Page 1

Roll Tarp

Grain Cart

SETUP MANUAL

ALL MODELS

284 Railroad Street - P.O. Box 547 | Fort Recovery, OH 45846 | Ph: (419) 375-2376 | Fax: (419) 375-2708

Rev. 11.13.2018

J&M Manufacturing Co, Inc

www.jm-inc.com

Page 2

Table of Contents

Manual Roll Tarp

3 ...............................................................................Endcap Assembly

4 ....................................................................... Hanger Bracket Locations

5 ....................................................................... Hanger Bracket Assembly

5 .................................................................................. Tightening Lip

6 ...........................................................................Installing Rear Endcap

7 .....................................................................Rear Endcap Support Braces

8 .........................................................................Tightening Rear Endcap

8 ................................................................................ Installing J-Bolts

9 ..........................................................................Installing Front Endcap

9 .......................................................................................Tarp Bows

10 ........................................................................ Installing Cable Clamps

11 ....................................................................... Installing Spring Returns

12 .......................................................................Installing 1-1/4” Roll Tube

12 .....................................................................Installing 1” Tie Down Tube

13 ....................................................................... Installing Roll Tarp Stops

13 ....................................................Installing Pop Rivets on 1-1/4” Roll Tarp Tube

14 .....................................................................Installing the Crank Handle

15 ......................................................................................Tarp Rope

Electric Roll Tarp

17 ........................................................Removing Parts (if previously equipped)

17 ........................................................................ Electric Roll Tarp Mount

18 ..................................................... Attaching Electric Roll Tarp Arm and Motor

18 ............................................................................Harness Installation

19 ...................................................................................Switchboard

20 .............................................................................. Wiring Schematic

21 ............................................................. Aligning the Tarp/Troubleshooting

Repair Parts List

22-23 ............................................................Repair Parts for Manual Roll Tarps

24 ................................................................Repair Parts List - Standard Carts

25 .........................................................Repair Parts List - Extended Reach Carts

26 ............................................................. Repair Parts List - Drag Series Carts

27-28 ............................................................Repair Parts for Electric Roll Tarps

2

Page 3

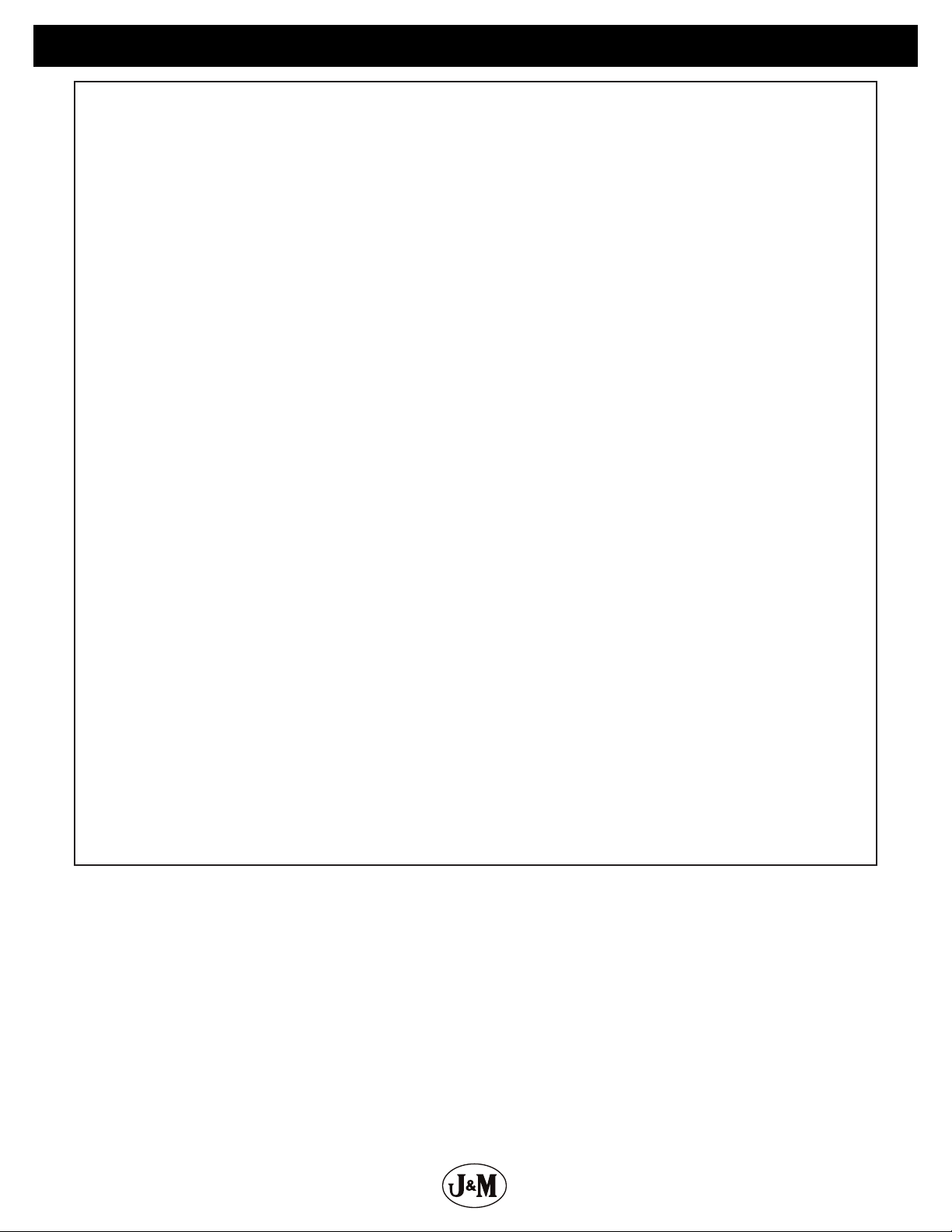

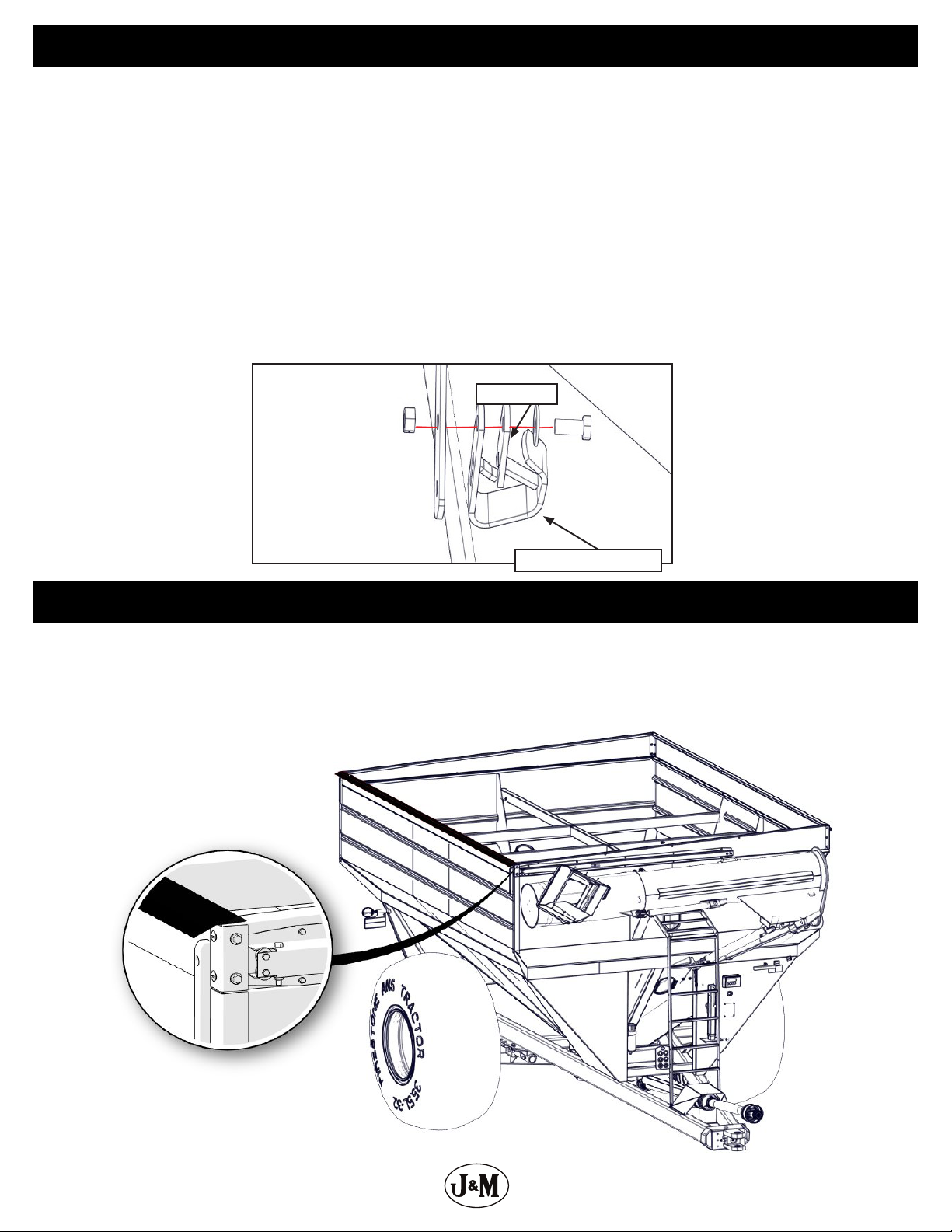

Endcap Assembly

NOTE: Before beginning assembly, read the grain carts operator’s manual and comply with all safety rules and

operation procedures.

