Page 1

B-03-1006, Rev. K

Model D700 Digital Floor Mount Tiltmeter

850 Perimeter Road

Manchester, NH 03103 USA

Tel (603) 669-6400

Fax (603) 622-2690

sales@jewellinstruments.com

www.jewellinstruments.com

Copyright ©2018 by Jewell Instruments LLC. All rights reserved.

Page 2

B-03-1006, Rev. K

TABLE OF CONTENTS

1.0 Introduction ........................................................................................................................................... 1

2.0 Technical Highlights ............................................................................................................................. 3

3.0 Specifications ......................................................................................................................................... 3

4.0 Digital Output Features and Wiring ................................................................................................... 4

4.1 RS232 Output ...................................................................................................................................................... 4

4.2 RS485 (RS422) Output ........................................................................................................................................ 4

4.3 Using the Test Cable ................................................................................................................................ ........... 4

5.0 Installation ............................................................................................................................................. 4

5.1 Initial Check-Out Procedures ............................................................................................................................. 4

5.2 Installing Your Tiltmeter ................................................................................................................................... 10

6.0 Grounding and Transient Protection ................................................................................................ 10

7.0 Communicating with the Model D711 Tiltmeter ............................................................................. 11

7.1 Basic Requirements and Settings ...................................................................................................................... 11

7.2 Firmware Command Format ............................................................................................................................ 11

7.3 Firmware Command Summary ......................................................................................................................... 12

7.4 Sample Data Using the XY Command ............................................................................................................... 13

7.5 Recording Data in Internal Memory or on a PC; Data File Sizes .................................................................... 15

7.6 Switching between RS232 and RS485 (RS422) Output ..................................................................................... 15

8.0 Maintenance and Troubleshooting .................................................................................................... 15

8.1 Routine Maintenance ........................................................................................................................................ 15

8.2 Determining the Cause of Malfunctions ............................................................................................................ 16

Appendix A: Custom Specifications for Your Digital Tiltmeter ........................................................... 18

1.0 RS232 Wiring and Connector Table ................................................................................................................. 18

2.0 RS485 (RS422) Wiring and Connector Table ................................................................................................... 19

Appendix B: Guidelines for Installing Surface Mount Tiltmeters ........................................................ 20

Appendix C: Firmware Commands ......................................................................................................... 21

Appendix E: Warranty and Limitation of Liability .......................................................................... 35

Appendix F: Revision Record ............................................................................................................. 36

Page 3

B-03-1006, Rev. K

TABLE OF FIGURES

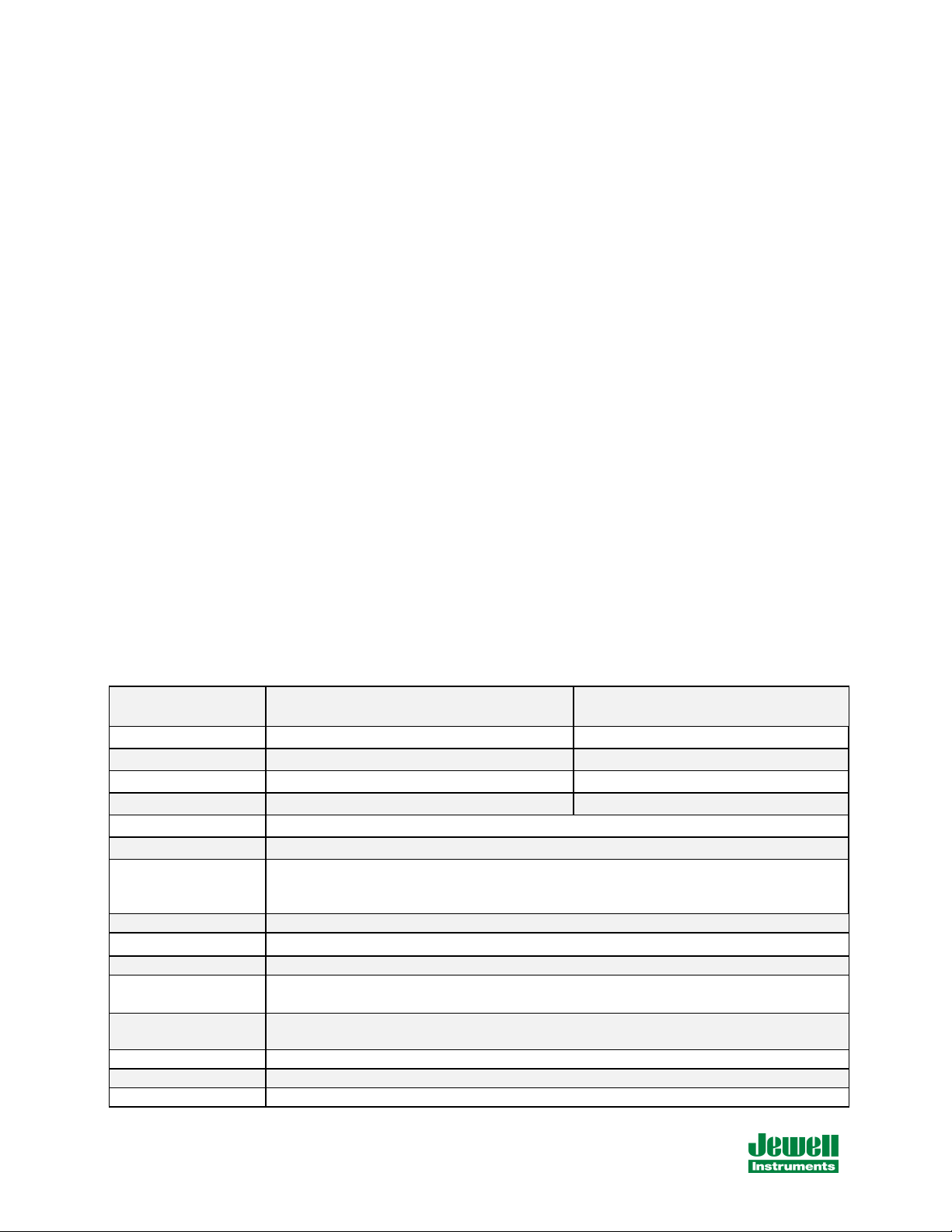

Figure 1: Model D711 Digital Floor Mount Tiltmeter (Biaxial) ............................................................. 1

Figure 2: Tiltmeter Dimensions ............................................................................................................... 2

Figure 3: Floor Mount Tiltmeter Sign Convention .................................................................................. 6

