Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Step Pulley Turret Mill

Model JTM-1, JTM-2

Model JTM-1 shown

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-690082

Ph.: 800-274-6848 Revision G2 12/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET® warrant s ever y pro duct i t sell s against m anuf actu rers’ defec ts. If one of ou r tools needs ser vice or rep air, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 About this manual .......................................................................................................................................... 5

5.0 JTM-1, JTM-2 installation layout .................................................................................................................... 6

6.0 Specifications ................................................................................................................................................. 7

7.0 JTM-1/JTM-2 Features and Terminology ....................................................................................................... 8

8.0 Setup and Assembly ...................................................................................................................................... 9

8.1 Unpacking .................................................................................................................................................. 9

8.2 Contents of shipping container ................................................................................................................... 9

8.3 Site preparation ........................................................................................................................................ 10

8.4 Lifting the mill ........................................................................................................................................... 10

8.5 Completing assembly ............................................................................................................................... 10

8.6 Lubrication ................................................................................................................................................ 11

9.0 Electrical connections .................................................................................................................................. 11

9.1 Wire Sizes ................................................................................................................................................ 11

10.0 Controls ...................................................................................................................................................... 11

11.0 Operations .................................................................................................................................................. 13

11.1 Operating precautions ............................................................................................................................ 13

11.2 Clamping workpiece to table .................................................................................................................. 13

11.3 Changing speed range ........................................................................................................................... 13

11.4 Setting up for fine hand feed .................................................................................................................. 13

11.5 Setting up for automatic feed ................................................................................................................. 14

11.6 Power feed operation ............................................................................................................................. 14

11.7 Draw bar operation; changing tooling ..................................................................................................... 15

12.0 Adjustments ............................................................................................................................................... 15

12.1 Head movement: left and right ............................................................................................................... 15

12.2 Head movement: Fore and aft ................................................................................................................ 16

12.3 Positioning ram ....................................................................................................................................... 16

12.4 Feed trip adjustment ............................................................................................................................... 16

12.5 Gib adjustment ....................................................................................................................................... 17

12.6 Table lead screw backlash adjustment .................................................................................................. 17

13.0 Maintenance ............................................................................................................................................... 19

13.1 Lubrication .............................................................................................................................................. 19

13.2 Periodic Maintenance Activities .............................................................................................................. 19

14.0 Belt position – speed ranges ...................................................................................................................... 20

15.0 Replacement Parts ..................................................................................................................................... 20

15.1.1 Upper Head Assembly – Exploded View ............................................................................................. 21

15.1.2 Upper Head Assembly – Parts List ..................................................................................................... 22

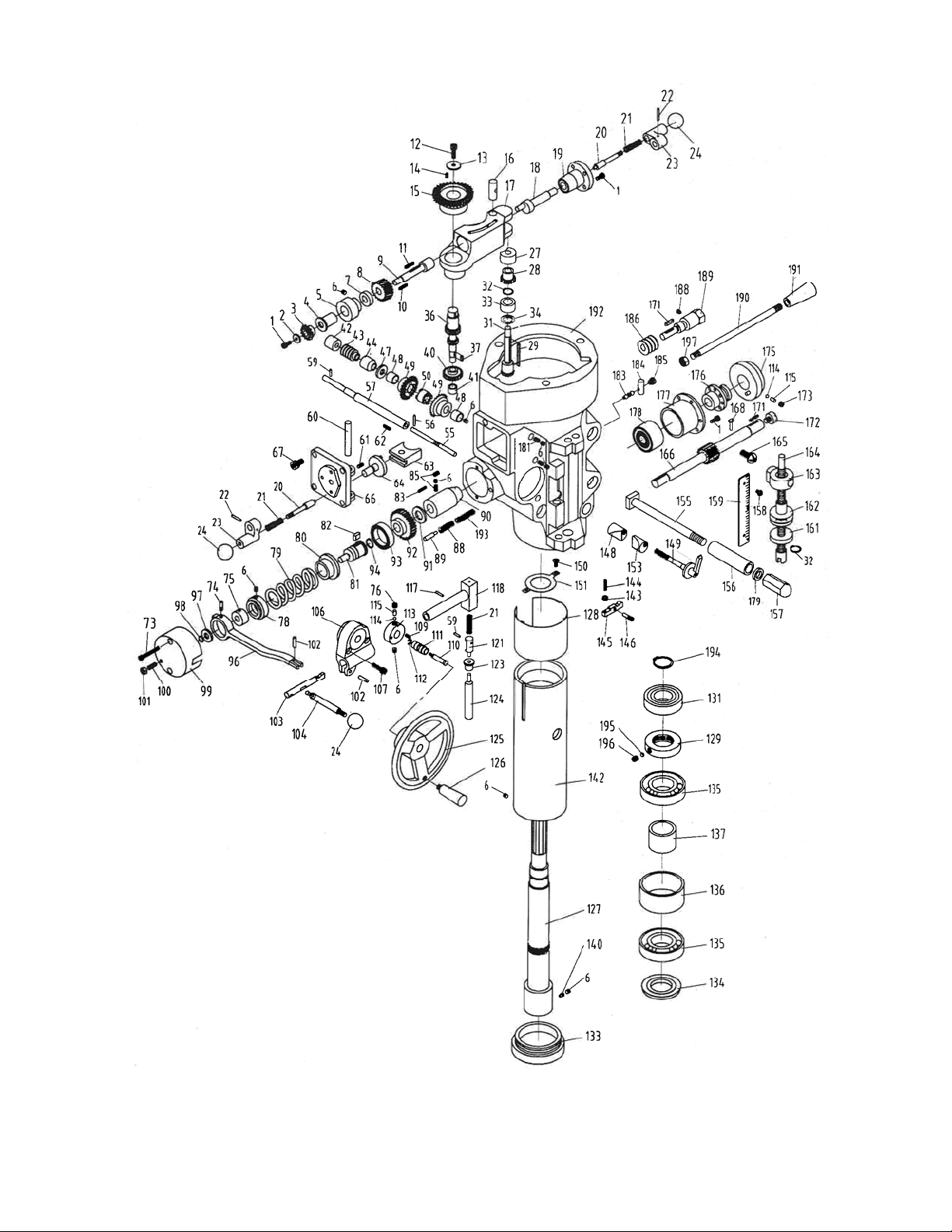

15.2.1 Head Assembly – Exploded View ....................................................................................................... 24

15.2.2 Head Assembly – Parts List ................................................................................................................ 25

15.3.1 Base Assembly – Exploded View ........................................................................................................ 28

15.3.2 Base Assembly – Parts List ................................................................................................................. 29

15.4.1 Table Leadscrew Assembly – Exploded View ..................................................................................... 31

15.4.2 Table Leadscrew Assembly – Parts List ............................................................................................. 31

15.5.1 One-Shot Lubrication System – Exploded View .................................................................................. 32

15.5.2 One-Shot Lubrication System – Parts List .......................................................................................... 32

16.0 Electrical Connections ................................................................................................................................ 33

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This turret mill is designed and intended for

use by properly trained and experienced

perso nnel on ly. If you are no t fam iliar w ith the

proper and safe operation of a turret mill, do

not use until proper training and knowledge

have been obtained.

5. Do not use this turret mill for other than its

intended use. If used for other purposes, JET,

disclaims any real or implied warranty and

hold s itself harmles s from a ny injury t hat may

result from that use.

6. Always wear approved safety glasses/face

shields while using this mill. Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.

7. Before operating this machine, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Remove all loose

clothi ng a nd confine long hair.

8. Non-slip safety footwear and anti-skid floor

strips are recommended. Do not wear gloves.

9. Never place hands near or around a revo lving

tool or part.

10. Wear ear protectors (plugs or muffs) during

extended periods of operation.

11. Some dust created by power sanding, sawing,

grinding, drilling and other construction

activities contain chemicals known to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead based paint.

•

Crystalline silica from bricks, cement and

other masonry products.

•

Arsenic and chromium from chemically

treated lumber.

Your risk of exposure varies, depending on

how often you do this type of work. To reduce

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, such as face or dust masks

that are specifically designed to filter out

microscopic particles.

12. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

13. Make certain the switch is in the OFF po sition

before connecting the machine to the power

supply.

14. Make certain the machine is properly

grounded.

15. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

16. Workpiece must be attached or clamped to the

table. Never hold a workpiece with your hand.

17. Use correct spindle speed and table feed for

the particular job.

18. Do not start machine with cutter in contact with

workpiece.

19. Disengage power feed when not in use.

20. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

21. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

completion of maintenance.

22. Check damaged parts. Before further use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

23. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

24. Keep the floor around the machine clean and

free of scrap material, oil and grease.

25. Keep visitors a safe distance from the work

area. Keep children away.

26. Make your workshop child proof w ith padlocks,

master switches or by removing starter keys.

27. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in

serious injury.

4

Page 5

28. Maintain a balanced stance at all times so that

you do not fall into the cutter or other moving

parts. Do not overreach or use excessive force

to perform any machine operation.

29. Use the right tool at the correct speed and

feed rate. Rotate spindle clockwise for righthand tools, counterclockwise for left-hand

tools. Do not force a tool or attachment to do a

job for which it was not designed. The right

tool will do the job bette r and more safely.

30. Use recommended accessories; improper

accessories may be hazardous.

31. Frequently clean this machine. Maintain tools

with care. Keep cutters sharp and clean for the

best and safest performance. Follow

instructions for lubricating and changing

accessories.

32. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use your hands.

Familiarize yourself with the following safety notices used in this manual:

33. Do not stand on the machine. Serious injury

could occur if the machine tips over.

34. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

35. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

36. Don’t use in dangerous environment. Don’t

use this machine in damp or wet locations, or

expose it to rain. Keep work area well lighted.

37. Some coolants used for machining contain

chemicals that may be hazardous to your

health if not used properly. Read and

understand all user information listed on the

coolant container and protect yourself

accordingly.

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or

possibly even death.

