Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

5-in ch x 8-in ch Horizontal Ban d Saw

Models: J-3130, J-3230

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M- 414453

Ph.: 800-274-6848 Revision C 11/2012

www.walt er meier.c om Copyright © 2012 Walt er Meier (M anufacturi ng) Inc.

Model J-3130 show n

Page 2

1.0 Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

WARRANTY

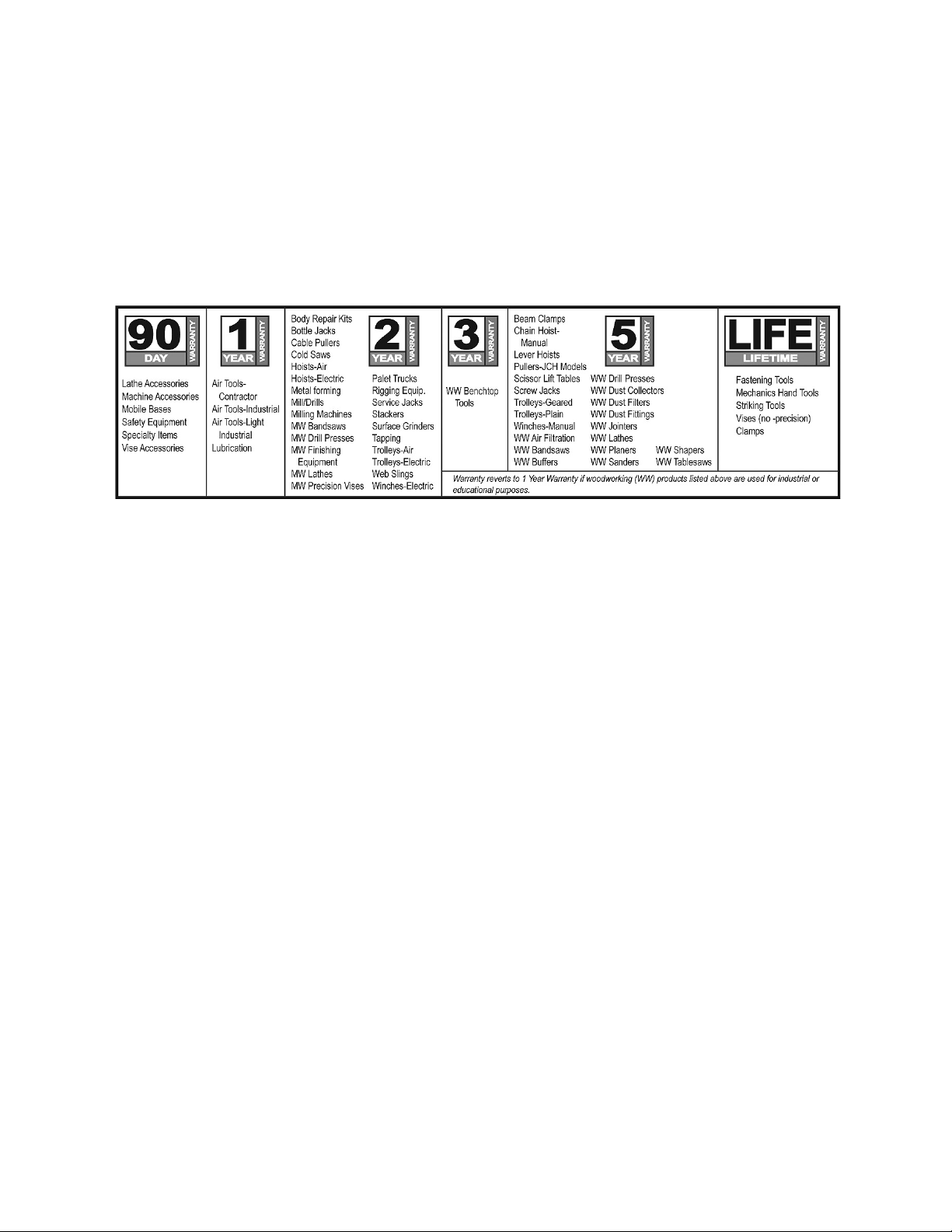

JET products carry a limited warranty which varies in duratio n based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the e xceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME ST ATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded products are not sold in Canada by Walter Meier.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ................................................................................................................... 2

2.0 Table of contents.......................................................................................................................... 3

3.0 Safety Warnings........................................................................................................................... 4

4.0 About this machine and manual .................................................................................................... 6

5.0 Features and Nomenclature .......................................................................................................... 6

6.0 Specifications............................................................................................................................... 7

7.0 Set-up and assembly .................................................................................................................... 8

7.1 Un packing and cleanup..................................................................................................................................... 8

7.2 Assembling the band saw .................................................................................................. ............................... 8

7.3 Installing coolant kit ........................................................................................................................................... 9

8.0 Electrical connections ................................................................................................................... 9

8.1 Wiring diagram ................................................................................................................................................... 9

9.0 Operating Instructions ................................................................................................................ 10

9.1 Clamping materials in the vise ........................................................................................................................ 10

9.2 Right angle cutting ........................................................................................................................................... 10

9.3 Angle cutting .................................................................................................................................................... 10

9.4 Clamping methods ........................................................................................................................................... 11

9.5 Using the stock stop ........................................................................................................................................ 11

9.6 Blade selection................................................................................................................................................. 11

9.7 Changing blade speeds .................................................................................................................................. 11

9.8 Evaluating cutting efficiency ............................................................................................................................ 12

9.9 Cutting procedure ............................................................................................................................................ 12

9.10 Using the hydrau lic feed control ................................................................................................................... 12

9.11 Blade break-in procedures ............................................................................................................................ 13

9.12 Changing blades ............................................................................................................................................ 13

10.0 Maintenance ............................................................................................................................ 13

10.1 Motor replacement......................................................................................................................................... 13

10.2 Adjusting guide bearings............................................................................................................................... 14

10.3 Blade tracking ................................................................................................................................................ 14

10.4 Replacing guide bearings ................................................................................................ ............................. 15

10.5 Adjusting back-up bearings .......................................................................................................................... 15

10.6 Adjusting the arm stop adjustment bolt........................................................................................................ 15

10.7 Adjusting motor switch actuator ................................................................................................................... 15

11.8 Replacing a back up bearing ............................................................................................. ........................... 15

11.9 Adjusting the bearing guide seats for blade vertical ................................................................................... 15

10.10 Test cutting to verify adjustment accuracy ................................................................................................ 16

11.0 Maintenance Chart ................................................................................................................... 17

12.0 Troubleshooting t he J-3130 and J-3230 ..................................................................................... 18

13.0 Replacement Parts ................................................................................................................... 21

13.1.1 Lower Saw Head – Exploded View ........................................................................................................... 22

13.1.2 Lower Saw Head – Parts List .................................................................................................................... 23

13.2. 1 Upper Saw Head – Ex ploded View ........................................................................................................... 24

13.2. 2 Upper Saw Head – Parts List .................................................................................................................... 25

13.3.1 Saw Base – Exploded View....................................................................................................................... 26

13.3.2 Saw Base – Parts List ................................................................................................................................ 27

13.4. 1 Stand and Coolant System – Exploded View........................................................................................... 29

13.4.2 Stand and Coolant System – Parts List .................................................................................................... 30

3

Page 4

3.0 Safety Warnings

General Caution s

- Misuse of this machine can cause serious injury.

- For safety, the machine must be set up, used and

serviced properly.

- Read, understand and follow the instructions in the

operator’s and parts manual which was shipped

with your machine.

When setting up the machine:

- Always avoid using the machine in da mp or poorly

lighted work areas.

- Always be sure the machine is securely anchored

to the floor or the work bench.

- Always keep the machine guards in place.

- Always put the st art switch in the “OFF” position

before plugging in the machine.

When using the machine:

- Never operate the machine with safety guards

missing.

- Always wear safety glasses with side shields (See

ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach; you may slip and fall into the

machine.

- Never leave the machine running while unattended.

- Always shut the machine off when not in use.

When servicing the machine:

- Always unplug the machine from the electrical

power before servicing.

- Always follow the instructions in the operators and

parts manual when changing accessory tools or

parts.

- Never modify the machine without consulting

Walter Meier (Manufacturing) Inc.

You — the stationary power tool user — hold the key

to safety.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly,

JET machinery is among the best in design and

safety. However, any machine used improperly can

be rendered inefficient and unsafe. It is mandatory

that those who use our products be properly trained in

how to use them correctly. They should read and

understand the Operator’s and Parts Manual as well

as all labels affixed to the machine. Failure in

following all of these warnings can cause serious

injuries.

General Machinery W arnin gs

1. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields which

comply with ANSI Z87.1 specifications. Use of

eye wear which does not comply with ANSI Z87.1

specifications could result in severe injury from

the breakage of the eye protection.

