Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

14-inch Woodworking Band Saw

Models: JWBS-14OS, JWBS-14CS

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708115

Ph.: 800-274-6848 Revision C1 02/2010

www.waltermeier.com Copyright © 2010 Walter Meier (Manufacturing) Inc.

Page 2

Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

®

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

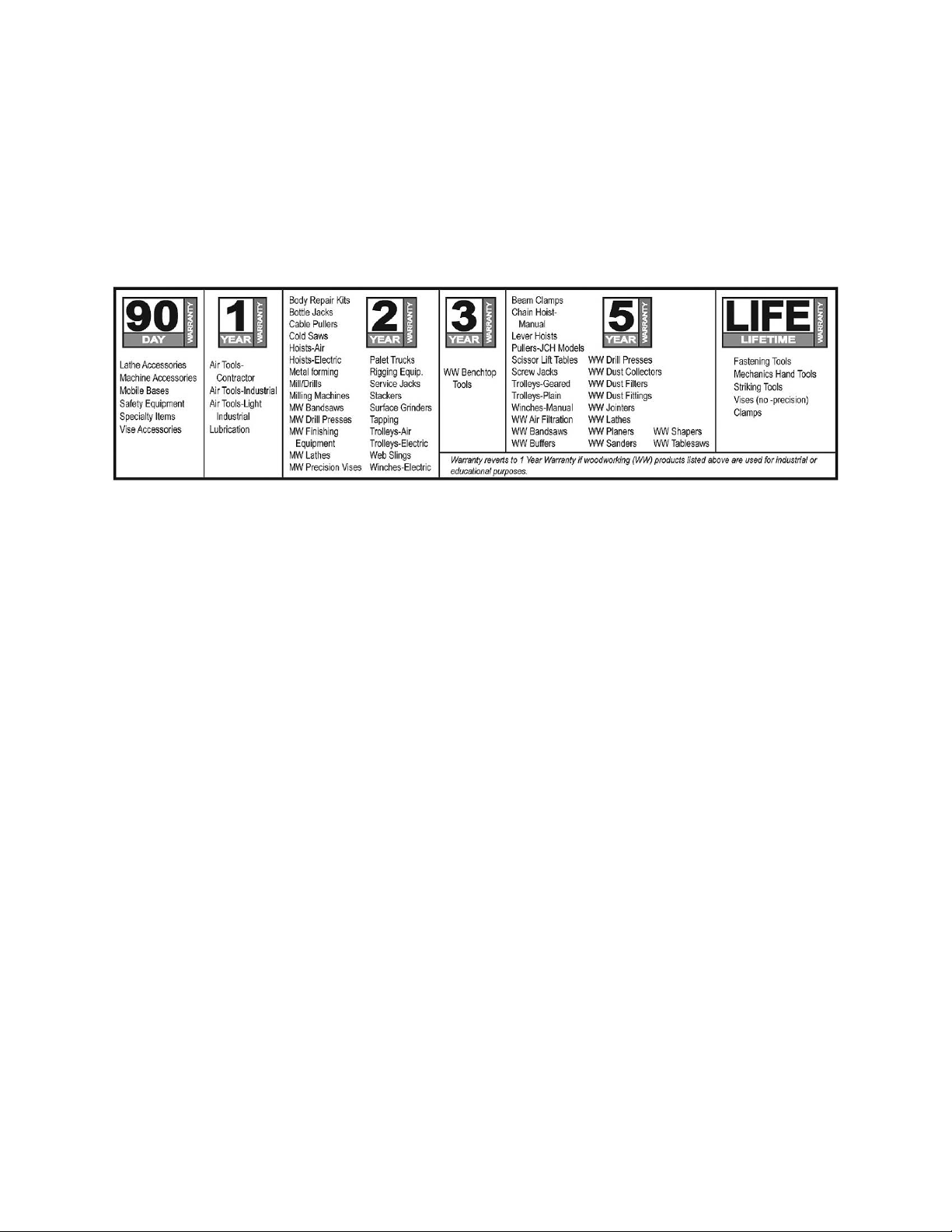

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

®

whatsoever. JET

branded products are not sold in Canada by Walter Meier.

tools. For the name of an Authorized Service Center in

2

Page 3

Table of Contents

Warranty and Service..........................................................................................................................2

Warning .............................................................................................................................................4

Introduction ........................................................................................................................................6

Specifications .....................................................................................................................................6

Unpacking – JWBS-14OS ...................................................................................................................7

Contents of the Shipping Container ..................................................................................................7

Fasteners .......................................................................................................................................7

Unpacking – JWBS-14CS ...................................................................................................................8

Contents of the Shipping Container ..................................................................................................8

Fasteners .......................................................................................................................................8

Assembly of JWBS-14OS....................................................................................................................9

Assembly of JWBS-14CS .................................................................................................................. 12

Grounding Instructions ...................................................................................................................... 14

115 Volt Operation ........................................................................................................................ 15

230 Volt Conversion ...................................................................................................................... 15

Extension Cords ............................................................................................................................ 16

Adjustments ..................................................................................................................................... 16

Tilting the Table............................................................................................................................. 16

Adjusting 90° Table Stop................................................................................................................ 16

Changing Blades ........................................................................................................................... 17

Adjusting Blade Tension ................................................................................................................ 17

Adjusting Blade Tracking ............................................................................................................... 18

Adjusting Upper Blade Guide Assembly .......................................................................................... 18

Adjusting Blade Guide and Blade Support Bearing .......................................................................... 19

Troubleshooting JWBS-14CS/OS Band Saw ...................................................................................... 21

Optional Accessories ........................................................................................................................ 22

Replacement Parts ........................................................................................................................... 22

Body Assembly (JWBS-14CS/OS Band Saw).................................................................................. 23

Body Assembly (JWBS-14CS/OS Band Saw).................................................................................. 24

Body Assembly (JWBS-14CS/OS Band Saw).................................................................................. 25

Closed Stand Assembly (JWBS-14CS Band Saw) ........................................................................... 26

Closed Stand Assembly (JWBS14-CS Band Saw) ........................................................................... 27

Open Stand Assembly (JWBS-14OS Band Saw) ............................................................................. 28

Open Stand Assembly (JWBS-14OS Band Saw) ............................................................................. 29

Electrical Connections – 115 volt (JWBS-14CS/OS Band Saw)............................................................ 30

Electrical Connections – 230 volt (JWBS-14CS/OS Band Saw)............................................................ 31

3

Page 4

Warning

1. Read and understand the entire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This band saw is designed and intended for use by properly trained and experienced personnel only.

If you are not familiar with the proper and safe operation of a band saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes, Walter Meier

(Manufacturing) Inc., disclaims any real or implied warranty and holds itself harmless from any injury

that may result from that use.

6. Always wear approved safety glasses/face shields while using this band saw. Everyday eyeglasses

only have impact resistant lenses; they are not safety glasses.

7. Before operating this band saw, remove tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clot hing and confine long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other constr uction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and ot her masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure the band saw is firmly secured to the stand, or bench, before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area. Keep children away.

