This .pdf document is bookmarked

Operating Instructions and Parts Manual

Portable Woodworking Dust Collector

Model DC-500P

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-717500

Ph.: 800-274-6848 Edition 1 06/2018

www.jettools.com Copyright © 2018 JET

1.0 IMPORTANT SAFETY

INSTRUCTIONS

When using an electrical appliance, basic

precautions should always be followed, including

the following:

READ ALL INSTRUCTIONS BEFORE USING THIS

DUST COLLECTOR.

WARNING – To reduce the risk of fire,

electric shock, or injury:

1. Read and understand entire owner’s manual

before attempting assembly or operation of this

dust collector.

2. Read and understand the warnings posted on

the machine and in this manual.

3. Replace warning labels if they become

obscured or removed.

4. This dust collector is designed and intended for

use by properly trained and experienced

personnel only. If you are not familiar with the

proper and safe operation of a dust collector, do

not use until proper training and knowledge

have been obtained.

5. Do not use this dust c ollector for other than its

intended use. If used for other purposes, JET

disclaims any real or implied warranty and holds

itself harmless from any injury that may result

from that use.

6. Always wear approved safety glasses/face

shield while using this dust collector. Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.

7. Keep hair, loose clothing, fingers, and all parts

of body away from openings and moving parts.

8. Wear hearing protection (plugs or muffs) during

extended periods of operation.

9. CALIFORNIA PROPOSITION 65 WARNING:

This product contains chemicals known to the

State of California to cause cancer, or birth

defects or other reproductive harm.

10. WARNING: Drilling, sawing, sanding or

machining wood products generates wood dust

and other substances known to the State of

California to cause cancer. Avoid inhaling dust

generated from wood products or use a dust

mask or other safeguards to avoid inhaling dust

generated from wood products.

11. Wood products emit chemicals known to the

State of California to cause birth defects or

other reproductive harm. (California Health and

Safety Code Section 25249.6)

12. Do not operate this machine while tired or under

the influence of drugs, alcohol or any

medication.

13. Make certain the switch is in the OFF position

before connecting the machine to the power

supply. Turn off all controls before unplugging.

14. Make certain the machine is properly grounded.

Connect to a properly grounded outlet only. See

Grounding instructions.

15. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

16. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine

before turning it on.

17. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

maintenance is complete.

18. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

19. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

20. Keep the floor around the machine clean and

free of scrap material, oil and grease.

21. Keep visitors a safe distance from the work

area. Keep children away.

22. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

23. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

24. The dust collector is intended for indoor use. To

reduce the risk of electric shock, do not use

outdoors or on wet surfaces.

25. Do not use this dust collector for anything

except wood dust. Materials such as liquids,

metal shavings, metal dust, screws, glass,

plastic or rock can cause sparks and/or damage

when coming into contact with any part of the

dust collector.

26. Do not use to pick up anything that is burning or

smoking, such as cigarettes, matches or hot

ashes.

27. Do not use to pick up flammable or combustible

liquids such as gasoline, or use in areas where

they may be present.

28. Do not pull or carry by cord, use cord as a

handle, close a door on cord, or pull cord

around sharp edges or corners. Do not run dust

collector over cord. Keep cord away from

heated surfaces.

29. Do not use this dust collector with a damaged

cord or plug. If the unit is not working as it

should, has been dropped, damaged, left

outdoors, or dropped into water, return it to a

service center.

30. Do not unplug by pulling on cord. To unplug,

grasp the plug, not the cord.

31. Do not use without dust bag and/or filters in

place.

32. Do not handle plug or machine with wet hands.

Familiarize yourself with the following safety notices used in this manual:

33. Do not put any objects into the openings. Do not

use with any opening blocked; keep free of

dust, lint, hair, and anything that may reduce air

flow.

34. Keep hands and fingers away from inlet and

exhaust ports during operation.

35. Do not operate without hose connected to the

inlet. Place cap on unused inlet port. Hazardous

moving parts inside.

36. Use recommended accessories; improper

accessories may be hazardous.

37. Maintain tools with care. Follow instructions for

lubricating and changing accessories.

38. Turn off machine and disconnect from power

before cleaning. Use a brush or compressed air

to remove chips or debris; do not use bare

hands.

39. Do not leave the machine when it is plugged in.

Unplug from outlet when not in use and before

servicing.

40. Do not stand on the machine. Serious injury

could occur if the machine tips over.

41. The dust collector is intended for household

(non-industrial) use.