2. Wear proper apparel. No loose clothing or jewelry

which can get caught in moving parts. Rubber

soled, nonslip, footwear is recommended for best

footing.

3. Do not overreach. Failure to maintain a proper

working position can cause you to fall into the

machine or cause your clothing to get caught —

pulling you into the machine.

4. Keep guards in place and in proper working

order. Do not operate the machine with the

guards removed.

5. Avoid dangerous working environments. Do not

use stationary machine tools in wet or damp

locations. Keep work areas clean and well lit.

6. Special electrical precautions should be taken

when working on flammable materials.

7. Avoid accidental starts by being sure that the

start switch is in the “OFF” position before

plugging in the machine.

8. Never leave the machine running while

unattended. The machine shall be shut off

whenever it is not being used.

9. Disconnect the electrical power before servicing,

whenever changing accessories or when general

maintenance is done on the machine.

10. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the

changing of accessories. No attempt shall be

made to modify or have makeshift repairs done to

the machine. This not only voids the warranty but

also renders the machine unsafe.

11. If there is any risk of tipping or sliding, the

machinery must be anchored to the floor.

12. Secure your work. Use clamps or a vise to hold

your work, when practical. It is safer than using

your hands and it frees both hands to operate the

machine.

13. Never brush chips away while the machine is in

operation.

14. Keep work area clean. Cluttered areas invite

accidents.

15. Remove adjusting keys and wrenches before

turning the machine on.

16. Use the right tool. Don’t force a tool or

attachment to do a job for which it was not

designed.

17. Use only recommended accessories and follow

manufacturer’s instructions pertaining to them.

4

Page 5

18. Keep hands in sight and clear of all moving parts

A

and cutting surfaces.

19. All visitors should be kept at a safe distance from

the work area. Make your workshop co mpletely

safe by using padlocks, master switches, or by

removing starter keys.

20. Know the tool you are using; its application,

limitations, and potential hazards.

General Electrica l Cautions

This machine should be grounded in accordance with

the National Electrical Code and local codes and

ordinances. The work should be done by a qualified

electrician. The machine should be grounded to

protect the user from electrical shock.

Wire Sizes

CAUTION: For circuits that are a great distance fro m

the electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended:

Conductor

length

240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

WG (American Wire Gauge) number

Table 1

Safety Instruct ions on Sa wing Syst ems

1. Always wear leather gloves when handling

saw blade. The operator shall not wear gloves

when operati ng the machine.

2. All doors shall be closed, all panels replaced,

and other safety guards in place prior to the

machine being star ted or oper ated.

3. Be sure that the blade is not in contact with the

workpiece when the motor is started. The

motor shall be started and you should allow

the saw to achieve full speed before bringing

the saw blade i nto contact with th e workpiece.

4. Keep hands away from the blade area.

5. Remove any cut off piece carefully while

keeping your hands free of the blade area.

6. Saw must be stopped and electrical supply

must be cut off before any blade replacement

or adjustment of blade support mechanism is

done, or before any attempt is made to change

the drive belts or before any periodic servi ce or

maintenance i s perfor m ed on the saw.

7. Remove all loose items and unnecessary

workpieces from the area before starting

machine.

8. Bring adjustable saw guides and guards as

close as pos sible t o the workpiece.

9. Always wear protective eye wear when

operating, servicing, or adjusting machinery.

Eyewear shall be impact resistant, protective

safety glasses with side shields complying with

ANSI Z87.1 specifications. Use of eye wear

which does not comply with ANSI Z87.1

specifications could result in severe injury

from br eakage of eye prot ection.

10. Nonslip footwear and safety shoes are

recommen ded.

11. Wear ear protectors (plugs or muffs) during

extended per iods of oper ation.

12. The workpiece, or part being sawed, must be

securely clamped before the saw blade enters

the workpiece.

13. Remove cut off pieces carefully, keeping

hands away from saw blade.

14. Saw must be stopped and electrical supply

disconnected before reaching into cutting area.

15. Avoid contact with coolant, especially guarding

your eyes.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine dama ge.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

5

Page 6

4.0 About this machine and manual

The JET 5”x8” Band Saw is available as a dry cutting saw or a wet cutting saw. If required, a dry cutting band

saw can be retr ofitted with a kit wh ich converts it to u se with cutting flu ids. Th e use of an hydraulic feed del ivers

consisten t, accur ate cuts and l onger blade l ife.

This manual is provided by Walter Meier (Manufacturing) Inc. covering the safe operation and maintenance

procedures for a JET Model J-3130 and J-3230 Band Saw. This manual contains instructions on installation,

safety precautions, general operating procedures, maintenance instructions and parts breakdown. Your

machine has been designed and constructed to provide years of trouble-free operation if used in accordance

with the instructions as set forth in this document.

If there are questions or comments, please contact your local supplier or Walter Meier. Walter Meier can also

be reached at ou r web site: www.walterm eier. com.

Retain this m anual for future re ference. If th e m achine tra nsfers ownershi p, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly

or operation! Failure to comply may cause serious injury!

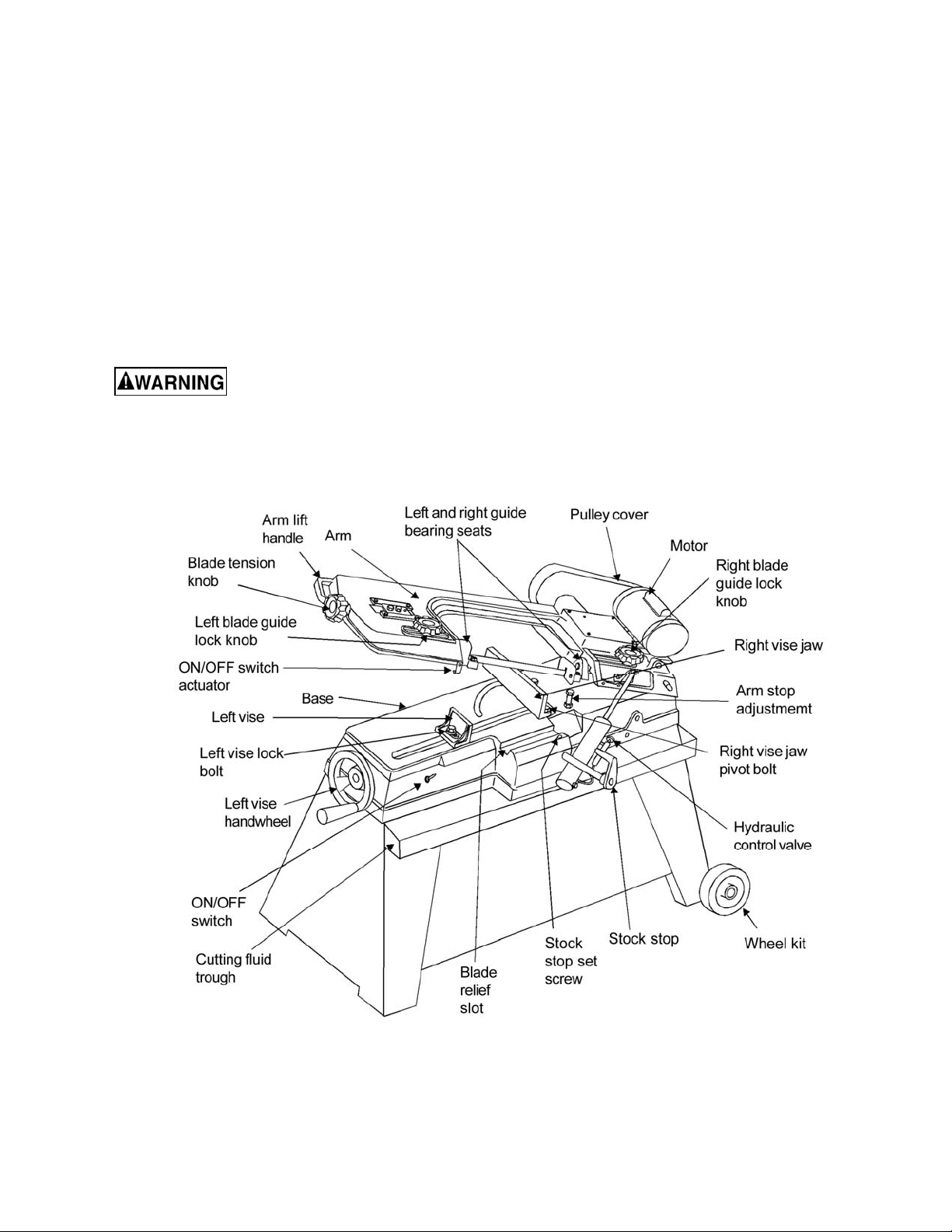

5.0 Features and Nomenclature

Figur e 1: Features and nom enclat ure

6

Page 7

6.0 Specific atio ns

Model numbers ...................................................................................... J-3130 .....................................................J-3230

