Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

4-ft. Radial Arm Drill Press

Models J-1 23 0R , J- 123 0R - 4

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-320036

Ph.: 800-274-6848 Revision C1 05/2014

www.jettools.com Copyright © 2014 JET

1

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of Contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of Contents ........................................................................................................................................... 3

3.0 Safety ............................................................................................................................................................. 5

3.1 Machinery General Safety Warnings .......................................................................................................... 5

3.2 General Electrical Cautions ........................................................................................................................ 6

3.3 Safety Instructions for Drill Presses ........................................................................................................... 6

4.0 Specifications ................................................................................................................................................. 7

4.1 Machining Capacities ................................................................................................................................. 7

4.2 Machine Environment ................................................................................................................................. 8

4.3 Power Supply Requirements ...................................................................................................................... 8

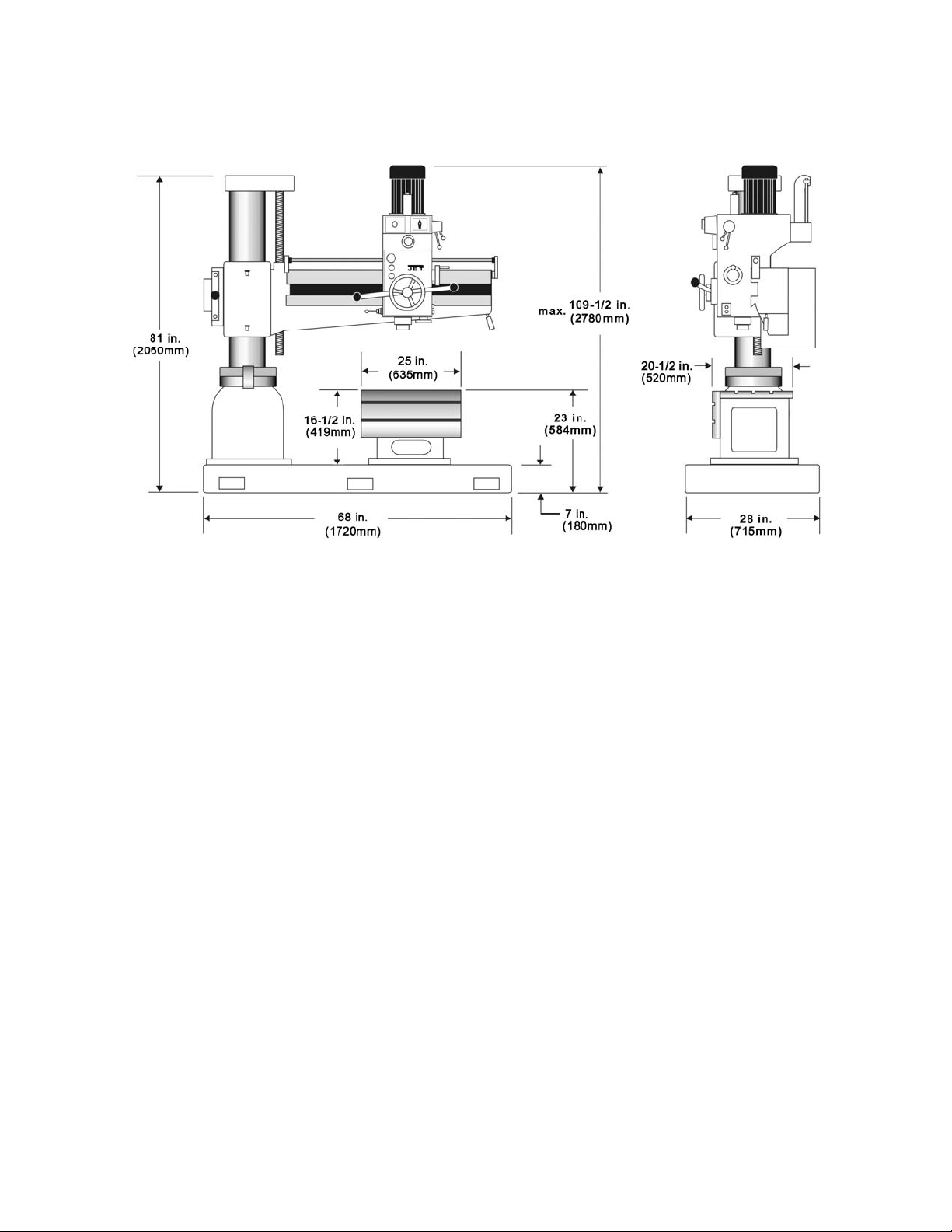

4.4 Overall Dimensions, J-1230R ..................................................................................................................... 9

5.0 General Features and Terminology ............................................................................................................. 10

6.0 Set-Up and Assembly .................................................................................................................................. 12

6.1 Floor Diagrams for J-1230R ..................................................................................................................... 12

6.2 Unpacking ................................................................................................................................................ 13

6.3 Machine Set-Up ........................................................................................................................................ 14

6.4 Electrical Connections .............................................................................................................................. 15

7.0 Operating Controls ....................................................................................................................................... 16

8.0 Operation ..................................................................................................................................................... 17

8.1 Clamping workpieces ............................................................................................................................... 17

8.2 Tool insertion ............................................................................................................................................ 17

8.3 Tool Positioning over workpiece ............................................................................................................... 17

8.4 Unlocking arm and column mechanisms .................................................................................................. 18

8.5 Raising and lowering radial arm ............................................................................................................... 18

8.6 Moving drill head along arm ..................................................................................................................... 18

8.7 Rotating arm on support column .............................................................................................................. 18

8.8 Setting spindle speed ............................................................................................................................... 18

8.9 Feed rate and depth of cut ....................................................................................................................... 19

8.10 Setting feed rate ..................................................................................................................................... 19

8.11 Setting depth of cut using power feed system ........................................................................................ 20

8.12 Spindle direction and power feed ........................................................................................................... 20

8.13 Hand feed – roughing operations ........................................................................................................... 20

8.14 Fine hand feed using power feed system ............................................................................................... 20

8.15 Tapping .................................................................................................................................................. 21

8.16 Power ON/OFF ....................................................................................................................................... 21

8.17 Power ON light ....................................................................................................................................... 21

8.18 Coolant control ....................................................................................................................................... 21

8.19 Spindle motor controls ............................................................................................................................ 21

8.20 Turning off spindle drive ......................................................................................................................... 21

8.21 Resetting STOP swi tch .......................................................................................................................... 21

8.22 Using load ammeter ............................................................................................................................... 21

8.23 Tapping operations ................................................................................................................................. 21

8.24 Arm/spindle control lever ........................................................................................................................ 22

9.0 Adjustments ................................................................................................................................................. 22

9.1 Clamping Device ...................................................................................................................................... 22

9.2 Head/Rail Backlash .................................................................................................................................. 22

10.0 Spindle Speed Chart .................................................................................................................................. 24

11.0 Troubleshooting the J-1230R ..................................................................................................................... 25

12.0 Maintenance ............................................................................................................................................... 26

12.1 General Cleaning ................................................................................................................................... 26

12.2 Lubrication .............................................................................................................................................. 26

13.0 Replacement Parts ..................................................................................................................................... 28

13.1.1 Riser Mechanism: Exploded View ....................................................................................................... 28

13.1.2 Riser Mechanism: Parts List ................................................................................................................ 29

13.2.1 Column and Base: Exploded View ...................................................................................................... 30

13.2.2 Column and Base: Parts List ............................................................................................................... 31

13.3.1 Arm (Front): Exploded View ................................................................................................................ 32

13.3.2 Arm (Front): Parts List ......................................................................................................................... 33

13.4.1 Arm (Rear) and Clamping Gearbox: Exploded View ........................................................................... 34

3

Page 4

13.4.2 Arm (Rear) and Clamping Gearbox: Parts List .................................................................................... 35

13.5.1 Coolant System: Exploded View ......................................................................................................... 37

13.5.2 Coolant System: Parts List .................................................................................................................. 37

13.6.1 Gearbox Assembly (Head): Exploded View ........................................................................................ 38

13.6.2 Gearbox Assembly (Head): Parts List ................................................................................................. 39

13.7.1 Rear of Head: Exploded View ............................................................................................................. 42

13.7.2 Rear of Head: Parts List ...................................................................................................................... 43

13.8.1 Counterweight Assembly: Exploded View ........................................................................................... 44

13.8.2 Counterweight Assembly: Parts List .................................................................................................... 44

14.0 Electrical Connections for J-1230R ............................................................................................................ 45

14.1 Electrical Connections for J-1230R: Parts List ....................................................................................... 46

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result i n minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious or even fatal

injury.

4

Page 5

3.0 Safety

- Misuse of this machine can cause serious

injury.

- For safety, machine must be set up, used and

serviced pr operl y .

- Read, understand and f oll ow instruct ions i n the

operator’s and parts manual which was

shipped with your machine.

When setting up machine:

- Always avoi d using machine in dam p or poorly

lighted work areas.

- Always be sure machi ne is securely anchored

to the floor.

- Always keep machine guar ds i n plac e.

- Always put start switch in “OFF” position before

plugging in machine.

When usin g ma chine:

-Never operate with machine guards missing.

-Always wear safety glasses with side shields

(See ANSI Z87.1)

-Never wear loose clothing or jewelry.

-Never overreach — you may slip and fall into

the machine.

3.1 Machinery General Safety Warnings

1. Always wear protective eye wear when

operating machinery. Eye wear shall be impact

resistant, protective safety glasses with side

shields which comply with ANSI Z87.1

specifications. Use of eye wear which does not

comply with ANSI Z87.1 specifications could

result in severe injury from breakage of eye

protection.

2. Wear proper apparel. No loose clothing or

jew elry w hic h ca n get c aug ht i n mov ing p art s.

Contain long hair. Rubber soled footwear is

recommended for best footing.

