Page 1

Operating Instructions and Parts Manual

SR-2024M and SR-2236M Slip Rolls

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-756020

Ph.: 800-274-6848 Revision A1 05/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warr ants every prod uct it sells against manu facturers’ d efects. If one of our tools n eeds service or r epair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty co vers a ny def ects in wor kman ship o r mat er ials subject to the limitations s tated bel ow. This wa r ranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provi d e pr o of

of initial purchase when calling. If a product requires furt h er in s p ection, the Technical Servi c e r epr esent a tive will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTI ES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

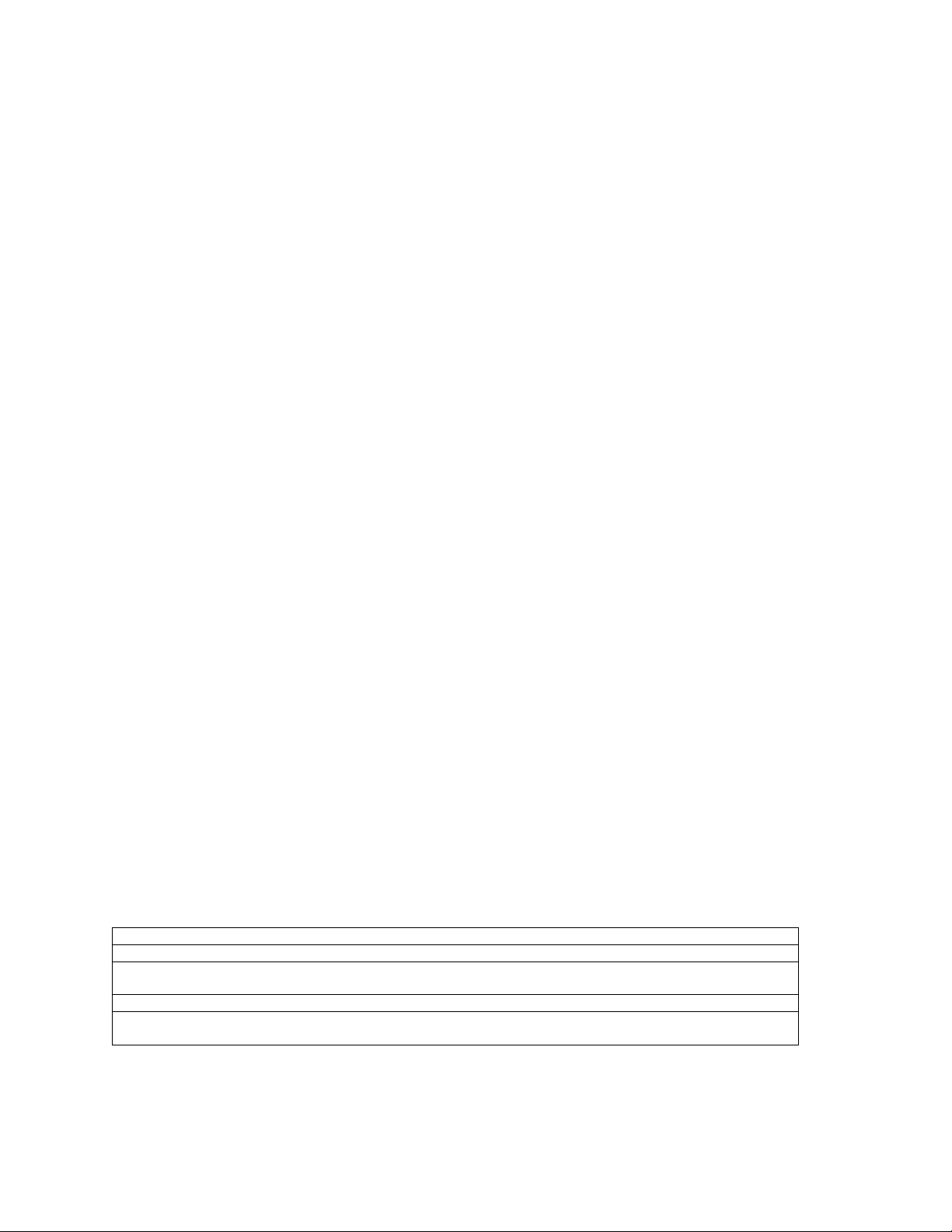

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

For your own safety, read the owner’s manual before operating the slip roll.

This slip roll is designed and intended for use by properly trained and experienced personnel

only. If you are not familiar with the proper and safe operation of a slip roll, do not use until

proper training and knowledge has been obtained.

1. KEEP GUARDS IN PLACE and in working order.

2. KEEP ALL BODY PARTS AWAY FROM MOVING PARTS. Avoid placing any part of your body

near belts, cutt er s, gear s, etc.

3. DO NOT EXCEED GAUGE RATED CAPACITY on this slip roll, 20 gauge for SR-2024M and 22

gauge for SR-2236M.