Stock numbers ...................................................................................... 414461 ....................................................414453

Type ............................................................................................................. dry .......................................................... wet

Motor and electricals:

Motor type ............................................................................... .totally enclosed fan cooled, induction, capacitor start

Horsepower .......................................................................................................................................................1/2 HP

Phase ................................................................................................................................................................. single

Voltage ...............................................................................................................................115/230V (prewired 115V)

Cycle ................................................................................................................................................................... 60Hz

Listed FLA (full load amps).................................................................................................................................. 9/4.5

Starting amps ....................................................................................................................................................... 44 A

Running amps (no load) ...................................................................................................................................... 7.2A

Start capacitor .............................................................................................................................. 200 MFD, 125 VAC

Power transfer ........................................................................................................................................................ belt

On/off switch............................................................................................................................................ toggle switch

Motor speed ................................................................................................................................................1725 RPM

Power cord length ................................................................................................................................ 6.4 ft. (195cm)

Power plug installed ............................................................................................................................................... yes

Recommended circuit size

Sound emission ........................................................................................ 70 dB at 40” (1m) from blade, without load

Wet cutting package - coolant pump (optional) .................................................................................. single phase, 120V

1

subject to local/national electrical codes.

Capacities:

90° Cutting (Round)................................................................................................................................... 5” (127mm)

90° Cutting (Rectangle) ................................................................................................. 7-1/2”w x 5”h (190 x 127mm)

90° Cutting (Flat Stock) .......................................................................................................8”w x 1”h (200 x 25.4mm)

45° Cutting (Round)............................................................................................................................. 4-3/4” (120mm)

45° Cutting (Rectangle) ................................................................................................. 4-3/4”w x 5”h (120 x 127mm)

Blade speeds..................................................................................................................................... 85,125,200 SFM

Wet cutting tank (optional)........................................................................................................... 1 gal (4.5L) capacity

Materials:

Table .................................................................................................................................... cast iron, ground surface

Bow ................................................................................................................................................................ cast iron

Stand .................................................................................................................................................................... steel

Blade drive .......................................................... steel, heat-treated worm driving a bronze worm gear in an oil bath

Side blade guides ............. ball bearings mounted on eccentric shafts (bearings sealed and permanently lubricated)

Rear blade guides .......................................................................... ball bearings, sealed and permanently lubricated

Band wheels ...................................................................................................................................... flanged cast iron

Dimensions:

Blade size ............................................................................................................................... 8/12T, 2” x 0.025” x 68”

Blade wheel diameter .......................................................................................................................... 7-3/8” (187mm)

Bed height from floor ......................................................................................................................... 23-1/2” (600mm)

Overall machine dimensions (arm horizontal) ........................................... 38”L x 16”W x 38”H (960 x 400 x 940mm)

Overall machine dimensions (arm vertical) ............................................. 38”L x 16”W x 58”H (960 x 400 x 1450mm)

Net Weight ....................................................................................................................................................134 lb (61kg)

1

................................................................................................................................... 15A

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Walter M eier (Manufacturing) Inc., reserves the ri ght to change speci fications at any time and wi thout

prior notice, without incurring obligations.

7

Page 8

7.0 Set-up and assembly

Read and understand all

assembly instructions before attempting

assembly. Failure to comply may cause serious

injury.

7.1 Un packing and cleanu p

1. Inspect contents for shipping damage. Report

damage, if any , to your distribu tor.

2. Compare contents of shipping carton with the

contents list in this manual. Report shortages,

if any, to your distributor.

7.2 Assemb l ing t he band saw

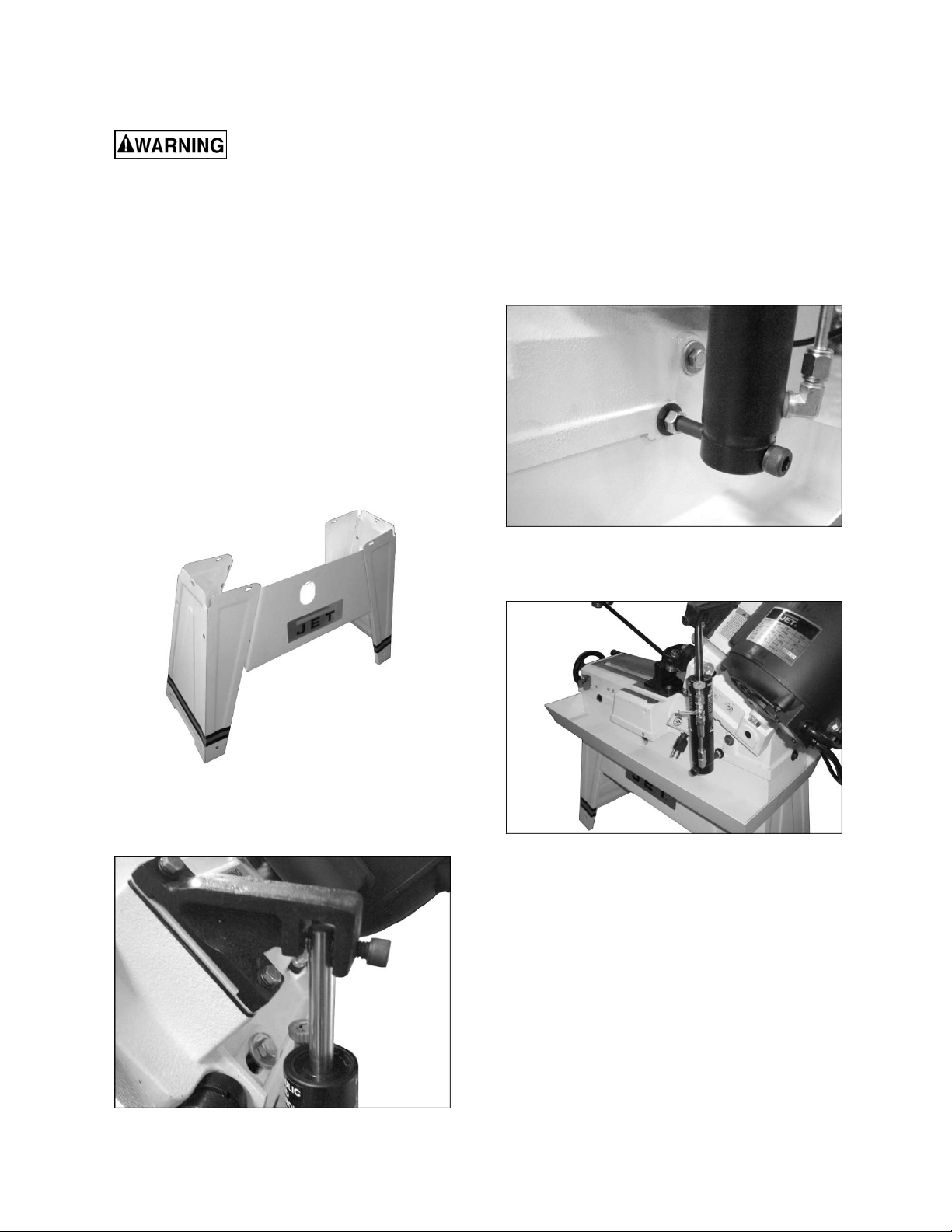

Refer to Figures 2 through 5. If further clarification

is needed, refer to exploded views in se ct.13.

1. I nstall the tray and skirt to the two floor stands

with the provided 5/16-18 x 1-1/4” screws,

washe rs and hex nuts . Finger tighten only.

3. Use an assistant to help lift band saw onto

stand, aligning the holes at the four corners

with the hole s in the s tand. Ma ke sure front of

band saw faces same direction as JET logo on

stand. Install a 5/16 x 1-1/4 hex cap screw with

two flat washers and a hex nut in each of the

holes.

4. Insert a 5/16” x 4” socket head cap screw

through the hydraulic cylinder, and install a

hex nut and washer on the threaded end, as

shown in Figure 4. Insert threaded end into

hole in base ca sting. Do not tighten yet.

Figur e 4

Figur e 2

2. Align holes in bracket and hydraulic cylinder

shaft, and secure with 3/8” x 1-1/4” socket

head cap screw (Figure 3) .

5. Install the trough between table and stand.

See Figur e 5.

Figur e 5

6. Tighten all screws and nuts securing the saw

to the stand, and the screw on the hydraulic

cylinder.

7. Tighten all hex nuts on stand assembly.

8. In stall han dle onto sta nd with cott er pins.

9. Install wheel kit onto stand with 1/4”x1/2”

screws, washers and hex nuts.

