Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

10-inch Band Saw

Model JWBS-10OS

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-707200

Ph.: 800-274-6848 Revision A3 04/2014

www.jettools.com Copyright © 2014 JET

R

CUS

162920

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please contact

Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official JET

branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty does not

cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair,

alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a Two Year

Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of of ini tial

purchase when calling. If a product requir es further inspection, th e Technic a l Service representati v e will expla in and assist

with any additional action needed. JET has Authorized Service Centers located throughout the United States. For the name of

an Authorized Service Center in your area call 1-800-274-6846 or use the Service Center Locator on the JET website.

More Informa t io n

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor or visit

the JET w ebsite.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are given as

general information and are not binding. JET reserves the right to effect at any time, without prior notice, those alterations to

parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET

are not sold in Canada by JPW Industries, Inc.

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries, Inc., or any

of its successors in interest to the JET brand .

®

branded products

2

Page 3

Table of Contents

Warranty and Servic e .......................................................................................................................................... 2

Table of Contents ................................................................................................................................................ 3

Warning ............................................................................................................................................................... 4

Introduction .......................................................................................................................................................... 6

Specifica tio ns ...................................................................................................................................................... 6

Feature s .............................................................................................................................................................. 6

Shipping Contents ............................................................................................................................................... 7

Contents of Shipping Container ........................................................................................................................ 7

Contents of Hardware Bag ............................................................................................................................... 7

Assembly ............................................................................................................................................................. 8

Stand ............................................................................................................................................................... 8

Table Installation .............................................................................................................................................. 8

90º Tabl e Stop ................................................................................................................................................. 9

Rail Guide and Fenc e ....................................................................................................................................... 9

Adjustments ....................................................................................................................................................... 10

Tilting the Table .............................................................................................................................................. 10

90º Tabl e Stop Adjustment ............................................................................................................................. 10

Changing Blades ............................................................................................................................................ 11

Adjusting Bl ade Tension ................................................................................................................................. 11

Upper Blade Guide P osi tioning ....................................................................................................................... 12

Blade Guide Adjustm ent ................................................................................................................................. 12

Operating Contr ols ............................................................................................................................................. 13

Adjusting Bl ade Trac ki ng ................................................................................................................................ 11

Replacing the Poly V-Belt ............................................................................................................................... 14

Adjustin g Poly V-Be lt Te n sion......................................................................................................................... 1 4

Grounding Inst r uc tions ....................................................................................................................................... 15

General Information ........................................................................................................................................ 15

115 Volt Operati on ......................................................................................................................................... 15

Extension Cords ............................................................................................................................................. 15

Troubleshooting ................................................................................................................................................. 1 6

Optional Accessories ......................................................................................................................................... 1 7

10" Band Saw Blades ..................................................................................................................................... 17

Parts .................................................................................................................................................................. 18

Replacement Parts ......................................................................................................................................... 18

Parts List ........................................................................................................................................................ 18

Assembly Drawing.......................................................................................................................................... 2 1

Electri c al Connec tions ....................................................................................................................................... 2 2

3

Page 4

Warning

1. Read and understand the ent ire owner's manual bef or e att em pting assembly or operation.

2. Read and understand the warnings posted on the m achine and in this manual. Failure to comply with all of

these warnings may c ause serious i njury.

3. Replace the warning labels if they become obscured or removed.

4. This band saw i s designed and intended f or use by properl y trained and ex perienced personnel onl y. If you

are not familiar with the proper and safe operation of a band saw, do not use until proper training and

knowledge have been obtained.

5. Do not use this band saw for other t han i ts intended use. If used for other purposes, JET disclaims any real or

implied warrant y and holds itself harmless from any injury t hat m ay result from that use.

6. Always wear approved safety glasses/f ace shields while using this band saw. Everyday eyegl asses only hav e

impact resistant lenses; they are not safety gl asses.

7. Before operating thi s band saw, r emove tie, rings, watches and other jewelry, and roll sl eev es up past the

elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gl ov es.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber .

Your risk of ex posure varies, depending on how of ten you do this type of work. To reduce your exposure to

these chemical s, work in a well-ventil ated area and work with approved safety equipment, such as face or

dust masks that are specifically designed to fil ter out microscopic partic les.

10. Do not operate this machi ne while tired or under the influence of drugs, alcohol or any medication.

11. M ak e c er tain the switch is in the OFF position before connecting the m achi ne to t he power supply .

12. M ak e c er tain the machine is properly grounded.

13. M ak e all machine adjustments or maintenance with the machine unplugged from the power source.

14. Rem ove adjusti ng keys and wrenches. F orm a habi t of checki ng to see that keys and adjusti ng wrenche s are

removed from the machine before turning it on.

15. K eep safety guards in pl ace at all tim es when the machine i s in use. If removed f or maintenance purposes,

use extreme caution and replace the guards immedi ately.

16. Check dam aged parts. Before further use of t he machine, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment of m ov ing par ts, binding of moving parts, breakage of par ts, mounting and any other c onditions that

may affect it s operati on. A guard or other part that is damaged shoul d be pr oper ly repaired or replaced.

17. P r ov ide for adequate space surroundi ng work area and non-glare, ov er head l ighting.

18. K eep the floor around the machi ne cl ean and free of scrap material, oil and grease.

19. K eep v isitors a safe distance from the work area. Keep children away.

20. M ak e y our workshop chi ld proof with padloc k s, m aster switc hes or by r em ov ing starter keys.

21. Giv e your work undivi ded attenti on. Looking around, carry i ng on a conversation and “horse-pl ay” are careless

acts that can resul t in seri ous i njury.

4

Page 5

22. Mai ntain a balanced stanc e at all times so that you do not fall or lean against the blade or other moving parts.

Do not overreach or use excessive force to perform any machine operation.

23. Use the ri ght t ool at the corr ect speed and f eed rate. Do not for ce a tool or attac hment to do a job f or which it

was not designed. The right tool will do the job better and safer.

24. Use recom mended accessories; improper accessories may be hazardous.

25. Maintain tools with care. Keep blades sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

26. Turn off the machine befor e cleaning. Use a brush or compressed air t o remove chips or debris — do not use

your hands.

27. Do not stand on the machine. Seri ous i njur y c ould occur if the machine tips over.

28. Nev er leave t he machine running unat t ended. Turn t he power off and do not l eave the machine unti l it c omes

to a complete stop.

29. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precaution s are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by JET covering the safe operation and maintenance pr ocedur es for the JET model JWBS-10OS

band saw. This manual contains instructions on installation, safety precautions, general operating procedures, maintenance

instructions and parts breakdown. This machine has been desi gned and constructed to provide years of trouble free oper ati on

if used in accordance with instructions set forth in this manual. If there are any questions or comm ents, please cont act either

your local supplier or JET can also be reached at our web site: www.jettools.com.

