Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Horizontal-Vertical Variable Speed Band Saw

Model HVBS-56V

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414548

Ph.: 800-274-6848 Edition 5 09/2018

www.jettools.com Copyright © 2017 JET

Page 2

1.0 IMPORTANT SAFETY

INSTRUCTIONS

Read and understand the entire instruction

manual before operating machine.

This band saw is designed and intended for use

by properly trained and exper ienced personnel

only. If you are not familiar wi th the proper and

safe operation of a band saw , do not use until

proper training and knowledge have been

obtained.

WARNING – To reduce risk of injury:

a. Wear eye protection.

b. Do not remove jammed cut off pieces until

blade has stopped.

c. Maintain proper adjustment of blade

tension, blade guides, and thrust bearing.

d. Adjust upper guide to just clear workpiece.

e. Secure workpiece firmly against table.

1. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

2. Replace the warning labels if they become

obscured or removed.

3. Do not use this band saw for other than its

intended use. If used for other purposes, JET

disclaims any real or implied warranty and holds

itself harmless from any injury that may result

from that use.

4. Always wear ANSI Z87.1 approved safety

glasses or face shield while using this band

saw. (Everyday eyeglasses only have impact

resistant lenses; they are not safety glasses.)

5. Before operating this machine, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Do not wear loose

clothing. Confine long hair. Non-slip footwear or

anti-skid floor strips are recommended. Do not

wear gloves.

6. Wear hearing protection (plugs or muffs) if

noise exceeds safe levels.

7. Do not operate this machine while tired or under

the influence of drugs, alcohol or any

medication.

8. Reduce the risk of unintentional starting. Make

sure switch is in off position before plugging in.

9. Make certain the machine is properly grounded.

10. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

11. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine

before turning it on.

12. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

13. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

14. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

15. Keep the floor around the machine clean and

free of scrap material, oil and grease.

16. Keep visitors a safe distance from the work

area. Keep children away.

17. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

18. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

19. Maintain a balanced stance at all times so that

you do not fall into the blade or other moving

parts. Do not overreach or use excessive force

to perform any machine operation.

20. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a

job for which it was not designed. The right tool

will do the job better and more safely.

21. Use recommended accessories; improper

accessories may be hazardous.

22. Maintain tools with care. Keep saw blades

sharp and clean for the best and safest

performance. Follow instructions for lubricating

and changing accessories.

23. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use your hands.

24. Do not stand on the machine. Serious injury

could occur if the machine tips over, or if the

cutting tool is unintentionally contacted.

2

Page 3

25. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

26. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

27. Make sure workpiece is securely clamped in

vise. Never use your hand to hold the

workpiece.

28. Never reach around or over a moving saw

blade.

29. Feed work into a blade or cutter only against the

direction of rotation of the blade or cutter.

30. Set blade guides for minimal exposure of blade

before operating.

31. Don’t use in dangerous environment. Don’t use

power tools in damp or wet location, or expose

them to rain. Keep work area well lighted.

32. Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. Table 2 (sect. 6.2) shows correct

size to use depending on cord length and

nameplate ampere rating. If in doubt, use the

next heavier gage. The smaller the gage

number, the heavier the cord.

WARNING: This product can expose you to

chemicals including lead which is known to the

State of California to cause cancer and birth

defects or other reproductive harm, and

ethylbenzene which is known to the State of

California to cause cancer. For more information

go to http://www.p65warnings.ca.gov.

WARNING: Some dust, fumes and gases

created by power sanding, sawing, grinding,

drilling, welding and other construction activities

contain chemicals known to the State of

California to cause cancer and birth defects or

other reproductive harm. Some examples of

these chemicals are:

• lead from lead based paint

• crystalline silica from bricks, cement and

other masonry products

• arsenic and chromium from chemically

treated lumber

Your risk of exposure varies, depending on how

often you do this type of work. To reduce your

exposure to these chemicals, work in a wellventilated area and work with approved safety

equipment, such as dust masks that are

specifically designed to filter out microscopic

particles. For more information go to

http://www.p65warnings.ca.gov/ and http://www.

p65warnings.ca.gov/wood.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

SAVE THESE INSTRUCTIONS

1.1 ON/OFF Switch padlock

To avoid accidental starting by young children or

others not qualified to use the tool, the use of a

padlock (not provided) is required.

To lock out an ON/OFF switch:

1. Open the padlock (Figure A).

2. Insert through hole in start button (Figure B).

3. Close the padlock.

4. Place the key in a safe place out of the reach of

children.

(A) (B)

3

Page 4

2.0 About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for a JET Model

HVBS-56V Band Saw. This manual contains instructions on installation, safety precautions, general operating

procedures, maintenance instructions and parts breakdown. Your machine has been designed and constructed

to provide consistent, long-term operation if used in accordance with the instructions as set forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET c an also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

Register your product using the mail-in card provided, or register online: http://www.jettools.c om/us/en/serviceand-support/warranty/registration/

4

Page 5

3.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

1.1 ON/OFF Switch padlock ............................................................................................................................. 3

2.0 About this manual .......................................................................................................................................... 4

3.0 Table of contents ............................................................................................................................................ 5

4.0 Specifications ................................................................................................................................................. 6

5.0 Setup and assembly ....................................................................................................................................... 7

5.1 Shipping contents ....................................................................................................................................... 7

5.2 Tools required for assembly ....................................................................................................................... 7

5.3 Unpacking and cleanup .............................................................................................................................. 7

5.4 Assembling stand ....................................................................................................................................... 8

5.5 Mounting saw to stand ............................................................................................................................... 8

5.6 Additional assembly ................................................................................................................................... 8

5.7 Vertical cutting plate ................................................................................................................................... 9

6.0 Electrical connections .................................................................................................................................... 9

6.1 GROUNDING INSTRUCTIONS ................................................................................................................. 9

6.2 Extension cords ........................................................................................................................................ 10

7.0 Adjustments ................................................................................................................................................. 10

7.1 Tools required for adjustments ................................................................................................................. 10

7.2 Blade guide adjustment ............................................................................................................................ 10

7.3 Blade tension ............................................................................................................................................ 10

7.4 Blade changes .......................................................................................................................................... 10

7.5 Blade guide bearings ................................................................................................................................ 11

7.6 Blade tracking ........................................................................................................................................... 11

7.7 Feed pressure adjustment ........................................................................................................................ 12

7.8 Blade-to-table squareness ....................................................................................................................... 12

7.9 Auto shut-off adjustment .......................................................................................................................... 13

7.10 Vise adjustment ...................................................................................................................................... 13

7.11 Vertical stop adjustment ......................................................................................................................... 13

8.0 Operation ..................................................................................................................................................... 13

8.1 Blade selection ......................................................................................................................................... 13

8.2 Blade break-in .......................................................................................................................................... 14

8.3 General operating procedure ................................................................................................................... 14

8.4 Evaluating cutting efficiency ..................................................................................................................... 14

9.0 User-maintenance ........................................................................................................................................ 15

9.1 General maintenance .............................................................................................................................. 15

9.2 Commutator brush inspection .................................................................................................................. 15

9.3 Lubrication ................................................................................................................................................ 15

9.4 Additional servicing .................................................................................................................................. 15

10.0 Troubleshooting HVBS-56V Band Saw ...................................................................................................... 16

10.1 Mechanical and electrical problems ....................................................................................................... 16

10.2 Operational problems ............................................................................................................................. 16

11.0 Replacement Parts ..................................................................................................................................... 17

