Warranty & Service

WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Repair Stations located throughout the United States can give you quick service.

In most cases, any one of these WMH Tool Group Repair Stations can authorize warranty repair,

assist you in obtaining parts, or perform routine maintenance and major repair on your JET,

Performax, Powermatic or Wilton tools.

For the name of an Authorized Repair Station in your area, call 1-800-274-6848.

More Information

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product

information, check with your local WMH Tool Group distributor or visit wmhtoolgroup.com.

Limited Warranty

WMH Tool Group (including JET, Performax, Powermatic and Wilton brands) makes every effort to

assure that its products meet high quality and durability standards and warrants to the original retail

consumer/purchaser of our products that each product be free from defects in materials and

workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS

SPECIFIED OTHERWISE. This warranty does not apply to defects due directly or indirectly to

misuse, abuse, negligence or accidents, normal wear-and-tear, repair or alterations outside our

facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. WMH TOOL GROUP SHALL IN

NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanation of the complaint must accompany the merchandise. If our inspection discloses a

defect, WMH Tool Group will either repair or replace the product, or refund the purchase price if we

cannot readily and quickly provide a repair or replacement, if you are willing to accept a refund.

WMH Tool Group will return repaired product or replacement at our expense, but if it is determined

there is no defect, or that the defect resulted from causes not within the scope of our warranty, then

the user must bear the cost of storing and returning the product. This warranty gives you specific

legal rights; you may also have other rights, which vary from state to state.

WMH Tool Group sells through distributors only. WMH Tool Group reserves the right to effect at any

time, without prior notice, those alterations to parts, fittings, and accessory equipment which they

may deem necessary for any reason whatsoever.

2

Specifications JVM-836

Stock Number ......................................................................................................690036 JVM-836-1

Stock Number ......................................................................................................690038 JVM-836-3

Spindle Taper................................................................................................................................R-8

Diameter of Quill (in).................................................................................................................. 3-3/8

Number of Spindle Speeds ......................................................................................... (5) JVM-836-1

Number of Spindle Speeds ....................................................................................... (10) JVM-836-3

Range of Spindle Speeds (rpm).......................................................................240-1,550 JVM-836-1

Range of Spindle Speeds (rpm).......................................................................120-1,550 JVM-836-3

Spindle Travel (in) .............................................................................................................................5

Collet Capacity (in) ................................................................................................................. 1/8-7/8

Head Movement ..............................................................................................................90° L and R

Maximum Travel of Ram (in) ................................................................................................... 10-1/2

Maximum Distance Spindle to Table (in) ................................................................................. 13-3/4

Minimum Distance Spindle to Column (in) ................................................................................ 5-1/4

Maximum Distance Spindle to Column (in) ............................................................................. 15-3/4

Maximum Longitudinal Table Travel (in).........................................................................................24

Maximum Cross Table Travel (in) .............................................................................................. 9-1/2

Maximum Knee Table Travel (in)....................................................................................................14

Size of Table (in) .................................................................................................................7-7/8 x 36

T-Slot (number) Size (in) ......................................................................................................... (3) 5/8

T-Slot Centers (in)...................................................................................................................... 2-1/2

Motor (JVM-836-1)....................................................................................... 1-1/2 HP, 1Ph 115/230V

.....................................................................................................................................prewired 115V

Motor (JVM-836-3)......................................................................................... 1-1/2 HP, 3Ph 2 Speed

...........................................................................................................................................230V Only

Floor Space Required (LxWxH/in) ..................................................................................55 x 52 x 77

Net Weight (approx.)...........................................................................................................1474 Lbs.

