Page 1

Talc Applicator Installation Manual

For Seed Tender Models 275 & 375

J. & M. Mfg. Co., Inc.

284 Railroad Street - P.O. Box 547

Fort Recovery, OH 45846

Ph: (419) 375-2376 Fax: (419) 375-2708

www.jm-inc.com

12/19/2013

Page 2

Step 1.

Measure from the top of the shell frame and make a mark on the front right side leg at 35” for the Model 375

Seed Tender and 42” for the Model 275 Seed Tender. is mark is for the height of the Talc Holding Container.

Next using the Talc Holding Container as a guide, mark 2 holes on the side of the leg. Drill both holes with a

7/16” bit. Once the holes are drilled, fasten the Talc Holding Container with (2) 3/8”x 1” Serrated Flange Hex

Nuts and Bolts. Tighten the hardware once nished.

42” (275ST)

35” (375ST)

Step 2.

Using the Talc Control Valve Body Assembly mark (2) holes in the front le leg gusset. e bracket should be

placed at the highest point possible on the front leg gusset. Once marked, drill 2 holes with a 7/16” drill bit.

Attach the Control Valve Body Assembly with (2) 3/8” x 1” Serrated Flange Hex Head Nuts and Bolts. Tighten

hardware once nished.

Page 3

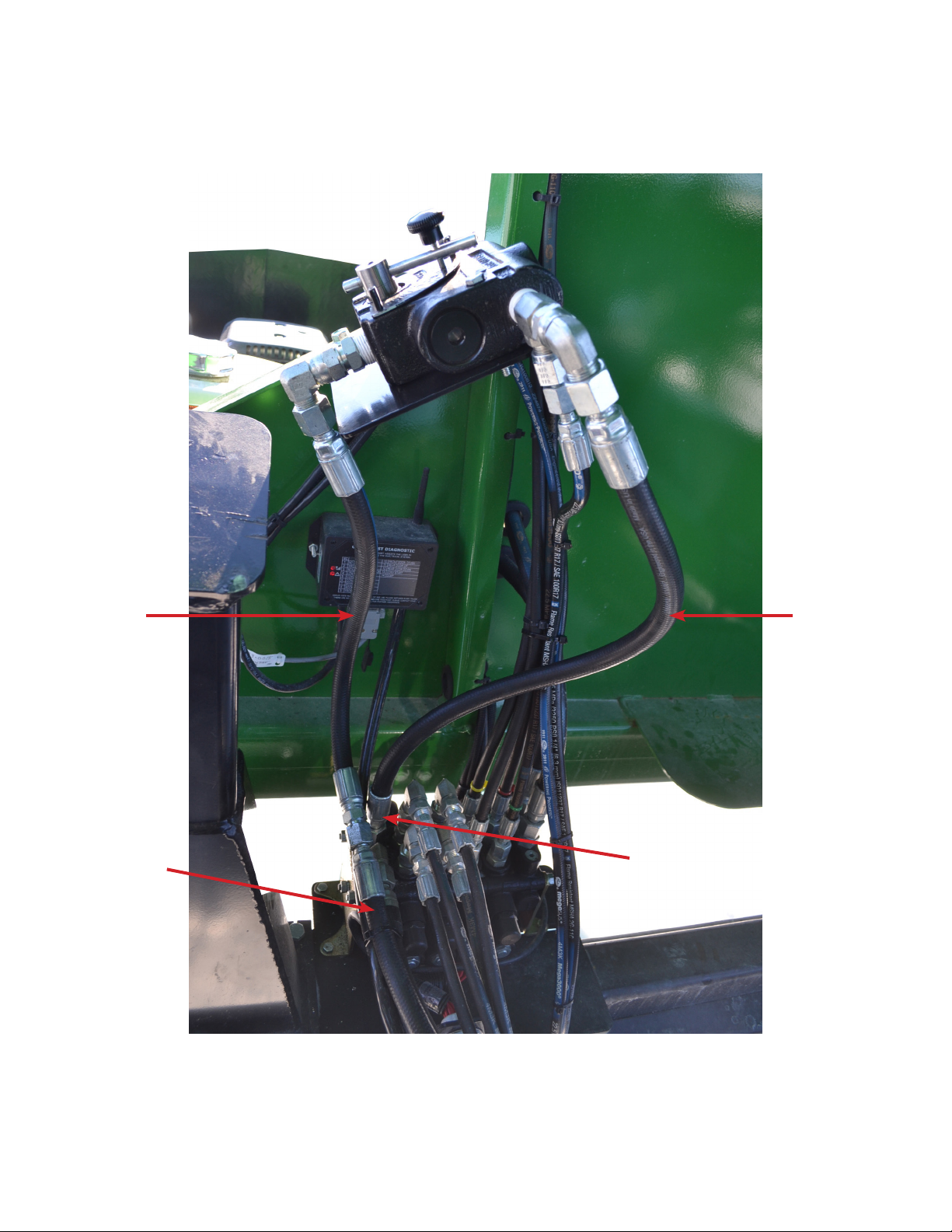

Step 3.

On the Hydraulic Spool Valve remove the “Return” hose on the valve body for the conveyor. Install the 1/2” by

17” hydraulic hose from the valve body to the Talc Applicator Control Valve. Connect hose to #3 on the talc

applicator valve body. Tighten all ttings once installed.

#3

17” Hydraulic

Hose

Conveyor

Return Hose

#4

17” Hydraulic

Hose

Remove Conveyor Return

Hose and 90 Deg. Fitting.

Step 4.

Install the last 1/2” x 17” hose. is hose connects to # 4 on the Talc Applicator Valve Body and to the Conveyor

Return Hose, which was removed from the Hydraulic Valve Body in step 3. Tighten all ttings once installed.

