Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

12-inch XACTA® Cabinet Saw

Model JTAS-12-DX

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708546

Ph.: 800-274-6848 Revision A1 02/2014

www.jettool s.c om Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 About this manual .......................................................................................................................................... 5

5.0 Glossary ......................................................................................................................................................... 6

6.0 Specifications ................................................................................................................................................. 7

7.0 Setup and assembly ....................................................................................................................................... 9

7.1 Tools required for assembly ....................................................................................................................... 9

7.2 Shipping contents ....................................................................................................................................... 9

7.3 Unpacking and cleanup ............................................................................................................................ 10

7.4 Installation and leveling ............................................................................................................................ 10

7.5 Installing table extensions ........................................................................................................................ 10

7.6 Installing motor cover ............................................................................................................................... 11

7.7 Installing handwheel ................................................................................................................................. 11

7.8 Installing storage hooks ............................................................................................................................ 11

7.9 Installing blade (not provided) .................................................................................................................. 11

7.10 Installing riving knife ............................................................................................................................... 12

7.11 Table insert adjustment .......................................................................................................................... 12

7.12 Installing anti-kickback pawls and blade guard assembly ...................................................................... 13

7.13 Installing rails and rip fence .................................................................................................................... 13

7.14 Installing switch and brace ..................................................................................................................... 13

7.15 Miter gauge operation ............................................................................................................................ 13

8.0 Electrical connections .................................................................................................................................. 14

8.1 Extension cords ........................................................................................................................................ 14

9.0 Adjustments ................................................................................................................................................. 14

9.1 Blade raising and tilting ............................................................................................................................ 14

9.2 Blade alignment ........................................................................................................................................ 14

9.3 Adjusting 90° and 45° positive stops ........................................................................................................ 15

9.4 Belt tension and replacement ................................................................................................................... 16

10.0 Maintenance ............................................................................................................................................... 16

11.0 Troubleshooting the JTAS-12-DX Table Saw ............................................................................................ 17

11.1 Mechanical Problems ............................................................................................................................. 17

11.2 Operational Problems ............................................................................................................................. 18

12.0 Replacement Parts ..................................................................................................................................... 18

12.1.1 Table and Cabinet Assembly (JTAS-12-DX) – Exploded View ........................................................... 19

12.1.2 Table and Cabinet Assembly (JTAS-12-DX) – Parts List .................................................................... 20

12.2.1 Trunnion and Motor Assembly (JTAS-12-DX) – Exploded View ......................................................... 22

12.2.2 Trunnion and Motor Assembly (JTAS-12-DX) – Parts List .................................................................. 23

12.3.1 Blade Guard Assembly (JTAS-12-DX) – Exploded View .................................................................... 25

12.3.2 Blade Guard Assembly (JTAS-12-DX) – Parts List ............................................................................. 26

13.0 Electrical Connections ................................................................................................................................ 27

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply wit h all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This table saw is designed and intended for

use by properly trained and experienced

perso nnel on ly. If you are no t fam iliar w ith the

proper and safe operation of a table saw, do

not use until proper training and knowledge

have been obtained.

5. Do not use this table saw for other than its JET

disclaims any real or implied warranty and

hold s itself harmles s from a ny injury t hat may

result from that use.

6. Always wear approved safety glasses/face

shields while using this table saw. Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.

7. Before operating this table saw, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Remove all loose

clothing and confine long hair. Non-slip

footwear or anti-skid floor strips are

recommended. Do not wear gloves.

8. Use the blade guard for every operation for

which it can be used, including all ''throughsawing'' operations. A through-sawing

operation is one in which the blade cuts

completely through the workpiece.

9. Kickback occurs when the workpiece i s throw n

towards the operator at a high rate of speed. If

you do not have a clear understanding of

kickback and how it occurs, DO NOT operate

this table saw!

10. Wear ear protectors (plugs or muffs) during

extended periods of operation.

11. S ome dust created by power sand ing, sawing,

grinding, drilling and other construction

activities contain chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead based paint.

•

Crystalline silica from bricks, cement and

other masonry products.

•

Arsenic and chromium from chemically

treated lumber.

Your risk of exposure varies, depending on

how often you do this type of work. To reduce

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, suc h as face or dust masks

that are specifically designed to filter out

microscopic particles.

12. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

13. Mak e certain the switch is in t he OFF position

before connecting the machine to the power

supply.

14. Make certain the machine is properly

grounded.

15. Make all machine adj ustments or maintenance

with the machine unplugged from the power

source.

16. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

17. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

18. Check damaged parts. Before further use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

19. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

20. Keep the floor around the machine clean and

free of scrap material, oil and grease.

21. Keep visitors a safe distance from the work

area. Keep children away.

22. Make your workshop child proof w ith padlocks,

master switches or by removing starter keys.

23. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in

serious injury.

24. Maintain a balanced stance at all times so t hat

you do not fall into the blade or other moving

parts. Do not overreach or use excessive force

to perform any machine operation.

4

Page 5

25. Use the right tool at the correct speed and

feed rate. Do not force a tool or attachment to

do a job for which it was not designed. The

right tool will do the job better and more safely.

26. Use recommended accessories; improper

accessories may be hazardous.

27. Maintain tools with care. Keep saw blades

sharp and clean for the best and safest

performance. Follow instructions for lubricating

and changing accessories.

28. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use your hands.

29. Do not stand on the machine. Serious injury

could occur if the machine tips over.

Familiarize yourself with the following safety notices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

30. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

31. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

32. Keep hands out of the line of saw blade.

33. Use a push-stick when required.

34. Pay particular attention to instructions on

reducing risk of kickba ck.

35. Do not perform any operation freehand.

36. Never reach around or over saw blade.

37. Don’t use in dangerous environment. Don’t

use power tools in damp or wet location, or

expose them to rain. Keep work area well

lighted.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

4.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model

JTAS-12-DX Table Saw. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide years of trouble-free operation if used in accordance with t he instructions as set forth in

this document.

Read and understand the entire contents of this manual before attempting assembly or operation.

This manual is not intended to be an exhaust ive guide to table saw operational methods, use of jigs or after-

market accessories, choice of stock, etc. Additional knowledge can be obtained from e xper ienced users or

trade articles. Whatever accepted methods are used, always make personal safety a priority.

If there are questions or comments, please contact your local supp lier or JET. JE T can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

5

Page 6

5.0 Glossary

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the saw

blade to prevent accidental contact with the cutting

edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used for cutting grooves and

rabbets. A stacked dado set can be used f or wider

grooves.

