Page 1

Operating Instructions and Parts Manual

This .pdf document is bookmarked

8-in x 13-in Horizontal Cut-Off Bandsaw

Models: EHB-8VS and EHB-8VSM

®

JET

427 New Sanford Road

LaVergne, Tennessee 37086

www.jettools.com

Ph.: 855-336-4032

Part No. M-891015

REV C1 9/2018

Copyright © 2017 JET

Page 2

1.0 WARRANTY AND SERVICE

JET® warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-855-336-4032, 8AM to 5PM CST, Monday through Friday.

WARRANTY PERIOD

The general warranty lasts for the time period specified in the literature included with your product or on the official JET

branded website, jettools.com.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product from the date of delivery.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty does not

cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair,

alterations or lack of maintenance.

HOW TO GET TECHNICAL SUPPORT

Please contact Technical Service by calling 1-855-336-4032. Please note that you will be asked to provide proof of initial

purchase when calling. If a product requires further inspection, the Technical Service representative will explain and assist

with any additional action needed. JET has Authorized Service Centers located throughout the United States. For the name

of an Authorized Service Center in your area call 1-855-336-4032 or use the Service Center Locator on the JET website.

2

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 3

MORE INFORMATION

JET® is constantly adding new products. For complete, up-to-date product information, check with your local distributor or

visit the JET website, jettools.com.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights, subject to applicable state law.

LIMITATIONS ON THIS WARRANTY

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STA TED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANT ABILITY AND FITNESS FOR A P ARTICULAR

PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only . The specifications listed in JET printed materials and on of ficial JET website are given as

general information and are not binding. JET reserves the right to effect at any time, without prior notice, those alterations to

parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET branded products

are not sold in Canada by JPW Industries, Inc.

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries, Inc., or

any of its successors in interest to the JET brand.

EHB-8VS | EHB-8VSM

3

Page 4

2.0 TABLE OF CONTENTS

1.0 WARRANTY AND SERVICE ...........................................................................................................................................2

2.0 TABLE OF CONTENTS ...................................................................................................................................................4

3.0 SAFETY WARNINGS ......................................................................................................................................................4

4.0 INTRODUCTION .............................................................................................................................................................6

5.0 SPECIFICATIONS ...........................................................................................................................................................6

6.0 MACHINE FEATURES ....................................................................................................................................................7

6.1 MACHINE BASE .........................................................................................................................................................7

6.2 SAW HEAD .................................................................................................................................................................7

6.3 WORK STOP ..............................................................................................................................................................8

6.4 CONTROL PANEL ......................................................................................................................................................8

6.5 AUXILIARY COOLANT HOSE ....................................................................................................................................8

7.0 UNPACKING AND ASSEMBL Y .................................................................................................... ...................................8

7.1 MACHINE SETUP .......................................................................................................................................................8

8.0 ELECTRICAL CONNECTION .........................................................................................................................................8

9.0 CONTROLS AND INDICATORS .....................................................................................................................................9

9.1 CONTROL PANEL ......................................................................................................................................................9

9.2 BLADE SPEEDS .........................................................................................................................................................9

10.0 BLADE SELECTION ...................................................................................................................................................10

10.1 BLADE BREAK-IN PROCEDURES ........................................................................................................................10

11.0 OPERATIONS .............................................................................................................................................................10

11.1 HYDRAULIC FEED CONTROL ...............................................................................................................................10

11.2 EVALUATING CUTTING EFFICIENCY ...................................................................................................................11

11.3 WORK SETUP ........................................................................................................................................................11

11.4 SETTING THE VISE FOR ANGLE CUTS (NON-MITERING VERSION ONLY) .....................................................11

11.5 SETTING THE VISE FOR SQUARE CUTS ............................................................................................................12

11.6 SETTING BED FOR MITERING CUTS (MITERING VERSION ONLY) ..................................................................12

11.7 STARTING THE SAW .............................................................................................................................................12

11.8 COOLANT FLOW AND NOZZLE POSITION ..........................................................................................................12

11.9 SETTING THE WORK STOP ..................................................................................................................................13

12.0 ADJUSTMENTS .............................................................................................................. ............................................13

12.1 BLADE TRACKING ADJUSTMENT ........................................................................................................................13

12.2 BLADE GUIDE ADJUSTMENT ...............................................................................................................................15

12.3 BLADE GUIDE BEARING ADJUSTMENT ..............................................................................................................15

12.4 DRIVE BELT TENSION ADJUSTMENT ..................................................................................................................16

12.5 VERIFYING ADJUSTMENT ACCURACY ...............................................................................................................16

12.6 SWITCH ADJUSTMENT .........................................................................................................................................17

12.7 COUNTERBALANCE SPRING TENSION ..............................................................................................................17

13.0 MAINTENANCE ..........................................................................................................................................................17

13.1 CHANGING BLADES ..............................................................................................................................................17

13.2 CHANGING THE DRIVE BELT ...............................................................................................................................18

13.3 REPLACING THE DRIVE MOTOR .........................................................................................................................19

14.0 CLEANING ..................................................................................................................................................................19

15.0 LUBRICATION .............................................................................................................................................................19

16.0 COOLANT ...................................................................................................................................................................19

17.0 TROUBLESHOOTING ................................................................................................................................................20

18.0 REPLACEMENT PARTS .............................................................................................................................................22

19.0 WIRING DIAGRAM .....................................................................................................................................................36

3.0 SAFETY WARNINGS

1. Read and understand the entire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This band saw is designed and intended for use by properly trained and experienced personnel only. If you are not familiar with the

proper and safe operation of a band saw, do not use until proper training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes, JET

holds itself harmless from any injury that may result from that use.

6. Always wear approved safety glasses/face shields while using this band saw. Everyday eyeglasses only have impact resistant

lenses; they are not safety glasses.

7. Before operating this band saw, remove tie, rings, watches and other jewelry, and roll sleeves up past the elbows. Remove all loose

clothing and confine long hair. Non-slip footwear or anti-skid floor strips are recommended. Do not wear gloves.

4

®

, disclaims any real or implied warranty and

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 5

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

10. Make certain the switch is in the OFF position before connecting the machine to the power supply.

11. Make certain the machine is properly grounded.

12. Make all machine adjustments or maintenance with the machine unplugged from the power source.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting wrenches are removed from the

machine before turning it on.

14. Avoid contact with coolant, especially guarding your eyes.

15. Always keeps hands and fingers away from the blade when the machine is running.

16. Never hand hold the material. Always use the vise and clamp it securely.

17. Always provide adequate support for long and heavy material.

18. Keep safety guards in place at all times when the machine is in use. If removed for maintenance purposes, use extreme caution and

replace the guards immediately after maintenance is complete.

19. Check damaged parts. Before further use of the machine, a guard or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged should be

properly repaired or replaced.

Do not use power tools in damp/wet locations or other dangerous environments. Do not expose them to rain. Keep work area well

20.

lighted. Provide for adequate space surrounding work area and non-glare overhead lighting.

21. Keep the floor around the machine clean and free of scrap material, oil and grease.

Keep visitors a safe distance from the work area. Keep children away. Workshop should be childproof; padlocks, master switches,

22.

remove starter keys.

23. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are careless acts that can result in

serious injury.

24. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other moving parts. Do not overreach or

use excessive force to perform any machine operation.

25. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for which it was not designed. The

right tool will do the job better and more safely.

26. Use recommended accessories; improper accessories may be hazardous.

27. Maintain tools with care. Keep blade sharp and clean for the best and safest performance. Follow instructions for lubricating and

changing accessories.

28. Maintain proper adjustment of blade tension, blade guides and thrust bearings.

29. Turn off the machine and disconnect from power before cleaning. Use a brush to remove chips or debris — do not use your hands.

30. Do not stand on the machine. Serious injury could occur if the machine tips over.

31. Never leave the machine running unattended. Turn the power off and do not leave the machine until it comes to a complete stop.

32. Be sure that the blade is not in contact with the workpiece when the motor is started. The motor shall be started and you should allow

the saw to come up to full speed before bringing the saw blade into contact with the workpiece.

33. Adjust upper guide to clear workpiece. Hold workpiece firmly against table.

34. Direction of feed — feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

35. Installation work and electrical wiring must be done by qualified electrician in accordance with all applicable codes and standards.

36. Do not remove jammed pieces until blade has stopped.

WARNING: This product can expose you to chemicals including lead which is known to the State of California to cause cancer

!

and birth defects or other reproductive harm, and ethylbenzene which is known to the State of California to cause cancer. For more

information go to http://www.p65warnings.ca.gov.

WARNING: Some dust, fumes and gases created by power sanding, sawing, grinding, drilling, welding and other construction

!

activities contain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead based paint

• crystalline silica from bricks, cement and other masonry products

• arsenic and chromium from chemically treated lumber

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to these chemicals, work

in a well-ventilated area and work with approved safety equipment, such as dust masks that are specifically designed to filter out

microscopic particles. For more information go to http://www.p65warnings.ca.gov/ and http://www.p65warnings.ca.gov/wood.

EHB-8VS | EHB-8VSM

5

Page 6

Familiarize yourself with the following safety notices used in this manual:

!

This means that if precautions are not heeded, it

may result in minor injury and/or possible machine

damage.

