Page 1

- - - - - - - - -- --

--- - -------

..JET

EQUIPMENT & TOOLS

OPERATOR'S MANUAL

HBS-916W & 1018W Bandsaws

j--

p

JET EQUIPMENT &.TOOLS, INC.

A WMH Company

www.jettools.com

.

.

P.O. BOX 1349

Auburn, WA 98071-1349

e-mail jet@jettools.com

253-351-6000

Fax 253-939-8001

M-414468 2/99

Page 2

Important Information

1-YEAR

LIMITED WARRANTY

JET offers a one-year limited

warranty on this product

REPLACEMENT PARTS

Replacement parts for this tool are available directlyform JET Equipment& Tools.

To place an order, call 1-800-274-6848. Pleasehavethefollowing information ready:

1. Visa, MasterCard, or Discover Card number

2. Expirationdate

3. Part number listed within this manual

4. Shipping address other than a PostOffice box.

REPLACEMENT PART WARRANTY

JET Equipment & Tools makes every effort to assure that parts meet high quality and durability standards

and warrants to the original retail consumer/purchaserof our parts that each such part(s) to be free from

defects in materials and workmanshipfor a period of thirty (30) days from the date of purchase.

PROOF OF PURCHASE

Please retain your dated sales receiptas proof of purchaseto validate the warranty period.

LIMITED TOOL AND EQUIPMENTWARRANTY

JET makes every effort to assure that its products meet high quality and durability standards and warrants to the

original retail consumer/purchaser of our products that each product be free from defects in materials and

workmanship as follows: 1 YEAR LIMITED WARRANTY ON THIS JET PRODUCT. Warranty does not apply to

defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or alterations outside our

facilities or to a lack of maintenance. JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED

ABOVE FROM THE DATE THE PRODUCTWAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY

IMPLIED WARRANTIES OR MECHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU. JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERY OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATESDONOTALLOWTHI; I;XCiLU~IONORLIMITATIONOF

INCIDENTAlORCONS~OUENTIAlDAMAG~S,~o T~~ AQOV~LIMITATIO~O~ ~~~LUQIO~UA V ~CT A~~L V

TO YOU. To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an authorized service station designated by our Auburn office. Proof of purchase date and an

explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, JET will either

repair or replace the product or refund the purchase price, if we cannot readily and quickly provide a repair or

replacement, if you are willing to accept such refund. JET will return repaired product or replacement at JET's

expense, but if it is determined there is no defect, or that the defect resulted from causes not within the scope of

JET's warranty, then the user must bear the cost of storing and returning the product. This warranty gives you

specific legal rights, and you have other rights, which vary, from state to state.

JET Equipment & Tools. P.O. Box 1349, Auburn, WA 98071-1349 . (253) 351-6000

Page 3

it WARNING

.

Read and understand the entire

instruction manual before attempting

assembly or operation.

.

All JET bandsaws are designed and

intended for use by properly trained and

experienced personnel only. If you are

not familiar with the proper and safe

operation of a bandsaw, do not use until

proper training and knowledge have

been obtained.

.

Always wear approved safety glasses/face

shields while using this machine.

.

Make certain the machine is properly

grounded.

.

Giveyour work undivided attention. Looking

around,carrying on a conversation, and

"horse-play"are careless acts that can

result in serious injury.

.

Keepvisitors a safe distance from the work

area.

.

Use recommendedaccessories; improper

accessories may be hazardous.

.

Make a habit of checking to see that keys

and adjusting wrenches are removed before

turning on the machine.

.

Always keep hands and fingers away from

the bladewhen the machine is running.

.

Before operating the machine, removetie,

rings,watches, otherjewelry, and roll up

sleeves above the elbows. Removeall

loose clothing and confine long hair. Do

NOT wear gloves.

.

Keepthe floor around the machineclean

and free of scrap material, oil and grease.

.

Keep machine guards in place at all times

when the machine is in use. If removedfor

maintenance purposes, use extreme caution

and replace the guards immediately.

.

Do NOT over reach. Maintaina balanced

stance at all times so that you do notfall or

lean against blades or other movingparts.

.

Make all machine adjustmentsor

maintenancewith the machineunplugged

from the power source.

.

Use the right tool. Don'tforce a tool or

attachment to do ajob which it was not

designed for.

.

Never hand holdthe material. Always use

the vise and clamp it securely.

.

Keepbelt guard, bladeguards, and wheel

covers in place and inworking order.

.

Always provideadequate support for long

and heavy material.

.

Use a sharp bladeand keepmachine clean

for best and safest performance.

.

Failureto comply with all of these warnings

may cause serious injury.

.

Replace warning labels if they become

obscured or removed.

.

Make certain the motor switch is in the OFF

position before connecting the machineto

the power supply.

Page 4

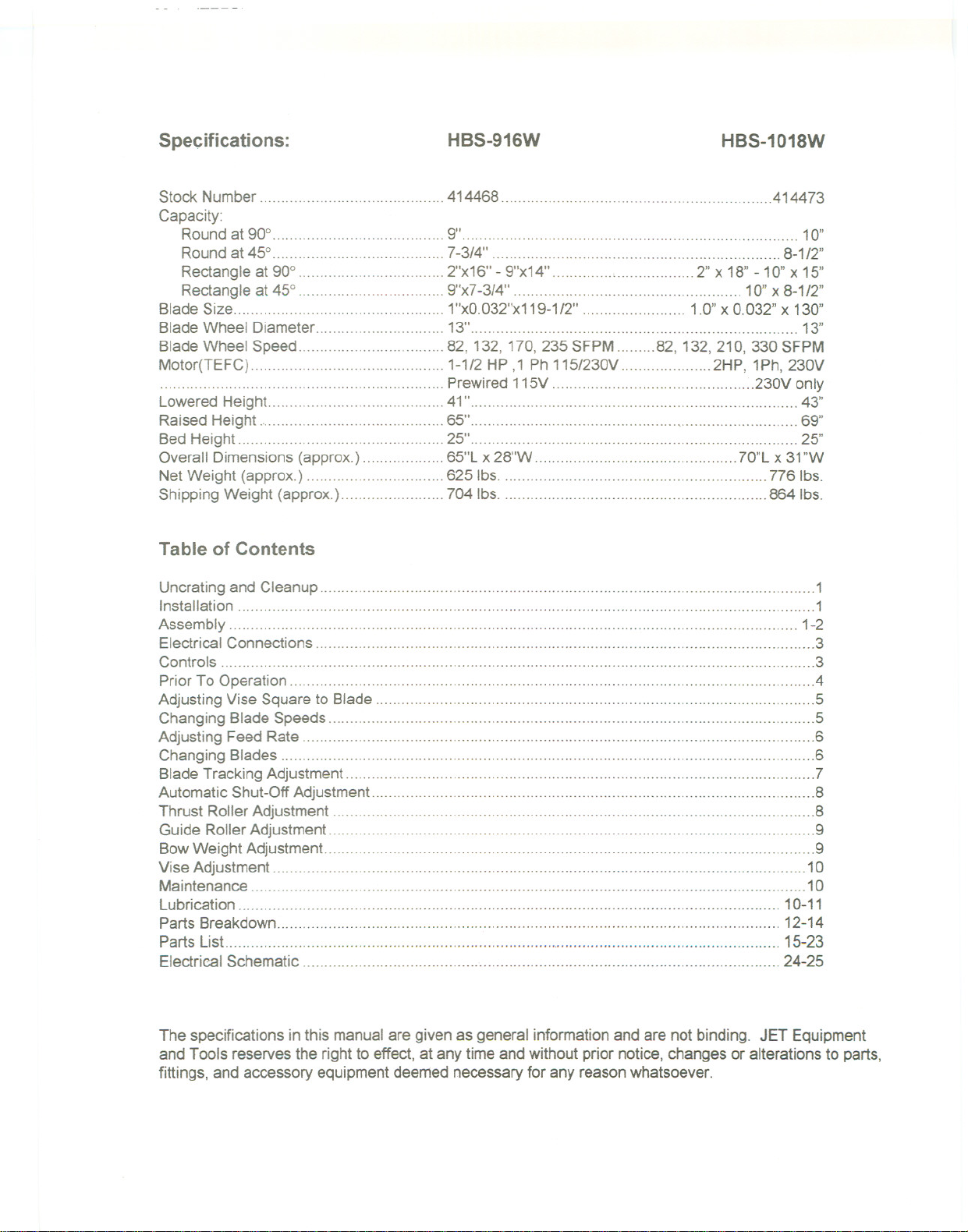

Specifications:

HBS-916W

HBS-1018W

StockNumber ""'" 414468 ..414473

Capacity:

Round at 900 9" 10"

Round at 450 7-3/4" 8-1/2"

Rectangle at 900 2"x16" - 9"x14"

' 2" x 18"- 10"x 15"

Rectangle at 450 9"x7-3/4" """""""""""""'"'''''''''''''''''''''''' 10"x 8-112"

Blade Size 1"xO.032"x119-1I2" 1.0"x 0.032" x 130"

Blade Wheel Diameter 13" 13"

Blade Wheel Speed 82,132,170,235 SFPM 82,132,210,330 SFPM

Motor(TEFC) 1-1I2 HP ,1 Ph 115/230V 2HP, 1Ph, 230V

Prewired 115V """"""""'''''''''''''''''''''''''''''' .230V only

Lowered Height ..0...41 " ".. """""'''' ..'"'' "'"''''

Raised Height 65"... " '''''' ""'''''' 69"

Bed Height 0" """"""""""""" 25" 0 0 0.00"""""""',," 0.0 25"

Overall Dimensions (approx.) "'"'' 65"L x 28"W """""""""""""""'"'''''''''''''' 70"L x 31"W

Net Weight (approx.) """"'''''''''''''''''''''''' 625 Ibs. " 776 Ibs.