Table of Contents Page

Warranty ...........................................................................................................................................2

Specifications....................................................................................................................................3

Table of Contents..............................................................................................................................3

Installation Layout.............................................................................................................................4

Shipping Container Contents............................................................................................................5

Unpacking and Clean-Up .................................................................................................................5

Rotating the Head.............................................................................................................................5

Site Preparation................................................................................................................................6

Lifting the Mill....................................................................................................................................6

Lubrication ........................................................................................................................................7

Electrical Connections ......................................................................................................................7

Controls ........................................................................................................................................ 8-9

Changing Speeds .............................................................................................................................9

Position of Ram ................................................................................................................................9

Adjustments ....................................................................................................................................10

Parts Lists and Breakdowns ......................................................................................................11-22

Wiring Diagram ...............................................................................................................................23

The specifications in this manual are given as general information and are not binding. JET Equipment

& Tools reserves the right to effect, at any time and without prior notice, changes or alterations to parts,

fittings, and accessory equipment deemed necessary for any reason whatsoever.

3

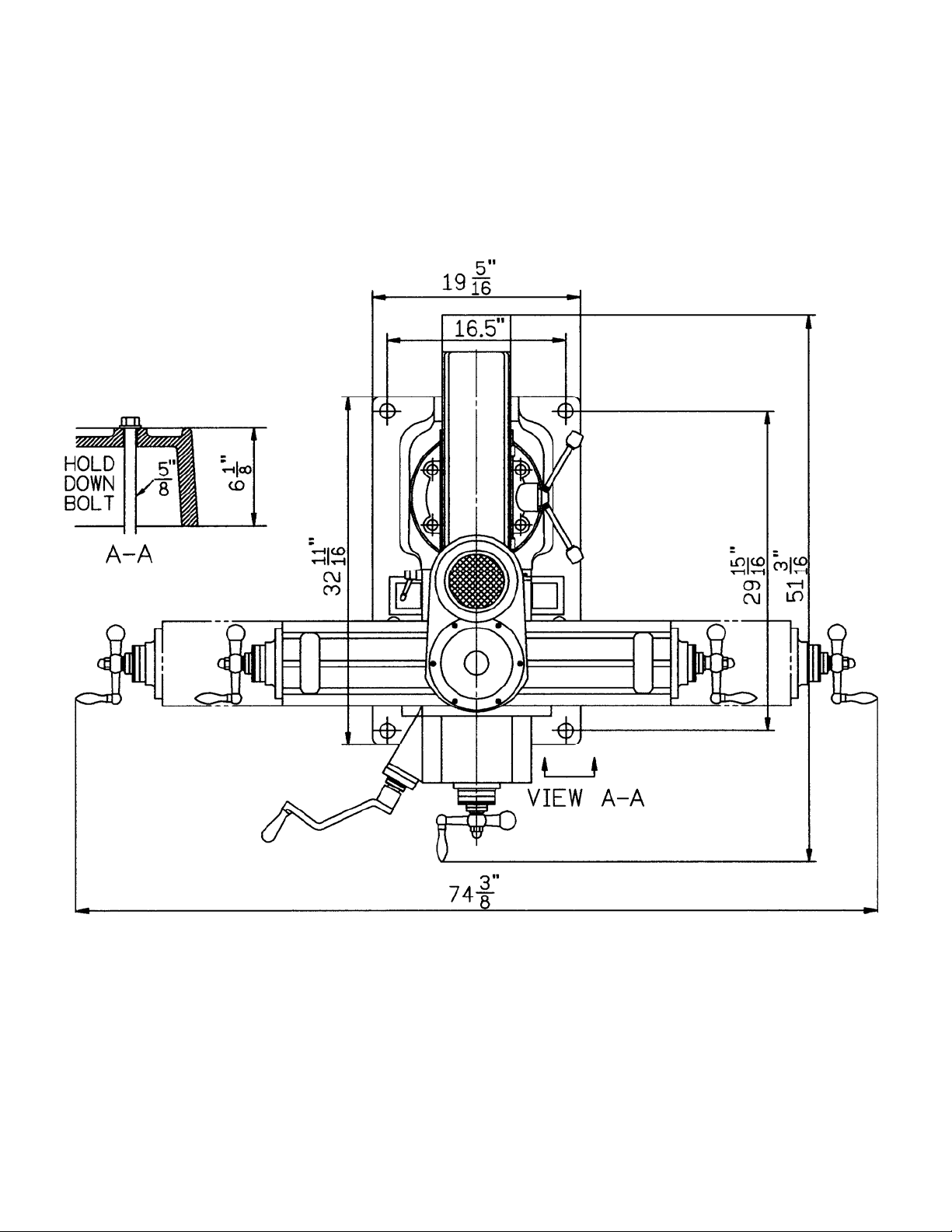

JVM-836 Installation Layout

4

Shipping Container Contents

1. Mill

1. Flat Way Cover (rear)

1. Accordion Way Cover (front)

1. Knee Crank

1. Drawbar

1. Tool Box:

1. Hex Wrench Set (1.5 - 10mm)

1. 17/19mm Combination Wrench

1. #2 Cross Point Screw Driver

1. #2 Flat Blade Screw Driver

1. Oil Can

1. Handwheel

1. Adjustable Wrench

5. Handles for Handwheels

1. Operator's Manual

1. Warranty Card

Unpacking and Clean-Up

1. Finish removing the sides and top of the

crate. Leave the mill bolted to the skid until

it is ready to be moved to its final location.

2. Clean all rust protected surfaces with

kerosene or a light solvent. Do not use

gasoline, paint thinner, or lacquer thinner.

These will damage painted surfaces.

3. Cover all machined surfaces with a film of

light machine tool oil to inhibit rust.

