Page 1

TF2

TF212

TF215

Soil Conditioners

OPERATORS MANUAL

Ph: (419) 375-2376 Fax: (419) 375-2708

Rev.3 .21 .2018

J. & M. Mfg. Co., Inc.

284 Railroad Street - P.O. Box 547

Fort Recovery, OH 45846

www.jm-inc.com

Page 2

Table of Contents

To The Dealer 3

General Information 4

Bolt Torque Chart 5

Specications 5

Safety Rules 7

Safety Signs 8

Set-Up Instructions 9-13

Coil Tine Pipe Bar & Round Bar Bracket Layout 14

Operations 15

Transporting, Un-hitching, Field Adjustments 16

Storage, Service, Troubleshooting 17

Parts List 18-32

A-Frame Assembly 18

Main Frame Assembly 19

Outside Wing 20

Wheel Assemblies 21

Torsion Arm 22

Rolling Baskets 23

Coil Tine & Diagonal Bar 24

TF2 Hydraulic Layout 25

TF212-TF215 2 Hoses w/ Lift Assist Hydraulic Layout 26-27

TF212-TF215 4 Hoses w/ Lift Assist Hydraulic Layout 28-29

TF212-TF215 4 Hoses WITHOUT Lift Assist Hydraulic Layout 30

TF212-TF215 2 Hoses WITHOUT Lift Assist Hydraulic Layout 31

Light Harness 32

2

Page 3

To The Dealer

General Information

Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists are completed

before releasing equipment to the owner.

The dealer must complete the Warranty Registration found on the Dealer Portal website located at dealer.jm-inc.com and return

it to J. & M. Mfg. Co., Inc. at the address indicated on the form. Warranty claims will be denied if the Warranty Registration has not been

submitted.

EXPRESS WARRANTY:

J. & M. Mfg. Co. Inc. warrants against defects in construction or materials for a period of ONE year. We reserve the right to inspect

and decide whether material or construction was faulty or whether abuse or accident voids our guarantee.

Warranty service must be performed by a dealer or service center authorized by J. & M. Mfg. Co., Inc. to sell and/or service the type

of product involved, which will use only new or remanufactured parts or components furnished by J. & M. Mfg. Co., Inc. Warranty

service will be performed without charge to the purchaser for parts or labor based on the Warranty Labor Times schedule. Under no

circumstance will allowable labor times extend beyond the maximum hours indicated in the Warranty Labor Times schedule for each

warranty procedure. The purchaser will be responsible, however, for any service call and/or transportation of the product to and

from the dealer or service center’s place of business, for any premium charged for overtime labor requested by the purchaser, and

for any service and/or maintenance not directly related to any defect covered under the warranty. Costs associated with equipment

rental, product down time, or product disposal are not warrantable and will not be accepted under any circumstance.

Each warranty term begins on the date of product delivery to the purchaser. Under no circumstance will warranty be approved

unless (i) the product warranty registration card has been properly completed and submitted to the equipment manufacturer, and

(ii) a warranty authorization number has been issued by the equipment manufacturer. This Warranty is eective only if the warranty

registration card is returned within 30 days of purchase.

This warranty does not cover a component which fails, malfunctions, or is damaged as a result of (i) improper modication or

repair, (ii) accident, abuse or improper use, (iii) improper or insucient maintenance, or (iv) normal wear or tear. This warranty

does not cover products that are previously owned and extends solely to the original purchaser of the product. Should the original

purchaser sell or otherwise transfer this product to a third party, this implied, with respect to tires or other parts or accessories not

manufactured by J. & M. Mfg. Co., Inc. Warranties for these items, if any, are provided separately by their respective manufacturers.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

In no event shall J. & M. Mfg. Co., Inc. be liable for special, direct, incidental or consequential damages of any kind. The exclusive

remedy under this Warranty shall be repair or replacement of the defective component at J. & M. Mfg. Co., Inc’s. option. This is the

entire agreement between J. & M. Mfg. Co., Inc. and the Owner about warranty and no J. & M. Mfg. Co., Inc. employee or dealer is

authorized to make any additional warranty on behalf of J. & M. Mfg. Co., Inc.

The manufacturer reserves the right to make product design and material changes at any time without notice. They shall not incur

any obligation or liability to incorporate such changes and improvements in products previously sold to any customer, nor shall

they be obligated or liable for the replacement of previously sold products with products or parts incorporating such changes.

SERVICE:

The equipment you have purchased has been carefully manufactured to provide dependable and satisfactory use. Like all

mechanical products, it will require cleaning and maintenance. Lubricate the unit as specied. Observe all safety information in

this manual and safety signs on the equipment.

For service, your authorized J. & M. dealer has trained mechanics, genuine J. & M. service parts, and the necessary tools and

equipment to handle all your needs.

Use only genuine J. & M. service parts. Substitute parts may void warranty and may not meet standards required for safe and

satisfactory operation. Record the model number and serial number of your equipment in the spaces provided:

Model No:______________ Serial No: ________________________ Date of Purchase: ___________________

Purchased From: ________________________________________________________________________________

Provide this information to your dealer to obtain correct repair parts.

3

Page 4

To The Dealer

General Information

TO THE OWNER:

The purpose of this manual is to assist you in operating and maintaining your soil conditioner in a safe manner. Read it carefully. It

furnishes information and instructions that will help you achieve years of dependable performance and help maintain safe operating

conditions. If this machine is used by an employee or is loaned or rented, make certain that the operator(s), prior to operating:

1. Is instructed in safe and proper use.

2. Reviews and understands the manual(s) pertaining to this machine.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to equipment. The

terms CAUTION, WARNING and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with an exclamation mark)

to indicate the degree of hazard for items of personal safety. When you see this symbol, carefully read the message that follows and

be alert to the possibility of personal injury or death.

This Safety-Alert symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER

WARNING

CAUTION

IMPORTANT

NOTE

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, will

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

4

Page 5

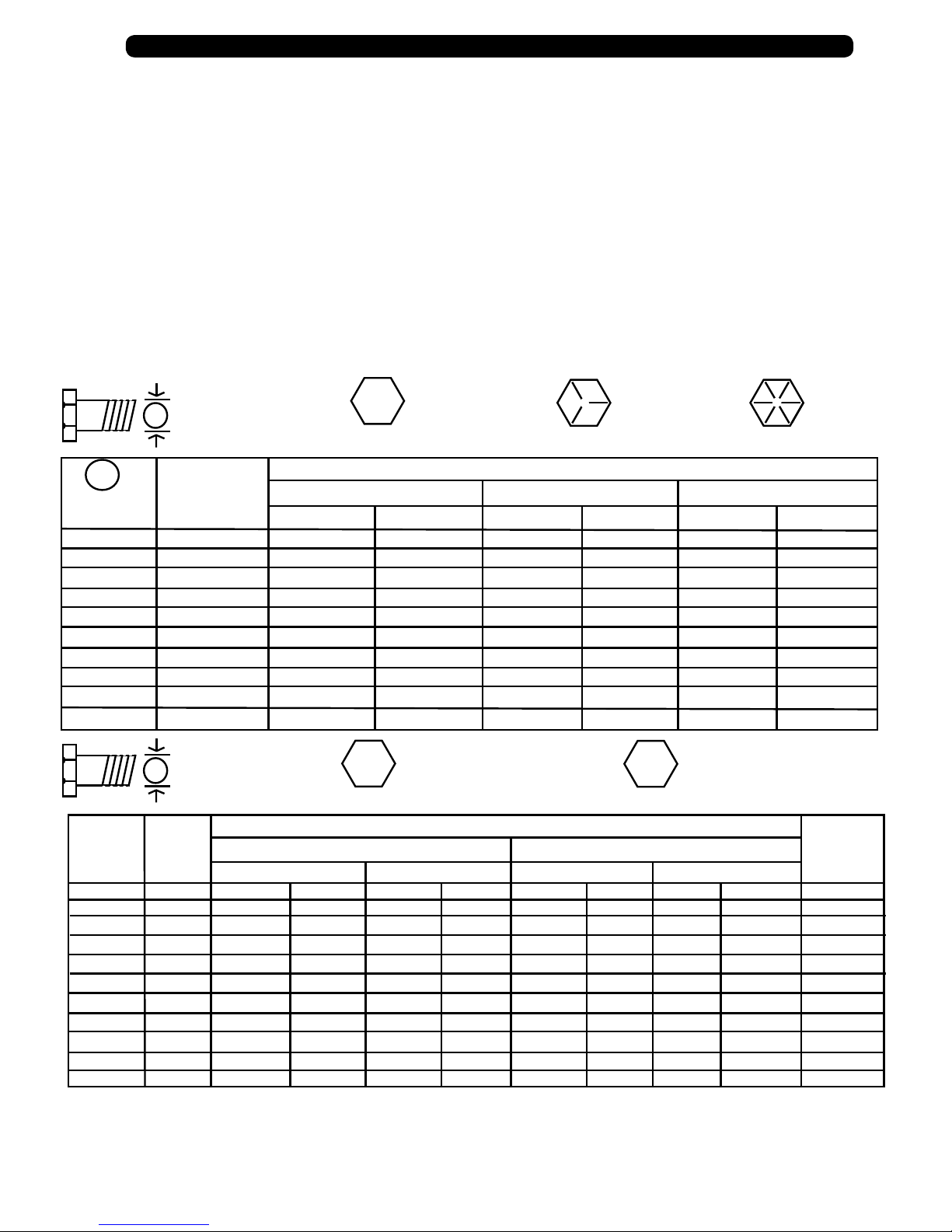

General InformationBolt Torque Chart

BOLT TORQUE CHART

Always tighten hardware to these values unless a dierent torque or tightening procedure is listed for a specic

application.

