This .pdf document is bookmarked

Operating Instructions and Parts Manual

10" Compound Miter Saw

Benchtop Series – Model No. JMS-10CMS

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-707100

Ph.: 800-274-6848 Revision B2 11/2014

www.jettools.com Copyright © 2014 JET

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please contact

Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official JET

branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty does not

cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair,

alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood. Use of these machines in

the processing of metal, plastics, or other materials may void the warranty. The exceptions are acrylics and other natural items

that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a Two Year

Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to pr ovi d e pr o of of ini tial

purchase when calling. If a product requires further inspectio n , the Technical Service r epr esent a tive will explain an d assist

with any additional action needed. JET has Authorized Service Centers located throughout the United States. For the name of

an Authorized Service Center in your area call 1-800-274-6846 or use the Service Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor or visit

the JET w ebsite.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTI ES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are given as

general information and are not binding. JET reserves the right to effect at any time, without prior notice, those alterations to

parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET

are not sold in Canada by JPW Industries, Inc.

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries, Inc., or any

of its successors in interest to the JET brand .

®

branded products

2

Table of Contents

Warranty and Servic e .................................................................................................................................... 2

Table of Contents .......................................................................................................................................... 3

Warnings ....................................................................................................................................................... 4

Compound Miter Saw Saf ety .......................................................................................................................... 6

Introduction .................................................................................................................................................... 7

Specifica tio ns ................................................................................................................................................ 7

Cutting Capacity ............................................................................................................................................ 7

Electrical ........................................................................................................................................................ 8

Feature s ........................................................................................................................................................ 9

Shipping Contents ....................................................................................................................................... 10

Assembly ..................................................................................................................................................... 11

Adjustments ................................................................................................................................................. 14

Operation..................................................................................................................................................... 18

Crown Molding Chart ................................................................................................................................... 23

Maintenance ................................................................................................................................................ 24

Troubleshooting – Motor .............................................................................................................................. 25

Troubleshooting – Operation ........................................................................................................................ 25

Parts ............................................................................................................................................................ 26

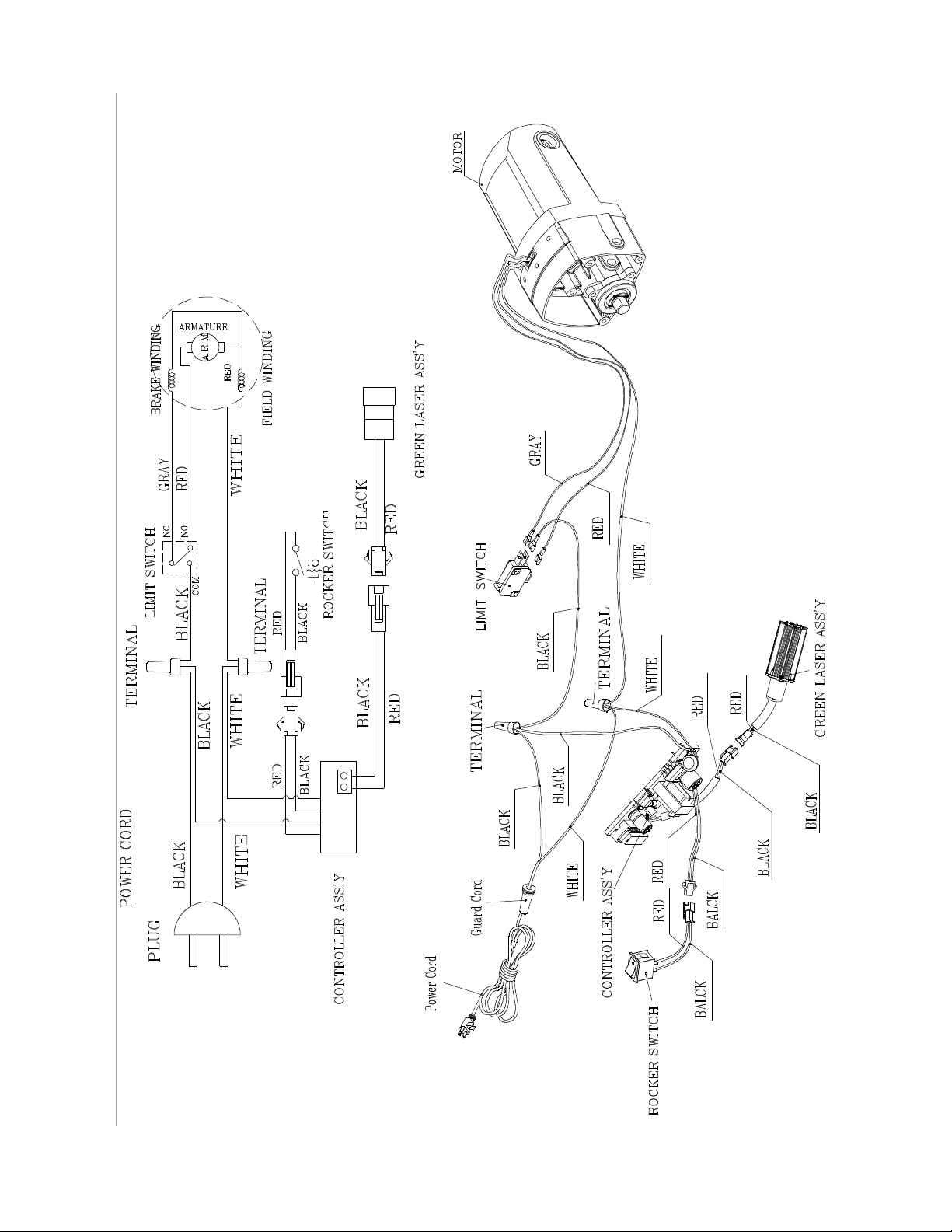

Wiring Diagram ............................................................................................................................................ 33

The specificati ons in t his manual are giv en as general inf ormation and are not bindi ng. JET reserv es the right

to effect, at any time and without prior notice, changes or alterations to parts, fittings, and accessory

equipment deemed nec essary for any reason whatsoever.

3

Warnings

1. Read and understand the ent ire owners' manual bef or e attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This saw is de si gned and intended for use by properly tr ained and experienced personnel only. If y ou

are not famili ar with the proper and saf e operati on of a compound mit er saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this saw for other than its intended use. If used for other purposes, J E T disclaims any real

or implied warranty and holds itself harmless f r om any injury that m ay result from that use.

6. Always wear approv ed safety glasses/face shields whil e using this miter saw. Everyday eyeglasses

only have impact resi stant lenses; they are not saf ety glasses.

7. Bef ore operati ng this saw, remov e tie, rings, watche s and other j ewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long hair . Non-slip footwear or anti - skid floor stri ps are

recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of dr ugs, alcohol or any medication.

11. M ak e certain the switch is i n the OFF position before connecting the machine to the power supply.

12. M ak e certain the machine is proper ly grounded.

13. M ak e all machine adjustm ents or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guar ds immediately.

16. M ak e sure this machine is firmly secured to the floor or bench befor e use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. P r ovide for adequate space surrounding work area and non-glare, overhead lighting.

19. K eep the floor around the m achi ne cl ean and free of scrap material, oil and grease.

4

20. Don' t use in dang er ous environm ent. Don't use power tools i n damp or wet locations, or expose them

to rain. Keep work area well lighted.

21. K eep v isitors a safe distanc e fr om the work area. Keep ch ildren away.

22. M ak e your workshop child proof wi th padlocks, master switches or by rem ov ing starter keys.

23. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

24. Maintain a balanced stance at all times so that you do not fall or lean agai nst the blade or other

moving part s. Do not over r eac h or use excessive force to perform any m ac hine oper ation.

25. Use the ri ght t ool at the cor rect speed and feed r ate. Do not for ce a tool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Use rec om mended accessories; i mproper accessories may be hazardous.

27. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

28. Disconnect tools before servicing and when changing ac c essories such as blades.

29. M ak e sure the work piece is securel y att ac hed or cl amped to the table.

30. Turn off the machine before c leaning. Use a brush or compressed air t o r emove chips or debr is — do

not use your hands.

31. Do not stand on the machine. S eri ous i njury could occur if the machine ti ps over.

32. Never leave the m ac hine r unning unattended. Tur n the power off and do not leav e the mac hine until it

comes to a complete stop.

33. Remove loose item s and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety no ti ces used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

5

Compound Miter Saw Safety

Specific safety instructions for this compound miter saw:

1. Do not operate the miter saw until it is completely assembled and installed according to these

instructions.

2. If you are not thoroughly familiar with the operation of miter saws, seek guidance from your

supervisor, instructor or other qualified person.

3. Always hold the work firmly against the fence and t able.

4. Do not perform any operat ion free hand (use clamp wherev er possible).

5. Keep hands out of the path of the saw blade. If the workpiece you are cutting would cau se your

hands to be within 6-3/4 in. of the saw blade, the workpiece should be clamped in place before

making the cut.

6. Be sure the blade is sharp, runs f r eely and is free of vibration.

7. Allow the motor to com e up to full speed before starting a cut.

8. Keep the motor air slot s clean and free of chips or dust.

9. Always make sure all handl es are tight before c utting, ev en if the table is positi oned in one of the

positive stops.

10. B e sure both the blade and the coll ar are clean and the arbor bolt is tightened securely.

11. Use onl y blade collars specified for your saw.

12. Never use blades larger in diam eter than 10 inches.

13. Never apply lubricants to the blade when it is running.

14. A lways check the blade for crack s or damage before operation. Replace a crac k ed or dam aged blade

immediately.

15. Never use blades recommended for operation at less than 4800 RPM.

16. A lways keep the blade guards in place and use at all times.

17. Never reach around the saw blade.

18. M ak e sure the blade is not contacting the workpiece bef or e the switc h is tur ned ON.

19. Impor tant : Aft er com pleting t he cut , rel ease the t ri gger and wait for the bl ade to stop before ret urni ng

the saw to the raised position.

