Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

20-Ga. Pittsburgh Lockformer

Model LF-20

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-756090

Ph.: 800-274-6848 Edition 1 09/2016

www.jettools.com Copyright © 2016 JET

Page 2

12. Make certain switch is in OFF position before

connecting the machine to the power supply.

13. Make certain the machine is properly grounded.

1.0 IMPORTANT SAFETY

INSTRUCTIONS

WARNING – To reduce risk of injury:

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace warning labels if they become

obscured or removed.

4. This lockformer is designed and intended for

use by properly trained and experienced

perso nnel on ly. If you are no t fam iliar w ith the

proper and safe operation of a lockformer, do

not use until proper training and knowledge

have been obtained.

5. Do not use this machine for other than its

intended use. If used for other purposes, JET

disclaims any real or implied warranty and holds

itself harm less from any inj ury t hat m ay res ult

from that use.

6. Always wear ANSI Z87.1 approved safety

glasses or face sh iel d whil e usin g th is machin e.

(Everyday eyeglasses only have impact

resistant lenses; they are not safety glasses.)

7. Before operating this machine, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Do not wear loose

clothing. Confine long hair. Non-slip footwear or

anti-skid floor strips are recom mended. Do not

wear gloves.

8. Wear hearing protection (plugs or muffs) if

noise exceeds safe levels.

9. CALIFORNIA PROPOSITION 65 WARNING:

This product contains chemicals know n to the

State of California to cause cancer, or birth

defects or other reproductive harm.

10. This product, when used for welding, cutting, or

working with metal, produces fumes, gases, or

dusts which contain chemicals known to the

State of California to cause birth defects and, in

some cases, cancer. (California Health and

Safety Code Section 25249.5 et seq.)

11. Do not operate this machine while tired or under

the influence of drugs, alcohol or any

medication.

14. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

15. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine

before turning it on.

16. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

17. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly a nd perform its i ntended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

18. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and

free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work

area. Keep children away.

21. Make your workshop child proof w ith padlocks,

master switches or by removing starter keys.

22. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

23. Maintain a balanced stance at all times so that

you do not fall onto moving parts. Do not

overreach or use excessive force to perform

any machine operation.

24. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a

job for which it was not designed. The right tool

will do the job better and more safely.

25. Use recommended accessories; improper

accessories may be hazardous.

26. Maintain tools with care. Follow instructions for

lubricating and changing accessories.

27. Turn off the machine before cleaning. Use a

brush to remove chips or debris — do not use

bare hands.

2

Page 3

28. Do not stand on the machine. Serious injury

could occur if the machine tips over.

29. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

30. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

31. Disconnect machine from power source

(unplug) before changing out roll sets.

32. Top covers must be properly installed before

feeding workpiece.

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

33. Don’t use in dangerous environment. Don’t use

power tools in damp or wet location, or expose

them to rain. Keep work area well lighted.

34. Use proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. Table 1 (sect. 6.2) shows correct

size to use depending on cord length and

nameplate ampere rating. If in doubt, use the

next heavier gage. The smaller the gage

number, the heavier the cord.

2.0 About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for a JET Model LF20 Lockformer. This manual contains instructions on installation, safety precautions, general operating

procedures, maintenance instructions and parts breakdown. Your machine has been designed and constructed

to provide consistent, long-term operation if used in accordance with the instructions as s et forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

Register your product online -

http://www.jettools.com/us/en /ser vice-and-support/warranty/registration/

3

Page 4

3.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTI ONS ....................................................................................................... 2

2.0 About this manual .......................................................................................................................................... 3

3.0 Table of contents ............................................................................................................................................ 4

4.0 Specifications ................................................................................................................................................. 5

5.0 Setup and assembly ....................................................................................................................................... 6

5.1 Shipping contents ....................................................................................................................................... 6

6.0 Electrical connections .................................................................................................................................... 6

6.1 GROUNDING INSTRUCTIONS ................................................................................................................. 6

6.2 Extension cords .......................................................................................................................................... 7

7.0 Operation ....................................................................................................................................................... 7

7.1 Pittsburgh Lock Seam procedure ............................................................................................................... 7

7.2 Double Seam procedure ............................................................................................................................ 8

7.3 Drive Cleat procedure ................................................................................................................................ 8

8.0 Adjustments ................................................................................................................................................... 9

8.1 Hold-downs ................................................................................................................................................ 9

9.0 User-maintenance .......................................................................................................................................... 9

9.1 Cleaning and lubrication ............................................................................................................................. 9

9.2 Additional servicing .................................................................................................................................... 9

10.0 Replacement Parts ....................................................................................................................................... 9

10.1.1 LF-20 Lockformer – Exploded View .................................................................................................... 10

10.1.2 LF-20 Lockformer – Parts List ............................................................................................................. 11

10.2.1 LF-20 Upper Bracket – Exploded View ............................................................................................... 12

10.2.2 LF-20 Upper Bracket – Parts List ........................................................................................................ 13

10.3.1 LF-20 Lower Bracket – Exploded View ............................................................................................... 14

10.3.2 LF-20 Lower Bracket – Parts List ........................................................................................................ 15

10.4.1 LF-20 Optional Rollers – Exploded View ............................................................................................. 16

10.4.2 LF-20 Optional Rollers – Parts List ..................................................................................................... 16

11.0 Electrical Connections for LF-20 ................................................................................................................ 17

12.0 Warranty and service ................................................................................................................................. 18

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without

incurring obligations.

