Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

2-1/4 Ton Short Chassis Service Jack

Model JSJ-2-1/4XA

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-454226

Ph.: 800-274-6848 Revision A1 05/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vere d

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

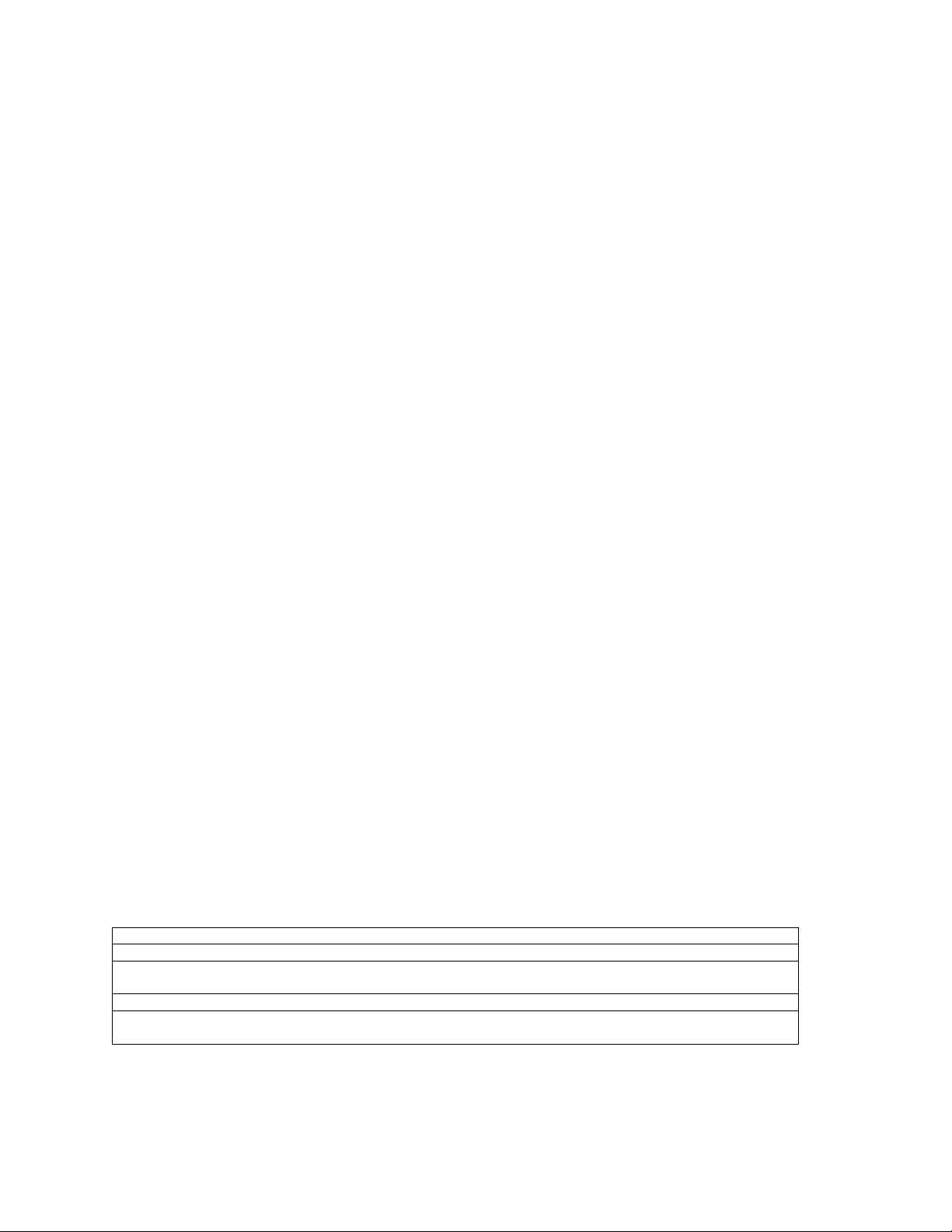

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 About this manual .......................................................................................................................................... 4

5.0 Specifications ................................................................................................................................................. 5

6.0 Assembly ........................................................................................................................................................ 6

7.0 Lubrication ...................................................................................................................................................... 6

8.0 Operating instructions .................................................................................................................................... 6

8.1 Raising the jack .......................................................................................................................................... 6

8.2 Lowering the jack ....................................................................................................................................... 6