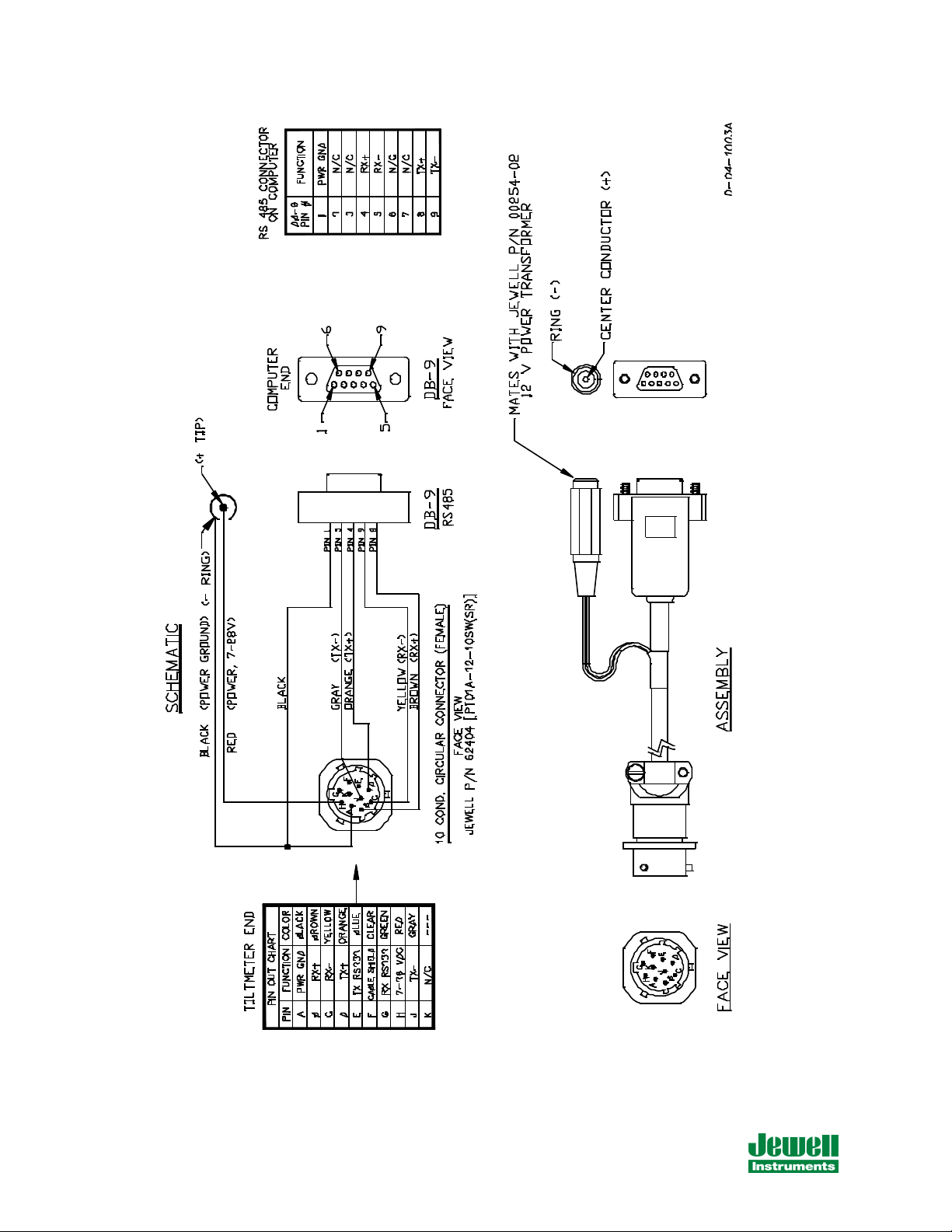

Figure 4: Model D711 Tiltmeter Cable Wiring ....................................................................................... 7

Figure 5: RS232 Test Cable (Part No. 89063) for Use with Model D711 Tiltmeter ............................... 8

Figure 6: RS485 (RS422) Test Cable (Par No. 89062) for Use with Model D711 Tiltmeter ................. 9

Figure 7: Layout of the IRIS Printed Circuit Assembly inside the Tiltmeter

Showing Connector Locations ............................................................................................... 17

Figure A1: Face View of Female DB9 Connector with Pin Assignments ............................................... 19

Figure B1: Installing Model D7ll Digital Floor Mount Tiltmeter ............................................................ 20

Page 4

B-03-1006, Rev. K 1

1.0 Introduction

The D711 is a precision biaxial digital tiltmeter packaged in a weatherproof housing (Figure 1). It was

formerly called the D711-2(4X). The high-gain version, Model D711-A, has the greatest sensitivity and an

angular range of ±0.5 degree. The mid-range version, Model D711-B, has a much greater angular range

(±5 degrees), but is less sensitive. Specifications for each version are in Section 3. Some typical

applications include precise alignment of telescopes, antennae, and air frames; monitoring of structures

and foundations; monitoring of volcanoes, and all jobs that call for precision measurements under

demanding operating conditions.

The Tiltmeter is available with either RS232 or RS485 digital output. RS232 is typically limited to

cable lengths less than 15 meters (49.2 feet). The RS485 output of the Tiltmeter, which is functionally

equivalent to RS422 output, can drive cable lengths greater than 1000 meter (3,231 feet). Your Tiltmeter

was shipped with the output protocol shown on the title page, and in Appendix A. To switch between

RS232 and RS485, refer to section 7.6 . RS485 multi-drop networks are not currently supported.

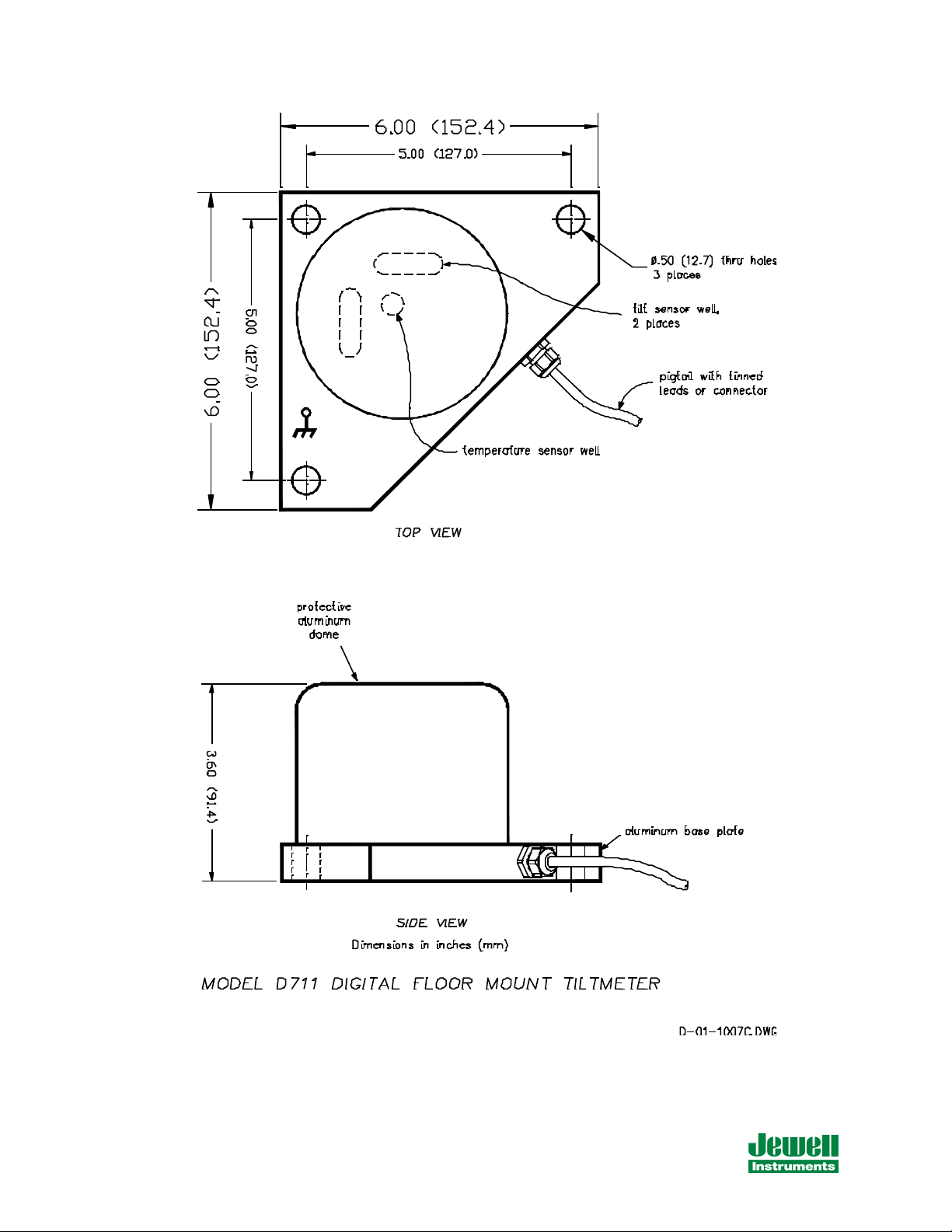

Model D711 bolts or clamps to any surface and can be used in areas of heavy traffic or vibration. The

12.7-mm (0.5-inch) holes in its three corners (Figure 2) fit over threaded stainless steel studs, provided

with each order. The tiltmeter is double-nutted to the studs after they are anchored in the mounting surface

(Appendix B).

In addition to this user's manual, the following accessories were shipped with your Tiltmeter. Please

verify that all are present:

Quantity

Test Cable (RS232 or RS485 Output, P/N 89063 or 89062) 1

Universal Power Transformer for 110 or 220 VAC (P/N 00254-02) 1

Mounting Stud Assembly (P/N 84410) 1

Mating 10-Socket Female Connector (P/N 62401) 1

Acrylic Bubble Level (P/N 00299) 1

Figure 1: Model D711 Digital Floor Mount Tiltmeter (Biaxial)

Page 5

B-03-1006, Rev. K 2

Figure 2: Tiltmeter Dimensions

Page 6

B-03-1006, Rev. K 3

2.0 Technical Highlights

Model D711 includes the following important features:

• Tilt angle is measured with an electrolytic sensor, similar to a spirit level.

• All electronics reside on a single internal printed-circuit board.

• All resistors are premium quality, 1% tolerance, metal-film type.

• The tiltmeter comes with a powerful set of user-selectable firmware commands.