4. Remove wood block from below the knee.

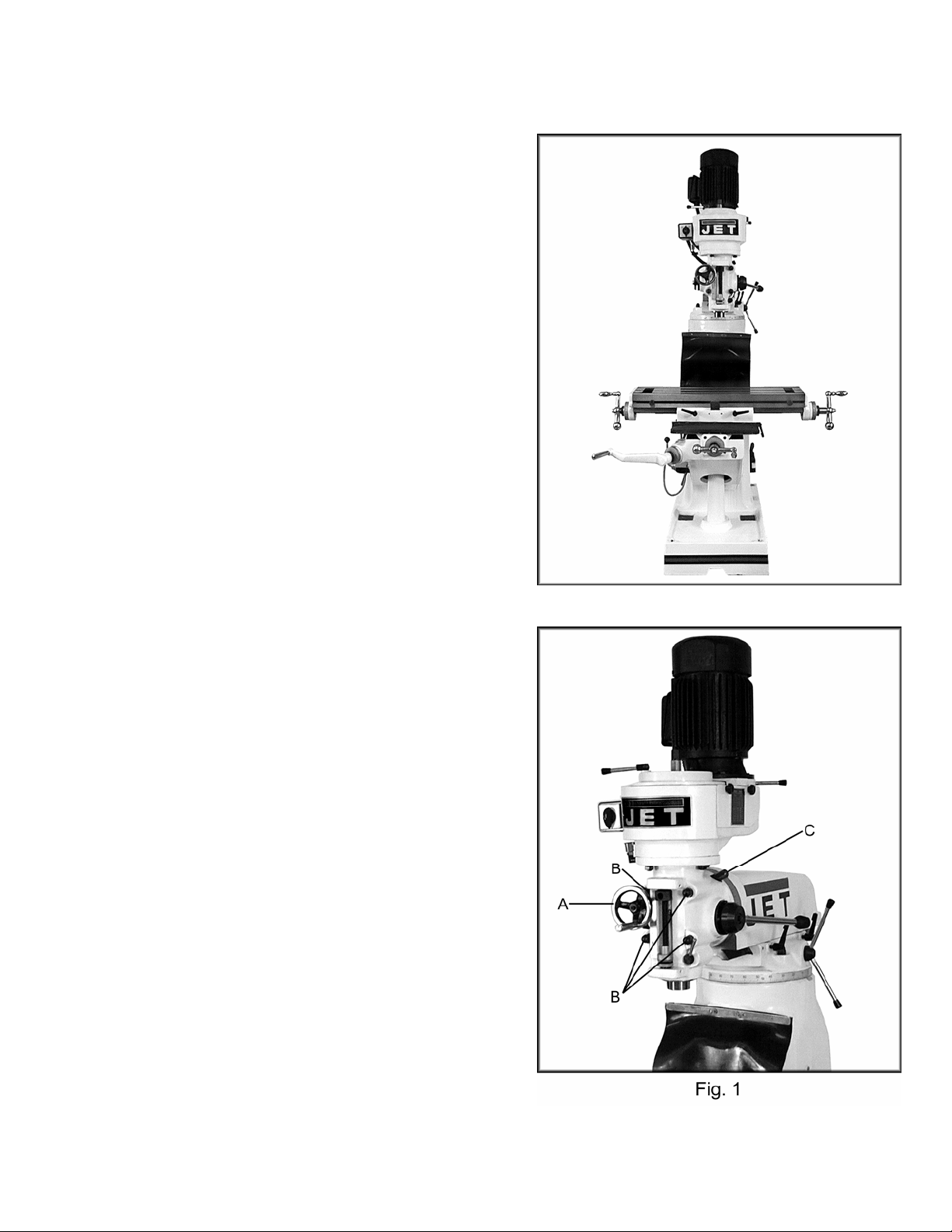

Rotating the Head

1. Remove handwheel (A, Fig. 1).

2. Loosen four cap nuts (B, Fig.1) with a ½

turn to unlock the head. Do not remove

these nuts unless you are prepared to

remove the head.

3. Use a 19mm socket and breaker bar on

adjusting nut (C, Fig. 1) to rotate the head.

5

Site Preparation

CAUTION!

Mill must be supported equally under all

four corners. Failure to comply may cause

the column to twist and put a bind in the

bedways.

The mill must be placed on an even surface

and bolted to the floor. Anchor bolts of

sufficient size and length must be fastened to

the floor according to the footprint of the mill.

See Installation Layout page 4.