3. Do not overreach. Failure to maintain proper

working position can cause you to fall into the

machine or cause your clothing to get ca ught

— pulling you into the machine.

4. Keep guards in place and in proper working

order. Do not operate the machine wit h guards

removed.

5. Avoid dangerous working environments. Do

not use stationary machine tools in wet or

damp locations, or in an explosive

environment. Keep work areas clean and wel l

lit. Special electrics should be used when

working on flammable materials.

6. Avoid accidental starts by being sure the start

switch is “OFF” before plugging in the

machine.

7. Machinery must be anchored to the floor.

8. Never leave the machine running while

unattended. Machine shall be shut off

whenever it is not in operation.

-Never leave machine running while you are

away from it.

-Always shut off the mac hine when not in use.

When servicing machin e:

-Always unplug machine from electrical power

while servicing.

-Always follow instructions in operator’s and

parts manual when changing accessory tools

or parts.

-Never modify the machine without consulting

JET.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly,

JET machinery is among the best in design and

safety. However, any machine used improperly can

be rendered inefficient and unsafe. It is mandatory

that those who use our products be properly

trained in how to use them correctly. They should

read and understand the Operating Instructions

and Parts Manual as well as all labels affixed to the

machine. Failure to follow all of these warnings can

cause serious injuries.

9. Disconnect electrical power before servicing.

Whenever changing accessories or general

maintenance is done on the machine,

electrical power to the machine must be

disconnected before work is done.

10. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and

the changing of accessories. No attempt shall

be made to modify or have makeshift repairs

done to the machine. This not only voids the

warranty but also renders the machine unsafe.

11. Secure work. Use clamps or a vise to hold

work, when practical. It is safer than using y our

hands and it frees both hands to operate the

machine.

12. Never brush away chips while the machine is

in operation .

13. Keep work area clean. Cluttered areas invite

accidents.

14. Remove adjusting keys and wrenches before

turning machine on.

15. Use the right tool. Don’t force a tool or

attachment to do a job for which it was not

designed.

16. Use only recommended accessories and

follow manufacturer’s instructions pertaining to

them.

17. Keep hands in sight and clear of all moving

parts and cutting surfaces.

5

Page 6

18. All vis itors s hould be kept a saf e distance f rom

the work area. Make workshop completely

safe by using padlocks, master switches, or b y

rem o vi ng st ar t e r keys.

19. Know the tool you are using; its application,

limitations, and potential hazards.

3.2 General Electrical Cautions

This machine should be grounded in accordance with the National Electrical Code and local codes and

ordinances. This work should be done by a qualified electrician. The machine should be grounded to protect

the user from electrical shock.

Caution: For circuits which are far aw ay from the electrical service box, the wire size m ust be increased in

order to deliver ample voltage to the motor. To minimize power lo sses and to prevent motor o verheating and

burnout, the use of wire sizes for branch circuits or electrical extension cords according to the f ollowing table is

recommended:

Conductor Length

0 – 50 Ft. No. 14 No. 14

50 – 1 00 Ft. No. 14 No. 12

Over 100 Ft. No. 12 No. 8

240 Volt Lines 120 Volt Lines

Table 1

AWG Num ber

3.3 Safety Instructions for Drill Presses

1. A ll work shall be secured using either clamps or a vise to the drill press table. It is unsafe to use your

hands to hold any workpiece being drilled.

2. Drill press head and table shall be securely locked to the column before operating the drill press. This must

always be checked prior to starting the machine.

3. A lways use the correct tooling. Tooling shall always be m aintained and properly sharpened. All tooling

must be run at the proper speeds and feeds as they apply to the job. Use only recommended accessories

and follow those manufacturer’s instructions pertaining to them. Tooling shall not be forced into any

workpiece but fed according to the proper specifications. Failure to follow these instructions will not only

ruin the tooling as well as the machine, but can cause serious injury.

4. Never brush away shavings or chips while the m achine is in operation. All clean up should be done af ter

the machine is stopped.

5. Keep hands in sight. Do not put hands or fingers around, on, or below any rotating cutting tools. Leather

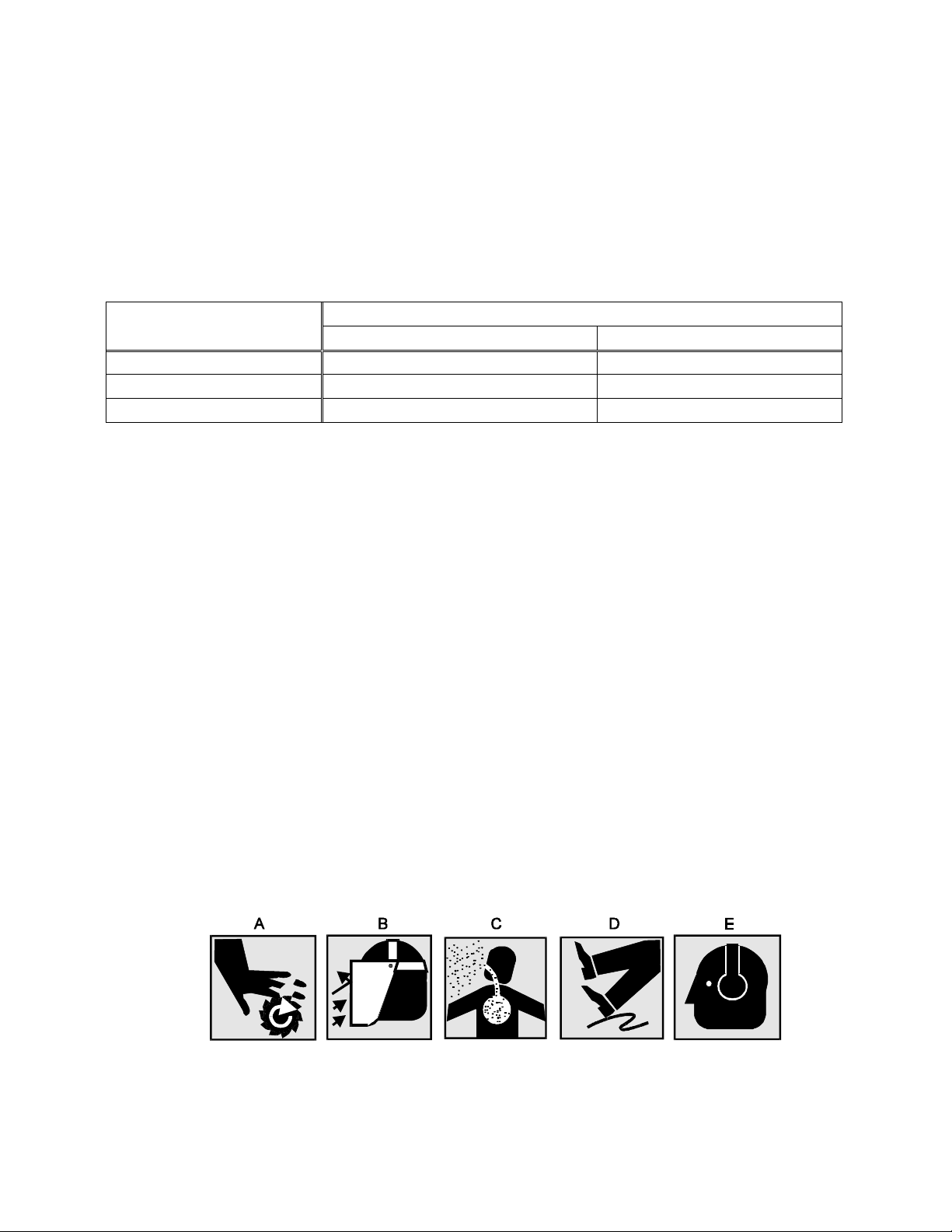

safety gloves should be used when handling any sharp objects or cutting tools. See Figure A.

6. Always wear protective eye wear when operating, servicing or adjusting machinery. Eyewear shall be

impact resistant, protective safety glasses with side s hields complying with ANSI Z87.1 specificat ions. Use

of eye wear which does not comply with ANSI Z87.1 specifications could result in severe injury from

breakage of eye protection. See Figure B.

7. When drilling in material which causes dust , a dust mask shall be worn. See Figure C.

8. Avoid contact with coolant, especially guarding the eyes.

9. Non-slip footwear and safety shoes are recommended. See Figure D.

10. Wear ear protectors (plugs or muffs) during extended periods of operation. See Figure E.

Figure 1

6

Page 7

4.0 Specifications

The JET Model J-1230R is a powerf ul and versatile radial arm dri ll pre ss. T he dri ll head is m ounted o n a n arm

and can slide along the arm to position the spindle over the work piece. The arm itself c an be rotated on its

support column to allow centering the spindle over the work piece.

Drilling can be performed manually or with power feed assistance. In addition, parameters of RPM, power feed

rate and drilling depth can be pre-set by the operator, using contr ols conveniently positioned on the drill head.

The power train gears and spline shaft are made of high quality heat-treated and ground nickel chrome steel,

offering greater strength and smoothness to high-torque loads. The spindle is of case hardened steel and

supported by dual row taper roller and thrust ball bearings at the nose, with thrust and axial bearings at the top.

The frame is made of Meehanite® and high-tensile strength cast iron.

A precision machined box table allows convenient posit ioning and clamping of smaller work pieces. The box

table can be removed from the base to allow larger workpieces to be clamped on the base itself. Both table and

base have multiple T-slots for clamping set-ups.