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

SAVE THESE INSTRUCTIONS

2.0 About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for a JET Model DC500P Dust Collector. This manual contains instructions on installation, safety precautions, general operating

procedures, maintenance instructions and parts breakdown. Your machine has been designed and constructed

to provide consistent, long-term operation if used in accordance with the instructions set forth in this document.

This manual is not intended to be a guide to dust removal strategies, installation of larger collection systems, or

the use of optional dust collecting accessories. Additional knowledge may be obtained from experienced users,

trade articles or website forums. Whatever accepted methods are used, always make personal safety a priority.

If there are questions or comments about this product, please contact your local supplier or JET. JET can also

be reached at our web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Register your product using the mail-in card provided, or register online:

http://www.jettools.com/us/en/service-and-support/product-registration/

3

3.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

2.0 About this manual .......................................................................................................................................... 3

3.0 Table of contents ............................................................................................................................................ 4

4.0 Specifications ................................................................................................................................................. 5

5.0 Setup and assembly ....................................................................................................................................... 6

5.1 Unpacking .................................................................................................................................................. 6

5.2 Shipping contents ....................................................................................................................................... 6

5.3 Tools required for assembly ....................................................................................................................... 6

5.4 Assembly .................................................................................................................................................... 7

5.5 Wall mounting ............................................................................................................................................. 8

6.0 Electrical connections .................................................................................................................................... 8

6.1 GROUNDING INSTRUCTIONS ................................................................................................................. 8

6.2 Voltage conversion ..................................................................................................................................... 9

6.3 Extension cords .......................................................................................................................................... 9

6.4 Grounding wire information ........................................................................................................................ 9

7.0 Operation ..................................................................................................................................................... 10

7.1 Switch key ................................................................................................................................................. 10

8.0 User-maintenance ........................................................................................................................................ 10

8.1 Additional servicing .................................................................................................................................. 10

9.0 Troubleshooting DC-500P Dust Collector .................................................................................................... 11

10.0 Replacement Parts ..................................................................................................................................... 12

10.1.1 DC-500P Portable Dust Collector – Exploded View ............................................................................ 12

10.1.2 DC-500P Portable Dust Collector – Parts List ..................................................................................... 13

11.0 Electrical Connections for DC-500P ........................................................................................................... 14

11.1 Electrical Connections for 3/4HP, 1PH, 115V only ................................................................................. 14

11.2 Electrical Connections for 3/4HP, 1PH, 230V only ................................................................................. 14

12.0 Warranty and service ................................................................................................................................. 15

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

4

4.0 Specifications

Table 1

Model number

Stock number 717500

Motor and electrical

Motor type totally enclosed fan cooled, induction, ca pac itor start

Horsepower 3/4HP (0.55 kW)

Phase 1 PH

Voltage 115/230 V

Cycle 60 Hz

Listed FLA (full load amps) 7.5/3.75 A

Starting amps 24/15 A

Running amps (no load) 6/3.1 A

Running capacitor

On/off switch HY7 Toggle with removable safety key

Motor speed (no load) 3450 RPM

Power cord 16AWG x 3C, 6-1/2 ft.

Power plug included 5-15P

Recommended circuit size 1 15 A

Sound emission 2 78 dB

Capacities

Dust inlet outside diameter 3-15/16 in. (100 mm)

Hose diameter 4 in. (102 mm)

Maximum nominal air flow 500 CFM (14.6 m3/min)

Air veloci ty at 4 in. 6690 FPM (34 m/s)

Maximum static pressure loss (WC) 5.8 inH2O (147.3 mmH2O)

Impeller

Type radial fin

Diameter 9 in. (228.6 mm)

Fin thickness 14 ga. (2mm)

Material steel

Collection bag

Bag material cloth, 5 micron

Bag size (Dia. x L), when inflated 16 x 24 in.

Bag capacity 4.7 cu. ft. (0.13 CBM)

Main materials

Base sheet metal

Body/housing sheet metal

Dust funnel plastic

Dust hose PVC

Paint finish powder coat

Dimensions

Approx. overall dimensions, assembled (LxWxH) 24 x 16 x 46 in. (610 x 407 x 1169 mm)

Shipping carton dimensions (LxWxH) 19 x 16.5 x 22 in. (480 x 420 x 560 mm)

Weights

Net weight 48 lbs. (22 kg)

Shipping weight 59.5 lbs. (27 kg)

1

Subject to local/national electrical codes. Recommendation based upon dedicated circuit.

2

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As workplace

conditions vary, this information is intended to allow the user to make a better estimation of the hazards and risks

involved only.