4.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Model

JTM-1 and JTM-2 Turret Mill. This manual contains instructions on installation, safety precautions, general

operating procedures, maintenance instructions and parts breakdown. Your machine has been designed and

constructed to provide years of trouble-free operation if used in accordance with the instructions as set forth in

this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

5

Page 6

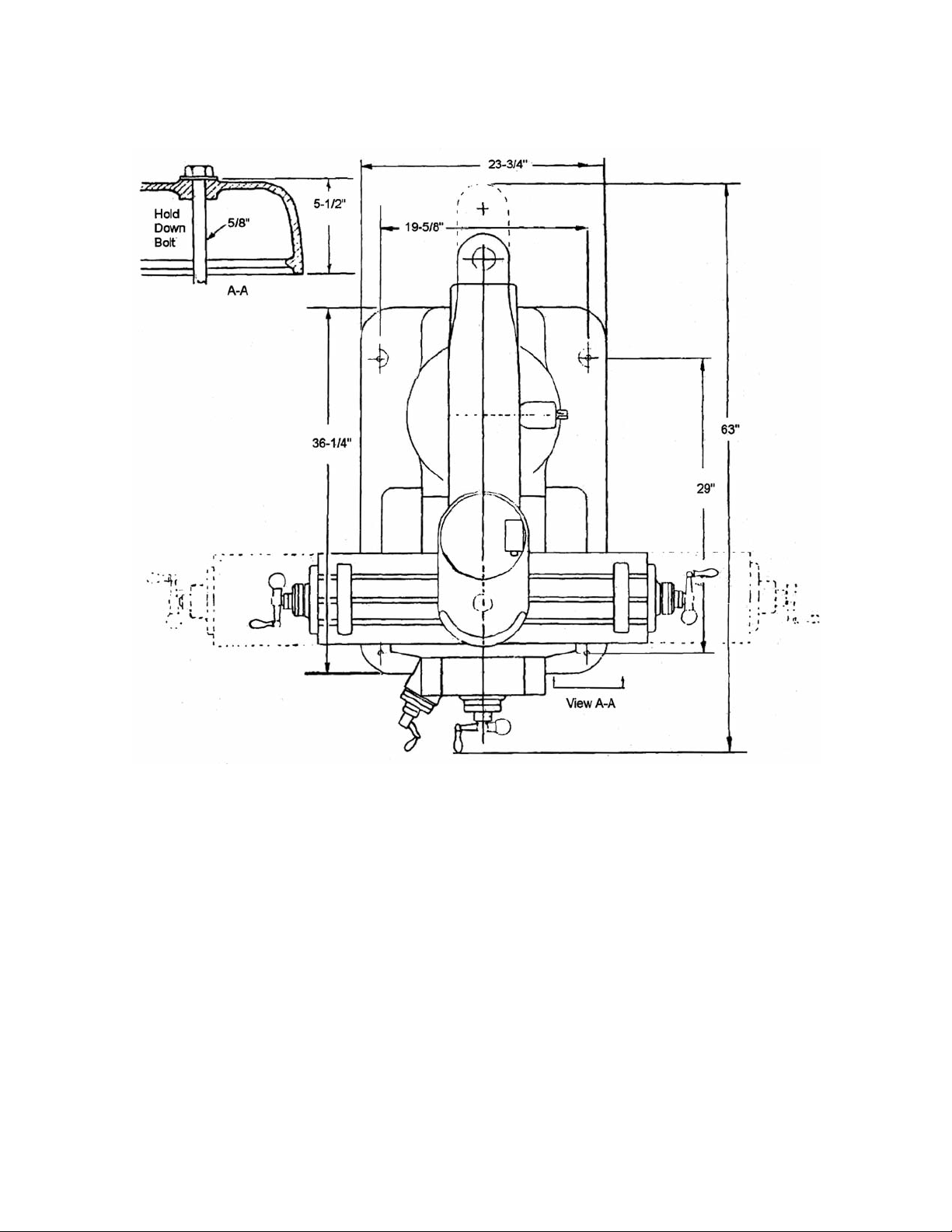

5.0 JTM-1, JTM-2 installation layout

Figure 1

6

Page 7

6.0 Specifications

Mode l Number .......................................................................................... JTM-1............................................ JTM -2

Stock Number ......................................................................................... 690082........................................... 690089

Motor an d Electricals:

Motor type ............................................................................................ induction....... T EFC induction, capacito r start

Horsepowe r ......................................................................................... 2 (1.5kW)....................................... 2 (1.5k W)

Phase ............................................................................................................... 3............................................. single

Voltage ............................................................................................... 230V only.............. 115/230V (prewired 230V)

Cycle ..........................................................................................................60Hz.............................................. 60Hz

Listed FLA (full load amps) ....................................................................... 6.5/5.6..............................................28/14

Start Capacitor................................................................................................. --........................... 500MFD 125VAC

Power Transfer ............................................................................................. belt................................................. belt

Motor Speed .............................................................................. 3450/1720 RPM...................................... 1720 RPM

Sound Emission (tested at 3 ft. from machine):

Without loa d.......................................................................................... 75 dB............................................. 75 dB

With load ......................................................................................... 80-85 dB........................................ 80-85 dB

Head and Spindle:

Spind le Taper ............................................................................................... R-8................................................. R-8

Spindle bearings ...................................................................................... clas s 7........................................... class 7

Quill Diameter ............................................................................................ 3-3/8 ”............................................. 3-3/ 8”

Number of Spindle Speeds.............................................................................. 16.................................................... 8

Range of Spindle Speeds:

Low (RPM) ............................................ 80,135 ,2 10 ,32 5 ,660 ,1 11 0 ,17 50 ,2 720 .............................. 8 0,13 5 ,21 0 ,325

High (RPM) ................................ 160, 270, 420, 650, 1320, 2220, 3500, 5440....................... 660,1110,1750,2720

Downfeed Distance per Revolution of Spindle ................... 0.0015”, 0.003”, 0.006”................... 0.0015”, 0.003”, 0.006”

Spindle Travel .................................................................................................5”................................................... 5”

Head Movement ...........................................................90° L and R, 45° F and B................ 90° L and R, 45° F and B

Maximum Distance Spindle to Table ......................................................... 17-1/2”........................................... 17-1 /2”

Maximum Distance Spindle to Column ........................................................... 19”................................................. 19”

Minimum Distance Spindle to Column ........................................................ 4-1/2”............................................. 4 -1/2”

Collet Capacity ................................................................................... 1/8” – 7/8”.......................................1/8” – 7/8”

Ram Travel .............................................................................................. 13-3/8”........................................... 13-3 /8”

Ram Rotation ...................................................................................90° L and R.................................... 90° L and R

Table:

Table Size ................................................................................................ 9”x42”............................................ 9 ”x42”

Longitudinal Table Travel ......................................................................... 23-7/8”........................................... 23-7/8”

Table Cross T ra vel .................................................................................. 12-1/2”.................. ......................... 1 2-1 /2”

T-Slots, Number ............................................................................................... 3.................................................... 3

T-Slots, Size ................................................................................................. 5/8”................................................ 5/8”

T-Slots, Spacing ........................................................................................ 2-1/2 ”............................................. 2-1/ 2”

Maximum Table Load ............................................................................... 550 lb............................................. 550 lb

Knee Travel ............................................................................................. 14-1/2”........................................... 1 4-1/2 ”

Dimensions:

Overall Dimensions, assembled ........................................... 57”W x 64”D x 82”H........................ 57”W x 64”D x 82”H

Shipping Dimensions ........................................................... 67”W x 56”D x 66”H........................ 67”W x 56”D x 66”H

Weights:

Net Weight (a p prox .) ............................................................................... 2056 lb........................................... 2056 lb

Shipping Weight (appro x) ........................................................................ 2200 lb........................................... 2200 lb

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET, reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