9.0 Maintenance ................................................................................................................................................... 6

10.0 Troubleshooting the JSJ-2-1/4XA Service Jack ........................................................................................... 7

11.0 Replacement Parts ....................................................................................................................................... 7

11.1.1 Main Body Assembly (2-1/4T Short Chassis Service Jack) – Exploded View....................................... 8

11.1.2 Main Body Assembly (2-1/4T Short Chassis Service Jack) – Parts List ............................................... 9

11.2.1 Power Unit Assembly (2-1/4T Short Chassis Service Jack) – Exploded View .................................... 10

11.2.2 Power Unit Assembly (2-1/4T Short Chassis Service Jack) – Parts List ............................................. 11

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings posted o n the jack and in thi s manual. Failure to com ply with all of

these warnings may cause serious injury.

3. Replace warning labels if they become obscured or removed.

4. This is a lifting device only. Do not move or dolly the vehicle while on the jack. The load shall be supported

immediately by jack stands, or other appropriate means.

5. Inspect jack before each use. Do not use jack if it is damaged, has been altered or parts have loosened.

6. Do not exceed rated lift capacity. Overloading can cause damage to, or failure of, the jack.

7. Always center load on saddle.

8. Do not introduce blocks or other items between load and jack saddle.

9. Lift only on areas of the vehicle specified by the vehicle manufacturer.

10. This jack is designed for use on hard, level surfaces capable of sustaining the load. Use on other than

hard, level surfaces can result in jack instability and possible loss of load.

11. Clear obstructions from around jack area, such as tools, gravel, etc., before lifting.

12. Do not get under vehicle while jack is being used as the only support.

13. If jack needs service, contact JET Consumer Relations at 1-800-274-6848, or visit www.jettools.com, for

the location of your nearest JET Authorized Service Center.

14. Jack service must be performed by qualified personnel only. Use only genuine JET factory replacement

parts; use of unauthorized parts may cause risk of injury, and may void warranties.

15. Use only approved hydraulic fluid (ISO 32 hydraulic oil, or “jack oil”). Use of other fluids, such as brake fluid

or transmission oil, can damage seals and cause possible jack failure.

16. Do not modify the jack.

17. Failure to comply with all of these warnings may result in loss of load, damage to jack, and/or failure

resulting in personal injury or property damage.

4.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model JSJ2-1/4XA Short Chassis Service Jack. This manual contains instructions on installation, safety precautions,

general operating procedures, maintenance instructions and parts breakdow n. Your jack has been designed

and constructed to provide years of trouble-free operation if used in accordance with the instructions as set

forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the jack transfers ownership, the manual should accompany it.

4

Page 5

5.0 Specifications

Model number ..................................................................................................................................... JSJ-2-1/4XA

Stock number .............................................................................................................................................. 454226

Rated Capacity ......................................................................................................................................... 2-1/4 Ton

Strokes to reach maximum he ight without load ............................................................................................. 2 to 3

Regulating pressure ................................................................................................................................. 73.5 MPa

Maximum Height – A ...................................................................................................................... 18.7” (475mm)

Minimum Height – B .......................................................................................................................... 5.3” (135mm)

Saddle Diameter – D ............................................................................................................................ 4” (100mm)

Overall Length – C .......................................................................................................................... 26.5” (672mm)

Overall Width – E ............................................................................................................................ 13.4” (340mm)

Handle Length (two pieces) – F .................................................................................................... 39.4” (1000mm)

Net Weight ..................................................................................................................................... 71.6 lb (32.5kg)

Shipping Weight ................................................................................................................................... 75 lb (34kg)

Figure 1

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specif ications at any time and without prior notice, without incurring

obligations.

5

Page 6

6.0 Assembly

Numbers in parenthesis (#) refer to parts

breakdown, page 6:

1. Insert Upper Handle (30) into Lower Handle

(29) and fasten with Hex Cap Bolt (28).

2. Remove Handle Bolt (25).

3. Insert handle assembly into Handle Socket

(23). Make sure handle assembly engages

Gear Shaft (27) by turning handle back and

forth and observing movement of Handle

Socket Gear (26).

4. Install Handle Bolt (25) to secure handle

assembly.

7.0 Lubrication

Note: Lubricate before initial operation, and

periodically to ensure smooth operation. Lubricate

jack at points 1 through 6, as indicated in Figure 1.

