Page 1

Assembly and Parts List

Folding Infeed/Outfeed Tables

for JWDS-2244, JWDS-2244OSC, and JWDS-2550 Drum Sanders

IMPORTANT SAFETY INSTRUCTIONS

• Read and understand entire owner's manual for your Drum Sander before attempting assembly or operation.

• Read and understand the warnings posted on the machi ne and in the manual. Failure to comply with all of

these warnings may cause serious injury.

• Replace warning labels if they become obscured or removed.

• WARNING: This product can expose you to chemicals including lead which is known to the State of

California to cause cancer and birth defects or other reproductive harm. For more information go to

http://www.p65warnings.ca.gov.

Open shipping carton and compare contents with

the following parts list to make sure all parts are

intact. Report any missing parts to your distributor.

Contents:

2 Infeed/Outfeed Tables – D

1 Rear (short) Fixed Bracket – E

1 Front (long) Fixed Bracket – F

2 Left Folding Table Brackets – G

2 Right Folding Table Brackets – H

1 Assembly and Parts List

1 Hardware Package, includes:

4 Locking handles – HP1

4 Disc washers – HP2

4 Oilite washers – HP3

16 Socket hd cap screws M8x16 – HP4

16 Flat washers M8 – HP5

4 Socket hd cap screws M6x20 – HP6

4 Flat washers M6 – HP7

4 Eccentric cams – HP8

Tools required for assembly

5mm, 6mm hex (Allen) wrenches

Straight edge (such as straight steel bar or carefully

jointed board)

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-723541

Ph.: 800-274-6848 Edition 2 10/2018

www.jettools.com Copyright © 2018 JET, a division of JPW Industries, Inc

Figure 1: Contents

Page 2

Figure 2: Assembly of Infeed/Outfeed Tables to Drum Sander

Assembly

The sander must be bolted to the stand or a work

table when using these table extensions. Maximum

working load of each table is 35 pounds. Fasteners

are provided with the extension tables.

NOTE: If using the folding feature of the

infeed/outfeed tables, make sure your table or

bench allows for such vertical drop at front and back.

To install infeed table:

1. Install front (F) fixed bracket to threaded holes

in sander base with screws and washers

(HP4/5). Make sure bracket is oriented as

shown. Bracket must be flush against base.

NOTE: Long bracket mounts to front

(infeed); short bracket to rear (outfeed).

2. Tighten screws (HP4).

3. Install eccentric cam (HP8) with screw and

washer (HP6/7). Finger tighten only at this time.

4. Install left (G) and right (H) table brackets, using

handles and washers (HP1/2/3).

Note: Handle (HP1) is adjustable – pull up and

rotate on pin to more convenient position, then

release allowing it to settle back onto pin.

5. Place infeed table (D) onto table brackets and

secure with screws and washers (HP4/5).

Finger tighten only.

Align infeed table with sander’s conveyor table as

follows. See Figures 3 and 4.

6. Place a straight-edge at one side of conveyor

table under drum and extending out over infeed

table. See Figure 3. You may wish to lower

drum until it contacts the straight edge to hold it

in place.

7. Raise infeed table until it evenly contacts

straight edge. If needed, loosen four screws

(HP4) beneath table and adjust table to level.

Tighten screws.

8. Loosen screw (HP6) and rotate eccentric cam

(HP8) until it contacts lip of table bracket. Do

this on both sides of infeed table. This ensures

infeed table will remain level with conveyor

table each time it is returned to operating

position. Tighten screws (HP6).

9. Install outfeed table using identical procedure

as above.

Figure 3: infeed table alignment

2

Page 3

TIP: It is often preferable to position infeed/ outfeed

tables slightly below conveyor table surface,

particularly if stock being sanded is bowed, warped

or otherwise inconsistent. Also, if stock slips on

conveyor, the tables may be positioned too high.

Adjustment

The tables can be swung down to allow easier

access for abrasive wrapping or other adjustments.

Loosen handles on each side, slide table away from

machine and then down. See Figure 4.

Specifications

Figure 4

Stock no.

Fits model JWDS-2244 JWDS-2550 / JWDS-2244OSC

Table size 22 x 10-1/4 in. (559 x 260mm) 26 x 10-1/4 in. (660 x 260mm)

Net weight (approx.) 23 lbs. (11 kg) 26 lbs. (12 kg)

Shipping weight (approx.) 28 lbs. (13 kg) 31 lbs. (14 kg)

723541 723551

Replacement Parts

Replacement parts are listed on the following page. To order parts or reach our s ervice depart ment, call 1-800274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial Number of

your machine available when you call will allow us to serve you quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from JET.

Some parts are shown for reference only, and may not be available individually.