20. Make sure the blade has come to a complete stop before removing or securing the workpiece,

changing the workpi ec e angle or changing the angle of the blade.

21. Nev er cut metal s or masonry product s wit h thi s tool . Thi s mit er saw is designed for use on wood and

wood-lik e pr oduc ts.

22. Never cut small pieces. If the workpiec e being cut would cause your hand or fingers to be within 6- 3/4

in. of the saw blade the workpiece is too small.

23. P r ovide adequate support t o the sides of the saw table for long work pieces.

24. Never use the miter saw in an area with flammable liquids or gases.

25. Never use solvents to c lean p lastic pa rts. S o lvents cou ld po s s ibly dissolve o r o therw ise da mage the mater ial.

26. S hut off the power befor e servici ng or adjusting the tool.

27. Disconnect the saw from the power source and clean the machine when finished using.

28. M ak e sure the work area is clean bef or e leav ing the machine.

29. Should any part of your miter saw be missing, damaged, or fail in any way, or any electrical

component f ail to perform properly, lock the switch and remov e the plug from the power suppl y outlet.

Replace missing, damaged, or failed parts before resuming operation.

6

Introduction

This manual is prov ided by JET covering t he safe op eration and maint enance procedures for the J ET

Model JMS-10CMS Compound Miter Saw with laser. This manual contains instructions on installation,

safety prec autions, general operating pr ocedures, maintenance i nstructi ons and parts breakdown. Thi s

machine has been designed and constructed to provide years of trouble free operation if used in

accordance with instructions set forth in this manual. If there are any questions or comments, please

contact eit her y our l oc al suppli er or JET. JET can also be reached at our web site: www.jettools.com.

Specifications

Model Number ....................................................................................................................... JMS-10CMS

Stock Number................................................................................................................................ 707100

Motor ............................................................................................................................... 120V, 60Hz, 15A

No Load Speed (Arbor) ............................................................................................................... 4800RPM

Motor Arbor Shaft Size ........................................................................................................................ 5/8"

Blade .................................................................................................................... 10", 40T, carbide tipped

Blade Arbor Size ................................................................................................................................. 5/8"

Net Weigh t ..................................................................................................................................... 33.3 lb.

The above specifications were current at the time this manual was published, but beca us e of our pol ic y of

continuous impr ovement , JET reserves the r ight to change specifications at any t ime and without prior

notice, without incurring obligati ons.

Cutting Capacity

Cutting Capacit y

Cut Type Miter Angle Bevel Angle Cutting Capacity

Cross Cut 0º 0º 2-5/8" x 5-1/2" 3-1/2" x 3-1/2"

Miter 45º Right & Left 0º 2-5/8" x 3-1/2" 3-1/2" x 2"

Bevel 0º 45º Left 1-1/2" x 5-1/2" 2" x 3-1/2"

Compound Cut 45º Right & Left 45º Left 1-1/2" x 3-1/2" 2" x 2"

Vertical Capacity (Base

Board)

-- -- 4"

with 3/4"

Auxiliary Fence

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious inju ry!

7

Electrical

Extens ion Cords

Power Supply and Motor

Specifications

The AC motor used in this saw is a universal,

nonreversible type (see Motor in the Specifica-

tions section on page 7).

To avoid electrical hazards,

fire hazards, or damage to the machine, use

proper circuit protection. Your saw is wired

at the facto ry for 120V operati on. Conn ect to

a 120V, 15 Amp circui t and use a 15 amp time

delay fuse o r circu it breaker. If power co rd is

worn or cut, or damaged in any way, have i t

replaced immediately to avoid shock or fire.

Electrical Requirements

This machine is double insulated to provide a

double thickness of insulation between the user

and the machine's electrical system. A ll exposed

metal part s are isolat ed from the inter nal metal

motor component s with pr otective insulati on.

This saw has a plug that looks like the one

shown in Figure A.

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your m achine will dr aw. An undersized

cord will cause a drop in the line voltage

resulting in power loss and overheating. The

table below shows the correct size to use

depending on the cord length and nameplate

ampere rati ng. If in doubt, use the next heavier

gauge. Remember, the smaller the gauge

number, the heavier the cord.

Cord Length AWG

00 – 25ft 016

25 – 50ft 014

Important: Make certain the receptacle in

question is properly grounded. If you are not

sure, have a registered electrician check the

receptacle.

Figure A

To reduce the risk of electrical shock, this saw

has a polarized plug (one blade is wider than the

other). This plug will fit in a polarized outlet only

one way; if the plug does not fit fully in the outlet,

reverse the pl ug. If it still does not fit , contact a

qualified electrician to install the proper outlet.

Do not change the plug i n any way.

Double insulation does not take the place of

normal safety precautions when operating this

tool.

To avoid electroc ution:

1. Use only identical replacement parts when

servicing a tool with double insulation.

Servicing shoul d be per formed by a qualified

technician.

2. Do not use power tools in wet or damp

locations or expose them to rain or snow.

8

Features

9

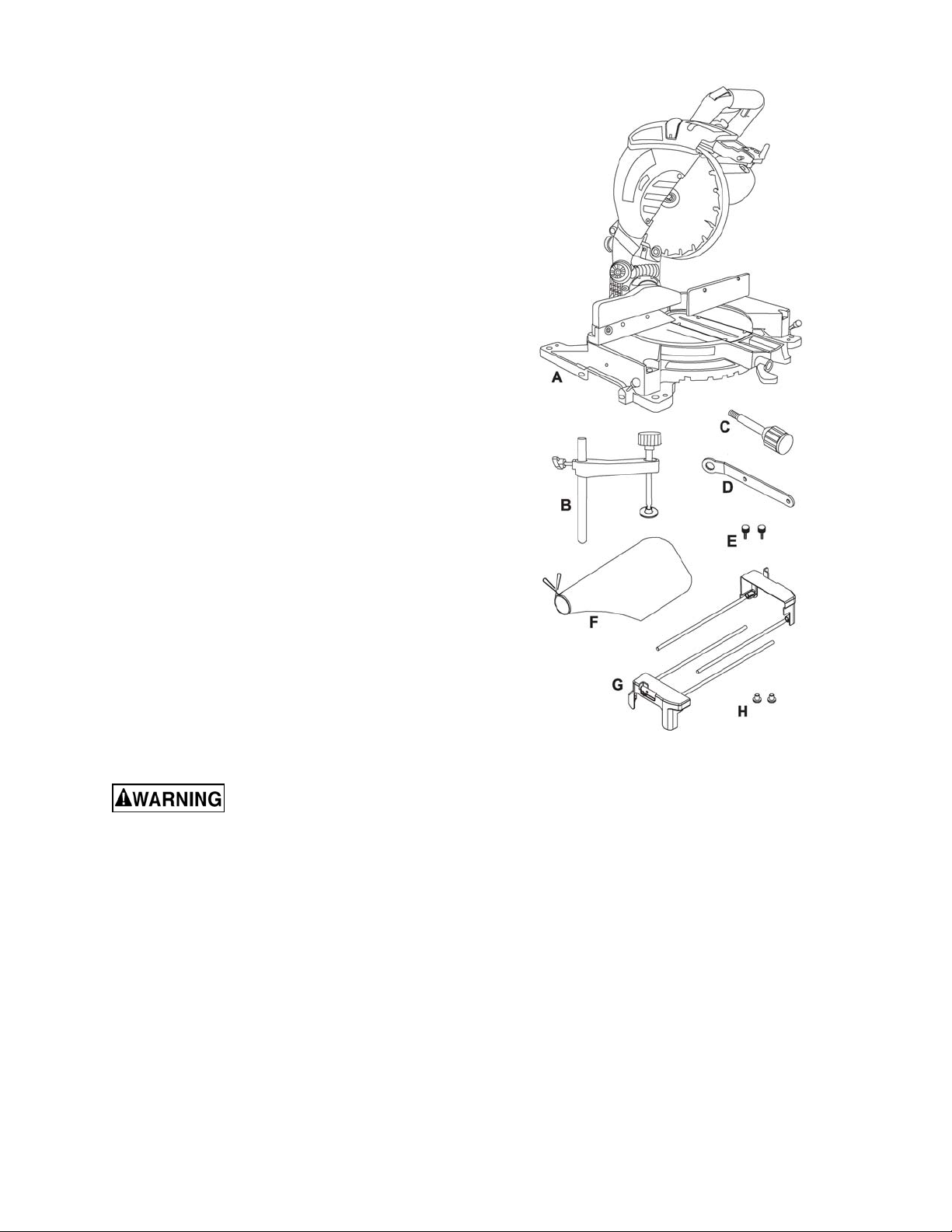

Shipping Contents

Unpacking

1. Remove the contents from the shipping

container.

2. Compare the contents of the shipping

container with the list found below. Make

certain that all items are accounted for

before discarding any packing material.

Report any shortages or damage to your

JET distri butor.

Contents of the Shipping Container

A Miter Saw (1)

B Hold-down Clamp (1)

C Miter Handle (1)

E Lock Knob (2)

F Dust Bag (1)

G Extension Table (2)

H Screw (2)

-- Owner’s Manual ( 1)

-- Warranty Registration Card

Tools Supplied for Assembly

D Blade Wrench

Tools not inc l uded

00Adjustable Wrench

006mm Hex Wrench

00Crosspoint Scr ewdriver

00Combination Wrench

Read and understand all

assembly instructions before attempting

assembly! Failure to comply may cause

serious injury!

Contents of Shipping Container

10

Assembly

Releasing the Cutting Head

When not in use, lock the

cutting head in the down position. Failure to

comply can cause serious injury or damage

equipment.

Refer to Figure 1.

Unlocking

1. Push down on the switc h handle (A).

2. Pull out the hold-down latch (B).

3. Raise the cutti ng head to the up position.

Locking

Note: When not i n use, l ock the cut ting head i n t he

down position.