11.1.1 HVBS-56V Bed Assembly – Exploded View ....................................................................................... 18

11.1.2 HVBS-56V Bow Assembly – Exploded View ....................................................................................... 19

11.1.3 HVBS-56V – Bow and Bed Assemblies Parts List .............................................................................. 20

11.2.1 HVBS-56V Stand – Exploded View ..................................................................................................... 23

11.2.2 HVBS-56V Stand – Parts List .............................................................................................................. 23

12.0 Electrical Connections – HVBS-56V Band Saw ......................................................................................... 24

13.0 Warranty and service ................................................................................................................................. 25

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

5

Page 6

4.0 Specifications

Model number

Stock number 414548

Motor and Electricals

Motor type DC brushed motor

Horsepower 1/2 HP (0.375 kW)

Motor phase single

Voltage 115 V only

Cycle 60 Hz

Listed FLA (full load amps) 4

Motor speed 1200-3600 RPM

On/off switches Magnetic push-button; toggle shut-off on bed

Power transfer Gear

Power cable SJT 3x18AWG, 300V, length 5-1/2 ft. (168 cm)

Power plug installed 120 V, 15A

Recommended circuit size 1 15 A

Sound emission without load 2 60~65 dB at 1m (40 in.)

Capacities

Horizontal

capacity

Throat depth 5 in. (127 mm)

Bow and blade

Blade type provided raker type, bi-metal

Blade size 1/2 x 0.025 x 64-1/2 in. (13 x 0.64 x 1638 mm)

Blade speeds variable, 80-230 SFPM (25-72 MPM)

Blade wheel diameter 7-3/8 in. (187 mm)

Bed and vise

Bed height from floor (mounted to stand) 25-1/2 in. (648 mm)

Vise swivel 0 – 45 deg.

Main materials

Bed cast iron, ground surface

Bow cast iron

Stand steel

Side blade guides ball bearings mounted on eccentric shafts

Rear blade guides ball bearings

Band wheels flanged cast iron

Dimensions

Vertical cutting plate 9-5/8 x 9-1/2 in. (244.5 x 241 mm)

Floor space required 16-1/4 x 42-1/2 in. (413 x 1080 mm)

Overall assembled (LxWxH) 37 x 17.72 x 41.34 in. (940 x 450 x 1050 mm)

Shipping dimensions (LxWxH) 38.78 x 13.98 x 17.80 in. (985 x 355 x 452 mm)

Weights

Net weight 115 lbs. (52 kg)

Shipping weight 143.30 lbs. (65 kg)

Round

Rectangle

(HxW)

90 deg. 5 in. (127 mm)

45 deg. 3 in. (76 mm)

90 deg. 5 x 5-3/4 (127 x 146 mm); and 2 x 6 in. (51 x 152.4 mm)

45 deg. 4-1/2 x 3 in. (114 x 76 mm)

HVBS-56V

Table 1

1

subject to local/national electrical codes.

2

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As workplace

conditions vary, this information is intended to allow the user to make a better estimation of the hazards and risks

involved only.

L = length, W = width, H = height SFPM = surface feet per minute RPM = revolutions per minute

6

Page 7

5.0 Setup and assembly

Read and understand all

instructions before attempting assembl y. Band

Saw must be disconnected from pow er during

all assembly procedures. Failure to comply may

cause serious injury.

5.1 Shipping contents

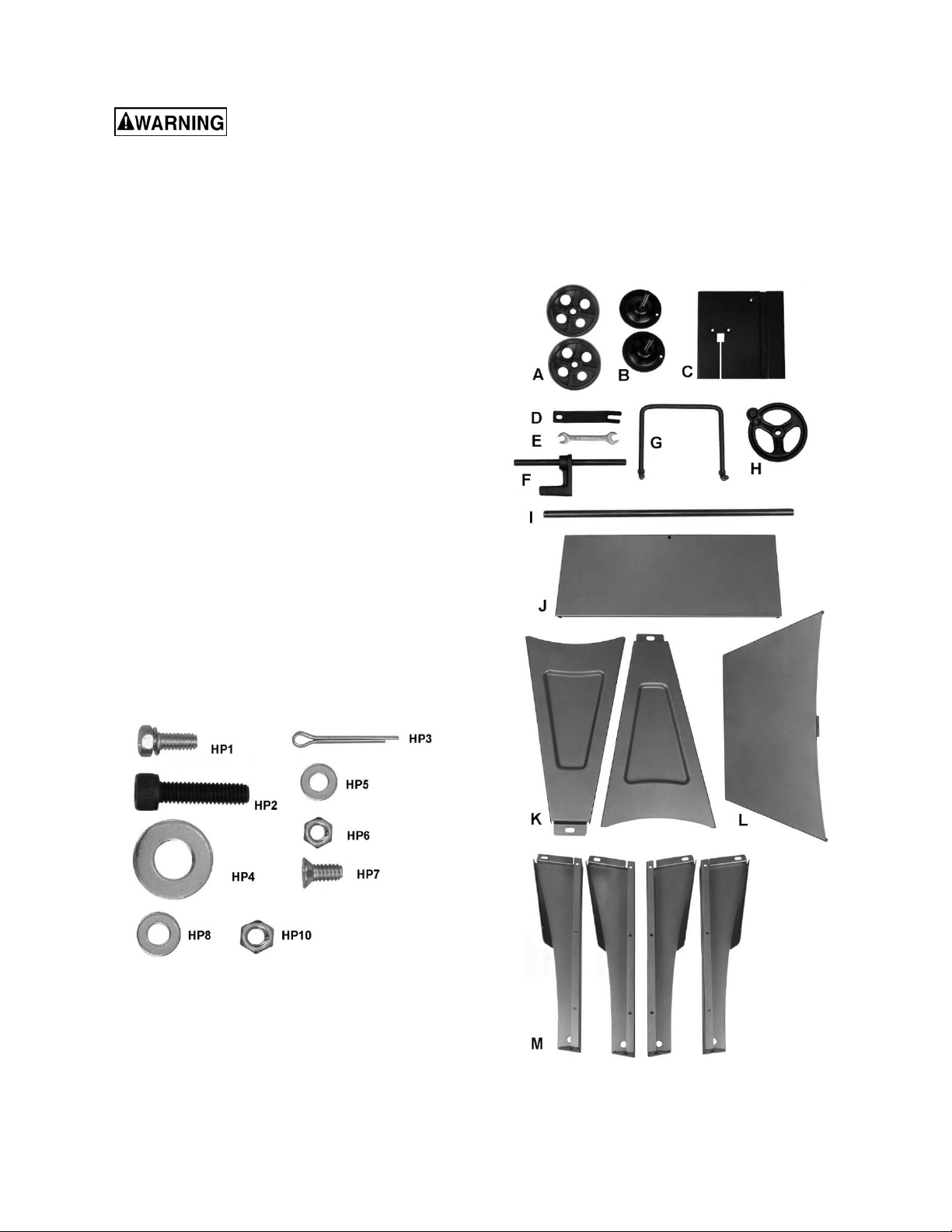

See Figures 5-1 and 5-2.

