Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

7x12 Horizontal Band Saw

Models: J-3410, J-3410-2

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414454

Ph.: 800-274-6848 Revision B3 01/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET, Wilton and Powermatic warrants every product they sell against manufacturers’ defects. If one of our tools

needs service or repair, please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday

through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET, Wilton or Powermatic branded websites.

• JET, Wilton and Powermatic products carry a limited warranty which varies in duration based upon the

product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provi de proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET, Wilton and Powermatic have Authorized Service Centers

located throughout the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846

or use th e Serv i ce Center Locator o n the JE T, Wi l ton or Powermatic website.

More Information

JET, Wilton and Powermatic are consistently adding new products. For complete, up-to-date product information,

check with your local distributor or visit the JET, Wilton or Powermatic website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET, WILTON AND POWERMATIC LIMIT ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU.

JET, WILTON AND POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

JET, Wilton and Powermatic sell through distributors only. The specifications listed in JET, Wilton and Powermatic

printed materials and on official JET, Wilton and Powermatic-branded websites are given as general information and

are not binding. JET, Wilton and Powermatic reserve the right to effect at any time, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

®

branded products are not sold in Canada by JPW Industries, Inc.

JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories

5 Year – Woodworking Machinery

Limited Lifetime – Wilton branded products; JET Parallel clamps; VOLT Series Electric Hoists

Manual Hoists; Manual Hoist Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET, Wilton and Powermatic are divisions of JPW Industries, Inc.. References in this document to JET,

Wilton and/or Powermatic also apply to JP W Indus trie s, Inc., or any of its succe ssors in inte re st to the JET, Wilton

and/or Powermatic brands.

Page 3

Table of Contents

Cover Page .......................................................................................................................... 1

Warranty................................................................................................................................2

T able of Contents .................................................................................................................. 3

General Specifications..........................................................................................................4

Warnings............................................................................................................................ 5-6

Using the Vise.................................................................................................................... 7-9

Setting Blade Guides ............................................................................................................9

Hydraulic Feed Control........................................................................................................ 10

Using Stock Stop................................................................................................................. 10

Changing Blade Speeds ..................................................................................................... 11

Blade Selection................................................................................................................... 11

Evaluating Cutting Eficiency ................................................................................................ 11

Blade Break-in Procedures................................................................................................. 11

St arting a Cut ...................................................................................................................... 11

Angle Cuts ..................................................................................................................... 12-13

Replacing Blades................................................................................................................14

Adjusting Blade Tracking..................................................................................................... 14

Blade Alignment Adjustments .............................................................................................. 15

When to Adjust Blade Guides .............................................................................................. 15

Replacing Blade Guides and Support Components............................................................. 16

Adjust Blade for Parallelism ................................................................................................ 16

Adjusting Blade V ertical ...................................................................................................... 17

T est Cutting to V erify Adjustment Accuracy........................................................................... 17

Adjusting Guide Bearings.................................................................................................... 18

Replacing Guide Bearings .................................................................................................. 18

Adjusting Blade Back Up Bearing ....................................................................................... 18

Replacing the Drive Wheel .................................................................................................. 19

Installing the V ertical Sawing T able ...................................................................................... 19

Replacing Idler Wheel or Bearings ...................................................................................... 19

Servicing the Hydraulic Control Cylinder .............................................................................. 20

Machine Set-up................................................................................................................... 21

Uncrating and Spotting the Saw........................................................................................... 21

Electrical............................................................................................................................. 21

Changing Operating Volt age ............................................................................................... 21

Installing the Coolant Kit ...................................................................................................... 22

Chip Brush Replacement .................................................................................................... 22

Adjusting Horizontal Stop and Motor Switch......................................................................... 22

T o Replace or Adjust the Horizontal S top ............................................................................. 22

Adjusting the Motor Switch Actuator..................................................................................... 22

Troubleshooting.............................................................................................................. 23-24

Replacement Parts and Breakdowns ............................................................................. 25-30

3

Page 4

General Specifications

Model Stock Number

J-3410 414454

J-3410-2 414455

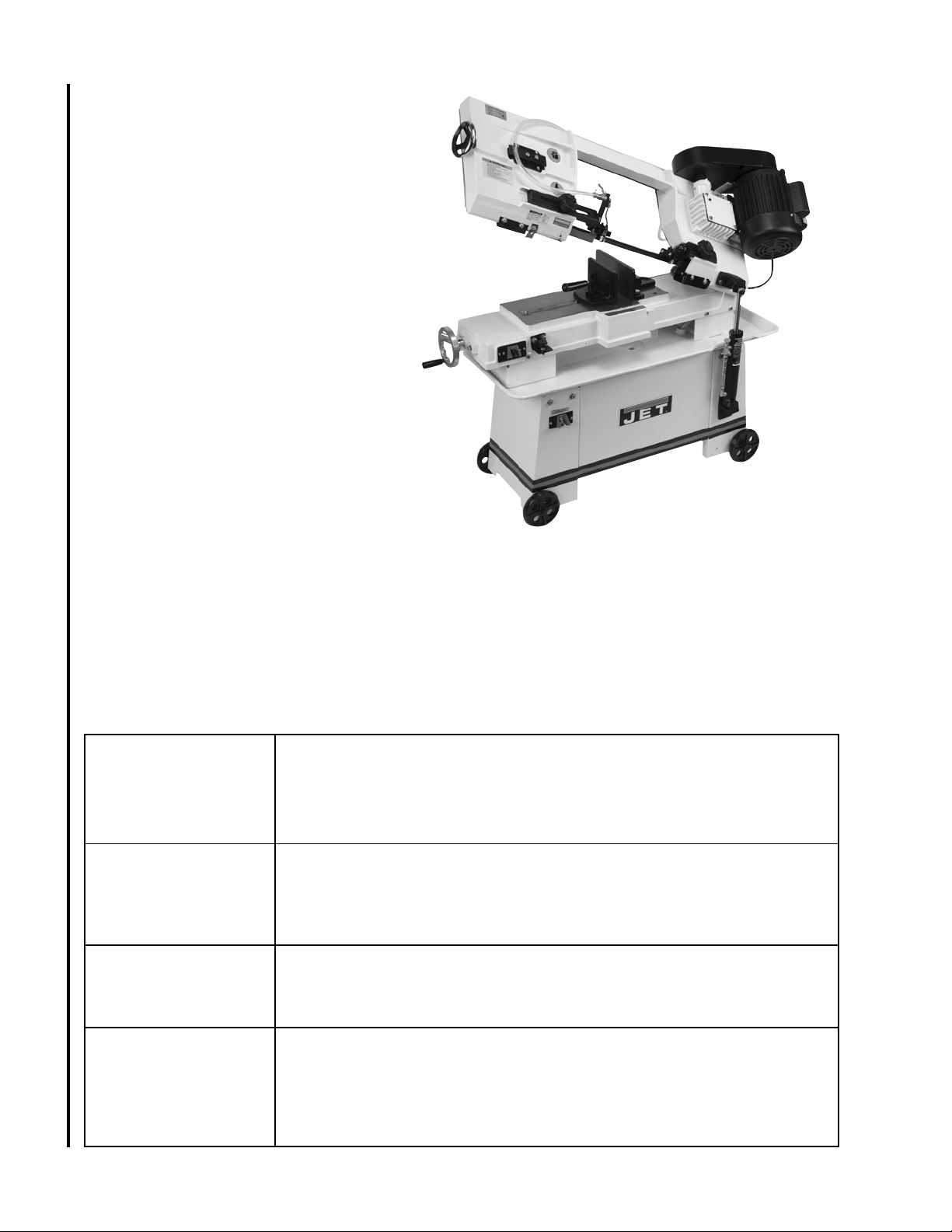

The JET Models J-3410 and J-3410-2 cut-off band

saws are designed for high production cut-off work. Four

cutting speeds and a hydraulic feed control allows the efficient cutting of virtually any material.

A removable table also allows the saw to function as

a vertical band saw.

The J-3410 and J-3410-2 come equipped with a coolant system which can greatly extend blade life and speed

the cutting of a variety of materials which are best cut with

cutting fluids and coolants.

Specifications:

Cutting capacity

4

Blade speeds

Blade drive

Motor

Blade guides

Blade size

Blade wheels

Dimensions (LWH)

Weight

Wet cutting package

Vertical saw operation

Table size (LW)

7 in. (178mm) round bar stock or tubing

9 1/2 in. wide x 7 in. high (240 x 178mm) rectangular stock

12 in. wide x 1 in. high (305 x 25.4mm) flat stock

3 3/4 in. wide x 6 in. high (95.3 x 150mm) at 45 degree angle

80, 130, 180 and 265 SFM -- belt selectable

Heat treated steel worm pinion driving a bronze

worm ring gear in an oil bath

3/4 HP, 1725 RPM, 115/230V, single phase, capacitor start

Side: Eccentric shaft with sealed ball bearings

Rear: Sealed ball bearing

3/4 x .033 x 93 in.

11 7/16 in. (280.56mm) diameter flanged cast iron

50 x 18 x 41 in. (1270 x 457 x 1041mm) in lowered position

275 lbs. (125kg)

1 gallon (4.4L) capacity tank with 3GPM (13L/M) pump -- Optional wet kit

Part No. 5635500 includes tank with baffle, pump 120V/240V, hoses,

flexible nozzle, shut-off valve and required electrics. This kit is delivered

installed on Model J-3410 saws.

9 1/2 x 10 in. (241 x 254mm)

Page 5

- Misuse of this machine can cause serious injury.

- For safety, machine must be set up, used and serviced

properly.

- Read, understand and follow instructions in the

operator’s and parts manual which was shipped with

your machine.

When setting up machine:

- Always avoid using machine in damp or poorly lighted

work areas.

- Always be sure machine is securely anchored to the

floor.

- Always keep machine guards in place.

- Always put start switch in OFF“ position before

plugging in machine.