1. Push the cutting head down.

2. Press the hold-dow n latch (B) in to lock.

Important: Always use the carryi ng handles when

lifting or moving to avoid damage to the machine.

Installing the Extension Table

Referring to figure 2:

1. Loosen the extension table lock knob (E).

2. Place the extension mounting tube (D) into the

two holes provi ded in the miter saw base.

3. From underneath the saw, i nsert one screw (B)

into the mounting tube hole (4) and tighten.

4. Slide the extension table to desired position

and tighten the extension table lock knob (E).

5. Install the right extension table in the same

manner.

Installing the Miter Handle

Figure 1

Figure 2

Thread the miter handle (F, Fig. 2) into the hole

located at the front of the miter table.

Installing the Dust Bag

Referring to Fi gur e 3:

1. Squeeze the meta l collar wings of the dust bag (A).

2. Place the dust bag neck opening around the

exhaust port ( B), and rel ease the c ollar wings.

To empty t he dust bag, remov e from exhaust port ,

open zipper on underside of bag and empty into

waste container.

Note: Check and empty bag frequently. Do not wait

for it to get ful l.

Figure 3

11

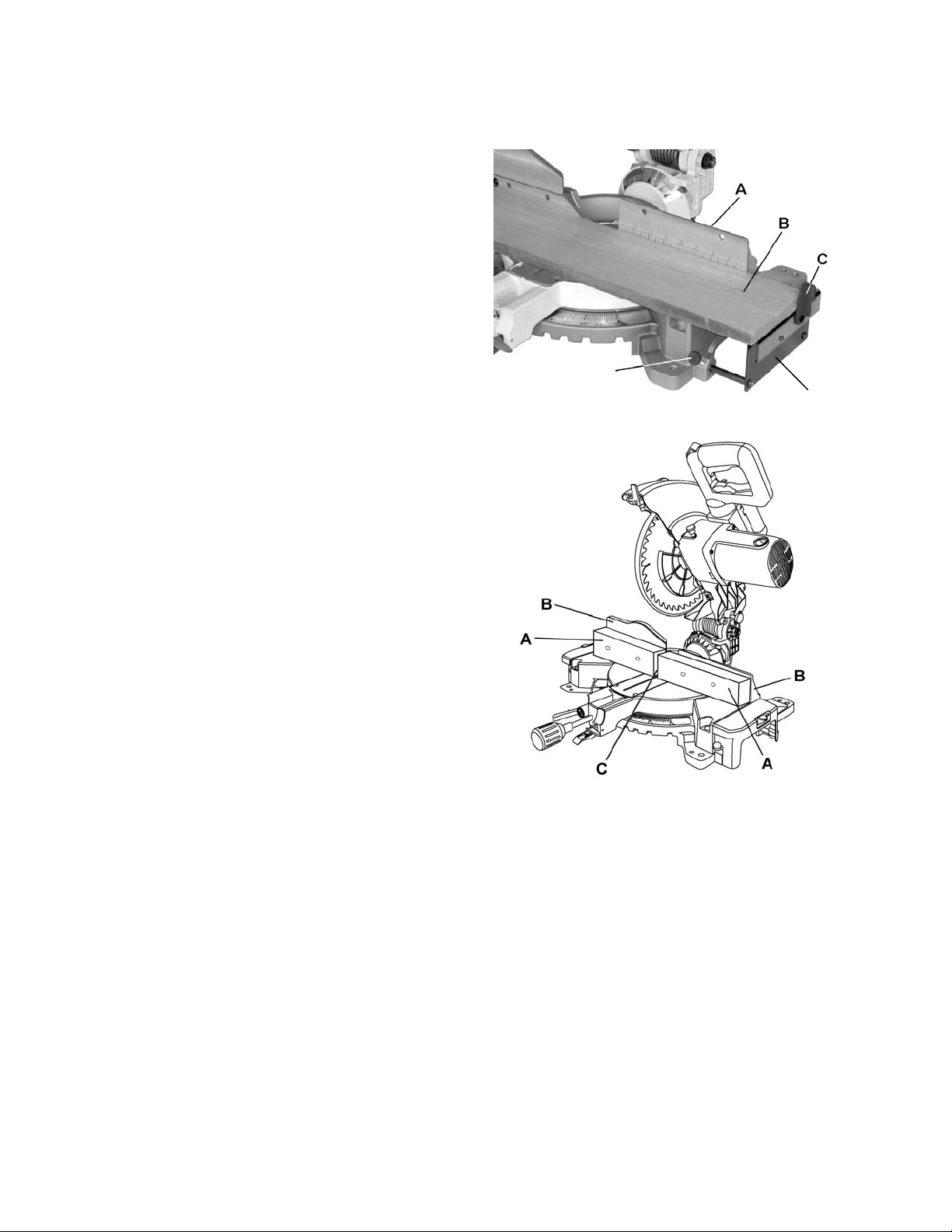

Installing the Safety Hold-down Clamp

Mounting the Saw

1. Place the hold-down clamp assembly (A, Fig.

4) in a mounti ng hole located behind t he right

or left (shown) fence (C).

2. Thread the hold-d own clamp knob (B) into the

hole located at the rear of t he saw base.

3. Tighten the hold-down clamp knob (B).

Figure 4

Table Inserts

Always unplug the saw to avoi d

accidental starting. Failure to comply may

cause serious inj ury!

Remove tabl e insert to r emove all small pi eces of

debris from the table cavity before performing

any cuts.

Be sure to reattach the table insert prior to

performi ng a cutting operation.

Observe the following safety measures to avoid

injury form unexpec ted saw movement:

• Disconnect the power cord and lock t he cutting

head in the lower position.

When lifting:

• Use the carry handle.

• Bend at the knees, not fr om the bac k.

• Clamp or bolt the saw on a lev el work surfac e.

For stationary us e:

Select a location for the saw, such as the top of a

workbench, making su r e to prov ide sufficient r oom for

handling the workpiece. Secure the saw to the bench.

Mounting hardware is not included and must be

purchased separately.

For portable use:

Place the saw o n a 3/4 in. thic k piece of plywood

and bolt the base securely t o the plywood usi ng the

mounting holes on the base. Mount ing hardware is

not included and must be pur c hased separately.

Use C-clamps to clamp this mounting board to a

stable work surface at the worksite.

Removing the Blade

Disconnect power and make

sure the swi tch is in the OFF posi tion to avoid

accidental starts. Failure to comply may cause

serious injury!

Referring to Fi gur e 5:

Do not start the saw without

checking for interference between the blade

and table insert.

Damage could result to the blade, table insert or

turntable if blade strike occurs during the cutting

operation.

To remove:

1. Loosen and remove four screws on the table

insert (see Features on page 9) with a cross-

point screwdriver

2. Remove the insert.

To install:

1. Reposition the table insert.

2. Install the f our screws and tighten.

Check for blade clearance by moving the slide

carriage through the f ull motion of the bl ade in the

table slot.

1. Unplug the saw from the outl et.

2. Raise the miter saw to the upright position.

3. Raise the lower blade guard (A) to the

uppermost posit ion.

4. While holdi ng the lower blade guard, loosen the

cover plate screw (B) with a cross-point

screwdriver.

5. Rotate the cover plate (D) to ex pose the arbor

bolt (C).

6. Place the blade w r enc h ov er the ar bor bolt (C).

7. Locate the arbor lock (F) on the motor, below

the switch handle (E).

8. Press the arbor lock, holding it in firmly while

turning the bl ade cl ockwise. The arbor l ock will

then engage and lock the arbor. Continue to

hold the arbor lock, while turning the wrench

clockwise to loosen the arbor bolt.

12

9. Remove the arbor bolt (H), arbor c olla

r

blade (K). Do not remove the inner blade collar.

Note: Pay attention to the pieces removed, noti ng

their position and direction they face. Wipe the

blade collars cl ean of any sawdust bef ore installi ng

a new blade.

(J), and

Installing Blade

Important: This machine requires a 10-inch

diameter blade.

Unplug the miter saw before changing and/or

installing the blade.

Referring to Fi gur e 5:

1. Instal l a 10-in. blade, making sure the rotati on

arrow on the blade matches the clockwise

rotation arrow on the upper guard and the

blade teeth are poi nting downward.

2. Place the arbor collar (J) again st t he blade a nd

on the arbor ( L). Thread the arbor bolt (H) on

the arbor in a counter cl oc k wise di r ection.

Important: Make sure that the flat edge inside

opening of the arbor collar (J) is aligned with the

flat edge on t he arbor shaft (L) . Also, the flat - si de of

the arbor collar (J) must be placed against the

blade (K).

3. Place the blade wrench on t he ar bor bolt (H).

4. Press the arbor lock (F), holding it in firmly

while turning the blade counterclockwise

(opposite the cutting direction of the blade).

When it engages, continue to pre ss the arbor

lock (F) in, while tightening the arbor bolt (H)

securely.

5. Rotate the cover plate (D) back to its original

position unti l the slot in the cover plat e engages

with the cover plate screw (B). While holding

the lower blade guard (A ) up as shown, tight en

the screw (B) with a cross-point screwdriver.

The cover pl ate keeps the ar bor bolt from falling out

if it accidentally loosens, and helps prevent the

spinning blade from coming off the saw.

6. Lower the blade guard (A) and v erify that the

operation of the guar d does not bind or stick.

7. Tur n the blade t o disengage the arbor loc k (F);

then verify that the blade will spin freely.

Figure 5

Never use the saw without the

cover plate secure in place. Failure to comply

may cause serious injury!

Verify that the collars are clean

and properly installed. Lower the blade into the

table and veri fy that it does not come in con tact

with the met al base or the turn table. Failure to

comply may cause seriou s injury!

13

Adjustments

Before attempting any adjustments, make sure the trigger is released and

remove the power cord from the power sou rce

to avoid injury from unexpected starting or

electrical shock. Failure to comply may cause

serious injury!

Note: Your mi ter saw was adjusted at the fact ory.

