Page 1

GB - ENGLISH

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new JET-product. This manual has been

prepared for the owner and operators of a JET AFS-500 air filtration system to promote safety during installation, operation and

maintenance procedures. Please read and understand the information contained in these operating instructions and the

accompanying documents. To obtain maximum life and efficiency from your air cleaner, and to use it safely, read this manual

thoroughly and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. Warranty

3. Safety

Authorized use

General safety notes

Remaining hazards

4. Machine specifications

Technical data

Noise emission

Contents of delivery

5. Assembly and start up

Assembly

Installation

Mains connection

6. Machine operation

7. Maintenance and inspection

Changing filters

8. Trouble shooting

9. Available accessories

1. Declaration of conformity

On our own responsibility we hereby

declare that this product complies with

the regulations* listed on page 2.

Designed in consideration with the

standards**.

2. Warranty

The Seller guarantees that the

supplied product is free from material

defects and manufacturing faults. This

warranty does not cover any defects

which are caused, either directly or

indirectly, by incorrect use,

carelessness, accidental damage,

repair, inadequate maintenance or

cleaning and normal wear and tear.

Guarantee and/or warranty claims

must be made within twelve months

from the date of purchase (date of

invoice). Any further claims shall be

excluded.

This warranty includes all guarantee

obligations of the Seller and replaces

all previous declarations and

agreements concerning warranties.

The warranty period is valid for eight

hours of daily use. If this is exceeded,

the warranty period shall be reduced

in proportion to the excess use, but to

no less than three months.

Returning rejected goods requires the

prior express consent of the Seller and

is at the Buyer’s risk and expense.

Further warranty details can be found

in the General Terms and Conditions

(GTC). The GTC can be viewed at

www.jettools.com or can be sent by

post upon request.

The Seller reserves the right to make

changes to the product and

accessories at any time.

3. Safety

3.1 Authorized use

This air cleaner is designed for the

filtration of air borne wood dust only.

Any other application is not permitted

and may be carried out in specific

cases only after consulting with the

manufacturer.

.

The product is not suitable for use in

wet or humid environment.

Don’t use appliance in places with a

risk of explosion.

Don’t use appliance at temperatures

below 0°C.

The proper use also includes

compliance with the operating and

maintenance instructions given in this

manual.

The air cleaner must be operated only

by persons familiar with its operation

and maintenance and who are familiar

with its hazards.

The required minimum age must be

observed.

3

The air cleaner must only be used in a

technically perfect condition.

Before connecting the air cleaner to

electric power, all safety mechanisms

and covers must be mounted.

In addition to the safety requirements

contained in these operating

instructions and your country’s

applicable regulations, you should

observe the generally recognized

technical rules concerning the dust

collection on woodworking machines.

Any other use exceeds authorization.

In the event of unauthorized use of the

product, the manufacturer renounces

all liability and the responsibility is

transferred exclusively to the operator.

3.2 General safety notes

Read and understand the entire

instruction manual before attempting

assembly or operation of the air

cleaner.

Keep this operating instruction close

by the product, protected from dirt and

humidity, and pass it over to the new

owner if you part with the tool.

No changes to the air cleaner may be

made.

Daily inspect the function and

existence of the safety appliances

before you start the air cleaner.

Do not attempt operation in this case,

protect the air cleaner by unplugging

the power cord.

Always disconnect the air cleaner

from the power source (unplug) before

servicing or changing filters.

Never reach into the machine while it

is operating or running down.

Replace contaminated filters.

Clogged filters will reduce the amount

of air circulation.

During the changing or cleaning of the

filters it’s necessary to use a mask

(mask with filtration).

Page 2

The machine is designed to operate in

closed rooms and can be placed on a

stable and levelled surface.

Make sure that the power cord does

not impede work and cause people to

trip.

Do not operate the machine under the

influence of drugs, alcohol or any

medication. Be aware that medication

can change your behaviour.

Never leave a running machine

unattended. Before you leave the

workplace switch off the unit.

Keep children and visitors a safe

distance from the work area.

Do not operate the electric tool near

inflammable liquids or gases.

Observe the fire fighting and fire alert

options, for example the fire

extinguisher operation and place.

Do not use the air cleaner in a dump

environment and do not expose it to

rain.

Never duct a machine directly into the

air cleaner.

Do not use this equipment to filter

volatile fumes or smoke.

Wood dust is explosive and can also

represent a risk to health.

Dust form some tropical woods in

particular, and from hardwoods like

beach and oak, is classified as a

carcinogenic substance.

The air filtration system will support,

but cannot subsidise the application of

a suitable dust extraction device for

your woodworking machines.

Do not stand on the air cleaner.

Connection and repair work on the

electrical installation may be carried

out by a qualified electrician only.

Have a damaged or worn power cord

replaced immediately.

3.3 Remaining hazards

When using the machine according to

regulations some remaining hazards

may still exist.

