Page 1

This manual is bookmarked

This .pdf document is bookmarked

Operating Instructions and Parts Manual

20-inch Planer

Models JW P-2 08 and JWP-208 HH

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708528

Ph.: 800-274-6848 Revision J3 12/2014

www.jettools.com Copyright © 2014 JET

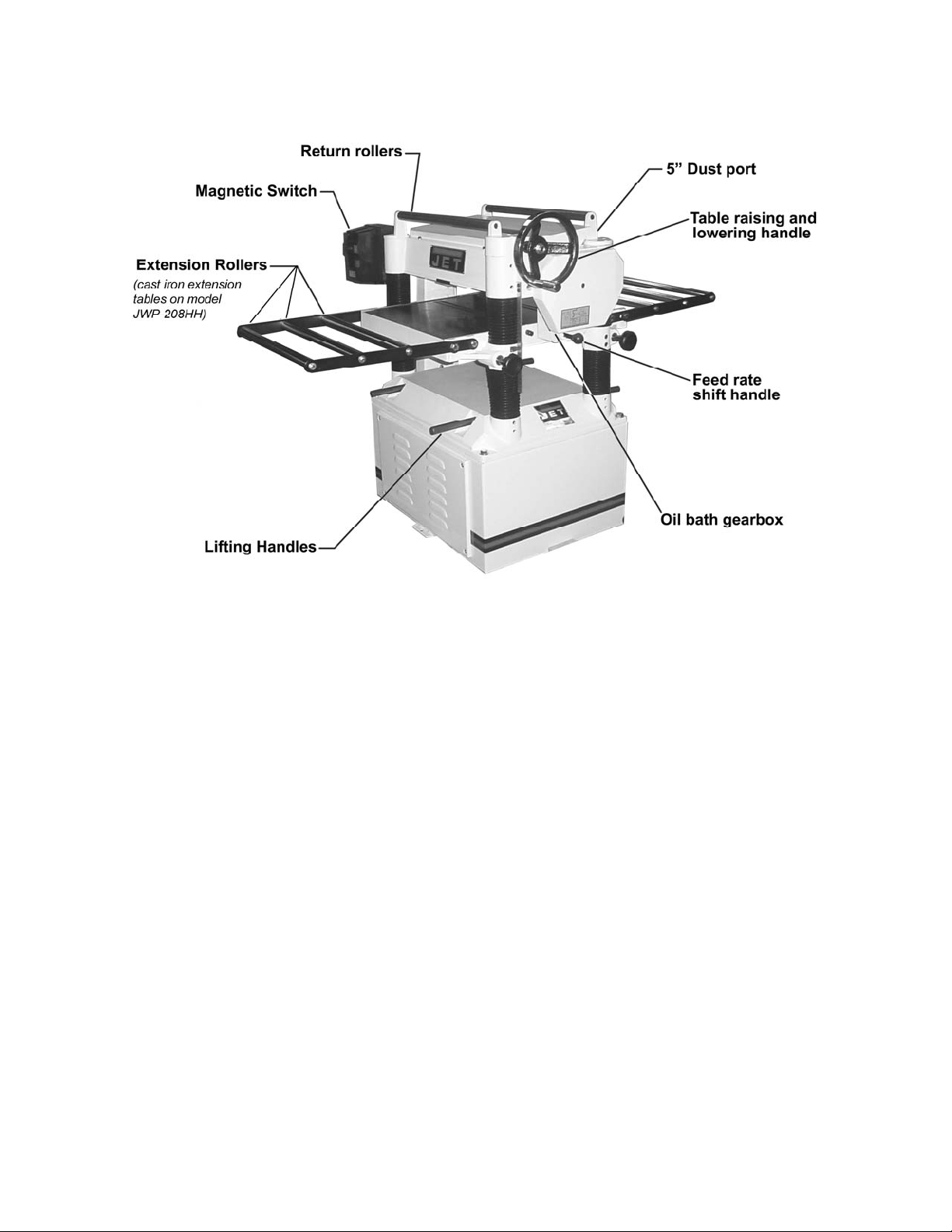

Model JWP-208HH shown

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Stand Mounting Holes ............................................................................................................................. 5

Features .................................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Recei ving ................................................................................................................................................ 7

Installation & Assembly ............................................................................................................................ 7

Starter Box ........................................................................................................................................... 7

Handwheel ........................................................................................................................................... 8

Table Extension Rollers (JWP-208 only) .............................................................................................. 8

Extension Tables (JWP-208HH only).................................................................................................... 8

Dust Collection Hood ........................................................................................................................... 8

Electri c al Connec tions ............................................................................................................................. 9

Extension Cords................................................................................................................................... 9

Adjustments ................................................................................................................... ......................... 9

Belt and Pulleys ................................................................................................................................... 9

Table Roller s ...................................................................................................................................... 10

Overview ........................................................................................................................................ 10

Adjusting Table Extension Rollers ................................................................................................... 11

Adjusting Depth of Cut ....................................................................................................................... 12

Cutterhead Adj ustment....................................................................................................................... 12

Overview ........................................................................................................................................ 12

Knife Adjustment (Model JWP-208 only) ......................................................................................... 12

Replacing & Resetting Knives (Model JWP-208 only) ......................................................................... 13

Replacing or Rotating Knife Inserts (Model JWP-208HH only) ............................................................ 14

Checking Work Tabl e P ar allel to Cutterhead ...................................................................................... 14

Adjusting Work Table Parallel to Cutterhead....................................................................................... 15

Anti-Kickback Fingers ........................................................................................................................ 16

Adjusting I nfeed & Outfeed Roller Spring Tension .............................................................................. 16

Height of Infeed Roller , Chipbreaker, Pressure Bar & Outfeed Roller .................................................. 16

Feed Speed Control ........................................................................................................................... 17

Changing Accessories for Lowest Feed Speed ................................................................................... 17

Return Rollers .................................................................................................................................... 17

Maintenance .......................................................................................................................................... 18

Lubrication............................................................................................................................................. 18

Troubleshooting ..................................................................................................................................... 20

Operating P ro blems ........................................................................................................................... 20

Mechanical and Elec trical Problems ................................................................................................... 20

Optional Accessories ............................................................................................................................. 2 2

Ordering Replacement Parts.................................................................................................................. 22

Parts ..................................................................................................................................................... 22

Head Assembly – Parts List ............................................................................................................... 22

Head Assembly – Exploded Vi ew ....................................................................................................... 25

Table and Roller – Parts and Assembly .............................................................................................. 26

Stand and Motor – Part s and Assembly .............................................................................................. 27

Base and Column – Parts Li st ............................................................................................................ 28

Base and Column – Assembly............................................................................................................ 29

Gearbox – Parts List .......................................................................................................................... 30

Gearbox – Assembly .......................................................................................................................... 31

Wiring Diagrams .................................................................................................................................... 32

230V 3HP Single Phase ..................................................................................................................... 32

230V 5HP Single Phase ..................................................................................................................... 33

230V 5HP Three Phase ..................................................................................................................... 34

460V 5HP Three Phase ..................................................................................................................... 35

3

Page 4

Warnings

Read the manual. Always read the owner’s manual carefully before attempting to use the machine.

Know the limitati ons and hazards a s sociated with the use of this pl aner .

Installation. If mounting m achine to the fl oor, use high quali ty anchor bol ts through the m ounting holes

on the base. If using a mobil e base, be sure t o loc k the wheels.

Eye protection. Always wear approv ed safety goggles, glasses, or a face shield when o perating this

machine. NOT E: Common eyeglasses are o nly impact resistant, t hey are not safety glasses. Also use

face or dust mask if the cutting operation is dusty.

Dress code. Do not wear loose cl othi ng, neckti es, j ewelry, or glov es that can get caught i n moving parts.

Confine long hair. Keep sleeves above the elbow.

Placement. Place machine so that potential kickback area is not in line with aisles, doorways, wash

stations or other work areas. Do n ot use machine in a damp or wet loc ation, or ex pose to r ain. Keep work

area well lighted.

Electrical g rounding. Your machi ne must be electricall y grounded. If a cord and pl ug are used, make

certain t he groundi ng l ug connect s to a suitabl e gr ound. F ollow the groundi ng proc edure i ndi cated by the

National Elect rical Code.

Guards. Be sure machine guards are in pl ace and in good working order. Do not operate while gear

cover is open. If a guard must be removed for adjustments or maintenance, it should be reinstalled

immediately upon c om pletion of the procedure and before operating the machine.

Housekeeping. Before turning on m achi ne, remove all extra equi pment such a s keys, wrenches, scrap,

stock, and cleaning rags from the machine. Keep the area around machine clean and free of scrap

material and sawdust to m inimize the danger of slippi ng.

Power off. Make sure the machine i s either unplugged or electri cally disconnect ed and locked out when

performi ng maintenance or serv ice work. Also, make sure switc h is in OFF position before pl ugging in

power cord. Never leave the machine running unattended. Do not leave machine until it comes to a

complete stop.

Cutterhead. Keep knives sharp and free of all rust and pitch. Make sure gib screws are tightened

securely.

Work piece. Chec k m ater ial f or l oose knots, n ai l s and other def ect s that c an dam age k niv es and po se a

safety hazard for the operator.

Keep hands away from feed r oller s and cut terhead while operating.

Use the proper exten sion cord. Make sure your extension cord i s in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. For runs up to

25 feet, use an 18 AWG or larger gauge cor d.

Do not op e r a te this machine while under the influence of drugs, alcohol or any medic ation.

If you are not thoroughl y f amiliar wit h the operati on of wood planers, obt ai n advi ce from your supervi sor,

instructor or other qualified person.

Health haz ards. Som e dust creat ed by p o wer sandi ng, sawing, gr indi ng, dri lli ng and other c onstr ucti on

activities contains chemicals known to cause cancer, birth defects or other reproductiv e harm. Some

examples of these chemicals are:

• Lead from lead-based paint .

• Crystalli ne sil ic a from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

4

Page 5

Your risk from these exposures v ari es, dependi ng on how often you do thi s type of work. To reduce your

exposure to these chemi cals, work in a well-ventil ated area, and work with approved safet y equipment,

such as those dust masks that ar e specif ically designed to filter out microscopic particles.

