Page 1

JET TURNING

Bench Lathes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Geared Head Engine Lathes . . . . . . . . . . . . . . . . . . . . . . 42

Large Spindle Bore Lathes . . . . . . . . . . . . . . . . . . . . . . . 44

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

DRO’s for Lathes

ANILAM®, ACU-RITE®, AND NEWALL® . . . . . . . . . . . . . 50

Page 2

34

JET TURNING

jettools.com

jettools.com

TURNING

35

JET TURNING

JET has the most extensive selection of turning machines available and offers

a full range of lathes and accessories. All models are available in a range of sizes.

We offer packages that include taper attachments, collet closers, and digital

readouts to meet the needs of any operation.

TURNING PACKAGES

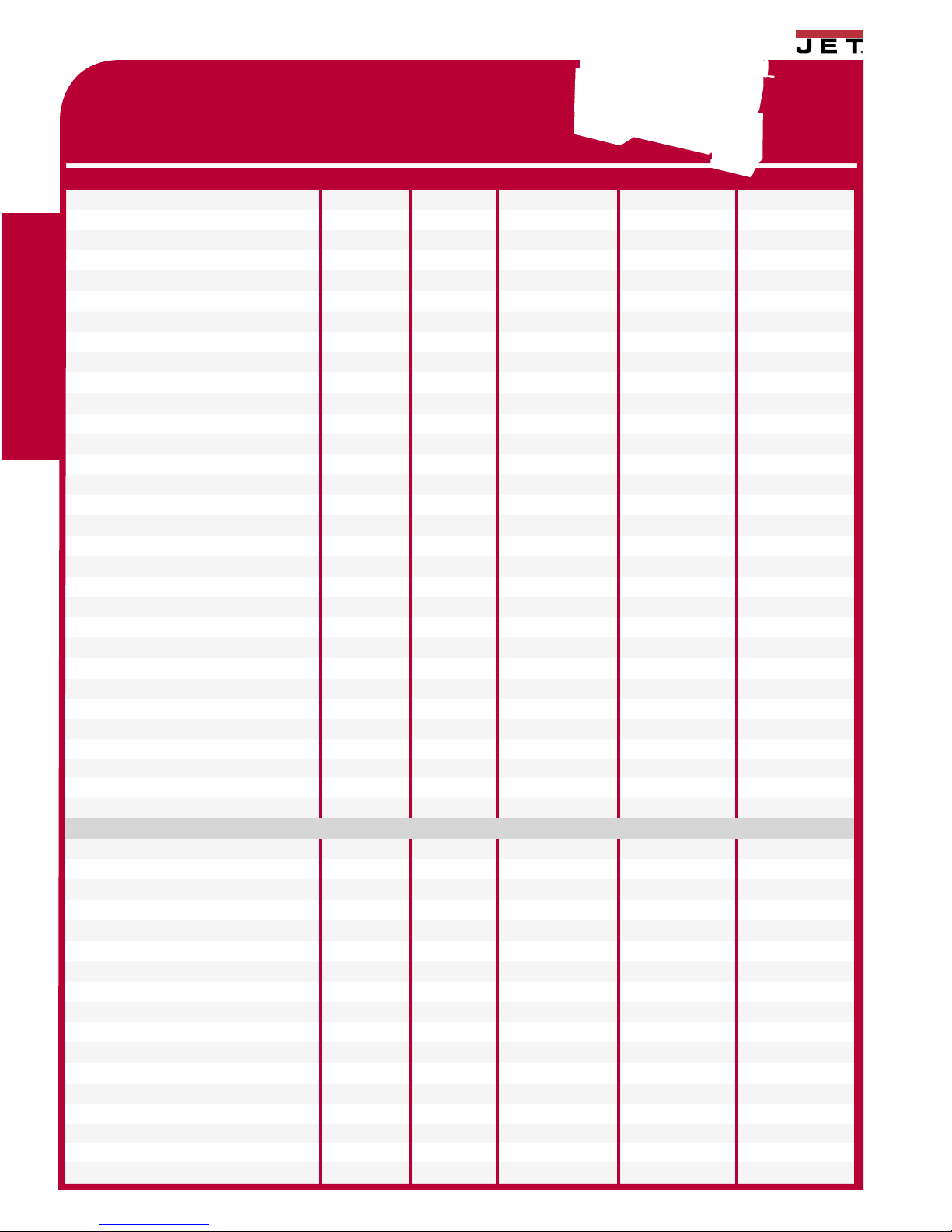

STOCK NUMBER 321360A 321357A 321810 321820 321830

Model Number

BDB-1340A GHB-1340A GH-1340W-1 GH-1340W-3 GH-1440W-1

Swing Over Bed (in.)

13 13 13 13 14

Swing Over Cross Slide (in.)

7-25/32 7-25/32 7-1/2 7-1/2 8-1/2

Swing Through Gap (in.)

18-3/4 18-3/4 19 19 20

Length of Gap (in.)

8 8

Distance Between Centers (in.)

40 40 40 40 40

Spindle Bore (in.)

1-3/8 1-3/8 1-1/2 1-1/2 1-1/2

Spindle Mount

D1-4 D1-4 D1-4 D1-4 D1-4

Spindle Taper (with sleeve)

MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3)

Number of Spindle Speeds

12 8 12 12 12

Range of Spindle Speeds (RPM)

60-1,240 70 - 2,000 40 - 1,800 40 - 1,800 40 - 1,800

Number of Longitudinal and Cross Feeds

40 40 40 40 40

Range of Longitudinal Feeds (in./rev.)

.0036 – 0.1005 0.0036 – 0.1005 0.0012 – 0.0294 0.0012 – 0.0294 0.0012 – 0.0294

Range of Cross Feeds (in./rev.)

.0012 – .0345 0.0012 – 0.0345 0.0003 – 0.0103 0.0003 – 0.0103 0.0003 – 0.0103

Number of Inch Threads

40 40 40 40 40

Range of Inch Threads (TPI)

4-112 4 - 112 4 - 112 4 - 112 4 - 112

Number of Metric Threads

27 27 22 22 22

Range of Metric Threads (mm)

0.2-6 0.2-6 0.45-7.5 0.45 -7.5 0.45-7.5

Tool Size (max./in.)

5/8 x 5/8 5/8 x 5/8 5/8 x 5/8 5/8 x 5/8 5 5/8 x 5/8

Compound Slide Travel (max./in.)

2-11/16 2-11/16 3-1/2 3-1/2 3-1/2

Cross Slide Travel (max./in.)

6-5/16 6-5/16 6-3/8 6-3/8 6-3/8

Carriage Travel (in.)

35 35 37-1/2 37-1/2 37-1/2

Tailstock Spindle Travel (in.)

3-3/4 3-3/4 4-3/4 4-3/4 4-3/4

Tailstock Taper

MT-3 MT-3 MT-3 MT-3 MT-3

Steady Rest Capacity (in.)

2-5/8 2-5/8 3-3/4 3-3/4 3-3/4

Follow Rest Capacity (in.)

2-3/4 2-3/4 2-3/4 2-3/4 2-3/4

Width of Bed (in.)