• All tiltmeters are hand-assembled, calibrated, and tested at our plant under stringent quality

control standards.

• Jewell maintains complete specifications and test records of every tiltmeter built.

Your tiltmeter contains two electrolytic level sensors (one for each tilt axis) that produce changes in

resistance in response to a rotation of the sensor. A voltage divider network senses the resistance change.

The electronics then sample and convert the sensor outputs into tilt angles using factory calibration data

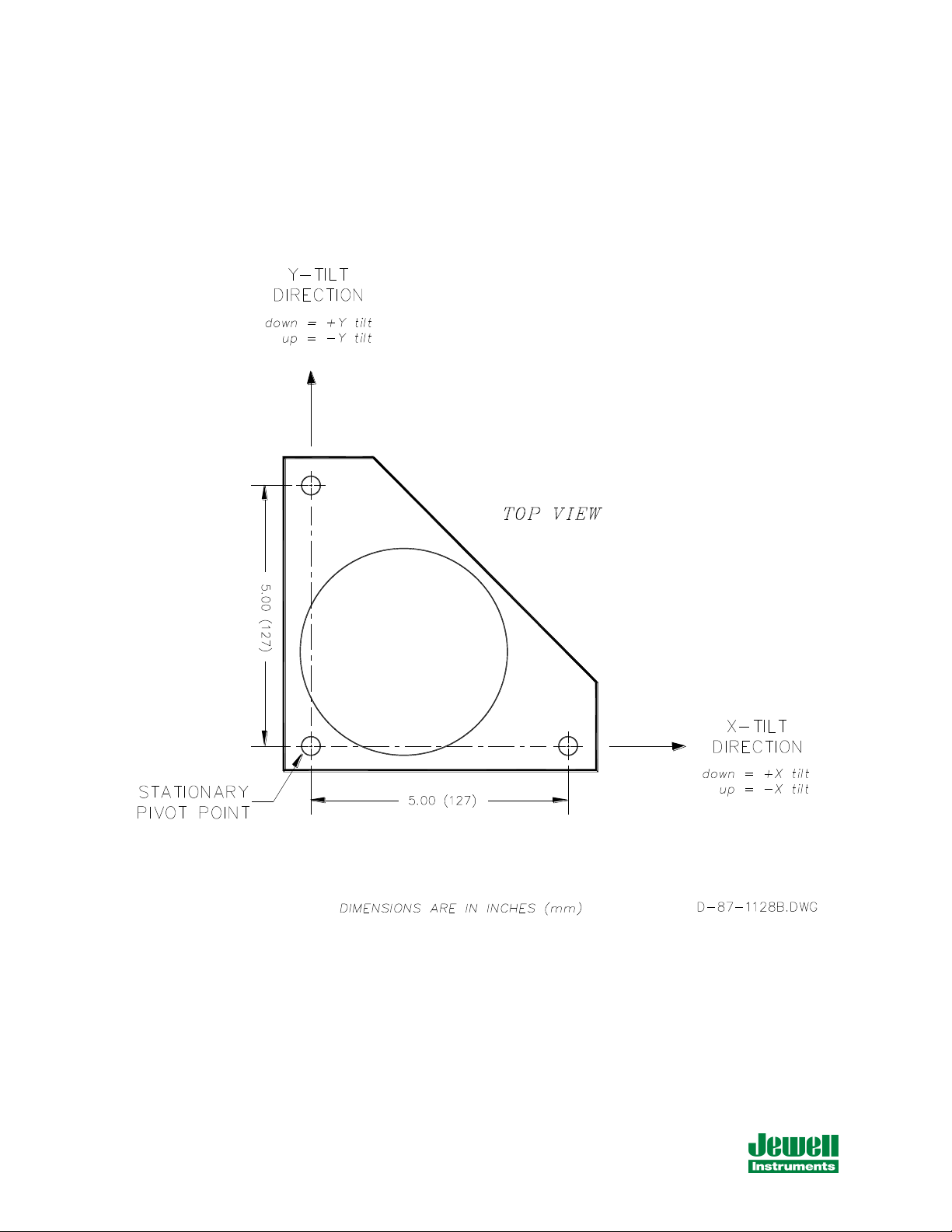

stored in nonvolatile memory. The sensors in your tiltmeter measure tilts in two orthogonal vertical planes,

X and Y (Figure 3). The vector sum of the outputs of both channels yields the direction and magnitude of

rotation with reference to the vertical gravity vector. Please contact us should you require technical

assistance when you process your tiltmeter measurements.

3.0 Specifications

General specifications are listed below. Appendix A contains custom specifications for your equipment.

Model D711-A

High-Gain Version

Model D711-B

Mid-Range Version

ANGULAR RANGE

±0.5 degree*

±5 degrees

RESOLUTION

1 radian

10 radians

REPEATABILITY

< 4 radians (static)

10 radians (static)

LINEARITY

0.4% of full span

0.1% of full span

TIME CONSTANT

0.15 second

TEMPERATURE COEF.

Zero, Kz = ±3.5 µradians/°C typical; Span, Ks = 0.02%/°C typical

DIGITAL OUTPUT

Two orthogonal tilt angles plus one temperature; RS232 or RS485 (RS422), transmit and receive

Baud rate: 9600 (default), 19200, 28800, 57600, 115200, 230400

Formats: NMEA XDR, Trimble proprietary, Ashtech compatible, Simple (x, y, temperature, serial no.)

OUTPUT DATA RATE

User-selectable from 10 samples/second to 1 sample/24 hours

RS485 TERMINATION

Cable length 12m: No termination resistors; Cable length > 12m: 100-130 termination resistors

POWER REQ'TS

7 to 28 VDC @ 27 mA, 250 mV peak-to-peak ripple maximum, reverse polarity protected

ENVIRONMENTAL

−25° to +70° C operation, −30° to +100° C storage. Rated NEMA 4X (IP65) for continuous operation

at 100% humidity. Withstands exposure to rainfall and spray. Not submersible.

MOUNTING

Three 0.5-inch (12.7 mm) mounting holes.

Tiltmeter fastens to stainless steel mounting studs (included).

MATERIALS

Anodized and painted aluminum

CABLE

10 ft (3m) multiconductor cable + overall shield, PVC jacket, connectors included

SIZE & WEIGHT

6 x 6 x 4 inches (152 x 152 x 102 mm), 3 lbs. (1.4 kg)

* 1 degree = 3600 arc seconds = 17453 radians (microradians)

Page 7

B-03-1006, Rev. K 4

4.0 Digital Output Features and Wiring

Your tiltmeter was set at the factory to have either RS232 or RS485 (RS4252) digital output. The

setting for your tiltmeter is indicated on the title page and in appendix A. Firmware commands are

summarized in Section 7 and in Appendix C.

4.1 RS232 Output

RS232 output is designed for signal transmission over cable lengths less that approximately 15

meters. Figure 4 and Appendix A list the RS232 pin assignments in the tiltmeter cable. Figure 5 shows the

wiring of the RS232 test cable.

4.2 RS485 (RS422) Output

RS485 and RS422 outputs are designed for signal transmission over long cables. These two output

protocols are equivalent in the Model D711 and will drive cables longer than 1,000 meters. Each tiltmeter

with RS485 (RS422) output requires its own serial port. It is not currently possible to operate a series of

tiltmeters in "multidrop" fashion on a single 4-wire cable. Figure 4 and Appendix A show the wiring and

pin assignments for RS485 (RS422) output. Figure 6 shows the wiring of the RS485 test cable. Wiring of

the DB9 connector at one end of the test cable corresponds to the National Instruments 8-port RS485 card

for the PCI databus, part no. 777641-08 (2004).

When cable length exceeds 12 meters, we recommend that termination resistors be used at the ends

of the transmit, and receive lines to dampen possible reflections and maintain good signal quality.

Recommended resistor values are between 100 and 130 Ohms. Connect one resistor between the

computer's Rx+ and Rx- inputs (same as the tiltmeters Tx+ and Tx- wires), at the computer end of the

cable. Similarly, connect one resistor between the tiltmeter's Rx+ and RX- inputs at the tiltmeter end of the

cable. Refer to Figure 6 for pin numbering.

4.3 Using the Test Cable

The test cable shipped with your tiltmeter is wired for the same output protocol as your tiltmeter.

The RS232 test cable is designed to connect the tiltmeter to the RS232 serial port of a personal computer.

The RS485 (RS422) test cable is designed to connect the tiltmeter to an RS485 (RS422) serial port.

Typically, this port will be on an expansion card or PCMCIA card in the computer.