Shipping Weight (approx.) 704lbs. 864Ibs.

43"

Table of Contents

Uncrating and Cleanup 0 0""""""',"'...0 0...1

Installation .1

Assembly 1-2

ElectricalConnections 0...0 0 0..3

Controls 0 0 00 0 0 0"""""""""""""""" 0 0 3

Prior To Operation 4

Adjusting Vise Square to Blade "'"'''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''' ''''''' 5

Changing Blade Speeds 0 5

Adjusting Feed Rate 0 6

Changing Blades 6

Blade Tracking Adjustment """""""'"'''' 0.7

Automatic Shut-Off Adjustment 0.0 0 0 8

Thrust Roller Adjustment 0 8

Guide Roller Adjustment

0

0

BowWeight Adjustment 0...0 0 0 0 9

ViseAdjustment 0 00...0 0 0 0 ..0..0 ..0 ..0 0 10

Maintenance 0..0...0 0 0...10

Lubrication 0 00..0.00 0 0 0..0 0.0...0 0"...0..0,,0 10-11

Parts Breakdown ... ..0 """"""""" 12-14

Parts List 0..0 0 """"""","""""""'" ,... "0.. 15-23

Electrical Schematic..o.. 0..0.0.0 ' 0 00"""..0...0.0.0..0 ""0 000""""""""""""0 24-25

9

The specifications in this manualare given as general information and are not binding. JET Equipment

and Tools reserves the right to effect, at any time and without prior notice, changes or alterations to parts,

fittings, and accessory equipment deemed necessaryfor any reason whatsoever.

Page 5

Uncrating and Cleanup

Note: Read and understand the entire manual before

attempting setup or operation.

1.

Finish uncrating the saw and inspectfor

damage. Should any have occurred, contact

your local distributor.

2.

Remove all boltsattaching machineto

shipping base.

3.

Leave packing material betweenvice clamps

and saw head intact until bandsaw has been

lifted to its final position.

4.

Clean all rust protected surfaces with

kerosene or diesel oilto removeprotective

coating. Do not use gasoline, paintthinner,

mineral spirits, etc. These may damage

painted surfaces.

5.

Lubricate all slideways with SAE 1OW oil.

Installation

For best performance, the bandsawshould be

located on a solid and level foundation. Allow room

for servicing and for moving large stock aroundthe

bandsaw when deciding a locationfor the machine.

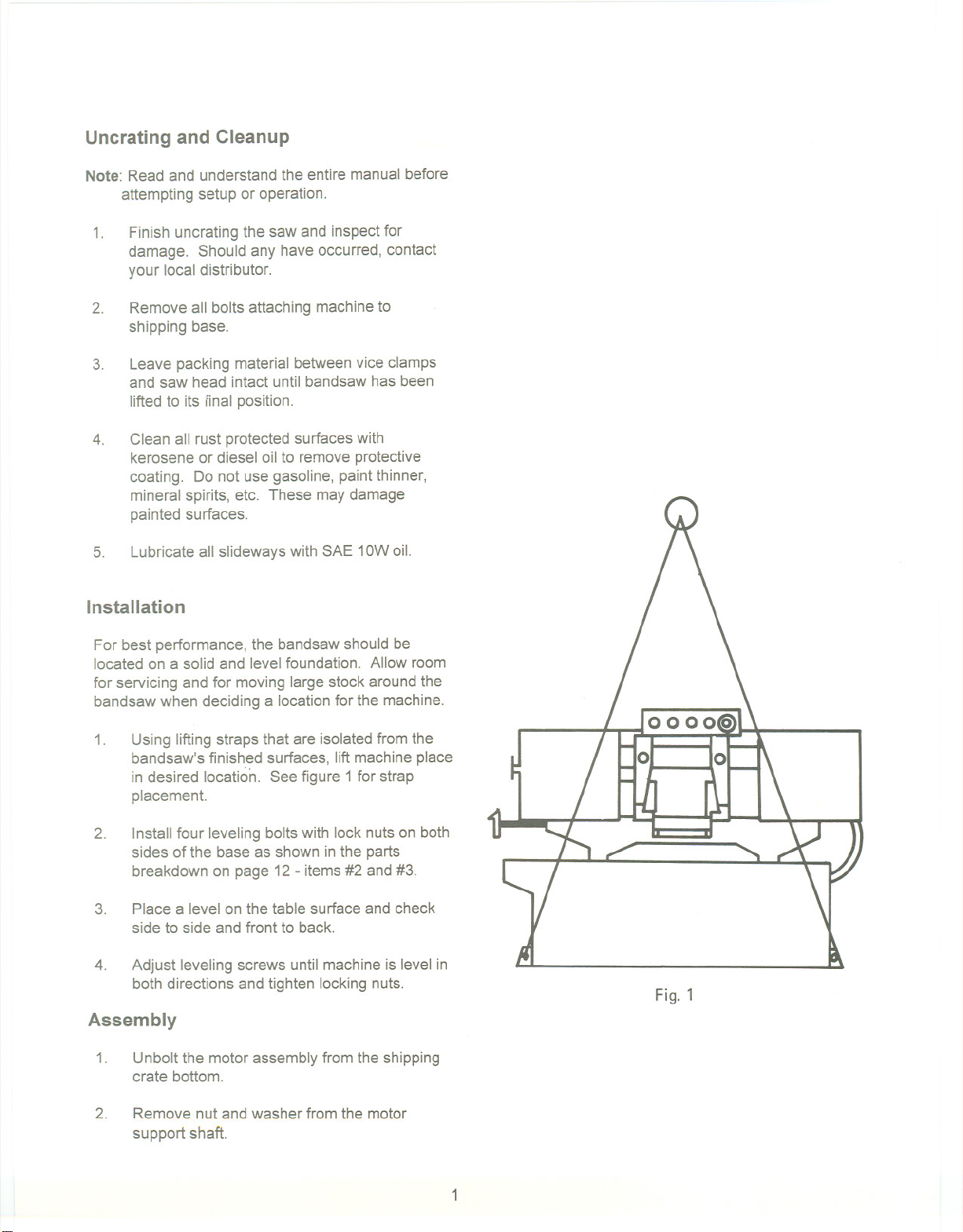

1.

Using lifting straps that are isolatedfrom the

bandsaw's finished surfaces, lift machineplace

in desired location. See figure 1 for strap

placement.

2.

Install four leveling bolts with lock nuts on both

sides of the baseas shown in the parts

breakdown on page 12- items #2 and#3.

3. Place a level on the table surface and check

side to side and front to back.

4.

Adjust leveling screws until machineis level in

both directions and tighten locking nuts.

Assembly

1.

Unbolt the motor assembly from the shipping

crate bottom.

Fig. 1

2. Remove nut and washer from the motor

support shaft.

