Page 1

O P E R A T O R ’ S M A N U A L

Set-Up Instructions and Parts Catalog for

Torsion-Flex Soil Conditioners

Models

TF2, TF212 and TF215

(serial # 2250 and higher)

12’ to 45’ Working Width

Torsion-Flex Double Rolling Baskets

J. & M. Manufacturing Co., Inc.

P.O. Box 547

Fort Recovery, OH 45846

Phone: (419) 375 2376 Fax: (419) 375-2708

E-mail: sales@jm-inc.com

Website: www.jm-inc.com

REV. 03-28-11

Pg. 1

Page 2

TO THE DEALER:

Read manual instructions and safety rules. Make sure all items on the Dealer’s Pr e-Delivery and Delivery Check

Lists in the Operator’s Manual are completed before releasing equipment to the owner.

The dealer must complete the Warranty Registration Card attached to the front inside cov er of this manual and retu rn

to J. & M. Mfg. Co., Inc. at the address indicated on the card. Warranty claims wi ll be denied if the Warranty

Registration Card has not been completed and returned.

EXPRESS WARRANTY:

J. & M. Mfg. Co. Inc. warrants against defects in construction or materials for a period of ONE year. We reserve the

right to inspect and decide whether material or construction was faulty or whether abuse or accident voids our

guarantee.

Warranty service must be performed by a dealer or service c enter authorized by J. & M. Mfg. Co. Inc. to sell and/or

service the type of product involved, which will use onl y new or remanufactured p arts or components furnished b y J.

& M. Mfg. Co. Inc. Warranty service will be performed without charge to the purchaser for parts or labor based on th e

Warranty Labor Times schedule. Under no circumstance will allowable labor times extend beyond the maximum

hours indicated in the Warranty Labor Times schedule for each warranty procedure. The purchaser will be

responsible, however, for any service call and/or transportation of the product to and from the dealer or service

center’s place of business, for any premium charged for overtime labor requested by the purchaser, and for any

service and/or maintenance not directly related to any defect covere d under the warranty. Costs associated with

equipment rental, product down time, or product disposal are not warrantable a nd will not be accepted under any

circumstance.

Each warranty term begins on the date of product delivery t o the purchas er. Under no circumstance will warranty be

approved unless (i) the product warranty registration card ( attached to the inside of the Operator’s Manual) has been

properly completed and submitted to the equipment manufact urer. This Warranty is effective only if the warranty

registration card is returned within 30 days of purchase.

This warranty does not cover a component which fails, malfunctions or is damaged as a result of (i) improper

modification or repair, (ii) accident, abuse or improper use, (iii) improper or insufficient mainte nance, or (iv) normal

wear or tear. This warranty does not cover products that are previously owned and extends solely to the original

purchaser of the product. Should the original purchaser sell or other wise transfer this product to a third party, this

Warranty does not transfer to the third part y purchas er i n an y way. J. & M. Mfg. Co. Inc. makes no warranty, express

or implied, with respect to tires or other parts or accessories not manufactured by J. & M. Mfg. Co. Inc. Warranties

for these items, if any, are provided separately by their respective manufacturers.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS,

IMPLIED OR STATUTORY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

PARTICULAR PURPOSE.

In no event shall J. & M. Mfg. Co. Inc. be liable for specia l, direct, incidental or consequential dam ages of any kind.

The exclusive remedy under this Warranty shall be repair or replacement of the defective component at J. & M. Mfg.

Co. Inc’s. option. This is the entire agreement between J. & M. Mfg. Co. Inc. and the Owner about warrant y and no J.

& M. Mfg. Co. Inc. employee or dealer is authorized to make any additional warranty on behalf of J. & M. Mfg. Co.

Inc.

The manufacturer reserves the right to make product design and material changes at any time without notice. They

shall not incur any obligation or liab ility to in corporate such changes and i mprovements in pr oducts previousl y sold to

any customer, nor shall they be obligated or liable for the replacement of previously sold products with products or

parts incorporating such changes.

SERVICE:

The equipment you have purchased has b een carefully manufactured to provide dependable and sat isfactory use.

Like all mechanical products, it will require cleaning and upk eep. Lubricate the unit as specified. Observe all s afety

information in this manual and safety signs on the equipment.

For service, your authorized J. & M. dealer has trained mec hanics, genuine J. & M. service parts, a nd the necessar y

tools and equipment to handle all your needs.

Use only genuine J. & M. service parts. Substitute parts may void the warranty and may not meet standards required

for safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

Serial # ___________ Purchase Date: _______ Purchased From: ________ ____________________________

Please provide this information to your dealer to obtain the correct parts:

Pg. 2

Page 3

GENERAL INFORMATION

TO THE OWNER:

The purpose of this manual is to assist you in operating and maintaining your running gear in a safe

manner. Read it carefully. It furnishes information and instructions that will help you achieve years of

dependable performance and help maintain safe operating conditions. If this machine is used by an

employee or is loaned or rented, make certain that the operator(s), prior to operating:

1. Is instructed in safe and proper use.

2. Reviews and understands the manual(s) pertaining to this machine.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause

damage to equipment. The terms CAUTION, WARNING and DANGER are used in conjunction with the

Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for items of

personal safety. When you see this symbol, carefully read the message that follows and be alert to the

possibility of personal injury or death.

This Safety-Alert symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result

in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

Pg. 3

Page 4

GENERAL INFORMATION (continued)

BOLT TORQUE CHART

Always tighten hardware to these values unless a different torque or tightening procedure is listed for a

specific application.

Fasteners must always be replaced with the same grade as specified in the manual parts list.

Always use the proper tool for tightening hardware. SAE for SAE hardware and Metric for metric

hardware.

Make sure fastener threads are clean and you start the thread engagement properly. All torque values

are given to specification used on hardware defined by SAE J1701 & J1701M (Jul 96).

Pg. 4

Page 5

SPECIFICATIONS

A

Specifications Basket Sizes and Layout

Working

Width

12’ 12’ 12’ N/A 2,195 lbs. 6’ 6’

13’ 13’ 12’ N/A 2,310 lbs. 4’ 5’ 4’

14’ 14’ 12’ N/A 2,425 lbs. 5’ 4’ 5’

15’ 15’ 15’ N/A 2,540 lbs. 5’ 5’ 5’

16’ 16’ 15’ N/A 2,655 lbs. 5’ 6’ 5’

Model TF2

17’ 17’ 15’ N/A 2,770 lbs. 6’ 5’ 6’

18’ 18’ 15’ N/A 2,885 lbs. 6’ 6’ 6’

20’ 13’ 5” 12’ 4’ 4,415 lbs. 4’ 6’ 6’ 4’

22’ 13’ 5” 12’ 5’ 4,645 lbs. 5’ 6’ 6’ 5’

23’ 13’ 5” 12’ 5’ 6” 4,760 lbs. 5.5’ 6’ 6’ 5.5’

24’ 13’ 5” 12’ 6’ 4,875 lbs. 6’ 6’ 6’ 6’

25’ 13’ 5” 12’ 6’ 6” 4,990 lbs. 3’ 3.5’ 6’ 6’ 3.5’ 3’

26’ 13’ 5” 12’ 7’ 5,105 lbs. 3.5’ 3.5’ 6’ 6’ 3.5’ 3.5’

27’ 13’ 5” 12’ 7’ 6” 5,220 lbs. 3.5’ 4’ 6’ 6’ 4’ 3.5’

28’ 13’ 5” 12’ 8’ 5,335 lbs. 4’ 4’ 6’ 6’ 4’ 4’

29’ 13’ 5” 12’ 8’ 6” 5,450 lbs. 3.5’ 5’ 6’ 6’ 5’ 3.5’

30’ 13’ 5” 12’ 9’ 5,565 lbs. 4’ 5’ 6’ 6’ 5’ 4’

Model TF212

31’ 13’ 5” 15’ 9’ 6” 5,680 lbs. 3.5’ 6’ 6’ 6’ 6’ 3.5’

32’ 13’ 5” 15’ 10’ 5,795 lbs. 5’ 5’ 6’ 6’ 5’ 5’

33’ 13’ 5” 15’ 10’ 6” 5,910 lbs. 5’ 5.5’ 6’ 6’ 5.5’ 5’

34’ 13’ 5” 15’ 11’ 6,025 lbs. 5.5’ 5.5’ 6’ 6’ 5.5’ 5.5’

35’ 13’ 5” 15’ 11’ 6” 6,140 lbs. 5.5’ 6’ 6’ 6’ 6’ 5.5’

36’ 13’ 5” 15’ 12’ 6,255 lbs. 6’ 6’ 6’ 6’ 6’ 6’

37’ 15’ 5” 15’ 11’ 6,370 lbs. 5’ 6’ 5’ 5’ 5’ 6’ 5’

38’ 15’ 5” 15’ 11’ 6” 6,485 lbs. 5.5’ 6’ 5’ 5’ 5’ 6’ 5.5’

39’ 15’ 5” 15’ 12’ 6,600 lbs. 6’ 6’ 5’ 5’ 5’ 6’ 6’

40’ 15’ 5” 15’ 12’ 6” 6,715 lbs. 3.5’ 4’ 5’ 5’ 5’ 5’ 5’ 4’ 3.5’

41’ 15’ 5” 15’ 13’ 6,830 lbs. 4’ 4’ 5’ 5’ 5’ 5’ 5’ 4’ 4’

42’ 15’ 5” 15’ 13’ 6” 6,945 lbs. 3.5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 3.5’

Model TF215

43’ 15’ 5” 15’ 14’ 7,060 lbs. 4’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’

44’ 15’ 5” 15’ 14’ 6” 7,175 lbs. 4’ 5’ 5.5’ 5’ 5’ 5’ 5.5’ 5’ 4’

45’ 15’ 5” 15’ 15’ 7,290 lbs. 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’

Transport

Width

Base

Width

Wing

s

Each

pprox.

