Page 1

O P E R A T O R ’ S M A N U A L

Set-Up Instructions and Parts Catalog for

Models TB-3500A and TB-6000A

Trail-Blazer Header Transports

Commercial Grade Header Transport

Ag Version

J. & M. Manufacturing Co., Inc.

P.O. Box 547

Fort Recovery, OH 45846

Phone: (419) 375 2376 Fax: (419) 375-2708

E-mail: sales@jm-inc.com

Website: www.jm-inc.com

REV-12-15-08

Pg. 1

Page 2

TO THE DEALER:

Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check

Lists in the Operator’s Manual are completed before releasing equipment to the owner.

The dealer must complete the Warranty Registration Card attached to the front inside cover of this manual and return

to J. & M. Mfg. Co., Inc. at the address indicated on the card. Warranty claims will be denied if the Warranty

Registration Card has not been completed and returned.

EXPRESS WARRANTY:

J. & M. Mfg. Co. Inc. warrants against defects in construction or materials for a period of ONE year. We reserve the

right to inspect and decide whether material or construction was faulty or whether abuse or accident voids our

guarantee.

Warranty service must be performed by a dealer or service center authorized by J. & M. Mfg. Co. Inc. to sell and/or

service the type of product involved, which will use only new or remanufactured parts or components furnished by J.

& M. Mfg. Co. Inc. Warranty service will be performed without charge to the purchaser for parts or labor based on the

Warranty Labor Times schedule. Under no circumstance will allowable labor times extend beyond the maximum

hours indicated in the Warranty Labor Times schedule for each warranty procedure. The purchaser will be

responsible, however, for any service call and/or transportation of the product to and from the dealer or service

center’s place of business, for any premium charged for overtime labor requested by the purchaser, and for any

service and/or maintenance not directly related to any defect covered under the warranty. Costs associated with

equipment rental, product down time, or product disposal are not warrantable and will not be accepted under any

circumstance.

Each warranty term begins on the date of product delivery to the purchaser. Under no circumstance will warranty be

approved unless (i) the product warranty registration card (attached to the inside of the Operator’s Manual) has been

properly completed and submitted to the equipment manufacturer. This Warranty is effective only if the warranty

registration card is returned within 30 days of purchase.

This warranty does not cover a component which fails, malfunctions or is damaged as a result of (i) improper

modification or repair, (ii) accident, abuse or improper use, (iii) improper or insufficient maintenance, or (iv) normal

wear or tear. This warranty does not cover products that are previously owned and extends solely to the original

purchaser of the product. Should the original purchaser sell or otherwise transfer this product to a third party, this

Warranty does not transfer to the third party purchaser in any way. J. & M. Mfg. Co. Inc. makes no warranty, express

or implied, with respect to tires or other parts or accessories not manufactured by J. & M. Mfg. Co. Inc. Warranties

for these items, if any, are provided separately by their respective manufacturers.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS,

IMPLIED OR STATUTORY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

PARTICULAR PURPOSE.

In no event shall J. & M. Mfg. Co. Inc. be liable for special, direct, incidental or consequential damages of any kind.

The exclusive remedy under this Warranty shall be repair or replacement of the defective component at J. & M. Mfg.

Co. Inc’s. option. This is the entire agreement between J. & M. Mfg. Co. Inc. and the Owner about warranty and no J.

& M. Mfg. Co. Inc. employee or dealer is authorized to make any additional warranty on behalf of J. & M. Mfg. Co.

Inc.

The manufacturer reserves the right to make product design and material changes at any time without notice. They

shall not incur any obligation or liability to incorporate such changes and improvements in products previously sold to

any customer, nor shall they be obligated or liable for the replacement of previously sold products with products or

parts incorporating such changes.

SERVICE:

The equipment you have purchased has been carefully manufactured to provide dependable and satisfactory use.

Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified. Observe all safety

information in this manual and safety signs on the equipment.

For service, your authorized J. & M. dealer has trained mechanics, genuine J. & M. service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine J. & M. service parts. Substitute parts may void the warranty and may not meet standards required

for safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

Serial # ___________ Purchase Date: _______ Purchased From: ____________________________________

Please provide this information to your dealer to obtain the correct parts:

Pg. 2

Page 3

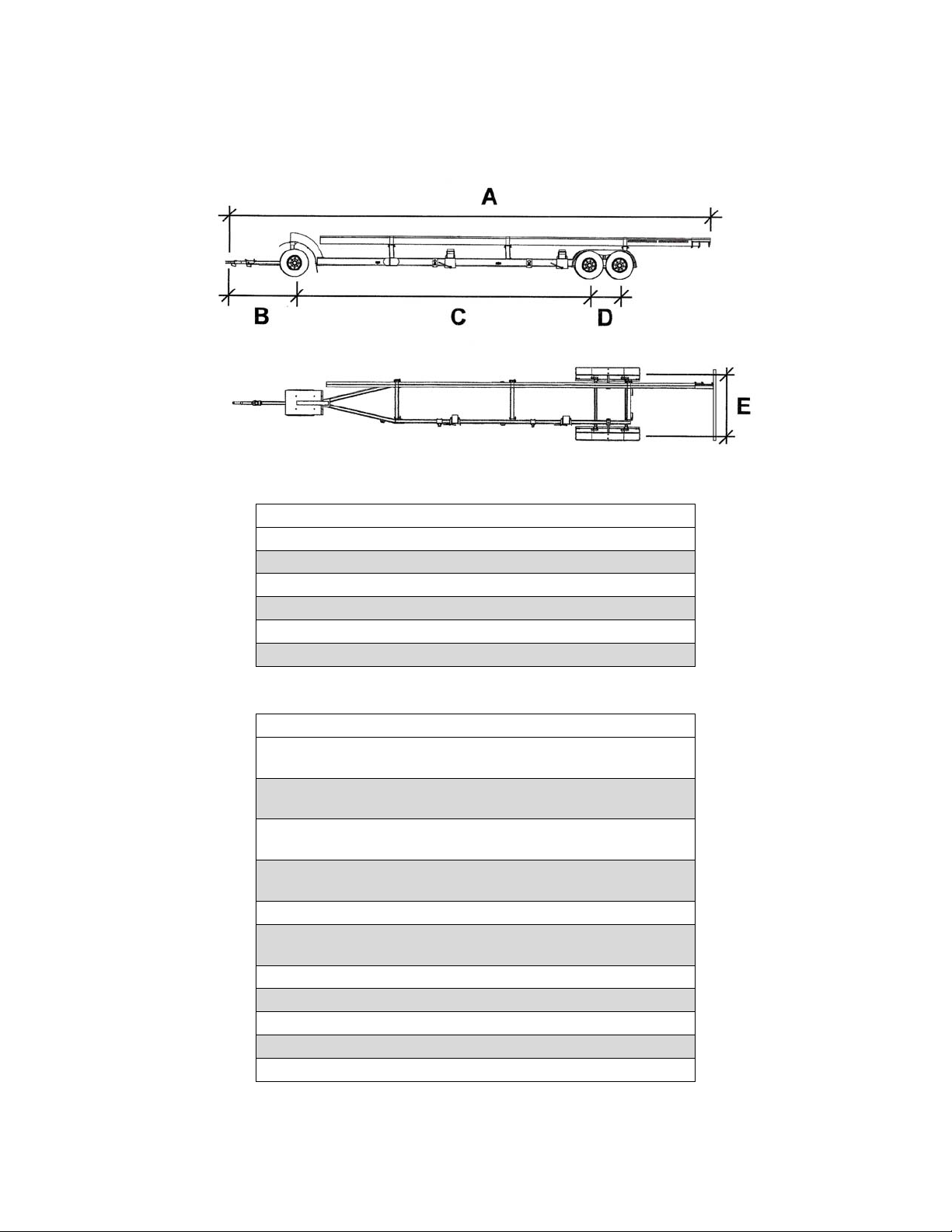

MODELS TB-3500A and TB-6000A Header Transports

Specifications

A 41’-0” 47’-0” 52’-6” 58’-6”

B 6’-0” 6’-0” 6’-0” 6’-0”

C 26’-0” 26’-0” 26’-0” 30’-0”

D 2’-10” 2’-10” 2’-10” 2’’-10”

E 6’-0” 6’-0” 6’-0” 6’-0”

DIMENSIONS (by Upper Bar Length)

32’ 38’ 42’ 48’

Capacity (Net) 8,750 lbs (TB-3500A)

Weight (approx.) 3,260 lbs (TB-3500A)

Wheels 15” x 6” (TB-3500A)

Tires 225/75R15D (TB-3500A)

Upper Bar Lengths 32’, 38’, 42’ or 48’

Adj. Header Mounts Standard

Hubs 6 bolt

Spindles Two - 2-1/4” dia. (front) and

Main Frame 4” x 8” x 3/16” steel tubing

Steel Upper Bar 4” x 8” x 3/16” steel tubing

Tie Down Straps Standard

SPECIFICATIONS

15,700 lbs (TB-6000A)

3,500 lbs (TB-6000A)

16” x 6” (TB-6000A)

235/85R16D (TB-6000A)

Four - 2-1/2” dia. (rear)

Pg. 3

Page 4

GENERAL INFORMATION

TO THE OWNER:

The purpose of this manual is to assist you in operating and maintaining your running gear in a safe

manner. Read it carefully. It furnishes information and instructions that will help you achieve years of

dependable performance and help maintain safe operating conditions. If this machine is used by an

employee or is loaned or rented, make certain that the operator(s), prior to operating:

1. Is instructed in safe and proper use.

2. Reviews and understands the manual(s) pertaining to this machine.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause

damage to equipment. The terms CAUTION, WARNING and DANGER are used in conjunction with the

Safety-Alert Symbol, (a triangle with an exclamation mark), to indicate the degree of hazard for items of

personal safety. When you see this symbol, carefully read the message that follows and be alert to the

possibility of personal injury or death.

This Safety-Alert symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result

in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

Pg. 4

Page 5

GENERAL INFORMATION (continued)

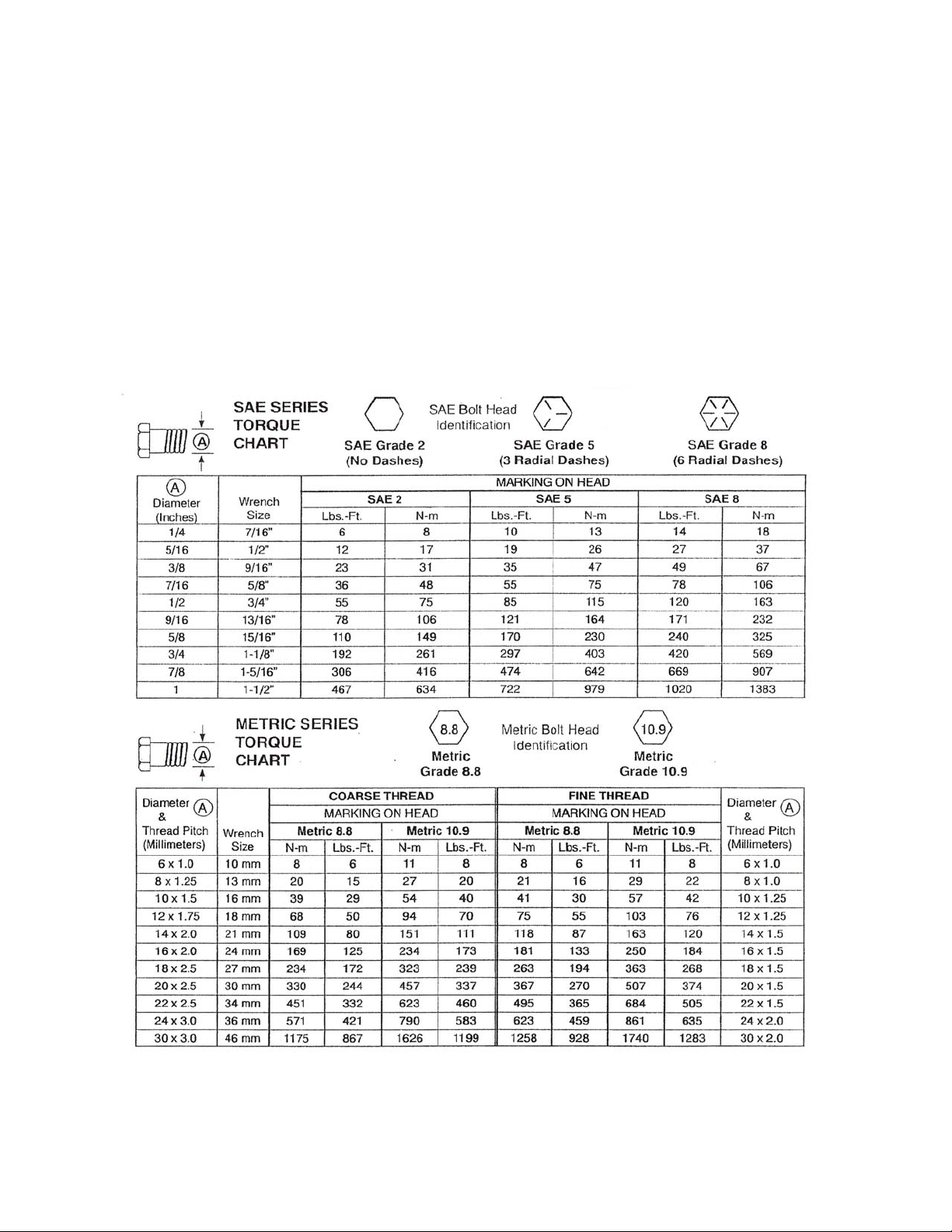

BOLT TORQUE CHART

Always tighten hardware to these values unless a different torque or tightening procedure is listed for a