7

Page 8

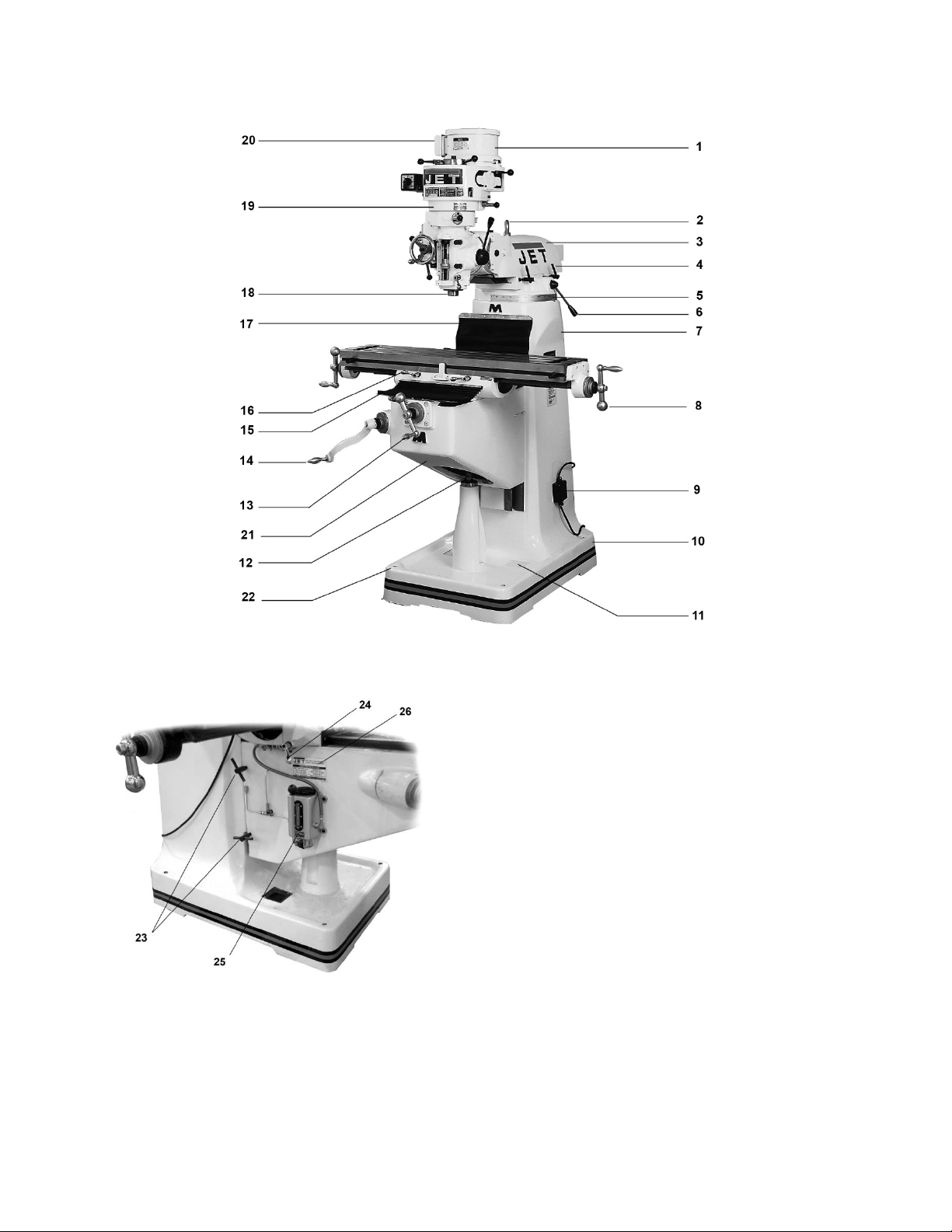

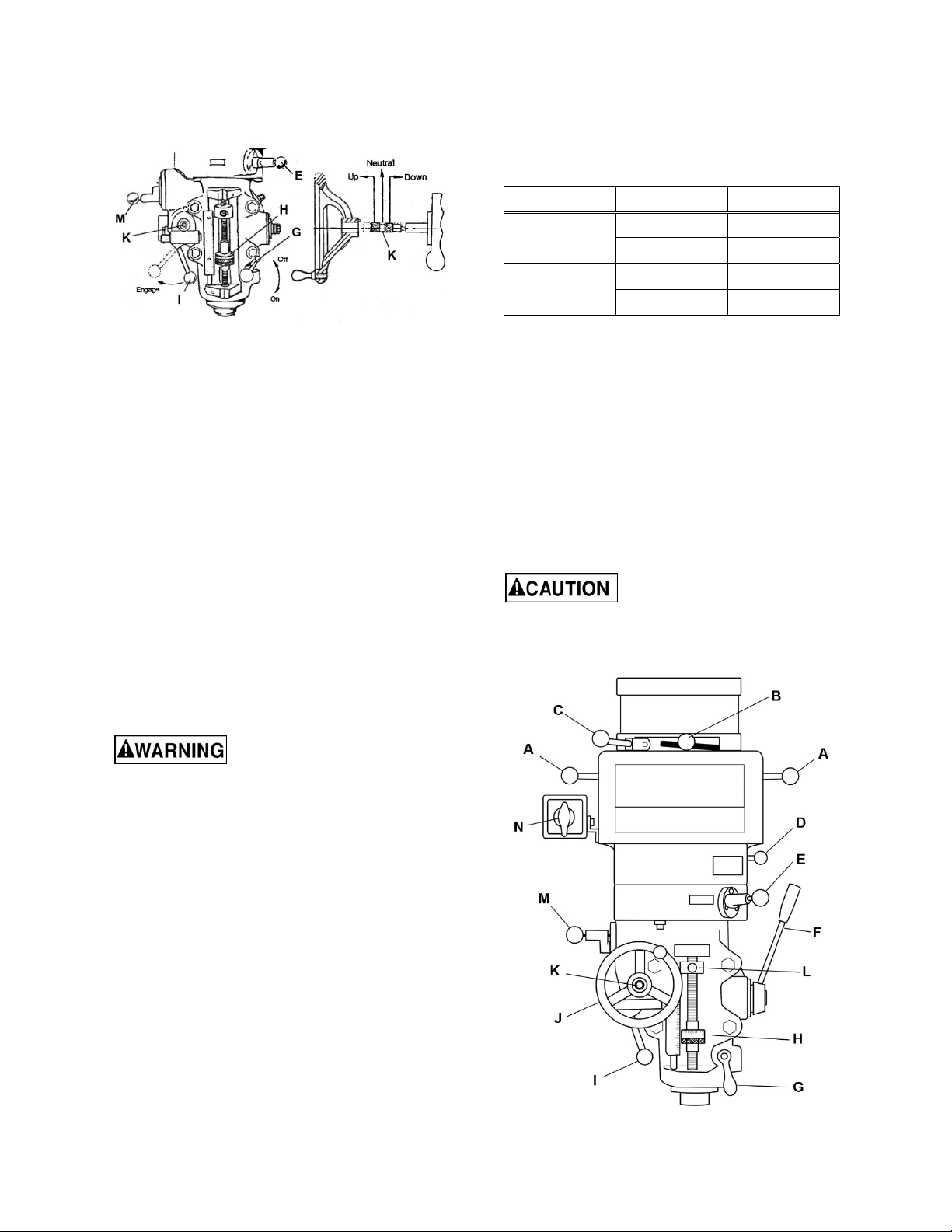

7.0 JTM-1/JTM-2 Features and Terminology

1. Motor

2. Lifting ring

3. Ram

4. Ram locking handle (x2)

5. Turret scale

6. Ram movement lever

7. Column

Figure 2: Features and Terminology (JTM-1 shown)

8. Table long i tudi nal cr ank hand le (x2)

9. Power connection box

10. Base

11. Filter screen (x2) (for use with optional flood

coolant systems)

12. Elevating leadscrew

13. Crossfeed handle

14. Knee crank handle

15. Pleated way cover

16. Table l o c king hand le ( x 2 )

17. Flat way cover

18. Spindle

19. Head Assembly (see section 10.0 for

explanation of controls)

20. Motor junction box

21. Knee

22. Holes for mounting bolts (x4)

23. Knee locking handle (x2)

24. Saddle locking handle

25. One-shot lube system

26. Lubrication chart

8

Page 9

8.0 Setup and Assembly

8.1 Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to your

distributor and shipping agent. Do not discard any

shipping material until the T urret Mill is assembled and

running properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor. Read the instruction manual thoroughly for

assembly, maintenance and safety instructions.

8.2 Contents of shipping container

Note: Some par ts may be pre-installed on the mill.

1 Turret Mill (not shown)

1 Flat Way Cover

1 Pleated Way Cover

1 Draw Bar

3 Table Adjustment Handles

2 Belt Guards

1 Tool Box, containing (Figure 3):

1 Hex Key Set (1.5-10mm) *

1 17/19mm Box Wrench *

1 Cross Point Screw Driver #2 *

1 Flat Blade Screw Driver #2 *

1 Plastic Oil Bottle *

1 Elevating Crank Handle

1 Handwheel

1 Coarse Feed Handle

1 Can White Touch Up Paint

1 Hoisting Ring

1 Operator’s Manual (not shown)

1 Warranty Card (not shown)

* parts with an asterisk are also included in the tool

box service kit, p/n JTM4VS-TB.

Figure 3: shipping contents

NOTE: If your mill is supplied with an optional Table Powerf eed and/or Digital Readout, be sure to consult the

separate instruction materials that accompany them.

9

Page 10

8.3 Site preparation

The mill must be placed o n an even surface and

bolted to the floor. Anchor bolts of sufficient size

and length must be f astened to the f loor according

to the mill’s footprint. See the site installation

diagram in Figure 1.

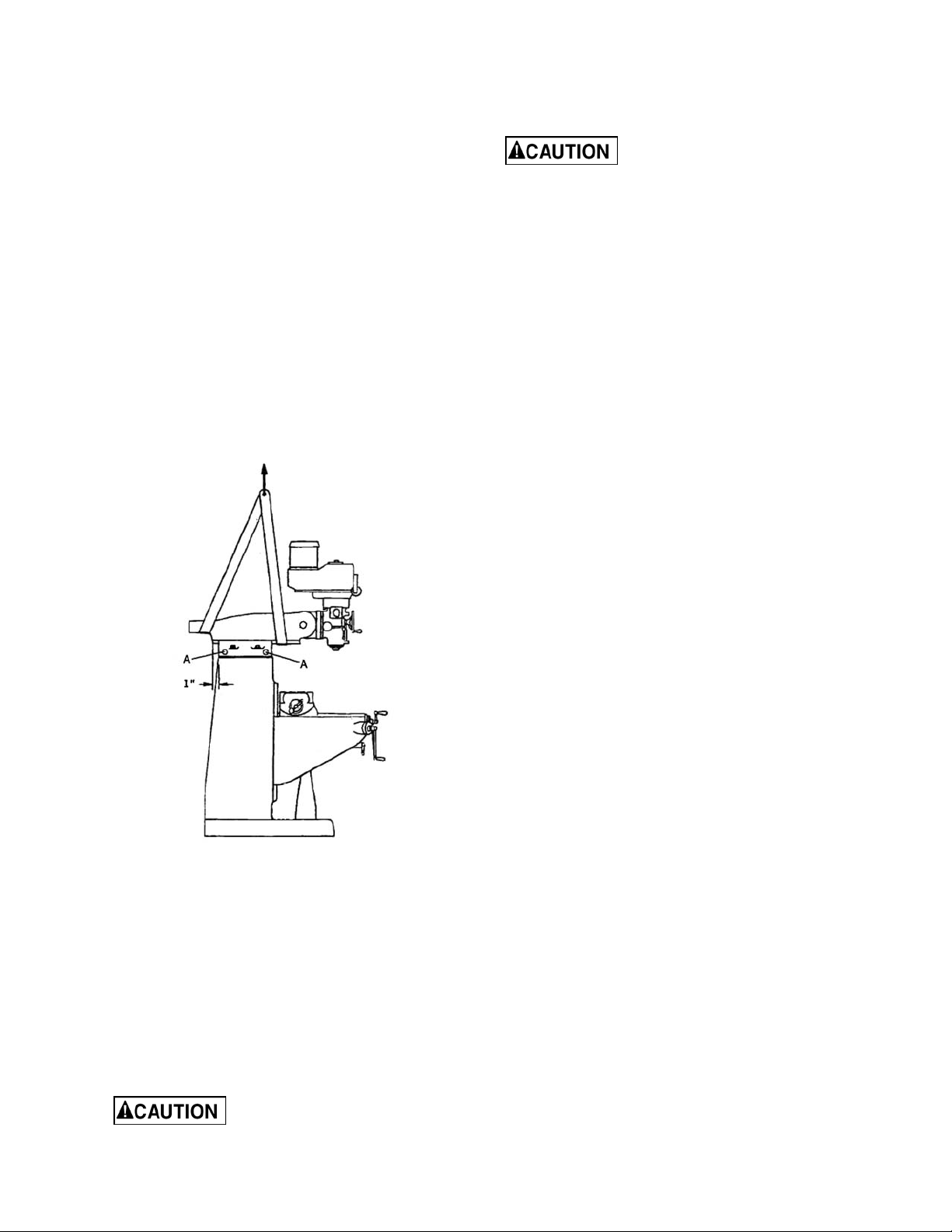

8.4 Lifting the mill

Finish removing the sides of the crate. Leave mill

bolted to pallet until ready to move to its final

location.