4

Page 5

4.0 Specifications

Model number ............................................................................................................................................... LF-20

Stock number .............................................................................................................................................. 756090

Motor and electricals:

Motor type ............................................................................................................................. TEFC, capacitor start

Horsepower .............................................................................................................................................. 1.5HP

Phase ........................................................................................................................................................ single

Voltage ...................................................................................................................................................... 115 V

Cycle .......................................................................................................................................................... 60Hz

Listed FLA (full load amps) ......................................................................................................................... 14 A

Running amps (no load) ............................................................................................................................. 7.1 A

Starting amps .............................................................................................................................................. 51 A

Start capacitor .......................................................................................................................... 200MF 125VAC

Run capacitor .............................................................................................................................. 40μF 250VAC

Power transfer ........................................................................................................................................... V-belt

On/off switch .................................................................................................... mushroom style with safety key

Power cord ........................................................................................................ SJT 3/14AWG; 6 ft. (1830 mm)

Power plug installed ...................................................................................................................... NEMA 5-15P

Recommended circuit and fuse/breaker size 1 ............................................................................................. 15A

Capacities:

Pittsburgh lock dimensions ........................................ Approx. 25mm (1-in.) of material, 0.5-1.0mm (20-26ga.)

8mm (5/16 in.) width of hammer-over edge, adjustable up to 9.5mm (3/8 in.)

Speed ..................................................................................................................................... 7.62m (25 ft.)/min

Minimum length of workpiece....................................................................................................... 7 in. (178mm)

Main materials:

Cabinet ....................................................................................................................................................... steel

Rolls ................................................................................................................................... hardened alloy steel

Guide fences .............................................................................................................................. hardened steel

Shafts ................................................................................... hardened and ground steel, with needle bearings

Dimensions:

Height table from floor ......................................................................................................... 819 mm (32-1/4 in.)

Overall dimensions (LxWxH) ..................................................... 914 x 419 x 927 mm (36 x 16-1/2 x 36-1/2 in.)

Shipping dimensions (LxWxH) .......................................... 1075 x 510 x 1075 mm (42-5/16 x 20 x 42-5/16 in.)

Weights:

Net.......................................................................................................................................... 266 lb. (120.6 kg)

Shipping ................................................................................................................................. 341 lb. (154.6 kg)