This means that if precautions are not heeded, it

may result in serious or even fatal injury.

!

4.0 INTRODUCTION

This manual is provided by JET® covering the safe operation and maintenance procedures for a JET Model EHB-8. This

manual contains instructions on installation, safety precautions, general operating procedures, maintenance instructions

and parts breakdown. Your machine has been designed and constructed to provide consistent, long-term operation if used

in accordance with the instructions as set forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our web site:

www.jettools.com. Retain this manual for future reference. If the machine transfers ownership, the manual should accompany

it.

5.0 SPECIFICATIONS

Model Number EHB-8VS EHB-8VSM

Stock Number 891015 891020

Capacity (in.):

Rectangular Stock at 90° (in.) 13(W) x 5-1/4(H), 13-1/4(W) x 2(H)

Rectangular Stock at 45° (in.) 8(W) x 8(H), 2(H) x 9-1/2(W) 8(W) x 8(H), 9-1/2(H) x 2(W)

Round Stock at 90° (in.) 8

Round Stock at 45° (in.) 8

Square Stock at 90° (in.) 8 x 8

Speeds (FPM) Variable 80~310

Motor

Blade Size (in.) 1 x 0.035 x 114.5

Blade Type Bi-metal

Blade Guides Tungsten carbide tip & ball bearing, eccentric shaft

Material Tungsten carbide inserts

Sides Eccentric shaft, ball bearings

Blade Wheel (in.) 11-5/8 diameter, cast iron

Bed Height (in.) 32 30

Dimensions (LxWxH) (in.) 62.5 x 22.4 x 48.4 (cutoff position)

Net Weight - approx. (lbs.) 660 792

Shipping Weight - approx. (lbs.) 770 924

Vise Rapid acting, screw tightening vise

Coolant Pump 1/8 Horsepower, 1Phase, 115/230V

The specifications in this manual were current at time of publication, but because of our policy of continuous improvement,

JET, reserves the right to change specifications at any time and without prior notice, without incurring obligations.

TEFC< 1-1/2 Horsepower, Capacitor Start, 1725 RPM,

1 Phase, 115/230V (prewired 115V), 18/9A

6

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 7

6.0 MACHINE FEATURES

Figures 1 and 2 depict the main features of the Model EHB8 Horizontal Cut-Off Bandsaw. The machine consists of a

machine base onto which is installed a saw head.

6.1 MACHINE BASE

The machine base consists of a coolant collection pan

mounted on two panels that form the legs of the machine.

A shelf is provided under the collection pan that supports a

coolant tank.

The machine bed mounts on the top of the collection pan.

The bed supports the vise and the vise-tightening lead

screw.

The coolant tank is equipped with a pump/motor assembly.

The pump/motor circulates coolant through tubing to cool

and lubricate the saw blade, the blade guides, and the

workpiece.

A drainpipe is provided to connect the collection pan to

the coolant tank. A screen is provided in the collection

pan to screen-out cutting debris as the coolant drains into

the coolant tank. Coolant is added to the tank by pouring

coolant into the collection pan. The tank is easily removed

from its shelf for cleaning and maintenance.

Saw Head

Control Panel

Guide Bearing Supports

Blade Wheel Cover (2)

Belt Cover

6.2 SAW HEAD

The saw head (Figure 2) consists of a drive motor, drive

pulleys, gearbox, blade wheels, blade guides and supports,

control panel, blade tension/blade tracking mechanism,

wire brush, and the saw blade.

The drive motor is mounted on a pivoting plate that swings

outward to provide drive belt tension. The motor is fitted

with a step pulley; the drive belt connects to a second step

pulley that is mounted on the input shaft of the gearbox.

A speed-reducing gearbox is mounted on the back side of

the blade wheel box on the right side of the machine. The

blade wheel (drive wheel) is installed on the output shaft of

the gearbox.

A second blade wheel is located in a blade wheel box on

the left of the machine. The blade wheel (driven wheel) is

mounted on a shaft that is part of the blade tension/tracking

mechanism. The blade tension mechanism is used to

tighten the saw blade on the blade wheels.

The mechanism also has adjustment screws that enable

the saw blade to “track” evenly on the blade wheels. The

adjustment screws change the angle of the driven blade

wheel shaft so the wheels are aligned. Tracking adjustments

are generally made after the saw blade is changed but may

be required periodically due to wear over time.

Blade

Tension

Handwheel

Driven Wheel

Blade Guards

Drive Wheel

Guide

Bearing

Housing

Floor Anchor Brackets

EHB-8VS | EHB-8VSM

Coolant

Drain

Screen

Fig. 1

Lifting

Handle

Vise

Handwheel

Chip

Brush

Cover

Fig. 2

7

Page 8

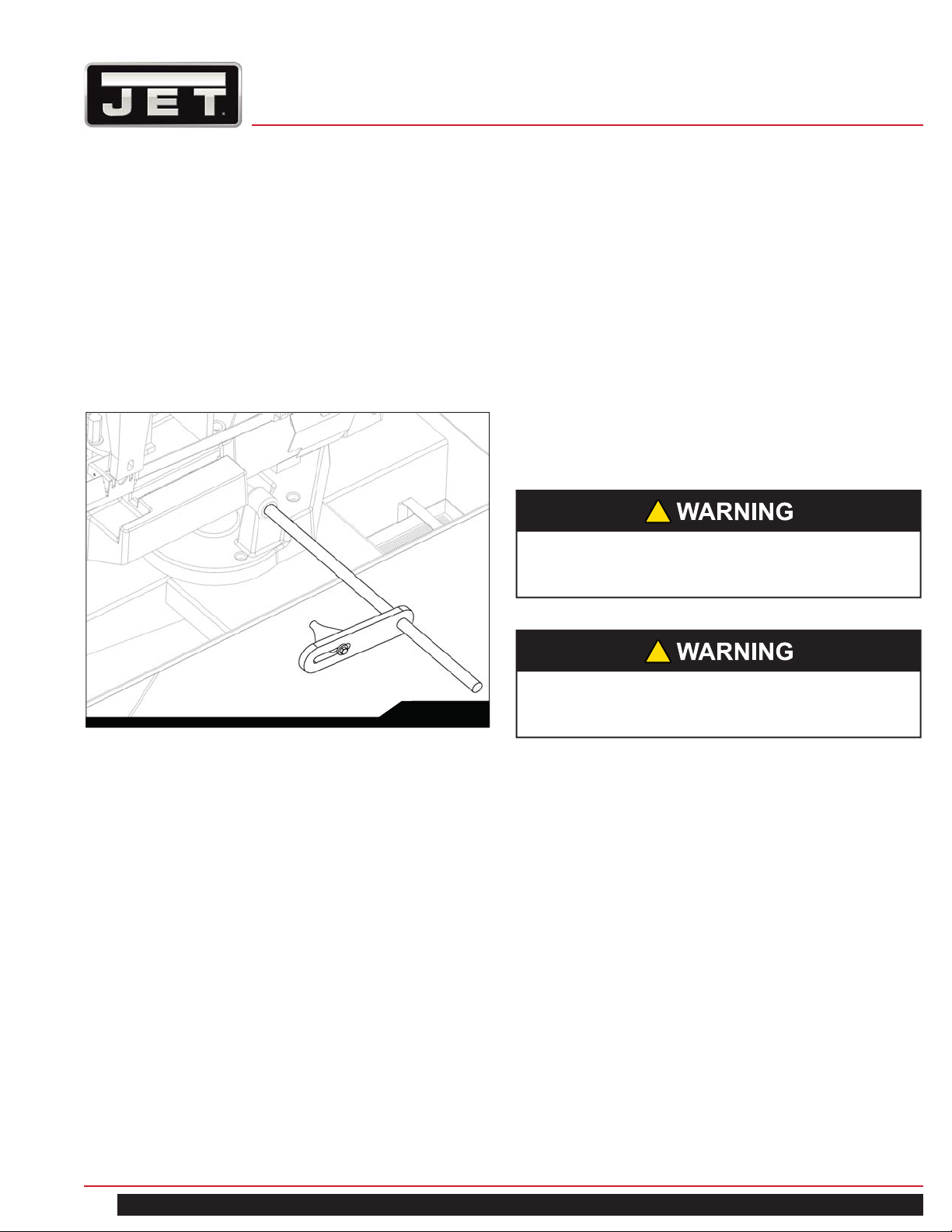

6.3 WORK STOP

A work stop (refer to Figure 3) is provided with the machine

to allow cutting multiple pieces of identical length (refer to

Figure 12). The stop consists of a rod onto which is installed

a stop bracket, a tapered stop, a clamping knob and a

locking handle. The rod is installed in a bore in the front

of the saw bed. The stop bracket is positioned on the rod

with the tapered stop toward the end of the workpiece. The

bracket is moved in or out on the rod to establish the length

of the workpiece.

7.0 UNPACKING AND ASSEMBLY

7.1 MACHINE SETUP

The cut-off saw has been pre-adjusted at the factory and

several test pieces have been cut to verify cutting accuracy .

Remove the saw from the shipping skid; discard any holddown devices. Place the saw on the shop floor; secure the

saw to the floor using mounting anchors secured through

four holes in the machine base. (Refer to Figure 1 for floor

anchor bracket location). If the saw will be used to cut long

pieces of stock, allow plenty of room for the length of the

stock.

