 2 2 2 2

Built-in Termination (SCSI Only)

2 2 2 2

Auto Termination (SCSI Only)

2 2 2 2

SAF-TE/SES Ready (Optional)

2 2 2 2

Fibre only

SAF-TE/SES Compatible

2 2 2 2

Fibre only

SCSI to SCSI RAID Support

2 2 2 2

Fibre to SCSI RAID Support

2 2

Fibre to Fibre RAID Support

2 2 2

Fibre to ATA RAID Support

2

SCSI to ATA RAID Support

2

(D)esktop/(T)ower/(R)ackmount D D DTR T TR R TR R

* 6/10/15-bay unit features apply to both Tower and Rackmount models

1 Features are based on a standard configuration with no internal host controller(s) installed

2 Fibre channel 10/15-bay enclosures have built-in SES

3 Fibre Channel 2Gb Model available. 2Gb models use SFP transceivers.

FORTRAForce4G6 Installation Guide Rev B

1-2

FORTRA

FFoorrccee

44

products use advanced mid-plane technology developed by

JMR, that allows power supplies, drives, and all other enclosure components to

interface into a single board. This provides superior performance and easy

connectivity.

The FORTRA

FFoorrccee

44

G6 RAID System host interface supports 2G Fibre

Channel interfaces as long as the drives have SCA connectors. Connection to the

Intel PCI Fibre Channel 2 host system is made using SFP transceiver connectors.

FORTRA

Force

4

G6 RAID System Components

The FORTRA

FFoorrccee

44

G6 RAID System includes the following components:

One - 6-Bay 2G Fibre Desk Top enclosure

One - Intel PCI Fibre Channel 2 RAID controller

Four - Seagate 36G or 73G HDDs

Two - 2G Copper Fibre Cables (HSSDC to HSSDC2)

6-bay Desktop Specifications

Dimensions/Weight

Unit Weight 19.7 lbs. (9.0kg)

Height 11-1/2" (292mm)

Width 7-3/4" (197mm)

Depth 12-1/2" (316mm)

Power Supply

Quantity: 1

Power: 300 Watts

Input: 115-230 VAC; 50-60Hz (auto-switching)

Output: +5V @ 20A

+12V @ 17A

Blower

Quantity: 1

Size: 125mm (4.92") each

Air Flow: 27.2CFM (0.76m

3

/min)

Noise: 51dB(A)

Fibre Channel Features

Loop Expansion

FORTRAFibre Channel enclosures include a loop expansion I/O connector on

each port.

Dual Loops (A & B)

A single loop is required for unit operation however both loops can be used to

connect to different hosts, dual host adapters, and other devices, for flexible and

even redundant configurations. For specific connection and installation

information, refer to Chapter 4

.

ID Selection

0-127 device ID addresses are addressable and can be easily set-up via ID jumpers

for each slot. For specific connection and installation information, refer to

Chapter 4

.

FORTRAForce4G6 Installation Guide Rev B

1-3

FORTRAForce4G6 Installation Guide Rev B

2-1

This chapter covers specification information for the FORTRA

FFoorrccee

44

G6 RAID

System enclosure.

Environmental Specifications

Operating Temperature: 5°C to 40°C (41°F to 104°F)

Storage Temperature: 0°C to 65°C (32°F to 149°F)

Maximum ambient temperature is dependent on the recommended temperature to

meet the MTBF rating as specified by the manufacturer of the installed devices.

Electrical Specifications

AC Inlet Type: IEC320/EN60320

Power Cord: NEMA5-15P

Power Supply: Auto-switching for 110/220V operation

Agency Compliance

FORTRAenclosures have been designed and built to comply with the FCC

Class A, UL, CSA/TUV, CE, and C-Tick standards. For more information on

FCC Class A compliance, see page 2.

Packaging Specifications

FORTRApackaging has been designed to be reusable and recyclable. Drives

may be installed and shipped in the canisters as long as the canisters are in their

original packaging location and are not installed in the enclosure. Shipping the

unit with canisters and/or power supplies installed in the enclosure may cause

damage to the enclosure or to the drives and will void the warranty.

Packaging complies with ISTA (International Safe Transit Association) standards

and has been ISTA certified.

Each canister is pre-packaged in an anti-static bag. Do not throw the packaging

away if the product is intended for re-shipping. When transporting or shipping a

JMR approved shipping container must be used.

