Page 1

This .pdf document is bookmarked

Operation and Maintenance Instructions

Belt Drive Bench Lathe, 13x40-inch

Model BDB-1340A

For Parts List and Electrical Diagrams, see document M-321357 A

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-321360A

Ph.: 800-274-6848 Revision G3 11/2014

www.jettools.com Copyright © 2014 JET

(shown with optional 321443AK stand)

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of th ese ma chines in the processing of metal , pl asti cs, or oth er m aterial s may void the warranty. The exceptio ns

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provid e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 3

Specifica tions ................................................................................................................ .......................... 5

Dimensions of optional stand (p/n 321443AK) .......................................................................................... 6

Assembly ................................................................................................................................................ 6

Contents of the Shipping Container ...................................................................................................... 6

Uncrating and Clean- Up ....................................................................................................................... 7

Chuck Preparation (Three Jaw) ............................................................................................................ 8

Lubrication ........................................................................................................................................... 9

Electri c al Connec tions ........................................................................................................................ 11

General Description ............................................................................................................................... 11

Contro ls ............................................................................................................................................. 13

Adjustments ................................................................................................................... ....................... 1 5

Break-In Pr oc edur e ............................................................................................................................ 15

Speed Selecti on ................................................................................................................................. 15

Feed and Thread Selection ................................................................................................................ 15

Change Gear Replacem ent ................................................................................................................ 16

Thread Cutting ................................................................................................................................... 16

Thread and Feed Chart ...................................................................................................................... 17

Automatic Feed O per ation and Feed Changes ................................................................................... 18

Powered Carriage Travel ................................................................................................................... 18

Saddle Adjustment ............................................................................................................................. 18

Cross Slide Adjustment ...................................................................................................................... 18

Compound Rest Adjustment ............................................................................................................... 19

Tailstock Adjustment .......................................................................................................................... 19

Half Nut Gib Adjustment ..................................................................................................................... 19

Headstock Alignment ......................................................................................................................... 19

Removing Gap Section ...................................................................................................................... 20

Install ing Ga p Section ........................................................................................................ ................ 2 0

Warning

1. Read and understand the ent ire contents of this manual before attempti ng assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. This manual is intended to famili arize you wit h the technical aspect s of this lathe. It is not, nor was it

intended to be, a training manual.

4. This mac hine is designed and intended for use by properly t r ained and experienc ed per sonnel only. If

you are not f amiliar wit h the pr oper and saf e operat ion of a lathe, do not use until proper t rai ning and

knowledge have been obtained.

5. Always wear approv ed safety glasses/face shields whil e using this lathe. Everyday eyeglasses only

have impact resistant lenses; they are not saf ety glasses.

6. Wear proper apparel. Remove tie, rings, watches and other jewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long hai r . Non-slip footwear or anti - skid floor strips are

recommended. Do not wear gloves.

7. Wear ear protector s (plugs or muffs) during ext ended periods of operation.

8. Do not operate this machine while tired or under the influence of dr ugs, alcohol or any medication.

9. Make certain t he switc h is i n the OFF position before connect ing the machine to the power supply.

10. Make certain t he machine is properly grounded.

3

Page 4

11. Do not place hands near the chuck while the machine is operating.

12. Make all machine adjustments or maintenance with the machine unplugged from the power source.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

14. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other r epr oduc tiv e harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately after m aintenance is complete.

16. Check damaged par ts. Check for ali gnment of moving parts, bi nding of moving part s, breakage of

parts, mounti ng and any other conditions that may affect it s operation. A guard or other part that is

damaged should be properly repaired or replac ed.

17. Keep the floor around the machine clean and free of scrap material, oil and grease.

18. Keep visit or s a safe di stanc e from the work area. Keep children away.

19. Make your workshop chil d pr oof with padlocks, master switc hes or by r em ov ing starter keys.

20. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

21. Do not overreach. K eep pr oper footi ng and balance at all times.

22. Use the right t ool. Do not f orce a tool or attachm ent to do a job f or which i t was not de signed. The

right tool will do the job bet ter and safer.

23. Use recommended accessories; improper accessories may be hazardous.

24. Maintain tools with care. Keep tools sharp and clean for the best and safest perf ormance. Follow

instructions for lubricating and c hanging accessories.

25. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

26. Never leave t he m ac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a complete stop.

27. Remove loose it em s and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safet y no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

even death.

This means that if precautions are not heeded, it may result in serious injury or possibly

4

Page 5

Specifications

Model Number ........................................................................................................................ BDB-1340A

Stock Number.............................................................................................................................. 321360A

Capacities:

Swing Over Bed ................................................................................................................................... 13"

Swing Over Cross Slide ................................................................................................................ 7-25/32 "

Swing Through Gap ........................................................................................................................ 18-3/4"

Length of Gap......................................................................................................................................... 8"

Distance Between Centers ................................................................................................................... 40"

Headstock:

Hole Through Spindle ....................................................................................................................... 1-3/8"

Spindle Nose ......................................................................................................................................D1-4

Taper in Spindle Nose ....................................................................................................................... MT-5

Spindle Taper Adapter ....................................................................................................................... MT-3

Spindle Bearing Typ e ................................................................................................ Taper Roller Bearing

Number of Spindl e Speeds .................................................................................................................... 12

Range of Spindle Speeds ...................................................................................................... 6 0- 1240 rpm

Gearbox:

Number of Longitudinal and Cross Feeds ......................................................................................... 2 2/2 2

Range of Longitudinal Feeds (inch/rev) .......................................................................... 0.0018" – 0.0374"

Range of Cross Feeds (inch/rev) ................................................................................... 0. 0012" – 0.0345"

Number of Inch Threads ........................................................................................................................ 40

Range of Inch Threads ........................................................................................................ 3-1/2 – 80 TPI

Number of Metric Threads ..................................................................................................................... 27

Range of Metric Threads ........................................................................................................... 0.2 – 6mm

Leadscrew ............................................................................................................................... 7/8" × 8 TPI

Feed Rod Diameter ............................................................................................................................. 3 /4”

Compound and Carriage:

Toolpost Type.................................................................................................................................. 4-Way

Maximum Tool Size ................................................................................................................... 5/8" x 5/8"

Maximum Compound Slide Travel ................................................................................................ 2-11/1 6"

Maximum Cross Slide Travel .......................................................................................................... 6-5/16"

Maximum Carriage T r av el ..................................................................................................................... 35"

Tailstock:

Tailstock Spindle Travel .................................................................................................................... 3-3/4"

Diameter of Tailstock Spindle ........................................................................................................... 1-1/4"

Taper in Tail stoc k Spindle .................................................................................................................. MT-3

Miscellaneous:

Steady Rest Capaci ty ............................................................................................................. 1/4" – 2-5/8"

Follow Rest Capacit y .............................................................................................................. 1/4" – 2-3/4"

Length of Bed ....................................................................................................................................... 54"

Width of Bed ..................................................................................................................................... 7-3/8"

Height of Bed........................................................................................................................................ 12"

Overall Dimensions ............................................................................................... 71"L x 32"W x 25-1/2"H

Main Motor ............................................................................................................... 2HP , 1PH, 230V only

Net Weight (approx.)

Shipping Weight (approx.) .......................................................................................................... 1,280 lbs.

................................................................................................................... 1,070 lbs.

The above specifications were current at the time this m anual was published, but because of our policy of

continuous impr ovement, JET reserves the ri ght to change specifications at any tim e and without prior

notice, without incurring obligations.

5

Page 6

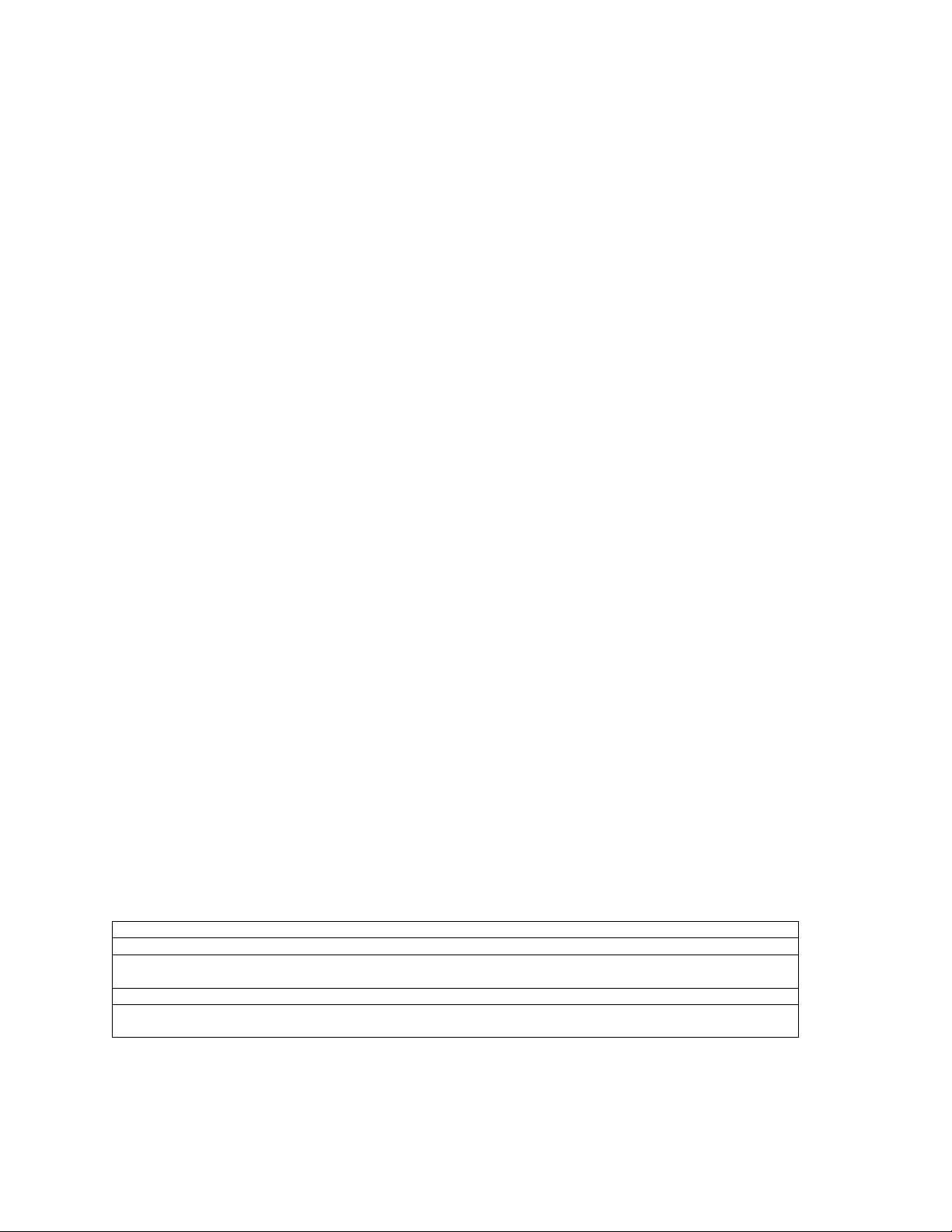

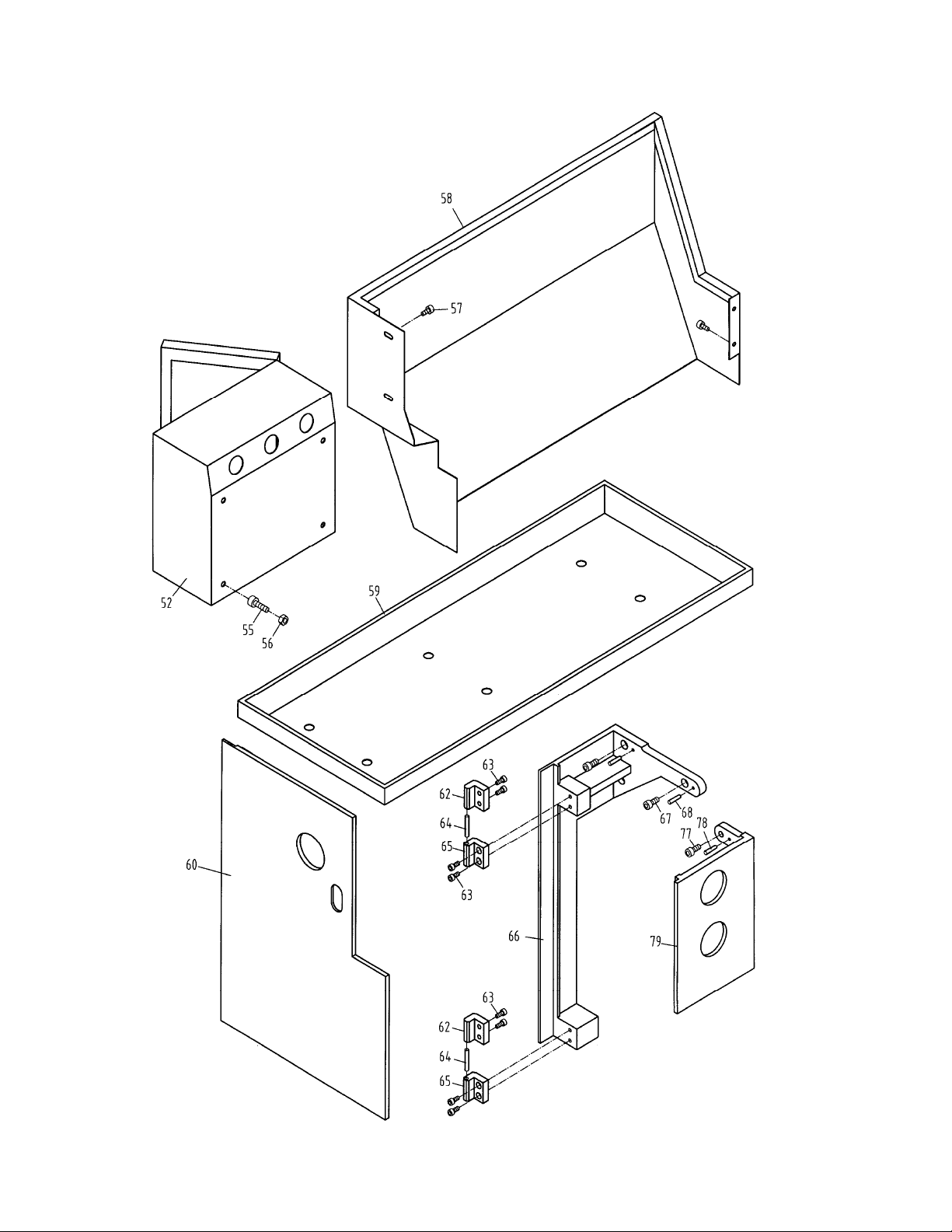

Dimensions of optional stand (p/n 321443AK)

To purchase this optional stand for the BDB-1340A Lathe, contact your dealer or call JET customer

service.

