Page 1

MANUAL HEADER

O P E R A T O R’ S M A N U A L

SPEED TENDER PRO 450

Revision 2/26/2013

J. & M. MFG. Co., Inc.

P.O. Box 547 Ft. Recovery, OH 45846

PH: (419) 375-2376

www.jm-inc.com

Page 2

TABLE OF CONTENTS

General Information

To e Dealer 4

Express Warranty 4

Service 5

To e Owner 6

Safety Rules 6-7

1.0 Operations

1.1 Preparing the Towing Vehicle 8

1.2 Preparing Speed Pro 8

1.3 Connecting Speed Pro to the Towing Vehicle 8

1.4 Transporting 9

1.5 Hydraulic Power Unit Operation 9-10

1.6 Field Operation 11

1.7 Basic Scale Operations 12

1.8 Auger Cleanout 12

2.0 Service

2.1 Tire Pressure 12

2.2 Tightening Lugnuts 12

2.3 Wheel Bearings 13

2.4 Hydraulic Power Unit 14

2.5 Electric Brakes 14-18

2.6 Daily Service 18

2.7 End of the Year Service 18-19

2.8 Removing From Storage 19

2.9 Troubleshooting 20-22

2.10 Bolt Torque Specications 23

3.0 Hydraulics 24

4.0 Wiring 25

5.0 Parts

5.1 Chassis 26-27

5.2 Frame Weldment 28-29

5.3 Auger Assembly 30-31

Page 3

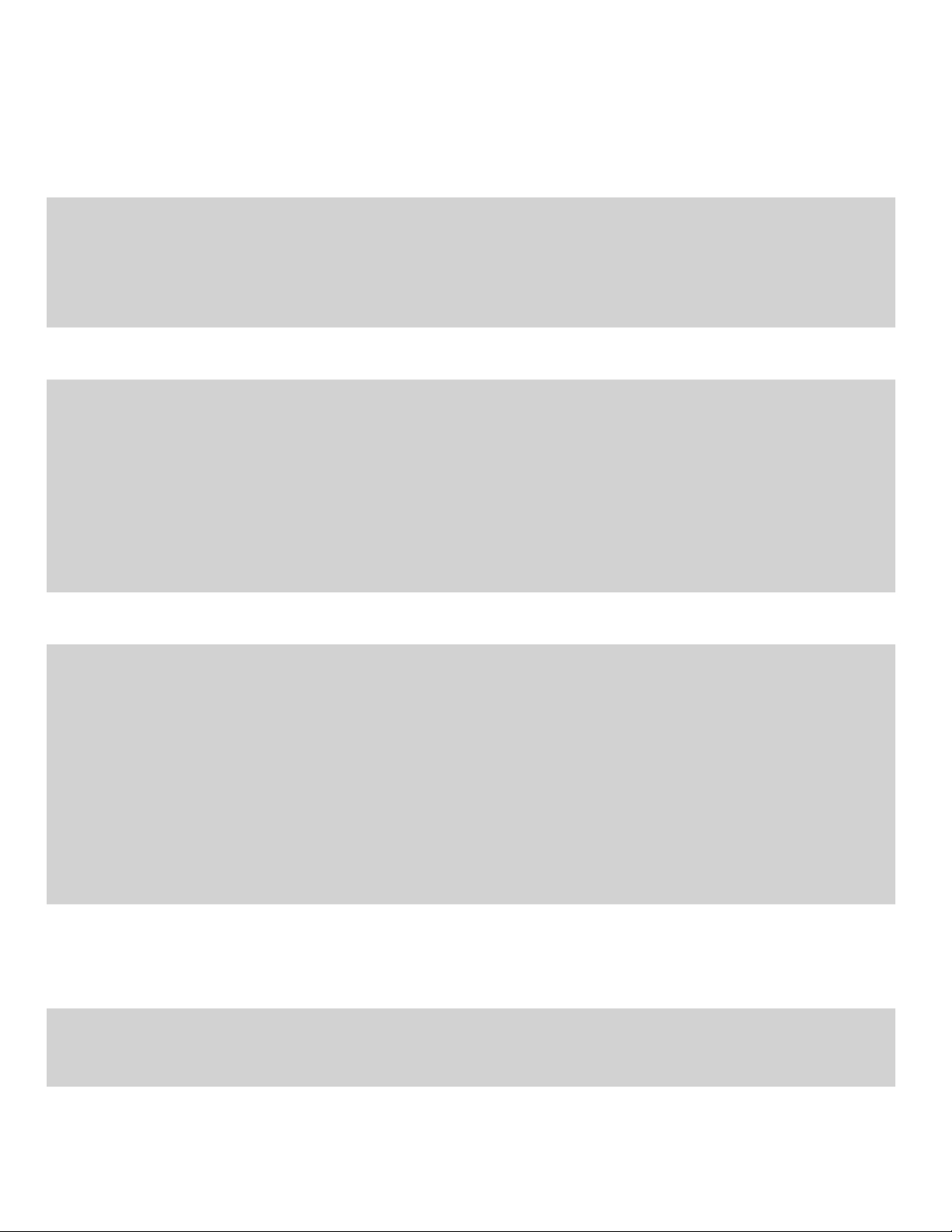

If a decal is torn or faded, it

needs to be replaced.

# Description Part. No.

1 Warning/Moving Parts JM0014993

2 Warning/Falling or Lowering JM0014992

3 Warning/Pinch Point JM0014994

4 Danger/Serious Injury Elec Lines JM0015099

5 Small J&M Oval JM0010179

6 Red & White Reective Tape JM0015079

7 Speed Pro 450 JM0025336

8 Warning/Safety Chains JM0014995

9 Warning/Trailer Can Roll JM0014997

10 Warning/High Pressure JM0010163

11 Chassis Manufacture # N/A

12 www.jm-inc.com JM0019239

13 Warning/Tire Wheel Lugnuts JM0014996

14 Warning/Do Not Adjust JM0014979

15 Warning/Open Flames JM0014983

Page 4

GENERAL INFORMATION

TO THE DEALER:

Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery

Check Lists in the Operator’s Manual are completed before releasing equipment to the owner.

The dealer must complete the Warranty Registration found on the Dealer Portal website located at

dealer.jm-inc.com. and return it to J. & M. Mfg. Co., Inc. at the address indicated on the form. Warranty claims

will be denied if the Warranty Registration has not been submitted.

EXPRESS WARRANTY:

J. & M. Mfg. Co. Inc. warrants against defects in construction or materials for a period of ONE year. We reserve the right to inspect and decide whether material or construction was faulty or whether abuse or accident

voids our guarantee.

Warranty service must be performed by a dealer or service center authorized by J. & M. Mfg. Co. Inc. to sell

and/or service the type of product involved, which will use only new or remanufactured parts or components

furnished by J. & M. Mfg. Co. Inc. Warranty service will be performed without charge to the purchaser for

parts or labor based on the Warranty Labor Times schedule. Under no circumstance will allowable labor times

extend beyond the maximum hours indicated in the Warranty Labor Times schedule for each warranty procedure. The purchaser will be responsible, however, for any service call and/or transportation of the product to

and from the dealer or service center’s place of business, for any premium charged for overtime labor requested

by the purchaser, and for any service and/or maintenance not directly related to any defect covered under the

warranty. Costs associated with equipment rental, product down time, or product disposal are not warrantable

and will not be accepted under any circumstance.

Each warranty term begins on the date of product delivery to the purchaser. Under no circumstance will warranty be approved unless (i) the product warranty registration card (attached to the inside of the Operator’s

Manual) has been properly completed and submitted to the equipment manufacturer, and (ii) a warranty authorization number has been issued by the equipment manufacturer. This Warranty is effective only if the warranty registration card is returned within 30 days of purchase.

