Page 1

Reliable, HigH PeRfoRmance PRoducts — excePtional seRvice

FEATURING: Precision Inclinometers

Jewell force-balanced (servo) Precision Inclinometers are extremely sensitive, rugged transducers designed

to provide horizontal angle or vertical deviation measurements with virtually innite resolution. Every Jewell

precision inclinometer responds to changes of slope as small as 0.1 second of arc, with a high-level DC output

signal proportional to the sine of the angle of tilt from as little as ±1° full range to ±90° full range.

Other Product Groups Available:

Force-Balanced Precision Accelerometer & Inclinometer

Rail Transportation Selector Guide

Force-Balanced Precision Accelerometer

Selector Guide

Electrolytic Tilt Sensors and Accessories

Selector Guide

Force-Balanced Precision Inclinometer

Selector Guide

Custom ApplicationSpecific Solutions

Jewell Instruments provides both

standard and custom solutions

for a diverse group of industries,

such as aerospace, medical,

industrial, telecommunications, and

rail markets. We manufacture our

components completely in-house

and work directly with our clients,

maintaining control over the entire

development processes. Our legacy

of experience and success, and

the expertise of our engineering

team, mean customers benet

from extensive resources at their

disposal.

Connecting Experience,

Quality & Expertise

For over 60 years, Jewell

Instruments has provided

commercial and industrial

sensors and controls, meters

and avionics, and industrial

test equipment solutions to a

range of global markets. Our ISO

9001:2008 certication ensures

that our customers receive

products and systems with the

dependability and reliability

that their applications demand.

Jewell Instruments’ experienced

engineering team works with

customers to produce high quality,

reliable products that meet or

exceed their requirements.

Exceptional

Customer Service

We specialize in reliability, value

and responsiveness. Cooperation

and joint planning between

our engineering groups and

our clients drive our customer

care experience. We work as

an extension of our customers’

engineering and manufacturing

teams to solve problems, improve

applications, shorten leadtimes and bring more value to

their products and services.

Superb customer support is

the cornerstone of our many

successful, long-term customer

relationships.

Rail Transportation

Selector Guide

Force-Balanced Precision

Acceleromter Selector

Guide

Jewell Instruments is a world leader in the manufacture and

distribution of panel meters, avionics components, inertial

sensors, and precision solenoids. From sales and design,

manufacturing and testing, and delivery and support, Jewell

Instruments offers complete customer care and engineering

expertise. We also offer two, fully modernized manufacturing

facilities, one in Manchester, New Hampshire and one in

Barbados, West Indies to handle the most stringent manufacturing

requirements with a cost-competitive advantage.

Electrolytic Tilt Sensors

and Accessories Selector

Guide

Jewell Facilities

Jewell offers two, fully modernized

manufacturing facilities, one in

Manchester, New Hampshire and

one in Barbados, West Indies.

Manchester Facility

Barbados Facility

Distributed By:

www.jewellinstruments.com

© 2013 Jewell Instruments LLC | 850 Perimeter Road | Manchester, NH 03103 | 603-669-6400

