Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

7-inch Horizontal-Vertical Band Saw

Model HVBS-7MW

WALTER M EIE R (Manufa c turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414459

Ph.: 800-274-6848 Revision H 01/2012

www.waltermeier.com Copyright © 2012 Walter Meier (Manufacturi ng) Inc .

Page 2

1.0 Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECI AL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded produc ts are not sold in Canada by Walter Meier.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ....................................................................................................................... 2

2.0 Table of contents .............................................................................................................................. 3

3.0 Safety warnings ................................................................................................................................ 4

4.0 About this manual ............................................................................................................................. 5

5.0 Specifications ................................................................................................................................... 6

6.0 Setup and assembl y ......................................................................................................................... 7

6.1 Shipping contents .......................................................................................................................... 7

6.2 Unpacking and clean- up ................................................................................................................ 7

6.3 Assembly ...................................................................................................................................... 7

6.4 Verti cal cutting plate ...................................................................................................................... 7

6.5 Coolant tank prepar ation ............................................................................................................... 8

6.6 Electrical connections .................................................................................................................... 8

6.7 Voltage conversi on ........................................................................................................................ 9

6.8 Extension cords ............................................................................................................................. 9

7.0 Adjustments .................................................................................................................................... 10

7.1 Hydraulic feed selec tor ................................................................................................................ 10

7.2 Changing blade speed................................................................................................................. 10

7.3 Adjusting blade gui des ................................................................................................................ 10

7.4 Vise adjustm ent ........................................................................................................................... 10

7.5 Blade tension .............................................................................................................................. 11

7.6 Changing blades ......................................................................................................................... 11

7.7 Adjusting blade square to t able .................................................................................................... 12

7.8 Adjusting blade square to v ise ..................................................................................................... 12

7.9 Adjusting blade tr ac ki ng .............................................................................................................. 13

7.10 Adjusting bl ade guide bear ings .................................................................................................. 13

7.11 Adjusting bow weight ................................................................................................................. 14

7.12 Adjusting automatic shutoff ........................................................................................................ 14

8.0 Operation........................................................................................................................................ 14

9.0 Maintenance ................................................................................................................................... 15

9.1 Lubricati on .................................................................................................................................. 15

9.2 Chip Cleaning Brush ................................................................................................................... 15

10.0 Replacement Parts ....................................................................................................................... 16

10.1.1 HVBS-7MW Bed Assembly – Exploded View .......................................................................... 17

10.1.2 HVBS-7MW Bow Assembly – Exploded View ......................................................................... 18

10.1.3 HVBS-7MW Bed and Bow Assembli es – Parts List ................................................................. 19

10.2.1 HVBS-7MW Cylinder A ssembly – Exploded View ................................................................... 23

10.2.2 HVBS-7MW Cylinder A ssembly – Parts List ............................................................................ 23

11.0 Electrical Connec tions................................................................................................................... 24

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand the warnings posted

on the machi ne and in this manual. F ai lure

to comply with all of these warnings may

cause serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This band saw is designed and int ended for

use by properly trained and experienced

personnel only. If you are not familiar with

the proper and safe operation of a band

saw, do not use until proper training and

knowledge have been obtained.

5. Do not use this machine for other than its

intended use. If used for other purposes,

Walter Meier (Manuf acturing) Inc., discl aims

any real or im plied warranty and holds it self

harmless from any injury that may result

from that use.

6. Always wear approved safety glasses/face

shields while using this table saw. Everyday

eyeglasses only have impact resistant

lenses; they are not s af ety glasses.

7. Before operati ng this band saw, rem ove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Remove all

loose clothing and confine long hair. Nonslip footwear or anti-skid floor strips are

recommended.

8. Wear ear protec tors (plugs or muffs) duri ng

extended periods of operation.

9. Some dust created by power sanding,

sawing, grinding, drilling and other

construction activities contain chemicals

known to cause cancer, birth defects or

other reproductiv e harm . Some ex amples of

these chemicals are:

•

Lead from lead based paint.

•

Crystalline sil ica from bricks, c ement and

other masonry products.

Arsenic and chromium from chemically

•

treated lum ber.

Your risk of exposure vari es, depending on

how often you do this type of work. To

reduce your exposure to these chemicals,

work in a well-ventil ated area and work with

approved safet y equipm ent, such as f ace or

dust masks that are specificall y designed to

filter out microscopic particles.

10. Do not operate this machine while tired or

under the infl uence of drugs, al cohol or any

medication.

11. Make certain the switch is in the OFF

position before connecting the machine to

the power supply.

12. Make certain the machine is properly

grounded.

13. Make all machine adjustments or

maintenance with the machine unplugged

from the power source.

14. Remove adjusting keys and wrenches. For m

a habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

15. Keep safety guards in place at all times

when the machine i s in use. If removed for

maintenance pur poses, use ext rem e cauti on

and replace the guards immediately after

completion of maintenance.

16. Never hold the material with saw in

horizontal position. Always use vise and

clamp it securely.

17. K eep hands and fingers away fr om blade at

all times duri ng oper ati on.

18. Provide adequate support for long and

heavy material.

19. Check dam aged parts. Bef ore furt her use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of

moving parts, breakage of parts, mounting

and any other condi tions that m ay affect its

operation. A guard or other part that is

damaged should be properly repaired or

replaced.

20. Provide for adequate space surrounding

work area and non-glare, overhead lighting.

21. Keep the floor around the machine clean

and free of scrap mat eri al, oil and grease.

22. Keep vi sitors a safe distance f rom the work

area. Keep childr en away.

4

Page 5

23. Make your workshop child proof with

padlocks, master switches or by removing

starter keys.

24. G ive your work undivi ded attention. Look ing

around, carrying on a conversation and

“horse-play” are c ar eless acts that can result

in serious injury.

25. Maintain a balanced stance at all times so

that you do not fall into the blade or other

moving parts. Do not overreach or use

excessive force to perform any machine

operation.

26. Use the right tool at the correct speed and

feed rate. Do not forc e a tool or att achment

to do a job for which it was not designed.

The right tool will do the job bet ter and m ore

safely.

27. Use recommended accessories; improper

accessories may be haz ar dous.

30. Do not stand on the m achi ne. Serious inj ury

could occur if the machine tips over.

31. Never leave the machine running

unattended. Turn the power off and do not

leave the machine until it comes to a

complete stop.

32. Rem ove loose it ems and unnecessary work

pieces from the area before starting the

machine.