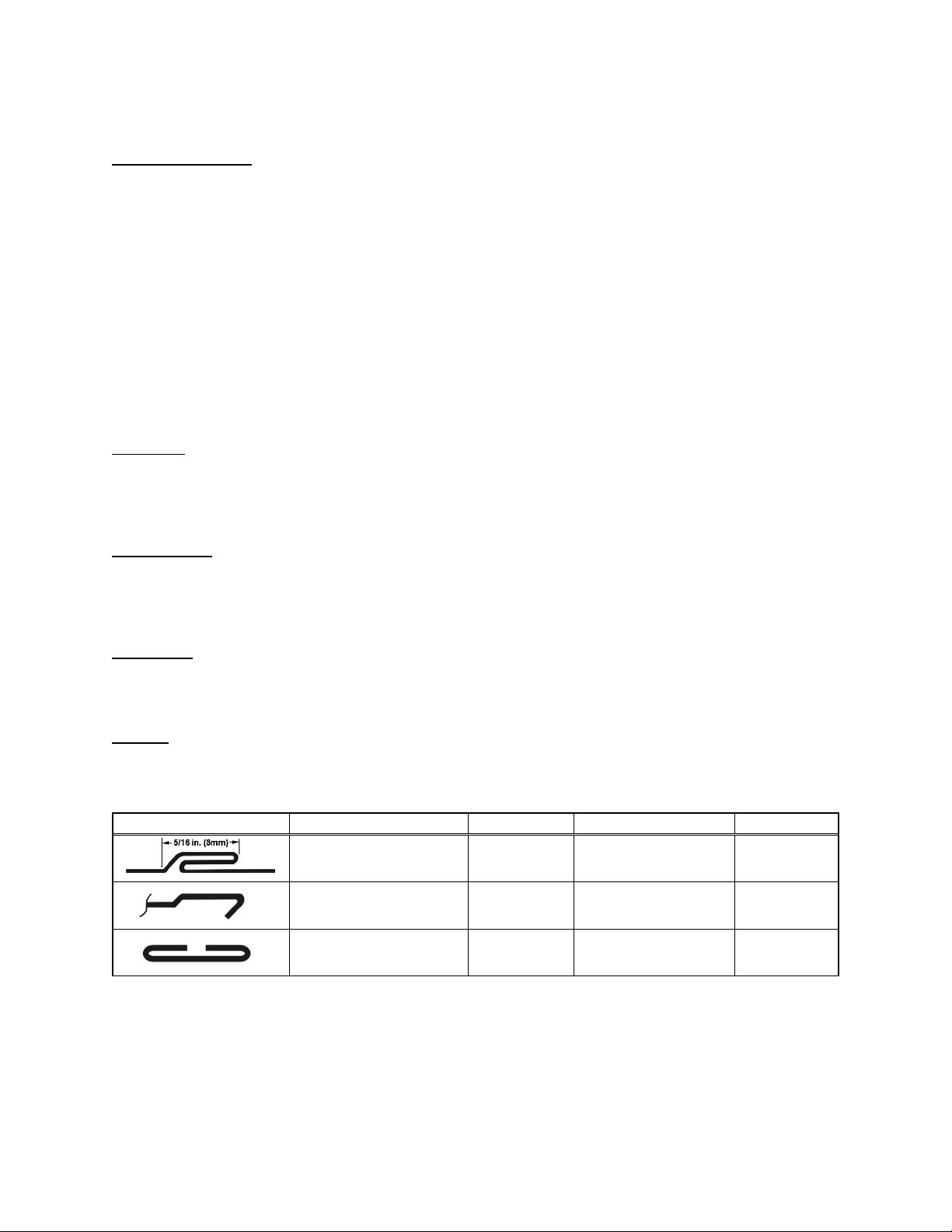

Type Roll set Capacity Approx. mat’l used Size

Pittsburgh lock seam

(standard, pre-mounted)

Double seam (DSS)

OPTIONAL 2

1

Subject to local and national electrical codes.

2

Optional Double Seam and Drive Cleat roll sets are available from JET. See sect. 10.4.1.

Drive cleat (DCS)

OPTIONAL

2

0.5 - 1.0 mm

20 to 26 ga

0.5 - 1.0 mm

20 to 26 ga.

0.5 – 1.0 mm

20 to 26 ga.

25mm (1”)

25.4mm (1”)

54mm (2-1/8”)

8 mm

5/16” width

10 mm

3/8” seam

28.5 mm

1-1/8” width

5

Page 6

Read and understand the entire

contents of this manual before attem pting setup or operation! Failure to comply may cause

serious injury.

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

5.0 Setup and assembly

Remove all crating and check for shipping damage.

Report any damage immediately to your distributor

and shipping agent. Do not discard any shipping

material until the Lockformer is assembled and

running properly.

Compare contents with the following list to make

sure all parts are intact. Any missing parts should be

reported to your distributor. Read this instruction

manual thoroughly for operation, maintenance and

safety instructions.

Remove fasteners holding machine to pallet, and

use forklift or hoist with straps to move lockformer to

position. Location should be well-lighted, with a

sturdy, level floor. It is recommended that the

machine be secured to the floor with lag screws or

other means for stability.

5.1 Shipping contents

1 Lockformer

2 Wrenches, 23/26 and 12/14mm

2 Hex wrenches, 4mm and 6mm

1 Formed sample plate

10 Double head round keys

6.0 Electrical connections

All electrical connections must

be done by a qualified electrician in compliance

with all local codes and ordinances. Failure to

comply may result in serious injury.