1 Band saw (not shown)

2 Wheels – A

2 Adjustable foot with nuts and washer – B

1 Vertical cutting plate – C

1 Vertical cutting plate stand – D

1 Open end wrench 12/14mm – E

1 Work stop assembly – F

1 Handle – G

1 Handwheel – H

1 Axle – I

1 Stand shelf – J

2 Stand cross braces – K

1 Stand front panel – L

4 Stand legs (2 LH, 2 RH) – M

1 Hardware package, includes:

19 Phillips hd screws, 1/4x5/8 – HP1

6 Socket hd cap screws, 5/16x1-1/4 – HP2

2 Cotter pins, 1/8x1 – HP3

6 Flat washers, 5/8 – HP4

20 Flat washers, 1/4 – HP5

20 Hex nuts, 1/4 – HP6

1 Flat head screw, 1/4 x 3/4 – HP7

6 Flat washers, 5/16 – HP8

6 Hex nuts, 5/16 – HP10

5.3 Unpacking and cleanup

1. Inspect all contents for shipping damage.

Compare contents of shipping carton with

contents list in this manual. Report any damage

or part shortages to your distributor.

2. Do not discard packing material until saw is

assembled and running properly.

3. Remove rust protectant from exposed surfaces,

such as bed, vise assembly, etc., with a clean

rag and cleaner/degreaser. Apply a light coat of

oil on these surfaces to inhibit rust.

Figure 5-1: Hardware package HVBS56V-HP

5.2 Tools required for assembly

Wrenches, 10mm, 12mm

Hex wrench, 4mm

#2 cross point screwdriver

Pliers

(Note: Ratchet wrench with sockets will speed

assembly.)

Figure 5-2: contents

7

Page 8

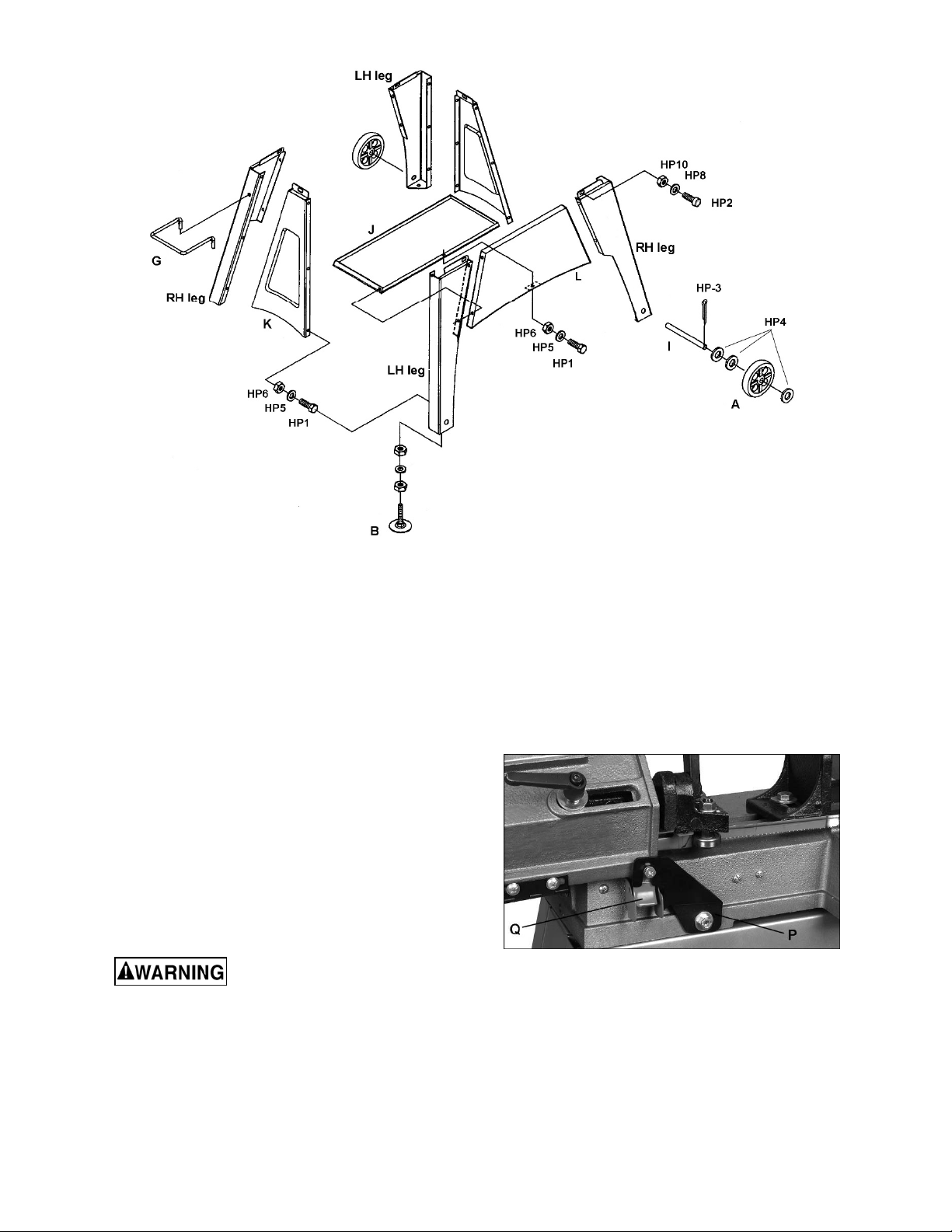

Figure 5-3: stand assembly

5.4 Assembling stand

Refer to Figure 5-3.

NOTE: Only make fasteners hand-tight at this time.

They will be fully tightened after band saw has been

settled atop stand.

1. Assemble legs, cross braces, front panel and

shelf, as shown in Figure 5-3.

2. Install handle (G) into end of assembled stand

3. Install axle and wheels on right side of stand.

Use two flat washers between wheel and stand

leg on each side. Insert cotter pin (HP3) at each

axle end and bend prongs to secure.

4. Install adjustable feet (B) at opposite end of

stand and adjust until stand is level.

5.5 Mounting saw to stand

Saw is heavy; two-person lift.

1. With help from another person, position saw

atop stand, and secure with socket head cap

screws and washers (HP2/8/10, Figure 5-3).

2. Fully tighten all fasteners on stand assembly.

5.6 Additional assembly

1. Remove shipping bracket (P, Figure 5-4) and

adjust switch tr ip (Q) so tha t it wil l turn o ff swit ch

when bow reaches down position. (Switch trip

is bendable for optimum positioning.) Retain

shipping bracket in case machine must be

transported in the future.

Figure 5-4

2. Install handwheel (H, Figure 5-5) onto vise lead

screw shaft, aligning the set screw with the flat

on the shaft. Tighten set screw.

3. Install workstop rod (F) into hole and tighten set

screw (F

with set screw.

). Slide work stop on rod and secure

1

8

Page 9

Figure 5-5

5.7 Vertical cutting plate

NOTE: The following steps apply only when using

band saw in vertical mode.

1. Disconnect band saw from power source.

2. Raise bow to vertical position.

3. Loosen bolt (S, Figure 5-6) just enough to slide

stand (D) behind bolt. Tighten bolt just enough

to hold stand in position.

4. Remove two flat head screws (T) and bearing

guard (U). [Note: Bearing guard (U) must be

reinstalled when returning to horizontal mode.]

5. Guide blade through slot in vertical cutting plate

(C, Figure 7) and fasten cutting plate with the

two screws.

6. Fasten stand (D) to underside of table using

screw and hex nut (HP6/7). Stand can be bent

slightly to accommodate plate.

7. Tighten bolt (S).

Figure 5-6

6.0 Electrical connections

fuse. If connected to a circuit protected by fuses, use

time delay fuse marked “D”. Local codes take

precedence over recommendations.