Page 2

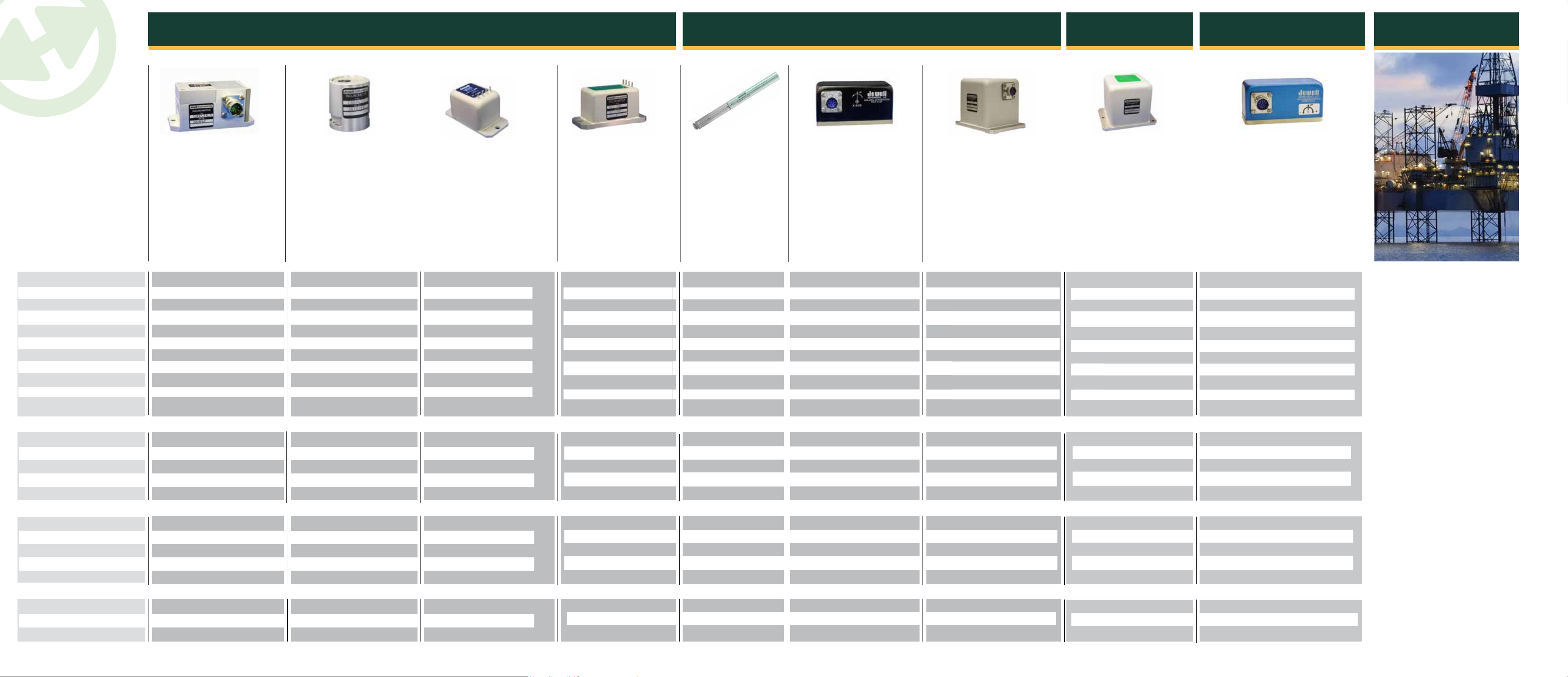

Single Axis Inclinometers

Dual Axis Inclinometers

Triple Axis

Inclinometers

Digital

Inclinometers

Custom

Applications

Features & Benets

Applications

LSO Series

• Extreme High Resolution

• Vibration >35grms

• Responds to changes in Slope

0.000006”/ft

• High Accuracy Closed-loop (Servo)

• 1,500g Shock Capability

• Steel Processing & Casting

• Heavy Off-road Contruction

• Structural Monitoring

• Train Automated Controls

• Rail Leveling & Grinding

LSR Series

• ± 1° to ± 90° Input Full Range

• 1.43” Dia x 1.60” Tall Size

• Withstands 20 grms Vibration

• Stackable for 2-axis Sensing

• Solder Pins Terminations

• Steel Mill Ladle Position

• Oil & Gas Well Bore Mapping

• Weapons Platform leveling

• Geophysical Monitoring

• Mobile Antenna Positioning

LCI Series

• Std 5 Hz Bandwidth Cutoff

• <100 dB Signal to Noise

• Resolves Angles > 1mrad

• > 100 ppm/°C Temp Sens

• -55°C to +85°C Temp Range

• Laboratory Testing

• Telescope Vert Ref Cal

• Vehicle Wheel Align

• Educational Research

• Moment Detection Sys

4

LCF-100 Series

• Direct Bogie Mount

• Filtering Available 5-50 Hz

Bandwidth

• Milli-g Bias & Scale Factor

• High level ±5Vdc Output

• -40°C to +80°C Temp Range

• Aircraft Flight Control

• Robot Vertical Reference

• Auto Mfging Suspension Install

• Geophysical Low Range Tilt

Testing

• Platform Orientation

LCF-196 Series

• Less > 0.02% Non-linearity

• Bias Temp Sens >50µg/°C

• Only 0.875” Dia Housing

• IP65 Sealed Housing

• 500g Shock Capability

• Strg Motion Data Logging

• Oil & Gas Well Logging

• Construction Monitoring

• Deviation Studies

• Test Platform Orientation

LCF-2330 Series

• ±1° to ±90° Input Full Range

• Micro Radian Resolution

• Available Internal Temp Sensor

• High level ± 5Vdc Output

• Low Impedance Output

• Fluid Damped

• 2-Axis Machine Tool Leveling

• Bridge Structural Monitoring

• Submersible Control Feedback

• Offshore Platform Stability

• Antenna Leveling & Orientation

Performance Specs

Input Range (°): ±1.0 ±3.0 ±14.5 ±30.0 ±90.0 ±1.0 ±3.0 ±14.5 ±30.0 ±90.0 ±3.0 ±14.5 ±30.0 ±90.0

1

Full Range Output (FRO V± 1.0%

2

Non Linearity (%FRO

Scale Factor (V/g, Nom), %: 286.5 95.5 20.0 10.0 5.0 286.5 95.5 20.0 10.0 5.0 95.5 20.0 10.0 5.0

Scale Factor Temp Sens (PPM, %/°C, Max.): 400 300 100 60 60 400 300 100 60 60 100 100 100 100

Natural Frequency (Hz, Nom.