Woodworking dust can be a health

hazard. The air filtration system will

support but cannot subsidise the

application of a suitable dust

extraction device for your

woodworking machines

The use of incorrect mains supply or a

damaged power cord can lead to

injuries caused by electricity.

4. Machine specifications

4.1 Technical data

Air volume flow 6, 8, 10 m³/min

Replacement outer filter 5 micron

Replacement inner filter 1 micron

Overall (LxWxH) 400x610x310mm

Net weight 15 kg

Mains 230V ~1/N/PE 50Hz

Output power 0,12kW (0,16HP) S1

Reference current 0.3 A

Extension cord (H07RN-F): 3x1,5mm²

Installation fuse protection 10A

4.2 Noise emission

Acoustic pressure level (EN 11202):

low speed 57 dB (A)

medium speed 59 dB (A)

high speed 61 dB (A)

4.3 Content of delivery

Electrostatic outer filter( 5 Micron)

Inner filter ( 1 Micron)

8 foam pads

Operating manual

Spare parts list.

5. Assembly and start up

5.1 Assembly

If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the unit!

Remove all packing from the inside of

the unit by removing the outer filter

and the inner filters.

Dispose of the packing in an

environmentally friendly manner.

5.2 Installation

This unit will work best if it is located

away from corners, and

heating/cooling vents.

This unit is specifically designed to

circulate air and filter dust, which is

generated throughout the work area.

The air cleaner is designed to operate

in closed rooms and can be operated

horizontally and vertically.

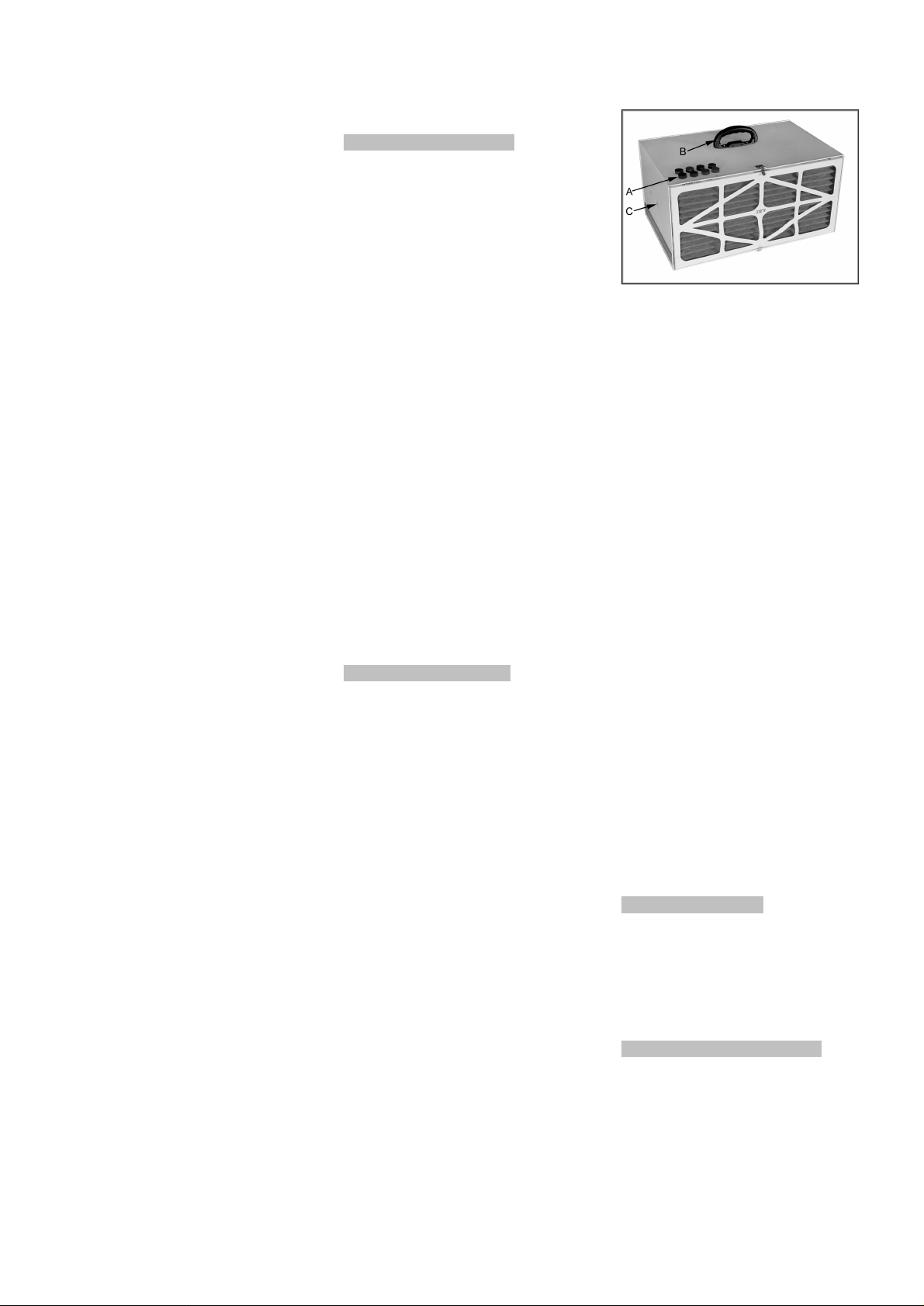

Before you set the unit on a stable and

levelled surface, stick four foam pads

(A, Fig 1) to the bottom corners of the

cabinet.