L = length, W = width, H = height

DC-500P

30μF 250VAC

5

Read and understand the

entire contents of this manual before attempting

assembly or operation. Failure to comply may

cause serious injury.

5.0 Setup and assembly

5.1 Unpacking

Remove all contents from shipping carton and

compare to the contents list in this manual. If

shipping damage or any part shortages are

identified, contact your distributor. Do not discard

shipping materials until dust collector is assembled

and running satisfactorily.

5.2 Shipping contents

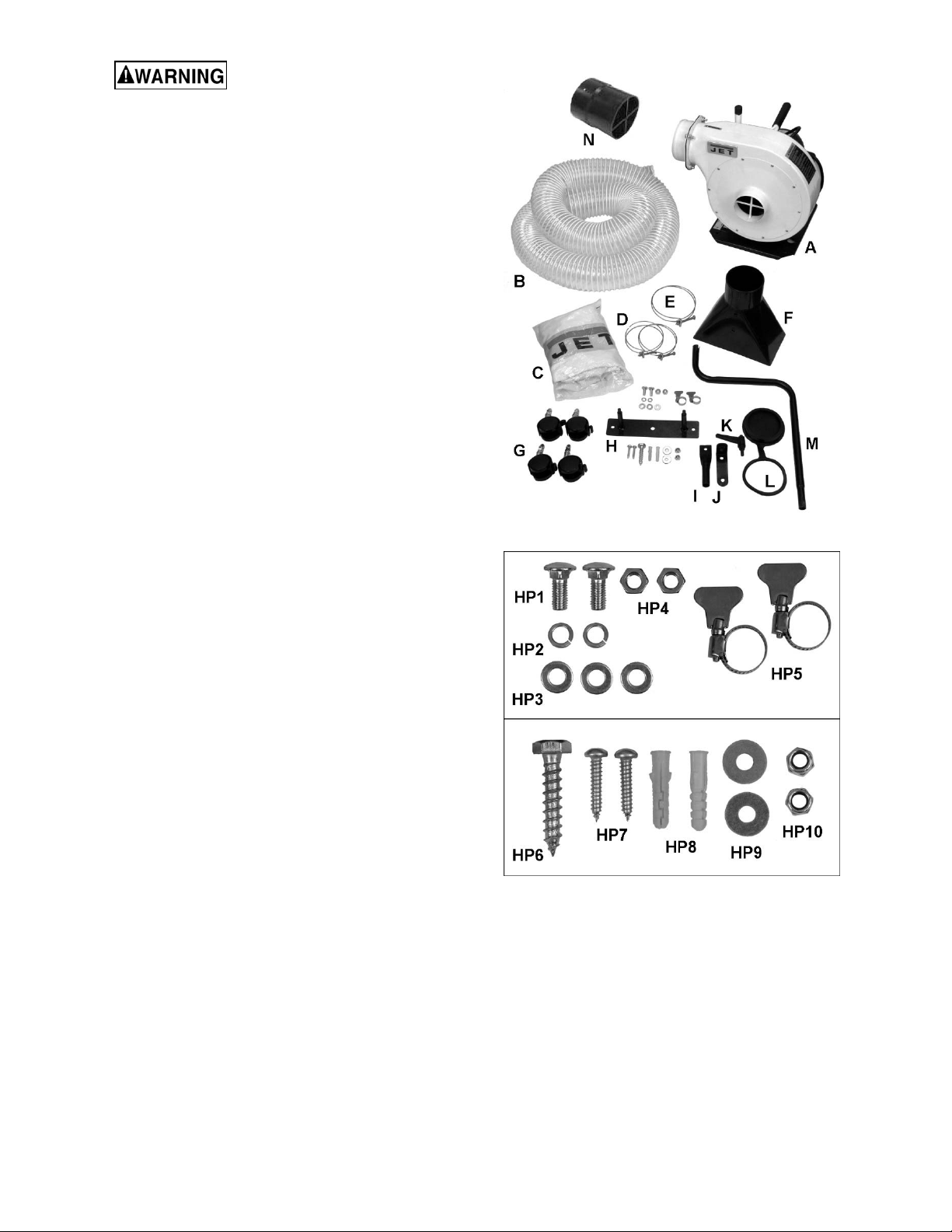

Main carton (see Figure 5-1)

1 Main unit – A

1 Flexible hose – B

1 Collection bag – C

2 4” Dia. Wire clamps – D

1 5” Dia. wire clamp – E

1 Dust funnel – F

4 Casters with fasteners – G

1 Wall mount plate – H

1 Upper support tube – I

1 Funnel support bracket – J

1 Locking lever – K

1 Inlet cap – L

1 Lower support tube – M

1 Inlet adaptor – N

Fasteners (see Figure 5-2):

