Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Dual-Sided 16ga. Box and Pan Brake

Model PBF-1650D

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-752130

Ph.: 800-274-6848 Edition 1 09/2016

www.jettools.com Copyright © 2016 JET

Page 2

1.0 IMPORTANT SAFETY

INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS

MACHINE.

WARNING – To reduce the risk of

injury:

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This box and pan brake is designed and

intended for use by properly trained and

experienced personnel only. If you are not

familiar with the proper and safe operation of a

brake, do not use until proper training and

knowledge have been obtained.

5. Do not use this brake for other than its intended

use. If used for other purposes, JET disclaims

any real or implied warranty and holds itself

harmless from any injury that may result from

that use.

6. Always wear ANSI Z87.1 approved safety

glasses or face shield while using this brake.

(Everyday eyeglasses only have impact

resistant lenses; they are not safety glasses.)

7. Before operating this machine, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Do not wear loose

clothing. Confine long hair. Non-slip footwear or

anti-skid floor strips are recommended.

8. Wear ear protectors (plugs or muffs) if noise

reaches unsafe levels.

9. CALIFORNIA PROPOSITION 65 WARNING:

This product contains chemicals known to the

State of California to cause cancer, or birth

defects or other reproductive harm.

10. This product, when used for welding, cutting, or

working with metal, produces fumes, gases, or

dusts which contain chemicals known to the

State of California to cause birth defects and, in

some cases, cancer. (California Health and

Safety Code Section 25249.5 et seq.)

11. Do not operate this machine while tired or under

the influence of drugs, alcohol or any

medication.

12. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine

before turning it on.

13. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

14. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

15. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

16. Keep the floor around the machine clean and

free of scrap material, oil and grease.

17. Keep visitors a safe distance from the work

area. Keep children away.

18. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

19. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

20. Maintain a balanced stance at all times so that

you do not fall into the blade or other moving

parts. Do not overreach or use excessive force

to perform any machine operation.

21. Use recommended accessories; improper

accessories may be hazardous.

22. Maintain tools with care. Keep blades sharp and

clean for the best and safest performance.

Follow instructions for lubricating and changing

accessories.

23. Do not stand on the machine. Serious injury

could occur if the machine tips over.

24. Remove loose items and unnecessary work

pieces from the area before operating the

machine.

25. Do not use in dangerous environment. Do not

use machine in damp or wet location, or expose

to rain. Keep work area well lighted.

2

Page 3

26. Sheet metal stock has sharp edges; use caution

when handling to prevent cuts.

27. Keep hands clear of bending area while

operating.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

injury.

28. Do not exceed rated capacity of brake.

29. The brake should be secured to floor with

appropriate fasteners.

SAVE THESE INSTRUCTIONS

2.0 About this manual

This manual is provided by JET, covering the safe operation and maintenance procedures for a JET Model BPF1650D Dual-Sided Box and Pan Brake. This manual contains instructions on installation, safety precautions,

general operating procedures, maintenance instructions and parts breakdown. Your machine has been designed

and constructed to provide consistent, long-term operation if used in accordance with the instructions as set forth

in this document.

This manual is not intended to be a guide to sheet m etal b ending, bend allowances, material cho ice, etc. Consult

a machinery’s handbook and/or experienced users for such information. Whatever accepted methods or

materials are used, always make personal safety a priority.

If there are questions or comments, please contact your local supplier or JET. JET c an also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

Register your product online -

http://www.jettools.com/us/en/service-and-support/warranty/registration/

3

Page 4

3.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

2.0 About this manual .......................................................................................................................................... 3

3.0 Table of contents ............................................................................................................................................ 4

4.0 Specifications for 16x50 Box and Pan Brake ................................................................................................. 5

4.1 Floor Diagram ............................................................................................................................................. 5

5.0 Features and terminology .............................................................................................................................. 6

6.0 Setup and assembly ....................................................................................................................................... 7

6.1 Unpacking and cleanup .............................................................................................................................. 7

6.2 Contents of shipping container ................................................................................................................... 7

6.3 Tools required for assembly ....................................................................................................................... 7

6.4 Assembly .................................................................................................................................................... 7