Fig 1

There are four extra pads for

mounting on the side for use in the

vertical position.

The handle (B, Fig 1) can be moved

from the top of the unit to the side (C)

if desired.

5.3 Mains connection

Mains connection and any extension

cords used must comply with

applicable regulations.

The mains voltage must comply with

the information on the machine

licence plate.

The mains connection must have a

10 A surge-proof fuse.

Only use power cords marked

H07RN-F

Connections and repairs to the

electrical equipment may only be

carried out by qualified electricians.

6. Machine operation

The buttons I, II, III on the back of the

machine control the air volume flow.

You can choose between low, medium

and high.

The button 0 turns the unti off.

7. Maintenance and inspection

General notes:

Maintenance, cleaning and repair

work may only be carried out after

the machine is protected against

accidental starting by pulling the

mains plug.

4

Page 3

Inspect the proper function of the air

filtration system daily.

Replace clogged filters.

Clean the unit regularly.

Defective safety devices must be

replaced immediately.

Repair and maintenance work on the

electrical system may only be carried

out by a qualified electrician.

7.1 Changing Filters

Disconnect the machine from the

power source.

During the changing or cleaning of

the filters it’s necessary to use a

mask (mask with filtration).

There are two filters that need to be

changed.

Fig 4

The outer filter (A, Fig 4) can easily

be removed by disengaging the two

clips (B, Fig 4).

Now you can simply pull the filter out.

The optionally availabel charcoal

outer filter can be used to reduce

certain chemical air contaminations.

The inner filter (C, Fig 4) can be

pulled out of the unit.

The inner filter can be blown out with

air (to be done outside of building

only!), or replaced.

The filters should be replaced

depending on the amount of usage

and the environment of your shop.

There is an arrow indicating the air

flow direction on the filters.

Make sure the filters are inserted

facing the proper direction.

8. Trouble shooting

Unit doesn’t start

*No electricitycheck mains.

*Defective switch, motor or cordconsult an electrician.

Air flow too weak

*Clogged outer filter-

Blow out with air or replace.

*Clogged inner filter-

Blow out with air or replace.

9. Available accessories

Stock number 708731

Electrostatic outer filter (5 Micron,

replacement filter)

Stock number 708735

Inner filter (1 Micron, replacement

filter).

Stock number 708734

Charcoal outer filter (replacement

filter, reduces certain chemical air

contaminations).

5

Page 4

DE - DEUTSCH

Gebrauchsanleitung

Sehr geehrter Kunde,

vielen Dank für das Vertrauen, welches Sie uns beim Kauf Ihres neuen JET-Produktes entgegengebracht haben. Diese

Anleitung ist für den Inhaber und die Bediener zum Zweck einer sicheren Inbetriebnahme, Bedienung und Wartung des

Luftfiltersystems AFS-500 erstellt worden. Beachten Sie bitte die Informationen dieser Gebrauchsanleitung und der beiliegenden

Dokumente. Lesen Sie diese Anleitung vollständig, insbesondere die Sicherheitshinweise, bevor Sie das Luftfiltersystem

zusammenbauen, in Betrieb nehmen oder warten. Um eine maximale Lebensdauer und Leistungsfähigkeit Ihres Gerätes zu

erreichen befolgen Sie bitte sorgfältig die Anweisungen.

Inhaltsverzeichnis

1. Konformitätserklärung

2. Garantieleistungen

3. Sicherheit

Bestimmungsgemäße Verwendung

Allgemeine Sicherheitshinweise

Restrisiken

4. Maschinenspezifikation

Technische Daten

Schallemission

Lieferumfang

5. Montage und Inbetriebnahme

Montage

Installation

Elektrischer Anschluss

6. Betrieb der Maschine

7. Wartung und Inspektion

Filterwechsel

8. Störungsabhilfe

9. Lieferbares Zubehör

1. Konformitätserklärung

Wir erklären in alleiniger

Verantwortlichkeit, dass dieses

Produkt mit den auf Seite 2

angegebenen Richtlinien*

übereinstimmt.

Bei der Konstruktion wurden folgende

Normen** berücksichtigt.

2. Garantieleistungen

Der Verkäufer garantiert, dass das

gelieferte Produkt frei von Materialund Fertigungsfehlern ist. Diese

Garantie trifft nicht auf jene Defekte

zu, welche auf direkten oder

indirekten, nicht fachgerechten

Gebrauch, Unachtsamkeit,

Unfallschaden, Reparatur,

mangelhafte Wartung bzw. Reinigung

sowie normalen Verschleiß

zurückzuführen sind.

