Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

8-inch Woodworking Jointer

Models JJ- 8C S an d JJ- 8 HH

Model JJ-8CS Model JJ-8HH

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708458

Ph.: 800-274-6848 Revision H2 02/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

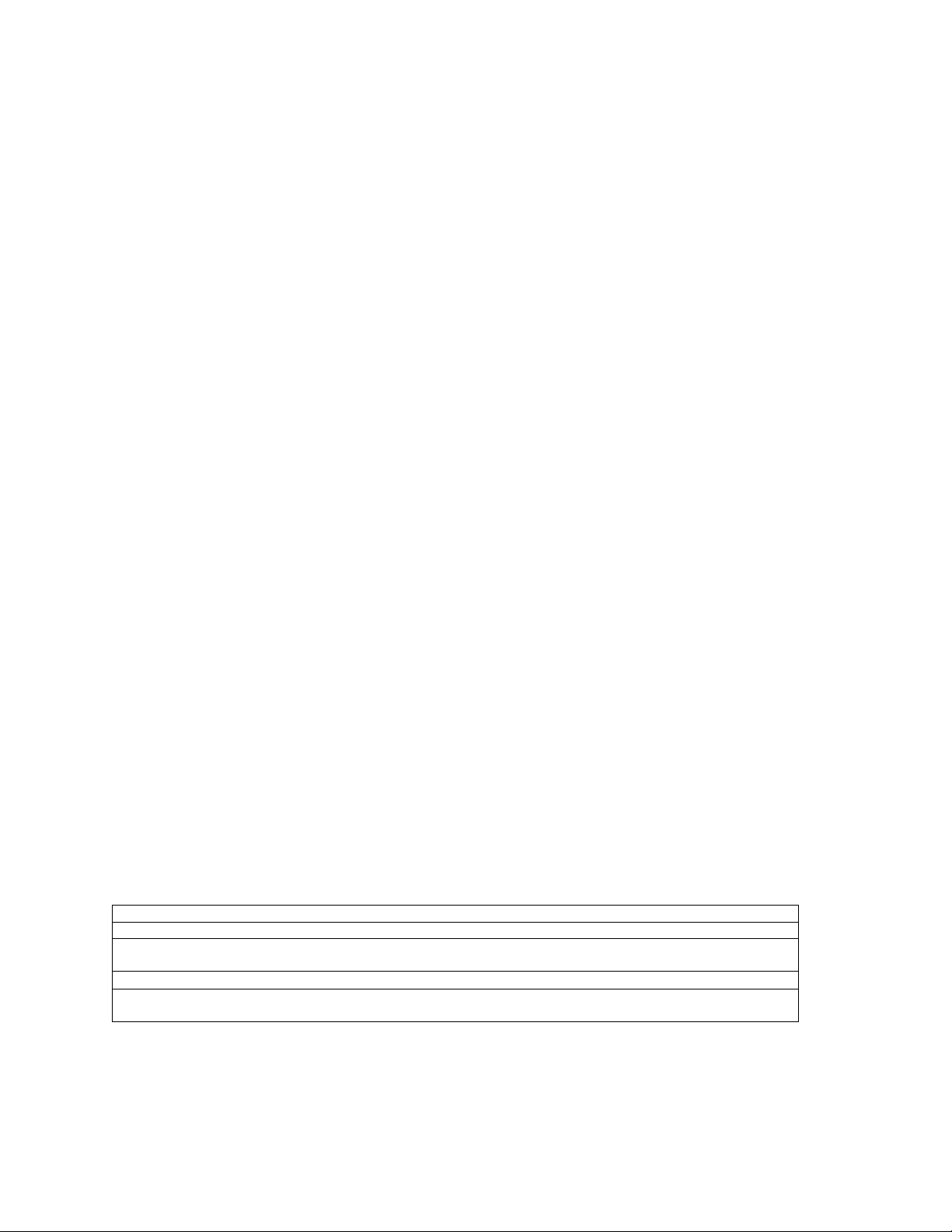

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 5

Levers and Controls ................................................................................................................................ 6

Specifica tions ................................................................................................................ .......................... 6

Unpacking and Cleanup .......................................................................................................................... 7

Unpacking and Cleanup ....................................................................................................................... 7

Installing B ed to Stand ......................................................................................................................... 8

Installing P edest al Switch (JJ-8HH only) .............................................................................................. 8

Installing Handwheel s .......................................................................................................................... 9

Assembling Knife-Setting Gauge (JJ-8CS only) .................................................................................... 9

Installing V-Belts .................................................................................................................................. 9

Installing Cutterhead Guard ................................................................................................................ 10

Installing Access Door ........................................................................................................................ 10

Installing Dust Chute .......................................................................................................................... 10

Electri c al Connec tions ........................................................................................................................ 10

Extension Cords................................................................................................................................. 11

Adjustments .......................................................................................................................................... 11

90° Fence Adjustment ........................................................................................................................ 11

45° Fence Adjustment ........................................................................................................................ 12

Leveling Outfeed Table to Cutterhead Knives .................................................................................... 12

Removing and Replacing Knives (JJ-8CS only) .................................................................................. 14

Replacing or Rotating Knife Inserts (JJ-8HH only) .............................................................................. 14

Gib Adjustment .................................................................................................................................. 15

Operation .............................................................................................................................................. 1 5

Jointing Warped Material .................................................................................................................... 16

Direction of Grai n ............................................................................................................................... 16

Bevel Cut ........................................................................................................................................... 16

Taper Cut ........................................................................................................................................... 17

Rabbet Cut ........................................................................................................................................ 17

Maintenance .......................................................................................................................................... 18

Lubrication ......................................................................................................................................... 18

Blade Care ......................................................................................................................................... 18

Sharpening the Kniv es (J J - 8CS only ) ................................................................................................. 18

Cutterhead Rem ov al .......................................................................................................................... 1 8

Replacement Parts ................................................................................................................................ 20

Fence As sembly (al l mod els) ................................................................................................... .......... 21

Parts List – Fence Assembly (all models) ........................................................................................... 21

Bed Assembly (all models) ................................................................................................................. 22

Parts List – Bed Assembly ( all m odels) ............................................................................................... 23

Stand and Motor Assembl y (JJ- 8CS only) .......................................................................................... 24

Parts List – Stand and Mot or Assembl y (JJ - 8CS only ) ........................................................................ 25

Stand and Motor Assembl y (JJ- 8HH only ) .......................................................................................... 26

Parts List – Stand and Mot or Assembl y (JJ-8HH only) ........................................................................ 27

Parts List – Cutterhead A ssembly (JJ-8CS only)................................................................................. 28

Parts List – Cutterhead A ssembly (JJ-8HH only) ................................................................................ 29

Electri c al Connec tions (JJ-8CS only) .................................................................................................. 30

Electric al Connec tions (JJ-8HH only).................................................................................................. 31

3

Page 4

Warning

1. Read and understand t he entire owners manual bef or e attempti ng assem bly or operation.

2. Read and understand the warning s posted on t he m achine and i n this manual. Failure t o comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace t he warning labels if they become obscured or removed.

4. This jointer is designed and i ntended for use by prope rly trai ned and experienced personnel only. If

you are not familiar with the proper and safe operation of a jointer, do not use until proper training and

knowledge have been obtained.

5. Do not use this j ointer for ot her than i ts intended u se. If used for ot her purpos es, JET di sclaim s any

real or implied warranty and holds itself harmless from any injury that m ay result from that use.

6. Always wear approved safet y glasses/face shi elds while using thi s jointer. Ev eryday eyeglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operati ng this jointer, remove tie, rings, watches an d other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine long hair. Non- sl ip footwear or anti-skid floor st r ips

are recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during ex tended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause c anc er , birth defects or other reproductive harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry produc ts.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tired or under t he influence of drugs, alcohol or any medic ation.

11. Make c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. Make c er tain the machine is properly grounded.

13. Make all machine adjustments or mai ntenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning i t on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure t he jointer is firmly secured to the stand or a bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Prov ide for adequate space surrounding work area and non-glare, over head lighting.

19. Keep t he floor around the machine clean and free of scrap mater ial, oil and grease.

20. Keep visitors a safe distance from the work area. Keep children away.

4

Page 5

21. Make y our workshop child proof with padlock s, m aster switches or by removing starter k ey s.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maintai n a balanced stance at all times so that you do not fall or lean against t he knives or other

moving part s. Do not over r eac h or use excessive force to perform any machine oper ation.

24. Use the right tool at the correc t speed and f eed rat e. Do not force a t ool or attac hment to do a j ob for

which it was not designed. T he ri ght tool will do the job better and saf er.

25. Use recommended accessories; improper accessories may be hazardous.

26. Mai ntain tools with care. K eep knives sharp and clea n for the best and saf est performance. Foll ow

instructions for lubricating and changi ng ac c essori es.

27. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

28. Do not stand on the machine. Serious injury c ould oc c ur if the mac hi ne tips over.

29. Never leave the machine runni ng unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

30. Remove loose items and unnecessary work pieces from the area before starti ng the mac hine.

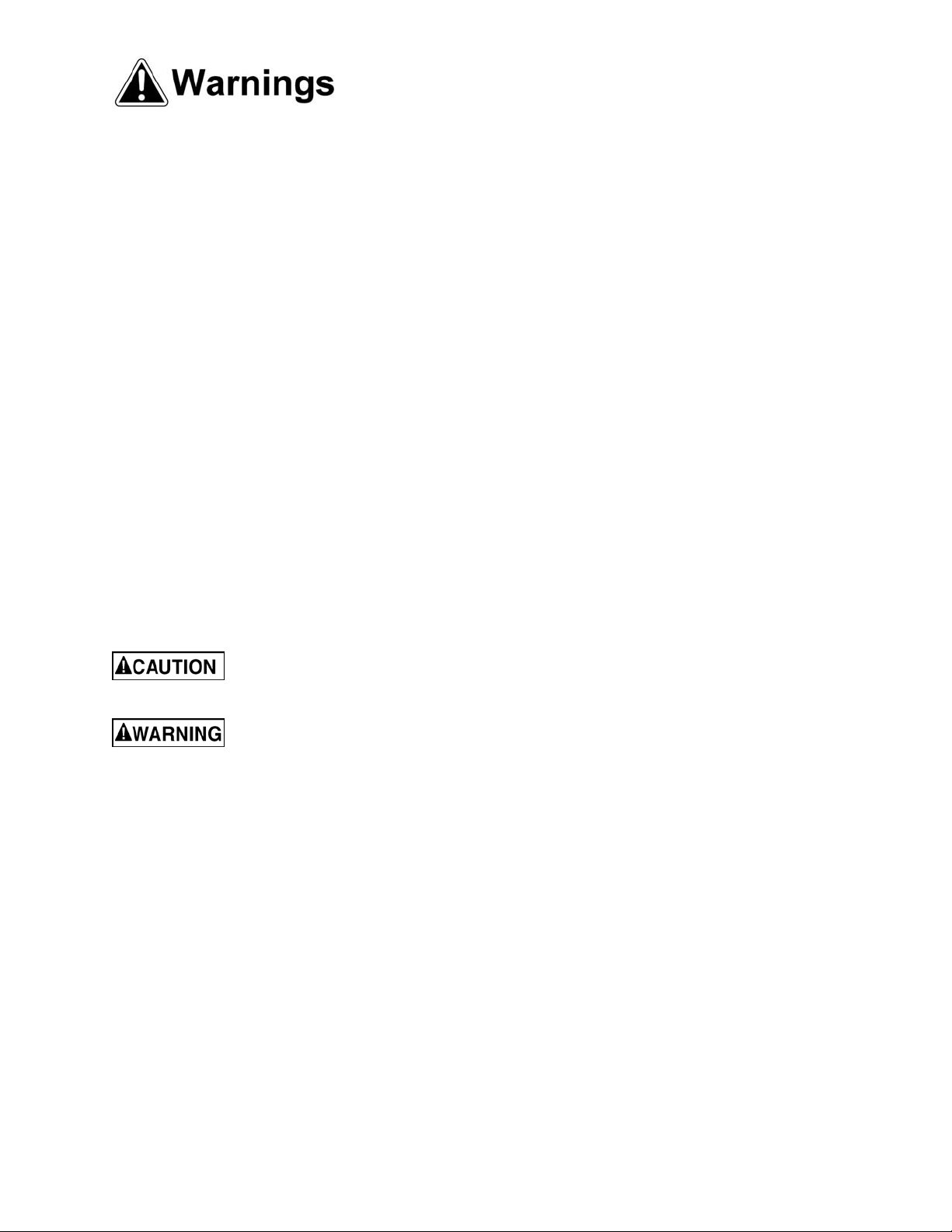

Familiariz e you rself with the following safety notices u sed in this manual:

This means that if precautions are not heeded, it may result in mi nor i njur y and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

Introduction

This manual is provi ded by JET covering the saf e operation and mai ntenance procedures for the JET

Model JJ-8CS and JJ-8HH Woodworking Jointers. This manual contains instructions on installation,

safety prec autions, general operating pr ocedures, maintenance i nstructi ons and parts breakdo wn. This

machine has been designed and constructed to provide years of trouble free operation if used in

accordance with instructions set forth in this manual. If there are any questions or comments, please

contact eit her y our l oc al suppli er or JET. JET can also be reached at our web site: www.jettools.c om .

5

Page 6

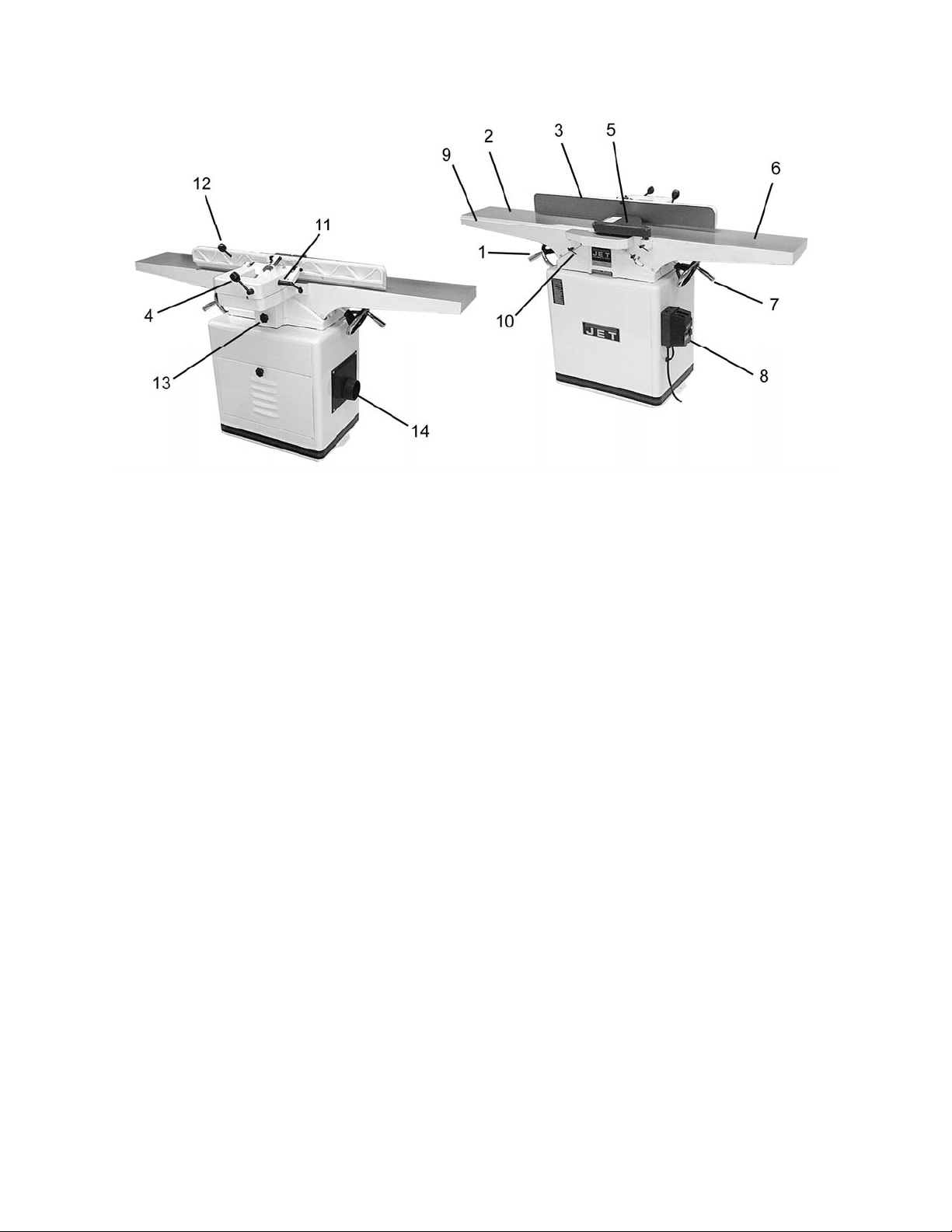

Levers and Controls

1. Handwheel for Outf eed Table 8. On/Off Switch (Pedestal style on JJ-8HH)

2. Outfeed Table 9. Rabbeting Ledge

3. Fence 10. Table Lock Knob

4. Fence Adjustment Handle 11. Fence Tilt Lock Handle

5. Cutter Guard 12. Fence Contr ol Handle

6. Infeed Table 13. Belt Guard

7. Handwheel for Infeed Table 14. Dust Chute

Specifications

Model JJ-8CS JJ-8HH

Stock Number – Bed and Stand Kit ................................ 708458K................................................ 708468K

Stock Number – Bed Assembly ..................................... 708458J................................................. 708468J

Stock Number Stand...................................................... 708458S................................................ 708460S

Cutting Capacity ....................................................... 8"W x 1/2"D ........................................... 8"W x 1/2"D

Cutterhead Speed ...................................................... 5500 RPM.............................................. 5500 RPM

Number of Knives ...................................................................... 3....................................... 36 knife inserts

Rabbeting Capaci ty .............................................................. 1/2"......................................... not applicable

Rabbet Ledge ........................................................ 3-1/8" x 8-3/4 "........................................ 3-1/8" x 8-3/4"

Table Surface .......................................................9”W x 66-1/2”L....................................... 9”W x 66-1/2”L

Fence ...................................................................4”W x 38-1/2”L....................................... 4”W x 38-1/2”L

Knife Size .................................................. 8”L x 11/16”W x 1/8”T......................... 0.59”L x 0.59”W x 0.10T

Fence Tilt ................................................................... 45ºL, 45ºR ............................................ 45ºL , 45ºR

Positive Stops...................................................... 45ºL, 90º, 45ºR...................................... 45ºL, 90º, 45ºR

Motor ................................................ 2HP, 1Ph, 60Hz, 230V only.................... 2HP, 1Ph, 60Hz, 230V only

Net Weight, Joint er and Stand ( appr ox .) ......................... 400 lbs.................................................... 411 lbs

Shipping Weight , Jointer and Stand ................................ 495 lbs.................................................... 505 lbs

The above specifications were current at the time this manual was published, but because of our policy of

continuous impr ovement, JET reserves the ri ght to change specific ations at any time and without prior

notice, without incurring obligations.

6

Page 7

Unpacking and Cleanup

Cont en ts of Shipping Carton s

Note: Unit shipped in two cartons.

Stand Carton

1 Stand with Mot or

1 Stand Door

1 Dust Chute with Mounting Hardware

1 Pedestal Switc h with Mounting Hardware

(JJ-8HH only)

Main Unit Carton

1 Bed Assembly

1 Fence Assembly

1 Cutterhead Guard

1 Belt Guard

2 V-Belts

2 Handwheels with handle

1 Fence Handle

3 Mounting Bolts

3 3/8" Lock Washers

1 Operating Instr uc tions and Parts Manual

1 Warranty Card

Tools Included with JJ-8CS

1 12/14mm Open End Wr enc h

1 8/10mm Open End Wrench

3 Hex Wrenches (3, 4 and 5 mm)

1 Knife Gauge Assembly

Tools included with JJ-8HH:

1 12/14mm Open End Wr enc h

1 8/10mm Open End Wrench

4 Hex Wrenches (3, 4, 5, 6 mm)

2 Star Point Screwdrivers

5 Knife Inserts

10 Knife Insert Screws

Tools Required for Assembl y:

#1 Cross Point Screwdriver

6-8” Adjustable Wrench or 17 & 19mm Wrench

Unpacking and Cleanup

1. Carefully finish removing all contents from

both shipping car tons. Compare cont ents of

the shipping car tons with the l ist of content s

above. Place part s on a prot ec ted surface.