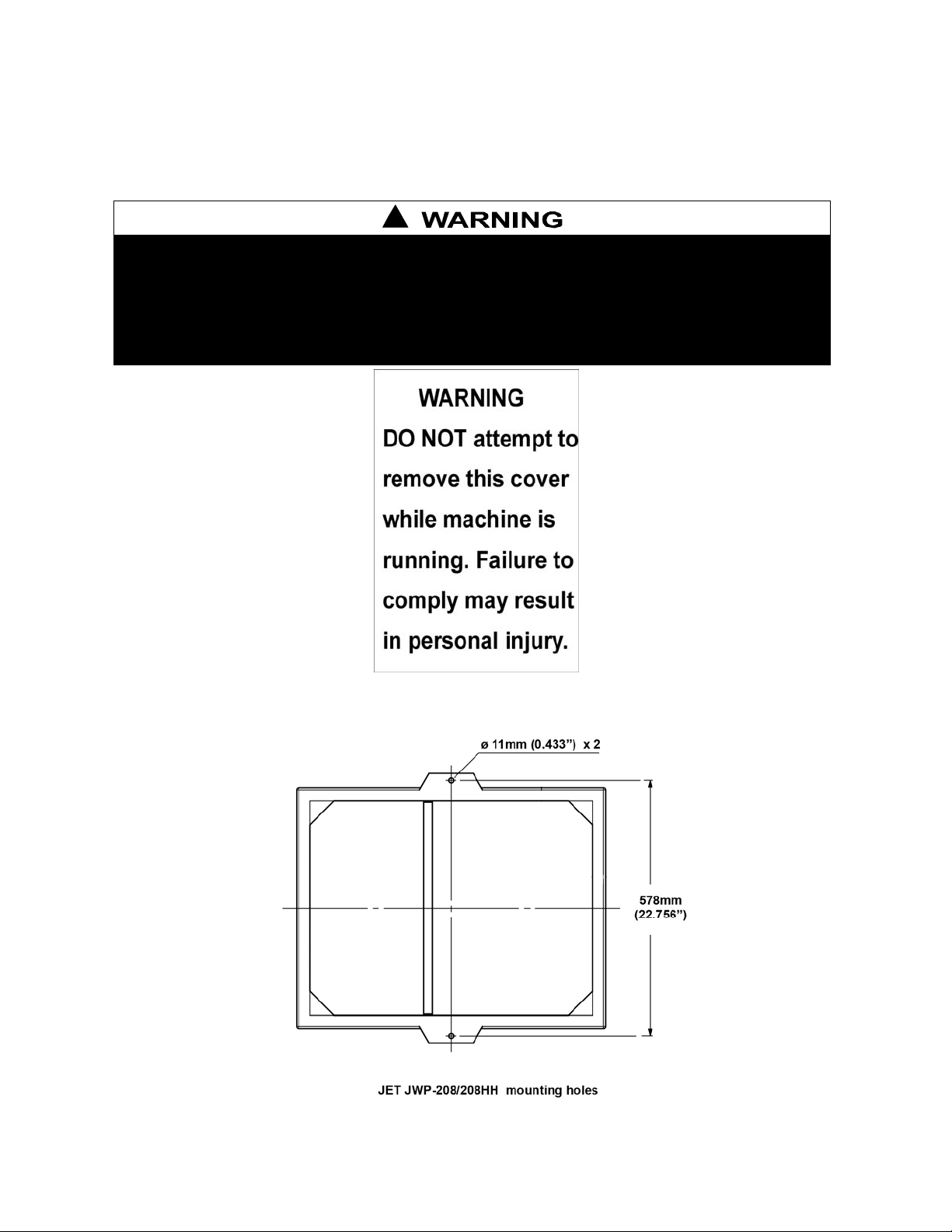

Safety Decals

Familiariz e y our self with the location and content of these decals on your planer.

!

1. Read instruction m anual before operating machine.

2. Do not operate without all gu ards properly installed.

3. Remove or fasten loose articles of clothing such as neckties, etc.

Contain long hair.

4. Remove jewelry such as finger rings, watches, bracelets, etc.

5. Use approved safety glasses and/or face shield to protect eyes, and

use other personal safety equipment as required. Do not wear

gloves.

DO NOT REMOVE OR OBSCURE THIS LABEL

Figure 1

6. Disconnect machine from po wer sou rce before making any

adjustments or cleaning chips away from machine.

7. Keep the floor around machine clean and free from scraps,

sawdust, oil and grease to minimize the danger of slipping.

8. Do not operate this machine while under the influence of alcohol

or drugs.

9. Failure to comply with these warnings may result in serious

personal injury.

Stand Mounting Ho les

Figure 1

5

Page 6

Features

Figure 2

Specifications

Model No. ............................................................................JWP-208 .................................... JWP-208HH

Stock No (3HP, 1Ph, 230V only ) . ........................................... 708528 ..................................................... --

Stock No (5HP, 1Ph, 230V) ............................................................ -- ........................................... 708544

Table Area (D x W/in.) ..................................................... 25-3/4 x 20 ...................................... 25-3/4 x 20

Maximum Planing Width (in.) ......................................................... 20 ................................................... 20

Maximum Planing Thickness (in.) .................................................... 8 ..................................................... 8

Full Width Cutting Depth (in.) ...................................................... 3/32 ................................................ 3/32

Minimum Planing Length (in.) .................................................... 6-3/4 ............................................... 6-3/4

Knives ...................................................................... (4) 20x1x1/8Thk ..................... (92) four-s ided inserts

Cutterhead Speed (RP M ) ......................................................... 5,000 .............................................. 5,000

Cuts per Minute ...................................................................... 20,000 ................................................. n .a.

Cutterhead Diameter (dia/in.) ................................................... 3-3/16 ............................................. 3-3/16

Feed Rate (FPM) ................................................................... 24 & 31 ........................................... 24 & 31

Motor .............................................. TEFC, 3HP,1PH,230V,60Hz,18A .... TEFC , 5HP,1PH,230V,60Hz,23A

Dust Chute Diamet er (di a/in.) ........................................................... 5 ..................................................... 5

Overall Dimensions (L x W x H/in.) ..................... 26 x 36-5/8 x 41-3/8 ........................ 26 x 36-5/8 x 41-3/8

Overall Dimensions (L x W x H/in.) ..................... 26 x 36-5/8 x 41-3/8 ........................ 26 x 36-5/8 x 41-3/8

Net Weight (approx. lbs.) ............................................................. 640 ................................................. 753

*pre-wired 230V

The specificati ons in thi s manual are given as general inf ormation and ar e not binding. JET reserv es the

right to effect, at any time and without prior notice, alterat ions to part s, fittings, and accessory equi pment

deemed necessary f or any reason whatsoever.

6

Page 7

Receiving

Carefully unpack the planer and any loose items

from the wood crate and inspect for damage. Any

damage should be reported immediately to your

distribut or and shipping agent. Bef ore proceeding

further, read your manual thoroughly to f amiliarize

yourself with proper assembly, maintenance and

safety proc edur es.

Remove the screws that hold the planer to the

shipping skid. Remove the protectiv e coating from

the table, bed rolls, feed rolls, cutterhead and

loose items packed with the machine, including

lifting handl es and motor pulley. This coati ng may

be removed with a soft cloth moistened with

Kerosene. Do not use acetone, gasoline or

lacquer thinner for this purpose. Do not use

solvents on plast ic par ts.

Use care when cleaning the

cutterhead ; th e kni ves are very sharp.

Installation & Assembly

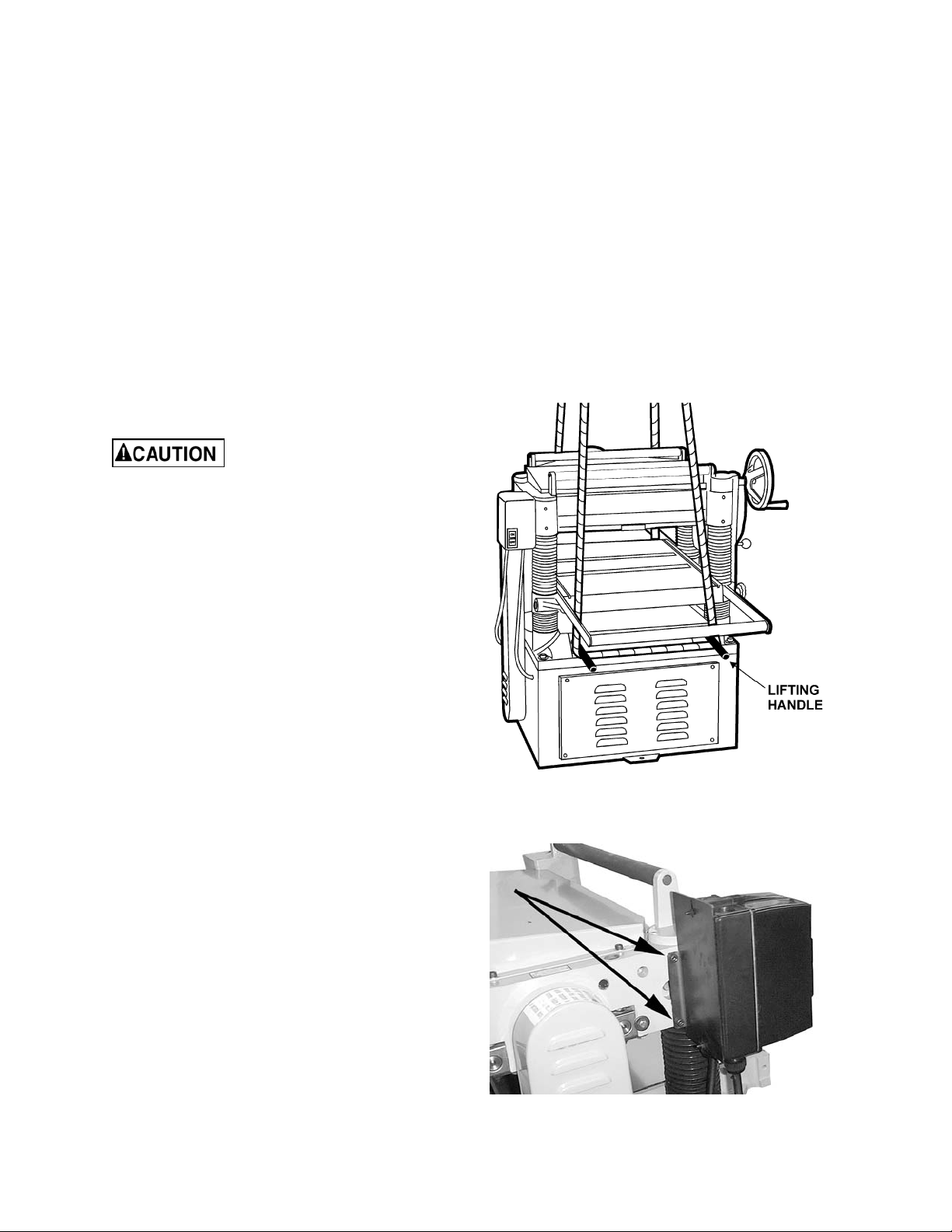

1. There are four lifting handles (Fig. 3) on the

machine. P ull the handles out f or use, push in

when not in use.