8.0 ELECTRICAL CONNECTION

!

Electrical connection must be made by a licensed

electrician. The wiring methods and practices must

comply with local electrical codes.

Fig. 3

6.4 CONTROL PANEL

The control panel is mounted on a movable arm to the left

of the saw. Refer to the Controls and Indicators section

(section 9.0) for a description of the controls.

6.5 AUXILIARY COOLANT HOSE

Your saw is equipped with an auxiliary coolant hose. This

can be used when a large amount of coolant needs to be

directed at the work piece.

!

The machine uses high voltage electrical power

that poses a significant risk of serious injury or

death if proper precautions are not observed.

Connect the machine to the electrical power branch circuit

(refer to the Wiring Diagram section 19.0). Observe the

following guidelines when connecting the saw to the power

source:

1. Make sure the saw is disconnected from the electrical

power branch circuit (trip the required circuit breakers

or remove the required fuses).

2. Place a warning placard or tag on the service panel

to prevent accidental electrical shock.

3. When installing the motor power cord into a

receptacle, make sure the plug is compatible with the

receptacle.

4. When using hard-wired connections, connect the

wires as shown in the Wiring Diagram section.

5. Install the fuses or reset the breakers.

Check operation of the saw.

8

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 9

9.0 CONTROLS AND INDICATORS

9.1 CONTROL PANEL

The operating controls for the cut-off saw are located on the

control panel (Figure 4) and consist of the following controls

and indicators:

Coolant Pump Switch (A) – turns coolant pump on and off.

Emergency Stop Switch (B) – press to stop the drive

motor.

Note: A micro switch also stops the motor when the

workpiece is cut and the saw head is completely down.

Start Switch (C) – press to start the drive motor. The saw

head must be in the raised position.

Power Light (D) – indicates that machine is plugged in and

the outlet circuit breaker is turned on. The machine does not

need to be running for the power light to be on.

!

If the bulb is out, lamp will not light, but machine

may still have power.

9.2 BLADE SPEEDS

The Model EHB-8 horizontal cut-off bandsaw is equipped

with electronic variable speed raging from 80-310 FPM. The

speed change is completed by turning the speed control

knob (Figure 5) located to the right of the machine on the

main motor. Change blade speeds as follows:

1. Raise the saw head so that it is not in contact with a

work piece.

2. Press the motor start button on the main control panel.

3. Adjust the speed to correspond with the material that

you are cutting (Figure 6 on page 9) Note: speeds

are approximate.

!

Adjust speed dial only when machine is running.

Feed Rate Control (E) – this knob is used to set the

amount of downward force that is applied to the saw blade.

The feed rate is proportional to the opening of the valve.

When set to zero, the saw head is locked in the raised

position. Increasing the valve opening (counterclockwise

adjustment) increases the feed rate; decreasing the valve

opening (clockwise adjustment) reduces the feed rate.

D

B

A

C

E

Fig. 4

Speed Rate Control Knob

Material to be Cut Belt Speed

60 Hz

fpm mpm

Tool Steel, Stainless Steel, Alloy

~80 25

Steel, Phosphor Bronze, Hard

Bonze, Hard Cast Iron, Malleable Iron

Mild Steel, Soft Cast Iron, Me-

~130 40

dium Hard Brass, Medium Hard

Bronze

Soft Brasses and Bronzes, Hard

~170 51

Aluminum, Plastics

Plastics, Soft and Medium Alu-

~235 71

minum, Wood, Other Light Materials

Fig. 5

Fig. 6

EHB-8VS | EHB-8VSM

9

Page 10

10.0 BLADE SELECTION

The cut-off saw is delivered with a saw blade that is

adequate for a variety of cut-off jobs on a variety of common

materials.

Refer to Figure 6 for the speeds recommended for various

materials. These speeds, while appropriate for many

common shop cutting needs, do not encompass the wide

variety of special blade configurations (tooth pitch and set)

and special alloys for cutting unusual or exotic materials.

A coarse blade could be used for a solid steel bar, but a

finer tooth blade would be used on a thin-wall steel tube.

In general, the blade choice is determined by the thickness

of the material; the thinner the materials; the finer the tooth

pitch.

A minimum of three teeth should be on the workpiece at all

times for proper cutting. The blade and workpiece can be

damaged if the teeth are so far apart that they straddle the

workpiece.

For very high production on cutting of special materials, or

difficult to cut materials such as stainless steel, tool steel,

or titanium, you can ask your industrial distributor for more

specific blade recommendations. The supplier that provides

the workpiece material should be able to provide you with

very specific instructions regarding the best blade (and

coolant or cutting fluid, if needed) for the material or shape

supplied.

10.1 BLADE BREAK-IN PROCEDURES

New blades are very sharp and, therefore, have a tooth

geometry that is easily damaged if a careful break-in

procedure is not followed. Consult the blade manufacturer’s

literature for break-in of specific blades on specific materials.

However, the following procedure will be adequate for breakin of Jet-supplied blades on lower alloy ferrous materials:

1. Clamp a section of round stock in the vise. The stock

should be 2 inches or larger in diameter.

2. Operate the saw at low speed. Start the cut with a

very light feed rate.

3. When the saw has completed 1/3 of the cut, increase

the feed rate slightly and allow the saw to complete

the cut.

4. Keep the hydraulic cylinder needle valve in the same

position and begin a second cut on the same or

similar workpiece.

5. When the blade has completed about 1/3 of the cut,

increase the feed rate.

Watch the chip formation until cutting is at its most

efficient rate and allow the saw to complete the cut

(refer to Evaluating Cutting Efficiency section 11.2).

The blade is now considered ready for use.

11.0 OPERATIONS

11.1 HYDRAULIC FEED CONTROL

The weight of the saw head provides the force needed to

cut through the workpiece. The cut-off saw has a hydraulic

cylinder that controls the feed rate of the saw.

The hydraulic feed control circuit consists of a single acting

hydraulic cylinder (Figure 7) and a feed rate control (Figure

4). The feed control cylinder resists motion in the downward

direction to control the feed rate. The control cylinder offers

no resistance when raised upward.

The feed rate control knob (Figure 4) controls the rate at

which the saw head is lowered. The control knob (needle

valve) controls the rate at which the hydraulic fluid is

released from the hydraulic cylinder. When the needle

valve is closed, the cylinder is locked. With the needle valve

slightly open, the cylinder permits slow, or light, downward

force. Opening the needle valve further increases the feed

rate and applies more force to the saw blade and workpiece.

The needle valve is adjusted until the saw is operating efficiently. The efficiency of operation is usually evaluated

by observing chip formation. Blade efficiency is further described on the following page.

Drive

Motor

Hydraulic Cylinder

Counterweight Spring

Fig. 7

10

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 11

11.2 EVALUATING CUTTING EFFICIENCY

Is the blade cutting efficiently? The best way to determine

this is to observe the chips formed by the cutting blade.

If the chip formation is powdery, then the feed is much too

light, or the blade is dull.

If the chips formed are curled, but colored – blue or straw

colored from heat generated during the cut – then the feed

rate is too high.

If the chips are slightly curled and are not colored by heat

– the blade is sufficiently sharp and is cutting at its most

efficient rate.

11.3 WORK SETUP

Referring to Figure 8:

1. Set the feed rate control knob (C) to zero.

2. With the lifting handle (A) raise the saw head (B).

3. Turn the vise handwheel (D) counter clock-wise

enough to free the moveable vise jaw (E). Then

pull the moveable vise jaw away from the fixed vise

jaw(H).

4. Place the workpiece (F) on the work table (G). For

long workpieces, provide support at the other end. If

necessary, provide additional downward clamping to

hold the workpiece securely on the worktable.

5. Clamp the workpiece (F) in the vise by first pushing

the moveable vise jaw (E) against the workpiece.

Then rotate the vise handwheel (D) clockwise to

secure the workpiece.

11.4 SETTING THE VISE FOR ANGLE CUTS (NON-MITERING VERSION ONLY)

Referring to Figure 9, the vise can be adjusted through a

45-degree arc as follows:

1. Loosen the lock handle (E) that secures the fixed vise

jaw (D).

2. Rotate the fixed vise jaw (D) to the desired angle,

setting it to the scale on the back edge of the table.

For accurate cuts, use a variable protractor to set the

position of the jaw, aligning one side of the protractor

with the blade.

3. Tighten the lock handle (E).

4. Loosen the hex head bolt (A) on the moveable vise

jaw (C).

5. Place the workpiece (B) between the vise jaws (C, D).

6. Set the moveable vise jaw (C), pressing it against the

side of the workpiece (B) and fixed vise jaw (D).

7. Tighten the hex head bolt (A) on the moveable vise

jaw to secure the jaw.

B

A

C

D

E

A

F

C

E

D

EHB-8VS | EHB-8VSM

B

G

H

Fig. 9

Fig. 8

11

Page 12

11.5 SETTING THE VISE FOR SQUARE CUTS

The procedure for setting the vise for square cuts is identical

to setting for angle cuts (above) except that a machinist’s

square is used to set the angle of the fixed vise jaw (A, Fig.