SAFETY TIP: Reshipping the enclosure with canisters, drives, or power

supplies installed in the enclosure may cause damage to these

components and will void the warranty

SICHERHEITSHINWEIS: Der Versand des Gehäuses mit eingebauten

Einschüben, Platten und Netzteilen kann zur Beschädigung dieser

Komponenten führen und somit den Garantieanspruch gefährden.

2. Hardware Specification

Disclaimer

The original product packaging has been tested and is safe under normal shipping

circumstances. Reshipping the product without using the original product

packaging will void the warranty. Do not ship the unit with canisters and/or

power supplies installed in the enclosure as this will void the warranty and could

cause damage to the unit and drives. The canisters should be packaged separately

within the product packaging, as provided.

Thermal Specifications

FORTRAenclosures have been designed to meet the air-flow/cooling

requirements for popular 7,200, 10,000 and 15,000 RPM disk drives. Using a

high performance blower, air is pulled in from all open vents and exhausted out

the back of the unit.

Rotation Vibration Specifications

FORTRAenclosures have been designed to meet the rotation vibration/shock

requirements for popular 7,200, 10,000 and 15,000 RPM disk drives.

Fault Indication Features

This section reviews the indicators that will notify the user of a power supply or

blower that is in a fault state. More information is available in Chapter 5

(blowers) and Chapter 6 (power supply).

Fault Indicators

All slots will blink 'Red' in color on a blower fault. On a power supply fault, the

front power supply LED will blink on and off.

Audible Alert

On a blower or power supply fault, an audible alert will sound. Pressing the Alert

Reset button on the back of the unit will turn the alert off.

FORTRAForce4G6 Installation Guide Rev B

2-2

FORTRAForce4G6 Installation Guide Rev B

3-1

This chapter covers Fibre Channel device installation for FORTRA

FFoorrccee

44

G6

desktop enclosure.

SCA Connection and Hot-Swapping

The unit uses SCA-2 type connectors which provide a safe means of

connection/disconnection when hot-swapping devices. In order to utilize this

feature, the host adapter or RAID controller and host operating software must

support the feature. Any SCA drive is capable of plugging directly into the

backplane of the unit and should not require any additional cabling or

connections.

Locking/Unlocking

A front lock prevents unwanted removal of the canisters including the power

supply canister. Before attempting to remove any drive or the power supply,

insure that the enclosure is in the Unlocked position.

Canister Removal/Insertion

1. The photo to the right shows the canister in a locked

position.

2. Pull the handle out to unlock the canister from the

FORTRA

unit. Ensure that the thumb is placed

below the line. Pressing the thumb against the

Status LED lens could break it. Notice that the

locking tab slides down as the handle is pulled out.

3. Pull the canister straight out to remove. Ensure

that any installed devices are spun down before

full removal to prevent damage to the drive.

Follow the steps in reverse to reinstall.

SAFETY TIP: After disengaging a device from the enclosure, allow 10 seconds

before pulling the canister out of the unit. This allows the device to

properly spin/shut down before transport.

SICHERHEITSHINWEIS: Nachdem ein Einschub vom Gehäuse wie in "Step

3" gezeigt gelöst wurde, warten Sie bitte ca. 10 Sekunden bevor der

Einschub ganz heraus gezogen wird Dies ermöglicht den Auslauf der

Festplatte bis zum vollständigen Stillstand der rotierenden Scheiben für

einen sicheren Transport.

3. Device Installation

Drive Installation

Device mounting screws are included with the unit for device mounting. The

JMR part number for the #6-32" mounting screws is HDS-01906.

1. After removing the canister, place it on a static free surface along with the

device to be installed.

2. Place the device in the canister and mount it using the provided screws

(use 4 screws to mount the drive).

3. Replace the canister into the unit by following the steps for Removal of a

Device Canister but in reverse order.