7.0 Operation ....................................................................................................................................................... 7

7.1 Finger spacing ............................................................................................................................................ 7

7.2 Adjusting setback ....................................................................................................................................... 7

7.3 Adjusting clamping pressure ...................................................................................................................... 8

7.4 Repeat bends ............................................................................................................................................. 8

7.5 General procedure ..................................................................................................................................... 8

8.0 User-maintenance .......................................................................................................................................... 8

8.1 Lubrication .................................................................................................................................................. 8

8.2 Additional servicing .................................................................................................................................... 8

9.0 Troubleshooting PBF-1650D Box and Pan Brake .......................................................................................... 8

10.0 Replacement Parts ....................................................................................................................................... 8

10.1.1 BPF-1650D Box and Pan Brake – Exploded View ................................................................................ 9

10.1.2 PBF-1650D Box and Pan Brake – Parts List ....................................................................................... 10

11.0 Warranty and service ................................................................................................................................. 12

4

Page 5

4.0 Specifications for 16x50 Box and Pan Brake

Model Number ...................................................................................................................................... PBF-1650D

Stock Number ............................................................................................................................................. 752130

Materials:

Frame .......................................................................................................................... welded steel plate/tubing

Clamping fingers .............................................................................................................................. ground steel

Clamping block ................................................................................................................. precision ground steel

Capacities:

Bending length .......................................................................................................................... 50 in. (1270 mm)

Maximum thickness, mild steel ................................................................................................... 16 ga. (1.5 mm)

Bending angle .................................................................................................................................. 0 – 135 deg.

Maximum beam lift ................................................................................................................ 1-13/16 in. (46 mm)

Maximum box depth ................................................................................................................. 2.5 in. (63.5 mm)

Minimum flange in capacity material ............................................................................................. 0.4 in. (10mm)

Nose angle (upper fingers) ...................................................................................................................... 42 deg.

Nose radius ............................................................................................................................. 1/32 in. (0.79 mm)

Number of fingers ............................................................................................................ ......12 upper, 12 lower

Finger widths ........................................................... 1, 1-1/8, 1-3/8, 1-1/2, 1-3/4, 2, 3, 4, 6, 7-3/4, 10, 10-5/8 in.

Weights:

Net ............................................................................................................................................... 772 lb (350 kg)

Shipping ....................................................................................................................................... 849 lb (385 kg)

Dimensions:

Height, floor to working surface ............................................................................................ 35-1/2 in. (902 mm)

Shipping (LxWxH) .......................................................................... 67-3/8 x 28 x 51-1/2 in. (171 x 71 x 131 cm)

Assembled (LxWxH) ................................................................................... 63 x 38 x 45 in. (160 x 97 x 114 cm)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