Figur e 3

8

Page 9

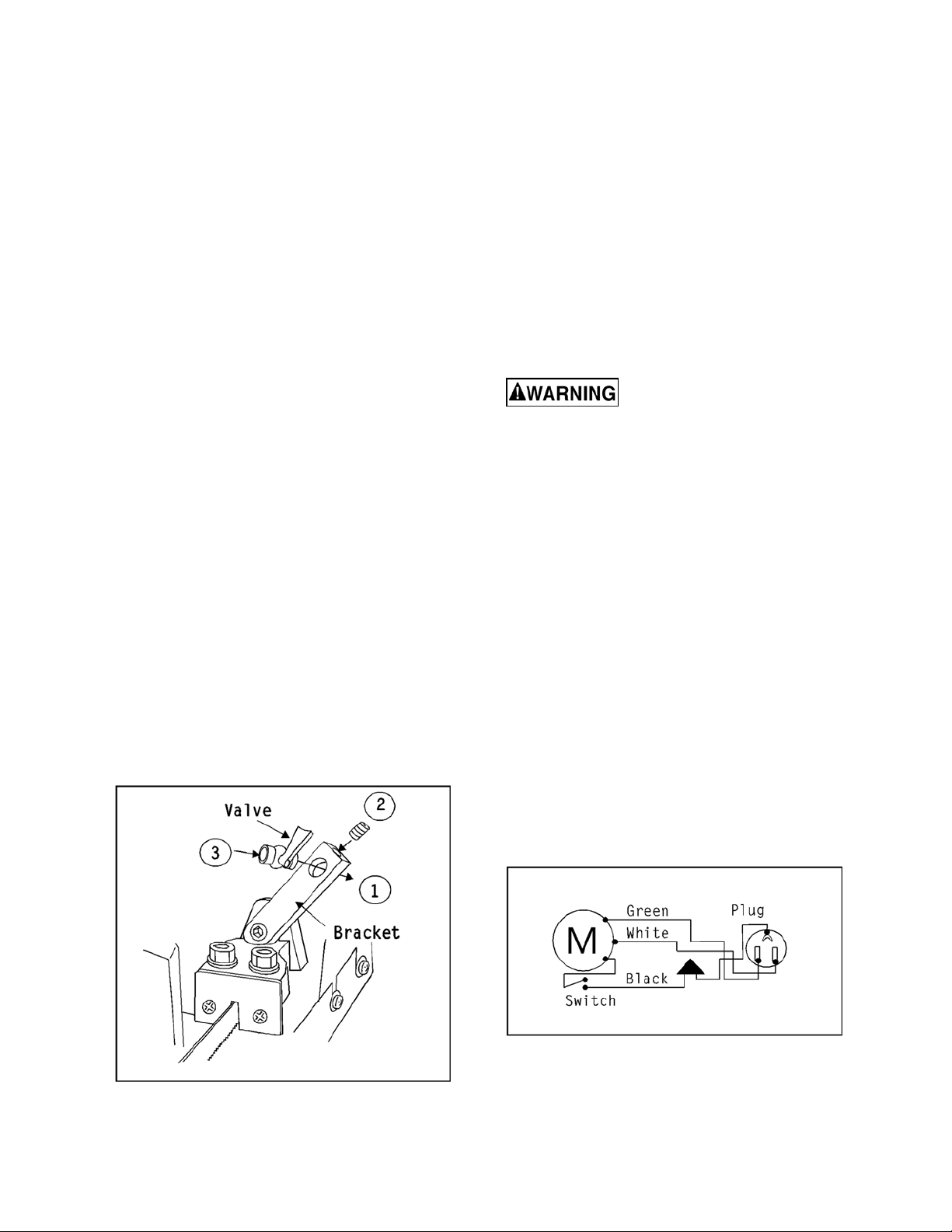

7.3 I nstallin g coolan t kit

Refer sect. 13.4.1 for a complete view of the

components in the coolant kit, and refer to Figu r e 6

for the attachment of the valve to the valve bracket

on the guide bea ring seat.

1. Install the baffle in the tank so the pump is

held at one end.

2. Install the 90 degree elbow and one of the

hose fittings in the bottom of the coolant pump.

7.3.1 Valve connection

Refer to Figure 6

1. Install the valve, back end first, into the

bracket.

2. Secure it with the set screw after being sure

the handle can turn its full 1/4 turn.

3. I nstall the nozzle on the front of the valve, then

install the hose fitting and hose on the back

end of t he valve.

3. Install one end of the coolant hose on the

pump fitting.

4. Put the pump in the ta nk and p ut the ass e m b ly

into the tray underneath the saw base.

Flanges are on the tray to keep the coolant

tank in position.

5. Put the valve into the holder on the right blade

guide assembly and secure it with the set

screw on the holder. Position the valve so the

handle i s easy to operate.

6. In stall the nozzle int o the valve.

7. Install the hose fitting into the valve.

8. Route the hose to the hose fitting on the valve

and install it on the fitting.

9. Fill the tank wit h eno ugh c oolant to flow over

the baffle i n the tank.

10. Put the valve handle in OFF position – at right

angle t o the dir ection of flow thr ough the valve.

11 . I nstall the coolant re t u rn hose and fitt ing t o the

tr ough and route the r eturn hose to the tank.

12. Connect th e pump t o its el ectri cal source.

Note: The pump cable is supplied with a standard

plug for a 120V single phase grounded branch

receptable. Always use a grounded receptable for

this pu rpose.

8.0 Electr ic al co n nect i on s

Plug the saw into a suitable service branch. The

saw is a 120V single phase motor and the motor

cable has a standard 3-prong grounded plug

installed.

Always connect the plug to a

grounded branch ci rcuit .

If local regulations require that the saw be

permanently wired, or if the environment in

which the saw is used makes this advisable,

the connection should only be made by a

licensed electrician who is familiar with all

nati onal and local electrical codes.

The service disconnect should have an external

ON/OFF switch or lever which permits the saw

operator to disconnect branch power to the

saw during set-up and maintenance operations

as describe d in thi s m anual.

8.1 W iring diag ram

The motor standard on the saw is a 120V single

phase, 1750RPM motor which can also be

reconfigured for 240V operation. If the saw will be

used on a 240V single phase branch circuit, the

el ec tric ian will fi nd a di agr am f o r rec o nfi guring the

motor wiring underneath the motor terminal plate.

The wiring diagram here is included for reference

when replaci ng the motor, O N/OFF sw itch or ca ble.

These operations should be performed only by a

li censed electr icia n.

Figur e 6: Inst alling va lve in va lve bracket

Figur e 7: Wiring d iagra m

9

Page 10

9.0 Operating Instructions

9.1 Clamping material s in the vise

Refer to Figure 1.

1. Li ft th e saw arm to it s full up positi on.

2. Lock the arm up using the hydraulic feed

control valve.

NOTE: Use the handle on the arm to lift the

arm. Never use any other part of the arm as a

lifting method.

3. Open the left vise by turning the vise

handwheel counterclock wise.

4. Adjust the vise jaws for the appropriate cutting

angle, if required. See sections on Right angle

cutting and Angle cutting.

5. Put the work piece material between the vise

jaws.

NOTE: If the work piece material is long,

support both the ends of the material as

needed to keep the material level on the saw

base.

6. Turn the vise handwheel clockwise until the

work piece is secu rely cla m ped in the vi se.

7. Proceed to cut according to instructions in

Cutt ing procedur e.