FORTRAForce4G6 Installation Guide Rev B

3-2

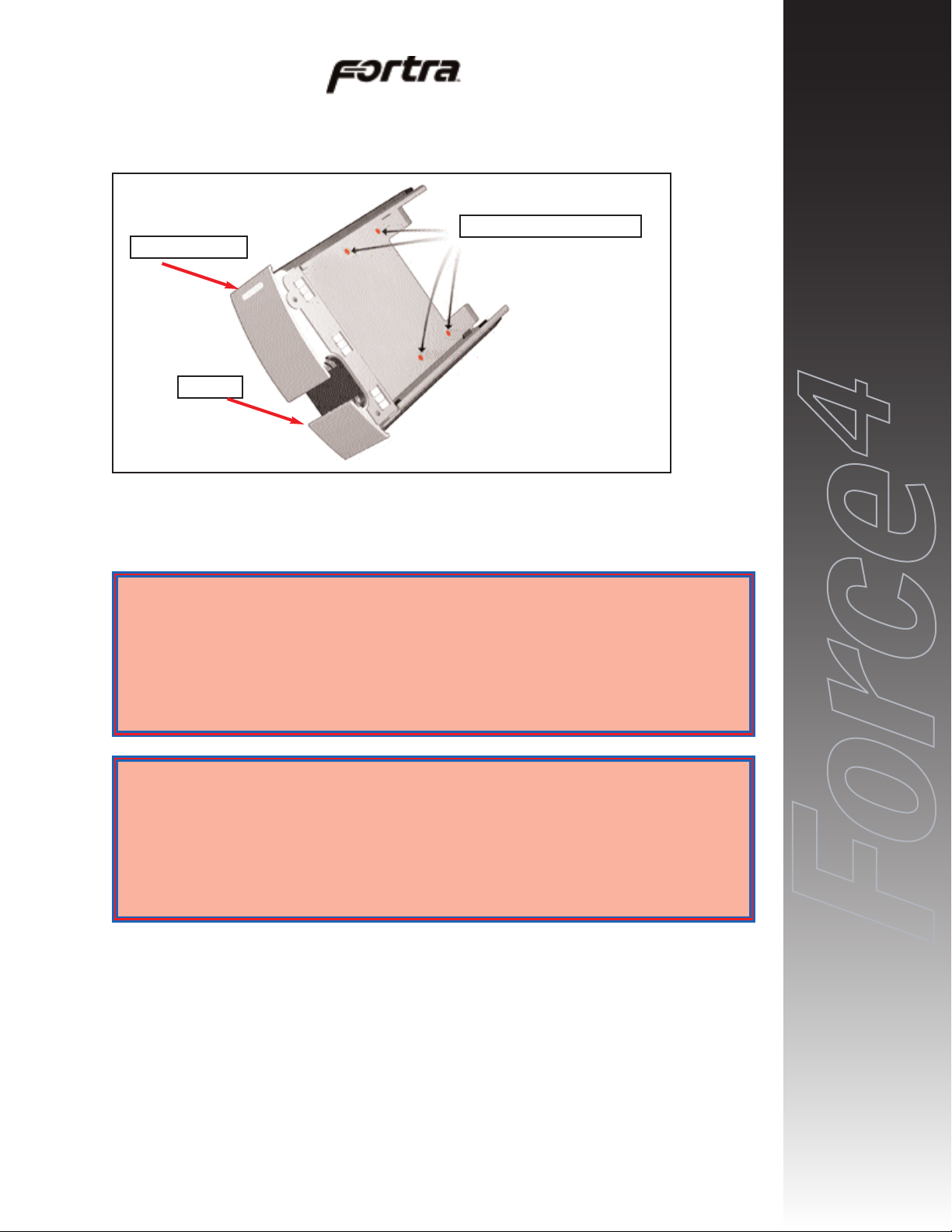

Device Mounting Holes (4)

Status Indicators

Handle

WARNING: Before device installation, alleviate any electro-static discharge by

touching a grounded metal assembly. Static can be potentially damaging

to enclosure components.

WARNUNG: Berühren Sie vor der Festplatteninstallation geerdete

Metallgegenstände, um elektro statische Aufladung abzuleiten. Statische

Aufladung kann elektronische Gehäusekomponenten schwer beschädigen.

WARNING: The #6-32 mounting screws that are provided have been specially

designed to fit the canisters. Do not install the device using any other

screws than the ones provided.

WARNUNG: Die mitgelieferten Befestigungsschrauben #6-32 wurden speziell

für die Einschübe angefertigt und zur Befestigung der Festplatte sollten

Sie keinesfalls andere als diese verwenden.

4. Repeat steps 1 through 3 until all devices are installed.

5. Configure ID, and other options as required (see Chapter 4

).

6. Establish host connection (see Chapter 4

).

