Page 1

GRAIN CART

Manual

OPERATOR’S MANUAL

MODEL

284 Railroad Street - P.O. Box 547 | Fort Recovery, OH 45846 | Ph: (419) 375-2376 | Fax: (419) 375-2708

Rev. 11.28.2018

J&M Manufacturing Co, Inc

www.jm-inc.com

Page 2

Opposite Auger

Side

Stance

Rear

Front

2

Auger Side

Page 3

Dealer Pre-Delivery Instructions Grain Cart

WHEEL NUTS

Check ALL wheel nuts for correct torque setting. (3/4”-400 Ft-Lbs, 22mm-640 Ft-Lbs)

Tighten as needed. Re-Check wheel nut torque settings during initial break in period

(during 1st, 2nd, 3rd loads, etc.), then periodically afterwards (every 10 hours of use for

rst 40 hours). Keep checking wheel nut settings until wheel nuts do not loosen. If wheel

nuts loosen and damage the surface of the wheel center, it will be impossible to keep

them tight. Failure to keep the wheel nuts tight could cause considerable damage to the

grain cart and surrounding. It is the Dealer’s responsibility to have wheel nuts torqued to

specication before delivery. Damage caused by failure to keep the wheel nuts tight is not

warrantable.

HITCH

Determine the hitch style of cart to be compatible with tractor. Tractor with hammer strap

(clevis type) should be used with grain carts equipped with a single prong (spade) hitch.

Tractors equipped with a single prong hitch (no hammer strap) should be used with grain

carts equipped with a double prong (clevis) hitch.

Be sure the tractor pin is at least 1/4” smaller in diameter than the pin hole in the grain cart

hitch to ensure enough free movement when traversing through uneven terrain.

POWER TAKE-OFF

Check for adequate clearance between telescoping PTO and tractor hitch. Suggested

clearance is 7 inches.

Check telescoping PTO for adequate extension. With the tractor hitched to the cart on at

level ground, the PTO should have approximately 10 inches extended from the collapsed

(shortest) length.

UPPER AND LOWER AUGERS

Raise the auger to the unload position. Run the auger from the PTO or optional hydraulic

motor. If the top auger is misaligned with the bottom auger, you will hear a ‘bang’ as

the upper auger realigns itself with the lower auger. This is normal as the top auger has

dropped to engage the lower auger. Be sure that the top auger engages the lower auger.

Check bearing at top of auger. Be sure to have approximately 1/8” to 3/16” of an inch gap

under/between top auger bearing. Some models have bearings inside and some models

have bearings outside of upper auger housing. If there is no gap under the bearing, or the

gap is greater than 1/8” to 3/16”, the bearing needs adjusted.

HYDRAULIC CYLINDERS AND HOSES

Run all functions of the hydraulic cylinders and inspect ttings and seals for leakage. (use

cardboard or wood to check for hydraulic leaks)

(Continued on Next Page)

3

Page 4

Dealer Pre-Delivery Instructions Grain Cart

GEARBOX

Check the gearbox oil level. For the process of checking the oil in your gearboxes, refer to

“Lubrication Service Schedule” in this manual. Add SAE 80W-90 lubricant as necessary.

LIGHTING & SAFETY FEATURES

Check the tractor lighting system for functions. Plug the grain cart wire harness into the

tractor receptacle and check the cart lighting for correct functions. Note: The auger spout

light is activated through a mercury switch located at the harness connection under the

discharge spout. The auger spout light should automatically turn on when the auger is

in the unload position, and turn o when the auger is returned to the storage position. If

the auger spout light does not turn on or shut o properly, the mercury switch may need

repositioned.

Check that the safety chains are properly installed. Use bolt-torque chart listed in

operator’s manual for correct torque value.

TIRES

All tires need to be inated to the specied air pressure given in the “Tire Pressure” section

on the “Initial Operation & Maintenance” page of this manual.

4

Page 5

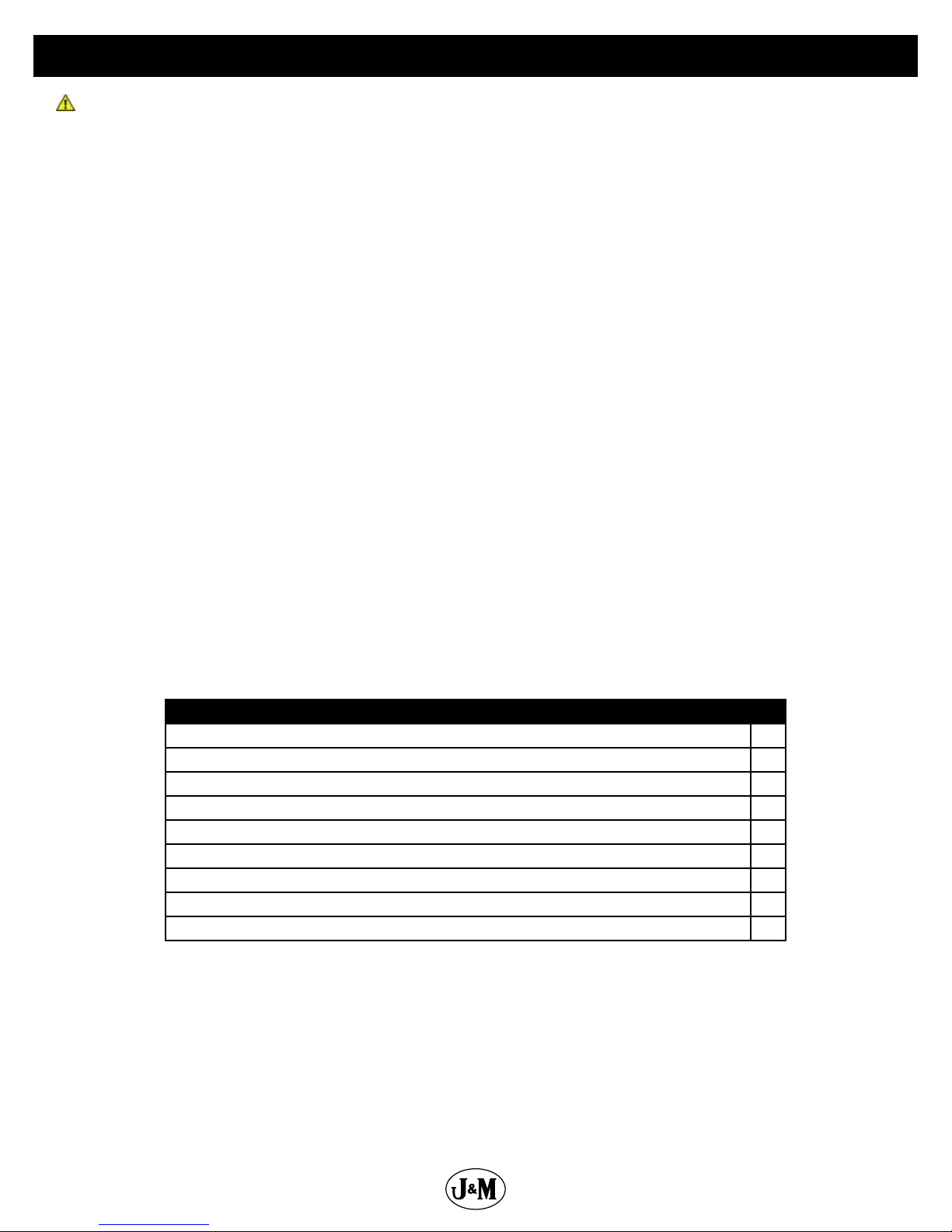

Table Of Contents

6 ....................................................................................To the Dealer

7 .............................................................................General Information

8 ...................................................................................Specications

8 .....................................................................................Dimensions

9 ............................................................................... Bolt Torque Chart

10-11 ......................................................................................Decals

12 ....................................................................................Safety Rules

13 ..............................................................Initial Operation and Maintenance

14-15 ...................................................................... Operating Instructions

15 .............................................................Walking Tandem Dual Row Spacing

16 ...................................................................Lubrication Service Schedule

17 .......................................................................... Routine Maintenance

17 ...............................................................................Troubleshooting

18 ..................................................................Adjusting the Lower Flighting

18 ......................................................................Adjusting Upper Flighting

19 ....................................Removing Dirt from the Restrictors on the Hydraulic Cylinder

19 ............................................................................Storage Preparation

19 ........................................................................Removing From Storage

Repair Parts & Diagrams

20 ....................................................................................Wheel Rims

20 ...........................................................................................Tires

21 .................................................................Hub & Spindle Assembly W-891

22 .................................................................Hub & Spindle Assembly W-881

23 ...........................................................Power Take-O (PTO) Shaft Assembly

24-25 ..............................................................130 Degree Gearbox Assembly

26 ................................................................................ Hitch Assembly

27 ............................................................................Drive Line Assembly

28 .........................................................................Lower Auger Assembly

29 ...........................................................................Upper Auger Linkage

30-31 ......................................................................Upper Auger Assembly

32-33 .................................................................Hydraulic Hoses & Cylinders

34-35 ....................................................................... Auto-Gate Hydraulics

36 .................................................................. Auto-Gate Shut-O Assembly

36 ...........................................................Auto-Gate Shut-O Wiring Schematic

37 .............................................................................. Lights and Wiring

38 ......................................Digi-Star 5-Point Scale System for Single Wheel Grain Carts

39 .......................................................Digi-Star 5-Point Scale System with Tracks

40 .................................Digi-Star 5-Point Scale System Hardware for Track & Bolt on Axle

41 .................Digi-Star 5-Point Scale System for Grain Carts with Walking Tandem Dual Wheels

42 ......................................................... Walking Tandem Dual Wheel Assembly

43 .....................................................................................Sideboards

44 ............................................................................Inspection Windows

44 ..........................................................................Door Wheel Assembly

45 ...............................................................................Ladder Assembly

46 ...........................................................................Auger Rest Assembly

47 ........................................................................Spring Return Assembly

48-49 ..........................................................................Roll Tarp Assembly

5

Page 6

To the Dealer

Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists are completed

before releasing equipment to the owner.

The dealer must complete the Warranty Registration found on the Dealer Portal website located at dealer.jm-inc.com. and return

it to J. & M. Mfg. Co., Inc. at the address indicated on the form. Warranty claims will be denied if the Warranty Registration has not

been submitted.

EXPRESS WARRANTY:

J. & M. Mfg. Co. Inc. warrants against defects in construction or materials for a period of ONE year. We reserve the right to inspect

and decide whether material or construction was faulty or whether abuse or accident voids our guarantee.

Warranty service must be performed by a dealer or service center authorized by J. & M. Mfg. Co., Inc. to sell and/or service the type

of product involved, which will use only new or remanufactured parts or components furnished by J. & M. Mfg. Co., Inc. Warranty

service will be performed without charge to the purchaser for parts or labor based on the Warranty Labor Times schedule. Under no

circumstance will allowable labor times extend beyond the maximum hours indicated in the Warranty Labor Times schedule for each

warranty procedure. The purchaser will be responsible, however, for any service call and/or transportation of the product to and

from the dealer or service center’s place of business, for any premium charged for overtime labor requested by the purchaser, and

for any service and/or maintenance not directly related to any defect covered under the warranty. Costs associated with equipment

rental, product down time, or product disposal are not warrantable and will not be accepted under any circumstance.

Each warranty term begins on the date of product delivery to the purchaser. Under no circumstance will warranty be approved

unless (i) the product warranty registration card has been properly completed and submitted to the equipment manufacturer, and

(ii) a warranty authorization number has been issued by the equipment manufacturer. This Warranty is eective only if the warranty

registration card is returned within 30 days of purchase.

This warranty does not cover a component which fails, malfunctions or is damaged as a result of (i) improper modication or

repair, (ii) accident, abuse or improper use, (iii) improper or insucient maintenance, or (iv) normal wear or tear. This warranty

does not cover products that are previously owned and extends solely to the original purchaser of the product. Should the original

purchaser sell or otherwise transfer this product to a third party, this implied, with respect to tires or other parts or accessories not

manufactured by J. & M. Mfg. Co., Inc. Warranties for these items, if any, are provided separately by their respective manufacturers.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

In no event shall J. & M. Mfg. Co., Inc. be liable for special, direct, incidental or consequential damages of any kind. The exclusive

remedy under this Warranty shall be repair or replacement of the defective component at J. & M. Mfg. Co., Inc’s. option. This is the

entire agreement between J. & M. Mfg. Co., Inc. and the Owner about warranty and no J. & M. Mfg. Co., Inc. employee or dealer is

authorized to make any additional warranty on behalf of J. & M. Mfg. Co., Inc.

The manufacturer reserves the right to make product design and material changes at any time without notice. They shall not incur

any obligation or liability to incorporate such changes and improvements in products previously sold to any customer, nor shall

they be obligated or liable for the replacement of previously sold products with products or parts incorporating such changes.