Specifications

Model Number ....................................................................................................................................... JWBS-10OS

Stock Number ............................................................................................................................................... 707200

Band Saw Size (in.) .............................................................................................................................................. 10

Cutting Capacity (height) (in.) .............................................................................................................................4-1/8

Cutting Capacity (wi dth) (in.) ..............................................................................................................................9-1/2

Maximum Rip Left of Blade w/Fence (in.)................................................................................................................. 5

Maximum Rip Right of Blade w/Fence (in.) .............................................................................................................. 5

Blade Length (in.) ............................................................................................................................................ 67-1/2

Blade Speed (FPM) ........................................................................................................................................... 2750

Minimum Blade Wid th (in.) ....................................................................................................................................1/8

Maximum Blade W idth (in.) ...................................................................................................................................1/2

Table Size (in.) .................................................................................................................................. 13-1/8 x 13-3/8

Table Size with Extension (in.) ................................................................................................................. 13-1/8 x 19

Table Tilt (degrees)...................................................................................................................................... 0° to 45°

Table Height from Fl oor (in.) ............................................................................................................................ 42-1/2

Wheel Diameter (in.) ............................................................................................................................................. 10

Dust Chute Diameter (in.) ....................................................................................................................................... 4

Overall Dimensions without stand (in.) .......................................................................................... 27 L x 16 W x 33 H

Overall Dimensio n s with s tand (in.) ............................................................................................. 30 L x 18 W x 60 H

Stand Dimens ions ( in.) ......................................................... 25-3/4H; Base: 18-1/2L x 21W; Top: 13-1/2L x 16-1/2W

Motor ........................................................................................................................................... 1/2 HP, 1Ph, 115V

Net Weight (a p prox.) (lbs .) .................................................................................................................................... 71

Shipping Weight (approx.) (lbs.) ............................................................................................................................ 75

The above specifications were current at the time this manual was published, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