33. F eed work into a blade or cutter agai nst the

direction of rotation of the blade or cutter

only.

34. Don’t use in dangerous environment. Don’t

use power tools in dam p or wet locati on, or

expose them to rain. Keep work area well

lighted.

35. Famili arize yoursel f wit h the f ollowing safet y

notices used in this manual:

28. Maintain tools with care. Keep saw blades

sharp and clean for the best and safest

performance. Follow instructions for

lubricating and changing accessories.

29. Turn off t he machine before cl eaning. Use a

brush or compressed air t o remove chips or

debris — do not use your hands.

are not heeded, it may result in minor injury

and/or possible machine damage.

are not heeded, it may result in serious i njury or

possibly even deat h.

This means that if precautions

This means that if precautions

4.0 About this manual

This manual is provided by Walter Meier (Manufacturing) Inc. covering the safe operation and

maintenance procedures f or a JET Model HVBS-7MW Band Saw. Thi s manual contai ns instructions on

installation, safety precautions, general operating procedures, maintenance instructions and parts

breakdown. Your m achine has been designed an d constructed t o provide y ears of troubl e-free operati on

if used in accordance with the instructions as set for th in this document.

If there are questions or c omments, please contact your local suppli er or Walter Meier. Walt er Meier can

also be reached at our web site: www.walt er meier.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should

accompany it.

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious inju ry!

5

Page 6

5.0 Specifications

Model number ........................................................................................................................... HBS-7MW

Stock num ber ................................................................................................................................ 414459

Capacity:

Round at 90°....................................................................................................................... 7” (178mm)

Round at 45°................................................................................................................. 4-1/2” (144 mm)

Rectangle at 90° ........................................... 2”H x 12”W (51x305mm); 7”H x 10-7/8”W (178 x 276mm)

Rectangle at 45° ................................. 7”H x 3-1/2”W (178 x 89mm); 5-1/2”H x 4-1/2”W (140 x 114mm)

Throat depth ............................................................................................................................ 7” (178mm)

Vertical worktable ............................................................................................ 9-3/8” x 10” (238 x 254mm)

Bed heigh t from floor ............................................................................................................. 23” (584mm)

Vise tilts ................................................................................................................................................ 45°

Blade size................................................................................. 3/4” x 0.035” x 93” (19 x 0.889 x 2362mm)

Blade speed ...........................................................................................................86, 132, 178, 260 sfpm

Blade wheel diam et er ...................................................................................................... 11-3/4” (300mm)

Motor (UL listed) ...................................................... TEFC, 3/4HP, 1PH, 115/230V ( pr ewir ed 115V ) , 60Hz

Floor space required .............................................49-1/2” L x 20-1/2” W x 41” H (1257 x 521 x 1041.5mm)

Net weight (approximate) .................................................................................................... 286 lb (130 kg)

Shipping weight ( appr oximate) ............................................................................................ 331 lb (150 kg)

The specifications in this manual were current at time of publication, but because of our policy of

continuous improvem ent, Walter M eier ( M anufacturing) Inc., reserves the r ight to change specific at ions at

any time and without pr ior not ice, without incurring obligations.

6

Page 7

6.0 Setup and assembly

6.1 Shipping contents

1 Band sa w

2 Wheel axles

4 Wheels

4 Split pins

2 Strain clamps

1 Material stop bar

1 Material stop

1 Belt cover

1 Vertical cutting plate

Tools requi red for assemb ly:

#2 cross point screwdriver

Pliers

6.2 Unpacking and clean-up

1. Finish uncrating the saw. Inspect it for

shipping damage. If any damage has

occurred, cont ac t y our distr ibutor.

Figure 1

2. Unbol t t he saw f rom the ski d and plac e it on

a level surface.

3. Clean rust protected surfaces with kerosene,

diesel oil, or a mild solvent. Do not use

cellulose based solvents such as paint

thinner or lacquer thinner. These will

damage painted surfaces.