Weight

Side Wing Base Unit Side Wing

Pg. 5

Page 6

TABLE OF CONTENTS

WARRANTY 2

GENERAL INFORMATION 3

BOLT TORQUE CHART 4

SPECIFICATIONS 5

SAFETY RULES 7

SAFETY SIGNS 8

SET-UP INSTRUCTIONS 9-15

OPERATIONS 16

TRANSPORTING 17

UNHITCHING 17

FIELD ADJUSTMENT 17

STORAGE 18

SERVICE 18

TROUBLESHOOTING 18

PARTS LIST

TONGUE ASSEMBLY 19

BASE ASSEMBLY 20-23

WING ASSEMBLY 24-25

WHEEL ASSEMBLY 26

LIGHT WIRING DIAGRAM 27

HYDRAULIC LINES AND FITTINGS

Models TF212 and TF215 Without Wing Wheels 28-29

Models TF212 and TF215 With Wing Wheels 30-31

Model TF2 32

OPTIONAL WING WHEEL ASSEMBLY 33

OPTIONAL LEVELING BAR HARROW 34-35

SERVICE / MAINTENANCE RECORD 36

Pg. 6

Page 7

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to

provide safe equipment can be erased by an operator’s single careless act. In addition, hazard control

and accident prevention are dependent upon the awareness, concern, judgment, and proper training of

personnel involved in the operation, transport, maintenance and storage of equi pment.

Make certain that the operator(s), prior to operating is instructed in safe and proper use and reviews and

understands the manual(s) pertaining to this machine.

Read this manual before you operate this machine. If you do not understand any part of this manual, or

need more information, contact the manufacturer or your authorized dealer.

SAFETY

Understand that your safety and the safety of other persons is measured by how you service, and operate

this machine. Know the positions and functions of all controls before you try to operate them. Make sure

to check all controls in a safe area before starting your work.

The safety information given in this manual does not replace safety codes, federal, state or local laws.

Make certain your machine has the proper equipment as designated by local laws and regulations.

A frequent cause of personal injury or death is from persons falling off equipment and being run over. Do

not permit persons to ride on this machine.

Travel speeds should be such that complete control and machine stability is maintained at all times.

Where possible, avoid operating near ditches, embankments and holes. Reduce speed when turning,

crossing slopes and rough, slick or muddy surfaces.

Collision of high speed road traffic and slow moving machines can cause personal injury or death. On

roads, use flasher lights according to local laws. Keep slow-moving-vehicle emblem visible. Pull over to

let faster traffic pass.

Never adjust, service, clean, or lubricate running gear until all power is shut off.

Keep all safety shields in place.

Keep hands, feet, hair and clothing away from moving parts while unit is in operation.

Make sure that everyone is clear of equipment before applying power or moving the machine.

Make sure that the implement is fastened securely to the tractor by using the proper hitch pin, clip and

safety chains.

Do NOT exceed speeds in excess of 20 MPH. Also be sure slow moving vehicle emblem is attached to

rear of transport.

Before unhooking the implement from the towing unit, be sure to properly block the wheels to prevent the

implement from moving. Be sure the jack assembly is positioned in the park position and the weight has

been transferred to the jack assembly before unhooking the implement.

Pg. 7

Page 8

SAFETY SIGNS

IMPORTANT: Install new safety signs if the old signs are destroyed, lost, painted over or cannot be read.

When parts are replaced that have safety signs, make sure you install a new sign with each new part.

New signs are available from the manufacturer or your authorized dealer.

DECAL PARTS LIST

Item # Part # Description

1 DW-107 Warning: Keep Lug Nuts Tight

2 DW-128 Warning: Rapidly Rising Tongue

3 DW-129 Warning: Electric Lines

4 DW-105 Warning: High Pressure Fluid

5 DW-126 Warning: Transport Locks

6 DW-127 Warning: Folding Wings

7 RD-1A Reflective Amber Decal

8 RD-1R Reflective Red Decal

9 RD-1O Reflective Orange Decal

10 DI-114M Medium Size J&M Oval

11 DI-125S Small “J&M Manufacturing” Decal

12 DI-TF2 “TF2” Decal

12 DI-TF212 “TF212” Decal

12 DI-TF215 “TF215” Decal

13 DI-130 “Torsion-Flex” Decal

Pg. 8

Page 9

SET-UP INSTRUCTIONS

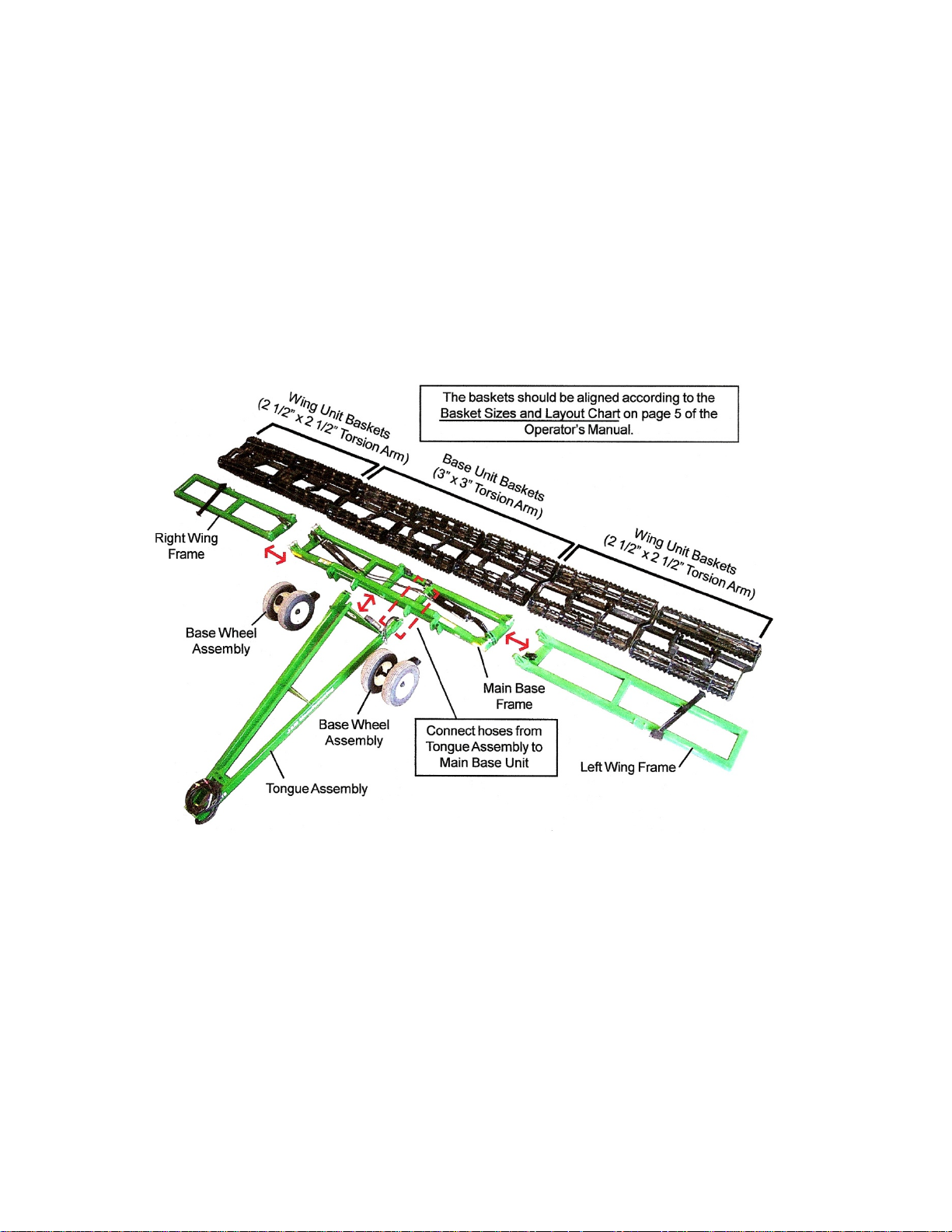

The J&M Torsion-Flex Soil Conditioner is shipped with components partially assembled. Hardware

required to connect the Base Wheel Assembly, Main Base Frame Assembly, Wing Frames and Tongue

Assembly should already be secured to the components at the point of attachment.

The hydraulic cylinders have the fittings already installed and are secured to the base wheel assembly.

The hydraulic hoses and light harness wires should inserted into the component tubing and simply require

the ends to be connected.

Each basket frame should have the rolling baskets and torsion flex arm installed. Refer to the Basket

Size and Layout, located on the right side of the chart on page 5 of the Operator’s Manual for

recommended basket layout. Be sure the baskets with the 3” x 3” Torsion Bars are secure to the Main

Base Unit and the baskets with the smaller 2 1/2” x 2 1/2” Torsion Bars are secured to the side wings.

The optional Lift Assist Bundle (wing wheels) and Harrow are also shipped partially assembled. Refer to

the Set-Up Instructions on the following pages for installation.

