Page 1

GB - ENGLISH

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new JET-machine. This manual has been

prepared for the owner and operators of a JET AP-0, AP-1, AP-2 AP-3, AP-5 arbor press to promote safety during

installation, operation and maintenance procedures. Read this manual thoroughly and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. Warranty

3. Safety

Authorized use

Safety notes

4. Machine specifications

Technical data

Machine description

5. Transport and Installation

Transport

Installation

Initial Lubrication

6. Machine operation

7. Adjustments

8. Maintenance

9. Environmental protection

1. Declaration of conformity

On our own responsibility we

hereby declare that this product

complies with the regulations*

listed on page 2. Designed in

consideration with the standards**.

2. Warranty

The Seller guarantees that the

supplied product is free from

material defects and

manufacturing faults. This

warranty does not cover any

defects which are caused, either

directly or indirectly, by incorrect

use, carelessness, accidental

damage, repair, inadequate

maintenance or cleaning and

normal wear and tear. Guarantee

and/or warranty claims must be

made within twelve months from

the date of purchase (date of

invoice). Any further claims shall

be excluded. This warranty

includes all guarantee obligations

of the Seller and replaces all

previous declarations and

agreements concerning warranties.

The warranty period is valid for

eight hours of daily use. If this is

exceeded, the warranty period

shall be reduced in proportion to

the excess use, but to no less than

three months.

Returning rejected goods requires

the prior express consent of the

Seller and is at the Buyer’s risk

and expense.

Further warranty details can be

found in the General Terms and

Conditions (GTC). The GTC can

be viewed at www.jettools.com or

can be sent by post upon request.

The Seller reserves the right to

make changes to the product and

accessories at any time.

3. Safety

3.1 Authorized use

The arbor press is designed for

pressing, broaching, bending and

straightening purposes only.

The proper use also includes

compliance with the operating and

maintenance instructions given in

this manual.

For machining, the workpiece must

allow to safely be loaded and

supported.

The machine must be operated

only by persons familiar with its

operation and maintenance and

who are familiar with its hazards.

The required minimum age must

be observed.

The machine must only be used in

a technically perfect condition.

When working on the machine, all

safety mechanisms and covers

must be mounted.

Any other use exceeds

authorization.

In the event of unauthorized use of

the machine, the manufacturer

renounces all liability and the

responsibility is transferred

exclusively to the operator.

3.2 Safety notes

Metal forming machines can be

dangerous if not used properly.

Read and understand the entire

instruction manual before

attempting assembly or operation.

Keep this operating instruction

close by the machine, protected

from dirt and humidity, and pass it

over to the new owner if you part

with the tool.

Install the machine so that there is

sufficient space for safe operation

and work piece handling.

Keep work area well lighted.

3

Page 2

The arbor press is designed to

operate in closed rooms, and must

be bolted to a solid work bench or

table securely attached to the floor.

Keep the floor around the machine

clean and free of scrap material,

oil and grease.

Remove all loose clothing and

confine long hair.

Before operating the machine,

remove tie, rings, watches and

other jewellery.

Wear safety shoes; never wear

leisure shoes or sandals.

Sheet metal stock has sharp

edges.

WEAR GLOVES when handling

sharp edged work pieces.

WEAR SAFETY GLASSES.

KEEP HANDS AND FINGERS

clear of the pressing area in front

and rear of the ram.

Stay alert!

Give your work undivided

attention. Use common sense. Do

not operate the machine when you

are tired.

Keep an ergonomic body position.

Maintain a balanced stance at all

times.

Do not operate the machine under

the influence of drugs, alcohol or

any medication. Be aware that

medication can change your

behaviour.

Keep children and visitors a safe

distance from the work area.

Keep guards in place and in

working order.

Specifications regarding the

maximum pressing force must be

observed.

Do not overload the press by using

handle extensions (cheater bars)

Work must be mounted on the

press securely. Do not use the

press with work mounted at an

angle.

The press is designed for pressing,

broaching, bending and

straightening purposes only.