FORTRAForce4G6 Installation Guide Rev B

3-3

This chapter covers the Fibre Channel setup for the FORTRA

FFoorrccee

44

G6

system.

This figure shows the slot numbering sequence used to refer to device canisters

and also shows the default ID value for each slot.

FORTRAForce4G6 Installation Guide Rev B

4-1

WARNING: Take care when connecting the unit to an AC power source to

ensure that it is plugged-in to a circuit of the appropriate rating (110v or

220v). For safe operation, the circuit should have over-current protection

to prevent damage to the unit in the event of circuit overloading.

WARNUNG: Vergewissern Sie sich, daß die Netzspannung (220V / 110V)

korrekt eingestellt ist, bevor Sie das Gerät mit dem Stromnetz verbinden.

Zur Sicherheit sollte das Netz über einen Überspannungsschutz zur

Vermeidung von Schäden im Falle einer Überlast verfügen.

WARNING: When connecting the unit to an AC outlet or power strip, ensure

that the outlet has the proper connection for grounding. The AC power

cables included with the unit have three prongs, one of which is used for

the ground connection. Do not use a two prong AC cable with the unit

since this will not allow for proper unit grounding and could cause

problems with normal unit operation.

WARNUNG: Bei der Verbindung der Unit mit einer Steckdose oder einer

Verteilerdose sollten sie auf eine korrekte Erdung derselben achten. Die

mitgelieferten Kaltgeräteanschlußkabel habe 3 Kontakte, von denen

einer zur Erdung verwendet wird. Verwenden Sie kein Stromkabel mit 2

Anschlüssen, da dieses keine korrekte Erdung ermöglicht und Probleme

während des regulären Betriebs verursachen kann.

4. Fibre Channel Setup

Slot 0, ID 0

Slot 1, ID 1

Slot 2, ID 2

Slot 3, ID 3

Slot 4, ID 4

Slot 5, ID 5

Power Supply

Canister Lock

Default Slot ID

Drive Bay Default ID/Jumper

Slot 0 (top) ID 0 / W1

Slot 1 ID 1 / W2

Slot 2 ID 2 / W3

Slot 3 ID 3 / W4

Slot 4 ID 4 / W6

Slot 5 ID 5 / W7

Setting Slot ID

The ID for each slot can be set using jumpers located on the backplane of the unit.

To access the jumpers the blower must be removed. To remove the blower refer

to Chapter 5

.

The following tables show the jumper settings for Fibre ID’s 0-127.

FORTRAForce4G6 Installation Guide Rev B

4-2

Jumper 6

Jumper 5

Jumper 4

Jumper 3

Jumper 2

Jumper 1

Jumper 0

W1 - Slot 0 ID

Jumpers

W2 - Slot 1 ID

Jumpers

W3 - Slot 2 ID

Jumpers

W4- Slot 3 ID

Jumpers

W6 - Slot 4 ID

Jumpers

W7 - Slot 5 ID

Jumpers

NOTE: W1 sits above

W2 behind a metal

plate. W1 can not be

seen in this photo.