specific application.

Fasteners must always be replaced with the same grade as specified in the manual parts list.

Always use the proper tool for tightening hardware. SAE for SAE hardware and Metric for metric

hardware.

Make sure fastener threads are clean and you start the thread engagement properly. All torque values

are given to specification used on hardware defined by SAE J1701 & J1701M (Jul 96).

Pg. 5

Page 6

TABLE OF CONTENTS

INTRODUCTION 2

EXPRESS WARRANTY 2

SPECIFICATIONS 3

GENERAL INFORMATION 4

BOLT TORQUE CHART 5

SAFETY RULES 7

SAFETY 7

SAFETY SIGNS 8

SET-UP INSTRUCTIONS 8-12

REPAIR PARTS LIST

Main Frame and Upper Bar 13

Front Axle Assembly 13

Tie-Down Bracket and Adjustable Header Mount 14

Adjustable Upper Bar Mount 14

Rear Axle Assembly 15-16

Rear Fender Assembly 16

Light Kit 17-18

INITIAL OPERATION / MAINTENANCE 19

SERVICE / MAINTENANCE RECORD 20

Pg. 6

Page 7

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to

provide safe equipment can be erased by an operator’s single careless act. In addition, hazard control

and accident prevention are dependent upon the awareness, concern, judgment, and proper training of

personnel involved in the operation, transport, maintenance and storage of equipment.

Make certain that the operator(s), prior to operating is instructed in safe and proper use and reviews and

understands the manual(s) pertaining to this machine.

Read this manual before you operate this machine. If you do not understand any part of this manual, or

need more information, contact the manufacturer or your authorized dealer.

SAFETY

9 Understand that your safety and the safety of other persons are measured by how you service, and

operate this machine. Know the positions and functions of all controls before you try to operate them.

Make sure to check all controls in a safe area before starting your work.

9 The safety information given in this manual does not replace safety codes, federal, state or local laws.

Make certain your machine has the proper equipment as designated by local laws and regulations.

9 A frequent cause of personal injury or death is from persons falling off equipment and being run over. Do

not permit persons to ride on this machine.

9 Travel speeds should be such that complete control and machine stability is maintained at all times.

Where possible, avoid operating near ditches, embankments and holes. Reduce speed when turning,

crossing slopes and rough, slick or muddy surfaces.

9 Collision of high speed road traffic and slow moving machines can cause personal injury or death. On

roads, use flasher lights according to local laws. Keep slow-moving-vehicle emblem visible. Pull over to

let faster traffic pass.

9 Make sure that the header is fastened securely to the transport before moving.

9 Make sure that everyone is clear of equipment before applying power or moving the machine. NEVER

position yourself under or near header when mounting on header transport.

9 Never adjust, service, clean or lubricate the header transport until all power if shut off.

9 Make sure that the implement is fastened securely to the tractor by using the proper hitch pin, clip and

safety chains.

9 Before unhooking the implement from the towing unit, be sure to properly block the wheels to prevent the

implement from moving.

9 Never overload the header transport. Overloading the header transport is dangerous and can cause

extensive damage.

9 Do NOT exceed speeds in excess of 25 MPH. The header transport is designed for heavy loads at slow

speeds. Also be sure slow moving vehicle emblem is attached to rear of wagon.

9 IMPORTANT: Use caution when transporting. Be alert of the transport unit’s overall width when

approaching obstacles, such as post signs and poles, along the road. Check the transport width of the

unit to ensure clearance before entering bridges.

9 COMPLY WITH ALL SAFETY WARNINGS AND CAUTIONS IN THIS MANUAL AND IN THE COMBINE

OPERATORS MANUAL.

9 WARNING: BE SURE ALL LIGHTS ARE WORKING PROPERLY BEFORE

Pg. 7

HIGHWAY TRAVEL.