The preferred method for lifting mill is with a hook

through the hoisting ring screwed into t he tapped

hole atop the ram. Steady mill to prevent it from

spinning.

An alternative method for lifting mill is with a sling.

Follow diagram in Figure 1 for proper position of

sling under ram. Note position of ram and that table

has been moved against column. Tighten ram

locking bolts (A, Figure 4) before lifting.

cause the column to twist and put a bind in the

ways.

8.5 Completing assembly

Before attempting to raise mill

head, familiarize yourself with instructions in

section 12.1, for procedures to sa fely raise a nd

set up the mill head.

1. Loosen four hexagonal nuts (see A, F igure 9)

about 1/4 turn each counterclockwise, just

enough to allow rotation of head.

2. Apply upward pressure on motor by hand to

relieve pressure on worm mechanism, and use

supplied wrench to turn worm nut and raise

head to upright position.

3. Slightly tighten nuts (A , Figure 9); not torq ued,

just snug. Before operating mill, follow

procedures in section 12.1 to verify angle

settings and properly tighten the four nuts.

4. Use mineral spirits, kero sene or other cleaning

solve nt , to rem o ve all rust- p r oo fing from wher e

it may have been applied. This is important;

moving the table or any other components

before removing rust proofing will only put rust

proofing where you don’t want it. (Do not use

gasoline, paint thinner, or lacquer thinner;

these will damage painted surfaces. )

Figure 4: sling location

Carefully lift mill and move to a position over the

anchor bolts. Lower mill over anchor bolts and

check for leve l, with a machi nist’s level plac ed on

the table. Mill must be level back to fro nt and side

to side. Shim if necessary, but remember that mill

must be supported equally at all four corners.

Check for level before tightening anchor bolt nuts,

and check again after tightening them.

It is advisable when plac ing the mill on a concrete

floor to use grout (thin mortar) to correct any

unevenness in the concrete and provide a solid

foundation at all points.

Mill must be supported equally

under all four corners. Failure to comply may

5. Lubricate exposed ways (see sect. 13.0), then

move each unit (table and ram) to the opposite

limit stop, and clean and lubricate the newly

exposed ways. Loosen bolts to unlock ram and

move it forward and backward to the full length

in order to clean and lubricate.

6. Cover all machined surfaces with a film of light

machine tool oil to inhibit rust.

Some of the following steps may have already

been performed on the machi ne. If so, ig nore the

instructions related to those particular steps.

Otherwise, perform them in the order listed. Refer

to Figures 2 and 5 to help locate items.

7. Install the table traverse and cross-feed

handles on their respective shafts. Tighten

each handle using a wrench on the flats.

8. Remove any rust proofing from drawbar. Install

drawbar with its washer into spindle center

through top of head assembly. When installing

tool into spindle, lock spindle and tighten

drawbar using provided wrench.

9. Slide the fine feed handwheel over the hub

and push it back until its roll pin engages hole

in hub, and handwheel is flush with hub

surface.

10. Place coarse feed handle on feed shaft,

alig ning rol l pin w ith a hole . Tap hand le lig htl y

until it is flush against hub surface.

10

Page 11

11. Unwrap and clean elevating (knee) crank and

insta l l it o n its shaft .

12. Install rubber way covers at front and behind

table.

13. Install belt guards.

8.6 Lubrication

Do not operate this milling

machine before fully lubricating it. Failure to

comply may damage machine.

prevent motor overheating and burnout, the use of

wire sizes for branch circuits or electrical extension

cords according to the following table is

recommended:

Conductor

Length

0 – 50 Ft. No. 14 No. 14

50 – 100 Ft. No. 14 No. 12

Over 100 Ft. No. 12 No. 8

230/460 Volt Lines 120 Volt Lines

AWG Number

Table 1

Familiarize yourself with all lubricating points in

section 13.0, and fully lubricate this machine before

operating it.

9.0 Electrical connections

All electrical connections

must be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly gro unded. Failure to

comply may result in serious injury.

Confirm that power at the site matches power

requirements of the mill before connecting to power

source.

The JTM-1 turret mill is rated at 2HP, 3PH, 230V

only.

The JTM-2 turret mill is rated at 2HP, 1PH,

115/230V and comes from the factory prewired at

230V.

To convert from 230V to 115V operation (JTM-2

only):

1. Open junction box on motor and change the

wires according to diagram found on inside of

cover.

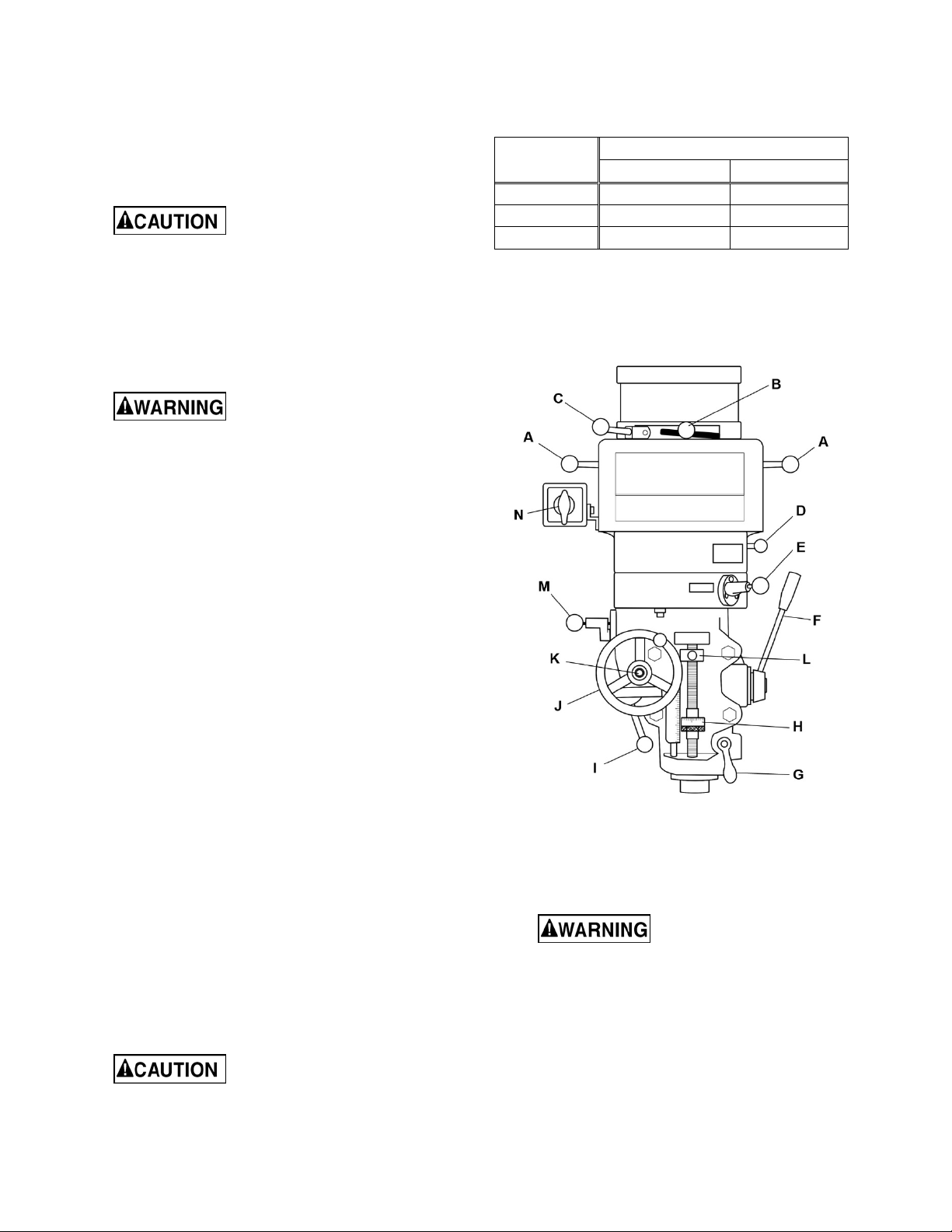

10.0 Controls

Refer to Figure 5:

2. Open Fwd/Rev switch box and change

connections according to diagram.

Similar diagrams are found in section 16.0 of thi s

manual. Note: If discrepancies arise, diagrams on

machine take precedence.

It is recommended that the JTM-1 be connected to

a dedicated 10 amp circuit with a circuit breaker or

time-delay fuse. Connect the JTM-2, using 230

volt power, to a dedicated 40 amp circuit with

circuit breaker or time-delay fuse, and the JTM-2

with 115 volt power, to a dedicated 30 amp circuit

with circuit breaker or time-delay fuse. Local

codes take precedence over recommendations.

9.1 Wire Sizes

For circuits which are far away

from the electrical service box, the wire size must

be increased in order to deliver ample voltage to

the motor. To minimize power losses and to

Figure 5: controls

A. Motor Lock (Belt Tension) Levers (A, Figure

5) – Slide levers to loosen motor mounting;

shift motor to release tension on belts and

reposition belts for different speed range.

Disconnect mill from

power source before changing belt

position. Reinstall belt guards before

operating mill.

B. Speed Range Selector (B) – Mill is in high

speed range when selector is in front position

(facing operator). Push selector to the side to

shift into low speed range. Rotate spindle to

assist engagement, by either turning spindle

nose by hand or turni ng drawbar knob with a

wrench, provided drawbar is pulled up tightly.

11

Page 12

Change speed range only

when motor is NOT running.

C. S pindle Brake (C, Figure 5) – Move in e ither

direction to prevent spindle from turning.

D. B ack Gear Control Lever (D, Figure 5) – P ull

out knob and rotate lever in to position. “IN”

position engages back gear for low speed.