This warranty does not cover a component which fails, malfunctions or is damaged as a result of (i) improper

modication or repair, (ii) accident, abuse or improper use, (iii) improper or insufcient maintenance, or (iv)

normal wear or tear. This warranty does not cover products that are previously owned and extends solely to the

original purchaser of the product. Should the original purchaser sell or otherwise transfer this product to a third

party, this Warranty does not transfer to the third party purchaser in any way. J. & M. Mfg. Co. Inc. makes no

warranty, express or implied, with respect to tires or other parts or accessories not manufactured by J. & M.

Mfg. Co. Inc. Warranties for these items, if any, are provided separately by their respective manufacturers.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS,

EXPRESS, IMPLIED OR STATUTORY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

In no event shall J. & M. Mfg. Co. Inc. be liable for special, direct, incidental or consequential damages of any

kind. The exclusive remedy under this Warranty shall be repair or replacement of the defective component at J.

& M. Mfg. Co. Inc.’s option. This is the entire agreement between J. & M. Mfg. Co. Inc. and the Owner about

warranty and no J. & M. Mfg. Co. Inc. employee or dealer is authorized to make any additional warranty on

behalf of J. & M. Mfg. Co. Inc.

4

Page 5

GENERAL INFORMATION

The manufacturer reserves the right to make product design and material changes at any time without notice.

They shall not incur any obligation or liability to incorporate such changes and improvements in products previously sold to any customer, nor shall they be obligated or liable for the replacement of previously sold products

with products or parts incorporating such changes.

SERVICE:

The equipment you have purchased has been carefully manufactured to provide dependable and satisfactory use.

Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specied. Observe all

safety information in this manual and safety signs on the equipment.

For service, your authorized J. & M. dealer has trained mechanics, genuine J. & M. service parts, and the necessary tools and equipment to handle all your needs.

Use only genuine J. & M. service parts. Substitute parts may void the warranty and may not meet standard required for safe and satisfactory operating. Record the model number and serial number of your equipment in the

spaces provided:

Serial #_______________ Purchase Date: _______________ Purchased From: ____________________

Please provide this information to your dealer to obtain the correct parts.

5

Page 6

GENERAL INFORMATION

TO THE OWNER:

The purpose of this manual is to assist you in operating and maintaining your Speed Pro in a safe manner. Read

it carefully. It furnishes information and instructions that will help you achieve years of dependable performance

and help maintain safe operating conditions. If this machine is used by an employee or is loaned or rented, make

certain that the operator(s), prior to operating:

1. Is instructed in safe and proper use.

2. Review and understands the manual(s) pertaining to this machine.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The terms CAUTION, WARNING and DANGER are used in conjunction with the Safety-Alert Sym-

bol. When you see this symbol, carefully read the message that follows and be alert to the possibility of personal

injury or death.

This Safety-Alert symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER:

WARNING:

CAUTION:

IMPORTANT:

NOTE:

Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury, and includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

SAFETY RULES:

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe equipment can be erased by an operator’s single careless act. In addition, hazard control and accident

prevention are dependent upon the awareness, concern, judgment, and proper training of personnel involved in

the operation, transport, maintenance and storage of equipment.

Make certain that the operator(s), prior to operating is instructed in safe and proper use and reviews and understands the manual(s) pertaining to this machine. Also make certain that the operator(s) reviews and understands

the operator’s manual of the tow vehicle prior to hooking up or operating the Speed Pro.

Read this manual before you operate this machine. If you do not understand any part of this manual, or need

more information, contact the manufacturer or your authorized dealer.

Safety Rules Next Page

6

Page 7

GENERAL INFORMATION

1. Understand that your safety and the safety of other persons are measured by how you service and operate

this ma chine. Know the positions and functions of all controls before you try to operate them. Make sure

to check all controls in a safe area before starting your work.

2. The safety information given in this manual does not replace safety codes, federal, state, or local laws.

Make certain your machine has the proper equipment as designated by local laws and regulations.

3. A frequent cause of personal injury or death is from persons falling off equipment and being run over. Do

not permit persons to ride on this machine.

4. Secure Speed Pro safety chain to towing vehicle before transporting. Do not transport without safety

chains being attached to tow vehicle.

6. Use good judgment when transporting Speed Pro on a highway. Maintain complete control at all times.

Regulate speed to road conditions. Do not transport unit with rear compartment full and front compartment

empty. The unit may not be properly balanced, offsetting the tongue weight of the Speed Pro.

7. When transporting on public roads, the conveyor must be in the forward position to meet with lighting and

visibility marking requirements.

8. Do not travel faster than 10 mph. during off highway travel. Drive slowly over rough ground, hill sides,

and around curves to avoid tipping. Use extreme care when operating close to ditches, fences, or on hill

sides.

9. Use care when moving or operating Speed Pro near electric lines as serious injury or death can result

from contact.

10. Never adjust, service, clean, or lubricate Speed Pro until all power is shut off and the battery is

disconnected. Keep all safety shields in place.

11. Carbon monoxide can cause severe nausea, fainting, or death. Do not operate engine in closed or conned

work area.

12. Explosive fuel can cause res and severe burns. Stop engine before lling fuel tank.

13. Hot parts can cause severe burns. Do not touch engine while operating or just after stopping.

14. Hydraulic oil leaking under pressure can penetrate skin and cause infection or other injury.

15. To prevent personal injury when working with hydraulic power unit:

a. Relieve all pressure before disconnecting uid lines.

b. Before applying pressure, make sure all connections are tight and components are in good

condition.

c. Never use your hand to check for suspected leaks under pressure. Use a piece of cardboard or wood

for this purpose.

16. Make sure that everyone is clear of equipment before applying power or moving the Speed Pro.

18. Before unhooking the Speed Pro from the transport vehicle, be sure to properly block the wheels to

prevent the Speed Pro from moving.

7

Page 8

OPERATIONS

1.1 Preparing the Towing Vehicle

Before towing the Speed Pro, refer to towing vehicle’s owner’s manual for information concerning hitch

capacities, hitch adjustments, and tire ination.

Towing vehicle must be equipped with proper electric braking components.

NOTE: The Speed Pro is equipped with LED lights. The towing vehicle may require a

asher upgrade for lights to operate properly.

Do not exceed towing vehicles GVWR (Gross Vehicle Weight Rating) or GCWR (Gross Combination Weight

Rating), or the maximum hitch load.

1.2 Preparing Speed Pro

Hydraulics: Check routing of all hydraulic hoses. Hoses should not be kinked, twisted or rubbing against sharp

edges. Check all hoses and ttings for hydraulic leaks. Tighten and /or repair or replace as required.

Lubrication: Lubricate Speed Tender as outlined in Service section 2.1. Refer to engine manual for proper uid

levels in engine.

Tires/Wheels: Check tire pressures and maintain at recommended operating pressure. It is important to check

wheel nut/bolts for proper torque as recommended. You can nd proper tire pressure and wheel torque located in

service manual section.

1.3 Connecting Speed Pro to the Towing Vehicle

WARNING: Do not stand between the Speed Pro and tow vehicle when hooking up.

NOTE: The Speed Pro comes standard with a 2 5/16” ball coupler and has an optional

3” lunette eye. Also the Speed Pro can come with an optional Gooseneck Frame in place

of the A-Frame. The Gooseneck Frame can feature either a 2 5/16” ball coupler or a 5th

Wheel hook up.

1. Back tow vehicle up to Speed Pro.

2. Align the vehicle’s ball or lunette eye with the coupler or ring on the Speed Pro.

3. Lift tongue latch lever.

4. Lower jack to set Speed Pro coupler down on ball or lunette eye hook.

5. Latch coupler and insert pin. Check to make sure that coupler is securely latched.

6. Pivot jack to transport position and pin in place.

7. Attach 7-way plug to tow vehicle. Check the length of the Speed Pro 7-way to make sure that

it is long enough to turn, but not too long to touch the ground.

NOTE: Check to make sure that lights are in proper operating condition and repair or

replace if necessary.