Page 8

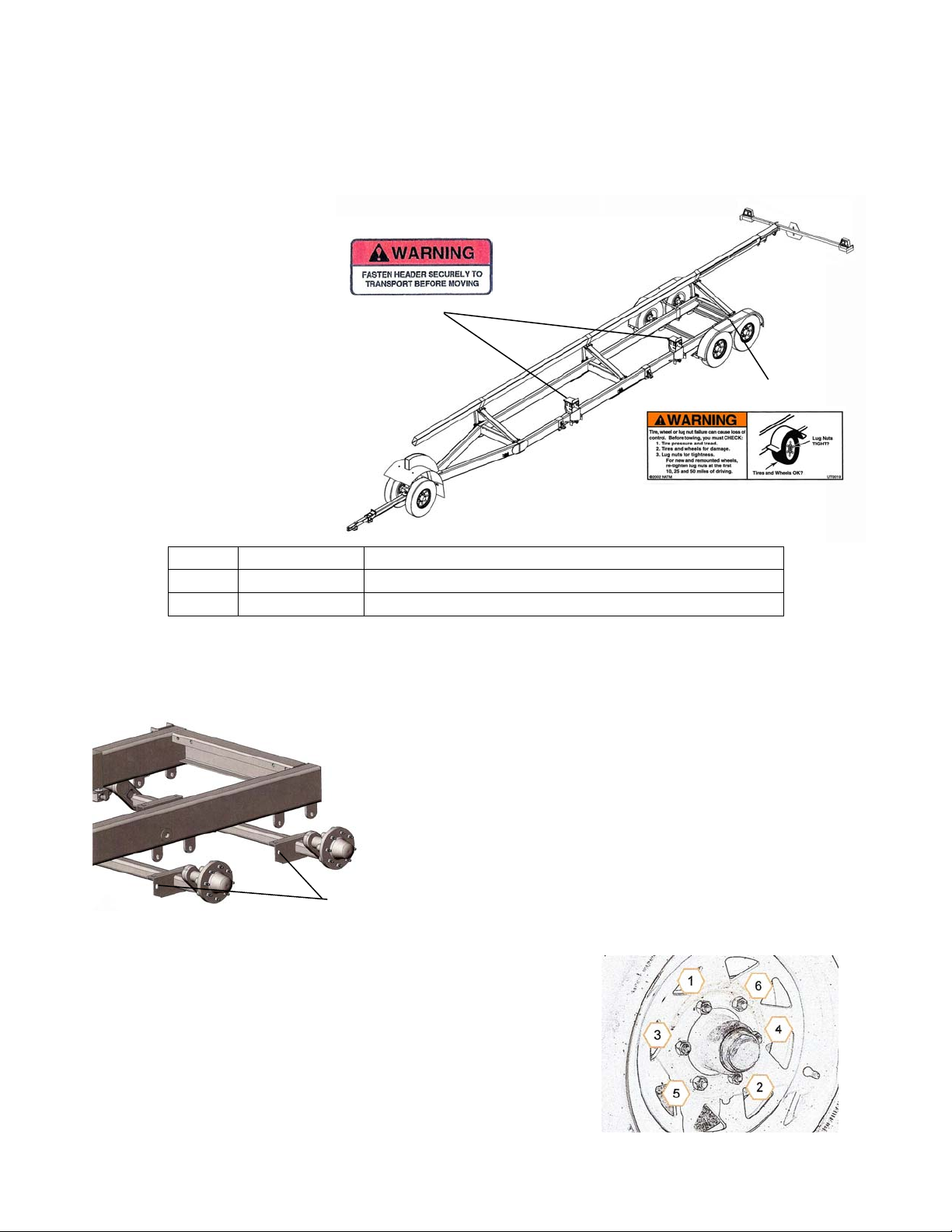

9 SAFETY SIGNS

ATTENTION: BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged or Missing!

IMPORTANT: Install new

safety signs if the old signs

are destroyed, lost, painted

over or cannot be read.

When parts are replaced that

have safety signs, make sure

you install a new sign with

DW-108

each new part. New signs

are available from the

manufacturer or your

authorized dealer.

DECAL PARTS LIST

Item # Part # Description

1 DW-121 Warning: Tire, Wheel, Lug Nut

2 DW-108 Warning: Fasten Header Securely

SET-UP INSTRUCTIONS

IMPORTANT: Set-up work to be performed by qualified servicemen only.

1. Mounting the Rear Axles

Secure the Dura-Flex Axles to the axle mounts located on the

underside of the Header Transport Main Frame using four 5/8” x 13/4” Grade 5 bolts with eight 5/8” flat washers and four 5/8”

locknuts. NOTE: The axle should be positioned so the spindle

is located toward the rear of the axle centerline.

Align the holes on each side of the Dura-Flex Axle with the

tabs welded to the underside of the Main Frame.

2. Mounting the Tires

Secure one tire and wheel assembly to each of the rear hub

assemblies using the wheel nuts provided. Use a star pattern to

tighten the spindle nuts according to SAE standards.

DW-121

Pg. 8

Page 9

SET-UP INSTRUCTIONS (continued)

pp

Base Fender

ort Rail

Su

Fender

Support

Arm

L-Bracket

Mount one Fender L-Brackets to the front end of the fender using two 3/8” x 1” flange bolts, two 3/8”

washers and two 3/8” whiz nuts. Secure one Fender L-Bracket and Light Mounting Bracket to the rear

end of the fender using two 3/8” x 1” flange bolt, two 3/8” washers and two 3/8” whiz nuts. Secure the

other side of the L-Bracket to the Base Fender Support Rail using two 3/8” x 1” flange bolts and two 3/8”

whiz nuts. Repeat on opposite side of transport.

3. Mounting the Rear Fenders

Place one of the Base Fender Support Rail (left or right) on top

of the two rear axles between the main frame and spindle as

shown. Align the holes in the support rail with the rear axles and

loosely secure to each axle using one 3/8” x 3 1/2” x 3 1/2” UBolt, two 3/8” flat washers and two 3/8” lock nuts.

IMPORTANT: Be sure the vertical face of the support rail faces

the outside of the transport (toward the tires) and the support rail

extends farther behind the second rear axle than it does the first

rear axle. If the support rail does not project farther behind the

second rear axle, the rail is located on the wrong side of the

transport and the other rail should be used.

Repeat on opposite side of transport.

Slide the Fender Support Arm across the header transport main

frame and loosely secure to the Angle Iron Support using two

1/2” x 1 1/2” Grade 5 bolts, two 1/2” washers and two 1/2” lock

nuts. Mount the Fender to the top of the Fender Support Arm

using two 3/8” x 1” flange bolts, two 3/8” rubber/metal washers

and two 3/8” whiz nuts. Be sure the side tear drop of the fender

is located toward the outside of the transport. Slide the Fender

Support Arm along the main frame until the fender is centered

above the tires to ensure proper clearance.

Repeat on opposite side of transport.

4. Mounting the Front Axle Assembly

Mount two wheels and tires to the hubs on the Ball Hitch Tongue

and Axle Assembly. Use a star pattern to secure the wheel rim

to the hub and tighten to SAE specifications. Once both wheels

are secured to the front axle, raise the spring loaded pin on the

Header Transport Main Frame and engage the ball hitch on the

Front Axle Assembly. (Be sure the ball is greased before

attaching to the gooseneck frame.) Once the ball hitch has

engaged the locking tube, lower the spring loaded pin into the

hole located on the Front Axle Assembly to prevent the

assembly from unlatching during transport.

Pg. 9

Page 10

SET-UP INSTRUCTIONS (continued)

Upper Bar Channel Support

5. Attaching the Adjustable Brackets and Upper Bar

Slide

Bracket

Secure the Upper Bar Channel Support to the left side of the

three cross frame channels on the Main Base Frame using one

5/8” x 6” pin and hair pin. Secure the Upper Bar Support Arm to

the vertical u-brackets located on the right side of the Main Base

Frame using one 5/8” x 6” pin and hair pin. Connect the channel

Support

Arm

arm to the support arm using one 5/8” x 6” pin and hair pin. The

support arms and channel arms can be adjusted and pinned to

obtain many different heights and positions.