Rear Endcap

1/4” SF Hex Nut

Rear Endplate

1/4” x 1/2” SF Hex Bolts

Assemble endcap at the ground level. Attach the endplate to the endcap using 1/4” x 1/2” serrated ange hex

bolts and 1/4” serrated ange hex nuts. Tighten the hardware once nished.

3

Page 4

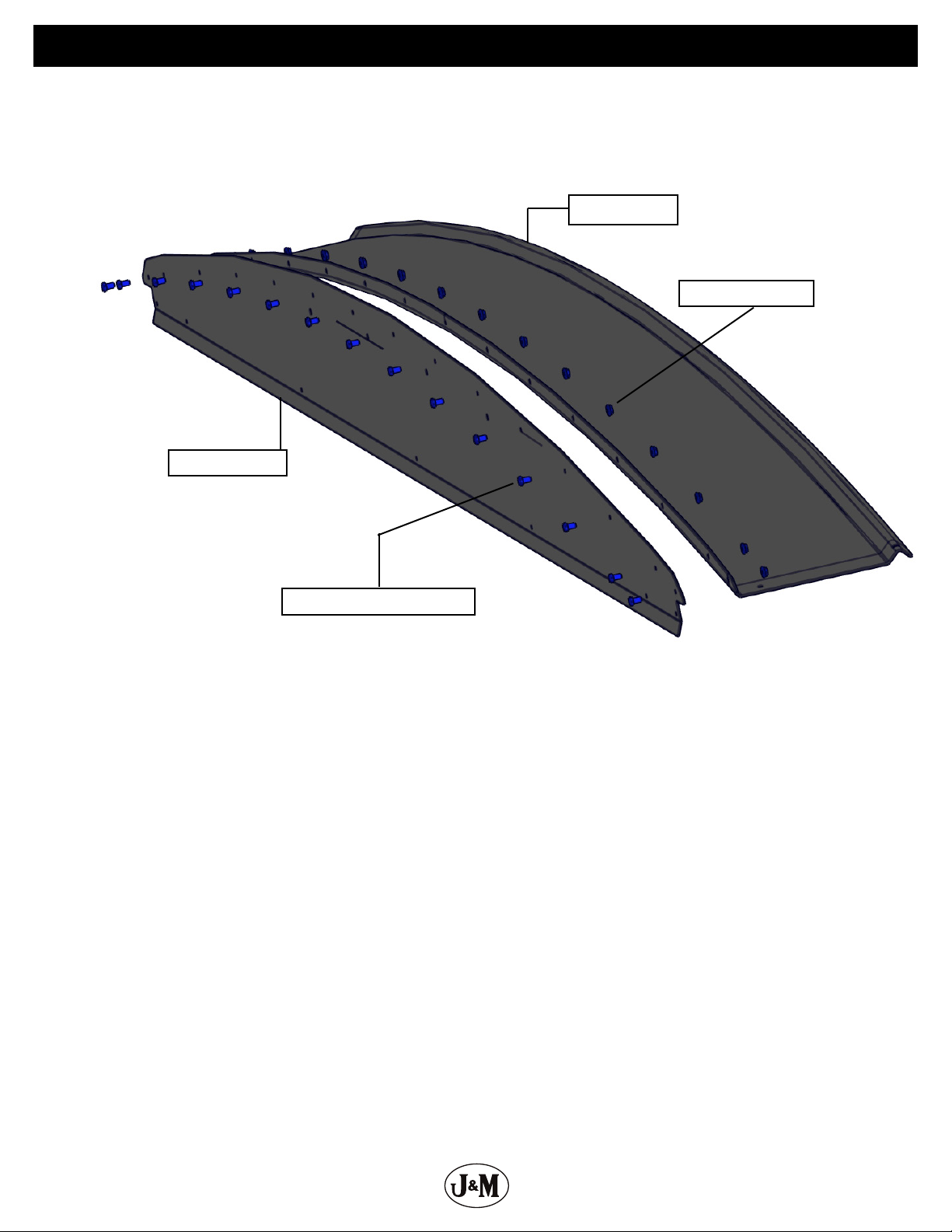

Hanger Bracket

NOTE: If you are installing the optional Electric Roll Tarp skip to Tightening Lip on pg. 5.

Place the hanger bracket with the four hole pattern, positioned at the top, in the center of the rear wall on the cart. Keep the hanger bracket as low as

possible on the rear wall. Mark the four holes then drill with a 7/16” bit. See gure bellow for specic model. For 1312, 1326, and 1522 models, the spring

return in the rear of the cart will obstruct where the hanger brackets are supposed to be installed. Instead use a bent hanger bracket (JM0048492 ) and

install directly under the sideboard at the top of the angled shell.

Model 525 to 875

Model 1122 to 1522 Leaner

Rear Runner

Model 1000 to 1412

Model X2431 and GC-31T International

NOTE: All Leaner models have (2) hanger brackets. Center the hanger brackets with the rear runners and place the bracket as low as possible on the rear wall.