10). Align one side of the square with the side of the slot (B,

Fig. 10) in the table.

!

Never operate the saw without blade covers in place.

!

CAUTION

A

B

Fig. 10

11.6 SETTING BED FOR MITERING CUTS (MITERING VERSION ONLY)

The saw head can be adjusted through a 45-degree arc as

follows:

1. Ensure that power is turned off and then loosen saw

head miter lock.

2. Rotate the saw head to the approximate desired angle

as specified on the miter angle gauge. Then verify the

exact angle with Engineers square.

3. Lock the saw head miter lock. The miter locking lever

extends through a slot in the front face of the saw bed.

Rotate the lever to the right to tighten the lock and to

the left to loosen.

4. Load the work piece and continue with steps below.

Make sure the blade is not in contact with the

workpiece when the motor is started. Do not drop

the saw head on the workpiece or force the saw

through the workpiece.

To start the saw:

1. Clamp the workpiece in the vise. Refer to Figures 10

and 11 for examples of workpieces in the vise.

Be sure the blade is not in contact with the workpiece

when the motor is started.

2. Start the motor and allow the saw to come up to

speed.

3. Slowly set the saw down onto the workpiece and

adjust cutting speed with the speed control knob

(described on page 9).

4. Do not drop the saw head or force the cut.

Let the weight of the saw head provide the

cutting force.

5. The saw will automatically shut off at the end of the

cut.

11.8 COOLANT FLOW AND NOZZLE POSITION

!

CAUTION

The coolant pump must be submerged before

operating to prevent damage to the pump.

11.7 STARTING THE SAW

Important: The efficient operation of the cut-off saw is dependent upon the condition of the saw blade. If the performance of the saw begins to deteriorate, the first item that

you should check is the blade.

If a new blade does not restore the machine’s cutting

accuracy and quality , refer to the Troubleshooting section (or

the blade manufacturer’s guide) for conditions to consider

and adjustments that can be made to increase the life of

the blade.

To change the blade, refer to the Changing Blades section

on page 17.

12

Adjust the coolant flow shut-off valves at the top of the saw

head weldment. The flow should be no more than the saw

blade can draw into the workpiece by the movement of the

blade.

The coolant flow can be stopped in two ways:

• by the coolant selector switch (A, Fig. 4) on the control

box (the preferred method)

• by closing the shut-off valves

Note: The coolant pump is self-circulating when the

shut-off valves are closed.

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 13

Flats/Strips

Rounds

Kn ock off sharp ed g e

here w ith file

Thread the stop rod (A) into the threaded opening on the

front of the saw bed (B) as shown.

Set the work stop as follows:

1. Loosen the stop arm (C).

2. Position the stop arm (C) on the stop rod (A) to

obtain the desired length of cut on the workpiece

(D).

3. Rotate the stop arm (C) so it contacts the end of the

workpiece (D).

4. Secure the stop arm.

Channels

S q ua res/Rec t an gles

Hexagonals

Angles

I-B eam s

Kn ock off sharp ed g

here with file

Tees

Fig. 11

11.9 SETTING THE WORK STOP

Referring to Figure 12:

The work stop is an accessory that is included with the Jet

EHB-8 Bandsaw. It is used to set up the saw for making

multiple cuts of the same length.

!

CAUTION

Do not allow the blade to rest on the workpiece

when the saw is not cutting.

C

A

B

D

Fig. 12

12.0 ADJUSTMENTS

12.1 BLADE TRACKING ADJUSTMENT

Refer to Figures 13 and 14.

Blade tracking has been set and tested at the factory.

Adjustment is rarely required when the blade is used

properly or if the blade is correctly welded.

If adjustment is needed:

1. Using the blade tension handwheel (D), make sure

the blade is properly tensioned.

Keep proper tension at all times.

Note: Blade tensioning is described in the Changing

Blades section on page 17.

EHB-8VS | EHB-8VSM

2. Raise the saw head (A) as shown.

3. Open the wheel guards (B).

4. Remove both of the blade-guide bearing

bracket assemblies (C).

5. Loosen three hex locking screws (E) in the

head weldment (G).

13

Page 14

A

1

B

8. Turn the adjustment screws (F) to stop the motion of

the blade on the wheel as it gets closer to the wheel

shoulder.

Put a 6-inch length of paper (J, Fig. 14) between the

blade and the wheel as shown (the saw is still turned

C

on). The paper should not be cut as it passes

between the wheel shoulder and the blade.

9. Turn the adjustment screws (F) slightly.

Repeat the insertion of the paper between the wheel

shoulder and the blade until the paper is cut in two

1

G

E,F

2

E

pieces.

D

2

E,F

F

G

Fig. 13

!

CAUTION

While performing the following, keep the blade from

rubbing excessively on the shoulder of the wheel.

Excessive rubbing will damage the wheel and/or the

blade.

6. Start the saw. Turn the adjustment screws (F) to tilt

the idler wheel (Figure 14) until the blade is touching

the shoulder of the idler wheel.

Note: As a general rule, make the same adjustment to

the two adjustment screws on the right (F, Fig. 13). The

single adjustment on the left is independent.

7. Next, turn the adjustment screws (F) so the blade

starts to move away from the shoulder of the wheel

then immediately turn the adjustment screws in the

other direction so the blade stops – then moves slowly

toward the shoulder.

!

Keep fingers clear of the blade and wheel to

avoid injury.

J, Place paper here

Blade

Tension

Handwheel

Lifting

Handle

Idler Wheel

Fig. 14

Note: You may have to repeat the check with the paper

several times before the blade and the shoulder cut the

paper into two pieces. Do not hurry the adjustment.

Patience and accuracy here will pay off with better, more

accurate, quieter cutting and much longer machine and

blade life.

When the paper is cut:

10. Turn the adjustment screws (F) slightly in the counter-

clockwise direction. This ensures that the blade is

not touching the shoulder of the wheel.

11. Shut off the saw.

12. Tighten the hex locking screws (E).

13. Install the blade-guide bearing bracket assemblies

(C, Fig. 13).

14. Position the guides so the top bearing just touches

the blade (see Blade Guide Bearing Adjustment on

page 16) .

15. Close the wheel covers (K, Fig. 15).

14

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 15

12.2 BLADE GUIDE ADJUSTMENT

Referring to Figure 15:

The EHB-8 Bandsaw has two adjustable blade guide

assemblies, each consisting of the blade guide support or

bracket (B, H) and blade guide (A).

The position of the blade guides is important in order to

make accurate cuts and prolong blade life and is determined

by the size of the workpiece. Adjustment is made as follows:

Left Blade Guide

1. Place the workpiece (G) in the vise (F) and clamp

tightly (refer to Work Setup on page 8).

2. Loosen the left lock knob (C) only.

3. Slide the guide support (D) left or right so that it just

clears the piece to be cut (G).

4. Tighten the lock knob (C).

Right Blade Guide

The right blade guide assembly is set at the factory and rests

against the stop (E). It normally does not require adjustment,

except to provide clearance for workpieces to be cut at a

great angle. If adjustment is required, the procedure is the

same as for the left blade guide adjustment.

It is always better to try a new blade when cutting

performance is poor. If performance remains poor after

changing the blade, check the blade guides for proper

spacing. For most efficient operation and maximum

accuracy, clearance between the blade and the guide

bearings should be 0.001 inch. The bearings will still turn

freely with this clearance. If the clearance is incorrect, the

blade tracking may be affected.

A

B

C

D

C

A

G

E

F

K

Fig. 15

12.3 BLADE GUIDE BEARING ADJUSTMENT

Referring to Figure 16:

Guide bearings and guide inserts are located on either side

of the saw blade and provide stability for the blade when the

saw is in operation. These bearings rotate on an eccentric

shaft so the distance from the blade can be adjusted for

optimal performance.

Blade guides provide blade support.

Guide bearings and blade guides are initially adjusted at

the factory and should rarely require adjustment

D

E

F

D

E

Fig. 16

!

Disconnect the cut-off saw from its electrical

power source.

!

Check the blade to make sure the welded section is

the same thickness as the rest of the blade. If the

blade is thicker at the weld, the guide bearings may

be damaged.

EHB-8VS | EHB-8VSM

15

Page 16

If required, adjust first one guide bearing and blade guide

assembly then the other as follows:

1. Using a 3mm hex wrench, loosen two set screws (A)

securing the eccentric bushings.

2. Using a 5mm hex wrench, loosen two socket head

cap screws (D) securing the carbide blade guides

(E).

3. Position the bearings (B) by turning the bushings

(C) with a flat-head screwdriver. Set the clearance

between the bearings (B) and blade (F) at

approximately 0.001 inch.

When properly adjusted, the blade should be in a

vertical position between the bearings as shown in

Figure 17.

4. Tighten the set screws (A).

5. Adjust the blade guides (E) so they support the blade

without pinching and tighten the socket head cap

screws.

6. When the adjustment is correct, the guide bearings

should rotate freely with slight pressure of the finger

(blade stopped).

12.5 VERIFYING ADJUSTMENT ACCURACY

Refer also to Figure 18.

T est cuts can be used to determine whether or not you have

adjusted the blade accurately . Use 2 inch round bar stock to

perform these test cuts, as follows:

1. With the bar stock securely clamped in the vise,

make a cut through the bar stock.

