Page 1

Operating Instructions and Parts Manual

14-inch Deluxe Band Saw

Models: JWBS-14DX

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-710115

Ph.: 800-274-6848 Revision D 7/04

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared for the owner and operators of a JET Model JWBS-14DX

Band Saw. Its purpose, aside from proper machine operation, is to promote safety

through the use of accepted operating and maintenance procedures. To obtain maximum

life and efficiency from your band saw, and to aid in using the machine safely, read this

manual thoroughly and follow all instructions carefully.

Warranty & Service

WM H Tool Group warrants every product it sell s. If one of our tools needs service or r epair, one of

our Authorized Repair Stations located throughout the United States can giv e y ou quick service.

In most cases, any one of these WMH Tool Group Repair Stations can authori z e warrant y r epair,

assist you in obtaini ng parts, or perform r outine m aintenance and m ajor repair on your J E T,

Performax, Powermatic or Wil ton tools.

For the nam e of an Authorized Repair Station in your area, call 1-800-274- 6848.

More Information

WM H Tool Group is consistently adding new products to the li ne. For complete, up- to-date product

infor mati on, check with your local WMH Tool Group distributor or visit wmht oolgroup.com.

Limited Warranty

WM H Tool Group (including JET, Perf or max, Powermati c and Wilton br ands) makes ev er y effort to

assure that its products meet high quality and durability standards and warrants to the original retail

consumer/purc haser of our products that eac h pr oduc t be free from defects in materials and

workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS

SPECIFIED OT HERWISE. This warranty does not apply to defects due directly or indirectly t o

misuse, abuse, negl igence or accidents, normal wear-and- tear, repair or alterations outside our

facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE I M P LIED WARRANT Y

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. WMH TOOL GROUP SHALL IN

NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTI NGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE

USE OF OUR P RODUCTS. SO M E S TATES DO NOT ALLOW THE EXCLUSIO N OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITAT I O N OR

EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of t his warranty, the product or part must be r eturned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. P r oof of pur c hase dat e and an

explanat ion of the complaint must accompany the merchandi se. If our inspection di scloses a

defect, WMH Tool G r oup will either repair or replace the product, or refund t he pur c hase price if we

cannot readily and quickly provide a repair or r eplacement, if you are willing to accept a refund.

WM H Tool Group will return repaired product or replacement at our expense, but if it is determined

there is no def ect, or that the def ec t resulted from causes not wit hin the scope of our warranty, then

the user must bear t he c ost of stori ng and r eturning the pr oduc t. This warranty gi ves you specific

legal rights; you may also have ot her r ights, which vary f r om state to state.

WM H Tool Group sells through distributors only. W M H Tool Group reserves the right to effect at any

tim e, without prior notic e, those alterations to parts, fittings, and accessory equipment which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty.....................................................................................................................................2

Safety Warnings......................................................................................................................4-5

Safety Decal ...............................................................................................................................6

Grounding Instructions ................................................................................................................7

115 Volt Oper ation......................................................................................................................7

230 Volt Oper ation......................................................................................................................8

Specifications .............................................................................................................................9

Fasteners..................................................................................................................................10

Receiving..................................................................................................................................11

Assembly ..................................................................................................................................11

Tilting the Tabl e ........................................................................................................................14

Adjusting 90

Changing Blades.......................................................................................................................15

Adjusting Blade Tension............................................................................................................15

Adjusting Blade Tracking...........................................................................................................16

Adjusting Upper B lade Guide Assem bly ....................................................................................16

Adjusting Upper B lade Guides & Blade Support Bearing...........................................................17

Adjusting Lower Blade Guides & Blade Support Bearing ........................................................... 18

Trouble-shooting.......................................................................................................................19

Parts Breakdowns:

Body Assembly..............................................................................................................20-23

Closed Stand Assembl y .................................................................................................24-25

Optional Accessories.................................................................................................................26

Electrical Sc hemati c – 115V ......................................................................................................27

Electrical Sc hemati c – 230V ......................................................................................................28

O

Stop....................................................................................................................14

3

Page 4

WARNING

As with al l mac hines, there i s a certain am ount of hazard i nvolv ed with the use of this band saw.

Use the machi ne with the respect and c aution demanded where saf ety precauti ons are concerned.

When normal safety precautions are overlooked or ignored, personal injury to the operator can

resul t.

• READ, UNDERSTAND AND FOLL OW the safety and oper ating instr uc tions found in this

manual. K now the lim itations and hazards associated with thi s machine.

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of c hec k ing to see that key s

and adjusting wrenches are remov ed from the tool before turning it on.

• KEEP THE WORK AREA CLEAN. Clut tered areas and benches invite ac c idents.

• DO NOT US E IN A DANGEROUS ENVIRONME NT. Don’t use power tool s i n damp or wet

locati ons, or expose them t o rain. Keep work area well lighted.

• KEEP CHILDREN AWAY. Al l visitor s should be kept a safe distanc e from the work area.

• MAKE THE WORKSHO P CHILD PROOF with padlocks, master switches, or by r emoving

starter keys.

• DON’T FORCE T HE TOO L . It will do the job better and safer at t he r ate for whic h it was

designed.

• USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was not

designed.

• USE THE PROPER EXTENSION CORD. Make sure your extension cor d is in good condition.

When usi ng an extension cor d, be sure to use one heavy enough to carry the c ur r ent your

product will draw. An undersize cord will cause a drop in line voltage resulting in l oss of power

and overheating. T he table below shows the correct siz e to use depending on cord lengt h and

nameplat e ampere rating. If in doubt, use the next heavier gauge. The smaller t he gauge

number, t he heavier the cord.

Cord Length Cord Gauge

115 volt 230 volt

25’ 50’ 16 AWG

50’ 100’ 16 AWG

100’ 200’ 14 AWG

150' 300' 12 AWG

• WEAR PROPER APPAREL. Do not wear loose clothing, glov es, nec k ties, ri ngs, br ac elets, or

other jewelry whic h may get caught in moving parts. Nonsli p footwear is recommended. W ear

protecti ve hair covering to c ontain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust masks if the cutting operation is

dusty. NOTE: Common eyeglasses only have im pact resistant lenses, they are NOT safety

glasses.

4

Page 5

• SECURE WORK. Use clamps or a vise to hold t he work when it’s practical. It’s saf er than

using your hand and it frees both hands to operate the tool.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN T OOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing ac cessories.

• DISCONNECT TO OLS bef ore servicing; when changi ng ac c essori es, such as blades, bits

cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the off

position before plugging in the machine.

• USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recommended

accessories. The use of improper ac c essories may cause a risk of injur y .