8. Connect the brake breakaway cable to towing vehicle.

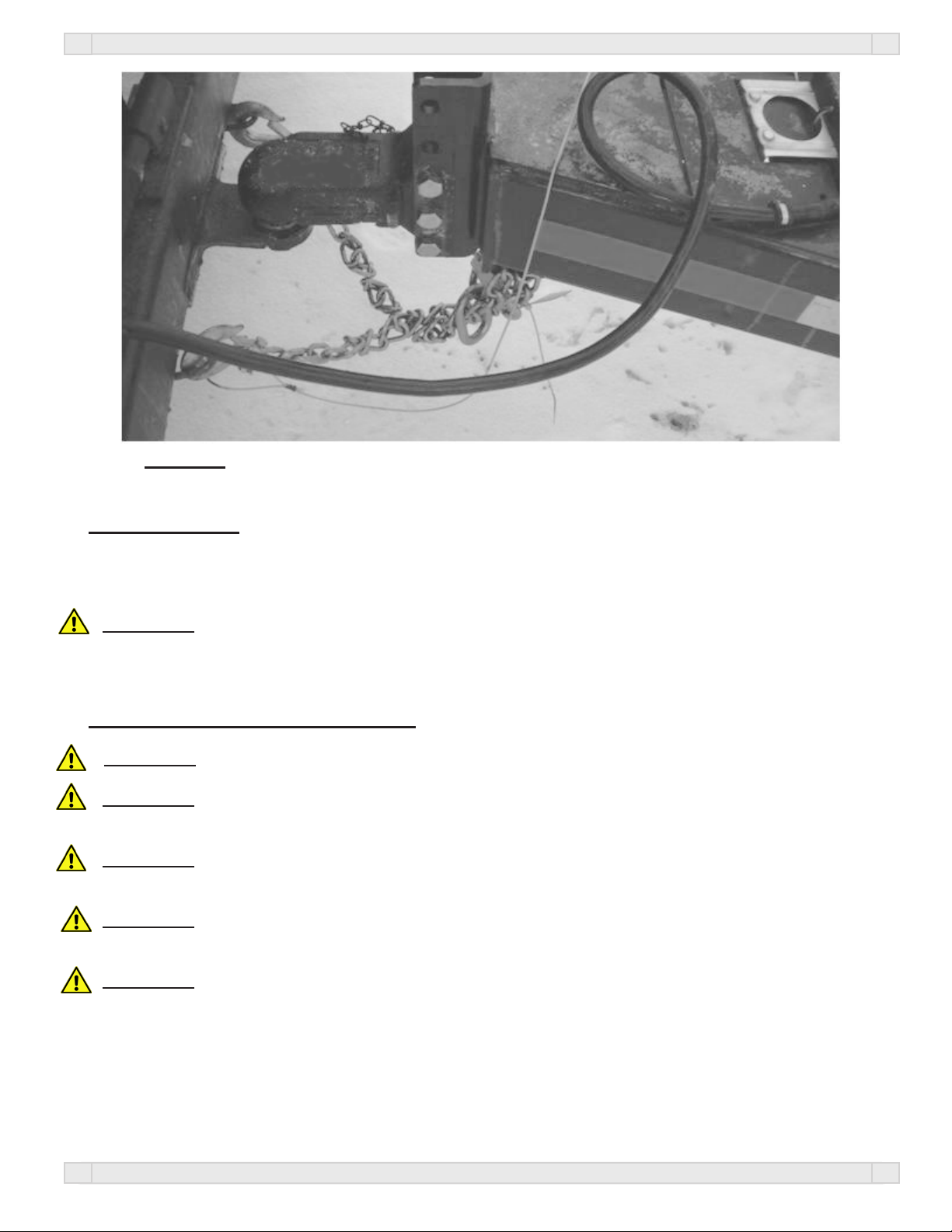

9. Attach safety chains to tow vehicle by crossing chains (Figure 1.1). Allow enough slack in

chains necessary for turning.

10. Test the brakes and all the lights on the Speed Pro

WARNING: Check safety chains for broken, stretched or damaged link or end ttings.

Replace chains if found to be damaged. Do not weld safety chains.

8

Page 9

Figure 1.1

OPERATIONS

1.4 Transporting

NOTE: Make sure the jack is in the horizontal position before transporting.

When transporting the Speed Pro on public roads, it is recommended to have the auger in the storage position.

WARNING: Travel at a safe speed that allows you to maintain complete control of towing vehicle and

Speed Pro at all times.

1.5 Hydraulic Power Unit Operation

WARNING: Explosive fuel can cause res and severe burns. Stop engine before lling fuel tank.

WARNING: Carbon monoxide can cause severe nausea, fainting or death. Do not operate

engine in an enclosed or conned area.

WARNING: Hot parts can cause severe burns. Do not touch engine while operating or just after

stopping.

WARNING: Acid from battery can cause res and severe acid burns. Make sure to charge

battery in well-ventilated area.

WARNING: Make sure to relieve hydraulic pressure before working on hydraulic system.

9

Page 10

OPERATIONS

WARNING: Purge hydraulic system of air before operating Speed Pro to prevent serious injury or

death.

WARNING: Wear proper hand and eye protection when searching for leaks. Use wood or cardboard

instead of hands.

1. Check to make sure all ttings and hardware are in proper operating condition. Replace if worn or

broken. Check engine uid levels and sight gauge on reservoir for proper operating levels.