8.0 Operating instructions

Important: During shipment and handling, air

sometimes gets into the hydraulic system caus ing

poor lifting performance. Before initial operation,

purge a ny air f rom system by fully openi ng pum p

release valve (turn handle counter-clockwise).

Then, while holding saddle down, pump handle

rapidly several times.

8.1 Raising the jack

1. Close release valve by turning handle

clockwise until resistance is felt. Do not over

tighten.

2. Place jack directly under object to be lifted,

and pump handle to raise saddle to contact

point. Make sure saddle accepts weig ht firmly

and centrally.

3. Check positioning under slight load to confirm

jack or load will not slip, or move suddenly.

4. Raise jack by pumping handle until desired

height is r e a ched.

5. After lifting, secure and transfer load to jack

stands or other appropriate means. Do not

use jack as the only means of support.

Figure 1 – Lubric ation points

1. Handle: Use #2 tube grease on release valve

gears below handle and lightly grease handle

at point where it fits into socket.

2. Wheels: Use 30W oil on axles and caster

bearings.

3. Lifting Arm: Inject #2 tube grease into grease

fitting.

4. Saddle and linkage: Use 30W oil on all moving

and pivoting parts.

5. Handle socket pivot bolts: L ubricate with 30W

oil.

8.2 Lowering the jack

Slowly turn handle counter-clockwise. Speed of

descent is controlled by amount release valve is

turned.

9.0 Maintenance

Store jack in a safe and dry environment, away

from children or unauthorized personnel. Always

store jack in fully lowered position, with handle in

upright position.

Keep jack clean and properly lubricated.

6. Plunger and plunger pin: Use #2 t ube grease

to lubricate connection between pump plunger

and p i n in hand le s o c ket.

6

Page 7

10.0 Troubleshooting the JSJ-2-1/4XA Servi ce Jack

Symptom Possible Cause Correction

Jack fails to lift load, or

only partially lifts.

Jack fails to rise to

heig ht limit.

Jack fails to hold load

in raised position.

Jack oil leaks Reservoir overfilled. Drain some oil from reservoir.

Handle wo n’t pum p full

stroke.

Release valve open. Close valve by rotati ng handle clockwise.

Weight c apacity exceeded. Use other lifting equipment; load must not

exceed rated capacity of jack.

Low hydraulic fluid. With jack on level ground, lower saddle

com plete ly. Rem ove fill pl ug and check oil

level. Fill as needed with approved

hydrauli c fl uid. Reinstall fill plug.

Low hydraulic fluid. With jack on level ground, lower saddle

com plete ly. Rem ove fill pl ug and check oil

level. Fill as needed with approved

hydrauli c fl uid. Reinstall fill plug.

Release valve open. Close valve by rotati ng handle clockwise.

Seals are worn. Have seals replaced by authorized serv ice

center.

Air in system. Bleed air from system by opening release

valve and pumping handle several times.

11.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

7

Page 8

11.1.1 Main Body Assembly (2-1/4T Short Chassis Service Jack) – Exploded View

8

Page 9

11.1.2 Main Body Assembly (2-1/4T Short Chassis Service Jack) – Parts List

Index No Part No Description Size Qty

1 ................ JSJ21/4XA-01 ........... Front Caster ............................................................. ...................................... 2

2 ................ JSJ3XA-02 ................ Wash er .................................................................... 18mm ............................ 2

3 ................ JSJ3XA-03 ................ C-Clip ....................................................................... 18 mm ............................ 2

4 ................ JSJ3S-07................... Swivel Caster Assembly .......................................... ...................................... 2

5 ................ JSJ3S-08................... Ball Ring .................................................................. ...................................... 2

6 ................ JSJ3S-09................... Steel Ball.................................................................. 6.35mm ....................... 38

7 ................ JSJ3S-10................... Ball Cover ................................................................ ...................................... 2

8 ................ JSJ3S-05................... Lock Washer ............................................................ 16mm ............................ 2

9 ................ JSJ3S-06................... Hex Nut .................................................................... M16 ............................... 2

10 .............. JSJ21/4XA-10 ........... Arm Shaft ................................................................. ...................................... 1

11 .............. JSJ3S-14................... C-Clip ....................................................................... 25mm ............................ 4

12 .............. JSJ3S-11................... Lock Washer ............................................................ 12mm ............................ 4