Dado Cut: Flat bottomed groo ve in the fac e of the

workpiece made with a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from saw blade.

Freehand: Moving the workpiece into the blade

using only the hands, without a fixed positioning

device. (This is a dangerous, unacceptable

procedure – always use appropriate devices to

feed the workpiece though the saw blade during

cutting operations.)

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is lifted

up and thrown back toward an operator, caused

when a workpiece binds on the saw blade or

between the blade and rip fence (or other fixed

object). To minimize or prevent injury from

kickbacks, see the Operations section.

Miter Gauge: A component that controls the

workpiece movement while performing a crosscut

of various angl es.

Non-Through Cut: A sawing operation that

requires the removal of the blade guard and

standard riving knife, resulting in a cut that does

not protrude through the top of the workpiece

(includes Dado and rabbet cuts).

The blade guard and riving knife must be reinstalled after performing a non-through cut to

avoid accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in distance

at every point to the side face of the saw blade.

Perpendicular: 90° (right angle) intersection or

position of the vertical and horizontal planes such

as the position of the saw blade (vertical) to the

table surface (horizontal).

Push Board/Push Stick: An instrument used to

safely push the workpiece through the cutting

operation.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of a board.

Rip Cut: A cut made along the grain of the

workpiece.

Riving Knife: A metal plate fixed relative to the

blade, which moves with the blade as cutting depth

is adjusted. Thus, it maintains not only the kerf

opening in the workpiece, but also the knife-toblade distance. A low-profile riving knife is used

whe n per fo rm ing a no n-t hro ug h c ut be ca use it s it s

lower than the top edge of the blade.

Splitter (Spreader): A stationary metal plate to

which the blade guard is attached that maintains

the kerf opening in the workpiece when performing

a cutting operation.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to c heck that a surface

is flat or parallel.

Through Sawing: A saw ing operatio n in whic h the

workpiece thickness is completely sawn through.

Proper blade height usually allows 1/8" of the top

of blade to extend above the wood stock. Keep t he

blade guard down, the anti-kickback pawls down,

and the riving knife in place over the blade.

6

Page 7

6.0 Specifications

Model number ....................................................................................................................................... JTAS-12 -DX

Stock number ........................................................................................................................................... 708546PK

Mot or and electricals:

Motor type ............................................................................ totally enclosed fan cooled, induction, capacitor start

Horsepower ..................................................................................................................................... 5 HP (3.7 kW)

Phase......................................................................................................................................................... single

Voltage ................................................................................................................................................. 230V only

Cycle ........................................................................................................................................................... 60 Hz

Listed FLA ( f ull load amps) ............................................................................................................................ 20 A

Starting amps ............................................................................................................................................... 7 0 A

Running am ps (no load) ............................................................................................................................... 5.5 A

Start capacitor ........................................................................................................................ 600MFD, 250V AC

Run capacitor ............................................................................................................................... 80μF, 350V AC

Power transfer ............................................................................................................................. poly-v drive belt

On/off switch ........................................................................................................... magnetic , with overload relay

Motor speed ........................................................................................................................................ 3450 RPM

Power plug installed ......................................................................................................................................... no

Recommended circu it and fuse /breaker size

Sound emission ............................................................................ 85 dB at 36” (914 mm) from blade, without load

1

subject to local/national electrical codes.

Arbor and blade:

Blade included ................................................................................................................................................. no

Blade diameter .................................................................................................................................1 2 ” (3 0 5mm)

Arbor diameter ...................................................................................................................................1” (25.4mm)

Arbor speed (RPM) .......................................................................................................................................4300

Arbor lock ....................................................................................................................................................... yes

Maximum depth of cut at 90 degrees .................................................................................................. 4” (10 2mm)

Maximum depth of cut at 45 degrees .............................................................................................. 2-7/ 8 ” (73mm)

Maximum rip to r igh t of bla d e .......................................................................................................... 50” (1270mm)

Maximum rip to le ft of bla d e ..............................................................................................................14” (35 6mm)

Dado maximum width ................................................................................................................. 13/16” (20.6mm)

Dado maximum diameter ................................................................................................................... 8” (200mm)

Blade height per one r evolution of handwheel .................................... 3/32 ” (2 .3mm) for 90°; 1/16” (1.7mm) for 45°

Blade tilt ...................................................................................................................................... left, 0 to 45 deg.

Materials:

Main table ................................................................................................................................... ground cast iron

Trunnion ................................................................................................................................................. cast iron

Enclosed cabinet .......................................................................................................................................... steel

Legs ............................................................................................................................................................. stee l

Table extensions ......................................................................................................................... ground cast iron

Handwheels ................................................................................................................................................. stee l

Table:

Main table without extensions .............................................................................. 31-1/2”L x 24”W (800 x 610mm)

Left table extension .............................................................................................. 31-1/2”L x 10”W (800 x 254mm)

Inner table extension............................................................................................ 31-1/2”L x 23”W (800 x 584mm)

Outer table extension ........................................................................................... 31-1/2”L x 23”W (800 x 584mm)

Table size with full left and right extensions ........................................................ 31-1/2”L x 80”W (800 x 2032mm )

Table area in front of blade at maximum depth of cut .........................................................................12” (305mm)

Table heig ht from floo r ......................................................................................................................3 4 ” (8 6 4mm)

Miter slot ...................................... two T-slots; 15/16”W x 0.15”H (24x3.8mm); opening 3/4”W x 3/8”H (19x9.6mm)

Edge bevel ............................................................................................................ front edge bevel on main table

Dust collection:

Dust p o rt outside d iameter ................................................................................................................. 4” (100 mm)

Minimum extraction volume required ..........................................................................................350 cfm (18cmm)

1

................................................................................................. 30A

7

Page 8

Dimensions:

Cabinet footprint ............................................................................................ 25-1/4”L x 24-3/4”W (645 x 629mm)

Overall dimensions of shipping crate (basic saw only) ......................35”L x 32-1/4”W x 46-1/2”H (89 x 82 x 118cm)

Overall dimensions, fully assembled, accessories mounted ................ 50”L x 84-1/2”W x 40”H (127 x 215 x 102cm)

Weights:

Saw Only (Net/Shipping) .................................................................................................. 531/573 lb (241/260 kg)

Saw assembled with all accessories ............................................................................................623 lb (282.5 kg)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specif ications at any time and without prior notice, without incurring

obligations.