Fasteners must always be replaced with the same grade as specied in the manual parts list.

Always use the proper tool for tightening hardware. SAE for SAE hardware and Metric for metric hardware.

Make sure fastener threads are clean and you start the thread engagement properly. All torque values are given

to specication used on hardware dened by SAE J1701 & J1701M (Jul 96).

A

Diameter

(Inches)

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

Diameter

&

(Millimeters)

Thread Pitch

6 x 1.0

8 x 1.25

10 x 1.5

12.1.75

14 x 2.0

16 x 2.0

18 x 2.5

20 x 2.5

22 x 2.5

24 x 3.0

30 x 3.0

SAE SERIES

TORQUE

A

CHART

Wrench

Size

7/16”

1/2”

9/16”

5/8”

3/4”

13/16”

15/16”

1-1/8”

1-5/16”

1-1/2”

METRIC SERIES

TORQUE

A

CHART

Wrench

Size

10 mm

13 mm

16 mm

18 mm

21 mm

24 mm

27 mm

30 mm

34 mm

36 mm

46 mm

109

169

234

330

451

571

1175

SAE Bolt Head

Identication

SAE Grade 2

(No Dashes)

SAE Grade 5

3 Radial Dashes

SAE Grade 8

6 Radial Dashes

MARKING ON HEAD

SAE 2

LBS.-FT.

6

12

23

36

55

78

110

192

306

467

8

17

31

48

75

106

149

261

416

634

8.8

Metric

Grade 8.8

COARSE THREAD FINE THREAD

8

20

39

68

125

172

244

332

421

867

6

15

29

50

80

11

27

54

94

151

234

323

457

623

790

1626

LBS.-FT.

Metric Bolt Head

Identication

8

20

40

70

111

173

239

337

460

583

1199

SAE 5 SAE 8

N-m N-m

10

19

35

55

85

121

170

297

474

722

13

26

47

75

115

164

230

403

642

979

10.9

Metric

Grade 10.9

MARKING ON THREADMARKING ON THREAD

11

29

57

103

163

250

363

507

684

861

1740

21

41

75

118

181

263

367

495

623

1258

8

6

16

30

55

87

133

194

270

365

459

928

Metric 10.9Metric 8.8Metric 8.8 Metric 10.9

LBS.-FT.N-m

1020

14

27

49

78

120

171

240

420

669

22

42

76

120

184

268

374

505

635

1283

18

37

67

106

163

232

325

569

907

1383

Diameter

&

(Millimeters)

Thread Pitch

8

6 x 1.0

8 x 1.0

10 x 1.25

12.1.25

14 x 1.5

16 x 1.5

18 x 1.5

20 x 1.5

22 x 1.5

24 x 2.0

30 x 2.0

5

Page 6

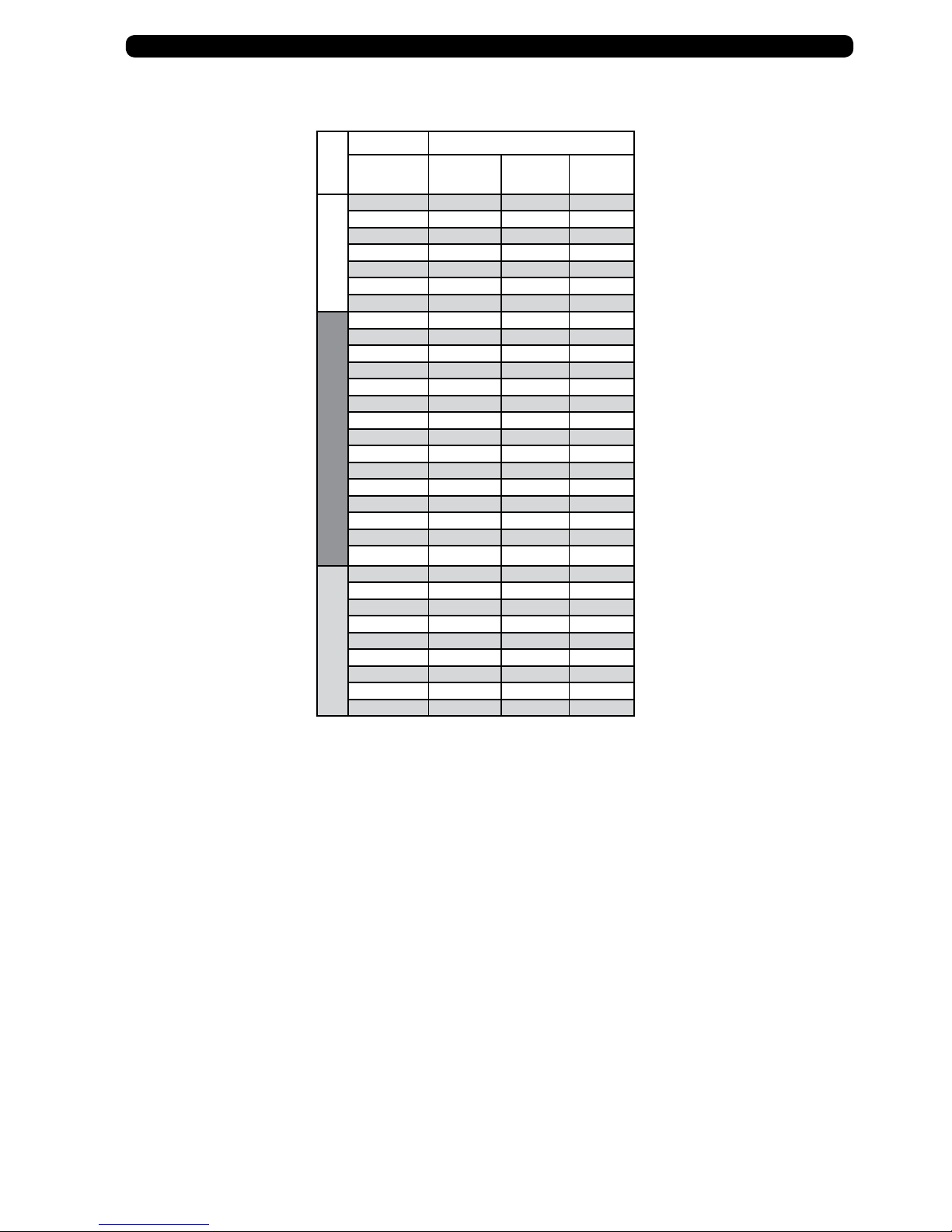

To The DealerSpecications

Specications Basket Sizes & Layout

Working

Width

Transport

Width

Base

Width

Wings Each Approx.

Width

Side Wing Base Unit Side Wing

12’ 12’ 12’ N/A 2,195 lbs. 6’ 6’

13’ 13’ 12’ N/A 2,310 lbs. 4’ 5’ 4’

14’ 14’ 12’ N/A 2,425 lbs. 5’ 4’ 5’

15’ 15’ 15’ N/A 2,540 lbs. 5’ 5’ 5’

16’ 16’ 15’ N/A 2,655 lbs. 5’ 6’ 5’

Model TF2

17’ 17’ 15’ N/A 2,770 lbs. 6’ 5’ 6’

18’ 18’ 15’ N/A 2,885 lbs. 6’ 6’ 6’

20’ 13’5” 12’ 4’ 4,415 lbs. 4’ 6’ 6’ 4’

22’ 13’5” 12’ 5’ 4,645 lbs. 5’ 6’ 6’ 5’

23’ 13’5” 12’ 5’6” 4,760 lbs. 5.5’ 6’ 6’ 5.5’

24’ 13’5” 12’ 6’ 4,875 lbs. 6’ 6’ 6’ 6’

26’ 13’5” 12’ 7’ 5,105 lbs. 3.5’ 3.5’ 6’ 6’ 3.5’ 3.5’

27’ 13’5” 12’ 7’6” 5,220 lbs. 3.5’ 4’ 6’ 6’ 4’ 3.5’

28’ 13’5” 12’ 8’ 5,335 lbs. 4’ 4’ 6’ 6’ 4’ 4’

29’ 13’5” 12’ 8’6” 5,450 lbs. 3.5’ 5’ 6’ 6’ 5’ 3.5’

30’ 13’5” 12’ 9’ 5,565 lbs. 4’ 5’ 6’ 6’ 5’ 4’

Model TF212

31’ 13’5” 12’ 9’6” 5,680 lbs. 3.5’ 6’ 6’ 6’ 6’ 3.5’

32’ 13’5” 12’ 10’ 5,795 lbs. 5’ 5’ 6’ 6’ 5’ 5’

33’ 13’5” 12’ 10’6” 5,910 lbs. 5’ 5.5’ 6’ 6’ 5.5’ 5’

34’ 13’5” 12’ 11’ 6,025 lbs. 5.5’ 5.5’ 6’ 6’ 5.5’ 5.5’

35’ 13’5” 12’ 11’6” 6,140 lbs. 5.5’ 6’ 6’ 6’ 6’ 5.5’

36’ 13’5” 15’ 12’ 6,255 lbs. 5 ’ 5.5’ 5’ 5’ 5’ 5.5’ 5’

37’ 15’5” 15’ 11’ 6,370 lbs. 5’ 6’ 6’ 6’ 5’ 5’

38’ 15’5” 15’ 11’6” 6,485 lbs. 5.5’ 6’ 5’ 5’ 5’ 6’ 5.5’

39’ 15’5” 15’ 12’ 6,600 lbs. 6’ 6’ 5’ 5’ 5’ 6’ 6’

40’ 15’5” 15’ 12’6” 6,715 lbs. 3.5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’ 3.5’

41’ 15’5” 15’ 13’ 6,830 lbs. 4’ 5’ 5’ 5’ 5’ 5’ 5’ 4’ 4’

42’ 15’5” 15’ 13’6” 6,945 lbs. 3.5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 3.5’

43’ 15’5” 15’ 14’ 7,060 lbs. 4’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’

Model TF215

44’ 15’5” 15’ 14’6” 7,175 lbs. 4’ 5’ 5.5’ 5’ 5’ 5’ 5.5’ 5’ 4’

45’ 15’5” 15’ 15’ 7,290 lbs. 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’

6

Page 7

Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our eorts to provide safe

equipment can be erased by an operator’s single careless act. In addition, hazard control and accident prevention are

dependent upon the awareness, concern, judgment, and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

Make certain that the operator(s), prior to operating is instructed in safe and proper use and reviews and understands

the manual(s) pertaining to this machine.