• NEVER STAND ON A TOOL. Serious injury could oc c ur if the tool is tipped or if the cutting

tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before fur ther use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform its

intended function. Check f or alignm ent of moving parts, binding of moving parts, breakage of

parts, mounting, and any ot her c onditions that may affec t its operation. A guard or other part

that is dam aged should be properly r epaired or replaced.

• DIRECTION OF FEED. Feed work into a bl ade or c utter against the direction of r otation of the

blade or cutt er only.

• NEVER LEAVE THE TOOL RUNNING UNAT TENDED. TURN THE POWER O FF. Don’t

leave the tool until it com es to a c omplet e stop.

• DRUGS, ALCOHOL, MEDICAT ION. Do not oper ate this mac hine while under t he influence of

drugs, alcohol , or medi c ation.

• HEALTH HAZARDS. Som e dust c r eated by power sanding, sawing, gri nding, drilling and

other construct ion activities contains chemicals known to cause cancer, birth def ec ts or other

reproducti ve harm. Some exam ples of these chemicals are:

* Lead from lead-based paint .

* Crystalline silica from bricks and cement and other masonry produc ts.

* Arsenic and chromium from chemically -treated l umber.

Your risk from t hese exposures varies, depending on how oft en y ou do this type of work. To

reduce your ex posure t o these chemic als, work in a well- ventilated ar ea, and work with

approved safety equi pment, such as those dust m asks that are specifically designed to filter out

microscopic particles.

5

Page 6

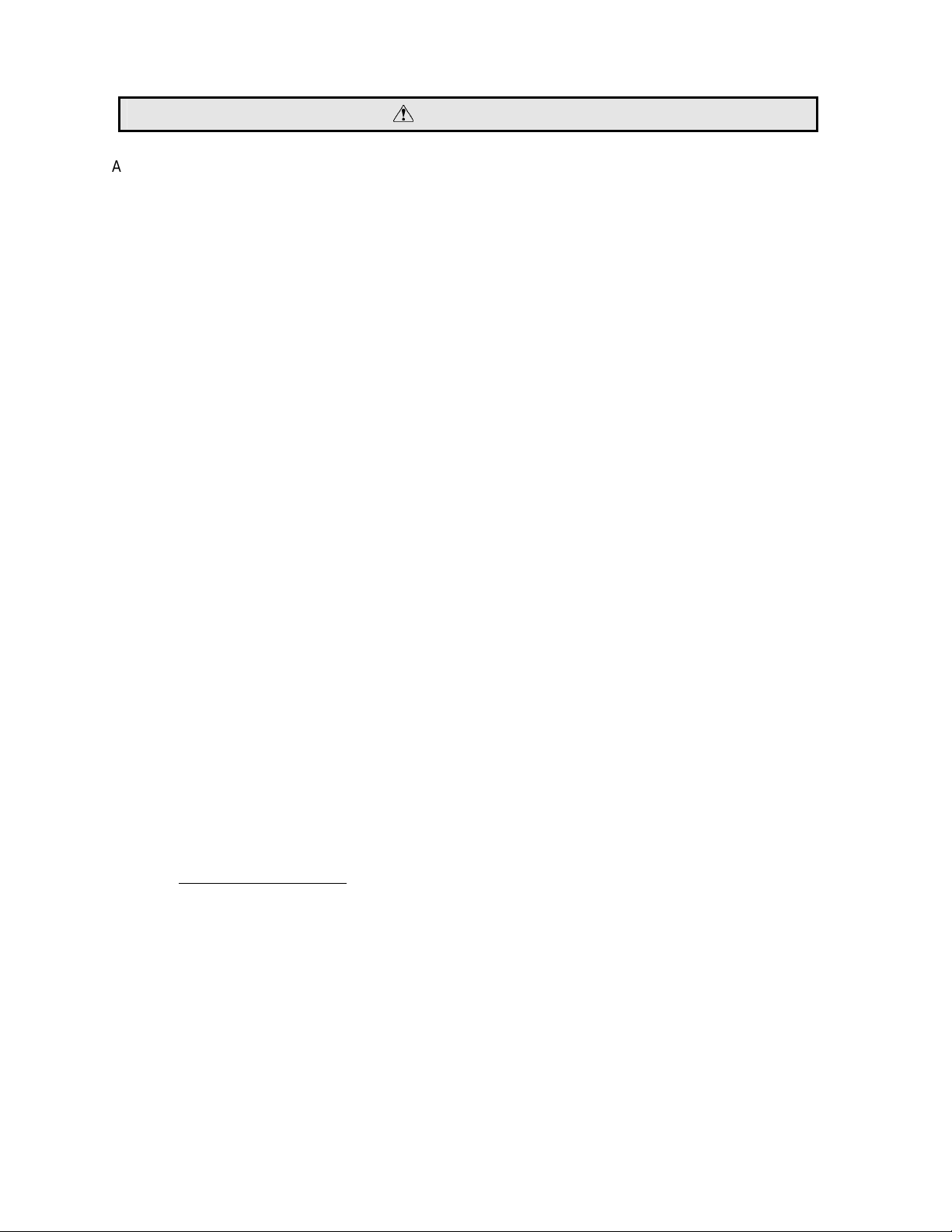

SAFETY DECAL

Familiarize yourself with the location and content of this decal on your machine.

Fig. 1

6

Page 7

Grounding Instructions

Caution: This tool must be grounded while in use to protect the operator from electric

shock.

In the event of a malfunction or breakdown, groundi ng pr ovides a path of l east r esi stanc e for

electric current to reduce the risk of el ec tric shock. This tool is equipped with an el ec tric cor d

having an equipm ent-grounding conduc tor and a grounding plug. The plug must be plugged into a

matching outlet that is properly instal led and grounded in acc or danc e with all local codes and

ordinances.

Do not modi fy the plug provided. I f it will not fit the outlet, have the proper outlet i nstalled by a

qualified el ec trician.

Improper connection of the equi pment-grounding conductor can r esult in a risk of el ec tric shock.

The conductor, with insulat ion having an outer surface that is green with or without yellow stripes, is

the equipm ent-grounding conduc tor. If repair or r eplacement of the electric cord or pl ug is

necessary, do not connect the equipment-grounding conduc tor to a live terminal.

Check with a qualified electr ician or service personnel if the groundi ng instructions are not

completely understood, or if in doubt as to whether the t ool is properl y gr ounded. Use only three

wire extensi on c or ds that hav e three-prong grounding plugs and three-pole receptacles that accept

the tool’s plug.

Repair or replace a damaged or worn cord immediately.