2 Carriage bolts M8x20 – HP1

2 Lock washers 8mm – HP2

3 Flat washers 8mm – HP3

2 Hex nuts M8 – HP4

2 Butterfly clamps – HP5

1 Hex cap lag screw – HP6

2 Phillips self-tapping screws – HP7

2 Screw anchors – HP8

2 Flat washers 8mm – HP9

2 Hex nylon lock nuts M8 – HP10

Figure 5-1

Figure 5-2 (detail of fasteners)

5.3 Tools required for assembly

13mm wrench

17mm wrench

Cross-point (Phillips) screwdriver

Drill with 1/4” and 5/16” bits (if mounting to wall)

6

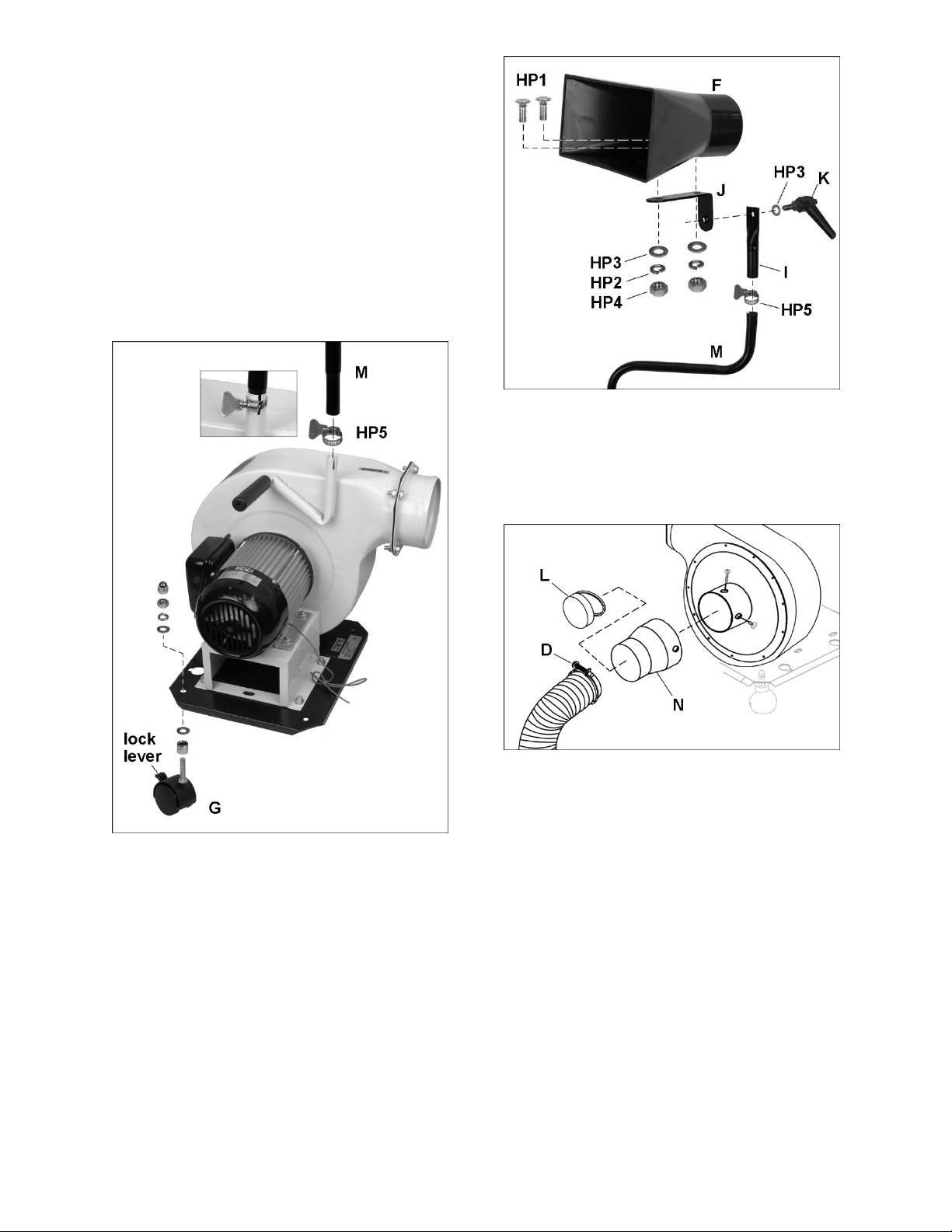

5.4 Assembly

1. Install casters (G, Figure 5-3), to base, using

the fasteners supplied with each caster, in the

order as shown. Tighten the hex nut and cap

nut to secure.