SERVICE:

The equipment you have purchased has been carefully manufactured to provide dependable and satisfactory use. Like all

mechanical products, it will require cleaning and maintenance. Lubricate the unit as specied. Observe all safety information in

this manual and safety signs on the equipment.

For service, your authorized J. & M. dealer has trained mechanics, genuine J. & M. service parts, and the necessary tools and

equipment to handle all your needs.

Use only genuine J. & M. service parts. Substitute parts may void warranty and may not meet standards required for safety and

satisfactory operation. Record the model number and serial number of your equipment in the spaces provided:

Model No:1012 Serial No: ________________________ Date of Purchase: ___________________

Purchased From: ________________________________________________________________________________

Provide this information to your dealer to obtain correct repair parts.

6

Page 7

General Information

TO THE OWNER:

The purpose of this manual is to assist you in operating and maintaining your grain cart in a safe manner. Read it carefully. It

furnishes information and instructions that will help you achieve years of dependable performance and help maintain safe operating

conditions. If this machine is used by an employee or is loaned or rented, make certain that the operator(s), prior to operating:

1. Is instructed in safe and proper use.

2. Reviews and understands the manual(s) pertaining to this machine.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to equipment. The

terms CAUTION, WARNING and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with an exclamation mark)

to indicate the degree of hazard for items of personal safety. When you see this symbol, carefully read the message that follows and

be alert to the possibility of personal injury or death.

This Safety-Alert symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER

WARNING

CAUTION

IMPORTANT

NOTE

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, will

result in death or serious injury, and includes hazards that are exposed

when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

7

Page 8

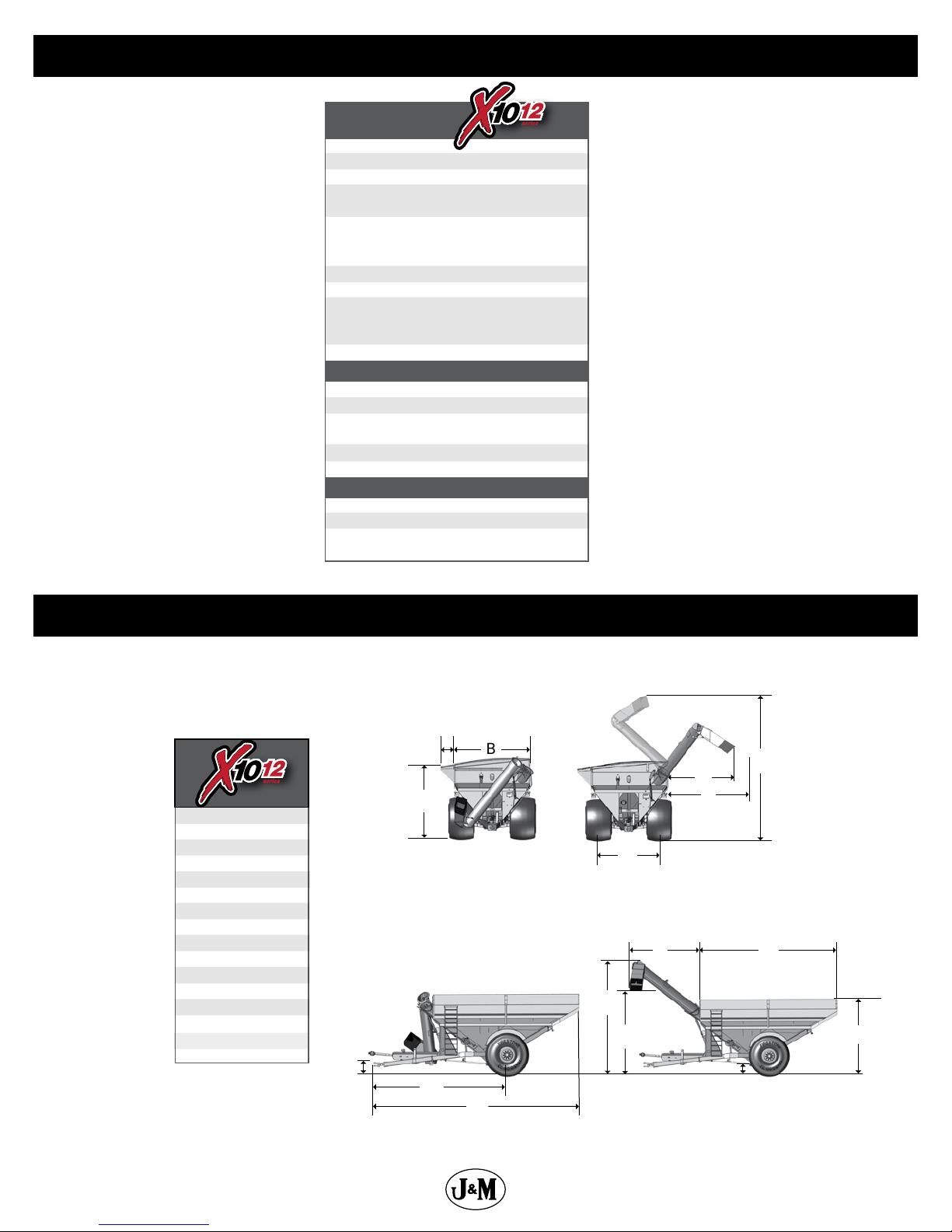

Specications

SPECIFICATIONS

Single Wheel Option

Capacity

Auger, One Vertical

Unload Time (minutes)

(2)

Wheels

Tires (2)

Hubs (2)

Spindles (2)

Tongue Weight

Empty

Loaded

Total Weight (approx.)

Walking Tandem Dual Wheels Option

Capacity

Wheels (4)

Tires (4)

Spindles (4)

Total Weight (approx.)

Tracks Option

Capacity

Total Weight (approx.)

Compaction Rate

Compaction Rate LT Series

1,025 Bushels

20” Bullet

1.8 minutes

30x32, 31x32,

32x36 or 44x32

900/60R32, 35.5x32,

1050/50R32, or

1250/50R32

10 Bolt

4 1/2” (Stress-Proof)

2,900 lbs.

4,200 lbs.

12,900 lbs.

1,000 Bushels

16x42, 18x38, 18x42

480/80R42, 520/85R38

or 520/85R42

4 1/2” Diameter

16,100 lbs.

1,050 Bushels

21,300 lbs.

9.93 lbs/sq inch

13.91 lbs/sq inch

Dimensions

C

B

D

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

10’-11”

11’-9”

NA

10’-10”

13’-6”

10’-0”

22’-3”

1’-6”

20’-1”

30’-7”

13’-6”

22’-0”

12’-0”

1’-5”

11’-2”

18’-2”

A

F

P

K

E

Eective Side Reach

(throw)

H

I

J

G

LO

M

N

8

Page 9

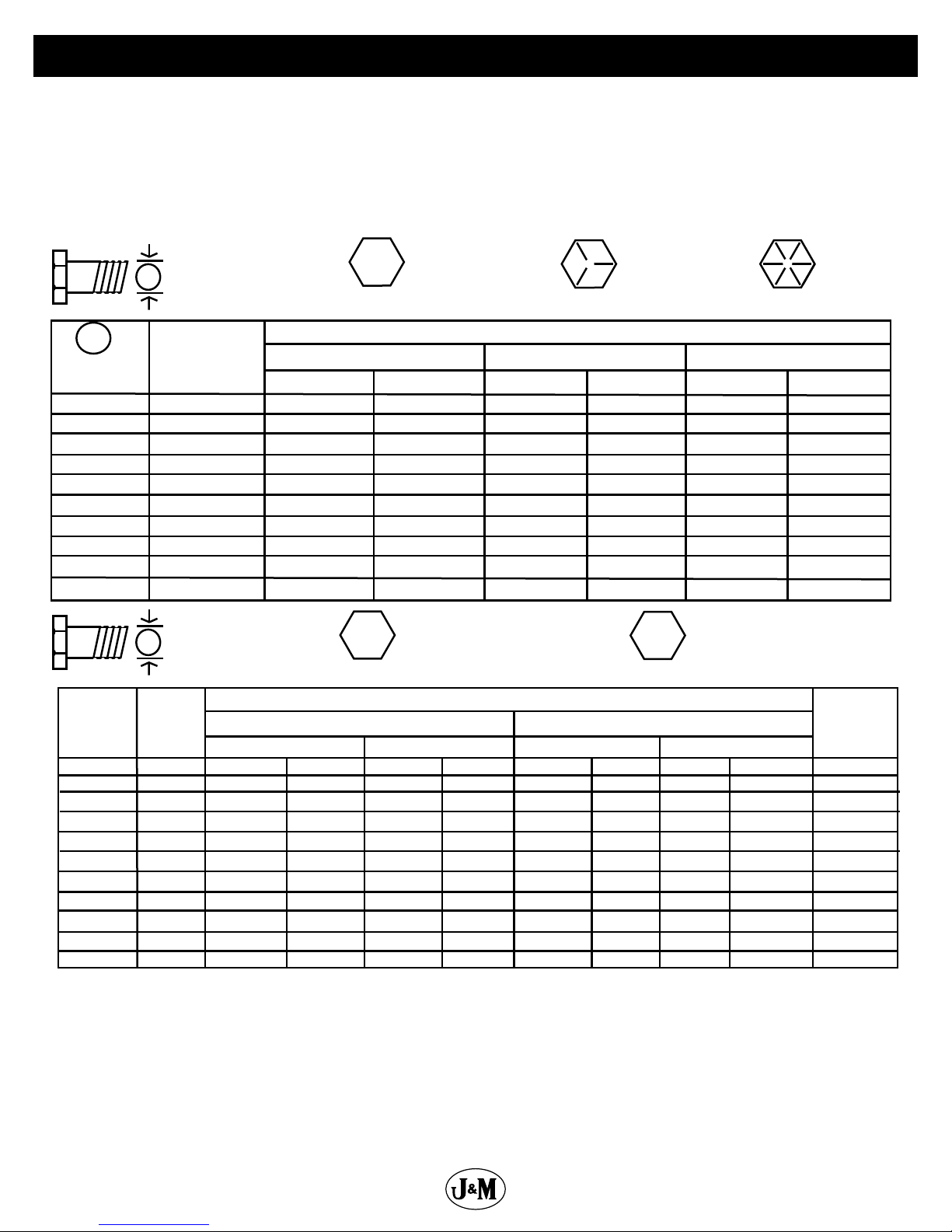

General Information

SAE SERIES

BOLT TORQUE CHART

Always tighten hardware to these values unless a dierent torque or tightening procedure is listed for specic application.

Fasteners must always be replaced with the same grade as specied in the manual parts list.

Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for Metric hardware.

Make sure fastener threads are clean and you start thread engagement properly.

All torque values are given to specications used on hardware dened by SAE J1701 & J1701M (JUL 96)

SAE Bolt Head

8

17

31

48

75

106

149

261

416

634

Identication

Metric Bolt Head

Identication

8

20

40

70

111

173

239

337

460

583

1199

SAE Grade 5

3 Radial Dashes

MARKING ON HEAD

SAE 5 SAE 8

LBS.-FT.

10

19

35

55

85

121

170

297

474

722

8

21

41

75

118

181

263

367

495

623

1258

N-m N-m

13

26

47

75

115

164

230

403

642

979

MARKING ON THREADMARKING ON THREAD

6

16

30

55

87

133

194

270

365

459

928

10.9

Metric

Grade 10.9

11

29

57

103

163

250

363

507

684

861

1740

LBS.-FT.N-m

1020

Metric 10.9Metric 8.8Metric 8.8 Metric 10.9

SAE Grade 8

6 Radial Dashes

14

27

49

78

120

171

240

420

669

635

1283

22

42

76

120

184

268

374

505

18

37

67

106

163

232

325

569

907

1383

Diameter

(Millimeters)

Thread Pitch

8

10 x 1.25

30 x 2.0

A

Diameter

(Inches)

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

Diameter

&

(Millimeters)

Thread Pitch

6 x 1.0

8 x 1.25

10 x 1.5

12.1.75

14 x 2.0

16 x 2.0

18 x 2.5

20 x 2.5

22 x 2.5

24 x 3.0

30 x 3.0

TORQUE

A

CHART

Wrench

Size

7/16”

1/2”

9/16”

5/8”

3/4”

13/16”

15/16”

1-1/8”

1-5/16”

1-1/2”

METRIC SERIES

TORQUE

A

CHART

Wrench

Size

10 mm

13 mm

16 mm

18 mm

21 mm

24 mm

27 mm

30 mm

34 mm

36 mm

46 mm

1175

68

109

169

234

330

451

571

SAE Grade 2

(No Dashes)

SAE 2

LBS.-FT.