FORTRAForce4G6 Installation Guide Rev B

4-3

FibreIDJmp0 Jmp1Jmp2Jmp3Jmp4Jmp5Jmp

6

0 C C C C C C C

1 O C C C C C C

2 C O C C C C C

3 O O C C C C C

4 C C O C C C C

5 O C O C C C C

6 C O O C C C C

7 O O O C C C C

8 C C C O C C C

9 O C C O C C C

10 C 0 C O C C C

11 O 0 C O C C C

12 C C O O C C C

13 O C O O C C C

14 C 0 O O C C C

15 O 0 O O C C C

16 C C C C O C C

17 O C C C O C C

18 C O C C O C C

19 O O C C O C C

20 C C O C O C C

21 O C O C O C C

22 C O O C O C C

23 O O O C O C C

24 C C C O O C C

25 O C C O O C C

26 C O C O O C C

27 O O C O O C C

28 C C O O O C C

29 O C O O O C C

30 C O O O O C C

31 O O O O O C C

32 C C C C C 0 C

33 O C C C C 0 C

34 C O C C C 0 C

35 O O C C C 0 C

36 C C O C C 0 C

37 O C O C C 0 C

38 C O O C C 0 C

39 O O O C C 0 C

40 C C C O C O C

41 O C C O C O C

42 C O C O C O C

43 O O C O C O C

44 C C O O C O C

45 O C O O C O C

46 C O O O C O C

47 O O O O C O C

48 C C C C O O C

49 O C C C O O C

FibreIDJmp0 Jmp1Jmp2Jmp3Jmp4Jmp5Jmp

6

50 C O C C O O C

51 O O C C O O C

52 C C O C O O C

53 O C O C O O C

54 C O O C O O C

55 O O O C O O C

56 C C C O O O C

57 O C C O O O C

58 C O C O O O C

59 O O C O O O C

60 C C O O O O C

61 O C O O O O C

62 C O O O O O C

63 O O O O O O C

64 C C C C C C O

65 O C C C C C O

66 C O C C C C O

67 O O C C C C O

68 C C O C C C O

69 O C O C C C O

70 C O O C C C O

71 O O O C C C O

72 C C C O C C O

73 O C C O C C O

74 C O C O C C O

75 O O C O C C O

76 C C O O C C O

77 O C O O C C O

78 C O O O C C O

79 O O O O C C O

80 C C C C O C O

81 O C C C O C O

82 C O C C O C O

83 O O C C O C O

84 C C O C O C O

85 O C O C O C O

86 C O O C O C O

87 O O O C O C O

88 CO C C O O C O

89 CO C C O O C O

90 CO O C O O C O

91 CO O C O O C O

92 C C O O O C O

93 O C O O O C O

94 C O O O O C O

95 O O O O O C O

96 C C C C C 0 O

97 O C C C C 0 O

98 C O C C C 0 O

99 O O C C C 0 O

Legend: O = Open (no jumper) C = Closed (jumper on)

Option Settings

Additional drive option jumpers for remote and delayed start are located on the

unit I/O board. They must be set at the factory.

Remote Start

This feature is disabled by default and can be enabled for OEM use.

Delayed Start

This feature is disabled by default and can be enabled for OEM use.

Rear I/O Connections

The rear of the unit and the I/O connections are described below.

FORTRAForce4G6 Installation Guide Rev B

4-4

FibreIDJmp0 Jmp1Jmp2Jmp3Jmp4Jmp5Jmp

6

100 C C O C C O O

101 O C O C C O O

102 C O O C C O O

103 O O O C C O O

104 C C C O C O O

105 O C C O C O O

106 C O C O C O O

107 O O C O C O O

108 C C O O C O O

109 O C O O C O O

110 C 0 O O C O O

111 O 0 O O C O O

112 C C C C O O O

113 O C C C O O O

114 C 0 C C O O O

115 O 0 C C O O O

116 C C O C O O O

117 O C O C O O O

118 C O O C O O O

119 O O O C O O O

120 C C C O O O O

121 O C C O O O O

122 C O C O O O O

123 O O C O O O O

124 C C O O O O O

125 O C O O O O O

126 C O O O O O O

127 O O O O O O O

CH-A 1

Loop A connection 1. This is a SFP fibre channel connector used to connect to a

host system or to an expansion chassis for Loop A.

CH-A 2

Loop A connection 2. This is a SFP fibre channel connector used to connect to a

host system or to an expansion chassis for Loop A.

CH-B 1

Loop B connection 1. This is a SFP fibre channel connector used to connect to a

host system or to an expansion chassis for Loop B.

CH-B 2

Loop B connection 2. This is a SFP fibre channel connector used to connect to a

host system or to an expansion chassis for Loop B.

System Fault Audible Alert

A system fault includes over temperature, power fault, or blower fault. The

buzzer will sound off with a sequence of beeps to indicate the fault that has

occurred.

2 beeps = Temperature Fault

3 beeps = Blower Fault;

5 beeps = Power Supply Fault.

Alarm Reset

This button will turn off the audible alert. Pressing this button will not reset

power to the unit, it will only silence the alarm.

FORTRAForce4G6 Installation Guide Rev B

4-5

CH B 2

CH B 1

Alarm Reset

Button

CH A 1 CH A 2

AC Input

Power

On/Off

FORTRAForce4G6 Installation Guide Rev B

5-1

This chapter covers operations of the blower for the FORTRA

FFoorrccee

44

G6 units.

Refer to Chapter 1 for blower specifications. The blower is easily removable.

Failure to replace a non-working blower within a reasonable period of time may

expose drives to extreme heat that could cause loss of data.