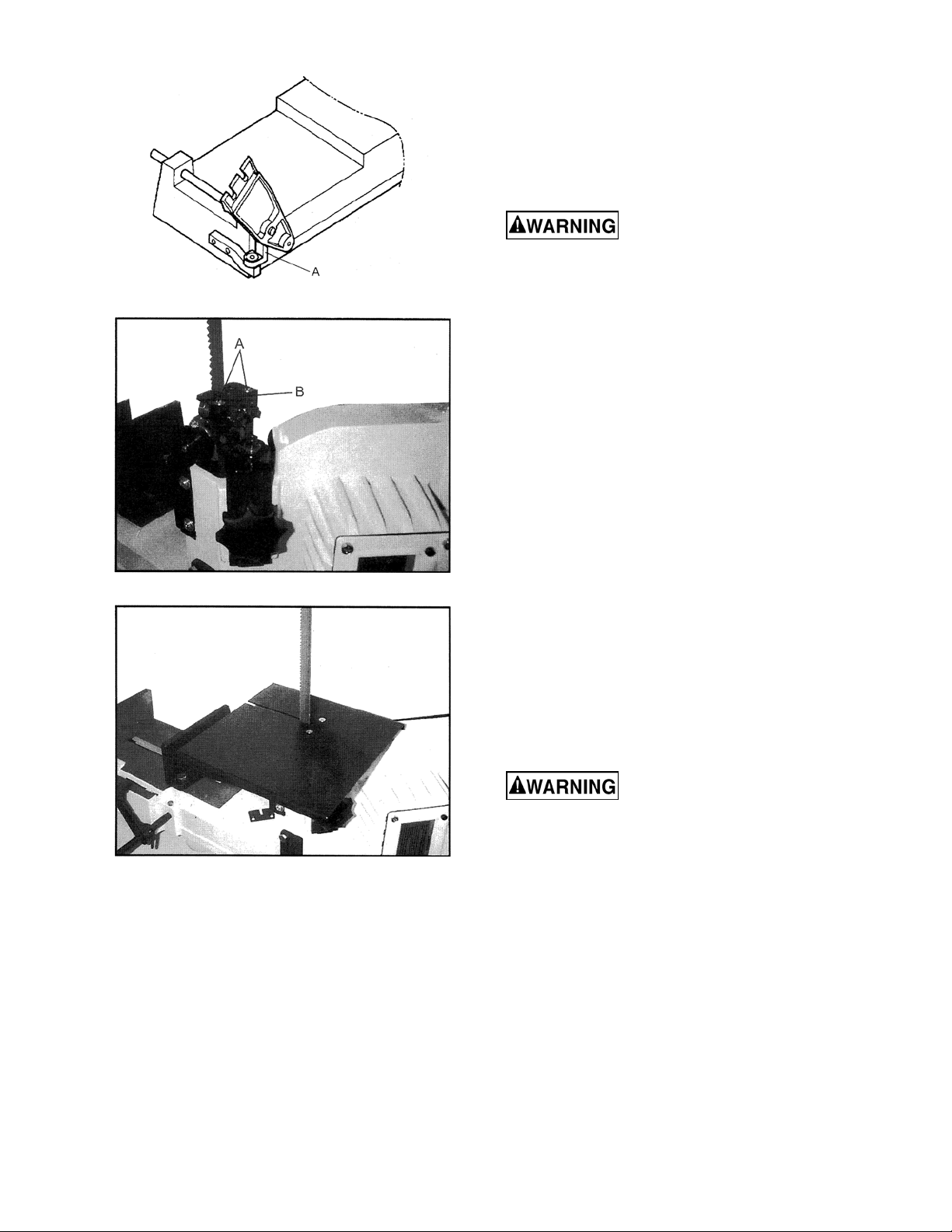

6.3 Assembly

1. Place blocking under the ends of the saw

base to allow wheel installation. Caution:

Make sure saw is steady while temporarily

supported.

2. Slide wheel axles through the holes in the

base.

3. Slide the wheels onto the axles and fasten

with pins. Bend the pins t o hold in place.

4. Slide mat erial stop bar (A, Figure 1) i nto the

base and secure by tightening bolt (B,

Figure 1). Slide material stop (C, Figure 1)

onto the bar and tight en bolt (D, Figure 1).

5. Slide belt cover ov er pulley assemblies and

fasten with screws and washers (A, Figure

2).

6. Close belt cover and secure with lock knob

(B, Figure 2).

7. Remove transportat ion strap which holds the

bow to the bed, and keep it for later use

should the saw be moved any distanc e.

Figure 2

6.4 Vertical cutting plate

Note: These steps are only necessary if using

the band saw in vertic al m ode.

Disconnect machine from

power source before making repairs or

adjustments.

1. Disconnect band saw fr om power source.

2. Raise bow to vertic al position by turning the

bow stop (A, Figure 3) a quarter turn

clockwise; slowly bring bow to v ertical and

lock in place by turning the hydraulic

cylinder valve to the off position. Caution:

Do not pinch fingers between bow stop

and bracket.

3. Remove two screws (A, Figure 4) and

remove defl ector plat e (B, Figure 4).

4. Guide blade through the slot in the table and

fasten with two screws. See Figure 5.

5. W hen v ertical operations are completed, to

lower bow turn hydraul ic cylinder lev er to on

position.

7

Page 8

Figure 3

4. Fill tank to approximately 80% of capacity.

5. Place lid back onto tank, and place tank

assembly bac k into base.

6. Replace return hose back into the hole in

the tank lid.

6.6 Electrical connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

1. All Grounded, Cord-c onnec ted Tools:

In the event of a malfunction or breakdown,

grounding prov ides a path of least resistance f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-groundi ng c onduc tor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accord ance wit h all l ocal codes and

ordinances.

Figure 4

Figure 5

6.5 Coolant tank preparation

Use of a water-soluble coolant will increase

cutting effi ciency and prolong blade lif e. Do not

use black cutting oil as a substitute. Change

cutting oil often and follow manufacturer’s

instructions as to its uses and precautions.

1. Disconnect machine from power source.

2. Remove coolant return hose from the tank

cover.

3. Slide tank out of saw base and carefully

remove the lid cont aining the coolant pump.

Do not modify the plug provided - if it will not fi t

the outlet , have the proper outlet i nstalled by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipmentgrounding conductor . If repair or replacement of

the electric cord or plug is necessary, do not

connect the equi pment-grounding conductor to a

live terminal.

Check with a qualified

electrician or service personnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause seriou s or fat al inju ry.

Use only 3-wire extension cords that have 3prong grounding plugs and 3-pole receptacles

that accept the tool ' s pl ug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cor d-connected tools intended for

use on a supply cir cuit having a nominal rat ing

less than 150 volts:

This tool i s int ended f or use on a ci rcui t that has

an outlet t hat looks like the one illustrat ed in A,

Figure 6. A n adapter, shown in B and C, may be

8

Page 9

used to connect thi s plug to a 2-pole rec eptacle

as shown in B if a properly grounded outlet is

not avail able. The temporary adapter should be

used only until a properly grounded outlet can

be installed by a qualified electrician. This

adapter is not permitted in Canada. T he greencolored rigid ear, lug, and the like, extending

from the adapter must be connected to a

permanent gr ound such as a properly grounded

outlet box.

3. Grounded, cor d-connected tools intended for

use on a supply cir cuit having a nominal rat ing

between 150 - 250 volts, inclusive:

This tool i s int ended f or use on a ci rcui t that has

an outlet t hat looks like the one illustrat ed in D,

Figure 6. The tool has a grounding plug that

looks lik e the plug illustrated in D. Make sure the

tool is connected to an outlet having the same

configuration as the plug. No adapter is

available or shoul d be used with this tool . If the

tool must be rec onnected for use on a different

type of electric circuit, the reconnection should

be made by qualified service personnel; and

after reconnection, the tool should comply with

all local codes and ordinanc es.

Figure 7

Figure 6

6.7 Voltage conversion

The HVBS-7MW band saw is rated at 115/ 230V

and comes from the factory prewired at 115V.

To switch to 230V operation, follow the wiring

diagram found on the inside of the motor

junction box. (Similar diagrams are shown in

Figures 7/8.) The plug must be replaced wit h a

plug that is rated at 230V. The coolant pump

wiring will hav e to be changed also. Follow the

diagram found on the coolant pump head to

switch to 230V oper ati on.

Before hooki ng up to the po wer source, be sure

the power and coolant switches are in the off

position.

Figure 8

6.8 Extension cords

The use of extension cor ds is discouraged. Tr y

to position machines within reach of the power

source. If an extension cord becomes

necessary, make sure the cord is in good

condition and heav y enough to carry the current

your product will draw. An undersized cord will

cause a drop in li ne voltage result ing in loss of

power and overheating. Table 1 shows correct

size to use depending on cord length and

nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge

number, the heavier the cord.