However, duri ng shipm ent slight mi salignment may

have occurred. Check the following settings and

adjust if necessary pri or to using this miter saw.

Bevel Stop Adjustments

To avoid injury from

unexpected starting or electrical shock, make

sure the trigger is released and remove the

power cord from the power source.

90°(0°) Bevel Adjust ment

1. Set the miter angle to 0° (see Miter Angle on

page 15).

Figure 6

Note: A bevel angle of 0° corresponds to a blade-

to-miter-table angle of 90°.

2. Turn the bevel lock handle (A , Fig. 6) c lockwise

to loosen and tilt t he cutting arm t o the 0° bevel

angle. Turn the bevel lock handle (A)

countercl oc k wise to tighten.

3. Place a combi nation square on the miter t able

with the rul e against the table and heel of the

square against the saw blade.

If the blade is not 90° to the miter table:

4. To adj ust, tilt t he cutting arm to 45°, l oosen the

lock nut (B, Fig. 7) and turn t he stop bolt (A,) in

or out accordingly.

5. Tilt the cutting arm back to the right and

recheck alignm ent.

6. Repeat steps 1–4 if necessary until t he blade is

90° to the table, then tighten the lock nut (B,

Fig. 7) to secure the stop bolt (A, Fig. 7).

Bevel Scale Indicat ors

1. Set the blade to be exactl y 90°(0° ) to the table.

2. With cross-point screwdriver, loosen two bevel

indicator screws (B, D, Fig. 8).

Figure 7

3. Adjust bevel indicat ors (A, E, Fig. 8) to the “0”

marks (C, F, Fig. 8) on the bevel scale and

retighten the screws (B, D).

Figure 8

14

45° Left Bevel Positive Stop Adjustment

1. Set the miter angle to 0° (Miter Angle - page

15) and fully extend the sliding fence (Sliding

Fence - page 19) c om pletely to the left.

2. Loosen the bevel lock handle (A, Fig. 6) and tilt

the cutting arm completely to the left.

3. Using a combination square, check t o see i f the

blade is 45° to the tabl e.

If the blade is not 45° to the miter table:

4. To adj ust, tilt the cutting arm t o zero degrees,

loosen the lock nut (B, Fig. 9) and t urn the stop

bolt (A, Fig. 9) in or out ac c or dingly.

5. Tilt the cutti ng arm back t o the l eft and recheck

alignm ent.

6. Repeat steps 1–4 if necessary until t he blade is

45° to the table, then tighten the lock nut (B,

Fig. 9) to secure the stop bolt (A, Fig. 9).

Miter Angle

The compound miter saw scale can be easily read,

showing miter angles from 0° to 45° to the left, and

0° to 45° to t he right . The mit er saw table has nine

of the most common angle settings with positive

stops at 0°, 15°, 22.5°, 31.6°, and 45°. These

positive stops position the blade at the desired

angle quickly and acc ur ately.

Figure 9

Follow the process below for quickest and most

accurate adj ustm ents.

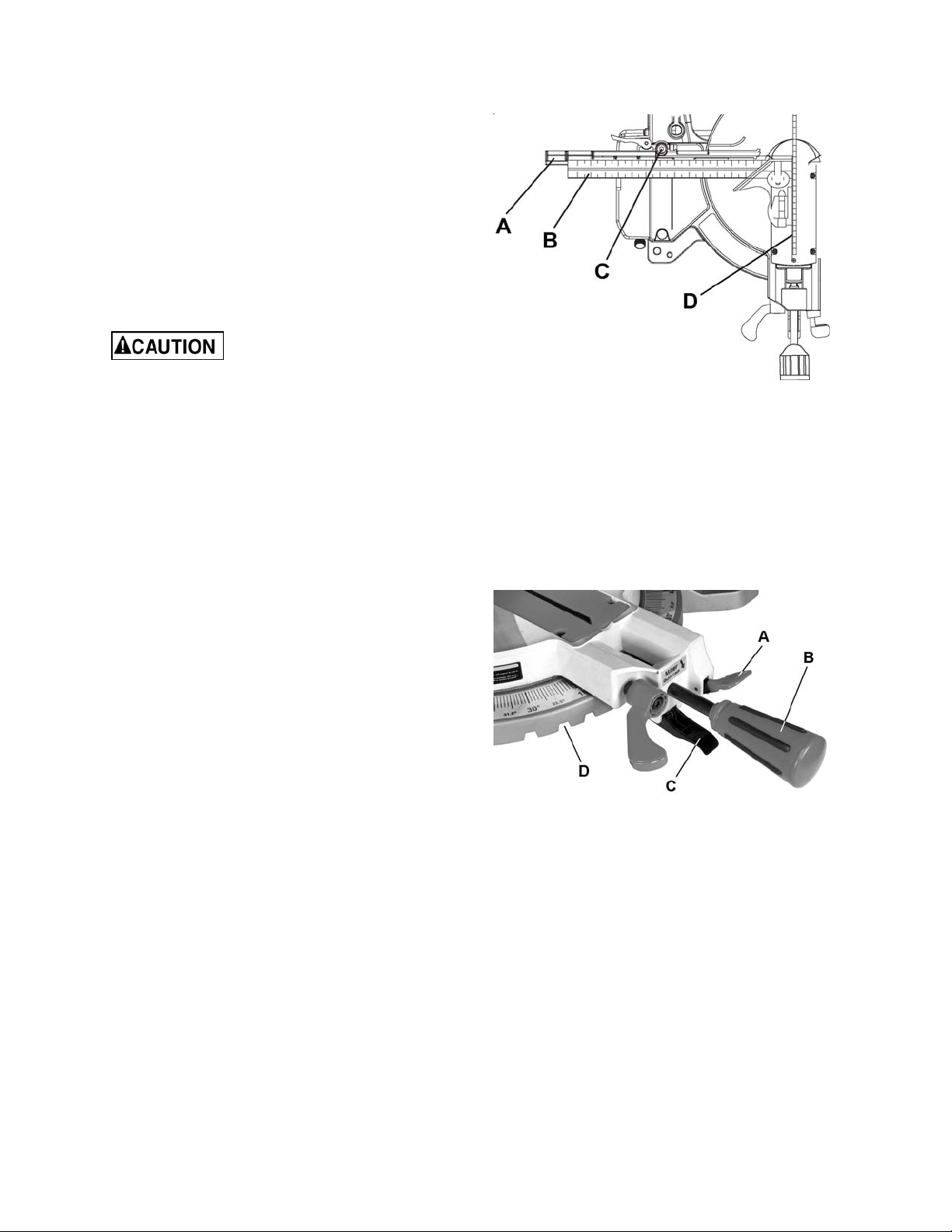

Referring to Fi gur e 10:

1. Lift up on the quick-cam m iter table lock (B) to

unlock the table.

2. Lift up on the posit ive stop locking lever (D) and

move the turnt able with handle (C) t o align the

indicator (E) to the desired degree

measurement.

3. Lock the table into position by pressing down

on the quick-cam m iter table lock (B).

Miter Scale Indicator Adjustment

1. Move the table to the 0° positive stop.

2. Remove the table ins er t (A).

3. Loosen the screw (F) that secures the indicator (E).

4. Adjust the indicator (E) to the 0° mark and

retighten screw (F).

5. Replace the table inser t (A).

Figure 10

15

Adjusting Fence Squareness

Referring to Fi gur e 11:

1. Loosen two fence locking sc r ews (C).

Note: One lo ck in g s cre w is lo c at e d on ea ch fence.

2. Lower the cutti ng arm and lock in position.

3. Using a square (B), lay the heel of t he square

against the blade (D) and t he ruler agai nst the

fence (A).

4. Adjust the fence 90° to the blade and tighten

the two fence locking sc r ews (C).

If the saw has not been used

recently, recheck blade sq uareness to the fence

and readjust if needed.

5. After fence has been aligned, using a scrap

piece of wood, make a cut at 90º then check

squareness on the piece. Readjust if

necessary.

Positive Stop Miter Angle Adjustment

Referring to Fi gur e 12:

1. Unlock the mi ter table by lifti ng up on the quick-

cam miter table lock (A).

Figure 11

2. Raise the positive stop locking lever (C) up; at the

same tim e grasp the miter han dle (B) and rot ate

the miter table left or right to the desired angle.

3. Release the posit ive stop locking lever (C) and

set the mit er at the desired angle making sure

the lever snaps int o plac e.

Note: There are ni ne posi tive stops into which the

lever will lock.

4. After t he angle is selected, press down on the

quick-cam miter table lock (A).

Quick-cam Miter Table Lock Operation

If a miter angl e required is not one of nine posit ive

stops, the miter table can be locked at any angle

between these positive stops by using the quickcam miter table lock.

Referring to Fi gur e 12:

1. Unlock the mi ter table by lifti ng up on the quick-

cam miter table lock (A).

2. Raise the positive stop locking lever ( C) up; at

the same time gr asp the miter handle (B) and

rotate the m iter tabl e left or r ight t o the desired

angle.

Figure 12

3. Release the positive stop locking lever (C).

4. Press do wn on t he quick-cam mit er table lock

(A) until it locks the miter table in place.

Note: The quick-cam miter table lock should lock

the tabl e and prevent it f rom m oving. If adj ustment

is needed, see Quick-cam Miter Table Lock

Adjustment on following page.