Pg. 9

Page 10

SET-UP INSTRUCTIONS

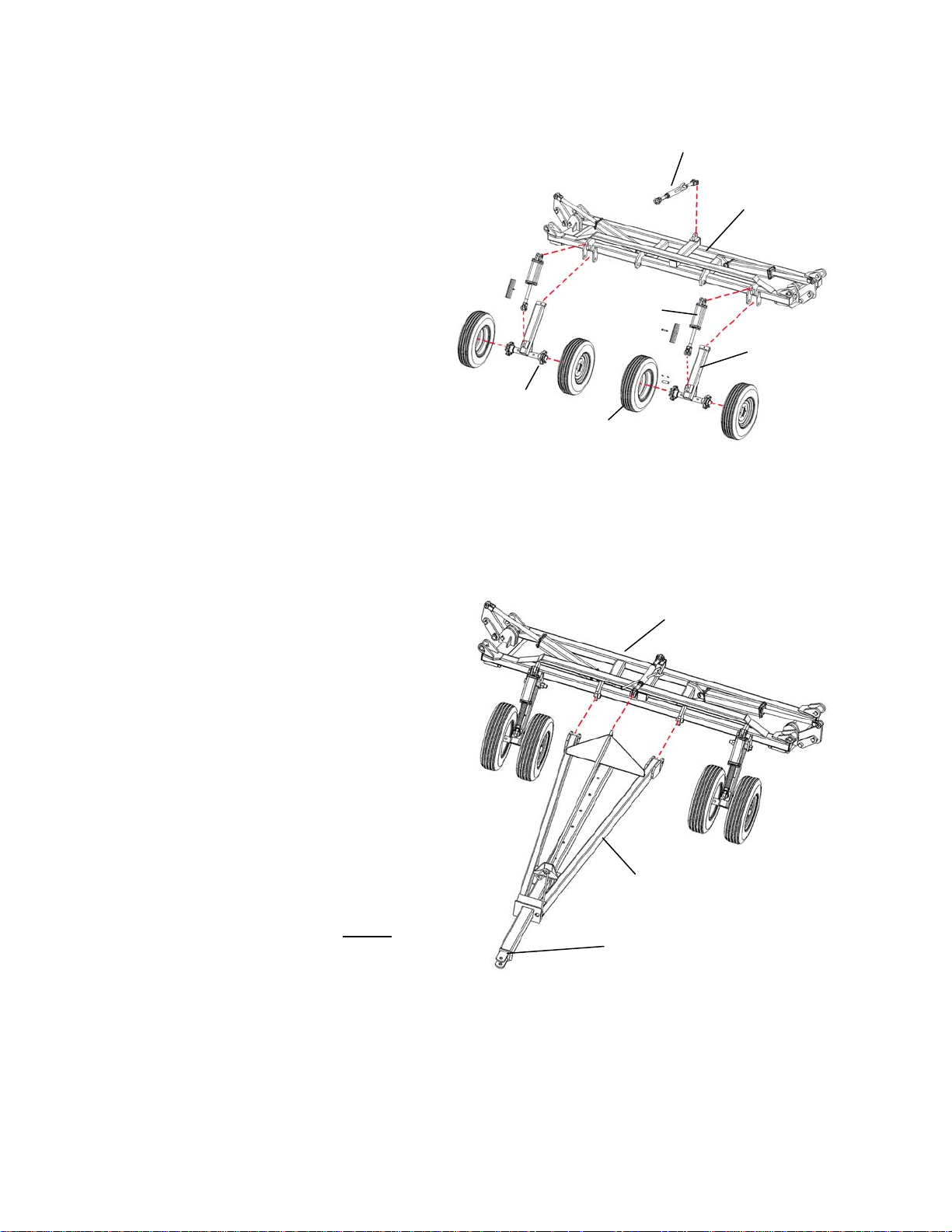

Step 1 – Installing the Base Unit Wheels

Using the 1” x 3 1/2" Pins and cotter pins,

secure the two wheel lift hydraulic cylinders to

the tabs welded on the front of the Base Unit

Main Frame. (NOTE: For implements

equipped with wing wheels, be sure a 3” MS

hydraulic cylinder is used on the right set of

wheels and a 2 3/4" MS hydraulic cylinder is

used for the left set of wheels.)

Hydraulic Cylinder

Bolt the Wheel Arm Weldments to the front of

the Base Unit Main Frame directly below the

hydraulic cylinder shown using one 1 1/4" x 9”

Grade 5 Bolt and 1 1/4" Nylon Lock Nut.

Pin the clevis end of the hydraulic cylinder to

Wheel Hub

Wheel and Tire Assembly

the lower tab on the Wheel Arm Weldment

and secure using the 1” x 3 1/2" pin and cotter pins. Align the wheel and hub and tighten the wheel

nuts in a star pattern to 80 Ft. Lbs. IMPORTANT: Check the w heel nuts periodically to ensure

they remain tight.

Secure one end of the Turn Buckle Assembly to the top of the Base Unit Main Frame as shown using one

1” x 3 1/2" pin and cotter pins.

Step 2 – Installing the A-Frame Tongue

Connect each side arm of the A-Frame

Tongue Assembly to the front of the Main

Frame Base Unit using one 1 1/4" x 6” Grade

5 Bolt and 1 1/4" Hex Nut.

Using the 1” x 3 1/2" pin and cotter pins,

secure the top of the A-Frame Assembly by

connecting the clevis end of the turn buckle to

the end of the upper bar as shown.

Slide the Inner Tongue Weldment into the

tongue A-Frame and secure using the 1” x 8”

Tongue Pin. Insert the 1/2" Hose Holder Rod

into the conduit on the front of the Inner

Tongue Weldment and secure using one 3/8”

x 3/4" Grade 5 Bolt.

Step 3 – Connect the Hydraulic Hoses

For soil conditioners equipped without

wheels, connect the hydraulic hoses and light

wing

Secure 1/2” Hose Holder Rod Here

main wiring harness located in the left side

tubing of the A-Frame to the corresponding

hoses/wires located on the Main Frame Base Unit. For more information, refer to the “Light Kit / Wiring

Harness” and “Hydraulic Hose and Fittings” diagrams at the end of the Set-Up Instructions.

WARNING: Before attaching the cylinders to the wing linkage, charge the cylinders with hydraulic

oil to bleed all air out of the system, and then check for any leaks. Failure to do so could cause

erratic, sudden movement of the wings which could damage the equipment and cause serious

injury or death.