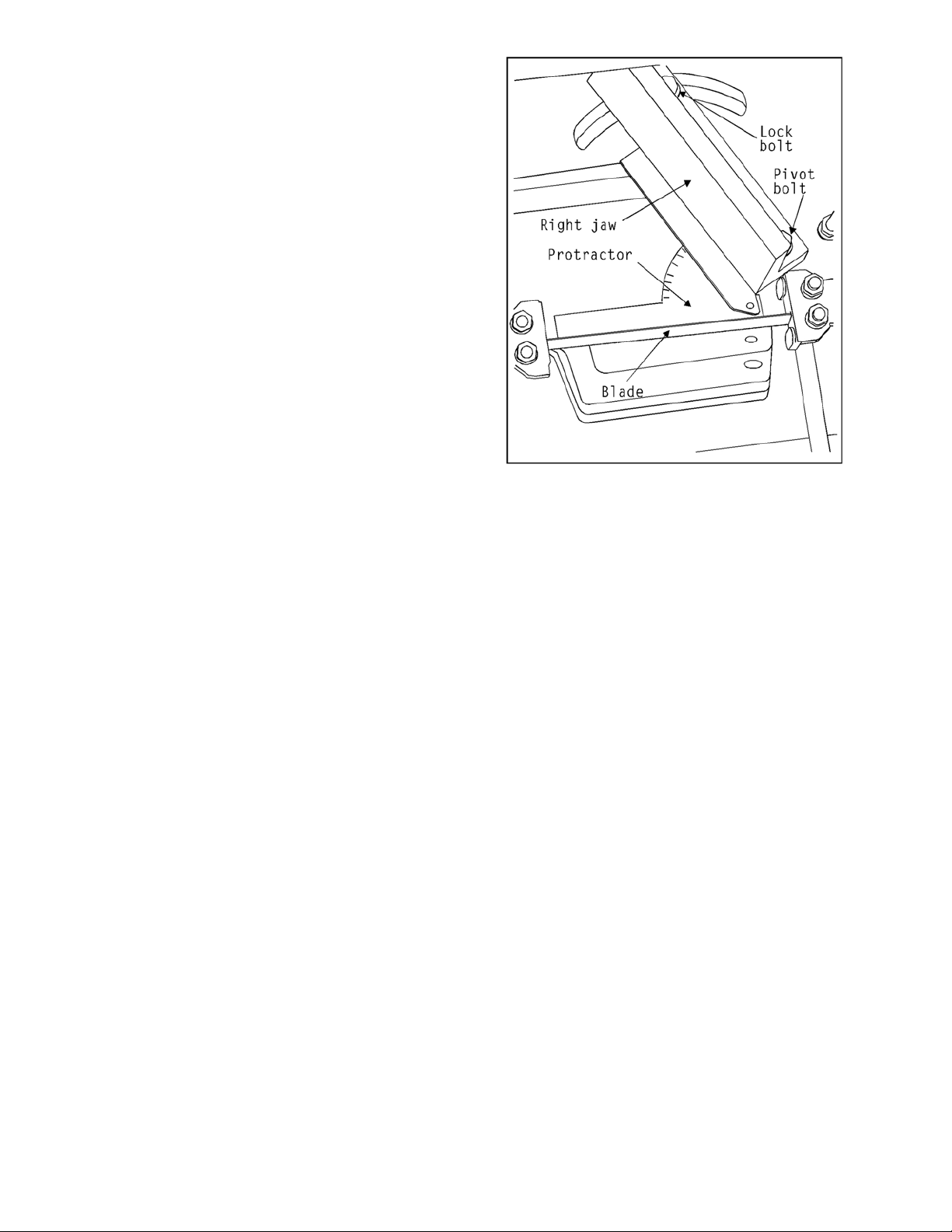

9.2 Right angle cutting

Refer to Figures 1 and 8.

If you want to be certain the workpiece is being

held in the vise at exactly 90 degrees to the blade

for cutoff work, use the following procedure to

check the bla de-to- jaw angle.

1. Disconnect the saw from its electric power

source.

2. W ith the saw arm in its fully lowere d positio n,

place a machinist's square,or a machinist's

protractor 90 degrees, against the saw blade

and rig ht vis e jaw. If the jaw is squa re to the

blade, then no adjustment is required.

3. If adjustment is required, see Angle Cutting.

The procedure for setting the jaw angle with

respect to the blade is described in that

section.

Figur e 8: Using a pr otractor to set the vise jaws at

desir ed angle. By setting the pr otractor to 90

degrees, or using a machinist's sq uare, t he jaws

can also be set square with res pect to t he blade.

4. Lift the saw arm to its full up position and lock

it up using the hy draulic feed control kn ob.

NOTE: Use the handle on the arm to lift the

arm. Never use any other part of the arm as a

lifting method.

5. Loosen t he left jaw lock bol t.

6. Use the handwheel to move the left jaw until it

touches the rig ht jaw firmly.

7. Snug the le ft ja w lock b olt. Bo th vise ja ws are

now the correct angle for the required cut.

NOTE: There is a scale on the back of the saw

tabl e w hi c h allows yo u t o set up f o r angle c u t s

without using a protractor. See Figure 9.

These angles should be considered

approxi m ate, and th e protractor m ethod should

be used where higher accuracy is r equired.

9.3 Angle cutting

Refer to Figure 8.

1. Loosen t he right jaw pivot and l ock bolts.

2. With the arm in its fully lowered position, and

using a machinist's protractor between the saw

blade and right vise jaw, set the angle of the

ri ght jaw to the required an gle.

3. Ti ghten the pivot and lock bolts.

10

Page 11

Figur e 9: Using the s cale on t he rear of t he saw

A

base to set the jaws for an gle sawing. Where t he

edge of the right j aw crosses the scale an

approxi mate angle cut c an be mad e to the

indi cated number of degr ees o n the scale.

9.4 Clamping methods

The method for clamping different cross-section

work pieces is sh own in Figure 10.

3. Slide the stock stop to the required distance

from t he blade.

4. Rotate the stock stop so the stop is at the

lowest possible position for stopping the work

piece at the required distance. T his will he lp

prevent any binding between the work piece

and blade when the cut is completed.

5. Tighten the st ock stop set screw securel y.

6. F or be st accurac y, m ake a tes t c ut o n a piec e

of scrap material to verify the length of cut

using th e stock stop.

Figur e 11: Settin g the stock st op cutoff length

9.6 Blade selecti on

The saw is delivered with a blade adequate for a

variety of jobs on a variety of common materials.

However, JET's blades, while appropriate to many

shop cutt ing needs, don't begin to exhaust th e w ide

variety of special blades available for special

cutting jobs.

For high production cutting of special materials, or

for hard-to-cut materials such as stainless steel,

tool steel, titanium, etc., ask your industrial

distributor for more specific blade

recommendations.

Figur e 10: Clamping methods for var ious crosssections of stock

9.5 Usi ng the st ock stop

When cutting a number of identical pieces, the use

of th e stock stop can speed operation s.

Refer to Figures 1 and 11.

1. Disconnect the saw from its electric power

source.

2. With the arm in its fully lowered position,

loosen t he stock stop set screw.

Material Speed

Steel shapes and low carbon steel

Medium and high carbon steel

Cr-Moly steel

Chromium steel

Tool steel

Cast iron

luminum

Most plastics

Wood

Table 2: Recommended blade speeds

125

85

125

125

85

85

85-125

200

200

9.7 Ch anging bl ade speeds

1. Refer to Table 2 for recommendations on

blade speed for v arious materials.

Note: These are approximate speeds.

Different alloys and section materials and the

use of cutting fluid may require other speeds.

Check your machinists' handbook, or ask for

recommen dations from your blade, cutti ng fluid

or work piece suppliers for specific

recommen dations on speci fic material.

11

Page 12

2. Disconnect the saw from its electrical power

source.

3. With the arm in its fully lowered position,

rem ove the pul ley co ver loc k screw and open

the pulley cover. Refer to Figure 12 for

speeds and belt positions.

If the chips formed are curled but not colored, then

the blade is sharp enough and cutting at an

efficient ra te.

9.9 Cutting procedure

1. Never start a cut with the blade resting on the

work piece.

2. Be certain you knock off the sharp corners of

any work piece material which might damage

the bla de. See Figur e 4.

Figur e 12: Blade speeds and belt posit ions

4. To cha nge the belt position (and, therefore, the

blade speed) first loosen the motor plate

adj us tm ent lo ck nut . Re fer to Figure 13 for the

position of the motor plate adjustment screw

and locknut.

Figur e 13: Motor plate adjustment screw

5. Turn the adjustment screw counterclockwise

until the belt can be mov e to the pulley position

required.

6. Turn the adjustment screw clockwise to

tension the belt until there is 1/2 inch of play in

the belt as show n in Figure 14.

3. Ha ve the moto r ON and run ning at full s pee d

befor e lowering th e blade i nto the cut.

4. Use the hydraulic control valve to feed the

blade in to the work piece.

5. If you use a cutting fluid, turn the valve on

befor e beginning the cut .

9.10 Usi ng the hydrauli c f eed cont rol

Refer to Figure 15.

The hydraulic feed control cylinder is a "single

action" hydraulic cylinder. This allows you to lift

the arm at any time, easily, but controls the

do wnward m ovem ent of the arm us ing a valve on

the top of the cylin der.

Figur e 14: Setting correct pl ay in drive belt

7. Tighten the adj ustment lock nut .

8. Close the pulley cover and secure it shut with

the lock screw.

9. Reestablish electrical power to the saw and

proceed with cutti ng.

9.8 Evaluating cut ting effici ency

Is the b lad e cutting e ff ic ie ntly? T he bes t way to te ll

is by observing the chips formed by the blade as it

cuts.

If the chip formation is powdery, then the feed is

much too ligh t or the blade is t oo dull.

If the chips formed are curled, but straw or blue

color ed, then the feed rate i s too hi gh.