A caster can be locked in position by pushing

down on the adjoining lever. Push up lever to

unlock caster.

NOTE: If Dust Collector will be wall-mounted,

proceed to sect. 5.5, then return to this section

for furt h e r as se mbly.

2. Remove protective cap from tube holder, and

install butterfly clamp (HP5) and lower support

tube (M). Tighten butterfly clamp to secure.

Figure 5-4

5. Push inlet adaptor (N, Figure 5-5) onto inlet port

until the holes align, and secure with the

provided self-tapping screws.

6. Press ring of inlet cap (L) onto adaptor. Press

cap over inlet when inlet is not being used.

Figure 5-3

3. Install upper support tube (I) and secure with

butterfly clamp (HP5). See Figure 5-4.

4. If funnel will be used, mount f unnel bracket (J)

to upper support tube (I) with locking lever (K)

and washer (HP3). Install funnel (F) with

carriage bolts, washers and nuts (HP1/2/3/4).

Figure 5-5

7. Place a 4-inch wire cl amp (D, Figure 5-5) onto

end of hose, and install hose to adaptor.

7

Tighten wire clamp with screwdriver.

8. If using the dust funnel, connect opposite end of

hose to funnel port and secure with 4-inch wire

clamp. Or, connect hose to dust port of

woodworking machine, and secure with wire

clamp.

9. Place 5-inc h diameter wire clamp (E, Figure 5-

6) onto end of collection bag, and slide bag onto

exhaust port. Tighten cloth strap and wire

clamp.

Figure 5-6

5.5 Wall mounting

The dust collector can be suspended from a wall for

operation or storage. The wall mount plate must

be centered over a wall stud.

The wall/supporting structure

must be capable of supporting the weight of the

dust collector and safely absorbing any

vibration from the machine.

1. Position mount plate (H, Figure 8-7) on wall,

make sure it is level, then mark the 3 hole

locations. The center hole must be centered

on a wall stud, and should be approximately 40

inches from floor – this ensures the collection

bag will contact the floor for support.

2. Remove mount plate, and drill 1/4-inch pilot

hole into wall stud at center mark.

3. Drill two 5/32-inch holes in wall at outer hole

locations, and push a screw anchor (HP8) into

each hole.

4. Install mount plate using lag screw (HP6)

through center, and pan head screws (HP7)

through outer holes. Tighten securely.

5. Install flat washer and nylon lock nut (HP9/10)

on the end of each stud.

6. Place the dust collector on the studs, as shown

in Figure 5-8, and tighten the lock nuts enough

to secure the unit to the wall. The casters should

not rotate when the unit is properly secured.

Figure 5-7

Figure 5-8

6.0 Electrical connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

The DC-500P Dust Collector is rated at 115/230V

power, and is pre-wired for 115 volt. The unit comes

with a plug designed for use on a circuit with a

grounded outlet that looks like the one pictured in A,

Figure 6-1.

Before connecting to power source, be sure switch

is in off position.

It is recommended that the dust collector be

connected to a dedicated 15 amp circuit with circuit

breaker or time-delay fuse marked “D”. Local

codes take precedence over recommendations.

6.1 GROUNDING INSTRUCTIONS

1. All Grounded, Cord-connected Tools:

This machine must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

8

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service personnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause ser ious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. Repair or replace damaged or worn

cord immediately.

2. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating less than

150 volts:

6.2 Voltage conversion

To convert the dust collector to 230-volt power,

remove motor junction box cover and change the

incoming power leads, according to diagram affixed

inside cover. This diagram is also shown in Figure

6-2. NOTE: In case of discrepancy, diagram on

machine takes precedence.

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

6-1. An adapter, shown in B and C, may be used to

connect this plug to a 2-pole receptacle as shown in

B if a properly grounded outlet is not available. The

temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician. This adapter is not permitted in

Canada. The green-colored rigid ear, lug, and the

like, extending from the adapter must be connected

to a permanent ground such as a properly grounded

outlet box.

Figure 6-1

3. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating between

150 - 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in D, Figure

6-1. The tool has a grounding plug that looks like the

plug illustrated in D. Make sure the tool is connected

to an outlet having the same configuration as the

plug. No adapter is available or should be used with

this tool. If the tool must be reconnected for use on

a different type of electric circuit, the reconnection

should be made by qualified service personnel; and

after reconnection, the tool should comply with all

local codes and ordinances.