When using machine:

- Never operate with machine guards missing.

- Always wear safety glasses with side shields (See

ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach — you may slip and fall into the

machine.

- Never leave machine running while away from it.

- Always shut off the machine when not in use.

When servicing machine:

- Always unplug machine from electrical power while

servicing.

- Always follow instructions in operators and parts

manual when changing accessory tools or parts.

- Never modify the machine without consulting Walter

Meier (Manufacturing), Inc.

You — the st ationary power tool user — hold the key

to safety.

Read and follow these simple rules for best

results and full benefits from your machine. Used

properly, JET machinery is among the best in design

and safety. However, any machine used improperly

can be rendered inefficient and unsafe. It is absolutely

mandatory that those who use our products be

properly trained in how to use them correctly. They

should read and understand the Operators and Parts

Manual as well as all labels affixed to the machine.

Failure in following all of these warnings can cause

serious injuries.

Machinery general safety warnings

1. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant, protective

safety glasses with side shields which comply with ANSI

Z87.1 specifications. Use of eye wear which does not

comply with ANSI Z87.1 specifications could result in

severe injury from breakage of eye protection.

2. Wear proper apparel. No loose clothing or

jewelry which can get caught in moving parts. Rubber

soled footwear is recommended for best footing.

3. Do not overreach. Failure to maintain proper

working position can cause you to fall into the machine or

cause your clothing to get caught — pulling you into the

machine.

4. Keep guards in place and in proper working

order. Do not operate the machine with guards removed.

5. Avoid dangerous working environments. Do not

use stationary machine tools in wet or damp locations.

Keep work areas clean and well lit. Special electrics

should be used when working on flammable materials.

6. Avoid accidental starts by being sure the start

switch is OFF” before plugging in the machine.

7. Never leave the machine running while unattended. Machine shall be shut off whenever it is not in

operation.

8. Disconnect electrical power before servicing.

Whenever changing accessories or general maintenance

is done on the machine, electrical power to the machine

must be disconnected before work is done.

9. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the changing

of accessories. No attempt shall be made to modify or

have makeshift repairs done to the machine. This not

only voids the warranty but also renders the machine

unsafe.

11. Secure work. Use clamps or a vise to hold

work, when practical. It is safer than using your hands

and it frees both hands to operate the machine.

12. Never brush away chips while the machine is in

operation.

13. Keep work area clean. Cluttered areas invite

accidents.

14. Remove adjusting keys and wrenches before

turning machine on.

15. Use the right tool. Don't force a tool or attachment to do a job it was not designed for.

16. Use only recommended accessories and follow

manufacturers instructions pertaining to them.

17. Keep hands in sight and clear of all moving

parts and cutting surfaces.

18. All visitors should be kept at a safe distance

from the work area. Make workshop completely safe by

using padlocks, master switches, or by removing starter

keys.

19. Know the tool you are using — its application,

limitations, and potential hazards.

5

Page 6

20.Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of

these chemicals are:

Lead from lead based paint

General Electrical Cautions

This saw should be grounded in accordance with

the National Electrical Code and local codes and

ordinances. This work should be done by a qualified

electrician. The saw should be grounded to protect the

user from electrical shock.

crystalline silica from bricks and cement and other

masonry products, and

arsenic and chromium from chemically-treated

lumber.

21.Your risk from those exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as

those dust masks that are specifically designed to filter

out microscopic particles.

Conductor length

AWG (American wire gauge) number

Wire sizes

Caution: for circuits which are far away from the

electrical service box, the wire size must be increased

in order to deliver ample voltage to the motor. To

minimize power losses and to prevent motor overheating and burnout, the use of wire sizes for branch

circuits or electrical extension cords according to the

following table is recommended:

240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

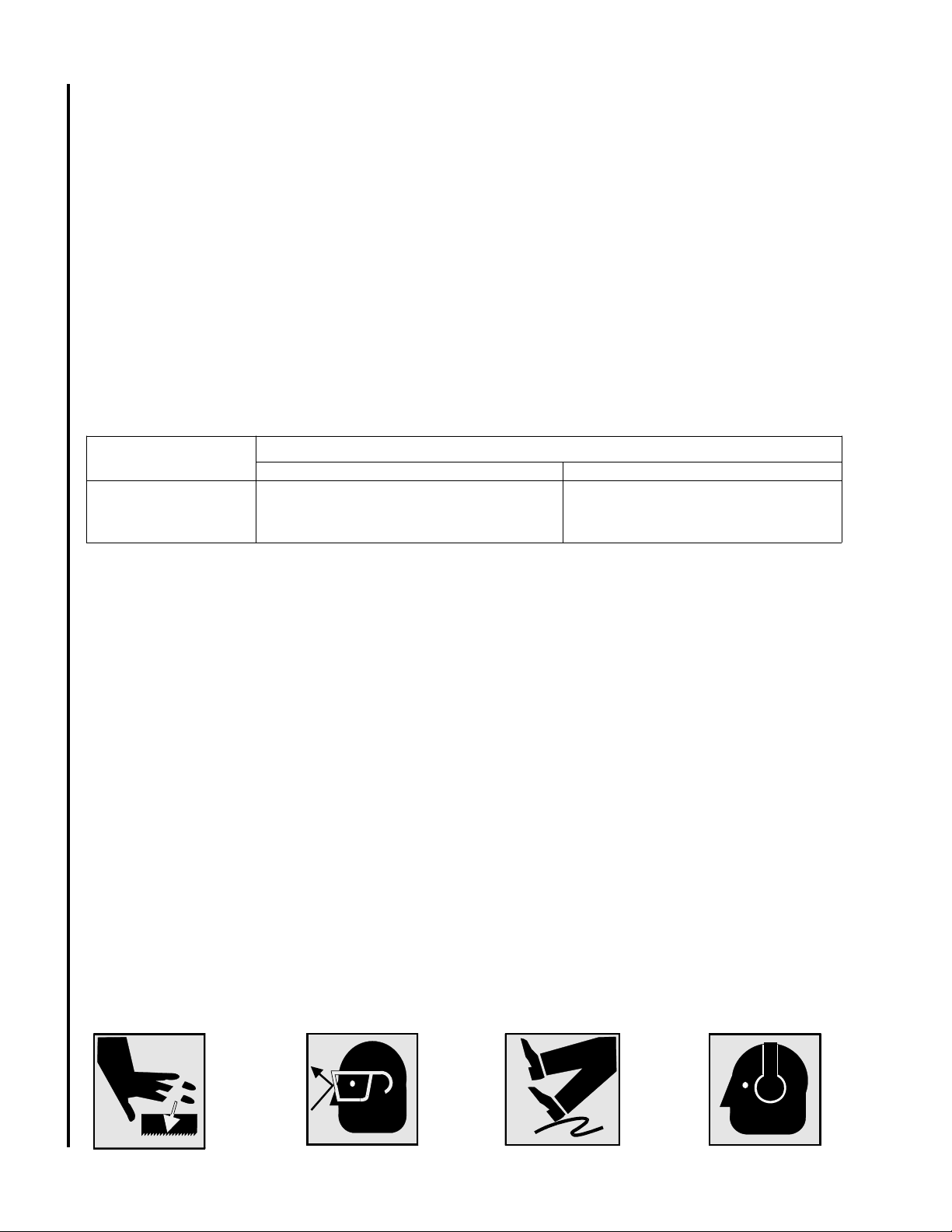

Safety instructions on sawing systems

1. Always wear leather gloves when handling

saw blade. The operator shall not wear gloves when

operating the machine.

2. All doors shall be closed, all panels replaced,

and all other safety guards in place prior to the machine

being started or operated.

3. Be sure that the blade is not in contact with the

workpiece when the motor is started. The motor shall

be started and you should allow the saw to come to full

speed before bringing the workpiece into the saw blade.

4. Keep hands away from the blade area. See

figure A.

6

5. Remove any cut off piece carefully while

keeping your hands free of the blade area.

6. Saw must be stopped and electrical supply

must be cut off before any blade replacement or

adjustment of blade support mechanism is done, or

before any attempt is made to change the drive belts or

before any periodic service or maintenance is performed on the saw.

7. Remove all loose items and any unnecessary

work pieces from the area before starting machine.

8. Bring adjustable saw guides and guards as

close as possible to the work piece.

9. Always wear protective eye wear when

operating, servicing or adjusting machinery. Eyewear

shall be impact resistant, protective safety glasses with

side shields complying with ANSI Z87.1 specifications.

Use of eye wear which does not comply with ANSI

Z87.1 specifications could result in severe injury from

breakage of eye protection. See figure B.

10. Non-slip footwear and safety shoes are

recommended. See figure C.

11. Wear ear protectors (plugs or muffs) during

extended periods of operation. See figure D.

12. The workpiece, or part being sawed, must be

securely clamped before the saw blade enters it.

13. Remove cut off pieces carefully, keeping

hands away from sawblade.

14. Saw must be stopped and electrical supply

cut off or machine unplugged before reaching into

cutting area.

15. Avoid contact with coolant, especially

guarding your eyes.

A

B

C

D

Page 7

Operating Instructions

Using the vise

The vise on the saw table has two jaws. The jaw

closest to the right hand side of the table is the stationary

jaw. This jaw is firmly secured to the table using its pivot

and lock bolts. When making a straight cut the stationary

jaw is at right angles to the saw blade. When making an

angle cut, the stationary jaw is first loosened, then

adjusted to the desired angle, then secured to the table,

again.

The jaw closest to the left hand side of the table is

the locking jaw. This jaw clamps the workpiece against the

stationary jaw to hold it securely for cutting. The locking

jaw can pivot to conform to the angle of the work piece

which is held in the stationary jaw.

Before cutting can begin, the vise must be properly

set and positioned. The procedures are different for right

angle cutting and for angle cutting. Setting procedures are

given in the following sections.