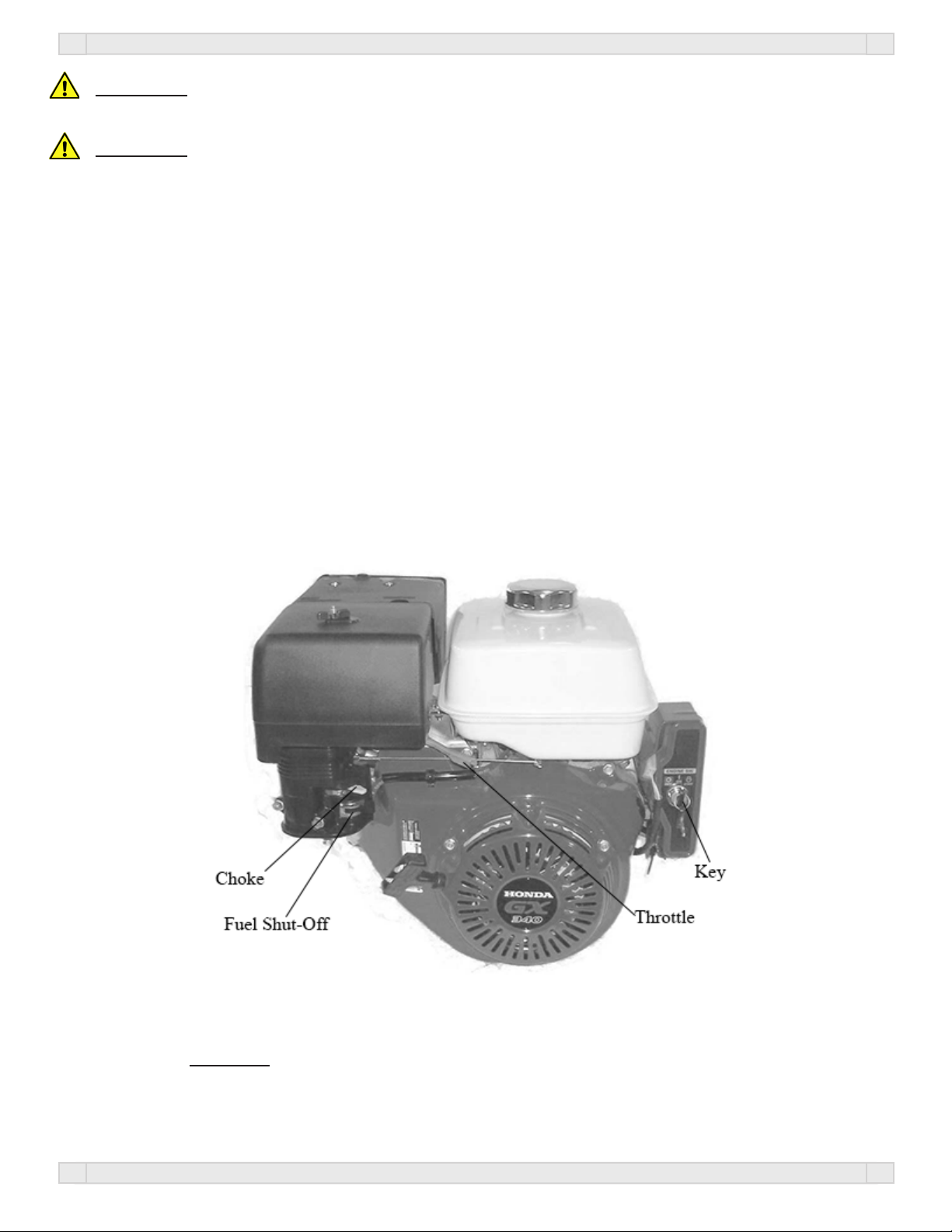

2. Slide the Fuel Shut-off Lever to the “ON” position (Figure 1.2).

3. Slide Choke Lever to the “ON” position (Figure 1.2).

4. Turn the key to the start position. Once engine starts, release key (Figure 1.2).

5. After starting, allow the engine to warm-up. Slide choke to the “OFF” position, and increase throttle

speed (Figure 1.2).

6. To turn the engine off, slide the Fuel Shut-off to the “OFF” position (Figure 1.2).

NOTE: In extremely cold weather, it is best to allow engine and hydraulics to warm-up before

increasing throttle speed.

NOTE: If a hydraulic leak appears, turn off immediately and take appropriate action.

NOTE: See Engine manual for more details on upkeep and service.

Figure 1.2

10

Page 11

OPERATIONS

1.6 Field Operation

WARNING: The Speed Pro must be hooked to the towing vehicle during loading and

unloading.

1. Position the Speed Pro next to the planter/drill so the auger will reach the planter box.

2. Start the hydraulic power unit and increase throttle speed. (Allow hydraulic uid to warm-up.)

(Figure 1.2).

3. Extend the auger to unload position using the handheld controller/wireless remote.

Conveyer/Auger

Up

E

F

JM0014984

Starts/Stops Motor

Raises/Lowers Conveyer

Start

Conveyer/Auger

J

N

M

E Blue

F Yellow

J Red

M Green/Black

N Green

WARNING: Empty-out the rear compartment rst to help prevent the chance of ipping the

Speed Pro.

9. Use the Handheld Control or Wireless Remote to start the auger.

10. Fill the planter/drill to desired level then repeat.

NOTE: Adjusting engine throttle will regulate auger speed.

11. Run the engine at 1/2 to full rpm for 20 minutes to recharge the battery.

12. Slide the fuel shut off lever to the “OFF” position. This will allow the engine to shutoff by running out

of gas.

13. Turn the key to the “OFF” position.

Reprogramming the Key Fob and Receiver:

To complete the learn procedure, simply do the following. Power up the unit. When you do so, the LED on the

receiver unit will ash “RED” four times. This indicates that the unit has received power. There is magnetically controlled

switching circuitry embedded in the receiver unit. Place a fairly powerful magnet on the back of the receiver for a brief

moment (3 seconds), and the remove it. The LED will go to a constant RED stare. Now immediately press any button on the

transmitter you are attempting to learn in. The LED will go to a GREEN/YELLOW color. This conrms that the receiver

has picked up a signal from the transmitter, and subsequently learned that signal. Communication has been established, and

it is now ready to function properly.

Troubleshooting:

Should the above procedure not complete successfully, wait until the LED light goes out, and repeat the procedure. If for

any reason you experience a second failure of the learn procedure, do the following. Place the magnet on the learn area

and the LED will go to a constant RED stare. Leave the magnet in place on the receiver until the LED light goes out.

(Approximately 10 seconds). This action completely clears the receiver’s memory. Once you have cleared the memory,

proceed with the standard learn procedure detailed above for the key fob transmitters.

11

Page 12

OPERATIONS

1.7 Basic Scale Operations

1. Turn the scale “ON” by pressing the on/off button. The display shows “Hello” then the current weight

value is displayed.

2. Press G/N to access the gross mode. (Live scale weight is displayed in the G/N weighing mode.)

3. In the gross mode, press the ZERO/CLEAR key to zero the indicator when the Speed Tender is empty.

4. After initial amount is placed on the scale, press the TARE Key. (Weight is tarred off and goes into net

mode, showing weight).

5. Load or unload material as needed (Shows + when loading and a – value when unloading).

6. When the display reaches the proper amount, stop loading or unloading.

7. Repeat steps 2 through 4 until complete.

NOTE: For more information, refer to the scale manual.

1.8 Auger Cleanout

1. Raise the clean out door on the auger.

2. Run the auger in reverse until all of the grain is removed.

3. Close the clean out door.

2.0 Service

1. Grease the auger bearing every 10 hours of operation and before storage. Use only two pumps of grease.

2.1 Tire Pressure

The following is to be used as a general guide

for tire ination. Figures can vary depending on

specic brand of tire used. It is important that tires

are inspected before and after unit is loaded. Start

with the minimum pressure indicated. The tire

should stand up with no side wall buckling or distress as tire rolls. Do not exceed maximum recom-

mended tire pressure. 80 psi is the cold rating on

the tire that is standard for the Speed Pro.. J&M

also recommends to rotate your tires front to back

(not side to side) every 1,200 miles or 12 months

(whichever comes rst) for longer tire life. Figure

2.3 is a troubleshooting chart used to ensure the

tires wear evenly.

Fig. 2.3

2.2 Tightening Lugnuts

Torque lug-nuts on new and removed wheels to 220 ft. lbs. after the rst 10, 25, and 50 miles of driving, then

recheck torque every 50 hours or every year, whichever comes rst.

12

Page 13

SERVICE

2.3 Wheel Bearings

The wheel bearings need to be cleaned, inspected, and repacked every 12 months or 12,000 miles. Use a number

2 wheel bearing grease to repack the bearings.

Bearing Inspection and Service:

1. Jack up Speed Pro.

2. Remove wheel lug-nuts.

3. Remove wheel from hub.

4. Remove grease cap.

NOTE: Be careful not to dent or cut a hole in grease cap.

5. Remove the cotter pin, nut, and washer.

6. Wiggle the hub to take the outer wheel bearing out.

7. Pull hub assembly straight off the axle. If you want to reuse the grease seal, (which is not recommended),

be careful to support the weight of the hub so that the end of the axle does not ruin the rubber part of the

grease seal.

8. To remove the inner bearing, you must remove the grease seal.

9. Remove inner bearing.

10. Wash all grease and oil from the bearing cone using a suitable solvent. Dry the bearing with a clean, lint-

free cloth and inspect each roller completely. If any pitting, scalding, or corrosion is present, then

the bearing must be replaced. The bearing cups inside the hub must be inspected.

NOTE: Bearings must always be replaced in sets of a cone and a cup (See bearing cup replacement

on following page.)

11. Repack inner bearing with new grease.

A. Place a moderate amount of grease in the palm of one hand.

B. Hold the inner bearing, large side down, in your other hand

C. Using the edge of the bearing like an ice-cream scoop, work it in until you see fresh grease

come out of the top side of the bearing.

D. Rotate 1/8 of a turn and repeat until the whole bearing is full of fresh grease.

12. Place the inner bearing in the back of the wheel hub and add a liberal dose of grease.

13. Position the new wheel seal in its recess and lightly set it with a hammer.

NOTE: Be careful to not deform the metal part of the seal.

14. Slide the hub assembly onto the spindle and push it back into position.

15. Grease the outer bearings by hand. (See step 11)

16. Slide it and the spindle washer onto the spindle and into the hub recess.

17. Install and bottom out the spindle nut, then back it off 1/4 turn.

18. Reinstall the spindle nut and replace the cotter pin with a new one.

NOTE: If the castle nut does not line up with the hole in the spindle, then loosen the nut

slightly until it does.