6

12

23

36

55

78

110

192

306

467

8.8

Metric

Grade 8.8

COARSE THREAD FINE THREAD

8

20

39

125

172

244

332

421

867

6

15

29

50

80

11

27

54

94

151

234

323

457

623

790

1626

&

6 x 1.0

8 x 1.0

12.1.25

14 x 1.5

16 x 1.5

18 x 1.5

20 x 1.5

22 x 1.5

24 x 2.0

Standard 3/4” wheel studs and nuts should be tightened to torque 400 Ft.-Lbs. and standard 22mm studs should be tightened

to torque 640 Ft.-Lbs. During initial operation of the grain cart and then checked for proper torque after every 10 hours of use.

Failure to do so may damage wheel nut seats. Once seats are damaged, it will become impossible to keep nuts tight.

TIGHTENING WHEEL NUTS

9

Page 10

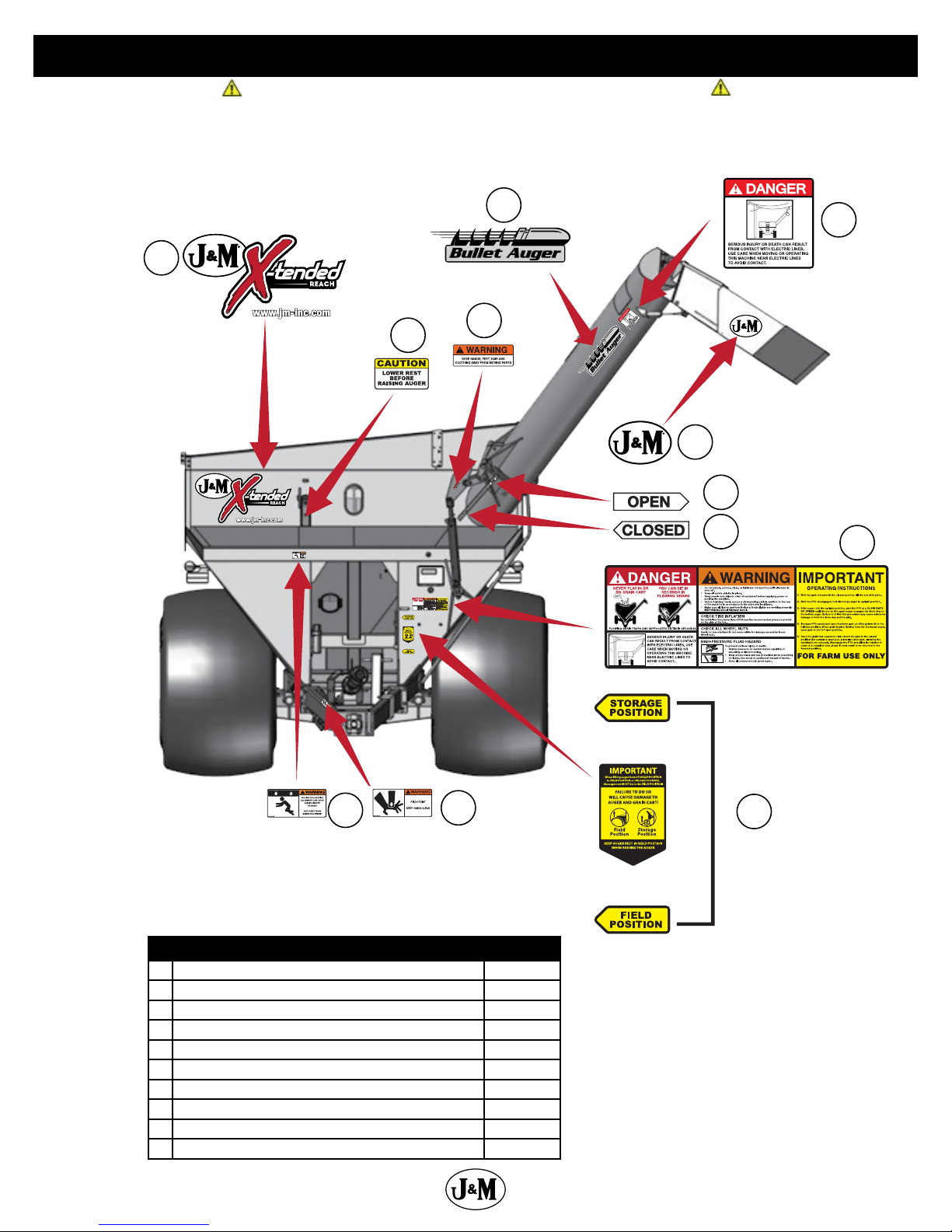

Decals

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged or Missing

2

3

4

5

7

8

9

6

10

Description Part No.

1 J&M Oval Decal (Large) 9-1/2” x 15” JM0015151

2 X-Tended Reach Decal JM0037663

3 Caution Lower Rest Decal JM0037662

4 Warning, Keep Hands Away Decal JM0018039

5 Bullet Auger Decal JM0037664

6 Danger, Electric Lines Decal JM0015099

7 J&M Oval Decal (Medium) 5-1/2” x 8-1/2” JM0010179

8 Open Decal JM0025433

9 Closed Decal JM0025434

10 Danger Warning Important Decal JM0037665

10

13

12

11

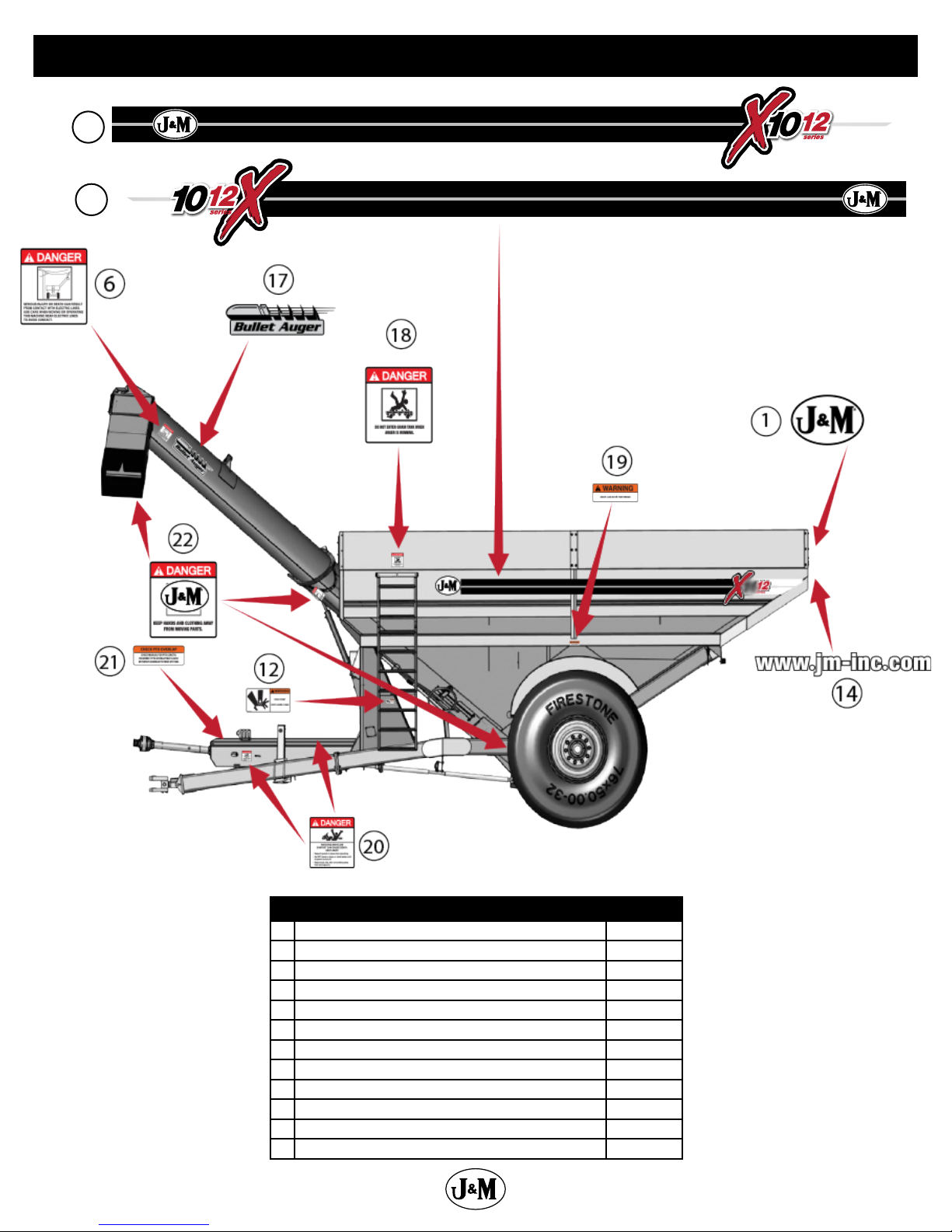

Page 11

16

15

Decals

Description Part No.

11 Field Position/Storage Position Decal JM0037661

12 Warning, Pinch Point Decal JM0014994

13 Warning, Falling Or Lowering Decal JM0014992

14 www.jm-inc.com Decal JM0019239

15 Opposite Auger Side Stripe Kit Specify

16 Auger Side Stripe Kit Specify

17 Bullet Auger Decal AS JM0041315

18 Danger, Do Not Enter Grain Tank Decal JM0018033

19 Warning, Keep Lug Nuts Tightened Decal 1-5/8” x 4” JM0010150

20 Danger, Rotating Driveline Decal JM0018036

21 Check PTO Overlap Decal JM0025435

22 Danger, Keep Hands and Clothing Away Decal JM0018035

11

Page 12

Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and manufacture of our products. Unfortunately, our eorts to provide safe equipment

can be erased by an operator’s single careless act. In addition, hazard control and accident prevention are dependent upon the

awareness, concern, judgment, and proper training of personnel involved in the operation, transport, maintenance and storage of

equipment.

Make certain that the operator(s), prior to operating is instructed in safe and proper use and reviews and understands the manual(s)

pertaining to this machine. Also make certain that the operator(s) reviews and understands the operator’s manual of the tractor

prior to hooking up or operating the grain cart.

Read this manual before you operate this machine. If you do not understand any part of this manual, or need more information,

contact the manufacturer or your authorized dealer.

SAFETY

Understand that your safety and the safety of other persons is measured by how you service and operate this machine. Know the

positions and functions of all controls before you try to operate them. Make sure to check all controls in a safe area before starting

your work.

The safety information given in this manual does not replace safety codes, federal, state or local laws. Make certain your machine

has the proper equipment as designated by local laws and regulations.

A frequent cause of personal injury or death is from persons falling o equipment and being run over. Do not permit persons to

ride on this machine.

Travel speeds should be such that complete control and machine stability is maintained at all times. Where possible, avoid operating

near ditches, embankments and holes. Reduce speed when turning, crossing slopes and rough, slick or muddy surfaces.

Collision of high speed road trac and slow moving machines can cause personal injury or death. On roads, use asher lights

according to local laws. Keep slow-moving-vehicle emblem visible. Pull over to let faster trac pass.

Hydraulic oil leaking under pressure can penetrate skin and cause infection or other injury. To prevent personal injury,

• Relieve all pressure, before disconnecting uid lines,

• Before applying pressure, make sure all connections are tight and components are in good condition,

• Never use your hand to check for suspected leaks under pressure. Use a piece of cardboard or wood for this purpose.

• If injured by leaking uid, see your doctor immediately.

When transporting the grain cart, always keep the auger in the stow position.

Use care when moving of operating the grain cart near electric lines as serious injury or death can result from contact.

Never adjust, service, clean, or lubricate the grain cart until all power is shut o. Keep all safety shields in place. Keep hands, feet,

hair and clothing away from moving parts while the grain cart is in operation.

The service ladder is for service work only. If you must climb into the grain tank, be certain that all power is shut o and then use

extreme caution when climbing into the grain cart.

Make sure that everyone is clear of equipment before applying power or moving the machine.

Make sure that the grain cart is fastened securely to the tractor by using a high strength hitch pin, clip and safety chains. Make sure

that the grain cart hitch properly matches the hitch type of the tractor. Use a single prong (spade) grain cart hitch with a double

prong (clevis) tractor hitch. Use a double prong (clevis) grain cart hitch with a single prong (spade) tractor hitch.

Before lling the grain cart, make certain that no one is inside the grain tank. Never allow children or anyone in, near, or on the

grain cart during transport or during loading and unloading of grain. Be aware that moving grain is dangerous and can cause

entrapment, resulting in severe injury or death by suocation.

Never operate the auger system with anyone inside the grain tank. Hands, feet, hair and clothing can t through the openings in

and around the grate. Contact with the auger can cause severe injury or death. Make certain that all power is shut o before service

work is performed.

Before unhooking the grain cart from the tractor, be sure the jack stand is properly mounted and in place and the wheels are

properly blocked to prevent the cart from moving.

12

Page 13

Initial Operation and Maintenance

WARNING

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE GRAIN CART.

Before the grain cart is put into service:

Have the safety instructions been read and clearly understood by the operator(s) of this machine?