Ampere

Rating

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Volts

120

240

AWG

Total length of

cord in feet

25

50

100

50

100

200

Recommended

150

300

Not

Extension Cord Recom m endations

Table 1

9

Page 10

7.0 Adjustments

7.1 Hydraulic feed selector

The hydraulic feed selector i s used to cont r ol the

blade feed rate and to lock the bow in vertical

position. To increase feed rate, turn knob (A,

Figure 9) counter-clockwise. To decrease feed

rate, turn k nob (A) clockwise. To turn off flow of

hydraulic fluid, turn lever (B) as shown in Figure

9. To turn hydrauli c cylinder on, raise lever ( B) t o

the 12 o'clock positi on.

Figure 10

7.3 Adjusting blade guides

1. Disconnect machine from power source.

2. Loosen knob (A, Figure 11) and bolt (B,

Figure 11). Slide bl ade guide assem blies as

close as possible to material without

interferi ng with the cut.

3. Tighten knob (A, Figure 11) and bolt (B,

Figure 11) and connect machine to power

source.

Figure 9

7.2 Changing blade speed

1. Disconnect machine from power source.

2. Loosen motor pl ate lock bolt (A, Fi gur e 10) .

3. Loosen motor plate slide bolt (B, Figure 10)

until the belt can be mov ed on the pulleys.

4. Move belt to desir ed pulley combination.

5. Tighten motor plate slide bolt (B) to retension belt.

6. Tighten motor plat e loc k bolt ( A).

7. Connect machine to power source.

Figure 11

7.4 Vise adjustment

Do not make any

adjustments or load/unload material from

vise while machine is running. Failure to

comply may cause seriou s injury.

To set the vise for 0 to 45 degree cutti ng:

1. Remove bolt and nut assemblies (C, Figure

12).

2. Posit i on the vi se and re-i nstal l as pi ctur ed in

Figure 13. P ay par ticular attention to the bolt

hole locati on.

10

Page 11

3. Set vi se to desired angle, re-instal l nuts and

bolts, and tighten the nut and bolt

assemblies.

1. Install blade bet ween the wheels, an d insert

blade between the bearings on the blade

guides.

4. Adjust the mov able vise parallel t o the fixed

vise by loosening bolt (A, Figure 13),

adjusting to par allel, and tightening bolt.

Figure 12

2. Tension blade slightly to r emove any sag in

blade between blade wheels.

3. Turn blade tension knob ( A, Figure 14) one

and three quarter to two revolutions

clockwise. T his equal s approximately 23,000

lbs. of blade tension.

Do not overtighten blade.

This may cause blad e to stretch and w arp.

Figure 13

To set vise fo r maximum width of stock cuttin g:

1. Remove the nut and bolt assem blies.

2. Position the vise and re-install the bolt

assemblies as pict ur ed in Figure 12.

7.5 Blade tension

Disconnect machine from

power source. Blades are sharp; use extra

care when remo ving, installing or adj usting.

Failure to compl y may cause seri ou s in ju ry.

Blade tension is important to the proper

operation of the saw. Proper blade tension is

22,000 to 25,000 lbs. per square inch as

measured on a blade t ensi on gauge.

To set the blade tension without the use of a

blade tension gauge:

Figure 14

4. After blade has been completely installed,

close the cov ers, connect to power source,

and run saw f or two t o three m inutes so the

blade can seat properl y .

5. Disconnect machine from power source.

Open the cov er and l oosen bl ade just u nt il it

begins to sag.

6. Tighten blade until it becomes straight

between the blade wheels and all sag has

been eliminat ed.

7. Tighten blade by turning blade tension

wheel two full revolutions. Blade is now

properly tensi oned and r eady for use.

8. Close the covers and connect machine to

power source.

7.6 Changing blades

Never operate this saw

unless all blade guards are installed and in

proper working order. Never adjust blade

brush while machin e is runni ng .

11

Page 12

This machine is designed

and intended for use with blades that are

3/4” wide by 0.032” thick x 93” long . Use of

blades with difference specifications may

cause inferio r performance.

1. Disconnect machine from power source.

2. Raise bow to vertical position and lock in

place by turning the hydr aulic cylinder off.

3. Remove red blade guard assembly (A,

Figure 15) by removing two screws (B,

Figure 15).

It is essential this guard

be install ed after the new blade has been

fitted.

4. Remove brush assembly (C, Figure 15) by

removing two screws (D, Fi gur e 15) .

13. Run the saw and make sure blade is

tracking properly (see section 7.9).

7.7 Adjusting blade square to table

1. Disconnect machine from power source.

2. Place a m achini st's square on t he tabl e and

against the blade, as shown in F igure 16.

3. Verify that bl ade makes contact with square

along the entire width of blade.

4. If adjustment is necessary, l oosen bolts (A,

Figure 16) and rotate blade guide

assemblies slightly in the same direction

until the blade makes contact with the

square along its entire width.

5. Tighten bolt s (A, Figure 16).

6. Connect machine to power source.

Note: If adj ustment to square blade t o table is

necessary, be sure to check blade adjustments

again.

Figure 15

5. Loosen blade tension by turning blade

tension knob counter-clockwise.

6. Carefully remove old blade. Caution: blade

teeth are sharp. Hand le with care.

7. Install new blade by placing the blade

between blade guides first. Make sure the

blade teeth face the same direction as

indicated on the label found on the saw bow.

8. Place the blade around both wheels. Make

sure the blade edge rests near the wheel

flange on both wheels.

9. Turn the blade tension knob clockwise to

tension the blade. Do not ov er tension. See

section 7.5, Blade tens ion.

10. Close bl ade cov er door and secure with l ock

knobs.

11. A ttach red blade guard and brush assembly.

12. Connect machine to power source.

Figure 16

7.8 Adjusting blade square to vise

1. Disconnect machine from power source.

2. Place a machinist's square flush against

vise and blade, as shown in Figure 17.

Square should l ie along the enti re length of

vise and blade without a gap.

3. If adjustment i s necessary, loosen the bol ts

holding the v ice and adj ust the vise so t hat

the square lines up properly. Tighten bolts.

4. Connect machine to power source.

12

Page 13

Figure 17

7.9 Adjusting blade tracking

Figure 18

Blade tracking adjustment

requires ru nn in g the saw with the back cover

open. This adjustment must be completed by

qualified persons only.

Note: Before m aking any tracking adj ustments,

try a new blade. Warped blades will not track.

Blade tracking has been set at the f actory and

should not require adjustment. If tracking

problems occ ur, adjust the machine as follows:

1. Move saw bow to vertical posi tion and lock

in place by shutting off hydraulic cylinder

valve.

2. Confirm that blade tension is set properly.

To adjust, see section 7.5, Blade tension.