6.1 GROUNDING INSTRUCTIONS

This machine must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service personnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause ser ious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

6-1. An adapter, shown in B, may be used to

connect this plug to a 2-pole receptacle as shown in

B if a properly grounded outlet is not available. The

temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician. The green-colored rigid ear,

lug, and the like, extending from the adapter must

be connected to a permanent ground such as a

properly grounded outlet box. Note: In Canada, the

use of a temporary adaptor is not permitted by the

Canadian Electrical Code, C22.1.

The HVBS-56V Band Saw is rated for 115V power

only. The band saw comes with a plug designed for

use on a circuit with a grounded outlet that looks like

the one pictured in A, Figure 6-1.

Before connecting to power source, be sure switch

is in off position.

It is recommended that the band saw be connected

to a dedicated 15 amp circuit with circuit breaker or

Figure 6-1

9

Page 10

6.2 Extension cords

The use of extension cords is discouraged; try to

position machines near the power source. If an

extension cord is necessary, make sure it is in good

condition. When using an extension cord, be sure to

use one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. Table 2 shows correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Ampere

Rating

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Table 2: Extension cord recommendations

Volts Total length of cord in feet

120 25 50 100 150

AWG

Not

Recommended

7.0 Adjustments

Disconnect band saw from

power source before making adjustments.

7.1 Tools required for adjustments

(Not all may be needed depending on adjustment.)

Wrenches 12,14,16mm

Hex wrench 4mm

Square

Straight edge

Small clamp

7.2 Blade guide adjustment

1. Disconnect band saw from power source.

2. Loosen handle (B, Figure 7-1) and slide left

blade guide assembly (C) as close as possible

without interference to material being cut.

Tighten handle.

3. Loosen bolt (D) and slide right blade guide

assembly (E) as close as possible to cutting

area, without interference with bed casting.

Tighten bolt. (Once the right blade guide

assembly is properly positioned, it can

generally remain in that position for all

operations.)

Figure 7-1

7.3 Blade tension

1. Disconnect band saw from power source.

2. Open blade cover by removing knob and 2

screws (G, Figure 7-2). Observe position of

blade on wheel. If blade is not adjacent to wheel

flange, first adjust blade tracking according to

sect. 7.6, Blade tracking, then proceed to step

3.

3. Turn blade tension handle (F, Figure 7-2)

clockwise to tighten blade. Pluck the blade with

your finger; a tensioned blade will emit a

“twang” sound.

For precise measurement, use a blade tension

gauge (not provided). Hard-back blades are

generally tensioned at about 25,000 PSI (1757

2

kg/cm

); bi-metal blades at about 35,000 PSI

2

(2460 kg/cm

4. Perform cutting operations with the saw, and

make further tension adjustments as deemed

necessary. As experience with the saw is

gained, the operator should develop a better

“feel” for how tight to set a particular blade. Tick

marks can be made on tension knob for quickly

resetting tension when re-installing a blade.

).

7.4 Blade changes

1. Disconnect band saw from power source.

2. Raise bow to vertical position, and open back

blade cover.

3. Remove red blade guards.

It is essential these red

guards be installed after new blade has been

fitted. Failure to comply m ay cause serious

injury.

4. Release tension on blade by turning tensioning

knob (F, Figure 7-2). Slide blade off wheels.

5. Place new blade between blade guide

assemblies and around each wheel. Make sure

blade teeth are pointing in proper direction (see

Figure 7-3).

10

Page 11

If teeth do not orient properly regardless of how

blade is positioned, turn blade inside-out.

Tension blade enough to hold in place.

Figure 7-2

4. Hold bottom nut (L

and retighten top nut (L

) to prevent it turning further,

2

).

1

5. Repeat above steps for opposite blade guide

assembly.

Figure 7-4

7.6 Blade tracking

Blade tracking adjustment

requires running saw with back cover open. Use

caution when making this adjustment. Failure to

comply may cause serious injury.

Figure 7-3

6. Install red blade guards with screws.

7. Tension blade fully (see sect. 7.3 Blade

tension.)

8. Place 2 to 3 drops of lightweight oil on blade.

9. Connect machine to power source.

10. Operate saw and make sure blade is tracking

properly (sect. 7.6, Blade tracking.)

11. Follow blade break-in procedures, sect. 8.2.

7.5 Blade guide bearings

1. Disconnect band saw from power source.

2. Loosen bolt (H, Figure 7-4) and adjust

assembly so that rear bearing (J) is slightly set

back from back edge of blade. Also, inside

bearing (K) should very lightly contact blade.

Tighten bolt (H).

3. Inside bearing (K) is fixed. Outside bearing (L)

rotates on an eccentric shaft. Loosen top nut

(L

) and rotate bottom nut (L2) to adjust

1

eccentric bearing to very slight distance away

from blade.

Blade tracking has been set by the manufacturer

and should not need immediate adjustment. If blade

tracking should ever require adjustment:

1. Confirm that blade tension is set properly. To

adjust, see sect. 7.4, Blade tension.

2. Raise bow to vertical position and open blade

cover.

While performing the

following steps, keep blade from rubbing

excessively on wheel flange. Excessive

rubbing will damage wheel and/or blade.

3. Run saw at low speed and observe blade.

Blade should run next to but not tightly against

wheel flange.

4. Loosen bolts (M, Figure 7-5) with 12mm

wrench.

5. Turn set screw (N) with 4mm hex wrench, while

observing blade tracking on wheel. Turn set

screw clockwise to track closer to wheel flange.

Turn set screw counterclockwise to track away

from wheel flange.

NOTE: This adjustment is sensitive; start with

1/4 turns on the set screw and allow blade to

respond to changes.

6. Once tracking is set, tighten bolts (M).

11

Page 12

Figure 7-5

7.7 Feed pressure adjustment

Feed pressure is the amount of weight the bow is

allowed to exert upon the workpiece. Turn handle

(O, Figure 7-6) clockwise to decrease feed

pressure; counterclockwise to increase feed

pressure.

A good indication of proper feed pressure is the

color and shape of the cutting chips. If the chips are

thin or powdered, increase feed pressure. If chips

are burned and heavy, decrease feed press ure. If

they are still burned and heavy, reduce blade speed.

Optimum feed pressure has been set when chips

are curled, silvery, and warm.

Figure 7-6

7.8 Blade-to-table squareness

The blade must be perpendicular to table to ensure

a straight cut. This setting should be checked.

Special blade setting gauges can be purchased for

this type of inspection; however, it can also be done

using more common shop items, as follows.

1. “Extend” the surface of blade by clamping a

straight, flat object to blade. (Figure 7-7 uses a

small, lightweight aluminum ruler.) Use a

lightweight clamp.

Figure 7-7

2. Place a s quare on table and against ruler. The

square should lie flat against ruler without a

gap.

3. If there is a gap, loosen bolt (H, Figure 7-4) on

each blade guide assembly and rotate blade

guide assembly until gap is eliminated between

square and ruler.

4. Retighten bolts (H, Figure 7-4).

5. After making this adjustment, be sure to recheck other blade adjustments as noted in this

manual.

7.8.1 Test cut to verify adjustment

Test cuts can be used to determine whether or not

the blade is accurately adjusted. Use 2-inch round

bar stock to perform these test cuts, as follows:

1. W ith bar stock securely clamped in vise, make

a cut through the bar stock. (See Figure 7-8.)

2. Mark the top of bar stock.

3. Move the bar stock about 1/4-inch past the

blade so that you can begin a second cut.