L=length, W=width, H=height

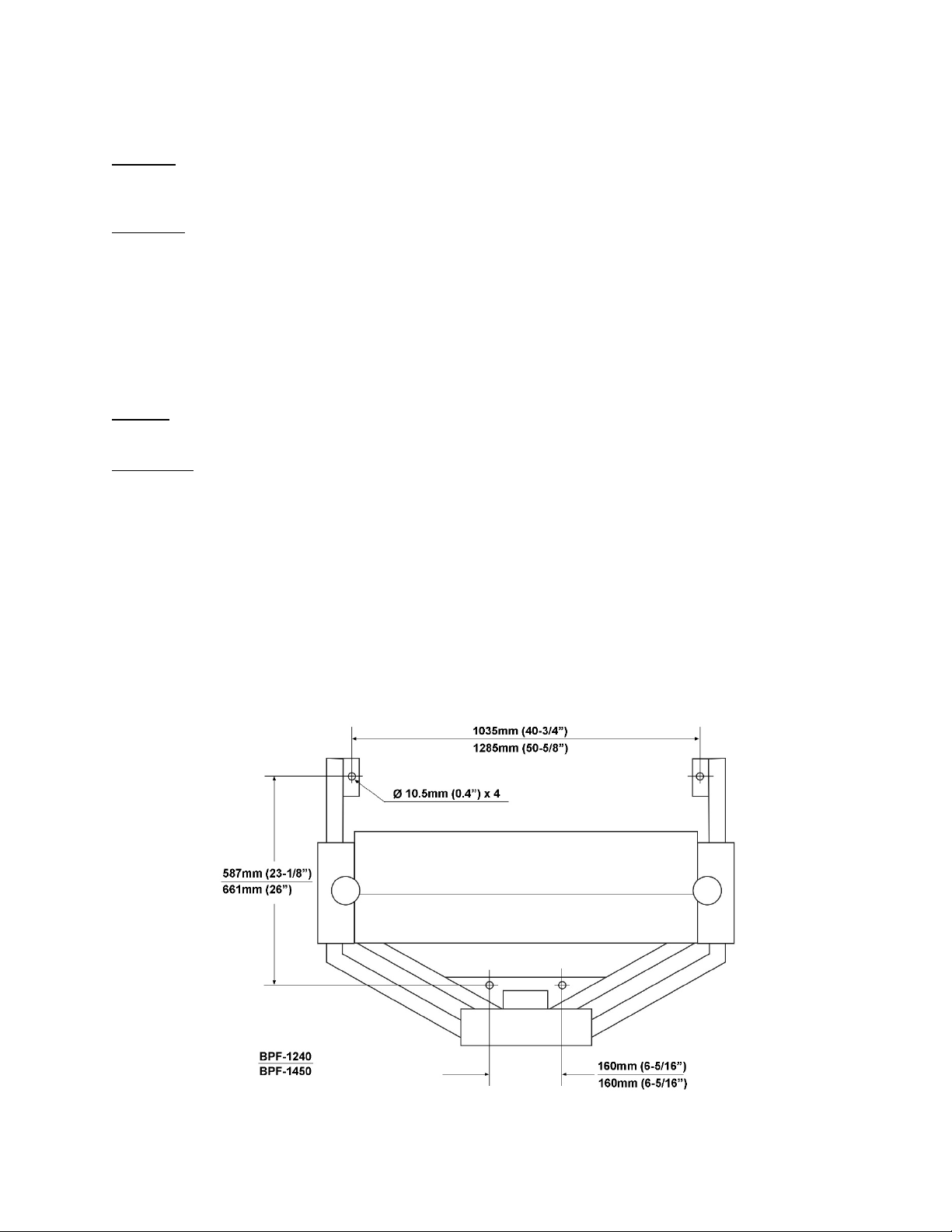

4.1 Floor Diagram

Figure 1

5

Page 6

5.0 Features and terminology

Figure 2

1. Clamping leaf

2. Clamping fingers

3. Clamping adjustment nut (x2)

4. Stop bolt

5. Setback locking screw (x2)

6. Setback knob (x2)

7. Bending leaf fingers

8. Bending leaf

9. Foot pedal for clamping

10. Foot pedal lock

11. Leg extension (x2)

12. Crown adjustment rod

13. Air spring

14. Grease fitting (x2)

15. Stop collar

16. Stop collar screw

17. Eccentric disc

6

Page 7

6.0 Setup and assembly

Read and understand all

assembly instructions before attempting

assembly. Failure to comply may cause serious

injury.

6.1 Unpacking and cleanup

Inspect contents of shipping container for shipping

damage. Report any damage to your distributor.

Remove all contents from carton, and compare to

the contents list in this manual. Report any part

shortages to your distributor.

Do not discard carton or packing material until

machine is assembled and working properly.

Exposed metal areas may have a rust protectant

applied. Remove this with a soft rag and solvent

such as kerosene. (Do not use gasoline, paint

thinner, acetone, etc., as these will damage painted

surfaces.)

6.2 Contents of shipping container

1 Box and Pan Brake

2 Support legs with screws

1 Instructions and Parts Manual (not shown)

1 Warranty Card (not shown)

6.3 Tools required for assembly

8mm hex key

2. Attach the two leg extensions (11) with the

provided socket head screws and flat washers.

3. Secure brake to floor using lag screws or similar

system. See diagram, Figure 1. Also level the

brake; use shims if needed.

4. The stop collar screw (16) has been tightened

for shipping purposes. This screw must be

loosened to allow clamping machine

adjustments.