GC-24T International

Drag Cart Series

4

Page 5

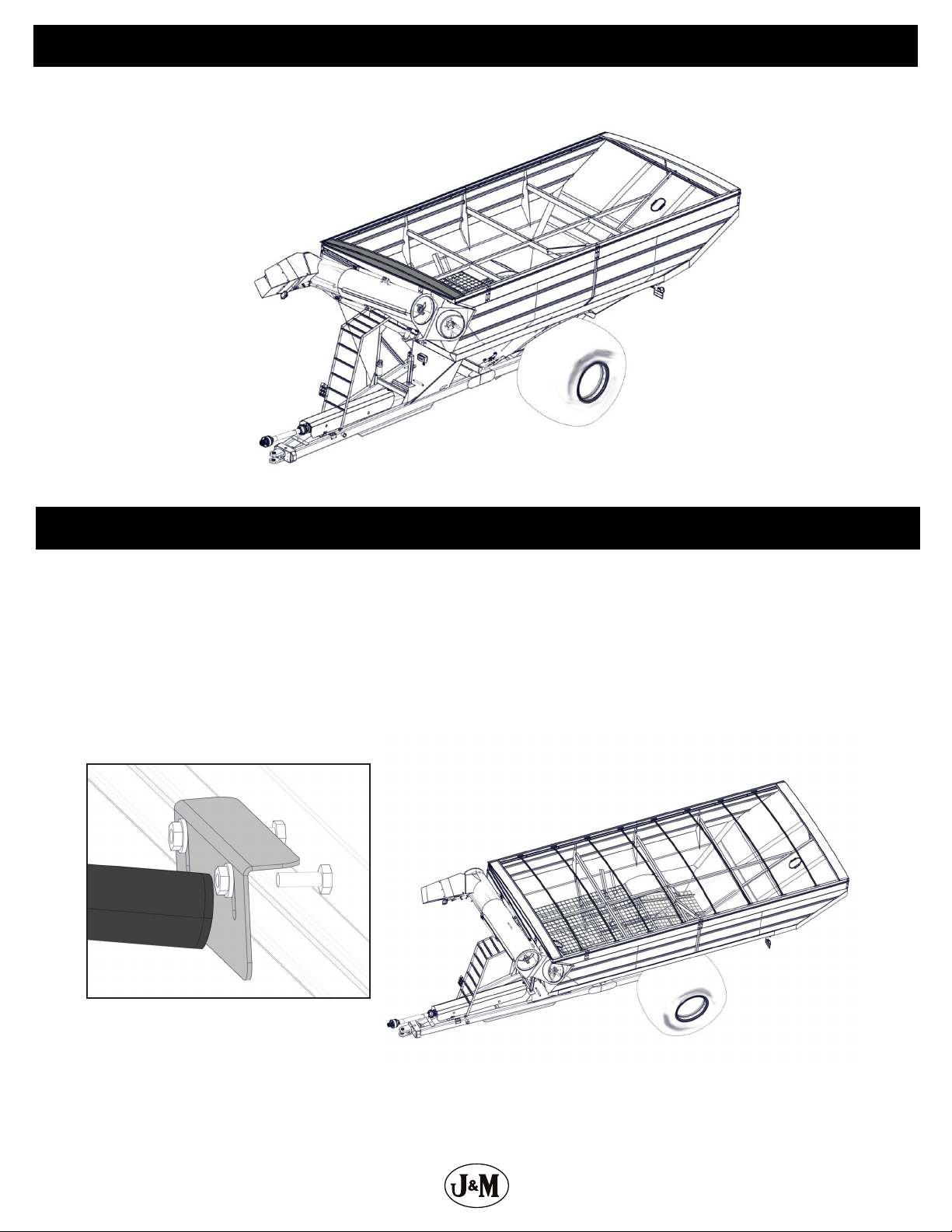

Hanger Bracket

Standard Grain Carts

Install the roll tarp hanger bracket. Use (4) 3/8”-16 x 1” Gr5 Z serrated ange hex bolts and (4) 3/8”-16 Gr5 Z serrated ange hex

nuts to attach the hanger bracket to the rear end panel brace. Tighten the hardware once installed.

Next install the hanger bracket hook and the rubber ap. Use a 1/2”-13 x 1-1/4” Gr5 Z hex bolt and a 1/2”-13 x 1-1/4” Gr5 Z centerlock

hex nut to attach the hook and ap to the hanger bracket. Tighten the hardware once installed.

Note: Make sure that hanger bracket hook is facing towards the cart when installed.

International Grain Carts

Install the roll tarp hanger bracket. Use (4) M10-1.5 x 25 Gr8.8 YZ serrated ange hex bolts and (4) M10-1.5 Gr8.8 YZ serrated ange

hex nuts to attach the hanger bracket to the rear end panel brace. Tighten the hardware once installed.

Next install the hanger bracket hook and the rubber ap. Use a M12-1.75 x 50 Gr8.8 YZ hex bolt and a M12-1.75 Gr8.8 YZ nylon locking hex nut to attach the hook and ap to the hanger bracket. Tighten the hardware once installed.

Note: Make sure that hanger bracket hook is facing towards the cart when installed.

Flapper

Hanger Bracket

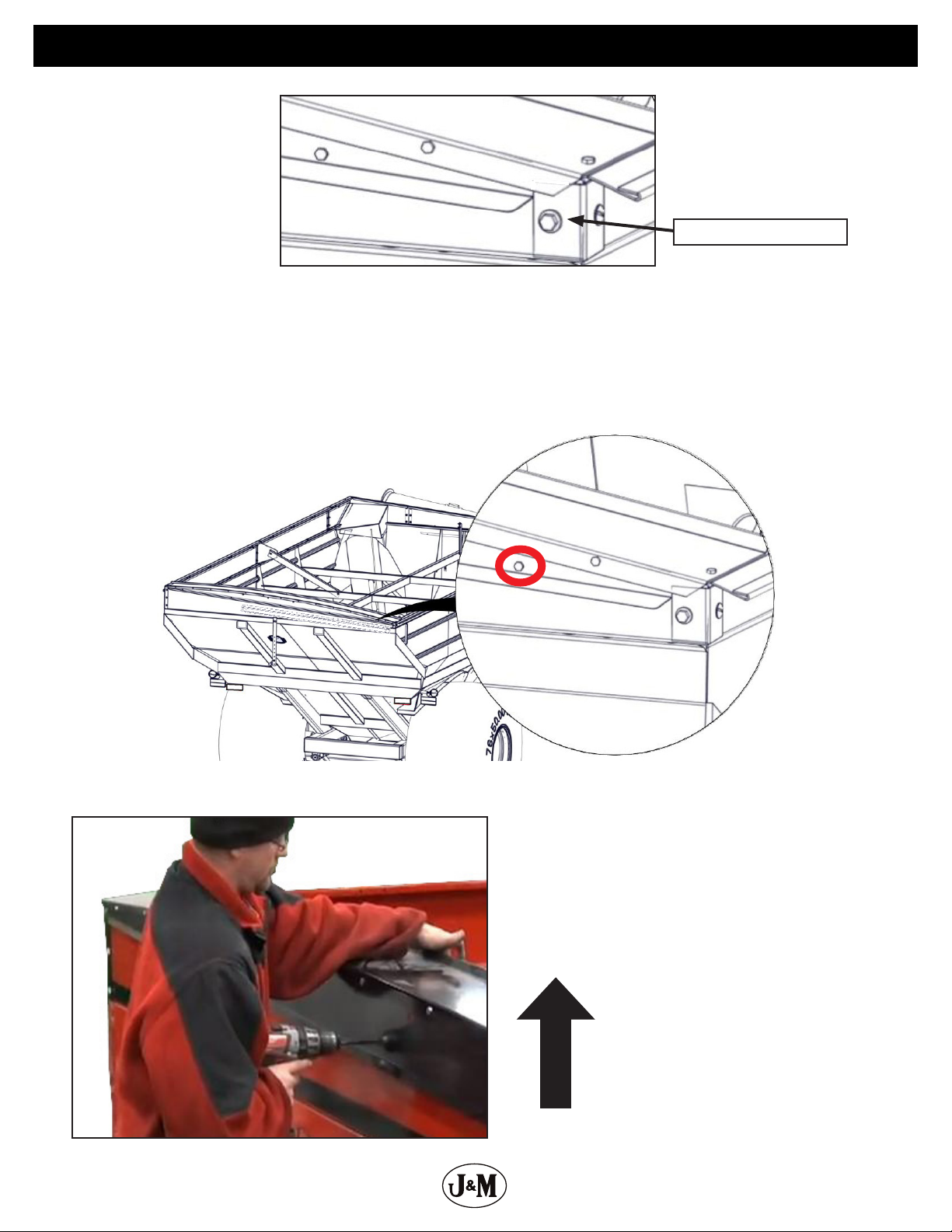

Tightening Lip

Center the tightening lip from the front to the rear of the cart on the opposite auger side of the grain cart. Depending on the

length of your grain cart, there maybe a total of two tightening lips. If there is two, position the inside edge of each tightening lip

to the center of the grain cart. Make sure that the tightening lip is ush to the inside of the sideboard. The holes may already be

pre-drilled for installation or they may need to be drilled out with a 1/4” drill bit. Use a pair of C-clamp vise grips to temporarily

hold the tightening lip in place. Bolts will be installed in a later step.

5

Page 6

Installing the Rear Endcap

Place the Rear Endcap Assembly onto the back of the grain cart. Slide the endcap to the right until it makes contact with the corner

bracket.

Sideboard Corner

Using a 1/4” drill bit, drill through the hole closest to the corner bracket. Once drilled, fasten with a 1/4” x 1/2” serrated ange hex

bolt and nut. Now drill the opposite side and fasten with a 1/4” x 1/2” hex bolt and serrated ange nut.

Now drill the remaining holes for the rear endcap. All the holes that need drilled run horizontally with the hole that was just

drilled.

Note: While drilling, pull up on the front of the endcap so the faceplate will lie parallel with the rear grain cart

wall.

Place 1/4” x 1/2” hex bolts and serrated ange nuts in the remaining holes and tighten the hardware once nished.

NOTE: While drilling, pull up on the front of the endcap

so the faceplate will lie parallel with the rear grain cart

wall.

6

Page 7

Rear Endcap Support Brace

Install the endcap brace. The purpose of the endcap brace is to hold the inside of the endcap up approximately 1” higher than the

outside of the endcap. Drill a hole using a 1/4” drill bit rst followed by a 7/16” drill bit. The hole should be placed onto the nearest

crossbrace which is welded to the shell body. The hole should be located somewhere between the middle of the endcap and the

inside of the endcap. To accomodate for height adjustment, two braces will be used to support the endcap. Use the combination

that raises the inside lip of the endcap 1” above the outside edge of the endcap. Use 3/8” x 1” serrated ange hex bolts and nuts to

attach the braces to the grain cart.