4. Rotate the bar stock 180 degrees so the mark

you made is now at bottom of cut.

5. Make a cut through the bar stock.

6. Use a micrometer to measure the thickness

variation of the disk you have cut from the bar

stock. Measure at top and bottom of disk.

The saw blade can be considered correctly adjusted

when the variation measure is no more than 0.012

inch across the face of the disk.

If you do not have a piece of 2-inch bar stock

available for a test cut, use a larger diameter test

piece rather than a smaller one. [Note: Do not

exceed material capacity of the machine – refer to

specifications.] The maximum thickness variation

on any test piece should be no more than 0.003

inch, per side, per inch of stock diameter.

12

Page 13

Figure 7-8

Slightly loosen bolt on floating jaw (S) to allow it to

conform to workpiece as jaw is brought into

clamping position. Tighten bolt before operating.

7.11 Vertical stop adjustment

The stop screw (Figure 7-10) can be adjusted to

ensure bow is at 90-degrees when using vertical

cutting plate. Loosen nut, adjust screw, then tighten

nut against casting to secure setting.

Figure 7-10

7.9 Auto shut-off adjustment

The saw is properly adjusted when blade shuts off

just after cut completion. To set this:

• If saw completes cut but blade continues

moving, adjust switch trip (P, Figure 7-9)

downward.

• If blade stops before cut is complete, adjust

switch trip (P) upward.

• If blade stops descending and continues

running without completing the cut, turn stop

bolt (Q) down.

Figure 7-9

7.10 Vise adjustment

Use handwheel (R, Figure 7-9) to open and close

vise.

Vise can be adjusted for square and miter cuts.

Loosen hex bolts on fixed jaw (T) and adjust to

desired angle. Refer to scale on back of bed for

angle. (For precise work, always verify with a square

against blade and vise.) tighten bolts.

8.0 Operation

The HVBS-56V is equipped with a motor driver

containing a voltage feedback device to provide

consistent torque during operation.

The saw is also provided with an overload protection

device to prevent overheating of the motor. If saw

shuts off because of overload, allow to cool a few

minutes, then restart.

8.1 Blade selection

The saw is provided with a blade that is adequate

for a variety of cut-off jobs on a variety of common

materials.

See Table 3 for recommended speeds for various

materials. These selections, while appropriate for

many shop cutting needs, do not encompass the

wide variety of blades of special configuration (tooth

pitch and set) and special alloys for cutting unusual

or exotic materials.

Speed

Material

Hardened Ferrous

Ferrous

Non-ferrous, Plastic, Wood

*SFPM = surface feet per minute

Table 3: Speed recommendations

A coarse blade could be used for a solid steel bar

but a finer tooth blade would be used on a thin-wall

tube. In general, the blade choice is determined by

the thickness of the material; the thinner the

material, the finer the tooth pitch.

(SFPM)*

80-130

130-180

180-230

13

Page 14

General rule for band saw blade speed: The

harder the material being cut, the slower the

blade speed.

A minimum of three teeth should be on the work

piece at all times for proper cutting. The blade and

workpiece can be damaged if the teeth are so far

apart that they straddle the workpiece.

For very high production on cutting of special

materials, or to work hard-to-cu t materials such as

stainless steel, tool steel, or titanium, ask your

industrial distributor for more specific blade

recommendations. Also, the supplier who provides

the workpiece material should be prepared to

provide specific instructions regarding the best

blade (and coolant or cutting fluid, if needed) for the

material and shape supplied.

Use of a cutting oil is recommended when cutting at

higher blade speeds.

8.2 Blade break-in

New blades are very sharp and therefore have a

tooth geometry which is easily damaged if a careful

break-in procedure is not followed. Consult the

blade manufacturer’s literature for break-in of

specific blades on specific materials. However, the

following procedure will be adequate for break-in of

JET-supplied blades on lower alloy ferrous

materials.

1. Clamp a round section workpiece in the vise.

The workpiece should be 2 inches or larger in

diameter.

2. Set the saw on low speed. Start the cut with a

very light feed rate.

3. When the saw has completed 1/3 of the cut,

increase feed rate slightly and allow saw to

complete the cut.

4. Keep the same hydraulic cylinder setting and

begin a second cut on the same or similar

workpiece.

5. When blade has completed about 1/3 of cut,

increase feed rate. Watch chip formation until

cutting is at its most efficient rate and allow saw

to complete the cut (see sect. 8.4, Evaluating

cutting efficiency).

6. The blade is now ready for regular service.

8.3 General operating procedure

1. Raise bow and secure in position using support

plate (V, Figure 7-9).

workpiece is profiled section, flat piece or

special shape, refer to examples in Figure 8-1

for proper clamping positions. The top row

shows acceptable clamping positions, the

bottom row shows unacceptable positions.

If the thickness of profile section is very thin, a

piece which duplicates the profile should be

fitted inside the workpiece itself, to prevent

workpiece being crushed between the jaws.

Do not load/unload material

from vise while machine is running. Ne ver hold

workpiece by hand when cutting; workpiece

must be firmly secured in vise. Do not reach into

cutting area during cutting operations.

Figure 8-1: clamping positions

3. Adjust blade guides to minimize exposed blade

area.

4. Release support plate (V, Figure 7-9) and turn

on saw. Lower bow until blade contacts

material. Release bow to allow cutting to

proceed. Weight of bow in conjunction with

spring tension will force blade through material

until cut is finished.

5. Switch trip tab must turn of f saw at completion

of cut. If it fails to do this, see sect. 7.9.

8.4 Evaluating cutting efficiency

Is the blade cutting efficiently? The best way to

determine this is to observe the chips formed by the

cutting.

If chip formation is powdery, then the feed rate is

much too light, or the blade is dull.

If chips are curled, but colored — that is, either blue

or straw-colored from heat generated during the cut

— then the feed rate is too high.

If chips are slightly curled and are not colored by

heat, the blade is sufficiently sharp and is cutting at

its most efficient rate.

Always secure bow in

raised position with support plate before

loading material. Never start a cut with blade

contacting workpiece.

2. Position workpiece in vise and tighten vise.

Workpiece should be fitted directly between

jaws without adding other objects. When

14

Page 15

9.0 User-maintenance

Always disconnect power to

the machine before performing maintenance.

Failure to do this may result in serious personal

injury.

9.1 General maintenance

Wipe down saw with a soft rag after each use, and

clear metal particles with a small paint brush or parts

cleaning brush. Do not use compressed air, as it

may force chips into guide bearings and other

critical areas of saw.

Periodically apply a light coat of oil, such as SAE30,

on exposed metal surfaces to inhibit rust.

Make frequent inspections of motor fan, and blow

out (with low pressure air hose) or vacuum any

accumulation of foreign material to maintain normal

motor ventilation.

Keep blade guides clean and free of metal particles.

Check guide bearings frequently to make sure that

they are properly adjusted and turning freely.

Inspect power cord; if worn, cut or damaged in any

way, have it replaced immediately.

9.2 Commutator brush inspection

To maintain motor efficiency, inspect the two carbon

brushes every two months, or more frequently if saw

is heavily used. Stalling or loss of power may be a

symptom of worn carbon brushes. If one brush is

worn out, replace both at the same time.

Continued use of a damaged or

worn brush may result in damage to motor

armature.

1. Unplug saw from power source.

2. Remove four button h ead screws, and remove

motor sleeve.

3. Unscrew and remove cap with flat blade

screwdriver. See Figure 9-1.