2. Mark the top of the bar stock.

3. Move the bar stock about 1/4 inch past the blade so

you can begin a second cut.

4. Rotate the bar stock 180 degrees so the mark you

made is now at the bottom of the cut.

5. Make a cut through the bar stock.

6. Use a micrometer to measure the thickness variation

between the top and bottom of the disk you have cut

from the bar stock.

The saw blade can be considered correctly adjusted when

the variation measured is no more than 0.012 inch across

the face of the disk. If you do not have a piece of 2-inch

bar stock available for a test cut, use a larger diameter

test workpiece rather than a smaller one. The maximum

thickness variation on any test piece should be no more

than 0.006 in. per inch of stock diameter.

INCORRECT CORRECT

Outer

Roller

Saw Blade

Inner

Roller

Locking Screw

Saw Blade

Fig. 17

12.4 DRIVE BELT TENSION ADJUSTMENT

The drive belt will stretch with use and may occasionally re-

quire tension adjustment. To adjust see the Changing Drive

Belt section (page 18) steps 1, 2, 6, and 7.

1. Clamp vise and mart top of bar stock here

2. Cut of a slice of

Rod

3. Rotate stock in vise

5. Measure

here ...

7. Difference between

measurements at edges

of disc should be less than

0.006 inches per inch of

6. ... and measure

here

stock di am et er

the bar stock

so mark is at bottom

4. Cu t o ff a new

slice from the

stock

Fig. 18

16

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 17

12.6 LIMIT SWITCH ADJUSTMENT

!

Disconnect the cut-off saw from its electrical

power source.

Referring to Figure 19:

Loosen the jam nut and set the adjustment screw so that

the limit switch will actuate to the off position when the saw

has cut through the workpiece.

Hydraulic Cylinder

Limit Switch

to 1-1/2 inches are exposed on the right side of the

eyebolt mount.

The saw can now be returned to service.

Spring

Adjustment Nut

Eyebolt

Fig. 20

13.0 MAINTENANCE

Switch Actuator

Adjustment Screw

Jam Nut

Fig. 19

12.7 COUNTERBALANCE SPRING TENSION

!

Disconnect the cut-off saw from its electrical

power source.

The counterbalance spring is located on the rear of the saw

table (refer to Figure 20). The counterbalance spring is used

to adjust the amount of down force the saw arm puts on the

workpiece when the hydraulic control cylinder is fully open.

If adjustment is needed:

1. Raise the saw arm to its full upright position and lock

it in position.

2. Set the spring tension by adjusting the nut until 1-1/4

13.1 CHANGING BLADES

!

Use leather gloves when changing the saw blade

to protect your hands from cuts and scratches.

Use protective eye wear that meets ANSI

Specification Z87.1

!

Disconnect the cut-off saw from its electrical

power source.

Referring to Figure 21 (pg. 18):

1. Raise the saw head (A). Set the feed rate control

knob to zero to lock the hydraulic cylinder, which

will hold the saw head in place.

2. Open two hinged blade wheel covers (C).

3. Remove the blade guard (D) and column blade cover

(E).

4. Turn the blade tension handle (F) counter-clockwise

until the blade hangs loose.

EHB-8VS | EHB-8VSM

17

Page 18

5. Using leather gloves to prevent cuts and scratches,

pull the blade off the drive wheels (H) and out of

the blade guides (J). Store the removed blade

carefully before proceeding.

6. Slide the new blade into the blade guides (J), then

loop the blade around the drive wheels (H) such

that the teeth face towards the back and the smooth

side faces towards the front.

This will permit the vertical side of the teeth

to contact the workpiece first.

7. Push the blade so it is seated against the

shoulders of the wheels (H).

When it is seated against the shoulder, turn the blade

tension handle (F) clockwise to increase the tension.

Do not over-tension the blade; tighten it just enough

so it does not slip while cutting.

8. When the blade is properly tensioned, reconnect the

saw to the electrical power source.

9. Check and adjust the tracking of the blade. Refer to

Blade Tracking Adjustment (on page 14) if necessary.

10. Close the wheel covers (C).

11. Put 2 to 3 drops of oil on the blade.

1. Set the arm at the full horizontal position.

2. Open the drive belt cover to expose the drive belt and

pulleys.

3. Loosen the belt tension adjust knob located in the

rear under the motor (see Figure 23 for knob

direction). Lift the motor upward to loosen the belt.

4. Remove the worn drive belt.

5. Put the replacement drive belt in the pulley position for

the speed you require (refer to the Blade Speeds

section on page 9).

6. Tighten the drive belt by turning the belt tension

adjustment knob (see Figure 23). The belt must be

secure enough it does not slip when the machine is

running. Do not over tighten. This will cause prema-

ture wear on belt and pulley bearings.

7. Reinstall drive belt cover and install knob.

Motor

Motor Pulley

E

A

C

H

F

D

C

J

13.2 CHANGING THE DRIVE BELT

Referring to Figures 22 and 23:

!

Disconnect the cut-off saw from its electrical

power source.

Fig. 21

Motor

Belt T ension

Adjust Knob

Drive Belt Pulley

Lock

Nut

Drive Belt

Fig. 22

Fig. 23

18

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 19

13.3 REPLACING THE DRIVE MOTOR

!

Disconnect the cut-off saw from its electrical

power source.

Referring to Figure 24:

1. Remove the drive belt (see Changing the Drive

Belt above).

2. Open the motor junction box and disconnect the

power cord wires from their terminals.

3. Remove four screws and washers (A) that secure the

motor (B) to the mounting plate (C).

4. Installation of a new motor is a reversal of the above

steps. Also, refer to Changing the Drive Belt (page 18)

to complete tensioning of the drive belt.

B

A

C

Fig. 24

4. Clean the chip sludge from the coolant tank. The

frequency should be determined by how often the

saw is used.

15.0 LUBRICATION

Lubricate the following components at the specified

frequencies and using the lubricants defined as follows:

Ball Bearings – the bearings are lubricated and sealed –

periodic lubrication is not required.

Blade Guide Bearing – the bearings are lubricated and

sealed – periodic lubrication is not required.

Upper Wheel Bushing – six to eight drops of oil each week.

Pivot Points, Shafts, and Bearing areas – six to eight drops

of oil each week.

16.0 COOLANT

Change coolant on a frequency appropriate to the type of

coolant being used. Oil based coolants can sour. Refer to

the coolant supplier’s instructions for change frequency.

The general-purpose coolant is a mixture of water-soluble

oil and water. Mix one part of soluble oil to ten parts of

water (one quart of oil to ten quarts water). Eleven quarts

of coolant is the amount required for the coolant pump to

operate properly.

There are numerous coolants on the market that are

formulated for special applications. Consult your local

distributor for details in the event you have a long range

production task, or are required to cut some of the more

exotic materials.

14.0 CLEANING

1. Clean off any preservative on machine surfaces.

After cleaning:

2. Coat machined surfaces of the cutoff saw with a

medium consistency machine oil. Reapply the oil

coating at least every six months.

3. Clean up accumulated saw cuttings after use. Make

sure the lead screw and rapid nut are kept free from

saw cuttings and other material that would cause

damage.

EHB-8VS | EHB-8VSM

19

Page 20

17.0 TROUBLESHOOTING

Fault Probable Cause Suggested Remedy

Excessive blade breakage

1. Material loose in vise.

2. Incorrect speed or feed.

3. Teeth too coarse for material.

4. Incorrect blade tension.

5. Saw blade is in contact with work

piece before the saw is started.

6. Blade rubs on the wheel flange.

7. Misaligned guides.

8. Cracking at weld.

1. Clamp work securely.

2. Check Machinist’s Handbook for

speed/feed appropriate for the

material being cut.

3. Check Machinist’s Handbook for

recommended blade type.

4. Adjust blade tension to the point

where the blade just does not slip on

the wheel.

5. Start the motor before placing the

saw on the workpiece.

6. Adjust blade tracking.

7. Adjust guides.

8. Longer annealing cycle.

Premature blade dulling

Bad cuts (crooked)

1. Blade teeth too coarse.

2. Blade speed too high.

3. Inadequate feed pressure.

4. Hard spots in workpiece or scale on

in workpiece.

5. Work hardening of material

(especially stainless steel).

6. Insufficient blade tension.

7. Operating saw without pressure on

workpiece.

1. Workpiece not square with blade.

2. Feed rate too fast.

3. Guide bearings not adjusted properly.

4. Inadequate blade tension.

5. Span between the two blade guides

too wide.

6. Dull blade.

7. Incorrect blade speed.

8. Blade guide assembly is loose.

9. Blade guide bearing assembly loose.

10. Blade track too far away from wheel

flanges.

11. Guide bearing worn.

1. Use a finer tooth blade.

2. Try a lower blade speed.

3. Decrease spring tension.

4. Increase feed pressure (hard spots).

Reduce speed, increase feed

pressure (Scale).

5. Increase feed pressure by reducing

spring tension.

6. Increase tension to proper level.

7. Do not run blade at idle in/on

material.

1. Adjust vise so it is square with the

blade. (Always clamp the workpiece

tightly in the vise.)

2. Decrease feed rate.

3. Adjust guide bearing clearance to

0.001 inch (0.002 inch maximum).