1”

Inside Outside

7

Page 8

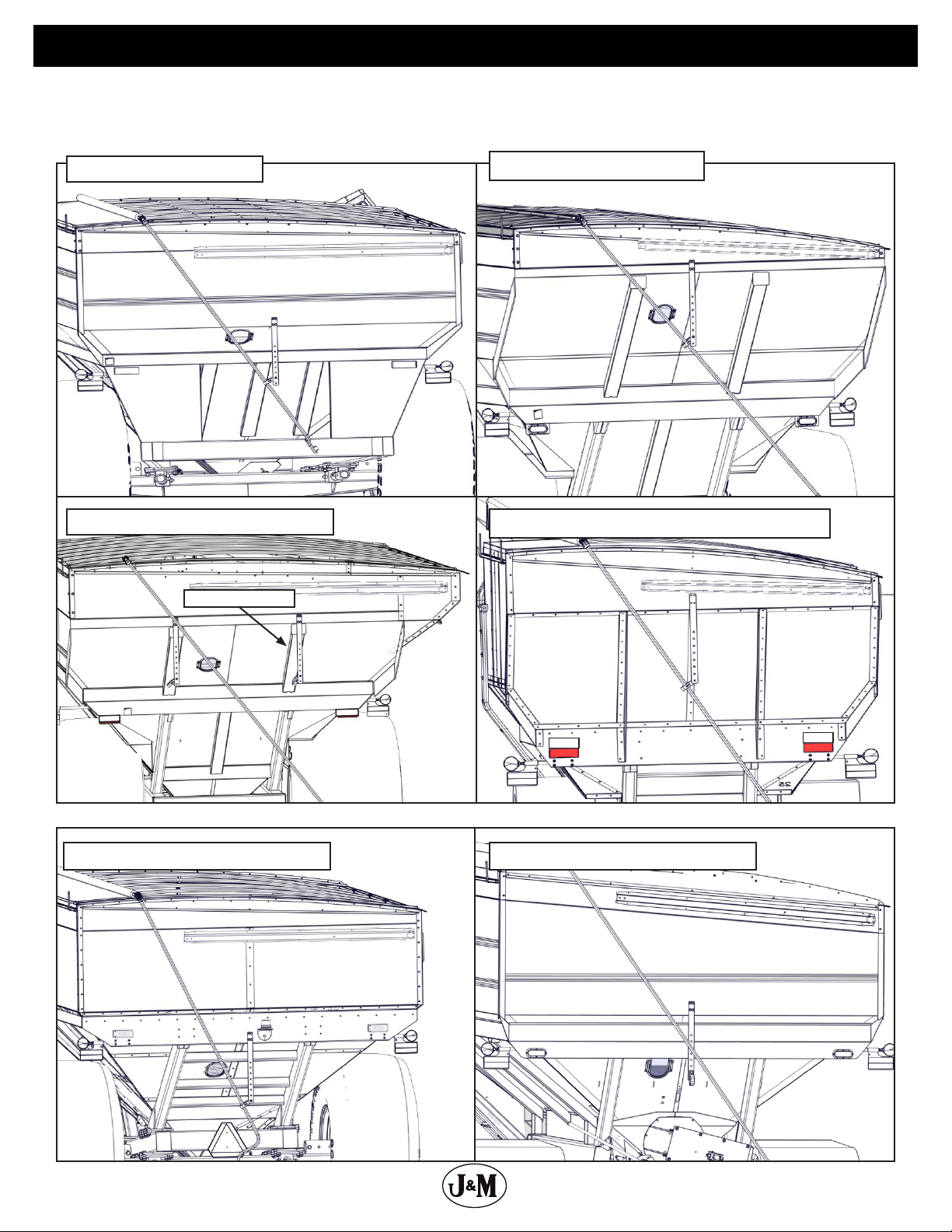

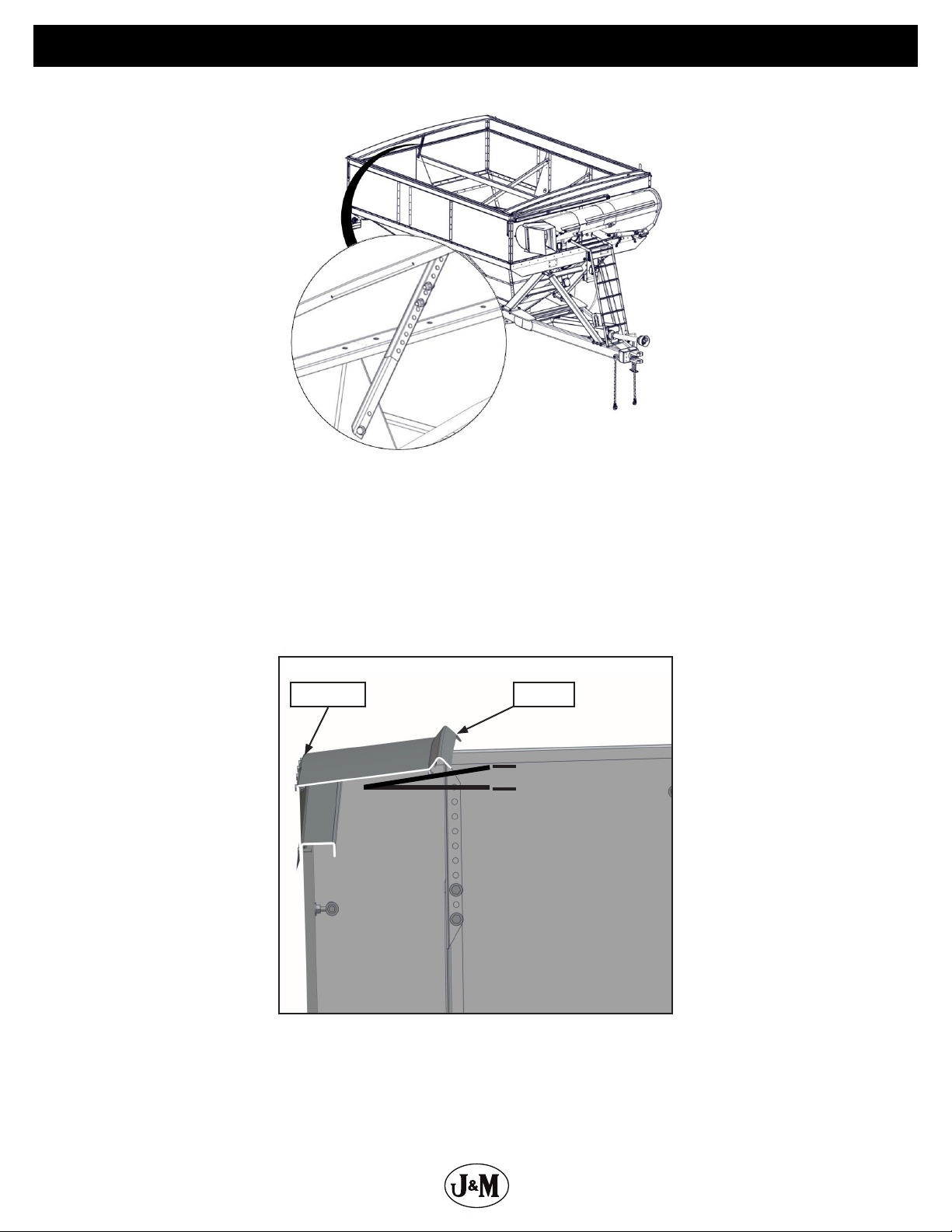

Tightening Rear Endcap

Pull the tightening lip tight against the opposite auger side of the grain cart. Using a 1/4” bit, drill through the hole on the top of

the endcap. Fasten the endcap by using a 1/4” x 1-1/2” bolt and 1/4” serrated ange nut. Tighten the bolt. Now go to the other end

of the endcap and repeat the same procedure.

Auger Side

Opposite Auger Side

Rear of Cart

Installing J-Bolts

Now place (3) 3/8” J-bolts into the three holes closest to the auger side in the rear endcap. Fasten the J-bolts with (3)

3/8” locknuts. Use the plastic 3/8” ribbed push in rivet to plug the remaining hole. Leaner carts use four J-bolts and

wont require a ribbed push in rivet.

NOTE: DO NOT tighten past ush.