16

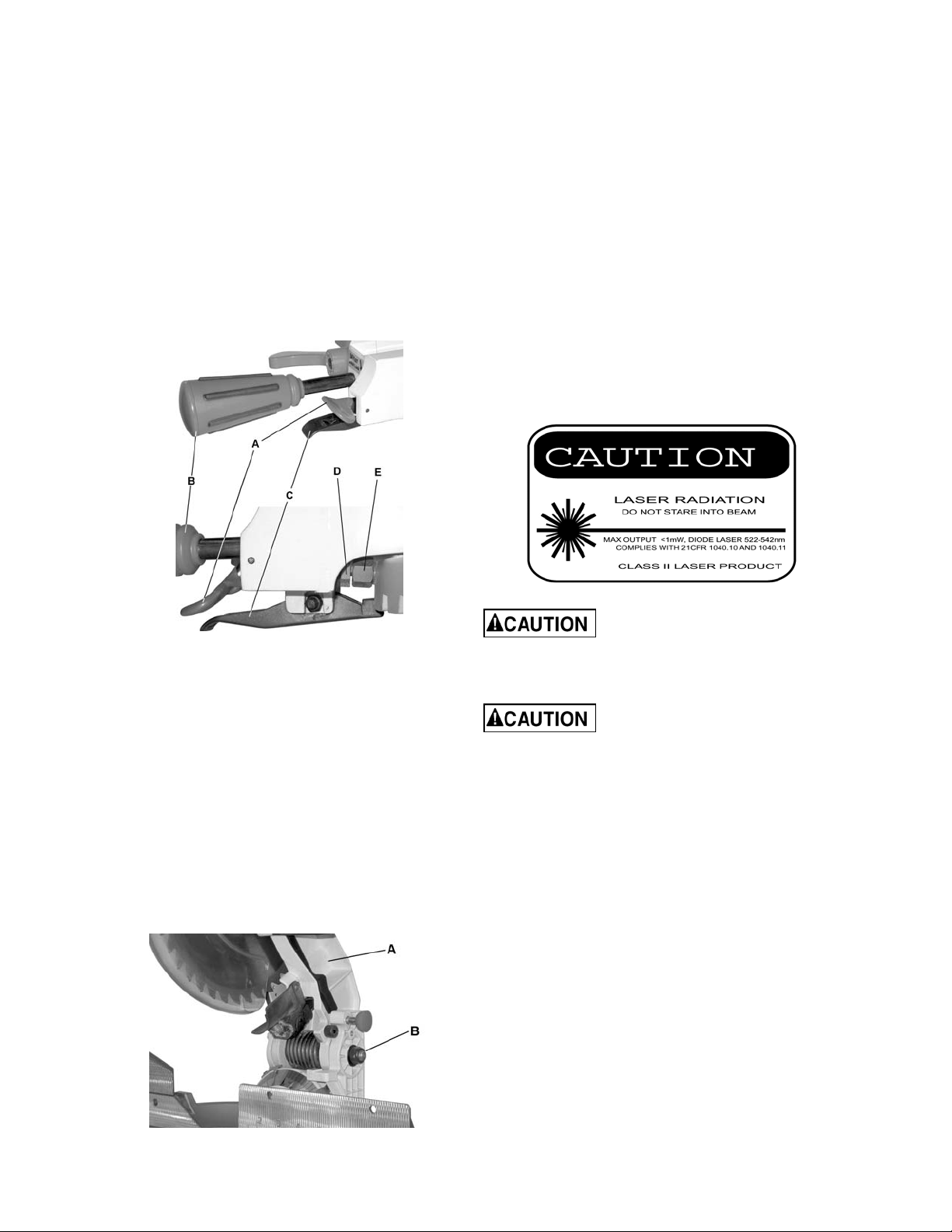

Quick-cam Miter Table Lock Adjustment

Laser Beam

Referring to Fi gur e 13:

1. Pl ace the qui ck-cam miter lock (A) in t he down

position t o loc k.

2. Loosen the lock nut (D) with a 13mm wrench,

then turn the stop nut (E) to ext end the loc king

arm against the base of the miter saw.

3. Test the qui ck-cam miter lock (C) to verify that

it locks the table securely into position.

4. Tighten the lock nut (D) to lock the miter

locking mechanism into place.

The laser is turned on with a switc h located on the

saw handle (C, Fi g. 15). W hen left on i ndefi nitely, a

sensor will turn the laser off after 20 minutes. The

switch must be reset (turned off for two seconds,

then on again) to restart.

The laser has no adjustments and should not

require adjustment. If adjustment should become

necessary, take the miter saw to an approved

service center.

• Laser radiat ion. Avoid direct eye exposure.

Always un-plug miter saw from power

source before making any adjustments.

• Laser Warning Label: Max output <1mW

DIODE LASER: 522-542nm, Complies with

21CFR 1040.10 and 1040.11.

Figure 13

Cutting Arm Pivot Adjustment

The raising and loweri ng of the cutting arm should

be free of si de-to-side play for accurate miter cuts.

It should be tight enough to prevent side-to-side

movement while still allowing the arm to move

freely up and down when cutting.

Referring to Fi gur e 14:

If the cut ting arm (A ) is too loose, tighten by turning

the cut ting arm a djusting nut (B) cl ockwise with a 19

mm wrench to tighten.

If cutt i ng arm tr avel is too ti ght, turn the cutting arm

adjusting nut counterclockwise.

Use of controls or adjustments

or performance of procedures other than those

specified in this manual may result in

hazardous radiat io n exp osure.

The use of optical instruments

with this produ ct will increase eye hazard.

• Do not attemp t to repair o r disassemble t he

laser. If unqualified persons attempt to

repair thi s laser p rodu ct, seri ous i nju ry may

result. Any repair required on this laser

product should be performed by authorized

service center personnel.

Figure 14

17

Operation

Before attempt in g an y op erat ion

with your miter saw, make sure that you have

read and thoroughly understand the warnings

contained on pages 4-5 and the Compound

Miter Saw Safety section on page 6. Failure to

comply may result in serious injury!

Starting a cut

1. Place hands at least 6-3/4 in. away from the

path of the blade.

2. Hold workpiece firmly against the fence to

prevent movement toward the blade.

3. Bri ng the saw blade down to the workpiece to

see the cutti ng path of the blade.

4. Squeeze the trigger sw itch (A, Fig. 15) to start

saw.

5. Lower blade into workpiece with a firm

downward motion.

Finishing a cut

C

1. Hold the cutting arm in the down position.

2. Release tri gger switch (A, Fig. 15) and wait for

all moving parts to stop before moving your

hands and raising t he c utti ng arm.

3. If the blade does not stop within 10 seconds,

unplug the saw and follow the instructions in

the Troubleshooting section.

Jammed Material

If material becomes jammed:

1. Release trigger switc h.

2. Wait for all moving parts to stop.

3. Unplug the mit er saw.

To Turn the Saw On

Depress the tri gger switc h ( A, Fig. 15).

Note: Make the On/Off switch child-proof by

inserting a padl ock through the hol e (B, Fig. 15) in

the trigger switch.

The miter saw is equipped with an autom atic blade

brake. When the trigger switch is released, the

electric blade brake will stop the blade within

approxim ately 10 seconds.

Figure 15

18

Sliding Fence

The sliding fence must be

extended to the left or right when making bevel

cuts. Failure to comply may cause serious injury!

Failure to extend the sliding fence will not allow

enough space for the blade to pass through. This

could result in serious injury. At extreme miter or

bevel angles the saw blade may also contact the

fence resul ting in damage t o equipment as well as

personal injury.

To adjust the sliding fence (refer to Figure 16):

1. Unlock the fence cam locking lever (A) (shown

locked in Figure 16) by pushing it toward the

rear of the machi ne.

2. Extend the fence (B) by sliding it out (C) to

ensure that the blade will clear the fence for

degree of the bevel cut selected. Lock the

fence cam locking lev er (A) as shown.

Note: Secure t he sliding f enc e in posi tion closest to

the saw blade when transporting the saw.

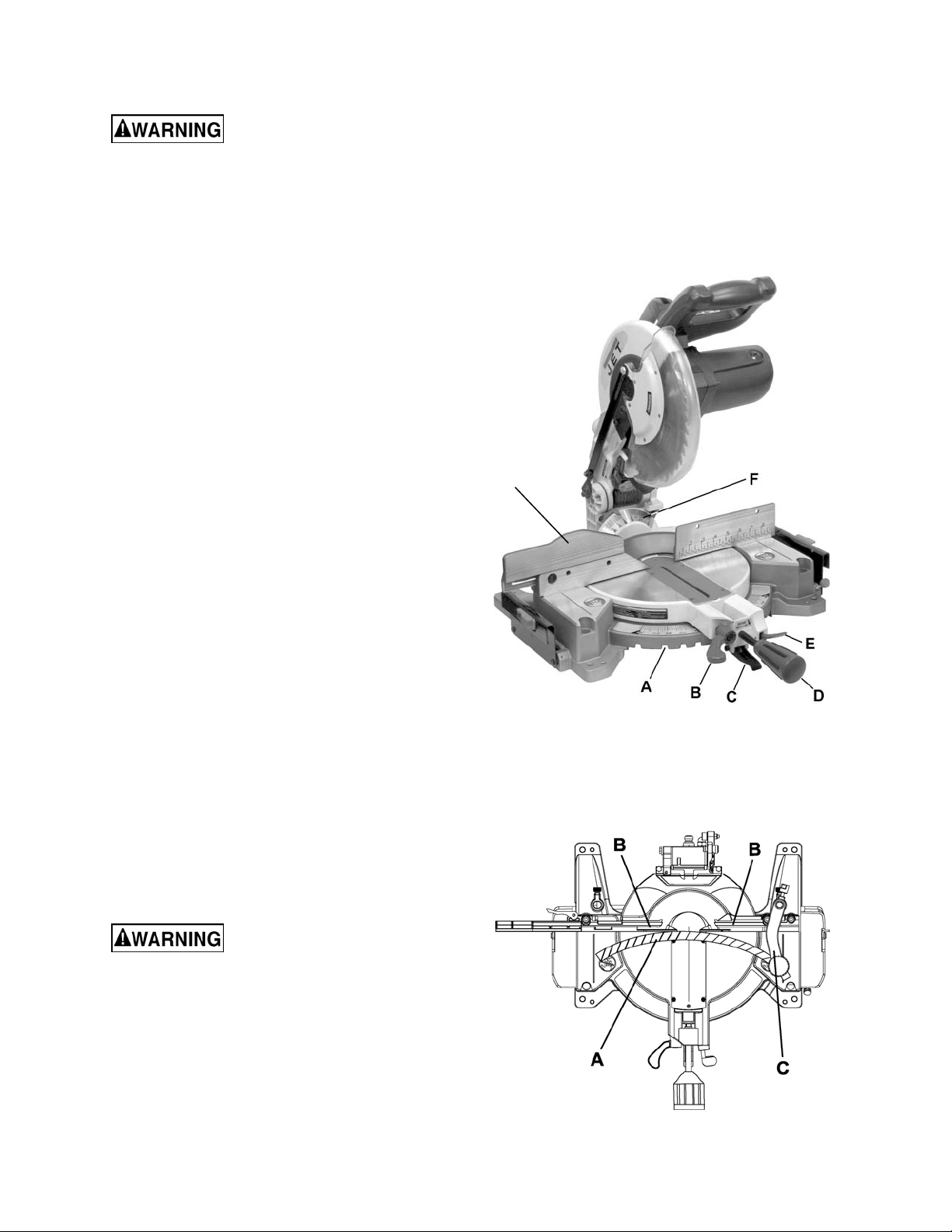

Miter Cut

Referring to Fi gur e 17:

The sliding com pound miter saw has nine positiv e

miter stop detents (A) located on the saw base.