Figur e 15: Hydraul ic feed cont rol

When the control valve is turned fully clockwise the

cylinder is "locked" and the saw arm will not move

do wnw ar d . You can l o c k the ar m , us ing the val ve ,

at any pos itio n i n its tr avel. T h is allo ws yo u to lo c k

the arm in its up position for operations which

require it. And it allows you to lock the arm in

positions which allow you to adjust work piece

length, etc.

Most important, use of the valve allows you to

begin any cuts "gently," which can greatly extend

the life of the blade. Simply open the valve slightly

to begin the cut, then open the valve to effective

cutting feed. See Evaluatin g cuttin g efficiency.

The valve is also important when breaking in any

new blades. See Blade br eak-in pr ocedures.

12

Page 13

9.11 Bl ade break-in procedures

New blades are very sharp, and therefore have a

toot h geometry which is easily damaged if a car eful

break-in procedure is not followed. You may want

to consult manufacturers' literature for break-in of

sp ecif ic b lades on speci f i c m ate r ial s . Ho wever, the

following break-in procedure will be adequate for

break- in of JET supplied blades.

1. Clam p a 2 inch or la rger work pi ece in the saw.

2. Set the blade speed to its required speed.

See Changing blade sp eeds.

3. If possible, use a cutting fluid during break-in

cuts.

4. Set the hydraulic control valve just enough to

begin a ver y light cut on the work pi ece.

5. When the blade has cut 1/3rd of the way

through the work piece, increase the feed rate

slightly and allow the blade to complete the

cut.

6. Make another cut on the stock. Begin the cut

with the c o ntro l valve s e t at the s am e feed rate

yo u fi ni s hed the fi rst cut.

7. 1/3rd of the way through the second cut,

increase the rate of feed until the blade is

cutting at its most efficient rate. See Evaluating

cutting efficiency.

8. Allow the saw to complete this second cut.

The blade can now be considered ready for

regular service.

Note: There are flanges on the back face of the

drive and idler wheels to prevent the blade from

"walking off" the back of the wheels. If these

fla nges are damaged the wh eels must be replaced.

Check blade tracking whenever changing a blade

to be certain the blade is positioned correctly on

the wheels. See Bl ade tracking in the Maintenance

secti on of thi s m anua l

9.12 Changing blades

1. Disconnect the saw from its electric power

source.

2. Lift the saw arm to its full up position and lock

it up using the hy draulic feed control kn ob.

6. Examine the drive and idler wheels for

evidence of wear on the flanges. If the flanges

are wearing, the blade is misadjusted. See

Blade t racking for correcting this condition.

7. Put a replacement blade in the blade guide

bearings and loop the ends of the blade over

the drive and idler wh eels.

NOTE: The saw blade teeth must point in the

dir ection of travel. See Figure 16.

8. Use the blade tension knob to put tension on

the bla de until it no l onger slips on the wheels.

NOTE: Do not overtighten the blade. Just

increase tension until the blade does not slip

on the wheels.

9. Close the blade guard cover and replace and

ti ghten the th umb scr ew.

10. Reconnect the saw to its electrical power

source.

Figure 16: Corrrect tooth direction when replacing

blade.

9.13 Ad j ustin g b lade guides

Refer to Figure 1.

Both the left and right blade guides should be

positioned as close as possible to the left and right

edges of any work piece being cut. This provides

support t o the bl ade so it can make a strai ght cut.

1. Loosen the bl ade gu ide knobs.

2. Slide t he blade guides to the correct spaci ng.

3. Tighten the lock knobs securely.

10.0 Maintenance

NOTE: The following maintenance operation

requi res the servi ces of a licen sed electri cian.

NOTE: Use the handle on the arm to lift the

arm. Ne ver us e any ot he r part o f t he arm as a

lifting method.

3. Remove the blade guard cover thumb screw

and open the cover.

4. Loosen the blade tension knob until the blade

come s off of its wheels.

5. Using leather gloves to protect from cuts, slip

the blade out of the blade guide bearings and

off o f the saw.

10.1 Motor replacement

1. Perform steps 2 through 5 in Changing blade

speeds, sect. 9. 7.

2. Remove t he drive belt.

3. Remove the set screw which retains the motor

drive pulley to the motor shaft.

4. Pull the pulley off o f the motor dr ive shaft .

5. BEING CERTAIN THAT THE SAW HAS BEEN

SAFELY DISCONNECTED FROM THE

SERVICE BRANCH, open the motor terminal

13

Page 14

cover and remove the three wires which

connect i t to th e power cable.

6. Remove the four nuts, bolts and washers

which hold the motor to its mounting plate.

7. Remove the motor from the saw.

8. Reinstall the replacement motor and pulley by

reversing steps 7 thr ough 4, above.

9. Loosen the motor mounting plate adjustment

screw so the screw puts no tension on the

plate.

10. Adjust the position of the motor so th at:

A. t he pu lleys a re parallel with ea ch other, and

B. the drive belt can just be installed over the

pulleys (It may be necessary to adjust the

drive pulley along the motor shaft to make

the pul leys par allel.)

11. Tighten the motor mounting bolts securely.

12. Tighten the pull ey set screw securel y.

13. In stall the drive belt.

14. Tension the drive belt and complete the

replacement task by performing instructions 6

throu gh 9 in Changing bla de speeds.

10.2 Ad j ustin g g ui de bearings

The outside guide bearing on each of the bearing

seats is mounted on an eccentric shaft to allow

adjustment of the bearing clearance between

bearin gs an d blade, as follows:

4. Remove the thumb screw and open the blade

guard cover. Prop it open so you can have

access to the idler wheel.

5. Refer to Figure 17. Use a wrench to loosen

bolt A, a small amount.

Figur e 17: Blade t racking mechanism

6. Turn the saw motor ON.

7. I nsert a hex wrench into the set screw, B, and

turn it slightly while observing the tracking

action of the blade on the idler wheel. Turning

the hex wrench clockwise will make the blade

track toward the wheel flange. Turning the

wrench counterclockwise will make the blade

tr ack away from the flange.

8. Adjust the set screw in very small amounts

until the blade just starts to track toward the

flange.

9. As you adjust the blade toward the flange,

insert a strip of paper between the blade and

wheel as shown in Figure 18.

1. Loosen the guide bearing shaft l ock nut.

2. Use an open end wrench on the hex flats

underneath the guide seat to adjust the

eccentric shaft so the bearing holds the blade

vertically against its opposing bearing. Overtightening the blade between the bearings will

only shorten bearing life. Adjust the bearings

so blade is just held firmly in vertical position.

3. While holding the shaft from turning, tighten

the lock nut on the upper side of the bearing

seat.

10.3 Bl ad e t racking

1. If the blade is fully tensioned, release tension

slightly while performing the tracking

operation.

2. If the blade is not on slow speed, change to

the slowest speed according to instructions in

Changing blade s peeds.

3. Lift the saw arm to its full up position and lock

it using the hydraulic feed control knob.

NOTE: Use the handle on the arm to lift the

arm. Ne ver us e any ot he r part o f t he arm as a

lifting method.

Use a strip of paper six

inches long or longer so your hands stay

clear of the m oving parts of the saw.

Figur e 18: Checking bla de trac king

10. Keep using small amounts of adjustment to

move the blade toward the flange, testing with

the paper strips, until the paper is cut between

the bla de and flange.

11. When the paper is cut, turn the hex wrench

slightly in the opposite direction so the blade

does not t rack w hil e touching the flange.

12. Tighten bolt A.

14

Page 15

13. Check with a paper strip to be certain the

blade has not moved back into contact with the

flange. Readjust, if necessary.

14. Using the blade tension knob, reapply tension

to t he blade so it does not slip on the wheels.

15. Turn the saw OFF.

16. Close the blade guard cover and install and

ti ghten the th umb scr ew.

10.6 Ad j ustin g the arm stop

adjustment bolt

Refer to Figure 1.

1. Lower the arm to its fully lowered position.

The saw blade should be level and the cutting

edge of the blade should be in the relief slot,

below the leve l surf ace of the s aw base . If this

is not the case, adjust the arm height as

follows:

10.4 Rep lacing guide b earings

1. Remove the blade according to instructions 1

throu gh 5 in Changing bla d es, sect. 9.12.

2. Remo ve t he snap ri ng wh i c h ho l d s the b e ar ing

to the shaft.

3. Press off th e bearing.

4. Press on the new bearing and secure it with

the snap ring.

5. Reinstall the blade according to instructions 6

throu gh 10 in Chang ing blad es.

6. Adjust the bearing spacing according to

instructions in Adjusting gu ide be ari ngs.

10.5 Ad j ustin g b ack- up bearings

Refer to Figure 19.

1. Disconnect the saw from its electrical power

source.

2. Loosen the guide bearing seat reta ining bolt.

3. Slide the bearing seat as necessary until the

back-up bearing just touches the back edge of

the saw blade.