Figure 6-2

6.3 Extension cords

The use of extension cords is discouraged; try to

position machines near the power source. If an

extension cord is necessary, make sure it is in good

condition. When using an extension cord, be sure to

use one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. Table 1 shows correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Ampere

Rating

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Volts

120

240

AWG

Total length of

cord in feet

25

50

100

50

100

200

Not

Recommended

150

300

Table 1: Extension cord recommendations

6.4 Grounding wire information

A green grounding wire is connected to the base of

the dust collector, and can be used to connect to

dust hose or pipe systems to prevent static

electricity buildup. If you are using the DC-500P as

part of a larger shop system with hoses or PVC pipe,

you should seek further information from website

forums or experienced users as to proper and safe

methods for prevention of static electricity buildup.

9

7.0 Operation

8.0 User-maintenance

7.1 Switch key

To prevent accidental or unauthorized use, turn

machine off and remove safety key (Figure 7-1).

Store key in a safe place, inaccessible to children.

Key must be reinserted to start unit.

Figure 7-1

Turn OFF dust collector and

remove plug from power source before

performing adjustments or maintenance. Failure

to comply may result in serious injury.

No lubrication is required for the dust collector. All

bearings are pre-lubricated and sealed and require

no further attention.

Empty collection bag when full.

The cloth dust collection bag is washable.

Make frequent inspections of motor fan, and blow

out (with low pressure air hose) or vacuum any

accumulation of foreign material to maintain normal

motor ventilation.

8.1 Additional servicing

Any other servicing should be performed by an

authorized service representative.

10

9.0 Troubleshooting DC-500P Dust Collector

Symptom Possible Cause Correction*

Motor will not start. No incoming current. Check connections at plug or circuit panel.

Safety key missing from switch. Install safety key.

Low voltage. Check power line for proper voltage.

Open circuit in motor or loose

connection.

Faulty start switch. Inspect and replace switch if needed.

Faulty start capacitor. Replace capacitor.

Faulty motor. Inspect and replace motor if needed.

Motor will not start:

fuse blows or circuit

breaker trips.

Motor overheats. Motor overloaded. Reduce load on motor.

Motor stalls, resulting

in blown fuses or

tripped circuit.

Too many machines on shared

circuit.

Short circuit in line cord or plug. Inspect cord or plug for damaged

Short circuit in motor or loose

connections.

Incorrect fuse or circuit breaker in

power line.

Air circulation through motor is

restricted.

Faulty capacitor. Replace run capacitor.

Motor overloaded. Reduce load on motor.

Impeller blocked with debris. Empty bag, clean out hoses and housing.

Short circuit in motor or loose

connections.

Low voltage. Correct low voltage conditions.

Inspect all connections to switch box and

motor for loose or open connections.

Turn off other machines on circuit, or

connect unit to dedicated circuit.

insulation and shorted wires.

Inspect all connections on motor for loose

or shorted terminals or worn insulation.

Install correct fuse or circuit breaker at

power source.

Clean motor fan with compressed air to

restore normal air circulation.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Incorrect fuse or circuit breaker in

power line.

Loud noise or

vibrations coming from

machine.

Poor performance; lack

of suction.

Loose fasteners. Inspect machine and tighten all fasteners.

Motor fan is hitting the cover. Tighten fan or shim cover. Replace fan

Impeller damaged. Replace impeller.

Hose improperly secured at dust

origination point.

Collection bag is full. Empty bag.

Wood has excess moisture content. Use lumber with lower moisture content.

Obstruction in dust hose or inlet port. Inspect and clear obstruction.

* WARNING: Some corrections may require a qualified electrician.

Install correct fuse or circuit breaker.

cover if damaged.

Inspect and remedy.

11

10.0 Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 Monday through Friday, 8:00 a.m. to 5:00

p.m. CST. Having the Model Number and Serial Number of your machine available when you call will allow us to

serve you quickly and accurately. Non-proprietary parts, such as fasteners, can be found at local hardware stores,

or may be ordered from JET. Some parts are shown for reference only, and may not be available individually.