4

Page 5

21. Make your workshop child proof with padlocks, master switches or by removing starter keys.

22. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

23. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving parts. Do not overreach or use excessive force to perform any machine operation.

24. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for

which it was not desig ned. The right tool will do the job better and safer.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep blade sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

27. Make sure the work piece is held firmly against the rip fence or miter gauge as it is fed through the

blade.

28. Turn off the machine before cleaning. Use a brush or compressed air to remove chips or debris — do

not us e your hands.

29. Do not stand on the machine. Serious injury could occur if the machine tips over.

30. Never leave the machine running unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

31. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Walter Meier (Manufact uring) Inc., covering the safe operation and

maintenance procedures for a Model JWBS-14OS and JWBS-14CS Band Saw. This manual contains

instructions on installation, safety precautions, general operating procedures, maintenance instructions

and parts breakdown. This machine has been designed and constructed to provide years of trouble free

operation if used in accordance with instructions set forth in this manual. If there are any questions or

comments, please contact either your local supplier or Walter Meier. Walter Meier can also be reached at

our web site: www.waltermeier.com.

Specifications

Model Number: ...................................................... JWBS-14OS......................................... JWBS-14CS

Stock Number .............................................................. 708113.............................................. 708115K

Cutting Capacity (height/in.) .................................................... 6.......................................................... 6

Cutting Capacity (width/in.) .............................................. 13-1/2.................................................. 13-1/2

Minimum Blade Width (in.) ................................................... 1/8....................................................... 1/8

Maximum Blade Width (in.)................................................... 3/4....................................................... 3/4

Blade Length (in.) ........................................................... 93-1/2.................................................. 93-1/2

Blade Speed (SFPM) ........................................................ 3000.................................................... 3000

Table Size (in.) ..............................................................15 x 15.................................................15 x 15

Table Slot Size (DxW/in.) ............................................. 3/8 x 3/4............................................... 3/8 x 3/4

Table Height From Floor (in.) ................................................. 44.................................................. 43-1/2

Table Tilt (deg.) ..................................................45 right, 10 left......................................45 right, 10 left

Dust Port Diameter (in.)........................................................... 4.......................................................... 4

Overall Dimensions (HxWxD/in.) ............................. 68 x 34 x 20......................................... 68 x 26 x 19

Motor ............................... 3/4HP, 1Ph, 115/230V (prewired 115)....... 1HP, 1Ph, 115/230V (prewired 115)

Net Weight (lbs.) ................................................................. 172...................................................... 185

Shipping Weight (lbs.) ......................................................... 183...................................................... 197

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, Walter Meier reserves the right to change specifications at any time and without

prior notice, without incurring obligations.

6

Page 7

Unpacking – JWBS-14OS

Open shipping container and check for shipping damage. Report any damage immediately to your

distributor and shipping agent. Read the instruction manual thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Stand top with motor support plate