2. If a sling or forklif t is used to lif t the mac hine,

be sure to lif t by the handles only . See Fi g. 3.

Make sure machine is kept in level position

while lifting.

3. For best planing performance, locate planer

on a solid, level f oundation and anchor to the

floor with good quality lag screws. Do not

tighten screws completely yet.

4. With machine in position, test table surface

lengthwise and crosswise with machinist’s

level. Place met al shims under low corners.

5. Check that all four corners are supported,

then tighten l ag screws.

6. Re-test level of table surfac e in both directions

and adjust if necessary.

Figure 3

Starter Box

Mount the starter box at the left side of the

machine with two socket head cap screws (Fig. 4).

Figure 4

7

Page 8

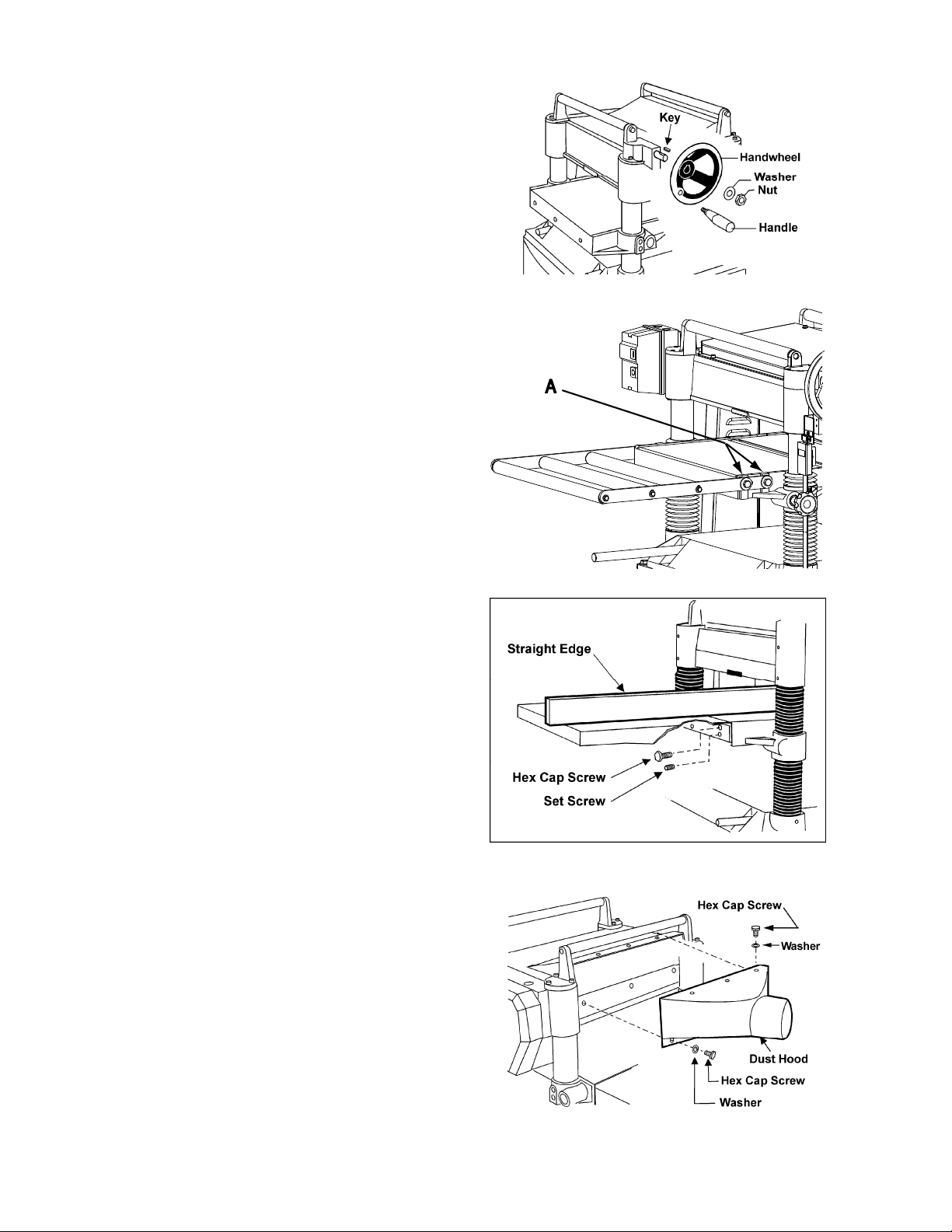

Handwheel

1. Rem ove t he nut and wash er f rom the gearbox

shaft, and pl ace the handwheel onto the shaf t

(Fig. 5), making sure it is oriented so the

handwheel slips over the key.

2. Place flat washer and hex nut on shaft and

tighten with wrench.

3. Mount the handle in the threaded hol e in the

handwheel, and ti ghten with a wrench placed

over the flat on the handle.

Table Extension Rollers (JWP-208 only)

Mount the table extension roller s to the table using

the provided hex cap screws and washers

(A, Fig. 6). The rollers should be adjusted bef ore

operating the planer; see Adjusting Table

Extension Rollers on page 11.

Figure 5

Extension Tables (JWP-208HH only)

1. Mount a cast iron table to the edge of the

main tabl e with t hree M8 x 25 hex c ap screws

(Figure 6a). Do not f ully tighten yet.

2. The ex tension table must be leveled wit h the

main table. Place a straight edge (such as a

jointed board) ac r oss both tables.

3. Insert three socket set screws with a hex

wrench, and scre w them in or out a s needed

until tables are level.

4. Securely tight en the hex cap screws.

5. Mount the second extension table to the

opposite side of the planer table, using the

same procedure.

6.

Dust Collection Hood

The dust collecti on hood (Fi g. 6b) comes standard

with the model JWP-208 planer, and helps

maintain a clean and safe work area. It is

assembled to the planer with the screws and

washers as shown.

Figure 6 - JWP-208 only

Figure 6a - JWP-208HH only

IMPORTANT: Make sure all knives or knife

inserts are ti ght before operating machin e. On

the helical head model, verify tightness of

each insert (re-torque) before using the

machine for the first time.

Figure 6b

8

Page 9

Electrical Connections

El ectrical conn ections must be

made by a qualified electrician in compliance

with all relevant codes. The machine mu st be

properly grounded to help prevent electrical

shock and possible fat al injury.

A power plug is not provided wit h the 208 planer.

You may either connect one or "hard-wire" the

machine dir ectly to your el ectrical panel provided

there is a disconnect near the machine. Consult

the wiring diagrams on pages 32-35 for further

clarific ation of wiring setup.

This machine must be grounded. Grounding

provides a path of least resistance to hel p divert

current away from the operator in case of

electrical malfunction.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the machine.