IMPORTANT: Make sure that all three assemblies are

positioned at the same location and height to ensure the upper

bar will fit properly.

Secure the Upper Bar Slide Bracket to each the three channel arm using two 5/8” x 6” pins and hair pins.

Be sure to position all three slide brackets at the same position on the channel arm. Position the Upper

Bar on top of the three slide brackets and secure using the Upper Bar Clamps and two 1/2” washers and

two 1/2” lock nuts. The angle of the Upper Bar can be adjusted by removing and repositioning the 5/8” x

6” Hitch Pins in the Upper Bar Adjustable Brackets.

6. Attaching the Adjustable Header Mounts and Tie-Down

Brackets

Adjustable

Header

Mount

Place the Adjustable Header Mounts and Tie-Down Bracket

Assemblies on the outside left tube of the header transport main

frame as shown. Position one Adjustable Header Mount and

Tie-Down Bracket Assembly on each side of the center cross

member. Secure the Adjustable Header Mount to the outside

TieDown

Bracket

tube using one 3/4” x 6 1/2” Stove Bolt and Clamp Handle

Assembly.

Secure the Tie-Down Bracket to the outside tube using two 1/2”

x 5 1/2” Bolts and two 1/2” Lock Nuts. Do Not Tighten the 1/2” bolts on the top of the assembly, but allow

the Tie-Down Brackets to move freely along the outer tube. The Tie-Down Bracket can be secured with

the bolts either above or below the main frame tubing as long as the ratchet is positioned with the strap

directed upward.

Pg. 10

Page 11

SET-UP INSTRUCTIONS (continued)

7. Installing the Light Kit

A. Insert the Main Wiring Harness, end opposite the Flat-

Four Connector End, through the grommet located at

the front of the gooseneck of the Header Transport Main

Frame and exit the A-Frame behind the gooseneck.

B. Extend the Main Wiring Harness along the inside right

side of the Header Transport Main Frame. Reinsert the

Main Wiring Harness through the grommet located along

the front of the A-Frame and extend the harness through

the main frame tubing toward the rear of the transport.

C. Exit the Main Wiring Harness at the grommet located

behind the rear axles.

D. Secure the Light Enhancer to the inside face of the rear

Main Frame using two self-tapping screws. Connect the

end of the Main Wiring Harness to the corresponding

connector end of the Light Enhancer.

E. Place the extension bracket at the rear end of the Upper

Bar. Attach using the two angle iron supports and

secure with four 1/2” x 7” bolts, washers and nuts.

F. Place the Light Mounting Bracket at the end of the Exension Bracket Arm so the Light Mounting

Bracket is level or horizontal and extends toward the center of the header transport. Secure

using two 1/2” x 1 1/4” Grade 5 Flange Bolts and Flange Nuts.

G. Slide the extendable portion of the Telescoping Arm into the Light Mounting Bracket and tighten

the Handle Nut until the bracket is secure. Extend the arm until the light assembly is within 16” of

the outer extremity of the unit.

H. Mount one light assembly at the end of the Light Mounting Bracket (L/H light) and another

assembly at the end of the Telescoping Arm (R/H light). Secure each light assembly using four

small self-tapping screws. Each light assembly should be mounted so the single amber light is

positioned toward the outside of the header, and the amber and red lights are facing rearward.

Secure the SMV Emblem to the Light Mounting Bracket using two 1/4” x 1” Bolts and Lock Nuts.

Be sure the SMV Emblem remains visible from the rear during highway transport.

I. Place one amber reflective decal at the outward and front side of both the Telescoping Arm and

Light Mounting Bracket as shown. Place one Red and Orange Reflective Decal on the rearward

end of the Telescoping Arm and Light Mounting Bracket. The red reflective decal should be

placed directly above the orange decal.

J. The Main Wiring Harness should already be installed in the Main Frame Base Unit and connected

to the Light Enhancer attached to the rear of the Main Frame Base Unit. Connect each light to

the Light Enhancer using the Light Wiring Harness. Using the enclosed self tapping screws,

secure the Wire Cover over the Light Wire Harness along the upper bar.

Pg. 11

Page 12

SET-UP INSTRUCTIONS (continued)

8. Placing the Amber, Red and Orange Reflective Decals

Place the reflective decals as shown below.

9. Installing the Safety Chain Around the Ball Hitch Axle

Weldment

Bolt the ring end of the safety chain to the underside of the

gooseneck using one 3/4” x 5” Grade 8 Bolt and 3/4” Lock

Nut. Loop the chain around the Strap Weldment located on

the back side of the front axle.

Amber Decal

Amber Decal Amber Decal

Amber Decal

Amber Decal

Red Decal

Orange Decal

Amber Decal

Pg. 12

Page 13

Main Frame and Upper Bar

# Part # Description

1 HHMF2 Header Transport Main Frame

1 HHMF2L Transport Main Frame (for units

equipped with 48' upper bar)

Front Axle Assembly

PARTS LIST

# Part # Description

2 UB-24H 4" x 8" x 24' Upper Bar (takes two

plus splice plate to make 48' bar)

2 UB-42H 4" x 8" x 42' Upper Bar

2 UB-38H 4" x 8" x 38' Upper Bar

2 UB-32H 4” x 8” x 32’ Upper Bar

3 SP-24H Splice Plate (2 pcs)

4 12312B 1/2” x 3 1/2” Bolt

5 12-W 1/2” Regular Washer

6 12-LN 1/2” Lock Nut

# Part # Description

1 OT-HC Outer Tongue Weldment

2 IT-610NS Inner Tongue Weldment

3 TL-610NS Tongue Latch

4 78214-BS 7/8” x 2 1/4” Bolt with spacer

5 LS-610 Latch Shaft, 1” dia. x 5 3/4”

6 SB-212 Spacer Blocks

7 SS-615NS Small Spring in Latch

# Part # Description

8 124BG5 1/2” x 4” Grade 5 Bolt

9 12LN 1/2” Lock Nut

10 FS-HC1 Front Spindle

11 27001500 Grease Seal

12 25580 Large Bearing (0170012C)

13 104082 Small Bearing

14 HC-SW Spindle Washer

15 SN-HC1 Slotted Spindle Nut

16 HC-CP Cotter Pin

17 3160333 Hub, 6 Bolt w/cups & studs

18 HCWS-1 Wheel Stud

19 WN-HC1 Wheel Nut

20 502019 Dust Cap

21 WR-156-6HC Wheel Rim, 15x6, 6 hole

21 WR-166-6HC Wheel Rim, 16x6, 6 hole

22 ST225-75E 15” New Tire (TB-3500A)

22 ST235-85D 16” New Tire (TB-6000A)

23 25520 Large Race (not shown)