3. Open back cover by loosening lock knobs.

4. Run the saw and observ e the blade. Blade

should run next to but not tightly against

wheel flange.

5. Loosen bolts (A, Figur e 18) .

6. Turn set screw (B, Figure 18) while

observing the blade tracking on the wheel.

Turn set screw cloc kwise to track the blade

closer to the wheel flange. Turn set screw

counter-clockwise to track blade away f rom

wheel flange.

7.10 Adjusting blade guide bearings

1. Disconnect machine from power source.

2. Raise bow to vertical position and lock in

place by turning off hy dr aulic c yli nder v alv e.

3. Loosen hex cap screw (A, Figure 19) and

adjust assembly so that the back roller

bearing is approximately 0.003" to 0.005"

from the back of the blade.

4. Turn nut (B, Figure 19) to adjust the

eccentric beari ng snug to the blade. Blade

should still move up and down freely when

grasped as in F igure 20. Warning! Make

sure power is disconnected and hands

are protect ed before handling blade. Be

sure that the blade teeth do not interfere

with the roller bearings.

5. Repeat for other blade guide assembly.

6. Connect machine to power source.

7. Once tr acking is set, ti ghten bolt s (A, Figure

18).

Figure 19

13

Page 14

Figure 20

7.11 Adjusting bow weight

Bow weight is one of the most important

adjustment s of t he saw. I f bow weight i s not set

properly, one can expect poor performance,

crooked cuts, tooth stripping, stalling, and the

blade popping off the blade wheels. The

hydraulic feed rate uni t will not compensate f or

improper bow weight . Bow weight has been set

at the factory and should not need adjustment.

7.12 Adjusting automatic shutoff

The saw should stop after the cut has been

completed:

1. If the saw completes the cut and continues

to run, adjust t he trip brack et (A, Fi gure 22)

down.

2. If the saw shuts off before the cut is

complete, adjust the trip bracket (A, Figure

22) up.

3. If the saw stop s cutti ng but conti nues to run,

adjust the stop bolt (B , Fi gur e 22) .

The saw is properly adjusted when the saw

shuts off just aft er the blade has finished the cut.

If adjustment bec om es necessary:

1. Disconnect machine from power source.

2. Turn on hydraulic cylinder valve and place

the saw bow in horizontal posi tion.

3. Turn feed rate valve on hydraulic cylinder

counter-clockwise until it stops.

4. Place a fish-type scale under the blade

tension handle and lift the saw bow. Scale

should indicate approximately 13 to 15 lbs.

5. Adj ust tensi on to approxim at ely 13 to 15 lbs.

by turning bolt (A, Figure 21).

6. Connect machine to power source.

Figure 22

8.0 Operation

Prior to Operation:

1. Check to see that the blade tooth direction

matches the diagr am on saw body.

2. Check to see that the blade is properly

seated on the wheels after proper tension

has been applied.

3. Set the blade guide roller bearings snug

against blade. See section 7.10, Adjusting

blade guide bearings, for more detail.

4. Check for a slight clearance between the

backup rollers and the bac k of t he blade.

5. Position bot h blade guides as clos e to work

as possible.

6. Select proper speed and feed rate for

material being c ut.

Figure 21

7. Material to be cut must be hel d securely in

vise.

8. Check to see that coolant lev el is adequat e.

9. Do not start a cut on a sharp edge.

14

Page 15

10. Keep machine lubricated. See section 9.1,

Lubrication.

4. Hold a container under the lower right corner

of the gear box with one hand whi le slowly

raising the saw bow with the other.

9.0 Maintenance

Disconnect machine from

power source before making any repair or

adjustment. Failu re to do this may result in

serious personal injury.

1. Keep all surfaces clean and free of rust,

slag, chips, and coolant build-up.

2. Do not use compressed air to clean the

band saw. Compr essed air m ay force chips

into the guide bearings and other critical

areas of the saw.

3. Use a small paint brush or parts cleaning

brush to remove metal par ticles.

4. W ipe the saw down with a clean, dry cloth

and oil all unpainted surfaces with light

machine oil.

5. Keep the blade guides clean and free of

metal chips.

6. Check the guide bearings frequently to

make sure they are properly adjusted and

turning freely.

9.1 Lubrication

Ball bearings on the blade guide as semblies and

the blade wheels are permanently sealed and

require no lubri c ation.

Lightly lubricate the vise screw with #2 tube

grease.

Change gear box oil after the first 90 days of

operation. Thereafter, change every six months.

To change gear box oil:

1. Disconnect machine from power source.

2. Place saw bow in horiz ontal position.

3. Remove screws (A, Figure 23) from gear

box and remove cover plate and gasket.

5. Place the saw bow in horizontal position

again. Wipe out rem aining oil with a rag.

6. Fill the gear box with approximat ely 3/4 pint

of 90 weight gear oil.

7. Replace the gasket and cover. Fasten the

cover with screws.

8. Connect machi ne to the power source.

Figure 23

9.2 Chip Cleaning Brush

Do not attempt to adjust

blade brush with machine running. Adjust

only when machine’s power cord has been

removed from power sou rce.

It is v ery im portant t hat the bl ade cleani ng brush

be properly adjusted and kept in good working

order. Replace t he brush if it becomes dam aged

or worn out. Blade lif e will be shortened severely

if the brush i s allowed to go out of adjustment,

becomes damaged, or is worn out.

15

Page 16

10.0 Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order par ts or reach our serv i ce departm ent, call

1-800-274-6848 Monday through Friday (see our website for business hours, www.waltermeier.com).

Having the Model Number and Serial Number of your mac hine available when you call will allow us to

serve you quickly and accurately.