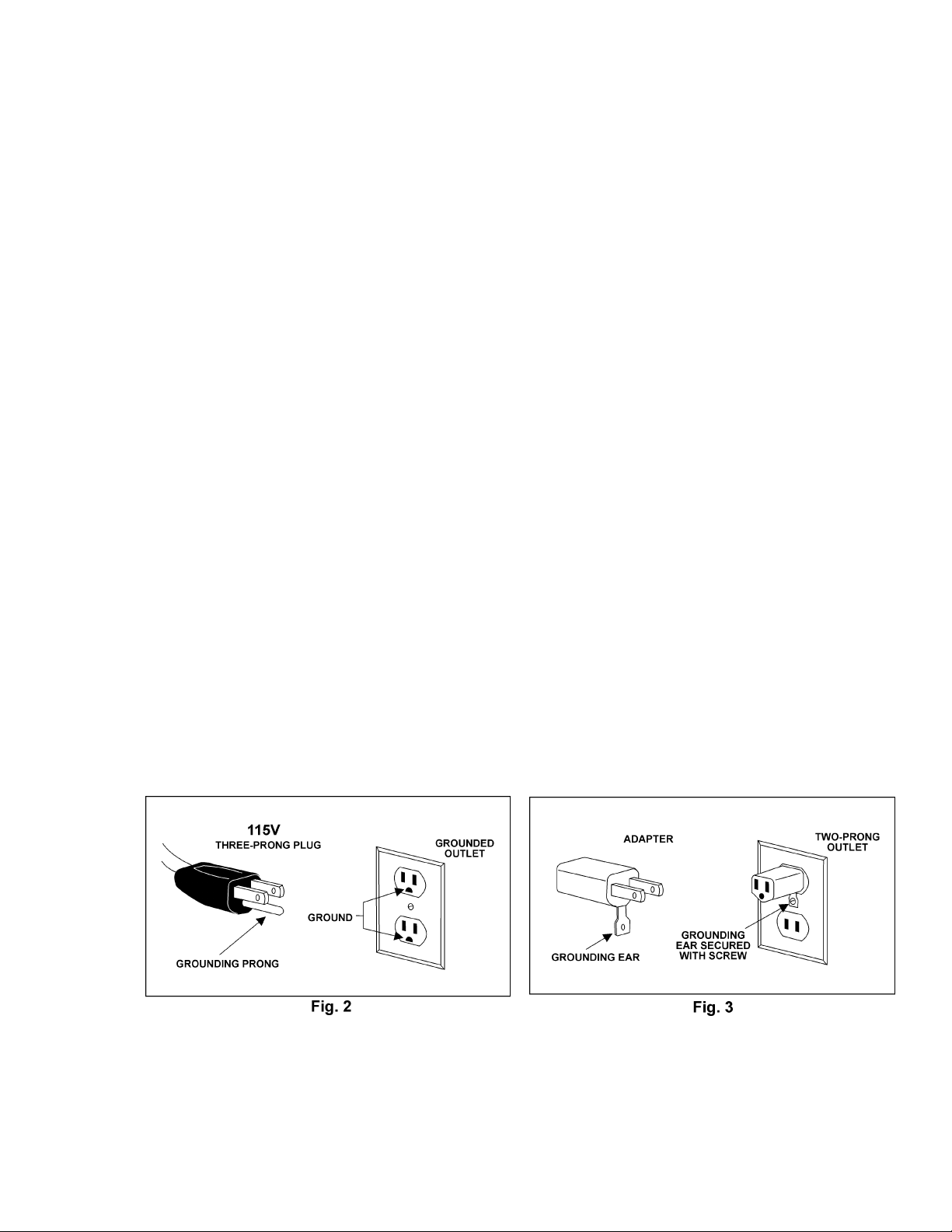

115 Volt Operation

As received fr om the factory, your bandsaw is ready to run at 115 volt oper ation. T his bandsaw,

when wired for 115 volts, is intended for use on a circuit that has an outlet and a plug t hat looks like

the one illustrated in Fig. 2. A temporary adapter, like the adapter in Fig. 3, may be used to connec t

this plug to a two-pole receptacle, as shown in Fig. 3, if a properly gr ounded outlet is not availabl e.

The tempor ary adapter should onl y be used until a proper ly grounded outlet can be installed by a

qualified el ec trician. This adapter is not applicable in Canada. The green colored rigi d ear , lug,

or tab, ex tending from t he adapter, must be connected to a permanent ground such as a properly

grounded outlet box, as shown in Fig. 3.

