Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

JBM-5 Benchtop Mortiser

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708580

Ph.: 800-274-6848 Revision G3 01/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET, Wilton and Powermatic warrants every product they sell against manufacturers’ defects. If one of our tools

needs service or repair, please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday

through Friday

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET, Wilton or Powermatic branded websites.

• JET, Wilton and Powermatic products carry a limited warranty which varies in duration based upon the

product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET, Wilton and Powermatic have Authorized Service Centers

located throughout the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846

or use th e Serv i ce Center L ocator on t he JET, Wilton or Powermatic web site.

More Informa t io n

JET, Wilton and Powermatic are consistently adding new products. For complete, up-to-date product information,

check with your local distributor or visit the JET, Wilton or Powermatic website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET, WILTON AND POWERMATIC LIMIT ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU.

JET, WILTON AND POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

JET, Wilton and Powermatic sell through distributors only. The specifications listed in JET, Wilton and Powermatic

printed materials and on official JET, Wilton and Powermatic-branded websites are given as general information and

are not binding. JET, Wilton and Powermatic reserve the right to effect at any time, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

®

branded products are not sold in Canada by JPW Industries, Inc.

JET

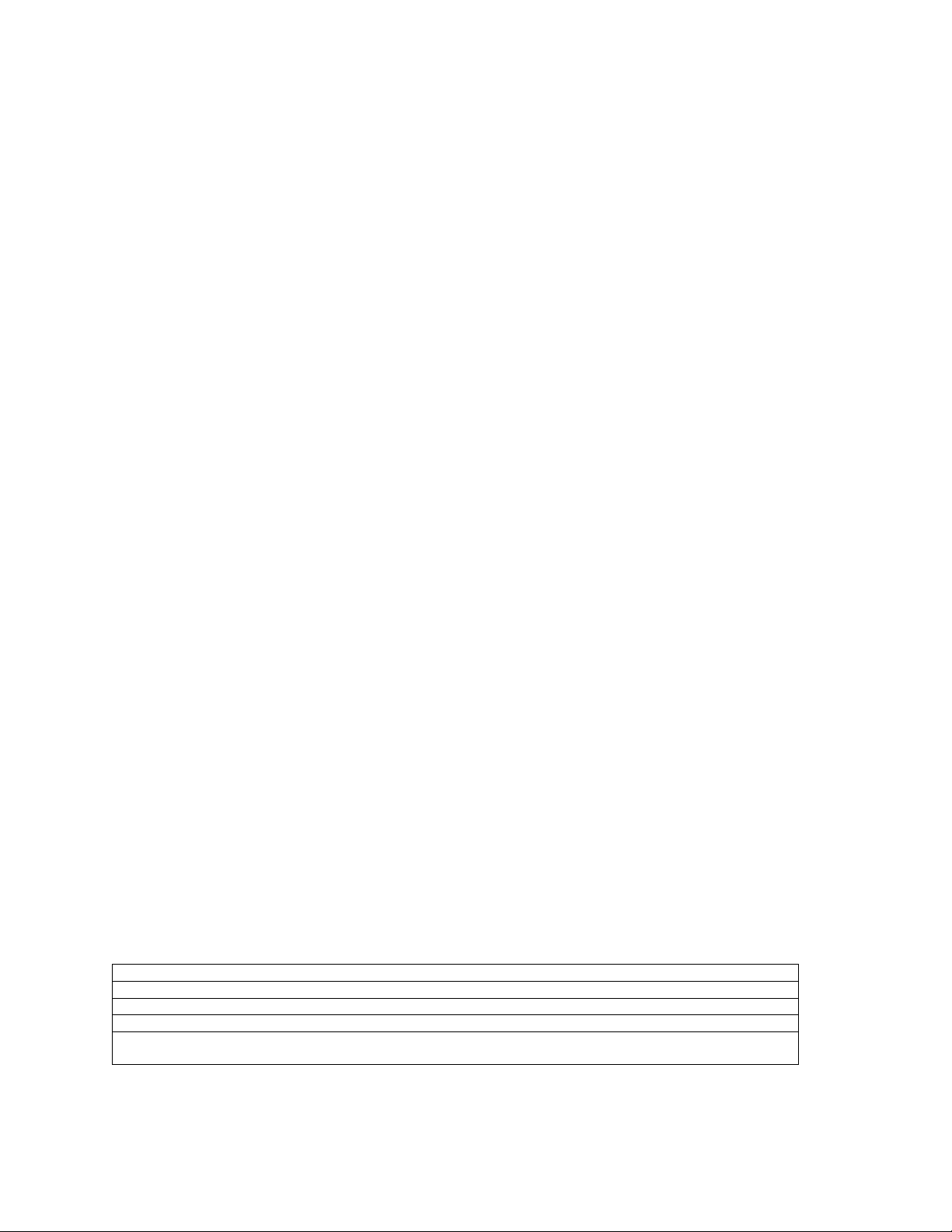

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories

5 Year – Woodworking Machinery

Limited Lifetime – Wilton branded products; JET Parallel clamps; VOLT Series Electric Hoists;

Manual Hoists; Manual Hoist Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET, Wilton and Powermatic are divisions of JPW Industries, Inc.. References in this document to JET,

Wilton and/or Powermatic also apply to JP W Indus trie s, Inc., or any of its succe ssors in inte re st to the JET, Wilton

and/or Powermatic brands.

2

Page 3

Table of Contents

Warranty and Service ............................................................................................................................................ 2

Table of Contents .................................................................................................................................................. 3

Introduction ........................................................................................................................................................... 3

Warning ................................................................................................................................................................. 4

Electrical Requirements ........................................................................................................................................ 5

Specifications ........................................................................................................................................................ 6

Unpacking ............................................................................................................................................................. 6

Assembly ............................................................................................................................................................... 7