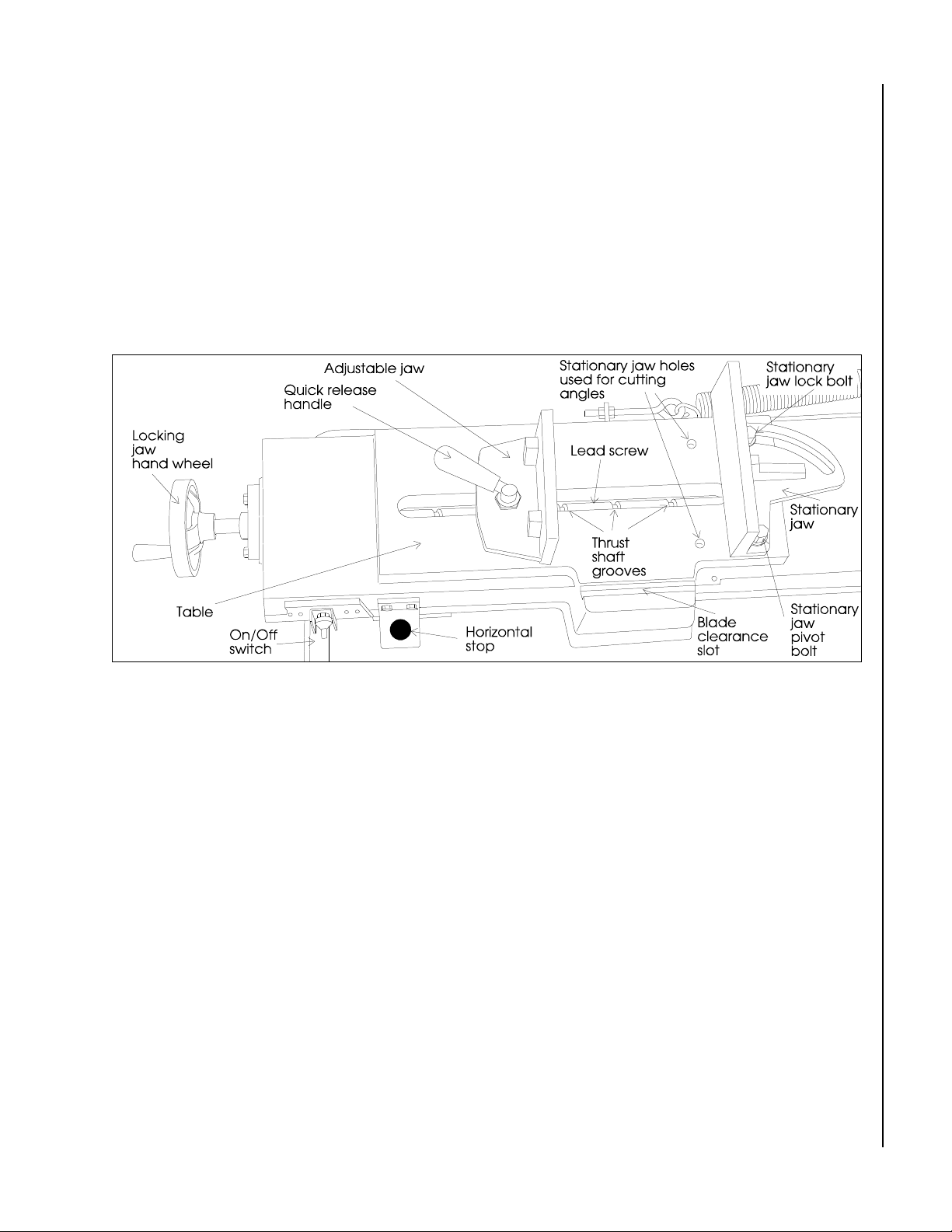

Figure 1: Vise jaw nomenclature

Locking vise jaw

The locking jaw is an assembly which includes the

lead screw nut which encases the lead screw, the lead

screw shaft (which screws into the lead screw nut,) the

thrust shaft, spring, and quick release handle.

The thrust shaft moves up or down when the quick

release handle moves up or down.

The thrust shaft has a nut under the quick release

handle which adjusts the clamping pressure between the

adjustable jaw and the table, itself. When this nut is too

tight, the adjustable jaw cannot pivot. When this nut is too

loose, the jaw can pivot, and also tilt upward. Therefore,

this nut should be slightly loose. This will allow the jaw to

pivot an conform to any angle at which the stationary jaw

is set.

However, you should guard against excessive

loosening of this nut. If too loose, the jaw can tilt when it

contacts the workpiece and full clamping pressure cannot

be effectively applied to the workpiece.

If the shaft is too tight to allow pivoting of the jaw,

loosen the shaft slightly by turning the nut under the quick

release handle counterclockwise. If the jaw tilts exces-

sively, use the nut under the quick release handle to

tighten the shaft slightly so the jaw slides easily, but flat

against the saw table.

The locking vise jaw is tightened or loosened against

the workpiece being cut by using the lead screw handle.

The handle is attached to a lead screw underneath the saw

table. The lead screw has a series of grooves on its

length. These grooves capture a thrust shaft on the lower

side of the locking jaw. As the lead screw handle is turned,

the grooves move to the left or right, and therefore the

locking jaw is moved to the left or right to open or close the

jaw against any workpiece on the table.

The thrust shaft on the locking vise jaw is a component part of the quick release handle on top of the locking

jaw. This quick release handle is spring loaded to force the

handle (and, therefore, the thrust shaft) downward.

When you pull up on the quick release handle, the

thrust shaft is removed from its groove. This allows you to

slide the jaw to a new position on the table. Releasing the

handle pushes the thrust shaft against the lead screw

shaft. When the lead screw handle is turned, a groove will

7

Page 8

eventually catch the thrust shaft and allow you to open or

close the locking jaw at its new lead screw position.

When you slide the jaw to a new position, you can

see where the nearest lead screw groove is by looking

through the slot above the lead screw. (See Figure 1.)

Changing the locking

jaw location:

1. Lift the quick release handle.

2. Slide the jaw until it contacts the workpiece.

3. Turn the lead screw handle until the thrust shaft drops

into a groove.

4. Further turning of the lead screw handle will either

clamp or release the workpiece in the vise. Turn

clockwise to increase clamping pressure. Turn

counterclockwise to release clamping pressure.

Stationary vise jaw

The stationary vise jaw pivots on the pivot bolt,

Figure 1, and is locked at any required angle by the lock

bolt.

There are two different table positions for the

stationary vise jaw. One position is used for right angle

cuts ("straight" cutting) and the other position is used for

cutting of all other angles. Moving the vise from one

position to the other requires unbolting and re-bolting the

jaw to the saw table.

Four tapped holes in the saw table allow a change

of pivot and lock bolt position. The holes in the right-most

position closest to the motor are used for right angle

cutting. The holes in the left-most position are used for all

angle cutting.

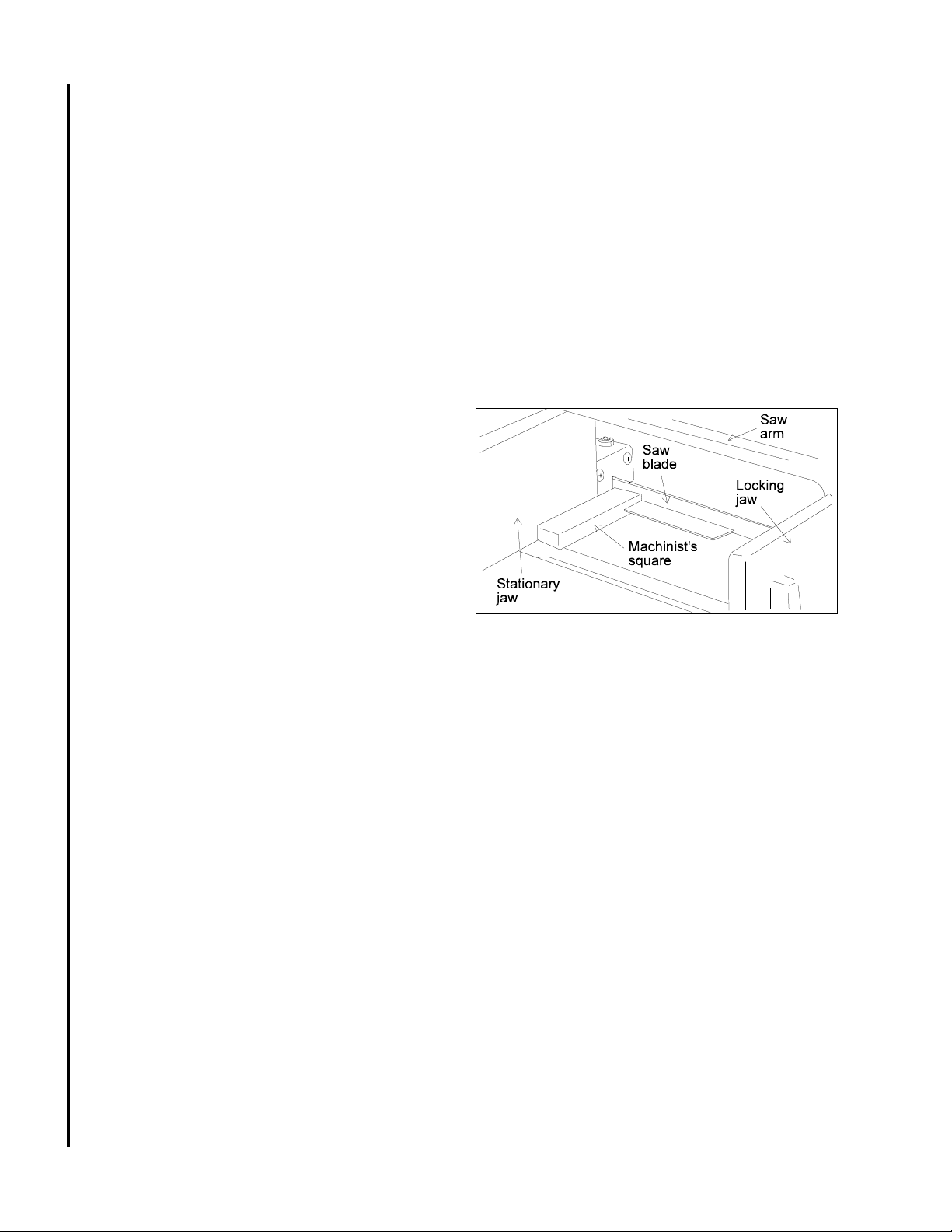

Adjusting stationary jaw: straight cuts

For accurate right angle or "straight" cutting, adjust

the vise as follows:

1. Disconnect the saw from its electrical power source to

prevent accidental start-ups.