4 Stand legs

2 Cross braces-short

2 Cross braces-long

1 Stand support plate

1 Saw body

1 Table

1 Motor

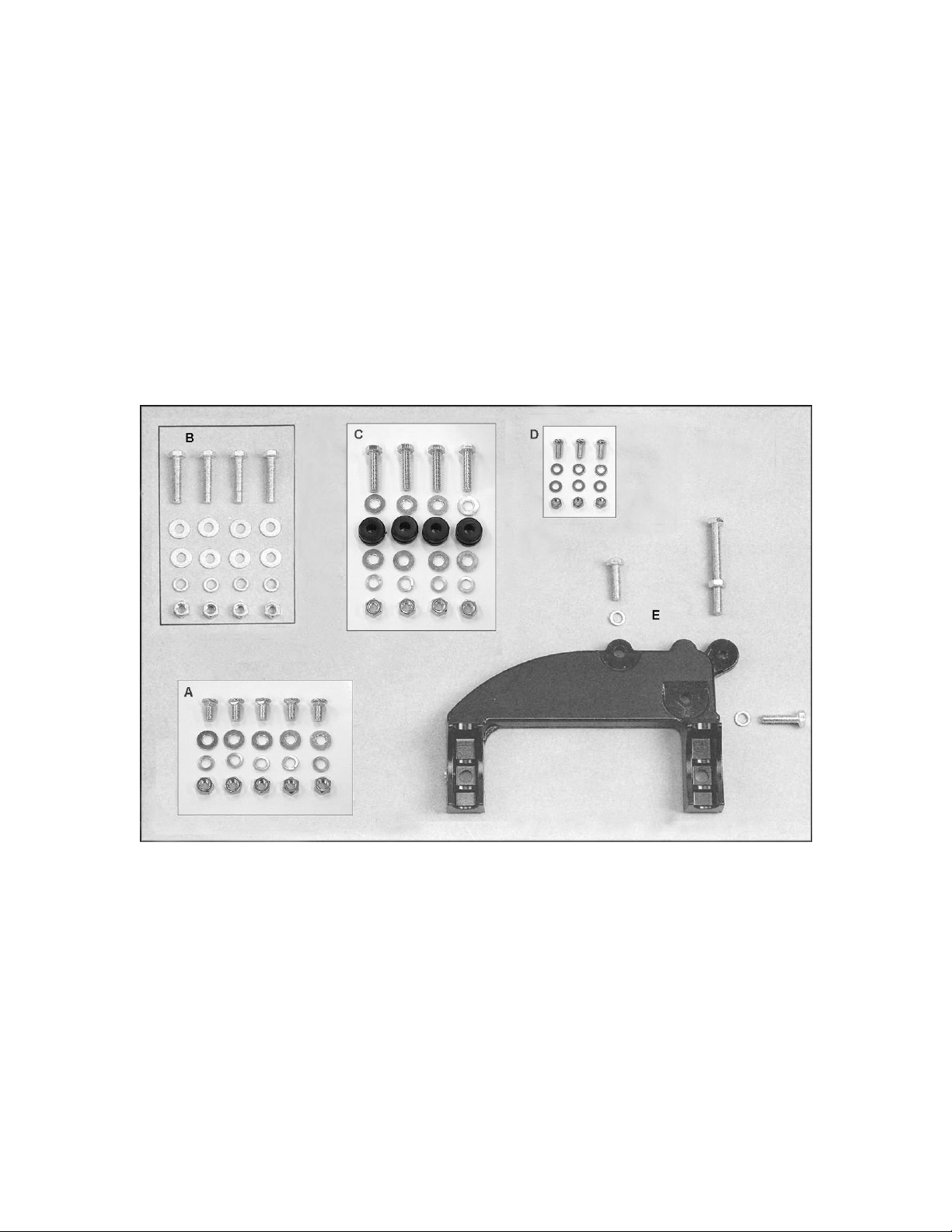

Fasteners

1 V-belt

1 Pulley cover

2 Table lock knobs

1 Table pin

1 Trunnion support bracket

1 Fastener package (see below)

1 Instruction Manual

1 Warranty Card

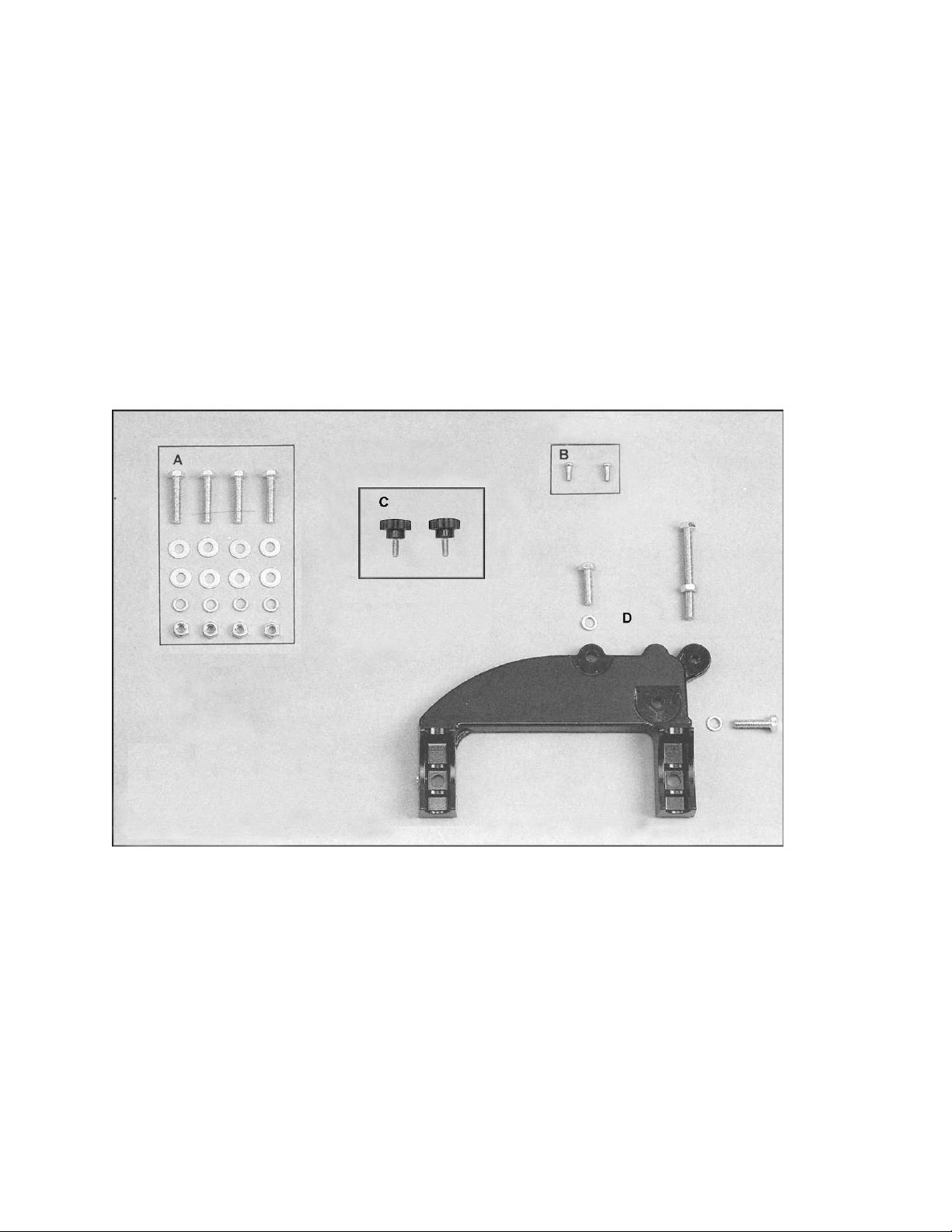

A. Stand Assembly (partial quantity shown)

40 – M8x16 carriage bolts

40 – M8 flat washers

40 – M8 lock washers

40 – M8 hex nuts

B. Saw Body to Stand

4 – M8x40 hex cap screws (approx. 1-1/2")

8 – M8 flat washers

4 – M8 lock washers

4 – M8 hex nuts

C. Motor to Stand

4 – M8x35 hex cap screws (approx. 1-3/8”)

8 – M8 flat washers

4 – rubber grommets

4 – M8 lock washers

4 – M8 hex nuts

D. Pulley Cover to Stand

3 – M5x12 pan head screws (approx. 1/2”)

6 – M5 flat washers

3 – M5 hex nuts

E. Trunnion Support Bracket to Saw Body

2 – M8x30 hex cap screws (approx. 1-1/4")

2 – M8 lock washers

1 – M8x80 hex cap screw (for table stop -

approx. 3-1/8” long)

1 – M8 hex nut (for table stop)

7

Page 8

Unpacking – JWBS-14CS

Open both shipping containers and check for shipping damage. Report any damage immediately to your

distributor and shipping agent. Read the instruction manual thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

Co ntai ner O ne:

1 Closed stand with motor

1 Pulley cover

1 V-belt

Co ntai ner Two:

1 Saw body

1 Table

Fasteners

2 Table lock knobs

1 Table pin

1 Trunnion support bracket

1 Fastener package (see below)

1 Instruction Manual

1 Warranty Card

A. Saw Body to Stand

4 – M8x40 hex cap screws

(approx. 1-1/2" long)

8 – M8 flat washers

4 – M8 lock washers

4 – M8 hex nuts

B. Strain Relief Plate to Stand

2 – M5x12 pan head machine screws

C. Pulley Cover to Base

2 – Knobs

D. Trunnion Support Bracket to Saw Body

2 – M8x30 hex cap screws

(approx. 1-1/4" long)

2 – M8 lock washers

1 – M8x80 hex cap screw (for table stop -

approx. 3-1/8” long)

1 – M8 hex nut (for table stop)

8

Page 9

Assembly of JWBS-14OS

NOTE: If any of the assembly procedures need

further clarification, refer to the exploded views

in the back of this manual.

Tools Required for Assembly

Metric combination wrench set and adjustable

wrench

#1 and #2 cross point screwdrivers

1. Place stand top upside down on a level

surface. Fasten four stand legs to stand top

using carriage bolts, washers, lock washers,

and nuts, as shown in item A on page 7.

Note: Stand legs fasten to outside of stand

top (Figure 1). Do not tighten at this time.

2. Fasten two long braces and two short

braces to stand legs using carriage bolts,

washers, lock washers, and nuts, as shown

in item A, page 7. Do not tighten at this time.

See Figure 2.

Figure 1

3. Turn assembly over and stand it on its legs.

Push down slightly on the top to make sure

the stand settles properly and all four legs

sit flat on a level surface. Tighten all nuts.

Saw body is heavy! Use

caution when lifting and stabilize until firmly

attached to the stand! Failure to comply may

cause serious injury!

4. With the aid of a second person, lift the saw

body out of the shipping container and place

onto the stand top. Be sure front of saw

(with JET logo) faces stand front (JET logo).

See photo on cover for orientation.

5. Line up holes in saw body with holes in

stand. Place support plate to the underside

of stand as shown in the parts diagram for

the open stand assembly (item 5, page 30).

Fasten saw body, stand, and support plate

together with four hex cap screws, eight flat

washers, four lock washers, and four hex

nuts, as shown in item B on page 7.