The blower is located on the back of the unit. If there is a blower fault, both of

the device canister status LEDs will blink ‘Red’ and an audible alert will sound.

Pressing the Alarm Reset button located on the back of the unit will turn off the

audible alert.

Blower Removal/Insertion

The blower is designed to be easily installed and removed.

1. Unfasten the blower thumbscrew by

turning counterclockwise. A Philips

head screwdriver can be used if the

thumbscrew is too tight to turn by

hand.

2. Remove the blower canister by pulling out

on the thumbscrews and lifting it out of

the bottom two slots.

WARNING: Blowers are a system critical component. Non-operating blowers

should be replaced as soon as possible to avoid data loss or device failure.

WARNUNG: Gebläse sind für die Funktion wichtige Komponenten. Nicht

funktionierende Gebläse sollten so schnell wie möglich ersetzt werden,

um Datenverluste oder Fehlfunktionen zu vermeiden.

WARNING: Because the blower continues to spin for a short while, the unit

should be turned off at least 10 seconds before replacing the fan to

prevent injury.

WARNUNG: Um Verletzungen zu vermeiden, sollte das Gerät wenigstens 10

Sekunden vor Entnahme der Gebläse ausgeschaltet werden, da die

Flügelräder der Gebläse nachlaufen.

5. Blower Operation

3. Unplug the blower from the backplane. The connector

is keyed so that it can be reinstalled correctly and has

also been placed through a holder on the fan bracket to

keep it out of the way during fan installation and

removal.

Reverse the steps to reinstall the blower.

The following figure shows the blower intake access hole.

Contact with the access hole must be avoided while the blower

is running to prevent injury.

Blower Replacement

If the blower has stopped running or the front device canister status LEDs are all

blinking ‘Red’, the blower may need to be replaced.

Before replacing, the cable connection should be checked to ensure that the

connector is firmly seated and that there is nothing blocking the blower intake

blades that could cause interference. If you believe a blower is in a nonfunctional

state, please contact the place of purchase for repair or replacement.

The JMR part numbers for a replacement blower is shown in the table below.

Replacement parts include the canister with the fan.

Model JMR Part Number

4-bay FAD-00014

FORTRAForce4G6 Installation Guide Rev B

5-2

WARNING: Avoid direct contact with the blower intake access hole while the

blower is running. The blower operates at high speeds and can cause

injury.

WARNING: Blowers are a system critical component. Non-operating blowers

should be replaced as soon as possible to avoid data loss or device failure.

WARNUNG: Gebläse sind für die Funktion wichtige Komponenten. Nicht

funktionierende Gebläse sollten so schnell wie möglich ersetzt werden,

um Datenverluste oder Fehlfunktionen zu vermeiden.

This chapter covers the operations of the power supply for FORTRA

FFoorrccee

44

G6 units. For operation, the AC cord (included) must be connected to the AC

Inlet at the back of the unit, and the On/Off switch must be switched ON. The

Status LED on the power supply will light to indicate the power supply is

functioning properly. If the power supply experiences a problem and cannot

operate within its normal specifications, the Status LED will light ‘Red’ and an

audible alert will sound. Pressing the Alarm Reset button located on the back of

the unit will turn off the audible alert.

Power Supply Removal/Insertion

Follow the following steps to remove a power supply in a 4-bay unit.

1. Unlock the unit (see Chapter 3 for Device

Installation instructions) & open the handle

by pulling out. This action will disconnect

the supply canister from the unit.

2. Grab the handle and pull straight out.

3. Carefully remove the supply from the unit. It is ok to grab the sides of

the supply to fully remove it.

Reverse the steps to reinstall the power supply.

FORTRAForce4G6 Installation Guide Rev B

6-1

Handle

Status LED

The Identification

symbol warns the

user that the

canister houses

an electrical

device that should

not be tampered

with.

6. Power Supply Operation

Power Supply Replacement

If the Power supply Status LED indicator is ‘Red’, the power supply may need to

be replaced. The unit should be reset (turned on & off), and the power supply

should be removed and then reinstalled. The AC cable connection in the back of

the unit should be checked to ensure that the plug is firmly seated in the power

supply. If the Status LED indicator is still ‘Red’, then the power supply should

be replaced.

If the power supply fan is not functioning but the power supply still works, the

power supply should be replaced as soon as possible. Leaving the power supply

running without the fan could cause the power supply to overheat and shutdown

at any time and may cause damage to the supply and other installed devices.