Turn Buckle Assembly

Base Unit Main Frame

Wheel Arm Weldment

Base Unit Main Frame

A-Frame Tongue Assembly

Pg. 10

Page 11

SET-UP INSTRUCTIONS

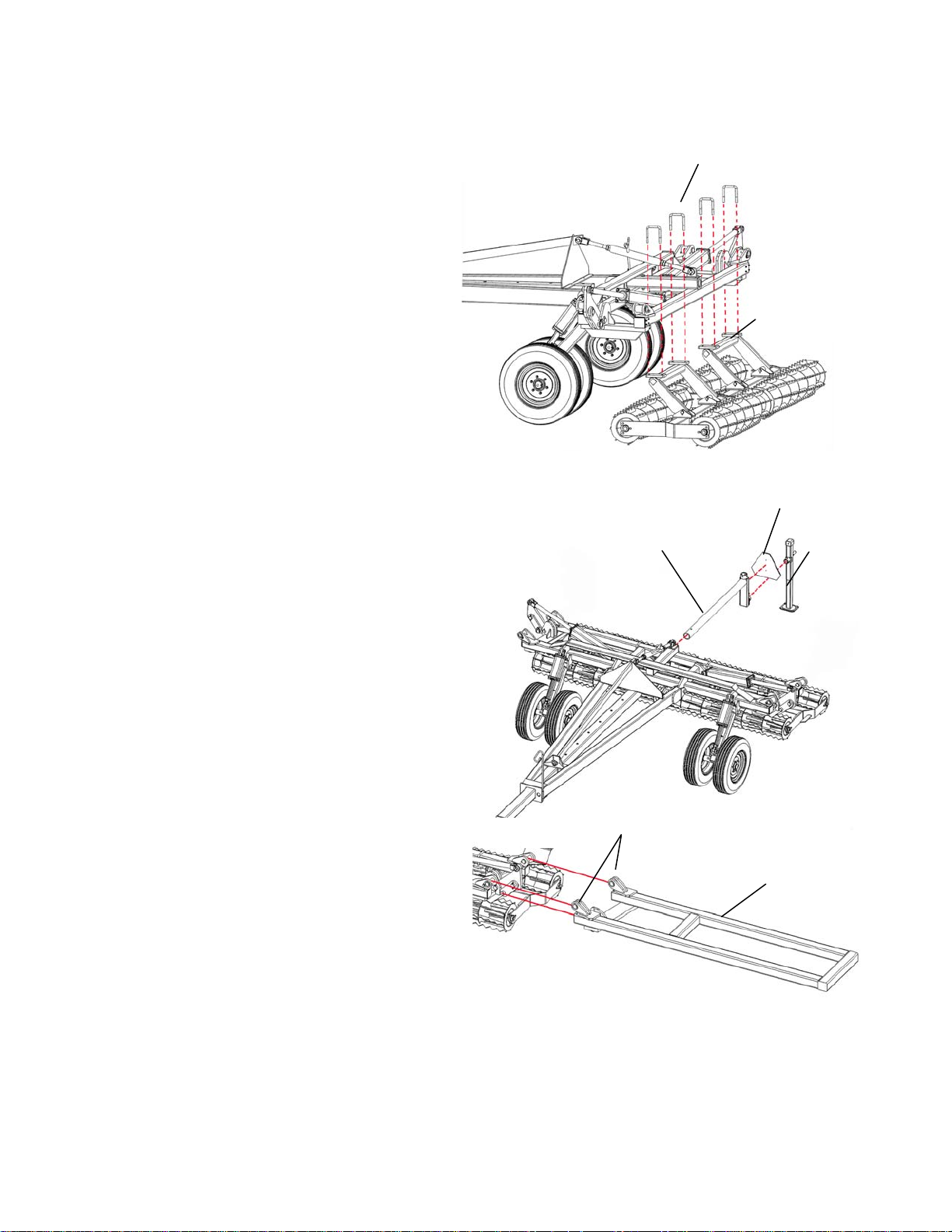

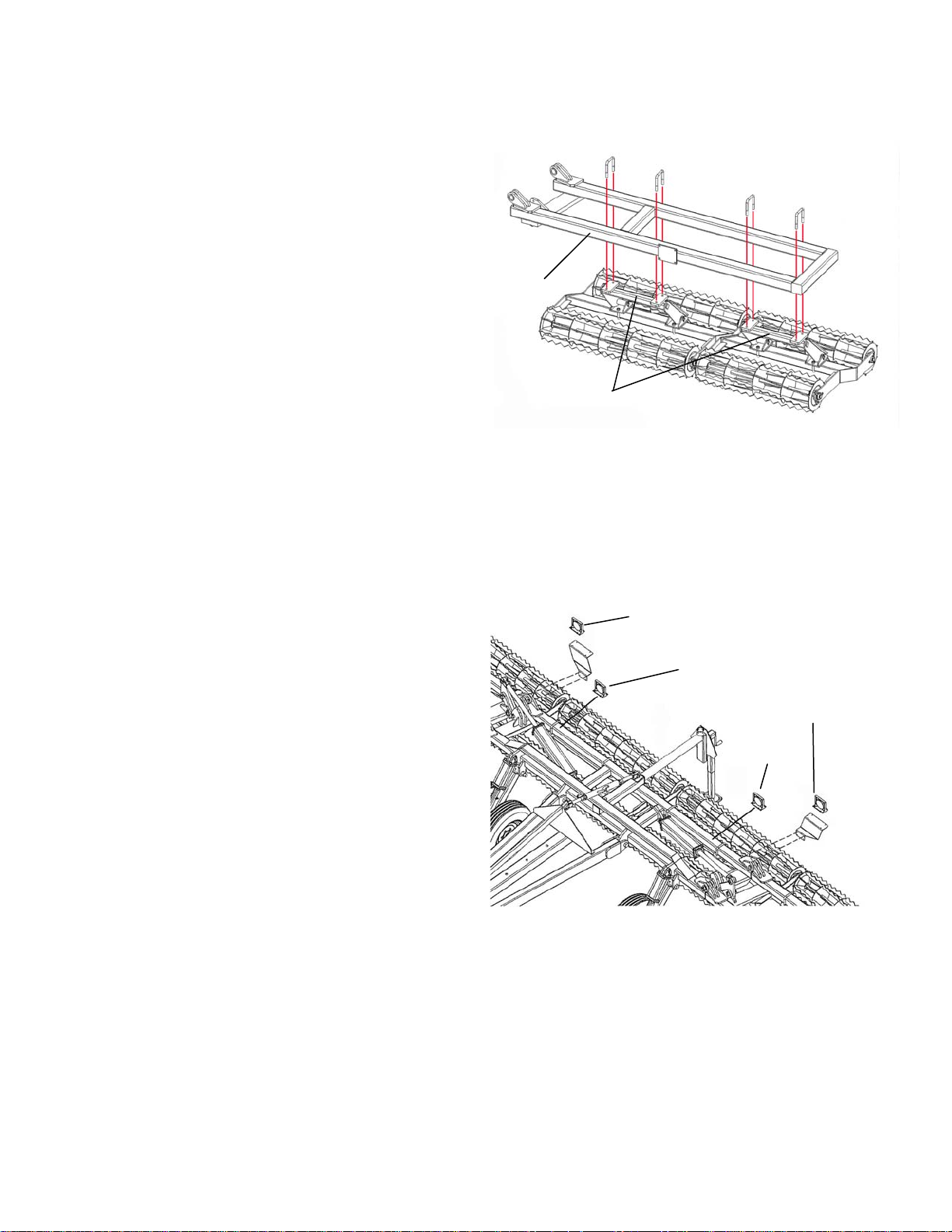

Step 4 – Installing the Base Unit Baskets

Secure the torsion-flex arm of the rolling basket

assembly to the rear tubing member of the Base

Unit Main Frame using two 5/8” x 4” x 5 1/2" UBolts and 5/8” Lock Nuts.

Make sure the baskets are symmetrically

placed on the Base Unit Main Frame and

have a 1 1/2” clearance between baskets.

Note: Be sure the basket assemblies with the 3”

x 3” torsion arms are secured to the Base Unit

Main Frame. The rolling basket assemblies for

the side wings have a smaller 2 1/2” x 2 1/2”

torsion arm.

Step 5 – Installing the Jack Stand

Slide the Storage Extension Arm into the square

tubing on the Base Unit Main Frame as shown

and secure using one 1/2" x 4 1/2" Grade 5 Bolt

and 1/2" Lock Nut. Pin the Jack Stand

Assembly to parking position on the extension

arm and lower the jack so the weight of the base

unit is transferred to the jack. Using two 1/4” x

1” Grade 5 Bolts, mount the SMV emblem to the

extension arm as shown. (Note: For soil

conditioners with side wings that are 5’ long or

smaller. If equipped with side wings longer than

5’, secure the SMV emblem to the right Wing

Arm Rest.

Step 6 – Installing the Wings

Align and connect the hinges on the side Wing

Frame to the matching hinge assembly on the

Main Unit Base Frame using two 1 3/4" x 5 1/4"

Grade 5 Bolt with 1 3/4” Lock Nut.

Connect the Pivot Linkage Arm on the base

main frame to the center tab on the folding wing

frame using one 1 3/4" x 4 3/4” Grade 5 Bolts,

one 1 3/4” Washer and one 7/16” x 2 3/4” Roll

Pin.

5/8” x 4” x 5 1/2” U-Bolts

Rolling Baskets with

3” x 3” Torsion Arm

SMV Emblem

Storage Extension Arm

Align and Secure Corresponding Hinge

Components

Jack Stand

Wing Frame

Pg. 11

Page 12

SET-UP INSTRUCTIONS

Step 7 – Installing the Wing Baskets

Secure the torsion-flex arm of the rolling basket

assembly to the rear tubing member of the Wing

Frame using two 5/8” x 4” x 5 1/2" U-Bolts and 5/8”

Lock Nuts.

Make sure the wing baskets are placed according to

the “Basket Sizes and Layout” section of the chart

found on page 5. IMPORTANT: Make sure the

wing baskets closest to the baskets on the Base

Unit baskets have a clearance of 2”. The spacing

between wing baskets should have a clearance

of 1 1/2”.

Note: Be sure the basket assemblies with the 2 1/2”

x 2 1/2” x 2’-0” torsion arms are secured to the side

wings. (The baskets on the base unit main frame should have a larger 3” x 3” torsion arm.)

Repeat for opposite side wing.

Step 8 – Installing the Wing Arm Rests

Attach the Wing Rest Arm to the Wing Frame as shown using four 1/2" x 1 1/2" Grade 5 Bolts and 1/2"

Lock Nuts. One wing rest arm is longer than the other. The longer wing arm should be mounted to the

left side wing and the short wing arm should be mounted to the right wing arm.

Step 9 – Mounting the Light Brackets and Lights

Mount the left and right Light Mounting Bracket to

the back of the Base Unit Main Frame using four

1/4” Self-Tapping Screws. Secure the Amber Light

to the mounting bracket using four 1/4” x 1” Grade 5

Bolts and 1/4” Lock Nuts. Place the Red Lights

approximately 18” from the hinges of the Main Base

Unit and secure to the top of the 4” x 4” tubing using

four self-tapping screws.

Snap the end plugs of each light into the light wiring

harness already located inside the frame of the Main

Frame Base Unit.

Front of

Wing

Frame

2 1/2” Torsion Arm

Amber Light

Red Light

Amber Light

Red Light

Pg. 12

Page 13

SET-UP INSTRUCTIONS

INSTALLING OPTIONAL WING WHEELS

For soil conditioners equipped with side wing

wheels, mount the Wing Arm Mount Bracket to the

front tubing member of the Wing Frame as shown

(approximately 6” from the end of the wing frame)

using two 1/2" x 5” Grade 5 Bolts and 1/2" Lock

Nuts.

Bolt the Wheel Arm Weldments to the front of the

Base Unit Main Frame directly below the hydraulic

cylinder shown using one 1 1/4" x 9” Grade 5 Bolt

and 1 1/4" Nylon Lock Nut. Pin the clevis end of the

hydraulic cylinder to the lower tab on the Wheel Arm

Weldment and secure using the 1” x 3 1/2" pin and

cotter pins. Align the wheel and hub and tighten the

wheel nuts in a star pattern to 80 Ft. Lbs.

MS Hydraulic

Cylinder

IMPORTANT: Check the wheel nuts periodic ally to

ensure they remain tight.

Wing Arm Weldment

Using the 1” x 3 1/2" Pins and cotter pins, secure the

two wheel lift hydraulic cylinders to the tabs welded

on the front of the Base Unit Main Frame.

NOTE: Soil Conditioners with working widths between 37’ and 39’ have a longer Wing Arm Rest and a

spacer on the hydraulic cylinder that folds the left side wing.

MAKE SURE THE MS CYLINDERS AND HYDRAULIC HOSES ARE MOUNTED ACCORDING TO THE

DIAGRAM ON PAGE 29.

ADJUSTING THE PRESET VALVE ON THE FOLDING WING CYLINDER

Wings wheels installed on the Torsion Flex Soil Conditoner are equipped with a preset valve on each

folding cylinder that allows the wings to fold in sequence (see hydraulic diagram). When folding the wings

for transport, the right side wing should fold first. When unfolding for field use, the left wing should fold

first. Failure to fold/unfold the wings in proper sequence could result in damage to the wings, wheel

assembly or baskets.

The rate at which the wings fold/unfold is dependent on the side

of the wings and the hydraulic pressure supplied by the tractor.

If the wings fold slower than 2 minutes, the preset valve can be

removed and adjusted to increase hydraulic flow (see diagram).

To increase the hydraulic flow through the preset valve, insert an

L-wrench through the nylon bushing located inside the preset

valve and rotate counter-clockwise up to one complete turn

.

(One complete counter-clockwise turn will increase the flow

through the valve up to 100 psi.) IMPORTANT: Be sure to

adjust the preset valve on each folding wing cylinder the same.

If your tractor supplies too much hydraulic pressure with the existing preset valve, causing the wings to hit

during the fold/unfold sequence, please call our Torsion-Flex Service Department at 419-375-2376 for a

free replacement preset valve set for higher hydraulic pressures.

Wing Arm Rest

Wing Arm Mount

Bracket

Pg. 13

Page 14

SET-UP INSTRUCTIONS

ADJUSTING THE PRESET VALVE ON THE FOLDING WING CYLINDER (continued)

NOTE: Be sure the baskets are free from excessive mud, rocks or debris before beginning the

folding/unfolding sequence. Excessive weight could effect the timing of the folding sequence, causing

possible collision.

WARNING: Charge the cylinders with hydraulic oil to bleed all air out of the system, and then

check for any leaks. Failure to do so could cause erratic, sudden movement of the wings which

could damage the equipment and cause serious injury or death. Units that have the gauge wheels

on the wings have a slave hydraulic system that must be “charged” so the cylinder ram extends

first on all four cylinders.

WHEN TWO SETS OF HYDRAULIC PORTS ARE NOT AVAILABLE…

Torsion Flex Soil Conditioners equipped with wing wheels have one set of hoses to fold the

wings and another set of hoses to raise and lower the wheels. When two hydraulic ports are not

available, we suggest teeing the hydraulic hoses that fold the wings into the hydraulic lines that

fold the wings on the front implement. Therefore, the wings of both implements will fold at the

same time.

INSTALLING THE OPTIONAL HARROW BAR

For part identification, refer to the Harrow Parts List

on pages 34-35.

For each harrow section, attach two Harrow Arm

Mounting Brackets (#2) to the rear tubing along the

wing or base unit using two 5/8” x 4” x 5 1/2” U-Bolt

(#3) and four 5/8” lock nuts (#4). Do not tighten, as

the bracket may need to be adjusted.