Assembly

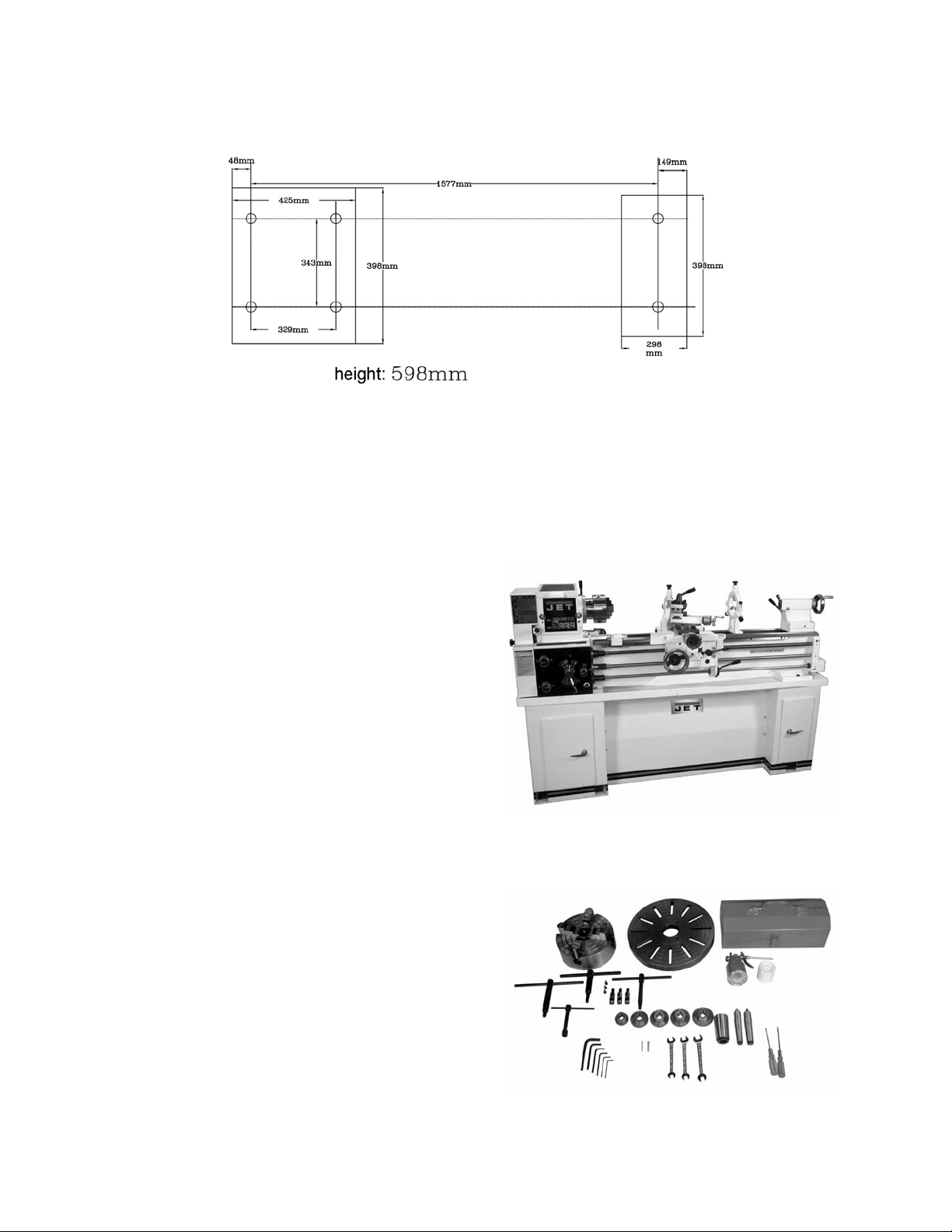

Contents of the Shipping Container

(Figures 1 and 2)

1 Lathe

1 Steady Rest (mount ed on lathe)

1 Follow Rest (mounted on lathe)

1 6" Three Jaw Chuck (mount ed on lathe)

1 8" Four Jaw Chuck

1 12" Face Plate (strapped t o c ontainer)

3 Cam Locks

3 Socket Head Cap Scr ews

1 Tool Box (strapped t o c ontainer)

1 Chip Tray

1 Lifting Hook

2 Lifting Blocks

Tool Box:

3 Open End Wrenches (9/ 11, 10/ 12,

12/14mm)

1 Touch-Up Paint

1 Oil Can

1 Hex Socket Wrench Set ( 2.5, 3, 4, 5, 6,

8mm)

2 Shear Pins

1 33T Gear

1 44T Gear

1 46T Gear

1 48T Gear

1 52T Gear

2 T-Handle Chuck Wrenches

1 Tool Post Wrench

2 MT-3 Centers

1 MT-3 to MT-5 Sleeve

1 Cross Point Screwdriver

1 Flat Head Screwdriver

1 Key for Cam Locks

1 Operating Instructions

1 Parts List

1 Warranty Card

Figure 1

(stand not included)

Figure 2

6

Page 7

Machine is heavy! Use an

appropriate lifting device and use extreme

caution when mo ving the machin e to its final

location. Failure to comply may cause

serious injury.

Uncrating and Clean-Up

1. Finish removing the wooden crate from

around the lathe.

2. Unbolt the lathe from the shipping crate

bottom.

3. Choose a location for the lathe that is dry,

has good light ing, and has enough room t o

be able to service t he lathe on all four sides.

4. Assemble par ts fastened to the crate bottom

used to lift the lathe. See Fig. 3. (Note:

Lifting parts are not tightened in Fig. 3 to

show detail.) Using a piece of leather or a

block of wood under the metal block to

protect the ways during lifting is highly

recommended. Do not lift the lathe by the

spindle. With adequate lifting equipment,

slowly raise the l athe off the shipping crate

bottom. M ake sure lathe is bal anced before

moving to a sturdy bench or optional stand.

5. To avoid twisting the bed, the lathe's

location must be absolutely flat and level.

Bolt the lat he to the stand (if used). If using

a bench, through-bolt for best performance.

6. Clean all rust protected surfaces using a

mild commer cial solvent , kerosene or di esel

fuel. Do not use paint thinner, gasoline, or

lacquer thi nner. These will damage pai nted

surfaces. Cov er all cleaned surf aces with a

ligh t f i lm of Mo b il DTE® Oil Heavy Medium.

Figure 3

7. Remove the end gear cover. Clean all

components of the end gear assembly and

coat all gears with a heavy, non-slinging

grease.

8. Using a machinist’s precision level on the

bedways, check to make sure lathe is level

side to side and front to back. Loosen

mounting bol ts, shim, and tighten mounti ng

bolts, if necessary. The lathe must be level

to be accurate.

7

Page 8

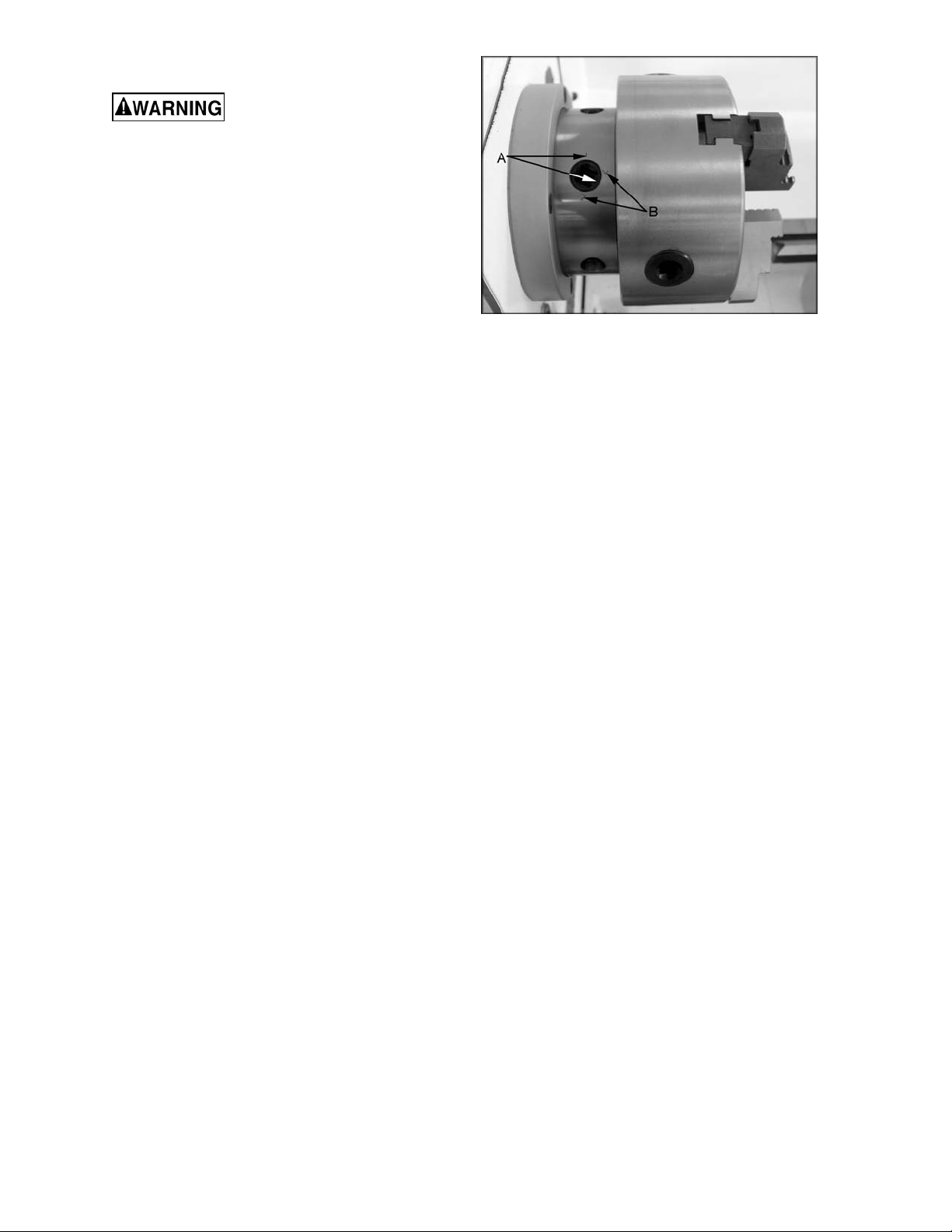

Chuck Preparation (Three Jaw)

Read and understand all

directions for chuck preparation! Failure to

comply may cause serious injury and/or

damage to the lath e!

Note: Before removing the chuck from the

spindle, pl ace a way board across the bed ways

under the chuck.

1. Support the chuck while turning three

camlocks 1/4 turn counter-clockwise with

the chuck key which is included in the tool

box.

2. Carefully remove t he chuck from the spindl e

and place on an adequate work surface.

3. Inspect the camlock studs. Make sure they

have not become crac ked or broken during

transit. Clean all parts thoroughly with

solvent. Also clean the spindle and

camlocks.

4. Cover all chuck jaws and scroll inside the

chuck with #2 li thium tube grease. Cov er the

spindle, cam locks, and chuck body with a

ligh t f i lm of Mo b il DTE® Oil Heavy Medium.

5. Lift the chuck up to the spindle nose and

press onto the spindle. Tighten in place by

turning the cam locks 1/4 turn clockwise.

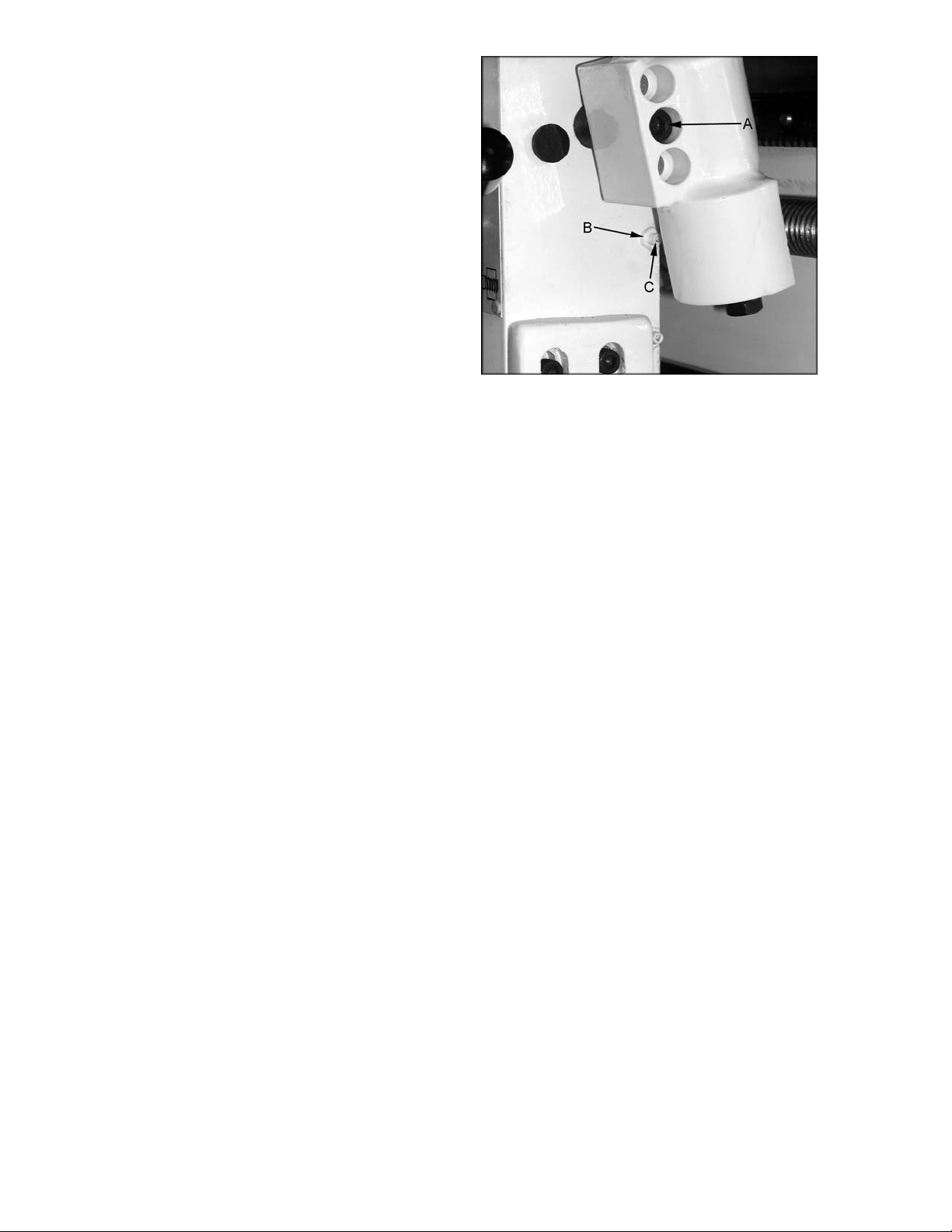

The index mark (A, Fig. 4) on the camlock

should be between the t wo indicator ar rows

(B, Fig. 4) when tight. If the index mark is

not between the two arrows, remove the

chuck and adjust the camlock studs by

either turning out one full turn (if cams will

not engage) or turning in one full turn (if

cams turn beyond indic ator marks).

6. Install chuck and tighten in place.

Figure 4

8

Page 9

Lubrication

Lathe must be serviced at all

lubrication points and all reservoirs filled to

operating level before the lathe is placed into

service. Failure to comply may cause serious

damage to the lath e.

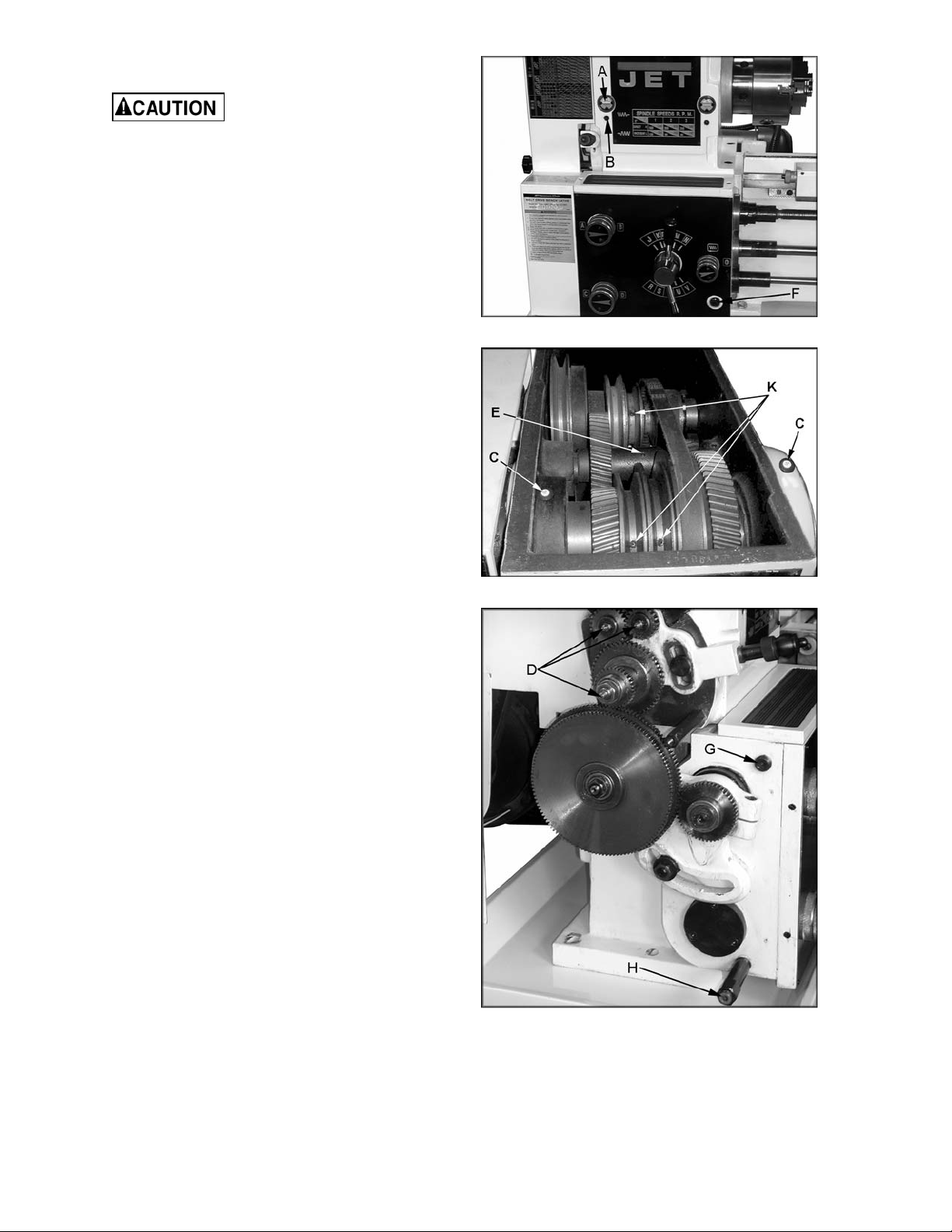

1. Headstock - Oil must be up to indicator

mark in both oil sight glasses (A, Fig. 5).

Top off with Mobil DTE® Oil Heavy Med ium.

The headstock should be drained and

refilled after the first three months of

operation. Then, change oil in the headstock

annually.