1

Page 6

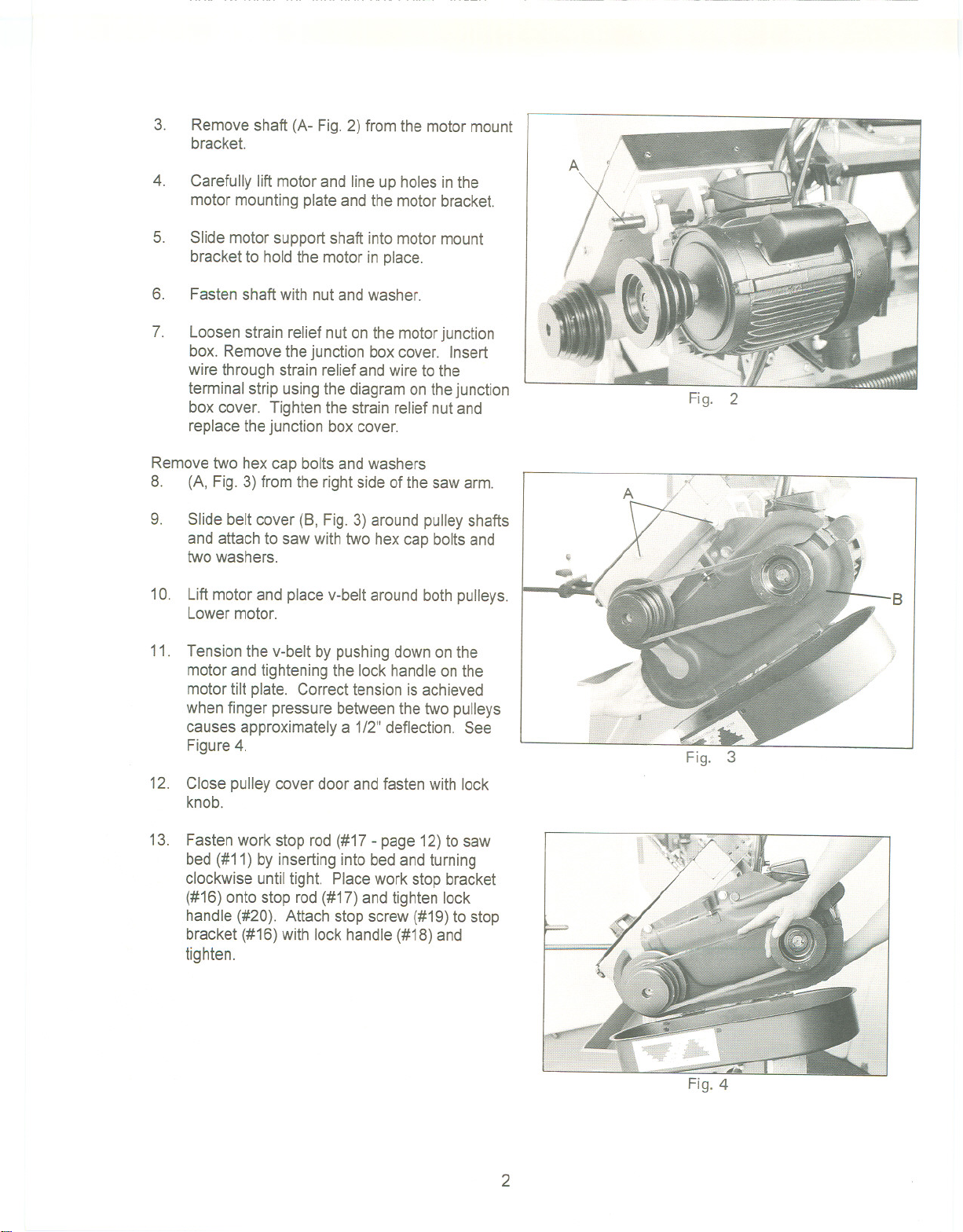

3.

Remove shaft (A- Fig. 2) from the motor mount

bracket.

4.

Carefully lift motorand line up holes in the

motor mounting plate and the motor bracket.

5.

Slide motor support shaft into motor mount

bracket to hold the motor in place.

6.

Fasten shaft with nut and washer.

7.

Loosen strain relief nuton the motorjunction

box. Removethe junction boxcover. Insert

wire through strain reliefand wire to the

terminal strip using the diagram on the junction

box cover. Tighten the strain relief nutand

replace thejunction box cover.

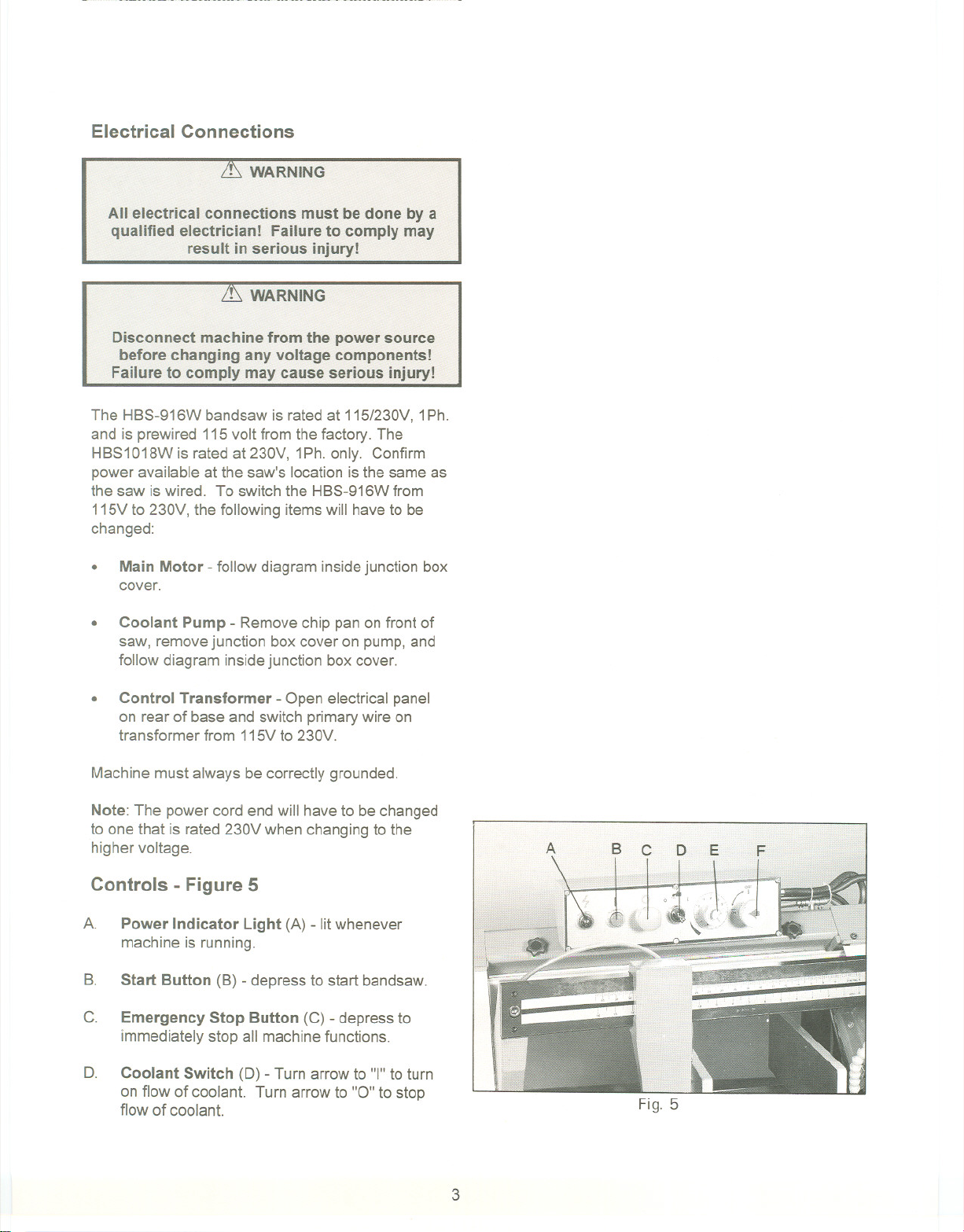

Remove two hexcap bolts and washers

8. (A, Fig. 3) from the right side of the saw arm.

9.

Slide belt cover (8, Fig.3) around pulleyshafts

and attach to saw with two hex cap boltsand

two washers.

Fig. 2

10. Lift motor and place v-belt around both pulleys.

Lower motor.

11. Tension the v-belt by pushing down on the

motor and tightening the lock handleon the

motor tilt plate. Correct tension is achieved

when finger pressure between the two pulleys

causes approximatelya 1/2"deflection. See

Figure4.

12. Close pulley cover door andfasten with lock

knob.

13. Fasten work stop rod(#17 - page 12)to saw

bed (#11) by inserting into bed and turning

clockwise until tight. Placework stop bracket

(#16) onto stop rod (#17)and tighten lock

handle (#20). Attach stop screw (#19)to stop

bracket (#16) with lock handle (#18) and

tighten.

Fig. 3

Fig. 4

2

Page 7

Electrical Connections

it WARNING

All electrical connections must be done by a

qualified electrician! Failure to comply may

result in serious injury!

it WARNING

Disconnect machine from the power source

before changing any voltage components!

Failure to comply may cause serious injury!

The HBS-916W bandsaw is rated at 115/230V,1Ph.

and is prewired 115 volt from the factory. The

HBS1018Wis rated at 230V, 1Ph.only. Confirm

power available at the saw's location is the same as

the saw is wired. To switch the HBS-916Wfrom

115Vto 230V, the following itemswill have to be

changed:

.

Main Motor - follow diagram insidejunction box

cover.

.

Coolant Pump - Removechip pan on front of

saw, removejunction boxcover on pump,and

follow diagram inside junction box cover.

.

Control Transformer - Open electrical panel

on rear of base and switch primarywire on

transformer from 115Vto 230V.

Machine must always be correctly grounded.

Note:The powercord end will have to be changed

to one that is rated 230V when changing to the

highervoltage.