2. With the saw arm and blade in horizontal position,

place a machinist's square against the blade and stationary vise jaw. (See Figure 2.)

3. If the vise jaw is not square to the blade, loosen both

the pivot and lock bolts shown in Figure 1, and adjust the

jaw until it is square.

4. Tighten the pivot and lock bolts.

5. Reconnect electrical power to the saw.

Figure 2: Setting the stationary jaw at right angles to the

saw blade.

Adjusting stationary jaw: angle cuts

The angle of the stationary vise jaw with respect to

8

Changing the stationary

vise jaw position:

1. Remove the pivot and lock bolts.

2. Slide the stationary jaw to the required position on the

table.

3. Re-insert the pivot and lock bolts.

4. Adjust stationary jaw angle according to requirements

for straight or angle cuts, then tighten both bolts securely.

the saw blade is what determines the cut angle on the

workpiece. The stationary jaw can be adjusted to any

angle between 0 degrees (right angle to the blade) and 45

degrees.

In order to cut angles, however, it will be necessary

for you to move the stationary vise jaw to its left-most set

of attachment holes as described in the following sections.

After placing the jaw in the angle cutting position,

you can adjust to the desired cutting angle using one of

the two following methods.

Page 9

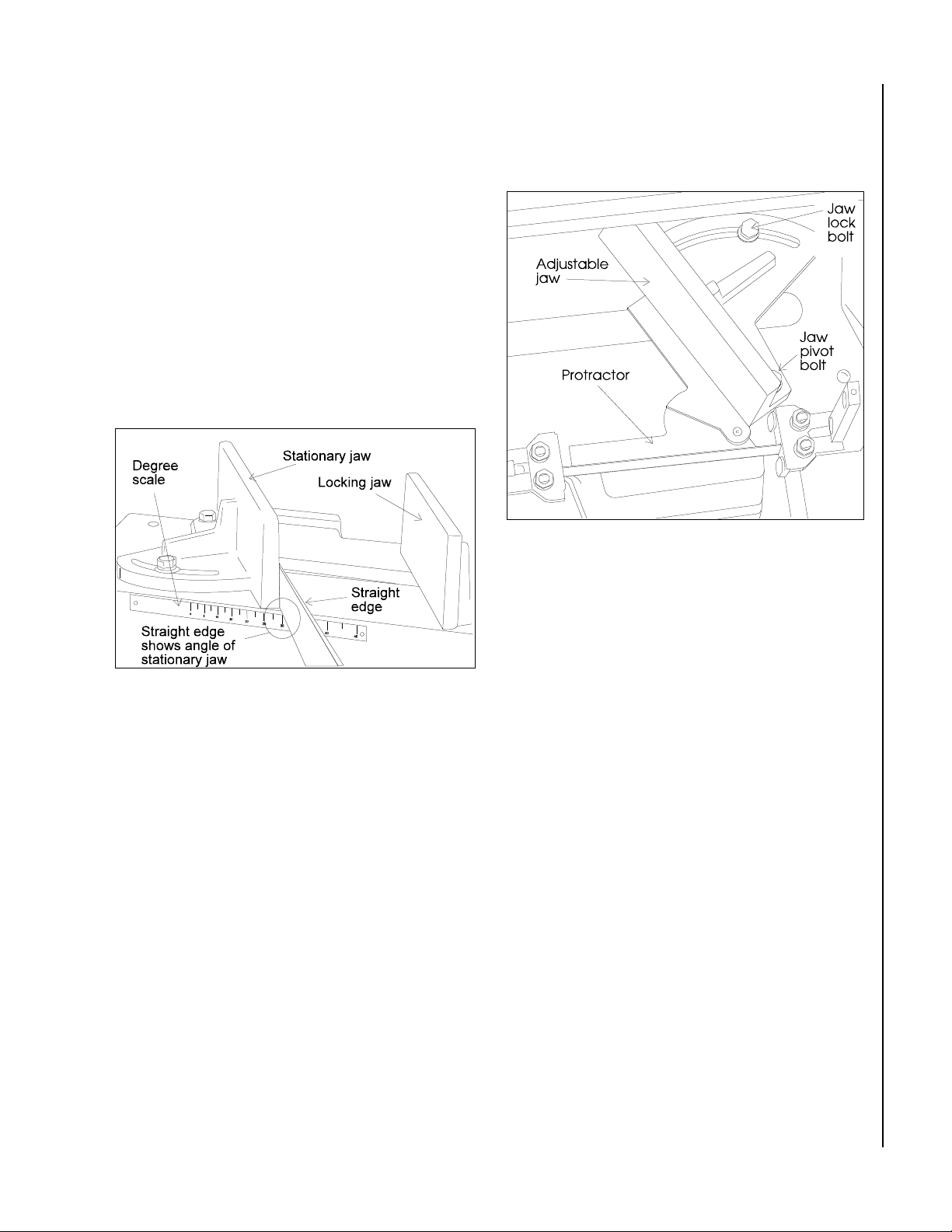

Adjusting angles with the scale on the saw table

There is a scale on the rear of the saw base which

can be used to establish the angle of cut.

1. Raise the saw arm to full height and lock it in position

with the quick shut-off valve.

2. Slide the locking jaw to full open position.

3. Loosen the pivot and lock bolts shown in Figure 1.

4. Lay a straight edge on the saw frame so it contacts the

stationary vise jaw. (See Figure 3.)

5. Turn the vise jaw until the straight edge is above the

angle of cut you require as shown on the angle gauge.

6. Tighten both the pivot and lock bolts.

7. Remove the straight edge and proceed to cut as

described in Angle sawing.

Figure 4: Using a protractor to set jaw angle

Figure 3: Using table scale to set jaw for angle cuts

Adjusting stationary jaw for

high accuracy angle cutting:

1. Raise the saw arm to full height and lock it in position

with the shut-off valve.

2. Open the vise to full width.

3. Loosen the pivot and lock bolts shown in Figure 1.

4. Open the shut-off valve and lower the saw arm until it

is at full horizontal position.

5. Take a machinist's protractor and set it to the angle you

need to cut.

6. Lay the protractor on the saw table and place one

edge of the protractor against the saw blade and the other

edge against the stationary vise jaw. (Figure 4.)

7. Adjust the stationary vise jaw until its angle is correct

with respect to the blade, then lock the stationary jaw

firmly using the pivot and lock bolts.

The saw is now accurately set to the exact angle

you have set on the machinist's protractor. You can now

saw the workpieces according to instructions on Angle

sawing.

Setting the blade guides

To produce accurate cuts the distance between the

blade guide/supports must be set correctly. Whenever

possible, set the blade guide assembly so it clears the

workpiece by approximately 1/8 inch on either side of the

workpiece.

The guides may be moved by loosening the lock

handles which secure the bracket bars to the saw arm.

There is, however, a limit to how close the guide can

be set with respect to the table. When set too close to the

blade clearance slot, the guide bearings can hit the table

casting and prevent the arm from moving to full horizontal.

When this happens, the saw cannot complete its cut.

This won't be a problem with the right-hand guide.

On the other hand, the left-hand guide typically cannot be

much closer to the right-hand guide than 6 inches or so.

Therefore, when cutting smaller section material, be sure

the blade is correctly adjusted, tensioned properly, sharp,

and appropriate to the type of material being cut.

9

Page 10

Controlling the cut:

Using the stock stop

10

Hydraulic feed control

The weight of the saw arm typically provides all of

the force needed to move the saw blade through the

workpiece. In fact, if the full weight of the arm is allowed

to make the cut, rapid blade wear and poor cutting

accuracy will result. Therefore, a hydraulic feed control is

provided which gives the operator control over the speed

and efficiency of cutting.

The hydraulic feed control is a single-acting

hydraulic cylinder attached between the saw base and

saw arm. The hydraulic control cylinder has two flow

controls. The control needle valve -- used by the operator

to control the rate of cutting -- is on top of the cylinder. A

quick shut-off valve is located in a hydraulic line on the

outside of the cylinder.

The control cylinder is single-acting because it can

be used to resist motion in the downward direction, only.

The control cylinder offers no resistance to upward

movement.

The amount of downward force can be controlled by

using the needle valve on top of the cylinder. When the

needle valve is closed the cylinder is "locked." With the

needle valve open slightly, the cylinder permits slow, or

light downward force. As the needle valve is opened

further, increasing weight of the saw arm presses on the

blade and workpiece.

The needle valve is opened, during any cut, until the

operator determines that the saw is operating efficiently.

This is usually evaluated by observing chip formation.

See the section on Blade Selection, for more information

on evaluating cutting efficiency.

The quarter-turn quick shut off valve in the external

line of the control cylinder can be turned to lock the

cylinder at any time. For instance, it can be used to lock

the blade above the work piece to allow you to measure

the length of cut on the workpiece. Or, it can be used for

making repeated cuts after the needle valve has been set

for best cutting efficiency. (This is described in the next

section.)

To close the hydraulic control circuit and lock the

cylinder, turn the quick shut off valve handle so it is at

right angles to the hydraulic line or hydraulic cylinder.

To open the hydraulic control circuit and return feed

control to the needle valve, turn the quick shut off handle

so it is parallel with the hydraulic line or hydraulic cylinder.