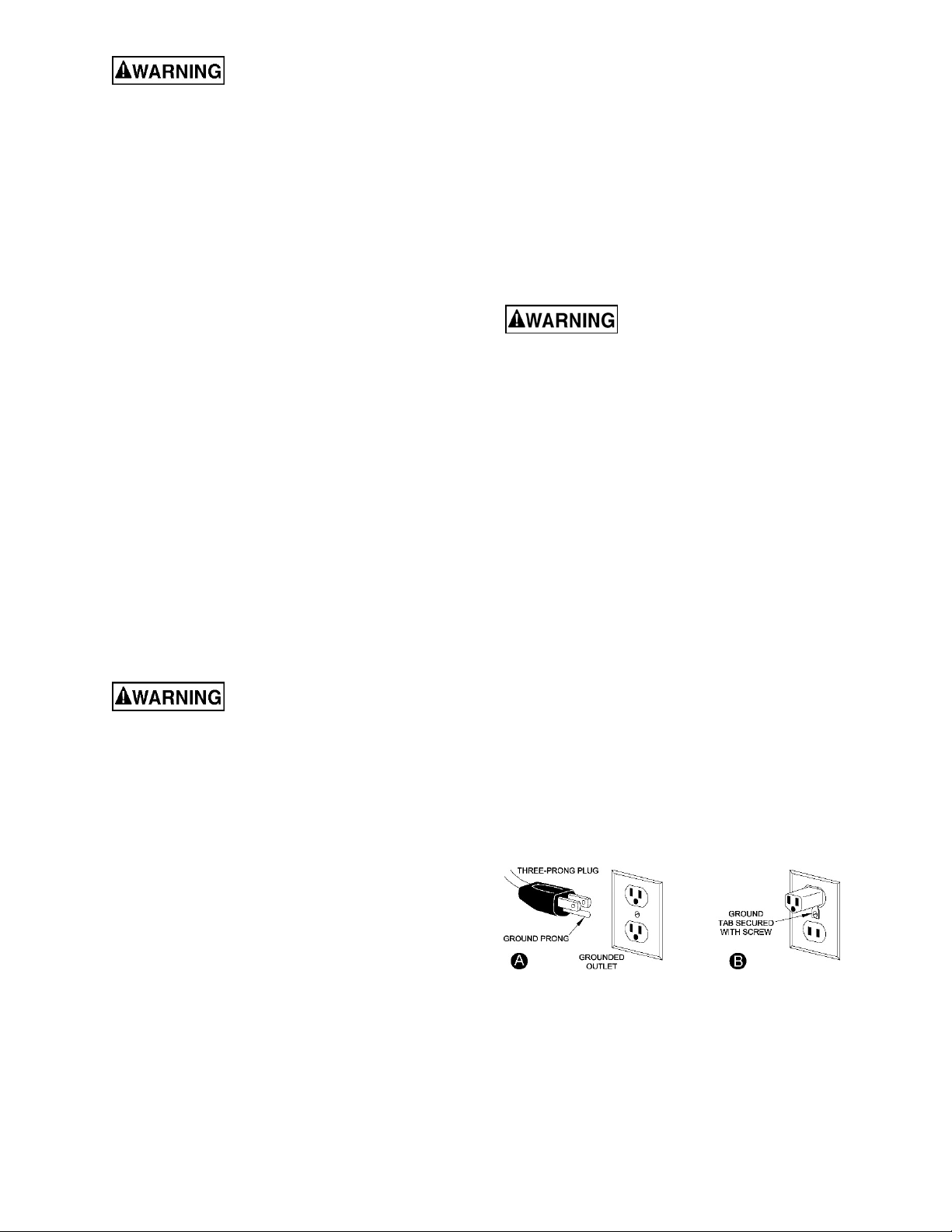

The LF-20 Lockformer is rated at 115-volt power

only, and is supplied with a plug designed for use on

a circuit with a grounded outlet that looks like the

one pictured in Figure 6-1.

Before connecting to power source, be sure switch

is in off position.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

cond uctor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service personnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause serious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

This machine is for use on a nomi nal 120-V circ uit,

and has a grounded plug that looks like the plug

illustrated in sketch A in Figure 6-1. A temporary

adaptor that looks like the adaptor illustrated in

sketch B may be used to connect this plug to a 2pole receptacle as shown in sketc h B if a properly

grounded outlet is not available. The temporary

adaptor should be used only until a properly

grounded outlet (sketch A) can be installed by a

qualified electrician. The green colored rigid ear,

lug, or the like extending from the adaptor must be

connected to a permanent ground such as a

properly grounded outlet box cover. W henever the

adaptor is used, it must be held in place by a metal

screw.

In Canada, the use of a temporary adapto r is not

permitted by the Canadian Electrical Code, C22.1.

It is recommended that the Lockformer be

connected to a dedicated 15 amp circuit with circuit

breaker or fuse. If connected to a circuit protected

by fuses, use time delay fuse marked “D”. Local

codes take precedence over recommendations.

6.1 GROUNDING INSTRUCTIONS

This machine must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped w it h

an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly

Figure 6-1

6

Page 7

6.2 Extension cords

The use of extension cords is discouraged; try to

position machines near the power source. If an

extension cord is necessary, make sure it is in good

condition. When using an extension cord, be su re to

use one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. Table 1 shows correct size to use

depending on cord length and nameplate ampere

rat ing . If in d o ubt , use t he ne xt hea v ie r g a uge . T he

smaller the gauge number, the heavier the cord.

Extension Cord Recommended Gauges (AWG)

Extension cord length *

25

50

75

100

150

200

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the rated

amperes. NR = Not Recommen ded.

feet

feet

feet

feet

feet

feet

Table 1

7.0 Operation

The following fig ures show top

cover removed for clarity only. All top covers

must be installed before operating machine.