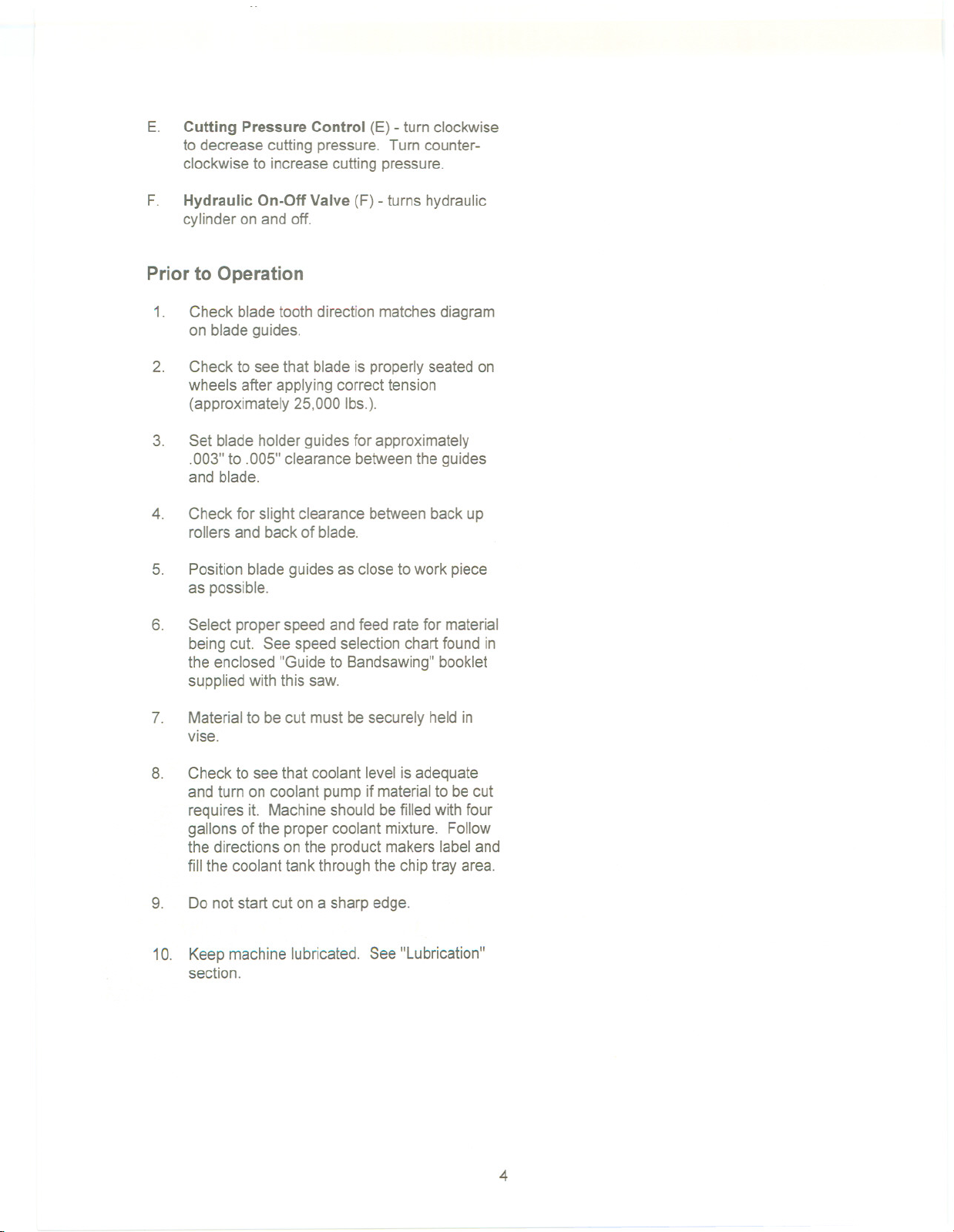

Controls - Figure 5

A.

Power Indicator Light (A) - lit whenever

machine is running.

B.

Start Button (B) - depress to start bandsaw.

C.

Emergency Stop Button (C) - depress to

immediately stop all machine functions.

o.

Coolant Switch (0) - Turn arrowto "I" to turn

on flow of coolant. Turn arrow to "0" to stop

flow of coolant.

Fig. 5

3

Page 8

E.

Cutting PressureControl (E) - turn clockwise

to decrease cutting pressure. Turn counter-

clockwise to increasecutting pressure.

F.

Hydraulic On-Off Valve (F) - turns hydraulic

cylinder on and off.

Prior to Operation

1.

Check blade tooth direction matchesdiagram

on blade guides.

2.

Check to see that blade is properlyseated on

wheels after applying correct tension

(approximately25,000 Ibs.).

3.

Set blade holder guides for approximately

.003"to .005" clearance betweenthe guides

and blade.

4.

Check for slight clearance between back up

rollers and back of blade.

5.

Position blade guides as close to work piece

as possible.

6.

Select proper speed and feed ratefor material

being cut. See speed selectionchart found in

the enclosed "Guide to Bandsawing" booklet

supplied with this saw.

7.

Material to be cut must be securely held in

vise.

8.

Check to see that coolant level is adequate

and turn on coolant pump if materialto becut

requires it. Machine should be filledwith four

gallons of the proper coolant mixture. Follow

the directions on the product makers label and

fill the coolant tank through the chip tray area.

9.

Do not start cut on a sharp edge.

10. Keepmachinelubricated. See "Lubrication"

section.

4

Page 9

Adjusting Vise Square to the Blade

1.

Disconnect the machine from the power

source.

2.

Place a machinist's square on the table

against the bladeand the vise. The square

should lie along the entire lengthof the vise

and blade without a gap.

3.

If adjustment is necessary, loosen bolts

holding the vise and adjust vise so square

lines up properly. Tighten bolts.

4.

Connect machine to the powersource.

Changing Blade Speeds

it. WARNING

Disconnect the machine from the power source

before making any repair or adjustment!

Failure to comply may cause serious injury!

1.

Disconnect machine from the power

source.

2.

Open pulley cover by supporting the belt cover

with one hand while removingthe belt cover

lock knob with the other. Lowerguard gently

to its full open position.

3.

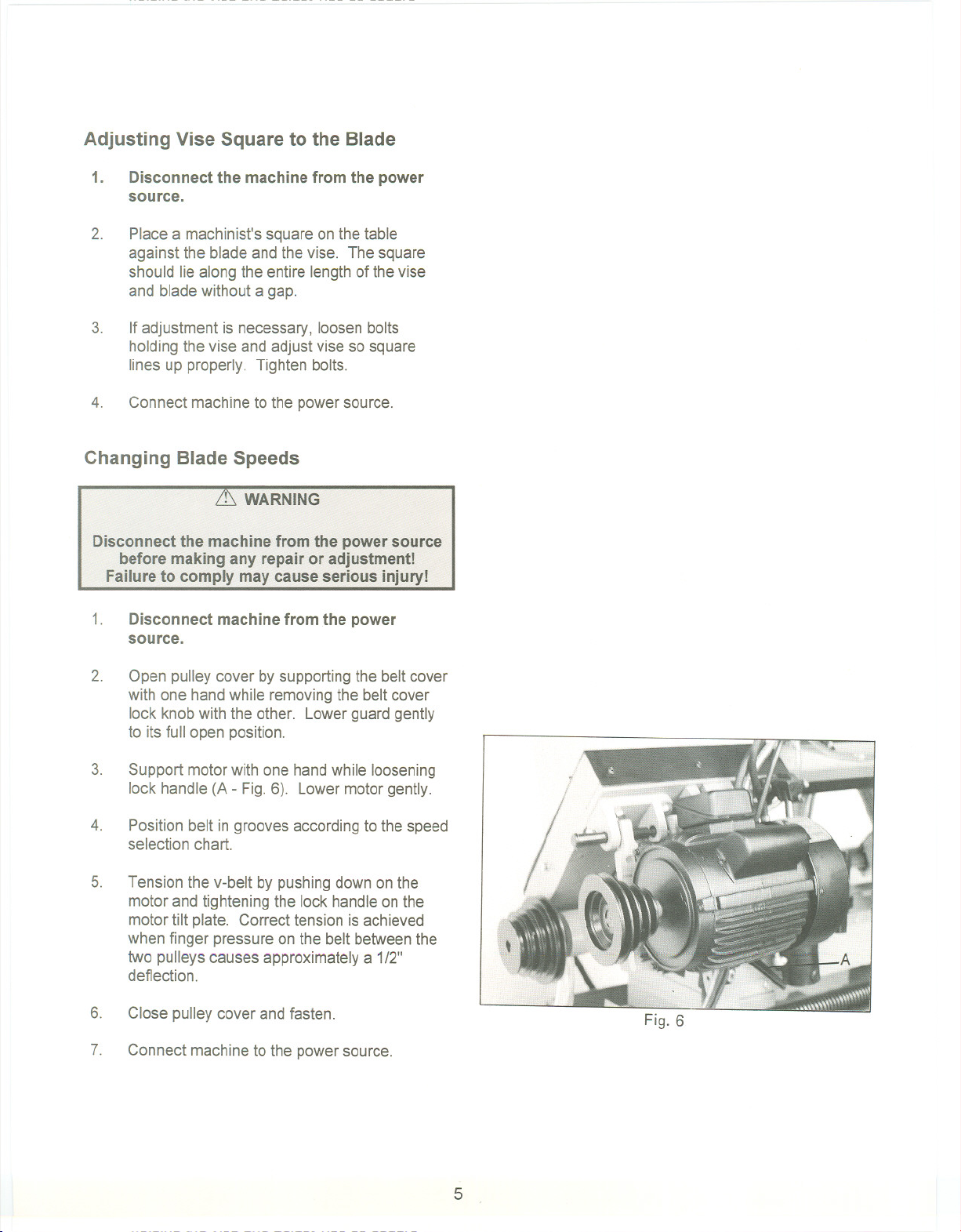

Support motor with one hand while loosening

lock handle (A - Fig. 6). Lower motor gently.