Garantie- bzw. Gewährleistungsansprüche müssen innerhalb von 12

Monaten ab dem Verkaufsdatum

(Rechnungsdatum) geltend gemacht

werden. Weitergehende Ansprüche

sind ausgeschlossen.

Die vorliegende Garantie umfasst

sämtliche Garantieverpflichtungen

seitens des Verkäufers und ersetzt alle

früheren Erklärungen und

Vereinbarungen betreffend Garantien.

Die Garantiefrist gilt für eine tägliche

Betriebszeit von 8 Stunden. Wird

diese überschritten, so verkürzt sich

die Garantiefrist proportional zur

Überschreitung, jedoch höchstens auf

3 Monate.

Die Rücksendung beanstandeter

Ware bedarf der ausdrücklichen

vorherigen Zustimmung vom

Verkäufer und geht auf Kosten und

Gefahr des Käufers.

Die ausführlichen Garantieleistungen

sind den Allgemeinen

Geschäftsbedingungen (AGB) zu

entnehmen. Die AGB sind unter

www.jettools.com einzusehen oder

werden auf Anfrage per Post

zugestellt.

Der Verkäufer behält sich das Recht

vor, jederzeit Änderungen am Produkt

und Zubehör vorzunehmen.

3. Sicherheit

3.1 Bestimmungsgemäße

Verwendung

Das Luftfiltersytem AFS-500 ist

ausschließlich zum Filtrieren von in

der Luft befindlichem Holzstaub

geeignet.

Jegliche andere Anwendung ist nicht

zulässig bzw. darf in Sonderfällen nur

nach Rücksprache mit dem

Maschinenhersteller erfolgen.

6

Das Gerät ist nicht für den Einsatz in

feuchter oder nasser Umgebung

geeignet.

Das Gerät nicht bei Temperaturen

unter 0°C verwenden.

Das Gerät nicht in

explosionsgefährdeten Räumen

betreiben.

Die bestimmungsgemäße

Verwendung beinhaltet auch die

Einhaltung der vom Hersteller

angegebenen Betriebs- und

Wartungsanweisungen.

Das Luftfiltersystem darf

ausschließlich von Personen bedient

werden, die mit Betrieb und Wartung

vertraut und über die Gefahren

unterrichtet sind.

Das gesetzliche Mindestalter ist

einzuhalten.

Das Gerät darf nur in technisch

einwandfreiem Zustand betrieben

werden.

Vor dem Netzanschluss sind

sämtliche Sicherheitseinrichtungen

und Abdeckungen zu montieren.

Neben den in der Gebrauchsanleitung

enthaltenen Sicherheitshinweisen und

den besonderen Vorschriften Ihres

Landes sind die für den Betrieb von

Holzstaub-Absauganlagen allgemein

anerkannten fachtechnischen Regeln

zu beachten.

Jeder darüber hinaus gehende

Gebrauch gilt als nicht

bestimmungsgemäß und für daraus

resultierende Schäden haftet der

Hersteller nicht. Das Risiko trägt allein

der Benutzer.

3.2 Allgemeine Sicherheitshinweise

Lesen und verstehen Sie die

komplette Gebrauchsanleitung bevor

Sie mit Montage oder Betrieb des

Luftfiltersystems beginnen.

Page 5

Bewahren Sie die

Bedienungsanleitung, geschützt vor

Schmutz und Feuchtigkeit, in der

Nähe des Gerätes auf, und geben Sie

sie an einen neuen Eigentümer weiter.

Am Luftfiltersystem dürfen keine

Veränderungen, An- und Umbauten

vorgenommen werden.

Überprüfen Sie täglich vor dem

Einschalten des Luftfiltersystems die

einwandfreie Funktion und das

Vorhandensein der erforderlichen

Schutzeinrichtungen.

Festgestellte Mängel am Gerät oder

den Sicherheitseinrichtungen sind zu

melden und von den beauftragten

Personen zu beheben.

Nehmen Sie das Luftfiltersystem in

solchen Fällen nicht in Betrieb,

sichern Sie das Gerät gegen

Einschalten durch Ziehen des

Netzsteckers.

Vor jeder Wartung und jedem

Filterwechsel muss das

Luftfiltersystem gegen Inbetriebnahme

gesichert werden.

Den Netzstecker ziehen!

Niemals in das laufende oder gerade

auslaufende Gerät greifen.

Verstopfte Filter reduzieren den

Luftdurchsatz, wechseln Sie sie aus.

Beim Wechseln und Warten der Filter

ist eine Staubschutzmaske

(Filtermaske mit Partikelfilter) zu

tragen.

Das Gerät ist für den Einsatz in

geschlossenen Räumen vorgesehen

und kann auf eine ebene und

belastbare Fläche gestellt, oder an die

Decke oder Wand montiert werden.