Model number .......................................................................................................................................... J-1230R

(J-1230R-4 is the same machine but wired for 460V operation)

Stock numbers:

J-1230R .................................................................................................................................................. 320036

J-1230R-4 .............................................................................................................................................. 320037

Head and Spindle:

Push button controls .................................................................................................................................. 110V

Spindle motor (model J-1230R) ..........................TEFC, 5/3 HP (3.7/2.2kW), 3 PH, 230V only, 13/18 A, 60Hz

Spindle motor (model J-1230R-4) .....................TEFC, 5/3 HP (3.7/2.2kW), 3 PH, 460V only, 6.6/7.5 A, 60Hz

Spindle taper .................................................................................................................................. Morse No. 4

Spindle speeds.......................................................................................... twelve speeds, within 45-1550 RPM

Quill (s pindle ) travel ............................................................................................................... 9-7/8 in. (247mm)

Quill (spindle) travel with powerfeed engaged ......................................................................... 9-7/16 (240mm)

Spindle travel along arm, total.................................................................................................... 35 in. (875mm)

Feed rates (distance per revolution) ......................................................................... 0.002, 0.004, 0.006 in/rev

Base surface to spindle, maximum (no tooling) ....................................................................... 54 in. (1350mm)

Base surface to spindle, minimum (no tooling) .................................................................... 19-3/8 in. (484mm)

Column to spindle center distance, maximum ......................................................................... 46 in. (117 0 mm)

Column to spindle center distance, minimum ...................................................................... 13-3/8 in. (334mm)

Sound level (approx. 3-1/4 ft./1m from gearbox) * .................................. 82 dB at 1500 rpm; 79 dB at 88 RPM

Arm and Co lumn:

Column diameter .............................................................................................................. 11-13/16 in. (300mm)

Arm vertical travel on column ............................................................................................... 34-5/8 in. (880mm)

Arm elevating motor ................................................... TEFC, 1 HP (0.75kW), 3 PH, 230/460V, 3.2/1.6A, 60Hz

Clamping motor .......................................................... TEFC, 1 HP (0.75kW), 3 PH, 230/460V, 3.2/1.6A, 60Hz

Base and Table:

Box table dimensions (LxWxH) .................................................. 25 x 20-1/2 x 16-1/2 in. (635 x 520 x 419mm)

T-slots in Table................................................................................................................. five at 3/4 in. (19mm)

Base dimensions (LxWxH) ...................................................................... 68 x 28 x 7 in. (1710 x 715 x 180mm)

T-slots in Base ...............................................................................................................

Additional specifications:

Coolant pump motor.................................................. TEFC, 1/8 HP (0.1kW), 3 PH, 220/440V, 0.2/0.1A, 60Hz

Machine height (floor to motor at maximum elevation) .................................................... 109-1/2 in. (2780mm)

Shipping Dimensions (LxWxH) ........................................................... 80 x 39 x 88 in. (2035 x 995 x 2240mm)

Net weight ............................................................................................................................... 4,630 lbs/2100kg

Shipping weight ....................................................................................................................... 5,070 lbs/2300kg

* Measur ed under test conditions SS41 material, 32mm thick, Ø32mm tool.

three at 3/4 in. (19mm)

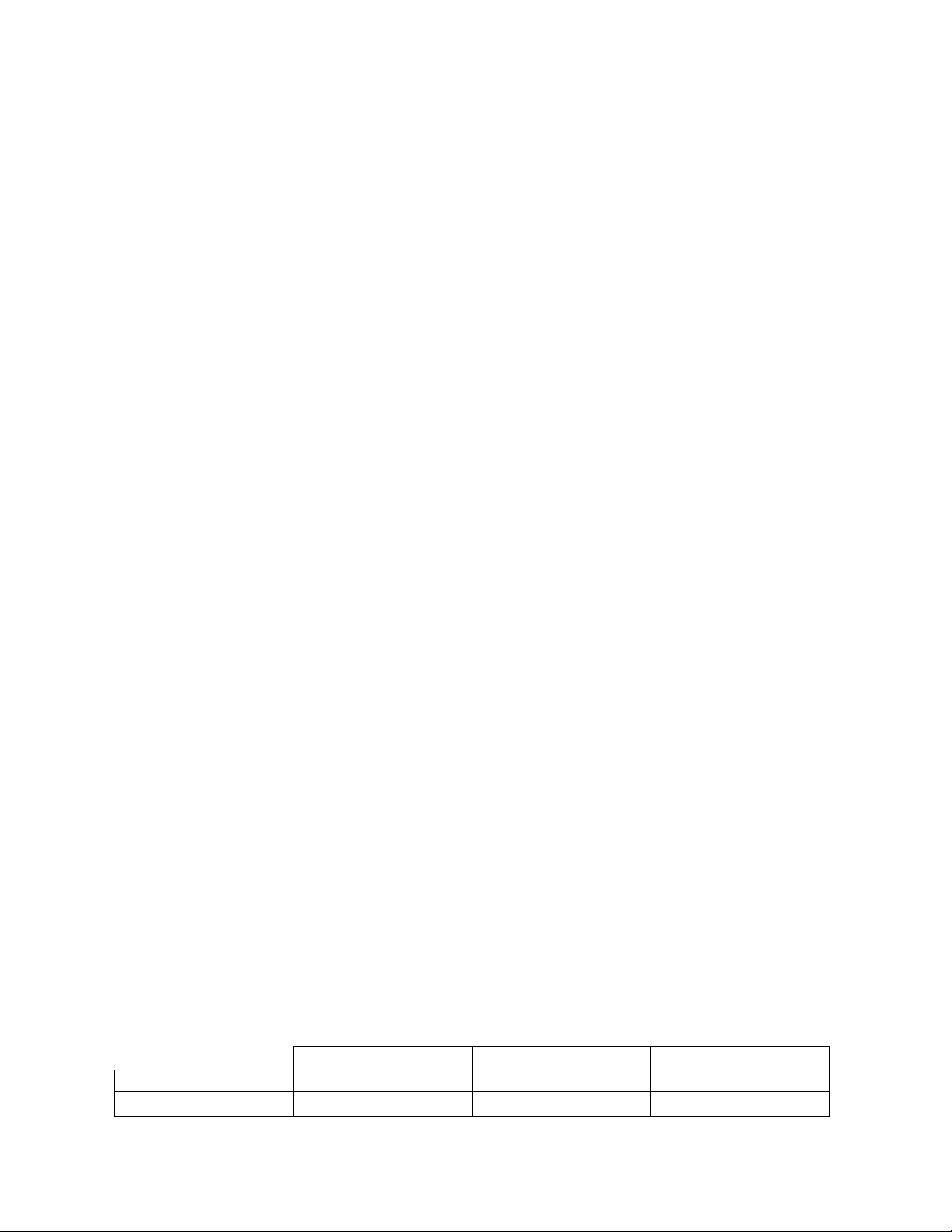

4.1 Machining Capacities

Drilling Tapping Boring

Mild Steel 1-7/8 in. (47.63mm) 1” (25.4mm) 3-3/8” (84mm)

Cast iron 2-5/16 in. (58.75mm) 1-1/2” (38.1mm) 4-3/4” (119mm)

Table 2

7

Page 8

4.2 Machine Environment

1. Do not position the machine where it receives direct sunlight.

2. Normal ambient temperature should be between +5°C (41°F) and 40°C (104°F).

3. Humidity: Between 30% and 95%. At maximum temperature of 40°C/104°F, relative humidity should not be

over 50%. Higher humidity is acceptable at relative lower temperatures (e.g. 90% humidity at 20C°).

4. Keep machine away from gasoline, chemical substances, dust, acid, sulfides, magnetic interfere nce and

ex plosive environments.

5. Keep machine away from electrical interference sources such as welding machines and EDM (Electric

Discharge Machining).

6. Illumination of work area should be greater than 500lux.

7. Work area must have adequate ventilation.

4.3 Power Supply Requirements

1. Acceptable voltage fluctuation: normally +/- 10%

2. Acceptable frequency fluctuation: +/- 1Hz (50/60Hz)

3. Acceptable momentary power-off duration: less than 10m.sec

4. Acceptable voltage impulse:

Peak value: 200% or less than the line voltage of the actual value (rms.value).

Duration: 1.5m.sec or less.

5. Acceptable AC voltage of the waveform distortion.

6. Acceptable imbalance of the line voltage: 5% or less.

8

Page 9

4.4 Overall Dimensions, J-1230R

Figure 2

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without

incurring obligations.