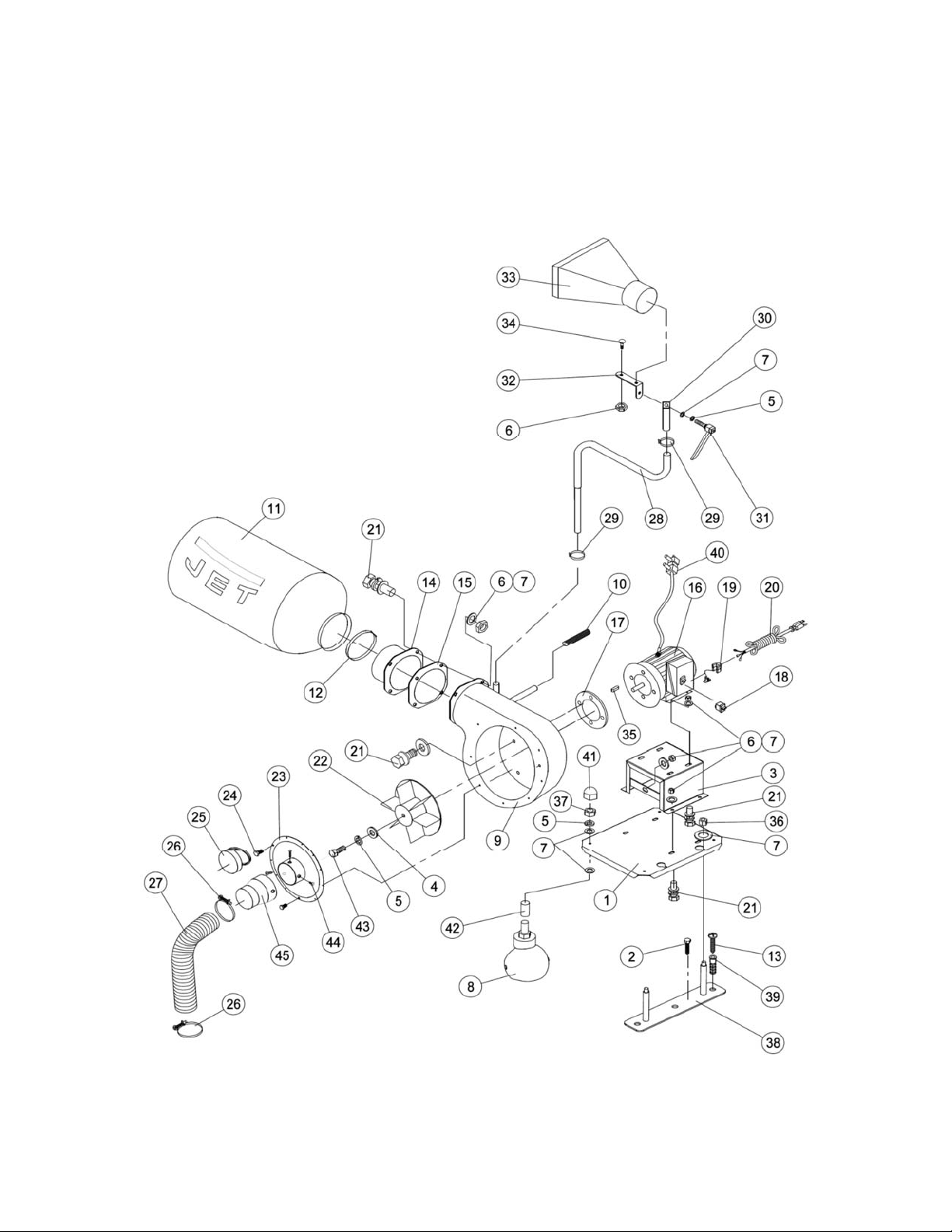

10.1.1 DC-500P Portable Dust Collector – Exploded View

12

10.1.2 DC-500P Portable Dust Collector – Parts List

Index No Part No Description Size Qty

1 ................ DC500P-001 ............. Base......................................................................... ...................................... 1

2 ................ DC500P-002 ............. Hex Cap Lag Screw ................................................. ST9.5x50 mm ............... 1

3 ................ DC500P-003 ............. Motor Base .............................................................. ...................................... 1

4 ................ DC500P-004 ............. Washer .................................................................... ...................................... 1

5 ................ TS-2361081 .............. Lock Washer ............................................................ 8mm .............................. 5

6 ................ TS-2311081 .............. Hex Nut .................................................................... M8 .. ............................. 15

7 ................ TS-1550061 .............. Flat Washer ............................................................. 8mm ............................ 11

8 ................ DC500P-008 ............. Caster ...................................................................... ...................................... 4

9 ................ DC500P-009 ............. Impeller Housing ...................................................... ...................................... 1

10 .............. DC500P-010 ............. Handle Grip.............................................................. ...................................... 1

11 .............. DC500P-011 ............. Collector Bag ........................................................... ...................................... 1

12 .............. DC500P-012 ............. Wire Clamp .............................................................. Ø5" ................................ 1