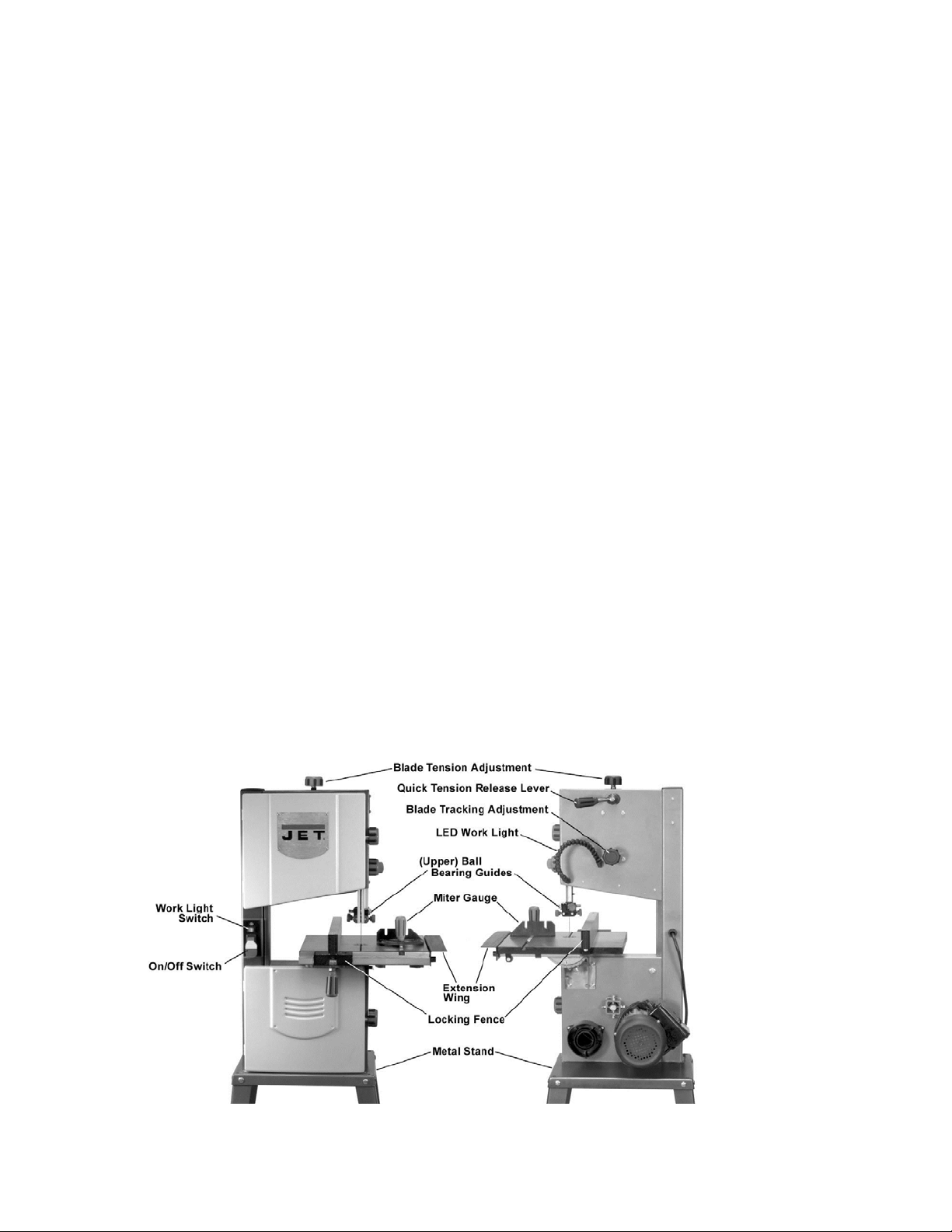

Features

6

Page 7

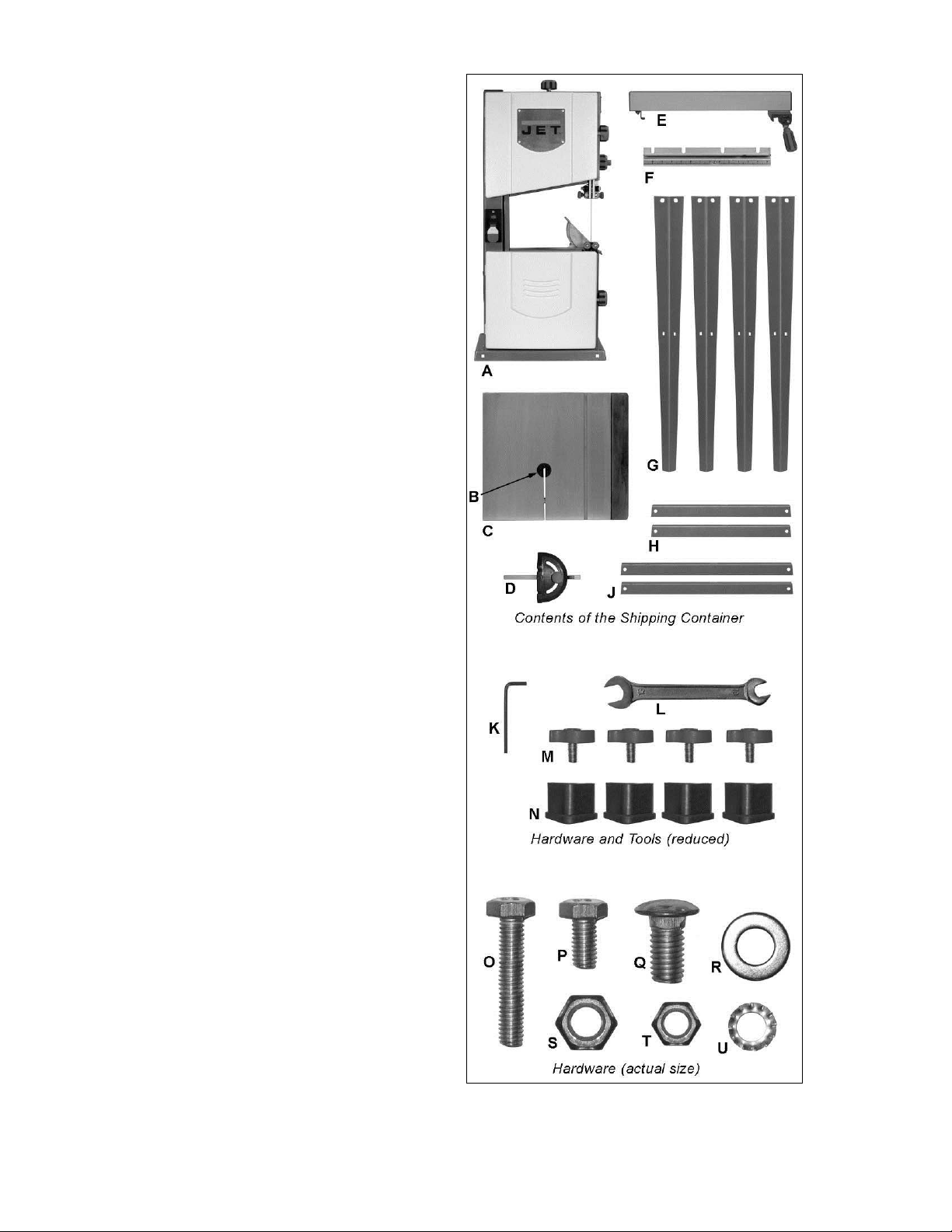

Shipping Contents

Remove all contents from the shipping carton. Do

not discard the c arton or packing material until the

band saw is assembled and is running

satisfactorily.

Compare the content s of the carton against the list

of parts in Contents of Shipping Container (below).

The letter identification i n the list corresponds to the

items shown at ri ght. This is your k ey for ident ifying

the parts used throughout t he Assembly section for

easy reference.

Remove the protectiv e coating that i s applied to the

table with a house hold grease and spot r emover.

Contents of Shipping Container

01 Band Saw (A)

01 Table Insert (B)

01 Table (C)

01 Miter Gauge (D)

01 Fence (E)

01 Rail Guide (F)

04 Stand Leg (G)

02 Short Support Plate (H)

02 Long Support Plate (J)

01 Owner's Manual (not shown)

01 Warranty Card (not shown)

01 Hardware Bag (see below for contents)

Contents of Hardware Bag

(p/n JWBS10OS-HB)

01 Hex Wrench 3mm (K)

01 Combination Wrench 10/13mm (L)

04 Rail Lock Knob (M)

04 Rubber Foot (N)

01 M6x32 Hex Cap Screw (O)

04 M6x12 Hex Cap Screw (P)

16 M8x16 Carriage Bolt (Q)

20 M8 Flat W asher (R)

16 M8 Hex Nut (S)

01 M6 Hex Nut (T)

04 M6 External Tooth Lock Washer (U)

Tools Required for Assembl y & Adj ustments

The tools listed below are not included but are

required for assembly.