Drain oil completely by r em ov ing drain plugs

(B, Fig. 5). Also loosen the t hree set screws

in the pulleys (K, Fig. 6) and shaft ( E , Fig. 6)

and drain the oil fr om these. When done, r etighten the set screws (K,E) and re-insert

the drain plugs (B). Refill by removing fill

plugs (C, Fig. 6). Grease three fittings (D,

Fig. 7) with Mobil 1® Synthetic Universal

Grease daily.

Figure 5

2. External Gears - Coat all gears with a

heavy, non-slinging grease, see Fi gur e 7.

3. Center Back Gear Shaf t - Remove the set

screw on the shaf t (E, Fig. 6) and oi l with a

couple of drops of Mobil DTE® Oil Heavy

Medium once weekly .

4. Quick Chang e Gearbox - Oil m ust be up to

indicator mark in oil sight glass (F, Fig. 5).

Top off with Mobil DTE® O il Heavy Medium.

Fill by removi ng plug (G, Fig. 7). Drain oil by

removing drain plug (H, Fig. 7) and refill

after the first month of operation. Then,

change oil in the gearbox annually.

Figure 6

Figure 7

9

Page 10

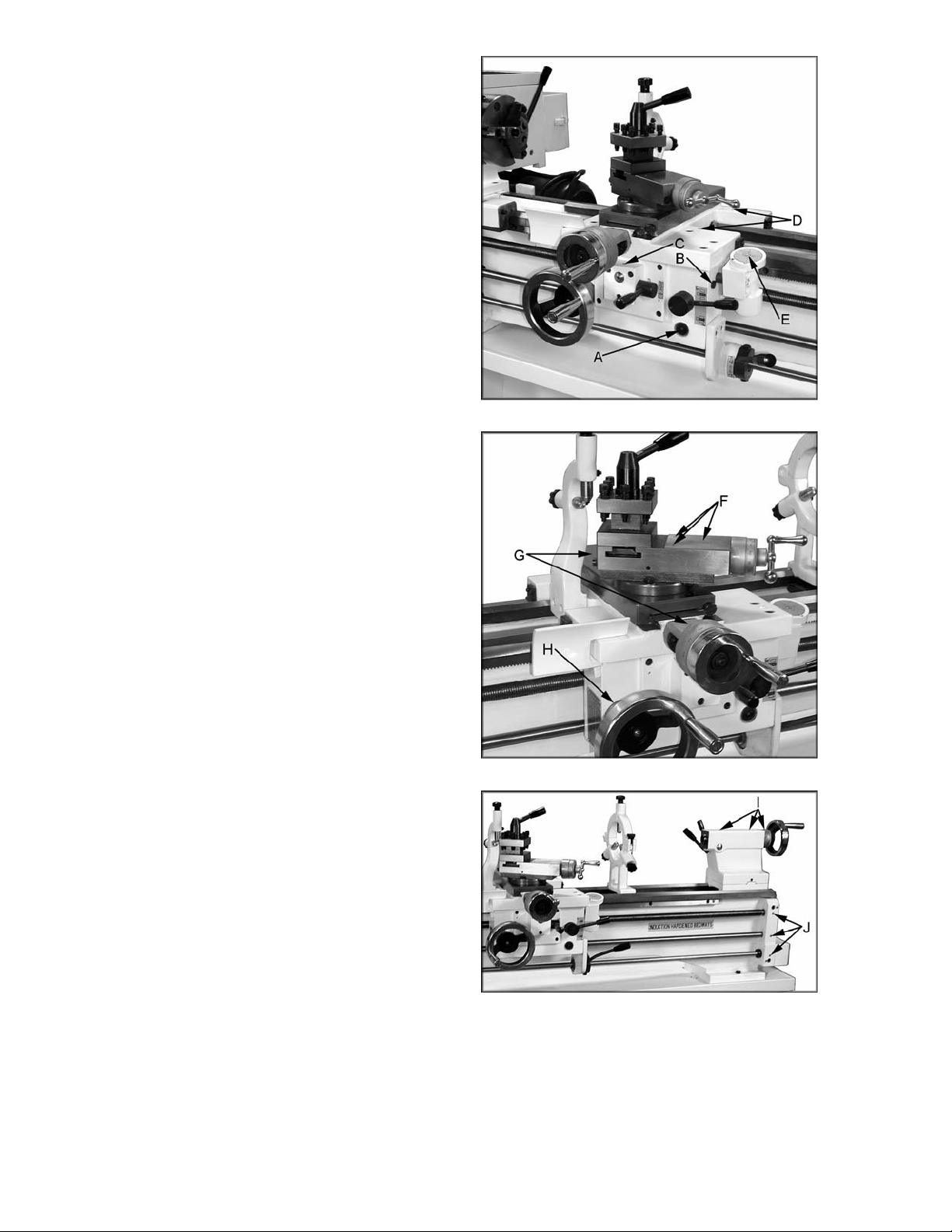

5. Apron - Oil must be up t o indicator mar k in

oil sight glass (A, F ig. 8). Top off with Mobil

DTE® Oil Heavy Medi um. Fill by removing

oil plug (B, Fig. 8). After the first three

months of operation, drain oil completely

(drain is on the bottom of the apron) and

refill with M obil DT E® Oil Heavy Medium, at

a level equival ent t o the indicat or li ne. Then,

change oil annually.

6. Feed Sel ector - Lubric ate ball oiler (C, Fig.

8) once daily with Mobil DTE® Oil Heavy

Medium.

7. Carriage - Lubr icate two ball oi lers (D, Fig.

8) once daily with Mobil DTE® Oil Heavy

Medium.

8. Thread Dial Indicato r - Lubricate ball oiler

(E, Fig. 8) once daily with Mobil DTE® O il

Heavy Medium.

Figure 8

9. Compound Rest - Lubricate three ball

oilers (F , Fig. 9) once daily with M obil DTE®

Oil He avy Me dium.

10. Cross Slide - lubricate four ball oilers (G,

Fig. 9) once daily with Mobil DTE® Oil

Heavy Medium.

11. Longitud inal Feed Handwheel - Lubri cate

ball oiler (H, Fig. 9) once daily with Mobil

DTE® Oil Heavy Me dium.

12. Tailstock - Lubricate thr ee ball oil ers (I , Fig.

10) once daily with Mobil DTE® Oil Heav y

Medium.

13. Leadscrew/F eed Rod - Lubri cate t hree ball

oilers once daily (J, Fig. 10) with Mobil

DTE® Oil Heavy Me dium.

Figure 9

Figure 10

10

Page 11

Electrical Connections

All electrical connections

must be compl eted by a qualifi ed electrician

and must comply with all relevant codes.

Failure to comply may cause serious injury

and/or damage to the machinery and

property.

The BDB-1340A bench lathe is rated at 2HP,

1PH, 230V only. Confi rm that power available at

the lathe's location is the same rating as the

lathe.

Make sure the lathe is properly grounded.

General Description

Lathe Bed

The lathe bed ( A, Fig. 12) i s made of high grade

cast iron. B y combini ng high cheek s with strong

cross ribs, a bed with low vibration and high

rigidity is realized. Two precision ground vee

slideways, reinforced by heat hardening and

grinding, are an accurate guide for the carriage

and headstock. The main drive motor is

mounted to the rear of the bed.

Carriage

The carriage (B, Fig. 12) is made from high

quality cast i ron. The slidi ng parts are smooth

ground. The cross-slide is mounted on the

carriage and mov es on a dove-tail ed slide whic h

can be adjusted for play by means of the gibs.

Figure 11

Figure 12

The compound slide (C, Fig. 12), which is

mounted on the c ross slide (D, Fi g. 12), can be

rotated through 360°. The compound slide and

the cross slide travel in a dovetail slide and hav e

adjustable gi bs. A f our-way tool post (E , Fig. 12)

is fitted on the com pound sli de.

Headstock

The headstock (F, Fig. 12) is cast from high

grade, low vibration cast iron. It is mounted to

the bed by four bolt s with two adjusting bol ts for

alignment. In the head, the spindle is mounted

on two precision taper roller bearings. The

hollow spindle has Morse Taper #5 wit h a 1-3/ 8"

bore.

Four Way Tool Post

The four-way tool (E, Fig. 12) post is mounted

on the compound slide and allows a maximum

of four tools to be mounted simultaneously.

Remember to use a mi nimum of two clamping

screws when installing a cutting tool.

11

Page 12

Apron

The apron (A, Fig. 13) is mounted to the

carriage. In the apron a hal f nut is fitted. The

half nut gi bs can be adjusted from t he outside.

The half nut is engaged by us e of a l ever. Quic k

travel of the apr on is accom pl i shed by m eans of

a bed-mounted rack and pinion, operated by a

hand wheel on the front of t he apr on.

Tailstock

The tailstoc k (B, Fig. 13) slides on a v- way and

can be locked at any location by a clamping

lever. The tailstock has a heavy-duty spindle

with a Morse Taper #3.

Leadscrew and Feed Rod

The leadscre w (C Fig. 13) and f eed rod ( D, Fi g.

10) are mounted on the front of the machine

bed. They are connec ted to the gearbox at the

left for automatic feed and lead. They are

supported by bushings on both ends. Both are

equipped with brass shear pins.

Gear Box

The gear box (E, Fig. 13) is made from high

quality cast i ron and is mounted to t he left side

of the machine bed.

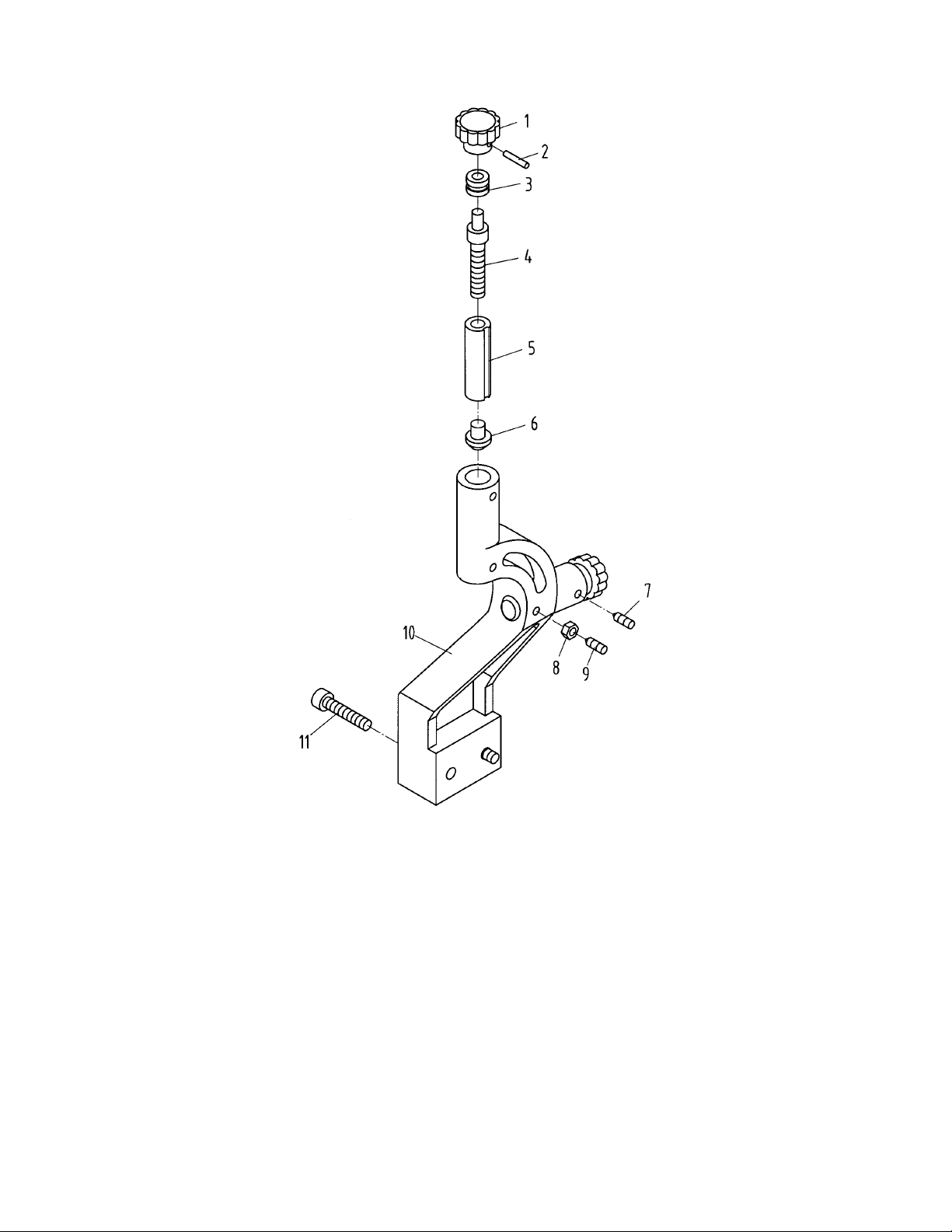

Steady Rest

The steady rest (F, Fig. 13) serv es as a support

for shaft s on the free tailstoc k end. The steady

rest is mounted on the bedway and secured

from below with a bolt, nut and locking plate.

The sliding fingers require c ontinuous lubri c ation

at the contact points with the workpiece to

prevent pr em ature wear.

Follow Rest

The traveli ng follow rest (G , Fig. 13) is mounted

on the saddle and f ollows the movement of the

turning tool . Only two finger s are requi red as the

turning tool takes the place of the third. The

follow rest is used for turning operati ons on l ong,

slender workpieces. It prevents flexing of the

workpiece f r om the pr essure of t he cutting tool.

The slidi ng fingers are set simi lar to the steady

rest, free of play, but not binding. The sliding

fingers require continuous lubrication at the

contact points with the workpiece to prevent

prematur e wear.