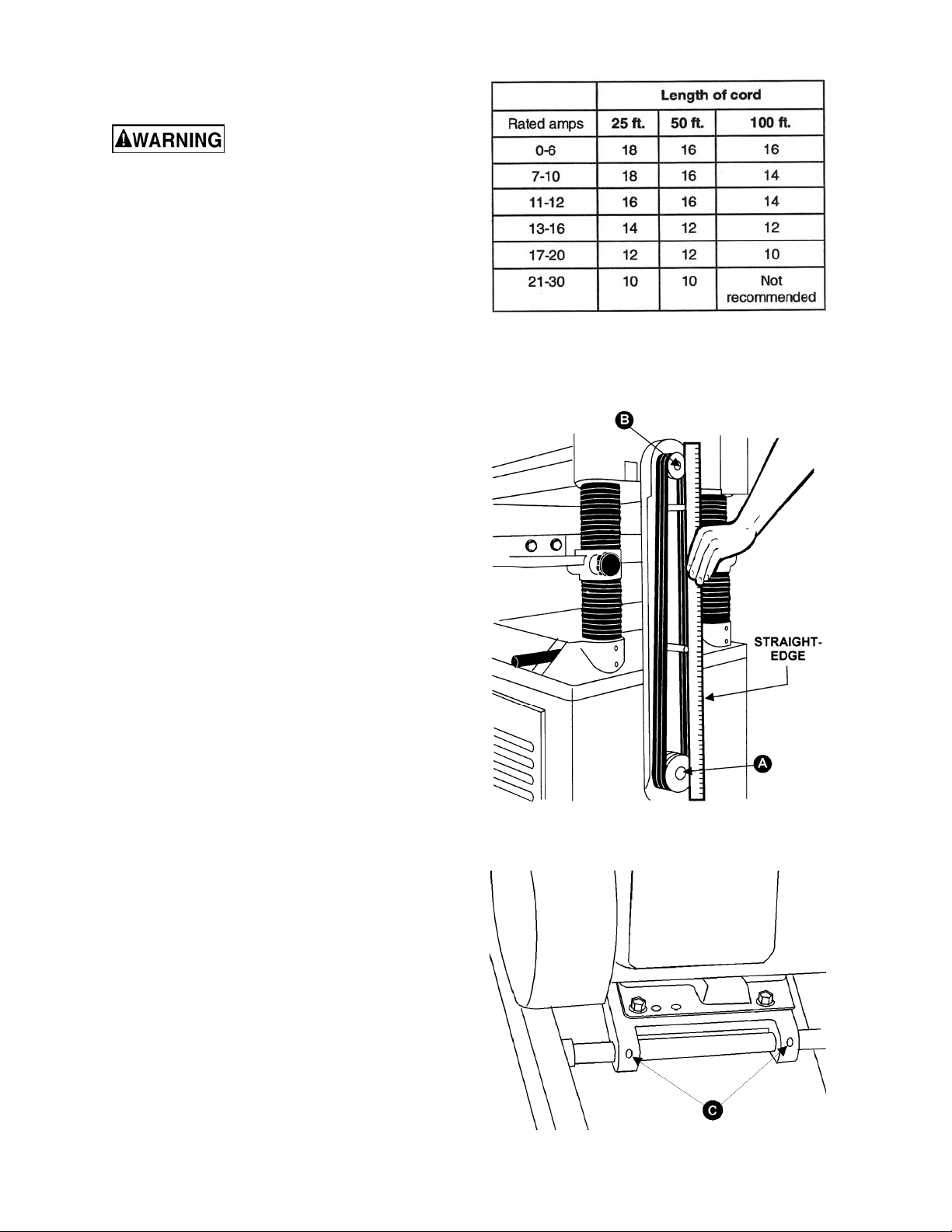

Extens ion Cords

The use of ex tension cords is discouraged; try to

position the machine within reach of the power

source. If an extension cord becomes nece ssary,

make sure the cord rating is suitable for the

amperage list ed on the mac hine's motor pl ate. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

Figure 7

The chart i n Figure 7 shows the cor rect size cord

to use based on cord l ength and m otor pl ate amp

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number the heavier the cord.

Adjustments

Belt and Pulleys

1. Using a straight edge, align the motor pulley

(A, Fig. 8 ) and cutterhead pulley (B, Fig. 8).

The motor plate can be moved for al ignment

by loosening the set screws (C, Fig. 9) in the

motor plate.

Figure 8

Figure 9

9

Page 10

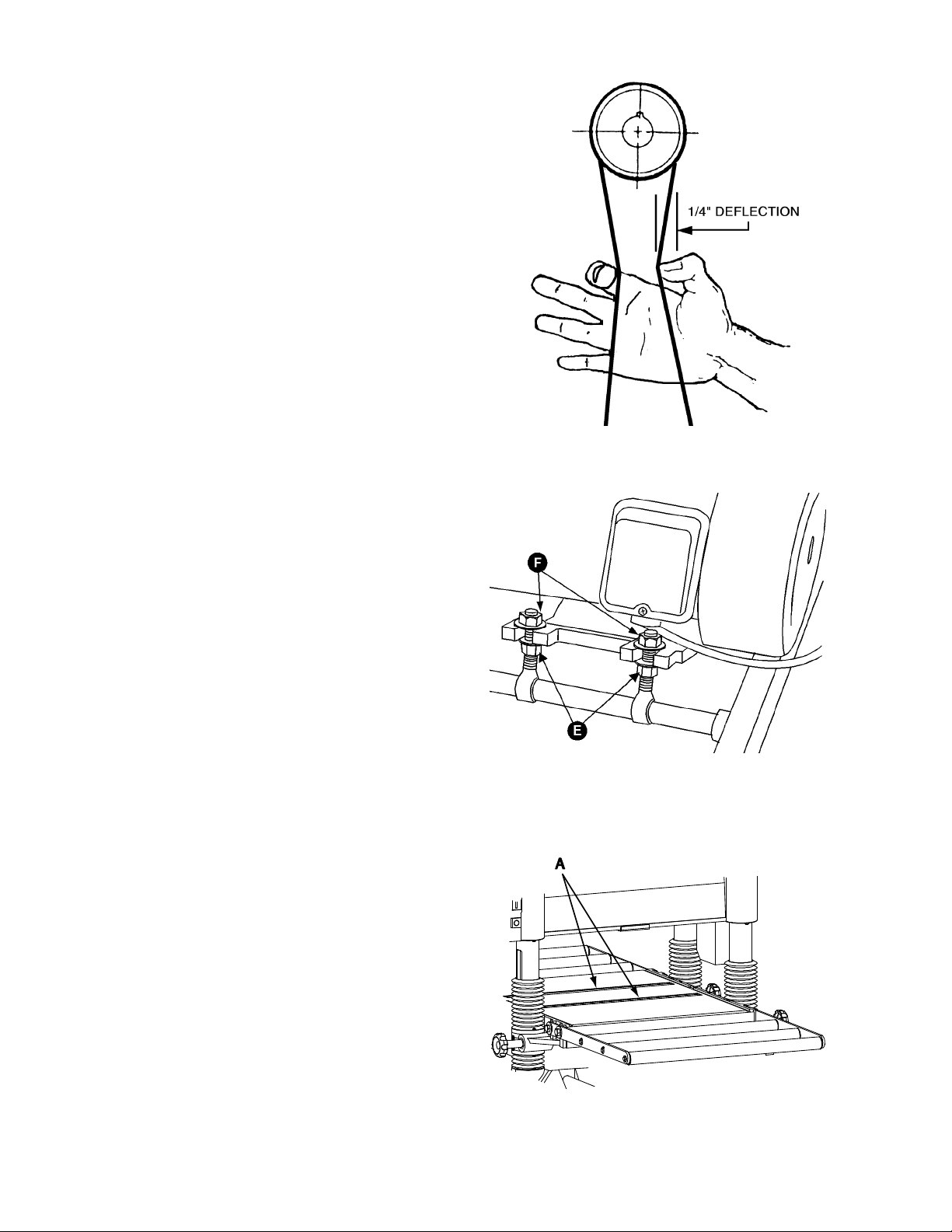

2. Check bel t tensi on. Pr oper tensi on is obtai ned

when there is approx imately 1/ 4” deflection of

the center span of the pulleys using light

finger pressure (Fig. 10).

3. If adjustment of belt tension is necessary,

loosen one pair of hex nuts (E & F, Fig. 11)

and turn the other pair to raise or lower the

motor plate. Re-tighten nuts.

Table Rollers

Figure 10

Figure 11

Overview

Your planer is supplied with two table rollers

(A, Fig. 12) which turn as the stock i s fed int o the

planer, thus reduc ing friction. It is not possible t o

give exact dimensions on the proper height setting

of the table rollers because each type of wood

behaves diff erently.

As a general rule, however, when planing rough

stock, the table rollers should be set at high

position. When planing smooth stock the rollers

should be set at low position.

Figure 12

10

Page 11

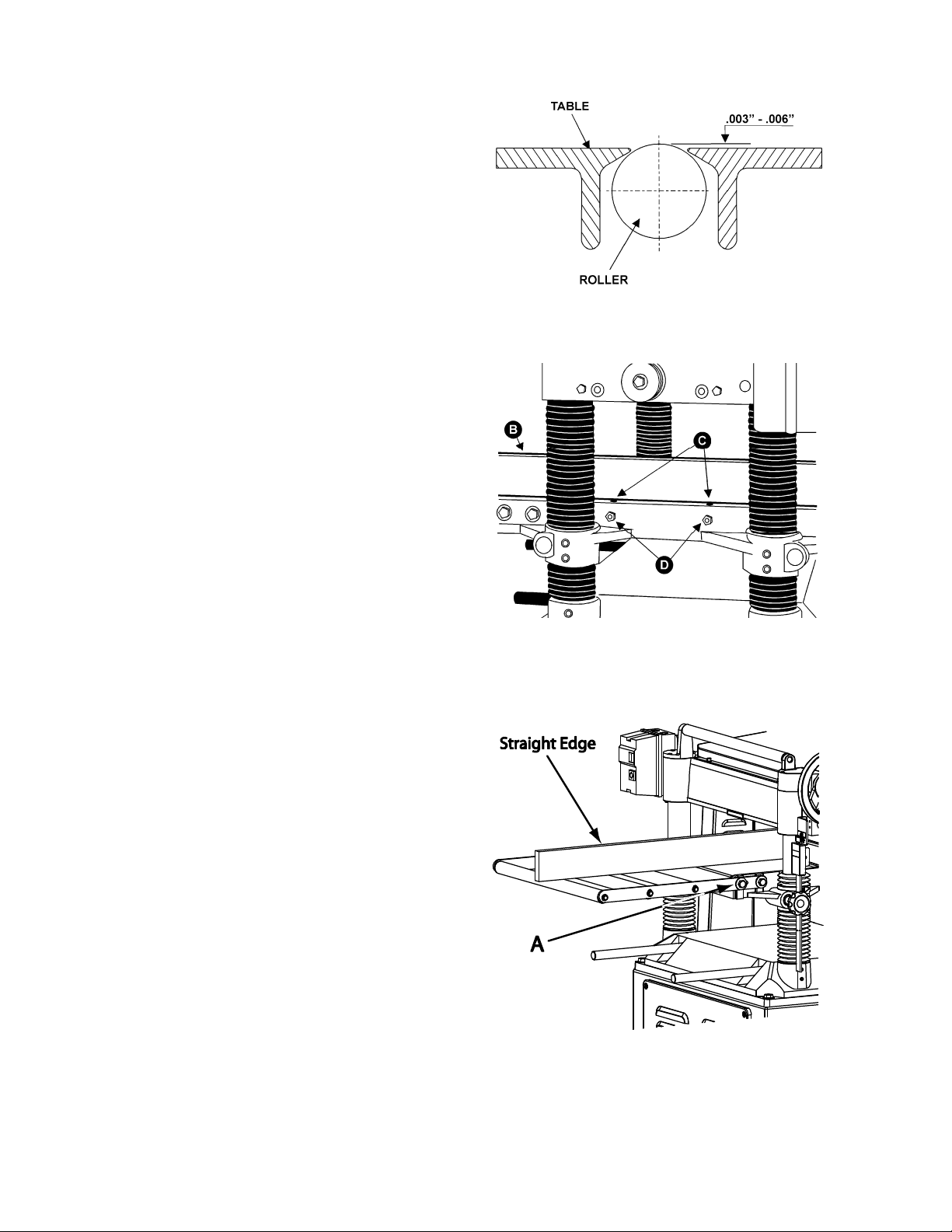

Note: When raising the roller higher above the

table, the available range is from .003” to .006”

See Fig. 13.