Attach one 2” x 8 1/4” Chain Plate (#7) on the front

tubing (directly across from the Harrow Arm

Mounting Bracket) using one 5/8” x 4” x 5 1/2” UBolt (#3) and two 5/8” lock nuts (#4). Do not tighten,

as the plate may need to be adjusted.

Connect one 3” x 21” Harrow Arm to each of the rear mounting bracket using one 3/4” x 6” Grade 5 bolt

(#5) and 3/4” lock nut (#6). Connect the Pivot Bracket (#12) to the lower end of each harrow arm using

one 3/4” x 6” grade 5 bolt (#5) and 3/4” lock nut (#6).

Connect one 16” long chain (#9) to the top of each pivot bracket using one 3/8” x 1” flange bolt (#10) and

3/8” flange nut (#11). Slide the top of the chain through the slot in the chain plate and pin in place using

the Clip Pin (#8). Be sure to pin all the chains to the same length to keep the harrow level.

To Install the Round Bar Assembly

Insert the Round Bar Hooks (#14) into the Round Bar Bracket (#13) and secure using the 1/2” x 1/2”

grade 5 bolts (#17), 1/2” x 2 1/4” oversized washers (#18) and 1/2” lock nuts (#16). Be sure all the round

bars are aligned in the same direction. Secure the round bar bracket to the pivot brackets using the 1/2”

x 4” x 4” U-Bolts (#15) and 1/2” lock nuts (#16).

FRONT

REAR

Pg. 14

Page 15

To Install the Coil Tine Spring Assembly

Slide the Coil Tine Springs (#22) around the Coil Tine Pipe (#21) and secure at each hole location using

the 1/2” x 3 1/2” J-Bolt (#23) and 1/2” Lock Nut (#16). Repeat for each pipe. Secure the Coil Tine Pipe to

the pivot brackets on the lower end of the harrow arm using the two Squeeze Blocks (#19) and four 1/2” x

4 1/2” Grade 5 Bolt (#20) with 1/2” Lock Nuts (#16).

Below is a recommended layout of the harrow pipe bar and round bar bracket lengths along the

width of the conditioner. Be sure the Harrow is properly and evenly spaced along the Base Unit

Main Frame and Wing Frames, making adjustments as necessary.

Coil Tine Pipe Bar and Round Bar Bracket Layout

for Optional Leveling Harrow

Working

Width

12’ 6’ 6’

13’ 4’ 5’ 4’

14’ 5’ 4’ 5’

15’ 5’ 5’ 5’

16’ 5’ 6’ 5’

Model TF2

17’ 6’ 5’ 6’

18’ 6’ 6’ 6’

20’ 4’ 6’ 6’ 4’

22’ 5’ 6’ 6’ 5’

23’ 5’ 6’ 6’ 5’

24’ 6’ 6’ 6’ 6’

25’ 6’ 6’ 6’ 6’

26’ 7’ 6’ 6’ 7’

27’ 7’ 6’ 6’ 7’

28’ 4’ 4’ 6’ 6’ 4’ 4’

29’ 4’ 4’ 6’ 6’ 4’ 4’

30’ 4’ 5’ 6’ 6’ 5’ 4’

Model TF212

31’ 4’ 5’ 6’ 6’ 5’ 4’

32’ 5’ 5’ 6’ 6’ 5’ 5’

33’ 5’ 5’ 6’ 6’ 5’ 5’

34’ 5’ 6’ 6’ 6’ 6’ 5’

35’ 5’ 6’ 6’ 6’ 5’ 6’

36’ 6’ 6’ 6’ 6’ 6’ 6’

37’ 5’ 6’ 5’ 5’ 5’ 6’ 5’

38’ 5’ 6’ 5’ 5’ 5’ 6’ 5’

39’ 6’ 6’ 5’ 5’ 5’ 6’ 6’

40’ 7’ 5’ 5’ 5’ 5’ 5’ 7’

41’ 4’ 4’ 5’ 5’ 5’ 5’ 5’ 4’ 4’

42’ 4’ 4’ 5’ 5’ 5’ 5’ 5’ 4’ 4’

Model TF215

43’ 4’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’

44’ 4’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’

45’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’

Wing Base Unit Wing

Pg. 15

Page 16

OPERATIONS

PREPARING THE TORSION-FLEX SOIL CONDITIONER

Before putting the soil conditioner into operation, check the machine for damaged or worn parts and

replace as necessary.

Hardware

Make sure all hardware is properly fastened according to the Bolt Torque chart found in this manual.

Recheck all hardware for tightness after the unit has been operated for several hours. Check all pins and

retaining rings are in good condition. Replace any pins of retaining rings that are worn, damaged or

missing.

Hydraulic Hoses

Check all the hydraulic hoses to make sure there are not rubbing against sharp edges or are kinked or

twisted. Hoses should be secured to the soil conditioner with nylon tie straps. Check hoses and fitting for

hydraulic leaks. Tighten or replace as necessary.

Lubrication

Lubricate the Torsion-Flex soil conditioner according to the Lubrication Schedule outlined in the SERVICE

section of this manual.

Tires and Wheels

Check the tire pressure in the transport tires. The recommended air pressure is 46 PSI. Make sure the

tire pressure is equal in all tires. Make sure the wheel lug nuts are tightened to 80 Ft. Lbs. Check the

wheel lug nuts before initial operation and after the unit has been operated for several hours to ensure the

lug nuts remain tight.

Adjusting the Inner Tongue

Before attaching the Torsion-Flex soil conditioner to your primary tillage tool, extend the inner tongue of

the A-Frame Tongue Assembly to ensure adequate turning clearance between the implements when

turning. Adjust the Inner Tongue length by removing the 1” x 8” Tongue Pin and Cotter Pin. Readjust the

Inner Tongue to the appropriate setting and re-pin as before.

Attaching to the Primary Tillage Tool

Back the primary tillage tool into position and attach the soil conditioner to the implement using a high

quality hitch pin and clip and lock into place. Install a transport chain. Transport chain should have a

minimum rating equal to the gross weight of implement and all attachments. Use only ASAE approved

chains. If the unit is parked in the transport position, turn the handle on the jack stand after the soil

conditioner has been connected to the primary tillage tool to remove pressure. Remove the Jack

Assembly from the storage position and re-pin to the transport position located on top of the Storage

Extension Arm.

Unfolding the Wings / Removing the Transport Locks

It is recommended to unfold the side wings in the field. Remove the wheel lift cylinder transport locks so

the unit may be lowered to the field working position. Pin the transport locks on the back of the A-Frame

Tongue Assembly for easy storage.

Pg. 16

Page 17

TRANSPORTING

Before the soil conditioner is transported, be sure to secure the Jack Assembly in the transport position

located on the top of the Storage Extension Arm.

The Torsion-Flex Soil Conditioner will increase the overall length of the primary tillage tool. Use extreme

caution when turning to avoid obstacles. Reduce ground speed as necessary to maintain control of

equipment.

Install hydraulic cylinder transport locks on the Base

Unit wheels BEFORE transporting.

Comply with ALL state and local laws governing

highway safety and regulations when moving

machinery on public roads. Be sure an SMV emblem

is in place and clearly visible on the rear of the

conditioner. Make sure all lights are clearly visible

and working properly BEFORE highway travel. Be

sure the amber, red and orange retroreflective tape on

the implement is in place and clearly visible.

The transport speed should not exceed 10 MPH in the

field or over rough terrain. Reduce transport speed

when necessary to maintain full control of the

implement at all times.

Transport

Cylinder Lock

UNHITCHING

WARNING – Before unhooking the soil conditioner, be sure to install the hydraulic cylinder transport

locks. Reposition the jack stand on the Storage Extension Arm to the parked position and lower the jack

stand to the ground by turning the handle until weight of the soil conditioner is transferred to the jack.

Keep hands and feet away from the jack stand when lowering.

Remove the Hitch Pin and unhook the safety chains.

WARNING – Always relieve hydraulic system pressure before disconnecting hoses from tractor or

servicing hydraulic system. See the tractor’s operators manual for proper procedures. Disconnect the

hydraulic hoses. Install dust covers over the hose plugs and outlets.

FIELD ADJUSTMENTS

The Torsion-Flex Soil Conditioner is designed to provide an excellent seedbed when used in conjunction

with you primary tillage tool. For maximum performance in normal field conditions, the soil conditioner

should be used with the transport wheels in the raised position to allow maximum transfer of weight to the

rolling baskets.

With the wheels in the raised position, adjust the Turn Buckle Adjustment Bar until the wheels are

approximately 2” above the ground. This will set your Torsion-Flex Soil Conditioner at the maximum

clearance height during transport.

The Spring Coil-Tine Harrow Bar is designed to improve the soil leveling capabilities of your conditioner.

To improve the ground leveling capabilities of the harrow in heavier soils, pin the harrow bar so the coiltines are positioned more vertically. In softer soils or to improve field residue flow through the leveler bar,

position the bar with a decreased vertical angle of the tines.

Pg. 17

Page 18

STORAGE

To add longer service and life to your Torsion-Flex Soil Conditioner, perform the following before placing

the implement in storage:

1. Remove dirt and trash that may cause rusting.

2. Repaint any areas where the paint has been chipped, scratched or worn away.

3. Coat all earth moving surfaces with a suitable rust preventative.

4. Inspect for damaged or worn parts and replace before next use.

5. Lubricate wing and wheel pivot points.

6. Block up the conditioner to keep the wheels and ground tools off the ground.

7. Replace all worn, torn and faded decals and reflectors.

8. Store the implement inside away from inclement weather.

SERVICE

To add longer life to your Torsion-Flex Soil Conditioner, perform the following on a regular basis:

1. Grease hinge, linkage area and wheel transport pivots

(3X) weekly or every 40 hours. Grease the 4-Hole Flange

Bearings (1X) on the Rolling Basket Assembly every

50 Hours.

2. Check lighting before over the road transport. Make

sure lights and SMV emblem are clean

from dirt and field debris.

3. Check implement for damage, cracked welds, loosened

hardware, etc. Promptly repair to prevent further damage.