Installing ................................................................................................................................................................ 7

Adjustments .......................................................................................................................................................... 8

On-Off Switch .................................................................................................................................................... 8

Handle Adjustment ............................................................................................................................................ 8

Fence Adjustment ............................................................................................................................................. 8

Hold Down Adjustment ...................................................................................................................................... 8

Depth Stop Rod Adjustment .............................................................................................................................. 8

180° Head Rotation ........................................................................................................................................... 8

Chuck Key Holder ............................................................................................................................................. 8

Using Bits with Short Shanks ............................................................................................................................ 8

Chisel and Bit Adjustment ................................................................................................................................. 8

Adjusting Chisel Par allel to Workpi ece .............................................................................................................. 9

Storage .................................................................................................................................................................. 9

Optional Accessories ............................................................................................................................................ 9

Replacement Parts ................................................................................................................................................ 9

JBM-5 Benchtop Mortiser – Exploded View .................................................................................................... 10

JBM-5 Benchtop Mortiser – Parts List ............................................................................................................. 11

Introduction

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model

JBM-5 Mortiser. This manual contains instructions on installation, safety precautions, general operating

procedures, maintenance instructions and parts b reakdown. Thi s machine has bee n de signed and co nstructed

to provide years of trouble free operation if used in accordance with instructions set forth in this manual. If there

are any questions or comments, please contact either your local supplier or JET at: www.jettools.com.

3

Page 4

Warning

• KEEP GUARDS IN PLACE and in order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning it on.

• KEEP THE WORK AREA CLEAN. Cluttered areas and benches invite acci den ts.

• DO NOT US E IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

• KEEP CHILDRE N A WAY . All visitors should be kept safe distance from the work area.

• MAKE THE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

• DON’T FORCE THE TOOL. It will do the job better and safer at the rate for which it was designed.

• USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was not designed.