Always make sure the ram

contacts the workpiece squarely

before applying pressure.

Some parts may have a tendency

to pop out of the press or explode

under pressure. Protect yourselves

accordingly.

Support long work pieces with

helping roller stands.

Do not stand on the machine.

4. Machine specifications

4.1 Technical Data

AP-0:

Throat 85mm

Working height above table 100mm

Tons pressure 0,5t

Ram Bore Ø9,5mm

Basic size (LxWxH) 240x100x250mm

Weight 8,5kg

AP-1:

Throat 102mm

Working height above table 125mm

Tons pressure 1t

Ram Bore Ø9,5mm

Basic size (LxWxH) 275x125x305mm

Weight 10,5kg

AP-2:

Throat 145mm

Working height above table 145mm

Tons pressure 2t

Ram Bore Ø12,7mm

Basic size (LxWxH) 430x160x410mm

Weight 28kg

AP-3:

Throat 137mm

Working height above table 290mm

Tons pressure 3t

Ram Bore Ø12,7mm

Basic size (LxWxH) 460x215x550mm

Weight 45kg

AP-5:

Throat 216mm

Working height above table 460mm

Tons pressure 5t

Ram Bore Ø12,7mm

Basic size (LxWxH) 660x250x860mm

Weight 140kg

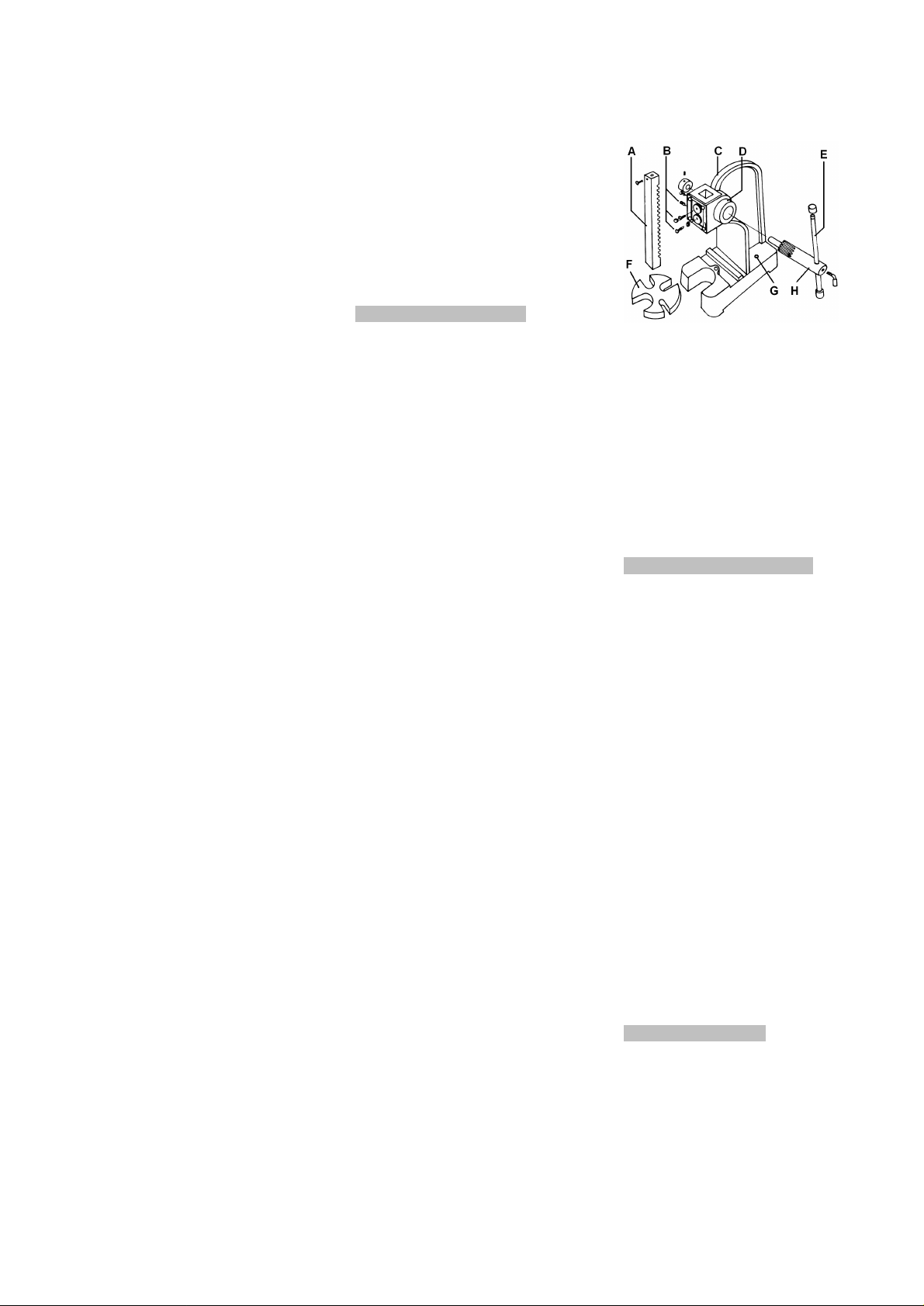

4.2 Machine Description

Fig 1

A…Ram

B….Ram guide adjust bolts

C….Arbour press body

D…Pinion oil hole

E…Press handle

F….Support plate

G….Bolt down holes

H….Pinion

5. Transport and installation

5.1 Transport

For transport use a forklift or hand

trolley. Make sure the machine

does not tip or fall off during

transport.

If you notice transport damage

while unpacking, notify your

supplier immediately. Do not

operate the machine!

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces

with petroleum, diesel oil or a mild

solvent.

Coat all machined surfaces with a

light coat of oil to inhibit rust.

5.2 Installation

The arbor press is designed to

operate in closed rooms, and must

be bolted to a solid work bench or

table securely attached to the floor.

5.3 Initial Lubrication

See chapter 8 for lubrication.