Read this manual before you operate this machine. If you do not understand any part of this manual, or need more

information, contact the manufacturer or your authorized dealer.

SAFETY

Understand that your safety and the safety of other persons is measured by how you service, and operate this machine.

Know the positions and functions of all controls before you try to operate them. Make sure to check all controls in a safe

area before starting your work.

The safety information given in this manual does not replace safety codes, federal, state or local laws. Make certain your

machine has the proper equipment as designated by local laws and regulations.

A frequent cause of personal injury or death is from persons falling o equipment and being run over. Do not permit

persons to ride on this machine.

Travel speeds should be such that complete control and machine stability is maintained at all times. Where possible,

avoid operating near ditches, embankments and holes. Reduce speed when turning, crossing slopes and rough, slick

or muddy surfaces.

Collision of high speed road trac and slow moving machines can cause personal injury or death. On roads, use asher

lights according to local laws. Keep slow-moving-vehicle emblem visible. Pull over to let faster trac pass.

Never adjust, service, clean, or lubricate running gear until all power is shut o.

Keep all safety shields in place.

Keep hands, feet, hair and clothing away from moving parts while unit is in operation.

Make sure that everyone is clear of equipment before applying power or moving the machine.

Make sure that the implement is fastened securely to the tractor by using the proper hitch pin, clip and safety chains.

Do NOT exceed speeds in excess of 20 MPH. Also be sure slow moving vehicle emblem is attached to rear of transport.

Before unhooking the implement from the towing unit, be sure to properly block the wheels to prevent the implement from moving. Be sure the jack assembly is positioned in the park position and the weight has been transferred

to the jack assembly before unhooking the implement.

7

Page 8

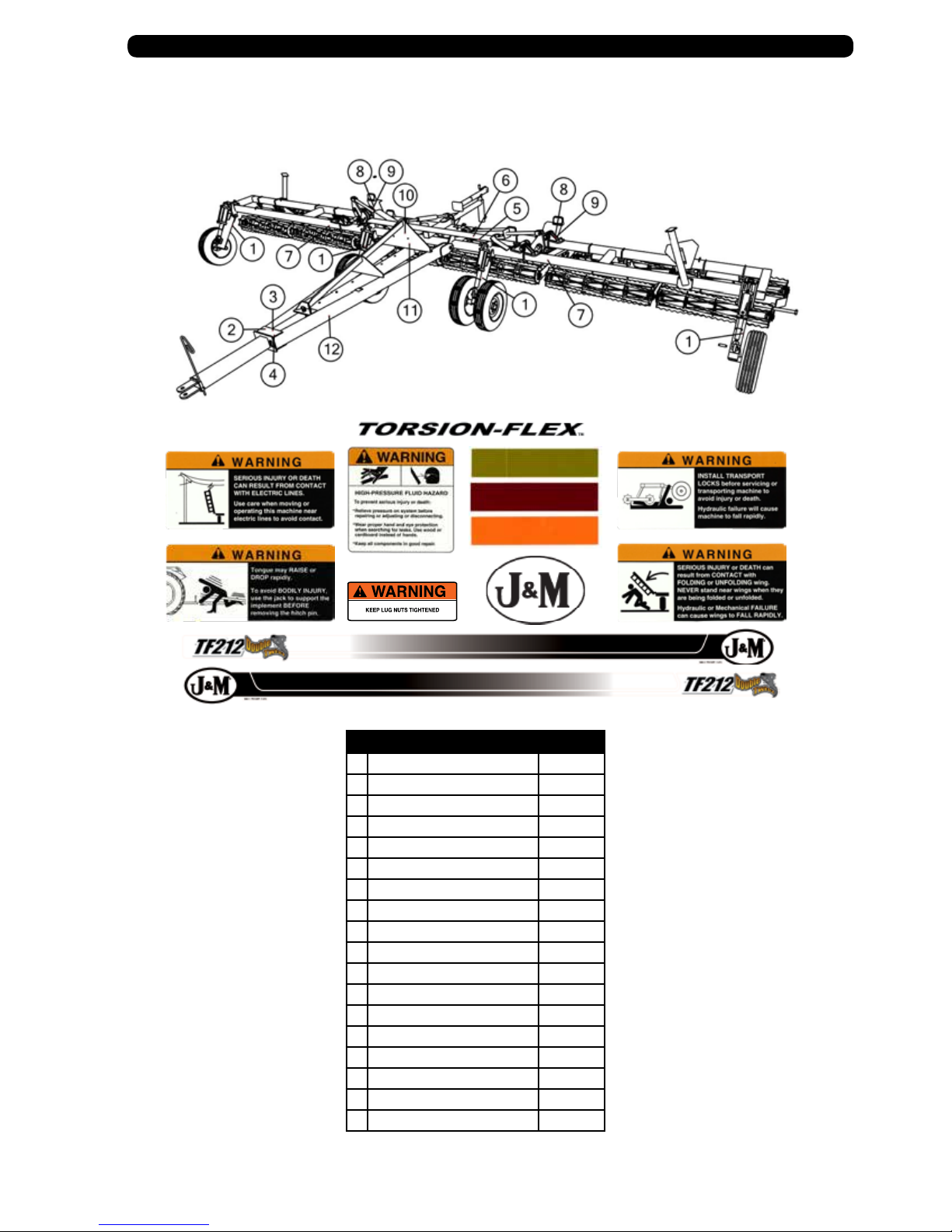

Safety Signs

IMPORTANT: Install new safety signs if the old signs are destroyed, lost, painted over or cannot be read. When parts are replaced that have safety signs,

make sure you install a new sign with each new part. New signs are available from the manufacturer or your authorized dealer.

# Description Part #

1 Warning: Keep Lug Nuts Tight JM0010150

2 Warning: Rapidly Rising Tongue JM0010181

3 Warning: Electric Lines JM0010182

4 Warning: High Pressure Fluid JM0010163

5 Warning: Transport Locks JM0010167

6 Warning: Folding Wings JM0014992

7 Reective Amber Decal JM0009946

8 Reective Red Decal JM0009945

9 Reective Orange Decal JM0009944

10 Medium Size J&M Oval JM0010179

11 Small “J&M Manufacturing” Decal JM0010180

12 “TF2” Decal Driver Side JM0027693

12 “TF2” Decal Passenger Side JM0027688

12 “TF212” Decal Drivers Side JM0027692

12 “TF212” Decal Passenger Side JM0027689

12 “TF215” Decal Drivers Side JM0027691

12 “TF215” Decal Passenger Side JM0027690

13 “Torsion-Flex” Decal JM0010173

8

Page 9

Set-Up Instruction

The J&M Torsion-Flex Soil Conditioner is shipped with components partially assembled. Hardware required to connect the Base Wheel

Assembly, Main Base Frame Assembly, Wing Frames and Tongue Assembly should already be secured to the components at the point of

attachment.

The hydraulic cylinders have the ttings already installed and are secured to the base wheel assembly. The hydraulic hoses and light harness

wires should be inserted into the component tubing and simply require the ends to be connected.

Each basket frame should have the rolling baskets and torsion ex arm installed. Refer to the Basket Size and Layout, located on the right

side of the chart on page 5 of the Operator’s Manual for recommended basket layout. Be sure the baskets with the 3” x 3” Torsion Bars are

secure to the Main Base Unit and the baskets with the smaller 2 1/2” x 2 1/2” Torsion Bars are secured to the side wings.

Optional Li Assist

Wheel Assembly

Wing Unit Baskets

2-1/2” x 2-1/2” Torsion Arm

Right Wing Frame

Base Unit Baskets

3” x 3” Torsion Arm

Base Wheel Assembly

Wing Unit Baskets

2-1/2” x 2-1/2” Torsion Arm

Main Base Frame

Le Wing Frame

Base Wheel Assembly Optional Li Assist

Wheel Assembly

Tongue Assembly

9

Page 10

To The DealerSet-Up Instructions

• Wheel Arm Weldment

Attach the wheel are weldment to the main frame.

Use a 1-1/4” x 9 “ hex bolt and 1-1/4” hex nut.

Tighten hardware.

• Wheel & Tire Assembly

Attach the wheel and tire assembly using (6) 1/2” wheel nuts.

Align the wheel and hub and tighten the wheel nuts in a star

pattern to 80 Ft. Lbs. Check the wheel nuts periodically to

ensure they remain tight.

• Lift Cylinder

Attach the lift cylinder to the main frame using a 1” x 5” hex bolt and a 1” nylon locking

hex nu t. Attach the lift c ylinder to the wheel arm weldment using a 1” x 3-1/2” clevis pin

and (2) cotter pins. Fasten hardware once secured.

Install the cylinder lock, fasten with provided lynch pin.