7.0 Operation

Numbers in parentheses refer to items in Figure 2.

7.1 Finger spacing

Upper (2) and lower (7) fi ngers are mounted on Tnuts that slide within the underlying channel.

Remove fingers by removing the screw(s); or

reposition fingers at any place along the beam by

loosening screw and sliding the T-nuts. Firmly

tighten screws on fingers before operating.

7.2 Adjusting setback

The bending leaf lower fingers (7) must be adjusted

for proper clearance or “setback” (A, Figure 3)

based on material thickness (B, Figure 3).

Generally, setback for material within four gauges of

capacity should be twice the thickness of material.

For lighter gauges, use 1-1/2 times the material

thickness. Consult a machinery handbook for bend

allowances.

6.4 Assembly

Numbers in parentheses refer to items in Figure 2.

1. Remove any straps or screws securing the

brake, and raise machine using properly rated

lifting equipment. See Figure 3 for lifting strap

placement.

Figure 3

Continue to stabilize machine

while installing support legs.

Figure 3

1. Loosen setback locking screws (5).

2. Rotate setback knobs (6) in equal amounts

(clockwise decreases distance). Refer to

adjoining scale, marked with 0.002-inch

graduations.

Note: When increasing distance (counterclockwise), you may have to pull back slightly

on the bending leaf to take up any backlash.

3. Bring clamping leaf into position and check

setback.

4. Repeat above steps until proper distance is

achieved.

7

Page 8

5. Tighten locking screws (5).

If a crown develops in the material, this can be

adjusted out by loosening or tightening the hex nuts

on the crown adjustment rod (12). Note: This rod

has been correctly set by the manufacturer and

should only be adjusted when needed.

4. Align material in machine and press foot pedal

until it locks.

5. Raise bending leaf to desired angle.

6. Lower bending leaf and press foot pedal lock to

release material.

7.3 Adjusting clamping pressure

Clamping pressure may vary depending upon

material gauge. Pressure should be great enough to

hold material securely, but not so much that it

becomes difficult to clamp.

Rotate clamping adjustment nuts (3) equally to set

clamping pressure. Proper adjustment will allow foot

pedal (9) to be locked (10).

7.4 Repeat bends

Loosen stop collar screw (16) and adjust stop bolt

(4) to limit swing of bending leaf. Retighten screw

(16).

7.5 General procedure

1. Adjust upper and/or lower f ingers for width of

material and type of bend.

2. Adjust for setback and clamping pressure.

3. Position stop bolt if needed.

8.0 User-maintenance

Periodically wipe down machine with a soft rag.

Keep upper and lower fingers clean and clear of

debris. Apply light coat of SAE30 oil to upper and

lower fingers.

Periodically check tightness of fasteners.

8.1 Lubrication

Daily insert a multi-purpose grease into the two

fittings (14).

Lightly apply grease to pivot points around machine,

such as setback rods and eccentric disc.

Apply light coat of SAE30 oil to all machined

(unpainted) parts when not in use, to inhibit rust.

8.2 Additional servicing

Any additional servicing should be performed by an

authorized service technician.

9.0 Troubleshooting PBF-1650D Box and Pan Brake

Symptom Possible Cause Correction

Bends created with

great difficulty.

Clamping leaf will not

clamp properly.

Bend radius not

consistent across

material.

Machine capacity exceeded. Use material within capacity.

Incorrect setback. Increase setback.

Improper adjustment.

Clamping not even across width. Rotate adjustment nuts equal amount.

Machine capacity exceeded. Use material within capacity.

Bending leaf edge not parallel to fingers. Adjust bending leaf equally on both ends.

Bending leaf has crown. Correct with crown adjustment rod.

Decrease distance between fingers and

beam.

10.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial Number of

your machine available when you call will allow us to serve you quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from JET.

Some parts are shown for reference only, and may not be available individually.