4. Check hydraulic system for leaks and hose damage, twists

or kinks and repair.

5. Check tire pressures and lug nuts periodically and adjust as

required.

TROUBLESHOOTING

When Hydraulics Are Not Functioning Properly…

PROBABLE CAUSE CORRECTION

Hoses are incorrectly connected to the tractor control

levers.

Insufficient hydraulic pressure from Tractor. Check the hydraulic reservoir oil level. See the tractor

Hydraulic components leaking oil. Locate the leak and replace or repair components.

Hydraulic hoses are kinked or twisted. Locate the twisted hose and correct.

Hydraulic cylinders are leaking. Repair or replace cylinders. See Repair Parts section for

The orifice in the wing-fold cylinder is plugged. Remove the contamination from the system. Flush

See the Tractor Operator’s Manual for valve and control

lever arrangement.

Operator’s Manual for hydraulic system

recommendations.

cylinder or seal kit part numbers.

system and change the oil and filter.

Pg. 18

Page 19

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Tongue Assembly

PARTS LIST

Item # Part # Description

1 AFTW-2 A-Frame Tongue Weldment (TF2)

1 AFTW-212 A-Frame Tongue Weldment (T F212)

1 AFTW-215 A-Frame Tongue Weldment (T F215)

2 ITW-TF1 Inner Tongue Weldment

3 12HHR 1/2” Hose Holder Rod

4 3834G5B 3/8” x 3/4" Grade 5 Bolt

5 18PCP 1” x 8” Tongue Pin

6 CP-316 Cotter Pin

7 1146G5B 1 1/4" x 6” Grade 5 Bolt

8 HLN-114 1 1/4" Hex Nut

Pg. 19

Page 20

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Base Assembly

Pg. 20

Page 21

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Base Assembly

PARTS LIST

Item # Part # Descrip tio n

1 BMF-2-12 Base Unit Main Frame (TF2 – 12’ or 13’ working width)

1 BMF-2-14 Base Unit Main Frame (TF2 – 14’ or 15’ working width)

1 BMF-2-16 Base Unit Main Frame (TF2 – 16’ or 17’ working width)

1 BMF-2-18 Base Unit Main Frame (TF2 – 18’ working width)

1 BMF-212 Base Un it Main Frame (TF212)

1 BMF-215 Base Un it Main Frame (TF215)

2 WAW-1 Wheel Arm Weldment (TF2)

2 WAW-2 Wheel Arm Weldme nt (TF212 or TF215)

3 38HC 3” x 8” Hydraulic Cylinder (left or right side wheel cylinder on

units equipped WITHOUT wing wheels)

3 3148HCMS 3 1/4” x 8” MS Hydraulic Cylinder (for units equipped WITH wing

wheels) (32TP08-125 639706)

3 3128HCMS 3 1/2" x 8” MS Hydraulic Cylinder (for units equipped W ITH wing

wheels) (35TP08-125 639707)

4 1149G5B 1 1/4" x 9” Grade 5 Bolt

5 114NLN 1 1/4" Nylon Lock Nut

6 1312P 1” x 3 1/2" Pin

7 CP-316 3/16” Cotter Pin

8 CYLK-2 Cylinder Lock

9 38212WLP 3/8” x 2 1/2" Wire Lock Pin

10 21220TFA 2 1/2” x 2 1/2” x 2’ 0” Torsion-Flex Arm (units under 25’ wide)

10 3330TFA 3” x 3” x 3’ 0” Torsion-Flex Arm (TF212 units 25’ to 36’ wide)

10 3320TFA 3” x 3” x 2’-0” Torsion-Flex Arm (TF215)

11 SWB-1 Swivel Bracket

12 16G5B 1” x 6" Grade 5 Bolt

13 1G5LN 1” Grade 5 Lock Nut

14 584512UB 5/8” x 4” x 5 1/2" U-Bolt

15 5844UB 5/8” x 4” x 4” U-Bolt

16 58G5LN 5/8” Grade 5 Lock Nut

17 12312G5B 1/2" x 3 1/2" Grade 5 Bolt

18 12G5LN 1/2" Grade 5 Lock Nut

19 134514G5B 1 3/4" x 5 1/4" Grade 5 Bolt

20 HN-134 1 3/4” Hex Nut

22 LA-2TF24 Leverage Arm (round hole) (for working widths 24’ and smaller)

22 LA-2TF212 Leverage Arm (oblong hole) (for model TF212, 25’ to 36’ wide)

22 LA-2TF215 Leverage Arm (for model TF215)

23 PLA-2 Pivot Linkag e Arm (TF212)

23 PLA-2L Pivot Linkage Arm, Long (TF215)

24 1344P 1 3/4" x 4” Pin

25 716234RP 7/16” x 2 3/4" Roll Pin

26 424HC 4” x 24” Hydraulic Cylinder (TF212)

26 430HC 4” x 30” Hydraulic Cylinder (TF215)

Pg. 21

Page 22

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Base Assembly (continued)

PARTS LIST

Item # Part # Description

27 TBCB-1 Turn Buckle Center Pipe

28 TBS-2RH Turn Buckle Shaft (both ends R/H thread)

28 TBS-1RH1LH Turn Buckle Shaft (1 end L/H thread; 1 end R/H thread)

29 HN-114 1 1/4" Hex Nut

30 CE-2 Turn Buckle Clevis End

31 TBW-1 Turn Buckle Wrench

32 LP-1 Lynch Pin

33 SEA-1 Storage Extension Arm

34 12412G5B 1/2" x 4 1/2" Grade 5 Bolt

35 JSA-TF Jack Stand Assembly

36 JSA-P1 Jack Stand Assembly Pin

37 LMB-TF-R Light Mounting Bracket (for Right Hand Light)

38 LMB-TF-L Light Mounting Bracket (for Left Hand Light)

39 14STS 1/4” Self Tapping Screw

40 AL-TF1 Single Amber Light

42 141G5B 1/4" x 1” Grade 5 Bolt

43 14LN 1/4" Lock Nut

44 SMV-2 Slow Moving Vehicle Emblem

45 BFS40-4 4’ Basket Frame Support Only (used with soil conditioners

equipped with 4-hole flange bearings)

45 BFS50-4 5’ Basket Frame Support Only (used with soil conditioners

equipped with 4-hole flange bearings)

45 BFS60-4 6’ Basket Frame Support Only (used with soil conditioners

equipped with 4-hole flange bearings)

46 RB40-4-114 4’ Rolling Basket Only (used with soil conditioners equipped with 4-

hole flange bearings with 1 1/4” diameter shaft)

46 RB50-4-114 5’ Rolling Basket Only (used with soil conditioners equipped with 4-

hole flange bearings with 1 1/4” diameter shaft)

46 RB60-4-114 6’ Rolling Basket Only (used with soil conditioners equipped with 4-

hole flange bearings with 1 1/4” diameter shaft)

47 ST491A-162-

114

48 12214G5B 1/2” x 2 1/4” Grade 5 Bolt

49 RL-TF1 Red Flashing L ight

50 1610BL Grease Fitting (not shown)

51 1633 Grease Fitting (not sho wn)

52 SK-3HC Seal Kit for 3” Hydraulic Cylinder (38HC) (SK-3HC)

53 SK639581 Seal Kit for 4” Hydraulic Cylinder (424HC)

54 SK639582 Seal Kit for 4” Hydraulic Cylinder (430HC)

55 FBSS-1 Set Screw in Flange Bearing

56 SK639558 Seal Kit for 3” M/S Hydraulic Cylinder

57 SK639560 Seal Kit for 3 1/4” M/S Hydraulic Cylinder

58 SK639561 Seal Kit for 3 1/2” M/S Hydraulic Cylinder

59 SK639563 Seal Kit for 3 3/4” M/S Hydraulic Cylinder

60 HCSS-1 Set Screw in Hydraulic Cylinder Clevis

1 1/4” Flange Bearing – 4 Hole (used on all soil conditioners with

serial numbers 2250 and higher)

Pg. 22

Page 23

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Base Assembly (continued)

PARTS LIST

Item # Part # Description

62 LW-114 1 1/4” Lock Washer

63 121PS 1/2” x 1” Pipe Spacer

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Wing Assembly

Pg. 23

Page 24

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Left and Right Side Wing Assemblies (TF212 and TF215 only)

PARTS LIST

Item # Part # Descrip tio n

1 WF-212-4 Wing Frame (TF212) (4’ L)

1 WF-212-5 Wing Frame (TF212) (5’ L)

1 WF-212-6 Wing Frame (TF212) (6’ L)

1 WF-212-7 Wing Frame (TF212) (7’ L)

1 WF-212-8 Wing Frame (TF212) (8’ L)

1 WF-212-9 Wing Frame (TF212) (9’ L)

1 WF-212-10 Wing Frame (TF212) (10’ L)

1 WF-212-11 Wing Frame (TF212) (11’ L)

1 WF-212-12 Wing Frame (TF212) (12’ L)

1 WF-215-11 Wing Frame (TF215) (11’ L)

1 WF-215-12 Wing Frame (TF215) (12’ L)

1 WF-215-13 Wing Frame (TF215) (13’ L)

1 WF-215-14 Wing Frame (TF215) (14’ L)

1 WF-215-15 Wing Frame (TF215) (15’ L)

2 WRA-1L Wing Rest Arm (for Left Hand Side Wing)

2 WRA-1R Wing Rest Arm (for Right Hand Side Wing)

3 12112G5B 1/2" x 1 1/2" Grade 5 Bolt

4 12LN 1/2" Lock Nut

5 134434G5B 1 3/4" x 4 3/4" Grade 5 Bolt

6 ------ ---------------------7 716234RP 7/16” x 2 3/4” Roll Pin

8 21220TFA 2 1/2” x 2 1/2” x 2’ 0” Torsion Flex Arm

9 SWB-1 Swivel Bracket

10 16G5B 1” x 6” Grade 5 Bolt

11 1G5LN 1” Grade 5 Lock Nut

12 584512UB 5/8” x 4” x 5 1/2" U-Bolt

13 58G5LN 5/8” Grade 5 Lock Nut

14 5844UB 5/8” x 4” x 4” U-Bolt

15 BFS30-4 3’ Basket Frame Support (used on soil conditioners equipped

with 4-hole flange bearings)