• Turnbuckle

Secure one end of the turn buckle assembly to the top of the main

frame as shown using one 1” x 3-1/2” clevis pin and cotter pin.

Turnbuckle

Li Cylinder

Wheel Arm Weldment

Cylinder Lock

Wheel & Tire Assembly

• A-Frame Weldment

Connect the A-Frame to the Base Unit.

Use (2) 1-1/4” x 6” hex bolts and (2) 1-1/4” nylon locking hex nuts.

Tongue Pin

Both bolts face the inside of the A-frame. Fasten hardware once secured.

• Turnbuckle

Secure the other end of the turn buckle assembly to the top of the

Hose Holder Rod

A-Frame

A-frame using a 1” x 3-1/2” clevis pin and cotter pin.

• Tongue Weldment

Slide Tongue Weldment inside the A-frame. Secure with 1” x 8” tongue pin.

Attach Hose Holder Rod to the Tongue Weldment.

Fasten with 3/8” x 3/4” hex bolt. Fasten hardware once secured.

Tongue Weldment

• Hydraulic Hoses & Light Harness

Based on your model go to pages 22-28 to nd the destination of each hydraulic

hose. Connect the A-Frame harness to the Main Frame harness. Secure with zip-ties.

WARNING: Before attaching the cylinders to the wing linkage, charge the cylinders with hydraulic oil to bleed all air out of the system, and then check for

any leaks. Failure to do so could cause erratic, sudden movement of the wings which could damage the equipment and cause serious injur y or death.

10

Page 11

General InformationSet-Up Instructions

• Base Unit Baskets

Attach the 3’ Heavy Torsion arms to the rolling basket. Secure with 1” x 6-1/2” hex

bolt and 1” nylon locking hex nut. Fasten hardware once secured.

(Rocker Pads may need installed. Use 4-1/8” x 4-1/2” x 5/8” U-Bolt and (2) 5/8”

nylon locking hex nuts.)

Make sure the baskets are symmetrically placed on the Base Unit Main

Frame and have a 1-1/2” clearance between baskets.

NOTE: Be sure the basket assemblies with the 3” x 3” torsion arms are secured to the

Base Unit Main Frame. The rolling basket assemblies for the side wings have a smaller

2-1/2” x 2-1/2” torsion arm.

• Attach the torsion arm - rolling basket assembly to the main frame. Secure each

torsion arm with (2) 5/8” x 4” x 6” U-bolts and a 5/8” centerlock hex nut.

Fasten hardware once secured.

• Jack Stand

Secure the Jack Stand Weldment to the Main Frame using (5) 1/2” x 1-1/2” hex

bolts and (5) 1/2” centerlock hex nuts. Fasten hardware once secured.

Attach the jack stand to the support arm using the supplied pin.

Torsion Arms

3” x 3”

Rolling Basket

Rocker Pad

5/8” x 4” x 6”

U-Bolts

Jack Stand

1/2” x 1-1/2”

• Wing Frame

Attach the Wing Frames to the Main Frame. For each wing use :

• 1-3/4” x 6-3/8” Welded Pin

• 1-3/4”x 5” Welded Pin

• (2) 1-3/4” Hex Nuts

• 4” Wing Pin

• (4) Roll Pins

Once secured, fasten hardware.

• Wing Rest

Attach a Wing Rest weldment to each wing. Secure using (4) 1/2” x 1-1/4” hex

bolts and (4) 1/2” centerlock hex nuts.

Once secured, fasten hardware.

Jack Stand Weldment

Wing Frame

Wing Rest

1-3/4” x 6-3/8” 4” Wing Pin 1-3/4”x 5”

11

Page 12

To The DealerSet-Up Instructions

• Wing Baskets

Attach the 2’ Light Torsion arms to the rolling basket. Secure with 1” x 6-1/2”

hex bolt and 1” nylon locking hex nut. Fasten hardware once secured.

(Rocker Pads may need installed. Use 4-1/8” x 4-1/2” x 5/8” U-Bolt and (2) 5/8”

nylon locking hex nuts.)

Make sure the wing baskets are placed according to the “Basket Sizes and Layout”

section of the chart found on page 5. IMPORTANT: Make sure the wing baskets

closest to the baskets on the Base Unit baskets have a clearance of 2”. The

spacing between each wing baskets should have a clearance of 1-1/2”.

• Attach each torsion arm - rolling basket assembly to the wing. Secure each

torsion arm with (2) 5/8” x 4” x 6” U-bolts and (4) 5/8” centerlock hex nuts.

Torsion Arms

2-1/2” x 2-1/2”

Rocker Pad

Rolling Basket

5/8” x 4” x 6”

U-Bolts

• Lights and Light Brackets

Secure both Red Lights to the Main Frame using (4) 1/4” self tapping screws for

each light.

Secure both Amber Lights and Light Brackets to the Main Frame using (4) 1/4” x

5/8” hex bolts and (4) 1/4” hex nuts per light.

Connect all lights to the main wiring harness. The main harness is installed and

located inside the frame. All remaining wiring needs to be stored inside the frame.

• Optional Wing Wheels

Secure the Wing Arm Mount Bracket to the Wing. Place bracket approximately 6” from

the outside of the Wing. Secure using (2) 1/2” x 6” hex bolts and (2) 1/2” centerlock hex

nuts. Fasten hardware once secured.

Attach the Wing Arm Weldment to the Mount Bracket. Secure with a 1-1/4” x 10” hex

bolt and 1-1/4” nylon locking hex nut.

Attach the wheel and tire assembly using (6) 1/2” wheel nuts.

Align the wheel and hub and tighten the wheel nuts in a star

pattern to 80 Ft. Lbs. Check the wheel nuts periodically to

ensure they remain tight.

Attach the hydraulic cylinder to the Wing Arm Weldment. Secure with a 1” x 5” hex

bolt, 1” nylon locking hex nut, 1” x 3-1/2” clevis pin, and (2) cotter pins. Fasten

hardware once secure. Install the cylinder lock, fasten with provided lynch pin.

NOTE: See page 22-26 for correct hydraulic cylinder layout.

Wing Arm Mount Bracket

Amber Light

Red Light

1” x 5” Hex Bolt

1-1/4” x 9” Hex Bolt

1/2” x 6” Hex Bolt

Hydraulic Cylinder

Wing Arm Weldment

1” x 3-1/2” Clevis Pin

Tire & Wheel Assembly

12

Page 13

General InformationSet-Up Instructions

• Coil Tine Spring Assembly

For part identication, refer to page 24.

For Coil Tine Spring Assembly layout see page 14.

Attach the Coil Tine Spring Assembly to the main frame or wing weldment.

Secure the Coil Tine Spring Assembly with (2) 1/2” x 4-1/8” x 5” U-bolts and (4) 1/2”

centerlock hex nuts. Fasten hardware once secured.

• Round Bar Assembly

For part identication, refer to page 24.

For Round Bar Assembly layout see page 14.

Attach the Round Bar Assembly to the main frame or wing weldment.

Secure the Round Bar Assembly with (2) 1/2” x 4-1/8” x 5” U-bolts and (4) 1/2”

centerlock hex nuts. Fasten hardware once secured.