8

Page 9

7.0 Setup and assembly

7.1 Tools required for assembly

Metric wrench set, or 6”-8” adjustable wrench

Metr ic he x ke y se t

Straight edge

7.2 Shipping contents

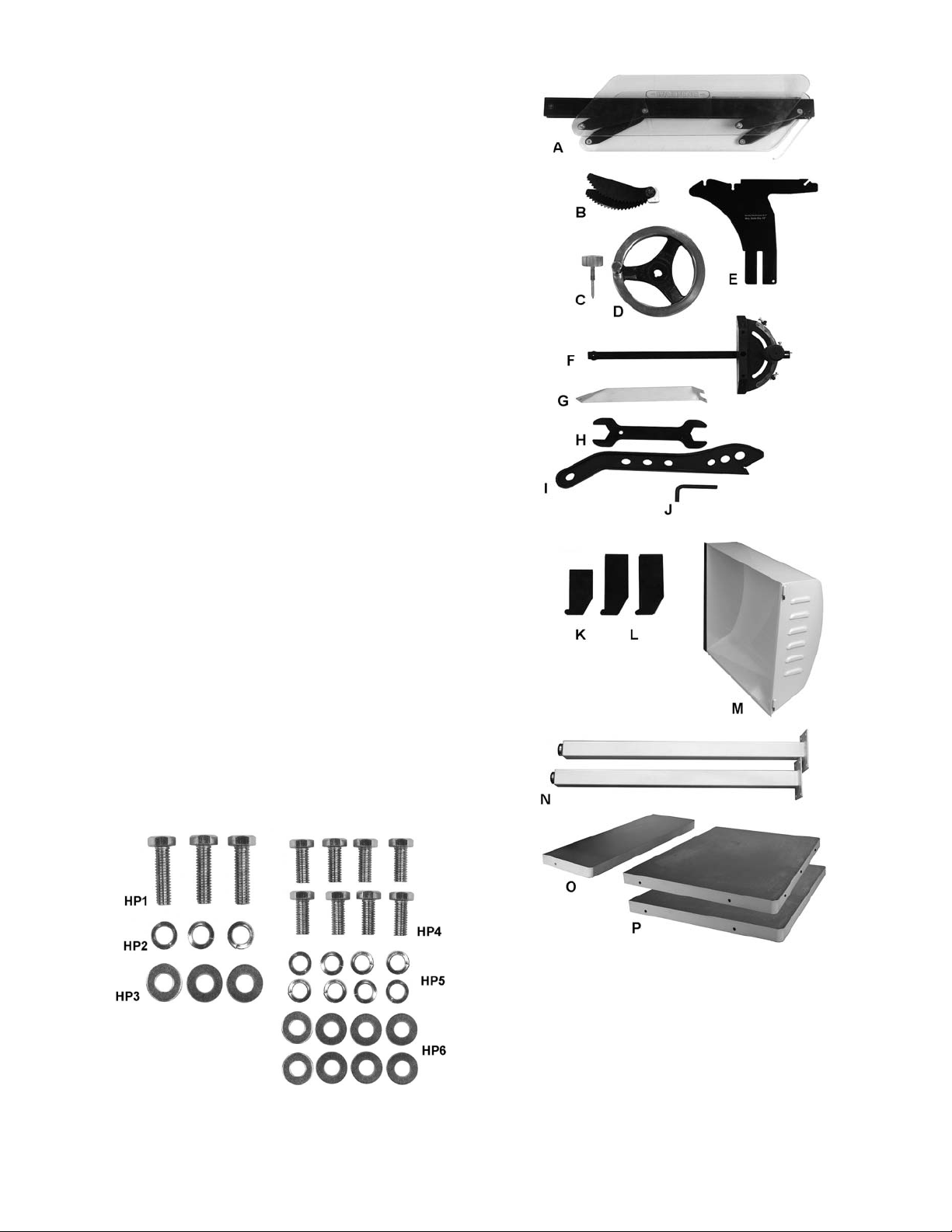

Carton contents (see Figure 1)

1 Table saw (not shown)

1 Blade guard – A

1 Anti-kickback pawl assembly – B

1 Lock knob – C

1 Handwheel with sw ivel handle – D

1 Riving knife – E

1 Miter gauge – F

1 Switch support brace – G

1 Arbor wrench – H

1 Push stick – I

1 Hex key 8mm – J

1 Storage hook, small – K

2 Storage hooks, large – L

1 Motor cover – M

2 Legs with leveling feet – N

1 Cast iron table extension, 10-inch – O

2 Cast iron table extensions, 23-inch – P

1 Operator’s Manual (not shown)

1 Warranty Card (not shown)

2 Hardware bags containing:

3 Hex cap screws, 7/16”x1-1/2” – HP1

3 Lock washers, 7/16” – HP2

3 Flat washers, 7/16” – HP3

8 Hex cap screws, 5/16”x3/4” – HP4

8 Lock washers, 5/16” – HP5

8 Flat washers, 5/16” – HP6

Note: Fence and rail assemblies are shipped in

separate cartons.

Figure 2

Figure 1

(items not to scale)

9

Page 10

7.3 Unpacking and cleanup

1. Remove all contents f rom shipping container.

Do not discard any shipping material until saw

is set up and running satisfactorily.

2. Inspect contents for shipping damage. Report

damage, if any, to your local distributor.

3. Compare contents of shipping carton with the

contents list in section 7.2. Also check saw in

case any listed parts have been pre-installed.

Report shortages, if any, to your distributor.

4. Exposed surfaces have been coated with a

protectant. This can be removed with kerosene

or a cleaner-degreaser.

7.4 Installation and leveling

• Tool: 12 mm w rench

1. Remove two screws holding saw to pallet.

2. Carefully move saw to its final locatio n. Final

location for the saw must be level, dry, well

lighted, and have enough room to allow

movement around the saw with long pieces of

wood stock.

3. Level the saw front to back and side to side

using a carpenter’s level placed on the table.

Use shims under the cabinet corners, if

nece ssa ry, b ut m ake sure sa w i s sta b le b ef or e

being placed into service.

7.5 Installing table extensions

• Hardware: (9 each) 7/16” screws (HP1), lock

washers (HP2), flat washers (HP3); and (8

each) 5/16” screws (HP4), lock washers (HP4),

fl at washers (HP6); and (3) table extensions.

• Tools: 17mm wr ench , 12mm wrenc h, st rai ght

edge, lift table or similar supporting device

1. Remove shipping bracket (A, Figure 3) from

table and switch. Keep the upper screw and

washers; they will be used to hold table

extension in p lace.