Has the gearbox been properly lled with SAE 80W-90 gearbox lubricant?

Have all nuts, bolts, bearings and braces been properly fastened?

Has the PTO been checked for proper overlap?

IMPORTANT: Has the slip clutch on the PTO been serviced? If the slip clutch is left unchecked, damages to the power-take-o

and drive shaft may result. Before using the grain cart, loosen the bolts around the slip clutch. Make sure the friction plates turn

free of each other and are not corroded together. Re-tighten the tension bolts. Run the auger system EMPTY and check for proper

engagement of the slip clutch.

CHECK PTO OVERLAP LENGTH. Overlap length may vary depending on the tractor model and hitch setting. Try to obtain the

greatest possible overlap without bottoming out in the extreme operating conditions. Too much overlap may cause the PTO to

bottom out and damage the driveline. Not enough overlap may cause the PTO front and back halves to separate. From the fully

compressed (shortest) length the PTO should be telescoped (extended) between 10” and 22”. Dierent PTO lengths may need

to be purchased to accommodate your terrain. A 4” shorter or a 10” longer PTO can be ordered through your dealer from J&M

Manufacturing.

GREASE BEARINGS: Are all bearings on the drive line properly greased? Are all set screws in the bearings and U-joints tight? Has

the power-take-o shaft been properly greased at all points including the cross bearings? Has the universal joint at the gearbox

been greased? Have all grease points at the auger hinge area, including the hanger bushing assembly been greased?

TIRE PRESSURE: Are the tires properly inated? The following is to be used as a general guide for tire ination for cyclic use.

Figures can vary depending on specic brand of tire used. It is important that tires are inspected before and after the unit is

loaded. The tire should stand up with no side wall buckling or distress as the tire rolls. Do Not Exceed The Tire Pressure

Indicated Below:

Tire psi

900/60R32 Lug Tires (Firestone) (176LI) (for 30x32-10 Hole Wheels) (136” c/c) 41

900/60R32 Lug Tires (Alliance) (176 LI) (for 30x32-10 Hole Wheels) (136” c/c) 66

35.5x32 Diamond Tires-20 ply (Firestone) (for 31x32-10 Hole Wheels) 26

1050/50R32 Lug Tires (Alliance) (185 LI) (for 32x36-10 Hole Wheels) 56

480/80R42 Lug Tires (Firestone) (154 LI) (for16x42-10 Hole Wheels) 35

480/80R42 Lug Tires (Alliance) (169 LI) (for16x42-10 Hole Wheels) 64

IF520/85R42 Lug Tires (Firestone) (169 LI) (for 18x42-10 Hole Wheels) 44

520/85R42 Lug Tires (Alliance) (169 LI) (for 18x42-10 Hole Wheels) 50

IF1250/50R32 Lug Tires (Firestone) (188 LI) (for 44x32-10 Hole Wheels) 23

13

Page 14

Operating Instructions

VERY IMPORTANT: Under no circumstance is it recommended to tow a loaded grain cart in excess of 8 mph.

WHEEL NUTS: Are the wheel nuts properly fastened? Torque to 640 Ft.-Lbs. for standard 22mm wheel studs and nuts. Torque to

400 Ft.-Lbs. for 3/4” wheel studs and nuts. Wheel studs and nuts should be checked after each load during initial operation

of the cart and then after every 10 hours of use. Failure to do so may damage wheel studs and nuts. Once the seats are

damaged, it will become impossible to keep the lug nuts tight.

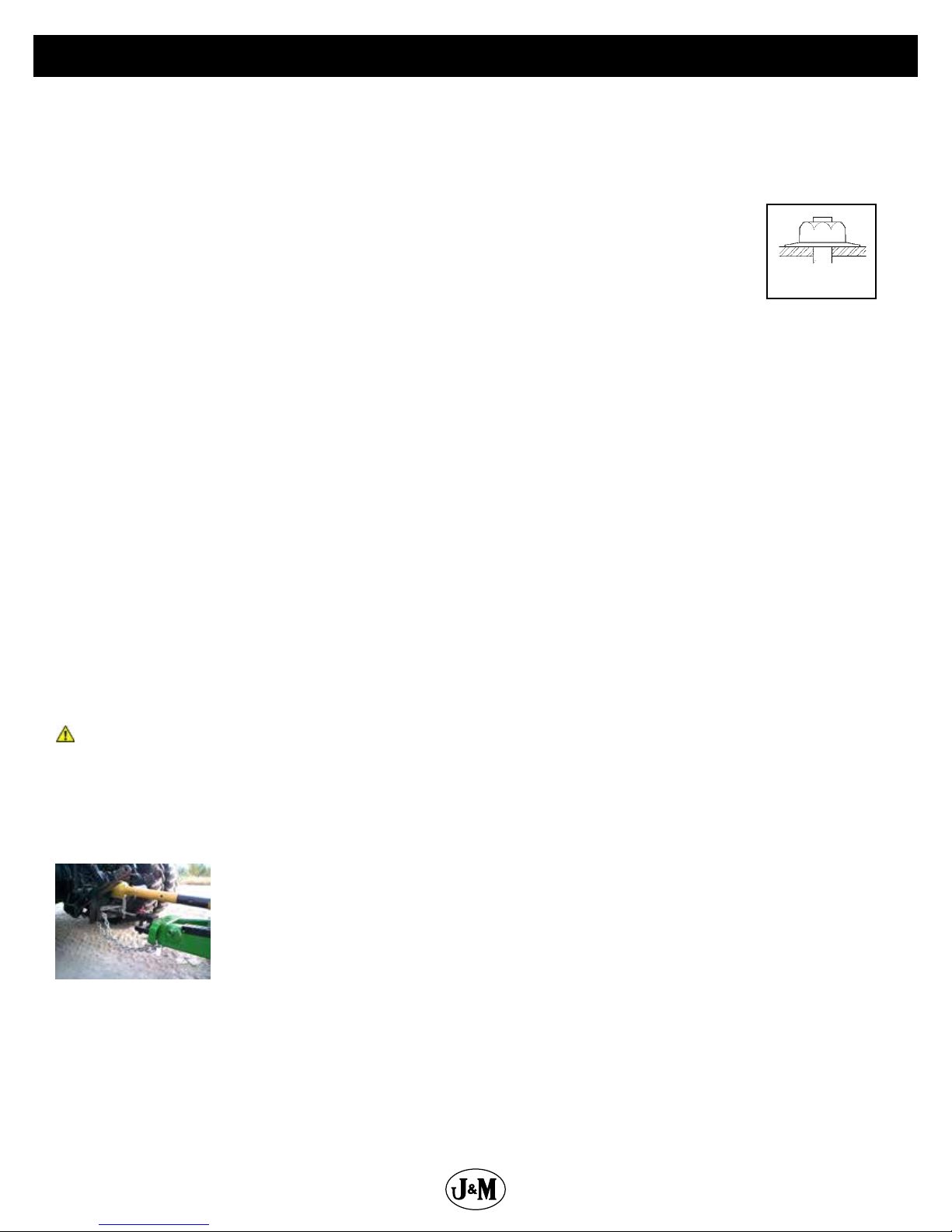

The drawing shows the proper way to mount the wheels using Budd-type nuts. The wheels supplied with

your grain cart have straight holes and the Budd nuts will be mounted according to Figure 1. Wheels that

are improperly installed on the grain cart, resulting in product failure, will nullify warranty and shift the

burden of liability to the owner/operator. We recommend you inspect your wheel nuts to make sure they

are properly installed. Also, check the wheel nuts on a regular basis to ensure they are tight.

LIGHTING AND SAFETY DECALS: Are the rear, amber extremity lights properly positioned? Extend the lights within 16” (40,6cm)

of the left and right extremities of the grain cart. Is an SMV Emblem attached to the rear of the grain cart?

Are the lights working properly? Are all lights and reective decals clean, visible and properly placed?

BE CERTAIN THAT ALL POWER IS SHUT OFF WHEN HOOKING UP TO TRACTOR OR CONNECTING HYDRAULIC LINES TO

TRACTOR.

Preparing the Grain Cart for Use: Model 1012 grain carts require a 225+ HP Tractor.

IMPORTANT: Do NOT pull a loaded grain cart on highway. For incidental highway travel, observe the section below.

Tow Loads Safely

Stopping distance increases with speed and weight of towed loads, and on slopes. Towed loads with or without brakes that are too

heavy for the tractor or are towed too fast can cause loss of control. Consider the total weight of the equipment and its load.

Observe these recommended maximum road speeds, or local speed limits which may be lower.

Road Travel (grain cart empty): Do not travel more than 32 km/hr (20 mph) and do not tow loads more than 1.5 times the

pulling unit’s weight.

Ensure the load does not exceed the recommended weight ratio. Use additional caution when towing loads under adverse surface

conditions, when turning, and on inclines.

WARNING: For greater stability on uneven or steep terrain, position non-scale wheel spindles at the furthest out setting.

Figure 1

IMPORTANT:

1) Connect grain cart hitch to tractor drawbar using a good quality hitch pin. Attach the safety chain to the tractor and through one

chain loop provided on either side of the grain cart frame as shown. Make sure the grain cart hitch properly matches the hitch of

the tractor. Use a single prong (spade) grain cart hitch with a tractor double prong (clevis) hitch. Use a double prong (clevis) grain

cart hitch with a single prong (spade) tractor hitch.

Safety Chain User Instruction

a) Secure the safety chain by looping it around each side of the grain cart as shown and

connecting to the towing machine’s attaching bar.

b) Do Not allow any more slack than necessary for articulation.

c) Do Not use any intermediate support as the attaching point.

d) Store the safety chain by securing it around the main axle A-frame of the grain cart.

e) Replace the safety chain if one or more links or end ttings are broken, stretched or otherwise

damaged or deformed.

2) Attach the power-take-o shaft to the tractor. The PTO must have at least 10” of engagement. Check tractor drawbar for clearance

and length and adjust if necessary. Make sure the PTO does not bottom out when making sharp turns as it may bend the drive

shaft.

3) Make sure the jack stand is removed from the lower support position before the cart is moved. Never use the jack to support

a loaded grain cart.

4) Be sure that no debris or foreign objects are in the grain cart.

5) Attach the hydraulic lines to the tractor. Two hydraulic lines (green band) operate the inside gate mechanism. Connect these

Continues on next page.

14

Page 15

Operating Instructions (Continued)

lines to one service outlet on the tractor. Two hydraulic lines (yellow band) operate the folding mechanism of the auger. Connect

these lines to a second service outlet on the tractor. The remaining two hydraulic lines (red band) operate the hydraulic ow control

spout located at the end of the upper auger. Connect these lines to a third service outlet on the tractor. Make sure the air is bled

from the hydraulic cylinders and hoses.

6) Run the auger system EMPTY before loading grain into the tank for actual use. Make certain that the slip clutch is operating and

that the upper and lower augers are properly engaged.

7) Connect the lighting 7-prong connector end on the main wiring harness to the tractor electrical outlet. Make sure that all asher

and turn indicator lights are working properly before incidental highway travel.

CAUTION

• Do NOT operate the grain cart before reading and understanding the Operator’s Manual and ALL danger, warning and

caution signs.

• Be sure that a Slow-Moving-Vehicle emblem is attached to the rear of the grain cart.

• Never exceed 1,000 rpm on the PTO and driveline system.

• Never fold or extend the auger until the PTO has come to a complete stop.

• Never ll the grain cart unless the gate indicator is in the closed position.

• Never allow foreign object (shovels, etc.) to be placed inside the grain cart.

• Never engage the lugs and drive dogs on the augers when the system is moving at a high rate of speed.

• Never perform maintenance work or service the grain cart with the tractor running.

Figure A

1 3/4” x

13 1/2”

Bolt

JACK

Figure B

Frame

Weldment

Figure C

For 36” row

spacing,

place

Frame

Weldment

9” from

edge of

Stop.