19. Pack the bearing cap with fresh grease and lightly drive it into the hub recess with a hammer.

20. Reinstall the wheel onto the hub and torque the wheel lug-nuts.

NOTE: See wheel nut/bolt torque requirements located in section 2.10.

Bearing cup replacement:

1. Place the hub on a at work surface with the cup to be replaced on the bottom side.

2. Using a brass drift punch, carefully tap around the small diameter end of the cup to drive it out.

3. After cleaning the hub bore area, replace the cup by tapping it with the brass drift punch. Be sure the cup

is seated all the way up against the retaining shoulder in the hub.

13

Page 14

SERVICE

2.4 Hydraulic Power Unit

Daily (every 5 hours of use):

1. Check oil level.

2. Inspect for oil leaks and repair as necessary.

3. Check all hoses, ttings, bolts and hardware to make sure that they are secure and properly tightened.

4. Check motor oil level. See Engine operator’s manual for details on oil levels, oil types, and service

intervals.

Once per season (every 20-25 hours of use):

Change hydraulic oil lter element with either a NAPA 155Z or a FRAM P1654A Filter.

Every two to three years (every 75-80 hours of use):

Drain oil reservoir and rell with clean, good quality hydraulic AW 32 oil. (It is not recommended to rell

with tractor hydraulic oil).

Replacing hydraulic parts:

Check parts section for proper part description and part # for replacement.

Purge air from system as follows:

1. Disconnect the rod end clevis of all cylinders in a circuit and block up cylinders so the rod can completely

extend and retract without contacting any other components.

2. Pressurize the system and maintain system at full pressure for at least 5 sec. after cylinder rods stop

moving. Check that all cylinders have fully extended or retracted.

3. Check hydraulic reservoir and rell as needed.

4. Pressurize system again to reverse the motion of step 2. Maintain pressure on system for at least 5 sec.

after cylinder rods stop moving. Check that cylinders have fully extended or retracted.

5. Check for hydraulic leaks using cardboard or wood. Tighten connections according to the

torque chart. (pg.23)

6. Repeat steps 2, 3, 4 and 5 (3 to 4 times).

7. Depressurize hydraulic system and connect cylinder rod clevises to their mating lugs.

2.5 Electric Brakes

The Speed Pro is equipped with electric brakes. They need to be inspected and serviced immediately if a loss of

performance is experienced. You need to service your Speed Pro brakes at least once a year with normal use.

How to use your electric brakes properly:

Your Speed Pro brakes are designed to work in synchronization with your tow vehicle brakes. Never use your

tow vehicle or Speed Pro brakes alone to stop the combined load.

Your Speed Pro and tow vehicle will seldom have the correct amperage ow to the brake magnets to give you

comfortable, safe braking unless you make proper brake system adjustments. Changing trailer load and driving

conditions, as well as uneven alternator and battery output, can mean unstable current ow to your brake magnets. It is therefore imperative that you maintain and adjust your brakes as set forth in this manual, use a properly

modulated brake controller, and perform the synchronization procedure noted below.

In addition to the synchronization adjustment detailed below, electric brake controllers provide a modulation

function that varies the current to the electric brakes with the pressure on the brake pedal or amount of deceleration of the tow vehicle. It is important that your brake controller provide approximately 2 volts to the braking

system when the brake pedal is rst depressed and gradually increases the voltage to 12 volts as brake pedal pressure is increased. If the controller “jumps” immediately to a high voltage output, even during a gradual stop, then

the electric brakes will always be fully energized and will result in harsh brakes and potential wheel lockup.

14

Page 15

To synchronize:

To insure safe brake performance and synchronization, read the brake controller manufacturer’s instruction

completely before preforming the synchronization procedure.

Make several hard stops from 20 mph on a dry paved road that is free of sand and gravel. If the Speed Pro

brakes lock and slide, decrease the gain setting on the controller. If they do not slide, slightly increase the gain

setting, adjust the controller just to the point of impending brake lockup and wheel skid.

How to adjust electric brakes:

1. Park the Speed Pro on rm and level ground.

2. Block the trailer tires on the opposite side securely so that no forward or rearward movement is possible.

3. Jack up the Speed Pro.

4. Secure the trailer on jack stands of adequate capacity front and rear.

5. At the back of the wheel, on the brake backing plate, there is a small rubber plug near the bottom of the

backing plate. Pry out this plug to give access to the star wheel adjuster.

6. Insert the brake adjuster tool and maneuver it so that the tool engages with the teeth in the star wheel.

The star wheel looks like a gear with exposed teeth on the perimeter.

7. Turn the adjuster until the brake locks up (you can no longer rotate the wheel by hand). This centers the

brake shoes on the brake drum so that they are in the correct position.

8. Now back off the star wheel 8 to 10 clicks or as specied by the manufacturer. The wheel should spin

freely with no apparent drag to slow it down. A slight scraping noise is normal as the wheel turns.

9. Repeat this procedure for all the wheels

SERVICE

When to adjust brakes:

1. After the rst 200 miles of operating when the brake shoes and drums have “seated.”

2. At 3,000 mile intervals or once a year, whichever comes rst.

Brake Cleaning and Inspection:

Your Speed Pro brakes must be inspected and serviced at yearly intervals, (or more often as use and performance requires). Magnets and shoes must be changed when they become worn or scored thereby preventing

adequate vehicle braking. Clean the backing plate, magnet arm, magnet, and brake shoes. Make certain that all

the parts removed are replaced in the same brake and drum assembly. Inspect the magnet arm for any loose or

worn parts. Check shoe return springs, hold down springs, and adjuster springs for stretch or deformation and

replace if required.

Brake Shoe and Lining Inspection:

A simple visual inspection of your brake linings will tell if they are usable. Replacement is necessary if the lining is worn (to within 1/16” or less), contaminated with grease or oil, or abnormally scored or gouged. Hairline

heat cracks are normal in bonded linings and should not be cause for concern (Figure 2.6). When replacement

is necessary, it is important to replace both shoes on each brake and both brakes of the same axle. This will help

retain the “balance” of your brakes.

Acceptable

Hairline Cracks

Figure 2.6

15

Page 16

SERVICE

Replacing Brake Linings:

1. Remove the brake shoe retract spring.

2. Remove the shoe hold down assembly by holding the back of the pin with one hand and pushing against

the spring and twisting with a hold down spring tool until the cup is released.

3. Remove both shoes together leaving the adjuster assembly and spring intact.

4. Clean the backing plate and lever arm.

5. Inspect magnet arm for any loose or worn parts.

6. Replace springs that are broken, bent, or weak.

7. Apply a light lm of lubricant to the anchor pin and shoe rest pads & backing plate areas that are in

contact with the lever arm.

8. Attach the adjuster screw and spring to the new brake shoes. The star wheel and adjuster must be

positioned as before.

9. Install the new shoes on the backing plate and reinstall shoe retract spring.

After replacement of brake shoes and linings, the brake must be re-burnished to seat in the new components.

This should be done by applying the brakes 20 to 30 times from an initial speed of 40 mph, slowing the vehicle

to 20 mph. Allow ample time for brakes to cool between applications. This procedure allows the brake shoes

to seat into the drum surface.

Brake Lubrication:

Before reassembling, apply a light lm of lubrication or similar grease, or anti-seize compound on the brake

anchor pin, the actuating arm bushing and pin, and the areas of the backing plate that are in contact with the

brake shoes and magnet lever arm. Apply a light lm of grease on the actuating block mounted on the actuating

arm.

Troubleshooting:

Most electric brake malfunctions that cannot be corrected by either brake adjustments or synchronization adjustments can generally be traced to electrical system failure. Mechanical causes are ordinarily obvious, bent or

broken parts, worn out linings or magnets, seized lever arms or shoes, scored drums, loose parts, etc. Voltmeter

and ammeter are essential tools for proper troubleshooting of electric brakes.