Beachten Sie dass die elektrische

Zuleitung nicht den Arbeitsablauf

behindert und nicht zur Stolperstelle

wird.

Arbeiten Sie niemals unter dem

Einfluss von Rauschmitteln wie

Alkohol und Drogen an der Maschine.

Beachten Sie, dass auch

Medikamente Einfluss auf Ihr

Verhalten nehmen können.

Halten Sie Unbeteiligte, insbesondere

Kinder vom Gefahrenbereich fern.

Eine laufende Maschine nie

unbeaufsichtigt lassen.

Vor dem Verlassen des Arbeitsplatzes

die Maschine ausschalten.

Benützen Sie das Elektrogerät nicht in

der Nähe von brennbaren

Flüssigkeiten oder Gasen.

Beachten Sie die Brandmelde- und

Brandbekämpfungsmöglichkeiten z.B.

Standort und Bedienung von

Feuerlöschern.

Benützen Sie das Luftfiltersystem

nicht in feuchter Umgebung und

setzen Sie es nicht dem Regen aus.

Niemals von einer Maschine direkt in

das Luftfiltersystem absaugen.

Verwenden Sie das Luftfiltersystem

nicht zum Filtrieren von Dämpfen oder

von Rauch.

Holzstaub ist explosiv und kann

gesundheitsschädigend sein.

Insbesondere tropische Hölzer und

harte Hölzer wie Buche und Eiche sind

als krebserregend eingestuft.

Das Luftfiltersystem kann den Einsatz

einer geeigneten Absauganlage für

Ihre Holzbearbeitungsmaschine

unterstützen aber niemals ersetzen.

Nicht auf dem Luftfiltersystem stehen

oder sich daran hängen.

Arbeiten an der elektrischen

Ausrüstung der Maschine dürfen nur

durch eine Elektrofachkraft

vorgenommen werden.

Tauschen Sie ein beschädigtes

Netzkabel sofort aus.

3.3 Restrisiken

Auch bei vorschriftsmäßiger

Benutzung der Maschine bestehen die

nachfolgend aufgeführten Restrisiken.

Gefährdung durch Staub.

Das Luftfiltersystem kann den Einsatz

einer geeigneten Absauganlage für

Ihre Holzbearbeitungsmaschine

unterstützen aber niemals ersetzen.

Gefährdung durch Strom, bei nicht

ordnungsgemäßer Verkabelung.

4. Maschinenspezifikation

4.1 Technische Daten

Volumenstrom 6, 8, 10 m³/min

Äußerer Wechselfilter 5 Mikron

Innerer waschbarer Filter 1 Mikron

Maschinenabmessungen

(LxBxH) 400x610x305mm

Maschinengewicht 15 kg

Netzanschluss 230V ~1/N/PE 50Hz

Abgabeleistung 0,12 kW ( 0,16PS) S1

Betriebsstrom 0.3 A

Anschlussleitung (H07RN-F)3x1,5mm²

Bauseitige Absicherung 10A

4.2 Schallemission

Schalldruckpegel( nach EN 11202):

Stufe Langsam 57 dB(A)

Stufe Mittel 59 dB(A)

Stufe Schnell 61 dB(A)

4.3 Lieferumfang

Elektrostatischer Außenfilter(5 Micron)

Innenfilter (1 Micron)

8 Schaumgummiauflagen

Gebrauchsanleitung

Ersatzteilliste

5. Montage und Inbetriebnahme

5.1 Montage

Wenn Sie beim Auspacken einen

Transportschaden feststellen,

benachrichtigen Sie umgehend Ihren

Händler, nehmen Sie das Gerät nicht

in Betrieb.

Entfernen Sie den äußeren und den

inneren Filter.

Entfernen Sie sämtliches

Verpackungsmaterial aus dem

Inneren des Gerätes.

Entsorgen Sie die Verpackung bitte

umweltgerecht.

5.2 Installation

Für eine optimale Funktion sollte das

Luftfiltersystem nicht in Raumecken

oder in der Nähe von Heiz/Kühllüftern

installiert bzw. aufgestellt werden.

Das Gerät ist darauf ausgelegt Luft

umzuwälzen und Staub

herauszufiltern welcher im gesamten

Werkstattbereich entsteht.

Das Luftfiltersystem ist für den Einsatz

in geschlossenen Räumen gebaut und

kann sowohl horizontal als auch

vertikal betrieben werden.

7

Page 6

Fig 1

Bevor Sie das Gerät auf einer ebenen

und belastbaren Fläche aufstellen

kleben Sie die gelieferten

Schaumgummiauflagen (A, Fig1)

unter die vier Gehäuseecken.

Der Tragegriff (B, Fig1) kann bei

Bedarf auf die Seitenfläche (C )

montiert werden.