“OUT” position disengages back gear f or high

speed. (Used in conjunction with Speed Range

Selector B.) Middle position is neutral and

allows free spindle rotation for such things as

setup work.

Shift back gear control

lever only when motor is NOT running.

Rotate spindle by hand to facilitate lever

engagement.

E. Power Feed Transmission Engagement

Lever (E, Figure 5) – When lever is in right

hole, power feed worm gear is disengaged. To

engage power feed, pull knob out and move

lever to left hole. Engage pin in hole.

Power feed may be

engaged when spindle is rotating; however,

it must be engaged gently to a void damage

to worm gear. It may be disengaged any

time. Do not use power feed at speeds

above 2700 RPM. It is recommended that

power feed worm gear be disengaged

whenever power feed is not required; this

avoids unnecessary wear on the worm

gear.

J. Manual Fine Feed Handw heel (J, Figure 5) –

Feed reversing knob (K, Figure 5) must be in

neutral position. The feed trip lever (I, Figure

5) must be engaged. Note: Manual feed

handwheel may be removed when not in use.

K. Feed Reversing Knob (K, Figure 5) – located

in ce nter of ma nual fe ed handw heel. P osition

of knob depends upon direction of spindle

rotation. If boring with right hand cutting tools,

pull knob towards operator until clutch

engages. Neutral position is between forward

and reverse positions (see Figure 7).

It is recommended that

feed reversing knob be left in neutral

posit ion when not in use.

F. C oarse Feed Handle (F, Figure 5) – Used for

manual operations. Rotate counterclockwise to

lower spindle. Return spring will automatically

retract spindle once handle is released.

Handle can be removed when not in use.

G. Quill Lock (G, Figure 5) – Rotate handle

clockwise to lock quill in position; counterclockwise to release.

H. Micr om eter Adjusting Nut (H, Figure 5) – For

setting specific spindle depth. Each graduation

on the nut represents 0.001” of depth, and

corresponds to the adjacent scale.

I. Feed Trip Lever (I, Figure 5) – Engages

overload clutch on pinion shaft when

positioned to the left. Stays engaged until quill

stop comes into contact with micrometer

adjusting nut (forcing feed trip lever to drop out

automatically), or until lever is released

manually by pushing it to the right.

IMPORTANT: Overload clutch is factory-set to

hold up to 200 lb. downfeed pressure on the

quill (accommodates drills up to 3/8”). Do not

attempt to adjust clutch pressure.

Figure 5 (repeated)

L. Quill Stop (L, Figure 5) – Disengages

automatic feed in either direction, as well as

the setting point for working to a given depth

during manual feeds.

M. Quill Feed Rate Selector (M, Figure 5) – Pull

knob out and locate handle over choice of

three feed rates: 0.0015”, 0.003”, 0.006”

downfeeds per revolution of spindle. Feed is

more readily engaged when spindle is turning.

N. Reversing Switch (N, Figure 5) – Turns

spindle on and off, and changes rotation

direction.

12

Page 13

11.0 Operations

11.1 Operating precautions

Observe the following

instructions before using this mill.

1. Verify that spindle brake is released before

starting motor.

2. Rotate spindle by hand to facilitate meshing of

clutch and gears.

3. Do not use quill power feed at speeds above

2700 RPM.

4. It is recommended that power feed worm gear

be disengaged whenever power feed is not

required. This will avoid unnecessary wear on

worm gear.

5. The power feed can be used for drills up to

3/8” diameter (in mild steel). Use manual feed

for drills larger than 3/8”.

6. Overload clutch is factory-set to hold up to 200

lb. downfeed pressure on the quill (accommodates drills up to 3/8”). Do not attempt to

adjust clutch pressure.

7. If using longitudinal table travel only, clamp

saddle and knee in place using the locking

handles; this will add rigidity and provide for

heav ier cuts w ith min imal vibrat ion. If not u s i ng

longitudinal travel, keep table locking handles

tightened.

8. On heavy milling work, keep head as close to

column as possible to obtain maximum rigidity.

Always tighten ram locking handles securely.

9. Do not engage back gear (“IN” position of D,

Figure 5) while leaving speed range selector

(B, Figure 5) in high position (facing operator).

This may cause gearing system to bind up.

11.2 Clamping workpiece to table

1. The worktable has 5/8-inch T-slots for

clamping work piece to table.

2. Set switch to OFF position.

3. Place work piece on table.

4. Clamp work piece using T-slot clamps, studs,

and step blocks as required (Figure 6).

Figure 6

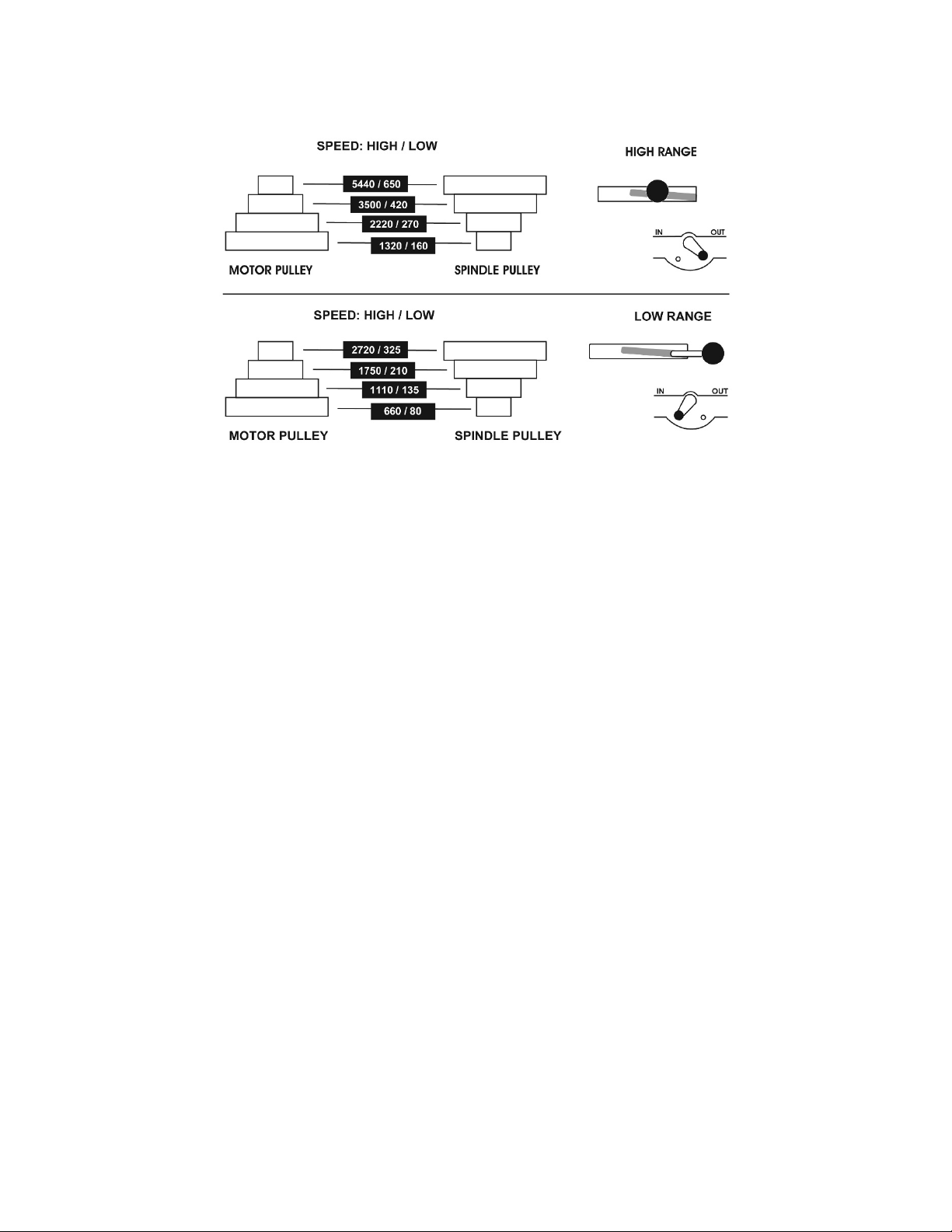

11.3 Changing speed range

Rotate spindle by hand to

ensure clutch is engaged prior to turning on

machine. Do not turn on machine unless

spindle can be moved freely.

Move belt to desired set of pulleys for specific

speeds. Speed range is then set to High or Low, as

follows (refer to Figure 5):

High speed range

1. Move speed range selector (B, Figure 5) to

front position.

2. Keep back gear control lever (D, Figure 5) at

“IN” position.

3. Move spindle pulley by hand until you feel it

me sh w it h c l ut c h ( sp i nd le p ul le y c a n no lo ng e r

be moved).

4. Move back gear control lever (D) to “OUT”

posit ion.

Low speed range

1. Move speed range selector (B, Figure 5) to

side position.

2. Move back gear control lever (D) to “IN”

position, while rotating spindle to help engage.

The above procedures are also shown o n a plate

on front of mill head.

See Figure 15 for speeds of each belt position

within each range.

11.4 Setting up for fine hand feed

Refer to Figure 7:

1. Disengage automatic feed by pulling out knob

(E, Figure 7) and moving lever to the right

hole.

13

Page 14

2. Position feed reversing knob (K) in the center

at neutral position.

3. Engage feed trip lever (I) by pulling away from

head assembly.

9. Set Feed Rate Lever (M) to the feed rate

required for the tooling and material used.

10. Place Quill Feed Engagement Le ver (E) in t he

Engaged position.

11. Select feed direction by setting the Feed

Direction Knob (K) position per Table 2:

Spindle Dir. Feed Dir. Knob Pos.

Figure 7

11.5 Setting up for automatic feed

Refer to Figure 8:

1. Ensure quill lock (G, Figure 8) is loosened by

rotating counterclockwis e.

2. Set micrometer dial (H) to desired depth.

3. Engage auto quill feed lever (D) by pulling out

lock knob and moving lever to left hole.

4. Select feed rate (M).

5. Select feed direction (K).

6. Engage feed trip lever (I) by pulling away from

head assembly.

11.6 Power feed operation

Establish the point at which the quill will reset

during power feed operations, as follows.

Refer to Figure 8:

CW

CCW

12. Engage Feed Trip Cam Lever (I) by pulling

away from head assembly.