Page 8

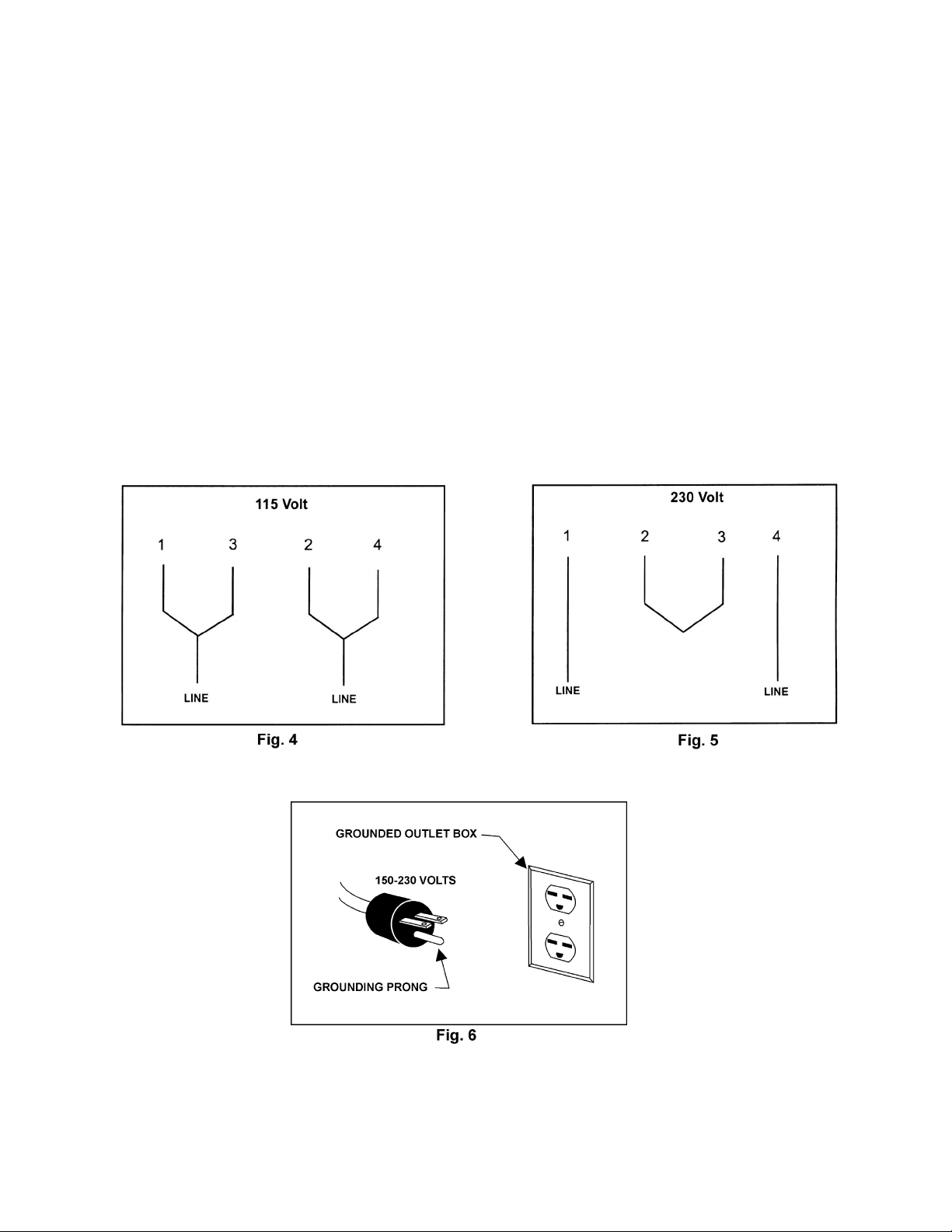

230 Volt Operation

If 230V, single-phase operation is desired, the following instr uc tions must be foll owed:

1. Disconnect the machin e f rom the po wer source.

2. This band saw is supplied with f our motor leads that are connect ed for 115V operation, as

shown in Fig. 4. Rec onnec t these four motor l eads for 230V operation, as shown in Fig. 5.

3. The 115V attachment plug supplied with the band saw must be replaced with a UL/CSA listed

plug suitable for 230V oper ation (Fig. 6). Contact your l ocal authorized WMH Tool Group

servi ce center or qual ified elect r ician for proper procedures to install the plug. The band saw

must comply with all loc al and national codes after the 230 volt plug is instal led.

4. The band saw with a 230 volt plug should only be connected to an out let having the same

confi gur ation (Fig. 6). No adapter is available or should be used with the 230 vol t plug.

Important: In al l cases (115 or 230 vol t s) , make certain the receptacle i n questi on is properly

grounded. If you are not sure, have a registered electrician check the receptacle.

8

Page 9

Specifications: JWBS-14DX Band Saw

Stock Number.................................................................................................................710115K

Cutting Capacity (height)............................................................................................................6”

Cutting Capacity (widt h) .....................................................................................................13-1/2”

Minimum Blade Width.............................................................................................................1/8”

Maximum B lade Width............................................................................................................3/4”

Blade Length......................................................................................................................93-1/2”

Blade Speed .............................................................................................................. 3000 SFPM

Table Size.......................................................................................................................15” x 15”

Table Slot Size........................................................................................................3/8”D x 3/4”W

Table Hei ght from Floor .....................................................................................................43-1/2”

Table Tilt (L-R)..............................................................................................................45°R / 10°

Dust Chute Diameter......................................................................................................... 4” O.D.

Overall Dimensions........................................................................................68”H x 26”W x 19”D

Motor.............................................................................1.25 HP, 1Ph, 115/230V (prewired 115V)

Net Weight (appr ox.).......................................................................................................... 185 lb.

Shipping Weight (approx.).................................................................................................. 197 lb.

The specif icati ons i n this manual are given as general information and ar e not binding. W M H Tool

Group reserves the right to effect, at any time and without pr ior noti c e, alterations to parts, fit tings,

and accessory equipment deemed necessary for any reason whatsoever.

9

Page 10

Fasteners for JWBS-14DX

A. Saw Body to Stand

4 – M8x40 hex c ap scr ews

(approx. 1-1/2" long)

8 – M8 fl at washers

4 – M8 lock washers

4 – M8 hex nuts

B. Strain Relief Plate to Stand

2 – M5x12 pan head m achine screws

C. Belt Co ver t o Base

2 – Knobs

D. Trunnion Bracket to Saw Body

2 – M8x30 hex c ap scr ews

(approx. 1-1/4" long)

2 – M8 lock washers

1 – M8x80 hex c ap scr ew (for tabl e stop -

(approx. 3-1/8” long)

1 – M8 hex nut

Page 11

Receiving

Open both shipping containers and check for shipping

damage. Report any damage immediately to your

distributor and shipping agent. Read the instruc tion

manual t horoughly for assembly, maint enanc e and

safety instructions.

Contents of Shipping Containers

Container One

1 Stand with motor

Container Two

1 Saw body

1 V-belt

1 Belt cover

1 Trunnion support br ac k et

1 Table

2 Table loc k knobs

1 Table pin

1 Table insert

1 Fastener package (see fastener page)

1 Instruction manual

1 Warranty card

Too ls Required for Assembly

3/8" to 1" combination wrench set and

adjustable wrench

#1 and #2 cross point screwdri vers

Assembly

Exposed met al surfaces, such as the table, have

been given a protective coating. This should be

cleaned with a soft clot h and sol vent , such as

kerosene. Do not use an abrasive pad, and do not

get solvents on plastic par ts.

1. Remov e belt cover from inside of stand.

2. Place cabinet stand upright on a lev el surface. If

desired, the stand can be further stabilized by

securing it to the floor with l ag screws through

the inside cor ner holes. If using a mobile base,

lock the cast er s before assembling or operating

the band saw.

3. Wi th the aid of a second person, lift the saw

body out of the shipping cont ainer and place

onto stand top. Be sure front of saw (with JET

logo) f ac es stand front (JE T logo).

11

Page 12

WARNING

Saw body is heavy! Use caution when lifti ng

and stabilize until firmly attached to the

stand! Failure to comply may cause

serious injury!

4. Line up holes in saw body with holes in the top

of the stand. Fasten saw body to the stand with

four M8 x 40 hex cap screws, eight M8 washers,

four M8 lock washers, and four M8 hex nuts (as

shown in item A , page 10).

5. Push motor cord and strain relief pl ate through

the opening in the side of the stand (Fig. 8).

Fasten the strai n r elief plate t o the stand with

two M5 x 12 pan head m ac hine screws (shown

in item B, page 10).

6. Check the alignment of the pulleys by placing a

straight edge against the flat sides of the motor

and wheel pulleys (F ig. 8a). If the pulleys lie in a

straight plane (Fig. 8b) they are aligned. If they

do not lie in a straight plane, loosen the set

screw on one of the pulleys and shift the pulley

in or out until both pulleys lie in a straight plane.

Tighten set screw.

7. Open the lower door, and place the v-belt

around the mot or pulley and the wheel pulley

(see Fig. 8a).

8. Loosen the nuts on the four motor m ounting

bolts (Fig. 8c) and tension the v - belt by pushing

down on the motor. Tighten the four motor

mounti ng nuts.

12

Page 13

9. The v-belt is properly tensioned when f inger

pressure between the two pulleys causes

approximatel y 1/2" deflecti on ( fig. 8d).