15 BFS36-4 3’ 6” Basket Support Frame (used on so il conditioners equipped

with 4-hole flange bearings)

15 BFS40-4 4’ 0” Basket Support Frame (used on so il conditioners equipped

with 4-hole flange bearings)

15 BFS50-4 5’ Basket Support Frame (use d on soil conditioners equipped

with 4-hole flange bearings)

15 BFS56-4 5’ 6” Basket Support Frame (used on so il conditioners equipped

with 4-hole flange bearings)

15 BFS60-4 6’ Basket Support Frame (use d on soil conditioners equipped

with 4-hole flange bearings)

16 RB30-4-114 3’ Rolling Basket (used on soil conditioners equipped with 4-hole

flange bearings with 1 1/4” diameter shaft)

16 RB36-4-114 3’ 6” Rolling Basket (used on soil conditioners equipped with 4-

hole flange bearings with 1 1/4” diameter shaft)

16 RB40-4-114 4’ Rolling Basket (used on soil conditioners equipped with 4-hole

flange bearings with 1 1/4” diameter shaft)

Pg. 24

Page 25

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Left and Right Side Wing Assemblies (TF212 and TF215 only)

PARTS LIST

Item # Part # Descrip tio n

16 RB40-4-114 4’ Rolling Basket (used on soil conditioners equipped with 4-hole

flange bearings with 1 1/4” diameter shaft)

16 RB50-4-114 4’ 6” Rolling Basket (used on soil conditioners equipped with 4-

hole flange bearings with 1 1/4” diameter shaft)

16 RB56-4-114 5’ 6” Rolling Basket (used on soil conditioners equipped with 4-

hole flange bearings with 1 1/4” diameter shaft)

16 RB60-4-114 6’ Rolling Basket (used on soil conditioners equipped with 4-hole

flange bearings with 1 1/4” diameter shaft)

17 ST491A-162-114 1 1/4” Flange Bearing – 4 Hole

18 12214G5B 1/2” x 2 1/4” Grade 5 Bolt

19 1633 Grease Fitting (not shown)

20 HN-114 1 1/4” Hex Nut

21 LW-114 1 1/4” Lock Washer

23 1234PS 1/2” x 34” Pipe Spacer

Pg. 25

Page 26

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Wheel Assembly

PARTS LIST

Item # Part # Descrip tio n

1 SS-134SC 1 3/4" Diameter Spindle

2 CP-316 Cotter Pin

3 103953 Grease Seal

4 104579 Cone (large) 1 04579 or LM-48548

5 104082 Cone (small) 1040 82 or LM-67048

6 104581 Spindle Washer

7 103289 Slotted Spindle Nut

8 105218 Hub with Studs , Nuts and Cups

9 5552 Wheel Nut

10 4187 Wheel Stud

11 103969 Dust Cap

12 1633 Grease Fitting

13 WR-156-6 Wheel Rim, 15” x 6” – 6 hole (WR-SC2)

13 WR-158-6 Wheel Rim, 15” x 8” – 6 hole

14 760-15SL New Tire (7.60-15SL, 8 ply) (for 15x6 wheel)

14 95L-15SL8PR New Tire (9.5L-15SL, 8 ply) (for 15x8 wheel)

104580 Cup (large) 104580 or LM-48510 (not shown)

104081 Cup (small) 104081 or LM-67 010 (not shown)

Pg. 26

Page 27

g

)

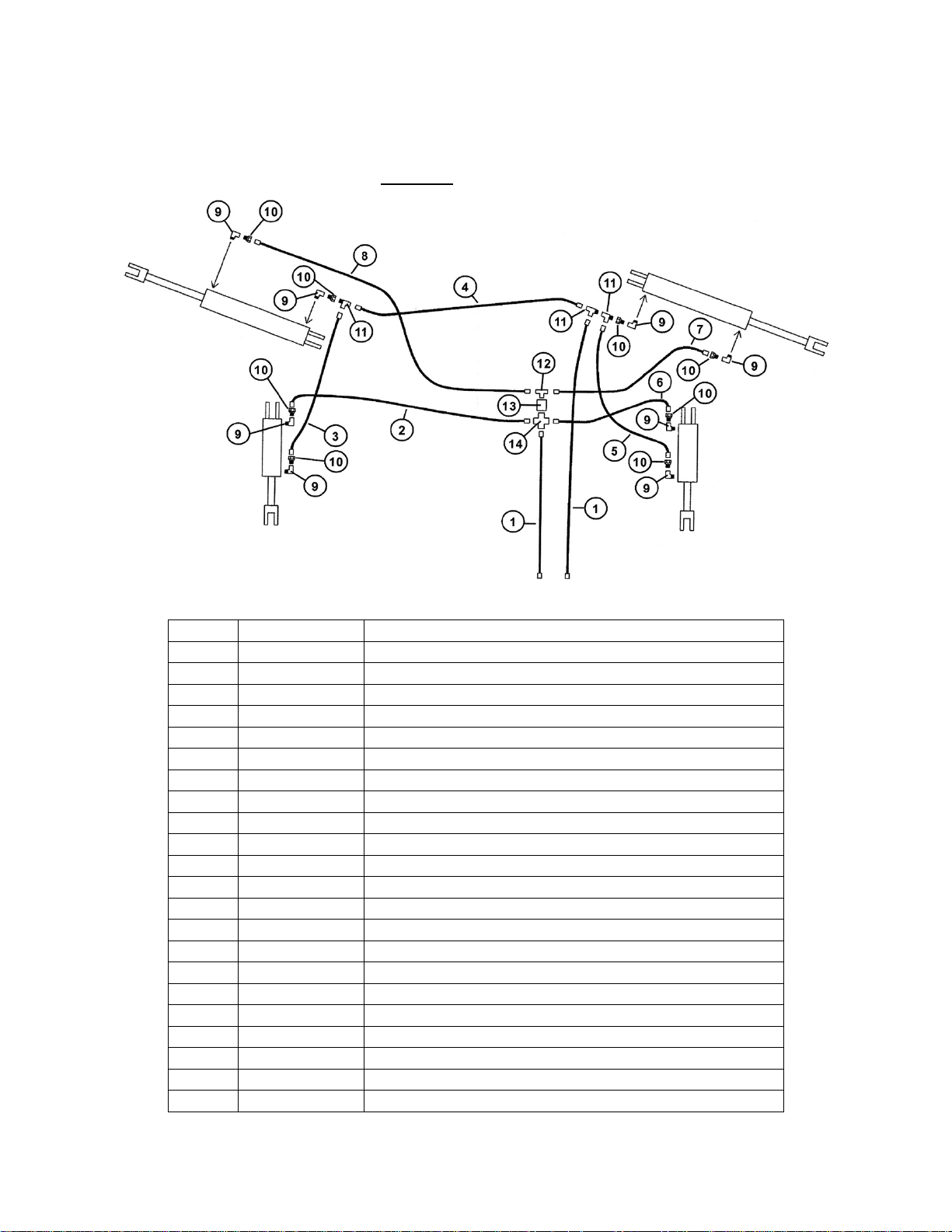

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Light Wiring Harness

Amber Light

Red Light

Run Light Harness through tubing at

grommet locations and connect to Amber

and Red Li

Light Enhancer

hts (typical each side

Red Light

Amber Light

Main Wiring

Harness

PARTS LIST

Item # Part # Descrip tio n

1 MWH-TF2 Main Wiring H arness with 7-Prong Connector End

2 LWH-TF2 Light Wiring Harness (from enhancer to red and amber lights)

3 LE-1B Lig ht Enha ncer (connects main wiring harness with rear lights)

GR-134 1 3/4” Rubber Grommet

Pg. 27

Page 28

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Hydraulic Lines and Fittings for Models TF212 and TF215

EQUIPPED WITHOUT

OPTIONAL WING WHEELS

PARTS LIST

Item # Part # Descrip tio n

1 HH-38336 3/8” x 336” Hydraulic Hose (TF212)

1 HH-38384 3/8” x 384” Hydraulic Hose (TF215)

2 HH-3866 3/8” x 66” Hydraulic Hose (TF212)

2 HH-3875 3/8” x 75” Hydraulic Hose (TF215)

3 HH-3843 3/8” x 43” Hydraulic Hose (TF212)

3 HH-3832 3/8” x 32” Hydraulic Hose (TF215)

4 HH-3840 3/8” x 40” Hydraulic Hose with swivel end (TF212)

4 HH-3860 3/8” x 60” Hydraulic Hose with swivel end (TF215)

5 HH-3843 38” x 43” Hydraulic Hose (TF212)

5 HH-3832 3/8” x 32” Hydraulic Hose (TF215)

6 HH-3834 3/8” x 34” Hydraulic Hose (TF212)

6 HH-3825 3/8” x 25” Hydraulic Hose (TF215)

7 HH-3829 3/8” x 29” Hydraulic Hose (TF212)

7 HH-3835 3/8” x 35” Hydraulic Hose (TF215)

8 HH-3862 3/8” x 62” Hydraulic Hose (TF212)

8 HH-3888 3/8” x 88” Hydraulic Hose (TF215)

9 12M38F Elbow, 1/2” Male, 3/8” Female

10 1404-045 3/8” Orifice Restrictor (.045)

11 38T-MFF 3/8” T ee (male-female-female)

12 38T-FFM 3/8” Tee (female-female-male)

13 BV-TF1 Ball Valve

14 C1M3F Cross (1 male / 3 female)

Pg. 28

Page 29

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Hydraulic Lines and Fittings for Models TF212 and TF215