The test cable includes a power jack (connector) that mates with the output jack of the power

transformer shipped with the tiltmeter. When the transformer is plugged into a 110 or 220 VAC wall

socket, it supplies 12 Volts DC to the tiltmeter. The standard transformer shipped with the tiltmeter accepts

100 to 240 Volts AC at 50-60 Hz. For safe operation, read the power rating printed on the transformer

and verify that it conforms to your wall socket power before use!

5.0 Installation

5.1 Initial Check-Out Procedures

Before installing your tiltmeter, verify that it is functioning properly by following the steps below.

Refer to the firmware command summary in Section 7.3.

Page 8

B-03-1006, Rev. K 5

Using HyperTerminal (Windows 95 and later)

1. Apply power and attach the tiltmeter to a PC according to wire color and pin assignment code in

Appendix A. Or, use the test cable (Figure 5 or 6) and power transformer supplied with your

tiltmeter.

2. Open HyperTerminal, selecting the proper COM port and baud rate (the default baud rate for your

tiltmeter is 9600).

3. Type the command “*9900XYC0” without typing the quotation marks (note that the tiltmeter is

case sensitive).

4. If properly attached, the tiltmeter will now start outputting data through the serial port at a rate of

10 readings per second, and the data will be displayed in HyperTerminal.

5. Tilt the unit in the +X and then the +Y direction (Figure 3). Next tilt it in the –X and –Y

directions. Verify that the tilt values move through the full angular range (Section 3), and that the

sign (polarity) of the output changes on opposite sides of null.

6. Type the command “*9900XYC-OFF” without typing the quotation marks to stop the output.

7. Your Model D711 tiltmeter is now ready for installation.

Page 9

B-03-1006, Rev. K 6

Figure 3: Floor Mount Tiltmeter Sign Convention

Page 10

B-03-1006, Rev. K 7

Figure 4: Model D711 Tiltmeter Cable Wiring

Page 11

B-03-1006, Rev. K 8

Figure 5: RS232 Test Cable (Part No. 89063) for Use with Model D711 Tiltmeter

Page 12

B-03-1006, Rev. K 9

Figure 6: RS485 (RS422) Test Cable (Part No. 89062) for Use with Model D711 Tiltmeter

Page 13

B-03-1006, Rev. K 10

5.2 Installing Your Tiltmeter

Jewell Instruments Model D711 tiltmeters are designed to be mounted on bolts or studs that are

threaded, anchored or cemented into a solid surface (see Appendix B for details). The bolts should be 1/4"

to 3/8" (6 to 9 mm) in diameter, and extend at least 2" (5.1 cm) above the surface to which the tiltmeter is

to be mounted.

First, thread a nut onto each stud, positioning it close to the surface. Place a flat washer above each

nut. Then place the tiltmeter over the studs followed by another washer, and finally another nut threaded

on top of each stud. Then use a small bull's-eye or carpenter's level to roughly level the tiltmeter.

Perform the final leveling by connecting the tiltmeter to a PC. Use HyperTerminal program

included with Microsoft Windows to view the tiltmeter readout (or equivalent serial communication

program). Adjust the mounting nuts slowly in sequence (Figure 3) while observing the output to level the

tiltmeter. If using HyperTerminal, refer to the firmware commands in Section 7 and Appendix C. It is

generally a good idea to install the tiltmeter at the middle of its sensing rage, i.e., with the output leveled

(nulled) on both channels, so that you will have the maximum dynamic range available for subsequent

readings.

6.0 Grounding and Transient Protection

Your tiltmeter has an earth ground circuit that provides protection from high-voltage transients

(surges) caused by nearby lightning strikes, unstable power supplies, and other sources. High-voltage

transients are the most common cause of failure of electronic field instruments. In a typical occurrence, a

induced transient from a lightning strike travels along the cable until it encounters the instrument’s

electronic circuitry, where the delicate, low-voltage components are overloaded and fail. To help avoid

such an occurrence, each tiltmeter input and output circuit is connected to the tiltmeter base plate through

variable-resistance type surge absorbers (transzorbs). The transzorbs normally have extremely high

resistance. They change to low-resistance conductors when the side connected to the tiltmeter circuitry

senses a high voltage, which is then shorted to the metal base plate. To activate this surge protection, you

must connect the tiltmeter base plate to earth (e.g. a water pipe or grounding rod) using the earth ground

screw location shown in Figure 2.

Transient protection and noise reduction can also be enhanced by earthing the cable shield (drain

wire) at one end only. Note that the tiltmeter cable shield is not connected to the tiltmeter case or to the

circuitry inside the tiltmeter (Figure 4).

The transzorbs in the tiltmeter provide a good, basic level of protection, but will not prevent damage

under all conditions. If you plan to operate your tiltmeter in an area with frequent lightning storms we

recommend keeping the instrument cable as short as possible. If long cables cannot be avoided, consider

adding a commercial lightning protection circuit at one or both ends of your cable. A good source of

transient protection products is the Citel company (http://www.citelprotection .com).

Page 14

B-03-1006, Rev. K 11

7.0 Communicating with the Model D711 Tiltmeter

7.1 Basic Requirements and Settings

You may communicate with the Model D711 tiltmeter using:

1. A terminal emulator program (e.g. Terminal in Windows 3.1, or HyperTerminal in Windows 95 and

later); or

2. A GPS receiver that is capable of sending and receiving terminal commands.

All communication to the tiltmeter is performed through the send (transmit), and receive wires of the

serial port. The default parameters for the serial port are set to no parity, 8 bits, and 1 stop bit with no

hardware or software flow control. The baud rate is the only parameter that is user-selectable. The default

baud rate is 9600. Baud rates up to 230400 are supported.

7.2 Firmware Command Format

The format of commands issued by the host is:

*9900<command><CR><LF>

Valid commands are summarized in Section 7.3 and described in detail in Appendix C.

The input/output processing on the serial port of the D711is as follows:

(1) Input is read until a <CR> or <LF> (carriage return or line feed) is received. (On a PC, this usually

means pressing the 'Enter or 'Return' key).

(2) When a line is received, it is parsed to see if it is a command of the device. If it is not, then it is echoed

back out, terminated with a <CR> <LF> and we go back to step (1). All strings that are not commands

for the unit are echoed. If the command is for the device, we then go to step (3).

(3) The command is processed and we return to step (1). All incoming characters are buffered (up to 1000)

while the command is being processed. If the command is for ID 99 and echoing of 99 commands is

enabled, the command is echoed after the command result is transmitted.

Default output of the D711 tiltmeter running firmware version 5 and above is a simple ("SIM") commadelimited string consisting of X tilt in degrees or microradians, Y tilt in degrees or microradians, temperature

in C, and the serial number of the device. Optional outputs consist of a Trimble Navigation proprietary

ASCII string with X (Roll) and Y (Pitch) tilts in degrees, and two output formats that follow NMEA Standard

0183, version 2.1, October 15, 1995. This standard may be obtained from:

National Marine Electronics Association (NMEA)

National Office

P.O. Box 3435

New Bern, NC 28564-3435 USA

Tel: 919/638-2626

Fax: 919/638-4885

Page 15

B-03-1006, Rev. K 12

7.3 Firmware Command Summary

The list below summarizes the most important user-accessible firmware commands. Precede these commands

with the string*9900. See Appendix C for additional details.

XY Outputs a single tilt and temperature measurement. The format of the output

depends on the setting of the SO command.

SO-xxx Selects the output format for the XY command. “xxx” selects format as follows:

ASH: Ashtech compatible NMEA format

SIM: Simple x,y,t,sn output string (default)

XDR: NMEA XDR format

TCM: Trimble Navigation proprietary pitch (Y) and roll (X) string

BAE: BAE Systems encoded 11-byte string containing a sync packet,

x, y, t, SN, and checksum information. Advanced users only—

typically for embedded system integration.

XY-MEMS Stores tiltmeter readings at selected output rate in nonvolatile memory.

(Versions 5.1 and higher)

XY-MEMD Downloads data from nonvolatile memory. (Versions 5.1 and higher)

XY-M1 Sets the tilt meter to Mode-1 operation.

XYVR Displays the sign-on string.

ID Sets the ID of units in the daisy chain.

XY-TR-PASH-ON Translates the Paros provided $PASHS,XDR,P sentences to standard

NMEA XDR format.

XY-TR-PASH-OFF Turns off translation of $PASHS,XDR,P sentences.

XY-EP Enables power on message.

XY-SP Disables power on message.

EE Enables echoing of global 99 commands.