10. Screw the two small k nobs (Fig. 9) into the

threaded holes in the saw body. Slide the pulley

cover down over the knobs, and tighten t he

knobs.

11. Attach trunnion support to saw body with two M8

x 30 hex c ap scr ews and two M8 lock washers

(as in item D, page two). See Figure 12.

12. Thread nut on to table stop bolt ( Fig. 12) and

attach to t r unnion support bracket as shown.

13

Page 14

13. To mount t he table, remove pin and insert from

the table (Fig. 13).

14. Rotate the table so that the saw blade will slide

through the slot in the table. Then orient the

table so the screws will slide into the holes on

the trunnion support brac ket. A ttach loc k k nobs

to these screws (Fig. 13).

15. Replace pin and i nsert .

16. Connect the plugs of the mot or cord and switch

cord (Fi g. 13a).

17. Transportation and handling may hav e c aused

some fastener s to loosen. Befor e operating,

check all screws, bolts, and nuts to make sure

they are snug. Operate machi ne only af ter

reading the entire manual including blade

tracking, blade guide adjustment s, and safety

rules.

Tilting the Table

WARNING

Unplug the machine from the power

source before making an y repair or adjustment!

Failure to comply may cause serious injury!

1. Loosen two lock knobs (Fig. 14).

2. Tilt table up t o 45 degr ees to the right or up to

10 degrees to the left, using the scale mounted

to the trunnion.

3. Tighten t wo l oc k k nobs (F ig.14).

Note: Tabl e stop must be rem oved t o tilt table to the

left.

14

Page 15

Adjusting 90°°°° Table Stop

1. Disconnect machin e f rom the po wer source.

2. Loosen lock knobs (Fi g. 14) and tilt tabl e left

until it rests against t able stop.

3. Use a square placed on the tabl e and against

the blade (Fig. 15) to see i f the t able is 90

degrees to the blade.

4. If an adjustment is necessary, loosen lock

knobs, tilt table to the right, and lock in place.

5. Loosen jam nut and t urn table stop (F ig. 14) l eft

or right to raise or lower the stop. Tighten jam

nut to hold t able stop in pl ac e.

6. Unlock table, ti lt back ont o table rest and

confi r m tabl e is 90 degrees with the blade.

7. If necessary, adjust scale pointer to zero.

Changing Blades

WARNING

Blade teeth are sharp! Use care wh en

handling the saw blade.

Failure t o comply may cause serious injury!

1. Disconnect machin e f rom power source.

2. Loosen blade tension by pushing up on t he

release lever (Fig. 16).

3. Remove the table insert and the table pin.

4. Open both wheel covers.

5. Remove the blade from between upper and

lower blade guides. Remove blade from upper

and lower wheels. Turn blade to direct through

slot in table.

6. Guide new blade thr ough table slot. P lace

blade in upper and lower blade guides. Note:

Make sure blade teet h point down toward table.

7. Place blade in the m iddle of the upper and

lower wheel.

8. Replace tabl e insert and tabl e pin.

15

Page 16

9. Tension and track blade before oper ating saw.

Find instructions for tensioni ng and tracking the

blade under "Adjusting Bl ade Tension" and

"Adjusti ng B lade Tracking".

Adjusting Blade Tension

1. Disconnect machin e f rom power source.

2. Turn blade tension knob (Fig. 16) clock wise to

tension blade. A gauge on the upper wheel

slide bracket indicates the approximate tension

according to the width of the blade. I nitially, set

the blade tension to correspond to blade wi dth.

3. As you become familiar with the saw, you may

find it necessary to change t he blade tension

from the initial setting. Changes in blade width

and the type of mater ial bei ng c ut will have an

effect on blade tension.

4. Keep in mind that t oo little or too much blade

tension can cause blade break age.

Adjusting Blade Tracking

WARNING

Disconnect machine fro m t he power source!

Never adjust b lade trackin g with t he

machine running!

Failure to comply may cause serious injury!

“Tracking” refer s t o how the blade is situated upon

the wheels while in motion. The blade should tr ac k in

the center of both wheels.

1. The blade m ust be pr oper ly tensioned before

adjusting blade tracki ng. The release l ever

should be in the down (tensioned) posi tion.

Make sure blade guides and bl ade bear ings do

not interfere with the blade.

2. Open top blade cover. Rotate the wheel

forward and observe the position of t he blade on

the wheel - it shoul d be in the center of the

wheel. See Fi g. 17a.

3. If adjustment is necessary, loosen wing nut (Fig.

17), and tighten tracking knob slight ly to move

blade toward rear of machine. Slightly

loosening the tracking knob will cause the blade

to track t oward t he front of the machine.

4. Tighten wing nut after blade is track ing in the

center of the wheel.

16

Page 17

Adjusting Upper Blade Guide Assembly

1. Disconnect machin e f rom the po wer source.

2. Loosen lock knob (A, Fig. 18) and raise or lower

upper blade guide assembly (B, F ig. 18) to just

above t he material being c ut.

3. Tighten lock knob. Mak e sure blade guide

blocks (C, Fig. 18) are still flat to the blade. If

adjustment is necessary, loosen lock k nob ( A ,

Fig. 18) and rotate assembly until guide blocks

are fl at to blade.

4. The upper blade guide is spring loaded. To

adjust the tensi on on the spring, remov e k nob

(A, Fi g. 18), tighten or loosen set screw (D, F ig.

18) until desired tension is reac hed, and replace

knob.

Adjusting Upper Blade Guide and

Blade Support Bearing

WARNING

Blade guard has been removed for p icture

clarity. Never o perate the bandsaw without

all guards in place and in workin g order!

Failure t o comply may cause serious injury!

1. Disconnect machin e f rom the po wer source.

2. Blade must already be tensioned and tracking

properly.

3. Loosen thumb screws (A, Fi g. 19) and move

guide blocks (B , Fig. 19) as close to the blade

as possible without pinc hing it.

4. Tighten t humb screws (A, Fi g. 19).

5. Loosen thumb screw (C, Fig. 19) and turn

knurled knob (D, Fig. 19) to move the guide

block brack et in or out unt il the front edge of the

guide blocks are just behind the " gullets" of the

saw teeth.

6. Tighten t humb screw (C, Fig. 19).

7. Loosen thumb screw (E, Fig. 19) and tur n

knurled knob (F, Fig. 19) to m ove the support

bearing (G, Fig. 19) in or out until the bear ing is

1/64" behind t he blade.

8. Tighten t humb screw (E, Fig. 19).

17

Page 18

9. The blade support bearing should be adjusted

so that the back edge of the blade overlaps the

front face of the ball bearing approximately 1/8".

To change position of the bear ing, remove

screw (H, Fig. 19) , and bearing (G , Fig. 19), and

back off knurl ed k nob ( F, Fi g. 19) completely to

remove the bearing shaft. Notice the bearing

holder on the shaf t is eccentric. Re-install the

bearing shaft , the bearing, and the screw.