9

Page 10

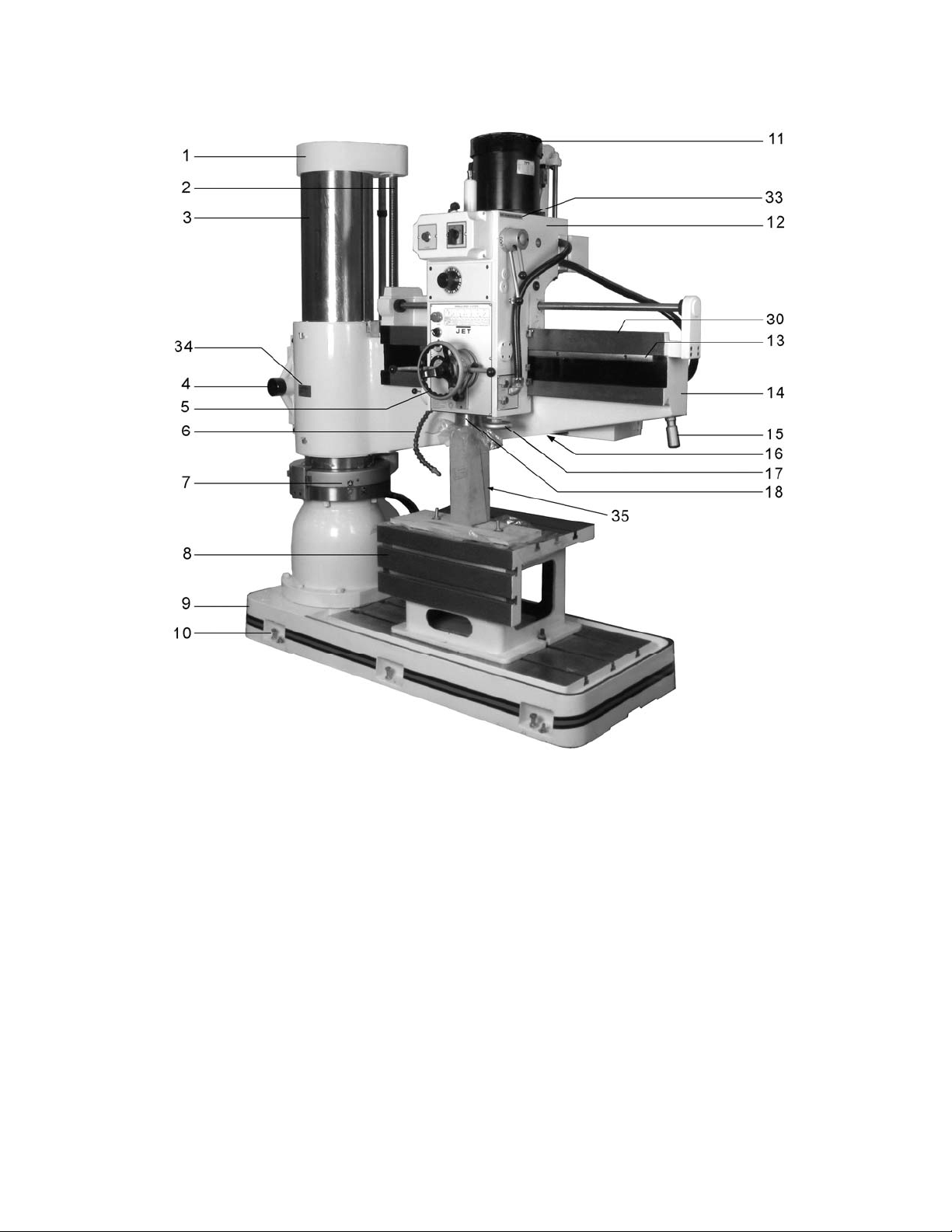

5.0 General Features and Terminology

Figure 3

1. Top Cap

2. Elevating Ball Screw

3. Column

4. Locking Nut

5. Handwheel (horizont al gear box travel)

6. Coolant Nozzle

7. Column Clamping Indicators

8. Box Table

9. Base

10. Leveling Screws

11. Spindle Motor

12. Drill Head/ Gearbox (see Fig ure 10 for details)

13. RaCK

14. Arm

15. Arm Rotation Handle

16. Work Lamp

17. Fine Feed Handwheel

18. Spindle

19. Work Lamp Toggle Switch

20. Electrical cabinet

21. Counterweight System

22. Clamping Rod

23. Guard Panel

24. Clamping Gear

25. Coolant Pump

26. Arm Rai sing Motor

27. Clamping Motor

28. Clamping Gearbox

29. Elevating Worm Gear Reducer

30. Arm Rail

31. Caut ion Label – High Voltage (p/n CL-HV)

32. Warning Lab el – Ti pping Risk (p/n J1230R-WL)

33. Caut ion Label – Stop Spindle (p/n J1 230R-CL)

34. Machin e Identification P l ate

35. Support Block (for shipping only)

10

Page 11

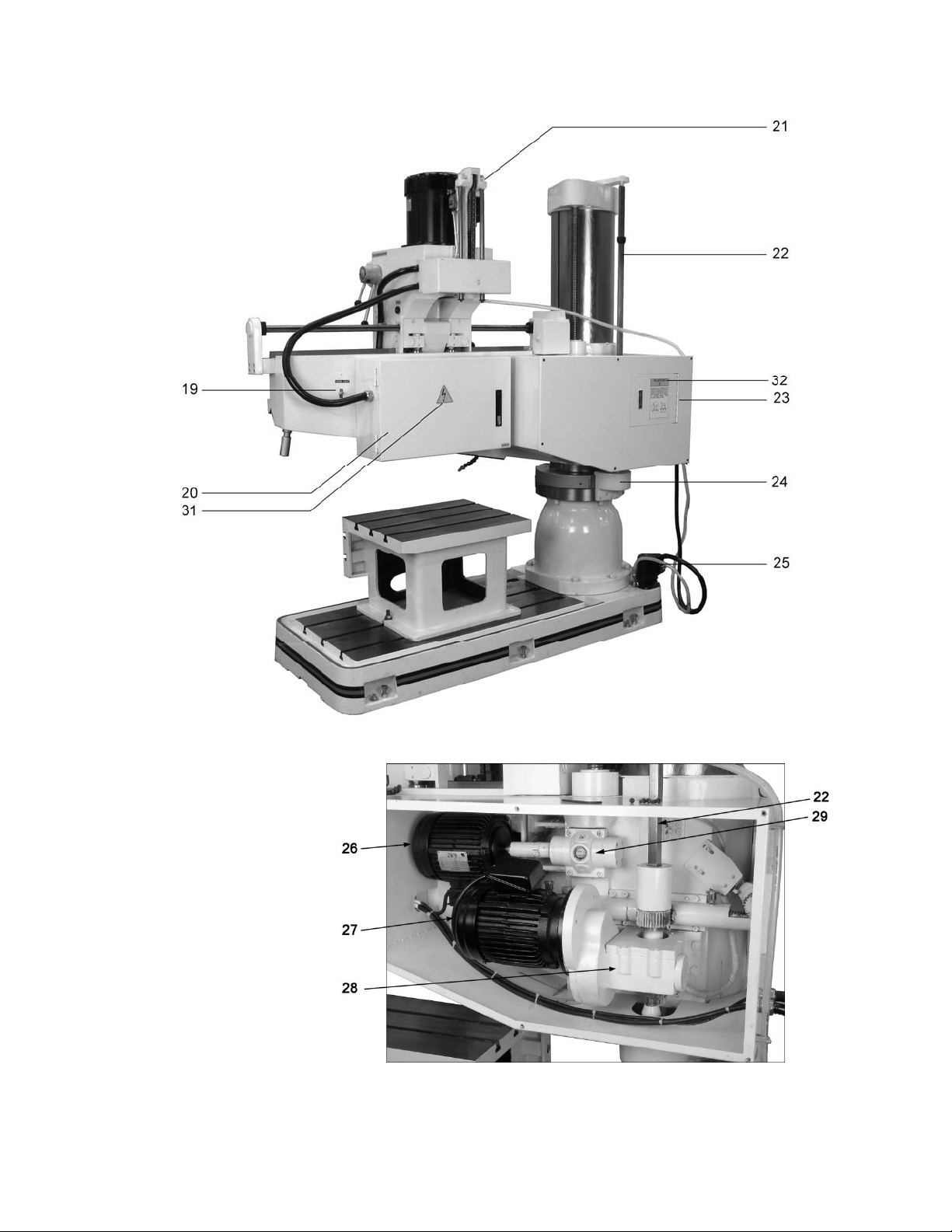

General Features and Terminology (cont.)

Figure 4

Figure 5

12

Page 12

6.0 Set-Up and Assembly

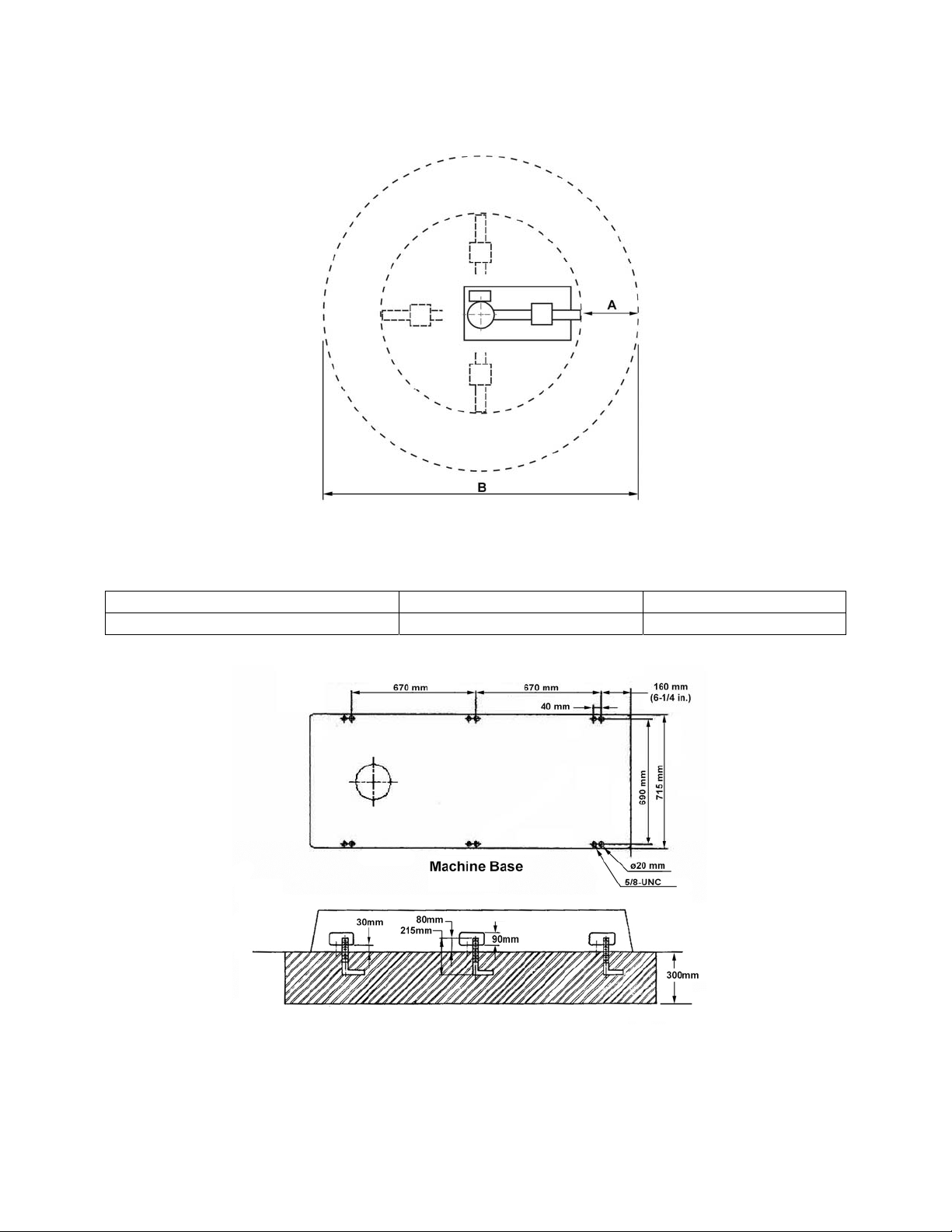

6.1 Floor Diagrams for J-1230R

Figure 6

Figure 4 shows spacing for the 360° rotational path of the arm, plus 1000mm (appro x. 40 inches) of general

maintenance area on each side.