Failure to comply may cause serious injury.

NOTE: Length of workpiece must be at least 7inches. If a shorter piece is required, process a

longer piece, then cut to length.

1. Make sure workp iece is free of burrs or twist

from snip cuts.

Twists or bent notches in

material can strike and damage the knifeedge roll that holds open the pocket of the

Pittsburgh Lock. Flatte n such edges before

feeding material.

2. Adjust entry fence, using a straight edge. See

Figure 7-2. Entry fence position determines

width of hammer-over edge. Tighten both nuts

on entry fence.

3. Adjust exit fence as follows: Run a test piece

through and stop machine when workpiece h as

reached end of exit table but is still pinched

between the rolls. Move fence into position just

flush or slightly clear of workpiece edge. Exit

fence must not bear pressure against

workpiece under normal circumstances.

Tighten down fence.

4. Hold material against entry fence and slide it

into forming head until machine engages

workpiece and pulls it through. Make sure

workpiece remains against entry fence until its

trailing end is engaged by the rolls.

If a wider or narrower hammer-over edge is desired,

move entry fence to give desired width. Move entry

fence in to produce wider edge, out to produce

narrower edge. Make sure to move both ends of

entry fence the same distance, keeping it parall el to

front edge of machine’s top plate. See Figure 7-2.

7.1 Pittsburgh Lock Seam procedure

This machine comes pre-installed with a Pitt sburgh

lock roll set, and requires only fence adj ustment to

proceed with this operation.

Figure 7-2: Pittsburgh Lock Seam setup

Figure 7-1

7

Page 8

Figure 7-3: Double Seam setup (optional roll set)

Figure 7-4: Drive Cleat setup (optional roll set)

Always disconnect machine

from power before installing roll sets. Failure to

comply may cause serious injury.

7.2 Double Seam procedure

See Figure 7-3.

1. Disconnect machine from power source.

reached end of exit table but is still pinched

between the rolls. Move fence into position just

flush or slightly clear of workpiece edge. Exit

fence must not bear against workpiece. Tighten

down fence.

9. Start machine and feed workpiece.

2. Remove top cover, and rear top plate.

3. Select first pair of rolls marked “T1” and “B1”,

and slide them on the shafts at the left, or entry

side, of machine. Place “T1” on top shaft, B1 on

bottom shaft. Insert key into keyway for each

roll. THE NUMBERED SIDES OF ROLLS

MUST FACE OUTWARD.

4. Repeat procedure with rolls “T2” and “B2”

through “T5” and “B5”, placing them in

sequence from left to right. All rolls marked “T”

should be on top shafts; all rolls marked “B”

should be on bottom shafts.

5. Fasten rolls to shafts with the provided socket

head cap screws and washers.

6. Lay straight edge against outside surface of

rolls, and position entry fence at 1-1/8”

clearance from straight edge, as shown in

Figure 7-3. Tighten dow n both screws on entry

fence.

7. Reinstall rear top plate, and top cover.

8. Adjust exit fence as follows: Run a test piece

through and stop machine when workpiece has

7.3 Drive Cleat procedure

See Figure 7-4.

IMPORTANT: Make sure to cut the material a full 2-

1/8 inch wide to ensure an accurate cleat.

1. Disconnect machine from power source.

2. Follow same procedure as for double seam

rolls, but leave roll “T2” loose. T his roll centers

itself to the bottom roll and should not be fixed

in place with a socket cap screw. However,

double head round keys are used with all the

rolls.

3. Position entry fence so that centerline of

material will ali gn with centerline of rolls. This is

importan t – if i t is not cente red , the cleat will n ot

be accurate. Tighten down fence.

4. Reinstall rear top plate, and top cover.

5. Tighten hold-down stud (see Figure 7-1) so that

“T5” and “B5” rolls do not separate w hen drive

cleat passes through.

8

Page 9

6. Adjust exit fence as follows: Run a test piece

through and stop machine when workpiece has

reached end of exit table but is still pinched

between the rolls. Move fence into position just

flush or slightly clear of workpiece edge. Exit

fence must not bear against workpiece. Tighten

down fence.

7. Start machine and feed workpiece.

8.0 Adjustments

8.1 Hold-downs

material starts working away from entry

fence, tighten hold-down bolt on entry side.

• If material curls up after leaving forming

head, or shows extremely heavy pressure

marks, loosen hold-down bolts (or studs)

slightly.

5. After adjustments, lock setting of the bolts by

tightening side screw (X, Figure 7-1). Lock

setting of studs by tightening top nuts.

9.0 User-maintenance

Refer to Figure 7-1.