Figure 13

12

Page 13

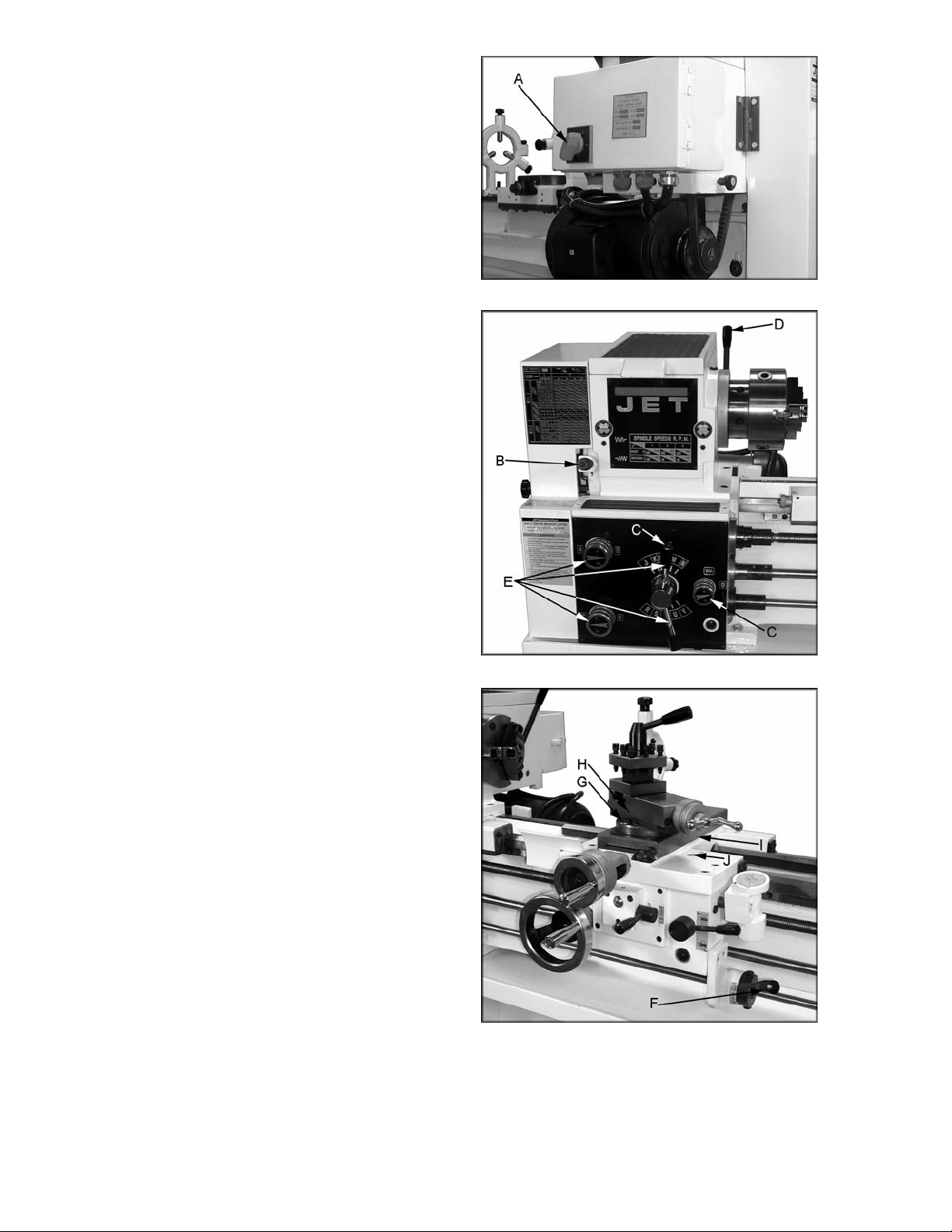

Controls

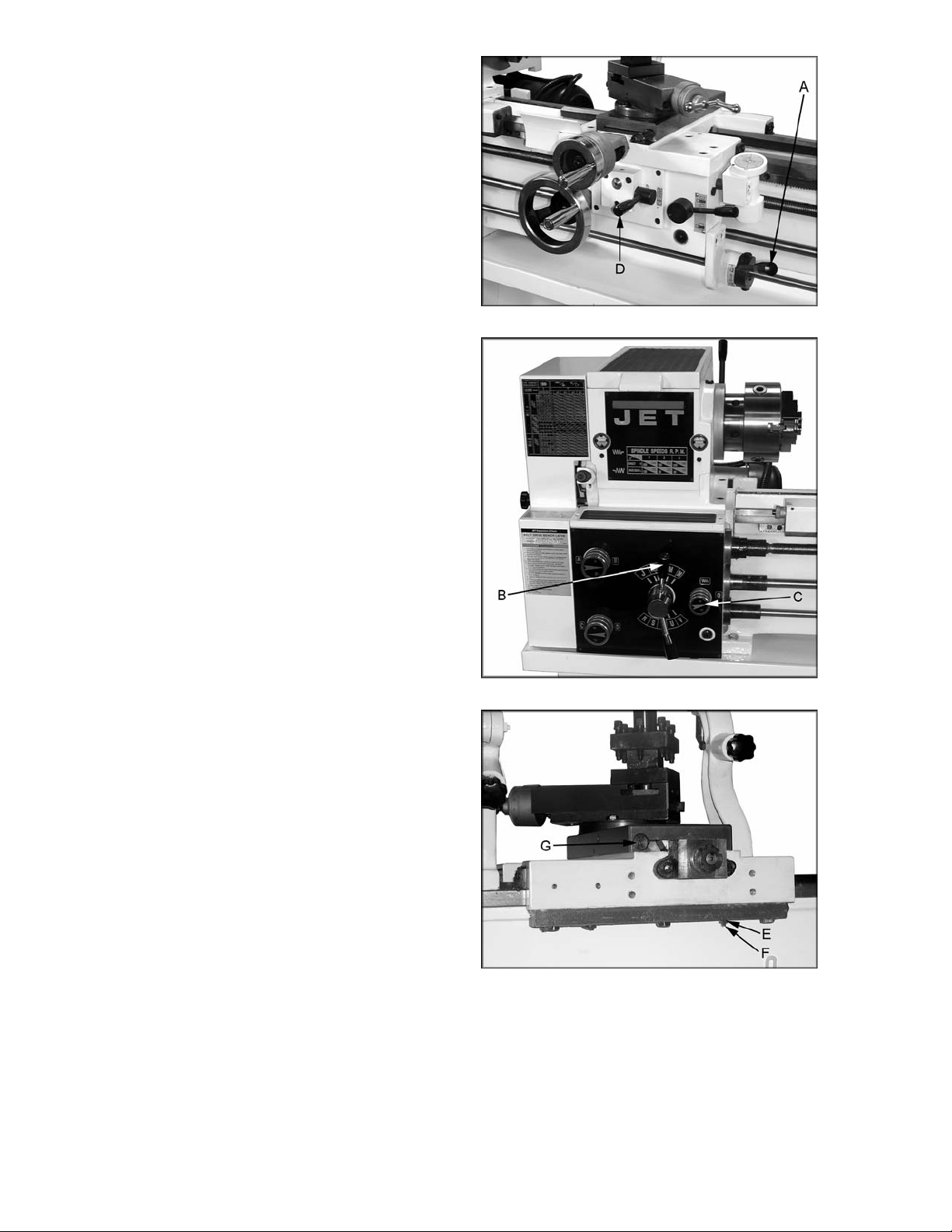

1. Main On-Off Switch (A, Fig. 14) – Power i s

off in the “0” position and on in the “I”

position.

2. Feed Direction Selector (B, Fig. 15) –

Arrows above the handle indicate saddle

travel dir ection when the chuck is rot ating in

the forward direction or counter-clockwise

as viewed from the front of the chuck.

3. Feed Rod/ Leadscrew Select or (C, Fi g. 15)

– Use knob and lever to activat e leadscrew

and feed rod.

4. Belt Tensioning Handle (D, Fig. 15) – Pull

forward to rel ease tension on the driv e belt.

Push toward the rear t o tension the belt.

5. Feed Rate Selector (E, Fig. 15) – Two

knobs and two handl es used to set desired

feed, or lead rat es.

6. Forw ard/Reverse Lever ( F, Fi g. 16) – Pull

lever up for clockwise spindle rotation

(reverse). Push lever down for counterclockwise spindl e rotation (f orward). Neutral

position is a center detent and the spindle

remains idle.

Figure 14

7. Compound Rest Lock (G, Fig. 16) – Turn

hex nut clockwise to lock and counterclockwise to unlock.

8. Compound Slide Lock (H, Fig. 16) – Turn

set screw cloc kwise to tighten and counter clockwise to loosen.

9. Cross Slide Lock (I, Fig. 16) – Turn set

screw clockwise, and tighten to lock. Turn

counter-clockwise and loosen to unlock.

Caution: cross slide lock screw must be

unlocked before engaging automatic feeds

or damage to the lathe may occur.

10. Carriage Lock (J, Fig. 16) – Turn hex

socket cap screw clockwise and tighten to

lock. Turn counter-clockwise and loosen to

unlock. Caution: Carriage lock screw must

be unlocked before engaging automatic

feeds or damage to lathe may occur.

Figure 15

Figure 16

13

Page 14

11. Longitud inal T raverse Hand wheel (A, Fig.

17) – Rotate handwheel cl ockwise to move

the apron assembly toward the tailstock

(right). Rotate the wheel counter-clockwise

to move the apron assembly toward the

headstock (left).

12. Feed Sel ector (B, Fig. 17) – Push l ever to

the left and down to activate the crossfeed

function. Pull lever to the right and up to

activate the longitudinal function.

13. Half Nut Engag e Lever (thread cutting) (C,

Fig. 17) – Move the l ever down to engage.

Move the lever up to disengage.

14. Cross T raverse Handwheel (D, Fig. 17) –

Clockwise rotation moves the cross slide

toward the rear of t he machine.

15. Compound Rest Traverse Handwheel (E,

Fig. 17) – Rotate clockwise or counterclockwise to mov e or positi on.

16. Tool Post Clamping Lever (F, Fig. 17) –

Rotate counter-clockwise to loosen and

clockwise to tighten. Rotate the tool post

when the lever is unl oc k ed.

Figure 17

17. Threading Dial (G, Fig. 17) – Engage by

pushing into the leadscrew. Pull out to

disengage. The di al indicator and chart will

specify at which point a thread can be

entered.

18. Tailstock Quill Clamping Lever (H, Fig.

18) – Lift up to lock t he spindle. Push down

to unlock.

19. Tailsto ck Clamping Lever (I, Fi g. 18) – Lift

up lever to lock. Push down lev er to unloc k.

20. Tailstock Quill Traverse Handwheel (J,

Fig. 18) – Rotat e clockwise to adv ance the

quill. Rot ate count er-clockwise to ret ract t he

quill.

21. Tailstock Off-Set Adjustment (K, Fig. 18)

– Three set screws located on t he tailstock

base are used to off-set the tailstock for

cutting tapers. Loosen lock screw on

tailstock end. Loosen one side s et scre w (K,

Fig. 18) while tightening the other until the

amount of off-set is indicated on scale.

Tighten lock screw.

Figure 18

14

Page 15

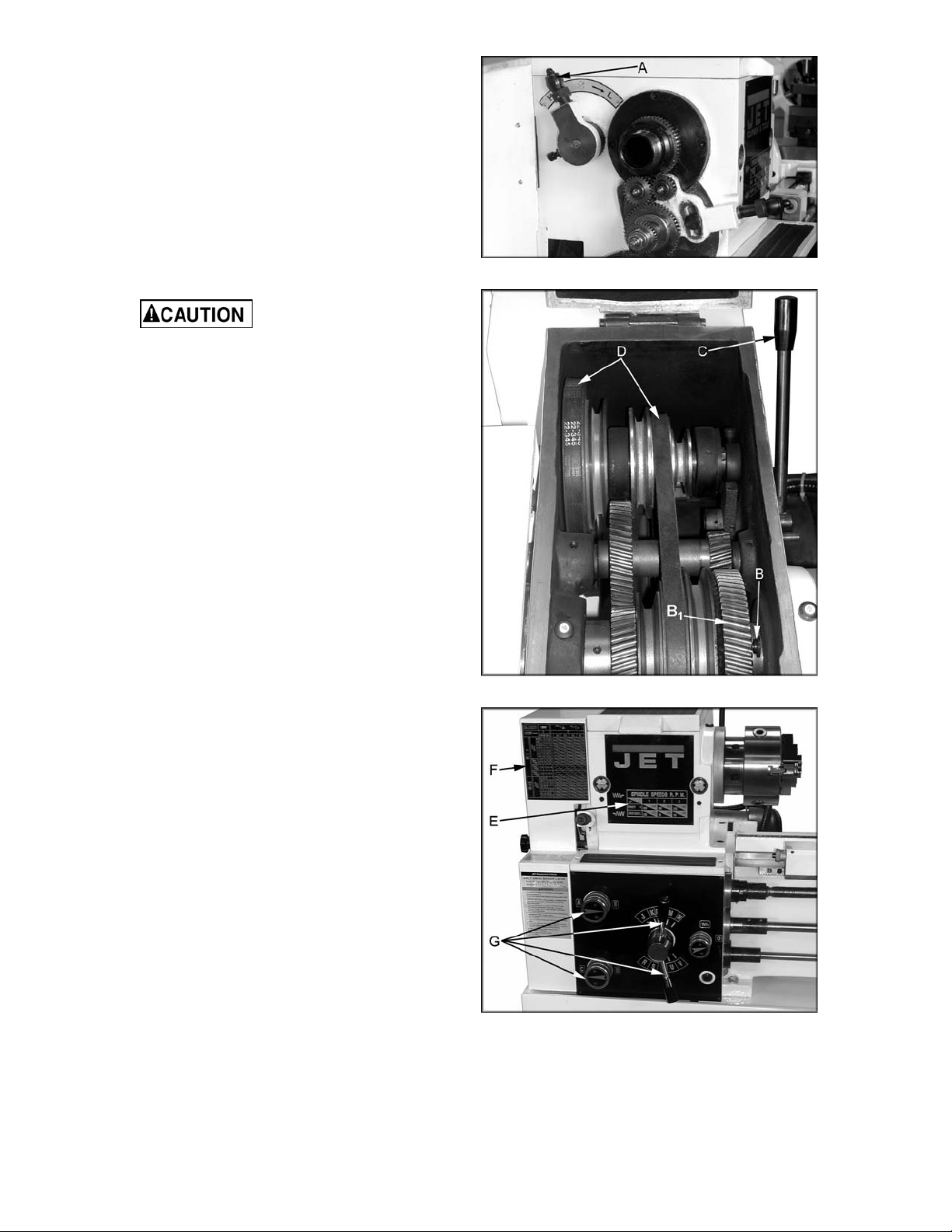

22. High-Low Speed Selector (A, Fig. 19) Push toward the re ar of t he machine f or the

high-speed range and pull toward the front

for the low speed range.

23. Lock Pin fo r Back Gear (B, Fig. 20) – For

high-speed operation, pull out pin and turn

pin 90° clockwise to engage back gear (B

To disengage the back gear for low-speed

operation, pul l t he pin out, turn 90° count erclockwise, and rot ate the chuc k until the pi n

seats.

Engage back gear only

for high -speed operation . Do not operate

in low-speed range while back gear (B

is engaged. Failure to comply may result

in gear damage.

).

1

)

1

Adjustments

Figure 19

Break-In Procedure

During manuf acturing and testi ng, thi s lathe has

been operated in the l ow R.P.M. range for t hree

hours.

To allow time for the gears and bearings to

break-in and run sm oothly, do not run the lathe

above 580 R.P.M. for the first six hours of

operation and use.

Speed Selection

To change speeds, disconnect the lathe from

the power source and remove the tension by

pulling handle (C, Fig. 20) forward. Move the

belts (D, Fig. 20) to the desired location

according to the speed selection chart (E, Fig.

21). Tension the belts by moving the handle

towards the rear.

Feed and Thread Selection

Figure 20

1. Reference the feed and thread tables (F,

Fig. 21).

2. Move levers and knobs (G, Fig. 21) to the

appropriate posi tion.

Figure 21

15

Page 16

Change Gear Replacement

Note: The 32T x 127T x 48T gears are i nstall ed

in the end gear compartment when delivered

from the factory. This combination will cover

most inch feeds and threads under normal

circumstanc es. The additional gears found in the

toolbox are used for some metric threads and

feeds.

1. Disconnect the machine from the power

source.

2. Open the end cover on the left end of the

headstock.

3. Loosen t he socket head cap screw (A, Fi g.

22) and hex nuts (B, Fig. 22). Move the

quadrant out of the way.

4. Change gears (C, Fig. 22) t o match t he feed

and thread chart.

5. Thoroughly cl ean and install new gears.

6. Move the quadrant so the large gear

meshes with the smaller gears and tighten

to secure in pl ace. Note: Make sure t here is

backlash of 0.002” – 0.003” between gears.

Setting the gears too tight will cause

excessiv e noise and wear.

Figure 22

7. Close the cover and connec t t he machine t o

the power source.

Thread Cutting

1. Set feed rate selectors (D, Fig. 23) i n proper

position for the correct feed rate of the

thread to be cut.

2. Mov e knob (E, Fi g. 23) to the “0” posi tion to

disengage the feed rod.

3. Engage the half nut lev er (F, Fi g. 24).

4. The half nut lever and threading dial are

used to thread in t he conventi onal manner.

The thread dial chart specifies at which

point a thread can be entered using the

threading di al .

5. To c ut metri c threads, the half nuts m ust be

left continuall y engaged once the start point

has been selec ted and the half nut is initiall y

engaged (thread dial cannot be used).

Figure 23

Figure 24

16

Page 17

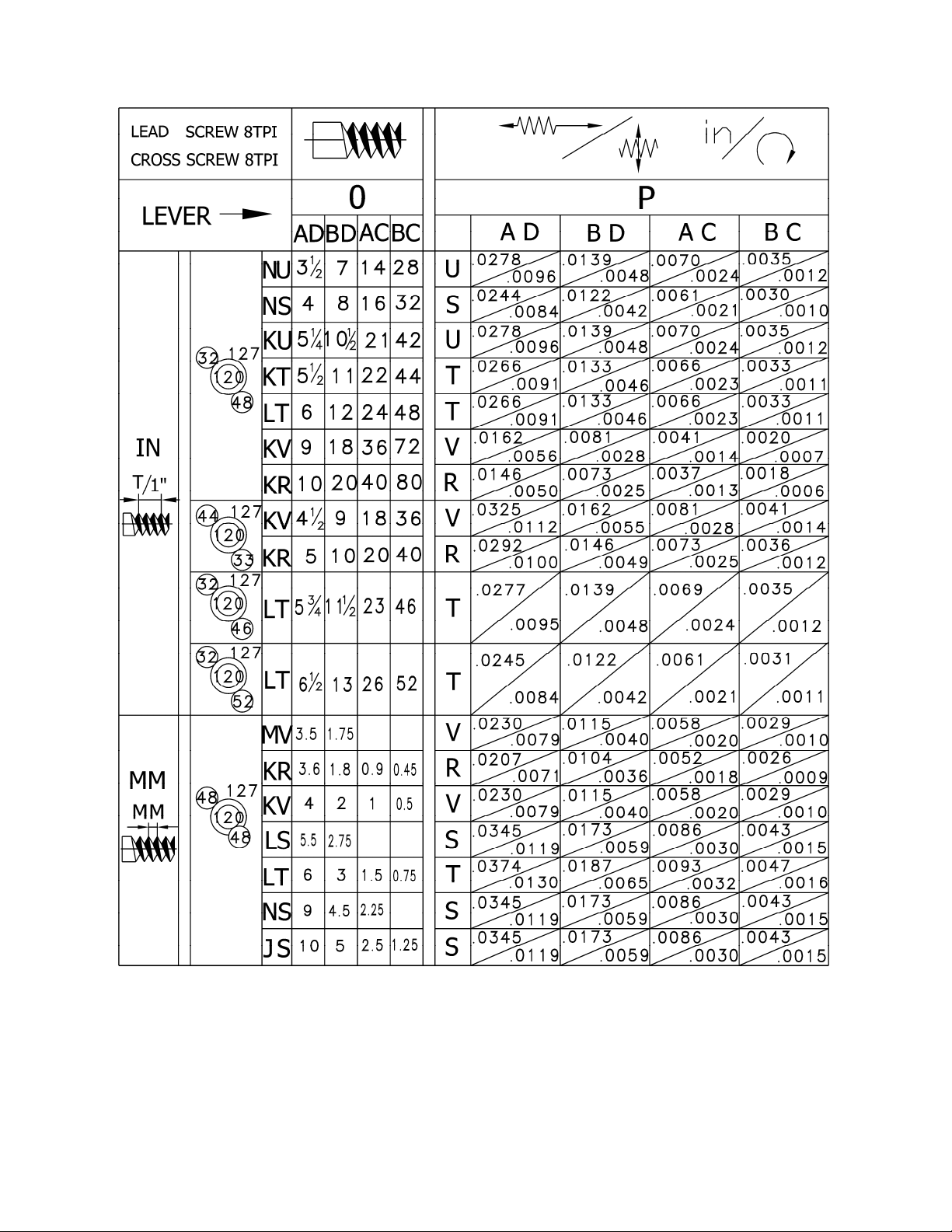

Thread and Feed Chart

17

Page 18

Automatic Feed Operation and Feed

Changes

1. Move forward/reverse selector (A, Fig. 25)

up or down depending on desired direction.