2. Set packing material and shippi ng c ar tons to

the side. Do not discard until machine has

been set up and is running properly.

3. Clean all rust protected surfaces (bed,

fence, etc.) with kerosene or diesel oil. Do

not use gasoline, paint thinner, mineral

spirits, etc. These may damage painted

surfaces.

7

Page 8

Cutterhead knives are

dangerously sharp! Use

extreme cautio n when cl eani ng.

4. Appl y a thi n layer of paste wax t o the bright

surfaces of the fence and t ables to prevent

rust.

Installing Bed to Stand

1. Use an assistant or hoist mechanism to

place bed assembly on top of stand. Be

sure identifi cati on label on t he bed fac es the

same direction as the label on the stand

(Fig. 1).

2. Line up two holes i n top of stand with holes

in bed assembl y by viewing through acces s

door in stand.

3. Attach bed assembl y to stand with two 3/8"

lock bolts and l ock washers (Fig. 2). Hand

tighten only at t his tim e.

4. Line up thir d hole in stand with hole in bed

assembly by viewing t hr ough dust c hute.

Figure 1

5. Install third 3/8" lock bolt and lock washer

through dust chute t o secure bed to stand.

6. Tighten all three mounting bolt s with 14mm

wrench.

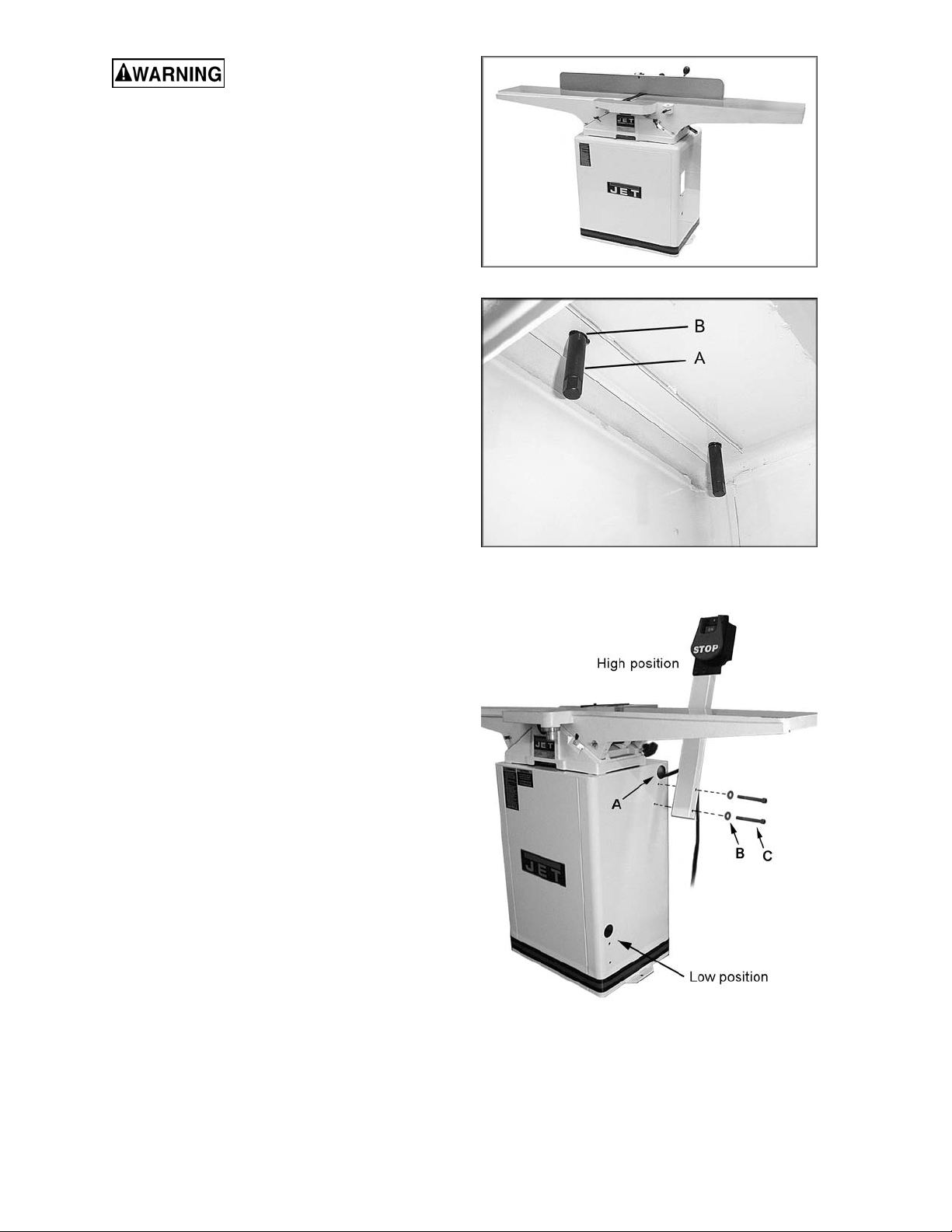

Installing Pedestal Switch (JJ-8HH only)

Referring to Fi gur e 3:

1. The switch may be installed in either high

position or l ow position to suit the operat or.

Slide the connection plug through the

opening (A) and secure the pede stal switch

using two 5/16”x3” screws (C) and 5/16” flat

washers (B).

2. Connect the plug from the pedestal switch

to the motor plug inside t he c abinet.

Figure 2

Figure 3

8

Page 9

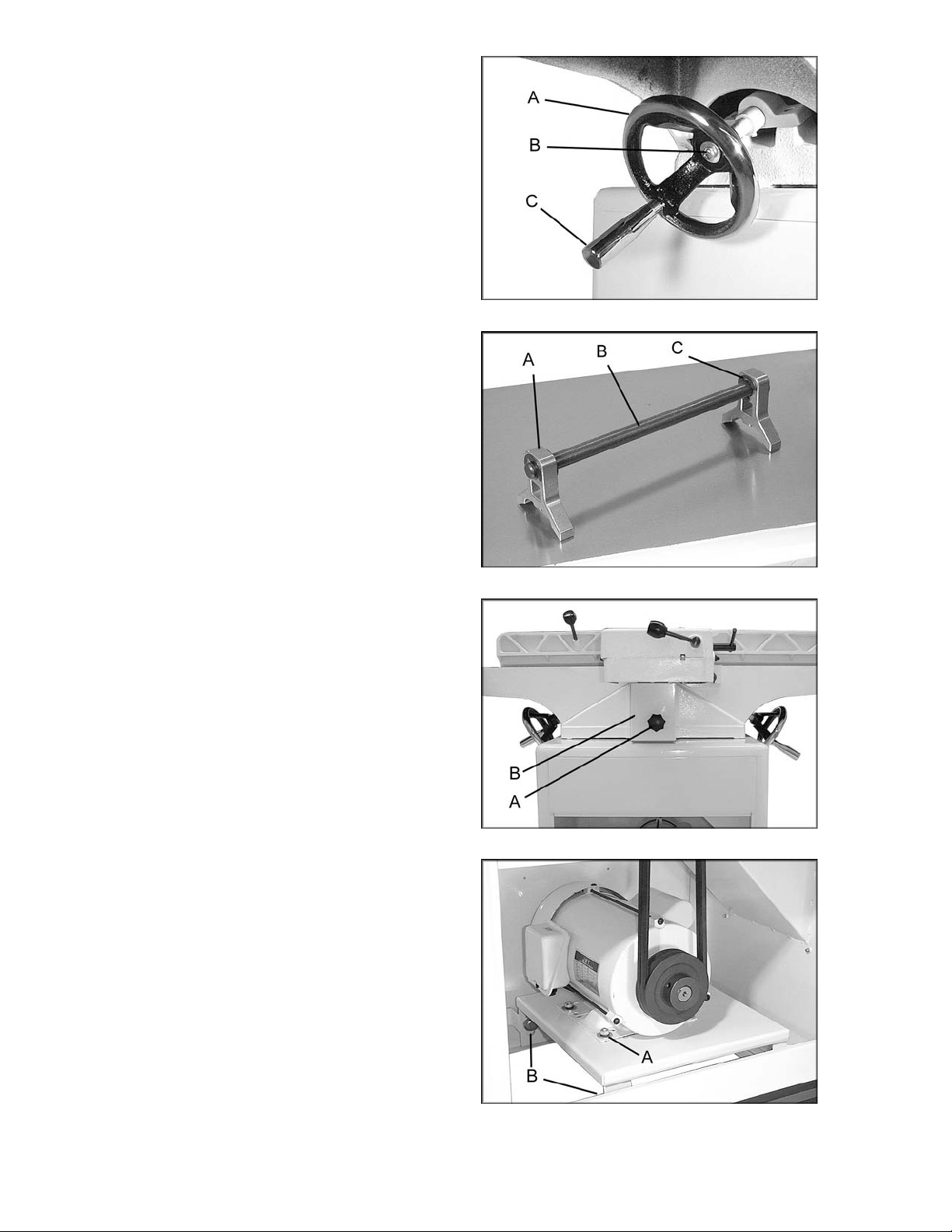

Installing Handwheels

1. Remove protective tape from shaft, and

remove screw and washer.

2. Press handwheel (A, Fig. 4) onto shaft,

aligning the keyway with the key. If

necessary, use a hammer with a block of

wood to tap the hand wheel complet ely onto

the shaft.

3. Re-install screw and washer (B, Fig. 4).

4. Mount handl e ( C, Fig. 4) onto handwheel.

Assembling Knife-Setting Gauge (JJ8CS only)

Place the t wo ba se s (A, Fig. 5) ont o eac h end of

the bar (B, Fig. 5). Snap the four E-rings (C,

Fig. 4) into the grooves on the bar as shown,

one E-ring on each si de of a base.