4. KEEP THE WORK AREA CLEAN. Cluttered areas and work benche s invite accidents.

5. KEEP CHILDREN AWAY. All visitors should be kept a safe distanc e from the work area.

6. MAKE THE WORKSHOP KID PROOF with padlocks, m aster switc hes, or by removing starter keys.

7. DON’T FORCE THE MACHINE. It will do the job better and safer at the rate for which it was

designed.

8. USE THE RIGHT MACHINE. Don’t force a machine or attachment to do a job for which it was not

designed.

9. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neck ties, rings, bracelets, or other

jewelry which may get caught in moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair.

10. ALWAYS USE SAFETY GLASSES. Also use face or dust masks if the cutt ing operation is dusty.

Everyday eyeglasses only have impact resistant lenses; they are not safety gl asses.

11. DON’T OVERREACH. Keep proper f ooting and balance at all times.

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp and cl ean for the best and safest performance.

Follow instructions for lubricati ng and c hanging accessories.

13. NEVER STAND ON A MACHINE. Serious injury c ould occur if t he m ac hine tipped.

14. CHECK DAMAGED PARTS. Before furt her use of the mac hine, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perf orm it s

intended function - check for alignment of moving par ts, binding of moving parts, breakage of parts,

mounting, and any ot her c onditions that may affect it s operati on. A guard or other part that is

damaged should be properly repaired or replaced.

15. SHEET METAL STOCK HAS SHARP EDGES. To prevent cuts, use caution when handling.

16. KEEP HANDS AND FINGERS clear of the area in front and rear of the rolls.

17. DO NOT USE THE MACHINE for any purpose other t han for whic h it was designed

18. FAILUR E TO C OM PLY with all of these warnings may cause serious i njury.

19. SOME DUST CREATED BY power sanding, sawing, gr inding, drilling and other construction

activities contains chemicals known to cause cancer, bir th defects or other reproduc tive harm. Some

examples of these chemicals are:

• Lead from lead based paint

• Crystalli ne sil ic a from bricks and cement and other masonry produc ts, and

• Arsenic and chromium from chemically-tr eated lumber.

20. YOUR RISK FROM THOSE EXPOSURES varies, depending on how often you do this type of work.

To reduce your exposure t o these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specifically designed to fil ter out microscopic

particles

21. DO NOT OPERATE TOOL while under the influence of drugs, alcohol or any m edic ation.

3

Page 4

Specifications

Model Number .................................................................... SR-2024M .................................................. SR-2236M

Stock Number ......................................................................... 756020 ....................................................... 756026

Capacity (mild steel) ................................................................ 20.......................................................... 22

Maximum Formi ng Length ......................................................24 ”......................................................... 36”

Number of Rolls ................................................................................ 3 ................................................................. 3

Diameter of Rolls .............................................................................. 2” ................................................................ 2”

Minimu m Forming Rad ius ........................................................ 1”........................................................... 1”

Wire Grooves ..................................................... 3/16” 1/4", 5/16”..................................... 3/16” 1/4", 5/16”

Overall Dimensions, assembled (LxWxH) ..............

Overall Dimensions, shipping (LxWxH) .............

Net Weight ................................................................................ 172 lb ......................................................... 212 lb

Shipping Weight ........................................................................ 216 lb ......................................................... 256 lb

Stand (Optional Accessory) .................................................... 754024 ....................................................... 754036

Dimensions (Lx WxH) .............................................. 30” x 14” x 28” ............................................ 42” x 14” x 28”

Net Weight ............................................................................. 35 lb ........................................................... 51 lb

Uncrating and Clean-Up

1. Remove the crate from around the machin e.

2. Carefully clean all rust protected surfaces with

a mild solvent or kerosene and a soft rag. Do

not use lacquer thinner, paint thinner, or

gasoline. These will damage painted surfaces.

3. Coat all machined surfaces wit h a light coat of

oil to inhibit rust.

4. Remove the bolts holding the machine to the

skid.

50” x 14” x 14”......................................... 62” x 14” x 14”

36” x 16” x 18-1/2”............................. 47-1/4” x 16-1/4” x 18”

2. The gap between the rear roll and the two front

rolls should be equal at both ends of the roll to

assure an equal radius at both ends of the

material.

Releasing the Material

1. Once the material has been rolled release t he

material from the roll by lifting handle #29.

Move the handle bracket out of the way.

2. Lift the upper roll #23 by moving lever #3 to

the right so that the material can be removed.

5. Carefully move the machine to a well lighted

area on a solid, level work bench, and secure

to the bench with lag screws or bolts.

6. Machine location must allow access to all

sides.

Front Rolls

The (#) in the text refers to the breakdown.

1. The upper and lower rolls #23 & #24 carry the

material through as the crank handle #33 is

turned in a clockwise direction.

2. The lower roll adjustment knobs #12 are used

to move the lower roll #24 up and down for

different gauge material.

3. The gap between the two front rolls should be

equal at both ends.

Rear Roll

1. The rear roll #25 can be adjusted to control the

radius by turning adjustment knobs #13.

Rolling Wires

There are three wire grooves i n the lower and rear

rolls that will accommodate a 3/16”, 1/4", and 5/16”

wire.