6. Machine operation

Specifications regarding the

maximum pressing force must be

observed.

Do not overload the press by using

handle extensions (cheater bars)

4

Page 3

Work must be mounted on the

press securely. Do not use the

press with work mounted at an

angle.

The press is designed for pressing,

broaching, bending and

straightening purposes only.

Always make sure the ram

contacts the workpiece squarely

before applying pressure.

Some parts may have a tendency

to pop out of the press or explode

under pressure. Protect yourselves

accordingly.

KEEP HANDS AND FINGERS

clear of the pressing area in front

and rear of the ram.

WEAR SAFETY GLASSES.

Support long work pieces with

helping roller stands.

Sheet metal stock has sharp

edges.

WEAR GLOVES when handling

sharp edged work pieces.

7. Adjustments

If ram is loose and falls by itselves,

snug bolts (B). All four bolts should

be tensioned equally.

8. Maintenance

Lubrication:

The machine must be lubricated

every day of service.

Oil the pinion through the oil port

(D).

Grease ram rack (A).

Lubricate all slide and pivot points

of the machine.

Lightly oil the machined parts

when not in use to prevent rust.

9. Environmental protection

Protect the environment.

Your appliance contains valuable

materials which can be recovered

or recycled. Please leave it at a

specialized institution.

5

Page 4

DE - DEUTSCH

Gebrauchsanleitung

Sehr geehrter Kunde,

vielen Dank für das Vertrauen, welches Sie uns beim Kauf Ihrer neuen JET-Maschine entgegengebracht haben. Diese Anleitung

ist für den Inhaber und die Bediener zum Zweck einer sicheren Inbetriebnahme, Bedienung und Wartung der Drehdornpresse JET

AP-0 / AP-1 / AP-2 / AP-3 / AP-5 erstellt worden. Lesen Sie diese Anleitung vollständig, insbesondere die Sicherheitshinweise,

bevor Sie die Maschine zusammenbauen, in Betrieb nehmen oder warten.