Distance column center to arm limit Maintenance area (A) Total space required (B)

1546mm (61 in.) 1000mm (40 inches) 5092mm (200 in.)

Figure 7

12

Page 13

6.2 Unpacking

Remove any remnants of the shipping crate and

check for shipping damage. Report any damage

immediately to your distributor and shipping agent.

Do not discard any shipping material until the

Radial Arm Drill Press is installed and running

properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor. Read the instruction manual thoroughly

for assembly, maintenance and safety ins tructions.

Contents of Shipping Container

(Figure 9)

1 Radial Arm Drill Press (not shown)

6 Leveling Pads

1 Tool Box, containing:

1 Grease gun

1 Oil bottle

1 Tapered Drift

1 Adjustable wrench

1 Set of hex keys

1 Flat blade screwdriver

1 Cross point screwdriver

1 Instructions and Parts Manual (not shown)

1 Warranty Card (not shown)

1 Manufacturer’s Test Chart (not shown)

Figure 8

Read and understand the entire contents of this manual before attem pting set-up or

operation! Failure to comply may cause serious injury.

13

Page 14

6.3 Machine Set-Up

1. After dismantling the crate, remove the toolbox

and any accessory items from around the

machine.

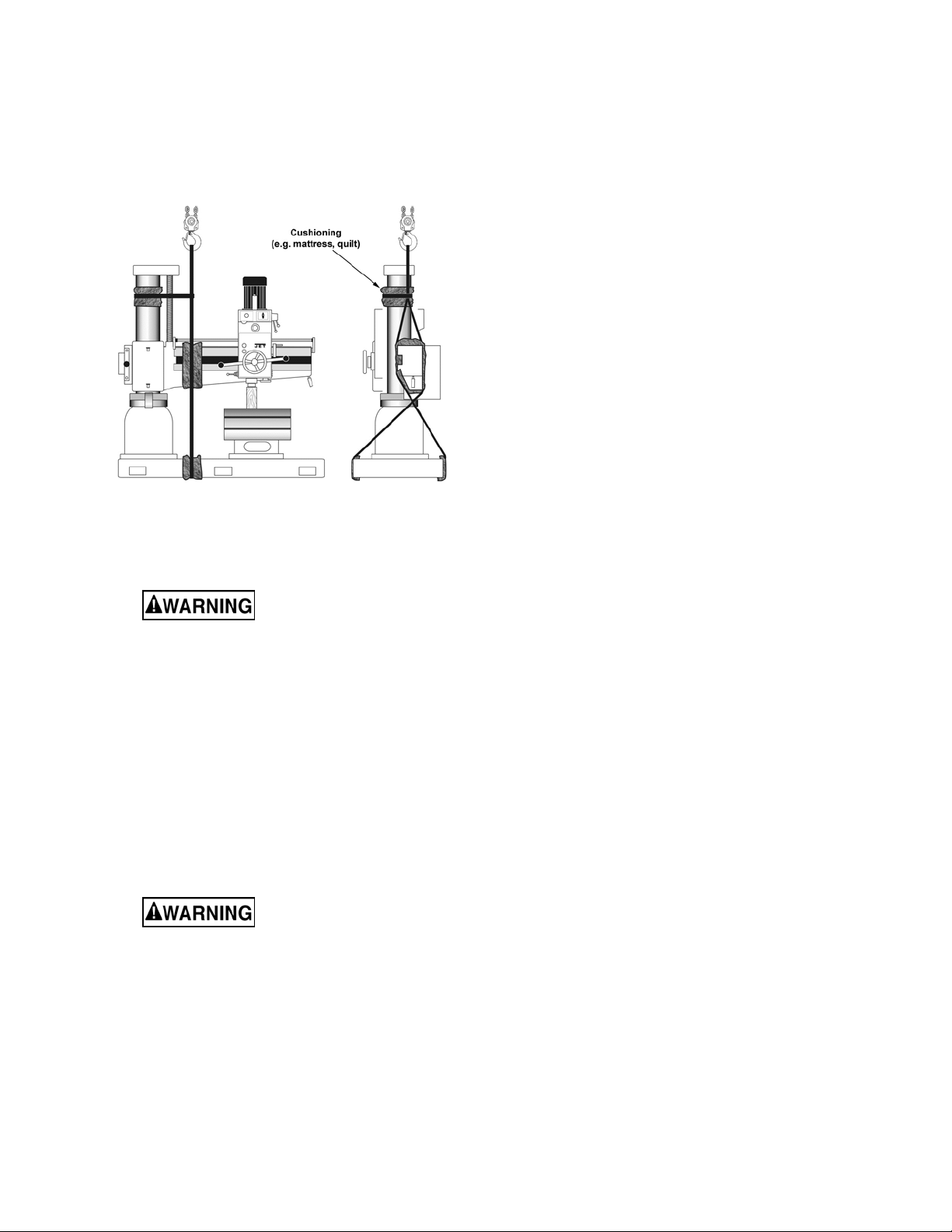

2. Place lifting straps as s hown in Figure 9. Use

cushioning to protect machine surfaces.

8. Turn on the drill press (see Section 8.0

Operation), push the unlock button, and move

the arm elevation lever to UP, until the quill

clears the shipping block. Remove shipping

block and wood platform from the box table.

9. Wipe the surfaces of the machine which have

been treated with a protective coating, using

mineral spirits or a cleaner/degreaser.

10. Inspect all sight glasses on the machine to be

certain they are filled to their level lines. If low,

add fluid as necessary according to

instructions in Section 11.2 Lubrication.

11. Perform a lubrication check at all points

recommended in Section 11.0.

12. Follow directions in Section 8.0 Operation to

check all operation functio ns of the drill press.

If coolant is being used, put coolant in the

sump and test coolant delivery.

13. When all of the above operations are

complete, the machine is ready for service.

Figure 9

3. Remove the bolts holding the machine to the

skid.

All lifti ng equipment must

be rated appropriately to safely sustain t he

weight of the drill press. Do not allow

anyone near or beneat h the machine while

it is being moved.

4. Lift the machine and position it over the anchor

bolts in an area with good lighting, and a level

and well-supported floor.

5. Place the leveling pads beneath the level

adjusting bolts. Place a level (its tolerance

should be within 0.02mm/m) on the box table

and level the machine.

6. The drill press MUST be anchored to the floor.

Use the layout diagram in Section 6.1 as a

guide, and mount the nuts to the ground bolts.

Failure to anchor the

machine properly, according to the

diagrams, could result in the machine

tipping over and consequent damage to the

machine and possible injury to the machine

operator and bystanders.

7. Connect the electrical service branch to the

machine according to the instructions which

follow in section 6.4 Electrical Connections.

This work should be done only by a qualified

and licensed electrician who is familiar with

machine service and national and local codes.

14

Page 15

6.4 Electrical Connections

Electrical set-up should be

performed only by a licensed electrician who is

familiar with national and local electrical codes.

This machine must be properly grounded to

help prevent electrical shock and possible fatal

injury.

Model J-1230R radial drills are tested before

shipping, for all functions and circuits under

electrical power specified for the machine and

motors. The only hook-up requirement should be

for correct connection to an appropriate cutout on

an appropriate service branch.

Where the following instructions do not agree with

local electrical codes and procedures, the

applicable codes and procedures should be

followed, exclusively.

Wiring diagram

A wiring diagram for the drill pre ss is found inside

the door of the electrical cabinet. It is also shown at

the back of this manual. This diagram is for

reference by your licensed installing or servicing

electrician. In addition to using a licensed

electrician for connection to the drill press service

branch, the servicing of components and circuits

inside the control box should be serviced only by a

qualified electrician. This includes fuse

replacement, if required. If any of these fuses,

upon replacement, should continue to fail at short

service intervals, the electrician should be asked to

check all machine components for excessive loads,

short circuits or other failures.

Electrical branch service

The machine is wired for either a 230V or 460V 3phase service branch. The cable supplying the drill

press will be tagged with the voltage at which the

machine was tested and corresponding to the

customer's order.

If the tag has been lost, it will be necessary for you

to open the electrical cabinet on the rear of the drill

press and examine the connections on the

transformer found inside the box. The transformer

can be connected to either a 230 or 460 volt

source and its taps are labeled for voltage. By

locating the source tap on the transformer you will

be able to determine the branch voltage required.

It is recommended that the 230 volt Drill Press be

connected to a dedicated 25 amp circuit with a 25

amp circuit breaker or time delay fuse. Connect the

460 volt drill press to a dedicated 15 amp circuit

with 15 amp circuit breaker or time delay fuse.

Local codes take precede nce over r ecomm enddations.

Connecting branch to drill pr ess

1. Disconnect the service branch to the machine

by moving the lever or rocker switch on the

cutout box to OFF.