Note: 1/4” Hoses will be installed in step 8.

Page 4

Step 5.

For 375 ST Model

Fasten the Transfer Tube to the Talc Holding Container using

the supplied bracket. Start installing the bracket by removing

the two bolts shown in the image above. Now fasten the bracket

to the door with the two nuts that were just removed. Install

the 3/8” x 3” U-bolt. Use (2) 3/8” serrated ange hex nuts and

(2) 3/8” lock nuts to fasten the U-bolt to the bracket. Tighten

hardware once installed.

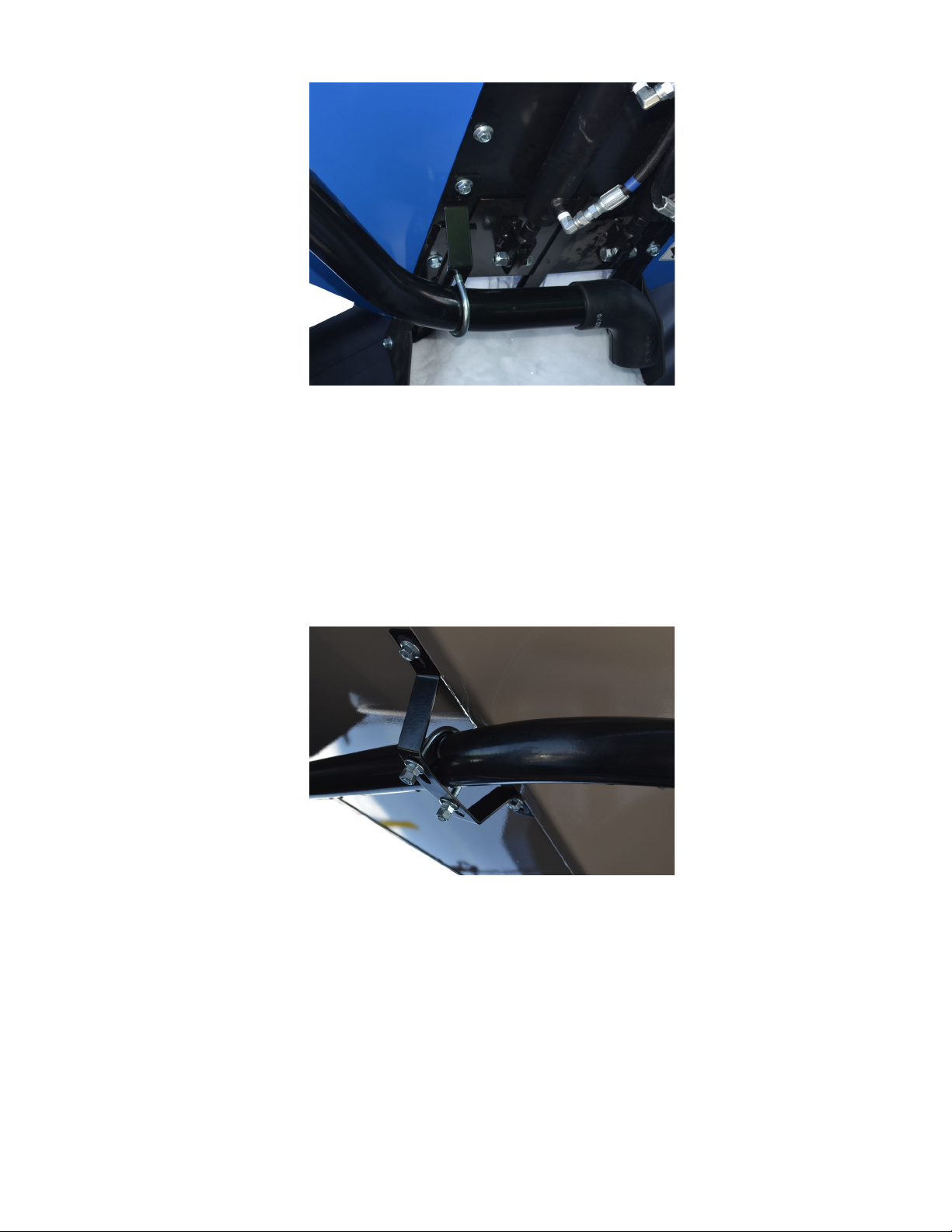

Step 5.

For 275 ST Model

Fasten the Transfer Tube to the Talc Holding Container using the supplied bracket. Two 3/8” clearance holes will need

to be drilled into the shell assembly to install the bracket.

Use (2) 3/8” x 1” hex bolts and nut to fasten the bracket to

the shell assembly. Install the 3/8” x 3” U-bolt. Use (2) 3/8”

serrated ange hex nuts and (2) 3/8” lock nuts to fasten the

U-bolt to the bracket. Tighten hardware once installed.

Page 5

Step 6.

Install the auger through the Talc Holding Container into the Talc Transfer Tube. Attach the motor to the auger

with the supplied set screw.

Attach the Motor to the Talc Holding Container using the supplied Exhaust Clamp. Tighten hardware once nished.

Note: When installing motor make sure the key-way is installed correctly.

Step 7.

Install both 1/4” x 107” Hydraulic Hoses from the Talc Motor to the Talc Control Valve Body. Hose coming

from Port A runs to Port 1 and Port B runs to Port 2. Route the hose through the conduit on the frame. Tighten

ttings once installed.

#1

#2

Step 8.

Use zip ties to fasten hydraulic hoses where necessary. Hose’s should be fastened where they will not rub any

moving components or catch any debris during transit.

Loading...

Loading...