Inhaltsverzeichnis

1. Konformitätserklärung

2. Garantieleistungen

3. Sicherheit

Bestimmungsgemäße

Verwendung

Sicherheitshinweise

4. Maschinenspezifikation

Technische Daten

Beschreibung der Maschine

5. Transport und

Inbetriebnahme

Transport

Montage

Erstschmierung

6. Betrieb der Maschine

7. Rüst- und Einstellarbeiten

8. Wartung und Inspektion

9. Umweltschutz

1. Konformitätserklärung

Wir erklären in alleiniger

Verantwortlichkeit, dass dieses

Produkt mit den auf Seite 2

angegebenen Richtlinien*

übereinstimmt. Bei der Konstruktion

wurden folgende Normen**

berücksichtigt.

2. Garantieleistungen

Der Verkäufer garantiert, dass das

gelieferte Produkt frei von Materialund Fertigungsfehlern ist. Diese

Garantie trifft nicht auf jene Defekte

zu, welche auf direkten oder

indirekten, nicht fachgerechten

Gebrauch, Unachtsamkeit,

Unfallschaden, Reparatur,

mangelhafte Wartung bzw.

Reinigung sowie normalen

Verschleiß zurückzuführen sind.

Garantie- bzw. Gewährleistungsansprüche müssen innerhalb von 12

Monaten ab dem Verkaufsdatum

(Rechnungsdatum) geltend gemacht

werden. Weitergehende Ansprüche

sind ausgeschlossen.

Die vorliegende Garantie umfasst

sämtliche Garantieverpflichtungen

seitens des Verkäufers und ersetzt

alle früheren Erklärungen und

Vereinbarungen betreffend

Garantien.

Die Garantiefrist gilt für eine tägliche

Betriebszeit von 8 Stunden. Wird

diese überschritten, so verkürzt sich

die Garantiefrist proportional zur

Überschreitung, jedoch höchstens

auf 3 Monate.

Die Rücksendung beanstandeter

Ware bedarf der ausdrücklichen

vorherigen Zustimmung vom

Verkäufer und geht auf Kosten und

Gefahr des Käufers.

Die ausführlichen Garantieleistungen

sind den Allgemeinen

Geschäftsbedingungen (AGB) zu

entnehmen. Die AGB sind unter

www.jettools.com einzusehen oder

werden auf Anfrage per Post

zugestellt.

Der Verkäufer behält sich das Recht

vor, jederzeit Änderungen am

Produkt und Zubehör vorzunehmen.

3. Sicherheit

3.1 Bestimmungsgemäße

Verwendung

Die Drehdornpresse ist geeignet zum

Pressen, Räumen, Biegen und

Richten.

Die bestimmungsgemäße

Verwendung beinhaltet auch die

Einhaltung der vom Hersteller

angegebenen Betriebs- und

Wartungsanweisungen.

Es dürfen nur Werkstücke bearbeitet

werden welche sicher aufgelegt und

festgehalten werden können.

Die Presse darf ausschließlich von

Personen bedient werden, die mit

Betrieb und Wartung vertraut und

über die Gefahren unterrichtet sind.

Das gesetzliche Mindestalter ist

einzuhalten.

Die Presse darf nur in technisch

einwandfreiem Zustand betrieben

werden.

Jeder darüber hinaus gehende

Gebrauch gilt als nicht

bestimmungsgemäß und für daraus

resultierende Schäden haftet der

Hersteller nicht. Das Risiko trägt

allein der Benutzer.

3.2 Sicherheitshinweise

Metallbearbeitungsmaschinen

können bei unsachgemäßem

Gebrauch gefährlich sein.

Lesen und verstehen Sie die

komplette Gebrauchsanleitung bevor

Sie mit Montage oder Betrieb der

Maschine beginnen.

6

Page 5

Bewahren Sie die

Bedienungsanleitung, geschützt vor

Schmutz und Feuchtigkeit, bei der

Maschine auf, und geben Sie sie an

einen neuen Eigentümer weiter.

Die Maschine so aufstellen, dass

genügend Platz zum Bedienen und

zum Führen der Werkstücke

gegeben ist.