13 .............. JSJ3S-12................... Screw ....................................................................... M12x25 ......................... 2

14 .............. JSJ3S-18................... Hex Nut .................................................................... M12 ............................... 2

15 .............. JSJ21/4XA-15 ........... Sh aft ........................................................................ ...................................... 2

16 .............. JSJ3S-16................... Washer .................................................................... 10m m ............................ 5

17 .............. JSJ21/4XA-17 ........... Lock Nut................................................................... M10 ............................... 4

18 .............. JSJ3S-19................... Bolt........................................................................... M 18 ............................... 1

19 .............. JSJ3S-20................... Lock Washer ............................................................ 18mm ............................ 2

20 .............. JSJ3S-26................... Torsi on Spring ......................................................... ...................................... 1

21 .............. JSJ3S-21................... Pin............................................................................ 2x 16mm ........................ 1

22 .............. JSJ3S-22................... Washer .................................................................... 8m m .............................. 4

23 .............. JSJ3S-27................... Han dle Socket ......................................................... ...................................... 1

24 .............. JSJ3S-24................... Pin............................................................................ ...................................... 1

25 .............. JSJ3S-25................... Bolt........................................................................... ...................................... 1

26 .............. JSJ3S-23................... Release Valve Gear................................................. ...................................... 1

27 .............. JSJ3S-29................... Screw ....................................................................... ...................................... 1

28 .............. JSJ3S-31................... Bolt........................................................................... M 6x35 ........................... 1

29 .............. JSJ3S-32................... Lower Handle........................................................... ...................................... 1

30 .............. JSJ3S-34................... Upper Handle........................................................... ...................................... 1

31 .............. JSJ3S-33................... Handle Grip.............................................................. ...................................... 1

32 .............. JSJ21/4XA-32 ........... Power Unit Assembly............................................... ...................................... 1

33 .............. JSJ3XA-33 ................ Gear ......................................................................... ...................................... 1

34 .............. JSJ3XA-34 ................ Wash er .................................................................... 8mm .............................. 1

35 .............. JSJ3XA-35 ................ Nut ........................................................................... M8 ................................. 1

36 .............. JSJ3S-42................... Return Spring........................................................... ...................................... 1

37 .............. JSJ3S-41................... Pin............................................................................ 4x 50mm ........................ 1

38 .............. JSJ21/4XA-38 ........... Connecting Bar ........................................................ ...................................... 1

39 .............. JSJ3XA-39 ................ Screw ....................................................................... ...................................... 1

40 .............. JSJ3S-39................... Grease Fitting .......................................................... M6 ................................. 1

41 .............. JSJ21/4XA-41 ........... Lifting Arm Assembly ............................................... ...................................... 1

42 .............. JSJ21/4XA-42 ........... Saddle...................................................................... ...................................... 1

43 .............. JSJ21/4XA-43 ........... Bolt........................................................................... ...................................... 3

44 .............. JSJ21/4XA-44 ........... Side Plate Assembly ................................................ ...................................... 1

45 .............. JSJ3S-15................... Hex Nut .................................................................... M10 ............................... 1

.................. JSJ21/4XA-WL .......... I.D./Warning Label (not shown) ............................... ...................................... 1

9

Page 10

11.2.1 Power Unit Assembly (2-1/4T Short Chassis Service Jack) – Exploded View

10

Page 11

11.2.2 Power Unit Assembly (2-1/4T Short Chassis Service Jack) – Parts List

Index No Part No Description Size Qty

.................. JSJ21/4XA-32 ........... Power Unit Assembly (in cludes 32-1 thru 32-45) .... ...................................... 1

32-1 ........... JSJ21/4XA-321 ......... Cylinder Cover ......................................................... ...................................... 1

32-2 ........... JSJ21/4XA-322 ......... O-Ring * ................................................................... ...................................... 1

32-3 ........... JSJ21/4 XA-323 ......... Seal Ring * ............................................................... ...................................... 1

32-4 ........... JSJ21/4XA-324 ......... Oi l Tank ................................................................... ...................................... 1

32-5 ........... JSJ21/4X-57.............. Oil Fill Plug * ............................................................ ...................................... 1

32-6 ........... JSJ21/4X-54.............. O-Ring * ................................................................... ...................................... 1

32-7 ........... JSJ21/4 XA-327 ......... Ram ......................................................................... ...................................... 1