EQUIPPED WITH 2-SETS OF HOSES

AND WITHOUT OPTIONAL WING WHEELS

PARTS LIST

Item # Part # Descrip tio n

1 HH-38336 3/8” x 336” Hydraulic Hose (TF212)

1 HH-38384 3/8” x 384” Hydraulic Hose (TF215)

2 HH-3877 3/8” x 77” Hydraulic Hose (TF212)

2 HH-3889 3/8” x 89” Hydraulic Hose (TF215)

3 HH-3865 3/8” x 65” Hydraulic Hose (TF212)

3 HH-3877 3/8” x 77” Hydraulic Hose (TF215)

4 HH-3832 3/8” x 32” Hydraulic Hose (TF212)

4 HH-3844 3/8” x 44” Hydraulic Hose (TF215)

5 HH-3840 3/8” x 40” Hydraulic Hose (TF212)

5 HH-3856 3/8” x 56” Hydraulic Hose (TF215)

6 HH-3862 3/8” x 62” Hydraulic Hose (TF212)

6 HH-3888 3/8” x 88” Hydraulic Hose (TF215)

7 HH-3844 3/8” x 44” Hydraulic Hose (TF212)

7 HH-3860 3/8” x 60” Hydraulic Hose (TF215)

8 HH-3829 3/8” x 29” Hydraulic Hose (TF212)

8 HH-3835 3/8” x 35” Hydraulic Hose (TF215)

9 12M38F Elbow, 1/2” Male, 3/8” Female

10 1404-045 3/8” Orifice Restrictor (.045)

11 38T3F Tee, 3/8” Female (3)

12 38T-FFM 3/8” Tee (female-female-male)

Pg. 29

Page 30

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Hydraulic Lines and Fittings for Model TF212

EQUIPPED WITH OPTIONAL WING WHEELS

PARTS LIST

Item # Part # Descrip tio n

1 HH-12336 1/2” x 336” Hydraulic Hose

2 HH-38210 3/8” x 210” Hydraulic Hose (TF212-32, TF212-33)

2 HH-38222 3/8” x 222” Hydraulic Hose (TF212-34, TF212-35)

2 HH-38234 3/8” x 234” Hydraulic Hose (TF212-36)

3 HH-38174 3/8” x 174” Hydraulic Hose (TF212-32, TF212-33)

3 HH-38186 3/8” x 186” Hydraulic Hose (TF212-34, TF212-35)

3 HH-38198 3/8” x 198” Hydraulic Hose (TF212-36)

4 HH-38162 3/8” x 162” Hydraulic Hose (TF212-32, TF212-33)

4 HH-38174 3/8” x 174” Hydraulic Hose (TF212-34, TF212-35)

4 HH-38186 3/8” x 186” Hydraulic Hose (TF212-36)

5 HH-3862 3/8” x 62” Hydraulic Hose

6 HH-3834 3/8” x 34” Hydraulic Hose

7 HH-3829 3/8” x 29” Hydraulic Hose

8 HH-38112 3/8” x 112” Hydraulic Hose

9 38M38F Elbow, 3/8” Male, 3/8” Female

10 1404-045 3/8” Orifice Restrictor (.045)

11 VBV-1 Valve

12 38T-FFM 3/8” Tee (female-female-male)

13 38M38F-O Elbow, 3/8” Male, 3/8” Female, O-Ring

Pg. 30

Page 31

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Hydraulic Lines and Fittings for Model TF215

EQUIPPED WITH OPTIONAL WING WHEELS

PARTS LIST

Item # Part # Descrip tio n

1 HH-38384 3/8” x 384” Hydraulic Hose

2 HH-38234 3/8” x 234” Hydraulic Hose (TF215-37, TF215-38)

2 HH-38246 3/8” x 246” Hydraulic Hose (TF215-39, TF215-40)

2 HH-38258 3/8” x 258” Hydraulic Hose (TF215-41, TF215-42)

2 HH-38270 3/8” x 270” Hydraulic Hose (TF215-43, TF215-44, TF215-45)

3 HH-38198 3/8” x 198” Hydraulic Hose (TF215-37, TF215-38)

3 HH-38210 3/8” x 210” Hydraulic Hose (TF215-39, TF215-40)

3 HH-38222 3/8” x 222” Hydraulic Hose (TF215-41, TF215-42)

3 HH-38234 3/8” x 234” Hydraulic Hose (TF215-43, TF215-44, TF215-45)

4 HH-38198 3/8” x 198” Hydraulic Hose (TF215-37, TF215-38)

4 HH-38210 3/8” x 210” Hydraulic Hose (TF215-39, TF215-40)

4 HH-38222 3/8” x 222” Hydraulic Hose (TF215-41, TF215-42)

4 HH-38234 3/8” x 234” Hydraulic Hose (TF215-43, TF215-44, TF215-45)

5 HH-3888 3/8” x 88” Hydraulic Hose

6 HH-3854 3/8” x 54” Hydraulic Hose

7 HH-3835 3/8” x 35” Hydraulic Hose

8 HH-38112 3/8” x 112” Hydraulic Hose

9 38M38F Elbow, 3/8” Male, 3/8” Female

10 1404-045 3/8” Orifice Restrictor (.045)

11 VBV-1 Valve

12 38T-FFM 3/8” Tee (female-female-male)

13 38M38F-O Elbow, 3/8” Male, 3/8” Female, O-Ring

Pg. 31

Page 32

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Hydraulic lines and Fittings for Model TF212

EQUIPPED WITH OPTIONAL WING WHEELS

(Since August 2010)

Item#Part#Description

1HH‐38336 1/2"x336"HydraulicHose

2HH‐38210 3/8"x210"HydraulicHose(TF212‐32,TF212‐33)

2HH‐38222 3/8"x222"HydraulicHose(TF212‐34,TF212‐35)

2HH‐38234 3/8"x234"HydraulicHose(TF212‐36)

3HH‐38174 3/8"x174"HydraulicHose(TF212‐32,TF212‐33)

3HH‐38186 3/8"x186HydraulicHose(TF212

‐34,TF212‐35)

3HH‐38198 3/8"x198"HydraulicHose(TF212‐36)

4HH‐38162 3/8"x162"HydraulicHose(TF212‐32,TF212‐33)

4HH‐38174 3/8"x174"HydraulicHose(TF212‐34,TF212‐35)

4HH‐38186 3/8"x186"HydraulicHose(TF212‐36)

5HH‐3862 3/ 8"x62"HydraulicHose

6HH‐3834 3/ 8"x34"HydraulicHose

7HH‐3829 3/ 8"x

29"HydraulicHose

8HH‐38112 3/8"x112"HydraulicHose

9 38M38F Elbow,3/8"Male , 3/8"Female

10 38T‐FFM 3/8"Tee(female‐female‐male)

11 106521 Parke rReliefValvePCK600s‐1.5(SinceAugust2010)

12 106522 Parke rReliefValvePCK600s‐5.0(SinceAugust2010)

13 38M38F‐OElbow,3/8"Male , 3/8"Female,O‐Ring

14 106523 3/8"Mal e 3/8"Male nipple0.62x2.4

15 103524 3/8"Mal e

3/8"FemaleSwiv el0.86x2.4

Pg. 32

Page 33

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Hydraulic Lines and Fittings for Model TF2

(12’ to 18’ Working Width)

PARTS LIST

Item # Part # Descrip tio n

1 HH-38264 3/8” x 264” Hydraulic Hose

2 HH-3877 3/8” x 77” Hydraulic Hose

3 HH-3844 3/8” x 44” Hydraulic Hose

4 HH-3832 3/8” x 32” Hydraulic Hose

5 HH-3865 3/8” x 65” Hydraulic Hose

6 38T3F Tee, 3/8” Female (3)

7 12M38F Elbow, 1/2” Male, 3/8” Female

Pg. 33

Page 34

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Optional Wing Wheel Assembly

PARTS LIST

Item # Part # Descrip tio n

1 WAW-2L Wing Arm Weldment (left)

1 WMB-2R Wing Arm Weldment (right)

2 WMB-2 Wing Arm Mount Bracket

3 125GR5B 1/2" x 5” Grade 5 Bolt

4 12LN 1/2" Lock Nut

5 1149G5B 1 1/4" x 9” Grade 5 Bolt

6 114NLN 1 1/4" Nylon Lock Nut

7 12312G5B 1/2" x 3 1/2" Grade 5 Bolt

8 12G5LN 1/2" Grade 5 Lock Nut

9 3348HCMS 3 3/4” x 8” Hydraulic Cylinder (37TP08-137 639708)

9 38HCMS 3” x 8” Hydraulic Cylinder (30TP08-125 639705)

10 1312P 1” x 3 1/2" Pin

11 CP316 3/16” Cotter Pin

12 1633 Grease Fitting

SK-38HC Seal Kit for Hydraulic Cylinder (not shown)

Pg. 34

Page 35

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Optional Leveling Harrow

REAR

FRONT

Pg. 35

REAR

FRONT

Page 36

TORSION-FLEX SOIL CONDITIONER PARTS LIST

Optional Leveling Harrow

PARTS LIST

# Part # Description # Part # Description

1 321HA 3” x 21” Harrow Arm 14 3415RB 3/4” x 15” Round Bar

2 21246MB 2 1/2” x 4” x 6” Mounting Bracket 15 1244UB 1/2” x 4” x 4” U-Bolt

3 584512UB 5/8” x 4” x 5 1/2” U-Bolt 16 12LN 1/2” Lock Nut

4 58LN 5/8” Lock Nut 17 12112G5B 1/2” x 1 1/2” Grade 5 Bolt

5 346G5B 3/4” x 6” Grade 5 Bolt 18 12214W 1/2” x 2 1/4” O v ersized Washer

6 34LN 3/4” Lock Nut 19 HSB-2 Squeeze Blocks (set)

7 2814CP 2” x 8 1/4” Chain Plate 20 12412G5B 1/2” x 4 1/2” Gr ade 5 Bolt

8 SCP2 Spring Clip Pin 21 CTP38 Coil Tine Pipe x 3’-8” L

9 16RC Chain, 16” L 21 CTP48 Coil Tine Pipe x 4’-8” L

10 381FB 3/8” x 1” Flange Bolt 21 CTP58 Coil Tine Pipe x 5’-8” L

11 38FN 3/8” Flange Nut 21 CTP68 Coil Tine Pipe x 6’-8” L

12 48PB 4” x 8” Pivot Bracket 21 CTP78 Coil Tine Pipe x 7’-8” L

13 RBB40 4’-0” L Round Bar Bracket 22 CTS-1 Coil Tine Spring

13 RBB50 5’-0” L Round Bar Bracket 23 12312JB 1/2” x 3 1/2” J-Bolt

13 RBB60 6’-0” L Round Bar Bracket

13 RBB70 7’-0” L Round Bar Bracket

Pg. 36

Page 37

SERVICE / MAINTENANCE RECORD

Date Description Notes

Pg. 37

Loading...

Loading...