Adjustment can be made to accommodate

variations in material thickness and hard ness. T he

hold-down bolts are adjusted for Pittsburgh lock set;

the hold-down studs are adjusted for optional roll

sets. These fasteners set the tension for top and

bottom plates to move, allowing material to slide

between them. Only adjust hold-downs if there is

a problem feeding the material. If material slips,

tends to leave the guide fence, or curls up at exit,

adjust as follows:

1. Disconnect machine from power source.

2. Remove top cover.

3. Tighten ho ld-down bolt s (or st uds) until snug,

then loosen them a quarter turn. This will

usually give proper adjustment for all material

thicknesses.

4. Reinstall top cover and run a test piece through

machine:

• If material slips, tighten both hold-down

bolts (or studs) equally until problem is

resolved. If it slips as it leaves the rolls,

tighten hold-down bolt on exit side. If

Before doing maintenance on

the machine, disconnect it from the electrical

supply by pulling out the plug or switching off

the main switch. Failure to comply may cause

serious injury.

9.1 Cleaning and lubrication

Insert oil every 4 hours of operation into the six oil

fittings at back of machine. These lubricate the main

bearings. Recommended oil is Mobil DTE Oil

LightTM, or equivalent.

Apply a multi-purpose lithium grease to the drive

gears after approximately 40 hours of operation, or

as needed.

Keep forming rolls and table surface clean and free

of deposits.

9.2 Additional servicing

Any additional servicing should be performed by an

authorized service technician.

10.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Havin g the Model Number and Serial Number of

your machine available when you call will allow us to serve y ou quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from JET.

Some parts are shown for reference only, and may not be available individually.

9

Page 10

10.1.1 LF-20 Lockformer – Exploded View

10

Page 11

10.1.2 LF-20 Lockformer – Parts List

Index No Part No Description Size Qty

1 ................ TS-0071151 .............. Hex Cap Screw ........................................................ 5/8-11x6 ........................ 2

2 ................ TS-155010 ................ Flat Washer ............................................................. M16 ............................... 2

3 ................ TS-0207021 .............. Socket HD Cap Screw ............................................. 1/4-20x1/2 ................... 10

4 ................ LF20-104 ................... Spacer .................................................................... ...................................... 2

5 ................ LF20-105 ................... Cover ...................................................................... ...................................... 1

6 ................ VB-B52 ...................... V-Belt ....................................................................... B52................................ 1

7 ................ TS-059303 ................ Cap Nut.................................................................... 3/8-16 ............................ 8

8 ................ TS-0561031 .............. Hex Nut .................................................................... Full 3/8-16 ................... 12

9 ................ TS-0680041 .............. Flat Washer ............................................................. 3/8 ............................... 10

10 .............. LF20-110 ................... Full Threaded Stud ................................................. 3/8"-16UNC*128L ......... 2

11 .............. LF20-111 ................... Oil Pipe .................................................................... 6*400 mm...................... 6

12 .............. LF20-112 ................... Motor Pulley ............................................................. ...................................... 1

13 .............. TS-1523041 .............. Socket Set Screw .................................................... M6x12 ........................... 1

14 .............. 5508945 .................... Double Head Round Key ......................................... 5*5*30L mm .................. 1

15 .............. LF20-115 ................... Motor………………………………… ………….1.5HP/115V/60Hz/4P/1Ph ....... 1

.................. LF20-115SC .............. Starting Capacitor (not shown) ................................ 200MF 125VAC ............ 1

.................. LF20-115RC.............. Running Capacitor (not shown) ............................... 40μF 250VAC ............... 1

.................. LF20-115MF.............. Motor Fan (not shown)............................................. ...................................... 1

.................. LF20-115CS .............. Centrifugal Switch (not shown) ................................ ...................................... 1

.................. LF20-115FC .............. Fan Cover (not shown) ............................................ ...................................... 1

16 .............. LF20-116 ................... Motor Plate .............................................................. ...................................... 2

17 .............. TS-0720091 .............. Lock Washer, Medium ............................................. 3/8 ................................. 8

18 .............. TS-0680041 .............. Flat Washer ............................................................. 3/8 ................................. 8

19 .............. TS-0060061 .............. Hex Cap Screw ........................................................ 3/8-16x1-1/4 .................. 4

20 .............. LF20-120 ................... Guide Fence ............................................................ ...................................... 4

21 .............. LF20-121 ................... Carriage Bolt ............................................................ 3/8-16x1 ...................... 12

22 .............. LF20-122 ................... Cabinet Cover ......................................................... ...................................... 2

23 .............. F010967 .................... Socket HD Flat Screw.............................................. 1/4-20x1/2 ..................... 4

24 .............. LF20-124 ................... Top Plate ................................................................. ...................................... 2

25 .............. F010752 .................... Socket HD Flat Screw.............................................. 3/8-16x1 ........................ 4

26 .............. LF20-126 ................... Soft Pad .................................................................. ...................................... 1