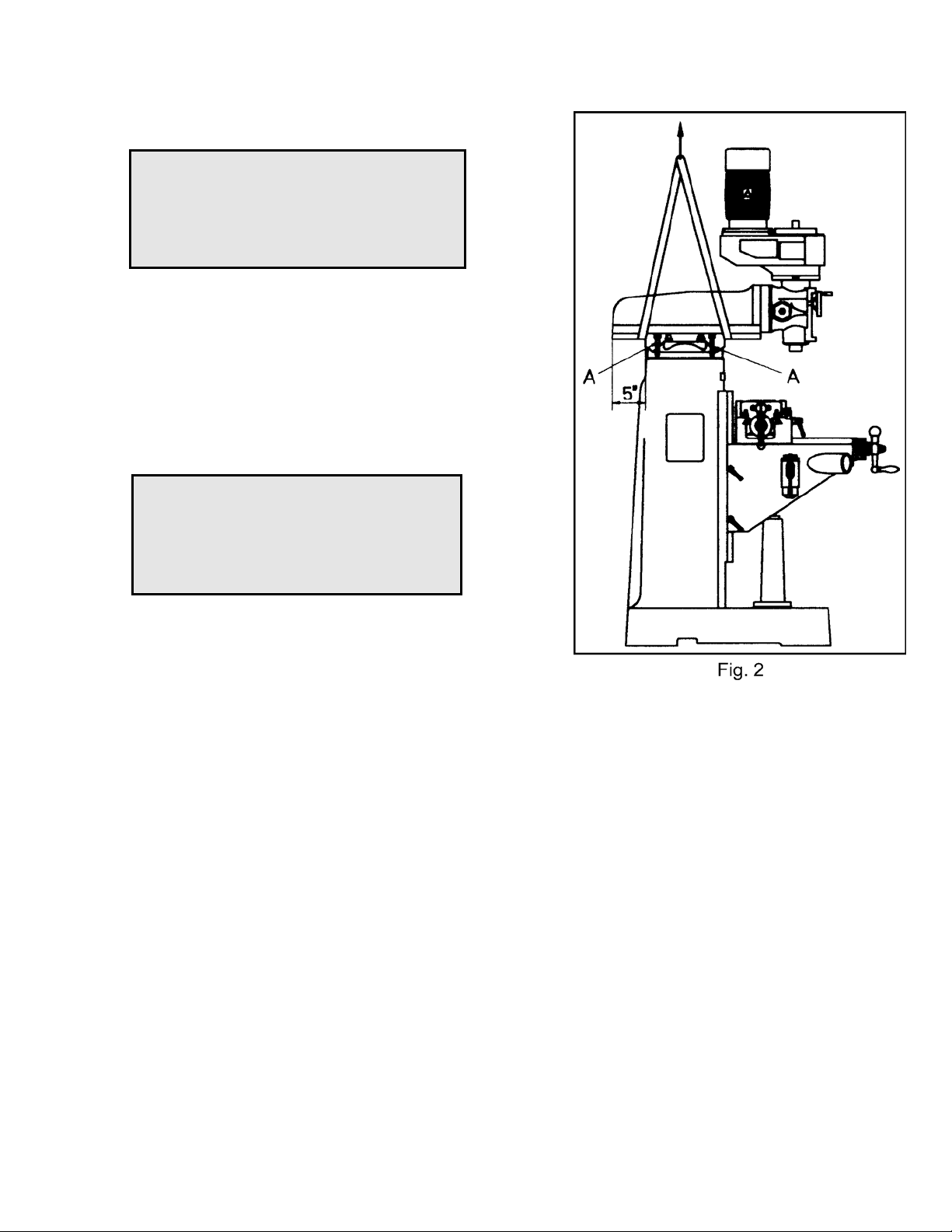

Lifting the Mill

,WARNING

Keep people a safe distance away from the

milling machine while it is being moved.

Failure to comply may cause serious

injury!

Lift the mill with appropriate sized lifting

straps. Follow the diagram in Fig. 2 for the

proper position of the straps under the ram.

Note: the position of the ram, and that the

table has been moved against the column.

Tighten ram locking bolts (A, Fig. 2) before

lifting.

Carefully lift the mill. Move into position over

the anchor bolts. Lower the mill onto the

anchor bolts. Check for level, and secure with

washers and anchor bolt nuts.

Check the mill for level with a machinist's

level placed on the table. Mill must be level

back to front and side to side. Shim if

necessary, but remember that the mill must be

supported equally at all four corners. Check for

level before tightening the anchor bolt nuts and

after tightening them. Adjust as necessary.

6

Lubrication

CAUTION!

Do not operate the mill before lubricating

the machine fully. Failure to comply may

cause damage to the machine.