5.3 Elektrischer Anschluss

Der kundenseitige Netzanschluss

sowie die verwendeten

Verlängerungsleitungen müssen den

Vorschriften entsprechen. Die

Netzspannung und Frequenz müssen

mit den Leistungsschilddaten an der

Maschine übereinstimmen.

Die bauliche Absicherung muss dabei

10A betragen.

Verwenden Sie nur

Anschlussleitungen mit

Kennzeichnung H07RN-F

Anschlüsse und Reparaturen der

elektrischen Ausrüstung dürfen nur

von einer Elektrofachkraft

durchgeführt werden.

6. Betrieb der Maschine

Die Tasten I, II, III auf der Rückseite

des Gerätes steuern den

Volumenstrom. Sie können zwischen

langsam, mittel und schnell wählen.

Die Taste 0 stoppt das Gerät

7. Wartung und Inspektion

Allgemeine Hinweise:

Vor Wartungs- Reinigungs- und

Reparaturarbeiten muss das

Luftfiltersystem gegen

Inbetriebnahme gesichert werden.

Netzstecker ziehen!

Prüfen Sie täglich die ausreichende

Funktion des Luftfiltersystems.

Tauschen Sie verstopfte Filter aus.

Reinigen Sie das Gerät in

regelmäßigen Zeitabständen.

Beschädigte Sicherheitseinrichtungen

sofort ersetzen.

Anschlüsse und Reparaturen der

elektrischen Ausrüstung dürfen nur

von einer Elektrofachkraft

durchgeführt werden.

7.1 Filterwechsel

Der Filterwechsel darf nur bei

gezogenem Netzstecker erfolgen.

Beim Wechseln und Warten der

Filter ist eine Staubschutzmaske

(Filtermaske mit Partikelfilter) zu

tragen.

Es gibt zwei Filter die gewechselt

werden müssen.

Der äußere Filter kann nach dem

Aufklappen der beiden Laschen (B,

Fig 4 entfernt werden.

Fig 4

Ziehen Sie den Filter von Hand heraus

(gegebenenfalls verwenden Sie dazu

vorsichtig einen Schraubenzieher).

Am Filter ist ein Pfeil aufgedruckt

welcher die Luftströmungsrichtung

anzeigt.

Setzen Sie den Filter immer richtig

ein.

Der äußere Filter sollte entsprechend

der Einsatzdauer und der

Staubbelastung in der Werkstatt

ausgetauscht werden.

Der optional erhältliche AktivkohleAußenfilter kann eingesetzt werden

um bestimmte chemische

Luftbelastungen zu reduzieren.

8

Der innere Filter (C, Fig4) ann aus

dem Gehäuse herausgezogen werden.

Der innere Filter kann mit Luft

ausgeblasen werden (nur im Freien

vornehmen!)

8. Störungsabhilfe

Gerät startet nicht

*Kein StromNetzsicherung prüfen.

*Motor, Schalter oder Kabel defektElektrofachkraft kontaktieren.

Luftstrom zu schwach

*Außenfilter verstopftFilter tauschen.

*Innenfilter verstopftFilter ausblasen oder tauschen.

9. Lieferbares Zubehör

Artikel Nummer 708731

Außenfilter (5 Mikron, elektrostatisch,

Wegwerffilter)

Artikel Nummer 708735

Innenfilter (1 Mikron, Wegwerffilter).

Artikel Nummer 708734

Aktivkohle Außenfilter (reduziert

bestimmte chemische

Luftbelastungen, Wegwerffilter)

Page 7

FR - FRANCAIS

Mode d‘emploi

Cher client,

Nous vous remercions de votre confiance que vous nous portez avec l’achat de votre nouvelle machine JET. Ce manuel a été

préparé pour l’opérateur du système de filtration d’air JET AFS-500. Son but, mis à part le fonctionnement du système, est de

contribuer à la sécurité par l’application des procédés corrects d’utilisation et de m aintenance. Avant de mettre l’appareil en

marche, lire les consignes de sécurité et de maintenance dans leur intégralité. Pour obtenir une longévité et fiabilité maximale

de votre système de filtration d’air, et pour contribuer à l’usage sûr de l’appareil, veuillez lire attentivement ce mode d’emploi et

suivre les instructions.

Table des Matières

1. Déclaration de conformité

2. Prestations de garantie

3. Sécurité

Utilisation conforme

Consignes de sécurité

Risques

4. Spécifications

Indications techniques

Emission de bruit

Contenu de la livraison

5. Montage et installation

Montage

Installation

Raccordement au réseau électr.

6. Fonctionnement de la

machine

7. Entretien et inspection

Changement de filtre

8. Détecteur de pannes

9. Accessoires

1. Déclaration de conformité

Par le présent et sous notre

responsabilité exclusive, nous

déclarons que ce produit satisfait aux

normes conformément aux lignes

directrices indiquées page 2.