2. Connect the green wire (or green with white

trace) to the branch ground.

3. Connect the remaining three wires in the cable

(labeled R, S and T) to the three power lines in

the branch.

4. Turn the power to the machine ON at the

cutout box.

5. Turn the coolant switch (See Figure 10) to the

ON position.

Make sure there is coola nt

in the flood coolant system before

operating the pump.

6. Observe the rotation through the glass atop

the pump. The shaft should be rotating in the

direction of the arrow cast into the pump

assembly. If the shaft is rotating the wrong

direction, the power leads need to be

switched. Correct as follows:

7. Disconnect power to t he machine by turning it

off at the cutout box.

8. Reverse any two of the power lead

connections.

9. Repeat steps 4, 5, and 6, above, and you

should observe the pump shaft turning in the

proper direction. The electrical service to the

machine is now complete.

A service disconnect is rec ommended. The use of

fuses or circuit breakers for each of the voltage

supply wires is required. Use fuses or circuit

breakers which are appropriate to the voltage for

the motor system delivered.

A positive cut-out/lock-out lever or rocker switch

should be located on the outside of the service

disconnect to allow the machine operator to

disconnect from the branch circuit when working

with tooling on the machine.

15

Page 16

7.0 Operating Controls

Figure 10

Operating Controls

16

Page 17

8.0 Operation

To remove tooling:

8.1 Clamping workpieces

To load/unload heavier workpieces, unlock t he arm

and rotate it out of the way. Lift the workpiece w ith

slings or other properly rated lifting equipment.

Both the box table and the base surface are slotted

to accept a suitably sized T-slot clamp. Before

beginning any work on the drill press, anchor the

work piece, and the box table if used, to be certain

that the workpiece and/or box table will not move

when the tool enters the workpiece.

If the box table will not be used, simply remove the

nuts at the base, and move the table off using

proper lifting equipment.

Failure to properly anchor

workpiece and box table could result in

damage to machine, damage to wor kpiece, a nd

severe injury to machine operator. Never work

on the drill press without clamping the

materials using a T-slot system set-up.

8.2 Tool insertion

The Model J-1230R uses a No. 4 Morse taper in

the spindle to secure tooling. Any drill, milling

cutter, or tool holder with an MT-4 can be inserted

into the quill.

8. Verify that machine is disconnected from

power.

9. Place a wood block under the tooling in the

spindle, to prevent it being damaged should it

fall out during the re moval process.

10. Lower the quill using the feed levers until t he

tool removal window is exposed.

11. Insert tapered drift (included in toolbox) into

the removal window, above the tip of the

tooling shank.

12. Use leather gloves to hold the tooling with your

hand to prevent it falling from the quill.

13. With your free hand, tap the tapered drift with

a hammer until the tooling can be removed.

8.3 Tool Positioning over workpiece

After the workpiece has bee n clamped to the base

or table, position the tooling over the workpiece,

using any or all of the following methods:

1. Adjusting the height of the arm on the support

column.

2. Moving the drill head along the arm.

3. Rotating the column upon which the arm and

head are attached.

The first step in removing or

inserting any tooling is to be absolutely certain

the machine cannot be accidentally started

during the insertion or removal operation. The

only way to be certain of this fact is to disconnect

power to the machine. The service box should

have a cut-out switch or lever on the outside of the

box. Put the switch or lever in the OFF position

before inserting or removing tooling.

To insert tooling:

1. Verify that machine is disconnected from

power.

2. Be certain the spindle is clean, free from oil,

and ready to accept the shank of any tooling.

3. Check the shank of the tooling to be certain

the tooling is free from dirt, nicks or burrs. If

nicks or burrs are discovered, file or sto ne the

shank until it is smooth.

4. Be certain quill is in full UP position.

5. Slide shank of tooling into the spindle until it

seats.

6. Use a soft-faced mallet (such as lead, plastic,

brass, etc.) to give the tooling a sharp tap on

its tip. This will secure the tooling in the taper.

7. Reestablish power to the machine and the drill

is ready to use.

17

Page 18

8.4 Unlocking arm and column

mechanisms

A motorized locking system is used to lock the

head to the arm, the arm to t he column, and the

column to the base.

When you push UNLOCK, all of the locks are

unlocked. When you push LOCK, all of the locks

are locked.

The buttons which control t he locks are located on

the right-hand side of the drill head (see Figure 10).

Press and hold the UNLOCK button until the arrow

(Figure 11) points to “B”. Release the button. The

clamping device is now disengaged. When locking,

press and hold the LOCK button until the arrow

points to “A”. The clamping device is now reengaged.

Always be certain the locks

are engaged before using the drill press. Pull

on the arm handle and try to rotate the

handwheel at the front of the head, before

starting the spindle. Failure to have all locks

secure may result in damage to tooling,

damage to workpiece, and possible injury to

the operator.

2. Turn handwheel to move the drill head along

the arm. See Figure 10.

3. When drill head is at desired position on the

arm and if no other adjustments to spindle

location are required, push the LOCK button to

secure all machine locks.

NEVER swing the drill press

arm on the support column unless you are

absolutely certain the drill press base is firmly

attached to the shop floor. If the arm is moved off

its position directly above the base and the base is

not bolted to the floor, THE DRILL MAY TIP OVER

AND CAUSE SERIOUS INJURY TO THE DRILL

PRESS OPERATOR, and will certainly result in

damage to the drill press itself.

8.7 Rotating arm on support column

1. Power to the drill press must be ON – then

release the machine locks by pushing the

UNLOCK push button .

2. Swing the arm using the handle (see Figure

10) to required spindle position.

3. When the spindle is positioned correctly and

no other adjustments are required, push the

LOCK button to secure all machine locks .

Figure 11

8.5 Raising and lowering radial arm

1. Power to the drill press must be ON – then

release the machine locks by pushing the

UNLOCK button.

2. Raise or lower arm to required height using the

arm/spindle control lever (see Figure 10). See

also Section 8.24 Using the control lever.

3. W hen the arm is at required height and if no

other adjustments to spindle location are

required, press the LOCK button to secure all

machine locks.

8.6 Moving drill head along arm

1. Power to the drill press must be ON – then

release the machine locks by pushing the

UNLOCK button.

8.8 Setting spindle speed

Spindle speeds are established using the gear

change levers on the upper right-hand side of the

drill head (See Figure 10). The shorter of the two

levers operates a two-speed mechanism which

puts the gearbox in either high gear or low gear. A

HI/LOW indicator on the upper left hand side of the

drill head identifies the selected speed range.

The longer gear change lever operates a three

speed gearbox mechanism. A detent in the middle

of the lever travel indicates when the lever is in

intermediate gear position.

This gearbox set-up gives you a tota l of si x spindle

speeds which may be selected. The two-speed

spindle drive motor, therefore, increases the

number of available speeds to 12. The speed

selected clearly depends on the position of both

gear change levers and whether the motor switch

on the top front of the drill head is on LOW or HI

speed.

A table on the front of the drill head shows gear

change lever and motor switch values required to

select each speed. A similar table is included in

Section 10.0 of this manual.

On the gear change table you will also find the

recommended drill sizes for the various speeds

which are selectable. These recommendations

are only approximate. With the wide variety of

drill types and coatings available, as well as cutting

fluids, and the even wider variety of work piece

materials which you might be machining – you

18

Page 19

need to consult with your tooling, coolant and/or

work piece suppliers to determine the best spindle

speed to use for any specific drilling operation.

Do not try to change gears

while the spindle is turning. This may cause

serious damage to the spindle drive system.

Allow the spindle to stop completely before

attempting to change gears. If the gear change

lever you want to move does not slip easily into the

new position, jog the motor for a second using the

control lever. Then allow the spindle to come to a

stop before attempting to change gears again.

Repeat this jogging process, as necessary, until

the gears match up properly for changing.

Plan for quill movement

during high speed spindle r otation. High speed

rotation without quill travel will increase

spindle temperatures.

8.9 Feed rate and depth of cut

The J-1230R has limit switches on the quill which

cut power to the drive motor when the quill has

reached either the upper or lower limit of its tra vel.

This system is designed to prevent gearbox

damage if the power feed mechanism is engaged –

damage which would occur if the quill were to

bottom out against the upper or lower limit of quill

travel. In the event of failure of either limit switch

there is also a safety clutch mechanism which will

slip when travel limits are reached.

However, while you are able to use virtually the full

travel of the quill for drilling or other operations, the

drill press operator typically sets both the rate of

feed (travel-per-revolution of the spindle), and the

depth of cut (quill travel to make the required cut).

Figure 12

Any of the three feed rates are available for

selection using any of the spindle speeds

available. There will be a recommended feed rate

for any drilling or boring operation, and this rate

must be determined by consulting appropriate

machining handbooks or by consulting with your

tooling and work piece suppliers.

These two operations are described here:

8.10 Setting feed rate

The feed rate is set using the knob and dial on the

front of the drill head. See Figure 12. The knob

can be rotated to select any of three different feed

rates, plus a neutral position where the power feed

does not operate on the quill.

Do not try to change feed rate

while the spindle is turning. This may cause

serious damage to the spindle drive system.

It is recommended that when doing operations not

requiring power feed that the dial be set to neutral.

This minimizes any wear on the power feed

mechanism.

Feed rate selection is indicated by a pair of rivet

heads (A, Figure 12) on opposing edges of the

dial. These values are indicated in smaller type on

the outer edge of the dial plate.

19

Page 20

8.11 Setting depth of cut using

power feed system

There is a mechanism for engaging power feed

and there is also a “trip” mec hanism which can be

set to disengage the power feed when a pre-set

depth has been reached.