1/2” x 4-1/8” x 5” U-Bolt

Coil Tine Spring Assembly

Round Bar Assembly

13

Page 14

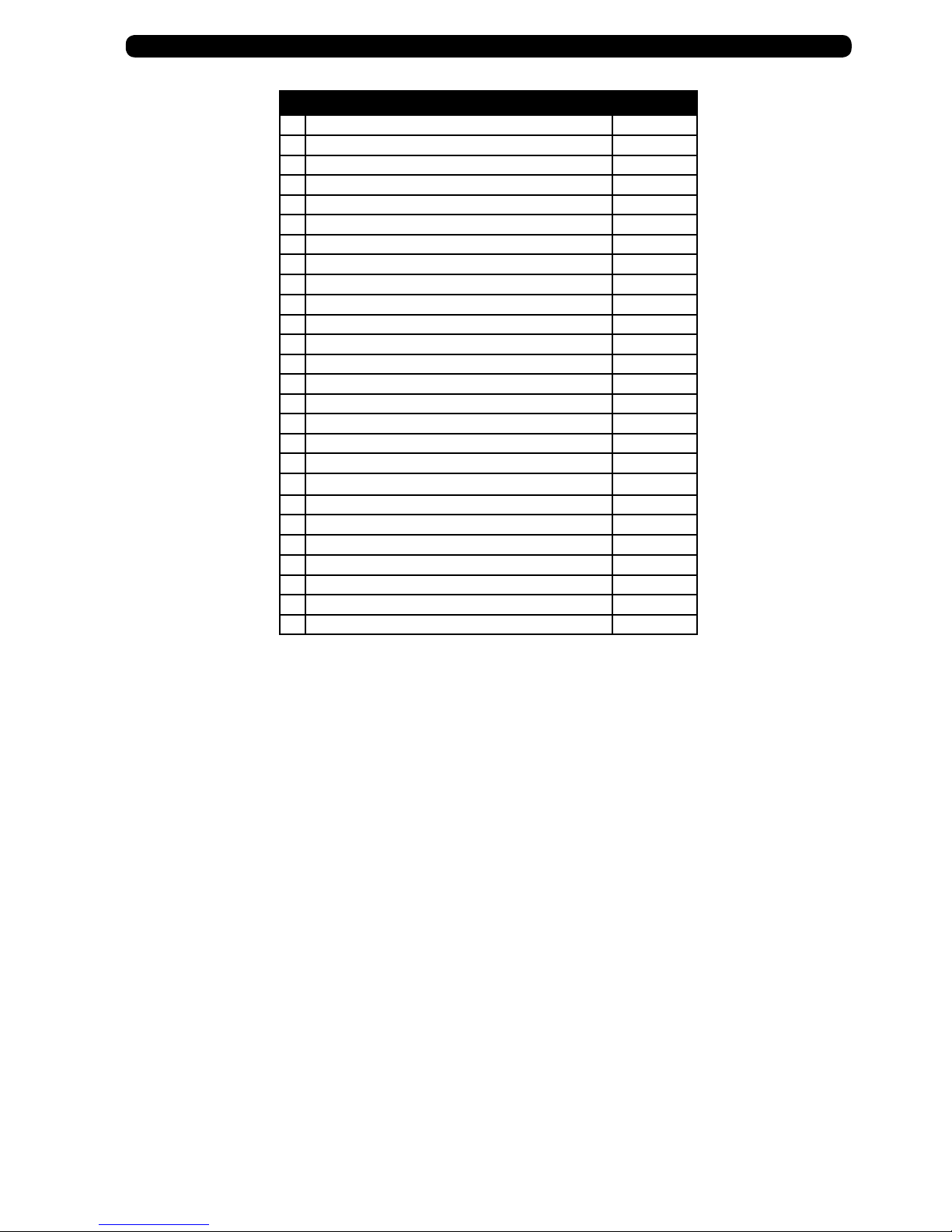

To The DealerCoil Tine Pipe Bar & Round Bar Bracket Layout

Below is a recommended layout of the harrow pipe bar and round bar bracket lengths along the width of the conditioner.

Be sure the Harrow is properly and evenly spaced along the Base Unit Main Frame and Wing Frames, making adjustments as

necessary.

Specications Basket Sizes & Layout

Working

Width

12’ 6’ 6’

13’ 4’ 5’ 4’

14’ 5’ 4’ 5’

15’ 5’ 5’ 5’

16’ 5’ 6’ 5’

17’ 6’ 5’ 6’

Model TF2

18’ 6’ 6’ 6’

20’ 4’ 6’ 6’ 4’

22’ 5’ 6’ 6’ 5’

23’ 5’ 6’ 6’ 5’

24’ 6’ 6’ 6’ 6’

26’ 7’ 6’ 6’ 7’

27’ 7’ 6’ 6’ 7’

28’ 4’ 4’ 6’ 6’ 4’ 4’

29’ 4’ 5’ 6’ 6’ 5’ 4’

30’ 4’ 5’ 6’ 6’ 5’ 4’

31’ 4’ 6’ 6’ 6’ 6’ 4’

32’ 5’ 5’ 6’ 6’ 5’ 5’

33’ 5’ 5’ 6’ 6’ 5’ 5’

34’ 5’ 6’ 6’ 6’ 6’ 5’

35’

36’ 6’ 6’ 6’ 6’ 6’ 6’

Model TF 212

37’ 5’ 6 ’ 6’ 6’ 5’ 5’

38’ 5’ 6’ 5’ 5’ 5’ 6’ 5’

39’ 6’ 6’ 5’ 5’ 5’ 6’ 6’

40’ 7’ 5’ 5’ 5’ 5’ 5’ 7’

41’ 4’ 4’ 5’ 5’ 5’ 5’ 5’ 4’ 4’

42’ 4’ 4’ 5’ 5’ 5’ 5’ 5’ 4’ 4’

43’ 4’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’

44’ 4’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 4’

Model TF215

45’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’ 5’

Side Wing Base Unit Side Wing

5’ 6’

6’ 6’ 6’ 5’

14

Page 15

Operations

PREPARING THE TORSION-FLEX SOIL CONDITIONER

Before putting the soil conditioner into operation, check the machine for damaged or worn parts and replace as necessary.

Hardware

Make sure all hardware is properly fastened according to the Bolt Torque chart found in this manual. Recheck all hardware for tightness after the

unit has been operated for several hours. Check all pins and retaining rings are in good condition. Replace any pins of retaining rings that are worn,

damaged or missing.

Hydraulic Hoses

Check all the hydraulic hoses to make sure there are not rubbing against sharp edges or are kinked or twisted. Hoses should be secured to the soil

conditioner with nylon tie straps. Check hoses and tting for hydraulic leaks. Tighten or replace as necessary.

Lubrication

Lubricate the Torsion-Flex soil conditioner according to the Lubrication Schedule outlined in the SERVICE section of this manual.

Tires and Wheels

Check the tire pressure in the transport tires. The recommended air pressure is 46 PSI. Make sure the tire pressure is equal in all tires. Make sure the

wheel lug nuts are tightened to 80 Ft. Lbs. Check the wheel lug nuts before initial operation and after the unit has been operated for several hours

to ensure the lug nuts remain tight.

Adjusting the Inner Tongue

Before attaching the Torsion-Flex soil conditioner to your primary tillage tool, extend the inner tongue of the A-Frame Tongue Assembly to ensure

adequate turning clearance between the implements when turning. Adjust the Inner Tongue length by removing the 1” x 8” Tongue Pin and Cotter

Pin. Readjust the Inner Tongue to the appropriate setting and re-pin as before.

Attaching to the Primary Tillage Tool

Back the primary tillage tool into position and attach the soil conditioner to the implement using a high quality hitch pin and clip and lock into

place. Install a transport chain. Transport chain should have a minimum rating equal to the gross weight of implement and all attachments. Use

only ASAE approved chains. If the unit is parked in the transport position, turn the handle on the jack stand after the soil conditioner has been

connected to the primary tillage tool to remove pressure. Remove the Jack Assembly from the storage position and re-pin to the transport position

located on top of the Storage Extension Arm.

Unfolding the Wings / Removing the Transport Locks

It is recommended to unfold the side wings in the eld. Remove the wheel lift cylinder transport locks so the unit may be lowered to the eld

working position. Pin the transport locks on the back of the A-Frame Tongue Assembly for easy storage.

15

Page 16

Transporting

Before the soil conditioner is transported, be sure to secure the Jack Assembly in the transport position located on the top of the Storage Extension

Arm.

The Torsion-Flex Soil Conditioner will increase the overall length of the primary tillage tool. Use extreme caution when turning to avoid obstacles.

Reduce ground speed as necessary to maintain control of equipment.

Install hydraulic cylinder transport locks on the Base Unit wheels BEFORE transporting.

Comply with ALL state and local laws governing highway safety and regulations

when moving machinery on public roads. Be sure an SMV emblem is in place and

clearly visible on the rear of the conditioner. Make sure all lights are clearly visible

and working properly BEFORE highway travel. Be sure the amber, red and orange

retroreective tape on the implement is in place and clearly visible.

The transport speed should not exceed 10 MPH in the eld or over rough terrain.

Reduce transport speed when necessary to maintain full control of the implement

at all times.

Unhitching

WARNING – Before unhooking the soil conditioner, be sure to install the hydraulic cylinder transport locks. Reposition the jack stand on the Storage

Extension Arm to the parked position and lower the jack stand to the ground by turning the handle until weight of the soil conditioner is transferred

to the jack. Keep hands and feet away from the jack stand when lowering.

Remove the Hitch Pin and unhook the safety chains.

WARNING – Always relieve hydraulic system pressure before disconnecting hoses from tractor or servicing hydraulic system. See the tractor’s operators manual for proper procedures. Disconnect the hydraulic hoses. Install dust covers over the hose plugs and outlets.

Field Adjustments

The Torsion-Flex Soil Conditioner is designed to provide an excellent seedbed when used in conjunction with you primary tillage tool. For maximum

performance in normal eld conditions, the soil conditioner should be used with the transport wheels in the raised position to allow maximum

transfer of weight to the rolling baskets.

With the wheels in the raised position, adjust the Turn Buckle Adjustment Bar until the wheels are approximately 2” above the ground. This will set

your Torsion-Flex Soil Conditioner at the maximum clearance height during transport.

The Spring Coil-Tine Harrow Bar is designed to improve the soil leveling capabilities of your conditioner. To improve the ground leveling capabilities of

the harrow in heavier soils, pin the harrow bar so the coil-tines are positioned more vertically. In softer soils or to improve eld residue ow through

the leveler bar, position the bar with a decreased vertical angle of the tines.

16

Page 17

Storage

To add longer service and life to your Torsion-Flex Soil Conditioner, perform the following before placing the implement in storage:

1. Remove dirt and trash that may cause rusting.

2. Repaint any areas where the paint has been chipped, scratched or worn away.

3. Coat all earth moving surfaces with a suitable rust preventative.

4. Inspect for damaged or worn parts and replace before next use.

5. Lubricate wing and wheel pivot points.

6. Block up the conditioner to keep the wheels and ground tools o the ground.

7. Replace all worn, torn and faded decals and reectors.

8. Store the implement inside away from inclement weather.

Service

To add longer life to your Torsion-Flex Soil Conditioner, perform the following on a regular basis:

1. Grease hinge, linkage area and wheel transport pivots (3X) weekly or

every 40 hours. Grease the 4-Hole Flange Bearings (1X) on the Rolling

Basket Assembly every 50 Hours.

2. Check lighting before over the road transport. Make sure lights and

SMV emblem are clean from dirt and eld debris.

3. Check implement for damage, cracked welds, loosened hardware,

etc. Promptly repair to prevent further damage.

4. Check hydraulic system for leaks and hose damage, twists or kinks

and make necessary repairs.

Bearings

5. Check tire pressures and lug nuts periodically and adjust as required.

Pivots

NOTE: Basket bearings do not need greased before the rst use. e basket bearings are greased at the factory.

Troubleshooting

When Hydraulics Are Not Functioning Properly...