2. Install the 10-inch table extension to left edge

of saw table with three screws, lock washers

and flat washers. Snug screws, but do not

tighten.

3. Slide extensio n toward front edge of saw table

until the two front edges are flush (D, Figure

4). This will ensure proper guide rail

installation.

Figure 4

4. Use a straight edge (C, Figure 4) to align

extension to saw table and tighten screws.

ASSEMBLY TIP: Align center section first and

tighten center screw almost completely. Then

place wood blocks at outer ends, spanning

main table and extension, and use clamps to

press blocks firmly against tables – this will

bring the outer ends of tables into alignment.

Tighten all three scre ws.

5. Identify the two 23-inch table extensions: the

inner table extension has hole s or slots on all

four edges; the outer table extension has one

blank edge and threaded holes underneath for

leg attachment.

The table extensions are

heavy! Exercise caution and use assistants or a

support device to hold the extensions while

assembling.

Figure 3

IMPORTANT: The tables must be aligned

carefully to allow smooth transition of rip fence

and workpieces over the seams.

6. Install inner table extension (E, Figure 5), w ith

slots toward saw, with three screws and

washers.

7. Follow steps 3 and 4 above. Continue

supporting inner table extension until outer

extension is installed.

8. Install legs (F) beneath outer table extension

(G) with eight screws and washers.

9. Install outer table extension to edge of inner

extension using steps 3 and 4. Rotate leveling

feet on legs as needed.

10

Page 11

Figure 5

7.6 Installing motor cover

1. Install motor cover by aligning pins on cover

with barrels on cabinet (A, Figure 6).

2. Fasten cover by p ulling out latc h (B, Figure 6),

closing door, and releasing latch.

Figure 6

7.7 Installing handwheel

• Hardware: Handle and handwheel, lock knob

• Tool: 3mm hex key

1. Remove tape holding key to shaft.

2. Line up key on shaft with keyway in handwheel

and slide handwheel (C, Figure 7) onto shaft.

3. Tighten set screw on handwheel hub sec ure ly

to hold in place.

4. Insert lock knob (D, Figure 7) into center hole

in shaft and rotate in clockwise direction.

Note: Rotate handwheel in order to free the

packing below the motor.

Figure 7

7.8 Installing storage hooks

• Hardware: Socket head cap screws and

washers (already in cabinet holes)

• Tool: 5mm hex key

Install small hook (E, Figure 7) in upper hole for

miter gauge storage. T he larger hooks (F, Figure 7)

are installed in the lower holes for fence storage.

7.9 Installing blade (not provided)

When installing or changing

saw blade, always disconnect saw from power

source. Failure to comply may cause serious

injury.

• Tool: Arbor wrench

1. Raise blade arbor fully with front handwheel

and lock it at zero degree s by tightening lock

knob in middle of handwheel.

2. Remove arbor nut (A, Figure 8) and flange (B).

3. Place blade on arbor shaft, making sure the

teeth po int down toward f ront of saw. Reinstall

flange and arbor nut.

4. Rotate arbor until hole (C) lines up wit h arbor

lock pin (D). Push pin into hole and hold.

5. Tighten arbor nut with provided wrench.

Figure 8

11

Page 12

7.10 Installing riving knife

• Hardware: rivi n g knife

• Tool: straight edge

1. Loosen handle (E, Figure 9).

2. Push tabs of riving knife into block as far down

as it will go and tighten handle.

Figure 9

3. Install blade (not provided).

4. Lay a straight edge against side of riving knife

and blade (Figure 10). Make sure it contacts

flat surface of blade, not an offset tooth.

5. If knife and blade are not flush, note the

dire c tion in which rivi ng knife needs to m o v e t o

align. Remove riving knife and adjust any of

four set screws (F, Figure 11).

6. Reinstall riving knife and check alignment

again. Repeat as needed until surfaces are

flush.

Figure 11

7.11 Table insert adjustment

• Hardware: Ta ble insert

• Tools: Straight edge, 2.5mm hex key

Install table insert and make it flush with table by

turning any of six leveling screws (G, Figure 12)

while verifying with a straight edge.

Figure 12

Figure 10

12

Page 13

7.12 Installing anti-kickback pawls

and blade guard assembly

1. Install riving knife and table insert.

2. Push the pin (H, Figure 13) at side of pawl

assembly, and slide pawl assembly into recess

of riving knife.

3. Push the pin (I, Figure 14) on rear of blade

guard, and slide it i nto recess at back of rivi ng

knife. Allow front of guard to lower to the table.

Figure 13

5. Fasten switch brace to switch bracket

assembly with the star washer and nut.

6. Align switch and tighten all hardware.

Figure 15

7.15 Miter gauge operation

1. Slide miter gauge into table T-slot.

2. Operate miter gauge by loosening lock knob

(A, Fig. 16) and turning miter body (B) to

desired angle. To move gauge beyond index

stops of 45° and 90°, flip stop (C) out of the

way.

3. Adjust index stops by turning one of three

adjustment screws (D).

Figure 14

7.13 Installing rails and rip fence

With table extensions properly aligned and

secured, the rail and fence assembly can be

mounted to saw. See owner’s manual M-708955Z,

XACTA Fence for JTAS-12-DX, for instructions.

7.14 Installing switch and brace

• Hardware: Swi tch brace

• Tool: 8mm hex key, 8mm wrench

1. Place switch bracket assembly behind both

front fence rail and lip of left table extension.

(Do not place between front fence rail and

table extension; this will cause front rail to

distort and the fence to bind).

2. Loosen (do not remove) screw (A, Figure 15).

3. Slide open tab of switch brace onto t he screw

and washer. Hand tighten only at this time.

4. Remove nut and star washer from screw at

bottom of switch plate.

Figure 16

Note: Always make test cuts. Do not rely solely on

miter gauge indicator marks. Holes are pro vided in

the miter gauge body to allow mounting a woode n

extension fence.

13

Page 14

8.0 Electrical connections

9.0 Adjustments

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to pr event

serious or fatal injury.

The JTAS-12-DX is rated for single phase, 230 volt

power only. A plug is not provided.

Confirm power at the site matches that of the saw

before making any electrical connections. Review

the electrical diagram in Section 13.0.