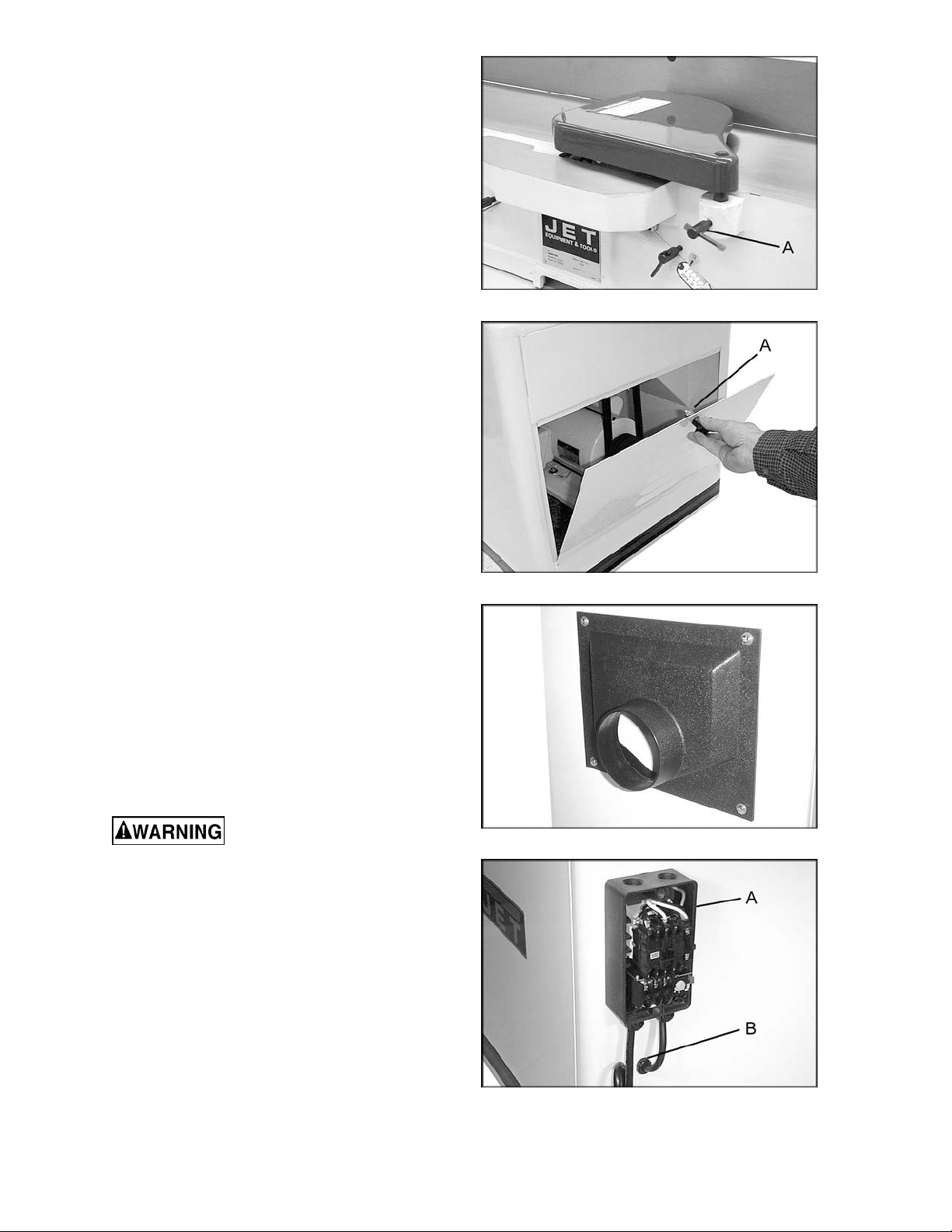

Installing V-Belts

Figure 4

1. Disconnect the machine from the power

source, unplug.

2. Remove the lock knob (A, Fig. 6) and belt

guard (B, Fig. 6).

3. Place v - belts onto cutterhead pul ley grooves

and through opening i n st and.

4. Pull v-belts down and place onto motor

pulley (Fig. 7). If necessary, loosen the

mounting screws (A, Fig. 7) and slightly lift

motor. Re-tighten the screws when belt is

placed.

5. Check to make sure that motor pulley and

cutterhead pulley are vertically aligned and

the v-belt does not contact the sides of the

opening in the base. If the pulleys are not

aligned, loosen t he screws (A, F ig. 7) on the

motor base and sli de the m otor unt il the belt

is aligned. Re-tighten screws.

6. The v -belt i s properly tensioned when f inger

pressure on the belt half way between the

two pulleys cau se s 1/2" deflection. If the belt

is too loose, loosen the lower screws (B,

Fig. 7) on the mounting plate and push

down on the plate. When belt tension is

correct, re-tighten screws.

Figure 5

Figure 6

7. After two hours of operation, check belt

tension again. Re-t ensi on if necessary.

8. Re-install belt guard and lock knob.

Figure 7

9

Page 10

Installing Cutterhead Guard

Orient guard (Fig. 8) in proper position and

insert post int o hole i n table. Tighten l ock screw

(A, Fig. 8) .

Installing Access Door

Install access door by placing bottom of panel

into access in stand and fastening by turning

latch ( Fig. 9) .

If the access door latch need s adju st ment:

1. Remove the acc ess door from the stand.

2. Loosen t he hex lock nut (A, Fig. 9). Rotate

the latch a quar ter turn clockwise to ti ghten

and countercl oc k wise to loosen.

3. Tighten the lock nut (A, Fig. 9).

4. Re-install the access door.

Installing Dust Chute

Attach the dust chute (Fi g. 10) t o the stand wit h

four screws and four flat washers, through the

pre-tapped holes i n the stand.

Figure 8

Figure 9

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

Model JJ-8CS: Rem ove the cover of the switch

box (A, Fi g. 11) and mount the box to the right

side of the stand using t he two scre ws prov i ded.

Insert the motor leads through the hole in the

stand as shown, and i nsert a grommet (B, Fig.

11).

Consult the wiri ng diagram insi de the switc h box

cover. The diagram is also on page 30 of this

manual.

Figure 10

Figure 11

10

Page 11

The JJ-8CS and JJ-8HH jointers are rated at

230V, single phase only. Confirm that the

power at the source is compatible with the

jointer bef ore inserting plug into the outl et. The

jointer is designed to be used with a plug and

outlet similar to that shown in Fig. 12.

Important: Make certain the receptacle in

question is properly grounded. If you are

not sure, have a regi stered electrician check

the receptacl e.

Extens ion Cords

Make sure the rating of the extension cord is

suitable for the amperage listed on the

machine’s motor plate. An undersize cord will

cause a drop in line volt age resulting in loss of

power and overheat ing.

Figure 12

Recommended Extension Cord Gauges (AWG)

Extension Cord Length in Feet *

Amps

25 50 75 100 150 200

< 5 16 16 16 14 12 12

Use the chart i n F igur e 13 as a gener al gui de i n

choosing the c orrect size cord. If in doubt, use

the next heavi er gauge. The smaller the gauge

number, the heavier the cord.

Adjustments

90° Fence Adjustment

Note: whenever making an adjustment to the

fence, lift the fence up slightly after rel easi ng the

lock handle to av oid scratching the table.

1. Set infeed table to the same height as the

outfeed tabl e.

2. Mov e the fence by releasing l ock handle (A,

Fig. 14) and pushing the fence assembly

until it overlaps the tables.

3. Adjust the f ence t o a 90

lock handle (B, Fig. 14), pulling up on

handle (C, Fig. 14), and re-tightening lock

handle (B, Fig. 14).

° angle by releasi ng

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting the lin e vol tage drop to 5V at 15 0% of th e

rated amp eres.

NR: Not Recommended.

Figure 13

Figure 14

4. Place a combination square on the infeed

table. (Fig. 15)

5. If fence is not square to t able, release lock

handle (B, Fig. 14), loosen nut (D, Fig. 14),

and turn bolt (E, Fig. 14) until fence is

square to table.

6. Ti ghten nut (D, Fig. 14) t o retain the setting.

Tighten loc k handl e ( B, Fig. 14).

Figure 15

11

Page 12

45° Fence Adjustment

Note: Whenever making an adjustment to the

fence, lift the fence up slightly after rel easi ng the

lock handle to av oid scratching the table.

1. Loosen lock handl e (A, Fig. 16) . Move the

stop plate (B, Fig. 16) out of the way and

position the fence at the 45

sure the fence sits agai nst the stop bolt (C,

Fig. 16).

2. Place a combinati on square (D, Fig. 16) on

the fence and table to confirm a 45

3. To adjust, l oosen lock nut (E, Fi g. 16), turn

bolt (C, Fig. 16) until a 45

obtained, and tighten lock nut (E, Fig. 16).

Tighten loc k handl e ( A, Fig. 16).

° angle. Make

° setting.

° angle is

Leveling Outfeed Table to Cutterhead Knives

Figure 16

Machine should be

disconnected from power source at this

time! Cutt erhead blades are extremely sh arp!

Use caution when hands are near the

cutterhead!

For most jointi ng operations, the surface of the

outfeed tabl e must be level wit h the knife ti ps of

the cutterhead at their highest point of

revolution. The knife tips must project equally

from the cutterhead.

The outfeed table and cutterhead are adjusted

at the factory and should not r equire adjustment.

1. On the JJ-8CS Jointer, carefully number

each blade with a magic marker to make

them easier to differentiate.

2. Rotate the cutterhead by turning the

cutterhead pulley and determine the 12

o’clock position of knife number one (or a

knife insert on the JJ-8HH model). The 12

o’clock posit ion is the highest poi nt a blade

will reach in the c utti ng ar c.

3. Loosen table lock screw (A, Fig. 17) and

raise the outf eed table t o the height of blade

number one by turning handwheel (B, Fig.

17). Counter-clockwise will cause the

outfeed tabl e to raise. Clockwise will cause

the outfeed table to lower.Set a straight

edge (C, Fig. 17) on the outf eed table and

across the cutt er head.

4. Position of the table and straight edge

should look like Figure 18. Use care when

handling the straight edge near the blades

so as not to damage them.