Bandwidth (-3db) (Hz, Nom.): 0.5 2.0 15.0 20.0 40.0 0.5 2.0 15.0 20.0 40.0 5.0 5.0 5.0 5.0

Input-Axis Misalignment (° Max.): 0.10 0.15 0.25 0.50 1.00 0.10 0.15 0.25 0.50 1.00 0.10 0.35 0.70 0.70

Output @ 0° Tilt (Bias) (V, Max), %/°C, m°/°C:

0° Output Temp Sensitivity (V/°C, Max.): .005 .003 .001 .0005 .0003 .005 .003 .001 .0005 .0003 .0048 .0003 .0003 .0003

Resolution and Threshold (µrad,°, Max.): 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

, Max.): 0.05 0.05 0.02 0.02 0.05 0.05 0.05 0.02 0.02 0.05 0.05 0.02 0.02 0.05

): ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0

3

): 0.5 2.0 15.0 20.0 40.0 0.5 2.0 15.0 20.0 40.0 5.0 5.0 5.0 5.0

0.10 0.04 0.02 0.02 0.02 0.10 0.04 0.02 0.02 0.02 0.10 0.05 0.05 0.025

±1.0 ±14.5 ±30.0 ±90.0 ±14.5 ±30.0 ±90.0 ±1.0 ±3.0 ±14.5 ±30.0 ±90.0 ±1.0 ±3.0 ±14.5 ±30.0 ±90.0

±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0 ±5.0

0.05 0.02 0.02 0.05 0.02 0.02 0.10 0.05 0.05 0.02 0.02 0.02 0.05 0.05 0.02 0.02 0.10

286.5 20.0 10.0 5.0 20.0 10.0 5.0 286.5 95.5 20.0 10.0 5.0 286.5 95.5 20.0 10.0 5.0

100 100 100 100 100 100 100 300 300 100 60 100 200 100 100 100 100

3.0 30.0 30.0 30.0 30.0 30.0 30.0 2.0 3.0 30.0 30.0 30.0 3.0 3.0 30.0 30.0 30.0

3.0 30.0 30.0 30.0 30.0 30.0 30.0 2.0 3.0 30.0 30.0 30.0 3.0 3.0 30.0 30.0 30.0

0.15 0.34 0.71 0.71 1.00 1.00 1.00 0.25 0.50 0.50 1.00 1.00 0.25 0.35 0.35 0.71 0.71

0.500 0.100 0.100 0.050 0.040 0.020 0.020 0.1 0.04 0.02 0.02 0.02 0.750 0.250 0.075 0.050 0.050

.015 .001 .0005 .0003 .0010 .0005 .0003 .0150 .0050 .001 .0005 .0003 .0150 .005 .0 010 .0005 .0003

1.0 1.0 1.0 1.0 3.0 3.0 3.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Electrical

Number of Axis 1 1 1

Input Voltage (Vdc) ±12 to ±18 ±12 to ±18 ±12 to ±18

Input Current (mA, Nom.) ±15 ±15 ±25

Output Impedance (Ohms, Nom.) 100 15000 100

Noise (Vms, Max.) 0.0020 0.0020 0.0005

1 2 2 2

±12 to ±18 ±12 to ±19 ±12 to ±18 ±12 to ±18

±15 ±15 ±30 ±30

100 100 100 100

0.0020 0.002 0.001 0.001 0.0020 0.0020

Environmental

Operating Temperature Range -18°C to +71°C -18°C to +71°C -55°C to +85°C

Survival Temperature Range -40°C to +71°C -60°C to +90°C -60°C to +90°C

Vibration 20 g 20 g

Shock 1500g, 0.5 msec, 1/2 sine 1500g, 0.5 msec, 1/2 sine 3 Foot Drop

Seal MIL-STD-202, Method 112 MIL-STD-202, Method 112 MIL-STD-202, Method 112

-40°C to +80°C -40°C to +80°C -40°C to +80°C -40°C to +80°C

-60°C to +90°C -60°C to +90°C -60°C to +90°C -40°C to +90°C

20 g 10 g 20 g 20 g

1000g, 1 msec, 1/2 sine 500g, 1 msec, 1/2 sine 1000g, 1 msec, 1/2 sine 1000g, 0.001 msec, 1/2 sine

MIL-STD-202, Method 112 MIL-STD-202, Method 112 MIL-STD-202, Method 112 MIL-STD-202, Method 112

Mechanical

Weight 13.0 oz. 4.0 oz. 4.0 oz.