2. Loosen the leveling bolt lock nut.

3. Adjust the leveling bolt until it supports the arm

and blade correctly as described above -- level

and below the t op of the saw base.

4. Tighten t he levelin g bolt lock nut.

10.7 Ad j ustin g mo t or swit ch actuator

This task should be performed whenever the arm

stop adjustment is corrected or whenever the saw

is turning off incorrectly.

Refer to Figure 1.

1. Rai s e the ar m unti l the switc h ac t u ator is not in

contact with the switch.

2. Turn the switch ON.

3. Open the hydraulic control valve so the arm

moves slowly downward.

4. The motor switch should shut off just as the

arm contacts its horizontal stop bolt and the

blade is fully below the blade relief in the saw

base. If the motor shuts off too soon, or not at

all, adj us t t he swit c h act u ator by bendi ng i t , as

required, to correct the faul t condit ion.

4. Tighten t he guide beari ng seat reta ining bolt.

5. Restore elect rical power to the saw.

Figur e 19: Adjusting ba ck-up beari ngs

11.8 Rep lacing a back up beari ng

1. Remove the blade according to instructions 1

throu gh 5 in sect. 9.12.

2. Remove the guide bearing assembly from the

saw arm by removing the guide lock knob and

sli ding the assembly from the arm.

3. Use a drift to knock out the pin until until the

bearin g can be rem oved.

4. Replace the bearing and press the shaft back

into the se at .

5. Reinstall the bearing assembly i n the arm.

6. Reinstall the blade according to instructions 6

throu gh 9 in sect. 9.12.

7. Adjust the back-up bearing spacing according

to instructions in Adjusting back up bearing

clearance.

11.9 Ad j ustin g the bearing guide

seats fo r blade vertical

1. I nstall a new blade according to instructions in

sect. 9.12.

15

Page 16

2. Adjust the guide bearings according to

instructions in sect. 10.2, Adjusting guide

bearings.

1. With the bar stock securely clamped in the

vise, make a cut through the bar stock. (See

Figur e 21.)

3. Adjust the back-up bearing according to

instructions in sect. 10.5, Adjusting back-up

bearings.

4. With the arm in its full horizontal position and

the blade guides moved apart to clear the

widest possible cutting area, clip a scale to the

blade, to provide a vertical reference surfa ce.

5. Place a machinist's square on the saw base,

against the scale. See Figure 20.

Figur e 20: Adjust ing the saw bla de for vert ical. Be

sure t o do this oper ation on both of the bearing

guide seat s so the blade is per fectly vertical along

its entire exposed cutting surface.

2. Mar k the top of the bar stock.

3. Move the bar stock about 1/4 inch past the

blade so you can begin a second cu t.

4. Rotate the bar stock 180 degrees so the mark

you made is now at the bot tom of the cut .

5. Make a cut through the bar st ock.

6. Use a micrometer to measure the thickness

variation between the top and bottom of the

disc you have cut from the bar stock. Unless

things are truly perfectly aligned, there is

almost certain to be a certain amount of

"wedge" to the shape of the disc you have cut.

The saw blade can be considered correctly

adjusted when the variation measured is no

more than .012 inch across the face of the

If you do not have a 2 inch bar stock

disc.

available for a t es t cut, use a larger diameter

test work piece rather than a smaller one.

The maximum thickness variation on any

test piece should be no more than .003

inches, per side, per inch of stock diameter.

6. Loosen the guide bearing seat attachment bolt

slightly and, using a wrench on the bearing

se at, ad jus t the ang le of the seat so the bl ade

is vertical. (There is a small amount of side

relief between the seat and guide bar to allow

for this adjustment.)

7. Tighten t he sea t atta chment bolt.

8. Move the scale and square to the other side of

the exposed blade and repeat steps 4, 5, 6

and 7, above.

10.10 T est cuttin g to verify

adj ustment accu racy

Test cuts can be used to determine whether or not

you have adjusted the blade accurately. Use 2

inch bar stock to perform these test cuts, as

follows:

Figur e 21: Making a test d isc.

16

Page 17

11.0 Ma intenanc e Chart

A

A

Item Action Interval Comments

Wheel, guide or back-up

bearings

Lead screw Wipe on lubricant Weekly Gear oil* (see note, below)

Drive belt Inspect and replace when

Gearbox Inspect for leakage – repair

Drive and idler wheels Inspect flange and blade

Hydraulic cylinder assembly Clean control rod with a

Table 3

* Note: Gearbox and lead screw lubrication: Lubricate the vise lead screw and gearbox with Shell Omala S1W

or i ts equival ent.

Inspect for leakage Daily

When changing blade

glazed or worn

if leaking

Replace lubricant

surfaces

clean rag

speeds

Daily

nnually Gear oil*(see note, below)

When changing blades Replace wheels if flanges

Daily Dirt on the control rod can

ll bearings are sealed –

any leaking bearing must

be replaced.

are worn

damage the seal and cause

leakage -- resulting in

replacement of the cylinder

assembly, complete

The g earbo x gears run in an oil b ath and will not require lubric ant cha nge m ore than o nce a ye ar u nle ss the

lubricant is accidentally contaminated or leakage occurs due to improper replacement of the gearbox cover or

gaske t. D uri ng the f irs t f e w d ays of o peratio n the d ri ve g e ars will r un hot. Unless the te m p e rature e xce e ds 20 0

degrees F., there is n o cau se for concern.

17

Page 18

12.0 Troubleshooting the J-3130 and J-3230

A

A

Table 4

Symptom Possible Cause Correction

Excessive blade

breakage.

Material loose in the vise. Use more pressure to tighten vise.

Check right jaw pivot and lock bolts for

tightness.

Check left jaw pivot bolt for looseness -- be

certain the jaw is not tilting upward when you

apply pressure to the work in the vise.

If you are stacking multiple pieces in the vise,

be sure all of the pieces are captured by the

vise pressure.

Incorrect feed or speed. Check technical literature for recommended

feeds and speeds for the material and blade

you are using.

Check chip formation to adjust speed and feed

to correct rate when sawing.

Incorrect blade tension.

Teeth in contact with work before saw is

started.

Blade rubs on wheel flange. Use paper cutting method of adjusting blade

Misadjusted blade guides.

djust blade tension to where it just does not

slip on the wheel.

Be sure the saw motor has co me fully up to

speed before beginning a cut and be sure the

blade is not resting on the work piece before

the motor has come up to full speed.

tracking. See Blade Tracking .

Check drive and idler wheels for looseness in

mounting parts or worn/damaged bearings.

djust blade guides.

Premature blade

dulling.

Blade too thick for wheel diameter Use a thinner blade. Check with your blade

Cracking at weld Replace blade.

Teeth too coarse. Use finer tooth blade.

Blade speed too high. Try next lower speed or check technical

Inadequate feed pressure. Increase pressure while observing chip

Hard spot or scale on material. Reduce speed of blade.

Work hardening of material (especially

stainless steel).

Blade installed backwards. Reinstall blade so teeth point toward right end

supplier for recommendations on blade

thickness for a specific wheel diameter.

literature for specific recommendations

regarding speeds for specific blade and

material being cut.

Check with materials supplier for

recommendations on the work piece material

supplied.

If using coolant, check with supplier regarding

correct coolant for the job.

formation to be sure you are cutting efficiently.

Increase feed pressure in scale or hard spots.

Work hardening materials such as stainless

require a heavy, continuous cut. Be sure you

are using a sharp blade, then, if necessary,

release some counterbalance spring pressure

by loosening the tension nut if work hardening

of the material is a problem.

of saw.

18

Page 19

Symptom Possible Cause Correction

A

A

Premature blade

dulling. (cont.)

Crooked cuts. Work not square.

Incorrect coolant or no coolant. Check with materials supplier and/or blade

Insufficient blade tension. Increase tension so blade is above the slipping

Feed pressure too great. Observe chip formation to be sure cutting is

Guide bearings not adjusted properly.

Inadequate blade tension. Increase blade tension so blade does not slip

Blade guides incorrectly spaced. Move guide brackets until they just clear the

Dull blade. Replace blade when it dulls.

supplier for coolant recommendations.

Check with coolant supplier for specific

recommendations on the blade and material

you are using.

point.

djust the right vise jaw so it is at right angles

to the blade.

Clamp work tightly in the vise.

Check blade for vertical and adjust, if

necessary.

Move guide bearings as close as possible to

work while still completing the cut.

Check guide bearings, seats and brackets for

possible looseness or wear.

efficient.

djust guide bearings according to instructions

in this manual.

on the wheels.

work piece while making a complete cut.

For small section pieces, be sure the blade is

sharp and correctly tensioned. Use less feed

pressure.

Consider using a coolant, if not already used.

Incorrect speed. Check technical literature for recommended

Blade guide assembly loose. Tighten guide bracket.