• USE THE PROPER EXTEN SI ON CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord

will cause a drop in the line voltage resulting in loss of power and overheating. For runs up to 25 feet, use a 16

AWG or larger gauge cord. For runs up to 50 feet, use a 16 AWG or larger cord. For runs up to 100 feet,

use a 14 AWG or larger cord. If in doubt, use the next heavier gauge. The smaller the gauge number, the

heavier the cord.

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry

which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to

contain long hair.

• ALWAYS USE SAFET Y GLASSES. Also use face or dust masks if the cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses, they are NOT safety glasses.

• SECURE WO R K. Use clamps or a vise to hold the work when it’s practical. It’s safer than using your hand and it

frees both hands to operate the tool.

• DON’T OVE RREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the off position before

plugging in the machine.

• USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recommended accessories. The use

of improper accessories may cause a risk of injury.

• NEVER STAND ON A TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted.

• CHECK DA MA GED PA RTS. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or replaced.

• DIRECTI ON OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or cutter

only.

• NEVER LEAVE THE TOOL RUNNING UNATTENDED. TURN THE POWER OFF. Don’t leave the tool until it

comes to a complete stop.

• WARNING: Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cemen t and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals, work in a well-ventilated area and work with approved safety equipment, such as face or dust masks

that are specifically designed to filter out microscopic particles.

4

Page 5

Electrical Requirements

In the event of a malfunction or breakdown, grounding provides a pat h of lea st resistance for electr ic c urrent to

reduce the risk of electric shock. T his tool is equipped with an electric cord having an equipment-gro unding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is green with or without yellow stripes, is the equipmentgrounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded.

Use only three wire extension cords that have three-prong grounding plugs and three-pole receptacles that

accept the tool’s plug.*

Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Figure A below.

The tool has a grounding plug that looks like the grounding plug as illustrated in Figure A below. A temporary

adapter, which looks like the adapter as illustrated in Figure B below, may be used to connect this plug to a

two-hole receptacle, as shown in Figure B if a properly grounded outlet is not available.** The temporary

adapter should only be used until a properly grounded outlet ca n be installed by a qualified electric ian. The

green colored rigid ear or tab, extending from the adapter, must be connected to a permanent ground such as

a properly grounded outlet box.

* Canadian electric al c odes require extension cords to be certified SJT type or better.

** Use of an adapter in Canada is not acceptable.

5

Page 6

Specifications

Stock Number ............................................................................................................................................. 708580

Model Number ............................................................................................................................................... JBM-5

Motor ............................................................................................................. TEFC, 1/2HP, 1PH, 115V, 60Hz, 6A

RPM ................................................................................................................................................................ 1725

Switch ................................................................................................................. toggle, with r e movable safet y key

Chuck Capacity (max. bit shank diameter) ....................................................................................................... 3/8”

Chisel Capacity ....................................................................................................................................... 1/2” x 1/2”

Chisel Shank Capacity .............................................................................................................................. 5/8”, 3/4”

Head Stroke ................................................................................................................................................... 4-3/4”

Chisel Center to Fence .................................................................................................................................. 3-1/2”

Under Hold-Down ................................................................................................................................................. 4”

Fence Size ................................................................................................................................... 1-9/16” x 13-3/4”

Table Size ........................................................................................................................................... 14” x 12-1/2”

Base Size ..................................................................................................................................... 7-5/8” x 12-3/16”

Bushing Size ....................................................................................................................................... 5/8” and 3/4”

Overall Height .............................................................................................................maximum 30”, minimum 21”

Net Weight ................................................................................................................................................... 44 lbs.

The above specifications were current at the time this manual was published, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

Unpacking

Open shipping container and check for

shipping damage. Report any damage

immediately to your distributor and shipping

agent. Do not discard any shipping material

until the Mortiser is assembled and running

properly.

Compare the contents of your container

with the following parts list to make sure all

parts are intact. Missing parts, if any,

should be reported to your distributor. Read

the instruction manual thoroughly for

assembly, maintenance and safety

instructions.