The table rollers are factory set for average

planing and are par allel t o the table surfac e. If you

desire to adjust the table rollers higher or lower,

proceed as follows:

1. Disconnect machine from power source.

2. Lay a straight edge (B, Fig. 14) across both

rollers.

3. On one side of the table, loosen the screws

(C, Fig. 14) with a hex wrench, and turn the

eccentri c shafts (D, Fig. 14) to rai se or lower

the rollers.

Figure 13

4. When the proper height is achieved, tighten

screws (C, Fig. 14).

5. Adj ust the r oll ers from t he opposit e side of the

table in the same manner.

Important: Be sure that the height of front and

rear rollers are the same. The table rollers must

always be set parallel to the table.

Adjusting Table Extension Rollers

1. Pl ace a str aight edge ov er t he extensi on rol l er

and the table, as shown in Fig. 15, to make

sure the extensi on roller and table are at the

same height. If necessary, adjust the table

extension roll er s as f ollows:

2. Loosen the screws and washers (A, Fig. 15)

to move the extension roller to the proper

position, then retighten the screws.

3. Adjust both front and rear extension rollers in

the same manner.

Figure 14

Figure 15

11

Page 12

Adjusting Depth of Cut

The cutting depth scale (A, Fig. 16) is a

combination i nch/metric scale with a cutt ing range

from 0 to 8” (204mm). T he distance of upward or

downward movement is controlled by the

handwheel (B, Fig. 16). One revolution of the

handwheel is .059” (1.5mm). Before moving the

table up or down, l oosen the lock nuts (C, Fig. 16).

After obtaining the proper table position, tighten

the lock nuts (C, Fig. 16).

Always tighten the lock nuts

before operating the planer.

Cutterhead Adjustment

Overview

Although your planer was carefully adjusted at t he

factory, it shoul d be checked bef or e being put i nto

operation. A ny inacc uracies due to rough handl i ng

in transit can easily be corrected by following

these directions.

To check the adjustm ents you will need a straight

edge, feeler gauge, and a homemade gauge bloc k

made of hardwood. This gauge block can be

made by following the dimensions shown in

Figure 17.

Figure 16

Knife Adjustmen t (Mod el JWP- 208 on ly)

When checki ng or adjusting the cutterhead k nives,

proceed as follows:

1. Disconnect machine from power source.

2. Remove the six screws (A, Fig. 18) and

remove upper cover (B, Fig. 18).

3. To check and adj ust knives, use the prov ided

knife gauge (F ig. 19 & 20) and check all four

knives. Kniv es should just contact the bot tom

of the center protrusion (D, Fig. 19) of the

knife gauge.

4. If an adjustm ent to one or m ore of t he knives

is necessary, slightly loosen the knife gib

(E, Fig. 19) by turning the six locking screws

(F, Fig. 19) into the gib. Turn the screws just

enough to relieve stress in the cutterhead

without distur bing t he setting of the k nives. Do

this for all f our knives at the same time.

5. With the gauge in place over a knife

(G, Fig. 19) continue to loosen the locking

screws (F, Fig. 19) until the springs

(H, Fig. 19) begi n r aisi ng the knife. When knif e

comes int o contact with the cent er protrusion

(D, Fig. 19) of the gauge, snug up the gib by

lightly backing out the six locking screws (F,

Fig. 19) agai nst the slot.

Figure 17

Figure 18

12

Page 13

NOTE: At this time, only tighten the knife in

the slot just enough to hold knife in position.

6. If additional knives must be reset, repeat

step 5.

7. After all four knives are set with screws just

snug, back out and tighten the six locking

screws (F, Fig. 19 & 20), against the slot

starting with the end screws first, then the

center screws, unt il the knif e is securely held

in the cutterhead. Tighten remaining three

knives in the same manner.

Important: Double check all screws for tightness.

Replacing & Resetting Knives (Model JWP-208 only)

If the knives are removed for sharpening, care

must be exer cise in replaci ng and resetting t hem.

Proceed as follows:

1. Disconnect machine from power source.

2. Remove six screws and upper cover (see

Fig. 18).

3. To remove knife, loosen the gib (E, F ig. 19) by

turning the si x l ocking screws (F , Fi g. 19) into

the gib. Remove gib (E, Fi g. 19), knife (G, Fi g.

16) and spring s (H, F ig. 19). NOTE: The inner

two springs m ay pop out when the knif e and

gib are removed.

Figure 19 – JWP-208 only

4. Remove the remaining three knives in the

same manner.

5. Thoroughl y clean t he knif e slots, gibs, spri ngs

and locking scr ews. Chec k the locking screws;

if the t hreads appear worn or stri pped or if t he

heads are becoming r ounded, replace them.

6. Inspect the cut ting edge of the knives for nicks

or wire edge. Hone the kniv es sl ightly usi ng a

stone, or if the knives are to be sharpened,

maintain a cutti ng angle of 35 degrees.

7. Insert springs, knives and gib into slot of

cutterhead. Back out locking screws just

enough to hold the knife in the cutterhead.

8. Place knife gauge (C, Fig. 19) over knife.

9. While holding down on the knife gauge,

loosen all six locking screws (F) by turning

them into the gi b (E) until cutting edge of knif e

comes into contact with the protrusion (D) of

the gauge. Snug up the gi b by slightly backing

out the six locki ng screws again st the slot.

Note: At this time, only tighten the knife into the

slot just enough t o hold the knife in position.

Figure 20 – JWP-208 only

13

Page 14

10. Replace and reset the other three knives in

the same manner.

11. After all four knives are set with the screws

just snug, back out an d ti ghten the six screws

(F) against the slot starting with the end

screws first and then the center screws until

the knife is securely held in the cutterhead.

Tighten the remaining three knives in the

same manner.

After replacing and checking

knives, CHECK AGAIN carefully. Make certain

the direction of knives is correct and all

twenty-four locking screws are tightened

securely.

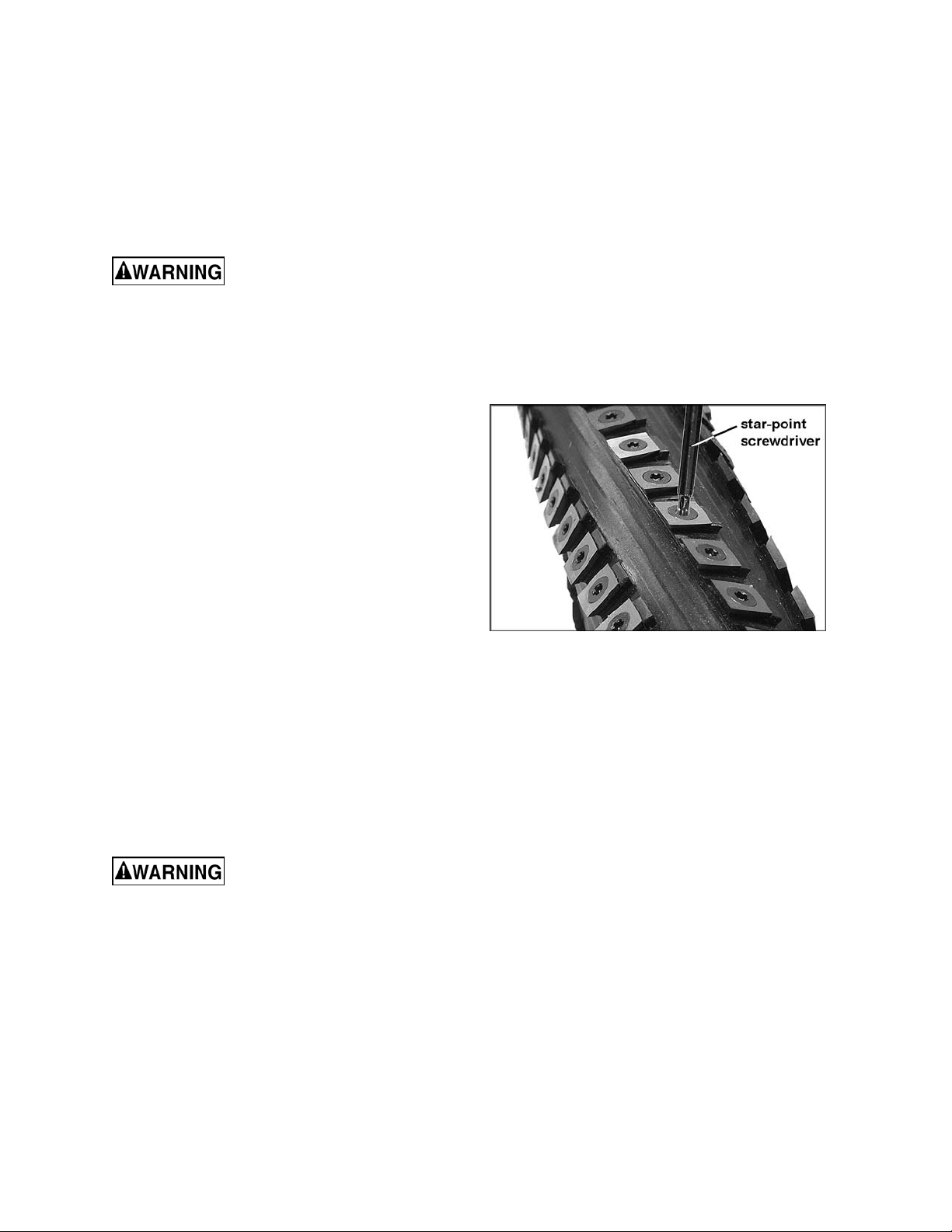

Replacing or Rotating Knife Inserts (Model JWP-208HH only)

The knife inserts on the model JWP-208HH are

four-si ded. When dull, simpl y remove each insert,

rotate it 90° for a fresh edge, and re- install it.

Use the provided st ar point screwdriv er to remove

the knife insert screw. See Figure 20a. It is

advisable to r otate all inserts at the sam e time to

maintain consistent cutting. However, if one or

more knife inserts develops a nick, rotate only

those inserts that are affected.