How to Measure Voltage:

System voltage is measured at the magnets. Connect the voltmeter to the two magnet lead wires at any brake.

This may be accomplished by using a pin probe inserted through the insulation of the wires dropping down

from the chassis or by cutting the wires. The engine of the towing vehicle should be running when checking the

voltage (so that a low battery will not affect the readings).

Brake Magnet Inspection:

Your electric brakes are equipped with high quality electromagnets that are designed to provide the proper force

and friction. Your magnets should be inspected and replaced if worn unevenly or abnormally (Figure 2.7). Even

if wear is normal as indicated by your straightedge, the magnets should be replaced if any part of the magnet

coil has become visible through the friction material facing of magnet. It is also recommended that the drum

armature surface be re-faced when replacing magnets. Magnets should also be replaced in pairs - both sides of

an axle.

16

Page 17

SERVICE

Straight Edge

Abnormal Wear

(Replace)

Figure 2.7

Voltage in the system should begin at 0 volts. As the controller bar is slowly actuated, the voltage should gradually increases to about 12 volts. This is referred to as modulation. No modulation means that when the controller begins to apply voltage to brakes it applies an immediate high voltage, which causes the brakes to apply

instantaneous maximum power.

The threshold voltage of a controller is the voltage applied to the brakes when the controller rst turns on. The

lower the threshold voltage, the smoother the brakes will operate. Threshold voltage in excess of 2 volts (quite

often found in heavy duty controllers) can cause grabbing, resulting in harsh braking.

How to Measure Amperage:

System amperage is the amperage being drawn by all brakes on the trailer. The engine of the towing vehicle

should be running when checking amperage.

One place to measure system amperage is at the blue wire of the controller which is the output to the brakes.

The blue wire must be disconnected and the amp meter put in series into the line. System amperage draw should

be as noted in the table below. Make sure your ammeter has sufcient capacity and note polarity to prevent

damaging your amp meter.

Normal Wear

Brake Size Amps/Magnet Two Brakes Four Brakes Six Brakes Magnet Ohms

Replacing brake magnet

1. Orient the magnet over the lever arm post such that the magnet leads are in the correct position for

routing

2. Push the magnet over the lever arm post by compressing the magnet spring between the magnet and the

lever arm.

3. Insert the magnet clip in the slot of the magnet. Be sure to orient the magnet clip so it will “snap” into

place.

4. Press down on the magnet and install the magnet clip.

5. Be sure that the magnet moves up and down freely on the lever arm post.

6. Route the wiring in the same manner noted on removal. Be sure that wires cannot bind, pinch, or rub.

Manually actuate lever arm to insure there is no interference.

7. Install strain relief bushing, allowing enough slack in the wiring to allow the lever arm to move without

straining the wires. Be sure the wire cannot come in contact with the armature.

8. Connect the magnet leads to the trailer wiring harness and then reinstall hub and drum.

12 X 2 3.0 6.0 12.0 18.0 3.2

17

Page 18

SERVICE

Brake Drum Inspection:

There are two areas of the brake drum that are subject to wear and require inspection. These two areas are the

drum surface where the brake shoes make contact during stopping and the armature surface where the magnet

contacts (only in electric brakes).

The drum surface should be inspected for excessive wear or heavy scoring. If worn more than .020” oversized,

or if the drum has worn out of round by more than .015”, then the drum surface should be turned. If scoring or

other wear is greater than .090” on the diameter, the drum must be replaced. When turning the drum surface,

the maximum re-bore diameter for a 12” brake drum is 12.090”

The machined inner surface of the brake drum that contacts the brake magnet is called the armature surface.

If the armature surface is scored or worn unevenly, it should be refaced to a 120 micro inch nish by removing not more than .030” of material. To insure proper contact between the armature face and the magnet face,

the magnets should be replaced whenever the armature surface is refaced and the armature surface should be

refaced whenever the magnets are replaced.

2.6 Daily Service (5 -10 Hours of Use)

NOTE: J&M recommends the following service to be performed daily (every 5-10 hours of

use)

1. Grease the auger bearing every 10 hours. Use only two pumps of grease per bearing

NOTE: Over lubrication of this bearing will result in premature failure.

2. Check hydraulic oil level.

3. Inspect for oil leaks and repair as appropriate.

4. Check all hoses, ttings, bolts, and hardware to make sure that they are secure and properly tightened.

5. Check engine oil level. See Engine operator’s manual for details on oil levels, oil types and service

intervals.

6. Check Speed Pro brakes and lights before towing.

7. Check the Speed Tender periodically for cracks in welds and for other structural damage. Have cracked

welds xed immediately.

NOTE: Failure to have cracked welds xed immediately could result in extensive damage to

the Speed Pro and greatly reduce its life.

8. Make sure tires are properly inated (See section 2.3).

9. Make sure wheel lug nuts are properly torqued (See section 2.4).

10. Clean out the Auger at the end of every day of use (Section 1.8).

2.7 End of the Year Service

IMPORTANT: When the Speed Pro is not going to be used for a length of time, J & M recommends

that you store the Speed Pro in a dry, protected place. Leaving your Speed Pro outside and open to the

weather will shorten its life.

18

Page 19

SERVICE

1. Grease the auger bearing. Use only two pumps of grease per bearing.

NOTE: Over lubrication of this bearings will result in premature failure.

2. Grease pivot points on boom arm before storage.

3. The wheel bearings need to be cleaned, inspected, repacked, and adjusted. Use a number 2 wheel bearing

grease to repack the bearings.

4. Inspect and service the brakes (magnets and shoes). They must be changed when they become

worn or scored, thereby preventing inadequate vehicle braking. Clean the backing plate, magnet

arm, magnet, and brake shoes. Make certain that all the parts removed are replaced in the same brake and

drum assembly. Inspect the magnet arm for any loose or worn parts. Check shoe return springs, hold

down springs, and adjuster springs for stretch or deformation, replace as needed.

5. Torque lug-nuts (Section 2.4).

6. Make sure that the tires are properly inated.

7. Remove all grain from inside the chutes.

8. Clean out the Auger at the end of every season (Section 1.8).

10. Check the Speed Pro periodically for cracks in welds and for other structural damage. Have cracked

welds xed immediately.

NOTE: Failure to have cracked welds xed immediately could result in extensive damage to

The Speed Pro and greatly reduce its life.

11. Check hydraulic hoses for wear and replace if needed.

13. Remove battery from the Speed Pro and place in a cool dry place.

NOTE: Attaching a trickle charger to the battery will help ensure a long life for your battery.

IMPORTANT: Be sure to disconnect the scales from the battery before charging.

14. Change hydraulic oil lter element with either a NAPA 155Z or a FRAM P1654A Filter.

15. Top off hydraulic oil tank with good quality hydraulic AW 32 oil.

NOTE: If the Hydraulic Oil appears to be “Milky” in color it should be changed immediately.

Otherwise, the Hydraulic Oil should be changed every 2-3 years. If the environment is extremely

dusty or dirty the Hydraulic Oil should be changed more often.

15. Check motor oil level. See Engine operator’s manual for details on oil levels, oil types, and service

intervals.

16. Retract all hydraulic cylinders to prevent the piston rods from rusting.

17. Touch-up spots where paint has been worn away (use good quality primer paint - especially before

applying graphite paint to the inside of the grain tank).

2.8 Removing From Storage

1. Grease the auger bearing. Use only two pumps of grease per bearing

NOTE: Over lubrication of this bearing will result in premature failure.

2. Grease pivot points on boom arm.

3. Torque lug-nuts (Section 2.4).

4. Make sure that the tires are properly inated.

6. Check oil level.

7. Inspect for hydraulic oil leaks and repair as appropriate.

8. Check all hoses, ttings, bolts, and hardware to make sure that they are secure and properly tightened.

9. Check engine oil level. See Engine operator’s manual for details on oil levels, oil types, and service

intervals.