2 14mm Open End Wrench

1 Cross Point Screw Driver

1 Combination Square

Shipping Contents

7

Page 8

Assembly

S

3

R

3

R

2

S

2

S

1

R

1

L

Q

2

A

Q

1

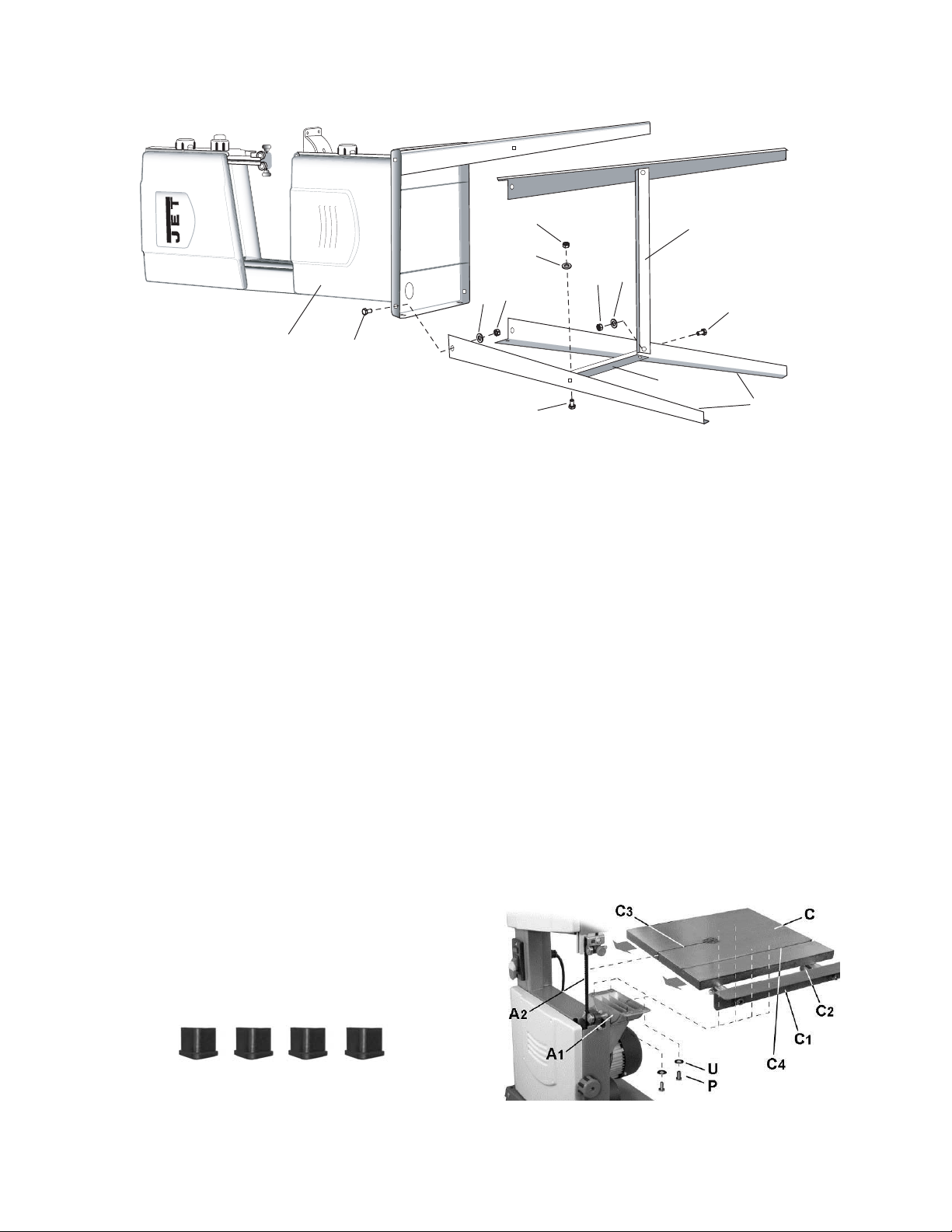

Stand

Referring to Fi gur e 1:

1. Place the band saw (A) on its back as

shown above, either on the floor or

preferably on a workbench.

2. Assemble four legs (G) to the inside of the

base of the band saw, securing each leg

with two ea. M8x16 carr iage bolts (Q

flat washers (R

Hand-tighten only at this time.

3. Attach a long plate (L) to the rear legs as

shown in Figure 1. Secure with 2 ea M8x16

carriage bolts (Q

and M8 hex nuts (S

this time.

4. Attach the remaining long plate to the front

legs in the same manner described above,

hand-tightening only

5. Attach two shor t plates (K) to the right legs

and left legs in the same manner. Secure

each leg with 2 ea M8x16 carriage bolts

3), M8 flat washers (R3), and M8 hex nut s

(Q

3). Hand-ti ghten only at this time.

(S

1) and M8 hex nuts (S1).

2), M8 flat washers (R2),

2). Hand-tighten onl y at

1), M8

Figure 1

Back

K

Q

3

Front

G

8. Tighten all nuts with a 13mm socket or

wrench.

Table Installation

Referring to Fi gur e 3:

1. Loosen lock knob (C

1) out from the table (C).

(C

2. Orient the table (C) as shown, then

maneuver to allow the saw blade (A

pass through the slot (C

3. Line up four threaded mounting holes

underneath the table (C) with the four

mounting through-holes on the trunnion (A

Important: Adjust table so miter slot (C

parallel with saw blade (A

4. Secure with four each M6x12 hex cap

screws (P) and M6x12 external tooth lock

washers (U).

5. Tighten the screws (P) with a 13mm wrench.

2) and pull extension

2) to

3) to the center.

1).

4) is

2).

6. Slip rubber feet (Figure 2) onto the ends of

the stand legs.

Figure 2

7. Place the saw and stand upright on a level

surface. Make sure that all four legs are

contacting the surface.

Figure 3

8

Page 9

90º Table Stop

Referring to Fi gur e 4:

1. Slighty loosen the lock knob (C

4) and tilt the

table (C) up as shown.

2. Thread the M6 hex nut (T) approximately half

way onto the M6x32 hex cap screw (O). Then

thread the screw half way into the threaded

mounting hole (C

5) underneath the table.

Adjustment will be m ade later.

Rail Guide and Fence

Installation

1. Attach the rail guide (F, Fig. 5) to the front of

the table (C). Secure with four lock knobs (M).

Referring to F igur e 6:

2. Place fence assembly (E, Fig. 6) onto the

table (C) at the mit er slot .

The rear hook should engage the rear of the

table. The fence body should engage the rail

guide (F).

If the fence is not parallel to the miter slot:

3. Loosen two socket head c ap s c r ews (S

4mm hex wrench. End cap (S2) may need to

be removed.

1) with a

Figure 4

4. Adjust the fence so it is para lle l to the miter slot.

5. Lock the fence handle, securing it to the rail

guide (F), and verify that the fence is still

parallel to the miter slot.

6. Re-tighten two screws (S

to the fence body and repl ac e end cap (S

1) to secure the fence

2).

This completes the r ail guide and fence installation.

Fence scale adjustment

Referring to Fi gur e 6:

1. Place fence assembly (E) onto the table (C)

against the saw blade and lock.

If the hairline on t he scale indicator does not point

to zero:

2. Remove fence assembly (E).

3. Loosen the screw (S

3) that secures the scale to

the rail guide (F).

4. Repeat step 1, then slide the scale until the

hairline on the scale indicator points to zero.

5. Being caref ul not to move the scale, unlock and

lift fence from the table.

6. Tighten screw (S

3) to secure scale.

If further adjustment is needed, lock knobs (M) c an

be loosened to a llow ad jus t ment of the rail guide (F).

Figure 5

Figure 6

9

Page 10

Adjustments

Unplug the machine from the

power source before making any repairs or

adjustments. Failure to comply may cause

serious injury.

Tilting the Table

Referring to Fi gur e 7:

1. Loosen the lock knob (A).

2. Tilt table (C) up to 50 degrees m aximum to the

right or down 5 degrees to the left. The angle

can be read on the scale (B) on the trunnion

bracket.

Note: Table perpendicular (90º) to the blade

corresponds to a scale indication of 0º.

3. Tighten the lock k nob (A).

Note: The table stop (E) must be adjusted t o permit

the table to tilt to the left.

Figure 7

90º Table Stop Adjustment

Adjusting the table stop

The table stop (E, Fig. 7) is typic ally set to stop the

table at 90º (perpendicular) with the blade.

1. Disconnect machine from power source.

2. Loosen lock knob (A, Fig. 7); then tilt the table

(C, Fig. 7) down, bri nging it to rest against the

table stop (E, Fig. 7).

3. Use a square (J, Fig. 8) placed on the table

(C, Fi g. 8) and against the blade (H, Fig. 8) to

see if the table is 90º to the blade.

4. If an adjustment is necessary, tilt the table up

to access the table stop (E, Fig. 7).

5. Loosen the jam nut (D, Fig. 7) and turn the

table stop (E, Fig. 7) in or out to raise or lower

the stop. Tighten the jam nut to hold the table

stop in place.