4.

Position belt in grooves accordingto the speed

selection chart.

5.

Tension the v-belt by pushingdown on the

motor and tightening the lock handle on the

motor tilt plate. Correct tension is achieved

when finger pressure on the belt betweenthe

two pulleys causes approximately a 1/2"

deflection.

6.

Close pulley cover and fasten.

7.

Connect machine to the powersource.

Fig. 6

5

Page 10

Adjusting Feed Rate

Rateof feed is adjusted by turning the cutting

pressure control knob on the control panel. Rate of

feed is important to bandsaw performance;

excessive pressure may break the bladeor stall the

saw. Insufficient pressure rapidly dulls the blade.

Materialchips or shavings are the best indicatorof

proper speed and pressure. The idealchip is thin,

tightly curled, and warm to the touch. Chips that

range from golden brown to black indicate

excessive force. Blue chips indicateextreme heat

from too high a bandspeed which will shorten blade

life. Thin or powderedchips indicateinsufficient

feed pressure.

A detailed explanation on feed ratecan be found in

the enclosed "Guide to Band Sawing" published by

American Saw and ManufacturingCompany.

Reprinted by permission.

Changing Blades

it. WARNING

Disconnect machine from the power source

before making any adjustments or repairs!

Failure tQ comply l1'1ayresult in serious injury!

1.

Disconnect machine from power source.

2.

Raise saw arm approximately6". Hold saw

arm in place by closing cutting pressure

control valve. Remove screw (#145),

washer(#146), and brush (#147)from the wire

brush post (#148) as shown on page 13.

3.

Open bothwheel covers and clean chips out

of bothwheel housings. Loosentwo lock

knobs and remove upper bladeguard.

4.

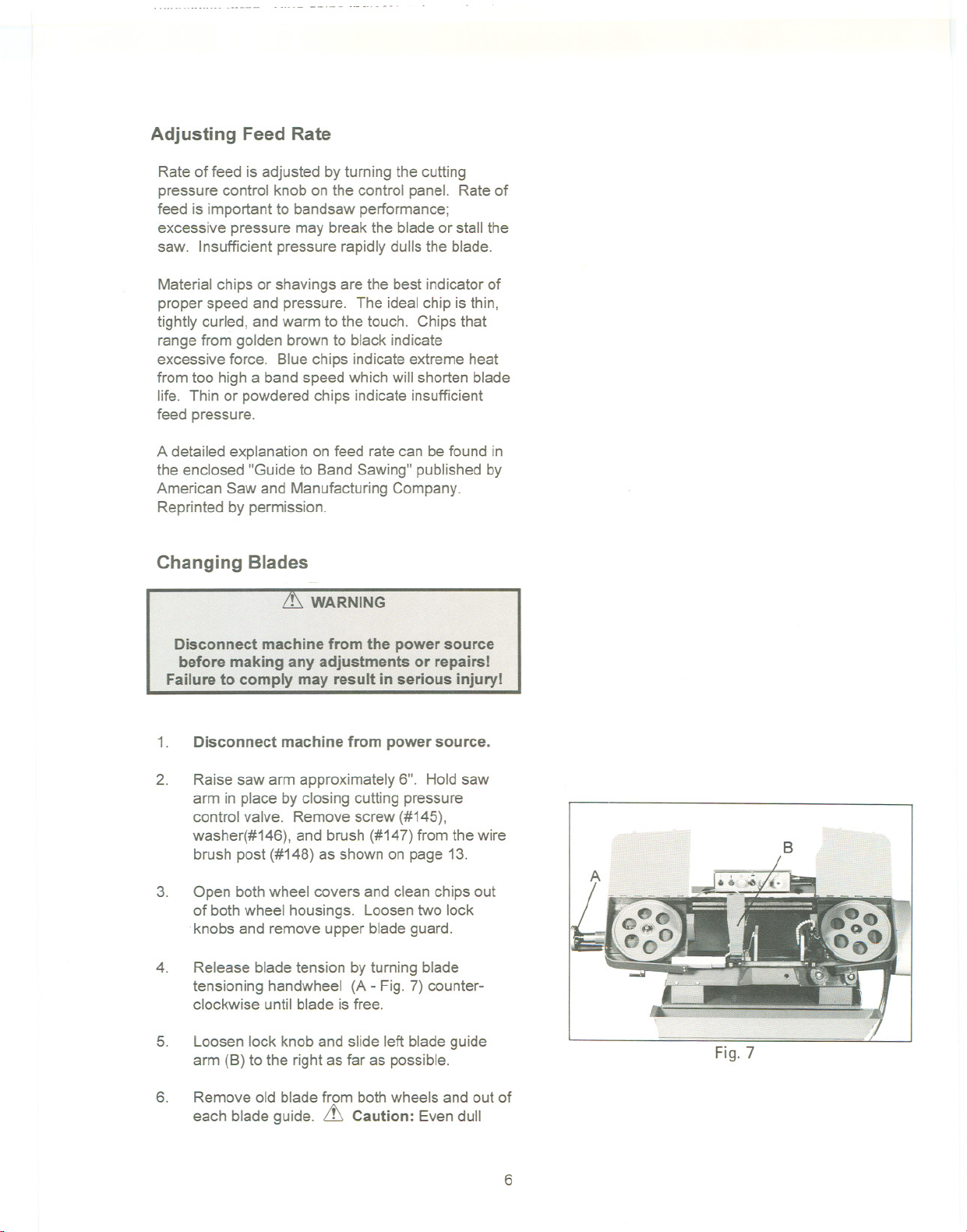

Release blade tension by turning blade

tensioning handwheel (A - Fig.7)counter-

clockwise until blade isfree.

5.

Loosen lock knob and slide left blade guide

arm (B) to the right as far as possible.

B

Fig. 7

6.

Remove old bladefrom bothwheels and out of

each blade guide. it Caution:Even dull

6

Page 11

blades are sharp to the skin! Use extra

caution handling bandsawblades!

7.

Install new blade makingsure teeth are

pointed downward in the proper cutting

direction. If necessary, turn bladeinside out.

8.

Position bladeon bandwheels and tightenjust

enough to holdblade on wheels. Make sure

back of blade rests lightlyagainst the wheel

flange of bothwheels. Twist blade slightly to

allow it to slip into guides.

9.

Tension blade to approximately 25,000 Ibs. of

blade tension, as indicatedon the blade

tension indicator found on the tensionwheel

shaft housing.

10. Attach wire brush to the wire brush postwith

screw and washer. Adjust wire brush postso

that brushjust comes into contactwith blade

teeth.

11. Close all covers and guards and fasten

securely. Connect machineto power and run

freely for approximately two minutes.

12. Turn power off and re-check blade tensionand

wire brush adjustment. If further adjustmentis

necessary, disconnect saw from power

source, make adjustments, and re-connectto

power.

Blade Tracking Adjustment

Blade tracking has been set at the factory and

should require no adjustment. If a tracking problem

occurs, adjust the machine as follows:

~ WARNING

Tracking adjustment is done with the wheel

covers open to observe the blade. Use extreme

caution so as not to come into contact withthe

blade!

Since tracking can only be adjustedwhile machine

is running, it is suggested that this adjustmentbe

accomplished by qualified personnelthat are

familiar with this type of adjustmentand the dangers

associated with it.

'7

Page 12

1.

Disconnect machine from the power

source.

2.

Raise saw arm to its highest position and

close cutting pressure control valve to hold

saw arm in place.

3.

Locate tracking adjustment plate on the back

side of the driven blade wheel.

4.

Loosen the three bolts (A - Fig. 8) locatedon

the top of the tracking nuts.

5.

Tracking adjustment is accomplished by either

looseningor tighteningthree adjusting nuts

(B - Fig.8).

6.

Tracking is set properly when the back of the

blade lightly touches the wheel flange. Note:

over-tracking (allowing blade back to rub hard

against wheel flange)will damage the blade

wheels and blade.

7.

Tighten locking bolts (A) once properly

tracking is completed.

8.

Connect machine to the power source.

Automatic Shut-Off Adjustment

The motor should shut off immediatelyafter the

blade has cut through the materialandjust before

the head comes to rest on the horizontalstop bolt.

If the machine continuesto runafter the work piece

has been fully cut, locateand adjust the micro

switch mounting plate down. If the machineshuts

off before the work piecehas been completelycut,

move the micro switch mounting plate up.

Thrust Roller Adjustment

1.

Disconnect machine from the power

source.

2.

Loosen two hex socket cap screws (A - Fig.

9). Note: Left guide roller has two hexsocket

cap screw; right guide roller has one (HBS-

916Wonly) The HBS-1018Whas two

screws on each guide..

3.

Move guide seat (B) up or down untila

clearance of .003"to .005" between back of

blade and thrust roller is obtained.

Fig. 9

8

Page 13

4.

Tighten two hex socket cap screws (A).

5.

Repeat for other blade guideassembly.

6.

Connect machineto power source.

Guide Roller Adjustment

1.

Disconnect machine from the power

source.