Figure 2

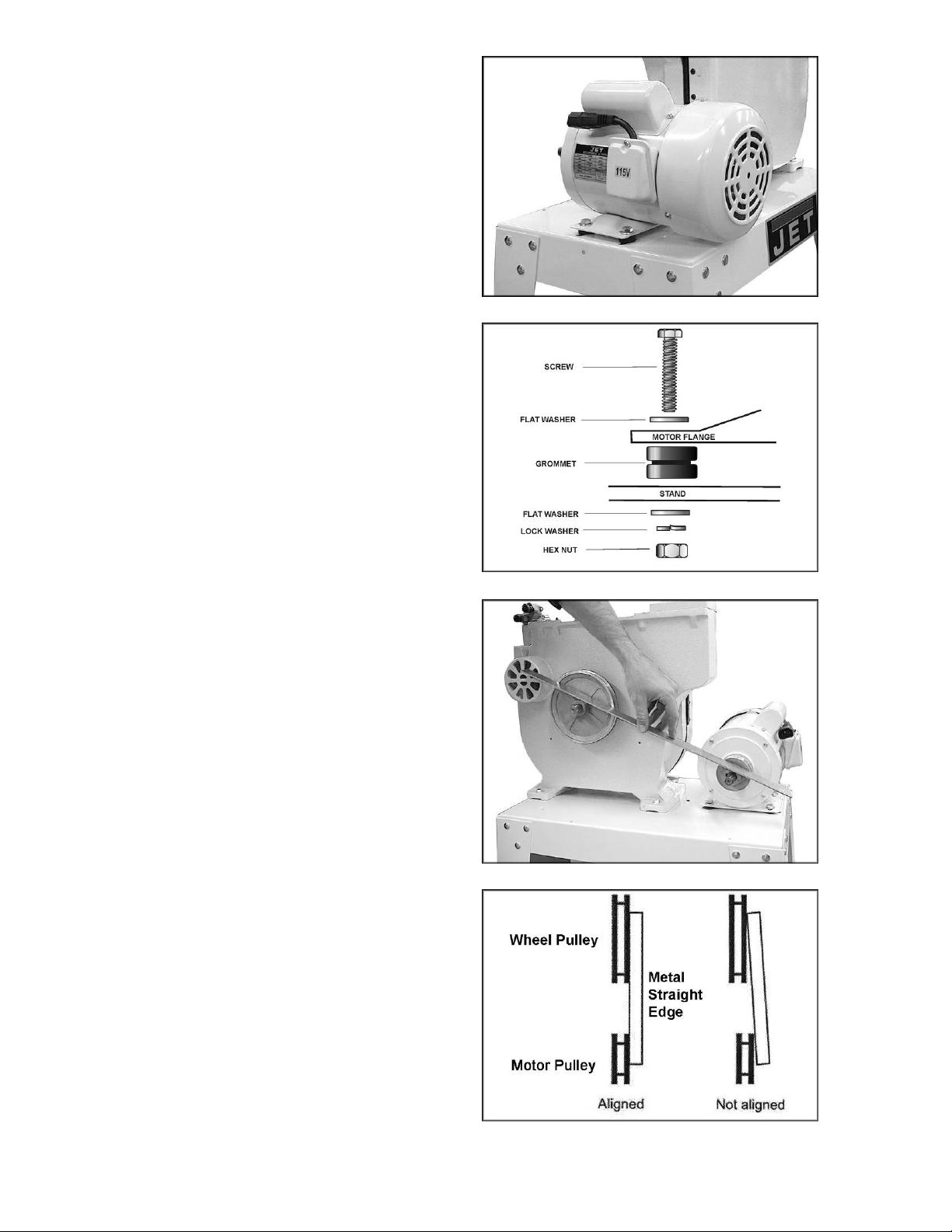

6. To mount the motor, place four rubber

grommets over holes in stand top (Figure 3).

Note: Use of rubber grommets is essential

for eliminating excessive vibration.

Figure 3

9

Page 10

7. Place motor over rubber grommets and

fasten to stand top wit h four hex cap

screws, eight flat washers, four lock

washers, and four hex nuts, as shown in

item C, page 7. See Figure 4. The

arrangement of these fasteners is shown in

Figure 5. Do not tighten at this time.

8. Align the motor pulley with the large pulley

using a straight edge against the flat sides

of the pulleys, as shown in Figure 6. The

pulleys should lie in a straight plane (F igure

7). Slide the motor as needed to align the

pulleys. If further adjustment is required,

loosen the set screw in one or more of the

pulleys and move the pulley(s) until they line

up. Tighten set screw(s).

IMPORTANT: When moving the pulleys, do

not position them beyond the end of the

shaft. Both pulleys must fully engage the

shaft and the key.

Figure 4

Figure 5

Figure 6

Figure 7

10

Page 11

9. Place v-belt over both pulleys. See Figure 8.

10. Tension v-belt by moving motor away from

the saw body and tighten the motor mount

nuts. (Do not over-tighten motor mount

bolts. Tighten just enough to tension belt.)

Belt is properly tensioned when finger

pressure between the two pulleys (Figure 8)

causes approximately 1/2” deflection.

11. Place pulley cover over both pulleys and

fasten to stand using three pan head

screws, six washers, and three hex nuts, as

shown in item D, page 7. See Figure 9.

12. Attach trunnion support bracket to saw body

with two hex cap screws and two lock

washers as shown in item E, page 7. See

Figure 10.

13. Thread nut onto table stop bolt (Figure 10)

and attach to trunnion support bracket.

14. To mount table, remove table insert and

table pin (see Figure 11). Orient the table so

that the saw blade will pass through the slot

in the table and into the center opening.

Continue holding up the table, and turn the

table so the two screws that are hanging

vertically from below the table will slide into

the holes on the trunnion support bracket.

Lower the table. The screws should now

protrude below the trunnion support bracket

- attach lock knobs to the ends of these

screws. See Figure 11.

Figure 8

Figure 9

15. Re-install table insert and table pin.

16. Join motor plug to switch plug.

17. Transportation and handling may have

caused some fasteners to loosen. Before

operating, check all screws, bolts, and nuts

to make sure they are snug. Operate

machine only after reading the entire

manual including blade tracking, blade

guide adjustments, and safety rules.

18. Exposed metal surfaces, such as the table,

have been given a protective coating. This

should be cleaned with a soft cloth and

solvent, such as kerosene. Do not use

acetone, gasoline, or lacquer thinner. Do not

use an abrasive pad, and do not get

solvents on plastic parts.

Proceed to “Grounding Instructions” on page 14.

Figure 10

Figure 11

11

Page 12

Assembly of JWBS-14CS

Tools Required for Assembly

Metric combination wrench set and

adjustable wrench

#1 and #2 cross point screwdrivers

Exposed metal surfaces, such as the table, have

been given a protective coating. This should be

cleaned with a soft cloth and solvent, such as

kerosene. Do not use an abrasive pad, and do

not get solvents on plastic parts.

1. Remove pulley cover from inside of stand.

2. Place cabinet stand upright on a level

surface. If desired, the stand can be further

stabilized by securing it to the floor with lag

screws through the inside corner holes. If

using a mobile base, lock the casters before

assembling or operating t he band saw.