24 67010 Small Race (not shown)

Pg. 13

Page 14

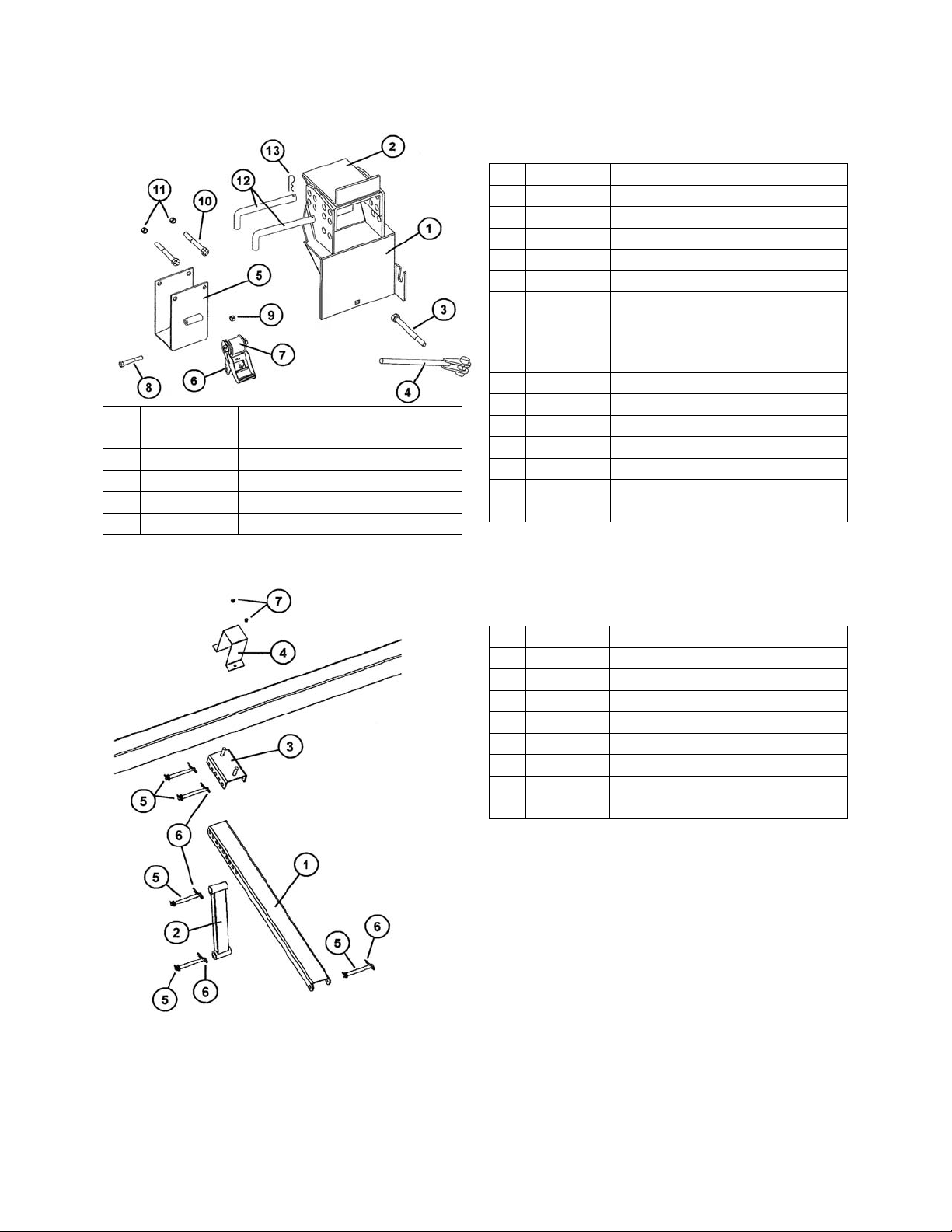

PARTS LIST

# Part # Description

1 AB-L2 Lower Adjustable Bracket

2 AB-U2L Upper Adjustable Bracket, Left

2 AB-U2R Upper Adjustable Bracket, Right

2 AB-U2L-MD R/H Upper Adj. Bracket, MacDon

2 AB-U2R-MD L/H Upper Adj. Bracket, MacDon

Adjustable Upper Bar Mount

Tie-Down Bracket and Adjustable Header Mount

# Part # Description

3 SB34612 Stove Bolt, 3/4” x 6 1/2”

4 CHA2 Clamp Handle Assembly

5 TDMB-2 Tie Down Mounting Bracket

6 RA-1 Ratchet

7 TDS-1 Tie-Down Strap and Hook Assy

7 TDS-1L Tie-Down Strap and Hook Assy

w/D-Ring Strap (MacDon Heads)

8 12234G8B 1/2” x 2 3/4” Grade 8 Bolt

9 12NLN 1/2” Nylon Lock Nut

10 12512G5B 1/2” x 5 1/2” Grade 5 Bolt

11 12LN 1/2” Lock Nut

12 3412P 3/4” x 12” Pin

13 HC-CP Cotter Pin

14 TDB-3 Tie Down Bracket Assy Complete

15 AHM-2 Adj. Header Mount Complete

# Part # Description

1 UBCM-3 Upper Bar Channel Mount

2 UBSA-3 Upper Bar Support Arm

3 UBSM-3 Upper Bar Slide Mount

4 UBC-3 Upper Bar Clamp

5 HP-586 5/8” x 6” Pin

6 316HP 3/16” Hair Pin

7 12LN 1/2” Lock Nut

8 12-WR 1/2” Regular Washer

Pg. 14

Page 15

(For Units Equipped WITHOUT Rear Brakes)

# Part # Description

1 7350881 Dura-Flex Axle Weldment

(TB-3500A)

1 7350881H Dura-Flex Axle Weldment

(TB-6000A)

2 58134G5B 5/8” x 1 3/4” Grade 5 Bolt

3 58FW 5/8” Flat Washer

4 58LN 5/8” Lock Nut

5 27001500 Grease Seal (TB-3500A)

(For Units Equipped WITH Optional Rear Brakes)

PARTS LIST

Rear Axle Assembly

# Part # Description

5 DL600 Grease Seal (TB-6000A)

6 25580 Large Bearing

7 104082 Small Bearing (TB-3500A)

7 15123 Small Bearing (TB-6000A)