The stops represent the f ollowing mit er cut angles:

0, 15, 22.5, 31. 6 and 45 de grees lef t and right. To

make a miter cut:

1. Unlock the mi ter table by lifti ng up on the quick-

cam miter table lock (E).

2. Raise the positive stop locking lever ( C) up, at

the same time grasp the mit er handle (D) and

rotate the m iter tabl e left or r ight t o the desired

angle.

3. Release the positive stop locking lever (C),

making sure the lev er snaps into plac e at one

of the miter stop detents (A).

Figure 16

Note: The mi ter can be set f or any angle bet ween

0° and 45° left and right. However, the lever will

only lock into place at one of the nine positive st ops

indicated above.

Once the desired miter angle is achieved:

4. Press down on the quick cam miter table

lock (E) to secure the table into position.

If the miter angle desired is not one of the nine

positive stops noted above:

5. Simply lock the table at the desired angle by

pressing down on the quick-cam miter table

lock (E).

Figure 17

19

Bevel Cut

The sliding fence must be

extended to the left when making bevel cuts.

Failure to comply may cause serious injury!

Failure to extend the sliding fence will not allow

enough space for the blade to pass through. This

could result in serious injury. At extreme miter or

bevel angles the saw blade may also contact the

fence resul ting in damage t o equipment as well as

personal injury.

Referring to Fi gur e 18:

1. Loosen the bevel loc k handle (B).

2. Tilt the cutting head to the desir ed level ranging

from 0° for a straight cut to a 45° left bevel as

displayed on the bev el s c ale (F).

3. Tighten the bevel lock handle (B) by pushing

down to lock the cutti ng head in posi tion.

Compound Cuts

Referring to Fi gur e 18:

G

Setting the bevel angle

1. Extend the fence (G) by sliding it out to the

required location (see Sliding Fence on page 19).

2. Loosen the bevel loc k handle (B).

3. Set the desired bevel angle; then lock the bevel

lock handle (B).

Setting the miter angle

4. Unlock the mi ter table by lifti ng up on the quick-

cam miter table lock (E).

5. Raise the positive stop locking lever (C) up, at the

same tim e grasp the miter handle (D) and rotate

the miter table left or right to the desired angle.

6. Release the positive stop locking lever (C).

7. Lock the mi ter table by pressing down on the

quick-cam miter table lock (E).

Cutting Bowed Material

Always unplug the saw when

removing small pieces of debris. Failure to

comply may cause seriou s injury!

Figure 18

Referring to Fi gur e 19:

1. Position a curved workpiece (A) again st th e fe nc e (B).

2. Secure the curved workpiece with a clamping

device (C).

Cutting a curv ed workpiece without t he support of

the fence and clamping device could result in

personal injury.

Figure 19

20

Repetitive Cutting

Note: Long workpieces need extension table

support.

Referring to Fi gur e 20:

Loosen the knob (E) then sli de the extension wing

(D) to desired position and tighten the knob.

The stop plate (C) is designed for use during

repetitiv e cutting. Sim ply r otate the stop plate (C) to

vertic al posi tion.

Auxiliary Wood Fence

Referring to Fi gur e 21:

When making repetitive cuts that produce cut-off

pieces of one i nch or less, i t i s possi ble f or t he saw

blade to catc h the cut-off piece and throw it out of

the saw or into the blade guard and housing,

possibly causing damage or injury. To minimize

this, construct an auxiliary wood fence (A) to be

mounted to y our saw which will provide additional

depth of cut. Mounting holes are provided on the

saw fence (B) for this purpose.

1. Construct the auxiliary wood fence (A) of a

single, straight piece of wood approximately 3/4

in. thick by 1-1/2 in. high by 22 in. long.

2. Attach the wood fenc e (A) securely to the saw

fence (B)

3. Make a full depth cut t o creat e a blade slot (C).

Check for interf erence between the wood f ence

and the lower blade guard.

E

Figure 20

Figure 21

D

4. Make adjustment if necessary.

Note: Adding a 3/ 4" thick auxiliary wood f ence will

also add cutti ng capacity (see Cutting Capacity on

page 7).

21

Cutting Base Molding

Crown Molding

Base moldings and many other moldings can be

cut on a compound miter saw. The setup of the

saw depends on molding characteristics and

application, as shown. Perform practice cuts on

scrap material to achieve best results:

1. Always make sure m oldings rest firmly against

fence and table. Use hold-down, crown mol ding

vise or C-clamps, whenever possible, and

place tape on the area bei ng clamped to avoid

marks.

2. Reduce spli ntering by taping the cut area prior

to making t he cut. Mark the cut line directly on

the tape.

3. Splintering typically happens due to an

incorrect blade applic ation and thinnes s of the

material.

Note: Always perform a dry run cut so you can

determine if the operation being attempted is

possible befor e power i s appl ied to the saw.

Your compound mi ter saw is suited for the dif ficult

task of cutting crown mol ding. To fit properly, crown

molding must be compound-mitered with extreme

accuracy. The two surfaces on a piece of crown

molding t hat fit flat against the cei ling and wall are

at angles that, when added together, equal exac tly

90°.

Most crown molding has a top rear angle (the

section that fit s flat against t he ceili ng) of 52°and a

bottom rear angl e (the section that fits flat against

the wall) of 38°.

In order to acc urately cut crown moldi ng for a 90°

inside or outside corner, lay the molding with its

broad back surfac e flat on t he saw table.

When setting the bevel and miter angles for

compound miters, remember that the settings are

interdependent; changing one changes the other,

as well.

Bevel/Miter Settings

Settings for standard crown molding lying flat on

compound mit er saw table.

Note: The chart bel ow references a com pound cut

for crown molding only when the angle between the

walls equals 90°.

Type of Cut Key

Inside corner – Left

Side

Inside corner – Right

Side

Outside corner – Left

Side

Outside corner –

Right Side

IL 33.9° 31.6° Right 1. Position top of molding against fence.

IR 33.9° 31.6° Left 1. Position bottom of molding against fence.

OL 33.9° 31.6° Left 1. Position bottom of molding against fence.

OR 33.9° 31.6° Right 1. Position top of molding against fence.

Bevel

Setting

Miter

Setting Procedure

2. Miter table set at RIGHT 31.6°.

3. LEFT side is finished piece.

2. Miter table set at LEFT 31.6°.

3. LEFT side is finished piece.

2. Miter table set at LEFT 31.6°.

3. RIGHT side is finished piece.

2. Miter table set at RIGHT 31.6°.

3. RIGHT side is finished piece

22

Crown Molding Chart

Compound miter saw miter and bev el angle settings, wall to crown molding angles

52/38º Crown Moldin g 45/45º Cr own Moldin g 52/38º Crown Moldi ng 45/45 º Crown Moldi ng