Figure 17

Figure 18

12

Page 13

5. When the outfeed table and blade number

one (or knife insert) are the same height,

tighten table lock screw.

After t he outf eed tabl e has been set, t he JJ-

8HH will need no further adj ustments to the

cutterhead – ski p steps 6 thr ough 9 below.

The JJ-8CS must have its knives parallel

with the outf eed table. Proceed as follows:

6. Bring the straight edge forward to the front

of the outf eed table and confi rm that blade

number one is at the same height at the

front of t he table as it is at the back of t he

table.

7. If blade is higher or lower at one point,

slightly loosen five screws (A, Fig. 19) by

turning clockwise as v iewed f rom the inf eed

table.

8. Place the knif e sett ing gauge ( B, Fi g. 19) on

the cutterhead over the blade. Continue

loosening the five screws until the springs

push the knife up into contact with the

gauge. Alter nately tighten the five screws to

hold each blade in plac e.

Figure 19

9. Repeat this process with blades two and

three. The outfeed table and cutterhead

knives are correc tly adjusted when all t hree

blades are paral lel to the outfeed t able and

all three bl ades are set at the same height in

the cutter head.

After the outfeed table has been set at the

correct height, do not change it except for

special operat ions or after replacing the knives.

If the outfeed table is set too high, a curved

finished surfac e r esul ts. (Fig. 20)

If the outfeed table is set too low, gouging

results at the end of the c ut. (Fig. 21)

Figure 20

Figure 21

Figure 22 illustrates the outfeed table at the

correct height .

Figure 22

13

Page 14

Removing and Replacing Knives (JJ8CS only)

Disconnect t he machine from

the power source before making any

adjustment or repair. All knife lock bolts

must be firmly tightened or risk ejection of

the knife(s) and lo ck bar fr om the cutterhead!

Failure to compl y may cause seri ou s injury!

1. Disconnect machine from power source.

2. Remove blade guard by loosening lock

screw (A, Fig. 23) and lifting up on blade

guard. Caution: blades are sharp! Use

great care when hands are around blade

area!

3. Loosen the fiv e lock screws (Fi g. 24). Note:

Loosen screws by turning in a clockwise

direction as viewed from the infeed table.

Carefully r emove the knife (A, Fig. 25), and

the lock bar with screws (B, Fig. 25).

Repeat for the other two blades.

4. Bef ore assembly, clean all parts thor oughly

and clear cut terhead knife slots of any dust

or debris.

5. Insert knife into the cutterhead channel

making sure it f aces the proper direction.

Figure 23

Figure 24

6. Insert lock bar and screws and tighten to

hold in place. Blades are set at the proper

height when the top of the blade is 1/16"

above the cutterhead.

7. Repeat for other two blades.

8. To set the kniv es to the outf eed tabl e and to

the same height in the cutterhead, see

section titled “Leveling Outfeed Table to

Cutterhead Kniv es” found on page 12 of t his

manual.

Replacing or Rotating Knife Inserts (JJ-8HH only)

The knife inserts on the model JJ-8HH Jointer

are four-sided. When dull, simply remove each

insert, rotate it 90° for a fresh edge, and reinst a ll it.

Use the two provi ded star point screwdriv ers to

remove the knife insert screw. See Figure 26.

Use one of the screwdrivers to help hold the

cutterhead i n position, and the ot her to remove

the screw. It is advisabl e to rotate all inserts at

the same time to maintain consistent cutting.

However, if one or more knife insert s develops a

nick, rotate only those inserts that are affect ed.

Figure 25

Figure 26

14

Page 15

Each knife insert has an etched referenc e mark

so that you can keep track of t he r otati ons.

IMPORTANT: When removing or rotating

inserts, clean saw dust from the screw, the

insert, and the cutterhead platform. Dust

accumulation between these elements can

prevent the insert from seating properly, and

may affect the quali ty of the cut.

Before installing each screw, lightly coat the

screw threads wit h m achine oi l and wi pe off any

excess.

Securely tighten each screw which holds the

knife inserts before operating the planer!

Make sure all knife insert

screws are tigh ten ed secu rely. Loo se inserts

can be propelled at high speed from a

rotating cutterhead, causing injury.

Gib Adjustment

After a period of use, the gibs may become

loose and need adjusting:

1. Loosen three loc k nuts (A, Fig. 27) and gib

lock screw (B, Fig. 27)

2. Tighten each set screw 1/4 turn starting at

the bottom and working up. If a 1/4 turn

does not remove all play, take another 1/4

turn. Repeat a 1/4 turn at a time for all three

set screws until play is removed.

Figure 27

3. Tighten lock screw (B, Fig. 27) and lock nuts

(A, Fig. 27).

Operation

Keep all gu ards in place an d

in adjust ment at all times durin g the cutting

procedure! Keep hands away from the

cutterhead ! Do not pass hand s di rectl y over

the cutterhead! The use of push sticks

and/or handle pads are highly recommended

when using the jointer! Failure to comply

may cause serious injury!

Jointing cuts or edge jointing are made to

square an edge of a workpi ece. The work piece

is positi oned on t he joi nt er with t he narr ow edge

of the workpiece on the infeed table and the

major flat surface of the workpiece against the

fence (Fig. 28).

Planing cuts are similar. The major surface of

the workpiece is placed on the table with the

narrow edge of the workpi ece against the fence

(Fig. 29).

Figure 28

Figure 29

15

Page 16

For jointi ng and planing cuts pressure is directed

three ways; into the fence to ensure a square

cut, forward to advance the stock, and

downward to avoid c hatt er and v ibr ation.

For jointi ng when the materi al is higher t han the

fence, the left hand applies pressure into the

fence and down toward t he table while t he right

hand pushes forward f rom behind. Be sure to

keep the right hand high up on the material.

(Fig. 28)

For jointi ng materi al that i s lower than t he fence,

use push sticks to protect the hands. For

planing, use handle pads. (Fig. 29) Never

place the right hand on the trailing edge of

the material . Hand p lacement on the trailin g

edge of the mat erial may cause the hand to

come into contact with th e bl ade.

Feed work from right to left at a steady,

moderate speed. If you feed the material too

slowly, the wood wil l burn in places. If you feed

the material too quic kly, ridges will appear i n t he

finished surfac e.

Jointing Warped Material

If the work to be jointed is cupped or warped,

take light, repeti tive cuts until the surface is fl at.

Forcing the material flat against t he table will still

leave a warped pi ece after the cuts hav e been

made.

Never joint any material

shorter th an eight inches! The material may

tip into the jointer’s throat and be kicked

back! Avoid jointing thin material which

could become jammed under the fence or

blade guard! Failure to comply may cause

serious injury!

Direction of Grain

Feed the material with of the grain to avoid

tearout (Fig. 30). If the direction of the grain

changes somewhere in the board, try reducing

depth of cut and slow the feed speed down to

avoid tearout. If results still aren’t satisfactory,

turn the materi al around and try feedi ng through

the other way.

Bevel Cut

To cut a bevel, lock the fence at the desired

angle and run the m at erial through, pressing t he

work firmly against the fence and tables (Fig.

31). Sever al passes may be necessary f or the

desired result.

Figure 30

Figure 31

16

Page 17

Taper Cut

Taper cuts require the

removal of the cutterhead guard. Use

extreme caution wh en making taper cuts and

replace the guard immediately

completion! Failure to comply may cause

serious injury!

One of the most useful jointer operations is

cutting an edge to a t aper. Thi s method can be

used on a wide vari ety of work; tapered legs of

furniture is a common example.

Instead of laying the piece down on the infeed

table, lower the forward end of the work onto the

outfeed table. Use caution, however, as the

piece will span the knives, and they will take a

“bite” from the work with a t endenc y to kick bac k

unless the piece is held firmly. Push the work

forward as in ordinary jointing. The eff ect is to

plane off all the st ock i n fr ont of the kniv es to an

increasing dept h, leaving a tapered surface.

The ridge left by the knives when starting the

taper may be r emoved by taki ng a very light cut

in the regul ar joi nting procedure, with the i nfeed

table raised to it s normal posi tion.

Practice i s requir ed in t hi s operati on. B eginner s

are advised to make trial cuts with scrap

material.

after

Rabbet Cut

Rabbeting requires the

removal of the cutterhead guard. Use

extreme cautio n when making rabb eting cuts

and replace the guard immediately after

completion!

serious injury!

Note: Rabbet cuts are not applicable with the

Model JJ-8HH Jointer with helical head.

1. Adjust the fence so that the distance

between the end of t he knives and fence is

equal to the width of the r abbet (Fig. 32).

2. Lower the infeed table an amount equal to

the depth of the rabbet. If the rabbet is quit e

deep, it m ay be necessary to cut i n two or

more passes.

3. In that ev ent, the table is lowered an amount

equal to about half the depth of the rabbet

for the first pass, then lowered again to

proper depth to com plete the cut.

Failure to comply may cause

Figure 32

17

Page 18

Maintenance

7. Take the same amount of passes for all

three blades.

Lubrication

1. Use a good grade of light grease on the

steel adjusti ng screws located in the raising

and lowering mechanisms of the work

tables.

2. Occasionally, apply a few drops of light

machine oil to the gibs. This permits the

tables to slide f r eely .

3. The cutterhead ball bearings are lifetime

lubricated and need no further care.

Blade Care

Blades are extremely sharp!

Use caution when cleaning or changing.

Failure to compl y may cause seri ou s injury!

When gum and pitch collect on the blades,

carefully r emove with a strong solv ent. Failure

to remove gum and pit ch build-up may result in

excessiv e fric tion and overheating.