3

Page 4

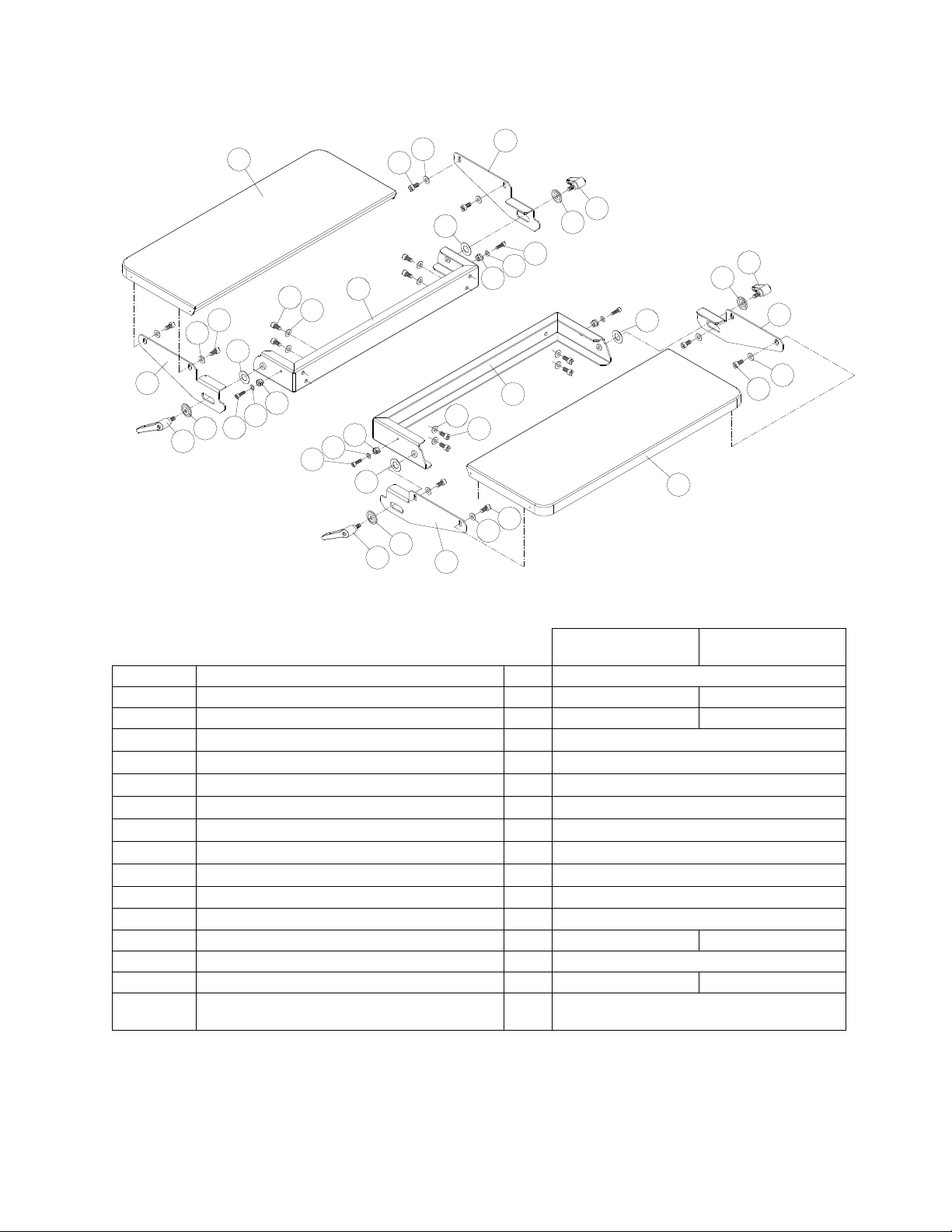

Folding Infeed/Outfeed Tables for JWDS-2244/-2244OSC/-2550

1

3

2

4

5

7

9

2

2

11

3

10

6

8

5

6

7

12

3

7

12

10

6

5

10

9

8

9

8

3

7

13

2

1

2

3

3

2

6

5

4

JWDS-2244 JWDS-2550

JWDS-2244OSC

Index No. Description Qty. Part No.

Folding Infeed/Outfeed Tables (#1-13) 723541 723551

1 Extension Table 2 JWDS2244-401 JWDS2550-401

2 Socket Head Cap Screw M8-1.25P x 16L 16 TS-1504031

3 Flat Washer 8.3 x 20 x 1.5T mm 16 TS-1550061

4 Left Folding Table Bracket 2 JWDS2244-404

5 Handle 4 JWDS2244-405

6 Disc Washer 4 JWDS2244-406

7 Oilite Washer 4 JWDS2244-407

8 Socket Head Cap Screw M6-1.0P x 20L 4 TS-1503051

9 Flat Washer 6.3 x 13 x 2T mm 4 TS-1550041

10 Eccentric Cam 4 JWDS2244-410

11 Rear Fixed Bracket 1 JWDS2244-411 JWDS2550-411

12 Right Folding Table Bracket 2 JWDS2244-412

13 Front Fixed Bracket 1 JWDS2244-413 JWDS2550-413

Hardware Package, Infeed-Outfeed Tables

(includes #2,3,5,6,7-10)

JWDS2244-420

4

Loading...

Loading...