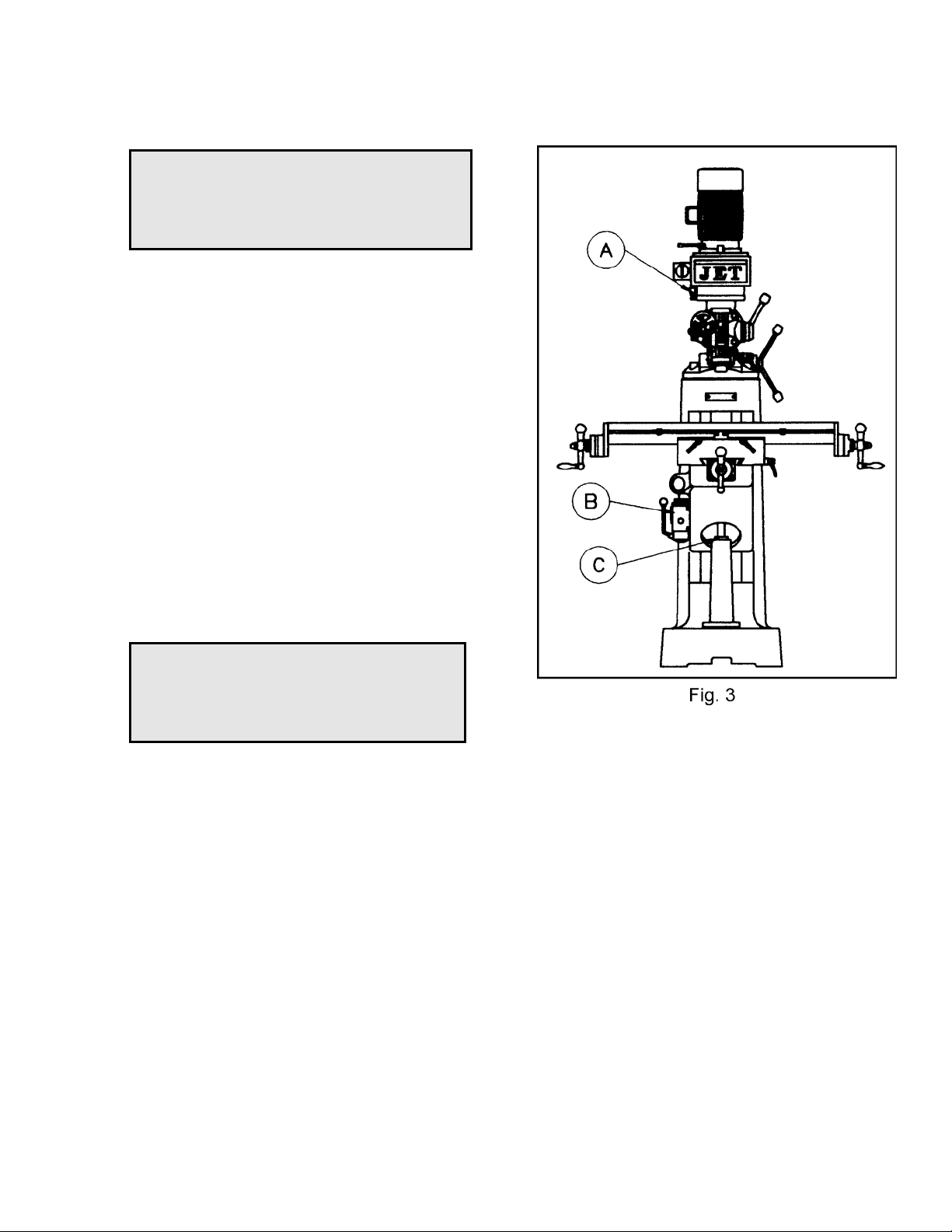

Reference Fig. 3 for parts of the mill to

lubricate:

A. Spindle Bearings - fill oil cup once daily

with Mobil DTE® Oil Light.

B. Oil Pump - fill reservoir as needed by

removing cap on top of tank and filling with

Mobil Vactra Oil No. 2. Pump oil with

release handle once for every hour of

operation. Way surfaces and leadscrews

are lubricated in this manner.

C. Knee Leadscrew - lubricate with Mobilith®

AW2 once a week.

Electrical Connections

,WARNING

All electrical connections must be made by

a qualified electrician! Failure to comply

may cause serious injury!

The JVM-836-3 Mill is rated 1-1/2HP, 3Ph,

230V only. The JVM-836-1 Mill is rated at

1-1/2HP, 1Ph 115/230V and comes from the

factory prewired at 115V.

Confirm power at the site matches power

requirements of the mill before connecting to

the power source.

To change from 115V to 230V operation

(JVM-836-1 only), remove the junction box

cover on the motor and change the wires

according to the diagram found on the inside of

the cover.

The mill must be properly grounded.