10. Check Speed Pro lights before each time you tow.

11. Make sure that the auger hopper guard is in place.

12. Reattach battery and check to make sure that it is fully charged.

IMPORTANT: Be sure to disconnect the scales from the battery before charging.

19

Page 20

TROUBLESHOOTING

2.9 Troubleshooting

Problems Solutions

Unit sways during travel

a. Check tire pressure.

b. Check tow vehicle for loosened hitch parts.

c. Check tow vehicle’s hitch height.

d. Reduce towing speed.

e. Check wheel lug-nuts.

f. Check wheel bearings for adjustment (See section 2.5).

Tires show excessive wear

a. Check tire pressure.

b. Rotate tires. (See section 2.3)

c. Check wheel bearings for adjustment. (See section 2.5).

Wheel makes grinding or squeaking noise

a. Service wheel bearings. (See section 2.5).

Noisy when brakes are being applying

a. Properly adjust brakes.

b. Replace any weak or broken springs in brakes.

c. Replace the brake linings if excessively worn or contaminated

d. Check wheel bearings for adjustment (See section 2.5).

No Brakes

a. Properly adjust brakes

b. Check for short in electric circuit

c. Replace any brake magnets that are worn or defective

Weak brakes

a. Properly adjust brakes

b. Replace any excessively worn or contaminated linings.

c. Check for short in electric circuit

d. Replace bent backing plate

Dragging brakes

a. Properly adjust brakes

b. Replace any weak or broken springs in brakes

c. Clean and lubricate the brake assemblies

20

Page 21

TROUBLESHOOTING

Problems Solutions

Locking brakes

a. Replace any weak or broken springs in brakes

b. Replace any excessively worn or contaminated linings

Grabbing brakes

a. Replace any excessively worn or contaminated linings

Surging brakes

a. Trailer is not adequately grounded

Auger is not moving - Hydraulic pump is not producing

sufcient pressure or volume to auger motor.

a. Check for pinched or leaking hydraulic line

b. Allow hydraulic oil to warm up

c. Increase engine R.P.M.

d. Charge battery or plug in to tow vehicle

e. Hydraulic uid level low

f. Hydraulic lter clogged

g. Check for proper oil viscosity

h. Check hydraulic output pressure.

Auger is not moving - Obstructed auger

a. Make sure auger is not clogged

Auger has insufcient output speed or R.P.M. - Hydraulic

pump is not producing sufcient pressure or volume to

auger motor.

a. Check for pinched or leaking hydraulic lines.

b. Allow hydraulic oil to warm up

c. Increase engine R.P.M.

d. Hydraulic uid level low

e. Hydraulic lter clogged

f. Check for proper oil viscosity

g. Repair or replace worn out pump.

Auger has insufcient output speed or R.P.M.

a. Check telescoping spout and conveyor for a clog.

b. Remove material from clean out door.

Auger has insufcient output speed or R.P.M. - Air in

hydraulic system.

a. Bleed air out of hydraulic system and ll reservoir

(See section 2.6).

b. Look for leaking or cracked ttings.

Auger has insufcient output speed or R.P.M. - Leak in mo-

tor, valve body, or bypass valves.

a. Replace or repair motor, valve body, or bypass valves.

b. Check for proper oil viscosity.

21

Page 22

TROUBLESHOOTING

Problems Solutions

Auger will not move up or down - Engine R.P.M.

slow.

a. Increase engine R.P.M.

Auger will not move up or down - Hydraulic

pump is not producing sufcient pressure or volume to hydraulic cylinder.

a. Check for pinched or leaking hydraulic lines.

b. Allow hydraulic oil to warm up.

c. Increase engine R.P.M.

d. Hydaulic uid level low.

e. Hydraulic lter clogged.

f. Check for proper oil viscosity.

g. Check to see if hydraulic pump is worn out

h. Make sure battery is fully charged.

i. Check wiring to valve body and hydraulic pump

Hydraulic unit squeals

a. Check sight glass on hydraulic unit reservoir and ll if necessary.

b. Run engine at reduced speed for 5-10 minutes to warm up oil.

c. Clean/replace ller cap/breather.

d. Clear obstruction in suction hose.

e. Replace plugged/dirty oil lter element.

Hydraulic unit has poor performance at high

R.P.M.

a. Clean pressure relief in control valve or replace

b. Check sight glass on hydraulic unit reservoir and ll if necessary.

c. Replace plugged/dirty oil lter element

d. Charge Battery

22

Page 23

2.10 Bolt Torque Specications

BOLT TORQUE SPECIFICATIONS

Standard Dry Torque in Foot-Pounds

Bolt Dia.

(in.)

1/4 20 6 9 10 12.5 13 14

5/16 18 12 17 19 24 25 29

3/8 16 20 30 33 43 44 47

7/16 14 32 47 54 69 71 78

1/2 13 47 69 78 106 110 119

9/16 12 69 103 114 150 154 169

5/8 11 96 145 154 209 215 230

3/4 10 155 234 257 350 360 380

7/8 9 206 372 382 550 570 600

1 8 310 551 587 825 840 700

1-1/8 7 480 872 794 1304 1325 1430

1-1/4 7 375 1211 1105 1815 1825 1975

1-3/8 6 900 1624 1500 2434 2500 2650

1-1/2 6 1100 1943 1775 2913 3000 3200

1-5/8 5.5 1470 2660 2425 3985 4000 4400

1-3/4 5 1900 3463 3150 5189 5300 5650

1-7/8 5 2360 4695 4200 6980 7000 7600

2 4.5 2750 5427 4550 7491 7500 8200

Pitch

(threads/

inch)

SAE

Grade 0-1-2

74,000 psi

Low Carbon

Steel

SAE

Grade 3

100,000 psi

Med. Carbon

Steel

SAE

Grade 5

120,000 psi

Med. Carbon

Heat T. Steel

SAE

Grade 6

133,000 psi

Med. Carbon

Temp. Steel

SAE

Grade 7

133,000 psi

Med. Carbon

Alloy Steel

Grade 8

150,000 psi

Med. Carbon

Alloy Steel

SAE

23

Page 24

HYDRAULICS

3.0 Standard Models (Raise and lower boom only)-JM0010317

MANUAL HEADER

# Description Part # Qty.

1 1/4” I.D. Hose; 1/4” male NPT rigid X #6 female JIC swivel; 12” OAL JM0010282 1

2 1/4” I.D. Hose; 3/8” male NPT rigid X 3/8” male NPT swivel; 170” OAL JM0025342 1

3 1/4” I.D. Hose; 3/8” male NPT rigid X 3/8” male NPT swivel; 158” OAL JM0025343 1

4 1/2” I.D. Hose; 3/8” male NPT swivel X #8 female JIC swivel; 30” OAL JM0025344 1

5 1/2” I.D. Hose; #8 female JIC swivel X #8 female JIC swivel; 91” OAL JM0025346 2

6 1/2” I.D. Hose; #8 female JIC swivel X #8 female JIC swivel; 34” OAL JM0025647 1

7 3/8” male NPT X 3/8” female NPT swivel; straight JM0010288 1

8 #8 male JIC X 1/2” male NPT; straight JM0010289 2

9 #8 male JIC X 3/4” male NPT; 90 degree elbow JM0010290 1

10 #6 male JIC X 1/2” male NPT X #6 male JIC; tee JM0010291 1

11 1/2” male NPT X 3/8” female NPT; 90 degree elbow JM0010292 1

12 #8 male JIC X #8 male o-ring; straight JM0010293 1

13 #8 male JIC X #10 male o-ring; straight JM0010294 2

14 #6 male JIC X #6 female JIC swivel; 90 degree elbow JM0010295 1

15 #8 male JIC X #8 female JIC swivel; 90 degree elbow JM0010296 1

16 #8 male JIC X #8 male o-ring; 90 degree elbow JM0010297 1

17 #8 male o-ring X 3/8” female NPT swivel; straight JM0010298 2

18 3/8” male NPT X 3/8” female NPT swivel; 90 degree elbow; with .062” orice JM0010299 2