2. Set the selector handle (B, Fig. 26) to the

“P” position and turn knob (C, Fig. 26)

counter-clockwise so the arrow is pointing

up to start the feed rod r otati ng.

Powered Carriage Travel

Push lev er (D, Fig. 25) to the l eft and down to

engage crossfeed. Pull lever to the right and up

to engage longitudinal feed.

Saddle Adjustment

1. Loosen f our hex nuts (E, Fig. 27) found on

the bottom rear of the c r oss slide.

2. Turn each of the four set screws (F, Fi g. 27)

equally with a hex wrench until a slight

resistance is felt. Do not over tighten.

3. Move the carriage wit h the hand wheel and

determine if drag is to y our preference. Readjust the setscrews as necessary to

achieve the desi r ed dr ag.

4. Hold socket set screw firmly with a hex

wrench and tighten hex nut to lock in place.

5. Move the carriage again and adjust if

necessary. Note: Over adjustment will

cause excessive premature wear of the

gibs.

Figure 25

Figure 26

Cross Slide Adjustment

If the cr oss slide i s too loose, f ollow procedure

below to tighten:

1. Loosen the rear gib screw (G, Fig. 27)

approxim ately one turn.

2. Ti ghten front gib screw a quarter tur n. Turn

the cross slide handwheel to see if the cr oss

slide is still loose. If it is still loose, tighten

the front screw a bit mor e and try again.

3. When cross slide i s properly adjusted, snug

rear gib screw. Do not ov er tighten. This

will cause premature wear on the gib and

mating parts.

Figure 27

18

Page 19

Compound Rest Adjustment

Follow the same proc edur e as for the cross slide

adjustment.

Tailstock Adjustment

If the handle will not lock the tailstock securely,

use the following procedur e:

1. Lower handle to the unl oc k ed posi tion.

2. Slide tail stock to an area that will allow you

to reach under the tailstock.

3. Tighten t ailstock clamping nut 1/4 t urn, and

re-test for proper locking. Repeat as

necessary.

Half Nut Gib Adjustment

1. Remove the thread dial assembly by

unscrewing the scre w (A, Fig. 28).

2. Loosen t hree hex nut s (B, Fig. 28) f ound on

the side of apr on, and turn t hree set scre ws

(C, Fig.28) equal ly with a hex wrench.

3. Adjust properly for wear and play. Hold

socket set screw firmly with a hex wrench

and tighten hex nut to lock in place. Note:

Over adjustment will cause excessive

prematur e wear on gib and mati ng par ts.

Headstock Alignment

The headstock has been aligned at the factory

and should not require adjustment. However , if

adjustment is deemed necessary, follow the

procedure below to al ign the headstock.

1. Using an engineer's precision level on the

bedways, make sure the lathe is level side

to side and f ront to back. If the lathe i s not

level, correct to a level condition before

proceeding. Re- test alignment if any leveli ng

adjustments were made.

2. From steel bar stock of approximately two

inches in diameter, cut a piece

approximately eight inches long.

3. Place two inc hes of bar stock into c huc k and

tighten chuck. Do not use the tailstock or

center to support the other end.

4. Set up and cut along fiv e inches of the bar

stock.

Figure 28

19

Page 20

5. Using a microm eter, measure the bar stock

next to the chuck and at the end. The

measurement should be the same.

6. If the measurements are not the same and

adjustment is required, loosen the f our bolt s

that hold the headstock to the bed. Do not

loosen completely; some drag should

remain.

7. Loosen two hex nuts found on the two

adjusting bolts located on the backside of

headstock just above the motor mount

bracket. A djust the bolts for ali gnment and

tighten hex nuts. Tighten the headstock

bolts and mak e another c ut. Keep adj usti ng

screws after each cut until the bar stock

measurements are the same. Tighten all

headstock bolts and jam nuts on adjusting

screws.

Removing Gap Bridge

1. Using an open end wrench, tighten the t wo

hex nuts (A, Fig. 29). This will cause the

taper pins (B, Fig. 29) to rel ease. Remove

the taper pins.

2. Rem ove the four hex socket cap screws (C,

Fig. 29) with a hex key wrench.

3. Gap bridge can now be removed.

Installing Gap Bridge

1. Clean the bottom and the ends of the gap

bridge thoroughly.

2. Set gap bridge in plac e and align.

3. Remove nuts (A, Fig. 29) from the taper

pins (B, Fig. 29).

4. Slide taper pins in their r espective holes and

seat using a m allet. Install nuts on the taper

pins finger tight.

Figure 29

5. Install four socket head cap screws (C, Fi g.

29) and tighten secur ely.

20

Page 21

This .pdf document is bookmarked

Parts List and Electrical Diagrams

For Lathe models BDB-1340A, GHB-1340 A, GHB-1440A

For GHB-1340A/1440A Operat ing Instructions, see document M-321357A-1

For BDB-1340A Operatin g Inst ructions, see document M - 321360A

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-321357A

Ph.: 800-274-6848 Revision

www.jettools.com Copyright © 2014 JET

(GHB-1340A shown with opt ional stand 321443AK)

I 11/2014

Page 22

Table of contents

Section Page

Table of contents ................................................................................................................................................... 2

Replacement parts ................................................................................................................................................ 3

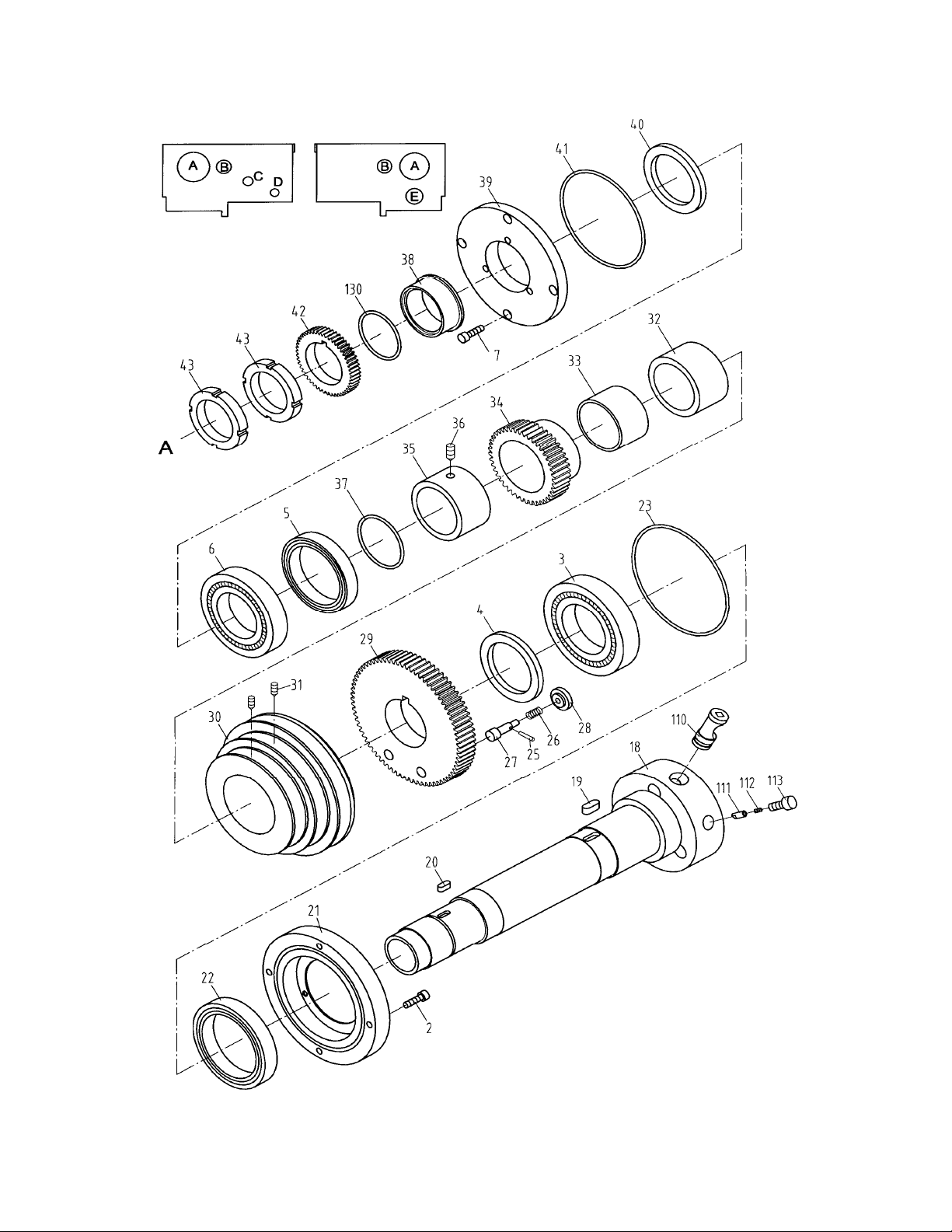

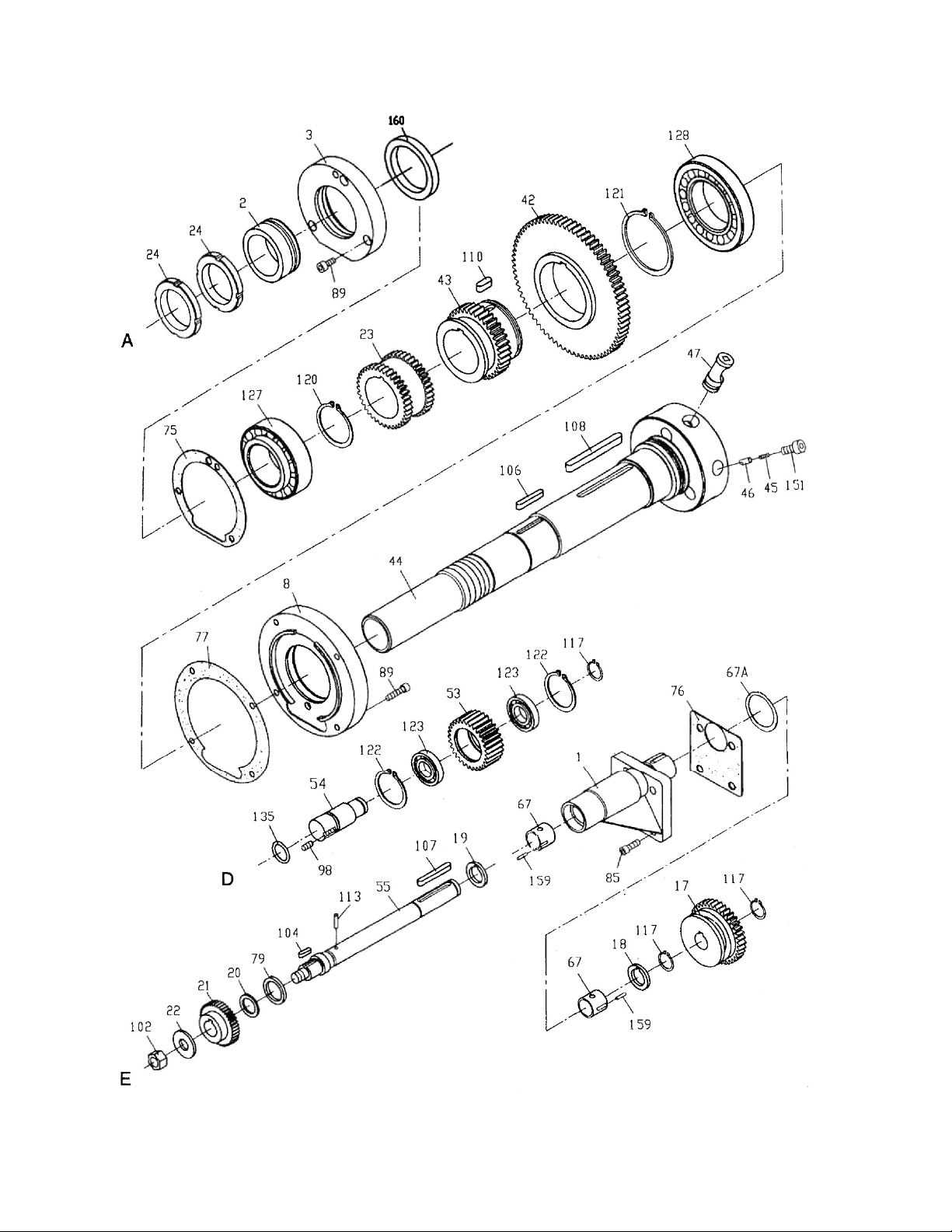

1.0 BDB-1340A Headstock Assembly I – Exploded View ................................................................................ 4

1.1 BDB-1340A Headstock Assembly I – Parts List ......................................................................................... 5

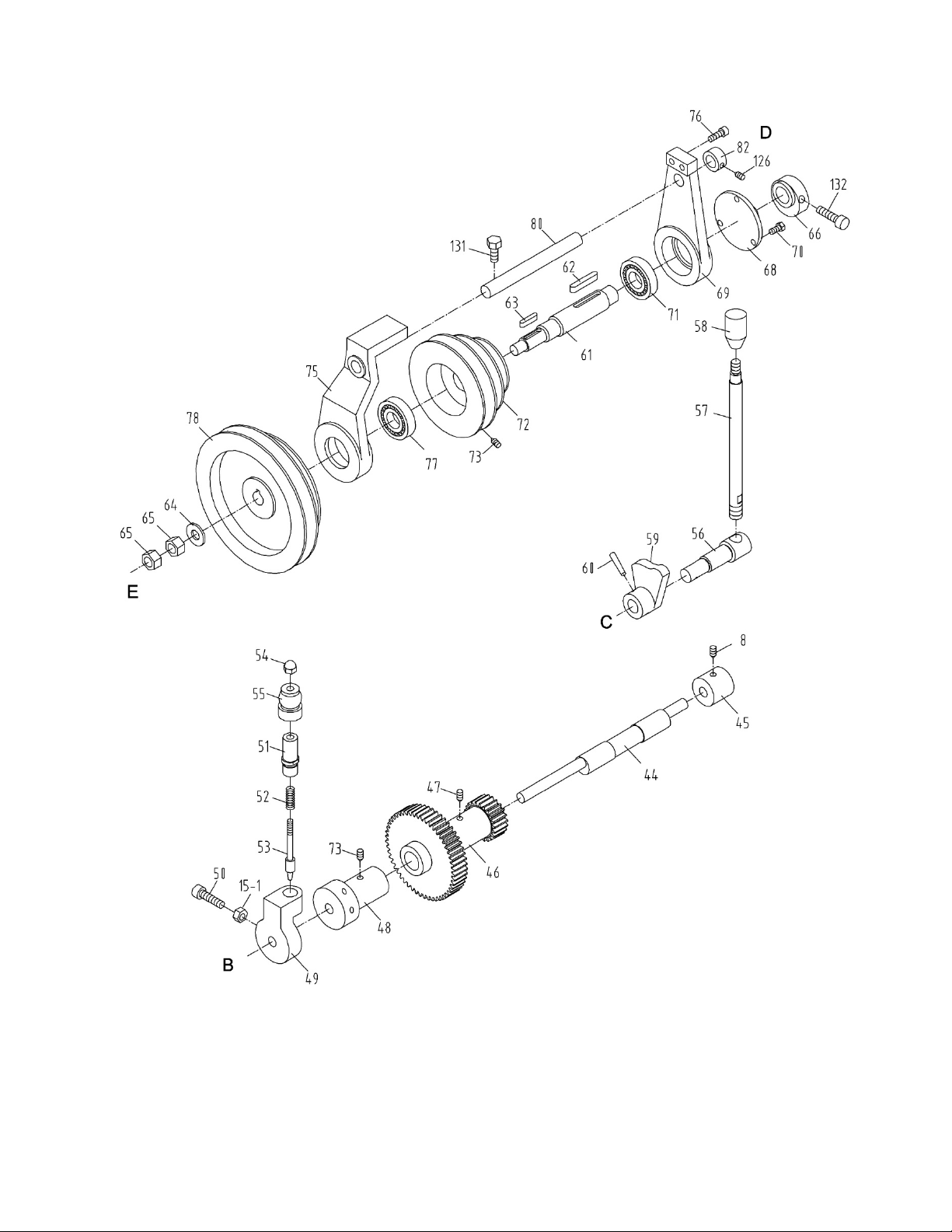

2.1 BDB-1340A Headstock Assembly II – Exploded View ............................................................................... 6