SE Disables echoing of global 99 commands.

XY-SET-BAUDRATE,x Sets baud rate to value of x in bits per second. Selectable values include

9600, 19200, 28800, 57600,115200 and 230400 baud.

XY-SET-N-SAMP,,x Sets number of samples that are averaged before a reading is transmitted;

x may have any value from 1 to 1000. Changing this value may also change

the output rate.

Page 16

B-03-1006, Rev. K 13

XY-SET-RSMODE,x Selects serial output mode:

x = 0 RS232

x = 1: RS485 (RS422)

XY-AUTOZ Turns on auto zero function.

XY-AUTOZOFF Turns off auto zero function.

XYCx Continuously sends XY data where x determines output rate as follows:

x = 0 8-10 outputs per second

x = 1: 4 outputs per second.

x = 2: 1 output per second (default).

x = 3: 1 output every 10 seconds.

x = 4: 1 output every 60 seconds.

x = 5: 1 output every hour

x = 6: 1 output every 12 hours

x = 7: 1 output every 24 hours

x = 0A: Averaging of the 8-10 outputs per second data

x = 1A: Averaging of the 4 outputs per second data

x = 2A or x = A: Averaging of the 1 output per second data

Once initiated, continuous output remains in effect until turned off with the

XYC-OFF command (see below).

XYC-OFF Turns off XYC mode.

XY-DUMP-SETTINGS Dumps settings of device.

XY-DUMP2 Dumps extended settings of device.

7.4 Sample Data Using the XY Command

The most commonly used command is the XY command, which returns the X and Y tilt angles in

degrees or microradians, and the internal temperature of the tiltmeter in ºC. The format of the returned

data depends on the setting of the SO command. The returned data are averages of a series of readings.

The number of samples used in the average is set by the XY-SET-N-SAMP command. The following

lines illustrate the format of the data returned by the XY command for the range of possible SO settings:

SO = “ASH.” Ashtech compatible NMEA output string which returns the North-South (Y) and East-West

(X) tilt angle in degrees or microradians and the internal temperature of the tiltmeter in ºC:

$PASHS,XDR,A,004.261,D,N,A,004.280,D,E,C,021.288,C,T-N1346

$PASHS,XDR,A,004.261,D,N,A,004.280,D,E,C,021.306,C,T-N1346

$PASHS,XDR,A,004.261,D,N,A,004.280,D,E,C,021.298,C,T-N1346

$PASHS,XDR,A,004.261,D,N,A,004.280,D,E,C,021.332,C,T-N1346

Page 17

B-03-1006, Rev. K 14

SO = “SIM” (default). Simple X,Y,T,SN output which returns the X and Y tilt angle in degrees or

microradians and the internal temperature of the tiltmeter in ºC:

$-0.619,0.023,18.910,N0000

$-0.619,0.023,18.923,N0000

$-0.620,0.024,18.932,N0000

$-0.620,0.023,18.951,N0000

SO = “XDR.” Standard NMEA XDR output string which returns the North-South (Y) and East-West (X)

tilt angle in degrees or microradians and the internal temperature of the tiltmeter in ºC:

$YXXDR,A,000.034,D,N,A,-00.625,D,E,C,021.651,C,T-N0000*47

$YXXDR,A,000.034,D,N,A,-00.624,D,E,C,021.675,C,T-N0000*40

$YXXDR,A,000.034,D,N,A,-00.624,D,E,C,021.686,C,T-N0000*4C

$YXXDR,A,000.034,D,N,A,-00.625,D,E,C,021.707,C,T-N0000*45

SO = “TCM.” Proprietary Trimble Navigation pitch (Y-tilt) and roll (X-tilt) output string which returns the

tilt angle in degrees and a checksum:

$P-00.907R002.186*1C

$P-00.906R002.183*18

$P-00.908R002.191*15

$P-00.908R002.191*15

$P-00.905R002.190*19

SO = “BAE.” Advanced users only, using the D711-A. BAE Systems encoded 11-byte output which

returns two synchronization bytes, the X (2 bytes) and Y (2 bytes) tilt angle, the internal temperature of the

tiltmeter (2 bytes), the serial number (2 bytes), and a checksum byte:

Uª Ä$é TæUª Ä$ä TáUª Ä$ß TÜUª Ä$é Tæ

The BAE output string is not clearly decipherable by HyperTerminal, which sometimes hides characters

that it has received and cannot understand. Because of this, it is difficult, if not impossible, to interpret

data in this format. The above output string shows four outputs taken from HyperTerminal.

This encoded output command is typically used to communicate with embedded systems as they can view

raw data and perform fast translations.

The first synchronization byte is 0x55, the second is 0xAA. The X and Y bytes use a scale factor that can

be found by issuing the *9900XY-DUMP2<CR> command. This scale factor is in arc seconds per LSB

and changes automatically with the range of each instrument (the scale factor is different for the D711-A

and D711-B). the temperature uses 0.004 degrees Celsius per LSB. The serial number is a two byte

integer. The checksum byte is the result of ANDing bytes 2-7 with 255.

BAE output mode reduces the total number of characters per output to 11 bytes, while transferring the

same data as the SIM output mode, which requires 33 bytes. BAE mode also includes checksum and frame

synchronization bytes. Refer to Appendix C, Firmware Commands, to decode the output.

Page 18

B-03-1006, Rev. K 15

7.5 Recording Data in Internal Memory or on a PC; Data File Size

You can log data from your model D711 tiltmeter in tow easy ways:

1. Use a serial communication program to log ASCII data to a storage device on your personal

computer.

2. Use the XY-MEMS command to store ASCII data in the tiltmeter's nonvolatile FLASH

memory.

The sizes of the data files stored to a PC are approximately:

Format

ASH 16.5 lines = 1 kilobyte

SIM 29.8 lines = 1 kilobyte

XDR 16.6 lines = 1 kilobyte

TCM 42.3 lines = 1 kilobyte

Data stored to FLASH memory must be stored in simple (SIM) format. Approximately 150 lines

of data may be stored at any sample rate..

7.6 Switching between RS 232 and RS485 (RS422) Output

You may switch the tiltmeter's output from RS232 to RS485 (RS422) or back again by issuing the

*9900XY-SET-RSMODE firmware command. After switching to RS485, the RS232 test cable (Figure 5)

cannot be used to communicate with the tiltmeter. Similarly, after a switch to RS232, the RS485 cable can

no longer be used (Figure 6). An additional test cable may be ordered from Jewell Instruments by

specifying P/N 89063 for the RS232 cable or P/N 89062 for the RS485 (RS422) cable.

Be sure you have the proper interconnect cable before switching to a new output protocol.

Without it, you will lose the ability to communicate with the tiltmeter!

8.0 Maintenance and Troubleshooting

Model D711 Digital Tiltmeters are rugged and require no maintenance other than normal cleaning.

Apart from the procedures described below, the tiltmeters are not field-serviceable. If you encounter

problems not described here, please contact Jewell Instruments LLC at (603) 669-6400 in New Hampshire.

A sales representative will assist you in determining the cause of any problem.

8.1 Routine Maintenance

Keep all tiltmeters away from extremes of heat and cold. Extreme temperatures shorten the life of

the seals and unnecessarily stress the electronic components. Keep tiltmeters out of direct sun because the

internal temperature can reach levels considerably greater than the ambient temperature.

Your Model D711 tiltmeter has been sealed at the factory to protect it against splashes and wet

weather. However, it should NEVER BE SUBMERGED in water or any other liquid. WATER DAMAGE

TO INTERNAL COMPONENTS VOIDS THE WARRANTY!

Page 19

B-03-1006, Rev. K 16

In addition to providing a seal, the cement between the dome and the base plate of the tiltmeter

provides the mechanical bond between these two parts. In normal use the cement will provide a strong and

secure attachment. To maximize the bond life and reduce the possibility of separation, lift the tiltmeter by

holding the base plate and not the dome. If the dome should separate from the base plate, it can be

reattached by: 1) cleaning off the old cement, 2) applying a continuous bead of new silicone rubber cement

in the circular groove and 3) holding the two sides firmly together until the cement has cured.

Connector locations on the IRIS circuit assembly inside the tiltmeter are shown in Figures 4 and 7.

Refer to these locations if the dome is removed and it is necessary to reattach the internal connectors.

8.2 Determining the Cause of Malfunctions

Although your model D711 Digital Tiltmeter is not field-serviceable, there are some basic things

you can do if you should encounter problems. If there is no output when you have connected the tiltmeter

to a PC while using HyperTerminal, check that all connectors are securely attached and properly wired to

the power and communication pins. Failure to obtain an output signal from the tiltmeter normally is the

result of lack of power or a broken wire or connection.