27 .............. LF20-127 ................... Female Thread Fitting.............................................. ∅6xPT 1/8" ................... 6

28 .............. LF20-128 ................... Oil Fitting.................................................................. PT 1/8" .......................... 6

29 .............. LF20-129 ................... Cable Gland ............................................................. PG 13.5 ......................... 2

30 .............. LF20-130 ................... Cabinet .................................................................. ...................................... 1

31 .............. LF20-131 ................... Switch Box ............................................................... ...................................... 1

32 .............. LF20-132 ................... Strain Relief ............................................................ SB8R-3 ......................... 2

33 .............. LF20-133 ................... Power Cord……............................................SA 14AWG/3C/285cm/CSA ..... 1

34 .............. LF20-134 ................... Motor Cord……… ……………………………...SJT 14AWG/3C/95cm ............. 1

35 .............. LF20-135 ................... Switch Assembly...................................................... PJ9501-1A .................... 1

36 .............. LF20-136 ................... Self-Drilling Screw .................................................. M3*16L ......................... 4

37 .............. LF20-137 ................... Wire Connector ........................................................ TM-2.............................. 1

38 .............. LF20-138 ................... JET Knob ................................................................ 1/4-20 ............................ 1

.................. JET-138..................... JET Logo (not shown).............................................. 138x57mm .................... 1

.................. LM000228 ................. ID Label, LF-20 (not shown) .................................... ...................................... 1

.................. LM000223 ................. Warning Label (n ot sh own) ...................................... ...................................... 1

.................. LF20-TP .................... Tool Package (includes items below) ...................... ...................................... 1

.................. .................................. Wrench (not shown) ................................................ 12*14 mm...................... 1

.................. .................................. Wrench (not shown) ................................................ 23*26 mm...................... 1

.................. .................................. Hex Wrench (not shown) ......................................... 4mm ............................. 1

.................. .................................. Hex Wrench (not shown) ......................................... 6mm ............................. 1

.................. .................................. Double Head Round Key (not shown) ..................... 5*5*25L mm ................ 10

11

Page 12

10.2.1 LF-20 Upper Bracket – Exploded View

12

Page 13

10.2.2 LF-20 Upper Bracket – Parts List

Index No Part No Description Size Qty

1 ................ TS-0270011 .............. Socket Set Screw .................................................... 5/16-18x1/4 ................... 1

2 ................ LF20-202 ................... Upper Front Die Clamping Plate .............................. ...................................... 1

3 ................ LF20-203 ................... Die T5 ...................................................................... ...................................... 1

4 ................ LF20-204 ................... Needle Bearing ........................................................ BA1012 ......................... 1

5 ................ LF20-205 ................... Shaft ....................................................................... ...................................... 1

6 ................ LF20-206 ................... Die T6 ...................................................................... ...................................... 1

7 ................ 6293358 .................... Double Head Round Key ......................................... 5*5*25L mm .................. 5

8 ................ LF20-208 ................... Die T4 ...................................................................... ...................................... 1

9 ................ LF20-209 ................... Die T3 ...................................................................... ...................................... 1

10 .............. TS-0070041 .............. Hex Cap Screw ........................................................ 1/2-13x1-3/4 .................. 8

11 .............. TS-0720111 .............. Lock Washer, Medium ............................................. 1/2 ................................. 8

12 .............. LF20-212 ................... Needle Bearing ........................................................ BA1412 ....................... 10

13 .............. LF20-213 ................... Die T2 ...................................................................... ...................................... 1

14 .............. LF20-214 ................... Die T1 ...................................................................... ...................................... 1

15 .............. LF20-215 ................... Connecting Rod ....................................................... ...................................... 2

16 .............. LF20-216 ................... Connecting Rod with Hole ....................................... ...................................... 2

17 .............. LF20-217 ................... Upper Rear Die Clamping Plate .............................. ...................................... 1

18 .............. TS-0680031 .............. Flat Washer ............................................................. 5/16 .............................. 5

19 .............. TS-0208071 .............. Socket HD Cap Screw ............................................. 5/16-18x1-1/4 ............... 5

13

Page 14

10.3.1 LF-20 Lower Bracket – Exploded View

14

Page 15

10.3.2 LF-20 Lower Bracket – Parts List

Index No Part No Description Size Qty

1 ................ TS-0070041 .............. Hex Cap Screw ........................................................ 1/2-13x1-3/4 ................ 11

2 ................ TS-0720111 .............. Lock Washer, Medium ............................................. 1/2" ............................. 11

3 ................ TS-1523051 .............. Socket Set Screw .................................................... M6x 16 ........................... 1

4 ................ LF20-304 ................... Double Head Round Key ......................................... 5*5*25L mm .................. 9