13 .............. DC500P-013 ............. Phillips Self-Tapping Screw ..................................... ST6.3x32 mm ............... 2

14 .............. DC500P-014 ............. Exhaust Flange ........................................................ ........... ........................... 1

15 .............. DC500P-015 ............. Gasket ..................................................................... ...................................... 1

16 .............. DC500P-016 ............. Motor Assembly ...................................................... 3/4HP 115V .................. 1

…………….DC500P-016WD ....... Wiring Diagram (not shown) .................................... ...................................... 1

.................. DC500P-016ML ........ Motor Label, DC500P (not shown) .......................... ...................................... 1

…………….DC500P-016MF ........ Motor Fan (not shown)............................................. ...................................... 1

…………….DC500P-016RC. ....... Running Capacitor (not shown) ............................... 40μF, 450V ................... 1

…………….DC500P-016JB ......... Junction Box (not shown) ........................................ ...................................... 1

…………….DC500P-016JBC ....... Junction Box Cover (not shown) .............................. ...................................... 1

17 .............. DC500P-017 ............. Motor Gasket ........................................................... ...................................... 1

18 .............. DC500P-018 ............. Switch with Key........................................................ ...................................... 1

19 .............. DC500P-019 ............. Strain Relief ............................................................. ....... ............................... 1

20 .............. DC500P-020 ............. Power Cord with Plug .............................................. 16AWGx3C, 7-1/2ft ....... 1

21 .............. TS-1490031 .............. Hex Head Bolt.......................................................... M8x20 ......................... 17

22 .............. DC500P-022 ............. Impeller .................................................................... ...................................... 1

23 .............. DC500P-023 ............. Cover Assembly....................................................... ...................................... 1

24 .............. DC500P-024 ............. Philips Pan Hd Self-Tapping Screw ......................... ST4.2x12.7 mm .......... 10

25 .............. DC500P-025 ............. Inlet Cap ................................................................. ...................................... 1

26 .............. DC500P-026 ............. Wire Clamp .............................................................. Ø4" ................................ 2

27 .............. DC500P-027 ............. Flexible Hose ........................................................... Ø4" x 10' ....................... 1

28 .............. DC500P-028 ............. Lower Support Tube ................................................ ...................................... 1

29 .............. DC500P-029 ............. Butterfly Clamp ........................................................ ...................................... 2

30 .............. DC500P-030 ............. Upper Support Tube ................................................ ...................................... 1

31 .............. DC500P-031 ............. Locking Handle ........................................................ ...................................... 1

32 .............. DC500P-032 ............. Funnel Support Bracket ........................................... ...................................... 1

33 .............. DC500P-033 ............. Dust Funnel ............................................................. ...................................... 1

34 .............. DC500P-034 ............. Carriage Bolt ............................................................ M8x20 ........................... 2

35 .............. DC500P-035 ............. Key Dbl Rd Hd ......................................................... C6x25mm ..................... 1

36 .............. TS-1541031 .............. Nylon Lock Hex Nut ................................................. M8 ................................. 2

37 .............. TS-2342101 .............. Nylon Lock Hex Nut ................................................. M10 ............................... 4

38 .............. DC500P-038 ............. Wall Mount Plate...................................................... ...................................... 1

39 .............. DC500P-039 ............. Screw Anchor .......................................................... ...................................... 2

40 .............. DC500P-040 .............

41 .............. TS-2331081 .............. Cap Nut .................................................................. M8 ................................. 4

42 .............. DC500P-042 ............. Sleeve ..................................................................... ...................................... 4

43 .............. TS-1490031 .............. Hex Cap Screw ........................................................ M 8x20 ........................... 1

44 .............. JWBS14SFX-179 ...... Philips Pan Head Self-Tapping Screw ..................... ST4.2x10 ...................... 3

45 .............. DC500P-045 ............. Inlet Adapter ............................................................ ...................................... 1

.................. LM000353 ................. ID Label, DC-500P (not shown) ............................... ...................................... 1

.................. LM000355 ................. Warning Label, DC-500P (not shown) ..................... ...................................... 1

.................. LM000356 ................. Rotation Label, DC-500P (not shown) ..................... ...................................... 1

.................. JET-92 ....................... JET Logo (not shown) ............................................. 92x38mm ...................... 1

Ground wire ........................................................... ...................................... 1

13

11.0 Electrical Connections for DC-500P

11.1 Electrical Connections for 3/4HP, 1PH, 115V only

11.2 Electrical Connections for 3/4HP, 1PH, 230V only

14

12.0 Warranty and service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

15

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

16

Loading...

Loading...