Each knife insert has an etched reference mark so

you can keep track of the rotations.

IMPORTANT: When rem oving or rotating i nserts,

clean saw dust from the scre w, the i nsert, and t he

cutterhead platform. Dust accumulation between

these elements can prevent the insert from

seating properl y, and may affect the quality of the

cut.

Before installing each screw, l ightly coat the screw

threads with mac hine oil and wipe off any excess.

Securely ti ghten each screw which holds the knif e

inserts befor e oper ating the planer!

Make sure all knife insert

screws are tightened securely. Loose inserts

can be propelled at high speed from a rotating

cutterhead , cau sin g inju ry.

Checking Work Table Parallel to Cutterhead

The work tabl e is set parall el to the c utterhead at

the factory and no further adjustment should be

necessary. If your machine is planing a t aper, first

check to see if t he knives are set properly in the

cutterhead. Then check to see if the work tabl e is

set parallel to the cutterhead. Proceed as follows:

Figure 20a – JWP-208HH only

14

Page 15

1. Disconnect machine from power source.

2. Place the gauge block (Figur e 21) on the work

table dir ectl y under the edge of a knife or knife

insert as shown. Make slight cont act with the

knife edge by gentl y raisi ng the table.

3. Move the gauge bloc k to the opposit e end of

the work table. The distance from the work

table to the edge of the knife should be the

same on both ends of the knife.

Adjusting Work Table Parallel to Cutterhead

If the work table i s not parallel to the cutterhead,

perform the adjustm ent procedure as follows:

1. Disconnect the m ac hine from power source.

2. Til t planer on its side to ex pose underside of

base, as shown in Fig. 22.

3. Remove bolt (A, Fig. 22) and loosen bolt (B,

Fig. 22) which will allow you to move the idler

sprocket assembl y (C, Fig. 22) far enough to

release tension on the c hain.

4. Remove chain from the parti cular sprocket on

corner of base that m ust be adjusted.

Turn the sprocket by ha nd to bri ng t hat cor ner

into adjustment with the other three corners.

NOTE: Turning sprocket clockwise will

increase the distance between the working

table and headcasting; counter-clockwise will

decrease the distance. This adjustment is very

sensitive and it should not be necessary to

turn the sprocket m or e than one or two teeth.

5. When adjustments are correct, replace chain

around corner sprock et, slide sprock et (C, Fig.

22) back to re-tension chain, tighten bolt (B,

Fig. 22) and repl ace and tighten bolt (A, Fig.

22).

Know the Transmit ting Rolle r s of Y o ur P la ne r

A – Anti-Kickback Fingers

B – Infeed Roller

C – Chipbreaker

D – Cutterhead

D – Pressure Bar

E – Outfeed Roller

The infeed roller (B, Fig. 23) and outfeed roller

(F, Fig. 23) are those part s of y our planer that feed

the stock whil e it i s being planed. The i nfeed and

outfeed rollers are under spring tension and this

tension must be sufficient to feed the stock

uniformly through the planer without slipping but

should not be so tight that it causes damage to t he

board. The tensi on should be equal at both ends

of each roller.

Figure 21

Figure 22

Figure 23

15

Page 16

Anti-Kickback Fingers

The anti- kickback fingers (A, Fig 23) hel p prevent

kickback of stock. They operate by grav ity and it i s

necessary to inspect them occasionally to make

sure they are f ree of gum and pitch, so that t hey

move independently and operate correctly.

Adjusting Infeed & Outfeed Roller Spring Tension

To adjust the spring tension of the infeed and

outfeed roller s, tur n screws (G & H, Fig. 24) with a

hex wrench. Turn screws on opposite end of

infeed/outfeed rollers in the same manner.

Figure 24

Figure 25

Height of Infeed Roller, Chipbreaker, Pressure Bar & Outfeed Roller

The infeed r oller, chipbreaker, pr essure bar and

outfeed roller are adjusted at the factory. The

infeed roller and the chipbreaker should be set

at 0.004” (0.1mm) below the cutting circle; and

the outfeed roll er should be set at 0. 02” (0.5mm )

below the cutting ci r cl e. See Fig. 25.

If an adjustment to the infeed roller, c hipbreaker,

pressure bar or outf eed roller is necessary, use

the following steps as an example of procedure.

To check and adj ust the out f eed rol l er bel ow the

cutting circl e, proceed as follows:

1. Disconnect machine from power source.

2. Make sure the kniv es are adjusted properl y

as previously explained under “Checking &

Adjusting of Knives.”

3. Place the gauge block (J, Fig. 26) on the

table dir ectl y underneat h the cut ter head (D,

Fig. 26). Usi ng a 0.02” (0.5mm) feeler

gauge (K, Fig. 26) placed on t op of the

gauge block, raise the working table

until the knife just touches the feeler

gauge when the knife is at its lowest

point. Do not move the working table

any further until the outfeed roller is

adjusted.

Figure 26

16

Page 17

4. Mov e t he gauge bl ock (J , F ig. 27) under one end

of the outfeed roll er (F, Fig. 27). The bottom of

the outf eed r oller should just touch the top of the

gauge block. If an adjustment to the outfeed

roller is necessary, loosen the lock nut (L, Fig

27) and turn screw (M, Fig. 27) until the outfeed

roller just touches the gau ge bl ock. Then t i ghten

lock nut (L, Fig. 27).

5. Check and adjust opposite end of the outfeed

roller in the same manner .

Figure 27

4. When the sprockets (B, Fig. 28) are

removed, replace the lower sprocket

which will be assembled on the gear

shaft.

5. Assemble the three sprockets and

chains to the shafts, and tighten the

hex cap screws (E, Fig. 28).

Return Rollers

The two return rollers on the top of the

machine serve as a convenient rest for

stock. They save time and motion for the

operator as the stock is returned to the

infeed side.

Feed Speed Control

Your machine i s equipped wit h a spiral , serr ated

infeed roll er and a sol i d outf eed roll er. When the

feed rollers are engaged, they turn to feed the

stock. The f eed rollers slow autom atically when

the machine is under heavy load f or best planing

in all conditions. The feed rollers are driv en by

chains (A, Fig. 28) and sprockets (B, Fig. 28)

which take power directly from the cutterhead

through the oil bath gear box (C, Fig. 28).

The gear box has two feed speeds. These are

set by pulling out or pushi ng in the shif t lev er (D,

Fig. 28) whil e the machine is running. The f eed

speed range is shown in Fig. 29.

Changing Accessories for Lowest Feed Speed

The lowest feed s peed f or your planer (16.2 fpm

& 20.7 fpm) can be obtained by replacing the

lower (gear shaf t) sprocket and the chain. See

Fig. 29. To change the sprocket and the chain

on your machine, proc eed as follows:

Figure 28

1. Disconnect machine from power source.

2. Remove the three hex cap screws and

washers (E, Fig. 28).

3. Remove the three sprockets (B, Fig. 28)

from the i nfeed roller, outfeed roller and t he

gear shaft at the same time.

Figure 29

17

Page 18

Maintenance

Periodic or regular inspections are required to

ensure that t he machine i s in proper adj ustment,

that all screws are tight, that belts are in good

condition, that dust has not accumulated in the

electric al enclosures, and that there are no worn

or loose elect ri c al c onnec tions.

Lubrication

The bearings on the cutterhead are factory

lubricated and sealed for life – no lubrication

required.

The lubricant in the gearbox must be replaced

every 2,500 hours. Multi-purpose gearbox

lubricant will be sui table.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not onl y r ecommended but mandat ory

for accurat e planing.

Close-fitting parts, such as the cutterhead slot

and gibs, should be cl eaned with a c lot h or brus h

and non-flammable solvent, and freed from

clinging foreign matter.

Remove resin and ot her acc um ulations f rom feed

rollers and table with a soft rag and nonflammabl e solven t.

Periodically check all the chains for proper

tension and adjust acc or dingly if required.

Tip: If a foreign object nicks the knives, i nstead of

throwing them away or trying to grind out the

deep nick, sim ply stagger t he knives i n the head,

moving one knife no more than 1/4" to the right

and another knif e no more than 1/4" to the l eft.

The nick should no l onger be noticeable.

The table shoul d be kept clean and free of rust.

Some users pref er a paste wax coating. A nother

option is talcum powder applied with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a

moisture barrier. This method provides a table

top that is sli ck and allows rust rings to be easil y

wiped from t he surface. Important al so is the fac t

that talcum powder will not stain wood or mar

finishes as wax pick up does.

To replace the gearbox lubr icant:

Remove the dr ain plug (A, Fig. 30), and filler cap

(B, Fig. 30). Drain dirty oil thoroughly.

Tighten the drain plug (A, Fig. 30).

Fill with cl ean lubricant through hole (B , Fi g.

30).

Tighten fill er cap ( B, Fig. 30).

Figure 30

18

Page 19

[The item numbers on this chart are referenced with the accompanying illustrations.]

t

No. Position Interval Suitable Types of Lubrican

1 Drive Chain Frequently Grease 30

2 Gear Box When operated more than

2,500 hours

3 Return Rollers Frequently SAE-30 32

4 Worm Gear Frequently Grease 33

5 Lead Screw Frequently Grease 33

6 Column Frequently Clean and SAE-30 33

7 Table Chain Frequently Grease 34

8 Feed Rollers Frequently SAE-30 35

70 to 90 weight gear oil 30

2

Fig. No.

Figure. 31

Figure 32

Figure 34

Figure 33

Figure 35

19

Page 20

Troubleshooting

Operating Problems

Problem Possible Cause Solution

Snipe.

(Snipe cannot be

eliminat ed, but can

be minimized so

as to become

negligible.)

Fuzzy Grain Planing wood with a high

Torn Grain Too heavy a cut.

Rough/Raised

Grain

Table rollers not set pr oper ly.

Inadequate support of long

boards.

Uneven feed roller pr essure

front to back.

Dull Knives.

Lumber not butt er properly.

moisture cont ent.

Dull knives.

Knives cutti ng against grain.

Dull knives.

Dull knives.

Too heavy a cut.

Moisture cont ent too high.

Adjust rollers to proper height.

Support long boar ds with ex tension rollers.

Adjust feed roller tension.