7

Controls

A. Belt Cover Lock Knobs (A, Fig. 4) located

on the right side of the head. Loosen and

remove belt cover to change belt position

on the pulleys.

B. Spindle Brake (B, Fig. 4) located on left

side of the head. Move in either direction to

stop spindle once power has been turned

off.

C. Quill Feed Handle (C, Fig. 4) located on

the right side of the head. Rotate

counter-clockwise to lower spindle. Return

spring will retract the spindle automatically

once the handle is released.

D. Quill Lock (D, Fig. 5) located on the right

side of the head. Rotate the handle

clockwise to lock the quill in a desired

position. Rotate the handle

counter-clockwise to release.

E. Micrometer Adjusting Nut (E, Fig. 4)

located on the front of the head. Use for

setting specific spindle depth.

F. Manual Fine Feed (F, Fig. 4) located on

the left side of the head. Must engage fine

feed (I, Fig. 5) for handwheel to function.

G. Quill Stop (G, Fig. 4) located on the front of

the head. Used in conjunction with

micrometer adjusting nut for predetermined

depth.

H. Reversing Switch (H, Fig. 5) located on

the left side of the head. Switches rotation

of spindle. For 3 Ph motor there is an

additional low and high-speed option.

I. Fine Feed Engagement (I, Fig. 5) located

on the left side of the head. Turn clockwise

until tight. This engages the manual fine

feed.

J. Draw Bar (J, Fig. 5) located on the top of

the head. This is used to tighten a R-8

collet or R-8 tool into the quill. Tighten

draw bar enough to hold tool securely

during milling operations.

8

K. Longitudinal Movement (K, Fig. 6)

handles located on opposite ends of the

table. This controls the X axis.

L. Cross Movement (L, Fig. 6) handle

located directly in front of the machine.

This controls the Y axis.

M. Knee Handle (M, Fig. 6) this raises the

table up and down.

Changing Speeds

1. Unscrew two knobs (A, Fig. 4) and remove

belt cover.

2. Loosen hex nut (A, Fig. 7).

3. Take the tension off the belt by moving

handle (B, Fig. 7).

4. Use the RPM chart, located on the back of

the belt cover, to place the belt in the

desired position.

5. Place tension on the belt by moving

handle.

6. Tighten hex nut.

7. Always replace the belt cover!

Note: The 3 Ph motor has an additional low

and high-speed setting (H, Fig.5).

Position of Ram

CAUTION!

Care should be taken to lock ram securely

after setting.

Ram can be moved by loosening two

handles (A, Fig. 8), and turning handle (B, Fig.

8) to desired position.

Note: It is recommended while doing heavy

milling work the head should be left as close to

face of turret as possible. Maximum rigidity is

then obtained.

9

Adjustments

1. Knee Gib Adjustment (#53, page 18)

adjust gib screw (#18, page 18) below

wiper on the left side of the knee for proper

travel and excess play.

Note: when adjusting the gibs always start

with the knee. Adjust the saddle second,

and adjust the table last.

2. Saddle Gib Adjustment (#47, page 18)

adjust gib screw (#18, page 18) found on

the right side front of the carriage for proper

travel and excess play.

3. Table Gib Adjustment (#45, page 18)

adjust gib screw (#18, page 18) found on

the left side of the table toward the front of

the carriage for proper travel and excess

play.

4. Ram Ware Plate (#10, page 18) adjust two

set screws (#19, page 18) found on the

side of the ram for proper travel.

5. Head Alignment the scales on the ram

adapter and head rotation are guides only.

Close tolerance work will require the use of

a dial indicator to make sure the head is

90º to the table in the X axis.

6. Longitudinal and Crossfeed Adjustment

- if there is excessive backlash in the handle.

a) Loosen hex socket head screw (#27,

page 16).

b) Turn feed screw nut (#26 or #29, page

16) to remove play.

c) Tighten hex socket head screw.

10

Loading...

Loading...