4. Gradually increase blade tension.

5. Move blade guide bracket closer to

work.

6. Replace blade.

7. Check blade speed

(refer to Figure 5).

8. Tighten blade guide assembly.

9. Tighten blade guide

bearing assembly.

10. Adjust blade tracking.

11. Replace worn bearing.

20

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 21

Fault Probable Cause Suggested Remedy

Bad cuts (rough)

1. Blade speed too high for

feed pressure.

2. Blade is too coarse.

1. Reduce blade speed and

feed pressure.

2. Replace with finer blade.

Blade is twisting

Unusual wear on side/back of blade

1. Blade is binding in the cut.

2. Blade tension too high

1. Blade guides worn

2. Blade guide bearings

not adjusted.

3. Blade guide bearing bracket

is loose.

1. Decrease feed pressure.

2. Decrease tension on Blade

1. Replace blade guides.

2. Adjust blade guide bearings.

3. Tighten blade guide

bearing bracket.

EHB-8VS | EHB-8VSM

21

Page 22

18.0 REPLACEMENT PARTS EHB-8VS/VSM

To order parts or reach our service department, call

1-855-336-4032 Monday through Friday (see our website

for business hours, www.jettools.com). Having the Model

Number and Serial Number of your machine available when

you call will allow us to serve you quickly and accurately.

®

JET

427 New Sanford Road

LaVergne, Tennessee 37086

www.jettools.com

Ph.: 855-336-4032

22

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 23

EHB-8VS SAW STAND & BED - PARTS BREAKDOWN

EHB-8VS | EHB-8VSM

23

Page 24

EHB-8VS SAW STAND & BED PARTS LIST

Index No. Part No. Description Size Qty.

1-1 TS-1499141 Hex Cap Screw M12x80 4

1-2 TS-1540081 Hex Nut M12 4

EHB8VS-2A Stand Assembly (Index 2-1 thru 2-5) 1

2-1 EHB8VS-2-1 Coolant Pan 1

2-2 EHB8VS-2-2 Right Leg 1

2-3 EHB8VS-2-3 Left Leg 1

2-4 EHB8VS-2-4 Front Panel/Shelf 1

2-5 EHB8VS-2-5 Back Door/Shelf 1

2-6 TS-0050031 Cross Head Hex Cap Screw 1/4"-20x3/4 10

2-8 TS-0561011 Hex Nut 1/4"-20 10

2-9 TS-0060051 Hex Cap Screw 3/8"-16x1 8

2-10 TS-0680041 Flat Washer 3/8" 16

2-11 TS-0561031 Hex Nut 3/8"-16 8

2-12 TS-1490071 Hex Cap Screw M8x40 8

2-13 TS-0680031 Flat Washer 5/16" 8

2-14 TS-1540061 Hex Nut M8 8

3 EHB8VS-3 Filter 1

4 TS-2246102 Button Head Socket Screw M6x10 1

5S EHB8VS-5S Electrical Box Assembly (Reference Only) 1

6-1 EHB8VS-6-1 Coolant Tank 1

6-2 EHB8VS-6-2 Hose 13x19-350mm 1

6-3 EHB8VS-6-3 Elbow PT1/2x1/4 1

6-4 EHB8VS-6-4 Coolant Pump 1/8HP,115/230V,1Ph 1

6-5 TS-0680021 Flat Washer 1/4" 4

6-6 TS-081F052 Pan Head Machine Screw 1/4"-20x3/4 4

6-7 EHB8VS-6-7 Hose Clamp 1

7 EHB8VS-7 Pivot Shaft 1

8S EHB8VS-8S Cylinder Assembly 1

9 EHB8VS-9 Ext. Retaining Ring S18 1

12 EHBS8VS-12 Cylinder Upper Bracket 1

13 TS-0720081 Lock Washer 5/16" 3

14 TS-1504061 Socket Head Cap Screw M8x30 3

15 TS-1505081 Socket Head Cap Screw M10x50 1

16S EHB8VS-16S Stock Stop Assembly (Index 16-1 thru 16-8)

not shown

16-1 EHB8VS-16-1 Bracket 1

16-2 TS-1550061 Flat Washer

16-3 EHB8VS-16-3 Lock Handle 2

16-4 EHB8VS-16-4 Distance Set Rod 1

16-5 EHB8VS-16-5 Shaft 1

16-6 TS-154010 Hex Nut M16 x P2.0 1

16-7 EHB8VS-16-7 Scale 1

16-8 TS-1540071 Rivet 4

17-1S EHB8VS-17-1S Hand wheel Assembly 1

17-2 TS-0680051 Flat Washer 7/16" 1

17-3 EHB8VS-17-3 Key 5x5x15L 1

17-4 EHB8VS-17-4 Acme Lead screw 1

17-5S EHB8VS-17-5S Acme Nut Assembly 1

M8

1

2

24

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 25

Index No. Part No. Description Size Qty.

17-6 EHB8VS-17-6 Bracket 1

17-7 EHB8VS-17-7 Pin 1

24 TS-1505031 Socket Head Cap Screw M10x25 2

24-1 TS-2361101 Lock Washer M10 2

25 EHB8VS-25 Pivot Shaft Washer 2

26 EHB8VS-26 Support Bracket 1

26-1 EHB8VS-26-1 Gap Ring 2

28-1 EHB8VS-28-1 Tube ID1/2"x2.8tx126cm 1

28-2 EHB8VS-28-2 Hose Clamp Ø19mm 3

28-3 EHB8VS-28-3 Tube ID1/2"x2.8tx320cm 1

28-4 EHB8VS-28-4 Spray Gun 1

28-5 EHB8VS-28-5 3 Way Connector PT1/2" 1

29 EHB8VS-29 Position Set Bracket 1

30 TS-0680031 Flat Washer 5/16" 2

31 TS-1490031 Hex Cap Screw M8x20 2

32 EHB8VS-32 Rear Pivot Bracket 1

33 EHB8VS-33 Plate 1

34 TS-2361101 Lock Washer M10 2

35 TS-149105 Hex Cap Screw M10x35 2

36 EHB8VS-36 Bed 1

37 TS-2245102 Button Head Socket Screw M5x10 2

38 EHB8VS-38 Angle Scale 1

39 TS-1524021 Socket Set Screw M8x10 1

40 TS-1540061 Hex Nut M8 1

41 TS-1490081 Hex Cap Screw M8x45 1

42 EHB8VS-42 Front Moveable Vise Jaw 1

43 EHB8VS-43 Bushing 1

44 TS-1550071 Flat Washer M10 1

45 TS-1505051 Socket Head Cap Screw M10x35 1

46 EHB8VS-46 Washer ø10.5xø27xt3mm 1

47 EHB8VS-47 Bolt 1

48 EHB8VS-48 Socket Set Screw M8x30 2

49 EHB8VS-46 Washer ø10.5xø27xt3mm 1

50 EHB8VS-50 Locking Handle M10x37 1

51 EHB8VS-51 Rear Fixed Vise Jaw 1

52 TS-1523031 Socket Set Screw M6x10 1

53 EHB8VS-53 Bushing 1

54 TS-1506041 Socket Head Cap Screw M12x35 1

55 TS-0561031 Hex Nut 3/8"-16 1

56 TS-0680041 Flat Washer 3/8" 1

57 EHB8VS-57 Spring Bracket 1

58 EHB8VS-58 Spring Eye Bolt 1

59 EHB8VS-59 Spring 1

60 TS-0081031 Hex Cap Screw 5/16"-18x3/4" 1

61 TS-0680031 Flat Washer 5/16" 1

62 TS-1505051 Socket Head Cap Screw M10x35 1

63 TS-2360121 Flat Washer M12 1

64 TS-2361011 Spring Washer M12 1

EHB-8VS | EHB-8VSM

25

Page 26

Index No. Part No. Description Size Qty.

71 EHB8VS-71 Limit Switch Holder 1

72 TS-1534042 Pan Head Machine Screw M6x12 2

73 EHB8VS-73 Limit Switch 1

74 TS-1550021 Flat Washer M4 2

74-1 TS-1540021 Hex Nut M4 2

75 TS-2284302 Pan Head Machine Screw M4x30 2

117 EHB8VS-117 Pivot Shaft 1

402 EHB8VS-402 Swivel Bushing 2

403 EHB8VS-403 Control Column 1

405 TS-1490011 Hex Cap Screw M8 x 12 4

407 TS-1550061 Flat Washer M8 4

408 EHB8VS-301 Handle 1

409 EHB8VS-409 Control Box 1

411 EHB8VS-411 Lock Handle M8 x 20 1

412 EHB8VS-412 C-Ring S-36 4

413 EHB8VS-413 Control Panel 1

414 TS-2244102 Socket Head Button Screw M4 x 10 5

415 EHB8VS-415 Electric Lamp 1

416 EHB8VS-416 Start Switch 1

417 EHB8VS-417 Emergency Stop Switch 1

418 EHB8VS-418 Coolant Pump Switch 1

419 EHB8VS-419 Hydraulic Feed Control Knob 1

26

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 27

EHB-8VSM SAW STAND & BED - PARTS BREAKDOWN

EHB-8VS | EHB-8VSM

27

Page 28

EHB-8VSM SAW STAND & BED PARTS LIST

Index No. Part No. Description Size Qty.