7-3/8 7-3/8 10-1/2 10-1/2 10-1/2

Overall Dimensions (in./L x W x H)

71 x 32 x 45 71 x 32 x 47 73-3/4 x 29-1/2 x 46-3/4 73-3/4 x29-1/2 x 47-1/2 73-3/4 x29-1/2 x 47-1/2

Motor

2 HP, 1Ph, 230V 2 HP, 1Ph, 230V 3HP, 1Ph, 230V 3HP, 3Ph, 230 /460V 3HP,1Ph, 230V

Prewired

230V

Net Weight (lbs.)

954 1,015 2081 2081 2191

LATHE INCLUDED IN ALL PACKAGE NUMBERS LISTED BELOW

Taper Attachment

321120 321119 321521 321516 321517

Collet Closer

321555 321518

Taper Attachment & Collet Closer

Acu-Rite 100S DRO

Acu-Rite 200S DRO

321121 321122 321532 321459 321549

Acu-Rite 200S 3-Axis DRO

Acu-Rite 200S DRO & Taper Attachment

321123 321550

Acu-Rite 200S DRO & Collet Closer

321526 321548

Acu-Rite 200S DRO, Taper Attachment & Collet Closer

321538 321546

Anilam 311 DRO

321545

Anilam 311 DRO & Collet Closer

Anilam 550 DRO

Anilam 550 DRO, Taper Attachment & Collet Closer

Newall C80 DRO

321130 321131 321132 321133 321134

Newall C80 DRO & Taper Attachment

321143

Newall C80 DRO & Collet Closer

321581 321536

Newall C80 DRO, Taper Attachment & Collet Closer

Page 3

jettools.com

TURNING

35

JET TURNING

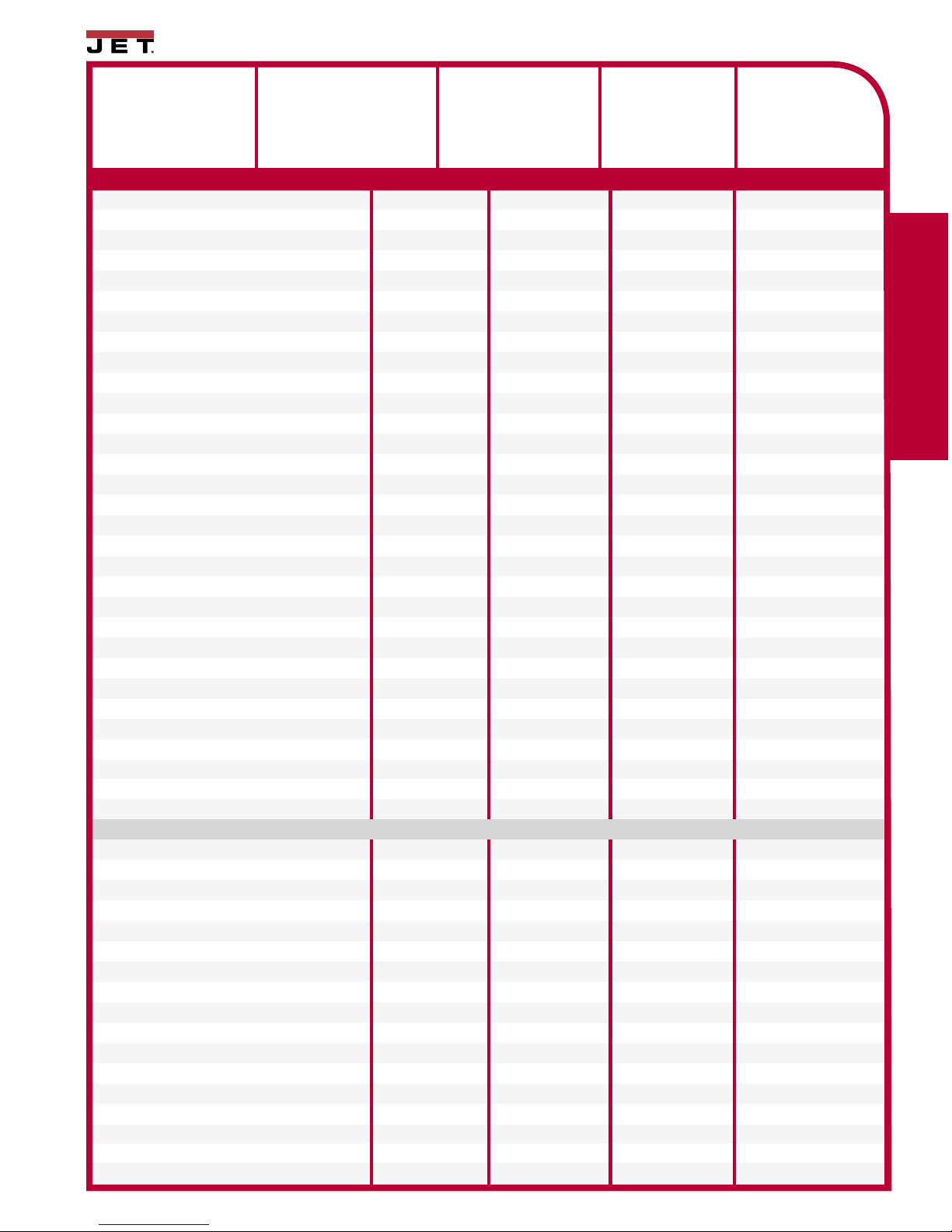

STOCK NUMBER 321840 321910 321920 321930

Model Number

GH-1440W-3 GH-1440ZX GH-1460ZX GH-1640ZX

Swing Over Bed (in.)

14 14 14 16

Swing Over Cross Slide (in.)

8-1/2 7-5/8 7-5/8 10

Swing Through Gap (in.)

20 23-5/8 23-5/8 25-7/8

Length of Gap (in.)

12-1/4 12-1/4 12-1/4

Distance Between Centers (in.)

40 40 60 40

Spindle Bore (in.)

1-1/2 3-1/8 3-1/8 3-1/8

Spindle Mount

D1-4 D1-8 D1-8 D1-8

Spindle Taper (with sleeve)

MT-5 (MT-3) MT-7 (MT-5) MT-7 (MT-5) MT-7 (MT-5)

Number of Spindle Speeds

12 12 12 12

Range of Spindle Speeds (RPM)

40 - 1,800 42 -1,800 42 -1,800 25 -1,800

Number of Longitudinal and Cross Feeds

40 122 122 122

Range of Longitudinal Feeds (in./rev.)

0.0012 – 0.0294 0.0015 – 0.0913 0.0015 – 0.0913 .0015 – .0913

Range of Cross Feeds (in./rev.)

0.0003 – 0.0103 0.0006 – 0.0365 0.0006 – 0.0365 .0006 – .0365

Number of Inch Threads

40 61 61 61

Range of Inch Threads (TPI)

4 - 112 1-5/8 - 72 1-5/8 - 72 1-5/8 - 72

Number of Metric Threads

22 24 24 24

Range of Metric Threads (mm)

0.45-7.5 0.05-20 0.05-20 .05-20

Tool Size (max./in.)

5/8 x 5/8 1 x 1 1 x 1 1 x 1

Compound Slide Travel (max./in.)

3-1/2 5-1/8 5-1/8 5-1/8

Cross Slide Travel (max./in.)

6-3/8 9 9 9

Carriage Travel (in.)

37-1/2 35 55 35

Tailstock Spindle Travel (in.)

4-3/4 5 5 5

Tailstock Taper

MT-3 MT-4 MT-4 MT-4

Steady Rest Capacity (in.)