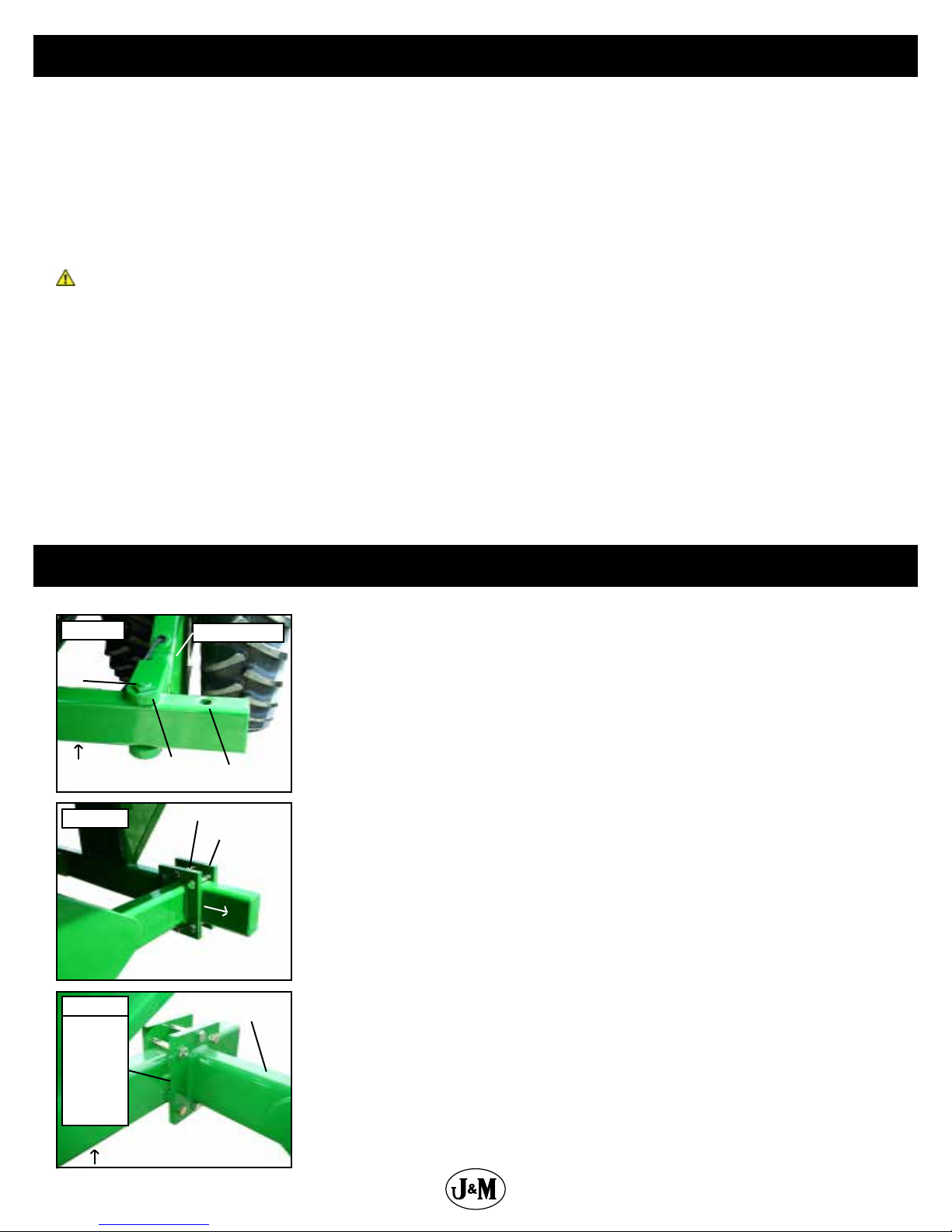

Adjusting Row Spacing for Walking Tandem Duals

Frame Weldment

30” Row

Spacing

1” x 7 1/2” Bolt

Slide Frame Weldment out

9” for 36” Row Spacing

36” Row

Spacing

Clamp Plate

Frame Weldment

for Dual Wheels

1) Securely position jacks under the frame of the grain cart as shown in Figures A and C.

2) Loosen the rear of the Frame Weldment by removing the 1” x 7 1/2” Gr 8 Bolts and

Clamp Plate.

3) Remove the 1 3/4” x 13 1/2” Bolt and Jam Nut from the front of the Frame Weldment.

4) Slide the Frame Weldment out to the bolt location for 36” row spacings as shown

in Figure A and secure using the 1 3/4” x 13 1/2” bolt and jam nut. If the grain cart is

equipped with an electronic scale system, be sure not to damage the electronic cord

when moving the Frame Weldment.

5) Swing the Frame Weldment outward. Switch the tire location by removing both

tires and remounting each tire to the hub on the opposite side of the weldment. The

tire originally on the outside of the weldment will now be located on the inside of

the weldment and vice versa. (The valve stems for 36” row spacing should be facing

toward the Frame Weldment, or toward each other.) Be sure to keep the tire tread

positioned in the same direction as before.

6) After the wheels have been tightened to the hubs, swing the Frame Weldment until

the new clamping location is 9” from the original 30” row spacing stop.

7) Tighten the rear of the Frame Weldment to the grain cart frame using the six 1” x 7

1/2” Gr 8 Bolts, Hex Nuts and Clamp Plate.

8) Torque all bolts to specications and Repeat on Other Side.

JACK

15

Page 16

Lubrication Service Schedule

IMPORTANT: Your grain cart has grease ttings at all critical points. These should be serviced before the grain cart is put into

operation.

WARNING

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE GRAIN CART

PTO & DRIVELINE: The grease ttings on the PTO should be serviced after every 8 hours of use. Service the grease ttings on each

of the drive bearings and also the universal joint after every 8 hours of use.

AUGER FOLDING MECHANISM: One grease tting is located on the pivot pin of the folding auger. This tting should be serviced

after every 8 hours of use. Service the grease tting on the hanger bushing assembly (top end of the lower auger assembly) after

every 8 hours of use or as needed.

SPRING LOADED UPPER AUGER BEARING: Service the grease tting on the upper auger bearing (located at the top end of the

upper auger assembly) after every 8 hours of use. Lubricate the springs and retaining bolts on the bearing before prolonged

storage of the grain cart.

Gearbox Lubricant

Model Ounces Input Sha Output Sha

1012 96 1-3/4” 2”

Pivot Pin Once Annually

Roll Tarp U-Joint Once Annually

Upper Auger Flighting Every 8hrs of use

Driveline Every 8hrs of use

GEARBOX: Gearbox lubricant has been added to the gearbox during nal assembly. Recheck the lubricant level before initial operation

of the grain cart, then periodically according to use. The uid level should rest at the inspection plug, pictured in blue below. When

lled to the proper level, the gearbox should have 96 ounces of

SAE 80W-90 lubricant. Change the oil annually before use.

16

Page 17

Routine Maintenance

WARNING

BE CERTAIN ALL POWER IS SHUT OFF WHEN SERVICING THE GRAIN CART

• Repack the bearings in the hub assembly once a year or as needed. Use a good quality LS EP2 Severe Duty, High Shock Load,

Lithium based Grease. Also check the seal for wear and replace if necessary.

• Check the grain cart periodically for cracks in welds and for other structural damage. Have cracked welds xed immediately.

Failure to do so could result in extensive damage to the grain cart and greatly reduce the life of the cart.

• Lubricate the slides on the clean-out door.

• Check all hydraulic hoses for wear and replace as necessary.

• Make sure all tires are properly inated. See INITIAL OPERATION AND MAINTENANCE in the Owner’s Manual for recommended

instructions for tire pressure. It is important that tires are inspected before and after unit loaded.

• Check PTO for wear of plates in the slip clutch. Replace if needed.

• Make sure that all guards and shields are in place before operating the grain cart.

Troubleshooting

WARNING

MAKE SURE THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE GRAIN CART. MAINTENANCE AND

REPAIR SERVICE WORK TO BE PERFORMED BY QUALIFIED SERVICE PERSONNEL ONLY.

Trouble Possible Cause Possible Remedy

Dirt in restrictor Remove restrictor ttings from outside hydraulic cylinder and clean out dirt

Faulty check valve Replace check valve

Auger will not return to down

position or move from stow

position

Hanger bushing assembly at

the top of the lower auger

ighting is hot

Excessive vibration

Grain ow stoppage

Auger tube is breaking away

from the grain cart at the

hinge area or the ram in the

hydraulic folding cylinder is

bent

Flip-up auger rest not

ipping over center

Upper ighting and lower ighting

are locked together

Feed gate open Close the feed gate

Lock and Load not operating

correctly

Top of the hanger bushing

assembly is rubbing against the

drive dog

Auger ighting or shaft is bent Straighten or replace auger ighting

Drive shaft is bent Replace or straighten drive shaft

Bolt sheared in drive dog Replace bolt in drive dog. Engage upper and lower ighting at a slow rate of

Folding auger before complete stop Upper and lower ightings are disengaging before auger comes to a complete

PTO key sheared Replace key and tighten set screw

Upper auger is extended in the

upright position while traveling in

the eld

Cable has loosened With auger in eld position, tighten cable to the handle.

Bearing on top of upper auger ighting needs adjusting. When the auger is

in the engaged position, there must be 1/8” (0,32cm) gap between bottom of

top bearing and top of upper tube housing (SEE ADJUSTING THE UPPER AUGER

FLIGHTING)

Make sure the limit switch on the feed gate indicator assembly is functioning

properly

Loosen the two bolts and re-adjust the position of the hanger bushing assembly.

Re-tighten bolts

Remove the lower ighting assembly and place a shim between the spline

coupler and the gearbox

speed. (Drive dogs and lugs are being engaged too fast.)

stop. Replace bolt in the drive dog. Never engage or disengage the upper and

lower ightings until the augers come to a complete stop.

Repair or place folding cylinder if necessary. Remember to lower auger to the

eld position after unloading.

17

Page 18

Adjusting the Lower Flighting

WARNING

MAKE SURE THAT ALL POWER IS SHUT OFF BEFORE ADJUSTING THE FLIGHTING ASSEMBLY.

If the drive-dog and hanger assembly are becoming excessively hot during unloading, the lower ighting and/or hanger may need

adjusting. The hanger bushing assembly has elongated holes where it attaches to the outer tube assembly. Loosen the two 3/8”

bolts on the hanger bushing assembly. Adjust the hanger either up or down and vertically center it between the ighting and drive

dog. Re-tighten the bolts. Make certain that the ighting center and drive-dogs do not rub the hanger bushing assembly, causing

them to become hot.

If the hanger can no longer be adjusted by moving it up or down on the elongated holes, both the hanger bushing assembly and

the lower ighting will have to be removed. See instructions on pg. 36 for ighting removal. After removing them from the tube

assembly, place a shim [between 1/8” (0,32cm) to 3/16” (0,48cm) thick] where the gearbox and the spline coupler (welded to the

lower ighting). Replace the lower ighting and reattach the hanger to the tube assembly. Readjust the hanger assembly. NOTE:

The bottom of the lower ighting is not attached to the gearbox with any bolts or set screws but may be ‘frozen’ fast. Be careful

when removing the lower ighting from the gearbox. For easier removal of the lower ighting, keep the gearbox at the bottom

intact, remove the 2 3/8” bolts from the hanger bushing assembly and pull the lower ighting o of the gearbox.

After adjusting the lower ighting, move the upper auger to the unload position and check the upper ighting for readjustment.

Adjusting the Upper Flighting

WARNING

MAKE SURE ALL POWER IS SHUT OFF BEFORE ADJUSTING THE FLIGHTING ASSEMBLY

If the upper and lower augers to do not properly separate during the unfolding sequence, the upper ighting may need adjusting.

Before making adjustment to the upper ighting, check to see if the lugs and drive dogs on the auger assemblies are locking

together. If they are not locked together, check to see if dirt is in the restrictor or if a faulty check valve on the hydraulic cylinder

used to raise and lower the upper auger assembly may be causing the problem. If dirt is in the restrictor, see “Removing Dirt From

Restrictors On Hydraulic Cylinders” below.

Fold the upper tube assembly into the upright position. Position the upper ighting in the engaged position with the lower ighting.

Locate the four-hole ange bearing on the top of the upper auger tube housing. With the upper ighting in the engaged position,

check the spacing between the upper bearing and the upper tube housing. There must be an 1/8” (0,32cm) space between the

base of the four-hole ange bearing and the upper tube housing. If there is NOT a space between the bearing and the upper tube

housing, or if there is more than 1/8” (0,32cm) space, the upper ighting will need to be adjusted. To adjust the upper ighting,

loosen the 1 1/4” hex nuts both above and below the four-hole ange bearing. Move the 1 1/4” hex nuts up or down the threaded

shaft on the top of the auger ighting shaft until the bearing moves to approximately 1/8” (0,32cm) above the base of the upper

tube housing. When the four-hole ange bearing is properly located, tighten both 1 1/4” hex nuts together to secure the bearing

position.

If the upper and lower ighting still does not separate properly during the folding sequence, a small bevel may need to be removed

from the inside of the lugs where they engage the drive dogs on the auger assemblies. Grind approximately 1/8” (0,32cm) from the

corner of the lugs where they touch against the drive dogs.

18

Page 19

Removing Dirt from the Restrictors on the Hydraulic Cylinder

WARNING

MAKE SURE THAT ALL POWER IS SHUT OFF AND THE UPPER AUGER TUBE IS IN THE DOWN POSITION BEFORE REMOVING

THE RESTRICTORS

Remove restrictors from the 90 degree street elbow on the hydraulic cylinder. Remove dirt from the tting to allow hydraulic oil to

ow through the restrictor. Reattach the restrictor to the street elbow. Use Teon sealant tape or equivalent on the threads of the

restrictor before re-attaching.

If the restrictor continues to plug with dirt, replace the restrictor or lter the hydraulic oil in your system.