Sorgen Sie für gute Beleuchtung.

Die Aufstellung der Presse sollte in

geschlossenen Räumen erfolgen.

Die Presse muss auf einem

belastbaren Untersatz oder auf einer

belastbaren Werkbank kippsicher

festgeschraubt werden.

Den Arbeitsplatz frei von

behindernden Werkstücken, etc.

halten.

Enganliegende Kleidung tragen,

Schmuck, Ringe und Armbanduhren

ablegen.

Tragen Sie Schutzschuhe, keinesfalls

Freizeitschuhe oder Sandalen.

Blechplatten haben scharfe Kanten:

Beim Handhaben Handschuhe

benutzen.

BEIM ARBEITEN IMMER

SCHUTZBRILLE TRAGEN.

Halten Sie mit Ihren Fingern und

Händen immer ausreichend

Abstand zum Pressbereich.

Seien Sie aufmerksam und

konzentriert. Gehen Sie mit Vernunft

an die Arbeit.

Achten Sie auf ergonomische

Körperhaltung.

Sorgen Sie für sicheren Stand und

halten Sie jederzeit das

Gleichgewicht.

Arbeiten Sie niemals unter dem

Einfluss von Rauschmitteln wie

Alkohol und Drogen an der

Maschine. Beachten Sie, dass auch

Medikamente Einfluss auf Ihr

Verhalten nehmen können.

Halten Sie Unbeteiligte,

insbesondere Kinder vom

Gefahrenbereich fern.

Angaben zur maximalen Presskraft

müssen eingehalten warden.

Überlasten Sie die Presse nicht

durch die Benutzung von

Hebelverlängerungen.

Teile und Vorrichtungen müssen

flach aufliegen und sicher montiert

sein.

Achten Sie auf rechtwinkelingen

Presskontakt, vermeiden Sie schräge

Dornbelastungen.

Es gibt Teile welche unter Druck

herausspringen oder explodieren

können; schützen Sie sich

entsprechend.

Lange Werkstücke durch Rollböcke

abstützen.

Nicht auf der Maschine stehen.

4. Maschinenspezifikation

4.1 Technische Daten

AP-0:

Ausladung 85mm

Max. Arbeitshöhe über Tisch 100mm

Presskraft 0,5t

Dorn-Aufnahmebohrung Ø9,5mm

Gesamtabmessung (LxBxH)

240x100x250mm

Gewicht 8,5kg

AP-1:

Ausladung 102mm

Max. Arbeitshöhe über Tisch 125mm

Presskraft 1t

Dorn-Aufnahmebohrung Ø9,5mm

Gesamtabmessung (LxBxH)

275x125x305mm

Gewicht 10,5kg

AP-2:

Ausladung 145mm

Max. Arbeitshöhe über Tisch 145mm

Presskraft 2t

Dorn-Aufnahmebohrung Ø12,7mm

Gesamtabmessung (LxBxH)

430x160x410mm

Gewicht 28kg

AP-3:

Ausladung 137mm

Max. Arbeitshöhe über Tisch 290mm

Presskraft 3t

Press-Aufnahmebohrung Ø12,7mm

Gesamtabmessung (LxBxH)

460x215x550mm

Gewicht 45kg

AP-5:

Ausladung 216mm

Max. Arbeitshöhe über Tisch 460mm

Presskraft 5t

Dorn-Aufnahmebohrung Ø12,7mm

Gesamtabmessung (LxBxH)

660x250x860mm

Gewicht 140kg

4.2 Beschreibung der Maschine

Fig 1

A…Pressdorn

B….Dornführung-Stellschrauben

C….Grundkörper

D…Ritzel Schmierstellen

E…Presshebel

F….Stützplatte

G….Befestigungsbohrungen

H….Ritzel

5. Transport und Inbetriebnahme

5.1. Transport

Zum Transport verwenden Sie einen

handelsüblichen Stapler oder

Hubwagen. Sichern Sie die Maschine

beim Transport gegen Umfallen.