Angle

Between

Walls

100 27.32 30.43 30.68 27.03 157 7.14 9.04 8.19 8.10

101 26.91 30.08 30.24 26.73 158 6.82 8.65 7.83 7.75

102 26.50 29.73 29.80 26.42 159 6.51 8.26 7.47 7.40

103 26.09 29.38 29.36 26.12 160 6.20 7.86 7.11 7.05

104 25.69 29.02 28.92 25.81 161 5.88 7.47 6.75 6.70

105 25.29 28.67 28.48 25.50 162 5.57 7.08 6.39 6.35

106 24.89 28.31 28.05 25.19 163 5.26 6.69 6.03 6.00

107 24.49 27.96 27.62 24.87 164 4.95 6.30 5.68 5.65

108 24.10 27.59 27.19 24.56 165 4.63 5.90 5.32 5.30

109 23.71 27.23 26.77 24.24 166 4.32 5.51 4.96 4.94

110 23.32 26.87 26.34 23.93 167 4.01 5.12 4.61 4.59

111 22.93 26.51 25.92 23.61 168 3.70 4.72 4.25 4.24

112 22.55 26.15 25.50 23.29 169 3.39 4.33 3.90 3.89

113 22.17 25.78 25.08 22.97 170 3.08 3.94 3.54 3.53

114 21.79 25.42 24.66 22.66 171 2.77 3.54 3.19 3.10

115 21.42 25.05 24.25 22.33 172 2.47 3.15 2.83 2.83

116 21.04 24.68 23.84 22.01 173 2.15 2.75 2.48 2.47

117 20.67 24.31 23.43 21.68 174 1.85 2.36 2.12 2.12

118 20.30 23.94 23.02 21.36 175 1.54 1.97 1.77 1.77

119 19.93 23.57 22.61 21.03 176 1.23 1.58 1.41 1.41

120 19.57 23.20 22.21 20.70 177 0.92 1.18 1.06 1.06

121 19.20 22.83 21.80 20.38 178 0.62 0.79 0.71 0.71

122 18.84 22.46 21.40 20.05 179 0.31 0.39 0.35 0.35

123 18.48 22.09 21.00 19.72

0Miter

0Setting

67 42.93 41.08 46.89 36.13 124 18.13 21.71 20.61 19.39

68 42.39 40.79 46.35 35.89 125 17.77 21.34 20.21 19.06

69 41.85 40.50 45.81 35.64 126 17.42 20.96 19.81 18.72

70 41.32 40.20 45.28 35.40 127 17.06 20.59 19.42 18.39

71 40.79 39.90 44.75 35.15 128 16.71 20.21 19.03 18.06

72 40.28 39.61 44.22 34.89 129 16.37 19.83 18.64 17.72

73 39.76 39.30 43.70 34.64 130 16.02 19.45 18.25 17.39

74 39.25 39.00 43.18 35.38 131 15.67 19.07 17.86 17.05

75 38.74 38.69 42.66 34.12 132 15.33 18.69 17.48 16.71

76 38.24 38.39 42.15 33.86 133 14.99 18.31 17.09 16.38

77 37.74 38.08 41.64 33.60 134 14.66 17.93 16.71 16.04

78 37.24 37.76 41.13 33.33 135 14.30 17.55 16.32 15.70

79 36.75 37.45 40.62 33.07 136 13.97 17.17 15.94 15.36

80 36.27 37.13 40.12 32.80 137 13.63 16.79 15.56 15.02

81 35.79 36.81 39.62 32.53 138 13.30 16.40 15.19 14.62

82 35.31 36.49 39.13 32.25 139 12.96 16.02 14.81 14.34

83 34.83 36.17 38.63 31.98 140 12.63 15.64 14.43 14.00

84 34.36 35.85 38.14 31.70 141 12.30 15.25 14.06 13.65

85 33.90 35.52 37.66 31.42 142 11.97 14.87 13.68 13.31

86 33.43 35.19 37.17 31.34 143 11.64 14.48 13.31 12.97

87 32.97 34.86 36.69 30.86 144 11.31 14.09 12.94 12.62

88 32.52 34.53 36.21 30.57 145 10.99 13.71 12.57 12.29

89 32.07 34.20 35.74 30.29 146 10.66 13.32 12.20 11.93

90 31.62 33.86 35.26 30.00 147 10.34 12.93 11.83 11.59

91 31.17 33.53 34.79 29.71 148 10.01 12.54 11.46 11.24

92 30.73 33.19 34.33 29.42 149 9.69 12.16 11.09 10.89

93 30.30 32.86 33.86 29.13 150 9.37 11.77 10.73 10.55

94 29.86 32.51 33.40 28.83 151 9.05 11.38 10.36 10.20

95 29.43 32.17 32.94 28.54 152 8.73 10.99 10.00 9.85

96 29.00 31.82 32.48 28.24 153 8.41 10.60 9.63 9.50

97 28.58 31.48 32.02 27.94 154 8.09 10.21 9.27 9.15

98 28.16 31.13 31.58 27.64 155 7.77 9.82 8.91 8.80

99 27.74 30.78 31.13 27.34 156 7.46 9.43 8.55 8.45

0Bevel

0Setting

0Miter

0Setting

0Bevel

0Setting

Angle

Between

Walls

0Miter

0Setting

0Bevel

0Setting

0Miter

0Setting

0Bevel

0Setting

23

Maintenance

Lower Blade Guard

To avoid injury while

performing maintenance, always unplug the

power cord before working on the saw.

Failure to compl y may cause seri ou s injury!

Never use gasoline or any

highly volatile solvents to clean the miter

saw. Failure to comply may cause serious

injury!

Use only replacement parts

that are id entical to the parts list at the end

of thi s manu al and reassembl e exact ly as the

original assembly to avoid electrical shock.

Failure to compl y may cause seri ou s injury!

Replacing Carbon Brushes

Replace both carbon brushes when either has

less than 1/4 in. length of carbon rem aining, or if

the spring or wire is dam aged or bur ned.

To inspect or repl ac e br ushes:

1. Unplug the saw.

2. Rem ove the bl ack plastic cap on the side of

the motor

Remove the cap cauti ousl y , because i t is springloaded.

3. Pull out the brush and repl ac e.

4. Reverse above steps to reassemble.

Tighten the cap snugly, but do not overtighten.

Replace the brush f or the ot her side in t he same

manner descri bed above.

Note: To rei nstall the same brushes, f irst make

sure the brushes go back i n the way they came

out. This will avoid a break-in period that

reduces motor performance and increases wear.

Do not use the saw without the lower blade

guard. The l ower blade guard is attached t o the

saw for your prot ection. S hould the lower g uard

become damaged, do not use the saw until the

damaged guard has been replaced. Develop a

regular check to make sure the lower guard is

working properly . Clean the lower guard of any

dust or buildup with a damp cloth.

When cleaning the lower

guard, unplug the saw from the power

source receptacle to avoid unexpected

startup.

Do not use solvents on the

guard. They coul d m ake t he pl astic “cl oudy” and

brittle.

Saw Dust

Periodic ally, saw dust will accumulate under t he

work table and base. Thi s could cause difficult y

in the m ovement of the worktable when setti ng

up a miter cut. Frequently blow out or v acuum

up the saw dust.

If blowing saw dust, wear

proper eye protection to keep debris from

entering eyes.

Lubrication

All the motor beari ngs in this tool are lubricated

with a suffi cient amount of hi gh grade lubricant

for the life of the unit under normal operating

conditions; therefore, no further lubrication is

required.

Lubricate the following as necessary:

Chop pivot: Apply light machine oil to points

indicated i n illust r ation.

Central pivot of plastic guard: Use light

household oil (sewing machine oil ) on metal-t ometal or m etal-to-plastic guard cont act areas as

required for smooth, quiet operation. Avoid

excessiv e oil, t o whic h saw dust wil l cli ng.

24

Troubleshooting – Motor

Trouble Probable Cause Remedy

1. Motor brushes not sealed or lightly

sticking.

2. Motor brake overheated from use of

defectiv e or wrong size blade or rapid

Brake does not stop

blade within 10

seconds.

Motor does not start

Bru sh sp ark when

switch released.

ON/OFF c y cling.

3. Arbor bolt loose.

4. Brus hes cr acked , damaged, etc.

5. Other.

1. Limit switch failure

2. Brush worn.

3. Fuse blown or circuit breaker tripped

on home panel.

1. Worn brush.

2. Other.

Troubleshooting – Operation

1. Inspect/clean/replace brushe s.

2. See MAINTENANCE section.

3. Use a recommended blade. Let cool

down. See REMOVING OR INSTALLING

THE BLADE section.

4. Retighten. See REMOVING OR

INSTALLING THE BLADE section.

5. Replace brushes.

Contact yo ur Service Center.

1. Replace limit swit c h.

2. Replace brushes. See Maintenance

section.

3. Verify th ere is electrical power at the

outlet.

1. Replace brushes. See Maintenance

section.

2. Cont act your Servi ce Center.

Trouble Probable Cause Remedy

Blade hits table.

Angle of cut not

accurate. Cannot

adjust miter.

Cutting arm wobbles. 1. Loose pivot points. 1. Contact Service Center.

Cutting arm will not

fully rise, or blade

guard won’t fully

close.

Blade binds, jams,

burns wood.

Saw vibrates or

shakes.

1. Misalignment. 1. See the Setting Cutting Depth section in

Adjustments

1. Miter table unlocked.

2. Saw dust under table.

1. Pivot spring not replaced properly after

service.

2. Saw dust build-up.

1. Improper operation.

2. Dull or warped blade.

3. Improper blade size.

4. Wood is moving during cut.

1. Saw blade not round / damaged /

loose.

2. Arbor bolt loose.

1. See th e M iter Angle Adjust ment section

in Operations

2. Vacuum or blow out dust.

Important: Wear eye p rot ection.

1. Contact Service Center.

2. Clean and lubricate moving parts.

1. See Op erations section .

2. Replace or sharpen blade.

3. Repl ace with 10 in. diam eter blade.

4. U se hold dow n clam p to sec ure

workpiece to table.

1. Replace blade.

2. Tighten arbor bolt.

Laser not aligned -- 1. Contact Service Center.

Las er turns off

1. Laser turns off after 20 minutes to

prevent hea t bui ldup.

1. Reset laser switch on trigger handle (turn

off for two seconds, then on again).

25

Parts

Ordering Replacement Parts

To order parts or reac h our serv i ce depar tment, call 1-800-274-6848 M onday t hrough Fr iday (see our websi te f or

business hours, www.jettools.com). Having the Model Number and Serial Number of your machine available

when you call will allow us to serve you quickly and accuratel y .

Parts List

Note: Parts without par t numbers are for reference only and cannot be pur c hased i ndividually.