Contents

A. Mortising Machine

B. Hydraulic Cylinder

C. Handle

D. 3/4” Chisel Bushing

E. 5/8” Chisel Bushing

F. Spindle Extension Adapter

G. Chuck Key

H. Table

I. Hold Down

J. Fence Assembly

K. Screws (2)

L. Owner’s Manual (not shown)

M. Warranty Car d (not shown)

6

Page 7

Assembly

Never connect t he mac hine to

the power source until assembly is completed.

Failure to comply may result in serious injury!

1. Screw the handle (A, Figure 2) into the pinion

shaft (B, Figure 2).

7. Attach the hold down (D, Figure 3) to the

vertical post using locking handle (E, Figure 3).

Figure 3

Installing

Make sure the Mortising

Machine is attached to a firm and stable

support surface.

Figure 2

(chisel and bit not provided)

2. Tighten the handle. The handle has a notch

(C, Figure 2) to accommodate a wrench.

3. Use the handle to raise the machine head to

the up position. The handle is spring loaded

and can be repositioned by pulling the handle

away from the machine, and turned to the

desired angle.

4. With the head in the up position press the

hydraulic cylinder onto the two fittings. The

upper fitting (D, Figure 2) is located on the

head. The lower fitting (E, Fig ure 2) is on the

column.

5. Attach the table to the base using two screws

(A, Figure 3).

6. Insert bar of fence assembly (B, Figure 3)

through the hole in the column. Use the fencelocking handle (C, Figure 3) to adjust fence

assembly.

This machine must be fastened to a supporting

surface to prevent it from tipping during operation.

Four holes (A, Figure 4) in the base are supplied

for this purpose.

Figure 4

7

Page 8

Adjustments

On-Off Switch

The switch (A, Figure 5) has a switch key that,

when p ulled o ut, a llows t he swit ch to b e lock ed in

the off position.

Hold Down Adjustment

The hold down (C, Figure 4) s hould be adjusted so

it just touches the top of the workpiece and allows

the workpiece to slide left or r ight. The hold down

can also be taken off and turned over for a thicker

workpiece. To adjust the hold down, loosen the

locking handle (D, Figure 4).

Depth Stop Rod Adjustment

The depth stop rod (B, Figure 5) is provided to limit

the depth of the chisel cut. Adjust the depth stop

rod using the locking handle (C, Figure 5). Lower

the head until the bottom of the chisel is at the

required depth. Lower the depth stop rod until it is

at rest against the base.

180° Head Rotation

Rem oving t he thre e he x sock et ca p scre ws at the

base will enable you to rotate the head and column

180°. Doing this will let the user mortise taller

items.

Chuck Key Holder

The chuck key holder is located on the left side of

the head.

Figure 5

Handle Adjustment

The handle can be adjusted for leverage and

comfort. Pulling the spring loaded handle (A,

Figure 6) away from the head and turning allows

you to change the position of the handle.

Figure 6

Fence Adjustment

Using Bits with Short Shanks

When using bits with short shanks, it will be

necessary to attach the spindle extension adaptor.

Place an open wrench on the flat part of the m otor

spindle. Use the chuck key to unscrew and remove

the chuck. Attach the spindle extension to the

chuck. Replace the chuck with the spindle

extension into the motor spindle.

Chisel and Bit Adjustment

See Figure 7.

Note: Chisels and bits are available as optional

accessories.

The fence can be moved in and out by loosening

the locking handle (B, Figure 4) on the column.

Figure 7

8

Page 9

1. Insert chisel bushing with hole f acing forward

into the head. Tighten the screw just enough to

hold the chisel in place.

2. Insert bit into the chisel. The opening in the

chisel should always face to the right or left.

The opening allows chips to escape during

operation.

3. Push the chisel up as far as possible into the

head. Then lower the chisel approximately

1/16” to 3/16”. This may vary depending upon

type of wood. Table 1 shows general

guidelines for distance between points of

chisel and bit point.