Sharpen knives.

Butt end to end each pi ec e of stock as they

pass through.

Remove high moisture c ontent from wood by

drying.

Sharpen or replac e.

Adjust proper dept h of cut.

Cut along the grai n.

Sharpen knives.

Sharpen knives.

Adjust proper dept h.

Remove high moisture c ontent from wood by

drying.

Rounded, glossy

surface

Poor feeding of

lumber

Dull knives.

Feed speed too slow.

Cutting dept h too shal low.

Inadequate f eed r oller

pressure.

Planer bed rough or dr y.

Transmission v-belt slipping.

Surface of feed rollers too

smooth.

Sharpen or replac e k niv es.

Increase speed.

Increase depth.

Adjust feed roller tension. If proper tension

cannot be achiev ed, replace feed rollers.

Clean pitch and resi due, and wax planer table.

Tighten transmission v-belt.

Lightly roughen t he feed roller surface with

sandpaper.

Mechanical and Electrical Problems

Problem Possible Cause Solution

Uneven depth of

cut side to side.

Board thickness

does not match

depth of cut scale.

Knife projection.

Cutterhead not level with bed.

Depth of cut scale incor r ec t. Adjust depth of cut scale.

Adjust knife pr ojec tion.

Level bed.

20

Page 21

Problem Possible Cause Solution

Chain jumping. Inadequate tension.

Sprockets misaligned.

Sprockets worn.

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blo ws fuses.

No incoming power.

Overload automatic reset has

not reset.

Planer frequently trips.

Building circuit breaker trips

of fuse blows.

Adjust chai n tension.

Align sprockets.

Replace sprockets.

Verify unit is connected to power.

When planer overl oads on the ci r c uit breaker

built into th e motor s ta rte r , i t ta ke s time for the

machine to cool down befor e r estar t. Allow

unit to adequately cool before attempting

restart. If pr oblem persists, check amp setting

on the motor starter insi de the electrical box.

One cause of overl oading trips which are not

electric al in nature is too heavy a cut. If too

deep a cut is not the problem, t hen c hec k the

amp setting on the overload relays. Match the

full load amps on the motor as noted on the

motor plate. If amp setti ng is cor r ec t then there

is probably a loose elec trical lead. Check amp

setting on mot or start er .

Verify that planer is on a circuit of correct size.

If circuit siz e is corr ect, there is probably a

loose electri c al lead. Check amp setting on

motor starter.

Loose electri c al c onnec tions.

Motor starter failure.

Motor starter failure.

Motor failure.

Go through all the elec trical connections on

the planer including motor connections,

verifyi ng the ti ghtness of each. Look for any

signs of electri c al ar ci ng whic h is a sure

indicator of loose connections or circuit

overload.

Examine motor star ter for burned or failed

components. If dam age is found, replace

motor starter . If m otor st ar ter looks okay but is

still suspect, y ou have two options: have a

qualified elec trician test the motor starter for

function, or pur c hase a new starter and

establish if t hat was the problem on changeout.

If you have access to a voltmeter, you can

separate a starter failure from a motor failure

by first, verifying incoming voltage at 220 +/20 and second, checking the voltage between

starter and motor at 220 +/- 20.

If incoming voltage is incorrect, you have a

power supply problem .

If voltage between starter and motor is correct,

you have a motor problem .

If electrical motor is suspect, you have two

options: Hav e a qualified electrician test the

motor for function or remove the motor and

take it to a qualifi ed el ec tric motor repair shop

and have it tested.

21

Page 22

Problem Possible Cause Solution

Miswiring of the unit.

On/off switch failure.

Double check to confi rm all electrical

connections are cor r ec t and tight. Refer to

wiring diagr am s on pages 32-35 to mak e any

needed corrections.

If the on/off switch is suspect you have two

options: Hav e a qualified electrician test the

switch for function, or purchase a new on/off

switch and establish if that was the problem on

changeout.

Optional Accessories

Stock No Description

708119 ........... Mobile Base

708520 ........... Digital Read-out Retrofit Kit

708583 ........... Low Speed Gear K it

708808 ........... Knives, Single Sided (set of 4) – model JWP-208 only

1791212 ......... Knife Inserts (set of 10) – model JWP-208HH only

Ordering Replacement Parts

To order parts or reac h our service departm ent, call 1-800-274-6848, Monday throug h Friday (see our

website for business hours, www.jettools.com). Having the Model Number and Serial Number of your

machine available when you call will allow us to serve you quickly and accurately.

Parts

Head Assembly – Parts List

Index Part No. Description Size Qty

1 ............... JWP208-001 ............Head Casting......................................................................................... 1

2 ............... TS-1525021 .............Set Screw ...........................................................M10 x 12 .................... 8

3 ............... JWP208-003 ............Cutterhead* ........................................................................................... 1

4 ............... 6292620...................Spring* .................................................................................................. 8

5 ............... 708808 ....................Knife* .................................................................................................... 4

6 ............... JWP208-006 ............Knife Gib* .............................................................................................. 4

7 ............... 6292623...................Hex Cap Bolt* .....................................................M8 x 10 .................... 24

8 ............... JWP208-008 ............Knife Gauge Bar .................................................................................... 1

9 ............... JWP208-009 ............Knife Gauge .......................................................................................... 2

10 ............. JWP208-010 ............Washer...............................................................3/8 .............................. 2

11 ............. JWP208-011 ............Nut .....................................................................M 10 ............................ 2

12 ............. BB-6206ZZ ..............Ball Bearing ........................................................6206ZZ....................... 1

13 ............. JWP208-013 ............Key.....................................................................8 x 8 x 36 ................... 1

14 ............. 6292630...................Pulley .................................................................................................... 1

15 ............. 6292631...................Washer .................................................................................................. 2

16 ............. TS-1523071 .............Set Screw ...........................................................M6 x 25 ...................... 2

17 ............. JWP208-017 ............Motor Pulley .......................................................................................... 1

18 ............. JWP208-018 ............Infeed Roller .......................................................................................... 1

19 ............. JWP208-019 ............Bushing ................................................................................................. 4

20 ............. JWP208-020 ............Sprin g.................................................................................................... 4

21 ............. JWP208-021 ............Screw .................................................................M22 x 20 .................... 4

22 ............. JWP208-022 ............Plate ...................................................................................................... 4

23 ............. TS-1490031 .............He x Cap S cr e w ..................................................M8 x 20 ...................... 8

24 ............. JWP208-024A ..........Jack Screw* .......................................................................................... 8

* Index # 3, 4, 5, 6, 7 and 24 are used only on the straight cutterhead, model JWP-208

22

Page 23

Head Assembly – Parts List

Index Part No. Description Size Qty

25 ............. TS-1540041 .............Hex Nut ..............................................................M6 .............................. 8

26 ............. JWP208-026A ..........Key.....................................................................5 x 5 x 24 ................... 2

27 ............. 6292643...................Sprocket ................................................................................................ 1

28 ............. TS-1550041 .............Washer...............................................................M6 .............................. 2

29 ............. JWP208-029A ..........Hex Wash er Head Screw....................................M6 x 16 ...................... 5

30 ............. JWP208-030 ............Outfeed Roller ....................................................................................... 1

31 ............. 6292647...................Sprocket ................................................................................................ 1

32 ............. JWP208-032 ............Locking Bolt ........................................................................................... 1

33 ............. JWP208-033 ............Retaining Ring ....................................................................................... 1

34 ............. JWP208-034 ............Chip Breaker ......................................................................................... 1

35 ............. TS-1540081 .............Nu t .....................................................................M12 ............................ 2

36 ............. JWP208-036 ............Plate S p rin g s ......................................................................................... 3

37 ............. JWP208-037 ............Washer...............................................................1/4 ............................ 12

38 ............. JWP208-038A ..........Hex Wash er Head Screw....................................M6 x 12 .................... 14

39 ............. JWP208-039 ............Sha ft ..................................................................................................... 1

40 ............. JWP208-040 ............Bracket .................................................................................................. 2

41 ............. JWP208-041 ............Pressure Plate ....................................................................................... 1

42 ............. TS-2361081 .............Lo ck Was h e r ......................................................M8 .............................. 2

43 ............. JWP208-043 ............Sha ft ..................................................................................................... 1

44 ............. TS-1523051 .............Set Screw ...........................................................M6 x 16 ...................... 9

45 ............. TS-1523061 .............Set Screw ...........................................................M6 x 20 ...................... 2

46 ............. JWP208-046 ............Plate S p rin g ........................................................................................... 3

47 ............. JWP208-047 ............Chip Deflector Plate ............................................................................... 1

48 ............. 6292664...................Anti-Kickback Finger ............................................................................ 87

49 ............. 6292665...................Collar .................................................................................................. 88

50 ............. JWP208-050 ............Sha ft ..................................................................................................... 1

51 ............. JWP208-051 ............Retaining Ring ....................................................................................... 2

52 ............. 6292668...................Cut Limit Plate ....................................................................................... 1

53 ............. JWP208-053A ..........Fl at Head Machine Screw ...................................M5 x 8 ........................ 2

54 ............. JWP

55 ............. JWP208-055 ............Gas ket................................................................................................... 1

56 ............. JWP208-056 ............Collector Tube ....................................................................................... 1

57 ............. JWP208-057 ............Roller Stand .......................................................................................... 3

58 ............. JWP208-058 ............Roller .................................................................................................... 3

59 ............. TS-1503041 .............Socket Head Cap Screw .....................................M6 x 16 ...................... 9

60 ............. JWP208-060 ............Wor m Gea r Bo x ..................................................................................... 1

61 ............. TS-1503111 .............Socket Head Cap Screw .....................................M6 x 50 ...................... 3

62 ............. JWP208-062 ............Wor m .................................................................................................... 1

63 ............. BB-6201Z ................Ball Bearing ........................................................................................... 1

64 ............. JWP208-064 ............Retaining Ring ....................................................6201Z ......................... 1

65 ............. JWP208-065 ............Key.....................................................................4 x 4 x 10 ................... 1

66 ............. JWP208-066 ............Hand Wheel .......................................................................................... 1

67 ............. JWP208-067 ............Washer...............................................................1/2 .............................. 1