Index No. Part No . Description Size Qty

1 ............... JMS10CMS-1 ..........Lower Handle ........................................................................................ 1

2 ............... JMS10SCMS-10 ......Cord Clamp ........................................................................................... 1

3 ............... JMS10CMS-3 ..........Compres sion Spring .............................................................................. 1

4 ............... JMS1 0C MS-4 ..........Sprin g Wire .............................................................................. ............. 1

5 ............... JMS10CMS-5 ..........Handle Segment .................................................................................... 1

6 ............... JMS10SCMS-19 ......Blade Wrench ........................................................................................ 1

7 ............... JMS10CMS-7 ..........Pan Head Tappi ng S crew ...................................M4-18x16 ................... 2

8 ............... JMS10SCMS-88 ......Termina l ................................................................................................ 2

9 ............... JMS10CMS-9 ..........Pan Head Tappi ng S crew ...................................M6-1x25 ..................... 2

10 ............. JMS10SCMS-69 ......Pan Head Tapping Screw ...................................M4-18x25 ................... 4

12 ............. JMS10CM S-12.........Limit Switch ........................................................................................... 1

13 ............. JMS10CMS-13.........Cord Guard ........................................................................................... 1

14 ............. JMS10SCMS-170 ....Rocker Switch ....................................................................................... 1

15 ............. JMS10CMS-15.........Lead Wire .............................................................................................. 1

16 ............. TS-1533062 .............Pan Head Screw ................................................M5x20 ........................ 1

17 ............. JMS10CMS-17.........Upper Handle ........................................................................................ 1

18 ............. JMS10CMS-18.........Trigger................................................................................................... 1

19 ............. JMS10CMS-19.........Green Laser Controller Assembl y .......................................................... 1

20 ............. JMS10CMS-20.........Pan Head Screw with Washer ............................M6x45 ........................ 2

21 ............. JMS10CMS-21.........Motor ..................................................................................................... 1

22 ............. JMS10CMS-22.........Motor Brush Cover ................................................................................ 2

23 ............. JMS10CMS-23.........Motor Brush ........................................................................................... 2

24 ............. TS-2342161 .............Nylon Insert Lock Nut .........................................M16 ............................ 1

25 ............. TS-1541041 .............Nylon Insert Lock Nut .........................................M10 ............................ 1

26 ............. TS-155010 ...............Flat Washer ........................................................M16 ............................ 2

27 ............. TS-0680041 .............Flat Wash er ........................................................3/8 .............................. 1

28 ............. JMS10CMS-28.........Special Bolt ........................................................................................... 1

29 ............. JMS10CMS-29.........Pivot Shaft ............................................................................................. 1

30 ............. TS-2171012 .............Pan Head Screw ................................................M4x6 .......................... 2

31 ............. JMS10CMS-31.........Pin......................................................................................................... 1

32 ............. JMS10CMS-32.........Table ..................................................................................................... 1

33 ............. JMS10CMS-33.........Shaft ..................................................................................................... 1

34 ............. JMS10CMS-34.........O-Ring................................................................................................... 1

35 ............. JMS10CMS-35.........Pointer................................................................................................... 1

36 ............. JMS10SCMS-14 ......Knob ..................................................................................................... 1

37 ............. TS-2342121 .............Nylon Insert Lock Nut .........................................M12 ............................ 1

38 ............. TS-0680061 .............Flat Wash er ........................................................1/2 .............................. 1

39 ............. JMS10CMS-39.........Pointer, Right......................................................................................... 1

40 ............. JMS10CMS-40.........Disc ....................................................................................................... 1

41 ............. JMS10CMS-41.........Pan Head Tapping Screw ...................................M5-16x10 ................... 1

42 ............. TS-2360121 .............Flat Washer ........................................................M12 ............................ 1

43 ............. JMS10SCMS-104 ....Bushing ................................................................................................. 1

44 ............. TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ........................ 1

45 ............. JMS10CMS-45.........Locking Rod .......................................................................................... 1

46 ............. TS-1540041 .............Hex Nut ..............................................................M6 .............................. 2

47 ............. TS-1541031 .............Nylon Insert Lock Nut .........................................M8 .............................. 1

26

Parts List

Index No. Part No . Description Size Qty

48 ............. TS-1550061 .............Flat Wash er ........................................................M8 .............................. 1

49 ............. TS-1533032 .............Pan Head Screw ................................................M5x10 ........................ 1

50 ............. JMS10CMS-50.........Pointer................................................................................................... 1

51 ............. JMS12SCMS-188 ....Handle................................................................................................... 1

52 ............. TS-1482041 .............Hex Cap Screw ..................................................M6 x20 ........................ 2

53 ............. JMS10SCMS-33 ......Flat Washer ........................................................1/4x1/2x3/32 ............... 1

54 ............. TS-2361061 .............Lock Washer ......................................................M6 .............................. 1

55 ............. TS-1503041 .............Socket Head Cap Screw .....................................M6x16 ........................ 1

56 ............. JMS10CMS-56.........Pin......................................................................................................... 1

57 ............. JMS10CMS-57.........Screw Stop ............................................................................................ 1

58 ............. J MS10SCMS-8 ........Nut ........................................................................................................ 1

59 ............. J MS10SCMS-4 1 ......E-Clip .................................................................E -6 ............................. 1

60 ............. JMS10CMS-60.........Miter Lock Handle Assembl y.................................................................. 1

61 ............. ................................Miter Lock Handle.................................................................................. 1

62 ............. ................................Link ....................................................................................................... 1

63 ............. ................................Shaft ..................................................................................................... 1

64 ............. ................................Spring Pin...........................................................Ø2.5 x8 ....................... 2

65 ............. JMS10CMS-65.........Compression Spring .............................................................................. 1

66 ............. TS-1541011 .............Nylon Insert Lock Nut .........................................M5 .............................. 1

67 ............. JMS10CMS-67.........Follower Plate........................................................................................ 1

68 ............. JMS10CMS-68.........Hex Cap Screw with Flat & Lock Washers ..........M6x16 ........................ 1

69 ............. JMS10CMS-69.........Compression Spring .............................................................................. 1

70 ............. TS-1523061 .............Socket Set Screw ...............................................M6x20 ........................ 1

71 ............. TS-1502081 .............Socket Head Cap Screw .....................................M5x35 ........................ 1

73 ............. JMS10CMS-73.........Table Insert ........................................................................................... 1

74 ............. TS-2284082 .............Pan Head Screw ................................................M4x8 .......................... 4

75 ............. JMS10CMS-75.........Bevel Arm.............................................................................................. 1

76 ............. JMS10CMS-76.........Locking Handle Assembly ...................................................................... 1

77 ............. JMS10CM S-77.........Release/Stop Lever ............................................................................... 1

78 ............. JMS10SCMS-37 ......Wave Washer .....................................................WW-8 ......................... 2

79 ............. TS-1533042 .............Pan Head Screw ................................................M5x12 ........................ 2

80 ............. TS-1541011 .............Nylon Insert Lock Nut .........................................M5 .............................. 2

81 ............. JMS10CMS-81.........Extension Rod ....................................................................................... 2

82 ............. JMS10CMS-82.........Pan Head Screw ................................................M5x6 .......................... 2

83 ............. JMS10CMS-83.........Stop Pl ate, Left ...................................................................................... 1

84 ............. JMS10CMS-84.........Extension Wing, Left .............................................................................. 1

85 ............. JMS10CMS-85.........Extension Rod ....................................................................................... 2

87 ............. JMS10CMS-87.........Fence Extension .................................................................................... 1

88 ............. JMS10CMS-88.........Fence .................................................................................................... 1

89 ............. JMS10SCMS-56 ......Socket Head Cap Screw with Washer .................M8x25 ........................ 1

90 ............. JMS10CMS-90.........Socket Head Cap Screw with Washer .................M8x30 ........................ 2

91 ............. JMS10SC MS-17 ......Center Bolt ............................................................................................ 1

92 ............. JMS10SCMS-95 ......Knob ..................................................................................................... 2

93 ............. JMS10CMS-93.........Slide Plate ............................................................................................. 3

94 ............. JMS12SCMS-118 ....Knob ..................................................................................................... 2

95 ............. JMS10CMS-95.........Locking Handle Assembly ...................................................................... 1

96 ............. ................................Cush ion ................................................................................................. 1

97 ............. ................................Lock Handle .......................................................................................... 1

98 ............. ................................Pin......................................................................Ø5 x16 ........................ 1

99 ............. ................................Lock Screw ............................................................................................ 1

100 ........... ................................Plate ...................................................................................................... 1

101 ........... ................................Flat Washer ........................................................M6 .............................. 1

102 ........... ................................Nylon Insert Lock Nut .........................................M6 .............................. 1

103 ........... JMS10CMS-103.......E xte n sion Wing, R ight ........................................................................... 1

104 ........... JMS10CMS-104.......Stop Plate, Right ................................................................................... 1

105 ........... JMS10CMS-105.......Base ...................................................................................................... 1

27

Parts List

Index No. Part No . Description Size Qty

106 ........... JMS10SCMS-54 ......Arbor Bolt .............................................................................................. 1

107 ........... JMS10CMS-107.......Torsion Spring ....................................................................................... 1

108 ........... JMS10SCMS-64 ......Truss Head Round Neck Screw ..........................M6x14 ........................ 1

109 ........... JMS10SCMS-16 ......Guard Spring ......................................................................................... 1

110 ........... TS-1541021 .............Nylon Insert Lock Nut .........................................M6 .............................. 1

111 ........... JMS10SCMS-64 ......Truss Head Round Neck Screw ..........................M6x14 ........................ 1

112 ........... JMS10CMS-112.......Guard Plate ........................................................................................... 1

114 ........... JMS10CMS-114.......Blade Guard .......................................................................................... 1

115 ........... TS-1541021 .............Nylon Insert Lock Nut .........................................M6 .............................. 1

116 ........... JMS10CMS-116.......Saw Arm ............................................................................................... 1

118 ........... JMS10SCMS-1 ........Shaft Sleeve .......................................................................................... 1

119 ........... JMS10CMS-119.......Lever ..................................................................................................... 1

120 ........... TS-1503041 .............Socket Head Cap Screw .....................................M6x16 ........................ 2

121 ........... JMS10CMS-121.......Shim ...................................................................................................... 1

122 ........... TS-1503041 .............Socket Head Cap Screw .....................................M6x16 ........................ 1

123 ........... JMS10CMS-123.......A nchor Block ......................................................................................... 1

124 ........... JMS10CMS-124.......Truss Head Screw ..............................................M6x8 .......................... 1

125 ........... JMS10SCMS-15 ......Collar .................................................................................................... 1

126 ........... TS-1534051 .............Flat Head Screw .................................................M6x16 ........................ 1

127 ........... TS-1541021 .............Nylon Insert Lock Nut .........................................M6 .............................. 1

128 ........... JMS10CMS-128.......Rubber Sleeve....................................................................................... 1