2. Prestations de garantie

Le vendeur garantit que le produit livré

est exempt de défauts de matériel et

de fabrication. La présente garantie ne

s’applique pas aux défauts résultant

d’une utilisation directe ou indirecte

incorrecte, de l’inattention, d’un

accident, d’une réparation, d’une

maintenance ou d’un nettoyage

insuffisant, ou encore de l’usure

normale.

Il est possible de faire valoir des

prétentions en garantie dans les 12

mois suivant la date de la vente (date

de la facture). Toute autre prétention

est exclue.

La présente garantie comprend toutes

les obligations de garantie incombant

au vendeur et remplace toutes les

déclarations et conventions

antérieures en termes de garanties.

Le délai de garantie s’applique pour

une durée d’exploitation de huit

heures par jour. Au-delà, le délai de

garantie diminue proportionnellement

au dépassement, mais pas en deçà

de trois mois.

Le renvoi d’une marchandise faisant

l’objet d’une réclamation requiert

l’accord préalable exprès du vendeur

et s’effectue aux frais et aux risques

de l’acheteur.

Les prestations de garantie détaillées

figurent dans les Conditions générales

(CG). Ces dernières sont disponibles

sur www.jettools.com ou peuvent être

envoyées par la poste sur demande.

Le vendeur se réserve le droit de

modifier à tout moment le produit et

les accessoires.

3. Sécurité

3.1 Utilisation conforme

Le système de filtration d’air AFS-500

convient au filtrage des poussières de

bois qui se trouve dans l’air.

Toute autre utilisation est interdite et

ne peut être effectuée que dans des

cas spéciaux et après accord du

fabricant de la machine.

L’appareil n’est pas conçu pour une

utilisation dans un environnement

humide.

Ne pas utiliser l’appareil à une

température en-dessous de 0°C.

Ne pas mettre votre système en

marche dans un local exposé aux

explosions.

9

Page 8

L’utilisation conforme implique le strict

respect des instructions de service et

de maintenance indiquées dans ce

manuel.

La machine doit être exclusivement

utilisée par des personnes

familiarisées avec le fonctionnement,

la maintenance et la remise en état, et

qui sont informées des dangers

correspondants.

L’âge requis par la loi est à respecter.

Toutes les directives relatives à la

prévention des accidents ainsi que les

consignes de sécurité doivent être

respectées scrupuleusement.

En cas d’utilisation non-conforme de

la machine, le fabricant décline toute

responsabilité qui est en tel cas

rejetée exclusivement sur l’utilisateur.

3.2 Consignes de sécurité

Lire attentivement ce mode d’emploi

avant de monter ou d’utiliser votre

appareil.

Conserver à proximité de la machine

tous les documents fournis (dans une

pochette en plastique, à l’abri de la

poussière, de l’huile et de l’humidité)

et veiller à joindre cette

documentation si vous cédez

l‘appareil.

Ne pas effectuer de modification au

système. Utiliser les accessoires

recommandés, des accessoires

incorrects peuvent être dangereux.

Contrôler chaque jour avant d’utiliser

la machine les dispositifs de

protection et le fonctionnement

impeccable.

En cas de défauts à la machine ou

aux dispositifs de protection avertir les

personnes compétentes et ne pas

utiliser l’appareil. Déconnecter la

machine du réseau.

Faire tous les travaux de maintenance

et le changement de filtre seulement

après avoir débranché le système de

filtration d’air du réseau.

Ne jamais mettre la main dans la

machine pendant l’utilisation.

Un filtre bouché réduit la perméabilité

de l‘air, remplacer ce filtre.

Porter un masque antipoussières

(masque avec filtre de particules) pour

le changement et la maintenance des

filtres.

L’appareil est conçu pour une

utilisation dans un local fermé et peut

être posé sur une surface plane et

stable, ou fixé au plafond ou au mur.

S’assurer que le câble d’alimentation

ne gêne pas le travail ni risque de

faire trébucher l‘opérateur.

Ne pas travailler sous l’influence de

drogues, d’alcool ou de médicaments.

Eloigner toutes personnes

incompétentes surtout des enfants de

la machine.

Ne jamais laisser la machine en

marche sans surveillance.

Arrêter la machine avant de quitter la

zone de travail.

Ne pas mettre l’appareil à proximité

de liquides ou de gaz inflammables.

Préserver le système de l’humidité et

ne jamais le mettre sous la pluie.

Ne jamais aspirer directement d’une

machine dans le système de filtration

d‘air.

Ne pas utiliser le système de filtration

d’air pour filtrer des vapeurs ou de la

fumée.

La poussière de bois est explosive et

peut être nocive pour la santé.

Les poussières de certains bois

exotiques et de bois durs, tel que le

hêtre et le chêne sont classés comme

étant cancérigènes. Le système de

filtration d’air peut aider mais ne peut

jamais remplacer un collecteur de

poussières pour votre machine à bois.

Ne pas se mettre sur le système de

filtration d’air ou se suspendre à

l‘appareil.

Tous travaux de branchement et de

réparation sur l’installation électrique

doivent être exécutés uniquement par

un électricien qualifié.