The feed levers (A, Figure 13) can be pulled

outward or pushed inward on pivots in the feed

lever hub. When the levers are pushed toward the

drill head, the power feed mechanism is

disengaged. When the feed levers are pulled

outward, the power feed system is engaged. In the

power feed position (outward) the quill and spindle

will be driven until one of the following happens:

• Spindle reaches limit of travel and the l imit

switches disable power; or

•

The “trip” mechanism automatically

disengages the power feed; or

•

The drill press operator pushes the feed

levers into the disengaged position.

To set depth of cut:

Refer to Figure 13.

1. Rotate feed levers (A) counterclockwise to

lower the drill until it just contacts the work

piece. Drill-to-workpiece contact represents

zero depth position.

2. Push lever (B) to unlock depth control.

3. Rotate dial (D) until the indicator (E) is at the

feed depth required on the scale (C).

4. Push lever (B) to lock depth setting.

5. Pull feed levers (A) outward to engage power

feed clutch.

8.12 Spindle direction and power

feed

Spindle rotation direction is managed by the

arm/spindle control lever on the left hand side of

the drill head. See Figure 10.

Clockwise or "forward" rotation is the direction of

rotation for right-hand tooling – the vast majority of

tooling used in machine operations. Reverse

spindle rotation for left hand tooling.

Power feed direction is determined by the spindle

direc t io n. W hen sp ind le is set to it s m ost co m mo n

direction – clockwise or forward – the quill and

spindle are driven downward. When spindle

direction is set counterclockwise (reverse), quill

and spindle are driven upward.

8.13 Hand fe ed – roughing

operations

When the feed levers are pushed toward the drill

head the power feed mechanism is disengaged. In

this position, the feed levers can be used to move

the quill and spindle and perform manual drilling or

other machining operations.

8.14 Fine hand feed using power

feed system

The fine feed control wheel is located on the

underside of the right-hand side of t he drill head.

See Figure 10. The fine feed control is used as

follows:

1. Set feed rate dial to N (neutral).

2. Pull feed levers out to engage power feed

clutch.

3. Turn on drill press, and set arm/spindle control

lever to desired direction.

Figure 13

Note: Because the dial (D) makes one rotation

before contacting the mechanical trip dog, you are

limited to 4 inches (100mm) of travel during any

power feed operation when using this dial depth

stop system. If you need to make deeper holes,

you must do the machining in steps.

Power feed is used only for drilling, not for

threading. Feed rate must be set (off neutral) for

power feed to be engaged.

4. Turn fine feed control wheel by hand. Quill

and spindle will move downward or upward

(depending upon which way you turn the

wheel and the direction t he spindle is turning)

until you stop turning the control wheel.

20

Page 21

8.15 Tapping

1. Insert screw tap into spindle.

4. The arm/spindle control lever must be

engaged for selected rotation. See Section

8.24 Arm/spindle contr ol lever.

2. Move spindle into position.

3. Set spindle control to Forward.

4. Rotate the feed levers counterclockwise until

desired tapping depth is reached.

5. Reverse spindle direction and allow tap to

withdraw completely from workpiece.

6. Stop spindle by moving spindle control switch

to center.

8.16 Power ON/OFF

If your J-1230R was connected to its service

branch correctly, there will be a service disconnect

with an external power cutoff lever or switch w hich

disconnects the drill press from the service bra nch.

This is your ultimate protection against accidental

machine start-up when clamping work pieces or

inserting and removing tooling. Always be certain

you have turned off power at this disconnect before

beginning such procedures.

8.17 Power ON light

When the cutout box power is ON, the red POWER

light on the upper left hand side of the drill head

(Figure 10) will be lit. In this mode, power to the

coolant pump and to the spindle drive motor is

controlled by the switches on the control console.

8.18 Coolant control

The flood coolant system is controlled by the dial

on the front of the gearbox (F igure 10). If coolant

has been turned on, but does not flow, check the

pump rotation by observing the pump shaft. It

should be rotating in the direction of the arrow on

the pump casting. If rotation is incorrect, see

Section 6.4 Electrical Connections, for more

information.

Open the valve to the coolant nozzle using the

handle at the left of the head (see Figure 10).The

proximity of the nozzle can be adjusted by

loosening the two knobs and sliding the coolant

pipe up or down as needed. Retighten knobs.

8.19 Spindle motor controls

Power to spindle motor is controlled as follows:

1. The cutout box control lever must be in the ON

position.

2. The motor speed control switch must be in

either HI or LOW position.

3. The Emergency Stop switch must be

disengaged.

8.20 Turning off spindle drive

To turn power OFF on the spindle drive motor do

one of the following:

1. Put the two speed motor switch in OFF

position, OR...

2. Put arm/spindle control lever in n eutral, OR...

3. Push red STOP switch, OR...

4. When servicing the tooling or other machine

components, put the service disconnect lever

in OFF position.

Once the STOP switch has been pushed (step 3

above) none of the other switches on the panel can

be used to control power to the spi ndle drive m otor

or coolant pump until the STOP switch has been

reset.

8.21 Resetting STOP switch

Turn the Stop switch clockwise in the direction of

the arrow on the red button. The switch is re-set

and the other spindle motor controls can be used.

8.22 Using load ammeter

An ammeter on the control console is used to

monitor the load on the spindle drive motor. It is

connected into one of the three power lines which

supply the main drive motor.

When the drive motor is ON and up to speed, and

there is no tooling being used to drill, tap or bore a

hole, the ammeter should read approximately 2.5

amps. If it exceeds this value there is a problem

internally (such as lack of lubrication in the

gearboxes, bad bearings, etc.). You should turn off

the machine and determine the cause of any

excessive free-running load.

Monitor the ammeter during machining operations.

The ammeter should stay below 9 amps of current

draw during machining. You should adjust spindle

speed, feed rate and coolant use to maintain full

load current draw below the 9 amp value.

If you exceed 9 amps current draw a thermal

overload switch in the electrical control panel will

trip. If this occurs, locate and reset the thermal

switch.

8.23 Tapping opera tions

1. Determine the most efficient tapping speed

(spindle speed) by consulting appropriate

machinist's tables, your tap supplier, coolant

supplier and/or workpiece supplier.

2. Be certai n that feed rate dial is at neutral. See

Section 8.10 Setting feed rate.

21

Page 22

3. Turn on spindle motor. Also, turn on the

coolant pump if coolant is being used.

4. Move arm/spindle control lever to Forward.

5. Use the feed levers to move the tap into its

pilot hole until the tap makes its init ial thread

cut and is engaged in the work piece.

6. Allow the tap to "self-feed" into the pilot hole

until it has completed its tapping operation.

7. Move arm/spindle control lever to neut ral and

allow spindle to stop completely.

8. Move arm/sp indle co ntro l lever to reverse, so

that tap unscrews itself from the hole it has just

threaded.

8.24 Arm/spindle control lever

The four-position arm/spindle control lever is

located on the left hand side of the drill head

console. See Figure 10. It controls spindle rotation

direction and raising and lowering of the arm.

The ability to control the height of the arm is

av ailable when:

1. The main power to the machine is ON at its

branch service panel.

2. The emergency STOP switch is disengaged.

3. The arm/spindle control lever is pushed up or

down.

4. The column and arm UNLOCK button (right

hand side of the drill head – see Figure 10) is

pressed to disengage the machine locks.

NOTE: The control lever does not ret urn to neutral

when released, but remains in position. This

means unless you return it to neutral, t he arm will

keep raising or lowering until it contacts a limit

switch.

3. Turn the five upper adjusting nuts (D)

counterclockwise (i.e. tighten them up against

the clamping ring) approximately 180°.

4. Re-tighten the five locking nuts (C).

5. Press and hold the lock button until the arrow

returns to (A). The clamping device is now

engaged.

Figure 14

6. Move arm/spindle control lever to Arm UP.

7. Press emergency stop button after the arm

has elevated a short distance.

8. Press the unlock button to release the

clamping device.

9. Adjust the nut (E, Figure 15) one notch

clockwise.

10. Move arm/spindle control lever to neutral.

11. Reset emergency stop button.

9.0 Adjustments

After extended use – usually several years – the

radial arm drill may require adjustment of certain

parts. Two areas require particular attention:

• The clamping device.

• The gap between head and rail.

9.1 Clamping Device

If there is backlash in the clamping device, correct

as fol lows.

Refer to Figure 14.

1. Press and hold the unlock button (see Figure

10) until the arrow (Figure 14) points to “B”.

Release the button. The clamping device is

now disengaged.

2. Loosen the five locking nuts (C).

Figure 15

9.2 Head/Rail Backlash

If backlash ever appears between the gearbox

head and the arm rail, the tightness between rail

and bearings can be corrected, as follows.

Refer to Figure 16.

1. Remove side plate (F) by removing screws.

2. Loosen set screws (G).

3. Insert hex key into holes (H), and rotate the

bearing shaft. Rotate handwheel on the front

of the head; it should be snug but still easily

turned.

22

Page 23

4. Tighten set screws (G).

5. Repeat steps 1 through 4 for oppo site side of

the head.

6. Back at the original side of head, loosen set

screws (I).

7. Insert hex key into hole (J) and rotate bearing

shaft. Test the handwheel tightness again.

When satisfied, retighten set screws (I).

8. Repeat steps 6 and 7 for opposite side of the

head.

9. Install side plates (F) on both sides of head.

Figure 16

23

Page 24

10.0 Spindle Speed Chart

Note: A similar chart is found on the front of the drill head.

Table 3

24

Page 25

11.0 Troubleshooting the J-1230R

Trouble Probable Cause Suggested Remedy

Drill b it is too la rg e. Turn off power, wai t three minutes after

Feed rate too fast.

Spindl e over loads,

causing relay to trip.

Spindl e over loads,

causing fuse to blow.

Operation n ot in c ompliance wit h speed

and feed rate tables.

Fuse is burned out.

Low voltage.

Drill bit is to o lar g e.

Feed rate too fast.