6. Til t the table back to level, letting it rest against

the stop and confirm table is 90º with the blade

as described in step 3.

For left tilt down to 5º, the table stop (E, Fig. 7)

must be adjusted further.

Figure 8

Adjusting the table tilt indicator

1. Set the table at 90º wit h the blade.

2. Confirm that the table tilt indicator (F, Fig. 8)

points to zero.

If adjustm ent is requi r ed:

3. Slightl y loosen screw securing i ndicator , adjust

indicator to point to zero; then re-tighten screw.

Figure 9

10

Page 11

Changing Blades

Bl ade teeth are sharp! Use care

when handling the saw blade. Failure to comply

may cause serious injury.

Note: The JWBS-10OS Band Saw comes

equipped with a 67.5"x.375"x.014"x6TPI blade

(Part No. JWBS10O S-8) factory installed.

1. Disconnect machine from power source.

2. Open both wheel covers (K, L, Fig. 9).

3. Loosen lock knob (G, Fig. 8) and pull exten-

sion (O, Fig. 9) away from the table (C).

4. Remove rail guide (F, Fi g. 5).

5. Release tension on the blade by moving the

tension handle (V, Fig. 10) to the right.

Referring to Fi gur e 9:

6. Remove blade (H) from upper and lower

wheels (M, R) and from between the upper and

lower blade guides (N, Q).

7. Remove the blade th rough the slot (P) in th e ta b le .

8. Guide the new blade through table slot (P)

leading wit h t he smooth edge. Place it around

the upper and lower wheels and into the upper

and lower blade guides (N, Q).

Note: The blade teeth should face the operator,

and they should point down toward the table.

9. Positi on the bl ade to track i n the middle of the

rubber tir es on the wheels (M, R).

10. Engage tension on the blade by moving the

quick tension handle (V, Fig. 10) to the left.

11. Replace rail guide (F, Fig. 5).

Before operating the saw, check that the blade is tracking

and has proper tension as described in Adjusting Blade

Tension and Adjusting Blade Tracking below.

the width of the bl ade.

4. Set the blade tension with knob (T) to correspond

to the blade width as marked on the gauge (X).

Note: A meter is recommended to preci sely set

tension the bl ade for the size of blade used.

Note 1: As you become mor e experienced wit h t he

saw, you may find it necessary t o change t he blade

tension from the initial setting. Changes in blade

width and the type of material being cut will have

an effect on blade tension.

Note 2: Keep in mind that too little or too much

blade tension can c ause bl ade br eak age.

Adjusting Blade Tracking

Referring to Fi gur e 10:

Disconnect machine from the

power source! Never adj ust blade tracking with

the machine running! Failure to comply may

cause serious inj ury!

Tracking refers to how the blade is situated upon

the wheels while i n motion. T he blade should t rack

in the center of both wheels .

The blade must be sli ghtly tensioned (see previ ous

section) bef ore adjusting bl ade tracki ng.

blade guides and bearings

interfere with the blade. If blade tracking is

required, blade guide adjustment is described on

the following page.

1. Open the top and bottom wheel covers. Rotate

the wheel forward by hand, and observe the

position of the blade on the wheel through the

window (S). It should be in the center of the

wheel.

If adjustm ent is necessary:

(N, Q, Fig. 9) do not

Make sur e

Adjusting Blade Tension

Referring to Fi gur e 10:

1. Disconnect machine from power source.

The blade tension knob (T) is used to adjust blade tension.

Note 1: The quick tension lever (V) must be engaged

before making tension adjustments with knob (T).

Note 2: All bearings on upper and lower guides

must be clear of blade (see Blade Guide and Guide

Bearing adjustments on following page).

2. Appl y just enough ten sion to tak e the slack out

of the blade.

3. Turn one wheel a few times to allow the blade

to position itself in the center of the tire.

Note: If blade does not center see Adjusting Blade

Tracking section (this page).

A scale (X) directl y behind the upper wheel (M)

indicates the approx imate tension according to

2. Loosen the wing nut ( U) and make adjustment

with tracking knob (W) while rotati ng wheel by

hand.

3. Tightening the tracking knob slightly will move

the blade so it tracks towards the rear of

machine. Loosening the tracking knob slightly

will cause the blade to track toward the front of

the machine.

4. After blade is tracking in the center of the

wheel, tighten the wing nut (U).

Figure 10

11

Page 12

Upper Blade Guide Positioning

Referring to Fi gur e 11:

The upper blade guide assembly (C) should be

adjusted to just above the material being cut. To

adjust:

Loosen lock knob (B) and raise or lower the upper

blade guide assembly (C) by turning the height

adjustment knob (A).

Blade Guide Adjustment

Overview

The blade guide assembly consists of two roller

guides (bearings) positioned on each side of the

blade to provide blade stabili t y. A third guide (thrust

bearing) is positioned behind the blade to provide

blade support.

There are two blade guide assembli es – an upper

assembly and lower assem bly (see Figure 12).

Adjustments are perform ed in the same m anner f or

each assembly. Each assembly must be adjusted

in turn using the adjustment procedures outlined

below.

Figure 11

Thrust Bearing Adjustment

Disconnect machine from the

power source! Never make adjustments with

the machine running! Failure to comply may

cause serious inj ury!

Referring to Fi gur e 12:

1. Disconnect machine from power source.

Note: Bl ade must already be tensioned and tr ack-

ing properl y (Adjus ting Blade Tension, page 10).

2. For the upper thrust bearing, loosen thumb-

screw (B). For the lower blade guide, loosen

setscrew (B) with the 3mm hex wrench

provided.

3. Slide the adjustment shaft (C) so the blade is

positioned in the middle of the thrust

bearing (A).

The thrust bearing (A) is mounted on a concentric

shaft (C). When the shaft is rotated, the relative

position of the bearing to the back of the bl ade can

be changed.

4. Rotate the adjustment shaft (C) so the thru st

bearing (A) just clears the back of the saw blade.

5. Tighten thumbscrew/setscrew (B).

If a blade is being replaced with a new one of a

different si ze, the adjustm ent described abov e may

fall out of range and further adjustment may be

required as f ollows:

Figure 12

12

Page 13

Loosen the hex cap screw (G, not visible) with

a 10mm wrench and adjust the entire assembl y

back or fort h t o just clear the back of the saw

blade. Tighten screw (G), then fine tune the

adjustment by repeating the first part of this

step.

6. Secure the roller guide (A) by tightening the

thumbscrew (B, upper guide) or setscrew

(B, lower guide).

Guide Bearing Adjustment

Disconnect machine from the

power source! Never make adjustments with

the machine running! Failure to comply may

cause serious inj ury!

Referring to Fi gur e 13:

1. Disconnect machine from power source.

Note: Bl ade must already be tensioned and tr ack-

ing properl y (Adjus ting Blade Tension, page 11).