If no communication is seen in HyperTerminal, check your port settings. Most com-puters

connect to their serial ports using COM 1-4. Verify that the software settings conform to the COM port

that you are using. The default baud rate of the D711 is 9600 baud, which is factory set and verified upon

shipment. If your computer requires a different baud rate, change the tiltmeter's baud rate setting using the

"Communications Setup" window or the XY-SET-BAUDRATE command. Check your wiring (Figures 4,

5 and 6, Appendix A), as RS485 (RS422) uses different signals than the single-ended RS232 protocol. For

either protocol, verify that the tiltmeter's transmit output is connected to the receive pin(s) on the computer,

and that its' receive is connected to the PC's transmit pin(s).

If the tiltmeter output is "pegged" at either end of the output range, the tiltmeter is probably tilted

off scale. Re-level the unit.

Your Model D711 tiltmeter cannot be open without special tools. If you are certain the the

problem in internal to the tiltmeter, contact us for an RMA number and the return the tiltmeter to Jewell for

repair.

Page 20

B-03-1006, Rev. K 17

WARNING! NEVER USE AN OHMMETER TO MEASURE THE TILT SENSORS INSIDE THE

TILTMETER. APPLYING DC CURRENT THROUGH THE SENSORS WILL CAUSE PERMANENT

DAMAGE THAT IS NOT COVERED BY THE WARRANTY.

Figure 7: Layout of the IRIS Printed Circuit Assembly inside the Tiltmeter, Showing

Connector Locations

Page 21

B-03-1006, Rev. K 18

Appendix A: Custom Specifications for Your Digital Tiltmeter

Model number: D711-A High-Gain Version D711-B Mid-Range Version

Serial number:

Digital Output Protocol: RS232 RS485 (RS422)

Output Units: Degrees Microradians

Circular Connector on the Tiltmeter Cable: Jewell P/N 62402, Bendix P/N PT06A-12-10PW(SR)

Mating In-Line Connector: Jewell P/N 62404, Bendix P/N PT01A-12-10SW(SR)

1.0 RS232 Wiring and Connector Table

Tiltmeter End

Computer End

Wire Color

Function

Pin

(Circular Connector)

Pin

(DB9 Connector)

Function

Red

Power (7V to 28V)

H

Black

Power Ground

A

5

Ground

Blue

Transmit Data, TX

(RS232)

E

2

Receive Data (RX)

Green

Receive Data, RX

(RS232)

G

3

Transmit Data (TX)

Orange

TX+ (RS485)

D

Gray

TX- (RS485)

J

Yellow

RX- (RS485)

C

Brown

RX+ (RS485)

B

Drain Wire

Cable Shield

F

White

Not Used

No Connection (NC)

Violet

Not Used

NC

Pins 4 and 6 in the DB9 connector are shorted. Pins 7 and 8 in the DB9 connector are shorted. Pins 1 and 9

are not used.

Page 22

B-03-1006, Rev. K 19

2.0 RS485 (RS422) Wiring and Connector Table

Tiltmeter End

Computer End

Wire Color

Function

Pin

(Circular Connector)

Pin

(DB9 Connector)

Function

Red

Power (7V to 28V)

H

Black

Power Ground

A

1

Ground

Blue

TX (RS232)

E

Green

RX (RS232)

G

Orange

TX+ (RS485)

D

4

RX+

Gray

TX- (RS485)

J

5

RX-

Yellow

RX- (RS485)

C

9

TX-

Brown

RX+ (RS485)

B

8

TX+

Drain Wire

Cable Shield

F

White

Not Used

No Connection (NC)

Violet

Not Used

NC

Pins 2, 3, 6 and 7 in the DB9 connector are not used.

Figure A1: Face View of Female DB9 Connector with Pin Assignments

Page 23

B-03-1006, Rev. K 20

Appendix B: Guidelines for Installing Surface Mount Tiltmeters

These guidelines will help you achieve stable and reliable tiltmeter readings. Jewell Instruments

supplies all of the installation accessories you need for an effective monitoring program.

• Surface mount tiltmeters are typically attached to the measurement surface by mounting studs

(threaded rods) fastened or anchored into the surface. Three-point mounting is best because it prevents

bending and torsion that can lead to unstable readings. Single-stud (monopod) mounting is more

prone to drift and disturbance. It is not recommended for long-term applications.

• Mounting studs should be as short as possible, of the same length and of the same material for

maximum thermal stability. In special cases thermally stable, but more expensive, invar studs can be

used.

• Anchoring a mounting stud in a concrete or rock surface is normally done by drilling a hole to a depth

of 4-5 cm (1½ - 2 inches), then injecting a small amount of anchoring epoxy. When the stud is

inserted into the hole, the epoxy squeezes to the top, surrounding the embedded part of the stud. Lead

anchors and expanding anchors can also be used, but only if the mounting plate or bracket is drawn

tight against the surface and cannot shift laterally.

Figure B1 illustrates installation techniques for your tiltmeter. Please contact Jewell with questions, or for

additional details.

Figure B1. Installing Model D711 Digital Floor Mount Tiltmeter

Page 24

B-03-1006, Rev. K 21

Appendix C

Firmware Commands

Page 25

B-03-1006, Rev. K 22

Valid commands are listed below. Some commands have more than one string to trigger

the command. "tt" stands for the target ID (99) and "ss" stands for the source ID (00). Settings

stored in nonvolatile memory remain in effect until disabled, even after a power cycle.

--------------------------------------XY Outputs a single tilt measurement. The format of the output

depends on the setting of the SO command.

Syntax: *ttssXY<CR><LF>

Error Strings: None.

Default: N/A

Persistence: N/A

Example:

command: *9900XY<CR><LF>

response: $YXXDR,A,-00.920,D,N,A,-00.210,D,E,C,030.045,C,T-N1212*57

Page 26

B-03-1006, Rev. K 23

--------------------------------------SO Selects the output format for the XY command. The possible formats

are:

-SIM

$x.x,y.y,t.t,sn<CR><LF>

| | | |

| | | Serial number

| | Temperature of tilt meter

| Y-tilt value in degrees or microradians (See Appendix A)

X-tilt value in degrees or microradians (See Appendix A)

Example:

$-00.920,-00.210,030.045,N1212

-XDR

$YXXDR,A,x.x,D,N,A,x.x,D,E,C,x.x,C,T-sn*hh<CR><LF>

| | | | | | | | | | | | | |

| | | | | | | | | | | | | Checksum

| | | | | | | | | | | | Serial number

| | | | | | | | | | | Comment, T for temperature

| | | | | | | | | | Units, C=degrees C

| | | | | | | | | Temperature of tilt meter

| | | | | | | | Data Type, C=Temperature

| | | | | | | Comment, E for East/West (X) direction

| | | | | | Units, M=microradians, D=degrees

| | | | | X (E)-tilt value

| | | | Data Type, A=Angular

| | | Comment, N for North/South (Y) direction

| | Units, M=microradians, D=degrees,

| Y (N)-tilt value

Data Type, A=Angular

Example:

$YXXDR,A,-00.920,D,N,A,-00.210,D,E,C,030.045,C,T-N1212*57

-ASH

$PASHS,XDR,A,x.x,D,N,A,x.x,D,E,C,x.x,C,T-sn<CR><LF>

| | | | | | | | | | | | |

| | | | | | | | | | | | Serial number

| | | | | | | | | | | Comment,T for temperature

| | | | | | | | | | Units, C=degrees C

| | | | | | | | | Temperature of tilt meter

| | | | | | | | Data Type, C=Temperature

| | | | | | | Comment, E for East/West direction

| | | | | | Units, M=microradians, D=degrees

| | | | | X (E)-tilt value

| | | | Data Type, A=Angular

| | | Comment, N for North/South direction

| | Units, M=microradians, D=degrees

| Y (N)-tilt value

Data Type, A=Angular

Example:

$PASH,XDR,A,-00.920,D,N,A,-00.210,D,E,C,030.045,C,T-N1212

Page 27

B-03-1006, Rev. K 24

-TCM

$Py.y,Rx.x*hh<CR><LF>

| | |

| | |

| | CheckSum

| Roll= X-tilt value in degrees

Pitch= Y-tilt value in degrees

Example:

$P-00.905R002.190*19

-BAE

abcdefghijk

|||||||||||

||||||||||Byte 10(k): Checksum of bytes 2-7 ANDed with decimal 255

||||||||||

||||||||Byte 8-9(i,j): Serial number in hexadecimal format

||||||||

||||||Byte 6-7(g,h): Temperature in Deg. C. Bits 14 – 0 = magnitude

|||||| (LSB bit = 0.004 Deg. C.), Bit 15 = sign

||||||

||||Byte 4-5(e,f): Y Axis Level Data. Bits 14 – 0 = magnitude

|||| (LSB bit scale factor found in XY-DUMP2), Bit 15 = sign

||||

||Byte 2-3(c,d): X Axis Level Data. Bits 14 – 0 = magnitude

|| (LSB bit scale factor found in XY DUMP2), Bit 15 = sign

||

|Byte 1(b): 0xAA, 2nd Synchronization Byte

|

Byte 0(a): 0x55, 1st Synchronization Byte

Syntax: *ttssSO-<output format><CR><LF>

Error Strings:

ERR XY-SO BAD PARAMETER

<output format> was invalid.