Saw body is heavy! Use

caution when lifting and stabilize until firmly

attached to the stand! Failure to comply may

cause serious injury!

3. With the aid of a second person, lift the saw

body out of the shipping container and place

onto stand top. Be sure front of saw (with

JET logo) faces stand front (JET logo).

4. Line up holes in saw body with holes in top

of stand. Fasten saw body to the stand with

four M8 x 40 hex cap screws, eight M8

washers, four M8 lock washers, and four M8

hex nuts (as shown in item A, page 8).

5. Push motor cord and strain relief plate

through the opening in the side of the stand

(Fig. 12). Fasten the strain relief plate to the

stand with two M5 x 12 pan head machine

screws (shown in item B, page 8).

6. Check the alignment of the pulleys by

placing a straight edge against the flat sides

of the motor and wheel pulleys (Figure 13).

If the pulleys lie in a straight plane (Figure

14) they are aligned. If they do not lie in a

straight plane, loosen the set screw on one

of the pulleys and shift the pulley in or out

until both pulleys lie in a straight plane.

Tighten set screw.

Figure 12

Figure 13

Figure 14

12

Page 13

IMPORTANT: When moving the pulleys, do

not position them beyond the end of the

shaft. Both pulleys must fully engage the

shaft and the key.

7. Open the lower door, and place the v-belt

around the motor pulley and the wheel

pulley (see Figure 13).

8. Loosen the nuts on the four motor mounting

bolts (Figure 15) and tension the v-belt by

pushing down on the motor. Tighten the four

motor mounting nuts.

9. The v-belt is properly tensioned when finger

pressure between the two pulleys causes

approximately 1/2" deflection (Figure 16).

10. Screw the two small knobs (Figure 17) into

the threaded holes in the saw body. Slide

the pulley cover down over the knobs, and

tighten the knobs.

11. Attach trunnion support bracket to saw body

with two M8 x 30 hex cap screws and two

M8 lock washers, as shown in item D, page

8. See Figure 18.

12. Thread nut onto table stop bolt (Figure 18)

and attach to trunnion support bracket as

shown.

Figure 15

Figure 16

Figure 17

Figure 18

13

Page 14

13. To mount the table, remove pin and insert

from the table (Figure 19).

14. Orient the table so the saw blade will pass

through the slot in the table and into the

center opening. Continue holding up the

table, and rotate the table so the two screws

that are hanging vertically from below the

table will slide into the holes on the trunnion

support bracket. Lower the table. The

screws should now protrude below the

trunnion support bracket - attach lock knobs

to the ends of these screws. (Figure 19).

15. Re-install table insert and table pin.

16. Connect the plugs of the motor cord and

switch cord (Figure 20).

17. Transportation and handling may have

caused some fasteners to loosen. Before

operating, check all screws, bolts, and nuts

to make sure they are snug. Operate

machine only after reading the entire

manual including blade tracking, blade

guide adjustments, and safety rules.

Grounding Instructions

This band saw must be

grounded while in use to protect the

operator from electric shock.

In the event of a malfunction or breakdown,

grounding provides a pat h of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug that looks similiar to the plug in

Figure 21. The plug must be inserted into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Figure 19

Figure 20

Do not modify the plug provided. If it will not fit

the outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Figure 21

14

Page 15

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace a damaged or worn cord

immediately.

115 Volt Operation

As received from the factory, your band saw is

ready to run at 115 volt operation. This band

saw, when wired for 115 volts, is intended for

use on a circuit that has an outlet and a plug

that looks like the one illustrated in Figure 21. A

temporary adapter, like the adapter in Figure 22,

may be used to connect this plug to a two-pole

receptacle, as shown in Figure 22, if a properly

grounded outlet is not available. The temporary

adapter should only be used until a properly

grounded outlet can be installed by a qualified

electrician. This adapter is not applicable in

Canada. The green colored rigid ear, lug, or tab,

extending from the adapter, must be connected

to a permanent ground such as a properly

grounded outlet box, as shown in Figure 22.

Figure 22

230 Volt Conversion

If 230V, single-phase operation is desired, the

following instructions must be followed:

1. Disconnect machine from power source.

2. This band saw is supplied with four motor

leads that are connected for 115V

operation, as shown in Figure 23.

Reconnect these four motor leads for 230V

operation, as shown in Figure 23.

3. The 115V attachment plug supplied with the

band saw must be replaced with a UL/CSA

listed plug suitable for 230V operation, as

shown in Figure 24. Contact your local

authorized Walter Meier service center or

qualified electrician for proper procedures to

install the plug. The band saw must comply

with all local and national codes after the

230 volt plug is installed.

4. The band saw with a 230 volt plug should

only be connected to an outlet having the

same configuration (Figure 24). No adapter

is available or should be used with the 230

volt plug.

Important: In all cases (115 or 230 volts),

make certain the receptacle in question is

properly grounded. If you are not sure, have

a registered electrician check the receptacle.

Figure 23

Figure 24

15

Page 16

Extension Cords

Use only three wire extension cords that have

three-prong grounding plugs and three-pole

receptacles that accept the tool’s plug.

Make sure the cord is in good condition, and

heavy enough to carry the current your band

saw will draw. An undersized cord will cause a

drop in line voltage, resulting in loss of power

and overheating. Figure 25 shows t he correct

size to use depending on cord length and the

ampere rating on your machine’s nameplate. If

in do ubt, us e t he ne xt hea vier ga uge. T he

smaller the gauge number, the heavier the cord.

Repair or replace a damaged or worn cord

immediately.

Adjustments

Unplug the machine from the

power source before making any repairs or

adjustments. Failure to comply may cause

serious injury.

Minimum Gauge Extension Cord

Amp

rating

0-6 120

6-10 120

10-12 120

12-16 120

Line

voltage

Total length of

cord in feet

0 to 25 18

25 to 50 16

50 to 100 16

over 100 14

0 to 25 18

25 to 50 16

50 to 100 14

over 100 12

0 to 25 16

25 to 50 16

50 to 100 14

over 100 12

0 to 25 14

25 to 50 12

over 50

Figure 25

Cord gauge

(AWG)

not recommended

Tilting the Table

1. Loosen two lock knobs (Figure 26).

2. Tilt table up to 45 degrees to the right or

up to 10 degrees to the left. The angle can

be read on the scale mounted to the

trunnion.

3. Tighten two lock knobs (Figure 26).

Note: Table stop must be removed to tilt table to

the left.

Adjusting 90°°°° Table Stop

1. Disconnect machine from power source.

2. Loosen lock knobs (Figure 26) and tilt

table left until it rests against the table

stop.

3. Use a square placed on the table and

against the blade (Figure 27) to see if the

table is 90 degrees to the blade.

4. If an adjustment is necessary, loosen lock

knobs, tilt table to the right, and lock in

place.

Figure 26

Figure 27

16

Page 17

5. Loosen jam nut and turn table stop (Figure

26) left or right to raise or lower the stop.

Tighten jam nut to hold table stop in place.

6. Unlock table, tilt back onto table rest and

confirm table is 90 degrees with the blade.