2. For the upper blade gui de, loosen two thumb-

screws (E). For the lower blade guide, loosen

two setscrews (E) with the 3mm hex wrench

provided.

3. Slide the adjustment shaf t (F) to position each

roller gui de (D) approximately 1/16" behi nd the

gullets of the saw blade.

The roller guide (D) is mounted on a concentric

shaft (F). When the shaft is rotated, the relative

position of the guide to the blade can be changed.

4. Rotate each adjustment shaft (F) to position the

guides (D) withi n 1/32" of the saw blade.

5. Secure the roller guides (D) by tightening

thumbscrews (E, upper guide) or setscrews

(E, lower guide).

Operating Controls

On/Off Switch – located on front of machine: pull

switch out to start; push switch in to stop. When

yellow safety key is removed, machine will not

start.

Figure 13

Work Lamp Switch – located on front of machine

above On/Off swit ch. Turns LED work lamp on and

off.

13

Page 14

Replacing the Poly V-Belt

Adjusting Poly V-Belt Tension

Disconnect machine from the

power source! Never make adjustments with

the machine runni ng! Failure to comply may

cause serious inj ury!

1. Unplug the machine from the power source.

2. Open the upper and lower wheel cover

doors.

3. Remove the saw blade as described in

Changing Blades on page 11.

4. Remove tension on the drive belt (D) by

loosening the hex c ap screw (13mm wrench

required) on the back of the cabinet that

secures t he m otor.

Referring to Fi gur e 14:

5. Using snap ring pli ers, rem ove the s nap ring

(E) that secures the lower wheel (B) to the

shaft (A).

6. Slide the lower wheel assembly off the

shaft (A) which will dislodge the belt (D) and

discard the ol d belt.

7. Place the new belt onto the lower wheel

pulley.

Disconnect machine from the

power source! Never make adjustments with

the machine runni ng! Failure to comply may

cause serious inj ury!

Referring to Fi gur e 14:

1. Unplug the machine from the power source.

2. With a 13mm wrench, loosen the hex cap

screw on the back of the cabinet that

secures t he m otor.

3. Push the m otor down to add tension to the

belt (D).

The belt is properly tensioned when

moderate finger pressure on the belt

between the two pulleys causes a 1/2"

deflection.

4. Tighten the hex cap screw t hat sec ures the

motor.

8. Reinstall lower wheel assembly by sliding it

back onto the shaft (A).

9. Replace snap ring (E).

10. Place the new belt (D) partially around the

motor pulley (C) to get it started, then turn

the wheel (B) by hand until the belt (D) is

completely seated on the motor pulley (C).

11. Push the mot or down to add tension t o the

belt (E).

The belt is properly tensioned when

moderate finger pressure on the belt

between the two pulleys causes a 1/2"

deflection.

12. Tight en the hex cap screw on the back of

the cabinet that secures the motor.

Re-install the blade as described in Changing

Blades on page 11.

Figure 14

14

Page 15

Grounding Instructions

r

e

General Information

This Band Saw must be

grounde d while in use to protect the ope r ator

from electri c sho ck.

In the event of a malfunction or breakdown,

grounding provi des a path of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an elec tric cord

having an equipment- groundi ng conduct or and a

grounding plug that looks similar to the plug in

Figure 15. The plug must be inserted into a

matching outlet that is properly installed and

grounded in accordanc e with all local codes and

ordinances.

Do not modify the pl ug pr ovided. If it will not fit

the outlet, have the proper outlet installed by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment -groundi ng conductor to a

live terminal.

receptacle as shown (Figure 11), if a properly

grounded outlet i s not available. The tempor ary

adapter should only be used until a properly

grounded outlet can be installed by a qualified

electrician. This adapter is not applicable in

Canada. The green col ored ri gi d ear, l ug, or tab,

extending fr om the adapter, must be connect ed

to a permanent ground such as a properly

grounded outlet box, as shown in Figure 5.

Figure 16

Extens ion Cords

Use only three wire extension cords that have

three-prong grounding plugs and three-pole

receptacles t hat accept the tool’s plug.

Make sure the cord is in good condition and

heavy enough to carry the current your band

saw will draw. An undersized cord will cause a

drop in line voltage, resulting in loss of power

and overheati ng. Table 1 shows the correct size

to use depending on cord l ength and the ampere

rating on your machine’s nameplate. If in doubt ,

use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Figure 15

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace a damaged or worn cord

immediately.

115 Volt Operation

As received from the factory, your band saw is

ready to run at 115-volt operation. This band

saw is intended f or use on a circuit that has an

outlet and a plug that looks like the one

illustrated in Figure 4. An adapter with a

grounding ear (Figure 16) may be used

temporarily to connect this plug to a two-pole

Repair or replace a damaged or worn cord

immediately.

Powe

Currant

(Amps)

0-6 120 0 to 25 18

6-10 120 0 to 25 18

10-12 120 0 to 25 16

12-16 120 0 to 25 14

Line

voltage

25 to 50 16

50 to 100 16

over 100 14

25 to 50 16

50 to 100 14

over 100 12

25 to 50 16

50 to 100 14

over 100 12

25 to 50 12

Extension Cord

Cord length

in feet

over 50

Cord gaug

(AWG)

not recommended

Table 1

15

Page 16

Troubleshooting

Trouble Probable Cause Remedy

Saw unplugged Check plug connections

Saw stops or will not

start

Does not make

accurate 45

cuts

Blade wanders during

cut

o

or 90o

Fuse blown, or cir c uit break er tr ipped Replace fuse, or r eset ci r c uit breaker

Cord damaged Replace cord

Check blade with square and adjust

Stop not adjusted corr ec tly

Angle pointer not set accurately

Fence not ali gned with blade Check and adjust fenc e

Warped wood Select another piece of wood

Excessive f eed r ate Reduce feed rate

Incorrect blade for cut Change blade to corr ec t t y pe

stop (see Adjusting Table St op on

page 10).

Check blade with square and adjust

pointer (see Adjusting Table Stop on

page 10).

Saw makes

unsatisfactory cuts

Blade does not come

up to speed

Saw vibrates

excessively

Blade tension not set properly

Guide bearings not set proper ly Review guide beari ng adjustment.