2.

Loosen blade guides (A - Fig. 10) by loosening

screws (B). Slide blade guides away from

blade.

3.

Loosen locking screws (C) by usinga hex

wrench.

4.

Adjust the eccentric bushingswith a

combination wrench until the ball bearingsare

snug to the blade. Note: bladeshould travel

freely up and down betweenthe ball bearings.

Do not pinch the blade.

5.

Tighten locking screws (C).

6.

Slide blade guides back into contact with blade

and tighten screws (B).

7.

Connect machineto the power source.

Bow Weight Adjustment

Bowweight is one of the most important

adjustments of the saw. Ifthe bow weight is not set

properly, one can expect poor performance,

crooked cuts, tooth stripping, stalling, andthe blade

popping off the bladewheels. The hydraulicfeed

rate unit will not compensatefor improper bow

weight. Bow weight has beenset at the factory and

should not need any adjustment. If adjustment is

necessary:

guideseat

B

A

Fig. 10

1.

Disconnect the machine from the power

source.

2.

Turn hydraulic valve to on (F - Fig. 5)

3.

Turn cutting pressure control valve (E - Fig.5)

counter-clockwise until it stops.

9

Page 14

1.

Place one end of a fish-type scale under the

blade tension handle and lift the saw with the

other end. The scale should indicate

approximately 18-20 Ibs.for the HBS-916W.

For the HBS-1018W, it should indicate 22-24

Ibs.

2.

Adjust tension to approximately 18-20 Ibs.(or

22-24 Ibs.) by turning the adjustable C-bolt

found at the end of the coil spring on the rear

of the bandsaw.

3.

Connect the machine to the power source.

Vise Adjustment

To position the moveable visejaw:

1.

Turn vise handwheel (A - Fig. 11) 1/2 turn

counter-clockwise.

2.

Move rack block (B - Fig. 11) to desired

location by sliding along the bed. Placethe

rack block onto the rack.

3.

Turn the handwheel to tighten the vise.

To adjust the vise for angle cutting:

1. Loosen bolts and move visejaw (C-Fig11) to

desired location.

2. Set the vise to desired angle, reinstall nuts and

Tighten the nut and bolt assemblies.

3.

Adjust the movable vise parallel to the fixed

vise by loosening bolt (D-Fig.11) adjustingto

parallel and tightening bolt.

Maintenance

c

Keepthe band saw and the motor clean.

Lubrication

All ball bearings are permanently lubricated and

sealed. They require no further lubrication.

The gear box lubricant should be changed after the

first 50 hours of operation. Change lubricant from

then on every 250 hours of operation.

10

Page 15

To check level of gear box lubricant, place saw arm

in down position and allow a few minutes to pass

so that oil drains down. Check level in sight glass

on side of gear casing. Correct level is the dot in

the middle of sight glass.

To change gear box lubricant:

1.

Disconnect machine from the power source.

2.

Open drain plug and allow lubricant to drain

completely. Drain plug may be found on lower

front of gear case under right wheel cover.

Remove drain plug with a hex wrench.

3.

Replace drain plug.

4. Remove filler cap (A - Fig. 12) and fill gear box

with Mobil DTE@ Oil Heavy Medium until level

reaches dot in middle of sight glass.

5.

Replace filler cap.

6.

Connect machine to the power source.

Use a light machine oil to lubricate all other moving

parts as needed

A detailed explanation on blade selection and

blade problems and their solutions can be found in

the enclosed "Guide to BandSawing" published by

American Saw and Manufacturing Company. Used

by permission.

Fig. 12

11

Page 16

/'

<t"

/

~

:c

E

Q)

en

en

<

"C

Q)

[Q

"C

C

ns

Q)

I/)

ns

[Q

73

69-( ---~ Ii 0

I

2~

~.

203

12161-

~

-1 201

,_./'-~ 202

W)JiJJ~

N

......

Page 17

~

.c

E

CD

1/1

1/1

<

E

'-

<

~

nI

tn

111

121(3)

T/6 ,.,

122

175111J:IJ

~

111

8~

('f)

~

&

~i"" 9O(" )

Page 18

171,

107 .~

1084010914) 110

<1(

"

0 ~ ~'

;;

O9-1(4 - 114

~

'.~ ~

112(41 113141

111 ',~ 12

""""

.

I

~

'~

114 )

~

/

&~

172 _/~

>

122

""'"

,

99

117

6

96-1

-80

HBS 916W

Page 19

Parts List for the HBS-916W/-1018W Bandsaws

Index Part

No. No.

1 HBS916W-01 Base (SIN8081108and lower) 1

HBS916W-01A Base (SIN8081109and higher) 1

HBS1018W-01 Base (SIN 808718and lower) 1

HBS1018W-01A Base (SIN 808719and higher) 1

2 TS-1492071 ,...Hex Cap Bolt M12x70 4

3 TS-1540081 Hex Nut M12 4

4 HBS916W-CP Coolant Pump 1

5 TS-1531051. Pan HeadScrew M6x16 2

6 TS-1551061 Lock Washer M6 2

8 HBS916W-08 Hose 1

9 HBS916W-09 CoolantGauge 1

9-1 TS-1491041 HexCap Bolt ,.M1OX30 2

9-2 TS-1540071... ""'''''''''''''''' HexNut M10 2

10 HBS916W-10 Chip Tray " 1

HBS1018W-10 Chip Tray " 1

11 HBS916W-11 Bed(SIN 8081108and lower) 1

HBS916W-11A Bed(SIN 8081109and higher) 1

Description

HBS1018W-11 Bed(SIN808718andlower) " 1

HBS1018W-11A Bed (SIN808719 and higher) 1

12 TS-1490051 HexCap BoiL M8x30 8

13 TS-1550061 Washer. """""'"'''''''''''''''''''''''''''''''''''''''''''''' M8 8

14 TS-1551081 LockWasher M8 8

15 TS-1540061 HexNut M8 8

16 HBS916W-16 Stop Bracket 1

17 HBS916W-17 Stop Rod 1

18 HBS916W-18 Lock Handle 1

19 HBS916W-19 Work Stop 1

20 HBS916W-20 Lock Knob 1

21 HBS916W-21 HandWheel Assembly 1

HBS1018W-21 HandWheel Assembly 1

22 HBS916W-22 Lead Screw Seat 1

HBS1018W-22 LeadScrew Seat 1

23 TS-1490051 HexCap BoiL M8x30 2

23-1 TS-1551061 Lock Washer M8 " 2

23-2 TS-1550061 Washer M8 2

24 HBS916W-24 Lead Screw (SIN 8081108and lower) 1

HBS916W-24A LeadScrew (SIN 8081109and higher) 1

HBS1018W-24 LeadScrew (SIN 808718and lower) 1

HBS1018W-24A LeadScrew (SIN 808719and higher) 1

30 HK-2516-2RS NeedleBearing 2

31 HBS916W-31 TorsionSpring '''''''''''''''''''''''''''''''''' 1

HBS1018W-31 Torsion Spring 1

32 HBS916W-32 PivotShaft 1

32-1 TS-1550041. Washer "'''''''''''''''''''''''''''''''''''''''''''''''''''''''''' M12 2

32-2 HBS916W-32-2 BoltwI Zerk Fitting 2

33 HBS916W-33 Pivot Bracket '''''''''''''''''''''''''''''''''' 1

HBS1018W-33 Pivot Bracket 1

Size

Qty.