3-3/4 1/2 to 3-1/2 1/2 to 3-1/2 1/2 - 3-1/2

Follow Rest Capacity (in.)

2-3/4 3/8 to 7 3/8 to 7 3/8 - 7

Width of Bed (in.)

10-1/2 13-3/8 3/8 to 7 13-3/8

Overall Dimensions (in./L x W x H)

73-3/4 x29-1/2 x 47-1/2 97-1/2 x 40 x 46-7/8 116-1/2 x 40 x 46-7/8 97-1/2 x 40 x 48

Motor

3HP,3Ph, 230V/460V 7-1/2HP,3Ph, 230/460V 7-1/2HP, 3Ph, 230/460V 7-1/2HP,3Ph, 230/460V

Prewired

230V 230V 230V 230V

Net Weight (lbs.)

2191 5187 5380 5475

LATHE INCLUDED IN ALL PACKAGE NUMBERS LISTED BELOW

Taper Attachment

321522 321467 321480 321474

Collet Closer

321531 321439

Taper Attachment & Collet Closer

Acu-Rite 100S DRO

Acu-Rite 200S DRO

321533 321469 321478 321475

Acu-Rite 200S 3-Axis DRO

321525

Acu-Rite 200S DRO & Taper Attachment

321563 321507 321503 321508

Acu-Rite 200S DRO & Collet Closer

321524 321501 321490 321495

Acu-Rite 200S DRO, Taper Attachment & Collet Closer

321572 321509

Anilam 311 DRO

321540 321523

Anilam 311 DRO & Collet Closer

321542

Anilam 550 DRO

321499

Anilam 550 DRO, Taper Attachment & Collet Closer

321541

Newall C80 DRO

321135 321136 321137 321138

Newall C80 DRO & Taper Attachment

321570 321571

Newall C80 DRO & Collet Closer

321441 321494

Newall C80 DRO, Taper Attachment & Collet Closer

TURNING PACKAGES

Page 4

36

JET TURNING

TURNING

jettools.com

jettools.com

TURNING

37

JET TURNING

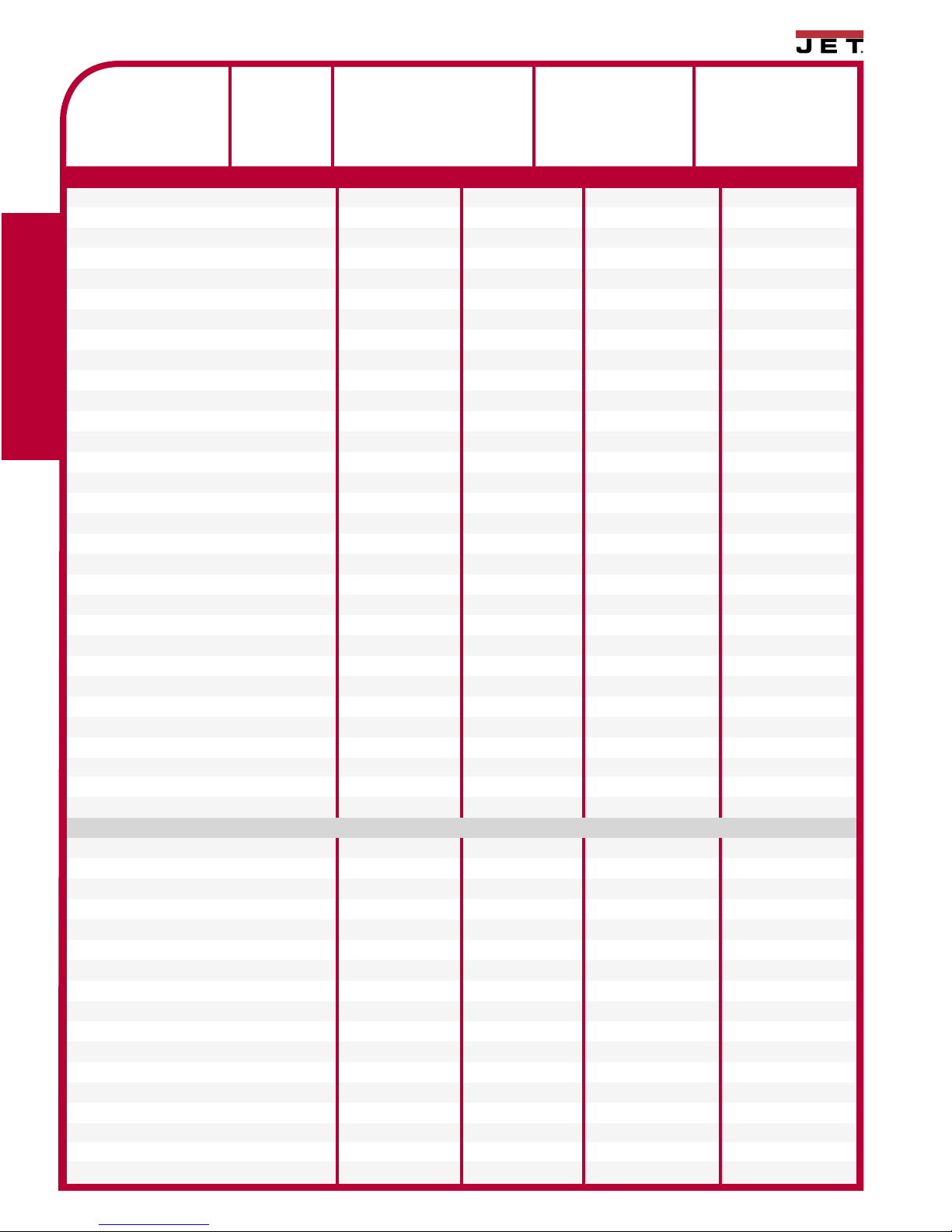

JET® TURNING PACKAGES

STOCK NUMBER 321940 321950 321960 321970

Model Number

GH-1660ZX GH-1840ZX GH-1860ZX GH-1880ZX

Swing Over Bed (in.)

16 18 18 18

Swing Over Cross Slide (in.)

10 11 11 11

Swing Through Gap (in.)

25-7/8 27-1/2 27-1/2 27-1/2

Length of Gap (in.)

12-1/4 12-1/4 12-1/4 12-1/4

Distance Between Centers (in.)

60 40 60 80

Spindle Bore (in.)

3-1/8 3-1/8 3-1/8 3-1/8

Spindle Mount

D1-8 D1-8 D1-8 D1-8

Spindle Taper (with sleeve)

MT-7 (MT-5) MT-7 (MT-5) MT-7 (MT-5) MT-7 (MT-5)

Number of Spindle Speeds

12 12 12 12

Range of Spindle Speeds (RPM)

25 -1,800 25 -1,800 25 -1,800 25 -1,800

Number of Longitudinal and Cross Feeds

122 122 122 122

Range of Longitudinal Feeds (in./rev.)

.0015 – .0913 .0015 – .0913 .0015 – .0913 .0015 – .0913

Range of Cross Feeds (in./rev.)

.0006 – .0365 .0006 – .0365 .0006 – .0365 .0006 – .0365

Number of Inch Threads

61 61 61 61

Range of Inch Threads (TPI)

1-5/8 -72 1-5/8 -72 1-5/8 -72 1-5/8 -72

Number of Metric Threads

24 24 24 24

Range of Metric Threads (mm)

0.05-20 0.05-20 0.05-20 0.05-20

Tool Size (max./in.)