7. If necessary, adjust scale pointer to zero.

Changing Blades

Blade teeth are sharp! Use

care when handling the saw blade. Failure to

comply may cause serious injury.

1. Disconnect machine from power source.

2. Loosen blade tension by turning the

tension knob counterclockwise (Figure 28).

3. Remove the table insert and the table pin.

4. Open both wheel covers.

5. Remove the blade from between upper

and lower blade guides. Remove blade

from upper and lower wheels. Turn blade

to direct through slot in table.

6. Guide new blade through table slot. Place

blade in upper and lower blade guid es.

Note: The blade teet h should face t he

operator, and they should point down

toward the table.

7. Place blade in the middle of the upper and

lower wheel.

8. Re-install table insert and table pin.

9. Tension and track blade before operating

saw. Find inst ruct io ns for tens io ni ng and

tracking the blade under "Adjusting Blade

Tension" and "Adjusting Blade Tracking".

Adjusting Blade Tension

1. Disconnect machine from power source.

2. Turn blade tension knob (Figure 28)

clockwise to tension blade. A gauge on the

upper wheel slide bracket indicates the

approximate tension according to the width

of the blade. Initially, set the blade tension

to correspond to the blade width as marked

on the gauge.

Figure 28

17

Page 18

3. As you become more experienced with the

saw, you may find it necessary to change

the blade tension from the initial setting.

Changes in blade width and the type of

material being cut will have an effect on

blade tension.

4. Keep in mind that too little or too much

blade tension can cause blade breakage.

Adjusting Blade Tracking

Disconnect machine from the

power source. Never adjust blade tracking

with the machine running. Failure to comply

may cause serious injury.

“Tracking” refers to how the blade is situated

upon the wheels w hile in motion. The blade

should track in the center of both wheels.

1. The blade must be properly tensioned

before adjusting blade tracking. Make sure

blade guides and blade bearings do not

interfere with the blade.

2. Open the top wheel cover. Rotate the wheel

forward by hand, and observe the position

of the blade on the wheel - it should be in

the center of the wheel.

3. If adjustment is necessary, loosen wing nut

(Figure 29), and tighten tracking knob

slightly to move blade toward rear of

machine. Slightly loosening the tracking

knob will cause the blade to track toward the

front of the machine.

4. After blade is tracking in the center of the

wheel, tighten the wing nut.

Adjusting Upper Blade Guide Assembly

Figure 29

1. Disconnect machine from power source.

2. Loosen lock knob (A, Figure 30) and raise

or lower upper blade guide assembly (B,

Figure 30) to just above the material being

cut.

Figure 29

18

Page 19

3. Tighten lock knob. Make sure blade guide

blocks (C, Figure 30) are still flat to the

blade. If adjustment is necessary, loosen

lock knob (A, Figure 30) and rotate

assembly until guide blocks are flat to blade.

4. If movement of the blade guide assembly

seems “stiff” when being raised or lowered,

it can be adjusted to slide more easily. This

is controlled by an internal spring and ball

which provide varying degrees of resistance

against the guide post. Use the set screw

(D, Figure 30) to adjust the tension of this

spring. To ad j ust t ension on t he spri ng,

loosen knob (A, Figure 30), use a hex

wrench to tighten or loosen set screw (D,

Figure 30) until desired tension is reached,

then re-tighten knob (A, Figure 30).

Adjusting Blade Guide and Blade Support Bearing

Blade guard has been

removed for picture clarity. Never operate

the band saw without all guards in place and

in working order.

1. Disconnect machine from power source.

2. Blade must already be tensioned and

tracking properly.

3. Loosen thumb screws (E, Figure 31) and

move guide blocks (C, Figure 31) as close

to the blade as possible without pinching it.

4. Tighten thumb screws (E, Figure 31).

5. Loosen thumb screw (F, Figure 31) and turn

knurled knob (G, Figure 31) to move the

guide block bracket in or out until the front

edge of the guide blocks are just behind the

"gullets" of the saw teeth.

6. Tighten thumb screw (F, Figure 31).

7. The blade support bearing (K, Figure 31)

should be adjusted so that the back edge of

the blade overlaps the front face of the ball

bearing approximately 1/8". To change

position of the bearing, remove screw (L,

Figure 31), and bearing (K, Figure 31).

Loosen thumb screw (H, Figure 31) and

back off knurled knob (J, Figure 31)

completely to remove the bearing shaft.

Figure 31

19

Page 20

8. Notice the bearing holder on the shaft is

eccentric. Index the bearing shaft to another

position and slide it back in, making sure the

flange on the thumb screw (H, Figure 31)

properly seats into the groove of the bearing

shaft. Re-install the bearing and the screw.

Examine the overlap between the bearing

face and the blade. Change the position of

the bearing shaft until the overlap is

approximately 1/8".

9. With the thumb screw (H, Figure 31) still

loosened, adjust the distance from bearing

to blade. Turn knurled knob (J, Figure 31) to

move the support bearing (K, Figure 31) in

or out until the bearing is 1/64" behind the

blade. (NOTE: To set this distance quickly,

you can place a dollar bill or piece of paper

between support bearing and back of

blade.)

10. Tighten thumb screw (H, Figure 31).

11. Repeat procedures 1 through 10 for the

Lower Blade Guide Assembly.

Figure 31

(repeated)

20

Page 21

Troubleshooting JWBS-14CS/OS Band Saw

Trouble Probable Cause Remedy

Saw unplugged. Check all plug connections.

Saw stops or will not

start.

Fuse blown, or circuit breaker tripped. Replace fuse, or reset circuit breaker.

Cord damaged. Replace cord.

Does not make

accurate 45 or 90

degree cuts.

Blade wanders during

cut.

Saw makes

unsatisfactory cuts.

Table stop not adjusted correctly.

Angle pointer not set accurately.

Miter gauge out of adjustment. Adjust miter gauge.

Fence not aligned with blade.

Warped wood. Select another piece of wood.

Excessive feed rate. Reduce feed rate.

Incorrect blade for cut. Change blade to correct type.

Blade tension not set properly.

Guides not set properly. Adjust guides.

Dull blade. Replace blade.

Blade mounted wrong.

Gum or pitch on blade.

Check blade with square and adjust

table stop.

Check blade with square and adjust

pointer.

Check and adjust fence (see fence

manual).

Set blade tension according to blade

size.

Teeth should face operator and point

downward.

Remove blade and clean with oven

cleaner or other solvent.

Blade does not come

up to speed.

Saw vibrates

excessively.

Incorrect blade for cut. Change blade to correct type.

Gum or pitch on table. Clean table.

Extension cord too light or too long.

Low shop voltage. Contact your local electric company.

Base on uneven floor. Reposition on flat, level surface.

Bad v-belt. Replace v-belt.

Motor mounting is loose. Tighten motor mount fasteners.

Loose fasteners. Tighten fasteners.

Replace with adequate size and

length cord.

21

Page 22

Optional Accessories

708718R JRF-14 Deluxe Rip Fence Assembly with Resaw

Includes guide bars, rip fence assembly, resaw post, fasteners, and mounting instructions with

parts list.