15

Page 20

34 TS-1540081 Nut M12 1

35 TS-1550081 Washer , M12 1

36 TS-1492041 HexCap Bolt M12x40 1

37 HBS916W-37 TorsionSpring Shaft 1

38 HBS916W-38 C-Ring S-22 1

39 TS-1490041 Hex Cap Bolt M8x25 1

39-1 TS-1551081 LockWasher M8 1

39-2 TS-1550061 Washer M8 1

40 HBS916W-40 MotorTilt Plate 1

HBS1018W-40 " MotorTilt Plate 1

41 HBS916W-41 LimitSwitch Plate 1

42 TS-1550061 Washer M8 2

43 TS-1490031 HexCap Bolt M8x20 2

43-1 ,TS-1551081 LockWasher M8 2

44 TS-1482021 Hex Cap Screw M6x12 4

44-1 TS-1441041 Washer M6 4

45 HBS916W-45 LimitSwitch 1

47 HBS916W-47.." Cylinder Pin 1

" HBS1018W-47A Cylinder Pin 1

48 HBS916W-48 C-Ring S-20 1

49 HBS916W-49 C-Ring S-25 2

50 TS-1491041 Hex Cap Bolt M10x30 1

50-1 TS-1540071 Hex Nut M10 1

51 HBS916W-51 HydraulicCylinderAssembly 1

HBS1018W-51 HydraulicCylinder Assembly 1

52 HBS916W-52 CylinderPin 1

52-1 HBS916W-52-1 , Pin 1

53 HBS916W-53 " Hydraulic MountingPlate- Top " 1

HBS1018W-53 HydraulicMountingPlate- Top 1

53-1 TS-1551071 LockWasher M10 2

53-2 TS-1491041 Hex Cap Bolt M1Ox30 2

54 TS-1492051 HexCap Bolt M12x50 2

55 ". TS-1550081 Washer... " M12 2

56 HBS916W-56 Plate " 1

57 TS-0561051 Hex Nut 1/2" 2

58 HBS916W-58. SpringBracket 1

59 HBS916W-59 ,...AdjustableC-Bolt 1

60 HBS916W-60 " Spring 1

HBS1018W-60 , Spring 1

61 HBS916W-61 AngleScale 1

62 TS-1492041 Hex Cap BoiL M12x40 2

63 TS-1551081 LockWasher M12 1

63-1 TS-1550081 Washer , M12 2

64 HBS916W-64 ViseJaw -left " 1

65 T8-1492051 HexCapBolt M12x50 , 1

66 TS-1551081 " LockWasher M12 1

66-1 TS-1550081 Washer M12 1

67 ., HBS916W-67 .. , Vise Jaw - right 1

68 TS-1492041 Hex Cap Bolt M12x40 1

68-1 TS-1551081 Lock Washer M12 1

69 TS-1503011 HexSocket Cap Bolt M6x8 4

69-1 ,HBS916W-69-1 , Nut M6 1

70 HBS916W-70 , Electrical Panel Cover (SIN 8081108 and lower HBS-916W) 1

HBS916W-70 " Electrical Panel Cover (SIN 808718 and lower HBS-1018W) 1

16

Page 21

HBS916W-70A ElectricalPanelCover (SIN8081109 and higher HBS-916W) 1

HBS916W-70A ElectricalPanelCover (SIN 808719 and higher HBS-1018W) 1

71 HBS916W-71 Fuse Block 2

HBS916W-71A Fuse 3A .. .. , 1

72 HBS916W-72B MagneticSwitch ".. 1

HBS1018W-72 MagneticSwitch 1

HBS916W-72-1 Contactor(main motor) 1

HBS916W-72A-1 , Overload Relay " 1

HBS916W-72A-2 Contactor (pump) " 1

73 HBS916W-73A Transformer , , 1

HBS1 018W-73 Transformer " 1

74 HBS916W-7 4 ".. Terminal Strip 1

75 HBS916W-75 Handle " 1

76 TS-1534051 Pan Head Screw M6x16 4

77 . TS-1482021 Hex Cap Bolt M6x12 2

77-1 TS-1551 041 Lock Washer M6 2

77-2 TS-1550041 , Washer M6 2

78 HBS916W-78 Wire Brush Guard " 1

79 TS-1503011 Hex Socket Cap Screw M6x8 12

HBS1018W-79A Adjustable Bracket Mount - rear (1018W only - not shown) 1

80 HBS916W-80 Blade Wheel Cover - right 1

HBS1018W-80A Blade Wheel Cover - righL 1

81 TS-1550041 Washer M6 4

82 HBS916W-82 . Bushing 1

83 HBS916W-83 Washer 1

84 HBS916W-84 Drive Wheel 1

HBS1 018W-84A Drive Wheel 14" 1

85 , Blade (local purchase - 916W) 1

" Blade (local purchase - 1016W) , , 1

86 HBS916W-86 Hose .." 1

87 TS-1533031 Pan Head Screw M5x10 " 2

88 HBS916W-88 Filter Screen 1

89 TS-1492031 Hex Cap BoiL M12x35 4

89-1 TS-1551 081 Lock Washer M12 4

90 HBS916W-90 Lock Knob 4

91 HBS916W-91 .." Hinge Pin 2

92 HBS916W-92 " Blade Wheel Box - right " 1

HBS1018W-92 Blade Wheel Box - right 1

93 HBS916W-93 , Connector ".. 1

HBS1 018W-93 , Connector ".. 1

94 HBS916W-94 Gear Box Assembly (can only order entire assembly) 1

HBS1018W-94 ,Gear Box Assembly (can only order entire assembly) 1

95 HBS916W-95 Key .., 7MM , 1

96 HBS916W-96 Pulley Cover , 1

HBS1 018W-96 ".. Pulley Cover " 1

96-1 HBS916W-96-1 Lock Knob 1

97 HBS916W-97 Gear Box Pulley 1

HBS1 018W-97 Gear Box Pulley 1

98 VB-A39... V-Belt 1

VB-A37 V-Belt " 1

99 HBS916W-99 Motor Pulley " 1

HBS1018W-99 Motor Pulley 1

100 TS-1482031 Hex Cap BoiL M8x16 2

100-1 ...TS-1550061 Washer M8 2

17

Page 22

100-2... TS-1551 061 Lock Washer M8 ""'"'''''''''''''''''''''' 2

101 HBS916W-1 01 .. Hose 1

101-1 ...HBS916W-1 01-1 Hose """"""""""""""""""""""""""" 1

102 """ HBS916W-1 02 Support Shaft """'"'''''''''''''''''''' 1

102-1 ...TS-1550081 Washer "'''''''''''''''''''''''''''''''''''''''''''''''''''''''''' M12 1

102-2... TS-1540081 Hex Nut M12 1

103 TS-1492021 Hex Cap BoiL M12x30 2

104 HBS916W-104 MotorMountBracket """""""'''''''''''''''''''' 1

105 HBS916W-1 05 Column... """""'''''''''''''''''''''''''''''''''''''''''''''''' 1

HBS1018W-105A Column """"'''''''''''''''''''''''''' 1

106 TS-1506011 HexSocket Cap Screw M12x20 6

107 HBS916W-107 Locking Handle """"'''''''''''''''''''''''''''''''''''''''' 1

108 TS-1550061 Washer "'''''''''''''''''''''''''''''''''''''''''''''''''''''''''' 8MM 1

109 TS-1490081 Hex Cap .Bolt M8x45 4

109-1 ...TS-1550061 Washer ""'''''''''''''''''''''''''''''''''''''''''''''''''''''''' M8"""""'"'''''''''''''''' 4

110 HBS916W-110 MotorMount Plate """"'''''''''''''''''''''''''' 1

111 HBS916W-111 Motor(1-1/2 HP, 1Ph, 115/230V) 1

HBS1018W-111 Motor (2 HP, 1Ph,230V only) 1

HBS916W-600250 Capacitor(not shown) 1

HBS916W-111-2 CapacitorCover (not shown)'"'''''''''''''''''''''''' """""""'''''''''''''''''''' 1