Operation n ot in c ompliance wit h speed

and feed rate tables.

If drill bit gets broken in the spindle:

1. Move arm/spindle control lever to neutral.

2. Press emergency stop button.

3. Push the head/gearbox out of the way.

4. Pinch the end of the broken bit with pliers.

5. Rotate counterclockwise and pull it out upwards.

Table 4

spindle stops turnin g, then push the re-s et

on the relay i n t he control box.

Correct initial problem by using shorter

drill bit or lower feed rate; consult

appropriate feed and speed rate tables.

Replace fuse if needed. Verify proper

voltage at power source.

Replace fuse in control box.

Correct initial problem by using smaller

drill bit or lower feed rate; consult

appropriate feed and speed rate tables.

If screw tap gets broken in the spindle:

1. Move arm/spindle control lever to neutral.

2. Press emergency stop button.

3. Using a thread releaser, rotate the screw tap counterclockwise until it comes out.

If something becomes entangled during operation:

1. Press emergency stop button.

2. Disconnect power.

3. Switch speed change lever to highest gear.

4. Rotate spindle by hand in reverse direction from that used during the operation, until the obstruction is free.

25

Page 26

12.0 Maintenance

A

t

A

Regularly scheduled maintenance is crucial to ensure a long service life for your machine. The schedule below shows

general cleaning, lubrication points and coolant replacement information for the J-1230R Radial Arm Drill Press. Item

numbers are located in figures 17-21. Using proper eye protection, clean parts using a metal brush and a rag dipped

with oil (Mobil Vactra AA or equivalent). Push stop button and power off before lubricating. Follow local

regula t ions for disp osal of used cool ant/ lubrica nts.

12.1 General Cleaning

No. Item

1 C olum n Cl ean an d li ghtly wip e wit h oil

2 Arm R ai l Clean and lightly wi p e wit h oil

3 Spi nd le Clean and lightl y wi p e wit h oil

4 B ox Table Clean and lightly wi p e wit h oil

5 B as e Remove s h avings; clean and wip e wi th oil

6 B all Screw Clean wit h m etal brush an d oil ed rag

7 C ounterweig ht gu id e rails Clean an d wipe with oil

8 Spi nd le motor Blow dust from fan housin g w it h c ompressed air Periodically --

ction Interval Lubrican

Daily Mobil Vactra oil AA

Daily Mobil Vactra oil AA

Daily Mobil Vactra oil AA

Daily Mobil Vactra oil AA

Daily Mobil Vactra oil AA

Weekly Mobilux Grease No. 3

Daily Daily

Table 5

12.2 Lubrication

No. Item Location

Oil Cup (for

9

arm/column

contact)

Oil Cup (for

10

spnidle)

Oil Cups - 2 (for

11

head/arm

contact)

12 Arm Raising

Worm Gear

13 Counterweight

Chain

14 Coolant Reservoir in

15 Grease nipple

(for spindle)

16 Rack On arm Lubricat e wit h lub e gun Every 3 days Mobil Vac tra oil AA

Oil Cups - 2 (for

17

clamping)

18 Gearbox Top and right

Top and bott om

of arm base at

column

Top of drill head Add lubricant to full capacity Daily Mobil Vactra oil AA

Right side of drill

head

Rea r of column Top off at fill hole (12 a). Fill to sight

Behind drill

head

base

On spindle Lubricate with lube gun Daily Mobilux Grease No. 3

Rear of column Add lubricant to capacity Daily Mobil Vactra oil AA

side of drill head

Add lubricant to full capacity Daily Mobil Vactra oil AA

Add lubricant to full capacity Daily Mobil Vactra oil AA

glass full level (12b).

Replac e annually; dr ain at (12c ) . Use

sight glass to fill to capacity. Capacity

= 2 liters (1/2 gal.)

Wipe with oil ed rag W eekly Mobil Vac tra oil AA

Monitor for cleanliness and efficiency.

Replac e wh en di r t y or when cuttin g

becomes inefficient. Capacity = 30

liters (8 gal.)

Top off at fill ho le (18a). Fil l to sight

glass full level (18b).

Replac e annually; dr ain at (18c ) . Use

sight glass (18b) to fill to capac ity.

NOTE: Put pipe thread compound on

drain plug before re-installing.

Capacity: 4.5 Liters (1.2 gal.)

ction Interval Lubricant*

Check sight

glass daily

Once per year

Frequent

inspection; top

off as needed

Check sight

glass daily

Once per year

Mobil Vactra oil AA

Use high quality coolant

of choice

Mobil Vactra oil AA

Table 6

* IMPORTANT: If switching brands of lubricants, prevent compatibility issues by thoroughly draining and, if possible,

cleaning the reservoir before filling with the replacement brand.

26

Page 27

Figure 17 Figure 18

Figure 19 Figure 20

Figure 21

27

Page 28

13.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800-2746848, Monday through Friday (see our website for business hours, www.jettools.com). Having the Model Number and

Serial Number of your machi n e avail abl e when you call will allow us to serve you quickly and accuratel y.

13.1.1 Riser Mechanism: Exploded View

28

Page 29

13.1.2 Riser Mechanism: Parts List

Index No. Part No. Description Size Qty

1 ................ 5232451 .................... Motor (Elevating) .............................................. 1HP, 230/460V .................... 1

2 ................ TS-1503091 .............. Socket Head Cap Screw................................... M6 x 40L ................ .............. 4

3 ................ TS-2361061 .............. Spring Washer .................................................. M6 ........................................ 4

4 ................ TS-1550041 .............. Flat Washer ...................................................... M6 ........................................ 4

5 ................ TS-1540041 .............. Hex Nut ............................................................. M6 ........................................ 4

6 ................ 5232461 .................... Key.................................................................... 6mm x 30L ........................... 1

7 ................ 5232481 .................... Adaptor ............................................................. ............................................. 1

8 ................ 5232471 .................... Set Screw ......................................................... M6 x 8L ................................ 4

9 ................ 5232491 .................... Plastic Joint....................................................... ............................................. 1

10 .............. 5232521 .................... Adaptor ............................................................. ......... .................................... 1

11 .............. 5232531 .................... Socket Head Cap Screw................................... M6 x 14L .............................. 4

12 .............. 5232541 .................... Cover ................................................................ ............................................. 1

13 .............. 5232591 .................... Worm Shaft ....................................................... ............................................. 1

14 .............. 5232571 .................... Key.................................................................... 5mm x 20L ........................... 1

15 .............. 5232581 .................... Key.................................................................... 5mm x 55L ........................... 1

16 .............. 5232551 .................... Oil Seal ............................................................. TC17 x 28 x 7 mm ............... 1

17 .............. 5232561 .................... Bearing ............................................................. 30303 ................................... 1

18 .............. 5232621 .................... Worm ................................................................ ............................................. 1

18-1 ........... M1312-S36................ Retain er ............................................................ S36 ...................................... 1

19 .............. 5232641 .................... Worm Housing .................................................. ............................................. 1

20 .............. TS-1504081 .............. Socket Head Cap Screw................................... M8 x 40L .............................. 1

21 .............. 5232631 .................... Oil Level Gauge ................................................ ............................................. 4

22 .............. M0604006 ................. Plug................................................................... PT1/4” .................................. 1

23 .............. 5232651 .................... Bearing ............................................................. 30303 ................................... 2

24 .............. 5232661 .................... Bearing Cover ................................................... ............................................. 1

25 .............. 5232671 .................... Socket Head Cap Screw................................... M6x14L ................................ 1

26 .............. J-5232681 ................. Top Cap ............................................................ ............................................. 1

27 .............. TS-1505051 .............. Socket Head Cap Screw................................... M10 x 35L ............................ 1

28 .............. 5232691 .................... Nut .................................................................... M24 ...................................... 6

29 .............. 5232711 .................... Key.................................................................... 6mm x 20L ........................... 1

30 .............. 5232721 .................... Lead Screw ....................................................... ............................................. 1

31 .............. TS-1533042 .............. Phillips Pan Head Machine Screw .................... M5 x 12L .............................. 1

32 .............. 10415 ........................ Compression Cover .......................................... ............................................. 2

33 .............. M1401-M6x65 ........... Socket Head Cap Screw................................... M6 x 65L .............................. 1

34 .............. 5232811 .................... Safety Device Cover ......................................... ............................................. 4

35 .............. 10177 ........................ Bolt ................................................................... ............................................. 1

36 .............. 5232791 .................... Safety Nut ......................................................... ............................................. 2

37 .............. TS-1503061 .............. Socket Head Cap Screw................................... M6 x 25L .............................. 1

38 .............. 5232781 .................... Bearing Cover ................................................... ............................................. 6

39 .............. TS-1503051 .............. Socket Head Cap Screw................................... M6 x 20L .............................. 1

40 .............. 5232761 .................... Brass Sleeve..................................................... ............................................. 4

41 .............. 5232751 .................... Ball Bearing ...................................................... 6014ZZ ................................ 1

42 .............. 5232741 .................... Collar ................................................................ ............................................. 1

43 .............. 5232731 .................... Bearing ............................................................. 51114 ................................... 1

44 .............. 5232881 .................... Up-Down Rolling Shaft ..................................... ............................................. 1

45 .............. 5232871 .................... Worm Gear ....................................................... ............. ................................ 1

46 .............. TS-1503081 .............. Socket Head Cap Screw................................... M6 x 35L .............................. 1

47 .............. 5232861 .................... Collar ................................................................ ............................................. 4

48 .............. 5232851 .................... Bearing ............................................................. 32010 ................................... 1

49 .............. 5232841 .................... Oil Seal ............................................................. TC50 x 72 x 12mm .............. 1

29

Page 30

13.2.1 Column and Base: Exploded View

30

Page 31

13.2.2 Column and Base: Parts List

Index No. Part No. Description Size Qty