16

Page 17

10.1.1 HVBS-7MW Bed Assembly – Exploded View

17

Page 18

10.1.2 HVBS-7MW Bow Assembly – Exploded View

18

Page 19

10.1.3 HVBS-7MW Bed and Bow Assemblies – Parts List

Index No Part No Description Size Qty

1 ............... HVBS7MW-1 ...........Coolant Pan .......................................................................................... 1

2 ............... HVBS7MW-2 ...........Base Leg (left) ....................................................................................... 1

3 ............... HVBS7MW-3 ...........Base Leg (right) ..................................................................................... 1

4 ............... HVBS7MW-4 ...........Skirt ....................................................................................................... 1

5 ............... HVBS7MW-5 ...........Shelf ...................................................................................................... 1

6 ............... HVBS7MW-6 ...........Toggle Switch ........................................................................................ 1

7 ............... HVBS7MW-7 ...........Electrical Box......................................................................................... 1

8 ............... TS-0051031 .............Hex Cap Bolt ......................................................5/16”x3/4” ................. 10

9 ............... TS-0720081 .............Lock Wash e r ......................................................5/16” ......................... 27

10 ............. TS-0680031 .............Flat Washer ........................................................5/1 6” ......................... 32

11 ............. TS-0561021 .............Hex Nut ..............................................................5/16” ......................... 27

12 ............. TS-0051011 .............Hex Ca p Bolt ......................................................5/16” x1/2” ................... 9

13 ............. HVBS7MW-13 .........Cylinder Assembly

13N .......... HVBS7MW-13N .......Cylinder Assembly

................. HVBS7MW-13-RK ...Cylinder Repair Kit (not shown) ............................................................. 1

14 ............. TS-150506 ...............Hex Socket Cap Screw ** ..................................M1 0x40 ...................... 1

15 ............. TS-0680041 .............Flat Washer ** ...................................................3/8” ............................. 4

16 ............. TS-0720091 .............Lock Washer ** ..................................................3/8”........................... 10

17 ............. TS-154007 ...............Hex Nut ** .........................................................M10 ............................ 1

18 ............. TS-0060051 .............Hex Cap Bolt ** .................................................3/8 ” x1” ........................ 2

19 ............. HVBS7MW-19 .........Support Rod ** ..................................................................................... 1

20 ............. TS-0050011 .............Hex Cap Bolt ** .................................................1/4 "x1/2” ..................... 1

21 ............. HVBS7MW-21 .........Bottom Support ** ................................................................................. 1

22 ............. 5518228N ................Flat Washer (S/N: 120141912 and higher) ..........23.8x13x2.7mm .......... 4

23 ............. HVBS7MW-23 .........Wheel (S/N: 120141911 and lower) ....................4" ............................... 4

23N .......... 5518229N ................Wheel (S/N: 120141912 and higher) ..................8" ............................... 4

24 ............. HVBS7MW-24 .........Wheel Shaft (S/N: 120141911 and lower) ................................................

24N .......... 5518230N ................Wheel Shaft (S/N: 120141912 and higher) ..........Ø16x432mm ............... 2

25 ............. 5518231N ................Cotter Pin (S/N: 120141912 and higher) ................................................ 4

................. J3410-WA ................Wheel Assembly (index # 22-25) (S/N: 120141912 and higher) .............. 1

26 ............. HVBS7MW-26 .........Power Cord ........................................................................................... 1

................. HVBS7MW-26-1 ......Power Cord (motor - main switch –not shown) ....................................... 1

................. HVBS7MW-26-2 ......Power Cord (main switch - pump - not shown) ....................................... 1

27 ............. HVBS7MW-27 .........Table ..................................................................................................... 1

28 ............. TS-0081051 .............Hex Cap Bolt ......................................................5/16”x1” .................... 10

29 ............. HVBS7MW-29 .........Filter Assembly ...................................................................................... 1

30 ............. HVBS7MW-30 .........Hex Head Screw

31 ............. HVBS7MW-31 .........Switch Box Assembly (S/N: 5011368 & lower) ....................................... 1

31N .......... HVBS7MW-31N .......Switch Box Assembly (S/N: 5011369 & higher) ...................................... 1

................. HVBS7MW-31A .......Sw itch (S/N: 5011368 & lower) .............................................................. 1

................. HVBS7MW-31AN .....Switch (S/N: 5011369 & higher) ............................................................. 1

32 ............. HVBS7MW-32 .........Wheel Handle ........................................................................................ 1

33 ............. HVBS7MW-33 .........Key.....................................................................5x20 mm ..................... 1

34 ............. HVBS7MW-34 .........Lead Screw ........................................................................................... 1

35 ............. HVBS7MW-35 .........Nut Seat ................................................................................................ 1

36 ............. HVBS7MW-36 .........Strain Relief Assembly ........................................................................... 1

37 ............. HVBS7MW-37 .........Support Plate......................................................................................... 1

38 ............. HVBS7MW-38 .........Stop Screw ............................................................................................ 1

39 ............. TS-0060061 .............Hex Cap Bolt ** .................................................3/8 ” x1-1/4” .................. 4

40 ............. TS-0561031 .............Nut ** .................................................................3/8”............................. 8

41 ............. HVBS7MW-41 .........90° Support ........................................................................................... 1

42 ............. TS-0060071 .............Hex Ca p Bolt ......................................................3/8”x1-1 /2” .................. 4

43 ............. TS-0270031 .............Set Screw ...........................................................5/16”x3/8” ................... 4

44 ............. HVBS7MW-44 .........Thumb Screw ........................................................................................ 1

45 ............. HVBS7MW-45 .........Stop Block ............................................................................................. 1

(S/N: 010218160 and lower)

(S/N: 010218161 and higher) ....

................................................3/16”x3/8” ................... 4

......................................... 1

................................... 1

19

Page 20

Index No Part No Description Size Qty

46 ............. HVBS7MW-46 .........Stop Rod ............................................................................................... 1

47 ............. TS-0561031 .............Hex Nut ..............................................................1/2" ............................ 2

48 ............. TS-0680061 .............Flat Washer ........................................................1/2 " ............................ 4

49 ............. TS-026702 ...............Set Screw ...........................................................1/4"x1/4” ..................... 2

50 ............. HVBS7MW-50 .........Support Shaft ........................................................................................ 1

51 ............. HVBS7MW-51 .........Pivot Arm (S/N: 80910746 and lower) .................................................... 1

51N .......... HVBS7MW-51N .......Pivot Arm (S/N: 80910747 and higher) ................................................... 1

52 ............. TS-0720091 .............Lock Washer ......................................................3/8”............................. 2

53 ............. HVBS7MW-53 .........Spring .................................................................................................... 1

54 ............. HVBS7MW-54 .........Spring Adj usting Rod ............................................................................. 1

55 ............. HVBS7MW-55 .........Spring Bracket ....................................................................................... 1

56 ............. TS-0051061 .............Hex Ca p Bolt ......................................................5/16” x1-1/2” ................ 5

57 ............. HVBS7MW-57 .........Vise Jaw (left) ........................................................................................ 1

58 ............. HVBS7MW-58 .........Vise Jaw (right) ...................................................................................... 1

59 ............. HVBS7MW-59 .........Scale (S/N: 010217984 and lower) ........................................................ 1