4. Tighten the screw to hold chisel in place.

5. Push bit up t hrough the chisel opening as f ar

as it will go. Lock the drill bit in place with

chuck key.

6. Loosen screw and push chisel up against t he

bushing, and tighten the screw. This should

provide the proper distance between the points

of the chisel and the bit.

Type of wood Chisel Size Distance

Softwoods

Hardwoods

1/4 to 3/8 1/32

1/2 1/16 to 3/32

1/4 to 3/8 1/16

1/2 3/32 to 1/8

Table 1

(all dimensions inches)

Adjusting Chisel Parallel to Workpiece

The chisel can be adjusted parallel to the

workpiece by loosening the screw (A, Figure 8) and

rotating the chisel until the back surface of the

chisel is flat against the workpiece. Tighten the

screw to hold chisel in place.

Figure 8

Storage

If the mortiser will be stored for an extended

period, use the depth stop to help secure the head

in position; this will relieve stress upon the

hydraulic cylinder.

Optional Accessories

1791091 Premium 1/4" Mortise Bit and Chisel Set

1791092 Premium 5/16" Mortise Bit and Chisel Set

1791093 Premium 3/8" Mortise Bit and Chisel Set

1791094 Premium 1/2" Mortise Bit and Chisel Set

Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial

Number of your machine availa ble w hen you call will allow us to serve you quickly and accurat ely.

9

Page 10

JBM-5 Benchtop Mortiser – Exploded View

10

Page 11

JBM-5 Benchtop Mortiser – Parts List

Index No. Part No. Description Size Qty

1 ................ 23011045W ............... Base......................................................................... ... ................................... 1

2 ................ 50302003 .................. Lock Washer ............................................................ 5/16” .............................. 3

3 ................ 50102018 .................. Hex Socket Cap Screw ............................................ M8x1.25x20 .................. 3

4 ................ 23011002W ............... Column .................................................................... ...................................... 1

5 ................ 23011053 .................. Lock Handle ............................................................. M8x1.2 5x10 .................. 1

6 ................ 23011046W ............... Head ........................................................................ ...................................... 1

7 ................ 23011004 .................. Depth Stop ............................................................... ...................................... 1

8 ................ 23011054 .................. Motor........................................................................ 1/2HP 1PH 115V........... 1

.................. 23011054-01 ............. Fan (not shown) ....................................................... ........ .............................. 1

.................. 23011054-02 ............. Fan Cover (not shown) ............................................ ...................................... 1

.................. 50154019 .................. Fan Cover Screw (not shown) ................................. ...................................... 1

.................. 23011054-03 ............. Capacitor ................................................................. 25uF, 250VAC .............. 1

9 ................ 23011005 .................. Rack......................................................................... ...................................... 1

10 .............. 50102032 .................. Hex Socket Cap Screw ............................................ M6x1.0x16 .................... 2

11 .............. 50201017 .................. Nut ........................................................................... M 8x1.25 ........................ 2

12 .............. 50102021 .................. Hex Cap Bolt............................................................ M8x1.25x30 .................. 2

13 .............. 23011055 .................. Tabl e ........................................................................ ...................................... 1

.................. 23011056AW ............ Fence Assembly (includes #14,16,17,19,20)........... ...................................... 1

14 .............. 23011056W ............... Fence ....................................................................... ...................................... 1

15 .............. 23011057 .................. Hold Down ............................................................... ...................................... 1

16 .............. 23011058 .................. Hold Down Pos t ....................................................... ...................................... 1

17 .............. 23011059 .................. Fen ce Rod ............................................................... ...................................... 1

18 .............. 50109001 .................. Wing Screw.............................................................. M8x 1.25 ........................ 1

19 .............. TS-1523011 .............. Set Screw ................................................................ M6x1x6 ......................... 2

20 .............. 50110005 .................. Flat Head Screw ...................................................... M6x1x22 ....................... 1

21 .............. 23011009 .................. Lock Handle ............................................................. M8x1.25x 30 .................. 1