Wenn Sie beim Auspacken einen

Transportschaden feststellen,

benachrichtigen Sie umgehend Ihren

Händler, nehmen Sie das Gerät nicht

in Betrieb.

Entsorgen Sie die Verpackung bitte

umweltgerecht.

Entfernen Sie das Rostschutzfett mit

einem milden Lösungsmittel.

Schützen Sie alle blanken

Oberflächen mit einem leichten

Ölfilm gegen Rost.

5.2 Aufstellung

Die Aufstellung der Presse sollte in

geschlossenen Räumen erfolgen.

Die Presse muss auf einem

belastbaren Untersatz oder auf einer

belastbaren Werkbank kippsicher

festgeschraubt werden.

7

Page 6

5.3 Erstschmierung

Siehe Schmierung, Kapitel 8.

6. Betrieb der Maschine

Angaben über die maximale

Presskraft müssen eingehalten

warden.

Überlasten Sie die Presse nicht

durch die Benutzung von

Hebelverlängerungen (Bruchgefahr).

Pressteile und Vorrichtungen

müssen flach aufliegen und sicher

montiert sein.

Achten Sie auf rechtwinkelingen

Presskontakt, vermeiden Sie schräge

Dornbelastungen.

Es gibt Teile welche unter Druck

herausspringen oder explodieren

können; schützen Sie sich

entsprechend.

Halten Sie mit Ihren Fingern und

Händen immer ausreichend

Abstand zum Pressbereich.

BEIM ARBEITEN IMMER

SCHUTZBRILLE TRAGEN.

Blechplatten haben scharfe Kanten:

Bei der Handhabung Handschuhe

benutzen.

7. Rüst- und Einstellarbeiten

Falls der Dorn wackelt und selbst

nach unten fällt stellen Sie die

Führung an den Schrauben (B)

gleichmässig nach.

8. Wartung und Inspektion

Schmierung:

Schmieren Sie die Maschine täglich

bei Gebrauch.

Ölen Sie die Ritzelachse an den

Schmierstellen (D).

Fetten Sie die Zahnstange und die

Führungsflächen des Dorns (A).

Schützen Sie alle blanken

Oberflächen mit einem leichten

Ölfilm gegen Rost.

9. Umweltschutz

Schützen Sie die Umwelt!

Ihr Gerät enthält mehrere

unterschiedliche , wiederverwertbare

Werkstoffe.

Bitte entsorgen Sie es nur an einer

spezialisierten Entsorgungsstelle.

8

Page 7

FR - FRANCAIS

Mode d‘emploi

Cher client,

Nous vous remercions de la confiance que vous nous portez avec l’achat de votre nouvelle machine JET. Ce manuel a été

préparé pour l’opérateur de la Presse à mandrin de tournage JET AP-0 / AP-1 / AP-2 / AP-3 / AP-5. Son but, mis à part le

fonctionnement de la machine, est de contribuer à la sécurité par l’application des procédés corrects d’utilisation et de

maintenance. Avant de mettre l’appareil en marche, lire les consignes de sécurité et de maintenance dans leur intégralité.

Table des Matières

1. Déclaration de conformité

2. Prestations de garantie

3. Sécurité

Utilisation conforme

Consignes de sécurité

4. Spécifications

Indications techniques

Description de la machine

5. Transport et montage

Transport

Montage

Premier graissage

6. Fonctionnement de la

machine

7. Réglages

8. Entretien et inspection

9. Protection de

l'environnement

1. Déclaration de conformité

Par le présent et sous notre

responsabilité exclusive, nous

déclarons que ce produit satisfait aux

normes conformément aux lignes

directrices indiquées page 2.

Lors de la construction, les

normes**suivantes ont été respectées.

2. Prestations de garantie

Le vendeur garantit que le produit livré

est exempt de défauts de matériel et

de fabrication. La présente garantie ne

s’applique pas aux défauts résultant

d’une utilisation directe ou indirecte

incorrecte, de l’inattention, d’un

accident, d’une réparation, d’une

maintenance ou d’un nettoyage

insuffisant, ou encore de l’usure

normale.