Dull blade Replace blade

Blade mounted wrong Teeth should point down

Gum or pitch on blade Remove blade and clean

Incorrect blade for cut Change blade to corr ec t t y pe

Gum or pitch on table Clean table

Extension cord too light or too long

Low shop voltage Contact your loc al elec tric company

Base on uneven floor Reposition on fl at, lev el surface

Bad v-belt Replace v-belt

Motor mount is loose Tighten motor mount hardware

Loose hardware Tighten har dware

Set blade tension acc or ding to blade

size

Replace with adequat e si z e and

length cord

16

Page 17

Optional Accessories

10" Band Saw Blades

Stock No. Applicatio n Leng th Width Thickness TPI

707201 Scrollwork 67.5” 0.125” 0.025” 18TR

707202 Resaw 67.5” 0.5” 0.032” 4HK

707203 General Purpose 67.5” 0.5” 0.025” 6HK

707204 General Purpose 67.5” 0.25” 0.025” 6SK

17

Page 18

Parts

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848 Monday thr ough Friday (see our website for business hours, www.jet tools.com). Hav ing

the Model Number and Serial Number of your machine availabl e when you call will allow us to serve you

quickly and acc ur ately.

Parts List

Index No. Part No. Description Size Qty

1 ............... TS-1503041 .............Socket Head Cap Screw .....................................M6x16 ........................ 2

2 ............... JWBS10 OS-2 ..........Spacer................................................................................................... 2

3 ............... TS-1541021 .............Nylon Insert Lock Nut .........................................M6 .............................. 2

4 ............... JWBS10 OS-4 ..........Lower Door ............................................................................................ 1

5 ............... JWBS10 OS-5 ..........Rivet ...................................................................2.5x5 .......................... 4

6 ............... JWBS10 OS-6 ..........JET Namep late ...................................................................................... 1

7 ............... JWBS10 OS-7 ..........Upper Door ............................................................................................ 1

8 ............... JWBS10 OS-8 ..........Blade ........................................................... 67.5 x .375 x .014, 6TPI .... 1

9 ............... JWBS10 OS-9 ..........Retaining Ring ....................................................10 ............................... 2

10 ............. BB-6000ZZ ..............Ball Bearing ........................................................6000ZZ....................... 4

11 ............. TS-1533032 .............Pan Head Machine Screw ..................................M5x10 ........................ 3

12 ............. TS-2361051 .............Lock Washer ......................................................M5 .............................. 3

13 ............. JWBS10OS-13.........Lower Wheel ......................................................................................... 1

14 ............. JWBS10OS-14.........Pulley .................................................................................................... 1

15 ............. JWBS10OS-15.........Tire........................................................................................................ 2

16 ............. JWBS10OS-16.........Nut .....................................................................M20 ............................ 1

17 ............. JWBS10OS-1 7.........Lower Wheel Sh aft ................................................................................ 1

18 ............. JWBS10OS-18.........Belt........................................................................................................ 1

19 ............. JWBS10 OS-19.........Space r Bushing ..................................................................................... 1

20 ............. JWBS10OS-20.........Brush .................................................................................................... 1

21 ............. JWBS10OS-21.........Carriage Bolt ......................................................M8 x70 ........................ 1

22 ............. JWBS10OS-22.........Switch Plate .......................................................................................... 1

23 ............. TS-2284121 .............Flat Head Machine Screw ...................................M4x12 ........................ 2

24 ............. JWBS10OS-24.........LED Lamp Swi tch .................................................................................. 1

25 ............. JWBS10OS-25.........Start/Stop Switch ................................................................................... 1

25-1 .......... JWBS10OS-25-1 .....Switch Safety Key.................................................................................. 1

26 ............. JWBS10OS-26.........Upper Wheel ......................................................................................... 1

27 ............. JWBS10OS-27.........Sleeve ................................................................................................... 1

28 ............. TS-1523011 .............Socket Set Screw ...............................................M6x6 .......................... 5

29 ............. JWBS10OS-29.........Eccentric Block ...................................................................................... 1

30 ............. JWBS10OS-30.........Square Housing ..................................................................................... 1

31 ............. TS-1540041 .............Hex Nut ..............................................................M6 .............................. 2

32 ............. TS-1523041 .............Socket Set Screw ...............................................M6 x12 ........................ 1

33 ............. TS-

34 ............. JWBS10OS-34.........Strain Relief ........................................................................................... 2

35 ............. JWBS10OS-35.........Cord with Plug ....................................................................................... 1

36 ............. JWBS10OS-36.........LED Lamp Assembly ............................................................................. 1

37 ............. JWBS10OS-37.........Locking Knob......................................................................................... 1

38 ............. JWBS10OS-38.........Spring.................................................................................................... 1

39 ............. TS-1550061 .............Flat Washer ........................................................M8 ............................ 2 3

40 ............. JWBS10OS-40.........Nut ........................................................................................................ 2

41 ............. JWBS10OS-41.........Knob ..................................................................................................... 3

42 ............. JWBS10OS-42.........Shaft ..................................................................................................... 1

43 ............. JWBS10OS-43.........Gear ...................................................................................................... 1

44 ............. JWBS10OS-44.........Blade G uar d .......................................................................................... 1

45 ............. JWBS10OS-45.........Rack ...................................................................................................... 1

46 ............. JWBS10OS-46.........Dust Cover ............................................................................................ 1

47 ............. JWBS10OS-47.........Self-Tapping Screw ............................................ST3.5x9.5 ................... 2

2171012 .............Pan Head Machine Screw ..................................M 4x6 ........................ 10

18

Page 19

Index No. Part No. Description Size Qty

48 ............. JWBS10OS-48.........Self-Tapping Screw ............................................ST2.2x6.5 ................... 1

49 ............. JWBS10OS-49.........Sliding Plate .......................................................................................... 1

50 ............. JWBS10OS-50.........Guide Block ........................................................................................... 2

51 ............. JWBS10OS-51.........Self-Tapping Screw ............................................ST4.2x13 .................... 4

52 ............. TS-1482021 .............Hex Cap Screw ..................................................M 6 x12 ...................... 11

53 ............. JWBS10OS-53.........Washer.................................................................................................. 2

54 ............. JWBS10OS-54.........Guide Seat ............................................................................................ 1

55 ............. JWBS10OS-55.........Lock Knob ............................................................................................. 3

56 ............. JWBS10OS-56.........Bearing Shaft......................................................................................... 4

57 ............. JWBS10OS-57.........Bearing Bracket ..................................................................................... 2

58 ............. JWBS10OS-58.........Ball Bearing ........................................................627ZZ......................... 6

59 ............. JWBS10OS-59.........Bearing Shaft......................................................................................... 2

60 ............. TS-1550041 .............Flat Washer ........................................................M6 .............................. 4

61 ............. JWBS10OS-61.........Guide Plate ........................................................................................... 1

62 ............. JWBS10OS-62.........Hex Flange Nut ..................................................M6 .............................. 8

63 ............. JWBS10OS-63.........U-Bracket .............................................................................................. 1

64 ............. JWBS10OS-64.........Semi-Sphere Segment .......................................................................... 1