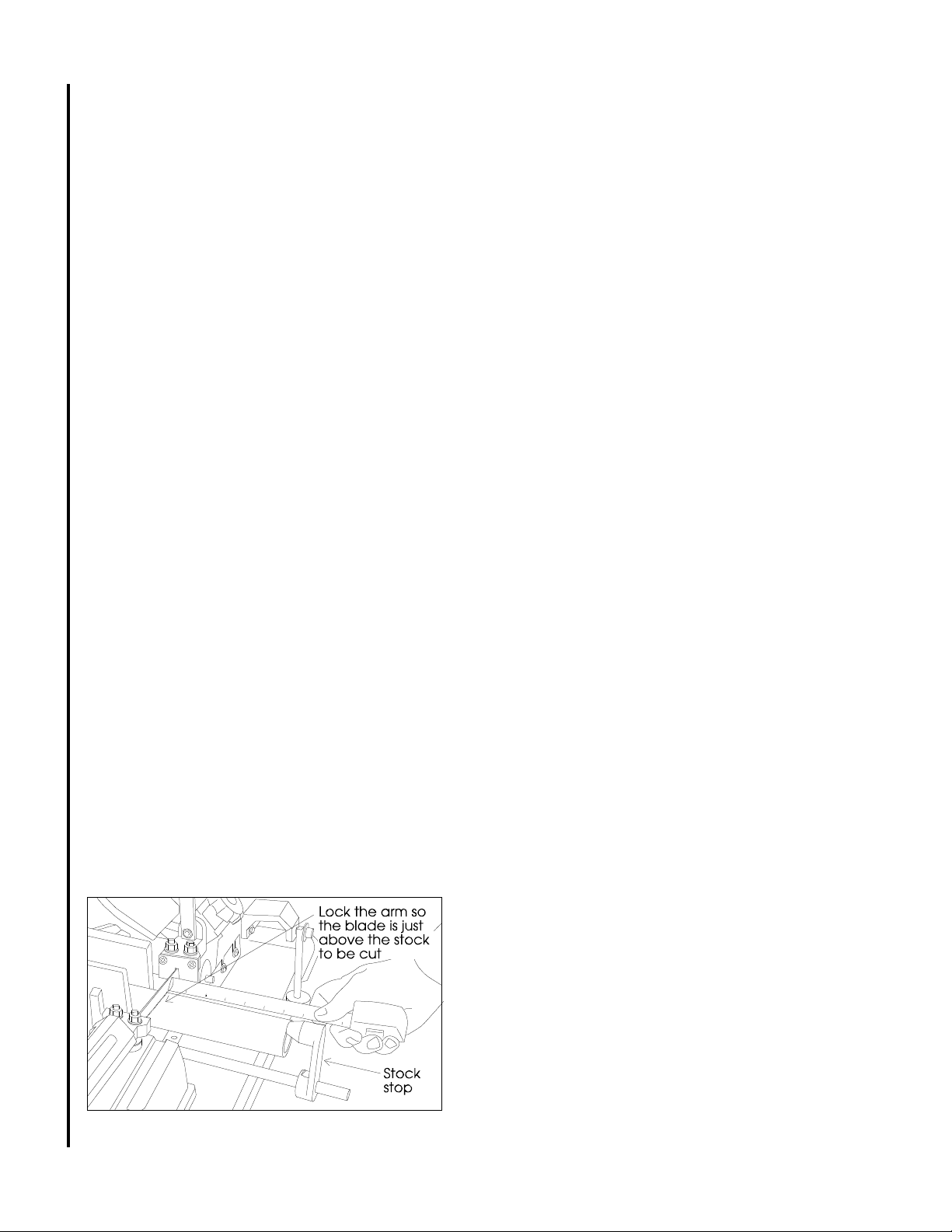

for repeated cuts

If you are cutting multiple pieces of stock, all to the

same specified length, use the stock stop.

1. Lower the saw arm to its horizontal position.

2. Loosen the stock stop set screws as necessary to slide

the stop upward and more-or-less into position.

(There are two set screws which are use to lock the stop

stock in position. One is on the saw table and is typically

used to adjust the distance between the stop and the

blade. The other set screw is on the stop, itself, and is

typically used to adjust the height of the stop above the

table. However, you can use any combination of set

screws you find convenient to adjust the stop to the

distance and height which works for the stock you are

cutting.)

3. Using a ruler or scale, measure the distance between

the blade and stock stop.

4. When the correct cut-off distance is obtained, be sure

the stock stop is at a position which allows the cutoff

piece to fall away from the blade as the cut is completed.

Then, tighten the stock stop set screws securely.

5. Raise the saw arm.

6. Place a workpiece in the saw vise and slide the

workpiece so it contacts the stock stop.

7. Open the hydraulic control cylinder quick shut off valve

and move the saw blade to just above the workpiece then close the needle valve so the arm is locked in

position.

8. Measure the distance between the end of the

workpiece and the blade to verify that you have set the

stock stop at the correct distance. (See Figure 6.)

9. When you are satisfied that your cut-off distance is

correct, you may begin cutting by turning on the saw and

opening the needle valve until the blade is cutting

efficiently.

To continue making multiple cuts take the following steps:

1. Do not change the setting on the needle valve.

2. Raise the saw arm so it clears the stock being cut and

lock the hydraulic control cylinder using the quick shut off

valve.

3. Release the vise slightly using the handle wheel -move the stock up to the stock stop -- tighten the vise

again.

4. Turn on the saw and open the quick shut off valve.

Because you established an efficient cutting rate on the

previous cuts using the needle valve, there is no reason to

change its setting. The quick shut off, alone, can be used

to begin and complete the cut.

Figure 6: Using the stock stop

Page 11

Changing blade speeds

The ModelsJ-3410 and J-3410-2 are 4-speed cutoff saws. The different speeds are obtained by changing

the position of the drive V-belt which connects the motor

pulley to the drivewheel gearbox pulley.

To change blade speeds:

1. Disconnect the saw from its electrical power source to

prevent any possibility of accidental motor start-up.

2. Allow the saw arm to rest at its full horizontal position.

3. Open the pulley cover to expose the V-belt and

pulleys.

4. Loosen the motor plate lock bolt jam nut and lock bolt.

5. Loosen the jam nuts on the motor plate adjustment

bolts, then loosen the motor plate adjustment bolts so the

motor can slide on its mounting plate to where the V-belt

can be removed from the pulleys.

6. Put the V-belt in the pulley position for the speed you

require --- refer to Figure 7 for belt locations and speeds

available.

7. Tension the belt by adjusting the motor adjustment

bolts until the V-belt has one belt's width of slack when

pressed firmly in the center of its travel.

8. Reverse steps 1 through 5, above, to complete the

speed change.

265 SFM

180 SFM

130 SFM

80 SFM

Gearbox

Motor

Evaluating cutting efficiency

Is the blade cutting efficiently? The best way to

determine this is to observe the chips formed by the

cutting blade.

If the chip formation is powdery, then the feed is

much too light, or the blade is too dull.

If the chips formed are curled, but colored -- that is,

either blue or straw colored from heat generated during

the cut -- then the feed rate is too high.

If the chips are slightly curled and are not colored by

heat -- the blade is sufficiently sharp and is cutting at its

most efficient rate.

Blade break-in procedures

New blades are very sharp and, therefore, have a

tooth geometry which is easily damaged if a careful breakin procedure is not followed. You may want to consult

manufacturers' literature for break-in of specific blades on

specific materials. However, the following procedure will

be adequate for break-in of JET supplied blades on

lower alloy ferrous materials.

1. Clamp a round section work piece in the vise. The

work piece should be 2 inches or larger in diameter.

2. With the saw on low speed, begin the cut with a very

light feed rate.

3. After the saw has completed 1/3rd of the cut, increase

the feed rate slightly and allow the saw to complete the

cut.

4. Without disturbing the position of the needle valve,

begin a second cut on the same or similar work piece.

5. After the blade has completed about 1/3rd of the cut,

increase the rate of feed and observe chip formation until

cutting is at its most efficient rate (see Evaluating blade

efficiency, above) ...then allow the saw to complete the

cut. The blade can now be considered ready for regular

service.

Figure 7: Belt position/speed relationships

Blade selection

The saw is delivered with a blade adequate for a

variety of cut-off jobs on a variety of common materials.

JET also can provide you with other blades. See the parts

listings for available blade types. See Table 1, for some

recommended speeds for various materials. However,

these selections, while appropriate to the many of shop

cutting needs, don't begin to exhaust the wide variety of

blades of special configuration (tooth pitch and set) and

special alloys for cutting unusual or exotic materials.

For very high production on cutting of special

materials, or to cut hard-to-cut materials such as stainless

steel, tool steel, titanium, etc., you can ask your industrial

distributor for more specific blade recommendations.

Also, the supplier who provides the workpiece material

should be prepared to provide you with very specific

instructions regarding the best blade (and coolant or

cutting fluid, if needed) for the material or shape supplied.

Starting a cut

To avoid blade damage, follow these procedures:

1. Never start a cut with the blade resting on the

workpiece.

2. Never start a cut on a sharp edge. If the workpiece

has a sharp edge, use a file to knock off the sharp edge

before lowering the blade onto the workpiece.

3. Have the motor on and running at full speed before

cutting.

4. Use the hydraulic control cylinder needle valve to

begin the cut of any single piece (although succeeding

pieces of the same type can be started using the quick

shut off valve.)

5. If you use coolant or cutting fluid, turn on the flow of

coolant before starting a cut.

11

Page 12

Right angle cuts -single pieces of stock

1. Raise the saw arm to its full up, open position.

2. Pull up on the quick release handle on the locking vise

jaw and slide the vise jaws apart.

3. Place the stock on the saw table, between the vise

jaws. If the stock is long, support the stock with

appropriate infeed and outfeed supports.

4. Pull up on the quick release handle and slide the

locking vise jaw up against the workpiece.