1-1 TS-1499141 Hex Cap Screw M12x80 4

1-2 TS-1540081 Hex Nut M12 8

6-3 EHB8VSM-6-3 Elbow PT1/2x1/4 1

6-4 EHB8VS-6-4 Coolant Pump 1/8HP,115/230V,1Ph 1

6-5 TS-0680021 Flat Washer 1/4" 4

6-6 TS-081F052 Pan Head Machine Screw 1/4"-20x3/4 4

7 EHB8VS-7 Pivot Shaft 1

8S EHB8VS-8S Cylinder Assembly 1

9 EHB8VS-9 Ext. Retaining Ring S18 1

12 EHBS8VS-12 Cylinder Upper Bracket 1

13 TS-0720081 Lock Washer 5/16" 3

14 TS-1504061 Socket Head Cap Screw M8x30 3

15 TS-1505081 Socket Head Cap Screw M10x50 1

16S EHB8VS-16S Stock Stop Assembly (Index 16-1 thru 16-8) 1

16-1 EHB8VS-16-1 Bracket 1

16-2 TS-1550061 Flat Washer

16-3 EHB8VS-16-3 Lock Handle 2

16-4 EHB8VS-16-4 Distance Set Rod 1

16-5 EHB8VS-16-5 Shaft 1

16-6 TS-154010 Hex Nut M16-2.0 1

16-7 EHB8VS-16-7 Scale 1

16-8 TS-1540071 Rivet 4

17-1S EHB8VS-17-1S Handwheel Assembly 1

17-2 TS-0680051 Flat Washer 7/16" 1

17-3 EHB8VS-17-3 Key 5x5x15L 1

17-4 EHB8VS-17-4 Acme Lead screw 1

17-5S EHB8VS-17-5S Acme Nut Assembly 1

17-6 EHB8VS-17-6 Bracket 1

17-7 EHB8VS-17-7 Pin 1

24 EHB8VSM-24 Locking Washer AW05 2

25 EHB8VSM-25 Locking Nut AN05 2

26 EHB8VS-26 Support Bracket 1

26-1 EHB8VS-26-1 Gap Ring 2

28-1 EHB8VS-28-1 Tube ID1/2"x2.8tx126cm 1

28-2 EHB8VS-28-2 Hose Clamp Ø19mm 3

28-3 EHB8VS-28-3 Tube ID1/2"x2.8tx320cm 1

28-4 EHB8VS-28-4 Spray Gun 1

28-5 EHB8VS-28-5 3 Way Connector PT1/2" 1

29 EHB8VS-29 Position Set Bracket 1

30 TS-0680031 Flat Washer 5/16" 2

31 TS-1490031 Hex Cap Screw M8x20 2

32 EHB8VS-32 Rear Pivot Bracket 1

33 EHB8VS-33 Plate 1

34 TS-2361101 Lock Washer M10 2

35 TS-149105 Hex Cap Screw M10x35 2

39 TS-1524021 Socket Set Screw M8x10 1

40 TS-1540061 Hex Nut M8 1

M8

2

28

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 29

Index No. Part No. Description Size Qty.

41 TS-1490081 Hex Cap Screw M8x45 1

42 EHB8VS-42 Front Moveable Vise Jaw 1

43 EHB8VS-43 Bushing 1

44 TS-1550071 Flat Washer M10 1

45 TS-1505051 Socket Head Cap Screw M10x35 1

46 EHB8VS-46 Washer ø10.5xø27xt3mm 1

47 EHB8VS-47 Bolt 1

48 EHB8VS-48 Socket Set Screw M8x30 2

49 EHB8VS-46 Washer ø10.5xø27xt3mm 1

50 EHB8VS-50 Locking Handle M10x37 1

51 EHB8VSM-51 Rear Fixed Vise Jaw 1

52 TS-1523031 Socket Set Screw M6x10 1

53 EHB8VS-53 Bushing 1

54 TS-1506041 Socket Head Cap Screw M12x35 1

55 TS-0561031 Hex Nut 3/8"-16 1

56 TS-0680041 Flat Washer 3/8" 1

57 EHB8VS-57 Spring Bracket 1

58 EHB8VS-58 Spring Eye Bolt 1

59 EHB8VS-59 Spring 1

60 TS-0081031 Hex Cap Screw 5/16"-18x3/4" 1

61 TS-0680031 Flat Washer 5/16" 1

62 TS-1505051 Socket Head Cap Screw M10x35 1

63 TS-2360121 Flat Washer M12 1

64 TS-2361011 Spring Washer M12 1

71 EHB8VS-71 Limit Switch Holder 1

72 TS-1534042 Pan Head Machine Screw M6x12 2

73 EHB8VS-73 Limit Switch 1

74 TS-1550021 Flat Washer M4 2

74-1 TS-1540021 Hex Nut M4 2

75 TS-2284302 Pan Head Machine Screw M4x30 2

71 EHB8VS-71 Limit Switch Holder 1

72 TS-1534042 Pan Head Machine Screw M6x12 2

73 EHB8VS-73 Limit Switch 1

74 TS-1550021 Flat Washer M4 2

74-1 TS-1540021 Hex Nut M4 2

75 TS-2284302 Pan Head Machine Screw M4x30 2

117 EHB8VSM-117 Pivot Shaft 1

152 EHB8VSM-152 Base 1

153 EHB8VSM-153 Bushing 2

154 EHB8VSM-154 Shaft 1

155 EHB8VSM-155 Block M30-1.5 1

156 EHB8VSM-156 Idle Gear 1

157 EHB8VSM-157 Special Washer 1

158 EHBS8VSM-158 Gear 1

159 TS-1540081 Hex Nut M12 1

160 TS-2310181 Hex Nut M18-2.5 1

161 EHB8VSM-161 Handle Bar 1

161-1 EHB8VSM-161-1 Instruction Label 1

EHB-8VS | EHB-8VSM

29

Page 30

Index No. Part No. Description Size Qty.

162 EHB8VSM-162 Handle 1

164 EHB8VSM-164 Slide Base 1

165 EHB8VSM-165 Stop Bracket 2

166 EHB8VSM-166 Socket Head Cap Screw M10x40 3

167 EHB8VSM-167 Scale 1

168 EHB8VSM-168 Rivet M2x5 3

169 TS-1505131 Socket Head Cap Screw M10x80 3

169-1 TS-1505041 Socket Head Cap Screw M10x30 3

170 EHB8VSM-170 Rotation Base 1

171 EHB8VSM-171 Bracket 1

172 EHB8VSM-172 Base 1

172-1 EHB8VSM-172-1 Door 1

172-2 EHB8VSM-172-2 Back Cover 1

172-3 EHB8VSM-172-3 Side Cover 1

172-4 EHB8VSM-172-4 Hook 1

172-5 EHB8VSM-172-5 Chip Tray 1

173 EHB8VSM-173 Plug 1

174 EHB8VSM-174 Coolant Gauge 1

175 EHB8VSM-175 Bracket 1

176 EHB8VSM-176 Round Head Cross Screw M5x10 8

177 TS-1503041 Socket Head Cap Screw M6x15 2

178 TS-1550041 Flat Washer M6 2

180 EHB8VSM-180 Pointer 1

181 EHB8VSM-181 Round Head Cross Screw M6x10 1

182 TS-2361121 Lock Washer M12 1

401 EHB8VSM-401 Tube Bracket 1

402 EHB8VS-402 Swivel Bushing 2

403 EHB8VSM-403 Control Column 1

404 EHB8VSM-404 Cover 1

405 TS-1490011 Hex Cap Screw M8 x 12 8

406 EHB8VSM-406 Round Head Cross Screw M5x8 2

407 TS-1550061 Flat Washer M8 8

408 EHB8VS-301 Handle 1

409 EHB8VS-409 Control Box 1

411 EHB8VS-411 Lock Handle M8 x 20 1

412 EHB8VS-412 C-Ring S-36 4

413 EHB8VS-413 Control Panel 1

414 TS-2244102 Socket Head Button Screw M4 x 10 5

415 EHB8VS-415 Electric Lamp 1

416 EHB8VS-416 Start Switch 1

417 EHB8VS-417 Emergency Stop Switch 1

418 EHB8VS-418 Coolant Pump Switch 1

419 EHB8VS-419 Hydraulic Feed Control Knob 1

420 EHB8VSM-420 Water T ray 1

30

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 31

SAW HEAD (BOTH MODELS) - PARTS BREAKDOWN

354-12

214

355-1

217

218

355

212

B

360-1

356

G

220-1

220-7

220-2

215-1

215-2

357

220-6

220-5

220-4

220-3

A

354-11

328

363

311

354-1

354-2

314-2

310

368

367

366

358

371

370

369

359

314-4

314-3

360

354-3

354-4

354-5

312

354-8

354-6

313

G

365

364

354-7

354-10

F

362

361

314

H

305

304

303

301

300

206

207

205

302

204

210

219

A

213

212

C

216

215

B

209

208

C

314-1

H

318

302-1

332

330-1

E

302-2

330

317

202

354-9

333

329

309

316

308

334

331

316-1

F

221

307

341

340

B

339

338

342

343

345S

337

336

335

*

319

*

*

*

327

FOR SV

351-1

352

*

*

*

*

*

*

326

325

351-3

314-5

314-6

322

351-2

321

323

320

345-2

350

351S

345-1

345-4

345-3

353

324

223-1

222-3

306-1

223

222-5

226

225

315-1

222-1

315

306

224

222-4

222-2

A

B

A

EHB-8VS | EHB-8VSM

211

200

209-1

31

Page 32

SAW HEAD (BOTH MODELS) PARTS LIST

Index No. Part No. Description Size Qty.