PROBABLE CAUSE CORRECTION

Hoses are incorrectly connected to the tractor control levers. See the Tractor Operator’s Manual for valve and control lever arrange-

ment.

Insucient hydraulic pressure from Tractor. Check the hydraulic reservoir oil level. See the tractor Operator’s

Manual for hydraulic system recommendations.

Hydraulic components leaking oil. Locate the leak and replace or repair components.

Hydraulic hoses are kinked or twisted. Locate the twisted hose and correct.

Hydraulic cylinders are leaking. Repair or replace cylinders. See Repair Parts section for cylinder or

seal kit part numbers.

The orice in the wing-fold cylinder is plugged. Remove the contamination from the system. Flush system and

change the oil and lter.

17

Page 18

A-Frame Assembly

# Description Part. No.

1 1/2" Hose Holder Rod JM0027120

2 3/8"-16 x 3/4" Gr5 Z Hex Bolt JM0001663

3 Telescoping Hitch Weldment JM0026437

4 Cotter Pin (Sold with item #5) JM0028344

5 1" x 8" Tounge Pin JM0027117

6 A-Frame Tongue Weldment (TF2) JM0027700

6 A-Frame Tongue Weldment (TF212) JM0026439

6 A-Frame Tongue Weldment (TF215) JM0026444

7 1-1/4"-7 x 6" Gr5 Z Hex Bolt JM0016690

8 1-1/4"-7 Gr5 Z Nylon Locking Hex Nut JM0026789

9 Manual Canister JM0010115

10 Wrench JM0015256

11 Cotter Pin (1/2" x 1-1/2" Clevis Pin) JM0016381

12 1" x 3-1/2" Clevis Pin JM0026782

13 Turn Buckle Clevis End JM0026759

14 Turn Buckle Threaded Shaft (Right Hand) JM0026755

15 1-1/4"-7 Gr5 Z Hex Nut JM0001700

16 Turn Buckle Center Pipe Weldment JM0026758

17 Turn Buckle Threaded Shaft (Left Hand) JM0026757

Wing Prop

# Description Part. No.

1 1/2-13 x 3” Gr5 Z Hex Bolt JM0016678

2 Adjustable Prop - Platform JM0044535

3 Adjustable Prop - Upright JM0044536

4 U-bolt 5/8” x 4-1/8” W x 6” L JM0014190

5 5/8”-11 Gr5 Z Centerlock Nut JM0002146

6 1/2”-13 Gr5 Z Centerlock Nut JM0001511

*Wing Prop only for TF212 & 215

w/ 13in basketes & harrow bars

18

Page 19

General InformationMain Frame Assembly

# Description Part. No.

1 1/4"-20 x 1" Gr5 Z Hex Bolt JM0002095

2 Amber Light (LED) JM0032204

3 1/4"-20 Gr5 Z Centerlock Hex Nut JM0001505

4 Light Bracket (Right Hand) JM0015232

4 Light Bracket (Left Hand) JM0015233

5 1/4"-20 Gr5 Z SF Hex Nut JM0001630

6 1/4"-20 x 5/8" Gr5 Z Hex Bolt JM0001479

7 1/4" x 1-1/2" Self Tapping Screw JM0001571

8 Red Light (LED) JM0032205

9 1/2"-13 Gr5 Z Centerlock Hex Nut JM0001511

10 1/2"-13 x 1-1/2" Gr5 Z Hex Bolt JM0002100

11 Jack Stand JM0026798

12 Bolt-On Jack Weldment (For TF212 & 215 w/ 13in baskets) JM0044131

12 Bolt-On Jack Weldment JM0026472

13 4" x 24" Hydraulic Cylinder (TF212) JM0018348

13 4" x 30" Hydraulic Cylinder (TF215) JM0019909

14 Leverage Arm (round hole) (for working widths 24’ and smaller) JM0015221

14 Leverage Arm (oblong hole) (for model TF212, 26’ to 35’ wide) JM0015222

14 Leverage Arm (for model TF215) JM0015223

15 1/2" x 1-1/2" Cotter Pin JM0016381

16 1" x 3-1/2" Clevis Pin JM0026782

17 1-3/4" x 4" Wing Pin JM0026689

18 7/16" x 2-3/4" Z Roll Pin JM0009895

19 Base Unit Main Frame (TF2 – 12’ or 13’ working width) JM0031862

19 Base Unit Main Frame (TF2 – 14’ or 15’ working width) JM0031863

19 Base Unit Main Frame (TF2 – 16’ or 17’ working width) JM0031864

19 Base Unit Main Frame (TF2 – 18’ working width) JM0031865

19 Base Unit Main Frame (TF212) JM0026374

19 Base Unit Main Frame (TF215) JM0026389

19

Page 20

To The DealerOutside Wing Assembly

# Description Part. No.

1 4" Wing Pin JM0026689

2 7/16" x 2-3/4" Z Roll Pin JM0009895

3 Pivot Linkage Arm Weldment (TF212) JM0026682

3 Pivot Linkage Arm Weldment (TF215) JM0026683

4 1-3/4"-5 Gr5 Hex Nut JM0019334

5 1-3/4" x 6-3/8" Wing Bolt JM0026691

6 1-3/4" x 5" Wing Bolt JM0026690

7 Long Wing Rest Weldment (Left Hand) JM0026639

7 Wing Rest Weldment (Right Hand) JM0026640

8 SMV Sign JM0001616

9 1/4"-20 x 1" Gr5 Z Hex Bolt JM0002095

10 1/4"-20 Gr5 Z SF Hex Nut JM0001630

11 1/2"-13 Gr5 Z Centerlock Hex Nut JM0001511

12 1/2"-13 x 1-1/4" Gr5 Z Hex Bolt JM0001513

13 Wing Frame (TF212) (4’ L) JM0026536

13 Wing Frame (TF212) (5’ L) JM0026535

13 Wing Frame (TF212) (6’ L) JM0026534

13 Wing Frame (TF212) (7’ L) JM0026533

13 Wing Frame (TF212) (8’ L) JM0026532

13 Wing Frame (TF212) (9’ L) JM0026372

13 Wing Frame (TF212) (10’ L) JM0026539

13 Wing Frame (TF212) (11’ L) JM0026540

13 Wing Frame (TF212) (12’ L) JM0026551

13 Wing Frame (TF215) (11’ L) JM0026552

13 Wing Frame (TF215) (12’ L) JM0026551

13 Wing Frame (TF215) (13’ L) JM0026550

13 Wing Frame (TF215) (14’ L) JM0026549

13 Wing Frame (TF215) (15’ L) JM0026548

20

Page 21

Main Frame Wheel Assembly

Wheel Assemblies

Wing Wheel Assembly

# Description Part. No.

1 1/2"-13 Gr5 Z Centerlock Hex Nut JM0001511

2 TF-Wing Wheel Mount Weldment JM0026429

3 1/2"-13 x 6" Gr5 Z Hex Bolt JM0016679

4 1"-8 Gr5 Z Nylon Locking Hex Nut JM0002161

5 1"-8 x 5" Gr5 Z Hex Bolt JM0016688

6 3/8" x 2-1/2" Z Round Wire Lynch Pin JM0014929

7 Wheel Cylinder Lock JM0015237

8 1-1/4"-7 x 10" Gr5 Z Hex Bolt JM0016691

9 1-1/4"-7 Gr5 Z Nylon Locking Hex Nut JM0026789

10 Wheel Arm Weldment - Right (TF212-TF215) JM0026714

10 Wheel Arm Weldment - Left (TF212-TF215) JM0026713

10 Wheel Arm Weldment - Main Frame (TF2) JM0031866

10 Wheel Arm Weldment - Main Frame (TF212-TF215) JM0026696

11 Cotter Pin JM0016381

12 Clevis Pin JM0026782

13 1/2"-13 X 3" Gr5 Z Hex Bolt JM0016678

14 1-3/4"" Dia. Spindle for G25-6 Hub JM0026569

15 Grease Seal, 6-8 Ton JM0026572

16 Cone (large) JM0019563

17 11L-15 Tire - 10 ply JM0027743

18 Wheel Rim, 6 hole 15 x 8 JM0026801

19 1/2" x 1-7/8" Stud JM0019559

20 G25 Hub with Studs, Nuts, and Cups JM0026566

21 Cone (small) JM0019564

22 3/4" USS Flat Washer JM0010006

23 3/4"-10 Gr5 Z Castle Hex Nut JM0002130

24 Cotter Pin JM0014348

25 Dust Cap, 6-10 Ton JM0026567

26 1/2" - 20 Lugnut JM0003062

27 3” x 8” Hydraulic Cylinder (left or right side wheel cylinder on

units equipped WITHOUT wing wheels)

27 3 1/4” x 8” MS Hydraulic Cylinder (for units equipped WITH

wing wheels) (32TP08-125 639706)

27 3 1/2" x 8” MS Hydraulic Cylinder (for units equipped WITH

wing wheels) (35TP08-125 639707)