You may either install a plug or “hard-wire” the

saw directly to a control panel. If saw is to be hardwired to a panel, make sure a disconnect is

available for the operator. During hard-wiring,

make sure the fuses have been removed or the

breakers have been tripped in the circuit to which

the machine will be connected. Place a warning

placard on fuse holder or circuit breaker to prevent

it being turned on while saw is being wired.

It is recommended that the JTAS-12-DX Table Saw

be connected to a dedicated 30 amp circuit with

circuit breaker or time delay fuse. Local codes

take precedence over recommendations.

The on/off switch is thermally protected. If the saw

motor is overloaded, or a momentary interruption of

electrical current is sensed, the saw will shut off.

Allow a few minutes for saw to cool down, then

reset by pushing the off button.

8.1 Extension cords

The use of extension cords i s discouraged. Try to

position machines within reach of power source. If

an extension cord becomes necessary, be sure to

use one heavy enough to carry the current your

product will draw. An unde rsized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

Table 1 shows correct size to use depending on

cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Amp Rating Volts Total length of cord in feet

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

More

Than

Extension Cord Recommendations

240 50 100 200 300

AWG

Not

Recommended

Table 1

9.1 Blade raising and tilting

1. To raise or lower saw blade, loose n lock knob

(A, Figure 17) and turn handwheel (B) on the

saw front until desired height is reached.

Tighten lock knob. Blade should be adjusted

no more than 1/8" to 1/4" above top surface of

material being cut.

2. To tilt blade, loosen lock knob (C, Figure 17),

turn handwheel on right of saw cabinet (D)

until desired angle is obtained, then tighten

lock knob .

Figure 17

All following adjustments

must be made with machine disco nnected fr om

power source. Failure to comply may cause

serious injury.

9.2 Blade alignment

• Tool: 8mm hex key, combinati on square, felt-

tip marker

Blade alignment is set by the manufacturer, but

should be verified by the operator. Also after a

period of use, or after relocating saw, the blade

may become misaligned with table. To check and

align blade:

1. Disconnect saw from power source.

2. Remove blade guard and anti-kickback pawls.

3. Use the right T-slot as a shoulder for a

combination square. See Figure 18.

4. Choose a toot h on the far edge of blade and

directly over the insert. Mark the tooth.

5. Measure the distance from side of blade to

right T-slot edge using a combination square.

Note: The square should contact flat surface of

blade between teeth, not a raised tooth edge.

6. Rotate blade toward front so that marked tooth

is just above insert. Measure distance from

marked point of blade to right T-slot edge. The

two measurements should be equal.

14

Page 15

Figure 18

7. If m easurements are not equal, locate the f our

screws that hold table to cabinet (E, Figure

17).

8. Loosen the four screws and bump the table as

needed to align it with blade. Retighten screws

firmly.

9.3 Adjusting 90° and 45° positive

stops

• Tool: 12mm Wrench, combination square

Stops have been set by the manufacturer, but

should be verified by the operator. Also after a

period of use, or after relocating saw, the stops

may need readjusting. To check and adjust the

stop s:

1. Disconnect saw from power source.

2. Raise saw blade to maximum height.

3. Set blade at 90-degrees to table by turning

blade tilting handwheel clockwise as far as it

will go.

4. Place a square on the table and chec k to see

that blade is at 90-degree angle to table

(Fig ure 1 9). M ake s ure squar e is not to uch ing

a blade tooth.

6. Loosen lock nut (A, Figure 20) and turn stop

screw (B) on front trunnion as needed. The

stop screw should contact front trunnion

bracket when blade is 90-degrees to table. Tilt

blade back to 90-degrees and verify.

7. Tighten lock nut (A, Figure 20).

Figure 20

8. Verify pointer accuracy (C, Figure 21). Adjust if

needed.

9. Set blade at 45-degrees to table by turning

blade tilting handwheel counter-clockwise as

far as it will go.

10. P lace an angle measuring device on t he table

and against blade.

11. If blade is not at 45-degrees, loosen lock nut

(D, Figure 21) and t urn stop screw (E) on t he

front trunnion as needed. The stop screw

should contact front trunnion bracket when

blade is 45-degrees to table. (Note: You may

wish to remove front handwheel for better

acce ss to st o p sc r ew.)

12. Verify pointer accuracy (C, Figure 21).

Figure 19

5. If blade is not at 90-degrees, open motor cover

and tilt blade to access the stop screw.

Figure 21

(shown with front handwheel removed)

15

Page 16

9.4 Belt tension and replacement

1. Disconnect machine from power source.

2. Lower blade to its lowest point.

3. Loosen bolt (A, Figure 22).

4. Take tension off belt (B) by lifting up on motor.

5. Remove belt from arbor and motor pulleys.

6. Install new belt. The weight of the motor

should apply sufficient tension to belt. Tighten

bolt (A, Figure 22).

NOTE: New belts may stretch slig htly until they are

worn in. Check belt tension after saw has been

used for a few hours, and adjust if necessary.

10.0 Maintenance

Always disconnect power to

the machine before performing maintenance.

Failure to comply may cause serious injury.

Use vacuum or compressed air to clear out cabinet

interior of sawdust and wood chips. Make sure

motor fan and fan cover are also kept clear of

sawdust.

Use a wire brush to clean worm gears and

trunnions. Apply white lithium grease or powdered

graphite to lubricate worm gears and trunnions.

Keep a light coat of rust-preventive on the table top

when not in use. If rust develops on tabletop,

remove it with WD-40® and a Scotch-Brite™ Hand

Pad.

The saw arbor is press fitted in the saw raising arm

housing. If the arbor ever needs to be rem oved for

bearing replacement, it should be done by a

qualified service technician. Call your customer

service representative at the phone number o n the

front cover.

Figure 22

16

Page 17

11.0 Troubleshooting the JTAS-12-DX Table S aw

11.1 Mechanical Problems

Symptom Possible Cause Correction

Motor will not start. Saw disconnected from power

source.

Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker.

Cord damaged. Replace cord.

Low voltage. Check power line for proper voltage.

Open circuit in motor or loose

connection.

Motor will not start:

fuses blow or circuit

breakers trip.

Blade will not come up

to speed.

Motor overheats. Motor overloaded. Reduce load on motor.

Motor stalls, resulting

in blown fuses or

tripped circuit.

Short circuit in line cord or plug. Inspect cord or plug for damaged

Short circuit or loose connections. Inspect all connections at junction box and

Incorrect fuses or circuit breakers in

power line.

Extension cord too light or too long. Replace with adequate size electrical

Low voltage. Check power line for proper voltage.

Air circulation through motor

restricted.