8

Page 9

10.1.1 BPF-1650D Box and Pan Brake – Exploded View

9

Page 10

10.1.2 PBF-1650D Box and Pan Brake – Parts List

Index No Part No Description Size Qty

1 ................ H40-210 .................... Adjusting Nut ........................................................... ...................................... 2

2 ................ PBF1650D-02 ........... Clamping Leaf. ........................................................ ...................................... 1

3 ................ PBF1650D-03 ........... T-Nut ........................................................................ .................................... 48

4-1 ............. PBF1650D-04-1 ........ Upper Finger ............................................................ 1” ................................... 1

4-2 ............. PBF1650D-04-2 ........ Upper Finger ............................................................ 1-1/8” ............................ 1

4-3 ............. PBF1650D-04-3 ........ Upper Finger ............................................................ 1-3/8” ............................ 1

4-4 ............. PBF1650D-04-4 ........ Upper Finger ............................................................ 1-1/2” ............................ 1

4-5 ............. PBF1650D-04-5 ........ Upper Finger ............................................................ 1-3/4” ............................ 1

4-6 ............. PBF1650D-04-6 ........ Upper Finger ............................................................ 2” ................................... 1

4-7 ............. PBF1650D-04-7 ........ Upper Finger ............................................................ 3” ................................... 1

4-8 ............. PBF1650D-04-8 ........ Upper Finger ............................................................ 4” ................................... 1

4-9 ............. PBF1650D-04-9 ........ Upper Finger ............................................................ 6” ................................... 1

4-10 ........... PBF1650D-04-10 ...... Upper Finger ............................................................ 7-3/4” ............................ 1

4-11 ........... PBF1650D-04-11 ...... Upper Finger ............................................................ 10” ................................. 1

4-12 ........... PBF1650D-04-12 ...... Upper Finger ............................................................ 10-5/8” .......................... 1

5 ................ TS-1505021 .............. Socket Head Cap Screw ......................................... M10x20 ....................... 66

6 ................ PBF1650D-06 ........... Clamping Block ........................................................ ...................................... 1

7 ................ PBF1650D-07 ........... Adjusting Nut Spring ................................................ ...................................... 2

8 ................ TS-155011 ................ Flat Washer ............................................................. 20mm ............................ 6

9 ................ PBF1650D-09 ........... Grease Fitting .......................................................... M8x1 ..... ........................ 2

10 .............. H40-227 .................... Bushing .................................................................... ...................................... 2

11 .............. H40-226 .................... Flat Washer ............................................................. 30 .................................. 2

12 .............. H40-209 .................... Bending Leaf Pin ..................................................... ...................................... 1

13 .............. TS-1505051 .............. Socket Head Cap Screw ......................................... M10x35 ......................... 1

14 .............. H40-204 .................... Stop Collar ............................................................... ...................................... 1

15 .............. TS-1540071 .............. Hex Nut .................................................................... M10 .. ............................. 1

16 .............. TS-1505061 .............. Socket Head Cap Screw ......................................... M10x40 ......................... 1

17 .............. PBF1650D-17 ........... Leg ........................................................................... ...................................... 2

18 .............. BPF1240-18 .............. Ext. Retaining Ring .................................................. 25mm .......................... 13

19 .............. H40-208 .................... Leg Pin .................................................................... ...................................... 3

20 .............. TS-1505041 .............. Socket Head Cap Screw ......................................... M10x30 ......................... 4

21 .............. H40-217-3G .............. Extension Bracket .................................................... ...................................... 2

22 .............. PBF1650D-22 ........... Disc Spring .............................................................. Ø40xø20x1mm ............. 4

23 .............. H40-205 .................... Rod .......................................................................... ...................................... 2

24 .............. H40-206 .................... Foot Pedal Lever ..................................................... ...................................... 4

25 .............. H40-207.................... Lever Pin .................................................................. ...................................... 4

26 .............. PBF1650D-26 ........... Foot Pedal ............................................................... ...................................... 1

27 .............. H40-402 .................... Tread Plate Rubber ................................................. ...................................... 1

28 .............. H40-211 .................... Roll Pin .................................................................... ...................................... 1

29 .............. BPF1240-29 .............. Ext. Retaining Ring .................................................. 10mm ............................ 2

30 .............. H40-213.................... Foot Pedal Lock ....................................................... ...................................... 1

31 .............. BPF1240-31 .............. Spring Pin ................................................................ 8x50mm ........................ 1

32 .............. TS-1550061 .............. Flat Washer ............................................................. 8mm .............................. 1

33 .............. H40-212 .................... Pedal Lock Spring ................................................... ...................................... 1

34-1 ........... PBF1650D-34-1 ........ Lower Finger ............................................................ 1” ..........