Storage Preparation

IMPORTANT: When the grain cart is not going to be used for a period of time, store the cart in a dry, protected place. Leaving your

grain cart outside, open to the weather will shorten its life.

Follow the procedure below when your grain cart is placed in storage for periods up to six months.

1. Cover electronic monitor (if equipped) with plastic before washing the grain cart. Wash or clean and completely lubricate the

grain cart. See the lubrication service section in this manual.

2. Remove all grain from inside the grain tank, auger tube assemblies, and at the clean-out door.

3. Check the gearbox oil and replace with new SAE 80W-90 gearbox lubricant or equivalent if necessary.

4. Touch up areas where paint may have worn away. Use a good quality primer paint, especially before re-applying graphite paint

to the interior slopes of the grain tank.

5. Retract all hydraulic cylinders to prevent the piston rods from rusting.

6. Clean the tires before storage. Inate the tires at regular intervals.

7. Open the clean-out door at the base of the grain tank.

Removing from Storage

• Check the gearbox to make sure it has the appropriate amount of oil.

• Inate the tires to the correct operating pressure.

• Close the clean out door at the base of the grain tank.

• Make sure all safety shields are in the proper position.

19

Page 20

Repair Parts List and Diagrams

When performing maintenance work, wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing

and head. Follow the Operator’s Manual instructions to ensure safe and proper maintenance and repair.

Your local, authorized dealer can supply genuine replacement parts. Substitute parts may not meet original equipment specications

and may be dangerous.

WARNING

MAKE SURE ALL POWER IS SHUT OFF BEFORE PERFORMING ANY MAINTENANCE OR REPAIR WORK.

Wheel Rims for Single Wheel Grain Carts

Description

30x32-10 Hole Wheel Rims

31x32-10 Hole Wheel Rims

32x36-10 Hole Wheel Rims

44x32-10 Hole Wheel Rims

Tires for Single Wheel Grain Carts

Description

900/60R32 Lug Tires (Firestone) (176LI) (for 30x32-10 Hole Wheels) (136” c/c)

900/60R32 Lug Tires (Alliance) (176 LI) (for 30x32-10 Hole Wheels) (136” c/c)

35.5x32 Diamond Tires-20 ply (Firestone) (for 31x32-10 Hole Wheels)

1050/50R32 Lug Tires (Alliance) (185 LI) (for 32x36-10 Hole Wheels)

IF1250/50R32 Lug Tires (Firestone) (188 LI) (for 44x32-10 Hole Wheels)

Wheel Rims for Walking Tandem Dual Wheel Grain Carts

Description

16x42-10 Hole Wheel Rims

18x42-10 Hole Wheel Rims

Tires for Walking Tandem Dual Wheel Grain Carts

Description

480/80R42 Lug Tires (Firestone) (154 LI) (for16x42-10 Hole Wheels)

480/80R42 Lug Tires (Alliance) (169 LI) (for16x42-10 Hole Wheels)

IF520/85R42 Lug Tires (Firestone) (169 LI) (for 18x42-10 Hole Wheels)

520/85R42 Lug Tires (Alliance) (169 LI) (for 18x42-10 Hole Wheels)

20

Page 21

Hub & Spindle Assembly W-891 (Single Wheels)

Torque Values

22mm Studs 640 Ft.-Lbs.

Description Part No.

1 Hub and Spindle Assembly 4-1/2” x 20-1/4” Spindle with 22mm Studs (HSA-1000) JM0019942

2 1”-8 Gr5 Z Centerlock Hex Nut JM0002149

3 1”-8 x 7” Gr5 Z Hex Bolt JM0016689

4 Spindle, 4 1/2” x 20 1/4” (281900S) JM0019937

5 Seal (4-1/4” ID, 6” OD) (CR-43771) JM0018955

6 Large Bearing (HM218248) JM0018849

7 Large Race (HM218210) JM0018848

8 891 Hub with Races, 22mm Studs, and Nuts (13.19 bolt circle) (11.13 pilot) (W-891) JM0021227

9 Wheel Stud (22mm x 90mm) (22-MMS) JM0019178

10 22mm Lug Nut with Washer (22-MMNW) JM0019192

11 Small Race (HM212011) JM0018854

12 Small Bearing (HM212049) JM0018852

13 2-1/8” ID, 3-3/4” OD Flat Washer (3/16”) JM0015900

14 2”-12 Gr5 Z Castle Hex Nut (912973) JM0015899

15 3/8” x 2-3/4” Z Roll Pin (905945) JM0018956

16 Dust Cap 6-1/4” OD (for W-881 & W-891 Hub)(909921) JM0018954

17 1/4”-20 x 1” Gr5 Z Hex Bolt JM0002095

18 891 Hub with Races, 22mm Studs, Nuts, Seal, Bearings, and Dust Cap JM0048171

21

Page 22

Hub & Spindle Assembly W-881 (Walking Tandem Dual Wheels)

Torque Values

3/4" Studs 400 Ft.-Lbs.

Description Part No.

1 Hub and Spindle Assembly Complete 20-1/4” (3/4” Studs) (HSA-650D) (Walking Tandem Duals)(FAA) JM0019940

1 W-881 Hub and 4-1/2” Weigh-Tronix Spindle Assembly Complete 20-1/4” (3/4” Studs) (Walking Tandem Duals)(FAA) JM0019975

2 1”-8 Gr5 Z Centerlock Hex Nut JM0002149

3 1”-8 x 7” Gr5 Z Hex Bolt JM0016689

4 Spindle, 4-1/2” x 20-1/4” (281900S) JM0019937

4 4-1/2” Weigh-Tronix Weigh Spindle (AWT27-500002) (450WTS) JM0019970

5 Seal (3-3/4” ID, 6” OD) for Hub with Scales (37605SA) JM0021456

5 Seal (4-1/4” ID, 6” OD) (CR-43771) JM0018955

6 Large Bearing (HM218248) JM0018849

7 Large Race (HM218210) JM0018848

8 Hub with large and small races, 3/4” Studs & Nuts (11.13 pilot)(W-881) JM0020510

9 Wheel Stud (3/4”-16 x 1-3/4”) 913564 JM0018957

10 Wheel Nut 3/4”-16 JM0018958

11 Small Race (HM212011) JM0018854

12 Small Bearing (HM212049) JM0018852

13 2-1/8” ID, 3-3/4” OD Flat Washer (3/16”) JM0015900

14 2”-12 Gr5 Z Castle Hex Nut (912973) JM0015899

15 3/8” x 2-3/4” Z Roll Pin (905945) JM0018956

16 Dust Cap 6-1/4” OD (for W-881 & W-891 Hub)(909921) JM0018954

17 1/4”-20 x 1” Gr5 Z Hex Bolt JM0002095

18 W-881 Hub 10 on 13.19 with Races Lugs, 3/4” Studs, Seals, Bearings, Dust Cap JM0048156

22

Page 23

Power Take-O (PTO) Shaft Assembly

Description Part No.

1 Back Half Weasler PTO (1-3/4”) (Auto Clutch) JM0018513

1 Back Half Weasler PTO (1-3/4”) (Auto Clutch) (XL) 5 “ Longer JM0030331

2 Front Half Weasler PTO (1-3/4”) (Auto Clutch) JM0018514

2 Front Half Weasler PTO (1-3/4”) (Auto Clutch) (XL) 5 “ Longer JM0030330

2 Front Half Weasler PTO (1-3/8”) (Auto Clutch) JM0024367

2 Front Half Weasler PTO (1-3/8”) (Auto Clutch) (XL) 5 “ Longer JM0030640

3 55E Cross Kit (Auto Clutch PTO) (1-3/4”) JM0018449

4 Auto Clutch (1-3/4” PTO) (Weasler) JM0018500

5 Yoke, Tube & Sleeve (1-3/4” PTO) (Weasler) JM0018519

5 Yoke, Tube & Sleeve (XL) Weasler JM0031647

6 Yoke & Shaft Assembly (1-3/4” PTO) (Weasler) JM0018520

6 Yoke & Shaft Assembly (XL) Weasler JM0031648

7 Spring Lock Yoke (1-3/4” PTO) (Weasler) JM0018506

7 Spring Lock Yoke (1-3/8” PTO) (Weasler) JM0024353

8 Weasler Auto Clutch Front Guard (30-3/4”) JM0018518

8 Weasler XL Auto Clutch Front Guard (36”) JM0030642

8 Weasler Auto Clutch Back Guard (27-3/4”) JM0018517

8 Weasler XL Auto Clutch Back Guard (34”) JM0030645

9 Complete 1-3/4” Weasler PTO (Auto Clutch) JM0018443

9 Complete 1-3/4” Weasler PTO (Auto Clutch) (XL) 10 “ Longer JM0030332

9 Complete 1-3/8” Weasler PTO (Auto Clutch) JM0024333

9 Complete 1-3/8” Weasler PTO (Auto Clutch) (XL) 10 “ Longer JM0030641

23

Page 24

130 Degree Gearbox Assembly (Weasler)

2

Takes 3 Quart (96 Ounces) ofSAE 80W-90

Gearbox Lubricant.

3

4

1

8 9 1110

5

6

7

11 910 1312

24

3

Page 25

130 Degree Gearbox Assembly (Weasler)

14 15 16 17 18

Description Part No.

1 1/2”-14 NPT Pipe Plug for Weasler Gearbox (72-20007) JM0025068

2 1/2” NPT Bushing 1/8” NPT Relief Plug (72-20011) JM0025067

3 2” Output Shaft & Gear Assembly for Weasler Gearbox (74-60125) JM0025058

4 3/8”-16 UNC x 2-1/2” Gr5 Cap Screw for Weasler Gearbox (72-0002) JM0025069

5 Housing Set For Weasler Gearbox (70-001114) JM0025053

6 1-3/4” Input Shaft & Gear Assembly for Weasler Gearbox (74-60123) JM0025057

7 Gearbox Eterior Dust Seal 1-3/4” ID JM0049020

8 End Cap Seal (3-3/16” x 5/16”) for Weasler Gearbox (71-40079) JM0025063

9 Spacer for Weasler Gearbox (71-50072) JM0025066

10 Bearing Cup (3720) for Weasler Gearbox (71-20033) JM0025056

11 Bearing Cone (3780) for Weasler Gearbox (71-20044) JM0025055

12 Gear - 34 Teeth (71-06135) JM0046061

13 Seal (2 x 3.196 x 0.4333) for Weasler Gearbox (71-40080) JM0025062

14 End Cap Seal (2” x 9/64”) for Weasler gearbox (71-40016) JM0025060

15 Spacer for Weasler Gearbox (71-50160) JM0025064

16 Bearing and Race Set (32210) for Weasler Gearbox (71-20017) JM0025054

17 Gear - 17 Teeth (71-06134) JM0046059

18 Spacer for Weasler Gearbox (71-50161) JM0025065

19 Seal (1-3/4” x 2-23/32” x 33/64”) for Weasler gearbox (71-40052) JM0025061

20 130° Gearbox (1-3/4” Input, 2” Output) (Weasler)(130-22W) JM0018677

1916

6

25

Page 26

Hitch Assembly

Description Part No.

1 1”-8 x 5-1/2” Gr5 Z Hex Bolt JM0002110

2 2-7/8” x 16-3/4” Non-Scale Hitch Bar JM0025227

3 1”-8 x 7” Gr8 YZ Hex Bolt JM0042653

4 Cast Iron Spade 2-1/4” Pin Hole JM0020529

5 Cast Iron Clevis (Bolt-On) 2-1/4” Pin Hole JM0020527

6 3/4”-16 x 2-1/2” Gr8 YZ Fine Thread Hex Bolt JM0015323

7 2-7/8” Digi-Star Weigh Bar, 1” Pin Hole (278WB-T1) JM0000355

8 1-1/4”-7 Gr5 Z Nylon Locking Hex Jam Nut JM0027201

9 1”-8 Gr5 Z Centerlock Hex Nut JM0002149

10 40k Lb Safety Chain JM0029261

11 1-1/4”-7 x 4” Gr8 Z Hex Bolt JM0026073

12 Cast Iron Clevis Hitch Assembly JM0020537

26

Page 27

Driveline Assembly

Description Part No.