4. Gently pry up an edge of the brass clip, until the

spring causes it to disengage from hole. (Notice

orientation of brush as you remove it; it should

be inserted in the same manner; curvature of

brush will match curvature of motor.)

5. Pull out brush and inspect. Brush should be

replaced if any of the following are discovered:

• Brush has worn to about 1/2-inch long.

• Signs of crumbling, burning, breaking.

• End of brush is rough or pitted.

• Abnormal coloration of spring

• Broken lead in spring

• Collapsed spring

6. Install new brush (or reinstall current brush) and

gently press it all the way into hole until brass

clip is secured.

7. Install cap.

8. Repeat for other brush.

9. Reinstall motor sleeve and screws.

NOTE: It is recommended that saw be run without

load for several minutes to seat new brushes.

Figure 9-1

9.3 Lubrication

Ball bearings on blade guide assemblies and blade

wheels are permanently lubricated and sealed, and

should require no further lubrication.

Lubricate the vise lead screw as needed with #2

tube grease.

9.4 Additional servicing

Any additional servicing on the band saw should be

performed by an authorized service representative.

15

Page 16

10.0 Troubleshooting HVBS-56V Band Saw

10.1 Mechanical and electrical problems

Symptom Possible Cause Correction *

Motor will not start. Low voltage. Check power line for proper voltage.

Open circuit in motor or loose

connection.

Overload condition. Allow machine to cool down, then restart.

Motor will not start, or

motor stalls, resulting

in blown fuse or tripped

breaker.

Motor overheats. Motor overloaded. Reduce load on motor: increase speed or

Machine slows when

operating.

* WARNING: Some corrections may require a qualified electrician.

Too many tools running on one

circuit.

Motor brushes worn. Inspect and replace brushes if needed.

Short circuit in line cord or plug. Inspect cord or plug for damaged insulation

Short circuit in motor or loose

connections.

Incorrect fuses or circuit breakers in

power line.

Air circulation through motor is

restricted.

Gears misaligned. Contact JET technical service.

Excessive feed pressure. Adjust spring tension to reduce feed

Motor brushes worn. Inspect and replace brushes if needed.

Table 3

Inspect all lead connections on motor for

loose or open connections.

Reduce number of tools connected to

circuit.

and shorted wires.

Inspect all connections on motor for loose

or shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

decrease feed pressure. Make sure blade

is appropriate for material.

Clean motor fan with vacuum to restore

normal air circulation.

pressure, or increase speed.

10.2 Operational problems

Symptom Possible Cause Correction

Cuts not square. Blade not square to vise/material. Adjust vise square to blade.

Premature dulling of

blade teeth.

Blade surface not perpendicular to

table.

Workpiece shifting in vise. Properly secure workpiece.

Low blade tension. Increase tension.

Blade guides out of adjustment. Adjust blade guides.

Improper blade break-in. Follow proper break-in procedure.

Excessive blade speed, blade teeth

overheating.

Insufficient downfeed pressure. Increase feed rate (adjust spring tension).

Insufficient blade tension. Increase blade tension.

Improper tooth pitch for material. Use proper blade.

Hard spots on, or work hardening of,

material

Adjust blade guides until perpendicular.

Decrease speed.

Reduce blade speed and increase

downfeed rate.

16

Page 17

Symptom Possible Cause Correction

Rough cut. Improper blade break-in. Follow proper break-in procedure.

Improper speed or feed rate. Adjust as needed.

Dull or damaged teeth. Replace blade.

Poor weld on blade. Replace or re-weld blade.

Frequent blade

breakage.

Blade refuses to track

properly on wheels.

Workpiece shifting in vise. Properly secure workpiece.

Improper blade selection; too few teeth

per inch or blade too thick.

Incorrect blade speed or downfeed

rate.

Improper blade tension. Tighten blade to prevent slippage on

Blade overstressed, pushing against

wheel flange.

Poor blade construction; cracks at

weld.

Blade contacting workpiece before

saw is started.

Guide bearing misalignment. Adjust blade guides according to

Improper blade tension. Tighten blade to prevent slippage on

Guide bearing misalignment. Adjust blade guides according to

Blade catching in workpiece. Use good quality blade of appropriate style

Improper wheel alignment. Inspect and adjust wheel alignment.

Wheel bearings/bushings worn. Inspect and replace if needed.

Table 4

Use blade with appropriate thickness and

tooth pitch for material.

Use proper speed and feed rates.

wheels.

Adjust blade tracking.

Use properly welded blades.

Blade must be clear of workpiece when

turning on saw.

instructions.

wheels.

instructions.

and tooth pitch for workpiece. Use a cutting

fluid when needed.

Contact JET technical service if needed.

11.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial Number of

your machine available when you call will allow us to serve you quickly and accurately.

Some parts are shown for reference only, and may not be available individually.

Non-proprietary parts, such as fasteners, can usually be found at local hardware stores or may be ordered from

JET.

17

Page 18

11.1.1 HVBS-56V Bed Assembly – Exploded View

18

Page 19

11.1.2 HVBS-56V Bow Assembly – Exploded View

19

Page 20

11.1.3 HVBS-56V – Bow and Bed Assemblies Parts List

Index No Part No Description Size Qty

2 ................. TS-0561011 ................ Hex Nut ........................................................................ 1/4"-20 ............................. 1

3 ................. TS-0680021 ................ Flat Washer .................................................................. 1/4" .................................. 3

8 ................. TS-0680031 ................ Flat Washer .................................................................. 5/16"x23xt2 ..................... 2

10 ............... TS-0680021 ................ Flat Washer .................................................................. 1/4" .................................. 1

11 ............... TS-0051051 ................ Hex Cap Screw ............................................................ 5/16"-18x1" ...................... 2

12 ............... TS-0460081 ................ Hex Nut ........................................................................ 5/16"-18 ........................... 2

15 ............... HVBS462-015 ............. Adjusting Rod ............................................................... ........................................ 1

16 ............... HVBS462-016 ............. Electric Cord ................................................................ 125mm

17 ............... HVBS462-017 ............. Pivoting Rod ................................................................. ........................................ 1

18 ............... HVBS462-018 ............. Support Plate ............................................................... ........................................ 1

19 ............... HVBS462-019 ............. Stock Stop.................................................................... ........................................ 1

20 ............... TS-0270021 ................ Set Screw .................................................................... 5/16"-18x5/16" ................. 4

21 ............... HVBS462-021 ............. Stock Stop Rod ............................................................ ........................................ 1

22 ............... HVBS462-022 ............. Wire Relief Retainer ..................................................... ........................................ 2

28 ............... HVBS462-028 ............. Handwheel ................................................................... ........................................ 1

29 ............... HVBS56M-029 ............ Toggle Switch Assembly .............................................. ........................................ 1

29-1 ............ HVBS56M-029-1 ......... Plastic Cover ................................................................ ........................................ 1

30 ............... F006078 ...................... E-Retaining Ring, Ext ................................................... E10 .................................. 1

31 ............... TS-0051051 ................ Hex Cap Screw ............................................................ 5/16"-18x1" ...................... 3

32 ............... HVBS462-032 ............. Lead Screw .................................................................. ........................................ 1

33 ............... HVBS462-033 ............. Vise Nut ....................................................................... ........................................ 1

34 ............... HVBS462-034 ............. Moveable Vise Plate .................................................... ........................................ 1

35 ............... TS-0680041 ................ Flat Washer .................................................................. 3/8" .................................. 3