22 .............. 23011010 .................. Brass Screw............................................................. M8x1.25x25 .................. 1

23 .............. 23011061 .................. Pini on Shaft ............................................................. ...................................... 1

24 .............. 50605005 .................. Key........................................................................... 5x 5x14 mm ................... 1

25 .............. 23011012 .................. Coll ar ....................................................................... ...................................... 1

26 .............. 23011013 .................. Gear ......................................................................... . ..................................... 1

27 .............. 23011014 .................. Lower Cylinder Fitting .............................................. ...................................... 1

28 .............. 23011030 .................. Cylin der Head (re:23011031A) ................................ ...................................... 1

29 .............. 23011031 .................. Hydrauli c Cylinder.................................................... ...................................... 1

.................. 23011031A ................ Hydraulic Cylinder Assembly (includes #28,29) ...... ...................................... 1

30 .............. 23011062 .................. Clu tch Block ............................................................. ..... ................................. 1

31 .............. 23011063 .................. Sprin g ...................................................................... ...................................... 1

32 .............. 23011064 .................. Washer .................................................................... ...................................... 1

33 .............. 50110006 .................. Flat Head Screw ...................................................... M6x1x11 ....................... 1

34 .............. 23011017 .................. Upper Cylinder Fitting .............................................. ...................................... 1

35 .............. 23011065 .................. Hand le Rod .............................................................. ...... ................................ 1

36 .............. 23011019 .................. Hand le Grip.............................................................. ...................................... 1

37 .............. 50102042 .................. Hex Socket Cap Screw ............................................ M5x0.8x16 .................... 3

38 .............. 23011020 .................. Adapter .................................................................... ...................................... 1

39 .............. 23011032 .................. Chu ck....................................................................... ...................................... 1

40 .............. 23011033 .................. Bushin g .................................................................... 5/8” ................................ 1

41 .............. 23011034 .................. Bushin g .................................................................... 3/4" ................................ 1

42 .............. 23011021 .................. Cap .......................................................................... ...................................... 1

43 .............. 50105006 .................. Flat Head Screw ...................................................... M6x1x20 ....................... 2

44 .............. 23011066W ............... Right Side Cover Assembly ..................................... ...................................... 1

45 .............. 23011067W ............... Left Side Cover Assembly ....................................... ...................................... 1

46 .............. 50104010 .................. Screw ....................................................................... M5x0.8x8 ...................... 2

47 .............. 50104011 .................. Screw ....................................................................... M5x0.8x12 .................... 2

48 .............. 50202006 .................. Nut ........................................................................... M 5x0.8 .......................... 2

49 .............. 23011068 .................. Sprin g ...................................................................... ...................................... 2

50 .............. 23011050 .................. Switch Base ............................................................. ...................................... 1

51 .............. 23011051 .................. Switch Cover............................................................ ...................................... 1

52 .............. 23011029 .................. Toggl e Switch .......................................................... ...................................... 1

53 .............. 50111002 .................. Tap Screw................................................................ M10x 2 ........................... 2

54 .............. 23011026 .................. Brass Pin ................................................................. ...................................... 2

11

Page 12

Index No. Part No. Descripti on Size Qt y

55 .............. 23011027 .................. Spring ...................................................................... ...................................... 2

56 .............. 50103013 .................. Set Screw ................................................................ M10x1. 5x20 .................. 2

57 .............. 50201014 .................. Nut ........................................................................... M10x1.5 ........................ 2

58 .............. 23011077 .................. Key Clip ................................................................... ...................................... 1

59 .............. 50322004 .................. Spring Washer ......................................................... M5 ................................. 1

60 .............. 50102002 .................. Hex Socket Cap Screw ............................................ M5x0.8x8 ...................... 1

61 .............. 23011076 .................. Chuck Key ............................................................... ...................................... 1

.................. 23010045 .................. “JET” Label (not shown) .......................................... ...................................... 1

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

12

Loading...

Loading...