708717 JRB-14 Riser Block Kit

Increases depth of cut from 6" maximum to 12" maximum. Includes 6" cast block, long frame

bolt, front and back blade guards, 105” blade, and mounting instructions with parts list.

708716 JMG-14 Miter Gauge Assembly

For straight and angle cutting. Includes guide bar, pivoting support body, and adjustable

stops.

708719 JBB-14 Blade Block Set

Includes upper and lower replacement blocks made from a non-metallic composite material

with a dry lubricant to reduce friction and heat.

708127 JRBG-14 Roller Bearing Guides

Dual bearing system maximizes contact and minimizes friction against the blade. Includes

upper and lower guide assemblies, mounting studs, adaptor blocks, and mounting hardware.

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.waltermeier.com).

Having the Model Number and Serial Number of your machine available when you call will allow us to

serve you quickly and accurately.

22

Page 23

Body Assembly (JWBS-14CS/OS Band Saw)

Index No. Part No. Description Size Qty

1 .............. 150100AW ..............Upper Arm Frame ............................................................................... 1

2 .............. 150037W ................Table ................................................................................................. 1

3 .............. 100038....................Table Pin............................................................................................ 1

4 .............. 708719....................Guide Block........................................................................................ 4

5 .............. 150005A .................Upper Support Bracket Post ................................................................ 1

6 .............. 150006A .................Support Bracket .................................................................................. 2

7 .............. 150007A .................Guide Post ......................................................................................... 1

8 .............. TS-1490021 ............Hex Cap Screw ................................................M8x16........................ 2

9 .............. WF083030 ..............Flat Washer......................................................M8 ............................. 1

10 ............ 150010A .................Nut .................................................................................................... 4

11 ............ 990708....................Screw ..............................................................M8x40........................ 2

12 ............ TS-1482031 ............Hex Cap Screw ................................................M6x16........................ 1

13 ............ 150013A .................Thumb Screw ...................................................M6x16........................ 3

14 ............ 150014A .................Thumb Screw ..................................................M6x12........................ 5

15 ............ 150015A .................Upper Spacing Sleeve ........................................................................ 2

16 ............ BB-6200ZZ ..............Ball Bearing........................................................................................ 2

17 ............ 990908....................Pan Head Screw* .............................................M6x8 ......................... 2

18 ............ 100002A .................Upper Wheel Blade Guard .................................................................. 1

19 ............ TS-148201 ..............Hex Cap Screw ................................................M6X10 ....................... 2

20 ............ TS-1550041 ............Washer ............................................................M6 ............................. 4

21 ............ 990651....................Lock Kno b ........................................................M10x30 ...................... 1

22 ............ 199037....................Table Insert ........................................................................................ 1

23 ............ 992311....................Spring Pin .......................................................................................... 1

25 ............ TS-1482041 ............Phillips Pan Head Machine Screw......................M6x20........................ 2

26 ............ 150024....................Catch Knob ........................................................................................ 2

27 ............ TS-1551061 ............Lock Washer* ...................................................M8 ....................... 2(2)*

28 ............ 150028W ................Inner Wheel Cover .............................................................................. 1

29 ............ 155029W ................Outer Wheel Cover ............................................................................. 1

30 ............ 100031....................Pin ..................................................................................................... 4

31 ............ 990180....................Hex Head Bolt ..................................................M16x55 ...................... 1

32 ............ WF-164030 .............Washer ............................................................M16 ........................... 2

33 ............ TS-1540101 ............Hex Nut............................................................M16 ........................... 1

34 ............ 100188....................Base .................................................................................................. 1

35 ............ 110045....................Trunnion Support Bracket.................................................................... 1

36 ............ 100042....................Trunnion ............................................................................................ 2

37 ............ 100051....................Scale ................................................................................................. 1

38 ............ 100041....................Trunnion Clamp Shoe ......................................................................... 2

39 ............ TS-1491081 ............Hex Cap Screw ................................................M10x50 ...................... 2

40 ............ TS-1482021 ............Hex Cap Screw ................................................M6x12........................ 6

41 ............ 110049....................Pointer ............................................................................................... 1

42 ............ 990821....................Pan Head Screw...............................................M5x6 ......................... 5

43 ............ TS-1490151 ............Hex Cap Screw* ...............................................M8x80........................ 1

44 ............ TS-1540061 ............Hex Nut* ..........................................................M8 ............................. 1

45 ............ TS-1490051 ............Hex Cap Screw* ...............................................M8X30 ....................... 2

46 ............ 990554....................Lock Knob ........................................................ ................................. 2

47 ............ TS-152303 ..............Set Screw ........................................................M6x10........................ 1

48 ............ 100063....................Belt Pulley .......................................................................................... 1

49 ............ 992547....................Retaining Ring .................................................................................... 1

50 ............ 110065....................Lower Wheel Shaft ............................................................................. 1

51 ............ 992009....................Key ..................................................................5x5x20 ....................... 2

52 ............ BB-6204RS .............Ball Bearing......................................................6204RS...................... 2

53 ............ 990293....................Hex Head Bolt (Left Thread) ..............................M8x25........................ 1

54 ............ 150054....................Hex Head Bolt .................................................................................... 2

55 ............ 150055....................Lower Support Bracket Post ................................................................ 1

56 ............ 150056....................Switch Backing Plate .......................................................................... 1

57 ............ 523028....................Switch Box ......................................................................................... 1

58 ............ 994542....................Switch ................................................................................................ 1

23

Page 24

Body Assembly (JWBS-14CS/OS Band Saw)

Index No. Part No. Description Size Qty

59 ............ 995001....................Power Cord (Switch To Motor) ............................................................. 1

60 ............ 995002....................Power Cord (Switch To Power Soure) .................................................. 1

61 ............ 990814....................Self Tapping Screw ...........................................M3.5x19 ..................... 2

62 ............ TS-1550021 ............Flat Washer......................................................M4 ............................. 2

63 ............ TS-1533042 ............Phillips Pan Head Machine Screw......................M5x12........................ 6

64 ............ 523024....................Wire Clip ............................................................................................ 1

65 ............ TS-1533032 ............Phillips Pan Head Machine Screw......................M5x10........................ 4

66 ............ 150066....................Stud ................................................................................................... 2

67 ............ 150902....................Lower Hinge ....................................................................................... 1

68 ............ WF051210 ..............Washer ............................................................M5 ............................. 2

69 ............ 150069N .................Lower Wheel Guard ............................................................................ 1

70 ............ 198672....................Lower Wheel ...................................................................................... 1

71 ............ 100025A ................Wheel Protector .................................................................................. 2

72 ............ 198242....................Upper Wheel ...................................................................................... 1

73 ............ 992522....................Retaining Ring ..................................................R35 ........................... 2

74 ............ BB-6202ZZ ..............Ball Bearing......................................................6202ZZ ...................... 2

75 ............ TS-1540083 ............Hex Nut............................................................M12 ........................... 1

76 ............ ...............................Saw Blade (Local Purchase)................................................................ 1

77 ............ 990804....................Self Tapping Screw ...........................................M4x8 ....................... 16

78 ............ 150901....................Upper Hinge ....................................................................................... 1

79 ............ 150079....................Catch ................................................................................................. 2