65 ............. JWBS10OS-65.........Spring.................................................................................................... 1

66 ............. JWBS10OS-66.........Tension Scale Pointer............................................................................ 1

67 ............. JWBS10OS-67.........Nut ........................................................................................................ 1

68 ............. JWBS10OS-68.........E-Clip .................................................................6 ................................. 2

69 ............. JWBS10OS-69.........Upper Wheel Axis Seat .......................................................................... 1

70 ............. JWBS10OS-70.........Upper Wheel Shaft ................................................................................ 1

71 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 1

72 ............. JWBS10OS-72.........Shaft ..................................................................................................... 1

73 ............. JWBS10OS-73.........Tension Scale........................................................................................ 1

74 ............. JWBS10OS-74.........Plug ....................................................................................................... 1

75 ............. JWBS10OS-75.........Voltage Adapter ..................................................................................... 1

76 ............. JWBS10OS-76.........Knob Cover ........................................................................................... 1

77 ............. JWBS10OS-7 7.........Hex Jam Nut ......................................................................................... 5

78 ............. JWBS10OS-78.........Fastening Shaft ..................................................................................... 1

79 ............. JWBS10OS-79.........Tension Sleeve ...................................................................................... 1

80 ............. JWBS10OS-80.........Nut .....................................................................M14x1.5P ................... 1

81 ............. JWBS10OS-81.........Hub ....................................................................................................... 1

82 ............. JWBS10OS-82.........Handle................................................................................................... 1

83 ............. JWBS10OS-83.........Handle Grip ........................................................................................... 1

84 ............. TS-1490081 .............Hex Cap Screw ..................................................M 8 x45 ........................ 1

85 ............. JWBS10OS-85.........Wing Nut ............................................................................................... 1

86 ............. JWBS10OS-86.........Blade Track ing Window ......................................................................... 1

87 ............. TS-1550021 .............Flat Washer ........................................................M4 .............................. 2

88 ............. JWBS10OS-88.........Pan Head Machine Screw ..................................M4x5 .......................... 2

89 ............. JWBS10OS-89.........Motor ..................................................................1/2HP, 1Ph, 115V ....... 1

................. JWBS10 OS-89-1 .....Capacitor (not shown).........................................25µF/250V ................. 1

90 ............. JWBS10OS-90.........Motor Pulley .......................................................................................... 1

91 ............. TS-1490021 .............Hex Cap Screw ..................................................M 8 x16 ........................ 2

92 ............. JWBS10OS-92.........Motor Mount .......................................................................................... 1

93 ............. TS-2361061 .............Lock Washer ......................................................M6 .............................. 4

94 ............. TS-1533042 .............Pan Head Machine Screw ..................................M5x12 ........................ 3

95 ............. JWBS10OS-95.........Dust Chute ............................................................................................ 1

96 ............. TS-1540031 .............Hex Nut ..............................................................M5 .............................. 3

97 ............. JWBS10OS-97.........Door Lock Knob ..................................................................................... 2

98 ............. TS-1503061 .............Socket Head Cap Screw .....................................M6x25 ........................ 2

99 ............. JWBS10OS-99.........Table Insert ........................................................................................... 1

100 ........... JWBS10OS-100.......Table ..................................................................................................... 1

101 ........... JWBS10OS-101.......Fence Guide Rail ................................................................................... 1

102 ........... JWBS10OS-102.......Wing Screw ........................................................................................... 4

103 ........... TS-1482071 .............Hex Cap Sc re w ..................................................M6x35 ........................ 1

104 ........... JWBS10OS-104.......Carriage Bolt ......................................................M6x30 ........................ 1

105 ........... JWBS10OS-105.......Slide Bl ock ............................................................................................ 1

106 ........... JWBS10OS-106.......Trunion .................................................................................................. 1

19

Page 20

Index No. Part No. Description Size Qty

107 ........... JWBS10OS-107.......External Tooth Lock Washer ...............................M6 .............................. 4

108 ........... JWBS10OS-108.......Support Bracket ..................................................................................... 1

109 ........... JWBS10OS-109.......Knob ..................................................................................................... 1

110 ........... JWBS10OS-110.......Carriage Bolt ......................................................M6x16 ........................ 4

111 ........... TS-1505011 .............Socket Head Cap Screw .....................................M10x16 ...................... 2

112 ........... TS-1551071 .............Loc k Washer ......................................................M10 ............................ 2

113 ........... TS-1550071 .............Flat Washer ........................................................M10 ............................ 4

114 ........... JWBS10OS-114.......Extension Wing ..................................................................................... 1

115 ........... JWBS10OS-115.......Extensi on Rod ....................................................................................... 2

116 ........... JWBS10OS-116.......Extensi on Bracket.................................................................................. 2

117 ........... TS-1533032 .............Pan Head Machine Screw ..................................M5x10 ........................ 4

118 ........... JWBS10OS-118.......Lock Knob ............................................................................................. 1

119 ........... JWBS10OS-119.......Rubber Foot .......................................................................................... 4

120 ........... JWBS10OS-120.......Stand Leg .............................................................................................. 4

121 ........... JWBS10OS-121.......Short Support Plate ............................................................................... 2

122 ........... JWBS10OS-122.......Long Support Plate ................................................................................ 2

123 ........... JWBS10OS-123.......Carriage Bolt ......................................................M8x16 ...................... 16

124 ........... TS-1540061 .............Hex Nut ..............................................................M8 ............................ 16

125 ........... JWBS10OS-125.......Miter Gauge .......................................................................................... 1

126 ........... JWBS10OS-126.......Comple te Fe n ce As sembly .................................................................... 1

................. JWBS10OS-HB........Hardware Bag (see page 7 for content s) ..................................................

20

Page 21

Assembly Drawing

124

39

123

83

82

81

80

41

77

40

76

77

78

112

113

114

113

121

124

39

123

76

84

41

87

77

86

85

79

89

88

120

122

99

94

90

91

39

92

124

95

93

52

33

115

52

116

119

100

96

98

60

97

18

118

117

104

56

111

52

106

107

105

31

39

102

101

28

62

53

108

109

110

103

125

59

74

75

33

35

34

38

36

39

40

41

42

45

46

47

48

43

44

49

63

31

27

28

29

30

37

52

51

53

50

51

54

52

60

61

64

65

66

73

33

22

23

19

32

15

55

56

59

55

62

67

71

72

20

24

25

68

21

25.1

55

57

58

58

69

70

17

16

15

14

10

10

26

10

9

12

11

58

57

58

126

13

10

8

9

7

5

6

1

2

3

4

21

Page 22

Electrical Connections

1/2HP, 1PH, 115V

Band Saw Model No.: JWBS-10Os

22

Page 23

23

Page 24

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

24

Loading...

Loading...