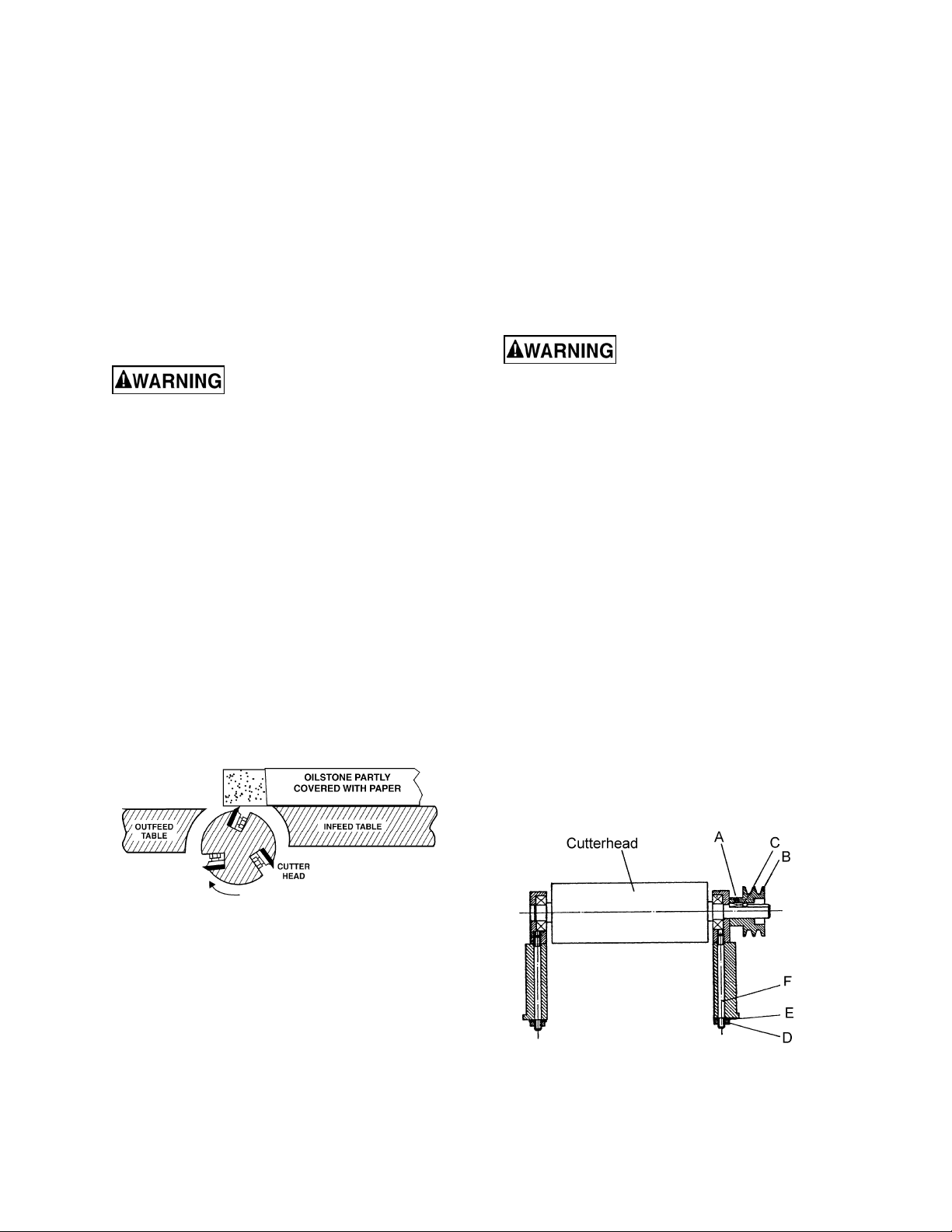

Sharpening the Knives (JJ-8CS only)

When blades becom e dull, touch up blades.

1. Disconnect the machine from the power

source.

2. Remove the fence, blade guard and belt

cover.

3. To protect the infeed table from scratches,

partially cover the sharpening stone with

paper. (Fig. 33)

When the blades hav e been sharpened, if they

still are not cutting efficientl y, trying to touch up

the blades fur ther will only cause the formation

of a second bev eled edge. When this starts to

happen, it is tim e to replace bl ades with another

set.

It is recommended to keep a second set of

blades on hand so that they may be installed

while the first set is being professionally

sharpened.

Cutterhead Removal

Bl ades in the cutterh ead are

sharp! Use extreme caution when handling

the removal of the cutterhead. Failure to

comply may cause seriou s injury!

The entire cutterhead assembly may be

removed for cleaning or for bearing and blade

replacement . Some woodworkers keep a spare

cutterhead with replacement blades should the

original c utt er head have to be repaired.

To remove the cutterhead (including bearings,

studs, and housing) from the base casting:

1. Disconnect the machine from the power

source.

2. Remove the fence assembly, cutterhead

guard, and belt guard.

3. Remove the v-belt from the cutterhead

pulley.

4. Loosen set screw (A, Fig. 34) using a hex

wrench and remove the cutterhead pulley

(B, Fig. 34) and key (C, Fig. 34).

Figure 33

4. Lay the stone on the infeed table.

5. Lower the infeed table and turn the

cutterhead by t urning the cutter head pulley.

The infeed t able hei ght is set properl y when

the stone’s surface is flush with the knife

bevel.

6. Keep the cutterhead from rotating by

grasping the cutterhead pulley while slidi ng

the stone back and forth across the table.

5. Remove nut s (D, Fig. 34) and lock washers

(E, Fig. 34).

Figure 34

18

Page 19

6. Lif t assembly str aight up. Studs (F, Fig. 34)

will still be attac hed to the bearing housings.

and the bearing housings of saw dust and

grease so that they seat pr oper ly.

7. Before replacing the cutterhead back into

the casting, thoroughly clean the “saddle”

8. To re-install the cutterhead, reverse the

above steps.

Troubleshooting

Trouble Probable Cause Remedy

Finished stock i s

concave on the end.

Back side of fi nished

stock is thicker than

the front side.

Stock is concave in

the middle.

Both ends of fi nished

stock are cut deeper

than the middl e.

Infeed or outfeed

tables are loose.

Knife tip is higher than outfeed table.

Outfeed table is higher than knife tip.

Table flatness should be chec k ed with

a machinist’s square.

Ends of tables are hi gher than middle.

Loose gib. Tighten gibs.

One blade set higher t han the others. Readjust blades

Raise outfeed table so it is level with

knife tip.

Adjust outfeed table so it is level with

knife tip.

Adjust the screws below the t able to

raise the table ends.

Raise table ends with adjustment

screws below tables.

Ripples on planed

surface.

Kickbacks

Excessive motor

noise.

Motor fails to develop

full power or stalls.

Motor starts slowly or

fails to come to full

speed.

Feeding wood too fast. Feed wood more slowly.

Cutting blades are set t oo high above

outfeed tabl e, or they m ay not be

level with outfeed table. (JJ-8CS)

Motor

Pulley set screw is loose. Tighten set screw.

Circuit ov erl oaded with lights, tools,

etc.

Undersize wires or cir c uit too long.

Voltage too low.

Fuses or circuit br eak er s do not hav e

sufficient c apaci ty.

Motor

Belt tension t oo tight. Adjust belt t ensi on.

Bad start capacit or . Replace start c apaci tor.

Readjust blades (JJ- 8CS ) .

Have motor check ed by a qualified

repair station.

Do not share the circuit .

Increase wire sizes, or reduc e length

of wiring.

Request voltage check from the

power company.

Have a qualifi ed elect ri c ian install

proper size fuses or cir c uit breakers.

Have motor check ed by a qualified

repair station.

19

Page 20

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848, Mon day t hrough Fr iday (see our web sit e f or busi ness hours, www.j ett ool s.com). Havi ng

the Model Num ber and S eri al Num ber of y our machi ne avail abl e when you cal l will allow us to serve you

quickly and acc ur ately.

20

Page 21

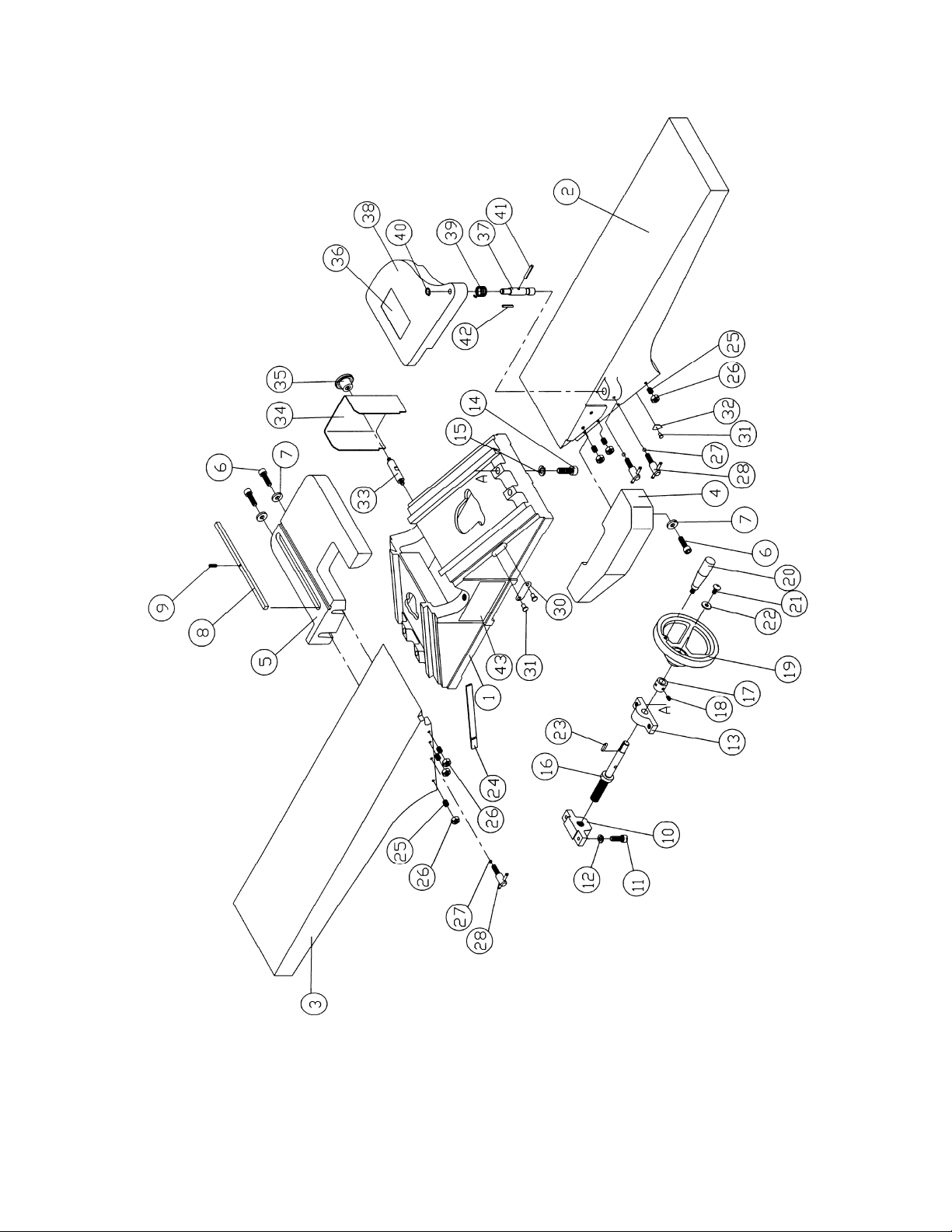

Fence Assembly (all models)