HBS1018W-111-1 Capacitor(not shown) 1

HBS1018W-111-2 CapacitorCover (notshown) 1

112 TS-1550061 Washer M8. """'''''''''''''''''''''' 4

112-1 ...TS-1551061 LockWasher M8 4

113 TS-1540061 Hex Nut M8 4

114 HBS916W-114 Key 7MM 1

115 TS-1550081 Washer M12 1

116 TS-1504041 HexSocket Cap Screw M8x20 1

117 HBS916W-117 BladeWheel Cover -left """""'''''''''''''''''''''''' 1

HBS1018W-117A BladeWheel Cover - left 1

118 BB-608W Ball Bearing 2

119 TS-1492011 Hex Cap BoiL M12x25 2

120 TS-1550081 Washer M12 1

121 BB-6205Z Ball Bearing 3

122 HBS916W-122 IdlerWheel 1

HBS1018W-122A IdlerWheel. . 1

123 HBS916W-123 BladeGuard """""""'''''''''''''''''''' 1

HBS1018W-123A BladeGuard 1

123-1...TS-1550061 Washer """"""""""""""""""""""""""" M8 1

123-2...TS-1551061 LockWasher M8 1

123-3...TS-1490021 HexCap Bolt M8x16 1

124 HBS916W-124 GuideBracket -left 1

HBS916W-124A Guide BracketAssembly -left 1

HBS1018W-124A Guide BracketAssembly -left 1

124-1...TS-1504031 HexSocketCapScrew(HBS-916W) M8x16 3

TS-1504031 Hex Socket Cap Screw(HBS-1018W) """"'''' M8x16 6

125 TS-1540061 Washer M8 4

126 BB-6201W Ball Bearing 8

127 HBS916W-127 EccentricSleeve (outside) (HBS916W) 2

HBS1018W-127 EccentricSleeve(outside)(HBA1018W)... 2

127-1 HBS916W-127-1 Sleeve (inside-notshow) (HBS916W) 2

.HBS1018W-127-1 Sleeve(inside-not show) (HBS1018W) 2

18

Page 23

128 TS-1551061.. LockWasher.... "... M8 4

129 TS-1504091 Hex Socket Cap Screw M8x45 4

130 TS-1503071 Hex Socket Cap Screw M6x30 4

130-1...TS-1550041 Washer M6 8

131 HBS916W-131 Blade Guide , 4

132 TS-1504081 HexSocket Cap Screw (HBS-916W) M8x40 2

TS-1504081 HexSocket Cap Screw (HBS-1018W) M8x40 4

133 TS-1551081 LockWasher (HBS-916W) M8 2

TS-1551081 LockWasher (HBS-1018W) M8 4

133-1...TS-1550081... Washer(HBS-916W) M8 2

. TS-1550081... Washer(HBS-1018W) M8 4

134 HBS916W-134 AdjustableBracket , 1

HBS1018W-134A Adjustable Bracket 1

135 HBS916W-135 Scale (1018W) 1

HBS1018W-135 DovetailScale 1

136 TS-1505031 Hex Socket Cap Screw M10x25 2

137 HBS916W-137 Slide 1

HBS1018W-137A Slide ".. 1

138 HBS916W-138 " Blade Bracket -left , 1

HBS1018W-138 Blade Bracket -left ..., 1

139 TS-1492021. Hex Cap Bolt M12x30 4

139-1...TS-551081 LockWasher M12 4

140 TS-1490041 HexCap Bolt (HBS-916W) M8x25 2

140-1...TS-1551061 LockWasher (HBS-916W) , M8 2

141 HBS916W-141 Knob """""'"'''''''''''''''''''''''''''''''''''''''''''' 1

HBS1018W-141 Knob 1

142...". HBS916W-142 Plate... ". 1

143 TS-1524021 Set Screw M8x10 4

144 HBS916W-144 Blade Bracket - right 1

HBS1018W-144 BladeBracket- right ,..1

145 TS-1482011 HexCap Bolt M6x10 1

146 TS-1550041 Washer M6 1

147 HBS916W-147 Wire Brush " 1

HBS1018W-147 Wire Brush 1

148 HBS916W-148 Wire Brush Rod " 1

HBS1018W-148 Wire Brush Rod " " 1

149 HBS916W-149 Guide Bracket- right 1

HBS1018W-149 , Guide Bracket- right ..." 1

HBS916W-149A Guide BracketAssembly - right 1

HBS1018W-149A Guide BracketAssembly- right 1

150 HBS916W-150.."'''''''''''''' Spring 1

HBS1018W-150 Spring 1

152 TS-1540071 Hex Nut M10 1

153 TS-1504091 HexSocket Cap Screw (HBS-916W) M8x45 2

153-1...HBS916W-153-1 Hex Socket Cap Screw M8x55 1

154 HBS1018W-154A Adjustable Bracket- right (HBS-1018W) 1

155 TS-1540081 Hex Nut M12 1

156""" TS-1492061... Hex Cap Bolt M12x60 1

157 HBS916W-157 Blade Guard 1

HBS1018W-157A BladeGuard " 1

157-1...HBS1018W-157-1 Blade Guard- down 1

158 HBS916W-158 Lock Knob """""""'''''''''''''''''''' 1

159 TS-1523021 Set Screw (HBS-1018W) M6x8 1

160 HBS916W-160 AdjustingValve 2

19

Page 24

160-1 ... HBS916W-160-1 Clamp 1

160-2 ...TS-1551 041 Lock Washer M6 4

160-3... TS-1482021 Hex Cap Bolt M6x12 4

161 HBS916W-161A PowerIndicator Light ""'''''''''''''''''''''''''''''' 1

162 HBS916W-162 StartSwitch 1

163 HBS916W-163""'''''''''''''' Stop Switch 1

164 HBS916W-164 PumpSwitch 1

165 HBS916W-165S FeedControl- HydraulicOn/OffValve """""" 1

HBS916W-165S-1 Speed ControlValve 1

HBS916W-165S-1-K Knob for Speed ControlValve ""'''''''''''''''''''''''''''''' 1

HBS916W-165S-K Knob for On/Off Valve 1

166 HBS916W-166 ConnectingTube 1

166-1...HBS916W-166-1 Hose Clamp """"""""""'''''''''''''' 3

168 HBS916W-168 ControlBox 1

169 HBS916W-169.." Control Panel 1

170 TS-1533031 Pan HeadScrew M5x10 6

171 HBS916W-171 Wheel Box -left 1

HBS1018W-171 Wheel Box-left 1

172 HBS916W-172 Handle 1

173 TS-1540081 Hex NuL M12 2

175 TS-1533031 Pan HeadScrew M5x10 2

176 HBS916W-176 IndicatorScale """"""""'''''''''''''''''' 1

177 HBS916W-177 SlideBracket """""""""'''''''''''''''' 1

178 HBS916W-178 Tension Shaft 1

179 HBS916W-179 Key 5MM 1

180 HBS916W-180 Handwheel 1

181 HBS916W-181 LockWasher M22 13

182 HBS916W-182 FlatSteelWasher 1

183 HBS916W-183 Tension Indicator 1

184 BB-51104 Thrust Bearing 1

187 HBS916W-187 Slide 1

188 TS-1524021 Set Screw M8x10 1

189 HBS916W-189 ExtensionBar 1

190 HBS916W-190 Wheel Shaft 1

191 HBS916W-191 Nutw/Hole For Set Screw M14 1

191-1...TS-1523021 Set Screw M6x8 1

192 TS-1504051 HexSocket Cap Screw M8x25 4

193 TS-1492011 HexSocket Cap Screw M12x25 1

194 HBS916W-194 Gib... 2

195 HBS916W-195 HexCap Screw (re: HBS916W-196) 3

196 HBS916W-196 ScrewAssembly 3

196-1...HBS916W-196-1 LockWasher (re: HBS916W-196) 3

197 HBS916W-197 HoseFitting 1

198 HBS916W-198 HoseClamp 1

199 HBS916W-199 HoseClamp 2

HBS1018W-199 HoseClamp 1

200 HBS916W-200 Nut 1

201 HBS916W-201 Strain ReliefFitting 1

202 HBS916W-202 PowerCord 1

203 HBS916W-203 Screw 1

204 HBS916W-204 Name Plate 1

205 HBS916W-205 Warning Label 1

206 HBS916W-206 SpeedChart Label 1

207 HBS916W-207 Hose """""""'''''''''''''''''''' 1

20

Page 25

208 HBS916W-208 Hose , 1

213 TS-1550071 Washer M10 2

214 HBS1018W-214 Clamp 2

215 ...". HBS916W-215 CuConnector 1

.. HBS1018W-215 Cu Connector 2

216 TS-1504051 Hex SocketCap Screw M8x25 2

217 HBS916W-217 SlideBracket 1

218 HBS916W-218 LeadScrewBracket 1

219 HBS916W-219 RackBlock 1

HBS1018W-219 RackBlock. 1

220 HBS916W-220 Rack 1

HBS1018W-220 Rack. 1

221 HBS916W-221 Pin 1

21

Page 26

w--~

-

-

'<

't:I

fa

:t>

tn

tn

CD

3

C"

G>

CD

Q)

""'I

C/)

CD

CD

a.

::c

CD

a.

t:

0

::s

m

0

><

+::0

u, -'jf

~~\~ ~~

+::0

-.c

\

~

oc

~--~

Page 27

Parts List For The Gear Speed Reducing Box Assembly

Index Part

No. No. Description Size Qty.

1 HBS916W-94-01 OIL .SEAL 35x55X8 1

2 HBS916W-94-02 BEARING 30207 1

3 HBS916W-94-03 BEARING 6207.. . 1

4 HBS916W-94-04 SHAFT '"'''''''''''''''''''''''''''''''''''''''''''''''''''''''' 1

5 HBS916W-94-05 KEY 8x7x30 1

6 HBS916W-94-06 GEAR WHEEL 1

7 HBS916W-94-07 BEARING 6206 1

8 HBS916W-94-08 OUTPUT SHAFT COVER 1

9 HBS916W-94-09 OUTPUT HEX CAP SCREW M10x20 4

10 HBS916W-94-10 INPUT HEX CAP SCREW "" M8x20 4

11 HBS916W-94-11 INPUT SHAFT COVER 1

12 HBS916W-94-12 WASHER 1

13 HBS916W-94-13 BEARING """"""'" 6025 1

14 HBS916W-94-14 INPUT SHAFT '"'''' 1

15 HBS916W-94-15 KEY """""'''''''' .. 7x7x60 1

16 HBS916W-94-16 BEARING 6205 1

17 HBS~16W-94-17 C-RING R52 1

18 HBS916W-94-18 OIL SEAL. ' 25x52x8.. 1

19 HBS916W-94-19 VENT BOLT... 1

20 HBS916W-94-20 ... GEAR BOX '" ..1

21 HBS916W-94-21 OIL LENS.. '" ..1

22 HBS916W-94-22 DRAW PLUG 1

23 HBS916W-94-23.. . KEY .7X7X45.. ... 4

23

Page 28

1PH

Electrical Schematic for the HBS-916W

R

AC 110/220V

s

220V

STOP

0

4 0 L

Electrical Panel Layout

Selec-Sw

Pump

5

6

0 4-1 T U,v, W, U, v, W, a 1 2 3 4 51 0

t~

R S 0 115V

115V 230V 6

R 230 0 115 , i m

TR 11OV/220V

0 0 0 0

S

U2V2

0

5

R S 2

U, V,

6

4

24

Page 29

1PH

Electrical Schematic for the HBS-1 a 18W

R

s

AC 1~

220V

2

110V

220V

STOP

Selec-Sw

Pump

0 4 a L 6

Electrical Panel Layout

0 Lt-iT U,V, w, U, v, W, 0 1 2 3 4 51 0

R S 0 115V

R 230 0 115

0 0 0 0

230V

s

u. v.

tt

6

5

U,V,

4

0

25

Page 30

Page 31

Page 32

Loading...

Loading...