Exam ine the overlap between the bearing f ace

and the blade. Change t he position of the

bearing shaft until the ov er lap is approx imately

1/8".

Adjusting Lower Blade Guides and Blade

Support Bearing

1. Disconnect machin e f rom the po wer source.

2. Blade must already be tensioned and tracking

properly.

3. Loosen thumb screws (A, Fi g. 20) and move

guide blocks (B , Fig. 20) as close to blade as

possible without pinching it.

4. Tighten t humb screws (A, Fi g. 20).

5. Loosen thumb screw (C, Fig. 20) and turn

knurled knob (D, Fig. 20) to move the guide

block brack et in or out unt il the front edge of the

guide blocks are just behind the " gullets" of the

saw teeth.

6. Tighten t humb screw (C, Fig. 20).

7. Loosen thumb screw (E, Fig. 20) and tur n

knurled knob (F, Fig. 20) to m ove the support

bearing (G, Fig. 20) in or out until the bear ing is

1/64" behind t he blade.

8. Tighten t humb screw (E, Fig. 20).

9. The blade support bearing should be adjusted

so that the back edge of the blade overlaps the

front face of the ball bearing approximately 1/8".

To change position of the bear ing, remove

screw (H, Fig. 20) and bear ing (G, Fig. 20), and

back off knurl ed k nob ( F, Fi g. 20) completely to

remove the bearing shaft.

10. Notice t he bear ing holder on t he shaft is

eccentric. Re-install the bearing shaft, the

bearing, and the scr ew. Examine the overlap

between the bearing face and the blade.

Change the position of the bearing shaft until

the ov er lap is approx imat ely 1/8". Re- tighten

thumb screw (E, Fig. 20).

18

Page 19

TROUBLE-SHOOTING (JWBS-14DX Band Saw)

PROBLEM POSSIBLE CAUSE SOLUTION

Saw stops or will not start 1. Saw unplugged 1. Check plug connections

2. Fuse blown or cir c uit breaker tripped 2. Replace fuse or reset

circuit breaker

3. Cord damaged 3. Replace cord

Does not make accur ate 1. Stop not adjusted correctly 1. Check blade with

45 deg. or 90 deg. cuts square and adjust stop

2. Angle poi nter not set accurately 2. Check blade with square

and adjust pointer

3. Miter gauge out of adjustment 3. Adjust miter gauge

Blade wanders during cut 1. Fence not aligned with blade 1. Check and adjust fence

2. Warped wood 2. Select another piece of

wood

3. Excessive feed rate 3. Reduce feed rate

4. Incorrec t blade f or c ut 4. Change blade to correct

type

5. Blade tension not set properly 5. Set blade tension

according to blade size

6. Guides not set pr oper ly 6. Adjust guides

Saw makes unsatisfac tory 1. Dull blade 1. Replace blade

cuts 2. Blade mount ed wrong 2. Teeth should point down

3. Gum or pitch on bl ade 3. Remove bl ade and c lean

4. Incorrec t blade f or c ut 4. Change blade to correct

type

5. Gum or pitch on table 5. Clean table

Blade does not come up 1. E xtension cor d too light or too long 1. Replace with adequate

size and to speed length cord

2. Low shop voltage 2. Contact your local electric

company

Saw vibrates excessively 1. B ase on uneven floor 1. Reposition on fl at, level

surface

2. Bad v-belt 2. Replace v-belt

3. Motor mount is loose 3. Tighten motor mount

hardware

4. Loose hardware 4. Tighten hardware

19

Page 20

Parts Breakdown

JWBS-14DX Body Assembly

20

Page 21

Part s List

JWBS-14DX Body Assembly

Index Part

No. No. Description Size Qty.

1 .........150100AW ................... Upper Arm Frame .............................................. ................................1

2 .........150037W......................Table.................................................................. ................................1

3 .........100038 .........................Table Pin ........................................................... ................................1

4 .........708719 .........................Guide Block....................................................... ................................ 4

5 .........150005A.......................Upper S uppor t Bracket P ost............................... ................................ 1

6 .........150006A.......................Suppor t Bracket ................................................. ................................ 2

7 .........150007A.......................Guide Post..................................................... ... ................................1

8 .........TS-1490021..................Hex Cap Screw..................................................M8x16...................... 2

9 .........TS-1550061..................Flat Washer.......................................................M8 ...........................1

10 .......150010A....................... Nut..................................................................... ................................ 4

11 .......990708 .........................Screw.................................................................M8x40...................... 2

12 .......TS-1482031..................Hex Cap Screw..................................................M6x16...................... 1

13 .......150013A....................... Thumb Screw.....................................................M6x16...................... 3

14 .......150014A....................... Thumb Screw ....................................................M6x12...................... 5

15 .......150015A....................... Upper S pac ing Sleeve ................................... ... ................................ 2

16 .......BB-6200ZZ...................Ball Bearing.......................................................6200ZZ .................... 2

17 .......990908 .........................Pan Head Screw*...............................................M6x8........................ 2

18 .......100002A....................... Upper Wheel Blade Guar d ................................. ................................1

19 .......TS-148201....................Hex Cap Screw..................................................M6X10..................... 2

20 .......TS-1550041..................Fl at Washer.......................................................M6 ...........................4

21 .......990651 .........................Lock Knob..........................................................M10x30 .................... 1

22 .......199037 .........................Table Insert........................................................ ................................ 1

23 .......992311 .........................Spring Pin.......................................................... ................................ 1

25 .......TS-1482041..................Hex Cap Screw..................................................M6x20...................... 2

26 .......150024 .........................Catch Knob........................................................ ................................ 2

27 .......TS-1551061..................Lock Washer*.....................................................M8 ......................2(2)*

28 .......150028W......................Inner Wheel Cover............................................. ................................ 1

29 .......155029W......................Outer Wheel Cover............................................ ................................ 1

30 .......100031 .........................Pin..................................................................... ................................ 4

31 .......990180 .........................Hex Head Bolt....................................................M16x55.................... 1

32 .......W F164030....................W asher..............................................................M16..........................2

33 .......TS-1540101..................Hex Nut..............................................................M16.......................... 1

34 .......JWBS14DX-134 ...........Base.................................................................. ................................1

35 .......110045 .........................Trunnion Suppor t Bracket................................... ................................ 1

36 .......100042 .........................Trunnion............................................................. ................................2

37 .......100051 .........................Scale.................................................................. ................................1

38 .......100041 .........................Trunnion Clamp Shoe ........................................ ................................ 2

39 .......TS-1491081..................Hex Cap Screw..................................................M10x50.................... 2

40 .......TS-1482021..................Hex Cap Screw..................................................M6x12...................... 6

41 .......110049 .........................Pointer............................................................... ................................ 1

42 .......990821 .........................Pan Head Screw................................................M5x6........................ 5

43 .......TS-1490151..................Hex Cap Screw*.................................................M8x80...................... 1

44 .......TS-1540061..................Nut*....................................................................M8 ...........................1

45 .......TS-1490051..................Hex Cap Screw*.................................................M8X30..................... 2

46 .......990554 .........................Lock Knob.......................................................... ...............................2

47 .......TS-152303....................Socket Set Screw...............................................M6x10...................... 1

48 .......100063 .........................Belt Pulley.......................................................... ................................ 1

49 .......992547 .........................Retaining Ring................................................... ................................ 1

50 .......110065 .........................Lower Wheel Shaft............................................. ................................ 1

21

Page 22

Part s List

JWBS-14DX Body Assembly

Index Part

No. No. Description Size Qty.