2.2 BDB-1340A Headstock Assembly II – Parts List ........................................................................................ 7

3.1 BDB-1340A Headstock Assembly III – Exploded View .............................................................................. 8

3.2 BDB-1340A Headstock Assembly III – Parts List ....................................................................................... 9

4.1 GHB-1340A/1440A Headstock Assembly I – Exploded View .................................................................. 10

4.2 GHB-1340A/1440A Headstock Assembly I – Parts List ........................................................................... 11

5.1 GHB-1340A/1440A Headstock Assembly II – Exploded View ................................................................. 13

5.2 GHB-1340A/1440A Headstock Assembly II – Parts List .......................................................................... 14

6.1 GHB-1340A/1440A Headstock Assembly III – Exploded View ................................................................ 15

6.2 GHB-1340A/1440A Headstock Assembly III – Parts List ......................................................................... 16

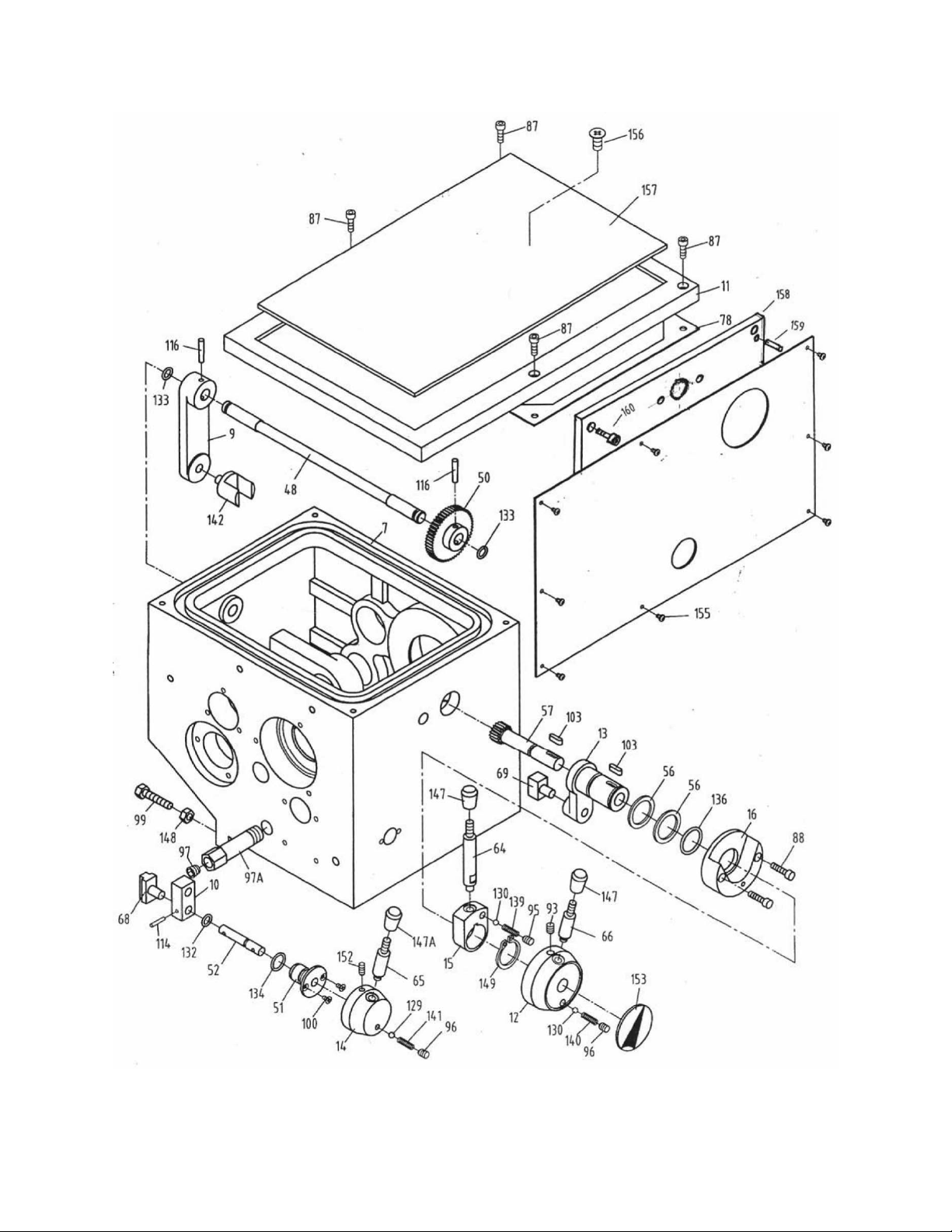

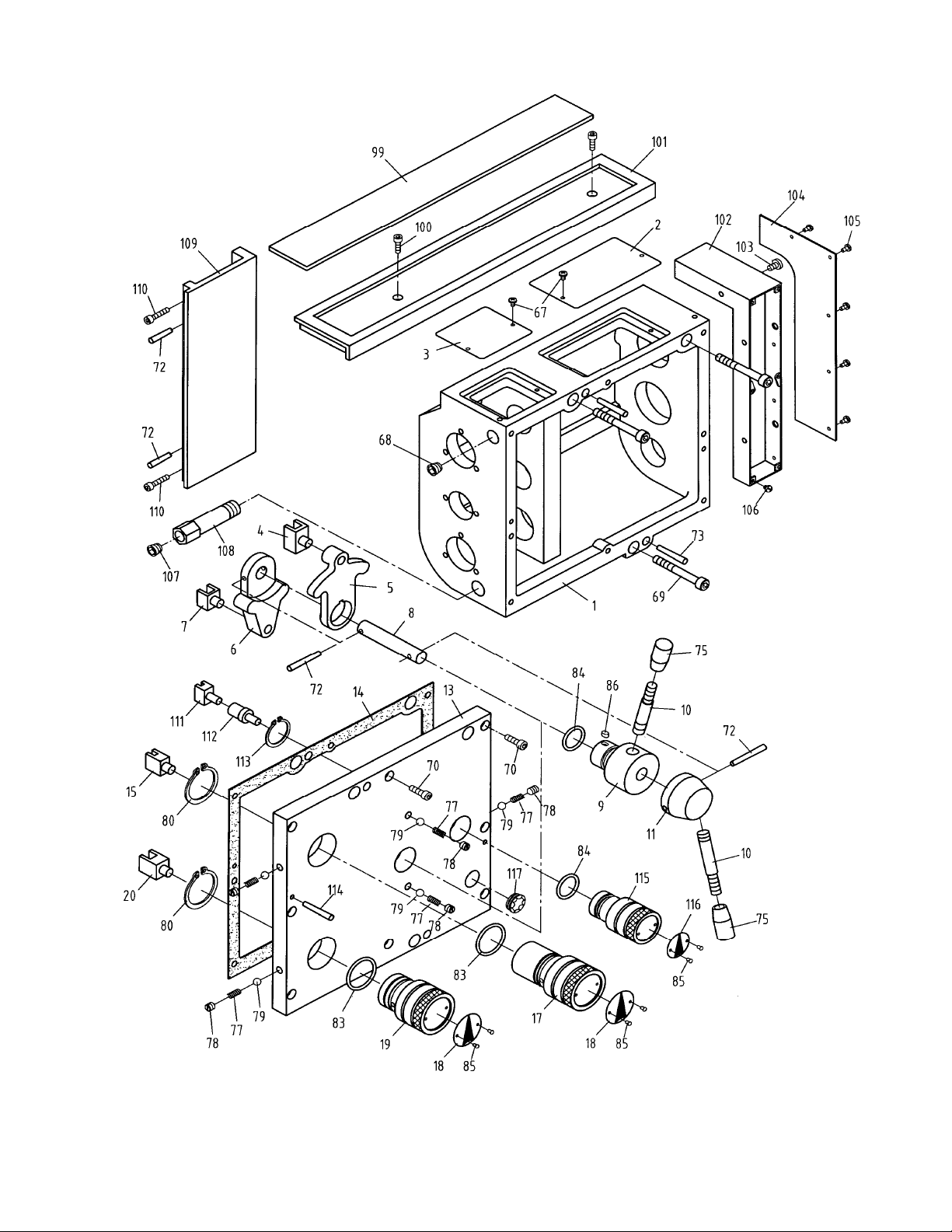

7.1 Bed Assembly I – Exploded View ............................................................................................................. 17

7.2 Bed Assembly I – Parts List ..................................................................................................................... 18

8.1 Bed Assembly II – Exploded View ............................................................................................................ 20

8.2 Bed Assembly II – Parts List .................................................................................................................... 21

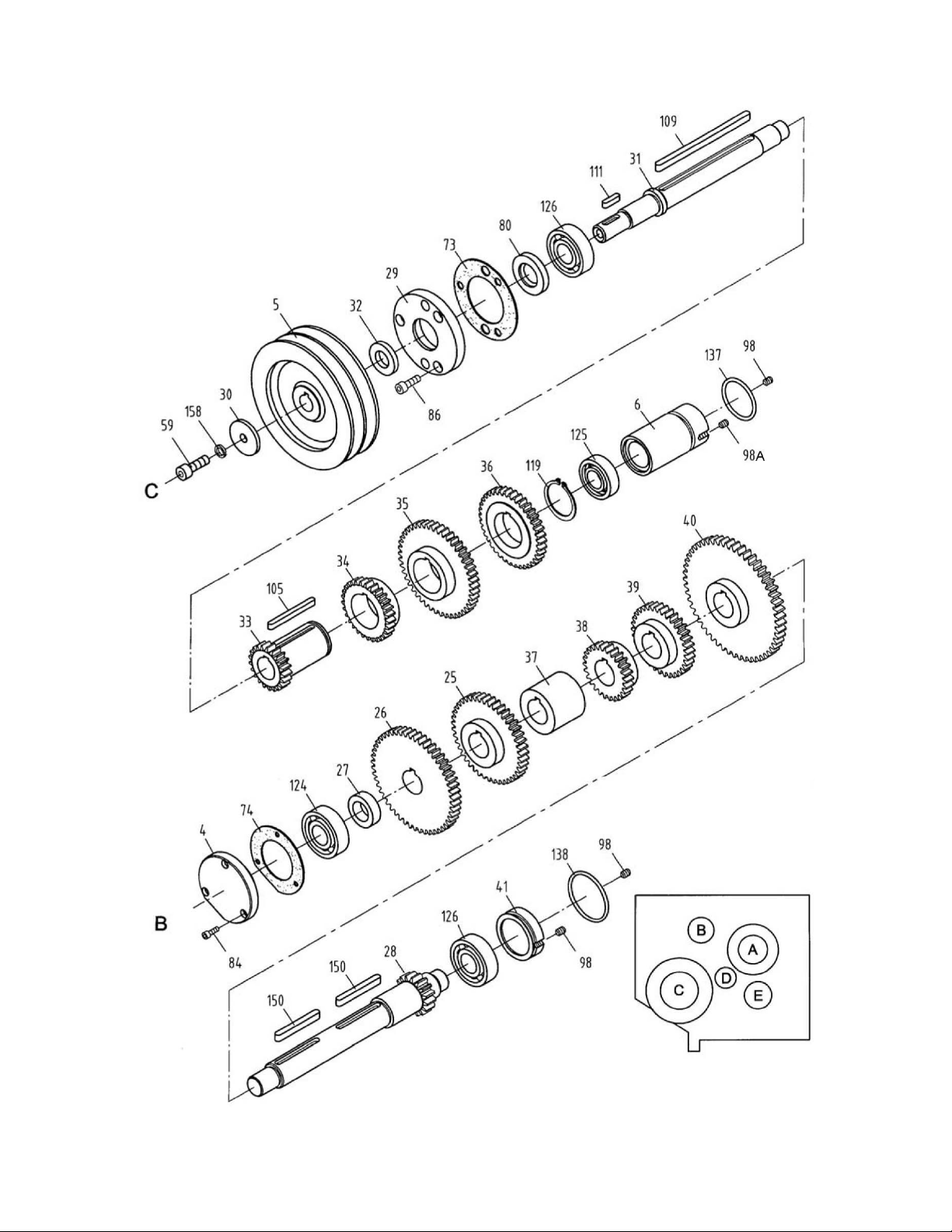

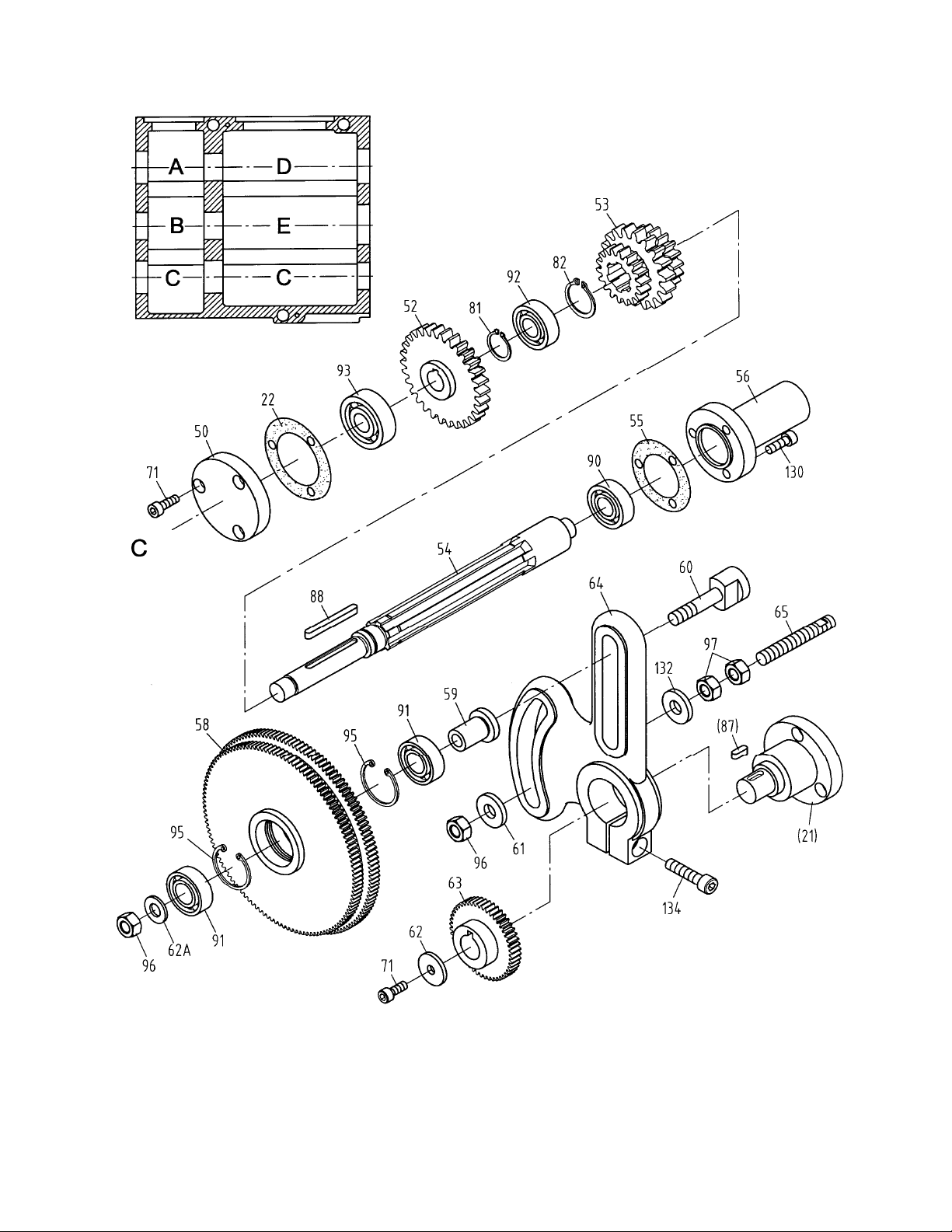

9.1 Gear Assembly I – Exploded View ........................................................................................................... 22

9.2 Gear Assembly I – Parts List .................................................................................................................... 23

10.1 Gear Assembly II – Exploded View ........................................................................................................ 24

10.2 Gear Assembly II – Parts List ................................................................................................................. 25

11.1 Gear Assembly III – Exploded View ....................................................................................................... 26

11.2 Gear Assembly III – Parts List ................................................................................................................ 27

12.1 Apron Assembly I – Exploded View ....................................................................................................... 28

12.2 Apron Assembly I – Parts List ................................................................................................................ 29

13.1 Apron Assembly II – Exploded View ...................................................................................................... 30

13.2 Apron Assembly II – Parts List ............................................................................................................... 31

14.1 Apron Assembly III – Exploded View ..................................................................................................... 32

14.2 Apron Assembly III – Parts List .............................................................................................................. 32

15.1 Micro Carriage Stop Assembly – Exploded View ................................................................................... 33

15.2 Micro Carriage Stop Assembly – Parts List ............................................................................................ 33

16.1 Top Slide, Tool Post, Saddle, and Cross Slide I – Exploded View ......................................................... 34

16.2 Top Slide, Tool Post, Saddle, and Cross Slide I – Parts List ................................................................. 35

17.1 Top Slide, Tool Post, Saddle, and Cross Slide II – Exploded View ........................................................ 36