59N .......... HVBS7MW-59N .......Scale (S/N: 010217985 and higher) ....................................................... 1

60 ............. HVBS7MW-60 .........Arm Support Plate ................................................................................. 1

61 ............. TS-020908 ...............Hex Socket Cap Screw .......................................3/8”x1-3/4” .................. 1

62 ............. HVBS7MW-62 .........Hos e ..................................................................................................... 1

63 ............. HVBS7MW-63 .........Pump .................................................................................................... 1

64 ............. TS-0050021 .............Hex Cap Bolt * ...................................................1/4”x5/8” ..................... 4

65 ............. HVBS7MW-65 .........Tank Cov er (S/N: 8091100 and lower) ................................................... 1

66 ............. HVBS7MW-66 .........Coolant Tank (S/N:

66N .......... HVBS7MW-66N .......New Coolant Tank (S/N:80911001 and higher) ...................................... 1

66-1 .......... HVBS7MW-66-1N ....Plastic Funnel (S/N: 80911001 and higher) ............................................ 1

67 ............. HVBS7MW-67 .........Hose Fitting ........................................................................................... 1

68 ............. HVBS7MW-68 .........Hose Clamp .......................................................................................... 1

69 ............. HVBS7MW-69 .........Hos e ..................................................................................................... 1

70 ............. HVBS7MW-70 .........Saw Bow (S/N: 8091100 and lower)....................................................... 1

70N .......... HVBS7MW-70N .......Saw Bow (S/N: 8091101 and hi gher ) ..................................................... 1

70N1 ........ HVBS7MW-70N1 .....Saw Bow (JET Mark) (S/N: 010218161 and higher) ............................... 1

71 ............. HVBS7MW-71 .........Vent Plug * ........................................................................................... 1

72 ............. HVBS7MW-72 .........Gear Box Cover * ................................................................................. 1

73 ............. HVBS7MW-73 .........Gear Box Gasket * ................................................................................ 1

74 ............. HVBS7MW-74 .........Worm Gea r *(S/N: 00114808 and lower) ............................................... 1

74N .......... HVBS7MW-74N .......Worm Gea r *(S/N: 00114809 and higher) ............................................. 1

75 ............. TS-051061 ...............Hex Cap Bolt * ...................................................5/16”x1-1/4” ................ 1

76 ............. BB-6005Z ................Ball Bearing * ........................................................................................ 3

77 ............. HVBS7MW-77 .........C-Ring * ............................................................R -4 7 ........................... 2

78 ............. HVBS7MW-78 .........Oil Seal * .............................................................................................. 1

79 ............. HVBS7MW-79 .........Gear Box * ............................................................................................ 1

80 ............. HVBS7MW-80 .........Blade Wheel (S/N: 00114808 and lower) ............................................... 1

80N .......... HVBS7MW-80N .......Blade Wheel (S/N: 00114809 and higher) .............................................. 1

81 ............. HVBS7MW-81 .........Worm Bushing * ................................................................................... 1

82 ............. HVBS7MW-82 .........Bi-Metal Blade ....................................................................................... 1

83 ............. HVBS7MW-83 .........Wheel Cover ......................................................................................... 1

84 ............. HVBS7MW-84 .........Rear Wheel Cover ................................................................................. 1

85 ............. HVBS7MW-85 .........Plum Screw ........................................................................................... 2

86 ............. HVBS7MW-86 .........Lock Knob ............................................................................................. 2

87 ............. HVBS7MW-87 .........Adjustable Bracket (right)....................................................................... 1

88 ............. BB-608ZZ ................Ball Bearing ........................................................................................... 2

89 ............. HVBS7MW-89 .........Adjustable Blade Seat (right) ................................................................. 1

90 ............. HVBS7MW-90 .........Bearing Pin ............................................................................................ 2

91 ............. HVBS7MW-91 .........Eccentric Shaft Assem bly (outside) ........................................................ 2

91A .......... HVBS7MW-91A .......Center Shaft Assembly(inside)(S/N: 80910747 and higher) .................... 2

................. BB-608ZZ ................Ball Bearing (not shown) ........................................................................ 8

................. HVBS7MW-91-2 ......Eccentric Shaft (outside) (not shown) ..................................................... 2

8091100 and lower) ................................................ 1

20

Page 21

Index No Part No Description Size Qty

................. HVBS7MW-91A-2 ....Center Shaft (inside)(S/N: 80910747 and higher) ................................... 2

................. HVBS7MW-91-3 ......C-Ring (not shown) ................................................................................ 4

92 ............. TS-0561031 .............Hex Nut ..............................................................3/8”............................. 4

93 ............. TS-081F021 .............Flat Head Machine Screw ...................................1/4"x3/8” ..................... 2

94 ............. HVBS7MW-94 .........Vertical Cutting Plate ............................................................................. 1

95 ............. HVBS7MW-95 .........Top Support ** ...................................................................................... 1

96 ............. TS-0813032 .............Round Head Screw ............................................1/4"x1/2” ..................... 4

97 ............. TS-0680021 .............Flat Washer ........................................................1/4 " .......................... 12

98 ............. HVBS7MW-98 .........Brush Holder ......................................................................................... 1

99 ............. TS-0060111 .............Hex Ca p Bolt ......................................................3/8”x2-1 /2” .................. 2

100 ........... HVBS7MW-100........Brush .................................................................................................... 1

101 ........... HVBS7MW-101........Nozzle Cock .......................................................................................... 1

102 ........... TS-0267021 .............Set Screw ...........................................................1/4"x1/4” ..................... 3

103 ........... HVBS7MW-103........Nozzle Cock Support ............................................................................. 1

104 ........... HVBS7MW-104........Valve ..................................................................................................... 1

105 ........... TS-0208071 .............Hex Socket Cap Screw .......................................5/16”x1-1/4” ................ 2

106 ........... HVBS7MW-106........Adjustable Bracket (left) ......................................................................... 1

107 ........... HVBS7MW-107........Adjustable Blade Seat (left) ................................................................... 1

108 ........... HVBS7MW-108........Bl ade Guard .......................................................................................... 1

109 ........... HVBS7MW-109........Brush Support ....................................................................................... 1

110 ........... TS-0050011

111 ........... HVBS7MW-111........Guide Plate ........................................................................................... 2

112 ........... HVBS7MW-112........Set Screw ...........................................................5/16”x3/4” ................... 1

113 ........... TS-0051071 .............Hex Cap Bolt ......................................................5/16”x1- 1/2” ................ 2