36 ............... TS-0090061 ................ Hex Cap Screw ............................................................ 3/8"-16x1-1/4".................. 1

37 ............... HVBS462-037G .......... Bed .............................................................................. ........................................ 1

38 ............... TS-081C022 ................ Phillips Pan Hd Machine Screw ................................... #10-24x3/8" ..................... 2

39 ............... HVBS462-039 ............. Scale ............................................................................ ........................................ 1

40 ............... HVBS462-040 ............. Electric Cord Clip ......................................................... ........................................ 1

41 ............... HVBS56V-041 ............. Cable Clamp ................................................................ 5/16" ................................ 1

41-1 ............ TS-081C022 ................ Phillips Pan Hd Machine Screw ................................... #10-24x3/8" ..................... 1

42 ............... TS-081C022 ................ Phillips Pan Hd Machine Screw ................................... #10-24x3/8" ..................... 2

43 ............... HVBS462-043 ............. Rubber Ring ................................................................. ........................................ 1

44 ............... HVBS462-044 ............. Power Cable with Plug ................................................. SJT 3x18AWG ................ 1

45 ............... HVBS462-045 ............. Nut Plate ...................................................................... ........................................ 1

45-1 ............ HVBS56M-045-1 ......... Spring Handle Bracket ................................................. ........................................ 1

46 ............... HVBS462-046 ............. Spring Adjusting Screw ................................................ ........................................ 1

47 ............... HVBS462-047 ............. Spring .......................................................................... ........................................ 1

49 ............... HVBS462-049 ............. Mitering Vise Plate ....................................................... ........................................ 1

50 ............... TS-0081031 ................ Hex Cap Screw ............................................................ 5/16"-18x3/4" ................... 5

51 ............... TS-0680031 ................ Flat Washer .................................................................. 5/16" ................................ 3

52 ............... TS-0081071 ................ Hex Cap Screw ............................................................ 5/16"-18x1-1/2"................ 1

53 ............... TS-0091071 ................ Hex Cap Screw ............................................................ 7/16"-14x2" ...................... 1

53-1 ........... TS-0051051 .............. Hex Cap Screw ............................................................ 5/16"-18x1" ...................... 2

54 ............... HVBS56M-054G ......... Pivot Bracket ................................................................ ..... ................................... 1

55 ............... HVBS462-055 ............. Vertical Cutting Plate ................................................... ........................................ 1

56 ............... HVBS462-056 ............. Stand for Vertical Cutting Plate .................................... ........................................ 1

57 .............. HVBS56M-057 .......... Adjustable Bracket LH ............................................. ................. ..................... 1

57A ............. HVBS56M-057A .......... Adjustable Bracket Assembly LH ................................. ........................................ 1

58 ............... HVBS462-058 ............. Knob ............................................................................ 1/4" .................................. 1

59 ............... HVBS56M-059 ............ Blade Back Safety Cover ............................................. ........................................ 1

59-1 ............ F000738 ...................... Truss Head Phillips Machine Screw ............................. 1/4"-20×3/8" .................... 2

60 ............... F006040 ...................... C-Retaining Ring, Ext .................................................. S10 .................................. 4

61 ............... BB-6000ZZ .................. Ball Bearing .................................................................. 6000ZZ ............................ 6

62 ............... HVBS462-062 ............. Guide Pivot .................................................................. ........................................ 2

62A ............. HVBS462-062A ........... Center Shaft Assembly (Includes #60-62) ................... ........................................ 1

62-1 ............ HVBS462-062-1 .......... Centrifugal Guide Pivot ................................................ ........................................ 2

62-1A ......... HVBS462-062-1A ........ Eccentric Shaft Assembly (Includes #60,61,62-1) ........ ........................................ 1

63 ............... HVBS462-063 ............. Bearing Shaft Pin ......................................................... ........................................ 2

64-1 ............ HVBS462-064-1 .......... Blade Seat Left ............................................................ ........................................ 1

64-2 ............ HVBS462-064-2 .......... Blade Seat Right .......................................................... ........................................ 1

65 ............... HVBS56M-065 ............ Adjustable Bracket-RH ................................................. ........................................ 1

................... HVBS56M-065A .......... Adjustable Bracket-Assembly RH ................................ ........................................ 1

66 ............... HVBS56M-066 ............ Lock Knob .................................................................... 3/8"-16UNCx30L ............. 1

20

2

x2C, 600V .......... 1

Page 21

Index No. Part No. Description Size Qty

67 ............... TS-0720081 ................ Lock Washer ................................................................ 5/16" ................................ 3

68 ............... TS-081F021 ................ Phillips Flat Head Machine Screw ................................ 1/4"-20x3/8" ..................... 2

68-1 ........... TS-081F051 .............. Phillips Flat Head Machine Screw *............................ 1/4”-20X3/4” .................. 1

69 ............... HVBS462-069 ............. Bearing Guard .............................................................. ........................................ 1

70 ............... TS-0561032 ................ Hex Nut ........................................................................ 3/8-24 UNF ...................... 4

71 ............... HVBS462-071 ............. Drive Blade Wheel ....................................................... ........................................ 1

74 ............... HVBS56M-060 ............ C-Retaining Ring .......................................................... S15 .................................. 1

75 ............... HVBS462-075 ............. Hex Cap Bolt (w/Washer) ............................................ 1/4”-20x5/8" ..................... 8

76 ............... HVBS462-076 ............. Switch Cut Off Trip ....................................................... ........................................ 1

77 ............... HVBS462-077 ............. Idle Blade Wheel .......................................................... ........................................ 1

78 ............... TS-0680031 ................ Flat Washer .................................................................. 5/16" ................................ 2

79 ............... HVBS462-079 ............. Blade Tension Knob ..................................................... 3/8"-16UNCx105L ........... 1

80 ............... HVBS462-080 ............. Spring .......................................................................... ........................................ 1

81 ............... HVBS56V-081 ............. Saw Bow ...................................................................... 128DC ............................. 1

87 ............... BB-6202ZZ .................. Ball Bearing .................................................................. 6202ZZ ............................ 6

95-1 ............ HVBS56V-95-1............ Gear Box Cover ........................................................... ........................................ 1

95-2 ............ TS-1503051 ................ Socket Head Cap Screw .............................................. M6x20L ........................... 4

95-3 ............ HVBS56V-95-3............ Oil seal ......................................................................... TC-12x20x5B .................. 1

95-4 ............ HVBS56V-95-4............ Motor Shaft .................................................................. ........................................ 1

95-5 ............ HVBS56V-95-5............ Motor ............................................................................ 1/2HP 1PH ...................... 1

………….HBS56MVS-095-MCB ..... Carbon Brush (not shown) ........................................... ........................................ 2

95-6 ............ HVBS56V-95-6............ Driver ........................................................................... ........................................ 1

95-7 ............ HVBS56V-95-7............ Magnetic Switch ........................................................... 110V ................................ 1

95-8 ............ HVBS56V-95-8............ Variable Resistor .......................................................... ........................................ 1

95-9 ............ HVBS56V-95-9............ Motor Sleeve ................................................................ ..... ................................... 1

95-10 .......... TS-1502041 ................ Socket Head Cap Screw .............................................. M5x16L ........................... 4

95-11 .......... HVBS56V-95-11.......... Gear Box ...................................................................... ..... ................................... 1

95-12 .......... HVBS56V-95-12.......... Electric Plate ................................................................ ........................................ 1

95-13 .......... HVBS56V-95-13.......... Phillips Pan Hd Machine Screw ................................... M3.5x16L ........................ 3