80 ............ 150080....................Clip .................................................................................................... 2

81 ............ 150081....................Bracket .............................................................................................. 2

82 ............ 110070....................Blade Guard ....................................................................................... 1

83 ............ 990811....................Self Tapping Screw ...........................................M3.5x12 ..................... 2

................ 100016ACP .............Sliding Bracket Assy (includes items 84 thru 93, and 104) ..................... 1

84 ............ 100016A .................Sliding Bracket ................................................................................... 1

85 ............ 100019....................Shaft Hinge ........................................................................................ 1

86 ............ 150086....................Upper Wheel Shaft ............................................................................. 1

87 ............ 100021....................Steel Pin ............................................................................................ 2

88 ............ 992314....................Spring Pin .......................................................................................... 1

89 ............ 100015A .................Coil Spring ......................................................................................... 1

90 ............ 150090....................Square Nut ......................................................................................... 1

91 ............ 990652....................Lock Kno b .......................................................................................... 1

92 ............ NW080000 ..............Wing Nut ..........................................................M8 ............................. 1

93 ............ 990653....................Blade Adjusting Screw ........................................................................ 1

95 ............ TS-1490071 ............Hex Cap Screw* ...............................................M8x40........................ 4

96 ............ TS-1550061 ............Flat Washer* ....................................................M8 ............................. 4

97 ............ 150097....................Washer .............................................................................................. 2

98 ............ 994181....................Steel Ball............................................................................................ 1

99 ............ 150099....................Spring ................................................................................................ 1

100 .......... TS-1525011 ............Socket Set Screw .............................................M10x10 ...................... 1

101 .......... 150101....................Lower Wheel Blade G uard .................................................................. 1

102 .......... WE050000 ..............Gear Washer ....................................................M5 ............................. 2

103 .......... 998654....................Strain Relief ....................................................................................... 2

104 .......... 100018....................Indicator ............................................................................................. 1

105 .......... WI080000................Gear Washer ....................................................M8 ............................. 2

................ JWBS14-HK ............Hardware Kit (not shown) .................................................................... 1

* .............. included in hardware kit

24

Page 25

Body Assembly (JWBS-14CS/OS Band Saw)

25

Page 26

Closed Stand Assembly (JWBS-14CS Band Saw)

Index No. Part No. Description Size Qty

1 .............. 150501W ................Stand ................................................................................................. 1

2 .............. 150502W ................Door .................................................................................................. 1

3 .............. 150503....................Door Latch Assembly .......................................................................... 1

4 .............. WBS14CS-04 ..........Washer .............................................................................................. 2

5 .............. WBS14CS-05 ..........Pan Head Screw...............................................M4x5 ......................... 2

6 .............. PG-M02 ..................JET Plaque ........................................................................................ 1

7 .............. TS-1533031 ............Flat Head Screw ...............................................M5x10........................ 2

8 .............. 150508W ................Plate .................................................................................................. 1

9 .............. 998621....................Strain Relief ....................................................................................... 1

10 ............ TS-1533042 ............Phillips Pan Head Machine Screw* ....................M5x12........................ 2

11 ............ 150511W ................Motor Plate......................................................................................... 1

12 ............ 150512W ................Motor ...............................................................1HP, 1Ph, 115/230V ... 1

13 ............ 600013....................Motor Pulley ....................................................................................... 1

14 ............ VB-A50 ...................V-BELT .............................................................................................. 1

15 ............ TS-1523011 ............Socket Set Screw .............................................M6x6 ......................... 1

16 ............ 100254....................Pulley Box .......................................................................................... 1

17 ............ 990624....................Knob*................................................................................................. 2

20 ............ TS-1490041 ............Hex Cap Screw ................................................M8x25........................ 4

21 ............ 991516....................Square Neck Bolt..............................................M8x16........................ 4

22 ............ TS-1550051 ............Flat Washer* ....................................................M8 ......................16(4)*

23 ............ TS-155108 ..............Lock Washer* ...................................................M8 ......................12(4)*

24 ............ TS-1540061 ............Hex Nut* ..........................................................M8 ......................12(4)*

26 ............ 995003A .................Motor Cord ......................................................................................... 1

27 ............ 150527....................Pad.................................................................................................... 2

................ WBS14CS-HK .........Hardware Kit (Not Shown) ................................................................... 1

* .............. included in hardware kit

26

Page 27

Closed Stand Assembly (JWBS14-CS Band Saw)

27

Page 28

Open Stand Assembly (JWBS-14OS Band Saw)

Index No. Part No. Description Size Qty

1 .............. 150602W ................Top Plate ........................................................................................... 1

2 .............. 150603W ................Stand Leg .......................................................................................... 4

3 .............. 150604W ................Support Plate-long .............................................................................. 2

4 .............. 150605W ................Support Plate-short ............................................................................. 2

5 .............. 150606W ................Support Plate-upper ............................................................................ 1

6 .............. 150607W ................Pulley Cover ....................................................................................... 1

7 .............. 150608W ................Inner Pulley Cover .............................................................................. 1

8 .............. 990804....................Self Tapping Screw ...........................................M4x8 ......................... 5

9 .............. 150609W ................Motor ................................................................................................. 1

10 ............ 600013....................Motor Pulley ....................................................................................... 1

11 ............ VB-A39 ...................V-belt ................................................................................................. 1

12 ............ TS-1523011 ............Socket Set Screw .............................................M6x6 ......................... 1

13 ............ PG-M02 ..................JET Plaque ........................................................................................ 1

14 ............ TS-1533031 ............Flat Head Screw ...............................................M5X10 ....................... 2

15 ............ TS-1490061 ............Hex Cap Screw* ...............................................M8x35........................ 4

16 ............ 991516....................Carriage Bolt* ...................................................M8x16...................... 40

17 ............ TS-15550051...........Washer* ...........................................................M8 ........................... 52

18 ............ TS-155108 ..............Lock Washer* ...................................................M8 ........................... 48

19 ............ TS-1540061 ............Hex Nut* ..........................................................M8 ........................... 48

20 ............ TS-1533042 ............Phillips Pan Head Machine Screw* ....................M5x12........................ 3

21 ............ TS-1550031 ............Flat Washer* ....................................................M5 ............................. 6

22 ............ TS-1540041 ............Hex Nut* ..........................................................M5 ............................. 3

23 ............ 150623....................Rubber Mount* ................................................................................... 4

24 ............ 150624....................Support Plate ..................................................................................... 1

25 ............ 995004A .................Motor Cord ......................................................................................... 1

26 ............ 150627....................Pad.................................................................................................... 1

27 ............ JWBS14OS-208 ......Rubber Foot (set of 4) ......................................................................... 1

................ WBS14OS-HK .........Hardware Kit (not shown) .................................................................... 1

* .............. included in hardware kit

28

Page 29

Open Stand Assembly (JWBS-14OS Band Saw)

29

Page 30

Electrical Connections – 115 volt (JWBS-14CS/OS Band Saw)

30

Page 31

Electrical Connections – 230 volt (JWBS-14CS/OS Band Saw)

31

Page 32

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.waltermeier.com

32

Loading...

Loading...