5. Turn the lead screw handle until the quick release

thrust shaft falls into a groove on the lead screw and puts

light clamping pressure on the workpiece.

6. Lower the saw arm until the blade is just above the

workpiece.

7. Lock the saw arm in position by turning the hydraulic

feed needle valve clockwise.

8. Adjust the position of the stock until the cut-off distance

you require is directly under the blade.

9. Tighten the vise so the workpiece is clamped firmly.

Note: if you are sawing a workpiece with a sharp

edge up -- use a file to knock off the sharp edge before

beginning any saw cuts. This will prevent damage to

teeth on the blade. See Figure 8 for details.

10. Turn the saw switch ON and allow the motor and

blade to come up to full speed.

11. If using a coolant system, turn on the valve at the

nozzle.

12. Carefully open the hydraulic control needle valve open

(counterclockwise) so the cutting arm lowers gently into

the workpiece and begins cutting.

13. Continue to open the hydraulic control valve until an

efficient cutting rate is established.

14. When the saw completes its cut, the motor will shut

off and the cut piece will fall away from the table.

15. If you are using a coolant system, turn it off the valve

at the nozzle.

Angle cutting

1. Raise the saw arm to full height and lock it in position

with the quick shut off valve.

2. Slide the vise open.

3. Set the stationary vise jaw to the angle required

according to the instructions in Adjusting stationary vise

jaw.

4. Put the workpiece in position on the saw table.

5. Adjust the locking vise jaw to the workpiece using

instructions in Adjusting the locking jaw.

6. Adjust the blade guide/support bearing brackets

according to instructions in Setting the blade guides.

7. Release the quick shut off valve and lower the arm and

blade to just above the workpiece, then lock the arm in

position using the hydraulic cylinder control needle valve.

8. Adjust the workpiece to the required cut-off position

under the blade.

9. Tighten the vise securely.

10. If you are starting your cut on a sharp edge, use a

file to knock off the sharp edge so the blade isn't damaged

at the start of the cut.

11. If using coolant or cutting fluid, turn on valve at the

nozzle.

12. Turn the saw switch ON.

13. Open the hydraulic cylinder needle valve until the

blade contacts the workpiece and establishes a cut -- then

open the control cylinder valve until the blade is cutting

efficiently.

14. When the cut is completed the motor will turn off and

the cut piece will fall away from the saw. Turn off the

coolant flow and repeat the steps above as necessary to

continue with more cuts.

Note: the stock stop can be used for multiple angle cuts in

the same way as described for straight cuts. See Using

the stock stop for repeated cuts.

Material Speed

12

Table 1: Suggested cutting speeds

Suggested cutting speeds for a variety of materials.

Speeds are recommended speeds for a 4 inch thick work

piece, a bi-metal blade, dry cutting. (No cutting fluid.

Speeds may be increased when cutting fluid is used -observe chip formation to determine most efficient cutting

rate.)

Decrease these speeds 30-50% for carbon steel blades.

Increase speed 15% for materials 1/4 inch thick, 12% for

materials 3/4 inch thick, 10% for materials 1 1/4 inch thick,

and 5% for 2 1/2 inch thick material. Decrease speed

12% when cutting eight inch material. When selecting

blade tooth pitch, be sure to have two or more teeth in

contact with the material at all times to avoid tooth

breakage.

Structural steel shapes

Low carbon steel

Medium carbon steel

High carbon steel

Cr-moly steel

Ni-Cr-moly steel

Chromium steel

Cr-vanadium steel

Tool steel

Stainless steel

Free machining steel

Cast iron

Copper alloy (CU-Zm)

Bronze

Al-bronze

Monel

Titanium alloy

Aluminum (T-6+)

165

160-165

115

90-100

105-135

90-115

80-140

105-115

40-80

40-70

80-100

55-90

55

90

40

40-45

25-40

80-160

Page 13

Figure 8: Placing workpieces in the vise

13

Page 14

14

Maintenance

Replacing blades

1. Disconnect the saw from its electrical power source to

prevent accidental start-ups.

2. Raise the saw arm to its full vertical position and lock it

in place using the quick shut off valve on the hydraulic

control cylinder.

3. Lift the safety cover in the lower portion of the blade

guard door by sliding it upward. There is no need to

remove it completely from its slot.

4. Remove the two screws with plastic knobs which hold

the blade guard door closed and swing the door open to

expose the drive and idler wheels, and the blade.

5. Turn the blade tension handle counterclockwise until

the blade hangs loose in the saw arm.

6. Use leather gloves to prevent cuts and scratches and

use protective eyewear which meets ANSI Specification

Z87.1. and pull the blade off of the drive wheels and out of

the blade guides. Store the blade carefully before

proceeding.

7. Slide the new blade into the blade guides -- then loop

the blade over the upper and lower drive wheels.

Note: it is possible to install the blade backwards. The

teeth on the blade should be pointing downward, toward

the motor, at the time the blade is installed.

8. Push the blade so it is seated against the shoulders of

the wheels. When it is seated against the shoulders...

9. ...turn the blade tension wheel clockwise to increase

tension on the blade. Don't over-tension the blade.

Tension it enough so it doesn't slip while cutting.

10. When you are satisfied that the saw is tensioned

correctly, reconnect the saw to its electrical power source.

11. Check the tracking of the blade according to

instructions in the section on Adjusting blade tracking,

below.

12. Close the wheel guard door and secure it using the

two plastic knobbed screws.

13. Slide the safety cover downward in its slot until it is

fully closed.

14. The new blade is installed and ready for the Blade

break-in procedures.

To adjust blade tracking:

1. Loosen the sliding plate draw block bolt slightly so the

adjustment set screw will be able to move the draw block.

2. Turn the coolant pump switch OFF, if coolant is used.

3. Turn the saw ON.

4. Insert a 4mm hex wrench in the socket head track

adjustment set screw.

5. Turn the track adjustment set screw so the blade starts

to move away from the shoulder -- then immediately turn

the screw the other direction so the blade stops -- then

moves slowly toward the shoulder.

6. Use the blade tracking adjustment screw to stop the

motion of the blade on the wheel as it gets close to the

shoulder. Now, put a strip of paper between the blade and

wheel as shown in Figure 9. KEEP FINGERS CLEAR OF

THE BLADE AND WHEEL. (That's why the paper strip

should be at least 6 inches long.)

7. The paper should not be cut, this first attempt. Next,

turn the track adjustment set screw a tiny amount more

and repeat the insertion of the paper between the blade

and wheel.

You may have to repeat this step several times before the

blade and shoulder cut the paper into two pieces. Don't

be in a hurry. Patience and accuracy here will pay off with

better, more accurate, quieter cutting and much longer

machine and blade life.

8. When the paper is cut, turn the adjustment screw

counterclockwise, slightly. This assures that the blade is

not touching the shoulder of the wheel.

9. Tighten the two bolts which hold the draw block.

Adjusting blade tracking

If the blade is fully tensioned, release tension

slightly before attempting to adjust the saw blade tracking.

A badly worn or bent blade will be extremely difficult to

track properly -- if it can be tracked successfully, at all.

The track of the saw blade is adjusted using the track

adjustment mechanism on the idler wheel. The track

adjustment tilts the wheel to "steer" the blade on the

wheels. Tracking adjustment is performed with the saw

arm in vertical position, blade guard doors open and the

saw running. Therefore, USE EXTREME CAUTION

WHEN PERFORMING BLADE TRACKING CHECKS AND

ADJUSTMENTS.

Figure 9: Inserting the paper strips between the blade

and wheel to adjust blade-to-shoulder clearance

Page 15

Blade alignment adjustments

The blade can suffer from several out-of-adjustment

conditions. These conditions are shown in Figure 10.

Figure 10: Blade alignment fault conditions

Establishing a reference surface for blade adjustment

So long as major changes and adjustments to the

blade guide system are not made, you will not have to

perform the following procedure. However, assuming the

"worst possible case" -- someone dismantles all of the

guides and components -- here is how to determine a

baseline reference surface for subsequent blade guide

system adjustments.

1. Disconnect the saw from its electrical power source to

prevent accidental start-ups.

2. Be sure the blade is fully tensioned and in good

condition. Use of a new blade is best for this operation.

3. Remove the blade guide, brackets, and all blade

guiding and supporting components which normally

capture and guide the blade at the cutting postion.

4. Lower the saw arm to full horizontal position.

5. Place a machinists square against the blade and

adjust the stationary vise jaw so it is at right angles to the

blade.

6. You have established a reference surface at the

stationary vise face. All subsequent adjustments of blade

parallelism and vertical can be made using the stationary

vise face or the saw table.

When to adjust the blade guides

The blade guides, when installed at the factory,

have been adjusted for maximum sawing effectiveness

and, if not disturbed, damaged or worn, should require no

field adjustment other than moving the guide brackets as

needed to clear the workpieces being sawed.

However, if the components get out of alignment or

need replacement the following instructions give you the

complete method for adjusting the system.

In particular, there five planes, angles or clearances

which need to be considered.

1. The blade must run parallel to the saw blade clearance

slot. (See Figure 10.)

2. The blade must be square with the vise jaws. (See

Figure 2.)

3. The blade must the vertical and square with respect to

the saw table and must not be twisted. (See Figure 10.)

4. The guide bearings must provide the correct side

clearance and support for the blade.

5. The blade back-up bearing must be correctly placed

behind the blade.

As we say, so long as no component relationships

are disturbed, the factory settings should be adequate to

your tasks. However, parts wear or damage does occur.

When parts are replaced, adjustment of the blade

positioning will almost certainly be necessary.

Of course, regardless of whether or not a component has been disturbed or replaced, at any time you are

not getting the cutting action or accuracy you expect, or

whenever the troubleshooting chart recommends it, you

can and should check the blade support components.