ERR XY-SO PARSE ERROR

Could not parse <output format>.

Default: SIM

Persistence: Setting is stored on nonvolatile memory.

Example:

command: *9900SO-XDR<CR><LF>

response: <none>

Page 28

B-03-1006, Rev. K 25

---------------------------------------

XY-MEMS Stores the tiltmeter readings in simple format (SO-SIM) at selected

output rate in nonvolatile memory.

Syntax: *ttssXY-MEMS<CR><LF>

Error Strings: None.

Default: N/A

Persistence: Subsequent tiltmeter readings stored in nonvolatile memory,

until memory is full. Maximum of approximately 150 lines of data.

Example:

command: *9900XY-MEMS<CR><LF>

response: <none>

---------------------------------------

XY-MEMD Downloads the tiltmeter readings in nonvolatile memory to PC.

Syntax: *ttssXY-MEMD<CR><LF>

Error Strings: None.

Default: N/A

Persistence: Stored tiltmeter readings downloaded at rate of

1 per second to PC in ASCII comma-delimited string.

Example:

command: *9900XY-MEMD<CR><LF>

response: $start:11-11-1997 18:43:09 4/sec

$000.699,-01.022,025.116,N1028

$000.699,-01.022,025.116,N1028

$000.698,-01.021,025.110,N1028

$000.698,-01.022,025.122,N1028

Page 29

B-03-1006, Rev. K 26

---------------------------------------

XY-M1 Sets the operation to Mode 1. This command groups several

other commands together for convenience. The commands that

are issued are:

XY-TR-PASH-ON

XY-SO-XDR

XY-SE

XY-SP

Syntax: *ttssXY-M1<CR><LF>

Error Strings: None.

Default: N/A

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900XY-M1<CR><LF>

response: AGI Model D711-A Firmware V2.2 SN-N1212 ID01

---------------------------------------

XYVR Displays the sign-on string.

Syntax: *ttssXYVR<CR><LF>

Error Strings: None.

Default: N/A

Persistence: N/A

Example:

command: *9900XYVR<CR><LF>

response: AGI Model D711-A Firmware V5.2 SN-N1212 ID01

Page 30

B-03-1006, Rev. K 27

---------------------------------------

XY-TR-PASH-ON Translates the Paros provided $PASHS,XDR,P sentences to

standard NMEA XDR format. An example input PASH string would be:

$PASHS,XDR,P,1.000123,B,SN123,C,22.12,C,SN123,H,32.11,P,SN123<CR><LF>

The translated string would the be:

$WIXDR,P,1.000123,B,SN123,C,22.12,C,SN123,H,32.11,P,SN123*hh<CR><LF>

Syntax: *ttssXY-TR-PASH-ON<CR><LF>

Error Strings: None.

Default: Off.

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900XY-TR-PASH-ON<CR><LF>

response: <none>

---------------------------------------

XY-TR-PASH-OFF Turns of translation of $PASHS,XDR,P sentences.

Syntax: *ttssXY-TR-PASH-OFF<CR><LF>

Error Strings: None.

Default: N/A

Example:

command: *9900XY-TR-PASH-OFF<CR><LF>

response: <none>

Page 31

B-03-1006, Rev. K 28

---------------------------------------

XY-EP Enables power on message. Power on message is:

AGI Tiltmeter Firmware V5.2 SN-N1212 ID01

Where V5.2 is the firmware version, SN-N1212 is the serial

number of the device, and ID01 is the target's ID.

Syntax: *ttssXY-EP<CR><LF>

Error Strings: None.

Default: On.

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900TR-EP<CR><LF>

response: <none>

---------------------------------------

XY-SP Disables power on message.

Syntax: *ttssXY-SP<CR><LF>

Error Strings: None.

Default: N/A

Persistence: Setting is stored in nonvolatile memory.

Example:

comand: *9900TR-SP<CR><LF>

response: <none>

---------------------------------------

EE Enable echoing of global 99 commands. If the unit receives

a command for ID 99, then the unit will respond to the command

and echo the command when it is done.

Syntax: *ttssEE<CR><LF>

Error Strings: None.

Default: On.

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900EE<CR><LF>

response: <none>

Page 32

B-03-1006, Rev. K 29

---------------------------------------

SE Disable echoing of global 99 commands. If the unit receives

a command for ID 99, then the unit will respond, but the

unit will NOT echo the command when it is done.

Syntax: *ttssSE<CR><LF>

Error Strings: None.

Default: N/A

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900SE<CR><LF>

response: <none>

---------------------------------------

XY-SET-BAUDRATE,x Changes communications baud rate. Maximum supported baud

rate is 57,600 baud. The parameter x is an integer with up

to six places defining the baud rate as follows:

9600 = 9600 baud

19200 = 19200 baud

28800 = 28800 baud

57600 = 57600 baud

115200 = 115200 baud

230400 = 230400 baud

Syntax: *ttssXY-SET-BAUDRATE,x<CR><LF>

Error Strings: ERR XY-SETBAUD,x PARSE ERROR.

Default: 9600

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900XY-SET-BAUDRATE,57600<CR><LF>

response: <none>

Page 33

B-03-1006, Rev. K 30

---------------------------------------

XY-SET-N-SAMP,x Sets the number of samples that are averaged before a reading

is transmitted. The parameter x is an integer between 1 and

1000 equal to the number of samples that are averaged.

Syntax: *ttssXY-SET-N-SAMP,x<CR><LF>

Error Strings: None.

Default: Depends on data output rate, as specified by the XYCx command.

The default numbers on samples averaged for each data rate are:

XYC0: 28

XYC1: 100

XYC2: 460

XYC3: 500

XYC4: 500

XYC5: 500

XYC6: 500

XYC7: 500

If the number of samples specified exceeds the number listed above for

XYC0, XYC1, or XYC2, the microprocessor reduces the data output rate

until it has enough time to collect and average all the the samples.

Persistence: Once initiated, the same averaging remains in effect even

with power cycle. (Setting is stored in nonvolatile memory). Can be

changed by reissuing the command with a different value for x,or by

changing the output rate with the XYCx command.

Example:

command: *9900XY-SET-N-SAMP,250<CR><LF>

response: <none>

Page 34

B-03-1006, Rev. K 31

---------------------------------------

XY-SET-RS-MODE,x Sets output protocol to RS232 or RS485 (RS422), as follows:

x = 0: RS232

x = 1: RS485 (RS422)

Syntax: *ttssXY-SET-RSMODE,x<CR><LF>

Error Strings: None.

Default: Set in factory to customer specification.

Persistence: Once initiated, remains in effect even with power cycle.

(Setting is stored in nonvolatile memory).

Example:

command: *9900XY-SET-N-SAMP,0<CR><LF>

response: <none>

CAUTION: If you change the output protocol, you will no longer be able to

communicate with the tiltmeter unless you have the correct

interconnect cable.

---------------------------------------

XY-AUTOZ Turns autozero function on, causing tiltmeter to subtract current X

and Y readings from all subsequent X and Y readings.

Syntax: *ttssXY-AUTOZ<CR><LF>

Error Strings: None.

Default: OFF

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900XY-AUTOZ<CR><LF>

response: <none>

---------------------------------------

XY-AUTOZOFF Turns autozero function off, causing tiltmeter to display

non-biased (unshifted) position readings.

Syntax: *ttssXY-AUTOZ-OFF<CR><LF>

Error Strings: None.