Note: Due to variables in tool diameter, coatings,

coo lant, and materials, no specific spindle speed or

feed rate recommendations are provided. Use

general shop manuals that have data applicable to

the milling and drilling operations being performed;

or contact the supplier of the too ling, coolant, and

material for specific recommendations.

IMPORTANT: The power feed can be used for

drills up to 3/8” in diameter (mild steel). Use

manual feed for drills larger than 3/8”.

set to hold up to 200 lb. downfeed pressure on

the quill (accommodates drills up to 3/8”). Do

not attempt to adjust clutch pressure.

Down In

Up Out

Down Out

Up In

Table 2

The overload clutc h is factory

Verify that manual fine feed

handwheel (J, Figure 8) has

been removed for power feeding. Failure to

comply may cause injury.

1. Loosen knurled lock nut on micrometer nut

(H).

2. Use Coarse Feed Handle (F) to advance quill

to the point where the feed should stop.

3. Engage Feed Trip Lever (I) by pulling it away

from head assembly.

4. Adjust Micrometer Adjusting Nut (H) against

Quill Stop (L).

5. Continue turning Micrometer Adjusting Nut (H)

until Feed Trip Lever (I) trips.

6. Tighten Locknut (H).

7. Disengage Quill Lock (G) by rotating

counterclockwise.

8. Start spindle by turning switch (N).

Figure 8

14

Page 15

11.7 Draw bar operation; changing

tooling

The drawbar has 7/16”-20 rig ht hand threads and

should be tightened with normal pressure using

provided wrench. To remove a tool:

1. Lock spindle by turning spindle brake (C,

Figure 8) left or right.

2. Use provided wrench to loosen draw bar two

or three turns (counterclockwise).

3. If collect does not open immediately, tap the

top of draw bar with a soft-faced hammer to

loosen collet from taper.

4. Remove tool from collet.

5. Insert new tool into collet.

6. Tighten draw bar firmly using provided wrench.

The tool is now ready for use.

7. Release spindle brake.

12.0 Adjustments

12.1 Head movement: left and right

Make sure machine base is

secured to floor before repositioning mill head.

The center of gravity can shift enough to ca use

machine to tip over, resulting i n serious injury

to operator and damage to machine.

1. Loosen four large hex nuts (A, Figure 9) that

secure mill head to ram adapter. O ne-quarter

(1/4) turn should be sufficient to allow head to

move.

NOTE: For angles greater than 10 degrees, use

your free hand to support mill head, relieving

weight off the brass worm gears. Doing so will

lengthen life of worm gears.

2. Turn worm nut (B, Figure 9) to tilt head left or

right as required. Use scale o n ram adapter to

establish angle.

Note: The scales on ram adapter and for head

rotation are guides only. Close tolerance work

will require use of a dial i ndicator to mak e sure

head is 90° to table in X and Y axes. Please

note the table is fitted to be slightly higher in

front, usually about 0.0005”.

Be sure to apply tor que in two

steps using a crossing patter n. Failure to do so

could distort the face of the ram adapter.

3. Tighten the four hex nuts. Tighten in two steps

using a calibrated torque wrench. Use a

crossing pattern to tighten the nuts. Tighten

initially to 25 foot-pounds.

Figure 9

4. Before applying final torque, check to make

sure mill head is perpendicular to worktable.

5. Set up a dial indicator in a collet (see Figure 9)

and secure using draw bar.

6. Put spin dle drive in neutral.

7. Set the dial indicator plunger on the worktable.

Zero indicator.

8. Rotate spindle 180 degrees (when rotating,

raise dial indicator plunger by hand to prevent

it from dropping into table T-slots).

9. Read dial indicator – it should read zero. If not,

loosen the four hex nuts and reposition mill

head.

10. Recheck perpendicularity using dial indicator.

Repeat the above procedure until dial indicator

reads zero in both positions.

Be sure to apply torque in two

steps using a crossing patter n. Failure to do so

could distort the face of the ram adapter.

11. Tighten the four hex nuts. Tighten in two steps

using a calibrated torque wrench. Use a

crossing pattern to tighten the nuts. Tighten

initially to 25 foot-pounds, then tighten to fi nal

torque of 50 foot-pounds. NOTE: Do not

overtighten, as it may cause binding of quill.

15

Page 16

12.2 Head movement: Fore and aft

1. Setting the angle:

a. Loosen the three ram adapter locking bolt s

(A, Figure 10). It is unnecessary to loosen the

bolts more than one-half (1/2) turn to allow

tilting.

Figure 10: Head movement

b. Support mill head with your free hand.

Press upward on spindle when changing the

angle.

c. Turn ram adapter worm nut (B, Figure 10)

to tilt head forward and backw ard. Use scale

on ram adapter to establish desired angle.

2. Returning to upright position:

a. When returning mill head to full upright

position, be sure to support head by upward

pressure on spindle as you turn worm nut.

b. Check to make sure mill head is perpendicular to worktable.

c. Set up a dial indicator in a collet and secure

using draw bar (refer to Figure 9).

d. Place spindle drive in neutral.

e. Set dial indicator plunger on worktable.

Zero indicator.

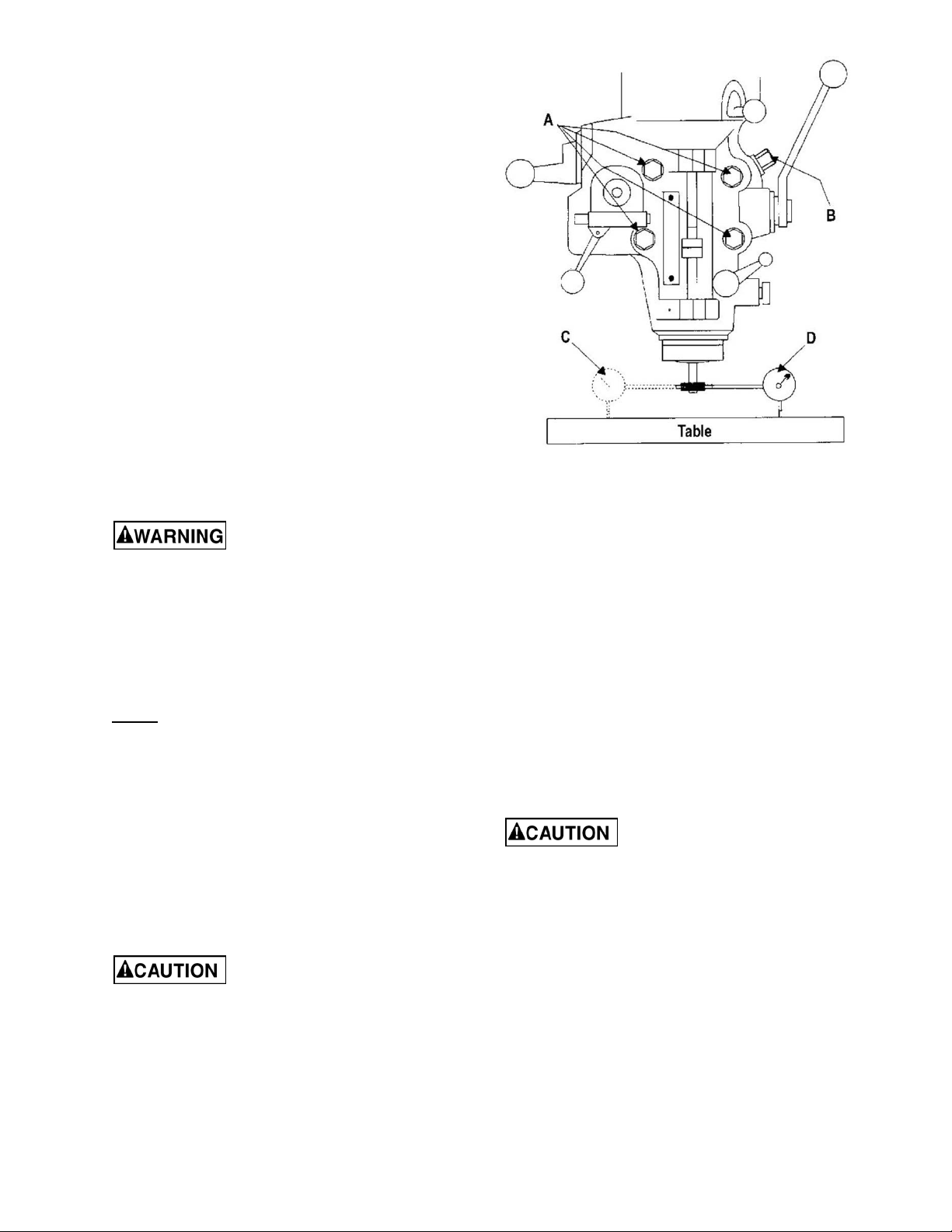

12.3 Positioning ram

12.3.1 Sliding ram fore and aft

1. Loosen two bolts (A, Figure 11) that lock ram

to its ways.

Figure 11: Ram positioning

2. Turn lever (B, Figure 11) to move ram on its

ways.

3. When desired position is reached, lock bolts

(A, Figure 11) securely.

12.3.2 Rotating ram on its turret

Make sure machine base is

secured to floor before r epositioning ram. The

center of gravity can shift enough to cause

machine to tip over, resulting in serious injury

to operator and damage to machine.

1. Loosen four turret lock bolts (C, Figure 11).

One-half (1/2) turn should be sufficient to allow

turret to move.

Note: Use gentle hand pressure to avoid rapid

movement.

2. Turn ram until spindle is in desired position.

Use scale on turret to establish turn degree.

3. Tighten four turret lock bolts (C. Figure 12).

f. Rotate spindle 180 degrees (w hen rotating,

raise dial indicator plunger by hand to prevent

it from dropping into table T-slots).

g. Read dial indicator – it should read zero. If

not, loosen the four hex nuts and reposition

mill head.

h. Recheck perpendicularity using dial

indicator. Repeat above procedure until dial

indicator reads zero in both positions.

i. When indicator reads zero, tighten ram

adapter locking bolts (A, Figure 10).

12.4 Feed trip adjustment

If feed trip mechanism does not disengage properly

when micrometer nuts contact quill stop, adj ust as

follows.