17.2 Top Slide, Tool Post, Saddle, and Cross Slide II – Parts List ................................................................ 37

18.1 Tailstock Assembly I – Exploded View ................................................................................................... 38

18.2 Tailstock Assembly I – Parts List ............................................................................................................ 39

19.1 Tailstock Assembly II – Exploded View .................................................................................................. 40

19.2 Tailstock Assembly II – Parts List ........................................................................................................... 40

20.1 Follow Rest – Exploded View ................................................................................................................. 41

20.2 Follow Rest – Parts List .......................................................................................................................... 41

21.1 Steady Rest – Exploded View ................................................................................................................ 42

21.2 Steady Rest – Parts List ......................................................................................................................... 43

22.1 GHB-1340A/1440A Chuck Guard Assembly – Exploded View .............................................................. 44

22.2 GHB-1340A/1440A Chuck Guard Assembly – Parts List ....................................................................... 44

23.0 Additional Parts (Not Shown) ................................................................................................................. 45

24.0 Additional Electrical Components (Not Shown) ...................................................................................... 45

25.1 Electrical Schematic – GHB-1340A/1440A ............................................................................................ 46

25.2 Electrical Schematic Parts List – GHB-1340A/1440A ............................................................................ 46

26.1 Electrical Schematic – BDB-1340A ........................................................................................................ 47

26.2 Electrical Schematic Parts List – BDB-1340A ........................................................................................ 47

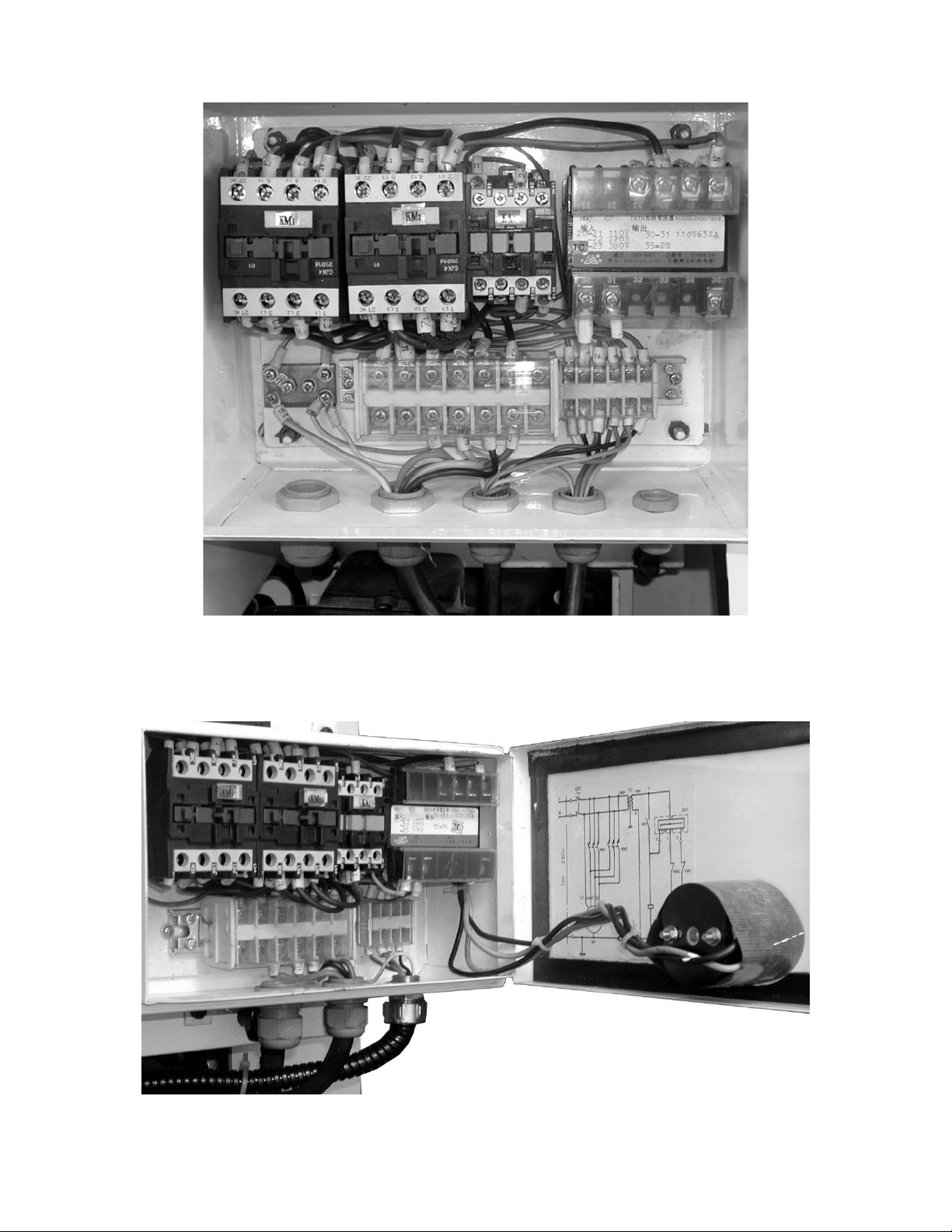

27.0 GHB-1340A/1440A Wiring Photo ........................................................................................................... 48

28.0 BDB-1340A Wiring Photo ....................................................................................................................... 48

2

Page 23

Replacement parts

To order parts or reach o ur service department, call 1-80 0-274-6848 Monday through Fr iday (see our w ebsite

for busin ess hours, www.jettools.com). Having the Model Number and Serial Number of your machine available

when you call will allow us to serve you quickly and accurately.

3

Page 24

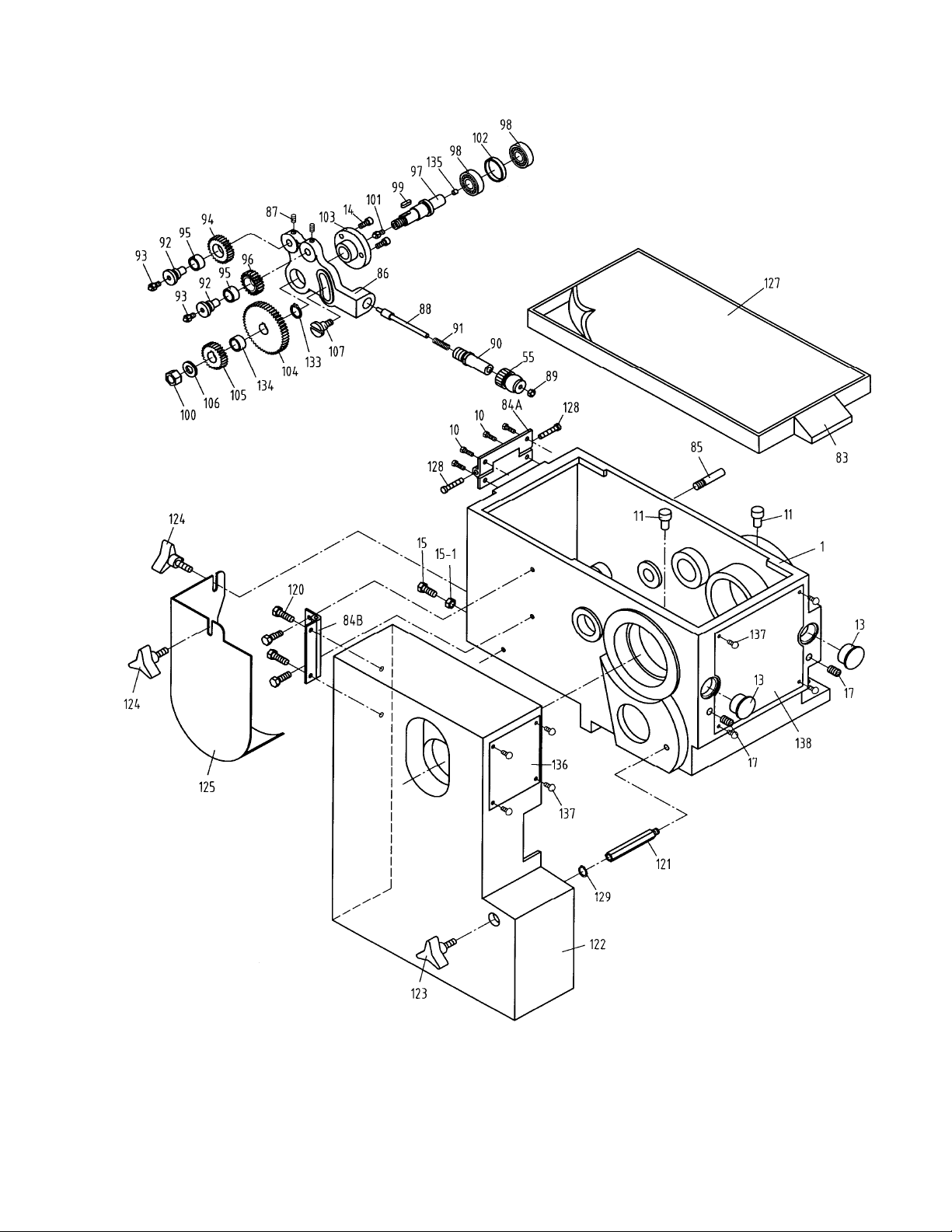

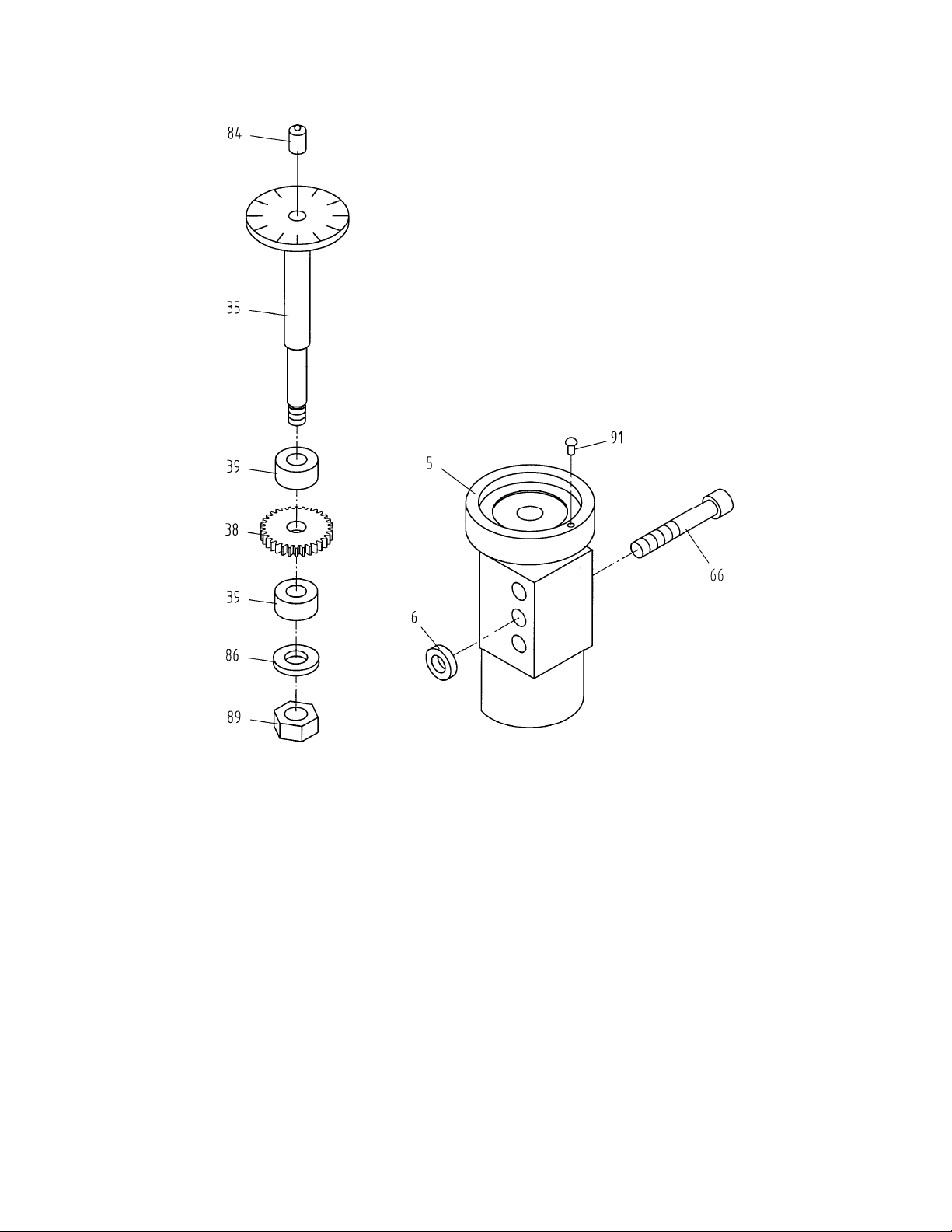

1.0 BDB-1340A Headstock Assembly I – Exploded View

4

Page 25

1.1 BDB-1340A Headstock Assembly I – Parts List

Index No Part No Description Size Qty

1 ................ 04101B ...................... Headstock Casting................................................... ...................................... 1

10 .............. TS-1482021 .............. Hex Socket Cap Screw ............................................ M6 x 12 ......................... 4

11 .............. 04501A ...................... Inlet Plug .................................................................. ...................................... 2

13 .............. BDB1340-H13 ........... Oil Sight Glass ......................................................... ...................................... 2

14 .............. TS-1503031 .............. Hex Socket Cap Screw ............................................ M6 x 12 ......................... 3

15 .............. TS-1490081 .............. Hex Cap Bolt............................................................ M8 x 45 ......................... 2

15-1 ........... TS-1540061 .............. Nut ........................................................................... M8 ................................. 2

17 .............. BDB1340-H17 ........... Screw ....................................................................... 1/8” ................................ 2

55 .............. 04733B ...................... Knob ........................................................................ ...................................... 1

83 .............. 04310 ........................ Cover ....................................................................... ...................................... 1

84A ............ 04723A ...................... Cover Hinge ............................................................. ...................................... 1

84B ............ 04723B ...................... End Cover Hinge ..................................................... ...................................... 1

85 .............. 04705 ........................ Strut ......................................................................... ...................................... 1

86 .............. BDB1340A-02118A ... Arm .......................................................................... ...................................... 1

87 .............. TS-1523031 .............. Set Screw ................................................................ M6 x 10 ......................... 2

88 .............. 04725B ...................... Plunger .................................................................... ...................................... 1

89 .............. BDB1340-H89 ........... Cap Nut.................................................................... ...................................... 1

90 .............. 04734B ...................... Spring Sleeve .......................................................... ...................................... 1

91 .............. BDB1340-H91 ........... Spring ...................................................................... 1x9x50 .......................... 1

92 .............. 04721 ........................ Idle Shaft.................................................................. ...................................... 2

93 .............. BDB1340-H93 ........... Oil Nipple ................................................................. ...................................... 2

94 .............. 04719 ........................ Gear ......................................................................... 1.5m26T ........................ 1

95 .............. 04303 ........................ Bushing .................................................................... ...................................... 2

96 .............. 04720 ........................ Gear ......................................................................... 1.5m21T ........................ 1

97 .............. BDB1340A-02717A ... Output Shaft............................................................. ...................................... 1

98 .............. BB-6202ZR ............... Ball Bearing ............................................................. 6202ZR ......................... 2

99 .............. BDB1340A-H99......... Key........................................................................... 5 x 5 x 50 ...................... 1

100 ............ TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 1

101 ............ BDB1340-H93 ........... Oil Nipple ................................................................. ...................................... 1

102 ............ 04716 ........................ Spacer ..................................................................... ...................................... 1

103 ............ 04119A ...................... Flange ...................................................................... ...................................... 1

104 ............ BDB1340A-02718A ... Gear ......................................................................... 1.5m50T ........................ 1

105 ............ GH1340A-05735 ....... Gear ......................................................................... 1.25m32T ...................... 1

.................. 32A5726A ................. Gear ......................................................................... 1.25m42T ...................... 1

………..BDB1340A-32A5726A ..... Gear ......................................................................... 1.25m44T ...................... 1

106 ............ BDB1340-H106 ......... Washer .................................................................... ...................................... 1

107 ............ 04714 ........................ Bolt........................................................................... ...................................... 1

120 ............ TS-1482021 .............. Cap Screw ............................................................... M6 x 12 ......................... 4

121 ............ BDB1340A-02722A ... Stud ......................................................................... ...................................... 1

122 ............ BDB1340A-02305A ... End Cover ................................................................ ...................................... 1

123 ............ BDB1340-H123 ......... Knob ........................................................................ ...................................... 1

124 ............ BDB1340-H124 ......... Knob ........................................................................ ...................................... 2

125 ............ 04724 ........................ Cover ....................................................................... ...................................... 1

127 ............ BDB1340-H127 ......... Rubber Mat .............................................................. ...................................... 1

128 ............ TS-1503081 .............. Hex Socket Cap Screw ............................................ M6 x 35 ......................... 2

129 ............ BDB1340-H129 ......... C-Clip ....................................................................... 8 .................................... 1