JM0026724

JM0014958

JM0014960

21

Page 22

Torsion Arm

# Description Part. No.

1 Square U-bolt 4-1/8" Inside Width x 6" Length, 5/8"-11TH JM0014190

2 Short 3' Heavy Torsion Arm Weldment JM0008446

2 Short 2' Heavy Torsion Arm Weldment JM0008447

2 Short 2’ Light Torsion Arm Weldment JM0008448

2 Long 3’ Heavy Torsion Arm Weldment JM0043556

2 Long 2’ Heavy Torsion Arm Weldment JM0044694

2 Long 2’ Light Torsion Arm Weldment JM0044651

3 5/8"-11 Gr5 Z Centerlock Hex Nut JM0002146

4 1"-8 X 6-1/2" Gr5 Z Hex Bolt JM0014192

5 5/8"-11 Gr5 Z Nylon Locking Hex Nut JM0008428

6 Square U-Bolt 4-1/8" Inside Width x 4-1/2" Length, 5/8"-11TH JM0014189

7 1"-8 Gr5 Z Nylon Locking Hex Nut JM0002161

8 Rocker Pad for 13" Baskets JM0008427

8 Rocker Pad for 16" Baskets JM0028405

*Long Torsion Arm

Only For TF212 & 215

w/ 13in baskets

22

Page 23

Rolling Basket

10

Optional Upgraded Basket Hub

# Description Part. No.

1 1-1/4"-12 x 3-1/4" Gr5 Z Hex Bolt JM0001529

1 3/4” x 3-1/2 ” Gr8 Z Hex Bolt (Upgraded Basket Hub) JM0042405

2 1/2"-13 x 1-1/4" Gr5 Z Hex Bolt JM0001513

3 1/4" Thick Crazy Leg Washer JM0001445

4 1-1/4" Dia 4 Bolt Bearing JM0001489

5 1/2"-13 Gr5 Z SF Hex Nut JM0002153

5 3/4” -16 Gr8 Z Hex Nut (Upgraded Basket Hub) JM0041245

6 1-1/4" Zinc Finish Lock Washer JM0001530

7 1-1/4"-12 Z Gr5 Hex Jam Nut JM0002158

7 3/4”-16 Z Gr5 Hex Jam Nut (Upgraded Basket Hub) JM0016699

8 16" Dia 6' Basket Weldment 2:1 JM0005747

8 16" Dia 5-1/2' Basket Weldment 2:1 JM0005745

8 16" Dia 5' Basket Weldment 2:1 JM0005742

8 16" Dia 4' Basket Weldment 2:1 JM0005740

8 16" Dia 3-1/2' Basket Weldment 2:1 JM0005734

8 13" Dia 6' Basket Weldment 2:1 JM0003259

8 13" Dia 5-1/2' Basket Weldment 2:1 JM0002586

8 13" Dia 5' Basket Weldment 2:1 JM0003252

8 13" Dia 4' Basket Weldment 2:1 JM0005713

8 13" Dia 3-1/2' Basket Weldment 2:1 JM0026962

9 6' Crazy Leg Weldment JM0001770

9 5-1/2' Crazy Leg Weldment JM0001769

# Description Part. No.

9 5' Crazy Leg Weldment JM0001768

9 4' Crazy Leg Weldment JM0001767

9 3.5' Crazy Leg Weldment JM0001766

10 16" Dia 6' Double Basket Weldment 2:1 JM0026944

10 16" Dia 5-1/2' Double Basket Weldment 2:1 JM0026945

10 16" Dia 5' Double Basket Weldment 2:1 JM0026946

10 16" Dia 4' Double Basket Weldment 2:1 JM0026949

10 16" Dia 3-1/2' Double Basket Weldment 2:1 JM0026938

10 13" Dia 6' Double Basket Weldment 2:1 JM0008551

10 13" Dia 5-1/2' Double Basket Weldment 2:1 JM0026929

10 13" Dia 5' Double Basket Weldment 2:1 JM0001671

10 13" Dia 4' Double Basket Weldment 2:1 JM0026935

10 13" Dia 3-1/2' Double Basket Weldment 2:1 JM0026963

11 Retaining Ring JM0041316

12 Dust Cap w/ Seal JM0041317

13 Retaining Ring JM0041318

14 Bearing (Qty 2) (6305-RSC3) JM0041319

15 Hub (A-2914-1) JM0041320

16 Bearing Sleeve JM0041321

17 Counterface JM0041322

18 Seal (1645A1\2) JM0041323

19 Grass Wrap Guard JM0041324

20 Flange Washer JM0041325

23

Page 24

Coil Tine Pipe Bar and Round Bar Bracket

# Description Part. No.

1 1/2"-13 x 5" Gr5 Z Hex Bolt JM0001594

2 Harrow Squeeze Block JM0027006

3 1/2-13 Gr5 Z x 4-1/4" J-Bolt JM0020373

4 3'8" Wide Coil Tine Pipe JM0026999

4 4'8" Wide Coil Tine Pipe JM0026996

4 5'8" Wide Coil Tine Pipe JM0010011

4 6'8" Wide Coil Tine Pipe JM0026998

5 Lower Harrow Tine Mount - Lobe JM0015242

6 3/4"-10 x 6" Gr5 Z Hex Bolt JM0016683

7 Harrow Arm Weldment - For TF5S215 Base JM0017558

8 Upper Harrow Tine Mount JM0015241

9 1/2" x 5" U-Bolt JM0010001

10 3/4"-10 Gr5 Z Centerlock Hex Nut JM0002147

11 1/2" x 5" U-Bolt JM0010001

12 Clevis Pin JM0010003

13 Cotter Pin JM0010005

14 1/2"-13 x 1-1/4" Gr5 Z SF Hex Bolt JM0010002

15 5/16" Z Yellow Chain - 11 link JM0020360

16 Harrow Tine Chain Attach - Cross Slot JM0015254

17 1/2" Gr5 Z Centerlock Hex Nut JM0001511

18 Soil Conditioner Coil Tine JM0020358

19 1/2" x 4" U-Bolt JM0026990

20 1/2"-13 x 1-1/2" Gr5 Z Hex Bolt JM0002100

21 4 ft. Harrow Tine Channel JM0015227

21 5 ft. Harrow Tine Channel JM0015228

21 6 ft. Harrow Tine Channel JM0015229

21 7 ft. Harrow Tine Channel JM0015230

22 3/4" Harrow Tine JM0026972

23 1/2" Flat Washer JM0026973

24

Page 25

TF2 (12’ to 18’ Working Width)

3

5

4

2

1

1

6

7

7

Li Cylinders

Hoses To Tractor

# Description Part. No.

1 3/8” x 264” Hydraulic Hose JM0030831

2 3/8” x 77” Hydraulic Hose JM0027152

3 3/8” x 44” Hydraulic Hose JM0027155

3/8” x 32” Hydraulic Hose JM0027143

4

5 3/8” x 65” Hydraulic Hose JM0027154

6 Tee, 3/8” Female (3) JM0018266

7 Elbow, 1/2” Male, 3/8” Female JM0010292

Li Cylinders

25

Page 26

TF212-TF215 with Lift Assist (2 Hoses)

13

17

2014 91115

10

142216

16

13

13

13

13

5

Li Cylinders

Fold Cylinders

Li Cylinders

Hoses To Tractor

26

Hydraulic Cylinder Seal Kits

Seal Kit for 4" x 24" Hydraulic Cylinder (2500PSI) JM0037753

Seal Kit for 4" x 24" Hydraulic Cylinder (3000PSI) JM0037754

Seal Kit for 4" x 30" Hydraulic Cylinder (2500PSI) JM0037755

Seal Kit for 4" x 30" Hydraulic Cylinder (3000PSI) JM0037756

Seal Kit for 4" x 8" Stroke Rephasing Hydraulic Cylinder JM0027599

Seal Kit for 3-3/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037757

Seal Kit for 3-1/2" x 8" Stroke Rephasing Hydraulic Cylinder JM0037758

Seal Kit for 3-1/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037759

Page 27

TF212-TF215 with Lift Assist (2 Hoses)