34-2 ........... PBF1650D-34-2 ........ Lower Finger ............................................................ 1-1/8” ............................ 1

34-3 ........... PBF1650D-34-3 ........ Lower Finger ............................................................ 1-3/8” ............................ 1

34-4 ........... PBF1650D-34-4 ........ Lower Finger ............................................................ 1-1/2” ............................ 1

34-5 ........... PBF1650D-34-5 ........ Lower Finger ............................................................ 1-3/4” ............................ 1

34-6 ........... PBF1650D-34-6 ........ Lower Finger ............................................................ 2” ................................... 1

34-7 ........... PBF1650D-34-7 ........ Lower Finger ............................................................ 3” ................................... 1

34-8 ........... PBF1650D-34-8 ........ Lower Finger ............................................................ 4” ................................... 1

34-9 ........... PBF1650D-34-9 ........ Lower Finger ............................................................ 6” ................................... 1

34-10 ......... PBF1650D-34-10 ...... Lower Finger ............................................................ 7-3/4” ............................ 1

34-11 ......... PBF1650D-34-11 ...... Lower Finger ............................................................ 10” ................................. 1

34-12 ......... PBF1650D-34-12 ...... Lower Finger ............................................................ 10-5/8” .......................... 1

35 .............. BPF1240-31 .............. Spring Pin ................................................................ 8x50mm ........................ 2

37 .............. PBF1650D-37 ........... O-Ring ..................................................................... 25x3.55mm ................... 2

38 .............. PBF1650D-38 ........... Setback Rod ............................................................ ...................................... 2

......................... 1

10

Page 11

Index No Part No Description Size Qty

39 .............. PBF1650D-39 ........... Setback Knob .......................................................... ...................................... 2

40 .............. PBF1650D-40 ........... Operating Handle .................................................... ...................................... 2

41 .............. PBF1650D-41 ........... Adjusting Rod .......................................................... ...................................... 1

42 .............. PBF1650D-42 ........... Bending Leaf ........................................................... ...................................... 1

43 .............. TS-1550111 .............. Flat Washer ............................................................. 20 .................................. 2

44 .............. TS-2310201 .............. Hex Nut .................................................................... M20 .. ............................. 2

45 .............. TS-2228161 .............. Hex Cap Screw ........................................................ M8x16 ........................... 2

46 .............. PBF1650D-46 ........... Fixing Plate .............................................................. ...................................... 1

47 .............. PBF1650D-47 ........... Air Spring ................................................................. ...................................... 1

48 .............. TS-2211451 .............. Hex Cap Screw ........................................................ M12x45 ......................... 2

49 .............. TS-2311121 .............. Hex Nut .................................................................... M12 .. ............................. 2

50 .............. PBF1650D-50 ........... Eccentric Holder ...................................................... ...................................... 1

51 .............. TS-155011 ................ Flat Washer ............................................................. M 20 ............................... 2

52 .............. TS-1502021 .............. Socket Head Cap Screw ......................................... M5x10 ........................... 2

53 .............. PBF1650D-53 ........... Rubber Pad ............................................................. ...................................... 2

54 .............. PBF1650D-54 ........... Bushing .................................................................... ....... ............................... 4

55 .............. TS-1521031 .............. Socket Set Screw .................................................... M4x8 ............................. 2

56 .............. PBF1650D-56 ........... Scale ........................................................................ ..... ................................. 2

.................. LM000240 ................. ID/Warning Label, PBF-1650D (not shown) ............ ...................................... 1

.................. JET-165 ..................... JET Logo (not shown) ............................................. 165x68mm .................... 1

11

Page 12

11.0 Warranty and service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, El ectric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

12

Page 13

This page intentionally left blank.

13

Page 14

This page intentionally left blank.

14

Page 15

This page intentionally left blank.

15

Page 16

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

16

Loading...

Loading...