Il est possible de faire valoir des

prétentions en garantie dans les 12

mois suivant la date de la vente (date

de la facture). Toute autre prétention

est exclue.

La présente garantie comprend toutes

les obligations de garantie incombant

au vendeur et remplace toutes les

déclarations et conventions

antérieures en termes de garanties.

Le délai de garantie s’applique pour

une durée d’exploitation de huit

heures par jour. Au-delà, le délai de

garantie diminue proportionnellement

au dépassement, mais pas en deçà

de trois mois.

Le renvoi d’une marchandise faisant

l’objet d’une réclamation requiert

l’accord préalable exprès du vendeur

et s’effectue aux frais et aux risques

de l’acheteur.

Les prestations de garantie détaillées

figurent dans les Conditions générales

(CG). Ces dernières sont disponibles

sur www.jettools.com ou peuvent être

envoyées par la poste sur demande.

Le vendeur se réserve le droit de

modifier à tout moment le produit et

les accessoires.

3. Sécurité

3.1 Utilisation conforme

Cette presse à mandrin de tournage

est conçue pour presser, poinçonner,

courber et aplanir.

L’utilisation conforme implique le strict

respect des instructions de service et

de maintenance indiquées dans ce

manuel.

La pièce doit se laisser poser et fixer

sans problème.

La presse doit être exclusivement

utilisée par des personnes

familiarisées avec le fonctionnement,

la maintenance et la remise en état, et

qui sont informées des dangers

correspondants.

L’âge minimum requis par la loi est à

respecter.

La presse ne doit être utilisée que si

elle est en parfait état.

Toute utilisation sortant de ce cadre

est considérée comme non-conforme

et le fabricant décline toute

responsabilité, qui est dans ce cas

rejetée exclusivement sur l’utilisateur.

3.2 Consignes de sécurité

L’utilisation non-conforme d‘une

machine pour le travail des métaux

peut être très dangereuse.

C’est pourquoi vous devez respecter

scrupuleusement les consignes de

lutte contre les accidents et les

instructions suivantes.

Lire attentivement et comprendre ce

mode d’emploi avant de monter ou

d’utiliser votre appareil.

Conserver à proximité de la machine

tous les documents fournis avec

l’outillage (dans une pochette en

plastique, à l’abri de la poussière, de

l’huile et de l’humidité) et veiller à

joindre cette documentation si vous

cédez l‘appareil.

Placer la machine de sorte à laisser

un espace suffisant pour la manœuvre

et le guidage des pièces à usiner.

Veiller à un éclairage suffisant.

La presse doit être installée dans un

local fermé.

Elle doit être visée sur un socle ou sur

un établi solide ne pouvant se

renverser.

Conserver le sol autour de la machine

propre, sans déchets, huile ou

graisse.

9

Page 8

Avant de mettre la machine en

marche, retirer cravate, bagues,

montre ou autres bijoux et retrousser

les manches jusqu’aux coudes.

Enlever tous vêtements flottants et

nouer les cheveux longs.

Porter des chaussures de sécurité,

surtout pas de tenue de loisirs ou de

sandales.

Les tôles ont des arrêtes coupantes,

pour les manipuler, porter des gants.

Porter des lunettes de protection

pendant le travail.

Toujours tenir les mains et les

doigts à une distance suffisante de

la zone de presse.

Rester vigilant et concentré et

travailler avec bon sens.

Eviter toute position corporelle

anormale.

Veiller à une position stable et garder

un bon équilibre à tout moment.

Ne pas travailler sous l’influence de

drogues, d’alcool ou de médicaments.

Eloigner de la machine toutes

personnes incompétentes surtout les

enfants.

Il faut respecter les données de

pression maximale.

Ne pas faire forcer la presse en

utilisant un prolongateur de levier.

Les pièces et les appareils doivent

être posés à plat et bien assurées.

Veillez à ce que le contact de pression

soit perpendiculaire, éviter de forcer

de biais sur le mandrin.