Parts List – Fence Assembly (all models)

Index No. Part No. Description Size Qty

1 ............... JC-F01 .....................Fence Body ........................................................................................... 1

2 ............... JC-F02 .....................Fence Link............................................................................................. 1

3 ............... TS-0051061 .............Hex Head Screw ................................................5/16”-18 x 1-1/4” ......... 1

4 ............... TS-0561021 .............Nut .....................................................................5/16 ”-18 ...................... 1

5 ............... JC-F03 .....................Fen ce Bracket ....................................................................................... 1

6 ............... JC-F04 .....................Bolt........................................................................................................ 2

7 ............... JC-F05 .....................Bo lt.....................................................................3/8”-16........................ 4

8 ............... TS-0561031 .............Nut .....................................................................3/8” ............................. 4

9 ............... JC-F06 .....................Locking Link .......................................................................................... 1

10 ............. JC-F07 .....................Joint P late ............................................................................................. 1

11 ............. 5C-E051 ..................Flat Head Bolt.....................................................5/16”-18 x 1-1/2” ......... 1

12 ............. JC-F08 .....................Screw .................................................................................................... 1

13 ............. TS-0207081 .............Socket Head Cap Screw .....................................1/4”-20 x 1-1/2 ” ........... 2

14 ............. TS-0207021 .............Socket Head Cap Screw .....................................1/4”-20 x 1/2” .............. 1

15 ............. TS-0050061 .............Nut .....................................................................1/4”-20........................ 2

16 ............. JC-F09 .....................Pin......................................................................5x50 ........................... 1

17 ............. JC-F10 .....................Stop Block ............................................................................................. 1

18 ............. TS-0561052 .............Nut .....................................................................1/2”-20........................ 2

19 ............. JC-F11 .....................Locking Bolt w/Handle ........................................................................... 1

20 ............. TS-0680061 .............Flat Wash er ........................................................1/2”............................. 2

21 ............. 6296081...................Nut ........................................................................................................ 1

22 ............. JC-F14 .....................Eccentric Shaft ...................................................................................... 1

23 ............. JC-F15 .....................Handle................................................................................................... 2

24 ............. LA-H34 ....................Knob ..................................................................................................... 2

25 ............. 6296083...................Hex Nut ..............................................................1/2”-12........................ 2

26 ............. JC-F16 .....................Eye Bolt ................................................................................................. 1

21

Page 22

Bed Assembly (all models)

22

Page 23

Parts List – Bed Assembly (all models)

Index No. Part No. Description Size Qty

1 ............... JC-T01 .....................Base ...................................................................................................... 1

2 ............... JC-T02 .....................Fro n t Ta b le ............................................................................................ 1

3 ............... JC-T03 .....................Rear Table ............................................................................................ 1

4 ............... JC-T04 .....................Rabbeting Arm ...................................................................................... 1

5 ............... JC-T05 .....................Tab le Bracket ........................................................................................ 1

6 ............... TS-0060071 .............Cap Screw..........................................................3/8”-16 x 1-1/2” ........... 4

7 ............... TS-0720091 .............Lock Was h e r ......................................................3/8”............................. 4

8 ............... JC-T07 .....................Ke y.....................................................................9 .5 x 9.5 x 273 ............ 1

9 ............... 5F-E153 ...................Spring Pin...........................................................4 x 16 ......................... 1

10 ............. JC-T08 .....................Feed Screw Bracket .............................................................................. 2

11 ............. TS-0060061 .............Socket Head Cap Screw .....................................3/8”-16 x 1-1/4 ” ........... 4

12 ............. TS-0720091 .............Lock Washer ......................................................3/8”............................. 4

13 ............. JC-T09 .....................Bracket .................................................................................................. 2

14 ............. JJ8HH-214 ...............Cap Screw..........................................................1/2”-12 x 1-1/2” ........... 4

15 ............. TS-0720111 .............Lock Washer ......................................................1/2”............................. 4

16 ............. JC-T10 .....................Feed Screw ........................................................................................... 2

17 ............. JC-T11 .....................Ring ...................................................................................................... 2

18 ............. TS-0267041 .............Set Screw ...........................................................1/4”-20 x 3/8” .............. 4

19 ............. PA-C42 ....................Handwheel ............................................................................................ 2

20 ............. JC-T12 .....................Handle................................................................................................... 2

21 ............. 5C-D003 ..................Pan Head Machi ne S crew ..................................5/16”-18 x 1/2” ............ 2

22 ............. TS-0680031 .............Flat Wash er ........................................................5/16” ........................... 2

23 ............. F5-G107 ..................Key.....................................................................5 x 5 x 22 ................... 2

24 ............. JC-T13 .....................Gib ...................................................................................................... .. 2

25 ............. TS-0270091 .............Set Screw ...........................................................5/16”-18 x 1” ............... 6

26 ............. TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 6

27 ............. 5I-D003 ....................Ball ........................................................................................................ 2

28 ............. JC-T15 .....................Stop Handle .......................................................................................... 3

30 ............. JC-T16 .....................Scale ....................................................................................................

31 ............. 5F-H051...................Rivet ...................................................................................................... 7

32 ............. JC-T17 .....................Depth Pointer ........................................................................................ 1

33 ............. PA-C49 ....................Guard Bolt ............................................................................................. 1

34 ............. JC-T18 .....................Pulley Cover .......................................................................................... 1

35 ............. PA-C53 ....................Nut ........................................................................................................ 1

36 ............. JC-T19 .....................Warning Label ....................................................................................... 1

37 ............. JC-T20 .....................Guard Shaft ........................................................................................... 1

38 ............. JC-T21 .....................Cutterhead Guard .................................................................................. 1

39 ............. JC-T22 .....................Spring.................................................................................................... 1

40 ............. 5F-A002 ...................Retaining Ring ....................................................STW-11 ...................... 1

41 ............. 5F-E208 ...................Spring Pin...........................................................5 x 28 ......................... 1

42 ............. 5F-E258 ...................Spring Pin...........................................................6 x 36 ......................... 1

43 ............. JJ8CS-ID .................I.D. Label ............................................................................................... 1

................. JJ8HH- ID .................I.D. Label ............................................................................................... 1

. 1

23

Page 24

Stand and Motor Assembly (JJ-8CS only)

24

Page 25

Parts List – Stand and Motor Assembly (JJ-8CS only)

Index No. Part No. Description Size Qty

1 ............... JC-M01 W .................Stand .................................................................................................... 1

2 ............... JC-M02 W .................Motor Mount .......................................................................................... 1

3 ............... JC-M03 W .................Cover .................................................................................................... 1

4 ............... JC-M04 ....................Screw .................................................................................................... 1

5 ............... JC-M05 ....................Key........................................................................................................ 1

7 ............... TS-0561031 .............Hex Nut ..............................................................3/8”-16........................ 1

8 ............... JC-M06 ....................Motor Pulley .......................................................................................... 1

9 ............... TS-0271071 .............Set Screw ...........................................................3/8”-16 x 3/4” .............. 2

10 ............. VB-M52....................V-Belt .................................................................................................... 2

11 ............. TS-0081031 .............Hex Head Screw ................................................5/16”-18 x 3/4” ............ 4

12 ............. TS-0680031 .............Flat Wash er ........................................................5/16” ........................... 4

13 ............. TS-0680031 .............Flat Wash er ........................................................5/16” ........................... 4

14 ............. TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 4

15 ............. JJ8HH-315 ...............Hex Head Screw ................................................1/2 ”- 1 2 x 1” ................. 4

16 ............. TS-0680061 .............Flat Wash er ........................................................1/2”............................. 4

17 ............. JCS10-079C ............Screw .................................................................3/16”-UNC x 3/4” ........ 2

18 ............. TS-0680021 .............Flat Wash er ........................................................1/4”............................. 4

19 ............. JC-M07 ....................Lock Bolt ............................................................3/8”-16........................ 3

20 ............. TS-0720091 .............Lock Washer ......................................................3/8”............................. 3

21 ............. JC-M03 ....................Dust Chute ............................................................................................ 1

22 ............. TS-0813032 .............Pan Head Screw ................................................1/4”-20 x 1/2” .............. 4

23 ............. JJ8-917W ................Motor ..................................................................2HP, 1Ph .................... 1

24 ............. JJ8-918 ....................Motor Cord ............................................................................................ 1

25 ............. JJ8-919 ....................Strain Relief ........................................................................................... 2

26 ............. JJ8-920 ....................Power Cord ........................................................................................... 1

27 ............. JJ8CS-327 ...............Switch ................................................................................................... 1

28 ............. JJ8-923 ....................Strain Relief ........................................................................................... 1

29 ............. PG-M02 ...................JET Label .............................................................................................. 1

30 ............. JC-T23 .....................Warning

31 ............. 5FK-C13 ..................Key.....................................................................5x5x35 ....................... 1

................. JJ8CS-HK ................Hardware Kit (not shown) ........................................................................