1 3 Keyed LF Hydraulic Hose Holder JM0021437

2 Hydraulic Hose Shield 82-1/2” (812, 1012, 1112, 1122, 1222) JM0036484

3 PTO Shield 85-1/4” (812, 1012, 1112, 1122, 1222) JM0036430

4 PVC (Cut to length) JM0027151

5 164-1/2” x 1-3/4” Drive Shaft (1012, 1112, 1122, 1222, 2431) JM0026002

6 Jack Stand Assembly w/ Plate (10,000 lbs.) JM0020936

7 5/8”-11 Gr5 Z Centerlock Hex Nut JM0002146

8 Square U-Bolt 7-1/8” Inside Width x 9” Length, 5/8”-11TH JM0024199

9 3/8”-16 x 1/2” Hex Head Set Screw JM0019044

10 44 Series U-Joint (252288) - Weasler 44063-A1 JM0017957

11 5/8”-11 x 3” Gr5 Z Hex Bolt JM0002105

12 3/8”-16 Gr5 Z SF Hex Nut JM0002152

13 2” Output Shaft Gearbox Spline Washer (22”) (3” OD) JM0020638

14 1/2” Gr2 Z Lock Washer JM0019021

15 3/8”-16 x 1” Gr5 Z SF Hex Bolt JM0002092

16 1/2”-13 x 1-1/2” Gr5 Z Hex Bolt JM0002100

17 U-Joint Shield JM0012698

18 Cross Kit (U-Joint) (44R) (CK-44R) JM0017958

19 3/8” x 1-1/2” Half Moon Key JM0018772

20 5/8”-11 x 1-3/4” Gr5 Z Hex Bolt JM0016681

21 1-3/4” 4 Bolt Flange Bearing, 5/8” Bolt Hole JM0018774

27

Page 28

Lower Auger Assembly

Description Part No.

1 Bottom Tube Liner X-Tended Reach (1012, 1112, 1122, 1222) JM0037362

2 S-Cap Yellow - 1/2” ID x 1-1/4” x 0.065” (REC-1) JM0016842

3 20” Lower Flighting Turbo (1012, 1112, 1122, 1222) JM0035010

4 1/2” Gate Indicator Rod (104” Rod Length) (1012, 1112, 1122, 1222) JM0027918

5 2” x 36” Hydraulic Cylinder (JD236) JM0018523

6 1/2”-13 Gr5 Z Centerlock Hex Nut JM0001511

7 1/2” -13 x 1-1/4” Gr5 Z Hex Bolt JM0001513

8 Spline Coupler 3” x 2” ID x 3-3/4” OD (for 22” ighting)(SC-334X3) JM0009701

9 2” Output Shaft Gearbox Spline Washer (3” OD) JM0020638

10 1” x 3” Clevis Pin with Cotter Pins JM0019407

11 1”-8 Gr5 Z Centerlock Hex Nut JM0002149

12 1”-8 x 6” Gr5 Z Hex Bolt JM0002111

13 Drive Dog Weldment, 2 1/2” ID (18” & 20”) (DDW-21218) JM0000093

14 1/2” Gr2 Z Lock Washer JM0019021

15 Hanger Bushing Assembly (20”) (HBA-20) JM0019655

16 2-1/2” ID Bronze Bushing (BB-212) JM0016841

17 M5- 4/5 x 12 Gr8.8 Z Hex Bolt JM0036046

18 Limit Switch for Field Light (ME-8111) JM0036040

19 Feed Gate Assembly for 12 Series Carts (1012 & Up) JM0048539

28

Page 29

Upper Auger Linkage

Description Part No.

1 1/4” Diameter Snap Ring JM0001870

2 Master Link w/ Keeper (11-1/8” x 3” x 3/4”) JM0035075

3 Main Fold Link (22-1/2” x 7-7/16” x 1”) JM0034658

4 1-1/4” ID x 1-1/2” OD x 2” Long Sleeve Composite Bearing JM0021957

5 5/8”-11 Gr5 Z Centerlock Hex Nut JM0002146

6 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

7 1-1/4” Pin Keeper (4-5/8” Lg) JM0035930

8 3/8”-16 x 1-1/4” Gr5 Z Hex Bolt JM0016675

9 22” Hinge Pin w/ Keeper Weldment (23” Lg)(12 Series 20” Augers) JM0024966

10 5/8”-11 x 1-1/2” Gr5 Z Hex Bolt JM0002103

29

Page 30

Upper Auger Assembly

1

2

3

4

5

3

6

7

8

10

9

1

17 21

11

19 2220188

12

13

14

15

16

15

31

14

30

22

23

24

25

26

27

28 29 30

Page 31

*-R = Red

*-B = Blue

*-G = Green

*-Y = Yellow

*-BLK = Black

Upper Auger Assembly

32

33 34 35

Description Part No.

1 20” Upper Flighting (All 20” 12-Series) (154-3/4”) JM0035058

2 1/2”-13 x 5-1/2” Gr5 Z Hex Bolt JM0001498

3 1-1/4”-12 PN Gr5 Hex Jam Nut JM0001606

4 1-3/8”, ID 3” OD Flat Washer JM0015731

5 Top Auger Collar (1-3/4” OD x 1-1/2” Lg) JM0021646

6 1-1/4” Flange Bearing, 4 hole (GRAF-206) JM0018560

7 4-1/2” Compression Spring (CMSUAA-4) JM0018559

8 1/2”-13 Gr5 Z Centerlock Hex Nut JM0001511

9 1” OD 33/64” ID x 3/4” L Black UV Nylon Spacer JM0001962

10 M4-0.7 x 20 Gr8.8 Z Hex Bolt JM0049074

11 M4-0.7 Gr8.8 YZ Nylon Locking Hex Nut JM0049075

12 Telescoping Spout Main Linkage Rod JM0034363

13 1/2”-13 x 1-1/2” Gr5 Z Hex Bolt JM0002100

14 5/16” - 18 Gr5 Z Nylon Locking Hex Nut JM0049059

15 Spout Guide (Nylon) JM0035132

16 5/16”-18 x 5/8” Flat Head Bolt Z JM0024963

17 1/2”-13 x 2” Gr5 Z Hex Bolt JM0001593

18 1-3/4” x 4” Hydraulic Cylinder (1/2” Clevis and Tab ends) (HC-FCS) JM0018564

19 1/2” x 1-3/4” Clevis Pin, Usable Length 1-1/2” JM0018264

20 5/32” x 1-1/2” Cotter Pin JM0014348

21 LED Field Light JM0001881

22 Outer Tip Spout (12 & 22-Series) JM0034365

23 Inner Tip Spout (12 & 22-Series) JM0034291

24 1/4”-20 x 3/4” Gr5 Z Hex Bolt JM0001507

25 1/4” ID, 3/4” OD Z Flat Washer JM0003090

26 4-Sided Telescoping Spout Rubber Extension (20”)(12 & 22-Series) JM0034417

27 1/4”-20 Gr5 Z Centerlock Hex Nut JM0001505

28 3/8”-16 x 1” Gr5 Z Carriage Bolt JM0001632

29 1/2” ID x 2-1/8” OD Flat Washer - 1/8” Thick JM0019081

30 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

31 UHMW - 0.25 Angle Iron - Spout Guide JM0034308

32 20” Upper Auger Tube Weldment (12 Series) JM0035994*

33 3/8”-16 Gr5 Z SF Hex Nut JM0002152

34 Upper Auger Rest Plate JM0034981

35 3/8”-16 x 1” Gr5 Z SF Hex Bolt JM0002092

36 12 Series Tip Spout Assembly JM0048158

12 Series Tip Spout Assembly includes: 10-12, 14-16, 22-31.

When requesting an item with color, end the part

number with -R, -B, -G, -Y, or -BLK. (e.g. JM0000000-R)

31

Page 32

Hydraulic Hoses & Cylinders

1-3/4”x4” Hydraulic Cylinder

15

“Tip Spout Cylinder”

2”x36” Hydraulic Cylinder

“Door Cylinder”

2*

24

1

4

6

25

26

7

13

9

3”x24” Hydraulic Cylinder

“Fold Cylinder”

3

18

5

14

14

8

11

12

16

17

13

23

16

10

22

21

20

“Door Cylinder”

*Couplers welded to Shell

19

“Tip Spout Cylinder”

“Fold Cylinder”

32

Page 33

Hydraulic Hoses & Cylinders

Description Part No.

1 1/4” x 236” Hydraulic Hose 236inch4M3k-4G-6MPX-4G-8MP JM0046664

2 3/8” Standard Coupling JM0019562

2 1/2” Standard Coupling JM0020407

3 1/4” x 43” Hydraulic Hose 43inch4M3k-4G-6MPX-4G-6MP JM0024904

4 1/2” x 43” Hydraulic Hose 43inch8M3k-8G-8MPX-8G-6MP JM0024906

5 2” x 36” Hydraulic Cylinder (JD236) JM0018523

5 Seal Kit for 2” x 36” Hydraulic Cylinder (JD472) JM0026544

6 1/4” x 304” Hydraulic Hose 304inch4M3k-4G-8MP-4G-6MP JM0046245

7 1/4” x 286” Hydraulic Hose 286inch4M3k-4G-8MP-4G-6MP JM0047274

8 1/4” x 21” Hydraulic Hose 21inch4M3k-4G-4MP-4G-6MPX JM0024896

9 3” x 24” x 1-1/2” Welded Cylinder (JD324) JM0019644

9 Seal Kit 3” x 24” Cylinder (JD324-1) (JD480) JM0037895

10 1-3/16” x 3-5/8” Clevis Pin (X-Tended Reach) JM0047300

11 3/8” Male NPT x 3/8” Female NPT; 90 Degree Elbow JM0030059

12 3/8” Male NPT x 3/8” Female NPT x 3/8” Female NPT; Street T JM0018266

13 Lock N Load Assembly JM0048754

14 1/4” x 478” Hydraulic Hose 478inch4M3k-4G-8MP-4G-4MP JM0046246

15 1-3/4” x 4” Hydraulic Cylinder (1/2” Clevis and Tab ends) JM0018564

15 Seal Kit for 1-3/4” x 4” Cylinder (SKHC-FCS) (JD459) JM0024892

16 1/4” Male NPT x 1/4” Female NPT; 90 Degree Elbow JM0020115

17 1/4” Male NPT-Swivel with .032 Orice (restrictor) JM0020113

18 1/2” Female NPT Pioneer (PQC-1) JM0018254

19 3/8” Male ORB x 3/8” Male NPT; 90 Degree Elbow JM0047350

20 1/2” Male ORB x 3/8” Female NPT; 90 Degree Elbow JM0047348

21 Solenoid Valve for Lock and Load (Black) JM0026256

22 Solenoid Coil for Lock and Load (Black) JM0026255

23 Check Valve for Lock and Load (Black) JM0026250

24 3/8” Male NPT x 3/8” Female NPT; 90 Degree Elbow JM0030059

25 1/2” Male NPT x 1/2” Female NPT; 90 Degree Elbow JM0047371

26 1/2” x 236” Hydraulic Hose 236inch8M3k-8G-8MP-8G-8MPX JM0047376

33

Page 34

Auto-Gate Shut-O Hydraulics

1-3/4”x4” Hydraulic Cylinder

15

“Tip Spout Cylinder”

20

19

20

21

2”x36” Hydraulic Cylinder

“Door Cylinder”

2*

24

4

6

25

7

13

“Door Cylinder”

9

3”x24” Hydraulic Cylinder

“Fold Cylinder”

3

23

1

22

3

4

18

5

16

17

16

14

14

8

11

12

13

10

29

28

30

27

26

*Couplers welded to Shell

“Tip Spout Cylinder”

“Fold Cylinder”

34

Page 35

Auto-Gate Shut-O Hydraulics

Description Part No.

1 1/4” x 236” Hydraulic Hose 236inch4M3k-4G-6MPX-4G-8MP JM0046664

2 3/8” Standard Coupling JM0019562

2 1/2” Standard Coupling JM0020407

3 1/4” x 43” Hydraulic Hose 43inch4M3k-4G-6MPX-4G-6MP JM0024904

4 1/2” x 43” Hydraulic Hose 43inch8M3k-8G-8MPX-8G-6MP JM0024906

5 2” x 36” Hydraulic Cylinder (JD236) JM0018523

5 Seal Kit for 2” x 36” Hydraulic Cylinder (JD472) JM0026544

6 1/4” x 304” Hydraulic Hose 304inch4M3k-4G-8MP-4G-6MP JM0046245

7 1/4” x 286” Hydraulic Hose 286inch4M3k-4G-8MP-4G-6MP JM0047274

8 1/4” x 21” Hydraulic Hose 21inch4M3k-4G-4MP-4G-6MPX JM0024896

9 3” x 24” x 1-1/2” Welded Cylinder (JD324) JM0019644

9 Seal Kit 3” x 24” Cylinder (JD324-1) (JD480) JM0037895

10 1-3/16” x 3-5/8” Clevis Pin (X-Tended Reach) JM0047300

11 3/8” Male NPT x 3/8” Female NPT; 90 Degree Elbow JM0030059

12 3/8” Male NPT x 3/8” Female NPT x 3/8” Female NPT; Street T JM0018266

13 Lock N Load Assembly JM0048754

14 1/4” x 456” Hydraulic Hose 456inch4M3k-4G-8MP-4G-4MP JM0030610

15 1-3/4” x 4” Hydraulic Cylinder (1/2” Clevis and Tab ends) JM0018564

15 Seal Kit for 1-3/4” x 4” Cylinder (SKHC-FCS) (JD459) JM0024892

16 1/4” Male NPT x 1/4” Female NPT; 90 Degree Elbow JM0020115

17 1/4” Male NPT-Swivel with .032 Orice (restrictor) JM0020113

18 1/2” Female NPT Pioneer (PQC-1) JM0018254

19 Auto-Gate Hydraulic Valve JM0026247

20 3/8” Female NPT x 1/2” Male ORB; Straight JM0034657

21 1/2” Male ORB x 1/2” Female NPT Swivel; 90 Degree Elbow JM0047392

22 1/2” Male ORB x 3/8” Female NPT Swivel; 90 Degree Elbow JM0027285

23 1/2” x 236” Hydraulic Hose 236inch8M3k-8G-8MP-8G-8MPX JM0047376

24 3/8” Male NPT x 3/8” Female NPT; 90 Degree Elbow JM0030059

25 1/2” Male NPT x 1/2” Female NPT; 90 Degree Elbow JM0047371

26 3/8” Male ORB x 3/8” Male NPT; 90 Degree Elbow JM0047350

27 1/2” Male ORB x 3/8” Female NPT; 90 Degree Elbow JM0047348

28 Solenoid Valve for Lock and Load (Black) JM0026256

29 Solenoid Coil for Lock and Load (Black) JM0026255

30 Check Valve for Lock and Load (Black) JM0026250

35

Page 36

Auto-Gate Shut-O Assembly

1 2

1 2

2

1

3

AUTO GATE ACTIVE

6

2

7

11

10

5

4

2

5

2

1

Description Part No.