8 HC-SW Spindle Washer

9 SN-HC1 Slotted Spindle Nut

10 HC-CP Cotter Pin

11 3160333 Hub, 6 Bolt (TB-3500A)

11 H-1206-S Hub, 6 Bolt (TB-6000A)

12 HCWS-1 Wheel Stud

13 WN-HC1 Wheel Nut

14 502019 Dust Cap (TB-3500A)

14 DC-250 Dust Cap (TB-6000A)

15 WR-156-

6HC

15 WR-166-

6HC

16 ST225-75E 15” New Tire (TB-3500A)

16 ST235-85D 16” New Tire (TB-6000A)

Rear Axle Assembly

Wheel Rim, 15x6 6 hole, HC

(TB-3500A)

Wheel Rim, 16x6 6 hole, HC

(TB-6000A)

# Part # Description

1 7350881B Dura-Flex Axle Weldment

complete with brakes (TB-3500H)

1 7350881BH Dura-Flex Axle Weldment

complete with brakes (TB-6000H)

2 58134G5B 5/8” x 1 3/4” Grade 5 Bolt

3 58FW 5/8” Flat Washer

4 58LN 5/8” Lock Nut

5 27001500 Grease Seal (HHS-30B, HHS-

36B)

5 DL600 Grease Seal (HHS-41B)

6 25580 Large Bearing

7 104082 Small Bearing (TB-3500H)

7 15123 Small Bearing (TB-6000H)

Pg. 15

Page 16

PARTS LIST

Rear Axle Assembly (continued)

(For Units Equipped WITH Optional Rear Brakes)

# Part # Description

8 HC-SW Spindle Washer

9 SN-HC1 Slotted Spindle Nut

10 HC-CP Cotter Pin

11 3160121G Hub, 6 Bolt with brake drum with cups

and studs (TB-3500H)

11 HD-1206-S Hub, 6 Bolt with brake drum with cups

and studs (TB-6000H)

12 HCWS-1 Wheel Stud

13 WN-HC1 Wheel Nut

14 502019 Dust Cap (TB-3500H)

14 DC-250 Dust Cap (TB-6000H)

15 WR-156-6HC Wheel Rim, 15x6 6 hole (TB-3500H)

15 WR-166-6HC Wheel Rim, 16x6, 6 hole (TB-6000H)

16 ST225-75E 15” New Tire (TB-3500H)

16 ST235-85D 16” New Tire (TB-6000H)

17 3160629G 12” Electric Brake (L/H) (TB-3500H)

17 3160630G 12” Electric Brake (R/H) (TB-3500H)

17 7705123 12” Electric Brake (L/H) (TB-6000H)

17 7705124 12” Electric Brake (R/H) (TB-6000H)

18 25520 Large Race (not shown)

19 67010 Small Race (TB-3500H)

19 15245 Small Race (TB-6000H)