68 ............. 6292684...................Handle................................................................................................... 1

69 ............. JWP208-069 ............Scale ..................................................................................................... 1

70 ............. JWP208-070 ............Machine Screw ...................................................M5 x 10 ...................... 2

71 ............. JWP208-071 ............Pointe r................................................................................................... 1

72 ............. 6292814...................Special Washer ..................................................M6 .............................. 3

73 ............. JWP208-073 ............Co ver .................................................................................................... 1

74 ............. JWP208-074 ............Spring Pin...........................................................6 x 20 ......................... 1

75 ............. JWP208-075 ............Safe ty P late ........................................................................................... 1

76 ............. JWP208-076 ............Machine Screw ...................................................M6 x 8 ........................ 4

77 ............. JWP208-077 ............Safety Latch .......................................................................................... 1

78 ............. TS-1504081 .............Socket Head Cap Screw .....................................M8 x 40 ...................... 1

79 ............. JWP208-079 ............Pul ley Gu a rd ......................................................................................... 1

80 ............. 6292696...................Bolt........................................................................................................ 2

208-054 ............Upper Cover .......................................................................................... 1

23

Page 24

Head Assembly – Parts List

Index Part No. Description Size Qty

81 ............. TS-0680041 .............Washer...............................................................5/16 ............................ 2

82 ............. TS-0561021 .............Nu t .....................................................................5/16-18 ....................... 2

83 ............. VB-M60....................V-Belt .................................................................................................... 3

84 ............. JWP208-084 ............Pulley Cover .......................................................................................... 1

85 ............. 6292710...................Knob ..................................................................5/16 ............................ 2

86 ............. JWP208-086A ..........Switch Mounting Plate ........................................................................... 1

87 ............. JWP208-087F ..........Magnetic Switch (JWP-208 only) ........................3HP, 1Ph, 230V .......... 1

................. JWP208-087FC .......Contactor (JWP-208 only, not shown) .................3HP, 1Ph, 230V .......... 1

................. JWP208-087FO .......Overload (JWP-208 only, not shown) ..................3HP, 1Ph, 230V .......... 1

................. JWP208HH-087A .....Magnetic Switch (JWP - 208HH only ) ...................5HP, 1Ph, 230V .......... 1

................. 209-5016BC.............Contactor (JWP-208HH only, not shown) ............5HP, 1Ph, 230V .......... 1

................. 209-5016CO ............Overload (JWP-208HH only, not shown) .............5HP, 1Ph, 230V .......... 1

................. JWP208HH-087B .....Magnetic Switch .................................................5HP, 3Ph, 230V .......... 1

................. 209-5016DC ............Contactor (not shown) ........................................5HP, 3Ph, 230V .......... 1

................. JWP208HH-087BO ..Overload (not shown) .........................................5HP, 3Ph, 230V .......... 1

................. JWP208HH-087C ....Magnetic Switch .................................................5HP, 3Ph, 460V .......... 1

................. 209-5016EC.............Contactor (not shown) ........................................5HP, 3Ph, 460V .......... 1

................. 209-5016EO ............Overload (not shown) .........................................5HP, 3Ph, 460V .......... 1

88 ............. TS-1540031 .............Nu t .....................................................................M5 .............................. 2

89 ............. TS-1482021 .............He x Cap S cr e w ..................................................M6 x 12 .................... 10

91 ............. JWP208-091 ............Cha in .................................................................................................... 1

92 ............. JWP208-092 ............Relie f Bushing ....................................................................................... 2

................. JWP208HH-092 .......Relief Bushing (for 5HP, 1PH, 230V only) .............................................. 2

93 ............. JWP208-093 ............Power Cord ........................................................................................... 1

................. JWP208HH-093 .......Power Cord (for 5HP, 1PH, 230V only) .................................................. 1

94 ............. JWP208-094 ............Tooth Washe r ........................................................................................ 4

95 ............. TS-1503021 .............Socket Head Cap Screw .....................................M6 x 10 .................... 12

96 ............. TS-1524011 .............Set Screw ...........................................................M8 x 8 ........................ 1

98 ............. JWP208-098 ............Collar .................................................................................................... 1

99 ............. 6292714...................Shaft ..................................................................................................... 1

100 ........... PA-C59 ....................Idler Pulley ............................................................................................ 1

101 ........... PA-C58 ....................Bracket .................................................................................................. 1

................. JWP208-106 ............Chain Tensioning Assy .......................................................................... 1

102 ........... PA-C59 ....................Shaft ..................................................................................................... 1

103 ........... PA-C60 ....................Hanger .................................................................................................. 1

104 ........... PA-C61 ....................Spring.................................................................................................... 1

105 ........... PA-C62 ....................Collar .................................................................................................... 1

106 ........... TS-1534042 .............Pan Head Screw ................................................M6X1 2........................ 1

107 ........... TS-1503021 .............Socket Head Cap Screw .....................................M6x10 ........................ 2

108 ........... JWP208-108 ............Hex Head Screw ................................................M8 x18 ........................ 4

................. MS-SA20 -24V ..........M agnetic Contactor f or 3HP Motor ( not shown) ...................................... 1

................. MS-SA20 -24VA........Magnetic Contactor for 5HP, 3PH Motor ( not shown) ............................. 1

................. MS-208HH-24V........Magnetic Contactor for 5HP, 1PH Motor ( not shown) ............................. 1

................. JWP208-087DTR .....Thermal Relay for 3HP Motor (not shown) ............................................. 1

................. JWP208-087ETR .....Thermal Relay for 5HP, 3PH Motor (not shown) ..................................... 1

................. JWP208HH-108TR ..Thermal Relay for 5HP, 1PH Motor (not shown) ..................................... 1

................. PG-M02 ...................JET Plaque ............................................................................................ 1

................. 6012192...................Warning Label (not shown) .................................................................... 1

................. 6292819

................. 6292820...................Guard Label (not shown) ....................................................................... 1

................. 1791224...................Helical Cutterhead Assembly (index #109 thru #111)** .......................... 1

109 ........... JWP208HH-109 .......Helical Cutterhead** .............................................................................. 1

110 ........... 1791212...................Knife Insert (sold in set of 10)** ..................................................... 92 total

111 ........... JWP208HH-111 .......Knife Insert Screw** ............................................#10-32 x 1/2” ............ 92

112 ........... JJ6HH-113 ...............Star Point Screwdriver (not shown)** ..................................................... 2

** Index # 109 thru 112 are used only on the helical cutterhead, model JWP-208HH

...................Lubrication Label (not shown) ................................................................ 1

24

Page 25

Head Assembly – Exploded View

25

Page 26

Table and Roller – Parts and Assembly

Index Part No. Description Size Qty

1 ............... JWP208HH-201 .......Middle Table .......................................................................................... 1

2 ............... 6292722...................Roller .................................................................................................... 2

3 ............... BB-6201ZZ ..............Ball Bearing ........................................................6201ZZ....................... 4

4 ............... 6292724...................Eccentric Shaft ...................................................................................... 1

5 ............... TS-1523041 .............Set Screw ...........................................................M6x12 ........................ 4

6 ............... 6292725...................Lock Bar ................................................................................................ 2

7 ............... 6292726...................Lock Bolt ............................................................................................... 2

8 ............... 6292727...................Lock Bushing (no thread) ....................................................................... 2

9 ............... 6292728...................Knob ..................................................................................................... 2

10 ............. TS-1504041 .............Socket Head Cap Screw .....................................M8x20 ........................ 8

11 ............. 6292730...................Roller Frame* ........................................................................................ 4

12 ............. 6292731...................Roller* ................................................................................................... 6

13 ............. TS-1491031 .............Hex Cap Screw* .................................................M10x25 ...................... 8

14 ............. TS-0680041 .............Wash er* .............................................................3/8” ............................. 8

15 ............. 6292808...................Shaft* .................................................................................................... 6

16 ............. 6292809...................Bushing* .............................................................................................. 12

17 ............. TS-1482021 .............Hex Head Screw* ...............................................M6x12 ...................... 12

18 ............. TS-1550041 .............Fla t Washer * ......................................................M6 ............................ 12

19 ............. JWP208HH-219 .......Extension Table** .................................................................................. 2

20 ............. TS-1524051 .............Socket Set Screw** ............................................M8x20 ........................ 6

21 ............. TS-1490041 .............He x Cap Screw** ................................................M8x25 ........................ 6

* Index #11 thru 18 are used only on the model JWP-208.

** Index #19, 20 and 21 are used only on the model JWP-208HH.

26

Page 27

Stand and Motor – Parts and Assembly

Index Part No. Description Size Qty

1 ............... JWP208-401 ............Stand .................................................................................................... 1

2 ............... JWP208-402 ............Cover .................................................................................................... 2

3 ............... TS-2286201 .............Flat Head Machine Screw ...................................M6 x 20 ...................... 8

4 ............... 6292796...................Bar ........................................................................................................ 2

5 ............... JWP208-405 ............Motor Mount .......................................................................................... 1

6 ............... TS-1524011 .............Set Screw ...........................................................M8 x 8 ........................ 4

7 ............... JWP208-407 ............Collar .................................................................................................... 1

8 ............... JWP208-408 ............Adjust Bolt ............................................................................................. 2

9 ............... TS-1540081 .............Nut .....................................................................M12 ............................ 8

10 ............. TS-0680061 .............Washer...............................................................1/2 .............................. 4

11 ............. TS-1490041 .............He x Cap S cr e w ..................................................M8 x 35 ...................... 4

12 ............. TS-0680031 .............Washer...............................................................5/16 ............................ 4

13 ............. TS-1540061 .............Nu t .....................................................................M8 .............................. 4

14 ............. JWP208-414 ............Motor (3HP, 1Ph, 230V) ........................................................................ 1

................. 209-5023 .................Motor (5HP, 1Ph, 230V) ........................................................................ 1

................. JWP208-414A ..........Motor (5HP, 3Ph, 230/460V) .................................................................. 1

15 ............. JWP208-415 ............Key........................................................................................................ 1

16 ............. TS-1492051 .............He x Cap S cr e w ..................................................M12 x 50 .................... 4

17 ............. JWP208-417 ............Power Cord ........................................................................................... 1