96-1 ............ HVBS56V-96-1............ Active Shaft .................................................................. ... ..................................... 1

96-2 ............ KF2R5525 ................... Double Round Hd Key ................................................. 5x5x25L mm .................... 1

96-3 ............ HVBS56V-96-3............ C-Retainer Ring, Internal ............................................. R42.................................. 2

96-4 ............ HVBS56V-96-4............ Band ............................................................................ 35x8t mm ........................ 1

96-5 ............ BB-6200ZZ .................. Ball Bearing .................................................................. 6200-ZZ ........................... 2

96-6 ............ HVBS56V-96-6............ Gear ............................................................................. ........................................ 1

96-7 ............ BB-6004-2RS .............. Ball Bearing .................................................................. 6004-2RS ........................ 2

96-8 ............ HVBS56V-96-8............ C-Retainer Ring, Internal ............................................. R30.................................. 1

96-9 ............ HVBS56V-96-9............ Pivot Pin ....................................................................... Ø6x20 mm ....................... 2

96-10 .......... HVBS56V-96-10.......... C-Retainer Ring, External ............................................ S20 .................................. 1

96-11 .......... TS-2361081 ................ Lock Washer ................................................................ M8 ................................... 4

96-12 .......... TS-1490041 ................ Hex Cap Screw ............................................................ M8x25L ........................... 4

97 ............... TS-0050021 ................ Hex Cap Screw ............................................................ 1/4"-20x3/8" ..................... 2

99 ............... HVBS462-099 ............. Spacer ......................................................................... ........................................ 1

100 ............. F000614 ...................... Truss Hd Phillips Machine Screw ................................. #8-32x3/8" ....................... 3

102 ............. TS-0720081 ................ Lock Washer ................................................................ 5/16" ................................ 2

103 ............. HVBS462-103 ............. Blade Tension Sliding Plate ......................................... ........................................ 1

104 ............. TS-0270071 ................ Socket Set Screw ......................................................... 5/16"-18x3/4" ................... 2

105 ............. F12072 ........................ Roll Pin..................................................................... .... Ø4x20L ............................ 1

106 ............. HVBS462-106 ............. Sliding Plate Draw Block .............................................. ........................................ 1

107 ............. HVBS462-107 ............. Blade Wheel Shaft ....................................................... ........................................ 1

108 ............. HVBS462-108 ............. Shaft Block ................................................................... ........................................ 1

109 ............. HVBS462-109 ............. Blade Tension Sliding Guide ........................................ .............

111 ............. TS-0680031 ................ Flat Washer .................................................................. 5/16” ................................ 1

113 ............. 414301 ........................ Blade………………………………………………...1/2 x 0.025 x 64-1/2 x 14T ........ 1

114 ............. TS-0680041 ................ Flat Washer .................................................................. 3/8" .................................. 4

115 ............. TS-0570011 ................ Hex Nut *...................................................................... 1/4"-20 ............................. 1

117 ............. TS-0090061 ................ Hex Cap Screw ............................................................ 3/8"-16x1-1/4".................. 1

122 ............. TS-0561041 ................ Hex Nut ........................................................................ 7/16"-14 ........................... 1

123 ............. TS-0050051 ................ Hex Cap Screw ............................................................ 1/4"-20x1" ........................ 1

124 ............. TS-081C052 ................ Phillips Pan Hd Machine Screw ................................... #10-24x3/4" ..................... 2

126 ............. HVBS462-126 ............. Bushing ........................................................................ ........................................ 1

132 ............. HVBS462-132 ............. Blade Guard-Right ....................................................... ........................................ 1

132-1 .......... HVBS462-132A ........... Blade Guard-Left .......................................................... ........................................ 1

156 ............. HVBS462-156 ............. Round Head Screw ...................................................... 3/16"x3/4" ........................ 1

157 ............. HVBS462-157 ............. Ext Tooth Lock Washer ................................................ 3/16" ................................ 3

........................... 2

21

Page 22

Index No. Part No. Description Size Qty

158 ............. TS-0680021 ................ Hex Nut ........................................................................ 3/16”-18 ........................... 2

160 ............. JET-92 ........................ JET Logo with 3M adhesive ......................................... 92x38 mm ....................... 1

................... JJ6CS-OEW2 .............. Open End Wrench (not shown) .................................... 12/14 mm ........................ 1

.................. LM000282 ................. ID Label, HVBS-56V (not shown) ............................ ...................................... 1

.................. HVBS56M-WL

................... LM000283 ................... Speed Chart, HVBS-56V (not shown) .......................... ........................................ 1

................... LM000284 ................... VR Speed Label, HVBS-56V (not shown) .................... ........................................ 1

................... HVBS56V-HP .............. Hardware

........... Warning Label (not shown) .......................................... ........................................ 1

Package (contains items with *) ............... ...................................... 1

22

Page 23

11.2.1 HVBS-56V Stand – Exploded View

11.2.2 HVBS-56V Stand – Parts List

Index No Part No Description Size Qty

................... HVBS56M-CSA ........... Complete Stand Assembly ........................................... ........................................ 1

4-1 .............. HVBS56M-S1 .............. Left Stand Leg ............................................................. ........................................ 1

4-2 .............. HVBS56M-S2 .............. Right Stand Leg ........................................................... ........................................ 1

4-3 .............. HVBS56M-S3 .............. Cross Brace ................................................................. ........................................ 1

4-4 .............. HVBS56M-S4 .............. Front Panel .................................................................. ........................................ 1

4-5 .............. HVBS56M-S5 .............. Shelf ............................................................................. ........................................ 1

4-6 .............. HVBS56M-2 ................ Hex Head Screw w/lock washer * ................................ 1/4”-20 x 5/8” ................. 19

4-7 .............. TS-0680021 ................ Flat Washer * ............................................................... 1/4” ................................ 19

4-8 .............. TS-0570011 ................ Hex Nut *...................................................................... 1/4” ................................ 19

4-9 .............. TS-0208071 ................ Socket Head Cap Screw *............................................ 5/16”-18 x 1-1/4” .............. 6

4-10 ............ TS-0680031 ................ Flat Washer* ................................................................ 5/16"x23xt2 ..................... 6

4-11 ............ TS-0570022 ................ Hex Nut*....................................................................... 5/16" ................................ 6

4-12 ............ HVBS462-014 ............. Floor Stand Handle ...................................................... ........................................ 1

9-1 .............. HVBS56M-09 .............. Wheel ........................................................................... ........................................ 2

9-2 .............. TS-0680081 ................ Flat Washer * ............................................................... 5/8” .................................. 6

9-3 .............. HVBS462-006 ............. Cotter Pin *................................................................... 1/8” x 1” ........................... 2

9-4 .............. HVBS56M-07 .............. Axle .............................................................................. ........................................ 1

13-1 ............ HVBS56M-013 ............ Adjustable Foot ............................................................ 3/8” .. ................................ 2

13-2 ............ TS-0561032 ................ Hex Nut ........................................................................ 3/8”-24 UNF .................... 4

13-3 ............ TS-0680041 ................ Flat Washer .................................................................. 3/8” .................................. 2

................... HVBS56V-HP .............. Hardware Package (contains items with *)................... ..........................................

23

Page 24

12.0 Electrical Connections – HVBS-56V Band Saw

SQ = Lower (toggle) limit switch

S = Electromagnetic switch

A = Driver board

VR = Variable resistor

M = Motor

24

Page 25

13.0 Warranty and service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may