Blade guide bearing assembly loose. Check tightness of bearing seat bolt.

Blade tracking too far away from wheel

flanges.

Worn upper wheel bearings. Replace bearings if worn.

Loose upper wheel mounting assembly. Tighten all bolts securing wheel to arm.

Rough cuts. Too much feed or speed. Try one step lower speed and observe chip

Blade too coarse. Use finer blade. Check with suppliers for

Incorrect blade for material. Check with blade suppliers for

Blade twisting.

Cut is binding blade. Be sure work piece is flat on saw base.

Too much blade tension. Reduce tension to just above point where

Loose guide bearing eccentrics. Check eccentric jam nuts for tightness.

Worn guide bearings. Check guide bearings for wear. Replace if

speeds and blade type for material being cut –

observe chip formation to verify efficient

cutting.

Use paper cutting method of setting blade

tracking.

formation for efficient cutting/feed rate.

recommendations for the material you are

cutting.

recommendations for exotic or unusual

materials or specifications.

Decrease feed pressure.

blade slips.

necessary.

19

Page 20

Symptom Possible Cause Correction

A

A

A

Blade twisting. (cont.)

Unusual wear on

side/back of blade.

Breaking teeth. Teeth too coarse for work. Use blade with finer pitch.

Motor running too hot. Blade tension too high. Decrease blade tension to just above slip

Incorrect guide bearing adjustment

Loose guide bearing bracket Tighten bracket on saw arm.

Loose bearing seat attachment screw Tighten bearing seat attachment screw –

Blade guides worn. Replace.

Blade guide bearings not adjusted

properly.

Blade guide bearing bracket loose. Tighten bracket to saw arm.

Blade running on wheel flange.

Too heavy feed. Decrease feed rate – observe chip formation to

Too slow speed. Increase blade speed. Check technical

Vibrating work piece. Be sure vise is tight.

Tooth gullets loading Use coarser blade or one with a tooth

Blade in contact with work piece before

motor is started.

Worn transmission and worm gear. Replace gears in transmission gearbox.

Gears need lubrication. Check gearbox and add oil as required.

djust guide bearings according to instructions

in this manual.

adjust bearing clearance.

Check and adjust for proper clearance.

djust blade tracking using the paper cutting

method.

verify efficient cutting.

literature or blade or work piece supplier for

blade speed recommendations.

Support slender cross section or long work

pieces with appropriate in feed and out feed

supports.

If stacking pieces in the vise, be sure all work

pieces are securely captured by the vise.

geometry more appropriate to the work piece

being cut.

lways allow motor to co me fully up to speed

before beginning cut.

point.

20

Page 21

13.0 Repla cement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1800-274-6848 Monday through Friday (see our website for business hours, www.waltermeier.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to se rve you quickly

and accurat e ly.

21

Page 22

13.1.1 Lower S aw Head – Exp loded View

22

Page 23

13.1.2 Lower S aw Head – Parts List

Index No Part No Descript ion Size Qty

01................5631421 ...................... Hex head Screw ...............................................1/4"-20x3/4" .............................. 4

02................5631431 ...................... Hex nut ..............................................................1/4"-20 ...................................... 4

03................5630221 ...................... Washer ..............................................................1/4"x5/8xt1.5mm ...................... 3

04................5631451 ...................... Washer .............................................................5/16"x23xt2............................... 8

05................56 30 061 ...................... Hex nut .............................................................5 /1 6 " -18 .................................... 1

06................5631161 ...................... Motor cable .......................................................................................................... 1

07................56 30 471 ...................... Hex head sc rew ...............................................5/1 6 " -18x1 -1 /4 "L ...................... 1

08................5630301 ...................... Washer .............................................................3/8"x27xt3 ................................. 1

09................5631481 ...................... HH screw ...........................................................5/16"-18x3/4"L .......................... 2

10................5630461 ...................... Washer ..............................................................5/16"x23xt3............................... 2

11................5630661 ...................... Wheel bearing Cover........................................................................................... 1

12................5630671 ...................... Key.....................................................................5x5x25mm ................................ 2

13................5632011 ...................... Motor key...........................................................5x5x30mm ................................ 1

14................5632021 ...................... Hex head screw ................................................1/4"-20x1/2"L ............................ 9

15................5630701 ...................... Switch activator bracket ...................................................................................... 1

16................5630731 ...................... Blade tension adjustment knob .......................3/8"-16UNCx94mmL................ 1

17................5630741 ...................... Spring ................................................................................................................... 1

18................J-5630751................... Head casting ........................................................................................................ 1

19................5630681 ...................... Set screw...........................................................M8-P1.25x8L ............................ 1

20................563077A ..................... Hex head screw ................................................3/8"-16x1-1/4"L ........................ 2

21................563078A ..................... Motor mounting plate........................................................................................... 1

22................J-5630791................... Motor .................................................................1/2HP,1PH,,115V..................... 1

23................5630811 ...................... Motor pulley.......................................................................................................... 1

24................5630821 ...................... Ball bearing ......................................................6202Z ........................................ 2

25................5633121 ...................... Transmission gear shaft...................................................................................... 1

25-1 ............5521940 ...................... Transmission Wheel Shaft .................................................................................. 1

25-2 ............5521941 ...................... Transmission Gear .............................................................................................. 1

25-3 ............5521942 ...................... Pin ......................................................................4x22mmL .................................. 1

25-4 ............5630821 ...................... Ball Bearing .......................................................6202ZZ...................................... 2

25-5 ............5521943 ...................... Bushing ................................................................................................................ 1

25-6 ............5630941 ...................... Oil Seal ..............................................................TC15x35x7 ............................... 1

27................5630871 ...................... Gearbox gasket ................................................................................................... 1

28................5630881 ...................... Gearbox cover ..................................................................................................... 1

29................5630921 ...................... Worm gear & shaft assy...................................................................................... 1

31................5630911 ...................... Bearing bushing ................................................................................................... 1

32................563093A ..................... Belt tension adj. screw ....................................5/16"-18x1-1/2"L ...................... 1

33................5630941 ...................... Oil Seal ..............................................................TC15x35x7 ............................... 1

34................5632031 ...................... RH Phillips screw.............................................. 5/32"-32x3/8"L......................... 3

35................5630961 ...................... Worm gear pulley ................................................................................................ 1

36................5630971 ...................... Blade tension guide block ................................................................................... 1

37................5630981 ...................... Set Screw ..........................................................M8-P1.25x15mmL .................. 1

38................5630991 ...................... Spiral pin ..........................................................4x20L ........................................ 1

39................5631001 ...................... Sliding plate draw block ...................................................................................... 1

40................5631011 ...................... Blade wh eel shaft ............................................................ .................................... 1

41................5631021 ...................... Tension block ....................................................................................................... 1

42................5631031 ...................... Guide block holder............................................................................................... 2

43................5631041 ...................... Guard plate .......................................................................................................... 1

44................5631051 ...................... Pulley guard ......................................................................................................... 1

45................5631061 ...................... V-Belt .................................................................4L230 ........................................ 1

46................5631151 ...................... Lock washer .....................................................1/4" ............................................ 1

47................5631311 ...................... Vent plug .............................................................................................................. 1

48................5632081 ...................... Rubber plug ......................................................................................................... 1

49................5521944 ...................... Cylinder Upper Bra cket ....................................................................................... 1

50................TS-2248162................ Socket HD button screw ..................................M8X16....................................... 2

50................55 21 951 ...................... Hex head sc rew ...............................................5/1 6 " -18x7 /8 "L .......................... 2

51................TS-1550061................ Flat Washer .......................................................M8 ............................................. 2

51................5521952 ...................... Lock Washer .....................................................5/16" .......................................... 2

52................5632021 ...................... Hex head screw ...............................................1/4"-20x1/2"L ............................ 2

53................5521945 ...................... Tension guard ...................................................................................................... 1

23

Page 24

13.2.1 Upper Saw Head – Exploded View

24

Page 25

13.2.2 Upper Saw Head – Parts List

Index No Part No Descript ion Size Qt y

01................5630221 ...................... Washer ................................................................ 1/4"x16xt1.5 .......................... 1

02................56 30 051 ...................... Hex head sc rew .................................................. 5/16" -18 x1-1/4"L .................. 2

03................5630301 ...................... Washer ................................................................ 3/8"x27xt3 ............................. 3

04................5631471 ...................... RH Phillips screw................................................. 3/16"-24x3/8"L ...................... 4

05................5631481 ...................... Hex head screw ................................................... 5/16"-18x3/4"L ...................... 3

06................5630461 ...................... Washer ................................................................. 5/16"x23xt3 ........................... 1

07................563051A ..................... Top guide bar ....................................................... ............................................... 1

08................5630521 ...................... Knob ..................................................................... ............................................... 1