1 x 1 1 x 1 1 x 1 1 x 1

Compound Slide Travel (max./in.)

5-1/8 5-1/8 5-1/8 5-1/8

Cross Slide Travel (max./in.)

9 9 9 9

Carriage Travel (in.)

55 35 55 75

Tailstock Spindle Travel (in.)

5 5 5 5

Tailstock Taper

MT-4 MT-5 MT-5 MT-5

Steady Rest Capacity (in.)

1/2 -3-1/2 1/2 -3-1/2 1/2 -3-1/2 1/2 -3-1/2

Follow Rest Capacity (in.)

3/8 - 7 3/8 - 7 3/8 - 7 3/8 - 7

Width of Bed (in.)

13-3/8 13-3/8 13-3/8 13-3/8

Overall Dimensions (in./L x W x H)

116-1/2 x 40 x 48 97-1/2 x 40 x 48-7/8 116-1/2 x 40 x 48-7/8 136-1/8 x 40 x 48-7/8

Motor

7-1/2HP, 3Ph, 230/460V 7-1/2HP, 3Ph, 230/460V 7-1/2HP, 3Ph, 230/460V 7-1/2HP, 3Ph, 230/460V

Prewired

230V 230V 230V 230V

Net Weight (lbs.)

5795 5980 6245 6590

LATHE INCLUDED IN ALL PACKAGE NUMBERS LISTED BELOW

Taper Attachment

321477 321466 321463 321486

Collet Closer

Taper Attachment & Collet Closer

321544

Acu-Rite 100S DRO

321489

Acu-Rite 200S DRO

321455 321481 321484 321487

Acu-Rite 200S 3-Axis DRO

321530

Acu-Rite 200S DRO & Taper Attachment

321543 321483 321504 321560

Acu-Rite 200S DRO & Collet Closer

Acu-Rite 200S DRO, Taper Attachment & Collet Closer

321505

Anilam 311 DRO

321528

Anilam 311 DRO & Collet Closer

Anilam 550 DRO

Anilam 550 DRO, Taper Attachment & Collet Closer

Newall C80 DRO

321139 321140 321488

Newall C80 DRO & Taper Attachment

321529 321452

Newall C80 DRO & Collet Closer

Newall C80 DRO, Taper Attachment & Collet Closer

321502

Page 5

jettools.com

TURNING

37

JET TURNING

STOCK NUMBER 321373

Model Number

BD-920N

Swing Over Bed (in.)

8-3/4

Swing Over Cross Slide (in.)

5-1/4

Distance Between Centers (in.)

20

Spindle Bore (in.)

25/32

Spindle Mount (in. x TPI)

1-1/2 x 8

Spindle Taper

MT-3

Spindle Speeds

6

Spindle Speed Range (RPM)

130-2,000

Longitudinal Feeds

27

Longitudinal Feed Range (in./rev.)

.005-.011

Inch Threads

27

Inch Thread Range (TPI)

8-56

Metric Threads

11

Metric Thread Range (mm)

.5-3

Maximum Tool Size (in.)

1/2 x 1/2

Compound Slide Travel (in.)

1-7/8

Cross Slide Travel (in.)

5

Carriage Travel (in.)

16

Tailstock spindle Travel (in.)

1-9/16

Tailstock Spindle Taper

MT-2

Steady Rest Capacity (in.)

1-7/8

Follow Rest Capacity (in.)

1-7/8

Bed Width (in.)

4-7/8

Overall Dimensions with Stand (in./L x W x H)

37-1/2 x 20 x 45

Motor

3/4HP, 1Ph, 115V only

Net Weight (lbs.)

235

9"X20" BELT DRIVE BENCH LATHE

• Spindle supported by precision tapered roller bearings

• Hardened and ground bedways

• Power longitudinal feed allows threading

• Standard 1-1/2” x 8 TPI spindle mount allows for many

aftermarket accessories

• Reversing switch included for added versatility

• Backlash adjustments provided throughtout the carriage

• Tailstock is adjustable for taper cuts

• Quick-change gear box provides wide range of inch and

metric threads

STANDARD EQUIPMENT

• 4" 3-jaw chuck with threaded back plate

• 7" 4-jaw with threaded back plate

• Face plate

• Four-way tool post

• Single tool post

• Steady and follow rest

• Metric change gears

• Centers

• Threading dial

• Tool box and tools

OPTIONAL

EQUIPMENT

STOCK

NUMBER

Cabinet Stand

321374

MT-2 Live Center

465302

9"x20" BELT DRIVE BENCH LATHE

Shown with Optional Stand

Page 6

38

JET TURNING

TURNING

jettools.com

jettools.com

TURNING

39

JET TURNING

13"x40" BELT DRIVE BENCH LATHE

• One of the most popular JET lathes now comes with an enclosed

gearbox as a standard feature

• Enclosed gearbox design provides smooth, quiet operation

• Fast, easy speed changes

• Low voltage motor controls

• Helical cut headstock gears reduce noise

• Change gears allow metric threading

• Spindle is supported by precision tapered roller bearings

• V-way bed is induction hardened and ground

• Gap bed section provided for large diameter work

• Independent leadscrew and feed rod

• T-slotted compound slide with four-way tool post

• Carriage mounted spindle control lever

• Automatic feeding and threading are fully interlocked

• Feed selectors travel in grooved ways

• Tailstock may be offset for turning tapers and includes an inch/

metric graduated quill

• Oil pan included

• Tolerance test certicate included

STANDARD EQUIPMENT

• 6" 3-jaw direct mount chuck with top

reversing jaws

• 8" 4-jaw chuck

• 12" faceplate

• Four-way tool post

• Steady and follow rest

• Metric change gear

• Centers with headstock center sleeve

• Threading dial

• Tool box with tools

Shown with Optional Stand

13"x40" BELT DRIVE BENCH LATHE

Page 7

jettools.com

TURNING

39

JET TURNING

STOCK NUMBER 321360A

Model Number

BDB-1340A

Swing over Bed (in.)

13

Swing over Cross Slide (in.)

7-25/32

Swing over Gap (in.)

18-3/4

Length of Gap (in.)

8

Distance between Centers (in.)

40

Spindle Bore (in.)

1-3/8

Spindle Mount

D1-4

Spindle Taper (with sleeve)

MT-5 (MT-3)

Number of Spindle Speeds

12

Range of Spindle Speeds (RPM)

60 – 1,240

Number of Longitudinal & Cross Feeds (in./rev.)

40

Range of Longitudinal Feeds (in/rev)

.0036 – .0325

Range of Cross Feeds (in/rev)

.0012 – .0345

Number of Inch Threads

40

Range of Inch Threads (T.P.I.)

4 – 112

Number of Metric Threads

27

Range of Metric Threads (mm)

0.2 – 6

Maximum Tool Size (in.)

5/8 x 5/8

Compound Slide Travel (in.)

2-11/16

Cross Slide Travel (in.)

6-5/16

Carriage Travel (in.)

35

Tailstock Spindle Travel (in.)

3-3/4

Tailstock Taper

MT-3

Steady Rest Capacity (in.)

2-5/8

Follow Rest Capacity (in.)

2-3/4

Width of Bed (in.)