J-Bolts

Lock Nuts

8

Page 9

Installing the Front Endcap

Install the front endcap assembly using the same procedure used to install the rear endcap assembly. Do not forget the endcap

brace. (See pages 6-8) On the front faceplate, use the plastic 3/8” ribbed push in rivets to ll the four 3/8” holes.

Installing Tarp Bows

Install all of the tarp bows. Use (4) 1/4” x 3” hex bolts and (4) 1/4” serrated ange nuts for each bow.

NOTE: If your tightening lip is centered and there are no holes visible through your lip lock and sideboard, holes

will need to be drilled wherever there are slots in the lip lock. Use a 1/4” drill bit to accomplish this. Now make sure that

all of the tarp bows are perpendicular to the auger side of the cart and drill 1/4” holes through the sideboards. This should

only be the case on later model grain carts.

9

Page 10

Installing Cable Clamps

Using a cable clamp, feed one end of the cable through the cable clamp, make a small loop, then tighten the cable. Do this with all three cables.

NOTE: Make sure that the base of the clip bears on the live end of the rope and the “U” of the

bolt bears on the dead end.

Live End

Dead End

Now thread all three cables through the front endcap pulling the end without the cable clamps through rst.

NOTE: Make sure to pull from front to back.

Next guide the cables over the arched bows and thread them through the existing holes on the rear endcap. Now feed the

cables through the cable clamps.

NOTE: Make sure that the base of the clip bears on the live end of the rope and the “U” of the

bolt bears on the dead end.

Place the loop into the J-bolt. Use a vise grip to pull on the cable. Pull the cable tight. To remove all slack from the cable, aggressively tap the cable while applying tension with the vise grips. Then tighten the cable clamp. Once the clamps are tightened,

tighten the J-bolts. Insert a wrench into the hook of the J-bolt and tighten the nut.

10

Use wrench or bolt to hold the J-bolt while tightening.

Page 11

Installing the Spring Return

Place the spring return as close to the front endcap and butt the side of the spring return, with the cable loop, against the welds

on the corner of the grain cart.

NOTE: For single auger cart make sure that the spring return is level with the ground and that the spring return is

not hindered by any part of the cart. The exception to this rule is the 32 series cart. They have the spring return

lined up with top of the cart.

Use a 1/4” drill bit to make your rst hole. Then fasten the spring return to the cart using 1/4” x 3” self tapping screws. Next drill

through the remaining holes and insert the self tapping screws. Repeat process for back side of grain cart, installing the spring

return on the opposite auger side.

Cable Loop

11

Page 12

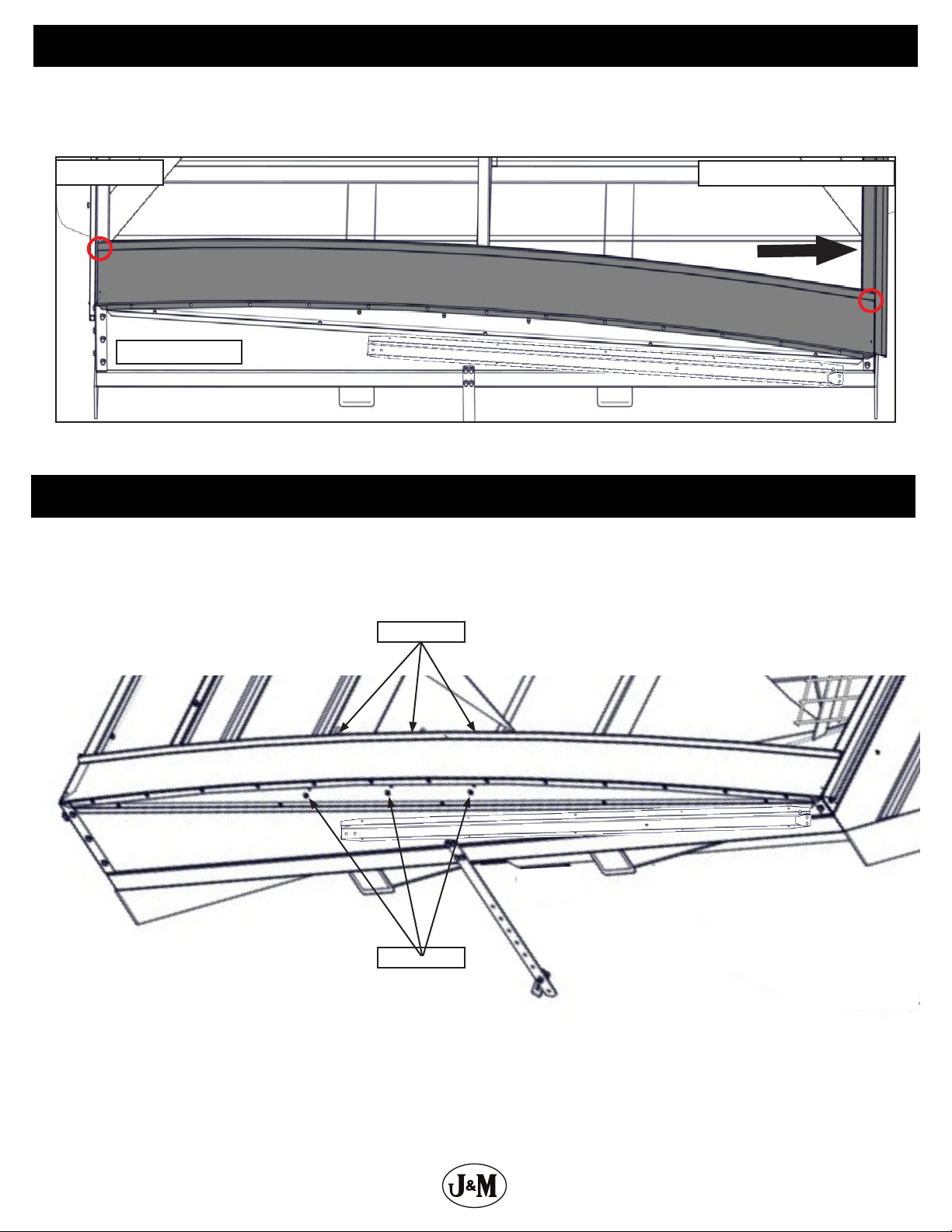

Installing 1-1/4” Square Roll Tube

Prepare the canvas tarp. Spread the canvas tarp out so that the stiening patches are on the opposite auger side with the shiny

side down.

For grain carts with a capacity of 875 bushels and lower, slide the tarp guide roller onto the 1-1/4” square roll tube. Install the

1-1/4” square roll tube through the front end of the opposite auger side canvas tarp end.

For grain carts with a capacity of 1,000 bushels or greater, slide the 1-1/4” square roll tube through the rear end of the opposite

auger side canvas tarp end. Slide the tarp guide roller onto the front end of the 1-1/4” square roll tube. Slide the cable spool into

the front end of the 1-1/4” square roll tube. Line up the holes in the cable spool with the holes in the 1-1/4” square roll tube and

insert the roll pin.

1-1/4” Square Roll

Tube

1-1/4” Square

Roll Tube

Canvas Tarp

1” Square TieDown Tube

Opposite

Auger

Side

1” Square Tie-

Down Tube

Auger Side

Front of Cart

Installing 1” Tie Down Tube

Feed the 1” square tie-down tube through the auger side tarp end. On the front of the grain cart, measure 3” from the end of the

tube. This is where the canvas tarp should stop. Now measure 3/4” on the canvas tarp. Drill a 1/4” hole through the tarp and the

rst wall on the tube. Next install a pop rivet using a hammer. Now go to the opposite end of the same tube and pull the tarp

tight. Measure 3/4” from the end of the tarp, drill a 1/4” hole and install another pop rivet.

3”

3/4”

12

Page 13

Installing the Roll Tarp Stops

Next place the 1” tube under the top bolt of the back corner bracket on the auger side. Drill a 1/4” hole through the tube and sidewall approximately 18” to 24” in from the corner of the cart. Then re-drill the hole with a 7/16” bit. Place a 3/8” x 2” bolt through the

roll tarp stop, 1” square tie-down tube, and grain cart sidewall. Fasten with a 3/8” serrated ange nut. Now repeat this process at

the front of the cart. For the center hole slightly lift the 1” square tie-down tube approximately 1” higher than the two other holes.

Repeat the process to drill a 7/16” hole. Place a 3/8” x 2” bolt through the roll tarp stop, 1” square tie-down tube, and grain cart

sidewall and fasten with a 3/8” serrated ange nut .