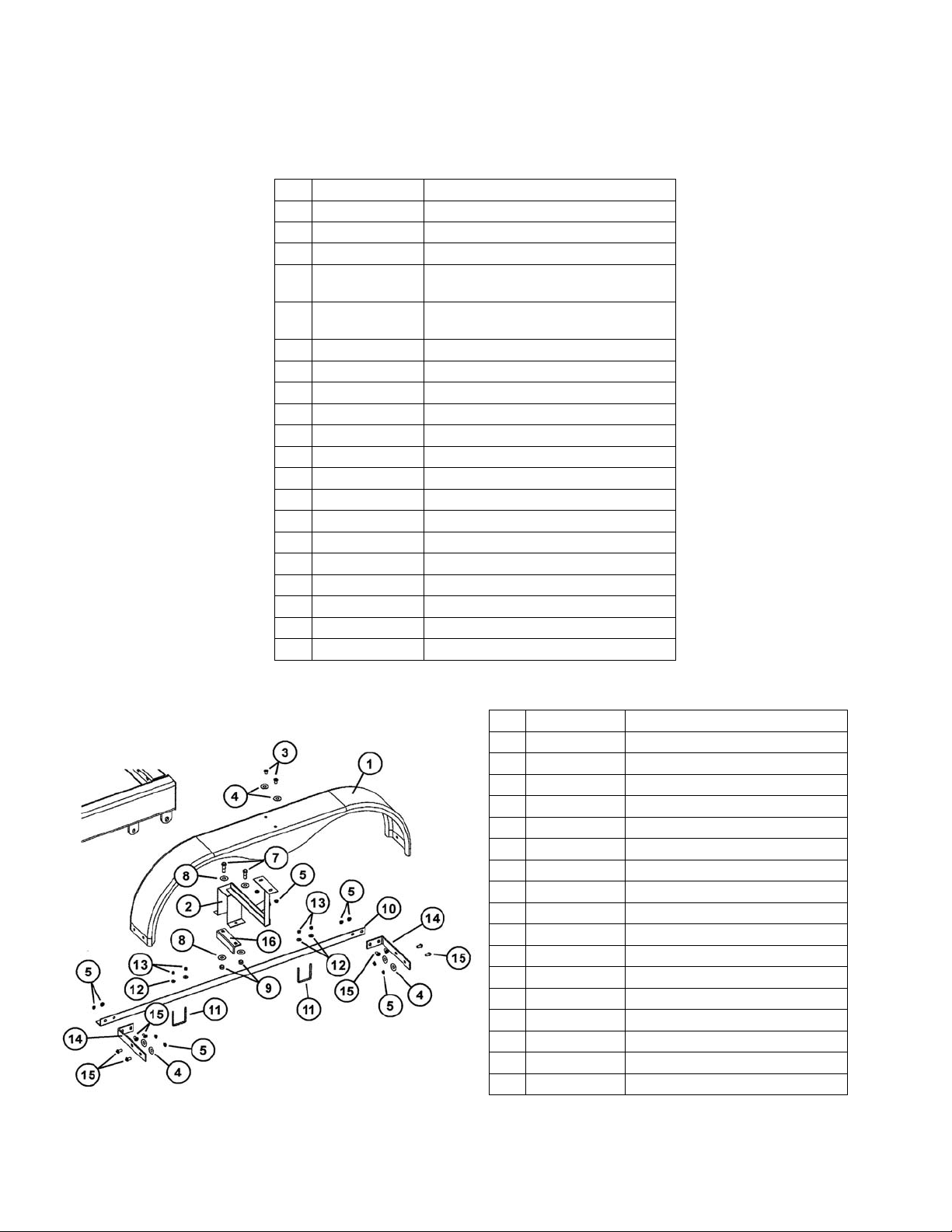

Rear Fender Assembly

# Part # Description

1 WF-1 Wheel Fender

2 FSA-2-15 Fender Support Arm (TB-3500A)

2 FSA-2-16 Fender Support Arm (TB-6000A)

3 381G5B 3/8” x 1” Grade 5 Bolt

4 38RMW 3/8” Rubber Metal Washer

5 38WN 3/8” Whiz Nut

7 12112G5B 1/2” x 1 1/2” Grade 5 Bolt

8 12-RW 1/2” Regular Washer

9 12LN 1/2” Lock Nut

10 BFSR-L Base Fender Support Rail (left)

10 BFSR-R Base Fender Support Rail (right)

11 38312312UB 3/8” x 3 1/2” x 3 1/2” U-Bolt

12 38-FW 3/8” Flat Washer

13 38LN 3/8” Lock Nut

14 FLB-1 Fender L-Bracket

15 381FB 3/8” x 1” Flange Bolt

16 AIS-2 Angle Iron Support

Pg. 16

Page 17

PARTS LIST

Light Kit Assembly

(For Transports Equipped WITHOUT Rear Brakes)

# Part # Description # Part # Description

1L RLT-L Light Assembly (L/H) 17 12114-G5-FB 1/2” x 1 1/4” Grade 5 Flange Bolt

1R RLT-R Light Assembly (R/H) 18 127-HB 1/2” x 7” Hex Bolt

2* LWH-HHC Light Wiring Harness (rear only) 19 14LN 1/4” Lock Nut

3* LE-1B Light Enhancer (speaker) 20 12-FN 1/2” Flange Nut

4* MWH-HHC Main Wiring Harness with Flat

Four Connector End

5 LMB-1 Light Mounting Bracket 23 14STS 1/4” Self Tapping Screw

6 TA-1 Telescoping Arm 24 12-WR 1/2” Regular Washer

7 HDN-12 Handle Nut 25 UBWC-2 Upper Bar Wire Cover

8 EB-1 Extension Bracket 26 WHB-1 Wire Harness Storage Bracket

9 AIS-2 Angle Iron Support 27 RCW-1 Rubber Cap for Storage Bracket

10 SMV-1 SMV Emblem 28 1434G5B 1/4” x 3/4” Grade 5 Bolt

11 GR-134 Rubber Grommet (large) 29 OMST-1 Manual Storage Container

12 WC-1 Wire Clip

13 RD-A1 Amber Reflective Decal

14 RD-R1 Red Reflective Decal

15 RD-O1 Orange Reflective Decal

16 141-CB 1/4” x 1” Bolt

21 12-N 1/2” Regular Nut

22 38STS Self Tapping Screw

* NOTE: For Models TB-3500A and TB-6000A equipped with optional rear brakes, please see the

following page for Wiring Harness changes and optional Brake-Away Kit and Switch.

Pg. 17

Page 18

PARTS LIST

Light Kit Assembly

(For Transports Equipped WITH Optional Rear Brakes)

# Part # Description

1 MWH-HS Main Wiring Harness with 7-Prong Connector End

2 MBH-2 Main Brake Harness (blue, white)

3 BHE-2 Brake Harness Extension (black, white) for Optional 4-wheel brakes

4 LHE-L Light Harness Extension, Long (brown, green, yellow, white)

5 LE-1B Light Enhancer

6 LWH-HHC Light Wiring Harness (rear only)

7 BAW-1C Optional Brake Away Kit (white, black, blue)

8 BAS-1 Optional Brake Away Switch with cable (black, blue)

Pg. 18

Page 19

INITIAL OPERATION / MAINTENANCE

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE HEADER TRANSPORT

Before the header transport is put into service:

9 Has the Slow-Moving Vehicle Emblem been properly positioned at the rear of the header

transport?

9 Have all danger, warning, caution and important signs on the equipment been read and

understood? If employees or others use or are near this equipment, make sure that they also

have read and understood all danger, warning, caution and important signs on the equipment and

have also read the operator’s manual.

9 Are all braces, bolts, nuts, lug bolts and lug nuts properly fastened?

9 Has the header transport been properly fastened to the towing unit? Use a good quality hitch pin

with clip and safety chains.

9 Are the rear amber extremity lights properly positioned? Extend lights within 16” of the left and

right extremities of the header.

SAFETY CHAIN USER INSTRUCTIONS

a) Secure the safety chain by looping it around the tongue

support located on the underside of the Outer Tongue. Run

the chain through the intermediate support located on the

underside of the inner tongue and connect to the towing

machine’s attaching bar.

b) Do Not allow more slack than necessary for articulation.

c) Do Not use any intermediate support as the attaching point.

d) Store the safety chain by securing it around the tongue.

e) Replace the safety chain if one or more links or end fittings are

broken, stretched or otherwise damaged or deformed.

OPERATING INSTRUCTIONS/MAINTENANCE

Adjust the brackets on the header transport to best fit your make and model header. When

mounting the header, NEVER position yourself under or near the header. Securely fasten the

header to the header transport.

Do not exceed the load and size limits of the unit.

Keep the tires properly inflated. Both under inflation and over inflation can greatly reduce tire life.

Inspect bracing and welds periodically and repair immediately if needed. Failure to repair could

cause extensive damage and greatly reduce the life of the unit.

Repack the bearings in the hub assembly once a year or as needed. Use a good quality bearing

lubricant such as Bearing Gard MK1 or equivalent.

Grease the ball using the zerk on the front gooseneck assembly every 8 hours or as needed.

Be sure to check the hub nuts often and keep them properly tightened.

BRAKING SYSTEM REQUIREMENTS:

Tow Loads Safely

Stopping distance increases with speed and weight of towed loads, and on slopes. Towed loads with or

without brakes that are too heavy for the tractor or are towed too fast can cause loss of control. Consider

the total weight of the equipment and its load.

Observe these recommended maximum road speeds, or local speed limits which may be lower:

If towed equipment does not have brakes, do not travel more than 32 km/h (20 mph) and

do not tow loads more than 1.5 times the tractor weight.

If towed equipment does have brakes, do not travel more than 40 km/h (25 mph) and do

not tow loads more than 4.5 times the tractor weight.

Ensure the load does not exceed the recommended weight ratio. Use additional caution when towing

loads under adverse surface conditions, when turning, and on inclines.

Pg. 19

Page 20

SERVICE / MAINTENANCE RECORD

Date Description Notes

Pg. 20

Loading...

Loading...