7-3/8

Overall Dmensions with Stand (in./LxWxH)

71 x 32 x 45

Motor

2HP, 230V, 1Ph

Net Weight (lbs.)

954

OPTIONAL EQUIPMENT STOCK NUMBER

Cabinet Stand

321443AK

5C Lever-Type Collet Closer

321515A

5C Collet Set

650014

Taper Attachment Kit

321442

Coolant System

321444

Rocker Style Tool Post

321431

MT-3 Live Center

465303

Digital Readouts

Available for installation and after-market sales

13"x40" BELT DRIVE BENCH LATHE

Page 8

40

JET TURNING

TURNING

jettools.com

jettools.com

TURNING

41

JET TURNING

STANDARD EQUIPMENT

• 6" 3-jaw direct mount chuck with top

reversing jaws

• 8" 4-jaw chuck

• 12" face plate

• Four-way tool post

• Steady and follow rest

• Metric change gear

• Splash guard

• Centers and headstock center sleeve

• Threading dial

• Tool box and tools

13"X40" GEARED HEAD BENCH LATHE

• One of the most popular JET lathes now comes with an enclosed gearbox

as a standard feature

• Enclosed gearbox design provides smooth, quiet operation

• Fast, easy speed changes

• Hardened and ground gears are featured in the headstock and gearbox

• D1-4 spindle is precision ground for accuracy and supported by high

quality tapered roller bearings

• Headstock is constantly oiled during operation

• Gear box gives wide inch threading and feed capabilities with no

gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work

• Independent leadscrew and feed rod

• Spindle actuation control is apronmounted

• Compound and cross slide have backlash elimination

• Adjustable gibs are incorporated in the carriage and slideways

• Tailstock may be offset for turning tapers and includes an inch-metric

graduated quill

• Oil pan included

• Tolerance test certicate included

13"x40" GEARED HEAD BENCH LATHE

Shown with Optional Stand

Page 9

jettools.com

TURNING

41

JET TURNING

OPTIONAL EQUIPMENT STOCK NUMBER

Cabinet Stand

321443AK

5C Lever-Type Collet Closer

321514A

5C Collet Set

650014

Taper Attachment Kit

321442

Coolant System

321444

Rocker Style Tool Post

321431

MT-3 Live Center

465303

Digital Readouts

Available for installation and

after market sales

STOCK NUMBER 321357A

Model Number

GHB-1340A

Swing Over Bed (in.)

13

Swing Over Cross Slide (in.)

7-25/32

Swing Through Gap (in.)

18-3/4

Length of Gap (in.)

8

Distance Between Centers (in.)

40

Spindle Bore (in.)

1-3/8

Spindle Mount

D1-4

Spindle Taper (With Sleeve)

MT-5 (MT-3)

Number of Spindle Speeds

8

Range of Spindle Speeds (RPM)

70 – 2,000

Number of Longitudinal and Cross Feeds

40

Range of Longitudinal Feeds (in./rev.)

.0036 – 0325

Range of Cross Feeds (in./rev.)

.0012 – .0345

Number of Inch Threads

40

Range of Inch Threads (T.P.I.)

4 – 112

Number of Metric Threads

27

Range of Metric Threads (mm)

0.2 – 6

Max. Tool Size (in)

5/8 x 5/8

Compound Slide Travel (in.)

2-11/16

Cross Slide Travel (in.)

6-5/16

Carriage Travel (in.)

35

Tailstock Spindle Travel (in.)

3-3/4

Taper in Tailstock Spindle

MT-3

Steady Rest Capacity (in.)

2-5/8

Follow Rest Capacity (in.)

2-3/4

Width of Bed (in.)

7-3/8

Overall Dimensions with Stand (in./L x W x H)

71 x 32 x 47

Motor

2HP, 230V, 1Ph

Net Weight (lbs.)

1015

13"x40" GEARED HEAD BENCH LATHE

Page 10

42

JET TURNING

TURNING

jettools.com

jettools.com

TURNING

43

JET TURNING

13"x40" AND 14"x40" GEARED HEAD ENGINE LATHES

• Uniquely designed exclusively by JET

• Hardened and ground gears are featured in the headstock

and gearbox

• D1-4 spindle is precision ground for accuracy and supported by

high-quality tapered roller bearings

• Headstock is constantly oiled during operation

• Splined, not keyed, shafts are utilized in the headstock

• Gearbox gives large threading and feed capabilities with no

gear changes

• V-way bed design is induction hardened and ground

• Gap bed section provided for larger diameter work

• Independent leadscrew and feed rod

• Spindle actuation control is apron mounted

• Inch-metric dials are standard

• Compound and cross slide have backlash elimination

• Adjustable gibs are incorporated in the carriage and slideways

• Tailstock may be offset for turning tapers and includes an

inch-metric graduated quill

• Tolerance test certicate included

STANDARD EQUIPMENT

• Heavy-duty stand

• 6" 3-Jaw direct mount chuck with top reversing

jaws

• 8" 4-jaw chuck

• 12" face plate

• Four-way tool post

• Steady and follow rest

• Micro-carriage bed stop

• Front removable chip tray

• Spindle jog button

• Foot brake

• Coolant system with splash guard

• Metric change gears

• Halogen work lamp

• Centers and headstock center sleeve

• Threading dial

• Tool box and tools

13"x40" & 14"x40" GEARED HEAD ENGINE LATHES

321810

Page 11

jettools.com

TURNING

43

JET TURNING

STOCK NUMBER 321810 321820 321830 321840

Model Number

GH-1340W-1 GH-1340W-3 GH-1440W-1 GH-1440W-3

Swing Over Bed (in.)

13 13 14 14

Swing Over Cross Slide (in.)

7-1/2 7-1/2 8-1/2 8-1/2

Swing Through Gap (in.)

19 19 20 20

Distrance Between Centers (in.)

40 40 40 40

Spindle Bore (in.)

1-1/2 1-1/2 1-1/2 1-1/2

Spindle Mount

D1-4 D1-4 D1-4 D1-4

Spindle Taper (with Sleeve)

MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3)

Number of Spindle Speeds

12 12 12 12

Range of Spindle Speeds (RPM)

40 – 1,800 40 – 1,800 40 – 1,800 40 – 1,800

Number of Longitudinal and Cross Feeds

40 40 40 40

Range of Longitudinal Feeds (in./rev.)

.0012 – .0294 .0012 – .0294 .0012 – .0294 .0012 – .0294

Range of Crossfeeds (in./rev.)

.0003 – .0103 .0003 – .0103 .0003 – .0103 .0003 – .0103

Number of Inch Threads

40 40 40 40

Range of Inch Threads

4 - 112TPI 4 - 112TPI 4 - 112TPI 4 - 112TPI

Number of Metric Threads

22 22 22 22

Range of Metric Threads (mm)

0.45 – 7.5 0.45 – 7.5 0.45 – 7.5 0.45 – 7.5

Maximum Tool Size (in.)

5/8 x 5/8 5/8 x 5/8 5 /8 x 5/8 5/8 x 5/8

Maximium Compound Slide Travel (in.)

3-1/2 3-1/2 3-1/2 3-1/2

Maximum Cross Slide Travel (in.)

6-3/8 6-3/8 6-3/8 6-3/8

Maximim Carriage Travel (in.)

37-1/2 37-1/2 37-1/2 37-1/2

Tailstock Spindle Travel (in.)