If you believe a power supply is in a nonfunctional state, please contact the place

of purchase for repair or replacement.

The JMR part number for a replacement power supply is shown in the following

table. Replacement parts include the canister with the power supply.

Model JMR Part Number Color

4-bay DSSH-085 Silver

4-bay DSSH-085-02 Black

FORTRAForce4G6 Installation Guide Rev B

6-2

This chapter covers the installation of the Intel PCI RAID Controller that is

shipped with the FORTRA

Force4 G6 RAID System. The model number of

the PCI RAID Controller is ICP Vortex number GDT8122RZ (ICP Vortex is a

wholly owned subsidiary of Intel Corporation)

Installing the PCI Controller

To install the PCI Controller, perform the following steps:

1) Switch off the PCI computer and disconnect all cables. Ensure that

the power cord is removed first.

2) Following the instructions in the computer manual, open the case of

the PCI computer, so that you have easy access to the PCI expansion

slots.

3) Select a free 64 Bit PCI bus-master slot or 32 Bit PCI bus-master slot

and remove the metal bracket, following the instructions in your PCI

computer manual. It is essential that the ICP Controller is plugged

into a bus-master slot (it will NOT work in a slave or non-busmaster

slot).

4) Push the ICP Controller firmly into the correct PCI bus-master slot.

Make sure that the controller fits tightly into it, and that the external

connectors stick out of the computer case. Now, fix the ICP Controller

by tightening the screw of its bracket.

5) Reconnect the PCI computer systems covers, cables and lastly the

power cord.

6) Before powering up the PCI computer system, connect the Fibre

Channel cable/cables to the G6 sub-system. The cable to be used

should have a HSSDC connector at one end and a HSSDC2 connector

at the other end.

7) The PCI computer system is now ready to be powered up.

Configuring RAID Sets

To configure the RAID sets, refer to the ICP Vortex User Manual located on the

CD shipped with the FORTRAForce4G6 RAID System.

FORTRAForce4G6 Installation Guide Rev B

7-1

7. Installing the Intel

PCI RAID Controller

FORTRAForce4G6 Installation Guide Rev B

8-1

For current information on this product, including updates to the manual and

technical support related issues, please contact the sales support section of our

web page at www.jmr.com, or you can contact our Technical Support division

directly at the address below.

US Corporate Headquarters

JMR Electronics, Inc.

ATTN: Technical Support Division

20400 Plummer St.

Chatsworth, CA 91311

Customer Support: (818) 739-1140

E-mail: techsupport@jmr

.com

Office Hours: Monday-Friday 8:00 A.M. to 5:00 P.M., Pacific Standard Time

Internet: http://www

.jmr.com

Manual Changes

Revision A - Initial Release

Revision B - Changed from 4-bay G4 to 6-bay G6

8. Product Support

FORTRAForce4G6 Installation Guide Rev B

A-1

Drive Manufacturers

Fujitsu

Internet Address: www

.fcpa.com

Hitachi

Internet Address: www

.hitachi.com

IBM (International Business Machines Corporation)

Internet Address: www

.ibm.com

Maxtor

Internet Address: www

.maxtor.com

Seagate Technology

Internet Address: www

.seagate.com

RAID Controller Manufacturers

Adaptec, Inc.

Internet Address: www

.adaptec.com

Chaparral Network Storage

Internet Address: www

.chaparralnet.com

Digi-Data Corporation

Internet Address: www

.digidata.com

Infortrend Corporation

Internet Address: www

.infortrend.com

Intel ICP VORTEX (Intelligent Computer Peripherals)

Internet Address: www

.icp-vortex.com

Mylex Corporation

Internet Address: www

.mylex.com

Silicon Image, CMD Storage Systems

Internet Address: www

.cmd.com

Appendix A. Drive and Controller

Manufacturers

Host Bus Adapter Manufacturers

Adaptec, Inc.

Internet Address: www

.adaptec.com

Antares Microsystems

Internet Address: www

.antares.com

Emulex Corporation

Internet Address: www

.emulex.com

JNI Corporation

Internet Address: www

.jni.com

QLogic Corp.

Internet Address: www

.qlogic.com

FORTRAForce4G6 Installation Guide Rev B

A-2

Loading...

Loading...