Motor overloaded. Reduce load on motor.

Short circuit in motor or loose

connections.

Low voltage. Correct the low voltage conditions.

Check plug or hard-wired connections.

Contact local electric company.

Inspect incoming leads for loose or open

connections.

insulation and shorted wires.

motor for loose or shorted terminals or

worn insulation.

Install correct fuses or circuit breakers.

cord.

Contact local electric company.

Clean motor fan with compressed air to

restore normal air circulation.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Incorrect fuses or circuit breakers in

power line.

Loud, repetitive noise

coming from machine.

Saw vibrates

excessively.

Pulley setscrews or keys are missing

or loose.

Motor fan is hitting cover. Tighten fan or shim cover.

V-belt is defective. Replace V-belt.

Cabinet on uneven floor. Reposition on flat, level surface.

Saw blade is damaged. Replace blade.

Loose hardware. Tighten hardware.

Pulley bent. Inspect and replace pulley.

Improper motor mounting. Check and adjust motor, tighten bolt(s).

V-belt is defective. Replace V-belt.

Install correct fuses or circuit breakers.

Inspect keys and setscrews. Replace or

tighten if necessary.

Table 2

17

Page 18

11.2 Operational Problems

Symptom Possible Cause Correction

Machine slows when

operating.

Blade not square with

miter slot, or fence not

square to blade.

Does not make

accurate 45- or 90degree cuts.

Rip fence binds on

guide rails.

Material binds in blade

when ripping.

Material ki cked back

from blade.

Applying too much pressure to

workpiece.

Belt loose. Tension belt.

Blade is warped. Replace saw blade.

Fence not parallel to blade. Adjust fence parallel to blade.

Table not parallel to blade. Adjust table parallel to blade.

Stops not adjusted properly. Check blade with angle measuring device,

Miter gauge out of adjustment. Use a square or angle-setting device to

Guide rails or extension table not

properly installed.

Fence locking system not adjusted

properly.

Fence not aligned with blade. Check and adjust fence.

Warped wood. Select different stock.

Applying excessive pressure to

workpiece.

Riving knife not aligned with blade. Adjust riving knife.

Fence out of alignment. Align fence wi th miter slot.

Riving knife not aligned with blade. Align riving knife with blade.

Feed workpiece more slowly.

and adjust stops.

adjust miter gauge to blade.

Re-assemble according to owner’s

manual.

Use set screws to adjust tension against

guide tube.

Feed workpiece more slowly.

Feeding stock without a fence. Always use fence or similar guide to feed

stock; do not feed freehand.

Dull blade. Replace blade.

Blade does not rise or

tilt freely.

Saw makes

unsatisfactory cuts.

Releasing material before it clears

blade.

Anti-kickback pawls are dull. Replace anti-kickback pawls, or resharpen

Sawdust/debris in raising and tilting

mechanisms.

Dull blade. Sharpen or replace blade.

Blade mounted backward. Turn blade around.

Gum or pitch on blade. Remove blade and clean.

Incorrect b lade f or desired cut. Change blade to correct style, tooth pitch,

Gum or pitch on table. Clean table.

Table 3

Push material completely past blade

before releasing it.

their points.

Clean and regrease problem areas.

etc.

12.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

18

Page 19

12.1.1 Table and Cabinet Assembly (JTAS-12-DX) – Exploded View

19

Page 20

12.1.2 Table and Cabinet Assembly (JTAS-12-DX) – Parts List

Index No Part No Description Size Qt y

1 ................ JTAS10-1 .................. Lock Knob ........................................................ .............................................. 1

2 ................ JTAS10-2 .................. Miter Gauge Body ............................................ .............................................. 1

3 ................ TS-1540031 .............. Hex Nut ............................................................ M5 ......................................... 3

4 ................ JTAS10-4 .................. Poin ter ............................................................. .............................................. 1

5 ................ JTAS10-5 .................. Stop Link .......................................................... .............................................. 1

6 ................ TS-1521011 .............. Socket Set Screw ............................................ M4x4 ...................................... 1

7 ................ JTAS10-7 .................. Special Pin ....................................................... M3x6 ...................................... 1

8 ................ TS-2205201 .............. Hex Cap Screw ................................................ M5x20 .................................... 3

9 ................ JTAS10-9 .................. Guide Bar......................................................... .............................................. 1

10 .............. JTAS10-10 ................ Guide Washer .................................................. .............................................. 1

11 .............. JTAS10-11 ................ Flat Head Screw .............................................. M6x8 ...................................... 1

.................. JTAS10-MG .............. Miter Gauge Assembly (#1 thru 11) ................. .............................................. 1

12 .............. TS-0267041 .............. Socket Set Screw ............................................ 1/4"-20x3/8” ........................... 6

13 .............. JTAS12DX-13 ........... Table Insert ...................................................... .............................................. 1

13A ............ JTAS12DX-13A ......... Dado Insert ...................................................... .............................................. 1

14 .............. JTAS12DX-14 ........... Table ................................................................ .............................................. 1

15 .............. JTAS12DX-15 ........... Left Table Extension ........................................ 31-1/2”L x 10”W ..................... 1

16 .............. JTAS12DX-16 ........... Inner Table Extension ...................................... 31-1/2”L x 23”W ..................... 1

17 .............. JTAS12DX-17 ........... Outer Table Extension ..................................... 31-1/ 2”L x 23”W ..................... 1

18 .............. TS-0061051 .............. Hex Cap Screw ................................................ 7/16”-14x1-1/2” ...................... 9

19 .............. TS-0720101 .............. Lock Washer .................................................... 7/16” ...................................... 9

20 .............. TS-0680051 .............. Flat Washer ..................................................... 7/16” .................................... 13

21 .............. JTAS12DX-21 ........... Leg ................................................................... .............................................. 2

22 .............. JTAS10-22W ............. Switch Plate ..................................................... .............................................. 1

23 .............. JTAS12-23 ................ Magn etic Switch .............................................. 5HP, 1 Ph, 230V .................... 1

24 .............. TS-081C052 .............. Pan Head Screw .............................................. #10-24x3/4 ............................ 1

25 .............. TS-0680031 .............. Flat Washer ..................................................... 5/16” ...................................... 8

26 .............. JTAS10-26 ................ Strain Relief Bushing ....................................... .............................................. 2

27 .............. JTAS10-27 ................ Strain Relief Bushing ....................................... .............................................. 2

28 .............. JTAS10-28 ................ Tap Screw........................................................ M5x10 .................................. 10