Refer to Figure 12:

1. Loosen locknut (A, Figure 12).

2. Engage trip lever (I) by pulling away from head

assembly.

3. Adjust micrometer nuts (H) against quill stop

(L).

4. Slowly turn adjusting screw (B) with provided

hex key until lever (I) trips.

5. T ighten lockn ut ( A).

16

Page 17

Figure 12: Feed trip adjustment

12.5 Gib adjustment

The table, saddle and knee are equipped with

adjustable gibs. The gibs may require adjustment if

unusual vibration is noted when locking

mechanisms are off, or if you experience unusual

vibration when spindle speed, tooth pitch or depth

of cut do not account for the vibration.

NOTE: When adjusting gibs, always start with the

knee first; adjust the saddle second, and adjust the

table last.

12.5.3 Table gib

Loosen table locking handles. The table gib

adjustment screw (C, Fig ure 13) is o n the lef t-hand

side, beneath table. Tighten screw until slight drag

is felt when turning longitudinal table cranks.

12.6 Table lead screw backlash

adjustment

Refer to Figure 14.

The milling machine table is moved by a lead

screw and nut for each machine axis. For proper

operation, there must be clearance between lead

screw and nut, which results in backlash. A second

feed screw nut is provided to eliminate most of the

backlash. The following procedures provide

instructions for obtaining acceptable backlash.

12.6.1 Cross feed backlash adjustment

Refer to Figure 14:

1. Use cross feed crank to move table to extreme

rear of its travel (toward column).

2. Remove pleated way cover.

3. Open the two chip guards (#48/49, sect.

15.3.1) enough to expose cross feed

adjustment nut (the nut toward rear of f eed nut

bracket is not adjustable; only front nut is

adjustable).

4. Loosen the two nut locking screws.

Figure 13: Gib locations

12.5.1 Knee gib

Loosen the two knee locking handles. The knee

gib adjustment screw (A, Figure 13) is located

under the chip wiper at rear of knee where it

contacts the column. Remove way cover and wiper

to expose gib adjustment screw. Tighten screw

until slight drag is felt when turning knee crank.

12.5.2 Saddle gib

Loosen saddle locking handle. The saddle gib

adjustment screw is on the left front of saddle (B,

Figure 13). Tighten screw until slight drag is felt

when turning cross-feed crank.

5. Turn nut slightly to tighten it agai nst opposing

nut.

6. Tighten the two nut locking screws.

7. Using cross-feed cra nk, move table to middle

position.

8. Set up a dial indicator to check cross feed

backlash. Gently move cross feed crank back

and forth while watching dial indicator.

Backlash should be between 0.003 inch and

0.005 inch.

9. If necessary, repeat the above steps to set

backlash.

10. Install pleated way cover.

12.6.2 Longitudinal backlash adjustment

Refer to Figure 14:

1. Only one of the longitudinal lead screw nuts

can be adjusted; the other nut is fi xed. T he left

hand nut is typically adjustable. This can be

determined by looking at nut from underside of

table.

2. Loosen the two nut locking screws.

3. Turn the nut slightly to tighten it against the

opposing nut.

17

Page 18

4. Tighten the two nut locking screws.

5. Using one of the longitudinal table cranks,

move table to middle position.

6. Set up a dial indicator to check longitudinal

backlash. Gently move crank back and forth

while watching dial indicator. The backlash

should be between 0.003 inch and 0.005 inch.

7. If necessary, repeat the above steps to set

backlash.

Figure 14: Lead screw backlash adjustment

18

Page 19

13.0 Maintenance

Before any intervention on machine, disconnect it from electrical supply by pulling out plug

or switching off main switch! Failu re to comply may cause serious injury.

13.1 Lubrication

The milling machine is equipped with a “one-shot” lubrication system. The system lubricates the lead screws and

ways. Oil cups provide lubrication for spindle bearings and back gear m echanism. Refer to Table 3 and Figures

15/16 for lubrication requirements and access points.

Key Description Action Recommended Lubricant

A Spindle bearings (oil cup) Fill daily.

B Gear case (oil cup) Fill daily.

Knee and table slide ways,

C

leadscrew (one-shot lube

system)

Knee elevating screw

D

(grease fitting)

Table surface, and other

exposed metal surfaces.

E Speed range selector Oil cam ring slot weekly. Mobil DTE Oil Light, or equivalent

Check oil daily – add if required.

Pull lube handle every hour during

operations.

Servic e weekly with lube gun.

Wipe down after use. Light coat of

oil for rust protection.

Table 3: Lubrication Points

Mobil DTE Oil Light,

or equivalent 10W machine oil

Mobilith AW1,

or equivalent NLGI-1 grease

Mobil Vactra Oil #2,

or equivalent lubricant designed

for slideways

Mobilith AW2,

or equivalent NLGI-2 grease

Mobil DTE Oil Light, or equivalent

13.2 Periodic Maintenance Activities

During operation, periodically vacuum and brush

chips and debris from machine.

Operate knee and table lead screws through full

range of movement to evenly distribute lubricant

(particularly when applied using the “one-shot”

system).

Figure 15

Figure 16

Apply light machine oil to work table and other

exposed metal surfaces to prevent rust or

corrosion.

Remove belt guards to check pulleys and belts for

unusual wear or grooving. NOTE: Operators

should vary speed occasionally to prevent

formation of grooves on pulley surfaces.

19

Page 20

14.0 Belt position – speed ranges

Figure 15: Belt position

15.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.

20

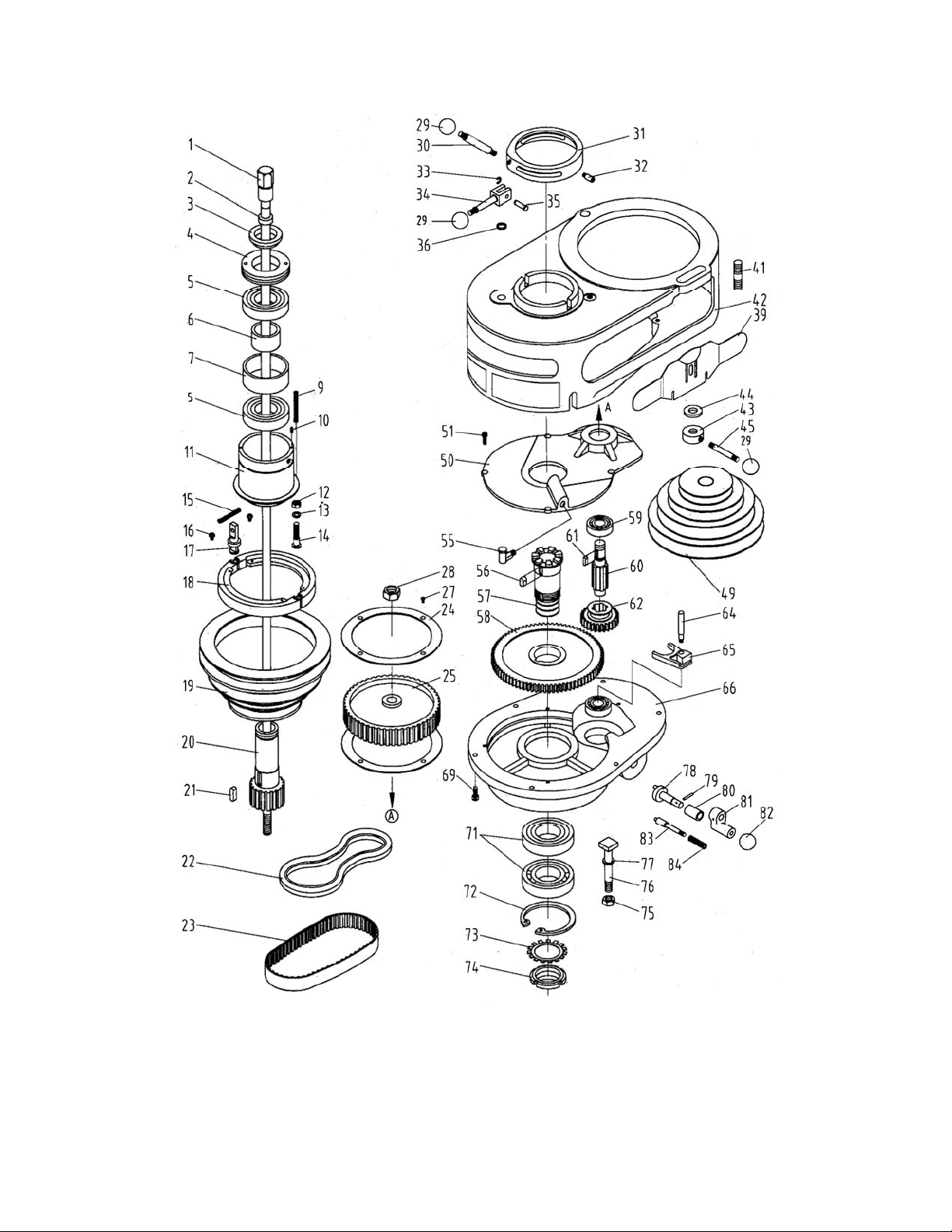

Page 21

15.1.1 Upper Head Assembly – Exploded View

21

Page 22

15.1.2 Upper Head Assembly – Parts List

Index No Part No Description Size Qty

1 ................ LA-072....................... Draw Bar .................................................................. R8 ................................. 1

2 ................ JTM4VS-A002B ........ Draw Bar Washer .................................................... ................ ...................... 1

3 ................ LA-071....................... Upper Bearing Lock Nut .......................................... ...................................... 1

4 ................ LA-070....................... Bearing Sleeve Lock Nut ......................................... ...................................... 1

5 ................ BB-6207ZZ ................ Ball Bearing ............................................................. 6207-ZZ ........................ 2

6 ................ LA-068....................... Upper Bearing Spacer (small) ................................. ...................................... 1

7 ................ LA-069....................... Upper Bearing Spacer (large) .................................. ...................................... 1

9 ................ LA-169....................... Compression Spring ................................................ ...................................... 4

10 .............. TS-1520041 .............. Set Screw ................................................................ M3x10 ........................... 4

11 .............. LA-066....................... Spindle Pulley Bearing Sleeve................................. ...................................... 1