15

Figure 11: Nomenclature for blade guide assembly and its

components

Page 16

Replacing blade guide and support components

All component parts are secured with nuts, bolts,

washers, or snap rings. To remove and replace any

component, first remove the blade according to instructions in Replacing blades. Then remove and replace the

faulty component(s).

The guide and support bearings are mounted on

eccentric shafts to permit adjustment of the bearing axis.

See Figure 11. By loosening the eccentric lock nuts and

using a wrench to turn the eccentric, all clearances and

positions can be adjusted.

Replacing a blade guide bearing is covered in the

section on Replacing guide bearings.

In the case of replacing a single faulty component

(such as a single bearing or pair of bearings on an

eccentric) you do not necessarily have to adjust all of the

other components -- however, their adjustment should be

checked when any other adjustment is made.

Before making any adjustments be certain to

disconnect the saw from its electrical power source to

prevent accidental motor start-ups.

Adjust blade for parallelism:

1. Use a new blade or a blade in nearly new condition and

have it fully tensioned and tracking correctly before

making any adjustments.

2. Be sure the stationary vise jaw is at a right angle to the

blade. If you are not certain the jaw is correctly adjusted,

use the procedure under Establishing a reference angle,

to be sure the jaw is correctly set.

3. Lower the saw arm to full horizontal position.

4. Use a machinist's protractor against the stationary vise

jaw and check the blade for parallel. If the blade is

parallel to the stationary jaw, no further parallelism

adjustment is required. However, if the blade is at an

angle to the jaw, determine which bearing set you are

going to move and the direction in which you need to

move it. Then proceed to the following steps.

4. Keep the bearing eccentric from moving by putting a

wrench on the adjustment tang of the eccentric. (See

Figure 12.)

5. Loosen the eccentric lock nut so you can rotate the

eccentric using the adjustment tang.

6. Turn the eccentric until you have shifted the bearing

assembly to where you want it to move.

7. Tighten the eccentric lock nut.

8. Adjust the bearing on the other side of the blade so the

bearing clearance adjustment is correct. YOU MUST

PERFORM THIS STEP. The blade is being twisted by the

bearing assemblies and a lot of pressure is being exerted

by the blade against the bearings. See Adjusting guide

bearings.

9. Check the blade for squareness and vertical and readjust as necessary until it is parallel to the clearance slot,

square to the vise jaw, vertical to the table, with side guide

bearings correctly adjusted.

Figure 12: Adjusting blade parallelism using the support

bearing eccentrics. Use two wrenches -- one to lock and

unlock the lock nut, the other to adjust the bearings using

the tang on the guide bearing shaft.

16

Page 17

Adjusting blade vertical:

The blade guide bearing seat can rotate as needed to

make the blade vertical to the saw table. Follow these

instructions.

1. With the saw arm in horizontal position, put a

machinists square on the table, and against the blade, as

shown. The blade should be square (vertical) to the table.

If not...

2. Slightly loosen the socket head cap screw which

secures the bearing seat to the bracket bar.

3. Use a wrench to rotate the seat until the blade is

vertical. (See Figure 13.)

4. Tighten the socket head cap screw securely.

5. Check the other blade guide for vertical. Adjust, if

necessary.

6. After adjusting for vertical, RECHECK THE BLADE

FOR PARALLEL. Changes in vertical can easily result in

changes in parallelism. See Adjusting blade parallelism.

Test cutting to verify adjustment accuracy

Test cuts can be used to determine whether or not

you have adjusted the blade accurately. Use 2 inch bar

stock to perform these test cuts, as follows:

1. With the bar stock securely clamped in the vise, make

a cut through the bar stock. (See Figure 14.)

2. Mark the top of the bar stock.

3. Move the bar stock about 1/4 inch past the blade so

you can begin a second cut.

4. Rotate the bar stock 180 degrees so the mark you

made is now at the bottom of the cut.

5. Make a cut through the bar stock.

6. Use a micrometer to measure the thickness variation

between the top and bottom of the disc you have cut from

the bar stock. Unless things are truly perfectly aligned,

there is almost certain to be a certain amount of "wedge"

to the shape of the disc you have cut. The saw blade can

be considered correctly adjusted when the variation

measured is no more than .012 inch across the face of the

disc.

If you do not have a 2 inch bar stock available for a

test cut, use a larger diameter test work piece rather than

a smaller one. The maximum thickness variation on any

test piece should be no more than .003 inches, per side,

per inch of stock diameter.

Figure 13: Adjusting blade vertical

17

Figure 14: Step-by-step method to produce a test disc

which can be measured for "wedge" - a measurement for

testing cutting accuracy.

Page 18

18

Adjusting guide bearings

There are eight side blade guide/support bearings.

These bearings are installed in the bearing seat, and the

seat is attached to the sliding adjustment bracket.

These bearings are stacked, with two bearings on

each adjustment eccentric. The width of each pair of

stacked bearings is slightly less than the width of a blade.

The force against each of the bearings in each

stack is not equal. This is because the bearings are

twisting the blade. This puts a much higher force against

the two bearings which are doing most of the twisting.

Look at Figure 15 for a diagram which shows this effect.

Figure 15: Guide bearing forces. Blade twist and clearance is exaggerated for demonstration. In practice, the

blade will be standing vertical between the bearings when

they are adjusted correctly.

The bearings are adjusted by moving the eccentrics

as required, and by using your fingers to twist the bearings to see if they can rotate, and how difficult it is to

rotate them.

The bearing clearance is correctly adjusted when

the bearings labeled with an "A" in Figure 15 cannot be

turned at all, and when bearings labeled with a "B" in

Figure 15 can barely be turned with your fingers.

If the supporting bearings don't turn at all -- the setup is too tight. If they can be turned easily using your

thumb and forefinger -- the set-up is too loose.

To adjust:

1. Put a wrench on the adjustment tang of the bearing set

you want to adjust. This prevents the eccentric from

turning.

2. Use another wrench to loosen the lock nut for the

eccentric bolt.

3. Turn the eccentric using the adjustment tang to loosen

or tighten the bearing set, as needed.

4. Tighten the jam nut.

5. Check bearing tightness on both sides of the blade.

Re-adjust as required until the conditions described in the

above paragraphs is obtained.

Replacing guide bearings

1. Remove the blade as outlined in steps 1 through 6 of

Replacing blades.

2. Remove the jam nut on the eccentric upon which you

are going to replace bearings.

3. Remove the clip which secures the bearings on the

eccentric shaft.

4. Tap the old bearings off and press the new bearings

on.

5. Replace the snap ring which secures the bearings on

the eccentric.

6. Reinstall the eccentric in its position and tighten the

jam nut loosely on the eccentric.

7. Install the blade according to instructions 7 through 14

in Replacing blades.

8. Adjust bearing clearance according to instructions in

the previous section: Adjusting guide bearings.

Adjusting blade back-up bearings

The back-up bearings support the rear of the saw

blade as it takes the pressure of cutting. (Refer to

Figure 11.)

1. Being careful not to disturb the vertical angle of the

guide bearing seat, loosen the socket head cap screw

which secures the seat.

2. Move the seat downward until the back-up bearing just

barely touches the back of the blade.

3. Tighten the socket head cap screw securely.

4. Perform this same operation on the other back-up

bearing, if required.

After adjusting the back-up bearings, CHECK FOR

BLADE VERTICAL according instructions in Adjusting

blade vertical. It is very easy to disturb the vertical plane

of the blade while performing this adjustment, and a blade

which is not vertical will NOT cut straight.

Page 19

Replacing the drive wheel

1. Complete steps 1 through 6 in Replacing blades.

2. Remove the snap ring which secures the lower wheel

to the gearbox output shaft.

3. Pull the wheel off of the gearbox output shaft using a

suitable puller.

4. Inspection: Examine the wheel for damage on its drive

edge, shoulder, or the shaft boss. Replace if any faults

are found.

5. Reinstall the wheel by pressing and/or tapping it back

onto the shaft using a soft-faced mallet.

6. Reinstall the snap ring which retains the wheel on the

shaft.

7. Complete steps 7 through 14 of Replacing blades and

any steps in Adjusting blade tracking, as needed to

complete the installation.

Installing the vertical sawing table

1. Disconnect the saw from its electrical power source to

prevent accidental motor start-ups.

2. Raise the saw to full vertical position and lock in

position using the quick lock valve.

3. Remove the two flat head cap screws which hold the

small cutting plate to the bearing seat.

4. Place the large vertical cutting plate in position and use

the two flat head cap screws to attach it firmly to the

bearing seat.

5. Reconnect the saw to electrical power and it is ready to

use as a vertical band saw.

Replacing idler wheel or bearings

1. Complete steps 1 through 6 in Replacing blades.

2. Remove center bolt and washer from the idler wheel.

3. Remove the two bolts which hold the sliding plate draw

block in the sliding plate and remove the wheel and draw

block from the saw as an assembly.

4. Using a suitable puller or press, pull or press the

wheel, complete with bearings, off of the draw block.

5. Using a suitable puller, remove the two bearings from

inside the wheel hub.

6. Inspections: Inspect the bearings for evidence of

leakage and turn them to feel for roughness or other

internal flaws. Replace if leaking or roughness is felt.

Examine the wheel for damage on its drive edge, shoulder, or the bearing mounting boss. Replace if any faults

are found.

7. To install new bearings use a suitable press to press

them in the center of the wheel until the races are flush

with the shoulder inside the wheel hub. (See Figure 17.)

8. Press the bearing and wheel assembly onto the shaft

of the sliding block.

9. Reinstall the washer and bolt which retain the wheel on

the shaft.

10. Reinstall the draw block and wheel assembly to the

saw arm using the bolts to secure it to the plate.

11. Complete steps 7 through 14 of Replacing blades and

any steps in Adjusting blade tracking, as needed to

complete the installation.

Figure 17: Idler wheel bearing

configuration

19

Page 20

20

Servicing the hydraulic control cylinder

Over a long period of service the hydraulic control

cylinder may need replacement of its internal seals. Use

the following procedure. (See Figure 18.)