29 .............. JTAS10-29 ................ Cord Plate ........................................................ .............................................. 1

30 .............. JTAS12DX-30 ........... I dentification Plate ........................................... .............................................. 1

31 .............. JTAS12DX-31 ........... Power Cord (switch to motor) .......................... 12AWG x 3C ......................... 1

32 .............. JTAS12DX-32 ........... Power Cord ...................................................... 12AWG x 3C ......................... 1

33 .............. JTAS10-33 ................ Power Cord Sleeve .......................................... .............................................. 1

34 .............. JTAS10L-34 .............. Tilt Scale .......................................................... .............................................. 1

35 .............. JTAS10-35 ................ Warning Label.................................................. .............................................. 1

36 .............. JTAS10-36 ................ JET Label......................................................... .............................................. 1

37 .............. TS-0720081 .............. Lock Washer .................................................... 5/16” ...................................... 8

38 .............. JTAS12DX-38 ........... Cabin et ............................................................ .............................................. 1

39 .............. TS-1482101 .............. Hex Cap Screw ................................................ M6x50 .................................... 1

40 .............. TS-0680021 .............. Flat Washer ..................................................... 1/4" ........................................ 2

41 .............. JTAS10-41 ................ Sprin g .............................................................. .............................................. 1

42 .............. JTAS10-42 ................ Foam Strip ....................................................... .............................................. 1

43 .............. JTAS12DX-43 ........... Motor Cover ..................................................... .............................................. 1

44 .............. TS-1541021 .............. Nylon Insert Lock Nut ...................................... M6 ......................................... 1

45 .............. JTAS10-45 ................ Handl e ............................................................. .............................................. 1

47 .............. TS-0210011 .............. Socket Head Cap Screw.................................. 7/16”-14x3/4” ......................... 4

48 .............. TS-0680011 .............. Flat Washer ..................................................... 3/16” ...................................... 2

49 .............. JTAS12DX-49 ........... Lower Panel ..................................................... .............................................. 1

50 .............. JTAS10L-50N............ Dust Hose Adapter .......................................... .............................................. 1

51 .............. JTAS12DX-51 ........... Switch Brace Kit............................................... .............................................. 1

52 .............. TS-081C062 .............. Screw ............................................................... #10-24x1 ............................... 1

53 .............. TS-0560071 .............. Hex Nut ............................................................ #10-24 ................................... 1

54 .............. TS-0733031 .............. Star Washer ..................................................... #10 ........................................ 1

55 .............. JTAS10L-55 .............. Hook (large) ............................................................. ...................................... 2

56 .............. TS-0680021 .............. Flat Washer ............................................................. 1/4" ................................ 6

57 .............. TS-0720071 .............. Lock Washer ............................................................ 1/4" ................................ 6

58 .............. TS-0207031 .............. Socket Head Cap Screw.......................................... 1/4"-20x5/8” .................. 6

59 .............. JTAS10L-59 .............. Hook (small)............................................................. ...................................... 1

20

Page 21

Index No. Part No. Description Size Qty

60 .............. TS-0561011 .............. Hex Nut .................................................................... 1/4"-20” ......................... 6

61 .............. JTAS10L-61 .............. Electrical Box ........................................................... ...................................... 1

62 .............. TS-0081031 .............. Hex Cap Screw ........................................................ 5/16” x3/4” ..................... 8

63 .............. TS-1540071 .............. Hex Nut .................................................................... M10 ............................... 2

64 .............. JTAS12DX-64 ........... Leveling Foot ........................................................... M10 x75 ........................ 2

.................. STRIPE-1-3/4 ............ Stripe (not shown).................................................... 1-3/4” wide .......

per 9.12 ft.

21

Page 22

12.2.1 Trunnio n and Motor Assembly (JTAS-12-DX) – Exploded View

22

Page 23

12.2.2 Trunnio n and Motor Assembly (JTAS-12-DX) – Parts List

Index No Part No Description Size Qty

101 ............ JTAS12L-101 ............ Arbor Nut ................................................................. ...................................... 1

102 ............ JTAS12DX-102 ......... Arbor Flange ............................................................ ...................................... 1

104 ............ JTAS12DX-104 ......... Arbor with Flange..................................................... ...................................... 1

105 ............ JTAS12DX-105 ......... Key .......................................................................... 1/4”x1/4”x1-3/4”............. 2

106 ............ BB-6005ZZ ................ Ball Bearing ............................................................. 6005ZZ.......................... 2

107 ............ JTAS12DX-107 ......... Wave Washer .......................................................... ...................................... 4

108 ............ JTAS12DX-108 ......... Rear Bearing Load Spacer ...................................... ...................................... 1

108-1 ......... JTAS12DX-108-1 ...... Front Bearing Load Spacer...................................... ...................................... 1

109 ............ TS-0267041 .............. Socket Set Screw .................................................... 1/4"-20x3/8” ................ 10

110 ............ JTAS-12DX-110 ........ Arbor Pulley ............................................................. ...................................... 1

111 ............ TS-0209081 .............. Socket Head Cap Screw.......................................... 3/8”-16x1-3/4” ............... 1

112 ............ JTAS10DX-112 ......... Key........................................................................... 1/4" x1/4”x45mm ........... 1

113 ............ TS-0720091 .............. Lock Washer ............................................................ 3/8” .............................. 10

114 ............ JTAS12DX-114 ......... Arbor Bracket ........................................................... ...................................... 1

115 ............ JTAS12-115 .............. Spanner Nut............................................................. ...................................... 1

116 ............ TS-0561081 .............. Nylon Hex Nut.......................................................... 3/4"-10 .......................... 1

117 ............ JTAS10-117 .............. Sprin g Pin ................................................................ M6x50 ........................... 1

118 ............ JTAS10-118 .............. Key ........................................................................... 1/4"x1/4”x2-5/16” .......... 1

119 ............ TS-0680051 .............. Flat Washer ............................................................. 7/16” .............................. 2

120 ............ TS-0091031 .............. Hex Cap Screw ........................................................ 7/16”-14x1”.................... 2

121 ............ JTAS10DX-121 ......... Shaft ........................................................................ ...................................... 1

122 ............ JTAS10-122 .............. Motor Bracket .......................................................... ...................................... 1

123 ............ JTAS10-123 .............. Pin............................................................................ ...................................... 1

124 ............ JTAS10L-124 ............ Spring Clip ............................................................... ...................................... 2