12 .............. TS-0571021 .............. Hex Jam Nut ............................................................ 5/16” .............................. 1

13 .............. TS-0720081 .............. Lock Washer ............................................................ 5/16” .............................. 1

14 .............. LA-034....................... Brake Ring Screw .................................................... ...................................... 1

15 .............. LA-036....................... Spring ...................................................................... ...................................... 2

16 .............. BUTW31612.............. Screw ....................................................................... 3/16”x1/2” ...................... 4

17 .............. LA-037....................... Brake Lock Stud ...................................................... ....... ............................... 1

18 .............. LA-035....................... Brake Assembly ....................................................... ...................................... 1

19 .............. LA-065....................... Spindle Pulley (four-step) ........................................ ...................................... 1

20 .............. LA-064....................... Spindle Pulley Hub .................................................. ...................................... 1

21 .............. JTM1-021 .................. Key........................................................................... 6x 6x25mm .................... 1

22 .............. VB-A33 ...................... V-belt ....................................................................... A33 ................................ 1

23 .............. VB225L100 ............... Timing Belt ............................................................... 225L .............................. 1

24 .............. LA-027....................... Timing Belt Flange ................................................... ...................................... 2

25 .............. LA-028....................... Timing Belt Pulley .................................................... ...................................... 1

27 .............. JTM1-C27 ................. Flat Head Screw ...................................................... ...................................... 8

28 .............. TS-0571072 .............. Hex Jam Nut ............................................................ 5/8”-18NF ...................... 1

29 .............. LA-006....................... Plastic Ball ............................................................... ...................................... 3

30 .............. LA-074....................... Spindle Clutch Lever................................................ ...................................... 1

31 .............. LA-073....................... Cam Ring ................................................................. ...................................... 1

32 .............. JTM1-032 .................. Cam Ring Pin........................................................... ...................................... 2

33 .............. JTM1-C33 ................. E-Ring ...................................................................... ...................................... 1

34 .............. LA-039....................... Brake Lock Handle .................................................. ...................................... 1

35 .............. LA-038....................... Brake Lock Pin......................................................... ...................................... 1

36 .............. TS-0680061 .............. Washer .................................................................... 1/2" ................................ 1

37 .............. JTM1-037 .................. Spindle Speed Plate (JTM-1)................................... ...................................... 1

.................. JTM1-037A................ Spindle Speed Plate (JTM-2)................................... ...................................... 1

39 .............. JTM1-039A................ Belt Guard................................................................ ...................................... 2

41 .............. LA-012....................... Motor Mount Studs .................................................. ...................................... 2

42 .............. LA-015....................... Belt Housing ............................................................ ...................................... 1

43 .............. LA-007....................... Motor Lock Nut ........................................................ ...................................... 2

44 .............. LA-008....................... Washer .................................................................... ...................................... 1

45 .............. LA-009....................... Motor Lock Nut Handle ............................................ ...................................... 4

49 .............. LA-011....................... Motor Pulley (four-step) ........................................... ...................................... 1

50 .............. LA-013....................... Gear Housing Cover ................................................ ...................................... 1

51 .............. JTM1-C51 ................. Hex Socket Cap Screw ............................................ M5x14 .......... ................. 4

55 .............. JTM1-055 .................. Oil Cup ..................................................................... ...................................... 1

56 .............. JTM1-C56 ................. Key........................................................................... .. .................................... 1

57 .............. LA-062....................... Spindle Gear Hub .................................................... ...................................... 1

58 .............. LA-061....................... Spindle Bull Gear Assembly .................................... ...................................... 1

59 .............. BB-6203ZZ ................ Ball Bearing ............................................................. ...................................... 1

60 .............. LA-026....................... Shaft ........................................................................ ...................................... 1

61 .............. JTM1-061 .................. Key........................................................................... 5x 5x15mm .................... 1

62 .............. LA-025....................... Gear ......................................................................... ...................................... 1

63 .............. BB-6203ZZ ................ Ball Bearing ............................................................. ...................................... 1

64 .............. LA-032....................... Dowel Pin................................................................. ...................................... 1

65 .............. LA-031....................... Back Gear Shifter Fork ............................................ ...................................... 1

66 .............. LA-014....................... Gear Housing........................................................... ...................................... 1

69 .............. TS-1503041 .............. Hex Socket Cap Screw ............................................ M6x16 ........................... 6

71 .............. BB-6208ZZ ................ Ball Bearing ............................................................. ...................................... 2

72 .............. JTM1-C72 ................. Snap Ring ................................................................ ...................................... 1

22

Page 23

Index No Part No Description Size Qty

73 .............. JTM1-C73 ................. Lock Washer ............................................................ ........ .............................. 1

74 .............. LA-059....................... Bearing Lock Nut ..................................................... ...................................... 1

75 .............. JTM1-C75 ................. Hardened Nut .......................................................... 7/16” .............................. 1

76 .............. LA-045....................... T-Bolt ....................................................................... ...................................... 3

77 .............. JTM1-C77 ................. Bolt Washer ............................................................. ...................................... 3

78 .............. LA-001....................... Shift Crank ............................................................... ...................................... 1

79 .............. JTM-C79 ................... Spring Pin ................................................................ ...................................... 1

80 .............. LA-044....................... Back Gear Shift Bushing.......................................... ...................................... 1

81 .............. LA-003....................... Shaft Crank Handle ................................................. ...................................... 1

82 .............. LA-006....................... Plastic Ball ............................................................... ...................................... 1

83 .............. LA-004....................... Gearshift Plunger ..................................................... ...................................... 1

84 .............. LA-005....................... Compression Spring ................................................ ...................................... 1

.................. JTM1-M2 ................... Motor (not shown) .................................................... 2HP 3PH 220 V.............. 1

.................. JTM1-598 .................. Fwd/Rev Switch (not shown) ................................... for 3PH, 2/4P ................ 1

.................. JTM1-598A................ Switch Speed Plate (not shown) .............................. ...................................... 1

.................. JTM1-598B................ Switch Knob (not shown) ......................................... ...................................... 1

.................. JTM1-598C ............... Switch Bracket (not shown) ..................................... ...................................... 1

.................. JTM1-598D ............... Metal Switch Box (not shown) ................................. ...................................... 1

.................. JTM2-M1 ................... Motor (not shown) .................................................... 2HP 1PH 115/230 V....... 1

.................. JTM2-SC ................... Start Capacitor ......................................................... 500MFD, 125AC ........... 1

.................. JTM2-598CP ............. Switch Assembl y CP (not shown) ............................ ...................................... 1

.................. JTM2-599 .................. Fwd/Rev Switch (not shown) ................................... for 1PH .......................... 1

.................. JTM2-599A................ Switch Plate (not shown) ......................................... ...................................... 1

.................. JTM2-599B................ Switch Plate Mounting Screw (not shown) .............. ...................................... 1

.................. JTM2-599C ............... Motor – Switch Wiring Harness (not shown)............ ...................................... 1

.................. BD1325R-X02 ........... Centrifugal Switch (not shown) ................................ ...................................... 1

23

Page 24

15.2.1 Head Assembly – Exploded View

24

Page 25

15.2.2 Head Assembly – Parts List

Index No Part No Description Size Qty

.................. LA-166A .................... Worm Gear Cradle Assembly (includes #1-17,36,37,40) ............................... 1

1 ................ TS-1533042 .............. Screw ....................................................................... M5x10 ........................... 6

2 ................ HA-002 ...................... Bev el Pinion Washer ............................................... ...................................... 1

3 ................ HA-003 ...................... Feed Gear................................................................ ...................................... 1

4 ................ LA-161....................... Shaft Sleeve ............................................................ ...................................... 1

5 ................ LA-162....................... Worm Cradle Bushing.............................................. ...................................... 1

6 ................ TS-1523011 .............. Set Screw ................................................................ M6x6 ............................. 9

7 ................ LA-163....................... Worm Gear Spacer .................................................. ...................................... 1

8 ................ LA-164....................... Feed Drive Worm Gear............................................ ...................................... 1

9 ................ LA-165....................... Worm Gear Shaft ..................................................... ...................................... 1

10 .............. HA-010 ...................... Worm Shaft Key....................................................... 3x3x8mm . ..................... 1

11 .............. HA-011 ...................... Key........................................................................... 3x 3x20mm .................... 1

12 .............. HA-012 ...................... Lock Nut................................................................... M6x 16 ........................... 1

13 .............. HA-013 ...................... Wash er .................................................................... ...................................... 1

14 .............. HA-014 ...................... Cluster Gear key ...................................................... 3x3x8.5 ......................... 1

15 .............. LA-154....................... Feed Reverse Bevel Gear ....................................... ...................................... 1

16 .............. LA-167....................... Feed Engage Pin ..................................................... ...................................... 1

17 .............. LA-166....................... Worm Gear Cradle................................................... ...................................... 1

18 .............. LA-033....................... Worm Gear Throw-out ............................................. ...................................... 1

19 .............. LA-002....................... Shift Sleeve.............................................................. ...................................... 1

20 .............. LA-004....................... Plunger .................................................................... ...................................... 2

21 .............. LA-005....................... Spring ...................................................................... ...................................... 3

22 .............. HA-022 ...................... Spring Pin ................................................................ 3x22mm ........................ 2

23 .............. LA-003....................... Cam Rod.................................................................. ...................................... 2

24 .............. LA-006....................... Plastic Ball ............................................................... ...................................... 3

27 .............. LA-147....................... Upper Bushing ......................................................... ...................................... 1

28 .............. LA-144....................... Cluster Gear Assembly ............................................ ...................................... 1

29 .............. HA-029 ...................... Cluster Gear Key ..................................................... 3x3x45mm .................... 1

31 .............. LA-143....................... Cluster Gear Shaft ................................................... ...................................... 1

32 .............. HA-032 ...................... Snap Ring ................................................................ ...................................... 2

33 .............. LA-142....................... Bevel Gear Bushing ................................................. ...................................... 1

34 .............. LA-141....................... Thrust Spacer .......................................................... ...................................... 1

36 .............. LA-156....................... Feed Drive Gear ...................................................... ...................................... 1

37 .............. HA-037 ...................... Key........................................................................... 3x 3x10mm .................... 1

40 .............. LA-157....................... Feed Drive Gear ...................................................... ...................................... 1