NOTE: For grain carts that have a center splice make sure that the 1” tube is above the top bolt of the center splice.

18”-24”

Installing Pop Rivets on Roll Tube

Push down on the 1-1/4” square roll tube on both ends and in the center to fully extend the canvas. Line the roll tube cable spool up

with the spring return cable. Drill a 1/4” hole through the rst stiening patch. Fasten the canvas tarp using a pop rivet. Go to the rear

of the cart, pull the canvas tarp tight, and repeat the process. Then install pop rivets at the remaining stiening patches. Once nished

slip the spring return cable loop over the cable spool.

13

Page 14

Installing the Crank Handle

NOTE: If you are installing the optional Electric Roll Tarp go to top of the next page.

Slide tarp guide roller over rear end of 1-1/4” square roll tube. Then slide one washer over, then the spring return cable, then the next

washer. Now attach the knuckle to the roll pipe. Use (2) 3/8” x 2” hex bolts along with (2) 3/8” lock nuts. Attach the crank handle to the

universal joint. Install the crank handle using (1) 1/4” x 2-1/2” bolt and (1) 1/4” locknut. The universal joint may be pre-assembled to the

crank handle.

Check for proper function of the of the Roll Tarp.

Auger Side

14

Opposite Auger Side

Page 15

Tarp Rope

The process below is to be completed at the front and back ends of the cart.

• Unroll the roll tarp completely and let it hang down to its lowest point on the opposite auger side.

• Line bracket up below where the roll tube ends and right behind the lip on the endcap, and use 1/4” x

1-1/2” self tapping screw to attach bracket to the cart. (See Pictures 1 & 2)

• Roll the tarp all the way up.

• Drape rope completely across the cart. Pull the rope to eliminate slack then let hang so that rope is

not too tight and aligned right behind endcap lip. (See Picture 3)

• Mark bracket where rope ends and fasten bracket to cart with 1/4” x 1-1/2” self tapping screws.

Picture 1

Picture 2

Picture 3

15

Page 16

Installing Electric Roll Tarp

16

Page 17

Removing Parts (if previously installed)

Remove the Knuckle from the roll tube if previously installed.

Un-tighten both 3/8” locknuts, then pull the knuckle away

from the tarp. Keep knuckle and crank handle.

The Spring return on the rear of the cart doesn’t need to be removed.

Un-install the hanger bracket if previously installed. Remove the (4) 3/8” x 1” serrated ange hex bolts and nuts

then remove the hanger bracket from the grain cart.

Install the bolts back into their original holes. Keep the

hanger bracket.

Electric Roll Tarp Mount

Place the electric roll tarp mount in the middle of rear slope as far up as it can go. Mark and drill (6) 7-16” holes. Attach the mount

to the grain cart using (6) 3/8”x 1” serrated ange hex nuts and bolts. Tighten hardware once installed.

17

Page 18

Attach Electric Roll Tarp Arm and Motor

Attach the electric roll tarp arm to the mount. Use (2) 1/2” x 1” hex bolts and (2) 1/2” hex nuts.

Adjust the roll tarp arm to the correct length, tighten the two set screws, and attach the motor to the roll tube. Once the motor is

attached drill a 3/8” hole through the spline using the hole in the motor shaft as a guide. Fasten the motor to the roll tube using a

5/16” x 2” hex bolt and a 5/16” locknut. Tighten hardware once nished.

Drill 3/8” hole

through spline

Harness Installation

Route the two wires coming from the electric tarp arm to the front leg. Drill holes accordingly.

18

Page 19

Switchboard

Position the Electric Roll Tarp Switch Mount on the front auger side leg in a position that it will not interfere with any other

component of the grain cart and so that the power cables will reach from the battery to the Switchboard. Use the electric roll tarp

switch mount as a guided to mark the two holes. Once marked, drill (2) 9/32” holes.

Black Spacers

Attach both of the relays to the electric roll tarp switch mount using a 1” x 1/4” hex bolt and 1/4” serrated ange hex nut. Attach

the 35 amp breaker with (2) 8-32 x 5/8” phillips pan head bolts. Using (2) 10-24 x 1” slotted hex head bolt and (2) 10-24 serrated

ange hex nuts attach the 20 amp breaker and snap the 12V to 12V battery charger into the bracket.

Now install the assembled mounting bracket using (2) 1/4” x 3-1/2” hex bolts, (2) 1/4” locking hex nuts and (2) 2” black spacers.

Relays

1” x 1/4” hex bolt

Black Spacers

Now make all of the connections using the provided wires and hardware according to the schematic on the next page.

35 Amp Breaker

Battery Charger

20 Amp Breaker

19

Page 20

M1

M1

M2

M2B-B+

S2 S1

CLOSEOPEN

RAISE

LOWER

TOW

CHARGER

2024-07

35 A

BLACK

YELLOWYELLOW

BLACK

RED

RED

BLACK

BLACK

Wiring

OPEN CLOSE

LOWERRAISE

GREEN BLUE

RED

BLACK

35 A

20 A

Gold Terminal

YELLOW

RED

BLACK

BLACK

RED

20

Main Wiring

Harness

Page 21

Aligning the Tarp/Troubleshooting

CorrectIncorrect

Figure 1 Figure 2

1. When the tarp is in closed position roll the tarp up to the tightening lip so the tarp is taught.

2. Open the tarp.

3. If the tarp is rolling at an angle (Figure 1), close the tarp until it’s in the same position as Figure 3.

4. Now insert a 5” section of 1/8” self-adhesive rubber into the rear end of the roll tube. Figure 4

5. Repeat steps 1-4 until the tarp rolls correctly.

NOTE: If the tarp is not rolling in the right direction when the open/close buttons are pushed, switch the black and

yellow wires that are connected to M1 and M2 of the motor.

Figure 3

1/8” Self Adhesive Rubber

Figure 4

21

Page 22

Repair Parts

22

Page 23

Repair Parts

Description Part No.

1 1/4”-20 x 1-1/4” Gr5 Z Hex Bolt JM0016673

2 1/4”-20 Gr5 Z SF Hex Nut JM0001630

3 Arched Top Endcap for DSR - Grain Cart 141-1/2” JM0044731

3 Arched Top Endcap for DSR - Leaner Large 121” JM0045289

3 Arched Top Endcap for DSR - Leaner Small 45” JM0045291

4 Endcap Splice for Leaner JM0007264

5 3/8”-16 Gr5 Z J-Bolt (384JB) JM0001519

6 1/4”-20 x 1/2” Gr5 Z Hex Bolt JM0001481

7 End Cap Plate for DSR - Grain Cart 140-7/8” JM0045315

7 End Cap Plate for DSR - Leaner Large 121-5/8” JM0045320

7 End Cap Plate for DSR - Leaner Small 45-5/8” JM0045322

8 3/8”-16 Gr5 Z Centerlock Hex Nut JM0001512

9 3/8” Ribbed Push in Rivet JM0037396

10 3/8”-16 Gr5 Z SF Hex Nut JM0002152

11 End Cap Prop 13” - Upper JM0021404

12 3/8”-16 x 1” Gr5 Z SF Hex Bolt JM0002092

13 Endcap Prop - Lower 19” (ABS-2) JM0000179

13 Endcap Prop - Lower 27” (ABS-2L) JM0021403

14 1/4” x 2” x 29” Bar for Crank Holder (1000 Bushel Carts and

Higher (ABCH-1EL))

14 1/4” x 2” x 29” Bar with 120° Bend for Crank Handle

(1312,1326,1522)

14 1/4” x 2” x 23” Bar for Crank Holder (875 Bushel Carts and

Lower)

15 1/2”-13 Gr5 Z Centerlock Hex Nut JM0001511

16 Crank Holder (zinc plated)(CH-1) JM0002967

17 Roll Tarp - Handle Hanger Rubber Flap JM0002551

18 1/2” ID 1-3/8” OD Z Flat Washer JM0003082

19 1/2”-13 x 1-1/4” Gr5 Z Hex Bolt JM0001513

20 Spool End for Roll Tube JM0002449

21 1/4” x 1-1/4” HD Spiro Roll Pin JM0046782

22 Roll Tarp Guide Roller JM0038446

23 1” USS Flat Washer JM0003063

24 Spring Return Cable (Grain Carts) JM0012981

25 3/8”-16 x 1-1/2” Gr5 Z Hex Bolt JM0001659

26 1/4”-20 Gr5 Z Centerlock Hex Nut JM0001505

27 1/4”-20 x 2-1/2” Gr5 Z Hex Bolt JM0001506

28 Universal Joint - Roll Tarp (SUJ-1) JM0001517

29 3/16” Cable x 144” (525) (316C-150) JM0024881

29 3/16” Cable x 158” (620) (316C-156) JM0024884

29 3/16” Cable x 168” (750) (316C-164) JM0024240

29 3/16” Cable x 198” (875, 812) (316C-198) JM0022194

29 3/16” Cable x 270” (1000-1151, 1012, 1112, 1222, GC31t-1)