Dimensions 1.60" W x 2.94” L x 1.70" H 1.43" Dia. x 1.60" H 1.50" W x 3.10” L x 1.50" H

Custom Ability Yes No Yes

Notes: 1 - Full range is dened as “from negative full input angle to positive full input angle.” The inclinometer ouput is proportional to the sine of the tilt angle., 2 - Referenced to theoretical sine value independent of misalignment., 3 - Output phase angle = -90° 4 - Other ranges available upon request

1.50" W x 3.10” L x 1.50" H 0.875" Dia x 9.420" Lg. Tube 1.61" W x 3.609" L x 1.83" H 2.88" W x 3.75" L x 2.75" H

4.0 oz. 11 oz. 8.0 oz. 16 oz.

Yes Yes Yes Yes

LCF-2000 Series

• ±1° to ±90° Input Full Range

• Dual Axis

• Shock Survival of 1000g

• High level ± 5Vdc Output

• Fluid Damped for High Shock

and Vibration Applications

• Antenna Leveling

• Weapons Platforms

• Barge & Offshore Platform

Leveling & Control

• Data Buoy Measurement

• Missile Launchers

LCF-3000 Series

• ±1° to ±90° Input Full Range

• Tri-axis Applications

• Micro Radian Resolution

• High level ± 5Vdc Output

• Low Impedance Output

• Fluid Damped

• 3-Axis Machine Tool Leveling

• Bridge Structural Monitoring

• Antenna Leveling & Orientation

• Platform Orientation

• Geophysical Low Range Tilt Testing

±3.0 ±14.5 ±30.0 ±90.0 ±1.0 ±3.0 ±14.5 ±30.0 ±60.0

±5.0 ±5.0 ±5.0 ±5.0 ±0.25 ±0.50 ±.87 ±1.00 ±2.00

0.02 0.02 0.02 0.10 0.02 0.015 0.02 0.02 0.03

95.54 20.0 10.0 5.0 0.05 0.05 0.05 0.05 0.05

100 100 100 100 0.01 0.01 0.01 0.01 0.01

3.0 30.0 30.0 30.0 - - - - -

3.0 30.0 30.0 30.0 3.0 6.0 30.0 30.0 30.0

0.50 0.50 1.00 1.00 30.0 30.0 30.0 30.0 30.0

0.25 0.075 0.050 0.050 0.01 0.01 0.05 0.05 0.05

.005 .001 .0005 .0003 5.0 5.0 5.0 5.0 5.0

1.0 1.0 1.0 1.0 .001 .001 .001 .001 .001

3 1 or 2

±12 to ±18 ±10 to ±30

±30 DXI-100 ±80 mA/DXI-200 ±100 mA

100 -

0.0020 0.005

-40°C to +80°C -40°C to +70°C

-40°C to +90°C -40°C to +70°C

20 g 20 g

1000g, 1msec, 1/2 sine 1500g, 1msec, 1/2 sine

MIL-STD-202, Mtd 112 MIL-STD-202, Mtd 112

16.0 oz. DXI-100 8.0 oz./DXI-200 10.0 oz.

2.88" W x 3.75" L x 2.75" H 1.62" W x 3.609" L x 1.83" H

Yes Yes

• Digital Output

• Resolution 8 µg

• Mechanical Shock 1500g 1msec ½ sine

• Industry Standard RS485 & RS422 Outputs

• High Precision and Performance

• Low Noise

• Radar/Antenna Control

• Structural Monitoring

• Linear Acceleration/Deceleration Measuring

• Automatic Train Position Control

• Seismic Monitoring

• Track Leveling

DXI-100/200 Series

THE JEWELL INSTRUMENTS ENGINEERING

TEAM PROVIDES THE FOLLOWING:

• Modifying or customizing an existing designed model series

• A new part number congured from existing

model series part and subassemblies

• A new application-specic custom design

requiring special features and specications

• Customized sensor for harsh environments

• A rst-time design solution requiring close

interaction between Jewell’s design engineering team and customer’s engineering team

• Design qualications to industrial, military,

and aerospace standards including FAA

DO-160

• Sensors designed to meet EMC requirements including lightning

• A customer proprietary sensors solution requiring non-disclosure agreement (NDA) between Jewell Instruments and our customer

CUSTOM CAPABILITIES

• 4-20mA Output signal with single-ended

24 Vac Input

• Internal temperature sensor and thermal

modeling for the highest levels of accuracy over a wide temperature range

• Factory set zero biasing for non-horizontal

measurements

• Solder terminals and ying leads in place

of circular connector

• Custom inclinometer input ranges from

+/-0.5 to +/-90.0 degrees available

• Custom accelerometer input ranges from

+/- 0.017g to +/- 20.000g available

• Custom output impedance available

• Custom ltering to provide a bandwidth

and response tailored to the application

• Custom mounting plates and mechanical

assemblies

Inclinometer Selector Guide

Loading...

Loading...