1. Lower the arm to its horizontal position.

2. Remove the upper fasteners, lower set screw, and pin

which secure the cylinder to the saw arm and saw base.

3. Working over a container suitable to hold the fluid, pull

the control rod to its full extended position.

4. Remove the nut on the bottom fitting of the valve and

line assembly. Being careful not to kink the copper line,

remove the end of the line from the fitting in the cylinder.

5. Slowly push the control rod to its fully collapsed

position. This will force most of the hydraulic fluid from

the cylinder.

6. Put the line back into its fitting and tighten its securing

nut.

7. Remove the needle valve assembly from the valve

body.

8. Pull off the plastic cap at the top of the cylinder.

9. Remove the internal snap ring at the top of the

cylinder.

10. Wrap a rag around the top of the cylinder to catch

and cushion the top cap when it is expelled from the

cylinder.

11. Use a source of VERY LOW PRESSURE air and

apply pressure to the needle valve cavity in the valve

body. The top cap will pop out of the cylinder and into the

rag.

12. Remove the lower snap ring from inside the cylinder.

13. Slide the piston assembly from the cylinder, complete.

14. Remove the bottom nut, washer and rubber ring from

the bottom of the piston rod.

15. Remove piston from the rod.

16. Remove the U-ring from the piston.

17. Remove the one external and the two internal O-rings

from the top cap.

Discard all soft parts.

18. Clean all metal parts with a suitable solvent.

19. Use clean hydraulic fluid as a lubricant for all subsequent operations. Install the three O-rings on the top cap

and the U-ring on the piston.

20. Install the piston, U-ring lip down, on the piston rod.

21. Install the rubber ring against the bottom of the piston

and secure it with the washer and nut.

22. Slide the piston assembly into the cylinder. A slight

twisting motion will help ease the U-ring into the cylinder.

Push the piston assembly all of the way to the bottom of

the cylinder.

23. Install the bottom snap ring inside the cylinder.

24. Again working over a container which can catch any

spilled fluid, fill the cylinder with hydraulic fluid until it

comes out the valve body. Use a high quality hydraulic

jack oil for the hydraulic fluid.

25. Install the top cap on the piston rod and slide it into

the cylinder, flush with the bottom snap ring. Again, a

slight twisting motion will help ease the top cap into

positon. You will almost certainly expel some fluid from

the valve body while doing this, which is why you are

doing it over a container.

26. Reinstall the needle valve assembly into the valve

body and tighten it.

27. Install the top snap ring.

28. Install the plastic cap on top of the cylinder.

29. Reinstall the cylinder on the saw by reversing

steps 1 to 3, above.

Note: do not dispose of discarded hydraulic

fluid carelessly. Use a licensed waste oil

disposal service to handle discarded fluids.

Figure 18: Hydraulic control cylinder exploded view

Page 21

Machine Set-up

The saw delivered to you has been adjusted at the

factory. A number of test pieces have been cut using the

saw to verify the accuracy of cutting.

Therefore, the only set-up operations required

before releasing the saw for service are spotting the saw

and establishing the electrical connections to the motor.

If ordered with the coolant kit, the kit is typically

installed at the JET factory. However, if the kit is ordered

separately by you, it must be installed by a set-up

mechanic, so instructions for this task are included in this

Machine set-up section, as well.

Uncrating and spotting the saw

Spot the saw where it makes the most sense for the

operations you will probably be doing. If you are going to

be doing cut-off work on very long pieces of stock, allow

plenty of room for the stock, infeed and outfeed supports,

etc.

Remove the saw from the shipping skid and discard

any hold-down devices which might have secured the saw

to the skid.

Note the lock plate on the arm of the saw which is

secured under the bump rubber. This lock plate must be

removed before the saw arm can be raised. You may

discard the lock plate and cap screw used to hold it in

place. Be sure, however, to replace the nut on the bottom

of the horizontal stop.

Electrical

The saw is delivered as either a 115 volt or 230 volt

saw, depending upon your order. Wiring diagrams for

either type of circuit are shown here.

The motor is connected, internally, to achieve the

voltage set-up required. However, you can change the

motor's internal wiring connections to change the

operating voltage, if necessary.

To change the operating voltage

1. Disconnect the saw from its electrical power source.

2. Open the motor plate. The requirements for

either 115 or 230 volt connection will be seen on a

diagram inside the motor plate.

3. After making the connections, close the motor plate.

4. If you are using a plug connection to a socket, you will

need to use the appropriate plug for the new power

source supplying the saw, then plug the cord into the

supplying receptacle to reconnect power to the saw.

5. If you are hard wired to a junction box, connect to the

wires in the box, close the box, and reestablish power to

the branch.

6. The saw is now ready for service.

Note: JET recommends that any wiring involving

hard wiring of the saw to a branch, or any change of

voltage supplied to the motor , be performed by a

licensed electrician.

Note: also --- if the coolant kit installed on the

Model J-3410 saw is prewired for 115 volt operation .

When changing the motor voltage to 230 volts, the

coolant pump must be changed to 230 volt following

Figure-20 or the wiring diagram on the pump label.

Figure 19: 115 volt wiring diagram

21

Figure 20: 230 Volt wiring diagram

Page 22

22

Installing the coolant kit

1. Install the baffle in the tank so the pump is held at one

end of the tank.

2. Put the tank and pump assembly in the flanges which

hold it in the saw base. The pump should be at the saw

motor end of the base.

3. Install the nozzle assembly in the fixture in the righthand guide bearing bracket and secure it with the set

screw in the fixture.

4. Install the delivery hose between the nipple on the

pump and the nipple on the nozzle assembly.

5. Install the return line between the nipple on the table

and the empty side of the tank.

6. Wire the pump motor to the pump switch according to

the wiring diagram on the facing page. Female spade

clips for the pump-to-switch connections are not supplied

with the kit and must be sourced locally, by you.

7. Test the system by putting coolant in the tank and

turning on the pump switch and motor switch.

8. The system is ready for use on the saw.

Chip brush replacement

The chip brush is a circular wire brush which is

mounted in a bracket at the right-hand side of the saw

arm. The purpose of the brush is to remove chips from

the saw teeth and off of the blade so excessive amounts

of chips don't get into the wheel guard section of the saw.

The brush shaft spins in the bracket and the shaft is

secured using a set screw and collar. With extended use

this brush will be worn and require replacement.

1. Disconnect the saw from its power source to prevent

accidental motor start-up.

2. Remove the set screw and collar from the brush shaft.

3. Remove the old brush and replace it with a new one.

4. Install the collar and set screw so the brush can spin

freely in the bracket.

5. Adjust the bracket, if necessary, so the brush makes

light contact with the saw blade.

Adjusting the horizontal stop and motor switch

The horizontal stop and motor switch are located on

the front of the saw table at the left hand side. The

horizontal stop is a rubber disc, mounted on a flat-headed

screw. The screw height, and therefore the horizontal

position of the saw arm, is adjusted using two nuts on the

screw.

The motor switch is supposed to turn the motor off

just before the arm contacts the horizontal stop. In this

way a complete cut can be made and the blade can be

automatically stopped before the arm is lifted to set up

another cut.

Adjust the horizontal stop whenever the rubber disc

is worn to the point where the stop requires replacement.

To replace or adjust the horizontal stop:

1. Disconnect the saw from its electrical power source to

prevent accidental motor start up.

2. Raise the saw arm to its full up position.

3. Remove the lower nut which secures the horizontal

stop screw to the saw and remove the horizontal stop

assembly, complete.

4. Install the new horizontal stop and make the nuts

which secure it finger tight.

5. Lower the saw arm to its horizontal position.

7. Adjust the horizontal stop height, using the upper and

lower nuts, until the saw blade is below the level of the

table surface and is fully into the blade relief slot on the

table.

8. To be certain the blade has made enough downward

travel to make a complete cut on the largest workpiece

which fits in the saw:

8.1. Open the adjustable vise jaw to its widest position

8.2. Place a straight edge flat on the saw table and

move it to where it contacts the blade.

8.3. The saw blade teeth should be below the saw table

along the entire distance you can slide the straight edge.

Adjust the horizontal stop until this condition is met.

9. Tighten the horizontal stop nuts securely.

10. Reestablish the electrical connection to the saw and

proceed to adjust the motor switch actuator.

Adjusting the motor switch actuator

1. Raise the arm until the switch actuator is not in contact

with the switch.

2. Turn the switch ON.

3. Lower the arm until the arm contacts the horizontal

stop. The motor switch should shut off the motor just

before the arm contacts the horizontal stop.

4. If necessary, bend the switch actuator and re-test the

system until the correct motor shut-off instant is obtained.

Page 23

Troubleshooting

Problem

Excessive

blade

breakage

Premature

blade

dulling

Crooked

cuts

Probable cause Potential solutions

Material loose in the vise

Incorrect feed or speed

Incorrect blade tension

Teeth in contact with work before saw is

started

Blade rubs on wheel flange

Misaligned blade guides

Blade too thick for wheel diameter

Cracking at weld

Teeth too coarse

Too much blade speed

Inadequate feed pressure

Hard spot or scale on material

Work hardening of material (especially

stainless steel)

Blade installed backwards

Incorrect coolant or no coolant

Insufficient blade tension

Work not square

1. Use more pressure to tighten vise.

2. Check stationary jaw pivot and lock bolts for tightness.

3. Check quick release handle nut for excessive tightness

-- nut should be just tight enough to keep adjustable jaw

from tilting when tightening.

4. If you are stacking multiple pieces in the vise, be sure

all of the pieces are captured by the vise pressure.

1. Check technical literature for recommended feeds and

speeds for the material and blade you are using.

2. Check chip formation to adjust speed and feed to

correct rate when sawing.

1. Adjust blade tension to where it just does not slip on

the wheel.

1. Be sure the saw motor has come fully up to speed

before beginning a cut and be sure the blade is not resting

on the workpiece before the motor has come up to full

speed.