(316C-1050)

29 3/16” Cable x 306” (1326, 1401, 1312, 1412, 1522) (316C-

1325)

29 3/16” Cable x 280” (1132, 1432) JM0048090

29 3/16” Cable x 359” (1832, 2032, 2332) JM0048576

30 Arched Tarp Bows (525) (116ATB) JM0021406

30 137” Arched Tarp Bows (Regular)(137ATB) JM0000157

30 160” Arched Tarp Bows (Leaner) JM0021405

31 1-1/4” x 150” Roll Tube for Roll Tarp (525) JM0024498

31 1-1/4” x 161” Roll Tube for DSR (620) JM0048400

31 1-1/4” x 171” Roll Tube for DSR (750) JM0048402

JM0000164

JM0048492

JM0029818

JM0021408

JM0015701

Description Part No.

31 1-1/4” x 195” Roll Tube for DSR (875, 812, GC24t-1) JM0048406

31 1-1/4” x 267” Roll Tube for DSR (1000-1151, 1012-1222) JM0048408

31 1-1/4” x 309” Roll Tube for DSR (1326, 1401, 1312, 1412,

1522)

31 1-1/4” x 277” Roll Tube for DSR (1132, 1432) JM0048577

31 1-1/4” x 364” Roll Tube for DSR (1832, 2032, 2332) JM0048613

32 1/8” Cable Clamp JM0001514

33 1/4”-20 x 3/4” Gr5 Z Hex Bolt JM0001507

34 Tightening Lip x 144” (525) JM0012670

34 Tightening Lip x 158” (620) JM0012671

34 Tightening Lip x 168” (750) JM0013083

34 Tightening Lip x 192” (875) JM0000155

34 Tightening Lip (1000 - 1151, 1012, 1112) Front JM0013654

34 Tightening Lip (1000 - 1151, 1012, 1112) Rear JM0013653

34 Tightening Lip (1130, 1131, 1250,1251) Front JM0021397

34 Tightening Lip (1130, 1131, 1250, 1251) Rear JM0021396

34 Tightening Lip Front 153” (1326, 1401, 1312, 1412, 1522) JM0017842

34 Tightening Lip Rear 153” (1326, 1401, 1312, 1412, 1522) JM0017843

34 Tightening Lip 137” Front 1132, 1432 JM0041727

34 Tightening Lip 137” Rear 1132, 1432 JM0041728

34 Tightening Lip 179-7/8” Front 1832, 2032, 2332 JM0042760

34 Tightening Lip 179-7/8” Rear 1832, 2032, 2332 JM0042848

35 Spring Return Assembly Complete (Grain Cart) JM0012965

36 S-Cap Yellow - 1.062 ID x 1-1/2” x 1/16 JM0018963

37 9-1/2’ Crank w/ Splined U-Joint (CUJ-1L) JM0000185

37 12’ Crank w/ Splined U-Joint (CUJ-1LN) JM0019888

38 1/4” x 3/4” Self Tapping Screw JM0001570

39 Tarp with Rivets (525) JM0021375

39 12’8” x 13’6” Tarp w/ Rivets for DSR (620) JM0048411

39 13’6” x 13’8” Tarp w/ Rivets for DSR (750) JM0048412

39 15’6” x 13’6’” Tarp w/ Rivets for DSR (875, 812, GC24t-1) JM0048348

39 21’8” x 13’6” Tarp w/ Rivets for DSR (1000-1151, 1012, 1112) JM0048415

39 25’2” x 13’6” Tarp w/ Rivets for DSR (1326, 1401, 1312, 1412) JM0048416

39 21’4” x 15’5” Tarp w/ Rivets for DSR (1131, 1251, 1122, 1222) JM0048417

39 25’ x 15’6” Tarp w/ Rivets for DSR (1522) JM0048418

39 22’4” x 13’6” Tarp w/ Rivets for DSR (1132, 1432) JM0048076

39 29’6” x 15’6” Tarp w/ Rivets for DSR (1832, 2032, 2332) JM0048071

40 1” x 144” Square Tie-Down Tube (525) (144TT) JM0021364

40 1” x 158” Square Tie-Down Tube (620) (158TT) JM0021366

40 1” x 168” Square Tie-Down Tube (750) (168TT) JM0021367

40 1” x 192” Square Tie-Down Tube (875, 812, GC24t-1)(192TT) JM0000188

40 1” x 264” Square Tie-Down Tube (1000-1151, 1012, 1112,

1122, 1222)(1050TT)

40 1” x 306” Square Tie-Down Tube (1326, 1401, 1312, 1412,

1522)(1325TT)

40 1” x 274” Square Tie-Down Tube (1132, 1432) JM0043692

40 1” x 360” Square Tie-Down Tube (1832, 2032, 2332) JM0048617

41 3/8”-16 x 2” Gr5 Z Hex Bolt JM0001510

42 Tarp Stop Bracket (TSB-1) JM0000187

43 Tarp Rope Bracket JM0047700

44 Tarp Rope Standard JM0048662

44 Tarp Rope Leaner JM0048670

45 1/4” x 1-1/2” Self Tapping Screw JM0001571

JM0048404

JM0021331

JM0018962

23

Page 24

Repair Parts List - Standard Carts

Part 620 750 875 1000 1051 1151 1326 1401

Tarp Crank Handle L L L XL XL

Square Tubing (1” x 1” Sq. Tube) 14 Gauge 158” 168” 192” 264” 306”

Roll Tube (1.25” x 1.25” Sq. Tube) 11 Gauge 164” 174” 198” 270” 312”

Tightening Lip 157.5” 168” 192” 132”x2 153”x2

Endcap (2 Per) 141.5” 141.5” 141.5” 141.5” 141.5”

Endcap Plate (2 Per) 140.875” 140.875” 140.875” 140.875” 140.875”

Tarp Bows 137.5” x 4 137.5” x 4 137.5” x 4 137.5” x 7 137.5” x 8

Ridge Cable (3 Per) (4 per Leaner) 158” 168” 192” 264” 306”

Canvas Tarp 620 750 875 1050 1325

Stop Bracket 3 3 3 3 3

Prop Up Bar - Upper (2 Per) 13” 13” 13” 13” 13”

Prop Up Bar - Lower (2 Per) 19” 19” 19” 27” 27”

J-Bolt Small 3 3 3 3 3

Hanger Bracket 23” 23” 23” 29” 29” (1326 - Bent)

Hanger Bracket Hook 1 1 1 1 1

1/4” Flange Nuts 70 70 70 110 114

1/4” x 1/2” SF Bolt 26 26 26 26 26

1/4” Locknut 1 1 1 1 1

1/4” x 2-1/2” Bolt 1 1 1 1 1

1/4” x 3/4” Bolt 44 44 44 84 88

3/8” SF Nuts 15 15 15 15 41

3/8” x 1” SF Bolts 12 12 12 12 38

3/8”-16 x 1-1/2” Gr5 Z Hex Bolt 2 2 2 2 2

3/8” x 2” Bolts 3 3 3 3 3

3/8” Locknuts 3 3 3 3 3

1/2” Locknuts 1 1 1 1 1

1/2” x 1-1/4” Bolts 1 1 1 1 1

3/16” Cable Clamp 6 6 6 6 6

Universal Joint 1 1 1 1 1

1/4” Drive Rivet 10 10 10 10 10

1/4” x 3/4” Self Tapping Screw 20 20 20 20 20

1/4” x 1-1/2” Self Tapping Screw 8 8 8 8 8

1” USS Flat Washer 2 2 2 2 2

Yellow Rubber Cap 1 1 1 1 1

Rubber Flap 1 1 1 1 1

GrainCart Spring Return (95” Long) 2 2 2 2 2

Endcap Splice for Leaner 0 0 0 0 0

3/8” Ribbed Push in Rivet 5 5 5 5 5

1/2” USS Washer 2 2 2 2 2

Spoll End for Roll Tube 0 0 0 1 1

1/4” Roll Pin 0 0 0 1 1

Roll Tarp Guide Roller 2 2 2 2 2

Tarp Rope Standard 2 2 2 2 2

Tarp Rope Leaner 0 0 0 0 0

Tarp Rope Bracket 4 4 4 4 4

24

Page 25

Repair Parts List - Extended Reach Carts

Part 812 1012 1112 1312 1412 1122 1222 1522

Tarp Crank Handle L XL XL XL XL

Square Tubing (1” x 1” Sq. Tube) 14 Gauge 192” 264” 306” 264” 306”