133 ............ BDB1340A-H133....... C-clip for Shaft ......................................................... 19 .................................. 1

134 ............ BDB1340A-02124 ..... Spacer ..................................................................... ...................................... 1

135 ............ BDB1340A-H135....... Plug.......................................................................... 5 .................................... 1

136 ............ BDB1340A-H136....... Sign Plate ................................................................ ...................................... 1

137 ............ BDB1340A-H137....... Half Round Cap Screw ............................................ M3x50 ........................... 8

138 ............ BDB1340A-H138....... Sign Plate ................................................................ ...................................... 1

5

Page 26

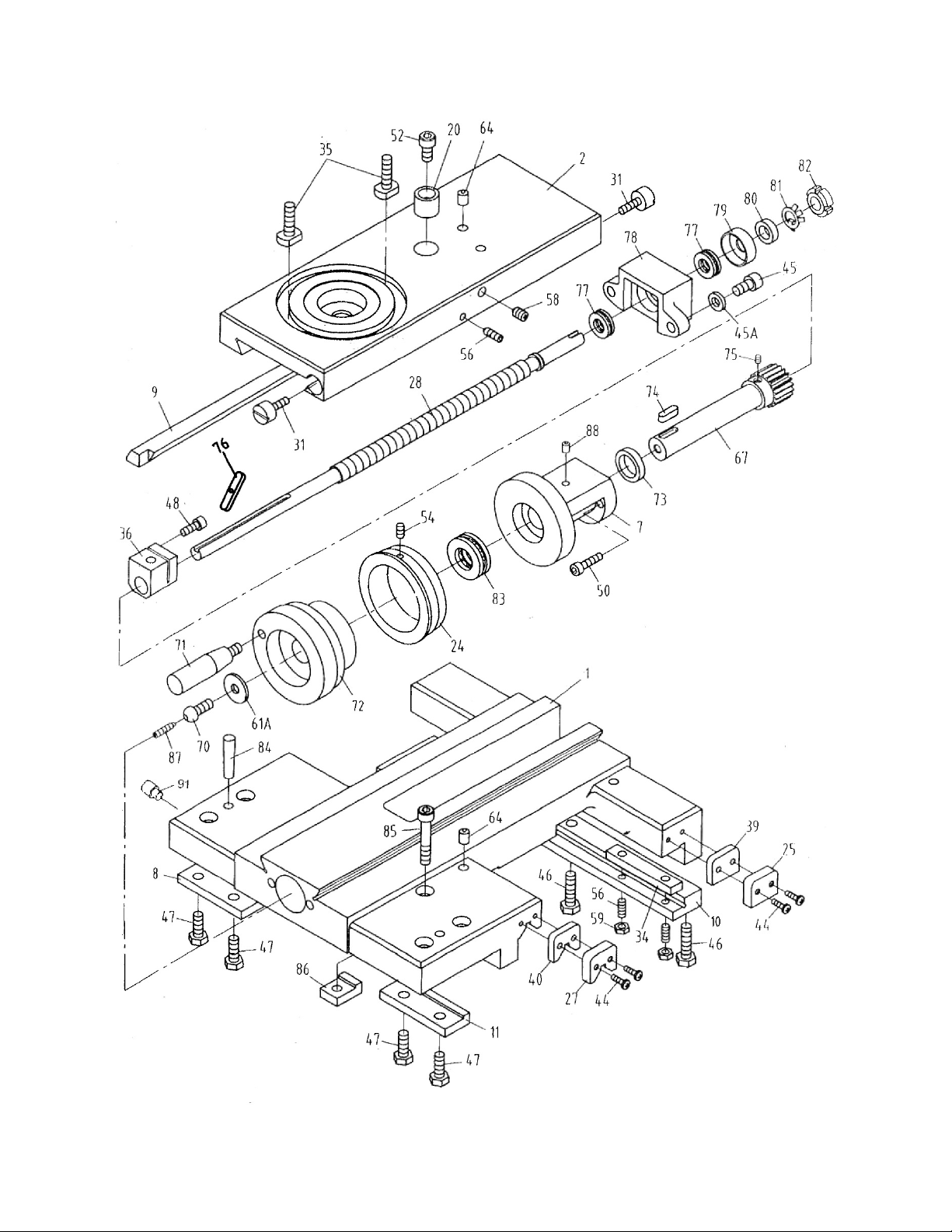

2.1 BDB-1340A Headstock Assembly II – Exploded View

6

Page 27

2.2 BDB-1340A Headstock Assembly II – Parts List

Index No Part No Description Size Qty

2 ................ TS-1503051 .............. Socket Set Screw .................................................... M8 x 10 ......................... 4

3 ................ BB-30212 .................. Taper Roller Bearing................................................ 60 x 110 x 22 ................ 1

4 ................ BDB1340-H4 ............. Oil Seal .................................................................... PG60 x 80 x 12 ............. 1

5 ................ OS-709012 ................ Oil Seal .................................................................... SG70 x 90 x 12 ............. 1

6 ................ BB-30211 .................. Taper Roller Bearing................................................ 55 x 100 x 21 ................ 1

7 ................ TS-1503041 .............. Hex Socket Cap Screw ............................................ M6 x 16 ......................... 4

18 .............. 04701 ........................ Spindle ..................................................................... D1-4 .............................. 1

19 .............. BDB1340-H19 ........... Key........................................................................... 8 x 7 x 18 ...................... 1

20 .............. BDB1340-H20 ........... Key........................................................................... 6 x 6 x 16 ...................... 1

21 .............. 04102 ........................ Bearing Cover (front) ............................................... ...................................... 1

22 .............. BDB1340-H22 ........... Oil Seal .................................................................... 75 x 100 x 12 ................ 1

23 .............. BDB1340-H23 ........... O-Ring ..................................................................... 125 x 3.1 ....................... 1

25 .............. BDB1340-H25 ........... Shaft Pin .................................................................. 3 x 18 ............................ 1

26 .............. BDB1340-H26 ........... Spring ...................................................................... 0.8 x 11 x 18 ................. 1

27 .............. 04703 ........................ Pin............................................................................ ...................................... 1

28 .............. 04702 ........................ Nut .......................................................................... . ...................................... 1

29 .............. 04117A ...................... Gear ......................................................................... 2m74T ........................... 1

30 .............. 04116 ........................ Pulley ....................................................................... ...................................... 1

31 .............. TS-1523031 .............. Set Screw ................................................................ M6 x 10 ......................... 2

32 .............. 04302 ........................ Bushing .................................................................... ...................................... 1

33 .............. 04301 ........................ Bushing .................................................................... ...................................... 1

34 .............. 04115 ........................ Gear ......................................................................... 2m44T ........................... 1

35 .............. 04114 ........................ Spacer ..................................................................... ...................................... 1

36 .............. TS-1524021 .............. Set Screw ................................................................ M8 x 6 ........................... 1

37 .............. BDB1340-H37 ........... O-Ring ..................................................................... 60 x 3.1 ......................... 1

38 .............. 04112A ...................... Spacer ..................................................................... ...................................... 1

39 .............. 04113 ........................ Bearing Cover (rear) ................................................ ...................................... 1

40 .............. BDB1340-H40 ........... Oil Seal .................................................................... W60 x 80 x 8 ................. 1

41 .............. BDB1340-H41 ........... O-Ring ..................................................................... 110 x 3.1 ....................... 1

42 .............. 04713 ........................ Gear ......................................................................... 1.5m50T ........................ 1

43 .............. 04743 ........................ Locking Nut .............................................................. ...................................... 2

110 ............ 04729 ........................ Cam ......................................................................... ...................................... 3

111 ............ 04741 ........................ Pin............................................................................ ...................................... 3

112 ............ BDB1340-H112 ......... Spring ...................................................................... 0.6 x 4 x 16 ................... 3

113 ............ TS-1504041 .............. Hex Socket Cap Screw ............................................ M8 x 18 ......................... 3

130 ............ BDB1340-H130 ......... O-Ring ..................................................................... 55 x 3.1 ......................... 1

7

Page 28

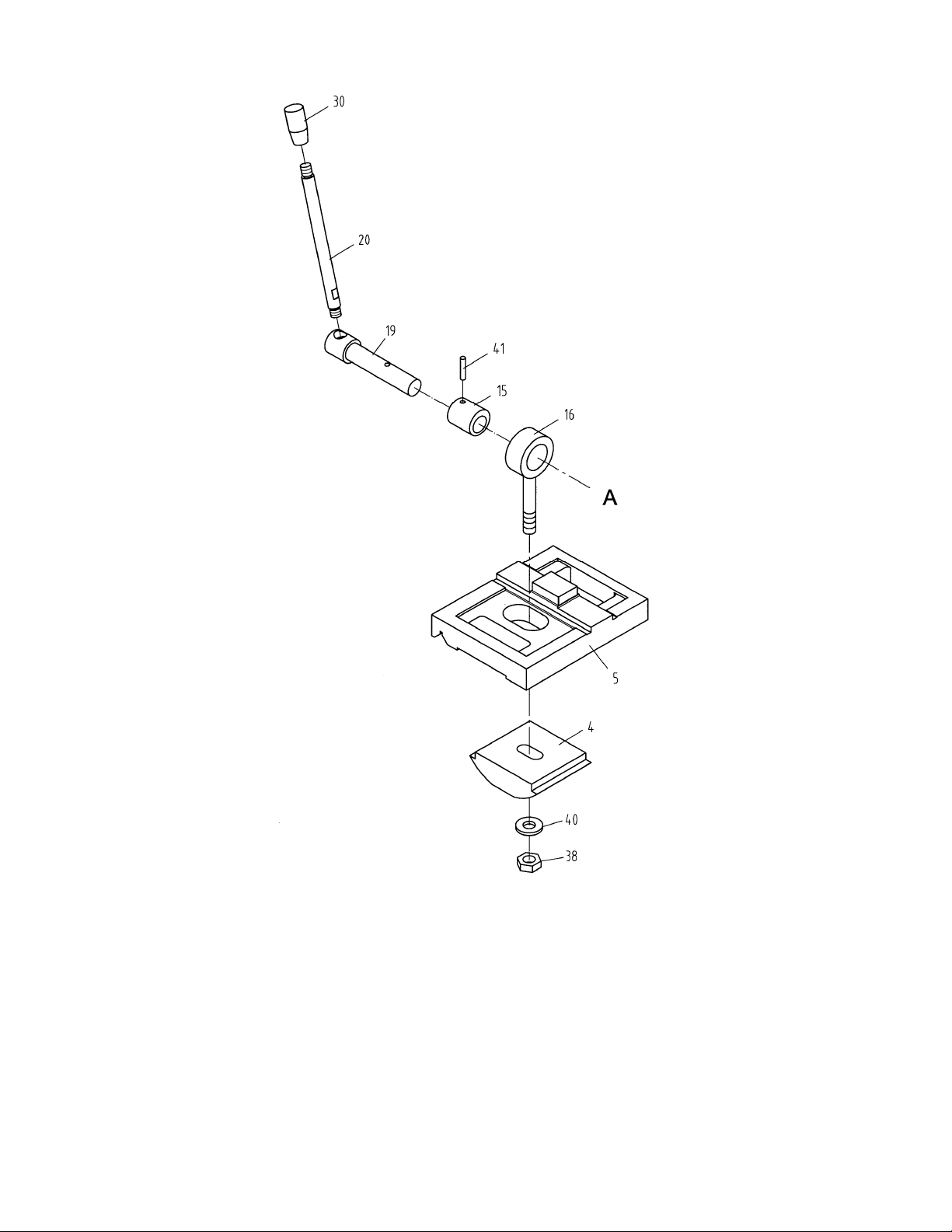

3.1 BDB-1340A Headstock Assembly III – Exploded View

8

Page 29

3.2 BDB-1340A Headstock Assembly III – Parts List

Index No Part No Description Size Qty

8 ................ TS-1524021 .............. Set Screw ................................................................ M8 x 10 ......................... 1

15-1 ........... TS-1540061 .............. Nut ........................................................................... M8 ................................. 1

44 .............. 04704 ........................ Eccentric Shaft......................................................... ...................................... 1

45 .............. 04103A ...................... Bushing .................................................................... ...................................... 1

46 .............. 04109A ...................... Gear ......................................................................... 2m52T, 2m22T.............. 1

47 .............. TS-1523011 .............. Set Screw ................................................................ M6 x 6 . .......................... 1

48 .............. 04111A ...................... Bushing .................................................................... ...................................... 1

49 .............. 04110 ........................ Moving Arm.............................................................. ...................................... 1

50 .............. TS-1504071 .............. Hex Socket Cap Screw ............................................ M8 x 35 ......................... 1

51 .............. 04726 ........................ Sleeve ...................................................................... ...................................... 1

52 .............. BDB1340-H52 ........... Spring ...................................................................... 1 x 9 x 40 ...................... 1

53 .............. 04725 ........................ Shaft ........................................................................ ...................................... 1

54 .............. BDB1340-H54 ........... Cap Nut.................................................................... M6 ................................. 1

55 .............. 04733B ...................... Knob ........................................................................ ...................................... 1

56 .............. 04706 ........................ Shaft ........................................................................ ...................................... 1

57 .............. 04707 ........................ Handl e ..................................................................... ...................................... 1

58 .............. BDB1340-H58 ........... Knob ........................................................................ ...................................... 1

59 .............. 04104A ...................... Cam ......................................................................... ...................................... 1

60 .............. BDB1340-H60 ........... Spring Pin ................................................................ 5 x 30 ............................ 1

61 .............. 04712 ........................ Inpu t Shaft ............................................................... ...................................... 1

62 .............. BDB1340-H62 ........... Key........................................................................... 6 x 6 x 40 ...................... 1

63 .............. BDB1340-H63 ........... Key........................................................................... 5 x 5 x 25 ...................... 1

64 .............. TS-1550081 .............. Washer .................................................................... M12 ............................... 1

65 .............. TS-1540081 .............. Hex Nut .................................................................... M12 ............................... 2

66 .............. 04708 ........................ Cam ......................................................................... ...................................... 1

68 .............. 04709 ........................ Strut ......................................................................... ...................................... 1

69 .............. 04105A ...................... Swing Arm ............................................................... ...................................... 1

70 .............. TS-1482021 .............. Hex Socket Cap Screw ............................................ M6 x 12 ......................... 3

71 .............. BB-6204ZR ............... Ball Bearing ............................................................. 6204ZR ......................... 1

72 .............. 04107 ........................ Pulley ....................................................................... ...................................... 1

73 .............. TS-1524021 .............. Set Screw ................................................................ M8 x 8 ........................... 2

75 .............. 04106A ...................... Swing Arm ............................................................... ...................................... 1

76 .............. TS-1503051 .............. Hex Socket Cap Screw ............................................ M6 x 20 ......................... 2

77 .............. BB-6204 .................... Ball Bearing ............................................................. 6204 .............................. 1

78 .............. BDB1340A-04108 ..... Pulley ....................................................................... ...................................... 1

80 .............. 04711 ........................ Shaft ........................................................................ ...................................... 1

82 .............. 04710 ........................ Spacer ..................................................................... ...................................... 1

126 ............ TS-1523011 .............. Set Screw ................................................................ M6 x 6 ........................... 1

131 ............ TS-1490041 .............. Hex Cap Bolt............................................................ M8 x 25 ......................... 1

132 ............ TS-1504041 .............. Hex Socket Cap Screw ............................................ M8 x 20 ......................... 1

.................. BDB1340A-02311 ..... Nameplate (not shown)............................................ ...................................... 1

.................. BDB1340A-02304A ... Nameplate (not shown)............................................ ...................................... 1

.................. 04308 ........................ Nameplate (not shown)............................................ ...................................... 1

.................. VB-B32 ...................... V-Belt (not shown) ................................................... B32................................ 1

.................. VB-B33 ...................... V-Belt (not shown) ................................................... B33................................ 1

9

Page 30

4.1 GHB-1340A/1440A Headstock Assembly I – Exploded View

10

Page 31

4.2 GHB-1340A/1440A Headstock Assembly I – Parts List

Index No Part No Description Size Qty

7 ................ GHB1340A-02101 ..... Gear Box Main Casting (GHB-1340A only) ............. ...................................... 1

.................. GHB1440A-02101 ..... Gear Box Main Casting (GHB-1440A only) ............. ...................................... 1

9 ................ 04109 ........................ Shift Lever................................................................ ...................................... 1

10 .............. 04111 ........................ Shaft Housing .......................................................... ...................................... 1

11 .............. GHB1340A-02102 ..... Cover (GHB-1340A only) ......................................... ...................................... 1

.................. GHB1440A-02102 ..... Cover (GHB-1440A only) ......................................... ...................................... 1

12 .............. GHB1340A-04117 ..... Handle Hub .............................................................. ...................................... 1

13 .............. 04121 ........................ Shaft Collar (GHB-1340A only)................................ ...................................... 1

.................. GHB1440A-02112 ..... Shaft Collar (GHB-1440A only)................................ ...................................... 1

14 .............. GHB1340A-04120 ..... Handle Hub .............................................................. ...................................... 1

15 .............. GHB1340A-04119 ..... Handle Block............................................................ ...................................... 1

16 .............. GHB1340A-04118 ..... Hub .......................................................................... ...................................... 1