200 EHB8VS-200 Blade Guard 1

202 EHB8VS-202 Knob M6-1.0Px10L 2

204 TS-1504051 Socket Head Cap Screw M8x25 2

205 TS-1551061 Lock Washer M8 2

206 TS-1550061 Flat Washer M8 2

207 EHB8VS-207 Knob 2

208 TS-1550071 Flat Washer M10 2

209 EHB8VS-209 Blade Guide Support Arm 2

209-1 EHB8VS-209-1 Blade Direction Label 2

210 EHB8VS-210 Gib 2

211 EHB8VS-211 Ext. Retaining Ring ø8 4

212 BB-608ZZ Bearing 608ZZ 10

213 EHB8VS-213 Eccentric Guide 2

214 EHB8VS-214 Eccentric Guide 2

215 TS-1503051 Socket Head Cap Screw M6x20 4

215-1 TS-1550041 Flat Washer M6 4

215-2 TS-2361061 Lock Washer M6 4

216 EHB8VS-216 Carbide Guide 4

217 EHB8VS-217 Bearing Shaft 2

218 TS-1523011 Socket Set Screw M6x6 4

219 EHB8VS-219 Guide Bracket (Left) 1

220-1 EHB8VS-220-1 Valve 2

220-2 EHB8VS-220-2 Hose ø6 2

220-3 EHB8VS-220-3 Straight Connector 2

220-4 EHB8VS-220-4 Hold Down Clamp 2

220-5 TS-2361061 Lock Washer M6 2

220-6 TS-2246122 Button Head Socket Screw M6x12 2

220-7 EHB8VS-220-7 Horse Clamp 2

221 EHB8VS-221 Right Guide Bracket 1

EHB8VS-222S Brush Assembly (Index 222-1 thru 222-5) 1

222-1 EHB8VS-222-1 Brush Holder 1

222-2 EHB8VS-222-2 Blade Brush 1

222-3 TS-1550041 Flat Washer M6 2

222-4 TS-1540041 Hex Nut M6 2

222-5 TS-1482071 Hex Cap Screw M6x35 1

223 TS-2246102 Socket Head Button Screw M6x10 1

223-1 TS-2361061 Lock Washer M6 1

224 TS-2246122 Socket Head Button Screw M6x12 2

225 EHB8VS-225 Blade Brush Guard 1

226 TS-1540041 Hex Nut M6 2

300 TS-1503051 Socket Head Cap Screw M6-1.0Px20L 6

301 EHB8VS-301 Handle 2

302 EHB8VS-302 Knob 2

302-1 TS-1550031 Flat Washer M5 6

302-2 TS-2245102 Button Head Socket Screw M5x10 6

303 EHB8VS-303 Left Blade Wheel Cover 1

304 TS-2361061 Lock Washer M6 4

32

8-in x 13-in Horizontal Cut-Off Bandsaw

Page 33

Index No. Part No. Description Size Qty.

305 TS-2311061 Hex Nut M6-1.0P 4

306 EHB8VS-306 Right Blade Wheel Cover 1

306-1 EHB8VS-306-1 Padding Strip 2

307 TS-1490031 Hex Cap Screw M8x20 1

308 EHB8VS-308 Washer ø16xø30xt3mm 1

309 BB-6205VV Bearing 6205-2RS 2

310 EHB8VS-310 Idler Wheel 1

311 EHB8VS-311 Shaft 1

312 EHB8VS-312 Handle 1

313 TS-0561031 Hex Nut 3/8"-16 2

314 EHB8VS-314 Body Frame 1

314-1 EHB8VS-314-1 Connector PT1/2" 1

314-2 EHB8VS-314-2 Hose 18x24-190mm 1

314-3 EHB8VS-314-3 Stop Bolt 1

314-4 TS-1540061 Hex Nut M8 2

314-5 EHB8VS-314-5 Screen 1

314-6 EHB8VS-314-6 Round Head Screw M5-0.8Px10L 1

315 EHB8VS-315 Cover 1

315-1 EHB8VS-315-1 Knob 2

316 EHB8VS-316 Scale 1

316-1 EHB8VS-316-1 Rivet ø2x5L 2

317 TS-1506011 Socket Head Cap Screw M12x20 2

318 EHB8VS-318 Slide Bar 1

319 TS-1524051 Socket Set Screw M8x20 4

320 TS-1492021 Hex Cap Screw M12x30 1

321 TS-2361121 Lock Washer M12 1

322 EHB8VS-322 Drive Shaft Washer 1

323 EHB8VS-323 Key 7x7x30L 1

324 891091 Blade (Standard) 1x.035x114.5” - 5/8T 1

325 EHB8VS-325 Drive Wheel Key Slot 7mm 1

326 TS-1505021 Socket Head Cap Screw M10x20 3

327 TS-1551071 Lock Washer M10 3

328 EHB8VS-328 Gear Box Assembly 1:30 1

329 TS-1541041 Nylon Nut M10 2

330 EHB8VS-330 Shaft 1

330-1 EHB8VS-330-1 Knurled Disc 1

331 TS-1540081 Hex Nut M12 1

332 TS-1505101 Socket Head Cap Screw M10x60 1

333 EHB8VS-333 Motor Adjusting Screw 1

334 EHB8VS-334 Motor Mount Plate 1

335 EHB8VS-335 Motor Mount Plate Bracket 2

336 TS-1550041 Flat Washer M6 4

337 TS-1482041 Hex Cap Screw M6x20 4

338 EHB8VS-338 Motor 1.5HP,115/230V,1Ph 1

339 EHB8VS-339 Key 8x7x35L 1

340 TS-1550061 Flat Washer M8 4

341 TS-1490021 Hex Cap Screw M8x16 4

342 TS-1482011 Hex Cap Screw M6x10 2

343 TS-1550041 Flat Washer M6 2

EHB-8VS | EHB-8VSM

33

Page 34

Index No. Part No. Description Size Qty.

345 EHB8VS-345 Pulley Guard 1

345-1 EHB8VS-345-1 Pulley Cover 1

345-2 EHB8VS-345-2 Knob 2

345-3 EHB8VS-345-3 Bracket 1

345-4 EHB8VS-345-4 Cross Head Screw M5x8 2

350 EHB8VS-350 Belt V-330 1

351S EHB8VS-351S Variable Speed Pulley Set 1

351-1 EHB8VS-351-1 Motor Pulley 1

351-2 EHB8VS-351-2 Gear Box Pulley 1

351-3 EHB8VS-351-3 Speed Chart 1

352 EHB8VS-352 Key 7x7x37L 1

353 EHB8VS-353 Speed Chart Label 1

354-1 EHB8VS-354-1 Hose Clamp ø12 2

354-2 EHB8VS-354-2 Straight Connector PT1/4"x1/4" 1

354-3 EHB8VS-354-3 Elbow PT1/4"x1/4" 1

354-4 EHB8VS-354-4 Hose Clamp ø19 1

354-5 EHB8VS-354-5 Hose ID1/4"x2.2tx80cm 1

354-6 EHB8VS-354-6 3 Way Coolant Block 1

354-7 EHB8VS-354-7 Straight Connector PT1/4"x1/4" 1

354-8 TS-1503071 Socket Head Cap Screw M6x30 2

354-9 EHB8VS-354-9 Hose ID1/4"x2.2tx143cm 1

354-10 EHB8VS-354-10 Hose ID1/4"x2.2tx32cm 1

354-11 EHB8VS-354-11 Hose Clamp 2

354-12 EHB8VS-354-12 Cross Head Screw 2

355 EHB8VS-355 Hub 1

355-1 EHB8VS-355-1 Blade Tension Handle 2

356 BB-51203 Thrust Bearing 51203 1

357 EHB8VS-357 Tension Indicator 1

358 EHB8VS-358 Lock Washer Tension ID16.3x31.5x1.8t 10

359 EHB8VS-359 Tension Shaft 1

360 EHB8VS-360 Tension Slide Base 1

360-1 EHB8VS-360-1 Tension Scale 1

361 TS-1523051 Socket Set Screw M6x16 1

362 EHB8VS-362 Tension Slide Block 1

363 TS-154010 Hex Nut M16 1

364 EHB8VS-364 Washer 1

365 TS-1490031 Hex Cap Screw M8x20 1

366 EHB8VS-366 Screw 3

367 TS-2361101 Lock Washer M10 3

368 TS-1491101 Hex Cap Screw M10x60 3

369 EHB8VS-369 Plate 2

370 TS-2361081 Lock Washer M8 4

371 TS-1490011 Hex Cap Screw M8x12 4

372 TS-2246122 Button Head Socket Screw M6x12 2

373 TS-0680021 Flat Washer 1/4" 2

374 EHB8VS-374 Control Box 1