1 1/4”-20 x 3-1/2” Gr5 Z Hex Bolt JM0046621

2 1/4”-20 Gr5 Z SF Hex Nut JM0001630

3 Auto-Gate Hydraulic Valve JM0026247

4 1/2” Male ORB x 3/8” Female NPT Swivel; 90 Degree Elbow JM0027285

5 3/8” Female NPT x 1/2” Male ORB; Straight JM0034657

6 Auto Gate Active Decal JM0046612

7 3-1/2” Round LED Mount JM0034956

8 3-1/2” Round LED Grommet JM0001902

9 3-1/2” Amber Round LED Light JM0001895

10 1/4”-20 x 3/4” Gr5 Z SF Hex Bolt JM0001642

11 1/2” Male ORB x 1/2” Female NPT Swivel; 90 Degree Elbow JM0047392

8

9

Auto-Gate Shut-O Wiring Schematic

Mounted Light

4

P

T

Note: Mount the hydraulic valve after all

the hoses are attached but not tightened.

This will ensure the hoses will reach.

36

2 1

+12V LOAD

Relay

2 1

A

23

B

To Mating Connector from

7-Prong Front Grain Cart Harness

(This Supplies +12V Power)

CELLS

1

AB

Description Part No.

1 GT 560 Digi-Star Scale Display Monitor JM0044177

2 Auto-Gate Harness (Standard GT 560) JM0026813

2 J&M Relay Harness (1 per IFM-GS-1P(auto-gate)) JM0037374

3 Auto-Gate Hydraulic Valve JM0026247

4 Auto Gate Light Harness (LED light “Y” Cable) JM0046624

To Junction Box

Page 37

Lights and Wiring

12

Field Light

(Black Wire)

10

10

13

Ground

(White Wire)

14

1

2

3

1

2

4

5

9

6

7

8

Tail Light

(Brown Wire)

11

Amber Flashing

& Turn Signal

(Yellow Wire)

Amber Flashing

& Turn Signal

(Green Wire)

Description Part No.

1 Red Oval LED Tail Light JM0034389

2 LED Amber Light (Circular) JM0018819

3 Extendable Amber Light Assembly (Left Side) JM0018817

4 Extendable Amber Light Assembly (Right Side) JM0018826

5 Wiring Harness, Rear Half of Grain Cart JM0020437

6 Light Enhancer and Adapter Kit (3 wires) JM0010566

7 Main Harness with 7-prong Connector End for Grain Cart JM0020439

8 Limit Switch for Field Light (ME-8111) JM0036040

9 Field Light Wire (Limit Switch) JM0048128

10 LED Field Light JM0001881

11 7-Prong Connector JM0010528

12 Lock and Load Assembly JM0048754

13 Grain Cart Lock and Load Harness JM0044755

14 Limit Switch for Lock and Load - 72” Long Cable JM0046717

37

Page 38

Digi-Star 5-Point Scale System for Single Wheel Grain Carts

5

8

1

3

1

6

6

1

1

5

1

2

7

4

GT 400 GT 560

Description Part No.

1 2-7/8” Digi-Star Weigh Bar, 1” Pin Hole (278WB-T1) JM0000355

2 Digi-Star 6-Point Junction Box (JB-5) JM0019038

3 8’ Cable from J-Box to Indicator (Digi-Star) JM0047238

4 GT 400 Digi-Star Scale Display Monitor JM0019040

4 GT 560 Digi-Star Scale Display Monitor JM0044177

5 2-7/8” Weigh Bar Weldment, Rear Right, Front Left, Digi-Star (6-1/8” Spool) JM0018985

6 2-7/8” Weigh Bar Weldment, Rear Left, Front Right, Digi-Star (6-1/8” Spool) JM0000354

7 1”-8 x 8” Gr5 Z Hex Bolt JM0001487

8 1”-8 Gr5 Z Centerlock Hex Nut JM0002149

9 20’ Extension Cord to Mount Indicator in Cab (ECI-2) JM0025816

10 Flash Drive Memory Stick for Digi-Star GT 560 (114991) JM0025819

38

Page 39

Digi-Star 5-Point Scale System for Grain Carts with Tracks

GT 400 GT 560

Description Part No.

1 2-7/8” Digi-Star Weigh Bar, 1” Pin Hole (278WB-T1) JM0000355

2 Digi-Star 6-Point Junction Box (JB-5) JM0019038

3 8’ Cable from J-Box to Indicator (Digi-Star) JM0047238

4 GT 400 Digi-Star Scale Display Monitor JM0019040

4 GT560 Digi-Star Scale Display Monitor JM0044177

5 2-7/8” Weigh Bar Weldment for Track Beam (WBW-278T) JM0018207

6 20’ Extension Cord to Mount Indicator in Cab (ECI-2) JM0025816

7 Flash Drive Memory Stick for Digi-Star GT 560 (114991) JM0025819

39

Page 40

Digi-Star 5-Point Scale System Hardware for Track & Bolt on Axle

GT 400 GT 560

1 1”-8 x 3” Gr5 Z Hex Bolt JM0016686

2 1” Zinc Finish Lock Washer JM0019203

3 1”-8 Gr5 Z Hex Nut JM0002127

4 1”-8 Gr5 Z Centerlock Hex Nut JM0002149

5 1”-8 x 5-1/2” Gr5 Z Hex Bolt JM0002110

6 3/8”-16 Gr5 Z SF Hex Nut JM0002152

7 GT 560 Scale Monitor Display Bracket JM0046976

7 GT 400 Scale Monitor Display Bracket JM0000361

8 3/8”-16 x 1” Gr5 Z SF Hex Bolt JM0002092

9 GT 400 Digi-Star Scale Display Monitor JM0019040

9 GT 560 Digi-Star Scale Display Monitor JM0044177

10 1/4”-20 x 3/4” Gr5 Z Hex Bolt JM0001507

11 1/4” x 3/4” Self Tapping Screw JM0001570

12 Digi-Star 6-Point Junction Box (JB-5) JM0019038

13 1/4”-20 Gr5 Z SF Hex Nut JM0001630

40

Description Part No.

Page 41

Digi-Star 5-Point Scale System for Grain Carts with Walking Tandem Dual Wheels

2

3

1

1

7

5

4

6

GT 400 GT 560

Description Part No.

1 3-3/4” Digi-Star Weigh Spindle (375WS) JM0021451

2 3-3/4” ID x 4-1/2” OD x 9-3/8” Adapter Pipe Tubing (ATP-375-GS) JM0021453

3 5/8”-11 x 6-1/2” Gr5 Zinc Hex Bolt JM0019979

4 5/8”-11 Gr5 Z Centerlock Hex Nut JM0002146

5 GT 400 Digi-Star Scale Display Monitor JM0019040

5 GT 560 Digi-Star Scale Display Monitor JM0044177

6 Digi-Star 6-Point Junction Box (JB-5) JM0019038

7 2-7/8” Digi-Star Weigh Bar, 1” Pin Hole (278WB-T1) JM0000355

8 8’ Cable from J-Box to Indicator (Digi-Star) JM0047238

9 20’ Extension Cord to Mount Indicator in Cab (ECI-2) JM0025816

10 Flash Drive Memory Stick for Digi-Star GT 560 (114991) JM0025819

41

Page 42

Walking Tandem Dual Wheel Assembly

Description Part No.

1 1”-14 Gr8 YZ Hex Nut JM0019926

2 1-1/4” x 8” x 14” Walker Frame Clamp Plate (114814CP) JM0010145

3 1”-14 x 7-1/2” Gr8 YZ Hex Bolt JM0019925

4 Walker Main Frame Weldment (Left)(FW-1L) JM0019922*

4 Walker Main Frame Weldment (Right)(FW-1R) JM0010082*

5 1-3/4” x 13-1/2” Bolt (1341312HB) JM0019981

6 1-3/4”-12 Z Gr5 Hex Jam Nut JM0009752

7 3-3/4” x 17-1/2” Pivot Pin (334PP) JM0019928

8 Walker - Triple Pivot Weldment - OAS (PBW-1R) JM0010170*

8 Walker - Triple Pivot Weldment - AS (PBW-1L) JM0025721*

9 3-3/4” ID, 4-1/2” OD Bronze Bushing (4” Lg) (BB-334) JM0010570

*-R = Red

*-B = Blue

*-G = Green

10 Walker Pivot Center Weldment (PCW-1) JM0010076*

11 3/4”-10 x 5-1/2” Gr5 Z Hex Bolt JM0015522

12 1”-14 x 3” Gr8 YZ Hex Bolt JM0019924

13 3/4”-10 Gr5 Z Centerlock Hex Nut JM0002147

*-Y = Yellow

*-BLK = Black

When requesting an item with color, end the part number

with -R, -B, -G, -Y, or -BLK. (e.g. JM0000000-R)

42

Page 43

Sideboards

15

Description Part No.

1 Low Sideboard Corner 5” (1000, 1012)(TTE-1000LSC) JM0013701

2 Front Low Sideboard 132” x 5-1/4” (1000, 1012)(TTE-1000LSF) JM0013675*

3 Low Sideboard Splice 5” (1000, 1012)(TTE-1000LSP) JM0013702

4 Back Low Sideboard 132” x 5-1/4” (1000, 1012)(TTE-1000LSR) JM0013674*

5 Back Endboard 141” x 19-1/4” (1000, 1012)(TTE-1000R) JM0013678*

6 High Sideboard Corner 19” (1000, 1012)(TTE-1000HSC) JM0013699

7 Back High Sideboard 132” x 19-1/4” (1000, 1012)(TTE-1000HSR) JM0013671*

8 High Sideboard Splice 19” (1000, 1012)(TTE-1000HSP) JM0013700

9 High Sideboard Brace End 18-1/2” (1000, 1012) JM0013731

10 Sideboard Brace 135” (1012, 1112, 1412, 1000-1151, 1401) JM0020624

11 Low Sideboard Brace End 4-1/2” (1000, 1012) JM0013732

12 Front High Sideboard 132” x 19-1/4” (1012) JM0026160*

13 Front Endboard Splice 15-5/8” (1000, 1012)( TTE-1000FSP) JM0013703

*-R = Red

*-B = Blue

*-G = Green

*-Y = Yellow

*-BLK = Black

When requesting an item with color, end the part

number with -R, -B, -G, -Y, or -BLK. (e.g. JM0000000-R)

14 Front Endboard 141” x 19-1/4” (1000, 1012)(TTE-1000F) JM0013676*

15 3/8”-16 x 1” Gr5 Z SF Hex Bolt JM0002092

16 3/8”-16 Gr5 Z SF Hex Nut JM0002152

17 3/8”-16 x 1” Gr5 Z Pan Head Bolt JM0002892

18 7/16” ID x 2-1/2” OD x 1/8” Z USS Flat Washer JM0018982

19 1012 Sideboard Complete Set JM0041386*

16

17

18

43

Page 44

Inspection Windows

7

Description Part No.

1 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

2 Inside Window Clip - Deep JM0000253

3 Outside Window Clip - Shallow JM0000256

4 3/8”-16 x 3/4” Gr5 Z Hex Bolt JM0001663

5 Window Seal 3/4” ‘S’ Strip JM0000254

6 Standard Inspection Window JM0000255

7 Inspection Window Kit JM0025752

Door Wheel Assembly (2016 & Newer)

Description Part No.

1 1/4”-20 x 1” Gr5 Z Hex Bolt JM0002095

2 1/4” ID, 3/4” OD Z Flat Washer JM0003090