5 ................ LF20-305 ................... Gear Pulley .............................................................. ...................................... 1

6 ................ LF20-306 ................... Gear Shaft ............................................................... ...................................... 1

7 ................ TS-0270011 .............. Socket Set Screw .................................................... 5/16-18x1/4 ................... 5

8 ................ LF20-308 ................... Needle Bearing ........................................................ BA1412 ....................... 13

9 ................ LF20-309 ................... Needle Bearing ........................................................ BA1012 ......................... 1

10 .............. LF20-310 ................... Die B5 ...................................................................... ...................................... 1

11 .............. LF20-311 ................... Shaft ....................................................................... ...................................... 1

12 .............. LF20-312 ................... Connecting Rod ....................................................... ...................................... 2

13 .............. LF20-313 ................... Connecting Rod ....................................................... ...................................... 1

14 .............. LF20-314 ................... Connecting Rod ....................................................... ...................................... 2

15 .............. LF20-315 ................... Bracket..................................................................... ...................................... 1

16 .............. LF20-316 ................... Gear ........................................................................ ...................................... 2

17 .............. LF20-317 ................... Needle Bearing ........................................................ BA1212ZOH.................. 6

18 .............. LF20-318 ................... Copper Adapter ....................................................... ∅6*PT 1/8" .................... 6

19 .............. TS-0211051 .............. Socket HD Cap Screw ............................................. 1/2-13x1 ........................ 1

20 .............. LF20-320 ................... Lower Front Die Clamping Plate .............................. ...................................... 1

21 .............. LF20-321 ................... Spring .................................................................... ...................................... 1

22 .............. LF20-322 ................... Disc ......................................................................... ...................................... 1

23 .............. LF20-323 ................... Pin ........................................................................... ...................................... 1

24 .............. TS-0208061 .............. Socket HD Cap Screw ............................................. 5/16-18x1 ...................... 1

25 .............. TS-0561021 .............. Hex Nut .................................................................... Full 5/16-18 ................... 1

26 .............. LF20-326 ................... Spur Gear ................................................................ ...................................... 3

27 .............. LF20-327 ................... Die B 3 ..................................................................... ...................................... 1

28 .............. LF20-328 ................... Spur Gear ................................................................ ...................................... 1

29 .............. LF20-329 ................... Die Shaft B 3............................................................ ...................................... 1

30 .............. LF20-330 ................... Die B2 ...................................................................... ...................................... 1

31 .............. LF20-331 ................... Connecting Rod ....................................................... ...................................... 1

32 .............. ST W22 ...................... C Ring ..................................................................... STW-22 ........................ 2

33 .............. LF20-333 ................... Needle Bearing ........................................................ BA1416 ......................... 1

34 .............. LF20-334 ................... Collar ....................................................................... ...................................... 2

35 .............. LF20-335 ................... Gear Shaft ............................................................... ...................................... 1

36 .............. LF20-336 ................... Gear Shaft ............................................................... ...................................... 1

37 .............. LF20-337 ................... Die B6 ...................................................................... ...................................... 1

38 .............. LF20-338 ................... Die B4 ...................................................................... ...................................... 1

39 .............. LF20-339 ................... Die B1 ...................................................................... ...................................... 1

40 .............. LF20-340 ................... Lower Rear Die Clamping Plate .............................. ...................................... 1

41 .............. TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 2

42 .............. LF20-342 ................... Pin ........................................................................... ...................................... 2

43 .............. TS-0680031 .............. Flat Washer ............................................................. 5/16 ............................... 5

44 .............. TS-0208071 .............. Socket HD Cap Screw ............................................. 5/16-18x1-1/4 ................ 5

15

Page 16

10.4.1 LF-20 Optional Rollers – Exploded View

10.4.2 LF-20 Optional Rollers – Parts List

Index No Part No Description Size Qty

1 ................ 756092 ...................... Drive Cleat Rolls, set of 10 ...................................... ...................................... 1

2 ................ 756091 ...................... Double Seam Rolls, set of 10 .................................. ...................................... 1

16

Page 17

11.0 Electrical Connections for LF-20

17

Page 18

12.0 Warranty and service

JET warrants ev ery product it sells against manufacturers’ defects. If one of our tools needs ser v i ce or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the t ime period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable wi t hin a

reasonable amount of use and ar e covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use o f these machin es in t he process i ng of metal, plastics, or oth er m aterials out side recom mended gui deli nes m ay

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on t he JET website.

More Information

JET is constantly adding new pr oducts. For complete, up-to-date product information, check wi th your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable st ate law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on of fi cial JET website are

given as gener al information and ar e not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Met al working Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machi nery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock pr oducts; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References i n t his document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sol d in Canada by JPW Industries, Inc.

18

Page 19

This page intentionally left blank.

19

Page 20

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

20

Loading...

Loading...