Remplacer immédiatement tout câble

endommagé ou usé.

3.3 Risques

Même en respectant les directives et

les consignes de sécurité existe les

risques suivants.

Danger par poussières.

Le système de filtration d’air peut

aider mais jamais remplacer un

collecteur de poussières pour votre

machine à bois.

Danger par câble électrique

endommagé, usé ou mal branché.

4. Spécifications

4.1 Indications techniques

Volume 6, 8, 10 m3/min

Filtre extérieur 5 microns

Filtre intérieur lavable 1 micron

Dimensions de la machine

(LxIxH) 400x610x305mm

Poids net 15 kg

Voltage 230V ~1/N/PE 50Hz

Puissance 0,12 kW (0,16 CV) S1

Courant électrique 0.3 A

Raccordement (H07RN-F)3x1,5mm²

Fusible du secteur électr. 10A

4.2 Emission de bruit

Niveau de pression sonore (selon EN

11202):

Petite vitesse 57 dB(A)

Moyenne vitesse 59 dB(A)

Grande vitesse 61 dB(A)

4.3 Contenu de la livraison

8 Rondelles en caoutchouc mousse

Mode d‘emploi

Liste pièces de rechange

5. Montage et mise en exploitation

5.1 Montage

Avertir JET immédiatement si vous

constatez en déballant des pièces

endommagées par le transport et ne

monter pas la machine.

Enlever le filtre extérieur et intérieur.

Eloigner l’emballage et le matériel qui

se trouve dans l’intérieur de l‘appareil.

5.2 Installation

Pour un fonctionnement optimal ne

pas installer le système de filtration

d’air dans un coin de la pièce ou près

d‘un réchauffeur ou réfrigérant d‘air.

Le système est conçu pour faire

circuler l’air et filtrer les poussières qui

se trouvent dans votre atelier.

10

Page 9

Le système de filtration d’air est

construit pour une utilisation dans un

local fermé et fonctionne en position

horizontale et verticale.

Fig 1

Avant de placer le système sur une

surface plane et stable, coller les

rondelles en caoutchouc mousse (A,

Fig1) en-dessous des quatre coins de

votre appareil.

5.3 Raccordement au réseau électr.

Le raccordement ainsi que les

rallonges utilisées doivent

correspondre aux instructions. Le

voltage et la fréquence doivent être

conforme aux données inscrites sur la

machine.

Le fusible de secteur électrique doit

avoir 10A.

Utiliser pour le raccordement des

câbles H07RN-F.

Tous travaux de branchement et de

réparation sur l’installation électrique

doivent être exécutés uniquement par

un électricien qualifié.

6. Fonctionnement de la machine

Les touches I, II, III régle le volume.

Vous avez trois vitesses à votre choix,

petite, moyenne et grande vitesse.

La touche 0 arrête l'appareil.

7. Entretien et inspection

Attention

Faire tous les travaux de

maintenance, réglage ou nettoyage

après avoir débranché le système du

réseau!

Vérifier chaque jour le fonctionnement

impeccable du système de filtration

d’air.

Remplacer un filtre bouché.

Nettoyer la machine régulièrement.

Remplacer immédiatement toutes

pièces endommagées ou usées.

Tous travaux de branchement et de

réparation sur l’installation électrique

doivent être exécutés uniquement par

un électricien qualifié.

7.1 Changement de filtre

Déconnecter la machine du réseau

pour le changement de filtre.

Porter un masque antipoussières

(masque avec filtre de particules) pour

le changement et la maintenance des

filtres.

Il y a deux filtres à changer.

Le filtre extérieur peut être retiré

après avoir ouvert les deux fixations

(B Fig 4.

Fig 4

Retirer le filtre à la main (si nécessaire

utiliser avec précaution un tournevis).

Une flèche sur le filtre indique la

direction de l’écoulement d‘air.

Toujours insérer le filtre dans la bonne

direction.

Changement du filtre extérieur selon

durée d’utilisation et la charge de

poussière dans votre atelier.

Le filtre en charbon extérieur

recevable en option peut être

appliqué pour réduire certaine

pollution chimique.

Le filtre intérieur (C, Fig 4) peut être

retiré du carter.

Purger le filtre intérieur avec un

pistolet à air (seulement dehors en

plein air!).

8. Détecteur de pannes

Appareil ne se met pas en

route

*Pas de courantVérifier le voltage.

*Défaut au moteur, bouton ou câbleContacter un électricien qualifié.

Filtration d’air trop faible

*Filtre extérieur bouchéRemplacer le filtre.

*Filtre intérieur bouchéRemplacer le filtre.

.

9. Accessoires

Article 708731

Filtre de rechange extérieur

(5 microns, électrostatique, filtre

jetable)

Article 708735

Filtre de rechange intérieur (1 micron,

filtre jetable).

Article 708734

Filtre en charbon (réduit certaine

pollution chimique, filtre jetable)

11

Loading...

Loading...