Default: Off

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900XY-AUTOZ-OFF<CR><LF>

response: <none>

Page 35

B-03-1006, Rev. K 32

---------------------------------------

XYCx Continuously sends XY data - even after power has been turned off and

then on again. Timing is determined by the microprocessor's crystal and

is approximate. The parameter x is an integer between 1 and 7, the

letter A, or 0A, 1A or 2A.

An A indicates the use of the moving average function, in which the

moving average of the data is output. When the moving average function is

used, the first output is delayed until the first n readings have been

taken, where n is the number of readings to be averaged. After that, the

outputs occur at the the same rate as the readings. For example, the

command XYC2A outputs the moving average of the same data that would be

output if the user issued the command XYC2. Since XYC2 outputs the data

once per second, XYC2A also outputs once per second. However, the first

output occurs after a four-second delay, in which the first four readings

(at a rate of 1 per second) are averaged. The second output is the

average of readings 2-5, the third output is the average of readings 3-6,

and so on, creating an output rate equal to that of XYC2.

The parameter x determines rate of continuous output as follows:

x = 0: 8-10 per second

1: 4 per second

2: 1 per second

3: 1 every 10 seconds

4: 1 every 60 seconds

5: 1 every 60 minutes

6: 1 every 12 hours

7: 1 every 24 hours

0A: Average of 8-10 outputs/sec data. 10 readings are averaged.

1A: Average of 4 outputs/second data. 4 readings are averaged.

2A or A: Average of 1 output/second. 4 readings are averaged.

Syntax: *ttssXYCx<CR><LF>

Error Strings: None.

Default: Off.

Persistence: Once initiated, continuous output remains in effect even

with power cycle. (Setting is stored in nonvolatile memory). Must be

turned off using the XYC-OFF command (see below).

Example (with SO=”SIM”):

command: *9900XYC1<CR><LF>

response: $-00.699,000.070,020.290,N0000

$-00.699,000.071,020.309,N0000

$-00.699,000.071,020.313,N0000

$-00.699,000.071,020.330,N0000

$-00.699,000.071,020.348,N0000

$-00.700,000.070,020.360,N0000

Page 36

B-03-1006, Rev. K 33

---------------------------------------

XYC-OFF Turns off XYC mode.

Syntax: *ttssXYC-OFF<CR><LF>

Error Strings: None.

Default: N/A.

Persistence: Setting is stored in nonvolatile memory.

Example:

command: *9900XYC-OFF<CR><LF>

response: *9900XYC-OFF<CR><LF>

---------------------------------------

XY-DUMP-SETTINGS Dumps settings of device.

Syntax: *ttssXY-DUMP-SETTINGS<CR><LF>

Error Strings: None.

Default: N/A

Persistence: N/A

Example:

command: *9900XY-DUMP-SETTINGS

response:

APPLIED GEOMECHANICS Tiltmeter Firmware V5.0 SN-N2144 ID01

01: Vbias= 2047.000000000 2047.000000000 NaN NaN

01: Vgain= 0.005000000 0.005000000 0.000610350 0.000610350

01: Vmin: -2.50 -2.50 2.50 2.50

01: Vmax: 2.50 2.50 2.50 2.50

01: a0= 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000

01: a1= 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000

01: a2= 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000

01: a3= 0.00000 0.00000 0.00000 0.00000 0.00000 0.00000

01: Tcoef 0: Ks= 0.0003 Kz= 0 Tcal= 25

01: Tcoef 1: Ks= 0.0003 Kz= 0 Tcal= 25

01: N_SAMP=1000 Xzero= 0.00 Yzero= 0.00

01: TR-PASH-OFF E99-ON SO-NMEA-SIM XY-EP 9600 baud FV-

Page 37

B-03-1006, Rev. K 34

---------------------------------------

XY-DUMP2 Dumps extended settings of device.

Syntax: *ttssXY-DUMP2<CR><LF>

Error Strings: None.

Default: N/A

Persistence: N/A

Example:

command: *9900XY-DUMP2

response:

01: TBias: 6.86

Above 0.00 (KZMinTemp): kz[0]= 0, kz[1]= 0

Below 0.00 (KZMinTemp): kz[2]= 0, kz[3]= 0

01: ADCDelay: 310

01: PCA Model 84833-04

01: Firmware Version: 5.2 Rev G

01: X Ch Gain= 1.0000, Y Ch Gain= 1.0000, Temperature Gain= 1.0000

01: Output Mode: ArcSeconds

01: Calibration performed in Degrees

01: Control: On

01: Using RS232

01: Real Time Clock: Not Installed

01: Use RTC for Timing: No

01: External Flash Capacity: 0 Bytes(Not Installed)

01: Relay Thresholds:

01: Xpositive=1.0000 Xnegative=-1.0000

01: Ypositive=1.0000 Ynegative=-1.0000

01: Relay Hysteresis:

01: Hysteresis: 0.0000

01: Calibration method: Dynamic

01: Positive Limit= 0.53 Negative Limit=-0.53

01: Calibration Points:025 X: Enabled Y: Enabled

01: Uniaxial (x2) Sensor Type (1)

01: ADC: 12-bit (internal)

01: DAC Output Scale Factor: 4.76 Volts/Degree

01: Total Sample Storage Capacity: 372

01: BAE Scale Factor: 0.05768 (arcseconds/bit)

Page 38

B-03-1006, Rev. K 35

APPENDIX E: WARRANTY and LIMITATION of LIABILITY

Standard goods (those listed in Jewell Instruments' published sales literature, excluding software)

manufactured by Jewell Instruments LLC are warranted against defects in materials and workmanship for

twelve (12) months from the date of shipment from Jewell’s premises with the following exceptions:

Series 900 analog or digital clinometers are warranted against defects in materials and workmanship for 90

days from the delivery date. Jewell will repair or replace (at its option) goods that prove to be defective

during the warranty period provided that they are returned prepaid to Jewell and:

(a) that the goods were used at all times for the purpose for which they were designed and in accordance

with any instructions given by Jewell in respect of them,

(b) that notice is received by Jewell within 30 days of the defects becoming apparent, and

(c) that return authorization is received from Jewell prior to the goods being sent back.

Should goods be damaged in transit to the Purchaser, Jewell will accept no liability unless the Purchaser

can show that such damage arose solely from Jewell’s failure to pack the goods properly for shipment.

Software products are warranted to perform substantially in accordance with their documentation for 90

days following your receipt of the software. Jewell and its suppliers do not and cannot warrant the

performance or results you may obtain by using the software or its documentation.

In respect of goods or parts thereof manufactured by others and resold by Jewell, Jewell will pass on to the

customer the benefit of any guarantee or warranty received by Jewell from the original manufacturer

insofar as such guarantee or warranty is assignable.

ANY OTHER CONDITIONS OR WARRANTIES WHETHER EXPRESS OR IMPLIED BY

STATUTE OR OTHERWISE ARE EXCLUDED. THE REMEDIES PROVIDED HEREIN

ARE THE BUYER’S SOLE AND EXCLUSIVE REMEDIES. JEWELL INSTRUMENTS

LLC SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL

OR CONSEQUENTIAL DAMAGES, INCLUDING LOST PROFITS OR LOST SAVINGS,

WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY. THIS

WARRANTY EXTENDS ONLY TO THE ORIGINAL PURCHASER AND IS EXPRESSLY

IN LIEU OF ALL OTHER WARRANTIES, WHETHER OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR USE, AND OF ALL OTHER OBLIGATIONS AND

LIABILITIES OF ANY KIND AND CHARACTER. THERE ARE NO WARRANTIES

WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

Jewell’s liability arising out of the sale of its goods is expressly limited to the repair and/or replacement of

defective parts or the cost of such repair and/or replacement.

If software does not perform substantially in accordance with the documentation, the entire and exclusive

liability and remedy shall be limited to either, at Jewell’s option, the replacement of the software or the

refund of the license fee you paid for the software. Liability for any other form of loss or damage is hereby

expressly excluded.

Customer shall indemnify Jewell against any third party claim arising out of the use of goods and/or

services supplied by Jewell, including any claim arising directly or indirectly out of alleged negligence on

the part of Jewell, its employees, servants, representatives or agents.

Page 39

B-03-1006, Rev. K 36

APPENDIX F: Revision Record

REV.

PAGE NOS.

ECN NO.

DESCRIPTION OF CHANGE

DATE

J

ALL

25579

"Jewell" was "Applied Geomechanics"

Revised Table of Contents - updated Appendix

E, added Appendix F for Revision Record

7/17/13

K

ALL

28811

Removed references to ZAGI software which is no

longer supported by Jewell Instruments

5/17/18

Loading...

Loading...