32-8 ........... JSJ21/4XA-328 ......... Retainer * ................................................................. ...................................... 1

32-9 ........... JSJ21/4XA-329 ......... Pis ton Ring .............................................................. ...................................... 1

32-10 ......... JSJ21/4XA-3210 ....... Washer * .................................................................. ...................................... 1

32-11 ......... JSJ21/4XA-3211 ....... O-Ring * ................................................................... ...................................... 1

32-12 ......... JSJ21/4XA-3212 ....... Pin............................................................................ ...................................... 1

32-13 ......... JSJ21/4XA-3213 ....... Spring ...................................................................... ...................................... 1

32-14 ......... JSJ21/4XA-3214 ....... Ram Rod.................................................................. ...................................... 1

32-15 ......... SB-4MM .................... Steel Ball.................................................................. 4mm .............................. 2

32-16 ......... JSJ21/4XA-3216 ....... Spring ...................................................................... ...................................... 1

32-17 ......... JSJ21/4XA-3217 ....... Screw ....................................................................... ...................................... 1

32-18 ......... JSJ21/4XA-3218 ....... O-Ring * ................................................................... ...................................... 2

32-19 ......... JSJ21/4XA-3219 ....... Retainer * ................................................................. ...................................... 1

32-20 ......... JSJ21/4XA-3220 ....... Ram ......................................................................... ...................................... 1

32-21 ......... JSJ21/4XA-3221 ....... Seal Ring * ............................................................... ...................................... 1

32-22 ......... JSJ21/4XA-3222 ....... Cylinder.................................................................... ...................................... 1

32-23 ......... JSJ21/4X-88.............. Back Up Ring * ........................................................ Ø50.2 x ø47 x 1.6 ......... 1

32-24 ......... JSJ21/4 X-89.............. O-Ring * ................................................................... Ø46.5 x ø 2.4 ................. 1

32-25 ......... JSJ21/4X-100............ Fil ter ......................................................................... ...................................... 2

32-26 ......... JSJ21/4XA-3226 ....... Screw ....................................................................... M8x16 .... ....................... 3

32-27 ......... SB-6MM .................... Steel Ball.................................................................. 6mm .............................. 4

32-28 ......... JSJ21/4 X-83.............. O-Ring * ................................................................... Ø14 x ø2.65 .................. 2

32-29 ......... JSJ21/4 XA-72 ........... Back Up Rin g * ........................................................ Ø18 x ø14 x 1.5 ............ 2

32-30 ......... JSJ21/4X-75.............. Pis ton Pump ............................................................ Ø14 ............................... 1

32-31 ......... JSJ21/4X-80.............. Adaptor .................................................................... ...................................... 1

32-32 ......... JSJ21/4X-81.............. Sprin g ...................................................................... ...................................... 1

32-33 ......... JSJ21/4X-69.............. Adjustment Screw .................................................... ...................................... 1

32-34 ......... JSJ21/4XA-3234 ....... O-Ring * ................................................................... ...................................... 1

32-35 ......... JSJ21/4XA-3235 ....... Screw ....................................................................... ...................................... 1

32-36 ......... JSJ21/4XA-3236 ....... Pin............................................................................ 4x16 .............................. 1

32-37 ......... JSJ21/4XA-3237 ....... O-Ring * ................................................................... 12.5 x 1.8 ...................... 1

32-38 ......... JSJ21/4XA-3238 ....... Release Valve Rod .................................................. ...................................... 1

32-39 ......... JSJ21/4XA-3239 ....... Pin............................................................................ 4x30 mm ....................... 1

32-40 ......... JSJ21/4XA-3240 ....... Steel Ball.................................................................. 5.5mm ........................... 2

32-41 ......... SB-8MM .................... Steel Ball.................................................................. 8mm .............................. 2

32-42 ......... JSJ21/4XA-3242 ....... Squ are Block ........................................................... ...................................... 2

32-43 ......... SB-10MM .................. Steel Ball.................................................................. 10mm ............................ 2

32-44 ......... JSJ21/4XA-3244 ....... Screw ....................................................................... M12x16x3 ..................... 2

32-45 ......... JSJ21/4XA-3245 ....... Valve Assembly ....................................................... ...................................... 1

.................. JSJ21/4XA-SK .......... Seal Kit (contains items with asterisk * ) .................. ........................................

11

Page 12

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

12

Loading...

Loading...