51........992009......................... Key.................................................................... 5x5x20......................2

52........BB-6204RS..................Ball Bearing.......................................................6204RS ....................2

53........990293......................... Hex Head Bolt (Left T hr ead) .............................. M8x25......................1

54........150054......................... Hex Head Bolt................................................... .................................2

55........150055......................... Lower Support Bracket Post............................... .................................1

56........150056......................... Switch Backing Plate......................................... .................................1

57........523028......................... Switch Box......................................................... .................................1

58........994542......................... Switch................................................................ .................................1

59........995001......................... Power Cord (Switch To Motor)........................... .................................1

60........995002......................... Power Cord (Switch To Power Soure)................ .................................1

61........990814......................... Self Tapping Screw............................................M3.5x19 ...................2

62........TS-1550021 .................Flat Washer ...................................................... M4............................2

63........TS-1533042 .................Phillips Pan Head Machine Screw...................... M5x12 ......................6

64........523024......................... Wire Clip ........................................................... .................................1

65........TS-1533032 .................Phillips Pan Head Machine Screw...................... M5x10 ......................4

66........150066......................... Stud................................................................... .................................2

67........150902......................... Lower Hinge ...................................................... .................................1

68........W F051210 ...................W asher.............................................................. M5............................2

69........JWBS14DX-169...........Lower Wheel Guard........................................... .................................1

70........100185......................... Lower Wheel ..................................................... .................................1

71........100025A ...................... Wheel Prot ec tor................................................. .................................2

72........100186......................... Upper Wheel ..................................................... .................................1

73........992522......................... Retaining Ring................................................... R35...........................2

74........BB-6202ZZ................... Bal l Bearing....................................................... 6202ZZ..................... 2

75........TS-1540083 .................Hex Nut.............................................................M12x1.25..................1

76........ .................................... Saw Blade (Local Purchase).............................. .................................1

77........990804......................... Self Tapping Screw............................................M4x8 ......................16

78........150901......................... Upper Hinge ...................................................... .................................1

79........150079......................... Catch................................................................. ................................ .2

80........150080......................... Clip.................................................................... .................................2

81........150081......................... Bracket.............................................................. .................................2

82........110070......................... Blade Guard...................................................... .................................1

83........990811......................... Self Tapping Screw............................................M3.5x12 ...................2

............100016ACP.................. Sliding Bracket Assy (includes items 84 thru 88) .................................1

84........100016A....................... Sliding Bracket .................................................. .................................1

85........100019......................... Shaft Hinge........................................................ .................................1

86........150086......................... Upper Wheel Shaft ............................................ .................................1

87........100021......................... Steel Pin............................................................ .................................2

88........992314......................... Spring Pin.......................................................... ................................. 1

89........100015A....................... Coil Spring......................................................... .................................1

90........150090......................... Square Nut........................................................ .................................1

91........990652......................... Lock Knob ......................................................... .................................1

92........NW080000...................Wing Nut........................................................... M8 ............................1

93........JWBS14DX-193...........Blade A djusting Scr ew....................................... .................................1

95........TS-1490071 .................Hex Cap Screw*................................................ M8x40......................4

96........TS-1550061 .................Flat Washer*...................................................... M8............................4

97........150097......................... Washer.............................................................. .................................2

98........994181......................... Steel Ball........................................................... .................................1

99........150099......................... Spring................................................................ ................................ .1

100......TS-1525011 .................Socket Set Screw ..............................................M10x10 ....................1

22

Page 23

Part s List

JWBS-14DX Body Assembly

Index Part

No. No. Description Size Qty.

101......150101 .........................Lower Wheel Blade Guar d ................................. ................................ 1

102......WE050000 ...................Gear Washer .....................................................M5 ........................... 2

103......998654 .........................Strain Relief....................................................... ................................2

104......100018 .........................Indicator............................................................. ................................1

105......WI 080000.....................Gear Washer .....................................................M8 ........................... 2

106......100174 .........................Fixed Collar ....................................................... ................................1

107......TS-1522031..................Socket Set Screw...............................................M5x10 ...................... 1

108......130044 .........................Fixed Collar ....................................................... ................................1

109......SS050100.....................Socket Set Screw...............................................M5x5........................ 1

110......TS-1550071..................Flat Washer.......................................................M10..........................1

111......100234 .........................Tension Lever Knob...........................................M8 ...........................1

112......100183 .........................Tension Lever Rod............................................. ................................ 1

113......NH121900....................Hex Nut..............................................................M12..........................1

114......100205 .........................Gasket...............................................................M8 ...........................1

115......100182 .........................Tension Lever.................................................... ................................ 1

116......100176 .........................Bushing.............................................................. ................................ 1

117......TS-2248202..................Socket Head Button Screw .................................M8x20...................... 1

118......100177 .........................Spacer............................................................... ................................ 1

119......TS-1490071..................Hex Cap Screw..................................................M8x40...................... 2

120......TS-1541031..................Nylon Lock Hex Nut ...........................................M8 ...........................2

121......TS-1550061..................Flat Washer.......................................................M8 ...........................6

122......100178 .........................Support Plate..................................................... ................................ 2

123......100179 .........................Fixed Base......................................................... ................................ 1

124......TS-2361081..................Lock Washer......................................................M8 ...........................2

125......TS-2248202..................Socket Head Button Screw .................................M8x20...................... 2

........... JWBS14-HK.................Hardware Kit (not shown)................................... ................................1

* included in hardware kit

23

Page 24

Parts Breakdown

JWBS-14DX Closed Stand Assembly

24

Page 25

Part s List

JWBS-14DX Closed Stand Assembly

Index Part

No. No. Description Size Qty.