4-3/4 4-3/4 4-3/4 4-3/4

Taper in Tailstock Spindle

MT-3 MT-3 MT-3 MT-3

Steady Rest Capacity (in.)

3-3/4 3-3/4 3-3/4 3-3/4

Follow Rest Capacity (in.)

2-3/4 2-3/4 2-3/4 2-3/4

Width of Bed (in.)

10-1/2 10-1/2 10-1/2 10-1/2

Motor

3HP, 230V, 1Ph 3HP, 230/460V, 3Ph, Prewired 230V 3HP, 230V, 1Ph

3HP, 230V/460V, 3Ph,

Prewired 230V

Overall Dimensions (in./L x W x H)

73-3/4 x 29-1/2 x 47-1/2 73-3/4 x29-1/2 x 47-1/2 73-3/4 x29-1/2 x 47-1/2 73-3/4 x29-1/2 x 47-1/2

Net Weight (lbs.)

2081 2081 2191 2191

OPTIONAL EQUIPMENT STOCK NUMBER

5C Lever-type collet closer

321519

5C collet set

650014

Taper attachment kit

321520

Rocker style tool post

321431

MT-3 live center

465303

Digital readouts

Available for installation

and after market sales

Rotary phase converter

See accessory section

NOTE: Use of Static Phase converter will void warranty.

13"x40" & 14"x40" GEARED HEAD ENGINE LATHES

Page 12

44

JET TURNING

TURNING

jettools.com

jettools.com

TURNING

45

JET TURNING

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 12" face plate

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mounting pads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

14" ZX SERIES LARGE SPINDLE BORE LATHES

• Uniquely designed exclusively by JET

• ISO 9001 certied manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground,

and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch

threads, no change gears required

• Carriage features one-shot lubrication and Turcite B on bed

sliding surfaces

• T-slotted compound slide featuring a four-way tool post

• One-piece cast iron base absorbs vibration allowing heavier cuts

• High quality ANSI Class 50 wear-resistant cast iron bed ways are

hardened and ground

• Removable gap allows up to 23-5/8" diameter work

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs complete this

impressive package

• Tolerance test certicate included

14" ZX SERIES LARGE SPINDLE BORE LATHES

321910

Page 13

jettools.com

TURNING

45

JET TURNING

STOCK NUMBER 321910 321920

Model Number

GH-1440ZX GH-1460ZX

Swing Over Bed (in.)

14 14

Swing Over Cross Slide (in.)

7-5/8 7-5/8

Swing Through Gap (in.)

23-5/8 23-5/8

Length of Gap (in.)

12-1/4 12-1/4

Distance Between Centers (in.)

40 60

Spindle Bore (in.)

3-1/8 3-1/8

Spindle Mount

D1-8 D1-8

Spindle Taper (with sleeve)

MT-7 (MT-5) MT-7 (MT-5)

Number of Spindle Speeds

12 12

Range of Spindle Speeds (RPM)

42 – 1,800 42 – 1,800

Number of Longitudinal and Cross Feeds

122 122

Range of Longitudinal Feeds (in./rev.)

.0015 – .0913 .0015 – .0913

Range of Cross Feeds (in./rev.)

.0006 – .0365 .0006 – .0365

Number of Inch Threads

61 61

Range of Inch Threads

1-5/8 – 72 1-5/8 – 72

Number of Metric Threads

24 24

Range of Metric Threads (mm)

.05 – 20 .05 – 20

Maximim Tool Size (in.)

1 x 1 1 x 1

Maximim Compound Slide Travel (in.)

5-1/8 5-1/8

Maximim Cross Slide Travel (in.)

9 9

Maximim Carriage Travel (in.)

35 55

Tailstock Spindle Travel (in.)

5 5

Tailstock Taper

MT-4 MT-4

Follow Rest Capacity (in.)

1/2 – 3-1/2 1/2 – 3-1/2

Steady Rest Capacity (in.)

3/8 – 7 3/8 – 7

Width of Bed (in.)

13-3/8 3/8 to 7

Overall Dimensions (in./L x W x H)

97-1/2 x 40 x 46-7/8 116-1/2 x 40 x 46-7/8

Motor

7-1/2HP, 230/460V, 3Ph,

Prewired 230V

7-1/2HP, 230/460V, 3Ph,

Prewired 230V

Net Weight (lbs.)

5187 5380

OPTIONAL EQUIPMENT STOCK NUMBER

5C Lever-type collet closer

321292

16-pc 5C collet set

650014

Taper attachment kit

321291

MT-4 live center

465304

Digital readouts

Available for installation or after market sales

Rotary phase convertors

See accessory section

NOTE: Rotary phase converter must be 10HP or higher with high torque kit.

Use of static phase converter will void warranty.

14" ZX SERIES LARGE SPINDLE BORE LATHES

Page 14

46

JET TURNING

TURNING

jettools.com

TURNING

47

JET TURNING

16", 18", AND 22" ZX SERIES LARGE BORE SPINDLE LATHES

• Uniquely designed exclusively by JET

• ISO 9001 certied manufacturer

• 3-1/8" bore spindle is supported by two tapered and one ball bearing

• Chrome molybdenum headstock gears are hardened, ground, and shaved

• Universal gearbox allows inch, metric, diametral, and module pitch threads,

no change gears required

• Carriage features one-shot lubrication and Turcite-B on bed

sliding surfaces

• T-slotted compound slide featuring a four-way tool post

• One-piece cast iron base absorbs vibration allowing heavier cuts

• High quality ANSI Class 50 wear-resistant cast iron bed ways are hardened

and ground

• Removable gap allows up to 23-5/8" diameter work on 16", 27-1/2" on 18"

• Five position automatic carriage stop increases productivity

• Attractive chrome control levers, dials, and knobs complete this

impressive package

• Tolerance test certicate included

STANDARD EQUIPMENT

• 10" 3-jaw chuck with top reversing jaws

• 12" 4-jaw chuck

• 12" face plate (16" models)

• 16" face plate (18" models)

• Four-way tool post

• Follow rest

• Large capacity steady rest

• Fully integrated coolant system

• Full length splash guard and coolant

return

• Large easy to use foot brake

• Articulating halogen work lamp

• Centrally located controls with jog button

• Threading dial

• Mounting pads and levelers

• Spindle sleeve (MT-7 to MT-5)

• Dead center

• Live center

• Tool box and adjusting tools

16", 18", AND 22" ZX SERIES LARGE SPINDLE BORE LATHES

321930

Page 15

TURNING

47

JET TURNING

STOCK NUMBER 321930 321940 321950 321960 321970 321980

Model Number

GH-1640ZX GH-1660ZX GH-1840ZX GH-1860ZX GH-1880ZX GH-2280ZX

Swing Over Bed (in.)

16 16 18 18 18 22

Swing Over Cross Slide (in.)

10 10 11 11 11 13

Swing Through Gap (in.)

25-7/8 25-7/8 27-1/2 27-1/2 27-1/2 29-1/2

Length of Gap (in.)

12-1/4 12-1/4 12-1/4 12-1/4 12-1/4 12-1/4

Distance Between Centers (in.)

40 60 40 60 80 80

Spindle Bore (in.)