19 2 Spool Valve Body JM0001829 1

20 Pilot Check Valve JM0010153 1

24

Page 25

4.0 Light Wiring Harnesses-JM0010319

4”

4”

6”

Green

White

Black

10”

6”

10” 10”

5”

White

Tan

White

Dark Blue

White

Dark Blue

White

Dark Blue

4”

Yellow

White

Black

6”

10”

12”

White

Tan

White

Tan

3”

Red

White

3”

3”

82”

9”

White

Red

32”

Red

Light Blue

9” total

18” 19” 40” 34” 37” 77”

To Electric Breaks

To Front

Harness

Main Ha rness

To Flood Light

Switch H arness

To Ba tte ry

To Battery Breakaway

To Right

Brea k Light

To Rear Right Ro und

Red Marker Light

To Lef t

Brea k Light

To Rear Left Round

Red Marker Light

To Lic ense

Plate Lig ht

To Rear Top Harness

Black

Blue

12”

White (Ground)

Battery Breakaway

L

A

B

DC

Brakes

M

F

WIRING

E

K

Brake

J

I

*375ST is shown

275ST & ST PRO

G

Brake

H

is same as

F

M

J

I

C

K

H

G

E

D

A

25

Page 26

5.1 Chassis Parts

PARTS

26

Page 27

PARTS

# Description Part. No.

1 5/8”-11 x 2” Gr8 Z Hex Bolt JM0001771

2 Titan-21,000lb 2.3125 Ball Coupling JM0001893

3 5/8” Gr5 Z Centerlock Hex Nut JM0002146

4 Breakaway Switch JM0001843

5 Speed Pro Jack w/ Lynch Pin JM0010191

6 Pro Box A-Frame Weldment JM0018547

7A Amber Round Light Assembly JM0001980

7B Amber Round Light JM0001895

7C Round Light Grommet JM0001902

8 Front Driver Side Step Fender JM0002339

9 7,000 Lb Axle with Electric Brakes JM0001957

10 Front Passenger Side Step Fender JM0002336

11 Fender Weldment JM0005874

12 235-85-R16 8 Bolt Wheel & Tire JM0016650

13 .562-18 Lugnut JM0008525

14 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

15 3/8-16 x 3/4” Gr5 Z SF Hex Bolt JM0001750

16 Rear Driver Side Step Fender JM0002491

17 Rear Passenger Step Fender JM0002490

18 Seed Tender Bumper JM0020862

19 375ST Non-Scale Weldment JM0002514

19 2-1/8” Diameter Weigh Bar JM0002797

20A Red Round Light Assembly JM0001905

20B Red Round Light JM0001901

20C Round Light Grommet JM0001902

21A Red Oval Brake Light Assembly JM0001903

21B Red Oval Brake Light JM0007114

21C Red Oval Brake Light Grommet JM0001897

22 3/8”-16 x 1” Gr5 Z SF Hex Bolt JM0002092

23 Gooseneck Weldment JM0007079

24 Gooseneck Jack JM0007078

25 5/8”-11 x 1-1/2” Gr5 Z Hex Bolt JM0002103

27

Page 28

PARTS

5.2 Frame Weldment

21

3

3

4

4

5

5

1

1

2

2

7

7

8

8

9

9

21

14

14

19

19

18

18

20

20

19

19

4

4

4

9

9

10

10

23

23

25

25

10

10

26

26

24

24

27

27

15

15

13

13

5

5

4

11

11

4

4

19

19

19

5

5

19

28

Page 29

PARTS

# Description Part.No.

1A Right Lock Weldment JM0020479

1B Le Lock Weldment JM0020480

2 Rubber Pipe Handle 1” ID Black JM0024290

3 3/8” x 2-1/2” Z Round Wire Lynch Pin JM0014929

4 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

5 3/8”-16 X 1” Gr5 Z SF Hex Bolt JM0002092

6A Spare Tire Assembly JM0025359

6B Tire Mount Square Bolt JM0024203

6C .562-18 Lugnut JM0008525

7 Auger Rest Weldment JM0020552

8 3/8”-16 X 1-1/2” Gr5 Z SF Hex Bolt JM0001633

9 1/2”-13 Gr5 Z Centerlock Hex Nut JM0001511

10 1/2”-13 X 2” Gr8 Z Hex Bolt JM0001620

11 3/8”-16 X 2-1/2” Gr5 Z Hex Bolt JM0001647

12 1/4”-20 X 3/4” Gr5 Z Hex Bolt JM0001507

13 0.313-18 Gr5 Z SF Hex Nut JM0014049

14 Battery Box JM0001846

15 Break Away Battery Box Assembly JM0001833

16 1/2” ID x 2-1/8” OD Flat Washer - 1/8” ick JM0019081

17 Power Unit Guard JM0000327

18 Hydraulic Power Unit JM0003027

19 3/8”-16 Gr5 Z SF Hex Nut JM0002152

20 3/8”-16 X 1-1/4” Gr5 Z Hex Bolt JM0016675

21 2 Spool Valve Body with Fittings JM0010464

22 Frame Weldment JM0020035

23 Molded Brush Seals JM0024293

24 Chute Assembly JM0022317

25 Center Bolt Plate JM0022318

26 1/4”-20 X 5/8” Gr5 Z Hex Bolt JM0001479

27 1/4”-20 Gr5 Z Centerlock Hex Nut JM0001505

28 Scale Display Unit JM0007293

29 Auger Rest Weldment JM0020565

28

29

Page 30

5.3 Auger Assembly

3

3

5

5

1

1

6

6

4

4

7

7

2

2

PARTS

33

33

32

32

21

21

12

12

31

31

20

20

12

12

19

19

18

18

17

17

26

26

27

27

25

25

28

28

8

8

22

22

24

24

23

23

11

11

12

12

9

9

30

30

29

29

10

10

15

15

13

13

14

14

13

13

16

16

30

Page 31

PARTS

# Description Part. No.

1 1” Sha Bearing JM0020794

2 1/2”-13 Gr5 Z Centerlock Hex Nut JM0001511

3 Field Light Assembly JM0001881

4 1/2-13” x 1-3/4” Gr5 Z Hex Bolt JM0002101

5 3/8”-16 X 3/4” Gr5 Z SF Hex Bolt JM0001750

6 Auger Down Spout Clamp JM0020580

7 1/2”-13 x 3-1/2” Gr5 Z Hex Bolt JM0009914

8 1/2”-13 Z Gr5 Hex Jam Nut JM0002157

9 Talc Applicator Hole Cover JM0024959

10 Bolt-on Hopper Cover JM0022278

11 3/8”-16 Gr5 Z SF Hex Nut JM0002152

12 3/8”-16 X 1” Gr5 Z SF Hex Bolt JM0002092

13 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

14 3/8” USS Flat Washer JM0003061

15 Clean Out Door Handle JM0022274

16 Rubber Pipe Handle 1” ID Black JM0024290

17 3/8”-16 X 2-1/2” Gr5 Z Hex Bolt JM0001647

18 3/8”-16 Gr5 Z Nylon Locking Hex Nut JM0001664

19 Pro-Box Auger Washer JM0020540

20 Auger Motor Bolt Plate JM0018154

21 White Drive Products RS series Hydraulic Motor JM0001983

22 Linkage Arm for Pro Box JM0016510

23 7/8”-9 Gr5 Z Centerlock Hex Nut JM0002148

24 Upper Link Bar JM0019805

25 7/8”-9 X 9” Gr8 Z Hex Bolt JM0024283

26 Cylinder 2” x 12” JM0025341

27 1” X 3” Clevis Pin - Cotter Pin JM0003064

28 1” X 3” Clevis Pin JM0003065

29 Lower Auger Assembly JM0018343

30 Bottom Auger Weldment JM0025295

31 Upper Auger Assembly JM0018344

32 Top Auger Weldment JM0025302

33 19’ ree Stage Spout JM0021785

31

Loading...

Loading...