114 ........... HVBS7MW-114........Bl ade Tension Block .............................................................................. 1

115 ........... HVBS7MW-115........Sliding Draw Block ................................................................................. 1

116 ........... HVBS7MW-116........Switch Cut-Off Bracket .......................................................................... 1

117 ........... HVBS7MW-117........Bearing Bus hing .................................................................................... 1

118 ........... BB-6203Z ................Ball Bearing ........................................................................................... 2

119 ........... HVBS7MW-119........Bl ade Wheel (left) .................................................................................. 1

120 ........... HVBS7MW-120........Bl ade Tension Handwheel ..................................................................... 1

121 ........... HVBS7MW-121........Vertical Cutting Plate ............................................................................. 1

122 ........... VB-3V270 ................V-Belt .................................................................................................... 1

123 ........... HVBS7MW-123........Worm Pulley .......................................................................................... 1

124 ........... HVBS7MW-124........Motor Pulley .......................................................................................... 1

125 ........... HVBS7MW-125........Hex Head Screw ................................................1/4"x3/8” ..................... 2

126 ........... HVBS7MW-126........Pulley Cov er ......................................................................................... 1

127 ........... HVBS7MW-127........Lock Screw ............................................................................................ 1

128 ........... TS-0720071 .............Lock Was h e r ......................................................1/4" ............................ 1

129 ........... HVBS7MW-129........Motor ..................................................................................................... 1

................. HVBS7MW-129A .....Motor Fan (not shown) ........................................................................... 1

................. HVBS7MW-129B .....Motor Fan Cover (not shown) ................................................................ 1

130 ........... HVBS7MW-130........Motor M

131 ........... HVBS7MW-131........C-Ring * ............................................................S-17 ........................... 1

132 ........... BB-6003Z ................Ball Bearing * ........................................................................................ 3

134 ........... HVBS7MW-134........Oil Seal * .............................................................................................. 1

135 ........... HVBS7MW-135........Bearing Bushing * ................................................................................. 1

136 ........... HVBS7MW-136........Worm Sha ft * ........................................................................................ 1

137 ........... HVBS7MW-137........Support Plate......................................................................................... 1

138 ........... HVBS7MW-138........Motor Support Plate ............................................................................... 1

139 ........... HVBS7MW-139........Hex Cap Bolt ......................................................1/2"x1-1/4” .................. 1

139A ........ HVBS7MW-139A .....Hex Ca p Bolt ......................................................1/2"x1-3 /16” ................ 1

140 ........... TS-0720111 .............Lock Was h e r ......................................................1/2" ............................ 2

141 ........... HVBS7MW-141........Key.....................................................................5x20 mm ..................... 1

142 ........... HVBS7MW-142........Key * .................................................................6x20mm ..................... 2

143 ........... HVBS7MW-143........Hose Clamp .......................................................................................... 3

143A ........ HVBS7MW-143A .....Round Head Screw ............................................3/16”x3/8” ................... 3

.............Hex Cap Bolt ......................................................1 /4"x1/2” ..................... 7

ount Plate ................................................................................. 1

21

Page 22

Index No Part No Description Size Qty

144 ........... HVBS7MW-144........Bearing Bus hing .................................................................................... 1

145 ........... HVBS7MW-145........Flat Washer ........................................................3/8”............................. 4

146 ........... HVBS7MW-146........Cross Screw .......................................................1/8”x1/4" ..................... 2

147 ........... HVBS7MW-147........Flat Washer ........................................................1/8”............................. 2

148 ........... HVBS7MW-148........Strain Relief Bushing ............................................................................. 2

149 ........... HVBS7MW-149........Strain Relief ........................................................................................... 2

150 ........... HVBS7MW-150........E-Ring ................................................................E-7 ............................. 2

151 ........... HVBS7MW-151........Support Screw ....................................................................................... 1

152 ........... HVBS7MW-152........Bracket .................................................................................................. 1

................. HVBS7MW-152A .....Arm Stop Assembly CP ......................................................................... 1

153 ........... HVBS7MW-153........Spring.................................................................................................... 1

154 ........... HVBS7MW-154........Spring Cap ............................................................................................ 1

155 ........... HVBS7MW-155........H e x Socket Cap Screw .......................................3/16”x1/2” ................... 1

156 ........... TS-0561031 .............Nut .....................................................................3 /8”............................. 1

157 ........... TS-0710091 .............Lock Was h e r ......................................................3/8”............................. 2

158 ........... TS-0060051 .............Hex Cap Bolt ......................................................3/8”x1” ........................ 1

159 ........... HVBS7MW-159........Hex Cap Bolt ......................................................5/16”x 3/4” ................... 1

160 ........... HVBS7MW-160........Hex Cross Head Bolt w/ Lock Washer *.....1/4x5/8 ................................. 4

................. HVBS7MW-GB ........Gear Box Assembly (not shown)(index #161 thru 163)

(S/N: 070935060 and higher) ................................. 1

161 ........... TS-0206021 .............Socket Head Cap Screw* ...................................3/16”x1/2” ................... 3

162 ........... HVBS7MW-162........Block Plate* ........................................................................................... 1

163 ........... TS-0271032

164 ........... HVBS7MW-164........Fix bracket............................................................................................. 1

* included in HVBS7MW-GB Gear Box Assembly

** included in HVBS7MW- 13- RK Cylinder Repair Kit

.............Socket Set Screw* ..............................................3/8”x3/8” ..................... 1

22

Page 23

10.2.1 HVBS-7MW Cylinder Assembly – Exploded View

10.2.2 HVBS-7MW Cylinder Assembly – Parts List

Index No Part No Description Size Qty

13N .......... HVBS17M W-13N ........... Cylinder Complete Assembly (S/N: 01028161 and higher) ............... 1

................. HVBS17M W-13N-1 ........ Dust Cover ...................................................................................... 1

................. HVBS17M W-13N-2 ........ C-Ring ............................................................................................ 2

................. HVBS17M W-13N-3 ........ Oil Seal ........................................................................................... 1

................. HVBS17M W-13N-4 ........ Oil Piston ........................................................................................ 1

................. HVBS17M W-13N-5 ........ O-Ring ............................................................................................ 1

................. HVBS17M W-13N-6 ........ Cylinder Body .................................................................................. 1

................. HVBS17M W-13N-7 ........ Oil Pressure Regulator .................................................................... 1

................. HVBS17M W-13N-8 ........ Open/Close Valve ........................................................................... 1

23

Page 24

11.0 Electrical Connections

24

Loading...

Loading...