3-1/8 3-1/8 3-1/8 3-1/8 3-1/8 3-1/8

Spindle Mount

D1-8 D1-8 D1-8 D1-8 D1-8 D1-8

Spindle Taper (with sleeve)

MT-7 (MT-5) MT-7 (MT-5) MT-7 (MT-5) MT-7 (MT-5) MT-7 (MT-5) MT-7(MT-5)

Number of Spindle Speeds

12 12 12 12 12 12

Range of Spindle Speeds (RPM)

25 – 1,800 25 – 1,800 25 – 1,800 25 to1,800 25 to1,800 25-1,800

Number of Longitudinal and Cross Feeds

122 122 122 122 122 122

Range of Longitudinal Feeds (in./rev.)

.0015 – .0913 .0015 – .0913 .0015 – .0913 .0015 – .0913 .0015 – .0913 .0015 – .0913

Range of Cross Feeds (in./rev.)

.0006 – .0365 .0006 – .0365 .0006 – .0365 .0006 – .0365 .0006 – .0365 .0006 – .0365

Number of Inch Threads

61 61 61 61 61 61

Range of Inch Threads

1-5/8 – 72 1-5/8 – 72 1-5/8 – 72 1-5/8 – 72 1-5/8 – 72 1-5/8 – 72

Number of Metric Threads

24 24 24 24 24 24

Range of Metric Threads (mm)

.05 – 20 .05 – 20 .05 – 20 .05 – 20 .05 – 20 .05 – 20

Maximim Tool Size (in.)

1 x 1 1 x 1 1 x 1 1 x 1 1 x 1 1 x 1

Maximim Compound Slide Travel (in.)

5-1/8 5-1/8 5-1/8 5-1/8 5-1/8 5-1/8

Maximim Cross Slide Travel (in.)

9 9 9 9 9 10

Maximim Carriage Travel (in.)

35 55 35 55 75 75

Tailstock Spindle Travel (in.)

5 5 5 5 5 5

Tailstock Taper

MT-4 MT-4 MT-5 MT-5 MT-5 MT-5

Follow Rest Capacity (in.)

1/2 – 3-1/2 1/2 – 3-1/2 1/2 -3-1/2 1/2 -3-1/2 1/2 -3-1/2 1/2 - 3-1/2

Steady Rest Capacity (in.)

3/8 – 7 3/8 – 7 3/8 – 7 3/8 – 7 3/8 – 7 3/8 – 7

Width of Bed (in.)

13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8

Overall Dimensions (in./L x W x H)

97-1/2 x 40 x 48 116-1/2 x 40 x 48 97-1/2 x 40 x 48-7/8 116-1/2 x 40 x 48-7/8 136-1/8 x 40 x 48-7/8 136-1/8 x 40 x 48-7/8

Motor

7-1/2HP, 230/460V,

3Ph, Prewired 230V

7-1/2HP, 230/460V,

3Ph, Prewired 230V

7-1/2HP, 230/460V,

3Ph, Prewired 230V

7-1/2HP, 230/460V,

3Ph, Prewired 230V

7-1/2HP, 230/460V,

3Ph, Prewired 230V

10HP, 230/460V, 3Ph,

Prewired 230V

Net Weight (lbs.)

5475 5795 5980 6245 6590 7400

jettools.com

16", 18", AND 22" ZX SERIES LARGE SPINDLE BORE LATHES

Page 16

JET TURNING

jettools.com

48

TURNING

49

jettools.com

JET TURNING

TURNING

COOLANT SYSTEM

• For use with BDB-1340 and GHB-1340

• 1/8HP, 115V, 3 gallon-per-minute ow rate

• Includes tank, pump, hoses and hardware

• Requires drilling of chip pan

STOCK NUMBER 321444

ROCKER STYLE TOOL POST

• For use with BDB-1340A, GHB-1340A, and W-Series

• 5/8" x 1-3/8" tool capacity

• Wrench included

TAPER ATTACHMENT

• Specially designed for each model

• 10° inclusive cutting capacity

• Mounts to predrilled and tapped holes

• Factory installation available

COLLET CLOSER

• Specially designed for each model

• Precision ground components

• Uses 5C collets

• Rear mounted lever action

• Some drilling and other

modication may be required

5–C COLLET SET

• Precision hardened and ground

• For lathes and tool and cutter grinder

applications

• 16-piece set

• 1/8" – 1-1/16" by 1/16" increments

• Does not include rack or case

STOCK NUMBER 321431

STOCK

NUMBER

MODEL NUMBER MAX. TAPER LENGTH (IN.) AT 10° ANGLE

321442

BDB-1340A 10

321442

GHB-1340A 10

321520

All W models 10-5/8

321291

All ZX models 18

STOCK

NUMBER

MODEL NUMBER

321515A

BDB-1340A

321514A

GHB-1340A

321519

All W models

321292

All ZX models

STOCK NUMBER 650014

TURNING ACCESSORIES

Page 17

49

jettools.com

JET TURNING

TURNING

LIVE CENTERS

• Precision ground, heavy-duty live centers

• Body is forged of chromium alloy steel

• Hardened high speed tip

• Ball, thrust, radial and tapered roller bearings used

for accuracy

• Spindle hardness 56° – 58° Rockwell C-Scale

• 60° Taper

STOCK

NUMBER

465302 465303 465304 465305

Model Number

MT-2 MT-3 MT-4 MT-5

Max RPM

2,800 2,000 1,500 1,000

Overall Length (in.)

5-7/16 6-3/32 7-1/4 9-1/2

Max Weight of

Workpiece (lbs.)

600 1,000 2,000 3,600

STOCK

NUMBER

MODEL NUMBER

LARGEST HP

MOTOR

TOTAL

MAXIMUM HP

CAPACITY

577305

JET-MF 1 3

577301

JET-MG 1-1/2 5

577302

JET-M 3 7

577309K

JET-M1 w/torque kit 3 7

577303

JET-A 5 12

577310K

JET-A1 w/torque kit 5 12

577306

JET-R 7-1/2 17

577311K

JET-R1 w/torque kit 7-1/2 17

577307

JET-B 10 25

577300K

JET-B1 w/torque kit 10 25

577308

JET-C 15 40

577304

JET-G 20 50

ARCO ROTARY PHASE CONVERTERS

• Recommended for most JET products with 3 phase

motors when only single phase 230V power is available

• Arco Phase converters are recognized as the industry

leader and the standard for quality, performance,

dependability and economy

• To pick the proper model you must determine the largest

HP motor that will be used. If this motor has high torque

starting characteristics or has a continuous load, it is

recommended to use the next largest model. After

you have picked the largest HP rating then you must

determine all other motors that will be on the system

to make sure they do not exceed the total maximum HP

capacity. See the chart for specications.

• Multiple speed motors can be used in the system

following the standard guidelines

• Special applications and sizes are available with factory

direct consultation to determine your needs

• 230V power, 460V available by special order

TURNING ACCESSORIES

Page 18

JET TURNING

jettools.com

50

TURNING

51

jettools.com

JET TURNING

TURNING

MODEL NUMBER 100S 200S

FLEXIBILTY/REDUCE SETUP

Number of Axis

2 2 or 3

Position-Trac™

NO YES

Auto Resolution Sensing

NO YES

ABS/INSR

YES YES

Inch/MM Conversion

YES YES

Radius/Diameter

YES YES

Axis Preset

YES YES

Scale Factoring (Mirroring)

NO YES

Axis Lock (Hold)

NO YES

INCREASED PRODUCTIVITY

Zero Reset

YES YES

Near-zero Warning

NO YES

Reference preset

NO YES

Tool Offset

2 10

Preset

YES YES

RELIABILITY

Construction

Die-Cast Metal Die-Cast Metal

Weight (lbs.)