Lubrication

The machine must be lubricated every day of

service with a few drops of oil. An oil pinhole is

located at both ends of the lower roll #24, and rear

roll #25. The upper roll #23 has two oil pinholes on

the left side. The right side can be lubed by

opening the handle #29, and lightly oiling the end

of the upper roll shaft.

Every thirty days of operatio n grease the gears by

removing the outer hex nut #7, and gear cover #18.

Lightly oil the rolls when not in use to prevent rust.

4

Page 5

Breakdown for the SR-2024M & SR-2236M Slip Roll

5

Page 6

Parts List for the SR-2024M & SR-2236M Slip Roll

Index Part Description Size Quantity

1 ................ SR2024N-1 ............... Base Assembly ........................................................ ...................................... 1

.................. SR2236N-1 ............... Base Assembly ........................................................ ...................................... 1

3 ................ SR2024N-3 ............... Lever ........................................................................ ...................................... 1

4 ................ SR2024N-4 ............... Rod .......................................................................... ...................................... 1

.................. SR2236N-4 ............... Rod .......................................................................... ...................................... 1

5 ................ SR2024N-5 ............... Socket Head Cap Screw.......................................... M8x20 ........................... 3

6 ................ SR2024N-6 ............... Socket Head Cap Screw.......................................... M10x25 ......................... 1

7 ................ SR2024N-7 ............... Hex Nut .................................................................... M10 ............................... 3

8 ................ SR2024N-8 ............... Hex Cap Screw ........................................................ M12x 20 ......................... 4

9 ................ SR2024N-9 ............... Left Support ............................................................. ...................................... 1

10 .............. SR2024N-10 ............. Upper Left Bearing Seat .......................................... ...................................... 1

11 .............. SR2024N-11 ............. Lower Left Bearing Seat .......................................... ...................................... 2

12 .............. SR2024N-12 ............. Knob ........................................................................ ...................................... 2

13 .............. SR2024N-13 ............. Knob ........................................................................ ...................................... 2

14 .............. SR2024N-14 ............. Gear ......................................................................... ...................................... 1

15 .............. SR2024N-15 ............. Set Screw Flat Point ................................................ M8x8 ............................. 4

16 .............. SR2024N-16 ............. Gear ......................................................................... ...................................... 1

17 .............. SR2024N-17 ............. Spring Pin ................................................................ 5x20 .............................. 3

18 .............. SR2024N-18 ............. Gear Cover .............................................................. ...................................... 1

19 .............. SR2024N-19 ............. Right Support ........................................................... ...................................... 1

20 .............. SR2024N-20 ............. Spring Pin ................................................................ 8x20 .............................. 1

22 .............. SR2024N-22 ............. Bearing Seat ............................................................ ...................................... 2

23 .............. SR2024N-23 ............. Upper Roll ................................................................ ...................................... 1

.................. SR2236N-23 ............. Upper Roll ................................................................ ...................................... 1

24 .............. SR2024N-24 ............. Lower Roll ................................................................ ...................................... 1

.................. SR2236N-24 ............. Lower Roll ................................................................ ...................................... 1

25 .............. SR2024N-25 ............. Rear Roll .................................................................. ...................................... 1

.................. SR2236N-25 ............. Rear Roll .................................................................. ...................................... 1

26 .............. SR2024N-26 ............. Link Rod................................................................... ...................................... 1

.................. SR2236N-26 ............. Link Rod................................................................... ...................................... 1

27 .............. SR2024N-27 ............. Spring Pin ................................................................ 8x45 .............................. 1

28 .............. SR2024N-28 ............. Cover ....................................................................... ...................................... 1

29 .............. SR2024N-29 ............. Handle ..................................................................... ...................................... 1

30 .............. SR2024N-30 ............. Cam ......................................................................... ...................................... 1

31 .............. SR2024N-31 ............. Handle Bracket ........................................................ ...................................... 1

32 .............. SR2024N-32 ............. Handle ..................................................................... ...................................... 1

33 .............. SR2024N-33 ............. Arm .......................................................................... ...................................... 1

34 .............. SR2024N-34 ............. Pin............................................................................ ...................................... 1

35 .............. SR2024N-35 ............. Flat Head Screw ...................................................... M4x5 ............................. 4

36 .............. SR2024N-36 ............. Plate......................................................................... .... .................................. 2

37 .............. SR2024N-37 ............. Set Screw Cone Point.............................................. M8x8 ............................. 2

38 .............. SR2024N-38 ............. Scale ........................................................................ ...................................... 2

39 .............. SR2024N-39 ............. Rivet......................................................................... .... .................................. 4

.................. SR2024M-ID ............. ID Label (not shown)................................................ ............ .......................... 1

.................. SR2236M-ID ............. ID Label (not shown)................................................ ............ .......................... 1

.................. SR2024N-W .............. Warning Label (not shown) ...................................... ...................................... 1

.................. SR2024N-J................ JET Label (not shown) ............................................. ...................................... 1

6

Page 7

Optional Accessories

754024 Stand for SR-2024M Slip Roll

754036 Stand for SR-2236M Slip Roll

7

Page 8

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

8

Loading...

Loading...