# Description Part. No.

1 1/2" x 336" Hydraulic Hose (TF212) (HH-12336) JM0027137

1 1/2" x 384" Hydraulic Hose (TF215) (HH-12384) JM0027263

2 3/8" x 200" Hydraulic Hose (TF212)(32',33') JM0027129

2 3/8" x 219" Hydraulic Hose (TF212)(34',35') JM0027125

2 3/8" x 295" Hydraulic Hose (TF215)(35'-47') JM0031975

2 3/8" x 283" Hydraulic Hose (TF215)(43',44') JM0031974

2 3/8" x 271" Hydraulic Hose (TF215)(41',42') JM0027239

2 3/8" x 259" Hydraulic Hose (TF215)(39',40') JM0027238

2 3/8" x 194" Hydraulic Hose (TF215)(36'-38') JM0027129

3 3/8" x 183" Hydraulic Hose (TF212)(32',33') JM0027128

3 3/8" x 169" Hydraulic Hose (TF212)(34',35') JM0031973

3 3/8" x 245" Hydraulic Hose (TF215)(35'-47') JM0027236

3 3/8" x 233" Hydraulic Hose (TF215)(43',44') JM0027126

3 3/8" x 221" Hydraulic Hose (TF215)(41',42') JM0027125

3 3/8" x 211" Hydraulic Hose (TF215)(39',40') JM0027124

3 3/8" x 146" Hydraulic Hose (TF215)(36'-38') JM0031972

4 3/8" x 176" Hydraulic Hose (TF212)(32',33') JM0027127

4 3/8" x 169" Hydraulic Hose (TF212)(34',35') JM0027127

4 3/8" x 235" Hydraulic Hose (TF215)(35'-47') JM0027126

4 3/8" x 223" Hydraulic Hose (TF215)(43',44') JM0027125

4 3/8" x 211" Hydraulic Hose (TF215)(41',42') JM0027124

4 3/8" x 201" Hydraulic Hose (TF215)(39',40') JM0027129

4 3/8" x 133" Hydraulic Hose (TF215)(36'-38') JM0031971

5 3/8" x 60" Hydraulic Hose (TF212) JM0027131

5 3/8" x 85" Hydraulic Hose (TF215) JM0027149

6 3/8" x 36" Hydraulic Hose (TF212) JM0027148

6 3/8" x 54" Hydraulic Hose (TF215) JM0027240

7 3/8" x 24" Hydraulic Hose (TF212) JM0027146

7 3/8" x 31" Hydraulic Hose (TF215) JM0027132

8 3/8" x 106" Hydraulic Hose (TF212) JM0031970

8 3/8" x 108" Hydraulic Hose (TF215) JM0031969

9 3/8" Female NPT x 1/2" Male NPT 90 degree elbow JM0010292

10 3/8" Tee (Female-Female-Male) JM0027116

11 Parker Relief Valve PCK600s-1.5 JM0027086

12 Parker Relief Valve PCK600s-5.0 JM0027085

13 Elbow, 3/8" Male, 3/8" Female, O-Ring JM0027082

14 3/8" Male, 3/8" Male Nipple 0.62 x 2.4 JM0027096

15 3/8" Male, 3/8" Female Swivel 0.86 x 2.4 JM0027110

16 4" x 24" Hydraulic Cylinder JM0018348

17 4" x 8" Stroke Rephasing Hydraulic Cylinder JM0014964

18 3-3/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0014963

19 3-1/2" x 8" Stroke Rephasing Hydraulic Cylinder JM0014960

20 3-1/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0014958

21 Ball Valve JM0027113

22 3/8” Female x 3/8” Female x 3/8” Female Tee JM0018266

27

Page 28

TF212 EQUIPPED with 2 sets of hoses & optional Wing Wheels

16

1412 15

Li Cylinders

Fold Cylinders

Li Cylinders

Hoses To Tractor

28

Hydraulic Cylinder Seal Kits

Seal Kit for 4" x 24" Hydraulic Cylinder (2500PSI) JM0037753

Seal Kit for 4" x 24" Hydraulic Cylinder (3000PSI) JM0037754

Seal Kit for 4" x 30" Hydraulic Cylinder (2500PSI) JM0037755

Seal Kit for 4" x 30" Hydraulic Cylinder (3000PSI) JM0037756

Seal Kit for 4" x 8" Stroke Rephasing Hydraulic Cylinder JM0027599

Seal Kit for 3-3/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037757

Seal Kit for 3-1/2" x 8" Stroke Rephasing Hydraulic Cylinder JM0037758

Seal Kit for 3-1/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037759

Page 29

TF212 EQUIPPED with 2 sets of hoses & optional Wing Wheels

# Description Part. No.

1 1/2" x 336" Hydraulic Hose JM0027264

2 3/8" x 210" Hydraulic Hose JM0027124

2 3/8" x 222" Hydraulic Hose JM0027125

2 3/8" x 234" Hydraulic Hose JM0027126

3 3/8" x 174" Hydraulic Hose JM0027127

3 3/8" x 186" Hydraulic Hose JM0027128

3 3/8" x 198" Hydraulic Hose JM0027129

4 3/8" x 162" Hydraulic Hose JM0027130

4 3/8" x 174" Hydraulic Hose JM0027127

4 3/8" x 186" Hydraulic Hose JM0027128

5 3/8" x 62" Hydraulic Hose JM0027131

6 3/8" x 34" Hydraulic Hose JM0027132

7 3/8" x 29" Hydraulic Hose JM0027133

8 3/8" x 112" Hydraulic Hose JM0027134

9 3/8" Female NPT x 1/2" Male NPT 90 degree elbow JM0010292

10 3/8" Tee (Female-Female-Male) JM0027116

11 Parker Relief Valve PCK600s-1.5 JM0027086

12 Parker Relief Valve PCK600s-5.0 JM0027085

13 Elbow, 3/8" Male, 3/8" Female, O-Ring JM0027082

14 3/8" Male, 3/8" Male Nipple 0.62 x 2.4 JM0027096

15 3/8" Male, 3/8" Female Swivel 0.86 x 2.4 JM0027110

16 4" x 24" Hydraulic Cylinder JM0018348

17 4" x 8" Stroke Rephasing Hydraulic Cylinder JM0014964

18 3-3/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0014963

19 3-1/2" x 8" Stroke Rephasing Hydraulic Cylinder JM0014960

20 3-1/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0014958

29

Page 30

TF212 & TF215 EQUIPPED with 2 set of hoses, w/out optional Wing Wheels

1

1

1

1

2 5 6

4

3

11

7

8

13

13

14

14

10

10

9

9

10

10

Li Cylinder

Fold Cylinders

Hoses To Tractor

# Description Part. No.

1 3/8” x 336” Hydraulic Hose (TF212) JM0027137

1 3/8” x 384” Hydraulic Hose (TF215) JM0027139

2 3/8” x 77” Hydraulic Hose (TF212) JM0027152

2 3/8” x 81” Hydraulic Hose (TF215) JM0030844

3 3/8” x 65” Hydraulic Hose (TF212) JM0027154

3 3/8” x 71” Hydraulic Hose (TF215) JM0027141

4 3/8” x 32” Hydraulic Hose (TF212) JM0027143

4 3/8” x 27” Hydraulic Hose (TF215) JM0027146

5 3/8” x 40” Hydraulic Hose (TF212) JM0027144

5 3/8” x 35” Hydraulic Hose (TF215) JM0027148

30

Li Cylinder

6 3/8” x 62” Hydraulic Hose (TF212) JM0027131

6 3/8” x 89” Hydraulic Hose (TF215) JM0027149

7 3/8” x 44” Hydraulic Hose (TF212) JM0027155

7 3/8” x 62” Hydraulic Hose (TF215) JM0027145

8 3/8” x 29” Hydraulic Hose (TF212) JM0027133

8 3/8” x 32” Hydraulic Hose (TF215) JM0027148

9 Elbow, 1/2” Male, 3/8” Female JM0010292

10 3/8” Orice Restrictor (.045) JM0027081

11 Tee, 3/8” Female (3) JM0018266

12 3/8” Tee (female-female-male) JM0027116

13 4" x 24" Hydraulic Cylinder JM0018348

14 3" x 8" Hydraulic Cylinder JM0026724

Hydraulic Cylinder Seal Kits

Seal Kit for 4" x 24" Hydraulic Cylinder (2500PSI) JM0037753

Seal Kit for 4" x 24" Hydraulic Cylinder (3000PSI) JM0037754

Seal Kit for 4" x 30" Hydraulic Cylinder (2500PSI) JM0037755

Seal Kit for 4" x 30" Hydraulic Cylinder (3000PSI) JM0037756

Seal Kit for 4" x 8" Stroke Rephasing Hydraulic Cylinder JM0027599

Seal Kit for 3-3/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037757

Seal Kit for 3-1/2" x 8" Stroke Rephasing Hydraulic Cylinder JM0037758

Seal Kit for 3-1/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037759

Page 31

TF212 & TF215 EQUIPPED with 1 set of hoses, w/out optional Wing Wheels

1

1

1610 9

11

10

9

1515 910 9

5

9

10 116

9

10 910

2

3

7

8

Li Cylinder

Fold Cylinders

Li Cylinder

JM0027144

JM0027145

Hoses To Tractor

swivel end (TF212)

# Description Part. No.

1 3/8” x 336” Hydraulic Hose (TF212) JM0027137

1 3/8” x 384” Hydraulic Hose (TF215) JM0027139

2 3/8” x 66” Hydraulic Hose (TF212) JM0027140

2 3/8” x 75” Hydraulic Hose (TF215) JM0027141

3 3/8” x 43” Hydraulic Hose (TF212) JM0027142

3 3/8” x 32” Hydraulic Hose (TF215) JM0027143

4 3/8” x 40” Hydraulic Hose with

swivel end (TF215)

4 3/8” x 60” Hydraulic Hose with

5 38” x 43” Hydraulic Hose (TF212) JM0027142

5 3/8” x 32” Hydraulic Hose (TF215) JM0027143

6 3/8” x 34” Hydraulic Hose (TF212) JM0027132

6 3/8” x 25” Hydraulic Hose (TF215) JM0027146

7 3/8” x 29” Hydraulic Hose (TF212) JM0027133

7 3/8” x 35” Hydraulic Hose (TF215) JM0027148

31

8 3/8” x 62” Hydraulic Hose (TF212) JM0027131

8 3/8” x 88” Hydraulic Hose (TF215) JM0027149

9 Elbow, 1/2” Male, 3/8” Female JM0010292

10 3/8” Orice Restrictor (.045) JM0027081

11 3/8” Tee (male-female-female) JM0018230

12 3/8” Tee (female-female-male) JM0027116

13 Ball Valve JM0027113

14 Cross (1 male / 3 female) JM0027115

15 4" x 24" Hydraulic Cylinder JM0018348

Hydraulic Cylinder Seal Kits

16 3" x 8" Hydraulic Cylinder JM0026724

Seal Kit for 4" x 24" Hydraulic Cylinder (2500PSI) JM0037753

Seal Kit for 4" x 24" Hydraulic Cylinder (3000PSI) JM0037754

Seal Kit for 4" x 30" Hydraulic Cylinder (2500PSI) JM0037755

Seal Kit for 4" x 30" Hydraulic Cylinder (3000PSI) JM0037756

Seal Kit for 4" x 8" Stroke Rephasing Hydraulic Cylinder JM0027599

Seal Kit for 3-3/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037757

Seal Kit for 3-1/2" x 8" Stroke Rephasing Hydraulic Cylinder JM0037758

Seal Kit for 3-1/4" x 8" Stroke Rephasing Hydraulic Cylinder JM0037759

Page 32

To The DealerLight Harness

1

3

2

# Description Part. No.

1 Base Harness JM0027080

2 A-Frame Harness JM0027077

3 Light Enhancer JM0010566

32

Page 33

33

Loading...

Loading...