125 ............ JTAS12DX-125 ......... Poly V-Belt ............................................................... PJ250 ............................ 1

126 ............ JTAS10DX-126 ......... Motor Mounting Bracket........................................... ...................................... 1

127 ............ JTAS10-127N............ Motor Pulley ............................................................. ...................................... 1

128 ............ TS-0680031 .............. Flat Washer ............................................................. 5/16” ............................ 10

129 ............ TS-0720081 .............. Lock Washer ............................................................ 5/16” .............................. 9

130 ............ TS-0081031 .............. Hex Cap Screw ........................................................ 5/16”-18x3/4”................. 4

131 ............ JTAS12DX-131 ......... Motor........................................................................ 5HP 1PH 230V only ...... 1

.................. JTAS10-131-017 ....... Centrifugal Switch Assembly (not shown) ............... ...................................... 1

.................. JTAS10-131D............ Fan Cover (not shown) ............................................ ...................................... 1

.................. JTAS10-131F ............ Motor Fan (not shown)............................................. ...................................... 1

.................. JTAS10-1315B .......... Start Capacitor (not shown) ..................................... 600MFD/250VAC .......... 1

.................. JTAS10-1315A .......... Run Capacitor (not shown) ...................................... 80uF/350VAC ............... 1

132 ............ TS-0209071 .............. Socket Head Cap Screw.......................................... 3/8”-16x1-1/2” ............... 6

133 ............ JTAS10DX-133 ......... Rear Trunnion Bracket............................................. ...................................... 1

134 ............ TS-0561031 .............. Hex Nut .................................................................... 3/8”-16........................... 5

135 ............ TS-0209051 .............. Socket Head Cap Screw.......................................... 3/8-“16x1”...................... 4

136 ............ JTAS10-136 .............. Sprin g Pin ................................................................ M8x25 ........................... 4

137 ............ TS-0561081 .............. Hex Nut .................................................................... 3/4"-10 .......................... 1

138 ............ JTAS10-138 .............. Fiber Washer ........................................................... ...................................... 4

139 ............ JTAS10DX-139 ......... Rear Trunnion ......................................................... ...................................... 1

140 ............ JTAS10-140 .............. Rear Bushing ........................................................... ...................................... 2

140-1 ......... JTAS10DX-140 ......... Fron t Bushing .......................................................... ...................................... 1

141 ............ JTAS12DX-141 ......... Yoke......................................................................... ...................................... 1

142 ............ TS-0270011 .............. Socket Set Screw .................................................... 5/16”-18x1/4”................. 4

143 ............ JTAS10-143 .............. Col lar ....................................................................... ...................................... 2

144 ............ JTAS12DX-144 ......... Shaft ........................................................................ ...................................... 1

145 ............ JTAS10-145 .............. Sprin g Pin ................................................................ M5x30 ........................... 2

146 ............ JTAS10-146 .............. Worm (Left thread)................................................... ...................................... 1

146-1 ......... JTAS10DX-146 ......... Worm (Right thread) ................................................ ...................................... 1

147 ............ JTAS10-147 .............. Lock Pin ................................................................... ...................................... 4

148 ............ JTAS10-148 .............. Key ........................................................................... M5x35 ........................... 2

149 ............ TS-0208021 .............. Socket Head Cap Screw.......................................... 5/16”-18x1/2”................. 4

150 ............ JTAS12DX-150 ......... Dust Deflector .......................................................... ...................................... 1

151 ............ JTAS10L-151N.......... Hose Clamp ............................................................. ...................................... 2

152 ............ JTAS10DX-152 ......... Front Trunnion ......................................................... ...................................... 1

.................. JTAS12DX-TA........... Trunni on Assembly (#113, 135, 136, 139 thru 141, 152) .............................. . 1

23

Page 24

Index No. Part No. Description Size Qty

153 ............ TS-0051021 .............. Hex Cap Screw ........................................................ 5/16”-18x5/8”................. 2

154 ............ TS-0561021 .............. Hex Nut .................................................................... 5/16”-18......................... 2

155 ............ JTAS10-155A ............ Lock Knob ................................................................ ...................................... 2

156 ............ JTAS10-156 .............. Fiber Washer ........................................................... ...................................... 2

157 ............ TS-0208061 .............. Socket Head Cap Screw.......................................... 5/16”-18x1”.................... 2

158 ............ JTAS10DX-158 ......... Front Trunnion Bracket ............................................ ...................................... 1

159 ............ JTAS10-159 .............. Handwh eel Handle .................................................. ...................................... 2

160 ............ JTAS10-160 .............. Handwheel ............................................................... ...................................... 2

161 ............ JTAS10-161 .............. Shield Plate.............................................................. ...................................... 1

162 ............ TS-0813022 .............. Round Head Screw.................................................. 1/4"-20x3/8” .................. 1

163 ............ JTAS10-163 .............. Poin ter ..................................................................... ...................................... 1

164 ............ JTAS10-164 .............. Poin ter Bracket ........................................................ ...................................... 1

165 ............ TS-081C102 .............. Pan Head Screw ...................................................... #10-24x2” .... .................. 2

166 ............ JTAS10DX-166 ......... Guide Block ............................................................. ...................................... 1

167 ............ TS-0680041 .............. Flat Washer ............................................................. 3/8” ................................ 1

169 ............ JTAS12DX-169 ......... Tilt Shaft................................................................... ...................................... 1

170 ............ JTAS12-170 .............. Wrench .................................................................... ...................................... 1

171 ............ JTAS10L-171 ............ Hose ........................................................................ 700mm .......................... 1

172 ............ JTAS10L-172 ............ Plate......................................................................... ...................................... 1

173 ............ TS-0208041 .............. Socket Head Cap Screw.......................................... 5/16”-18x3/4”................. 3

174 ............ JTAS12DX-174 ......... Chip Plate ................................................................ ...................................... 1

175 ............ TS-0680011 .............. Flat Washer ............................................................. 3/16 ............................... 3

176 ............ TS-0720051 .............. Lock Washer ............................................................ #10 ................................ 3

177 ............ JTAS10L-177 ............ Hex Cap Bolt............................................................ #10-24x3/8 .................... 3

178 ............ JTAS10L-178 ............ Special Screw .......................................................... ...................................... 1

179 ............ JTAS10L-179A .......... Arbor Lock Ins ert Assembly (#179-1 thru 179-5) ..... ...................................... 1

179-1 ......... JTAS10L-179-1 ......... Arbor Lock Insert ..................................................... Ø8 ................................. 1