7 7.5

Designed to UL/CSA/CE

YES YES

ISO-9001 Certiied

YES YES

EASE OF USE

Key Legends

Words Words

Keypad Technology

Sealed Membrane Sealed 3-D Tactile Feel

Display Technology

LED Vacuum Florescent

Conversational message prompts

Encrypted YES

ACCURACY & WORKPIECE QUALITY

Linear Error Compensation

1 Segment 3 Segment

Scale Resolutions

NO YES

Screen Saver (Sleep)

YES YES

Switchable count direction

YES YES

Number Display Resolutions

Multiple Multiple

Warranty Period

3-Year Hassle-Free 3-Year Hassle-Free

FITS JET LATHE 100S 200S

2-Axis

BDB-1340A

J840-200S

GHB-1340A

J840-200S

GH-1340W

J840-200S

GH-1440W

J840-200S

GH-1440ZX

J1240-100S J1240-200S

GH-1460ZX

J1260-100S J1260-200S

GH-1640ZX

J1240-100S J1240-200S

GH-1660ZX

J1260-100S J1260-200S

GH-1840ZX

J1240-100S J1240-200S

GH-1860ZX

J1260-100S J1260-200S

GH-1880ZX

J1284-100S J1284-200S

3-Axis

GH-1340W

GH-1440W

GH-1440ZX

J12405-200S

GH-1460ZX

J12605-200S

GH-1640ZX

J12405-200S

GH-1660ZX

J12605-200S

GH-1840ZX

J12405-200S

GH-1860ZX

J12605-200S

GH-1880ZX

J12845-200S

DIGITAL READOUTS FOR JET® TURNING

ACU-RITE

®

FEATURES OF 100S

• Two-axis digital display

• Tool offset capability

• Preset and zero reset capability

• Absolute/incremental display

• Inch/millimeter conversion

• Selectable count direction

• Linear error compensation

• Sealed precision glass scales

• Message prompts/error codes

• Die-cast enclosure

• ACU-RITE precision glass scales

FEATURES OF 200S

• Sixteen tool offsets for easy compensation of different tool sizes

• Lock axis feature, used in conjunction with tool offsetting, lets you

establish tool offsets with the tool under load, resulting in reduced

tool deection

• Instant radius/diameter conversion reduces math errors and allows

you to machine to print dimensions

• Two or three-axis display

• Preset and zero warning

• Inch/millimeter conversion

• Three-segment linear error compensation

• Includes Position-Trac™, a unique feature

thatenables you to easily, quickly and accurately

reestablish workpiece zero afterpower loss.

• ACU-RITE Precision Glass Scales

3

Year

Hassle–Free

Warranty

Page 19

51

jettools.com

JET TURNING

TURNING

ANILAM

®

WIZARD Digital Readouts include EverTrack™, an

absolute reference system that always keeps track of

the position, so you will never lose your work datum.

EverTrack™ eliminates the need for awkward battery

backup and is a standard feature on the x-axis.

®

MODEL WIZARD 311 WIZARD 550

Number of Axis

1, 2 or 3 1, 2 or 3

Housing

Die-Cast Metal Die-Cast Metal

Display Technology

Vacuum Florescent Vacuum Florescent

Diagnostics

YES YES

BASIC

Congurable axis

designation

YES YES

Display resolution

.0005/.0001 inch

EverTrack™

YES YES

Support inch-grating

encoders

YES YES

Inch/MM Conversion

YES YES

Reset

YES YES

Preset

YES YES

Absolute/Incremental mode

YES YES

Radius/Diamter mode

YES YES

Machine error compensation

LINEAR 4-POINT LINEAR

Mid-point Calculation

YES YES

Near-zero Warning

.5"/10mm SELECTABLE

Add/Subtract calculator

YES YES

ADVANCED

Interactive message display

VFD

Help Function

YES

Feed-rate Display

YES

Job Clock

YES

Edge Finder input

YES

Tool length offsets

99

Taper calculation

YES

Axis coupling

YES

DIGITAL READOUTS FOR JET® TURNING

FITS JET LATHE WIZARD 311 WIZARD 550

2-Axis

BDB-1340A

J842-311 J740-550

GHB-1340A

J842-311 J740-550

GH-1340W

J842-311 J740-550

GH-1440W

J842-311 J740-550

GH-1440ZX

J1242-311 J1240-550

GH-1460ZX

J1260-311 J1260-550

GH-1640ZX

J1242-311 J1240-550

GH-1660ZX

J1260-311 J1260-550

GH-1840ZX

J1242-311 J1240-550

GH-1860ZX

J1260-311 J1260-550

GH-1880ZX

J1280-311 J1284-550

3-Axis

GH-1340W

J7403-550

GH-1440W

J7403-550

GH-1440ZX

J12405-550

GH-1460ZX

J12605-550

GH-1640ZX

J12405-550

GH-1660ZX

J12605-550

GH-1840ZX

J12405-550

GH-1860ZX

J12605-550

GH-1880ZX

J12845-550

3

Year

Hassle–Free

Warranty

Page 20

JET TURNING

jettools.com

52

TURNING

NEWALL

®

C80 DRO

• This innovative design allows the operator to

easily congure the unit for either mill or lathe

specic features

• Includes a feed rate display that allows for longer

tool life and increased cutting tool performance

• Built-in interface allows for easy software upgrades

via a personal computer. Upgrades can be

downloaded from the Internet

• Available in two and three axis congurations

MODEL NUMBER C80

Absolute/Incremental Operations

Yes

Inch/Metric Conversion

Yes

Zero Reset/Data Preset

Yes

Data Recall

Yes

Data Hold

Yes

Radius/Diameter Readings

Yes

Center Find

Yes

Home Reference

Yes

Bolt Hole Circle

Yes

Grid Hole Array

Yes

Arc Contouring

Yes

Zero Approach Warning

Yes

Linear Error Compensation

Yes

Segmented Error Compensation

99 segments

Memory Back-up

Programmable Memory

99 points

Edit Capabilities

Yes

Self Diagnostics

Yes

Polar Coordinates

Yes

Line Hole Calculator

Yes

Tool Offsets

Yes

Taper Calculations

Yes

Axis Vectoring/Summing

Yes

Feed Rate Display

Yes

Software Upgradeable

Yes

Keypad

Membrane

Audible Keystroke Entry

Yes

Chassis

Die Cast

Encoder Input

FITS JET LATHE C80

2-Axis

BDB-1340A

J640C80L

GHB-1340A

J640C80L

GH-1340W

J840C80L

GH-1440W

J840C80L

GH-1440ZX

J1040C80L

GH-1460ZX

J1060C80L

GH-1640ZX

J1040C80L

GH-1660ZX

J1060C80L

GH-1840ZX

J1040C80L

GH-1860ZX

J1060C80L

GH-1880ZX

J1080C80L

NOTE: NEWALL® products are warranted to be free from defects in

materials and workmanship for ve (5) years. During the rst three (3)

years, Newall's No-Fault Warranty covers system failures caused by

accidental damage, customer abuse and improper installation.

DIGITAL READOUTS FOR JET® TURNING

Loading...

Loading...