Roll Tube (1.25” x 1.25” Sq. Tube) 11 Gauge 198” 270” 312” 270” 312”

Tightening Lip 192” 132”x2 153”x2 99”Front 165” Back 153”x2

Endcap (2 Per) 141.5” 141.5” 141.5” 45” & 121” 45” & 121”

Endcap Plate (2 Per) 140.875” 140.875” 140.875” 45.625” & 121.625” 45.625” & 121.625”

Tarp Bows 137.5” x 4 137.5” x 7 137.5” x 8 161.75” x 7 161.75” x 8

Ridge Cable (3 Per) (4 per Leaner) 192” 264” 306” 264” 306”

Canvas Tarp 875 1050 1325 1130 1250 1500

Stop Bracket 3 3 3 3 3

Prop Up Bar - Upper (2 Per) 13” 13” 13” 13” 13”

Prop Up Bar - Lower (2 Per) 19” 27” 27” 27” 27”

J-Bolt Small 3 3 3 4 4

Hanger Bracket 23” 29” 29” (1312-Bent) 29” 29” Bent

Hanger Bracket Hook 1 1 1 1 1

1/4” Flange Nuts 70 110 114 80 84

1/4” x 1/2” SF Bolt 26 26 26 44 44

1/4” Locknut 1 1 1 1 1

1/4” x 2-1/2” Bolt 1 1 1 1 1

1/4” x 3/4” Bolt 44 84 88 36 40

3/8” SF Nuts 15 15 41 15 41

3/8” x 1” SF Bolts 12 12 38 12 38

3/8”-16 x 1-1/2” Gr5 Z Hex Bolt 2 2 2 2 2

3/8” x 2” Bolts 3 3 3 3 3

3/8” Locknuts 3 3 3 4 4

1/2” Locknuts 1 1 1 1 1

1/2” x 1-1/4” Bolts 1 1 1 1 1

3/16” Cable Clamp 6 6 6 8 8

Universal Joint 1 1 1 1 1

1/4” Drive Rivet 10 10 10 10 10

1/4” x 3/4” Self Tapping Screw 20 20 20 20 20

1/4” x 1-1/2” Self Tapping Screw 8 8 8 8 8

1” USS Flat Washer 2 2 2 2 2

Yellow Rubber Cap 1 1 1 1 1

Rubber Flap 1 1 1 1 1

GrainCart Spring Return (95” Long) 2 2 2 2 2

Endcap Splice for Leaner 0 0 0 2 2

3/8” Ribbed Push in Rivet 5 5 5 4 4

1/2” USS Washer 2 2 2 2 2

Spoll End for Roll Tube 0 1 1 1 1

1/4” Roll Pin 0 1 1 1 1

Roll Tarp Guide Roller 2 2 2 2 2

Tarp Rope Standard 2 2 2 0 0

Tarp Rope Leaner 0 0 0 2 2

Tarp Rope Bracket 4 4 4 4 4

25

Page 26

Repair Parts List - Drag Series Cart

Part 1132, 1432 1832, 2032, 2332

Tarp Crank Handle XL XL

Square Tubing (1” x 1” Sq. Tube) 14 Gauge 274” 360”

Roll Tube (1.25” x 1.25” Sq. Tube) 11 Gauge 280” 366”

Tightening Lip 137” x 2 179-7/8” x 2

Endcap (2 Per) 141.5” 45” & 121”

Endcap Plate (2 Per) 140.875” 45.625” & 121.625”

Tarp Bows 137.5” x 8 161.75” x 8

Ridge Cable (3 Per) (4 per Leaner) 280” 359”

Canvas Tarp

Stop Bracket 3 3

Prop Up Bar - Upper (2 Per) 13” 13”

Prop Up Bar - Lower (2 Per) 27” 27”

J-Bolt Small 4 4

Hanger Bracket 29” 29”

Hanger Bracket Hook 1 1

1/4” Flange Nuts

1/4” x 1/2” SF Bolt

1/4” Locknut 1 1

1/4” x 2-1/2” Bolt 1 1

1/4” x 3/4” Bolt

3/8” SF Nuts

3/8” x 1” SF Bolts

3/8”-16 x 1-1/2” Gr5 Z Hex Bolt

3/8” x 2” Bolts

3/8” Locknuts

1/2” Locknuts 1 1

1/2” x 1-1/4” Bolts 1 1

3/16” Cable Clamp

Universal Joint

1/4” Drive Rivet

1/4” x 3/4” Self Tapping Screw 20 20

1/4” x 1-1/2” Self Tapping Screw 8 8

Yellow Rubber Cap 1 1

Rubber Flap 1 1

GrainCart Spring Return (95” Long) 2 2

Endcap Splice for Leaner 2 2

3/8” Ribbed Push in Rivet 5 4

1” USS Flat Washer 2 2

1/2” USS Washer 2 2

Spoll End for Roll Tube 1 1

1/4” Roll Pin 1 1

Roll Tarp Guide Roller 2 2

Tarp Rope Standard 2 0

Tarp Rope Leaner 0 2

Tarp Rope Bracket 4 4

26

Page 27

Repair Parts

1

21

20

2

7

8

6

5

4

3

11

12

10

19

18

17

16

# Description Part. No.

1 Pivot Pin, Raw 5-Spring (No Snap Ring) JM0022096

2 Screw, 1/2” x 5/8” Set Screw JM0022139

3 Terminal, D1R 8ga. Ring with 1/4” Ring JM0027586

4 Shrink Tube 3/8” x 1-1/2” Red JM0027584

5 Boot, Rubber for Motor JM0022132

6 Shrink Tube 3/8” x 1-1/2” Black JM0027588

7 Wire, Dual Conductor 8 Gage 43’ 1” JM0027587

8 Gear Motor, Super Duty Extreme JM0022098

9 Hardware Bag, Clevis Pins for Single Arm 5 Spring Ext Pivot Power Kit JM0022108

10 Nut, 1/2” - 13 Nylock JM0022149

11 Washer, 1/2” Flat Washer JM0022143

12 Pivot Pin, 3 spring knuckle pivot pin for SS arm No face Plate JM0022164

13 Bushing, Axle Stabilizer for 1.75” Axle Adapter JM0022100

14 Pivot Tube, Raw 26-1/4” Upper w/SD Mount ( No T- Bushings) JM0022103

15 Bushing, 1-1/4” Poly T- Bushing for Pivot Pin JM0022160

16 Plate, Knuckle Pin Plate w/o Pin (Double Ended, Al) JM0022163

17 Bolt, 1/2” x 1 1/2” Button Head Bolt JM0022140

18 Pivot Tube, Raw Base Tube for top Mount STS (31” tube) JM0022097

19 Pivot tube, Raw 5 spring Ext Pivot Tube Socket (30”- No T-bushings or hardware) JM0022102

20 Spring, Spiral Torsion Sp 1-1/4” JM0022161

21 Snap Ring, 1 1/4” External for Pivot Pin JM0022159

22 Arm Kit, Adjustable Arm for 142” -166” Grain Carts JM0022105

15

9

13

14

27

Page 28

Repair Parts

9

10

8

# Description Part. No.

1 12V to 12V Battery Charger JM0027090

2 Breaker, 35A Outdoor Manual Reset Circuit Breaker JM0022133

3 Electric Roll Tarp Key Fob JM0027061

4 Electric Roll Tarp Switch Mount JM0040671

5 RF Module JM0027059

6 Reversing Relay JM0022088

7 20 Amp Auto-Reset Breaker JM0022133

8 Wire, 8 Gage Jumper w 3/8” Ring Terminals 16” JM0027589

9 Wire 8 Gauge Jumper with 1-3/8” and 1-1/4” Terminal 16” JM0027590

10 Wire 8 Gauge Jumper with 1-3/8” and 1-1/4” Terminal 9” JM0027591

11 Wire 8 Gauge Jumper with 2-1/4” Terminal 9” JM0027592

11

28

Page 29

29

Loading...

Loading...