1 .........150501W......................Stand................................................................. ............................... 1

2 .........150502W......................Door................................................................... ............................... 1

3 .........150503 .........................Door Latch Assembly (Items 4 & 5).................... ............................... 1

4 .........WBS14CS-04 ...............Washer.............................................................. ............................... 2

5 .........WBS14CS-05 ...............Pan Head Screw ................................................M4x5....................... 2

6 .........PG-M02........................Plaque ............................................................... ............................... 1

7 .........TS-1533031..................Flat Head Screw.................................................M5x10 ..................... 2

8 .........150508W......................Plate.................................................................. ............................... 1

9 .........998621 .........................Stran Relief ........................................................ ...............................1

10 .......TS-1533042..................Pan Head Screw*...............................................M5x12..................... 2

11 .......150511W......................Motor Plate........................................................ ............................... 1

12 .......100180 .........................Motor (TEFC).......................................1-1/4 HP, 1Ph, 115/230V....... 1

13 .......600013 .........................Motor Pulley....................................................... ............................... 1

14 .......VB-A50.........................V-Belt................................................................. ............................... 1

15 .......TS-1523011..................Set Screw ..........................................................M6x6....................... 1

16 .......100254 .........................Belt Cover.......................................................... ............................... 1

17 .......PWBS14-306................Knob*.................................................................M6x12..................... 2

20 .......TS-1490041..................Hex Head Bolt....................................................M8x25..................... 4

21 .......991516 .........................Square Neck Bolt...............................................M8x16..................... 4

22 .......TS-1550051..................Washer*.............................................................M8 ................... 16(4)*

23 .......TS-155108....................Lock Washer*.....................................................M8 ...................12(4)*

24 .......TS-1540061..................Nut*....................................................................M8 ...................12(4)*

26 .......995003A....................... Motor Cord......................................................... ...............................1

27 .......150527 .........................Pad.................................................................... ............................... 2

........... WBS14CS-HK..............Hardware Kit (includes it ems marked with *)....... ............................... 1

25

Page 26

Optional Accessories for JWBS-14DX Band Saw

708114 Three speed ki t for WBS-14CS

Produces speeds of 965, 1470, and 2465 S P FM. Includes four step motor pul ley,

intermediat e pulley, V -belts, fasteners, and mounting instr uc tions with parts l ist.

708718 JRF-14 Rip Fence Assembl y

Includes guide bars, rip fence assembly, fasteners, and mounting instructions with parts li st.

708717 JRB-14 Riser Block Kit

Increases depth of cut f r om 6" m aximum to 12" maximum. Includes 6" cast block, long

frame bolt, front and bac k blade guards, and mounting instruc tions with parts list.

(Blade not included - r equires 105-1/2" bl ade) .

708716 JMG-14 Mi ter Gauge Assembly

For straight and angle cutt ing. Includes guide bar, pivoting support body, and adjustable

stops.

708719 JRB-14 Blad e Block Set

Includes upper and lower replacement bloc k s made from a non-m etallic composite material

with a dry lubr icant to reduce friction and heat.

26

Page 27

JWBS-14DX Electrical Schematic – 115V

27

Page 28

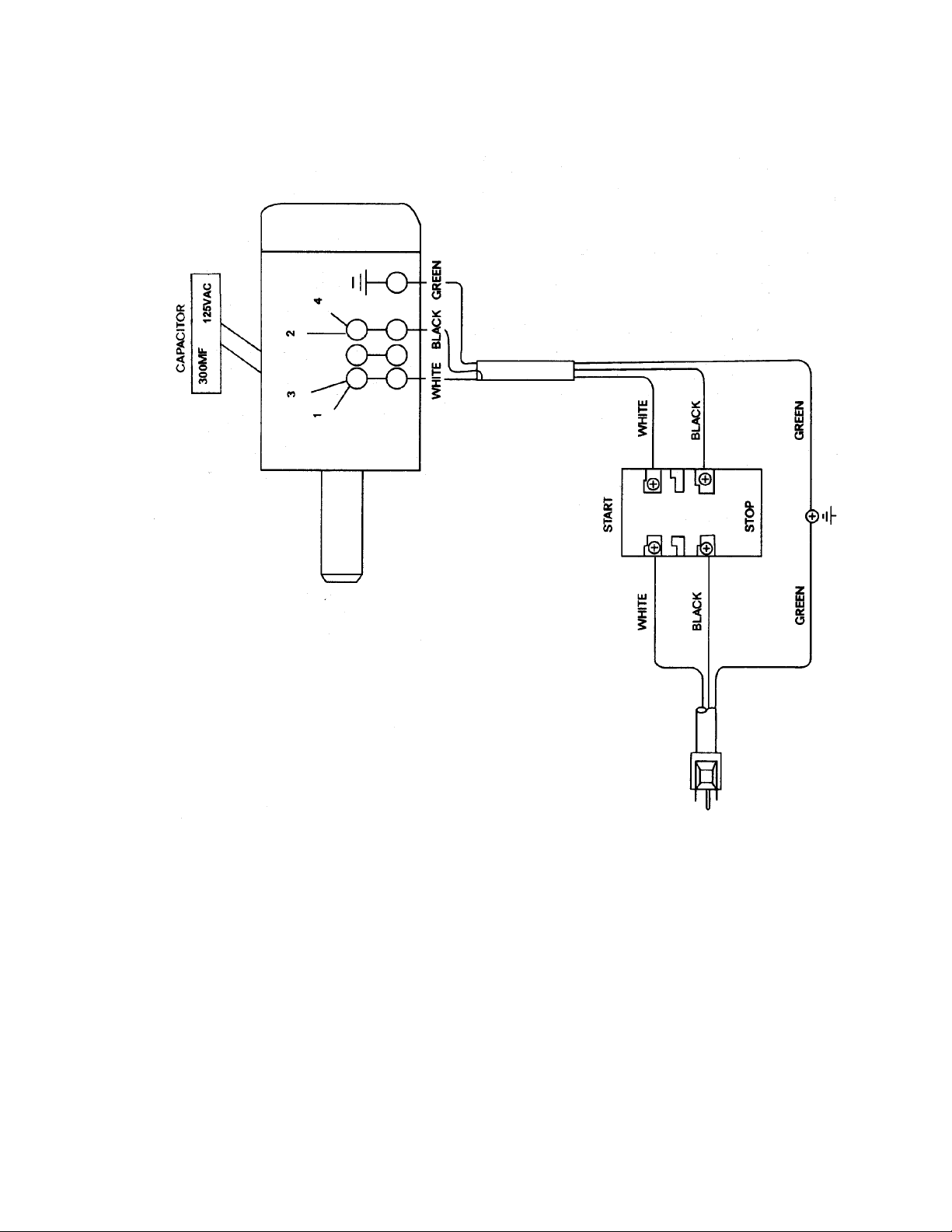

JWBS-14DX Electrical Schematic - 230V

WMH TOOL GROUP

2420 Vantage Drive

Elgin, IL 60123

Ph: 800-274-6848

www.wmhtoolgroup.com

28

Loading...

Loading...