Label ....................................................................................... 1

25

Page 26

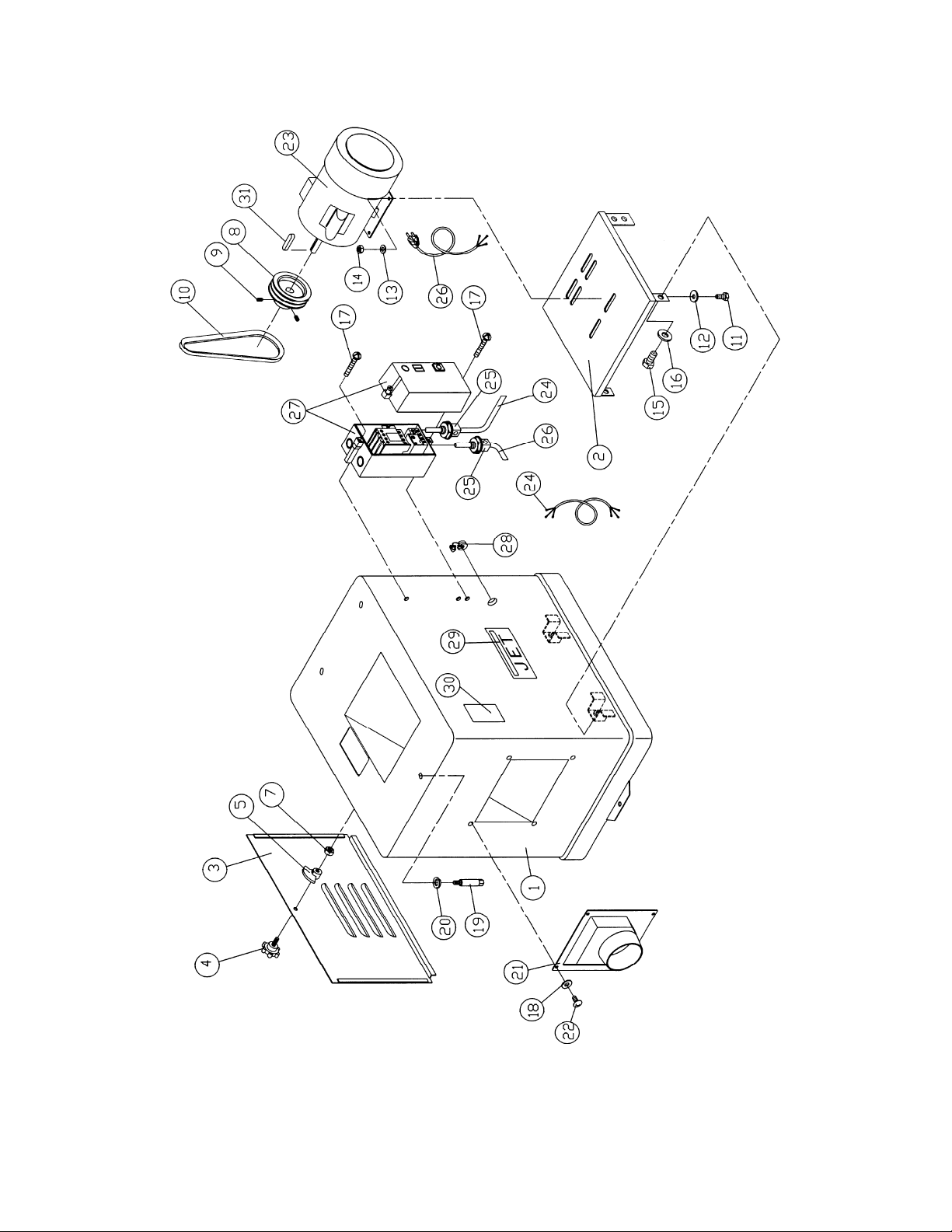

Stand and Motor Assembly (JJ-8HH only)

26

Page 27

Parts List – Stand and Motor Assembly (JJ-8HH only)

Index No. Part No. Description Size Qty

1 ............... JJ8HH- 301 ...............Stand .................................................................................................... 1

2 ............... JC-M02 W .................Motor Mount .......................................................................................... 1

3 ............... JC-M03 W .................Cover .................................................................................................... 1

4 ............... JC-M04 ....................Knob Screw ........................................................................................... 1

5 ............... JC-M05 ....................Door Latch............................................................................................. 1

7 ............... TS-0561031 .............Hex Nut ..............................................................3/8”-16........................ 1

8 ............... JC-M06 ....................Motor Pulley .......................................................................................... 1

9 ............... TS-0271031 .............Set Screw ...........................................................3/8”-16x3/8” ................ 2

10 ............. VB-M52....................V- Belt ...............................................................M-52 ........................... 2

11 ............. TS-0081031 .............Hex Cap S cr e w ..................................................5/16 ” -1 8 x3/4 ” .............. 4

12 ............. TS-0680031 .............Flat Wash er ........................................................5/16” ......................... 12

14 ............. TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 4

15 ............. JJ8HH-315 ...............Hex Bolt .............................................................1 /2 ” -1 2 x1 ” ................... 4

16 ............. TS-0680061 .............Flat Wash er ........................................................1/2”............................. 4

18 ............. TS-0680021 .............Flat Wash er ........................................................1/4”............................. 4

19 ............. JC-M07 ....................Lock Bolt ............................................................................................... 3

20 ............. TS-0720091 .............Lock Washer ......................................................3/8”............................. 3

21 ............. JC-M03 ....................Dust Chute ............................................................................................ 1

22 ............. TS-081F032 .............Screw .................................................................1/4”-20x1/2” ................ 4

23 ............. JJ8-917W ................Motor ..................................................................2HP, 1Ph .................... 1

29 ............. PG-M02 ...................JET Label .............................................................................................. 1

30 ............. JC-T23 .....................Warning Label ....................................................................................... 1

31 ............. 5FK-C13 ..................Key.....................................................................5x5x35 ....................... 1

32 ............. JJ6HH-316 ...............Cord Protector ....................................................................................... 2

33 ............. JJ6HH-315 ...............Switch Arm ............................................................................................ 1

34 ............. JPS10TS-343 ..........Main Switch ........................................................................................... 1

35 ............. TS-0208141 .............Socket Head Cap Screw .....................................5/16”-18x3” ................. 2

37 ............. JJ6HH-348 ...............Screw .................................................................M4x25 ........................ 2

38 ............. JPS10TS-342 ..........Stop Switch Face Pla te .......................................................................... 1

39 ............. TS-2171012 .............Screw .................................................................M4x6 .......................... 2

40 ............. JJ6HH-351 ...............Star Washe r .......................................................M 4 .............................. 2

41 ............. JJ6HH-352

42 ............. JPS10TS-347 ..........Switch Box ............................................................................................ 1

44 ............. JJ8HH-344 ...............Motor Cord ............................................................................................ 1

45 ............. JJ8HH-345 ...............Strain Relief ........................................................................................... 2

46 ............. JJ8HH-346 ...............Power Cord ........................................................................................... 1

47 ............. TS-0208021 .............Socket Head Cap Screw .....................................5/16”-18x1/2” .............. 2

................. JJ8HH- HK ................Hardware Kit (not shown) ...................................................................... 1

...............Switch P late ......................................................................................... 1

27

Page 28

Parts List – Cutterhead Assembly (JJ-8CS only)

Index No. Part No. Description Size Qty

1 ............... JC-C01 ....................Cutterhead ............................................................................................ 1

2 ............... JC-C02 ....................Bearing Housin g .................................................................................... 2

3 ............... 5H-A104 ..................Bearing .................................................................................................. 2

4 ............... JC-C03 ....................Cutterhead Set Bolt ............................................................................... 2

5 ............... TS-0680041 .............Flat Washer ........................................................3/8”............................. 2

6 ............... TS-0561031 .............Nut .....................................................................3/8” -16........................ 2

7 ............... PA-C05 ....................Spring.............................................................................. ...................... 6

8 ............... 708802 ....................Knife ...................................................................................................... 3

9 ............... JC-C05 ....................Knife Lock Bar ....................................................................................... 3

10 ............. JC-C06 ....................Screw .................................................................................................. 15

11 ............. JC-C07 ....................Knife Gauge Rod ................................................................................... 1

12 ............. JC-C08 ....................Knife Gauge .......................................................................................... 2

13 ............. JJ8-0013 ..................Retaining Ring ....................................................STW-9” ....................... 4

15 ............. JC-C09 ....................Machine Pulley ...................................................................................... 1

16 ............. 5F-G107 ..................Key.....................................................................5 x 5 x 22 ................... 1

17 ............. TS-0270031 .............Set Screw ...........................................................5/16”-18NC x 3/8” ....... 2

28

Page 29

Parts List – Cutterhead Assembly (JJ-8HH only)

Index No. Part No. Description Size Qty

................. JJ8HH- CA ................Cutterhead Assembly (Index # 1 thru 11) ............................................... 1

................. 1791222-4 ...............Helical Cutterhead Unit (Index # 1, 7, 8)................................................. 1

1 ............... JJ8HH- 101 ...............Helical Cutterhead ................................................................................. 1

2 ............... JC-C02 ....................Bearing Housin g .................................................................................... 2

3 ............... BB-6204VV ..............Ball Bearing ........................................................6204VV ...................... 2

4 ............... JC-C03 ....................Bolt........................................................................................................ 2

5 ............... TS-0680041 .............Flat Washer ........................................................3/8”............................. 2

6 ............... TS-0561031 .............Hex Nut ..............................................................3/8”-16........................ 2

7 ............... 1791212...................Knife Insert (set of 10) .................................................................. total 36

8 ............... JWP208HH-111 .......Knife Ins e rt Scre w ..............................................#10-32x1/2 .............. 36

9 ............... 5 F-G10 7 ..................Key.....................................................................5 x5x22 ...... ................. 1

10 ............. TS-0270031 .............Socket Set Screw ...............................................5/16”-18x3/8” .............. 2

11 ............. JC-C09 ....................Cutterhead Pulley .................................................................................. 1

12 ............. JJ6HH-113 ...............Star Point Screwdriver (not shown) ........................................................ 2

29

Page 30

Electrical Connections (JJ-8C S on ly )

Motor

BLACK

WHITE

1L2

3L2A15L3

GREEN

WHITE

BLACK

4T2

2T1

4T2

2T1

6T3

6T3

13NO

17

18

14NO

A2

9798

96 95

GREEN

GROUND

GREEN

GREEN

WHITE

BLACK

BLACK

WHITE

30

Page 31

Electrical Connections (JJ-8H H on ly )

31

Page 32

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

32

Loading...

Loading...