La pression peut faire éjecter ou

éclater des pièces, il faut se protéger

en conséquence.

Poser les pièces trop longues sur un

support roulant.

Ne pas se mettre sur la machine.

4. Spécifications

4.1 Indications techniques

AP-0:

Distance broche/bâti 85mm

Hauteur max. de travail sur la table

100mm

Force de pression 0,5t

Perçage par pression Ø9,5mm

Dimensions (Lxlxh) 240x100x250mm

Poids net 8,5kg

AP-1:

Distance broche/bâti 102mm

Hauteur max. de travail sur la table

125mm

Force de pression 1t

Perçage par pression Ø9,5mm

Dimensions (Lxlxh) 275x125x305mm

Poids net 10,5kg

AP-2:

Distance broche/bâti 145mm

Hauteur max. de travail sur la table

145mm

Force de pression 2t

Perçage par pression Ø12,7mm

Dimensions (Lxlxh) 430x160x410mm

Poids net 28kg

AP-3:

Distance broche/bâti 137mm

Hauteur max. de travail sur la table

290mm

Force de pression 3t

Perçage par pression Ø12,7mm

Dimensions (Lxlxh) 460x215x550mm

Poids net 45kg

AP-5:

Distance broche/bâti 216mm

Hauteur max. de travail sur la table

460mm

Force de pression 5t

Perçage par pression Ø12,7mm

Dimensions (Lxlxh) 660x250x860mm

Poids net 140kg

4.2 Description de la machine

Fig 1

A…Mandrin de pression

B….Vis de réglage de la coulisse du

mandrin

C….Corps de base

D…Graisseurs du pignon

E…Levier de presse

F….Plaque d’appui

G….Perforations de fixation

H….Pignon

10

5. Transport et mise en

exploitation

5.1. Transport

Pour le transport, utiliser un élévateur

courant ou un chariot à fourche.

Assurer la machine pour qu’elle ne

tombe pas pendant le transport.

Si vous constatez des dégâts de

transport lors du déballage, avertissez

immédiatement votre fournisseur et

ne montez pas la machine.

Eliminer l´emballage dans le respect

de l´environnement.

Enlever la protection antirouille avec

un dissolvant doux

Protéger toutes les surfaces brillantes

contre la rouille avec une fine couche

d’huile.

5.2 Mise en place

Effectuer le montage de la presse

dans un local fermé.

Il faut pouvoir accéder à la machine

par tous les côtés.

La presse doit être visée sur un socle

ou sur un établi solide ne pouvant se

renverser

5.3 Premier graissage

Voir graissage, chapitre 8.

6. Fonctionnement de la machine

Il faut respecter les données de

pression maximale.

Ne pas faire forcer la presse en

utilisant un prolongateur de levier

(danger de casse).

Les pièces et les appareils à travailler

doivent être posés à plat et bien

assurées.

Veillez à ce que le contact de pression

soit perpendiculaire, éviter de forcer

de biais sur le mandrin.

La pression peut faire éjecter ou

éclater des pièces, il faut se protéger

en conséquence.

Les tôles ont des arrêtes coupantes,

pour les manipuler, porter des gants.

Porter des lunettes de protection

pendant le travail.

Toujours tenir les mains et les

doigts à une distance suffisante de

la zone de presse.

Page 9

7. Réglages

Si le mandrin a du jeu et tombe, régler

la coulisse en manipulant

uniformément les vis (B).

8. Entretien et inspection

Graissage

Lors de l’usage, graisser la machine

quotidiennement.

Huiler les graisseurs de l’axe du

pignon (D).

Graisser la tige dentée et les surfaces

de la coulisse du mandrin (A).

Protéger toutes les surfaces brillantes

contre la rouille avec une fine couche

d’huile.

9. Protection de l'environnement

Protégez l'environnement !

Votre appareil comprend plusieurs

matières premières différentes et

recyclables. Pour éliminer l'appareil

usagé, veuillez l'apporter dans un

centre spécialisé de recyclage des

appareils électriques.

11

Loading...

Loading...